Page 1

®

ED25/ED2500/ED2620/ED27

Series Environmental Domes

Installation/Operation Manual

C437M-B (9/95)

PELCO • 3500 Pelco Way • Clovis, CA 93612-5699 • USA • www.pelco.com

(800) 289-9100 or (1-559) 292-1981 • FAX (800) 289-9150 or (1-559) 292-3827

Page 2

TABLE OF CONTENTS

Section Page

1.0 WARNINGS .......................................................................................................................................1

2.0 SCOPE ...............................................................................................................................................2

2.1 DESCRIPTION ......................................................................................................................... 2

3.0 INSTALLATION .................................................................................................................................. 3

3.1 MOUNTING ..............................................................................................................................3

3.2 PAN/TILT INSTALLATION/REMOVAL .................................................................................... 4

3.3 ELECTRICAL WIRING ............................................................................................................. 4

4.0 PAN/TILT LIMIT ADJUSTMENTS ...................................................................................................11

5.0 CARE AND MAINTENANCE ........................................................................................................... 12

6.0 SERVICE AND REPAIR .................................................................................................................. 12

6.1 RECOMMENDED EQUIPMENT AND TOOLS ......................................................................12

6.2 SERVICE TIPS ....................................................................................................................... 12

7.0 EXPLODED ASSEMBLY DIAGRAM ...............................................................................................13

8.0 MECHANICAL PARTS LIST ............................................................................................................ 14

9.0 PAN/TILT ELECTRICAL PARTS LIST ............................................................................................ 14

10.0 MODELS ..........................................................................................................................................15

11.0 SPECIFICATIONS ...........................................................................................................................16

11.1 RECOMMENDED MOUNTS/CONTROLS .............................................................................. 17

12.0 WARRANTY AND RETURN INFORMATION..................................................................................18

LIST OF ILLUSTRATIONS

Figure Page

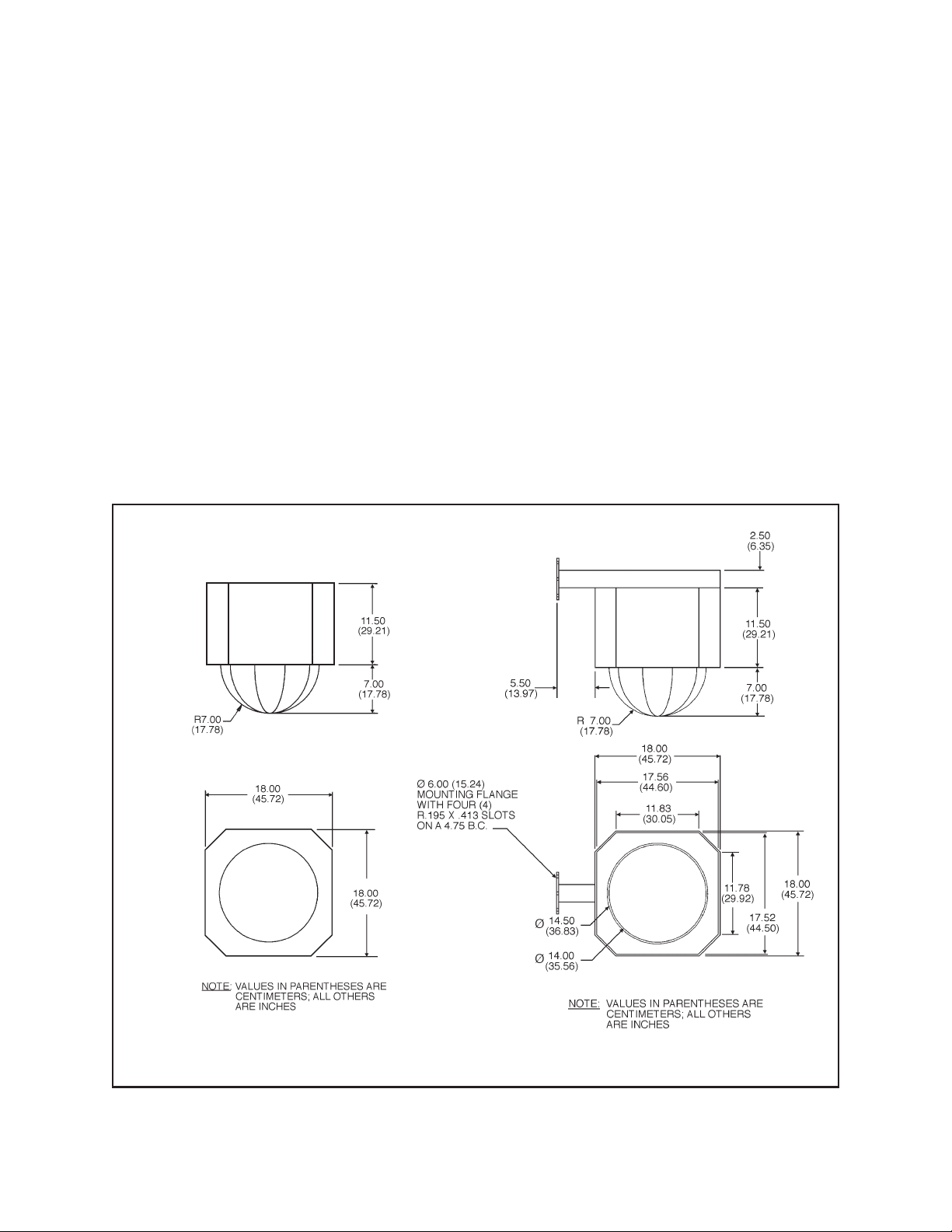

1 Dimension Drawing ......................................................................................................................... 2

2 FMED25 Installation .......................................................................................................................3

3 PMED25 Installation ....................................................................................................................... 4

4 Power Supply Connection .............................................................................................................. 5

5 ED2520 Series Receiver/Driver Wiring Diagram ............................................................................ 6

6 ED2620/ED2620-SL Wiring Diagram ............................................................................................. 7

7 ED2520/ED2720 Wiring Diagram ...................................................................................................8

8 ED2520-SL/ED2720-SL Wiring Diagram ........................................................................................ 8

9 ED2520-PP/ED2720-PP Wiring Diagram ....................................................................................... 9

10 ED2520SL-PP/ED2720SL-PP Wiring Diagram .............................................................................. 9

11 Video Synch/Alarm Terminal Diagram ......................................................................................... 10

12 Tilt Limit Stop Modification............................................................................................................11

13 Pan Limit Stop Locations ..............................................................................................................11

14 ED25/ED26/ED27 Series Enclosure Exploded Assembly Diagram ............................................. 13

REVISION HISTORY

Manual # Date Comments

C437M-A 10/94 Incorporated addendum covering Section 3.3.3, Video Synchronization,

Alarm Terminal Diagram and Figure 11. Incorporated addendum covering Figure 6, DD2000/DD2000-SL Wiring Diagram.

