Page 1

C3909M-EN (03/12)

(FD1-F Series)

FD1 Series 540 TV lines

High Resolution Camera

Installation/Operation Manual

(FD1-IR Series)

Before attempting to connect or operate this product, please read these instructions

carefully and save this manual for future use.

FD1-F Series: FD1-F3-4(X), FD1-F4-4(X)

FD1-IR Series: FD1-IRF4-4(X), FD1-IRV9-4(X)

1

Page 2

CONTENTS

Important Safety Instructions ........................................................................................................................ 3

Troubleshooting Tips ..................................................................................................................................... 4

Regulatory Notices ........................................................................................................................................ 5

1. Introduction ................................................................................................................................................ 6

1.1 Package Contents ............................................................................................................................ 6

1.2 Dimensions ...................................................................................................................................... 6

1.3 Names of Camera Parts .................................................................................................................. 7

1.4 Routine Maintenance ....................................................................................................................... 8

2. Installation ................................................................................................................................................. 9

2.1(A) Inserting Screw Anchors ............................................................................................................. 9

2.2(A) Connecting the Wiring ................................................................................................................. 9

2.3(A) Mounting the Camera ................................................................................................................. 9

2.4(A) Adjusting the Camera Position ................................................................................................. 10

2.5(A) Locking (fixing) the Camera Body ............................................................................................. 11

2.1(B) Disassembling the Camera ....................................................................................................... 12

2.2(B) Connecting the Wiring ............................................................................................................... 13

2.3(B) Mounting the Camera ............................................................................................................... 13

2.4(B) Adjusting the Camera Position ................................................................................................. 14

2.5(B) Adjusting the Lens (if equipped with varifocal lens) ................................................................. 15

2.6(B) Completing the Installation ........................................................................................................ 15

3. Specifications .......................................................................................................................................... 16

PRODUCT WARRANTY AND RETURN INFORMATION ......................................................................... 18

C3909M-EN (03/12)

2

Page 3

Important Safeguards and Warnings

Important Safety Instructions

1. Read Instructions. All the safety and operating instructions should be read before the camera is

operated.

2. Retain Instructions. The safety and operating instructions should be retained for future reference.

3. Heed Warnings. All warnings on the camera and in the operating instructions should be adhered to.

4. Follow Instructions. All operating and use instructions should be followed.

5. Cleaning: Unplug the power unit from the wall outlet before cleaning. Do not use liquid cleaners or

aerosol cleaners. Use a damp cloth for cleaning.

6. Attachments: Do not use attachments not recommended by your appliance dealer, as they may cause

hazards.

7. Water and Moisture: Do not use the camera in any location in which it may be exposed to water or

moisture. (For example, dripping, splashing, or liquid near equipment etc.)

8. Accessories: Do not place the camera on an unstable cart, stand, tripod,

bracket, or table. The camera may fall, causing serious injury to a child or adult,

and serious damage to the camera. Use only with mounting accessories

recommended by your appliance dealer or sold with the camera. Any mounting

of the camera should follow your appliance dealer's instructions.

The camera must be installed in a location or on a piece of equipment that can

withstand three times the total weight of the camera, including the lens, camera,

mount, adapter, etc.

9. Any appliance and cart combination should be moved with care. Quick stops, excessive force, and

uneven surfaces may cause the appliance and cart combination to overturn.

10. Ventilation: The camera should never be placed near or over a radiator or heat register. The camera

should not be placed in a built-in installation such as a bookcase or rack unless proper ventilation is

provided or your appliance dealer's instructions have been adhered to.

11. Power Sources: The camera should be operated only from the type of power source indicated on the

rating plate. If you are not sure of the type of power supply for your installation site, consult your

appliance dealer or local power company.

12. Power Cord Protection: Power supply cords should be routed so that they are not likely to be walked on

or pinched by items placed upon or against them, paying particular attention to cords at plugs,

convenience receptacles, and the point where they exit from the camera.

13. Lightning: For added protection for the camera during a lightning storm, or when it is left unattended and

unused for long periods of time, unplug it from the wall outlet and disconnect the cable system. This will

prevent damage to the camera due to lightning and power line surges.

14. Overloading: Do not overload the wall outlet and extension cord, as this can result in a risk of fire or

electric shock.

15. Object and Liquid Entry: Never push objects of any kind into the camera through openings, as they may

touch dangerous voltage points or short out parts that could result in a fire or electric shock. Never spill

liquid of any kind on the camera.

