Page 1

)

ADDENDUM

Addendum No. C1531M

Date October 25, 2005

Manuals Affected C1525M-B

Manual Update Installation of Support Rails

The instructions provided in this section replace the steps listed on page 11 of the Installation/Operation manual for

installing the VMX200 in a 19-inch equipment rack.

Connecting Analog Video to the VMX200-SYS-Q

The instructions provided in this section replace the steps listed on page 15 of the Installation/Operation manual for

connecting analog video inputs to the VMX200-SYS-Q.

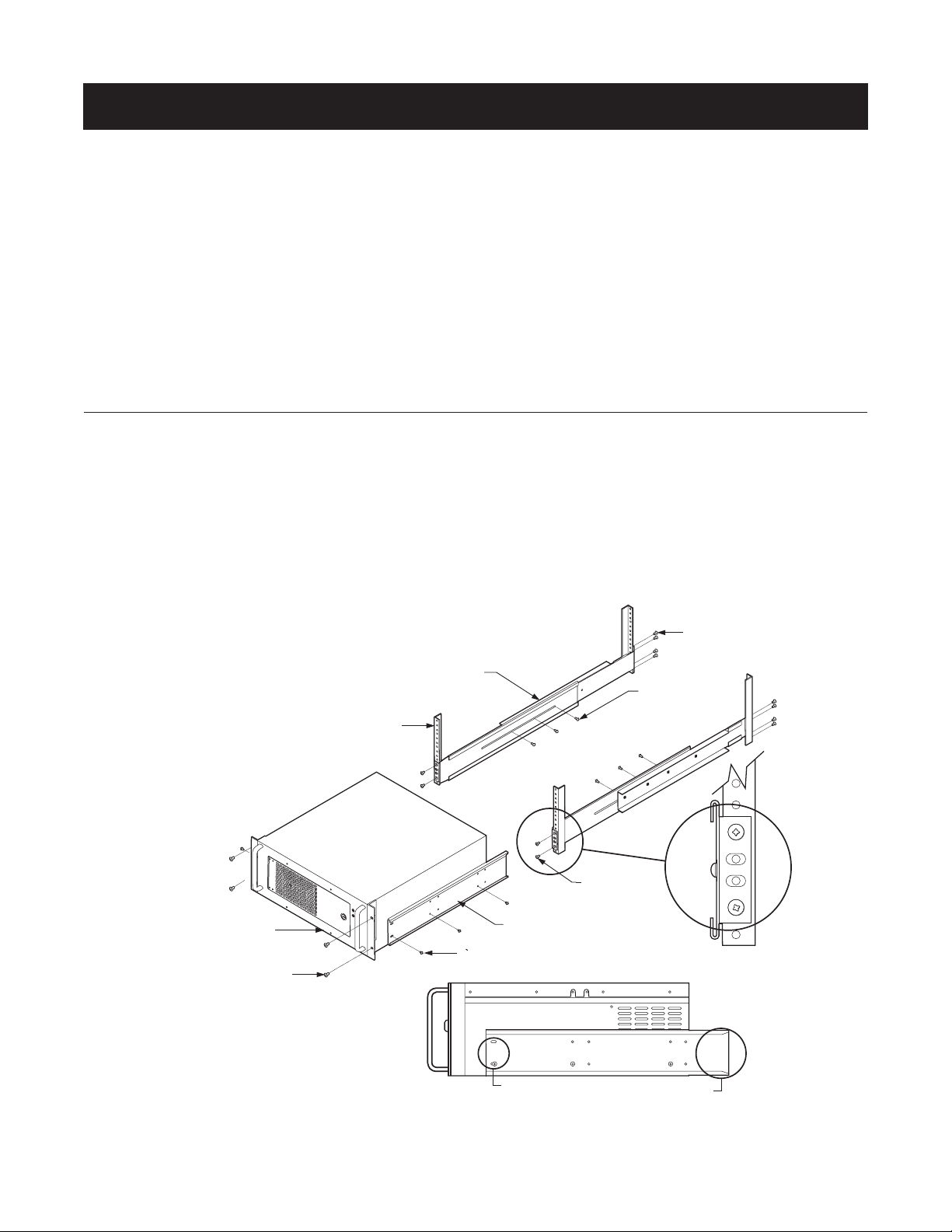

Installation of Support Rails

The following instructions replace the steps listed on page 11 of the Installation/Operation manual for installing the VMX200 in a 19-inch equipment rack.