C437M-B 9/95 Updated Figure 4 and Section 11 to show two (2) 40 Watt heaters per

ECO 95-207. Updated Figure 6 to show correct wiring.

1/96 Figure references in Section 4.0 revised.

Pelco, the Pelco Logo, Camclosure, Esprit, Genex, Legacy, and Spectra are registered trademarks of Pelco. © Copyright 1995, Pelco. All rights reserved.

Endura and ExSite are trademarks of Pelco.

ii PELCO Manual C437M-B (9/95)

Page 3

INSTALLATION/OPERATION MANUAL

ED25/ED2520/ED2620/ED27/ED2720

SERIES ENVIRONMENTAL DOMES

1.0 WARNINGS

Prior to installation and use of this product, the following WARNINGS should be observed.

1. Installation and servicing should only be done by

Qualified Service Personnel and conform to all

Local codes.

2. Unless the unit is specifically marked as a NEMA

Type 3-6P enclosure, it is designed for Indoor use

only and it must not be installed where exposed to

rain and moisture.

3. The product bears the following marks:

CAUTION:

This device is designed to operate at

24 volts AC power.

Input voltage must not exceed 28 volts

or drop below 22 volts or else

DAMAGE TO THE MOTORS

WILL OCCUR.

Should you need technical assistance,

please call (800) 289-9100.

4. Only use replacement parts recommended by

PELCO.

5. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

PELCO Manual C437M-B (9/95) 1

Page 4

2.0 SCOPE

The information contained in this manual covers the

ED25/ED2520/ED2620/ED27/ED2720 Series Environmental Domes.

2.1 DESCRIPTION

The ED25/ED27 Series can be ordered as a dome only

or with factory installed heater/blower and service light.

Other options include factory assembled integral pan/

tilt and/or Coaxitron/Wiretron receiver/driver.

The ED25 Series is designed for flush mount or pen-

dant mount applications.

The ED25/ED2520/ED2620/ED27/ED2720 Series of

environmental domes have been designed primarily for

outdoor applications, but also can be used indoors. The

14-inch diameter black opaque lower dome has a

smoked viewing window with less than 1 f-stop light

loss. This provides for effective camouflage of the

CCTV security/surveillance system without compromising the quality of the video picture.

The ED2620 Series is a pendant mount dome with in-

tegral pan/tilt and is designed specifically for hard-wire

control applications.

The ED27 Series includes an integral arm and can be

used for wall, parapet, or universal mount applications.

ED25/26 Series ED27 Series

Figure 1. Dimension Drawings

2 PELCO Manual C437M-B (9/95)

Page 5

3.0 INSTALLATION

CAUTION: Make certain that the mounting

surface is capable of supporting the full load of

the mount, pan/tilt, camera/lens and enclosure

• Handle the lower dome with care so as not to

scratch or get fingerprints on the viewing window.

• When installing the unit, loosen the two (2) fasteners and remove the pan/tilt or camera mount to

reduce the total weight of the enclosure.

• When the pan/tilt or camera mount is removed,

install the camera/lens and make sure the electrical connections to the pan/tilt (camera power, lens

power and video) are made.

• When closing the enclosure, be sure the drive tab

on the dome engages the slot on the drive arm of

the pan/tilt.