16. Servicing: Do not attempt to service the camera yourself, as opening or removing covers may expose

you to dangerous voltage or other hazards. Refer all servicing to qualified service personnel.

17. Damage Requiring Service: Unplug the power unit from the wall outlet. Refer servicing to qualified

service personnel under the following conditions.

C3909M-EN (03/12)

3

Page 4

Important Safeguards and Warnings

a. When the power supply cord or plug is damaged.

b. If liquid has been spilled or objects have fallen into the camera.

c. If the camera has been exposed to rain or water.

d. If the camera does not operate normally by following the operating instructions. Adjust only those

controls that are covered by the operating instructions, as an improper adjustment of other controls

may result in damage and will often require extensive work by a qualified technician to restore the

camera to its normal operation.

e. If the camera has been dropped or the cabinet has been damaged.

f. When the camera exhibits a distinct change in performance. This indicates a need for service.

18. Replacement Parts: When replacement parts are required, be sure the service technician has used

replacement parts specified by a qualified dealer or that have the same characteristics as the original

part.

Unauthorized substitutions may result in fire, electric shock, or other hazards.

19. Safety Check: Upon completion of any service or repairs to the camera, ask the service technician to

perform safety checks to determine that the camera is in proper operating condition.

Troubleshooting Tips

Ensure that all power cords are attached.

Ensure that all power switches are in the ON position.

Ensure that all cables are installed in the proper location and are fully seated.

C3909M-EN (03/12)

4

Page 5

Important Notices

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Changes and Modifications not expressly approved by the manufacturer or registrant of this equipment

can void your authority to operate this equipment under Federal Communications Commission’s rules.

In order to maintain compliance with FCC regulations shielded cables must be used with this equipment.

Operation with non-approved -equipment or unshielded cables is likely to result in interference to radio

and television reception.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Operating Notes:

Connect to DC12V power adapter.

Operating Conditions

• Avoid viewing very bright objects (example, light fixtures) for extended periods.

• Avoid operating or storing the unit in the following locations:

- Extremely humid, dusty, hot/cold environments where the operating temperature is outside the

recommended range of 14°F to 122°F (-10°C to +50°C)

- Close to sources of powerful radio or TV transmitters

- Close to fluorescent lamps or objects reflecting light

- Under unstable light sources (may cause flickering)

C3909M-EN (03/12)

5

Page 6

Introduction

Figure 1-1 FD1-F3-4(X)/FD1-F4-4(X)

1. Introduction

The dome camera series are ideal for indoor installation in commercial environment. With 2 or 3-axis

mount support, it provides flexible installation: 2 axis mounts on ceilings only and 3 axis mounts on a

ceiling or wall even at an angle.

1.1 Package Contents

Check that the items received match those listed on the order form and packing slip. The dome camera

series packing box includes:

• One fully assembled camera

• One Installation manual

• Two screw anchors

• Two TP4x15mm tapping screws

• One guide pattern (FD1-IR series only)

• One TP1.7x3mm tapping screw (FD1-F series only)

If any parts are missing or damaged, contact the dealer you purchased the camera from.