Refer to Figure 1 for the following instructions.

1. Attach the rack ears to the front sides of the VMX200 with the 10-32 x 0.250-inch screws.

2. Attach the brackets to the sides of the equipment with the 8-32 x 0.250-inch screws.

3. Fasten the front and rear support rails together with the 8-32 x 0.375-inch screws with lock washers.

4. Attach the support rails to the equipment rack with the 10-32 x 0.375 inch screws.

5. Slide the brackets on the equipment onto the support rails.

6. Fasten the rack ears to the equipment rack with

the 10-32 x 0.750-inch screws and washers.

RACK

VMX200

(4) SCREWS,

10-32 X 0.750-INCH

PHILLIPS, PAN HEAD

WITH WASHERS

SUPPORT RAILS

(6) SCREWS, 8-32 X 0.250-INCH

PAN HEAD (3 EACH SIDE)

BRACKET

(SIDE VIEW)

(4) SCREWS,

10-32 X 0.375-INCH

FLAT HEAD

(8) SCREWS,

10-32 X 0.375-INCH,

FLAT HEAD

(6) SCREWS,

8-32 X 0.375-INCH,

PAN HEAD WITH

WASHERS

SLOTTED HOLES

TOWARDS FRONT

OF UNIT

Figure 1. Installation of Support Rails

TAPERED ENDS

TOWARDS REAR

OF UNIT

(Continued on next page

Page 2

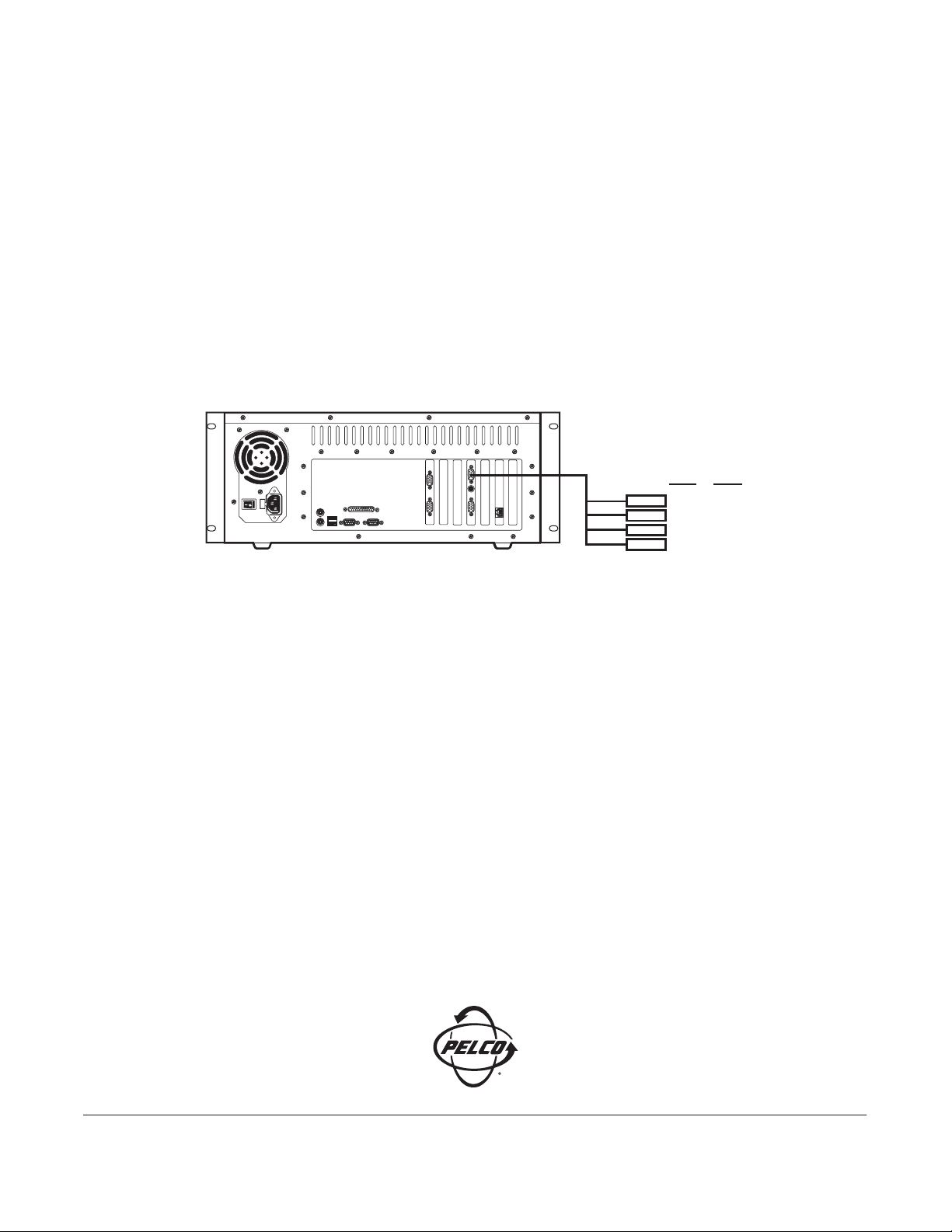

Connecting Analog Video to the VMX200-SYS-Q

The video input card that is supplied with the VMX200-SYS-Q has changed, and now it has only four video input connectors. The original configuration

described in the VMX200 Installation/Operation manual included the yellow input connector. Now the configuration uses the black input connector instead

of the yellow.

To connect video inputs to the VMX200-SYS-Q, complete the following steps and refer to Figure 2:

1. Connect the “spider” video input cable to the video port on the VMX200-SYS-Q rear panel.

2. Connect the four BNC connectors on the spider cable to the video source (for example, cameras or the monitor output of a switcher or multiplexer).

The spider cable contains four input connectors, coded by color. Use the BNC connectors as follows:

• Input 1 (Red)

• Input 2 (Green)

• Input 3 (Blue)

• Input 4 (Black)

NOTE: Refer to the appropriate installation manual for each video input device for additional instructions.

VMX200-SYS-Q

SPIDER

CABLE

Figure 2. How to Connect Analog Video to the VMX200-SYS-Q

INPUT COLOR

1

RED

2

GREEN

3

BLUE

4

BLACK

Worldwide Headquarters • 3500 Pelco Way • Clovis, California 93612 USA • www.pelco.com

USA & Canada • Tel: 800/289-9100 • Fax: 800/289-9150

International • Tel: 1-559/292-1981 • Fax: 1-559/348-1120

Page 3

INSTALLATION/OPERATION

VMX200 Video

®

Management System

VMX200-SYS Series

C1525M-B (10/02)

Page 4

2 C1525M-B (10/02)

Page 5

CONTENTS

Section Page

IMPORTANT SAFEGUARDS AND WARNINGS .................................................................................................................................................................. 4

DESCRIPTION ..................................................................................................................................................................................................................... 5

MODELS .................................................................................................................................................................................................................... 5

OVERVIEW ................................................................................................................................................................................................................. 6

FRONT VIEW .....................................................................................................................................................................................................7