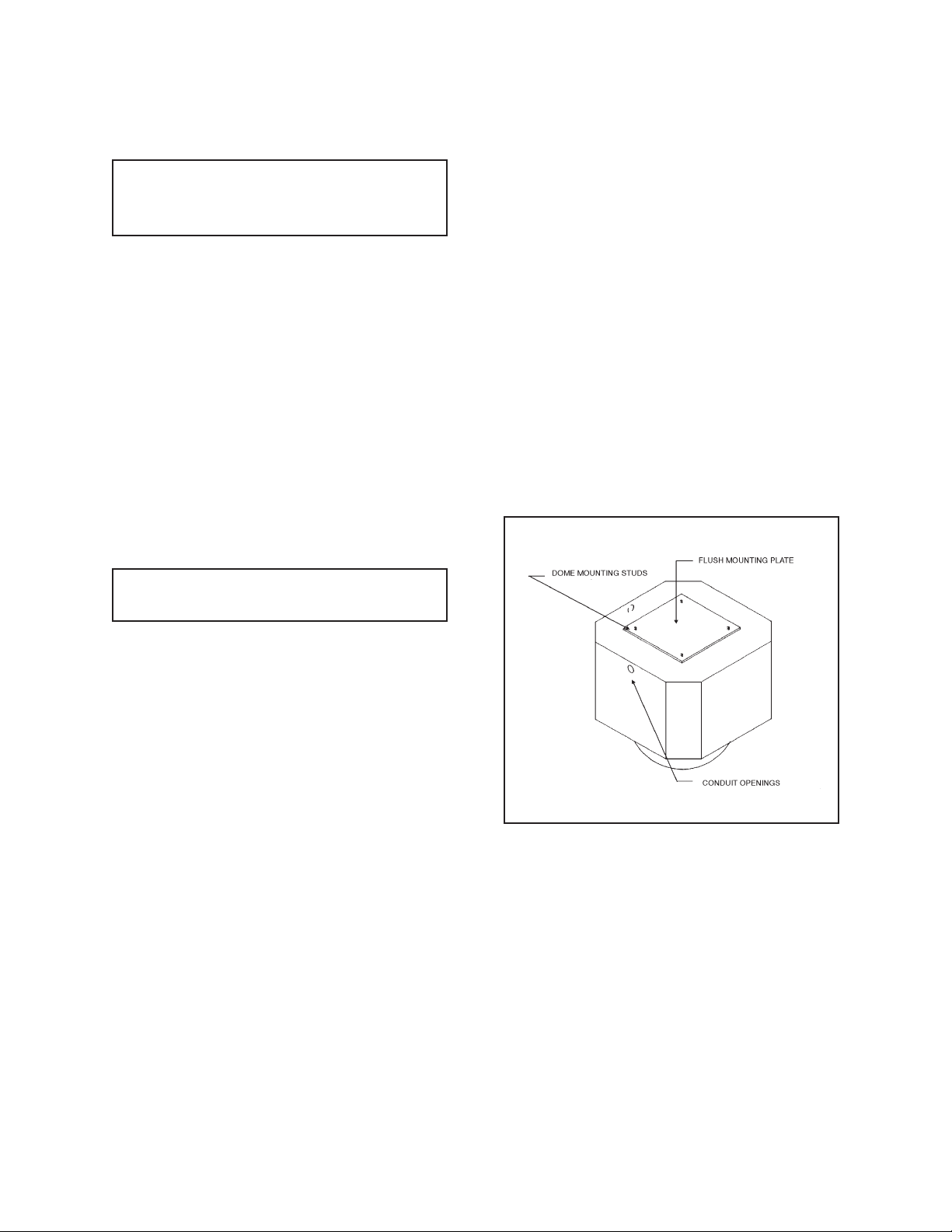

3.1.1 FMED25 Flush Mount Installation

To mount the enclosure using the FMED25 flush mount,

perform the following steps. Refer to Figure 2.

1. Secure the FMED25 flush mounting plate to a suitable surface and secure with suitable fasteners (not

supplied) capable of supporting the weight of the

dome, pan/tilt, camera and lens. Due to the wide

range of installations this mount could be used in,

drilling of holes in the mounting plate will be required.

2. Install the provided gasket over the four (4) studs

on the FMED25 mounting plate.

3. Align the four (4) studs in the FMED25 with the

four (4) holes in the top of the dome. Then, secure

the dome to the mounting plate by using the four

(4) 1/4-20 nuts supplied with the mount.

WARNING: Do not rotate pan/tilt by hand.

Rotate by controller only.

3.1 MOUNTING

The ED25/ED2520/ED2620 Series of environmental

domes can be installed by using one of the following

mounts:

• FMED25 Flush mount adapter. Adapts dome

to ceiling. Required for all flush

mount applications.

• PAED25 Discontinued. (Use PA102 with

ED27 Series dome.)

• PMED25 Pendant mount adapter.

• UMED25 Discontinued.

• WMED25 Discontinued. (Use ED27 Series

dome with integral mount.)

Mount the enclosure according the following directions

for the selected mount.

Figure 2. FMED25 Installation

PELCO Manual C437M-B (9/95) 3

Page 6

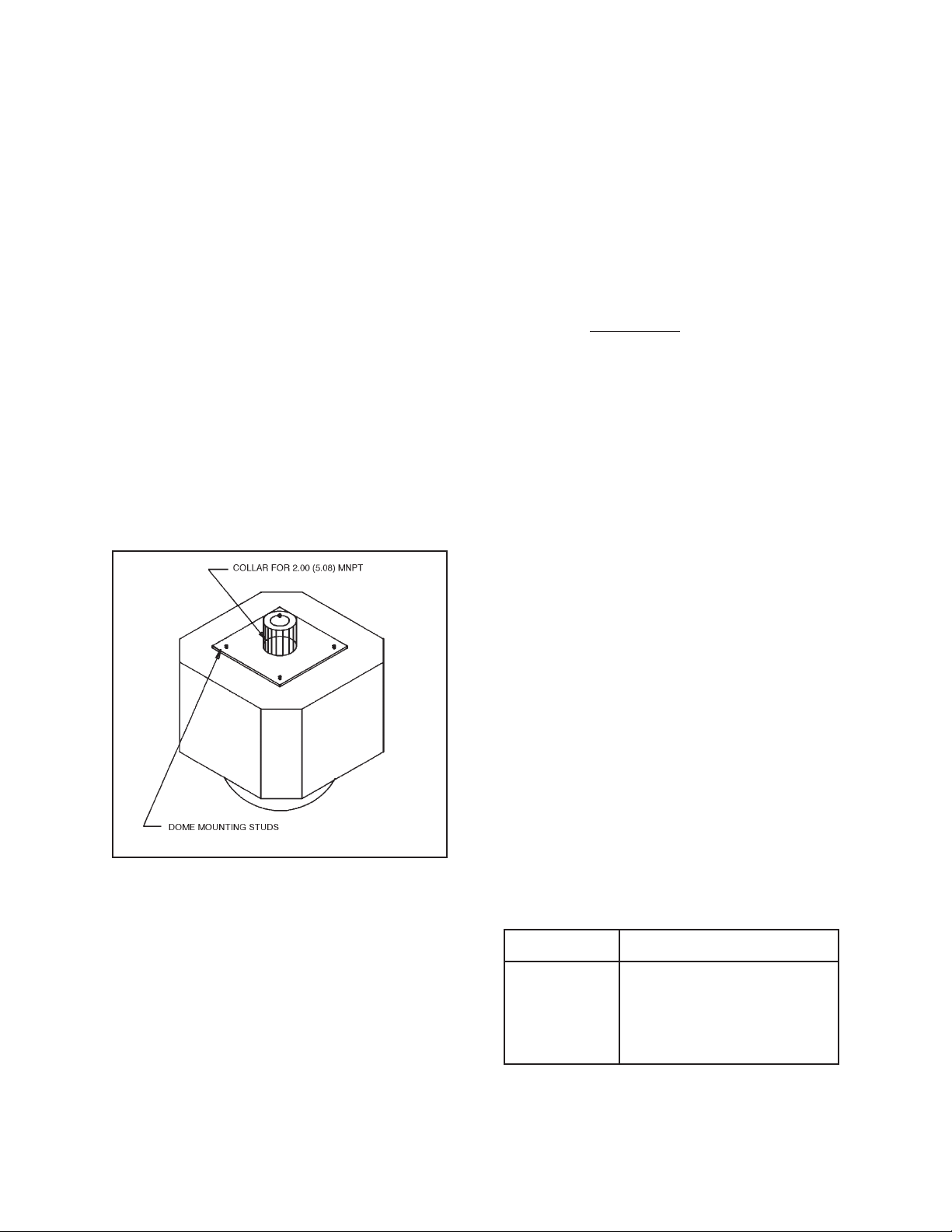

3.1.2 PMED25 Pendant Mount

Installation

3.2 PAN/TILT INSTALLATION/

REMOVAL

To mount the enclosure using the PMED25 pendant

mount, perform the following steps. Refer to Figure 3.

