Page 1

INSTALLATION

EE500 Series

™

Endura Xpress

C4649M-D (4/13)

Page 2

Contents

Important Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Legal Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Regulatory Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Video Quality Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

User-Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Product Serial Number Label Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Placing the Equipment and Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the Hard Drive Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Connecting the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Mounting on a Desktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mounting in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installing the Hard Drive Carriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Startup and Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Starting Up the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Shutting Down the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Appendixes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix A: Expanding Video Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix B: Installing an Uninterruptible Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Appendix C: Integration with an Endura System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Modifying DHCP Settings on the EE500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configuring the EE500 for Endura Enabled Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Configuring EE500 Cameras in the Endura Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2 C4649M-D (4/13)

Page 3

List of Illustrations

1 Rear Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Front Panel: Bezel Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Front Panel: Bezel Closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Major Package Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Accessory Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Rack Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Product Serial Number Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Installing Rubber Feet and Removing Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

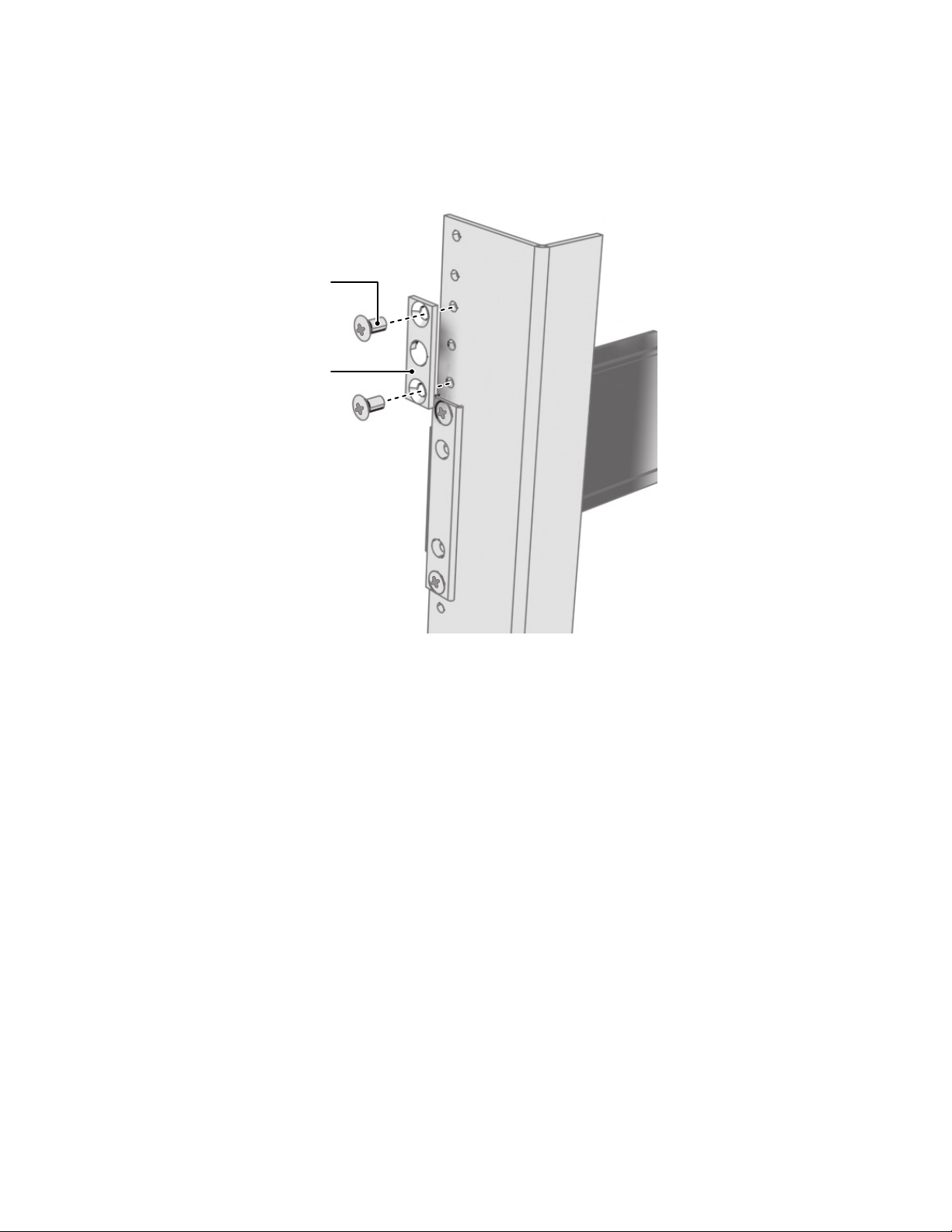

9 Fastening Mounting Brackets to Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10 Assembling a Support Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11 Inserting the Cage Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12 Attaching the Support Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

13 Attaching the Rack Rail Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

14 Mounting the EE500 into the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

15 Tightening the Thumbscrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

16 Attaching the Cable Management Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

17 Bundling the Power Supply Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

18 Opening the Bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

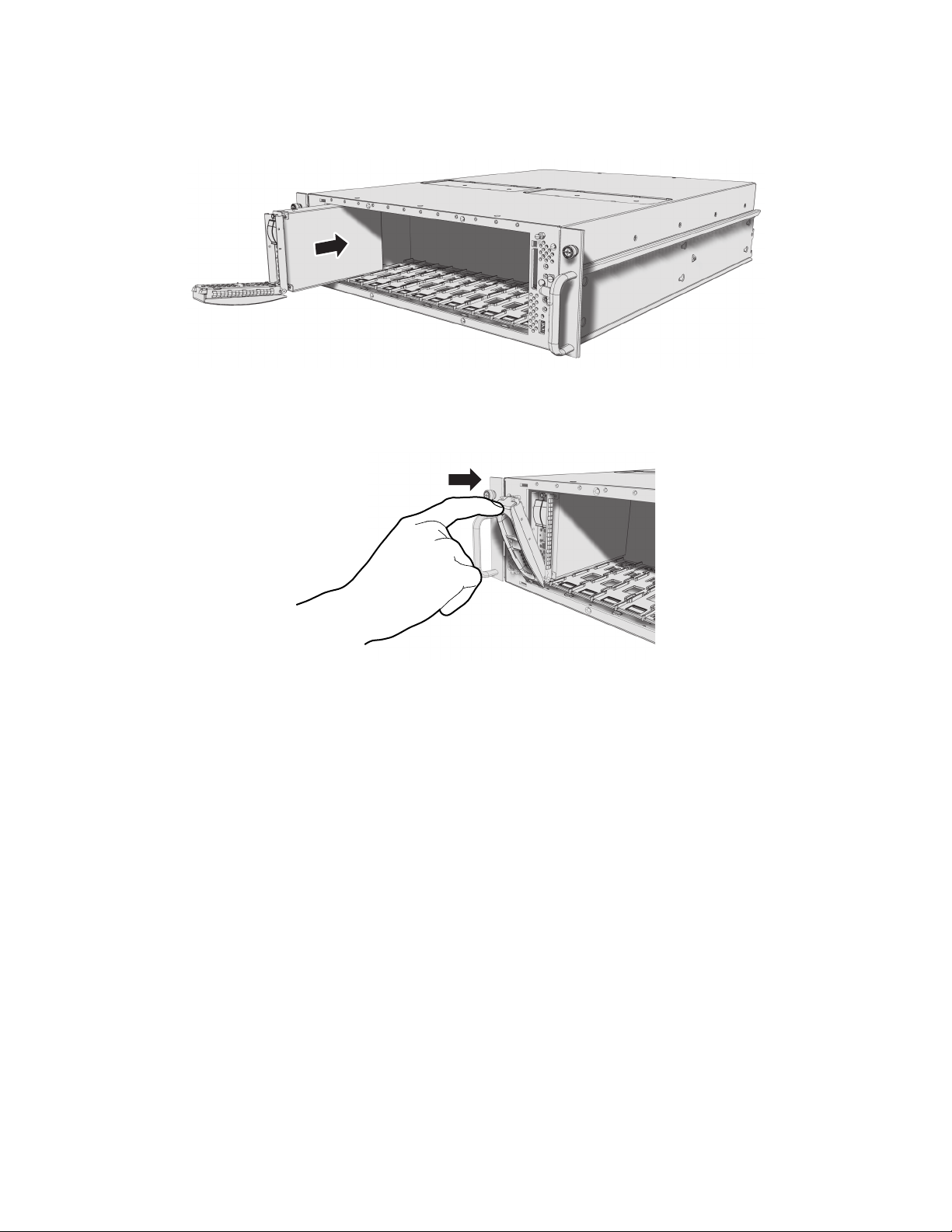

19 Installing a Hard Drive Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

20 Closing and Locking a Hard Drive Carrier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

21 Network Cable Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

22 Opening the Bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

23 Fibre Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

24 Connecting a UPS to an EE500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

C4649M-D (4/13) 3

Page 4

List of Tables

A Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

C Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 C4649M-D (4/13)