REAR VIEW ....................................................................................................................................................................................................... 8

INSTALLATION................................................................................................................................................................................................................... 10

MOUNTING .............................................................................................................................................................................................................. 11

CONNECTIONS ......................................................................................................................................................................................................... 12

MOUSE AND KEYBOARD ................................................................................................................................................................................ 12

MONITOR OUTPUTS ........................................................................................................................................................................................ 13

VIDEO INPUTS ................................................................................................................................................................................................. 14

DATA CONTROL ...............................................................................................................................................................................................16

SPECTRA/ESPRIT CONTROL CONNECTIONS.................................................................................................................................................. 16

CM6800 CONTROL CONNECTIONS ................................................................................................................................................................ 17

CM6700 CONTROL CONNECTIONS ................................................................................................................................................................ 18

CM9760/9740 CONTROL CONNECTIONS....................................................................................................................................................... 19

SERCOM PORTS ..................................................................................................................................................................................... 19

DATA TRANSLATOR................................................................................................................................................................................ 20

CM8500 CONTROL CONNECTIONS ................................................................................................................................................................ 21

GENEX MULTIPLEXER CONTROL CONNECTIONS ...........................................................................................................................................22

TLR3000 SERIES VCR CONTROL CONNECTIONS ........................................................................................................................................... 23

CM9760-ALM CONTROL CONNECTIONS ....................................................................................................................................................... 24

CM9760-REL CONTROL CONNECTIONS .........................................................................................................................................................25