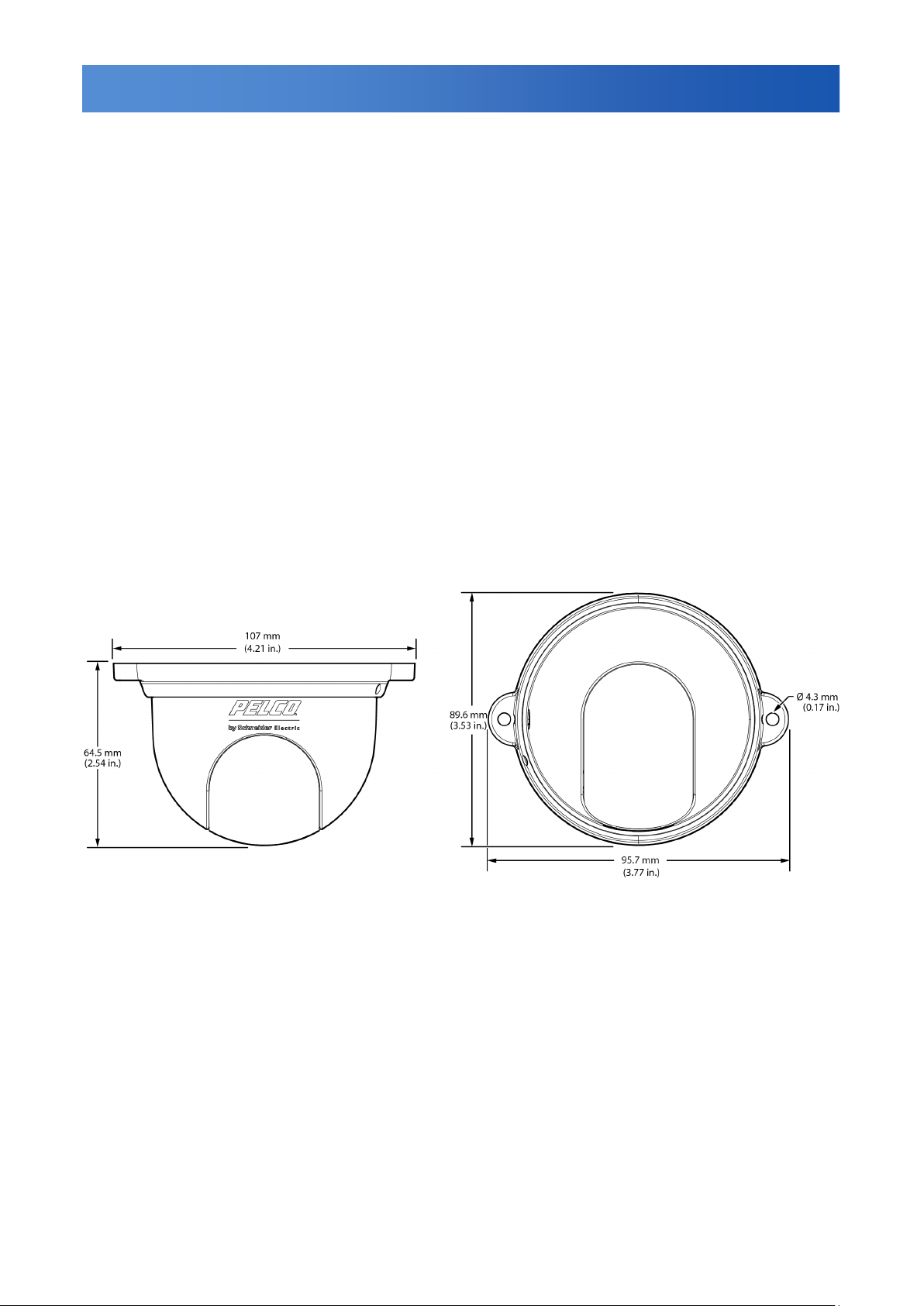

1.2 Dimensions

C3909M-EN (03/12)

6

Page 7

Introduction

Figure 1-2 FD1-IRF4(X)/FD1-IRV9(X) (typical)

1.3 Names of Camera Parts

Figure 1-3 FD1-F3-4(X)/FD1-F4-4(X)

C3909M-EN (03/12)

7

Page 8

Introduction

Figure 1-5 FD1-IRV9

Figure 1-4 FD1-IRF4

1. FD1-F series: Cable Y used for surface run

power/video connector

FD1-IR series: Conduit hole used for

surface run power/video connector

2. Bottom case

3. Camera housing

4. Dome cover

5. Zoom lever

6. Focus lever

A. Video Output Terminal

B. DC12V Power Connector ( Red+/Black- )

Note: See Figure 2-3 for camera board controls.

1.4 Routine Maintenance

• The dome cover is an optical part. Use a soft, dry cloth to remove any fingerprints or dust.

• Clean the camera housing with a soft, dry cloth. For more stubborn stains, use a cloth dampened with

a small quantity of neutral detergent, then wipe dry.

Caution: Do not use volatile solvents such as alcohol, benzene or thinners to avoid damaging the

surface finish.

C3909M-EN (03/12)

8

Page 9

Installation

2. Installation

Section 2(A) is installation for FD1-F Series.

2.1(A) Inserting Screw Anchors

1. Mark hole positions on the desired location.

2. Drill 2 holes according the two fixing holes in camera bottom case and insert screw anchors provided.

Figure 2-1(A) Insert Screw Anchors

2.2(A) Connecting the Wiring

Refer to Figure 1-3 to connect the video connect output connector (A) and DC12V power connector

(B).

Caution: For DC power supply use, make sure the polarity is correct to avoid malfunction and / or

camera damage.