Page 5

Important Notices

LEGAL NOTICE

SOME PELCO EQUIPMENT CONTAINS, AND THE SOFTWARE ENABLES, AUDIO/VISUAL AND RECORDING CAPABILITIES, THE IMPROPER USE OF

WHICH MAY SUBJECT YOU TO CIVIL AND CRIMINAL PENALTIES. APPLICABLE LAWS REGARDING THE USE OF SUCH CAPABILITIES VARY

BETWEEN JURISDICTIONS AND MAY REQUIRE, AMONG OTHER THINGS, EXPRESS WRITTEN CONSENT FROM RECORDED SUBJECTS. YOU

ARE SOLELY RESPONSIBLE FOR INSURING STRICT COMPLIANCE WITH SUCH LAWS AND FOR STRICT ADHERENCE TO ANY/ALL RIGHTS OF

PRIVACY AND PERSONALTY. USE OF THIS EQUIPMENT AND/OR SOFTWARE FOR ILLEGAL SURVEILLANCE OR MONITORING SHALL BE DEEMED

UNAUTHORIZED USE IN VIOLATION OF THE END USER SOFTWARE AGREEMENT AND RESULT IN THE IMMEDIATE TERMINATION OF YOUR

LICENSE RIGHTS THEREUNDER.

REGULATORY NOTICE

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Changes and modifications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate this

equipment under Federal Communications Commission’s rules.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

VIDEO QUALITY CAUTION

FRAME RATE NOTICE REGARDING USER-SELECTED OPTIONS

Pelco systems are capable of providing high quality video for both live viewing and playback. However, the systems can be used in lower quality

modes, which can degrade picture quality, to allow for a slower rate of data transfer and to reduce the amount of video data stored. The picture

quality can be degraded by either lowering the resolution, reducing the picture rate, or both. A picture degraded by having a reduced resolution

may result in an image that is less clear or even indiscernible. A picture degraded by reducing the picture rate has fewer frames per second,

which can result in images that appear to jump or move more quickly than normal during playback. Lower frame rates may result in a key event

not being recorded by the system.

Judgment as to the suitability of the products for users’ purposes is solely the users’ responsibility. Users shall determine the suitability of the

products for their own intended application, picture rate and picture quality. In the event users intend to use the video for evidentiary purposes in

a judicial proceeding or otherwise, users should consult with their attorney regarding any particular requirements for such use.

C4649M-D (4/13) 5

Page 6

Description

The EE500 Series EnduraXpress™ combines the performance, reliability, and robustness of an enterprise-class, mission-critical storage

management system. It offers ease of installation and management that are critical for delivering a cost-effective solution to small-scale

installations. As the physical security requirements change over time, the EE500 series can be integrated into an Endura® system for unlimited

future expansion and scalability.

Hardware Built for Performance and Reliability

The demands of surveillance applications place unique strains on storage subsystems. Storage systems require the bandwidth and capacity to

keep up with incoming streams. They must also simultaneously manage all other common disk and RAID functions. In addition, physical security

applications are typically mission critical. Any downtime, degraded performance for routine maintenance, or loss of recorded footage is

extremely disruptive to the organization's physical security mission.

The EE500 is engineered to meet these unique performance and reliability demands. Custom hardware components have been specifically

designed to deliver sustained high throughput for recording and playback. The EE500 can handle a maximum of 250 Mbps of sustained write

throughput across 32 or 64 streams and an additional 32 simultaneous playback streams. This performance is maintained whether the system is

operating under normal conditions, dealing with disk drive errors, or rebuilding the RAID array.

The EE500 improves the total cost of ownership and energy efficiency by consolidating disparate components into a single chassis. The

integration of the recording server, recording software, and storage array into a highly optimized chassis can easily support standard resolution

and megapixel camera recording workloads. The purpose-built, highly optimized design reduces annual operating costs by eliminating the cost of

additional servers and the associated heating, ventilation, and cooling requirements they introduce.

Reliability is enhanced through the use of redundancy at all common failure points. A CompactFlash card hosts the operating system for higher

reliability over traditional hard disk drives. To mitigate any downtime resulting from CompactFlash errors, the database is striped across the

storage array. The RAID 6 storage configuration provides double parity protection of recorded data. The hard drive bay is cooled through the use

of high capacity, redundant fans to ensure that the drives are kept at an optimum operating temperature. Finally, fully redundant power supplies

guard against any power supply failure.

As with any other system, maintenance is an important and vital part of sustained operation. The EE500 incorporates various innovations to make

maintenance more efficient and to allow the system to continue operating at peak performance levels. Easy access to hard disk drives and the

CompactFlash card is available from the front panel. A unique rail system allows access to a failed fan should it need to be replaced.

Temperature sensors throughout the chassis detect possible airflow obstruction or clogged intake filters. The use of enterprise-class SAS

technology provides advanced enclosure management and monitoring. Notifications of potential or actual issues are transmitted to the specified

user interfaces for action through Simple Network Management Protocol (SNMP) messages and traps.

If additional storage capacity is required, the capacity can be expanded using third-party storage arrays with an optional fibre channel interface.

®

Software Built for Flexibility, Reliability, Cost Optimization

The EE500 incorporates a wizard-driven installation procedure that guides the integrator through a step-by-step installation procedure and

automates most processes. The integrated Dynamic Host Configuration Protocol (DHCP) server provides DHCP addresses to IP cameras or client

workstations. The integrated network time protocol manager can be directed at a network time server, or it can act as the time source for all

cameras and client workstations on the network. The deterministic performance of the hardware and software combination allows integrators to

easily estimate, size, and configure the system to meet their storage and performance requirements.

Cameras from the EE500 are viewed through a PC running the supplied Endura workstation client software. The software provides access to all

operation and configuration features in a unified, intuitive graphical user interface. The interface utilizes drag and drop operations, keyboard

shortcuts, built-in ToolTips, and online Help to enable the most direct, intuitive interactions with cameras and components distributed across the

network.

The software includes the following features:

• Accommodates standard resolution, high definition (HD), and megapixel camera sources

• Decodes MPEG-4 and H.264 (baseline, main, and high profile)

™

• Supports Zone of Interest

• Supports alarm management

• Provides the option to utilize camera sources with intelligent video content analysis at the edge

• Provides efficient search and export mechanisms

• Includes a complete administration and configuration console

, direct PTZ control, and digital zoom

6 C4649M-D (4/13)

Page 7

The EE500 includes built-in support for Pelco IP Cameras. Third-party cameras can be added using an optional UDI5000-CAM universal device

interface. Additional user interfaces, including network decoders and virtual console displays, can be added to expand viewing capabilities into a

full virtual matrix.