1. Screw the PMED25 pendant mount to a suitable

length of 1-1/2-inch MNPT threaded pipe which

has been securely fastened to a surface capable of

supporting the weight of the dome, pan/tilt, camera and lens.

(The Pelco MRCA ceiling adapter is recommended

for ceiling mounting applications.)

2. Install the provided gasket over the four (4) studs

on the PMED25 mounting plate.

3. Align the four (4) studs in the PMED25 with the

four (4) holes in the top of the dome. Then, secure

the dome to the mounting plate by using the four

(4) 1/4-20 nuts supplied with the mount.

The following installation instructions are for removing/installing the pan/tilt assembly.

1. The pan/tilt is secured to the back box by two (2)

1/4-20 nuts which hold the pan/tilt mounting

bracket to the integral studs on top of the back box.

2. To remove the pan/tilt, first position the pan/tilt by

using the controller only so it is perpendicular with

the mounting nuts. Then, use a 7/16" socket on a

long extension to reach the nuts holding the pan/

tilt.

3. The mounting nuts need not be removed, just loosened. Once the nuts have been loosened, slide the

pan/tilt so the nuts fit through the “key holes”.

4. To install the pan/tilt, reverse the procedure.

3.3 ELECTRICAL WIRING

The following installation instructions describe how to

connect power to the camera, lens and pan/tilt.

1. The supply circuit should be connected to the input circuit board (pins 8, 9 & 10) as shown in Figure 7.

Figure 3. PMED25 Installation

3.1.3 ED27 Wall Mount Installation

The following installation instructions are for mounting the ED27 Series mount with integral wall mount

arm to an appropriate surface.

1. Mount the mounting plate of the ED27 enclosure

on a suitable surface and secure with suitable fasteners (not supplied) capable of supporting the

weight of the dome, pan/tilt, camera and lens.

2. The pan/tilt and video connection to the receiver/

driver are shown in Figure 8.

3. Basic motor wiring detail for the pan/tilt assembly

is shown in Figure 9.

4. The dome drive pinouts for all models are shown

in Figure 10. Select the appropriate model for your

installation.

3.3.1 Replacement Dome, Pan/Tilt

Chart

Pan/Tilt Dome Enclosure

DD2500 ED2520/ED2720

DD2500-PP ED2520-PP/ED2720-PP

DD2500-SL ED2520-SL/ED2720-SL

DD2500LS-PP ED2520SL-PP/ED2720SL-PP

4 PELCO Manual C437M-B (9/95)

Page 7

3.3.2 Conductor Requirements

The ED25/ED2520/ED27 Series environmental domes

can be connected by a “hard-wire” system, Coaxitron

or Wiretron system. The ED2620 Series dome is designed for hard-wire applications only. The distances

for each of these system is as follows:

Hard-wire Systems Coaxitron System Wiretron System

Cable Size Max. Cable Distance Max. Cable Distance Max. Cable Distance

14 Awg 680 ft (207.3 m) — —

16 Awg 425 ft (129.54 m) — —

18 Awg 265 ft (80.77 m) — —

20 Awg 165 ft (50.29 m) — 10 miles (16,093.44 m)

22 Awg — — 5 miles (8,046.72 m)

RG-59U — 750 ft (228.6 m) —

RG-11U — 1,800 ft (548.64 m) —

RG-6U — 1,500 ft (457.2 m) —

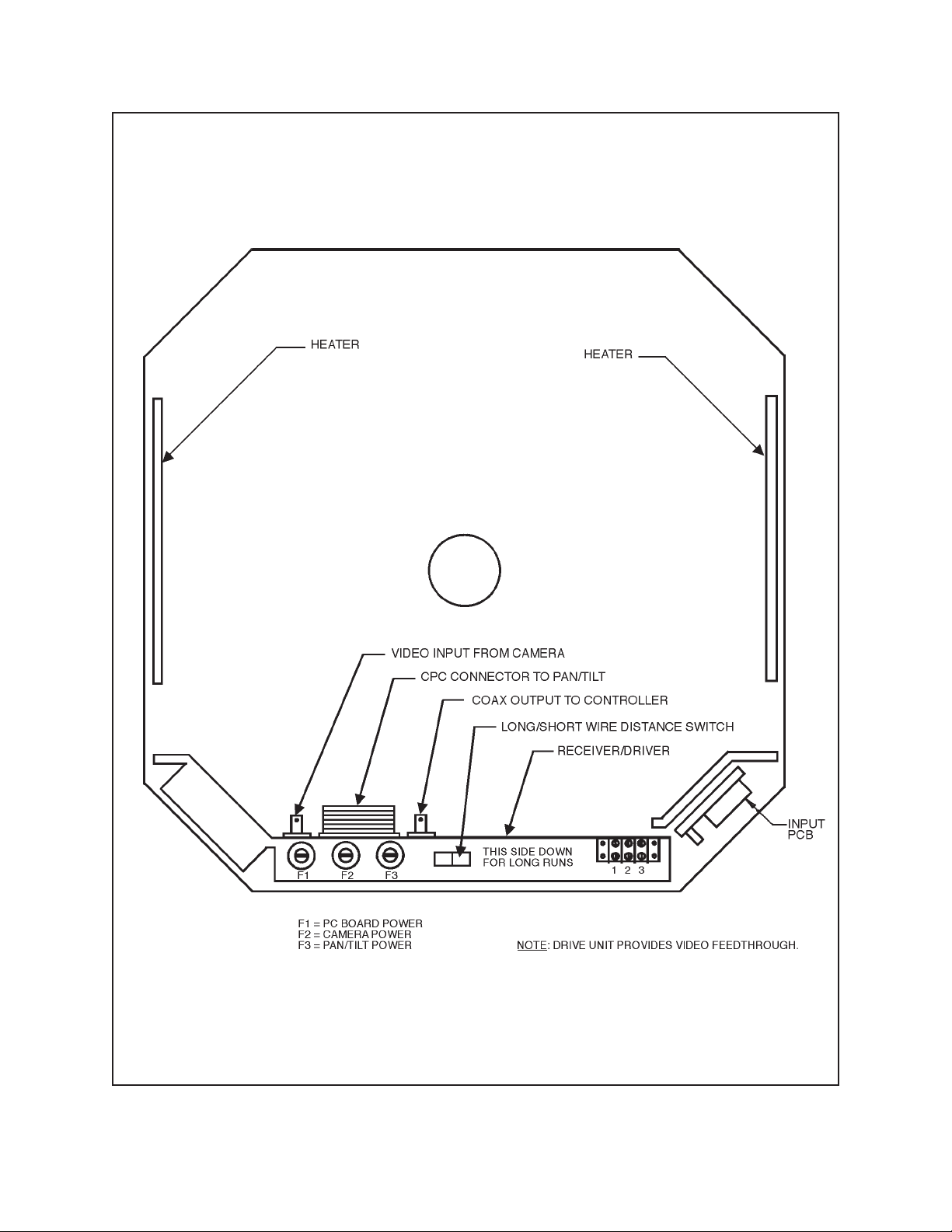

Figure 4. Power Supply Connection

PELCO Manual C437M-B (9/95) 5

Page 8

Figure 5. ED2520/ED2720 Series Receiver/Driver Wiring Diagram

6 PELCO Manual C437M-B (9/95)

Page 9

ED2620/ED2620-SL Pan/Tilt Wiring Diagram

Qty Sym Description Part Number

1 C1 Capacitor, 15 MFD 100 V CAPU0015.0/100N

1 C2 Capacitor, 15 MFD 100V CAPU0015.0/100N

1 M1 Pan Motor PT350010010

1 M2 Tilt Motor 2508001

1 J2 Connector CONMAB6100

14 – Connector Pins CON66102-7

4 S1-S4 Switch SWI1SM1

1 – Input Connector CON206305-1

1 – Mating Connector SS1000ASSY

1 – Actuator SWIJS138B

1 – Lens Mating Connector CONMAS6100

1 2

456

12 13 14

Front View

3

9108

7

11

Video Shield 4

Lens Common 13

Safety Ground 8

Common 1

Left 3

Right 7

Down 5

Up 6

Video 2

Camera 9

24 VAC 14

Iris 10

Focus 11

Zoom 12

BRN

RED

BLU

YEL

ORG

W/VIO

W/BLK

WHITE

W/YEL

BLACK

W/BRN

W/RED

W/ORG

GREEN

S1

S2

S3

S4

C1

C2

1

3

2

4

5

M1

M2

J2

Lens

Connector

Input Connector

Figure 6. Wiring Diagram for ED2620/ED2620-SL Dome Drives

PELCO Manual C437M-B (9/95) 7

Page 10

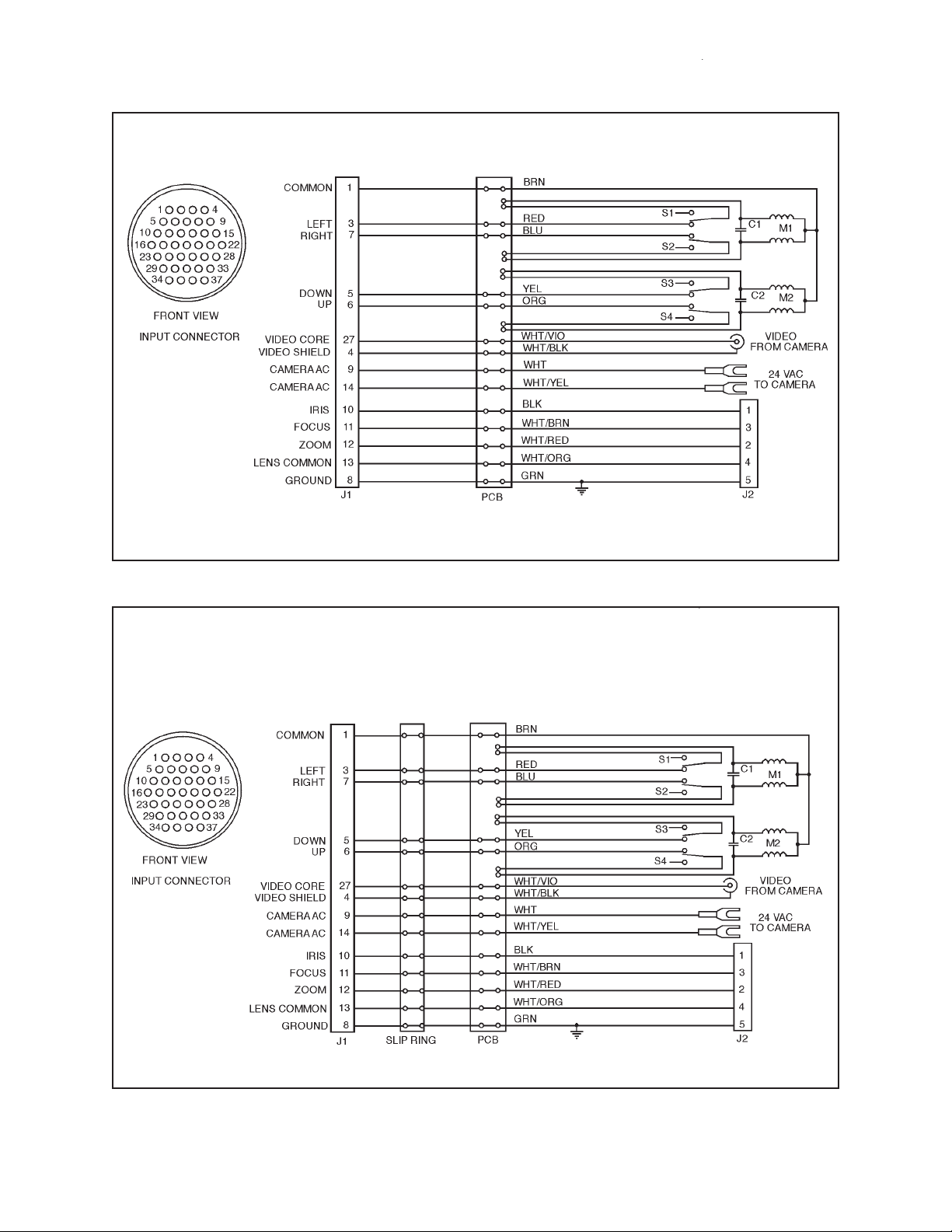

Figure 7. Wiring Diagram for ED2520/ED2720 Dome Drives

Figure 8. Wiring Diagram for ED2520-SL/ED2720-SL Dome Drives

8 PELCO Manual C437M-B (9/95)

Page 11

Figure 9. Wiring Diagram for ED2520-PP/ED2720-PP Dome Drives

Figure 10. Wiring Diagram ED2520SL-PP/ED2720SL-PP Dome Drives

PELCO Manual C437M-B (9/95) 9

Page 12

3.3.3 Video Synchronization, Alarm

Terminal Diagram

The following wiring diagram illustrates the configuration of an additional four-position and six-position

alarm terminal strip and additional video synchronization connection. These terminal strips are factory installed as standard features on ED2520RX-PP,