2.3(A) Mounting the Camera

1. In order to get a suitable position and angle, please adjust the pan/tilt angle.

2. Secure the bottom case to the wall or ceiling with the TP4 x 15 mm tapping screws supplied (#2).

Note: Depending on the material of your mounting surface, you may require different screws and

anchors than those supplied.

C3909M-EN (03/12)

9

Page 10

Installation

Figure 2-2(A) Camera Installation

2.4(A) Adjusting the Camera Position

The dome camera has two axes for positioning the camera. While monitoring the picture on the

monitor, adjust the camera position as follows:

• Pan Adjustment: Rotate 3D assembly in the base. Do not turn assembly more than 360° as this

may cause the internal cables to twist and disconnect or break.

• Tilt Adjustment: After loosening the screw on the bracket, position the camera as desired, then tighten

the screw back to the bracket.

10

C3909M-EN (03/12)

Page 11

Installation

This screw is used to fix body.

Tilt angle hole.

2.5(A) Locking (fixing) the Camera Body

Adjust the camera position and lock the camera body by tightening screws.

Figure 2-3(A) Completing the Installation

C3909M-EN (03/12)

11

Page 12

Installation

1. Bottom case

2. Tilt adjustment bracket

3. Dome cover

FD1-IRF4

FD1-IRV9

Section 2(B) is installation for FD1-IR Series.

2.1(B) Disassembling the Camera

Before you mount and adjust the camera, follow these steps to disassemble the camera.

1. Insert a coin or flat tool to the side hole and twist to remove the dome cover.

2. Remove the dome cover (#3) by gently pulling it free from the tilt adjustment bracket (#2).

3. Set the dome cover (#3) aside.

C3909M-EN (03/12)

Figure 2-1(B) Disassemble the Camera

12

Page 13

Installation

1. Screw anchors (x2), supplied

2. TP4 x 15 tapping screws (x2),

supplied

FD1-IRF4 (typical)

2.2(B) Connecting the Wiring

Refer to Figure 1-4 and Figure 1-5 to connect the video connect output connector (A) and DC 12V

power connector (B).

Caution: For DC power supply use, make sure the polarity is correct to avoid malfunction and / or

camera damage.

2.3(B) Mounting the Camera

1. Attach the mounting template to the wall or ceiling.

2. Drill two holes, then insert the screw anchors (#1) into the holes.

3. Secure the bottom case to the wall or ceiling with the TP4 x 15 mm tapping screws supplied (#2).

Note: Depending on the material of your mounting surface, you may require different screws and

anchors than those supplied.

C3909M-EN (03/12)

Figure 2-2(B) Camera installation

13

Page 14

Installation

FD1-IRF4

FD1-IRV9

1. Rotate 3D assembly in base for pan

adjustment

2. Tilt adjustment bracket and screw

for vertical adjustment

3. Axis ring for horizontal rotation for

wall mount and tilted ceilings

4. Focus lever

5. Zoom lever

2.4(B) Adjusting the Camera Position

The dome camera has three axes for positioning the camera. While monitoring the picture on the

monitor, adjust the camera position as follows:

• Pan Adjustment: Rotate 3D assembly in the base. Do not turn assembly more than 360° as this

may cause the internal cables to twist and disconnect or break.

• Tilt Adjustment: After loosening the screw on the bracket, position the camera as desired, then

tighten the screw back to the bracket.

• Horizontal Rotation: For wall mount and tilted ceilings, rotate the lens base (maximum 360°) until

you are satisfied with the field of view.

C3909M-EN (03/12)

Figure 2-3(B) Camera Adjustment

14

Page 15

Installation

FD1-IRF4 (typical)

1. Bottom case

2. Tilt adjustment bracket

3. Dome cover

2.5(B) Adjusting the Lens (if equipped with varifocal lens)

Refer to Figure 2-3(B), for FD1-IRV9, please carry out the following steps to adjust the lens:

1. Loosen the zoom lever (#5) counter-clockwise a little, then rotate the zoom lever and determine

the image view.

2. Loosen the focus lever (#4) counter-clockwise a little, then adjust the focus for optimum picture

sharpness.

3. Re-tighten the zoom lever and focus lever after adjustment.

Note: It is important that you lock the zoom and focus levers after making adjustments. This will avoid

the positions moving (for example, from temperature changes or vibrations).