FEATURES

• Recording throughput up to 250 Mbps meets demanding performance requirements for real-time video, audio, and data applications

• Hardware designed to eliminate single points of failure including redundant fans, power supplies, and RAID 6 storage for optimum

• Built-in EnduraStor

•

• Performance levels maintained in normal and RAID error conditions

• Built-in diagnostic monitoring provides preventative maintenance and SNMP monitoring

• Reduced cost of ownership and increased energy efficiency through consolidation of multiple hardware components into a fully

• Ships with two Endura WS5200 advanced system management software licenses

• Software runs on a standard PC with Microsoft

• Support for standard resolution and megapixel resolution cameras

• Support for MPEG-4 and H.264 (Baseline, Main, and High profile codecs)

• Zone of Interest allows independent view and management of specified areas within a cameras field of view in live or playback views

• Digital zoom in live or playback views

• Convenient tear-off options to customize display

• EnduraView

• Integrated configuration and administration interface provides full-management capability for all components

• On-Screen pan/tilt/zoom (PTZ) controls including click to center and ptz to selected area

• Advanced search capabilities including motion, alarm, event, and camera

• Integrated event and alarm monitoring and management interface

• Expandable with integration into a larger Endura system

reliability

™

storage management increases storage efficiency by grooming video from Pelco video encoders and IP cameras based

on age and priority

Capable of up to 32 simultaneous video/audio playback streams

chassis

®

Windows® XP Professional and 32-bit versions of Windows Vista® Business, Ultimate, or

Enterprise operating systems

™

technology mitigates CPU processing requirements and network bandwidth consumption for multiscreen configurations

integrated

C4649M-D (4/13) 7

Page 8

MODELS

The following table describes the EE500 Series model numbers. For example, the model number for an EE564, 24 TB unit with United Kingdom

power cords is EE564-24B-UK.

NOTE: Models shipped to China do not include power cords. A CCC approved power cord must be used to power the equipment when used in

China.

EE532 or EE564 (no expansion)

EE532F or EE564F (fibre channel expansion)

*Storage capacities are subject to change. Contact Pelco Product Support for current capacity

information.

OPTIONAL ACCESSORIES

NSM5200-PS Replacement power supply module

NSM5200-FAN Replacement system fan (upper middle)

NSM5200-FANB Replacement rear chassis fan (rear panel)

NSM5200-FC Fibre channel expansion card

HD5200-500 Replacement 500 GB hard drive and carrier

HD5200-2T-72K Replacement 2 TB hard drive and carrier

HD5200-3000 Replacement 3 TB hard drive and carrier

Table A. Models

Models Storage* Country Code

6 TB

24B TB

36 TB

US = North America

EU = Europe

UK = United Kingdom

CN = China

AU = Australia

AR = Argentina

8 C4649M-D (4/13)

Page 9

Product Overview

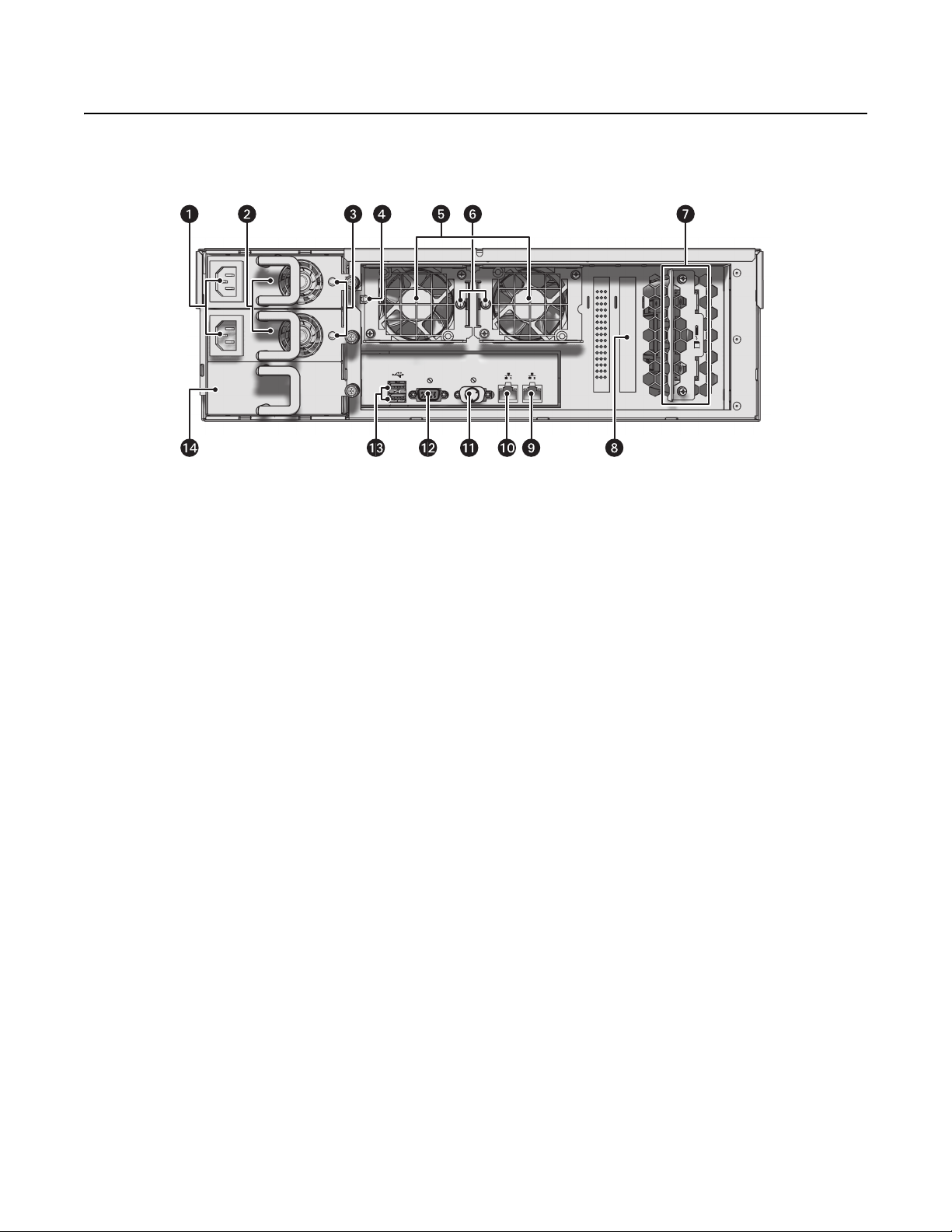

REAR PANEL

Familiarize yourself with the EE500 rear panel before connecting any equipment to the unit.

Figure 1. Rear Panel Layout

ì

Power Supply Connectors (hot-swappable)

î

Power Supplies (hot-swappable)

ï

Power Supply LEDs (status)

ñ

Power Supply Alarm Mute Button

ó

Hot-Swappable Rear Chassis Fans

r

Hot-Swappable Rear Chassis Fan Alarm LEDs

s

Controller Card Backup Battery

t

Card Options: No Expansion (shown);

Fibre Channel Connector

u

Ethernet Port 2 (reserved)

~í

Ethernet Port 1

~â

VGA Port

~ä

Serial Port

~ã

USB 2.0 Port (2 ea.)

~å

Blank Power Supply (reserved)