ED2520SL-RX/PP, ED2720RX-PP and ED2720SLRX/PP models.

Follow the diagram in Figure 11, for appropriate video

synchronization and alarm terminal wiring installation.

Figure 11. Four-position and Six-position Alarm Terminal Strips and Video Synch Connection

10 PELCO Manual C437M-B (9/95)

Page 13

4.0 PAN/TILT LIMIT ADJUSTMENTS

CAUTION: DO NOT attempt to adjust limit

stops when the pan/tilt is in operation. Damage

to the equipment can result. Do not operate

equipment without limit stops.

To adjust limit stops, perform the following steps:

5. Loosen the limit stop actuator (shown in Figure

12). Use the joystick to move the tilt table to the

maximum tilt-up location and then move the limit

stop actuator until it clicks the tilt-up limit switch.

Then lock the limit stop actuator by tightening the

locking screw.

6. Tilt up and down to verify position of the tilt table.

1. Pan to the right using the joystick control until the

desired pan limit is reached. Remove the drive unit

from the back box and adjust the pan limit stop

until it clicks the limit switch. Lock the limit stop

into position and replace pan/tilt. (See Figure 13.)

2. Pan left to the desired stop location and follow the

limit stop adjusting procedure outlined in step #1.

3. Pan left and right to verify that the limit stops have

been positioned properly.

4. The tilt table is designed to move -90° from the

horizontal plane. Note that the tilt adjustment must

never be adjusted beyond the 8 to -90° boundaries.

Note:

• Factory pan limits are set to 0-355° and tilt limits

are set to 0-90° (horizontal to vertical).

• Under normal conditions, the tilt limits should not

have to be reset.

• SL models feature the 360° pan option and are not

supplied with pan limit stops, therefore, only the

tilt limits can be adjusted.

• Pan and tilt spindles are not corrosion protected

and will show signs of corrosion deposit. This is a

normal condition and will not affect the performance of the unit.

Figure 12. Tilt Limit Stop Modification Figure 13. Pan Limit Stop Locations

PELCO Manual C437M-B (9/95) 11

Page 14

5.0 CARE AND MAINTENANCE

6.0 SERVICE AND REPAIR

Regularly scheduled maintenance will prolong the operational life and appearance of the equipment.

IMPORTANT: The lower dome of the ED25

environmental dome is an optical surface. When

cleaning the inner surface of the dome and viewing window, treat as carefully as you would a

fine camera lens.

1. If dust or other debris accumulates on the inside of

the lower dome, remove them with clean air pressure. Compressed air cans are available from photographic equipment dealers.

WARNING: Do not use water, liquid or spray

cleaners of any kind on coated inner surfaces

of the dome.

2. Clean the outer surface of the dome and the inner

surface of the viewing window with a nonabrasive

cleaning cloth and antistatic cleaner that is safe for

use on acrylic plastics. Do not use kerosene or similar substances that can scratch the surface.

6.1 RECOMMENDED EQUIPMENT AND

TOOLS

1. Voltmeter or ohmmeter

2. Allen wrench set

3. Wrench set

4. Screwdriver

5. Pliers, long nose

6.2 SERVICE TIPS

Some common problems encountered with pan/tilt systems include mis-wiring, overloading, and not using

the units for the correct application. Should a failure

occur, it is recommended that the following procedures

be used.

1. If the pan/tilt ceases to operate, turn the control

unit off and remove the supply circuit from the unit.

2. Check the fuse in the control unit using either a

voltmeter or ohmmeter. If open (blown), replace

with the proper recommended fuse.

3. Connect the supply circuit and turn the control on.

If the fuse continues to open (blow), disconnect

the power from the unit.

4. Check the control cable between the control unit

and pan/tilt for shorts, high resistance, or opens.

5. If shorts are not found in the control cable, consult

the factory for further assistance.

12 PELCO Manual C437M-B (9/95)

Page 15

7.0 EXPLODED ASSEMBLY DIAGRAM

Figure 14. ED25/ED26/ED27 Series Enclosure Exploded Assembly Diagram

PELCO Manual C437M-B (9/95) 13

Page 16

8.0 MECHANICAL PARTS LIST

The following parts list corresponds to the exploded assembly diagram in Figure 14.