2.6(B) Completing the Installation

Once all adjustments are done, attach and secure the camera housing:

1. Use a soft, lint-free cloth to wipe the dome cover clean and remove fingerprints.

2. Attach the dome cover (#3) to the tilt adjustment bracket (#2). Push down until it clicks into place.

3. Assemble the dome cover (#3) and the bottom case (#1).

C3909M-EN (03/12)

Figure 2-4(B) Completing the Installation

15

Page 16

Specification

Camera System Type

FD1-F3-4

FD1-F3-4X

FD1-F4-4

FD1-F4-4X

Format

NTSC

PAL

NTSC

PAL

Optical System

Image Size

1/3"

IR Cut Filter

Fixed

Electronic

Syncronization

Internal

Horizontal resolution

540 TVL

Field Of View

Horizontal: 90°

Vertical: 80°

Horizontal: 72°

Vertical: 52°

Min. Object Distance

1.2m~∞

Lens Options

F2.0, f 2.8mm

F2.0, f 3.6mm

Sensitivity

f/2.0; 2,850°K;

30IRE

Color (17 ms)

0.2 Lux

f/2.0; 2,850°K;

30IRE

Color (20 ms)

0.2 Lux

f/2.0; 2,850°K;

30IRE

Color (17 ms)

0.2 Lux

f/2.0; 2,850°K;

30IRE

Color (20 ms)

0.2 Lux

Shutter

NTSC: Auto: 1/60~1/10,000, only

PAL: Auto: 1/50~1/10,000, only

Noise Reduction

2D

Languages

Manual only English, Spanish,

no OSD

Connection/Termination

Flying leads (through the back)

Power supply

Power

12VDC (+10%/-15%)

Power consumption

1W

Environment

Operating temperature

-10ºC ~ 50ºC (14 ºF ~ 122 ºF)

Operating humidity

20% ~ 80% non-condensing

Mechanism

Back Box Construction

ABS Plastic

Bubble Diameter

<86mm

Easy adjustment

Manual 2 Axis Gimble

Dimension

107mm x 64.5 mm

Weight (unit)

120g

3. Specifications

FD1-F Series

C3909M-EN (03/12)

16

Page 17

Specification

Camera System Type

FD1-IRF4-4

FD1-IRF4-4X

FD1-IRV9-4

FD1-IRV9-4X

Format

NTSC

PAL

NTSC

PAL

Optical System

Image Size

1/3"

IR Cut Filter

Dual band OLPF

Electronic

Syncronization

Internal

Horizontal resolution

up to 540 TVL

Lens Options

F2.0, f3.6mm

F1.2, 3-9mm, DC AI

Field Of View

Horizontal: 72°

Vertical: 52°

fW 3mm Horizontal: 85.3°

Vertical: 63.8°

fT 9mm Horizontal: 31.5°

Vertical: 23.7°

Min. Object Distance

1.2m~∞

0.5m~∞

Sensitivity

f/2.0; 2,850°K;

30 IRE

Color (17 ms)

0.2 Lux

Mono (with IR)

0 Lux

f/2.0; 2,850°K;

30 IRE

Color (20 ms)

0.2 Lux

Mono (with IR)

0 Lux

f/2.0; 2,850°K;

30 IRE

Color (17 ms)

0.13 Lux

Mono (with IR)

0 Lux

f/2.0; 2,850°K;

30 IRE

Color (20 ms)

0.13 Lux

Mono (with IR)

0 Lux

IR Illumination Type

Standard

IR Illumination Distance

15 meters

20 meters

IR Sensitivity

850nm >40% Peak Response

Low Light Technology

LED only

Shutter

Auto:

1/60~1/10,000,

only

Auto:

1/50~1/10,000,

only

1/60 only

1/50 only

Noise Reduction

2D

Languages

Manual only English, Spanish,

no OSD

Connection/Termination

Flying leads (through the back)

Power supply

Power

12VDC (+10%/-15%)

Power consumption

2.7W

Environment

Operating temperature

-10ºC ~ 50ºC (14 ºF ~ 122 ºF)

Operating humidity

20% ~ 80% non-condensing

Mechanism

Back Box Construction

ABS Plastic

Bubble Diameter

< 101mm

Easy adjustment

Manual 3 Axis Gimble

Dimension (L W H)

116mm X 106mm

Weight (unit)

250g

260g

FD1-IR Series

C3909M-EN (03/12)

17

Page 18

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any

merchandise proved defective in material or

workmanship for a period of one year after the

date of shipment.