C4649M-D (4/13) 9

Page 10

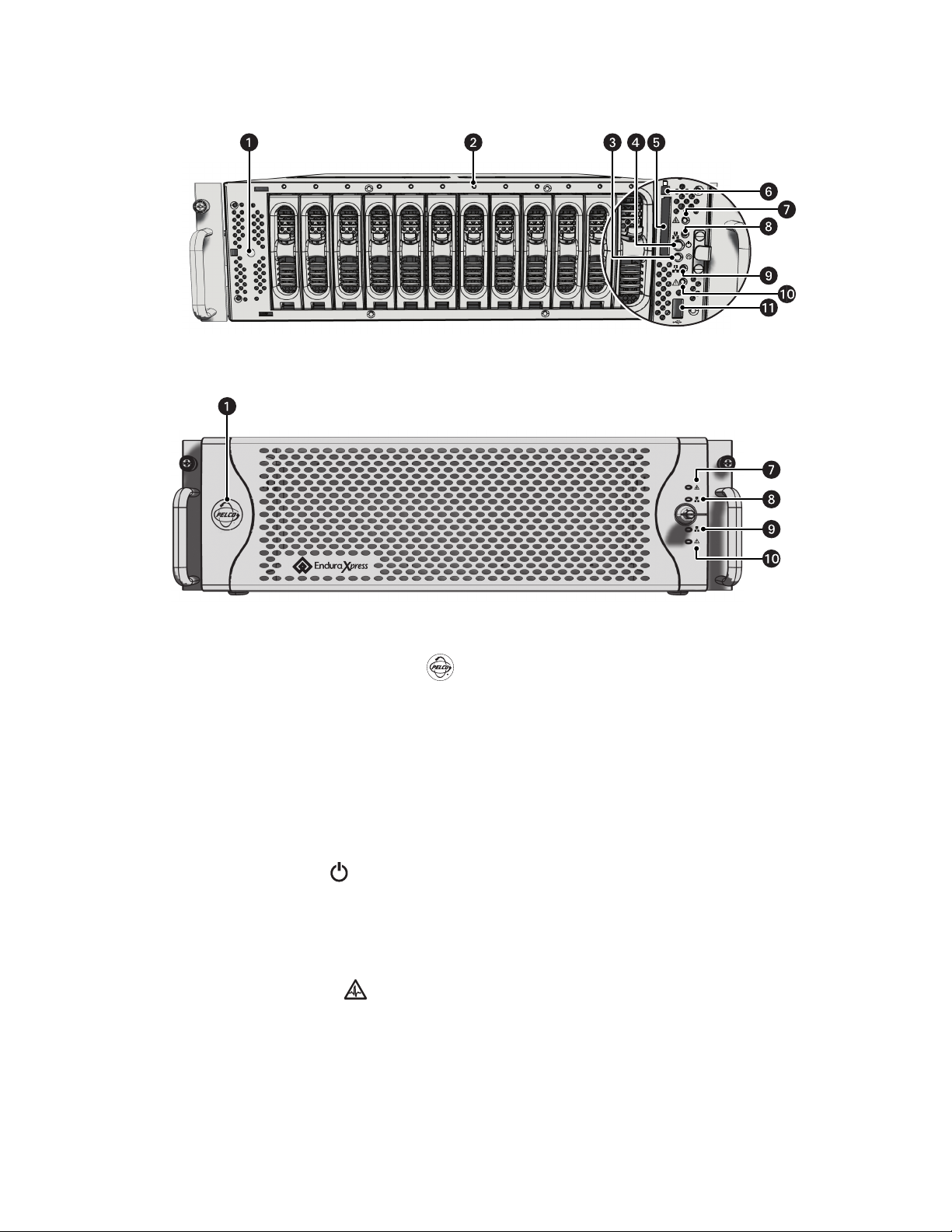

FRONT PANEL CONTROLS AND INDICATORS

1 2 3 4 5 6 7 8 9

10 11 12

Figure 2. Front Panel: Bezel Open

Figure 3. Front Panel: Bezel Closed

ì

Pelco Badge (power indicator)

The Pelco badge glows blue when the unit has power. If the bezel is open, this indicator glows white.

î

Drive Status

The drive status indicator reports the operating status of each individual hard drive as follows:

• Solid Green: The read or write operation on a specific hard drive.

• Solid Red: A problem exists with the hard drive.

• Flashing Red: The unit is initializing the hard drive.

ï

Reset Button

The reset button silences certain audible alarms, which includes working in conjunction with

the power supply silence alarm on the rear of the unit.

ñ

Power Button

Use the power button to turn the unit on and off (refer to Startup and Shutdown on page 27).

ó

Compact Flash Drive

Contains the operating system

r

Compact Flash Eject Button: Use this button to remove the CompactFlash drive.

s

Software Status

• Green: The software is operating normally.

• Amber: A minor software malfunction is detected; for example, an excessive network packet loss.

• Red: A fatal software error has occurred: for example, ceasing to record.

10 C4649M-D (4/13)

Page 11

t

Network Port 1 Speed and Activity

Network status (connection and speed) is indicated by one of the following conditions:

• Off: The unit is not connected to the network.

• Solid Green: The unit is connected to the network using the 1000Base-T standard.

• Solid Red: The unit is connected to the network using the 10/100Base-T standard.

NOTE: For proper operation, you must use the 1000Base-T standard.

u

Network Port 2 Speed and Activity

Network status (connection and speed) is indicated by one of the following conditions:

• Off: The unit is not connected to the network.

• Solid Green: The unit is connected to the network using the 1000Base-T standard.

• Solid Red: The unit is connected to the network using the 10/100Base-T standard.

NOTE: For proper operation, you must use the 1000Base-T standard.

~í

Unit Status

Unit status is indicated by one of the following three colors:

• Green: The unit is functioning normally.

• Amber: The unit is nearing operational thresholds; maintenance is recommended.

• Red: The unit is in an error condition (refer to Troubleshooting on page 28).

~â

USB 2.0 Port: One USB 2.0 port on the front panel.

C4649M-D (4/13) 11

Page 12

Before You Begin

Endura is a network system that requires a continuous amount of bandwidth to transmit full resolution, live video; therefore, always include your

network administrator when planning and installing Endura components.

You will need the following items:

• Access to a Gigabit Ethernet network port

• A personal computer that meets the minimum requirements of the WS5200 advanced system management software

NOTE: For best results, make sure your installation meets the power, environmental, and networking guidelines described in the

Endura Installation Guidelines and Best Practices document, which can be found on our Web site at www.pelco.com.

Refer to the Web Configuration manual that is shipped with the unit for details on how to access and configure the EE500.

NOTE: Diagnostic messages from the EE500 are reported on the WS5200. It can also be reported on an SNMP monitoring system.

During operation, monitor the unit status and services indicator lights to make sure that the system is operating properly. If failures occur, system

alarms and error messages will display on Endura workstations and SNMP monitoring systems.

USER-SUPPLIED PARTS

In addition to the standard tools and cables required for a video security installation, you will need to provide the following items:

Qty Description

1 Cat5e (or better) cable and connectors for connecting the EE500 to the Endura network

1 Power source (110/220 VAC)

1 Small flat-tip screwdriver, if mounting the unit into a rack

1 Small Phillips screwdriver, if mounting the unit into a rack

You also need to provide all network equipment, such as switches and camera sources.

12 C4649M-D (4/13)

Page 13

PACKAGE CONTENTS

The following three diagrams show the contents of the three boxes. When installing the EE500, refer to these diagrams.

Figure 4. Major Package Components

ì

EE500

î

Accessory Pack

ï

Hard Drive Pack (12 hard drives in carriers)

ñ

Important Safety Instructions; Installation manual;

Quick Start Guide

C4649M-D (4/13) 13

Page 14

Figure 5. Accessory Pack

ì

Rack Mount Kit (1 ea.)

î

Standard Power Cord (1 ea.)

ï

Resource Disc (1 ea.)

ñ

Screws, 8-32 x 0.375-Inch,

Phillips Pan Head (4 ea.)

ó

Rubber Feet (4 ea.)

r

Bezel Keys (2 ea.)

s

Security Tool (1 ea.)

t

ESD Disposable Wrist Strap (1 ea.)

14 C4649M-D (4/13)

Page 15

Figure 6. Rack Mount Kit

ì

Chassis Mounting Brackets (2 ea.), Installed

î

Rear Mount Rails (2 ea.)

ï

Front Mount Rails (2 ea.)

ñ

Screws, 6-32 x 0.25-Inch, Phillips Pan Head (2 ea.)

ó

Screws, 10-32 x 0.25-Inch, Phillips Pan Head (12 ea.), Installed

r

Screws, 8-32 x 0.375-Inch, Phillips Truss Head (8 ea.)

s

Screws, 10-32 x 0.5-Inch, Phillips Flat Head (8 ea.)

t

Screws, 10-32 x 0.75-Inch, Phillips Pan Head (4 ea.)

u

Cage Nuts, 10-32 (14 ea.)

~í

Rack Rail Spacers (2 ea.)

~â

Cable Management Bracket (1 ea.)

~ä

Cable Management Clips (3 ea.)

C4649M-D (4/13) 15

Page 16

PRODUCT SERIAL NUMBER LABEL PLACEMENT

Product serial number labels help identify your system and its factory configuration in the event that your EE500 or its components require

service.