Item Quantity

1 1 Enclosure front plate assembly ED25001003ASSY

2 1 Lower shock mount ED25004005COMP

3 2 Closing fasteners ED2510000

4, 8 8 Nylon washer SB310005

5 1 Dome ED254004COMP

6 4 Roller insert SB310007

7 4 Dome roller SB34020COMP

4 Roller “O” Ring (not shown) ED210100

9 1 Gas shock EH450010020

10 1 Back box assembly (ED25/ED26 only) ED25001000ASSY

1 Back box for ED27 Series only (not shown) ED241000WA

11 2 Heater Bracket ED25004006COMP

11A 4 Heater Blanket, 120/230 VAC (not shown) EHWD10087

12 1 Lower shock bracket ED25004004COMP

2 Spacer SPA8542

13 Light assembly

1 Lamp holder ED210020

1 Lamp, 120 VAC LAP7C7

Lamp, 230 VAC LAP10S6/10

1 Switch SWIV3L

14 1 Blower EH18013

4 Fan spacer SPA8404

15 1 Terminal input circuit board PCB9000255EASSY

1 Terminal input circuit board, 230 VAC only PCB9000255A

16 1 Mounting plate ED25004011COMP

17 1 Hinge spacer ED25004010COMP

Description

Part Number

9.0 PAN/TILT ELECTRICAL PARTS LIST

Schematic ID

C1–C2 Capacitor, 15 MFD, 100V CAPU0015.0/100N

J1 Input connector CON206044-1

– Mating input connector CONA37S

J2 Lens connector CONMAB6100

Lens connector (SL and PP models) CON206705-1

– Lens mating connector CONMAS6100

Lens mating connector (PP models only) CON206708-1

PCB Interconnecting PCB PCB3000100

Slip Ring Slip Ring (SL models only) 28010000

S1–S4 Limit switches SWI1SM1

M1 Pan motor PT350010010

M2 Tilt motor 2508001

Tilt Pot Preset pot, tilt POTP010.0K

Pan Pot Preset pot, pan POTP010.0K

Preset pot, pan (SL models only) POTDARM010.0K

14 PELCO Manual C437M-B (9/95)

Description

Part Number

Page 17

10.0 MODELS

ED25 14" diameter environmental dome

fixed camera mount. Black opaque

lower dome has smoked viewing window (1 f-stop light loss). (CE)

ED25-1 Same as ED25 except supplied with

service light and heater/blower.

ED2520 14" diameter environmental dome with

black opaque lower dome with smoked

viewing window and integral pan/tilt.

Heater/blower and service light are

standard features. (CE, UL)

ED2520-RX Same as ED2520 except supplied with

Coaxitron receiver/driver.

ED2520-RX-3 Same as ED2520-RX except 230 VAC

input.

ED2520-WX Same as ED2520 except supplied with

Wiretron receiver/driver.

ED2520-SL Same as ED2520 except supplied with

SL option (360° pan setting). (CE)

ED2520SL-RX Same as ED2520-SL except supplied

with Coaxitron receiver/driver. (UL)

ED2520SL-WX Same as ED2520-SL except supplied

with Wiretron receiver/driver.

ED2520-PP Same as ED2520 except supplied with

preset pan/tilt. (CE)

*ED2520RX-PP Same as ED2520-PP except supplied

with Coaxitron receiver/driver.

ED2520SL-PP Same as ED2520-SL except supplied

with preset pan/tilt. (CE)

*ED2520SL-RX/PP Same as ED2520SL-PP except sup-

plied with Coaxitron receiver/driver.

ED2620 14" diameter pendant mount environ-

mental dome with black opaque lower

dome with smoked viewing window

and integral pan/tilt for hard-wired applications. Heaters, blower and light

are standard features. Must be used

with PMED25 pendant mount. (CE)

ED2620-PP Same as ED2620 except supplied with

preset (PP) pan/tilt. (CE)

ED2620-SL Same as ED2620 except supplied with

SL option (360° pan setting). (CE)

ED27 14" diameter environmental dome with

fixed camera mount and integral mount

arm. Black opaque lower dome with 1

f-stop smoked viewing window. (UL)

ED27-1 Same as ED27 except supplied with

service light and factory-installed heater

and blower. (UL)

ED2720 14" diameter environmental dome with

integral mount arm. Dome equipped

with service light, pre-wired integral

pan/tilt and heater/blower. (CE, UL)

ED2720-PP Same as ED2720 except supplied with

preset (PP) pan/tilt. (CE)

ED2720-RX Same as ED2720 except supplied with

Coaxitron receiver/driver.

ED2720-RX-3 Same as ED2720-RX except 230 VAC

input.

*ED2720RX-PP Same as ED2720-RX except supplied

with preset (PP) pan/tilt.

ED2720-WX Same as ED2720 except supplied with

Wiretron receiver/driver.

ED2720-SL Same as ED2720 except supplied with

SL pan/tilt (360° pan rotation). (CE)

ED2720SL-PP Same as ED2720-SL except supplied

with preset (PP) pan/tilt. (CE)

ED2720SL-RX Same as ED2720-SL except supplied

with Coaxitron receiver/driver. (UL)

*ED2720SL-RX/PP Same as ED2720SL-RX except sup-

plied with preset (PP) pan/tilt.

ED2720SL-WX Same as ED2720-SL except supplied

with Wiretron receiver/driver.

* NOTE: Equipped with 4-position and 6position alarm terminal strips and video synchronization connection.

PELCO Manual C437M-B (9/95) 15

Page 18

11.0 SPECIFICATIONS

Enclosure

MECHANICAL

Pan/Tilt

Pan Rotation: 0-355° horizontal

0-360° horizontal (SL models only)

Pan Speed: 24°/sec ±1 degree (no load condition)

Tilt Rotation: -90° movement from horizontal

plane

Tilt Speed: 12° /sec ±.5 degree (no load

condition)

Gearing: Chain and direct drive

Bearings: Pan — Ball bearing and bronze

oilite bushings

Tilt — Bronze oilite bushings

Braking: Friction

ELECTRICAL

Pan/Tilt

Input Voltage: 24 VAC, 50/60 Hz

vA Required for Pan: 7.2 vA

vA Required for Tilt: 9.1 vA

Maximum Current: 2 amps per conductor

(SL models only)

Limit Switches: 5 amp, 250 VAC

Motors: Continuous duty reversing induc-

tion type

Power Cable

Conductor Requirements:

Pan/Tilt 10 conductors

Lens 6 conductors

Camera 2 conductors

Connectors

Pan/Tilt: Pre-wired AMP CPC, 37 pins

Lens:

The following specifications apply to these models:

ED25-1, ED2520, ED2520-SL, ED2520-PP,

ED2520SL-PP, ED2620, ED2620-SL, ED27-1,

ED2720, ED2720-SL, ED2720SL-PP

Input Voltage: 120 VAC, 50/60 Hz

vA Required: 187 vA

Blower: 80 cfm at 13 watts

(continuous operation)

Heaters: Four (4) at40 watts each. Heaters

are thermostatically controlled

to activate ON @ 40°F (4.5°C)

and OFF @ 60°F (15.6°C)

Service Light: 7 watts

Pwr Cable Required: 3 conductor, 18 Awg

(not supplied)

The following specifications apply to these models:

ED2520-RX, ED2520-RX-3, ED2520-WX,

ED2520SL-RX, ED2520SL-WX, ED2520RX-PP,

ED2520SL-RX/PP, ED2720-RX, ED2720-RX-3,

ED2720-WX, ED2720SL-RX, ED2720SL-WX,

ED2720RX-PP, ED2720SL-RX/PP

Input Voltage: 120 VAC or 230 VAC, 50/60 Hz

vA Required: 247 vA

Blower: 80 cfm at 13 watts

(continuous operation)

Heaters : Four (4) at 40 watts each. Heaters

are thermostatically controlled

to activate ON @ 40°F (4.5°C)

and OFF @ 60°F (15.6°C)

Non-PP models: Hirschmann MAB6100, mate

provided

PP models: AMP CPC, 9 socket, mate pro-

vided

Video: Standard BNC

Camera Sync: Standard BNC

Camera Power: Spade lugs

16 PELCO Manual C437M-B (9/95)

Service Light: 7 watts

Pwr Cable Required: 3 conductor, 18 Awg

(not supplied)

Page 19

GENERAL

Enclosure

Max. Camera/Lens

Length: 12.50"L x 4.50"W x 3.25"H

(31.75cm x 11.43cm x 8.25cm)

Construction:

Back Box 0.080" aluminum

Viewing Window Optically clear acrylic which has

been tinted, rated UL94HB.

(Less than 1 f-stop light loss.)

Finish: Semigloss beige,

self-textured baked enamel

Environment: Outdoor

Dimensions: See Figure 1

Ambient Operating

Temperature Range: -10° to 120°F (-23° to 49°C)

Pan/Tilt

Maximum Load: 10 lbs (4.6 kg)

Construction: 0.025" aluminum frame

(Product specifications subject to change without

notice.)

11.1 RECOMMENDED MOUNTS/

CONTROLS

For information on recommended mounts and controls, please contact Pelco for a copy of specification

sheet C437.

WEIGHTS

Back Box Mount Pan/Tilt Rec./Driver Unit

ED25 18 lbs (8.16 kg) 3 lbs (1.36 kg) — — 21 lbs (9.52 kg)

ED25-1 19 lbs (8.61 kg) 3 lbs (1.36 kg) — — 22 lbs (9.97 kg)

ED2520, ED2620 19 lbs (8.61 kg) — 8 lbs (3.63 kg) — 27 lbs (12.25 kg)

ED2520-RX, RX-3 or WX 19 lbs (8.61 kg) — 8 lbs (3.63 kg) 10 lbs (4.54 kg) 37 lbs (16.78 kg)

ED2520-SL, ED2620-SL 19 lbs (8.61 kg) — 9 lbs (4.08 kg) — 28 lbs (12.70 kg)

ED2520-PP, ED2620-PP 19 lbs (8.61 kg) — 9 lbs (4.08 kg) — 28 lbs (12.70 kg)

ED2520SL-PP 19 lbs (8.61 kg) — 9 lbs (4.08 kg) — 28 lbs (12.70 kg)

ED2520SL-RX or -W 19 lbs (8.61 kg) — 9 lbs (4.08 kg) 10 lbs (4.54 kg) 38 lbs (17.24 kg)

ED2520RX-PP 19 lbs (8.61 kg) — 9 lbs (4.08 kg) 11 lbs (4.98 kg) 39 lbs (17.69 kg)

ED2520SL-RX/PP 19 lbs (8.61 kg) — 9 lbs (4.08 kg) 11 lbs (4.98 kg) 39 lbs (17.69 kg)

ED27 23 lbs (10.43 kg) 3 lbs (1.36 kg) — — 26 lbs (11.79 kg)

ED27-1 24 lbs (10.89 kg) 3 lbs (1.36 kg) — — 27 lbs (12.25 kg)

ED2720 24 lbs (10.89 kg) — 10 lbs (4.54 kg) — 34 lbs (15.42 kg)

ED2720-PP 24 lbs (10.89 kg) — 10 lbs (4.54 kg) — 34 lbs (15.42 kg)

ED2720-RX, RX-3, WX 24 lbs (10.89 kg) — 10 lbs (4.54 kg) 11 lbs (4.98 kg) 45 lbs (20.41 kg)

ED2720-SL 24 lbs (10.89 kg) — 10 lbs (4.54 kg) — 34 lbs (15.42 kg)

ED2720SL-PP 24 lbs (10.89 kg) — 10 lbs (4.54 kg) — 34 lbs (15.42 kg)

ED2720SL-RX or WX 24 lbs (10.89 kg) — 10 lbs (4.54 kg) 11 lbs (4.98 kg) 45 lbs (20.41 kg)

ED2720SL-RX/PP 24 lbs (10.89 kg) — 10 lbs (4.54 kg) 11 lbs (4.98 kg) 45 lbs (20.41 kg)

PELCO Manual C437M-B (9/95) 17

Page 20

12.0 WARRANTY AND RETURN

INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved

defective in material or workmanship for a period of one year after the date

of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

keyboard).

• Three years on Camclosure

CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

DF5/DF8 Series fixed dome products.

• Two years on Spectra®, Esprit®, ExSite™, and PS20 scanners, includ-

ing when used in continuous motion applications.

• Two years on Esprit

wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300

Series network video recorders, and Endura

network-based video products.

• One year (except video heads) on video cassette recorders (VCRs).

Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in

continuous motion applications (that is, preset scan, tour and auto scan

modes).

Pelco will warrant all replacement parts and repairs for 90 days from the

date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by

reason of misuse, alteration, normal wear, or accident are not covered

under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or

loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract,

negligence, infringement of any rights of any party or product liability,

relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special,

incidental or consequential damages (including loss of use, loss of profit

and claims of third parties) however caused, whether by the negligence

of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The

Dealer may also have additional rights, which are subject to variation from

state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)

289-9100 or (559) 292-1981 to obtain a Repair Authorization number

(RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice

number

3. Details of the defect or problem If there is a dispute regarding the

warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by

which the item was received by Pelco.

®

Series products (multiplexers, server, and

®

and fixed camera models, except the

®

, CM6700/CM6800/CM9700 Series matrix, and

®

and WW5700 Series window wiper (excluding

™

Series distributed

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an

authorization number (CA number if returned for credit, and RA number

if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking

and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the

assigned CA or RA number and freight should be prepaid. Ship to the

appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto

Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto

Rico and are instructed to return goods to the USA, you may do one of the

following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods

to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

18 PELCO Manual C437M-B (9/95)

Loading...

Loading...