Exceptions to this warranty are as noted below:

• Five years:

– Fiber optic products

– Unshielded Twisted Pair (UTP) transmission

products

– CC3701H-2, CC3701H-2X, CC3751H-2,

CC3651H-2X, MC3651H-2, and MC3651H2X camera models

• Three years:

– FD Series and BU Series analog camera

models

– Fixed network cameras and network dome

cameras with Sarix® technology

– Sarix thermal imaging products (TI and ESTI

Series)

– Fixed analog camera models (C20 Series,

CCC1390H Series, C10DN Series,C10CH

Series)

– EH1500 Series enclosures

– Spectra

®

IV products (including Spectra IV

IP)

– Spectra HD dome products

– Camclosure

®

Series (IS, ICS, IP) integrated

camera systems

– DX Series video recorders (except DX9000

Series which is covered for a period of one

year), DVR5100 Series digital video

recorders, Digital Sentry® Series hardware

products, DVX Series digital video recorders,

and NVR300 Series network video

recorders

– Endura

®

Series distributed network-based

video products

– Genex

®

Series products (multiplexers,

server, and keyboard)

– PMCL200/300/400 Series LCD monitors

– PMCL5xxF Series and PMCL5xxNB Series

LCD monitors

• Two years:

– Standard varifocal, fixed focal, and

motorized zoom lenses

– DF5/DF8 Series fixed dome products

– Legacy

®

Series integrated positioning

systems

– Spectra III

™

, Spectra Mini, Spectra Mini IP,

Esprit®, ExSite®, ExSite IP, and PS20

scanners, including when used in

continuous motion applications

– Esprit Ti and TI2500 Series thermal imaging

products

– Esprit and WW5700 Series window wiper

(excluding wiper blades)

– CM6700/CM6800/CM9700 Series matrix

– Digital Light Processing (DLP

®

) displays

(except lamp and color wheel). The lamp

and color wheel will be covered for a period

of 90 days. The air filter is not covered

under warranty.

• Six months:

– All pan and tilts, scanners, or preset lenses

used in continuous motion applications

(preset scan, tour, and auto scan modes)

Pelco will warrant all replacement parts and

repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair

shall be sent freight prepaid to a Pelco

designated location. Repairs made necessary

by reason of misuse, alteration, normal wear, or

accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to

no liability for damages or loss resulting from the

specific use or application made of the Products.

Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of

any rights of any party or product liability,

relating to the Products shall not exceed the

price paid by the Dealer to Pelco for such

Products. In no event will Pelco be liable for any

special, incidental, or consequential damages

(including loss of use, loss of profit, and claims

of third parties) however caused, whether by the

negligence of Pelco or otherwise.

The above warranty provides the Dealer with

specific legal rights. The Dealer may also have

additional rights, which are subject to variation

from state to state.

If a warranty repair is required, the Dealer must

contact Pelco at (800) 289-9100 or (559) 2921981 to obtain a Repair Authorization number

(RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order

number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a

product that does not fall under the warranty

conditions stated above, please include a

C3909M-EN (03/12)

18

Page 19

PRODUCT WARRANTY AND RETURN INFORMATION

This equipment contains electrical or electronic components that must be recycled

properly to comply with Directive 2002/96/EC of the European Union regarding the

disposal of waste electrical and electronic equipment (WEEE). Contact your local

dealer for procedures for recycling this equipment.

written explanation with the product when

returned.

number if returned for credit, and RA number if

returned for repair) and designated return

location.

Method of return shipment shall be the same or

equal to the method by which the item was

received by Pelco.

All merchandise returned for credit may be

subject to a 20 percent restocking and

refurbishing charge.

RETURNS

To expedite parts returned for repair or credit,

please call Pelco at (800) 289-9100 or (559)

Goods returned for repair or credit should be

clearly identified with the assigned CA or RA

number and freight should be prepaid.

292-1981 to obtain an authorization number (CA

Pelco, the Pelco logo, and other trademarks associated with Pelco products referred to in this publication are trademarks of Pelco, Inc. or its affiliates. © Copyright 2012, Pelco, Inc.

All other product names and services are the property of their respective companies. All rights reserved.

Product specifications and availability are subject to change without notice.

C3909M-EN (03/12)

19

Page 20

www.pelco.com

Pelco by Schneider Electric 3500 Pelco Way Clovis, California 93612-5699 United States

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

20

Loading...

Loading...