Three labels citing your product’s serial number are attached to the unit. One large label is attached to the right side panel of the unit. A smaller

label is attached to the unit’s front panel on the lower-right side, behind the bezel.

Because rack mounting and other installation options may obscure the factory-applied labels, a third label is provided for you to attach to your

product documentation or other product location that will not be obscured by installation.

To use this label:

1. Locate the small label on the bezel of your EE500, attached with a yellow sticker that reads, “Extra serial number labels: remove prior to

installation.”

2. Remove the yellow sticker.

3. Peel away the backing of the small label and attach it to this installation manual, other product documentation, or an unobscured product

location.

S

N

0

3

2

6

7

-3

9

-

0

0

2

0

SERIAL NUMBER

Figure 7. Product Serial Number Labels

PRODUCT LABEL

16 C4649M-D (4/13)

Page 17

Installation

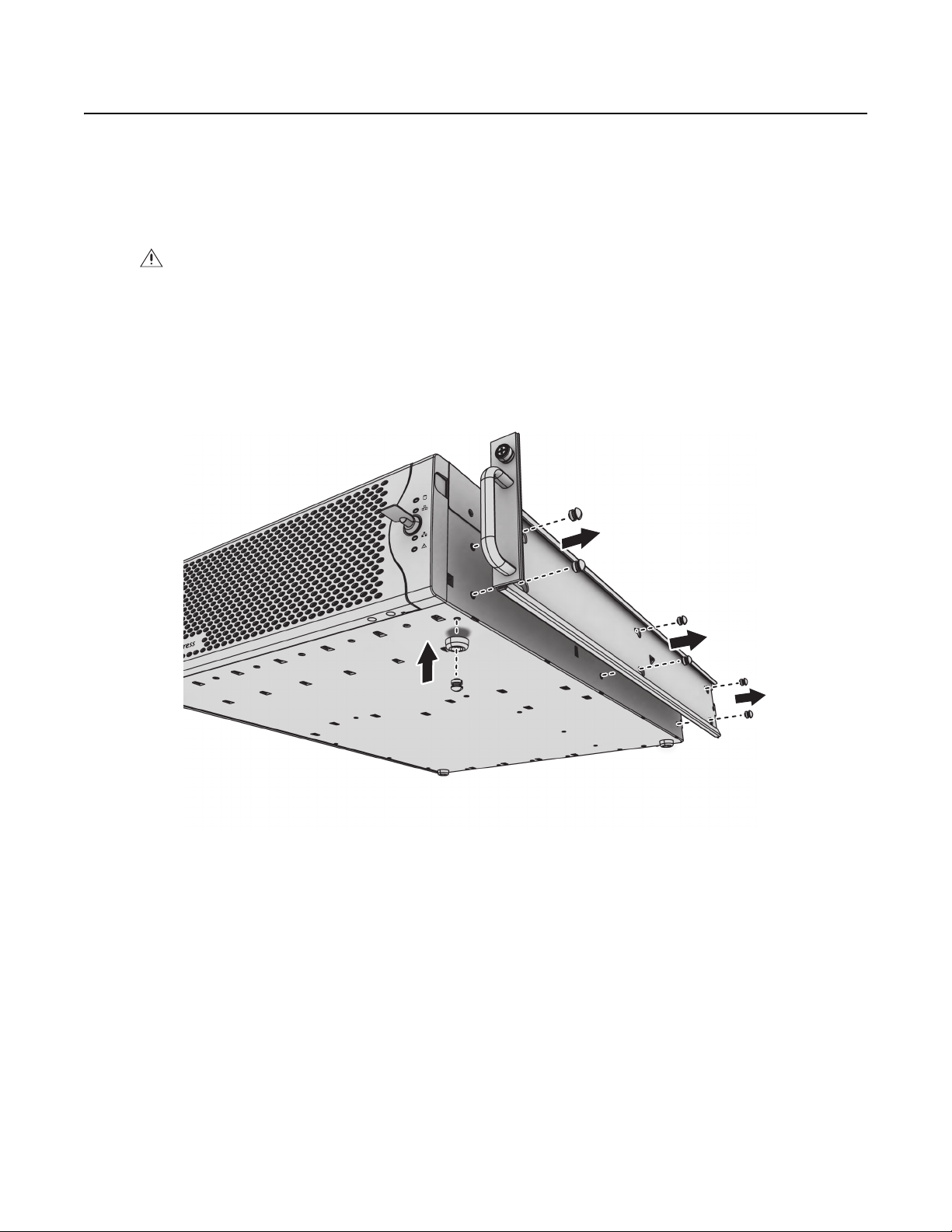

REMOVE BRACKETS

AND SCREWS

PLACING THE EQUIPMENT AND RACK MOUNTING

The EE500 Series can be mounted on a desktop or into an industry-standard 48 cm (19-inch) equipment rack.

MOUNTING ON A DESKTOP

WARNING: Do not place the EE500 on its side; in this position, the unit is likely to fall over and may cause equipment damage or personal

injury.

To install the EE500 on a desktop:

1. Make sure the rubber feet are installed to prevent surface damage. If not, secure each rubber foot to the bottom panel of the unit (refer to

Figure 8). Use the four 8-32 x 0.375-inch Phillips pan head screws (supplied).

2. (Optional) Remove the two chassis brackets from the sides of the unit, if they are attached. Remove the 10-32 x 0.25-inch Phillips pan head

screws (six per bracket). Save the brackets and screws for possible future use.

3. Position the unit to allow for cable and power cord clearance at the rear of the unit.

Figure 8. Installing Rubber Feet and Removing Brackets

MOUNTING IN A RACK

The EE500 occupies three rack units (13.3 cm or 5.25 in.) of vertical rack space. The hardware necessary to mount the EE500 into a rack is

supplied with the unit.

The rack must meet the following requirements:

• Rack standard: 48 cm (19-inch) EIA-310-D compliant (rear column required)

• Rack column depth: 61 to 76 cm (24 to 30 inches)

• Column mounting hole provisions: 10-32 UNF-2B threaded holes or square window holes on front and rear columns

• Door systems (optional): Front doors must have at least 5.1 cm (2 inches) between the EE500 bezel and the inside of the door. Rear doors

may be used only on rack columns that are more than 66.0 cm (26 inches) deep.

C4649M-D (4/13) 17

Page 18

WARNINGS:

(6) SCREWS

10-32 X 0.25-INCH

PHILLIPS PAN HEAD

ATTA CH BRACKETS

• Secure the front and rear screws to the support rails.

• Make sure the EE500 is level.

• Slots and openings in the cabinet provide ventilation to prevent the unit from overheating. Do not block these openings. Never place

the unit near or over a radiator or heat register. When placing the unit in a rack, be sure to provide proper ventilation.

• Four of the six redundant fans are located in the upper-middle portion of the unit. If the unit must be pulled out to replace a fan, make

sure that all cables connected to the unit have sufficient length to avoid being disconnected.

To install the EE500 in a rack:

NOTE: Figure 6 on page 15 identifies each piece of hardware for this procedure.

1. If chassis mounting brackets are not attached: Attach one mounting bracket to each side of the EE500. Use six 10-32 x 0.25-inch Phillips

pan head screws for each bracket. Attach the brackets so that the tapered ends are positioned toward the rear of the unit.

Figure 9. Fastening Mounting Brackets to Chassis

2. Remove the rubber feet from the underside of the unit if they are attached.

18 C4649M-D (4/13)

Page 19

3. Attach one front-mount rail to one rear-mount rail. Make sure the rails are mounted back to back, as shown in Figure 10. Depending on rack

(4) SCREWS 8-32 X 0.375

PHILLIPS TRUSS HEAD

FRONT-MOUNT RACK REAR-MOUNT RACK

ALIGN

ALIGN

CAGE NUT

CAGE NUT

depth, use either three or four 8-32 x 0.375-inch Phillips truss head screws for each rail set. Leave the screws untightened until later in the

installation.

Figure 10. Assembling a Support Rail

4. Repeat the previous step for the other rail set.

5. If you are installing the unit into a square-hole rack: Insert 14 cage nuts into the square-hole rack as shown in Figure 11. Align the bottom

cage nuts on the front racks with the bottom cage nuts on the rear racks. Then align the top cage nuts with the front racks.

Figure 11. Inserting the Cage Nuts

C4649M-D (4/13) 19

Page 20

6. Attach one support rail assembly to the equipment rack in the desired location (refer to Figure 12):

RACK FRONT RACK REAR

(4) SCREWS

10-32 X 0.75-INCH

PHILLIPS PAN HEAD

(4) SCREWS

10-32 X 0.5-INCH

PHILLIPS FLAT HEAD

REAR-MOUNT RAIL

FRONT-MOUNT RAIL

NOTE: The support rail assemblies are identical and may be used on either the right or left side of the rack.

a. Position the ear of the front-mount rail against the front of the equipment rack. Align the top and bottom holes in the ear of the rail

with the threaded holes (or cage nuts) in the rack.

b. Using two 10-32 x 0.5-inch Phillips flat head screws, attach the ear of the rail to the front of the rack. Insert the screws from the

outside of the rack, pointing toward the back of the rack.

c. Adjust the rails to the correct depth of the equipment rack by sliding the rear-mount rail to the back of the equipment rack.

d. Position the ear of the rear-mount rail against the rear exterior of the equipment rack. Align the top and bottom holes in the ear of the

rail section with the threaded holes (or cage nuts) in the equipment rack.

e. Using two 10-32 x 0.75-inch Phillips pan head screws, attach the ear of the rail to the rear of the rack. Insert the screws from the

outside of the rack, pointing toward the front of the rack.

7. Repeat the previous step for the second support rail assembly.

Figure 12. Attaching the Support Rails

20 C4649M-D (4/13)

Page 21

8. Attach one rack rail spacer to the front of the equipment rack (refer to Figure 13):

a. Position the bottom hole of the spacer above the ear of the front-mount rail.

b. Insert two 10-32 x 0.5-inch Phillips flat head screws into the spacer, one in the top hole and one in the bottom hole. Leave the middle

hole empty; the top thumbscrew on the EE500 will use it.

c. Tighten the two screws to secure the spacer to the rack.

10-32 X 0.5

PHILLIPS

FLATHEAD

SPACER

Figure 13. Attaching the Rack Rail Spacers

9. Repeat the previous step for the second spacer.

10. Tighten the 8-32 x 0.375-inch Phillips truss head screws that are attached to the front- and rear-mount rails, which were left untightened

earlier in the installation.

C4649M-D (4/13) 21

Page 22

11. Place the unit onto the mount rails by sliding the chassis brackets onto the rails. This step may require two people to lift and slide the unit

THUMBSCREW

into place. The unit should slide in and out of the rack easily.

NOTE: The EE500 stops mid-way in the rack to facilitate system fan replacement. To pull the EE500 completely out of the rack, press the

clips on either side of the rack to release the unit.

WARNING: When sliding out the EE500, be careful not to let the unit fall out of the rack or equipment damage or personal injury

could result.

Figure 14. Mounting the EE500 into the Rack

12. After the unit is in place, tighten the two thumbscrews to secure the unit to the rack.

Figure 15. Tightening the Thumbscrews

22 C4649M-D (4/13)

Page 23

13. Install the cable management bracket on the rear panel of the unit as follows:

Figure 16. Attaching the Cable Management Bracket

a. Position the bracket so that the screw holes on the unit and bracket are aligned.

b. Insert two 6-32 x 0.25-inch Phillips pan head screws (supplied) into the screw holes located on each side of the unit.

c. Tighten the two screws.

d. Attach the three cable clips (supplied) to the cable management bracket.

14. Position the EE500 power supply cords along the cable management bracket, and then close the cable clips. You can also use cable ties (not

supplied) to bundle all the cords (refer to Figure 17).

Four redundant fans are located in the upper-middle portion of the unit. If the unit must be pulled out of the rack to replace a fan, be sure to

observe the following information:

• All cables connected to the unit must have sufficient length to avoid being disconnected.

• All cables should be bundled and placed along the cable management bracket.

Figure 17. Bundling the Power Supply Cords

C4649M-D (4/13) 23

Page 24

INSTALLING THE HARD DRIVE ARRAY

1

2

3

4

5

6 7

8

9

10 11

12

The EE500 stores data using RAID (Redundant Array of Independent Disks) technology. All EE500 Series recorders operate in a RAID6

configuration to maximize fault tolerance and enhance disk-access performance.

The EE500 has a single RAID controller that manages a single array of 12 drives. The RAID 6 configuration allows any 2 of the 12 drives to fail

without any data loss. On any drive failure, the user is notified of the failure and the unit continues to operate.

WARNING: After a failed hard drive is replaced, the unit must rebuild it before it returns to service. If a third drive in the array

fails before either of the first two failed drives have completed the rebuild process, the array will go off line and data loss will

occur.

INSTALLING THE HARD DRIVE CARRIERS

After you have securely mounted the EE500, install the 12 hard drives in the front of the chassis. Each hard drive is already mounted in its own

drive carrier so you can easily install and remove a hard drive, even while the unit is operating.

NOTE: You must install all 12 hard drive carriers before you apply power to the EE500. The hard drive bays are numbered 1 through 12 (starting

from the left side). The hard drives are not preconfigured and can be placed in any empty hard drive bay.

To install the hard drive carriers:

1. Review all instructions in this section before proceeding.

2. Make sure you protect the unit and its components, which are susceptible to damage from improper handling and ESD. Refer to the

Safe Handling of Hard Drives document for more information.

3. Unlock and open the bezel.

Figure 18. Opening the Bezel

24 C4649M-D (4/13)

Page 25

4. Install each hard drive carrier as follows:

a. Open the hard drive latch (press down and pull the spring latch).

b. With the hard drive latch open, slide the hard drive carrier gently into an open hard drive bay.

Figure 19. Installing a Hard Drive Carrier

c. Close the hard drive latch; make sure the hard drive carrier locks into place.

Figure 20. Closing and Locking a Hard Drive Carrier

5. After all 12 hard drive carriers are inserted, close and lock the bezel.

NOTE: During operation, monitor the unit status indicators to make sure that all drives are operating properly. If a failure occurs, system alarms

and error messages will also display on Endura workstations and VCD5200 or VCD5202 virtual console display.

CONNECTING THE POWER SUPPLIES

The EE500 is equipped with two hot-swappable power supplies. These autoranging power supplies adapt automatically to voltages from

100 to 240 VAC (50/60 Hz). You should also install an uninterruptible power supply (UPS), which is not supplied. UPS devices maintain a limited

amount of backup battery power if the main power fails. Refer to Appendix B: Installing an Uninterruptible Power Supply on page 32 for more

information.

NOTE: Connect each power supply to a different branch circuit. This ensures optimal performance, reduces possible video loss, and reduces

power leakage to a safe level.

To connect the power supplies:

1. Connect each power cord to a power supply connector.

2. Connect the other end of each power cord to the appropriate power source.

When connected, the power supply status indicators glow solid amber. As soon as the unit starts, the indicators glow solid green. During

operation, if either indicator is not lit or glows red, there is a problem with a power supply.

C4649M-D (4/13) 25

Page 26

CONNECTING THE NETWORK

The EE500 supports remote administration from an Endura workstation. The EE500 is compatible with all Endura devices except for the SM5000

and the NSM5200. Consult your network administrator before installing the EE500 to avoid possible network conflicts.

Use the left Gigabit Ethernet adapter port to connect the EE500 to the Endura network. This is required for Endura operation.

NOTE: For best results, you should only implement an Endura system on a 1000Base-T network. Unless the Endura installation is very small with

a dedicated Endura network, a 100Base-T network will not support the necessary data throughput requirements.

To connect the EE500 to the Endura network using a switched Gigabit Ethernet network:

1. Connect one end of the unshielded twisted pair (UTP) cable to the left network connector on the EE500 rear panel. Use standard Cat5e or

better UTP cable with RJ-45 connectors.

ENDURA NETWORK

RESERVED

Figure 21. Network Cable Connection

2. Connect the other end of the UTP cable to an available port on a Gigabit Ethernet switch that meets the minimal switch requirements, as

described in the Endura Network Design Guide.

There are two indicators on the network connector on the rear panel. The left indicator glows orange when there is a good connection

between the EE500 and a Gigabit Ethernet switch that is powered up. If the indicator does not glow, check the cable and the switch.

Disregard the right indicator, which shows network activity.

26 C4649M-D (4/13)

Page 27

Startup and Shutdown

1

2

3

4

5

6

7

8

9

10

11

12

POWER BUTTON

STARTING UP THE UNIT

To start the unit:

1. Unlock and open the bezel.

2. Press the power button. The power indicator glows white.

3. Close and lock the bezel. The Pelco badge now glows blue.

Figure 22. Opening the Bezel

SHUTTING DOWN THE UNIT

You can shut down the EE500 by performing one of the following options:

• An orderly shutdown lets the unit close its files and shut down without affecting the data files. Use the orderly shutdown in most cases.

• An immediate shutdown is the same as disconnecting power and can result in corrupted data files. Only use the immediate shutdown in an

emergency or when there is not enough time for an orderly shutdown.

To shut down the unit:

1. Unlock and open the bezel.

2. Select one of the following options:

• For an orderly shutdown, press and release the power button quickly.

• For an immediate shutdown, press and hold the power button until the unit shuts down.

3. Close and lock the bezel.

C4649M-D (4/13) 27

Page 28

Troubleshooting

If the following instructions fail to solve your problem, contact Pelco’s Product Support at 1-800-289-9100 (USA and Canada) or +1-559-292-1981

(international) for assistance.

Access the properties dialog boxes for the EE500 on the Endura workstation. Refer to the Endura WS5200 Advanced System Software Operation

manual, which can be found on Pelco.com, and note the software version before contacting Pelco. The software version is located in the

Advanced Properties dialog box.

NOTE: Do not try to repair the unit yourself. Opening it immediately voids any warranty. Leave maintenance and repairs to qualified technical

personnel. Exchange the defective unit and return it for repair.

Problem Possible Causes Suggested Solution

Unit not ready. Power turned off. Check that the power indicator is lit.

The unit is not ready for operation

after firmware upload.

Unit status indicator is red. Unit fan failure. Replace the failed fan.

Unit status indicator is red and

the power supply alarm sounds.

Unit status and hard drive

indicators are red and the unit

alarm sounds.

Tab le B. Troubleshooting

Faulty cable connections. Check all leads, plugs, contacts, and connections.

Defective encoder. Check the camera on a different encoder.

Network connectivity issues. Contact your network administrator.

Voltage failure during programming

of update file.

Power supply failure.

Temperature exceeds specifications

(internal or external).

Power loss to either power supply. Check each power supply, line voltage, and the UPS.

Power supply module failure. Replace the failed power supply.

Hard drive failure. Replace the failed hard drive.

Replace the EE500 and have it checked by Pelco.

Check power supplies.

Check all fans; check the external temperature.

POWER SUPPLIES

The two power supplies are equipped with status indicators. Replace the appropriate power supply if a failure should occur. Table C describes

the status by color and indicator.

Power Supply Status Power Supply Indicator Front Panel Status Indicator Power Supply Audible Alarm

Normal Solid green Solid green Silent

Power problem Solid amber Solid red Alarm sounds

Power supply failure Not lit or solid red Solid red Alarm sounds

Table C. Status Indicators

28 C4649M-D (4/13)

Page 29

Specifications

SYSTEM

Operating System Linux

RAID Level RAID 6

Effective Capacity Up to 27.2 TB

Drive Interface SAS/SATA

User Interface Remote operation from Endura workstation, VCD5200, or VCD5202

Minimum Requirements Internet Explorer

®

®

6.x (or later) with Adobe® Flash® Player 10 (or later)

NETWORK

Interface 2, 1 Gbps Ethernet RJ-45 ports (1000Base-T)

Auxiliary Interfaces

USB 2.0 3 ports (2 rear, 1 front)

FRONT PANEL INDICATORS

Power Blue Pelco badge

Software Status Green, amber, red (based on diagnostics)

Ethernet Port 1 Green, red

Ethernet Port 2 Reserved

Hardware Status Green, amber, red

Hard Drive Status Green, red

POWER

Power Input 100 to 240 VAC, 50/60 Hz, autoranging

Power Supply Internal, dual-redundant, hot-swappable

Power Consumption Operating Average

262 W, 2.65 A, 895 BTU/H

263 W, 2.31 A, 895 BTU/H

254 W, 1.25 A, 868 BTU/H

Power Cord 2, United States standard (117 VAC, 3 prongs, molded connector, 1.8 m or 6 ft);

2, European standard (220 VAC, 3 prongs, molded connector, 1.8 m or 6 ft);

2, United Kingdom standard (250 VAC, 3 prongs, molded connector, 1.8 m or 6 ft);

2, Australian (250 VAC, 3 prongs, molded connector, 1.8 m or 6 ft); or

2, Argentinian (250 VAC, 3 prongs, molded connector, 2.4 m or 8 ft)

NOTE: Models shipped to China do not include power cords. A CCC approved power cord must be used to

power the equipment when used in China.

ENVIRONMENTAL

Operating Temperature 10° to 35°C (50° to 95°F) at unit air intake

Storage Temperature –40° to 65°C (–40° to 149°F)

Operating Humidity 20% to 80%, noncondensing

Maximum Humidity Gradient 10% per hour

Operating Altitude –16 to 3,048 m (–50 to 10,000 ft)

Operating Vibration 0.25 G at 3 Hz to 200 Hz at a sweep rate of 0.5 octave/minute

NOTE: The temperature at the unit air intake can be significantly higher than room temperature. Temperature is affected by rack configuration,

floor layout, air conditioning strategy, and other issues. To prevent performance failure and unit damage, make sure the temperature at the unit is

continuously within the operating temperature range.

C4649M-D (4/13) 29

Page 30

PHYSICAL

Construction Steel cabinet

Finish

Bezel Gray metallic with black end caps

Chassis Black matte finish

Dimensions 61.8 x 43.2 x 13.2 cm

(24.3" D x 17.0" W x 5.2" H)

Mounting Desktop (feet); Rack, 3 RU per unit (rack rails and hardware are supplied)

STANDARDS/ORGANIZATIONS

• Pelco is a member of the MPEG-4 Industry Forum

• Pelco is a member of the Universal Plug and Play (UPnP) Forum

• Pelco is a member of the Universal Serial Bus (USB) Implementers Forum

• Pelco is a contributor to the International Standards for Organization/Electrotechnical Commission (ISO/IEC) Joint Technical Committee

1 (JTC1), “Information Technology,” Subcommittee 29, Working Group 11

• Compliance, ISO/IEC 14496 standard (also known as MPEG-4)

• Compliant with International Telecommunication Union (ITU) Recommendation G.711, “Pulse Code Modulation (PCM) of Voice Frequencies”

30 C4649M-D (4/13)

Page 31

Appendixes

FIBRE CHANNEL CARD

APPENDIX A: EXPANDING VIDEO STORAGE

To connect the EE500F to a fiber channel storage area network (SAN) or network attached storage (NAS):

1. Consult the storage system configuration manuals to allocate capacity, configure the RAID level, and assign volumes to available ports.

2. Connect the EE500 to an available fiber channel link on the storage unit.

3. Open the EE500's configuration menu to make sure that the volumes are seen and mounted. The EE500 will format and start writing to the

presented volumes.

NOTE: When using non-Pelco storage systems, several critical elements can impact performance. The write throughput of the system must

accommodate the number and bit-rate of cameras assigned to the EE500. In addition, if more than one EE500 will be connected to the same SAN,

make sure the system latency is guaranteed to avoid lost packets. Avoid intermixing video surveillance recording and basic data management

workloads on the same SAN and dedicate a storage system to surveillance if possible.

Figure 23 shows a unit with a fibre channel configuration.

Figure 23. Fibre Channel Configuration

C4649M-D (4/13) 31

Page 32

APPENDIX B: INSTALLING AN UNINTERRUPTIBLE POWER SUPPLY

You should connect each EE500 to a UPS (not supplied). UPS devices maintain a limited amount of backup battery power if the main power fails.

WARNING: Most UPS devices can be used to supply backup battery power. The EE500 works in conjunction with the SmartUPS from APC.

The SmartUPS signals the EE500 to begin a graceful shutdown if the standby power in the UPS falls below a certain threshold.

To connect communication and power from the UPS to the EE500 (refer to Figure 24):

1. Connect a power cord from one of the EE500 power supplies to a standard wall socket.

2. Connect a power cord from the UPS to a standard wall socket or other power source.

3. Connect a USB cable from the APC Smart-UPS to the USB connector on the EE500.

4. Connect a power cord from the UPS to the other EE500 power supply. In this configuration, the unit will not lose power if either the power

source or the UPS fails.

5. Power up the UPS device.

6. Power up the EE500, if necessary (refer to Startup and Shutdown on page 27).

POWER SOURCE

USB

OUTPUT POWER

INPUT POWER

UPS

Figure 24. Connecting a UPS to an EE500

32 C4649M-D (4/13)

Page 33

APPENDIX C: INTEGRATION WITH AN ENDURA SYSTEM

The EE500 Series can be integrated with an Endura system to provide future expandability and scalability. When integrated into an Endura

system, the EE500 acts as an NSM5200 with 32 or 64 camera connections.

Because an EE500 operates much like a scaled-down Endura system, the following features must be reset so that it can be integrated into an

Endura system.

• The IP address of the unit must be reset to a static IP address instead of DHCP.

• The EE500 must be configured for Endura Enabled operation.

• Cameras that are attached to the EE500 must be reconfigured after the EE500 is properly integrated into the Endura system.

Only an Endura-certified integrator should configure an EE500 for integration into an Endura system.

MODIFYING DHCP SETTINGS ON THE EE500

This section describes how to modify the DHCP settings on the EE500 to avoid disruptions on the Endura system.

1. Connect an Ethernet cable to the EE500 network connector on the rear of the unit labeled ENDURA NETWORK. Refer to Connecting the

Network on page 26 for more information.

2. Connect the other end of the network cable to a computer’s network connector.

3. Open a Web browser from that computer.

4. Type the unit’s IP address or host name in the address bar, and then press Enter. The default IP address is 192.168.5.10.

5. Type admin, and then click Login.

6. Follow the prompts in the EE500 Quick Setup Wizard to configure the unit until you are prompted to set up DHCP.

7. Under Network Settings, select “No (use a static IP address).”

WARNING: Enabling DHCP can disrupt operations on the Endura system.

8. Click Next. The next screen prompts you to enter the static IP address.

9. Enter a static IP address that is within the network range, and then click Next. The next screen prompts with you with the question: “Would

you like to use this unit as your network's DHCP server?”

10. Select No, and then click Next.

11. Follow the remaining prompts in the EE500 Quick Setup Wizard to complete configuring the unit, and then click Save.

12. Wait for the unit to restart.

CONFIGURING THE EE500 FOR ENDURA ENABLED OPERATION

The EE500 must be configured for Endura Enabled operation before it can be integrated into an Endura network. The SM5200 must be available,

configured, and operating within the Endura network.

1. Open a Web browser from any computer on the Endura system.

2. Type the unit’s static IP address in the address bar, and then press Enter.

3. Log on to the unit.

4. Using the unit’s Web interface, select the Settings menu.

5. Click Endura Enabled.

6. (Optional) Click DHCP.

7. Click Save.

8. Type the administrator’s password, and then click Continue. The EE500 restarts automatically.

C4649M-D (4/13) 33

Page 34

CONFIGURING EE500 CAMERAS IN THE ENDURA NETWORK

1. Open a Web browser from a computer on the Endura network.

2. Type the static IP address of the EE500 in the address bar, and then press Enter.

3. Select the cameras from the Available pane that you want the EE500 to record.

4. Click the Add button. The selected cameras now appear in the Recording pane.

5. Click Save.

34 C4649M-D (4/13)

Page 35

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in

material or workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years:

– Fiber optic products

– Unshielded Twisted Pair (UTP) transmission products

– CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and

MC3651H-2X camera models

• Three years:

– FD Series and BU Series analog camera models

– Fixed network cameras and network dome cameras with Sarix

– Sarix thermal imaging products (TI and ESTI Series)

– Fixed analog camera models (C20 Series, CCC1390H Series, C10DN Series,

and C10CH Series)

– EH1500 Series enclosures

– Spectra

– Spectra HD dome products

– Camclosure

®

IV products (including Spectra IV IP)

®

IS Series integrated camera systems

– DX Series video recorders (except DX9000 Series which is covered for a

period of one year), DVR5100 Series digital video recorders, Digital Sentry

Series hardware products, DVX Series digital video recorders, and NVR300

Series network video recorders

®

– Endura

– Genex

Series distributed network-based video products

®

Series products (multiplexers, server, and keyboard)

– PMCL200/300/400 Series LCD monitors

– PMCL5xxF Series and PMCL5xxNB Series LCD monitors

– PMCL5xxxBL Series LED monitors

• Two years:

– Standard varifocal, fixed focal, and motorized zoom lenses

– DF5/DF8 Series fixed dome products

®

– Legacy

– Spectra III

Series integrated positioning systems

™

, Spectra Mini, Spectra Mini IP, Esprit®, ExSite®, ExSite IP, and

PS20 scanners, including when used in continuous motion applications

– Esprit Ti and TI2500 Series thermal imaging products

– Esprit and WW5700 Series window wiper (excluding wiper blades)

– CM6700/CM6800/CM9700 Series matrix

– Digital Light Processing (DLP

®

) displays (except lamp and color wheel). The

lamp and color wheel will be covered for a period of 90 days. The air filter is

not covered under warranty.

®

technology

•Six months:

– All pan and tilts, scanners, or preset lenses used in continuous motion

applications (preset scan, tour, and auto scan modes)

Pelco will warrant all replacement parts and repairs for 90 days from the date of

Pelco shipment. All goods requiring warranty repair shall be sent freight prepaid

to a Pelco designated location. Repairs made necessary by reason of misuse,

alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s liability

for any claim, whether based on breach of contract, negligence, infringement of

any rights of any party or product liability, relating to the Products shall not exceed

the price paid by the Dealer to Pelco for such Products. In no event will Pelco be

liable for any special, incidental, or consequential damages (including loss of use,

loss of profit, and claims of third parties) however caused, whether by the

negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the

®

following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall under

the warranty conditions stated above, please include a written explanation with

the product when returned.

Method of return shipment shall be the same or equal to the method by which the

item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100

or (559) 292-1981 to obtain an authorization number (CA number if returned for

credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and

refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned

CA or RA number and freight should be prepaid.

Revised 10-9-12

The materials used in the manufacture of this document and its components are compliant to the requirements of Directive 2002/95/EC.

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

REVISION HISTORY

Manual # Date Comments

C4649M 3/10 Original version.

C4649M-A 5/11 Added the number of WS5200 licenses shipped with the unit.

C4649M-B 7/11 Added the 36 TB storage option, the 3 TB hard drive replacement, and revised the effective capacity.

C4649M-C 1/12 Removed the 3 TB and 12 TB storage options, replaced the 24 TB with the 24B TB storage option, and replaced the HD5200-2000 with the HD5200-2T-72K storage

C4649M-D 4/13 Added the Endura Enable setup section as Appendix C.

Pelco, the Pelco logo, and other trademarks associa ted with Pelco products referred to in this publication are trademarks of Pelco, Inc. or its affilia tes. © Copyright 2013, Pelco, Inc.

ONVIF and the ONVIF logo are trademarks of ONVIF Inc. All other product names and services are the property of their respective companies. All rights reserved.

Product specifications and availability are subject to change without notice.

option. Also removed the 250 GB and 1 TB hard disk drive replacement options.

Page 36

Pelco by Schneider Electric 3500 Pelco Way Clovis, California 93612-5699 United States

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

www.pelco.com www.pelco.com/community

Loading...

Loading...