OPERATION........................................................................................................................................................................................................................ 26

SPECIFICATIONS................................................................................................................................................................................................................ 26

REGULATORY NOTICES ..................................................................................................................................................................................................... 27

WARRANTY AND RETURN INFORMATION ...................................................................................................................................................................... 27

LIST OF ILLUSTRATIONS

Figure Page

1 System Overview .............................................................................................................................................................................................. 6

2 VMX200 Front View.......................................................................................................................................................................................... 7

3 VMX200 Rear View .......................................................................................................................................................................................... 8

4 Rack Mount Installation .................................................................................................................................................................................. 11

5 Mouse and Keyboard Connections ................................................................................................................................................................. 12

6 Monitor Connections ....................................................................................................................................................................................... 13

7Video Inputs .....................................................................................................................................................................................................15

8 Spectra/Esprit Control Connections ................................................................................................................................................................ 16

9 CM6800 Control Connections ......................................................................................................................................................................... 17

10 CM6700 Control Connections ......................................................................................................................................................................... 18

11 CM9760/CM9740 Control Connections to SERCOM Ports ............................................................................................................................. 19

12 CM9760/CM9740 Control Connections Using Data Translator ...................................................................................................................... 20

13 CM8500 Control Connections ......................................................................................................................................................................... 21

14 Genex Multiplexer Control Connections ......................................................................................................................................................... 22

15 TLR3000 Series VCR Control Connections ...................................................................................................................................................... 23

16 CM9760-ALM Control Connections ................................................................................................................................................................ 24

17 CM9760-REL Control Connections .................................................................................................................................................................. 25

C1525M-B (10/02) 3

Page 6

IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be observed:

1. Installation and servicing should be done only by qualified service personnel and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use

only and it must not be installed where exposed to rain and moisture.

3. The installation method and materials should be capable of supporting four times the weight of the unit and equipment.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a risk of

electric shock is present within this unit.

RISK OF ELECTRIC SHOCK.

This symbol indicates that there are important operating and maintenance instructions in the literature accompanying this unit.

Please familiarize yourself with the information in this manual prior to installation and operation.

CAUTION:

DO NOT OPEN.

4 C1525M-B (10/02)

Page 7

DESCRIPTION

The Pelco VMX200 Video Management System uses a Windows®-based interface for video security system control. You can

control matrix switchers, multiplexers, DVRs, VCRs, and Spectra

configurations and a visual interface. With a mouse, you can click a camera icon within your site map and drag it to a video

display window.

The VMX200 uses an interactive system schematic to simplify system configuration. This unique technique automatically

configures ports and devices while providing a schematic representation of the overall system.

With the VMX200 Video Management System, you have the option of using one of three dedicated workstations. Each

workstation includes a keyboard and mouse, a video capture card, and pre-installed VMX200 software.

The VMX200-SYS model uses a single monitor. A background map showing camera positions is overlaid with a display window

showing the camera video.

The VMX200-SYS-1 model uses two monitors. The left monitor shows a graphical map and the right monitor shows the camera

video.

VMX200-SYS-Q model also uses two monitors with the VMX map on the left monitor and the video from cameras displayed on

the right monitor.

You have full vision and control of a surveillance area with the two monitors mounted next to each other.

The following features are found on the VMX200:

•Visual interface for control of switchers, multiplexers, and other devices

• Simple and intuitive system control

• Drag and drop camera selection from maps to display monitors

• No more camera and monitor keyboard codes to remember

• On-screen, mouse-controlled PTZ functions

• Importation of maps directly from graphic programs

• Hierarchical linking of sets of maps (for example, buildings, floors, rooms)

• Automatic configuration of data ports and video buses

• Simplification of equipment integration, system growth, and modifications

• Easy definition, saving, and use of presets, sequences, and macros

• Automatic activation of presets, sequences, and macros in response to alarms

• Manual or automatic image capture

®

/Esprit™ camera positioning systems by using mapping

MODELS

VMX200-SYS Workstation to support video and graphical map on one monitor (monitor not supplied)

VMX200-SYS-1 Workstation to support a graphical map on one monitor and video on a second monitor (monitors not

supplied)

VMX200-SYS-Q Workstation to support a graphical map on one monitor and four interactive video displays on a second

monitor (monitors not supplied)

C1525M-B (10/02) 5

Page 8

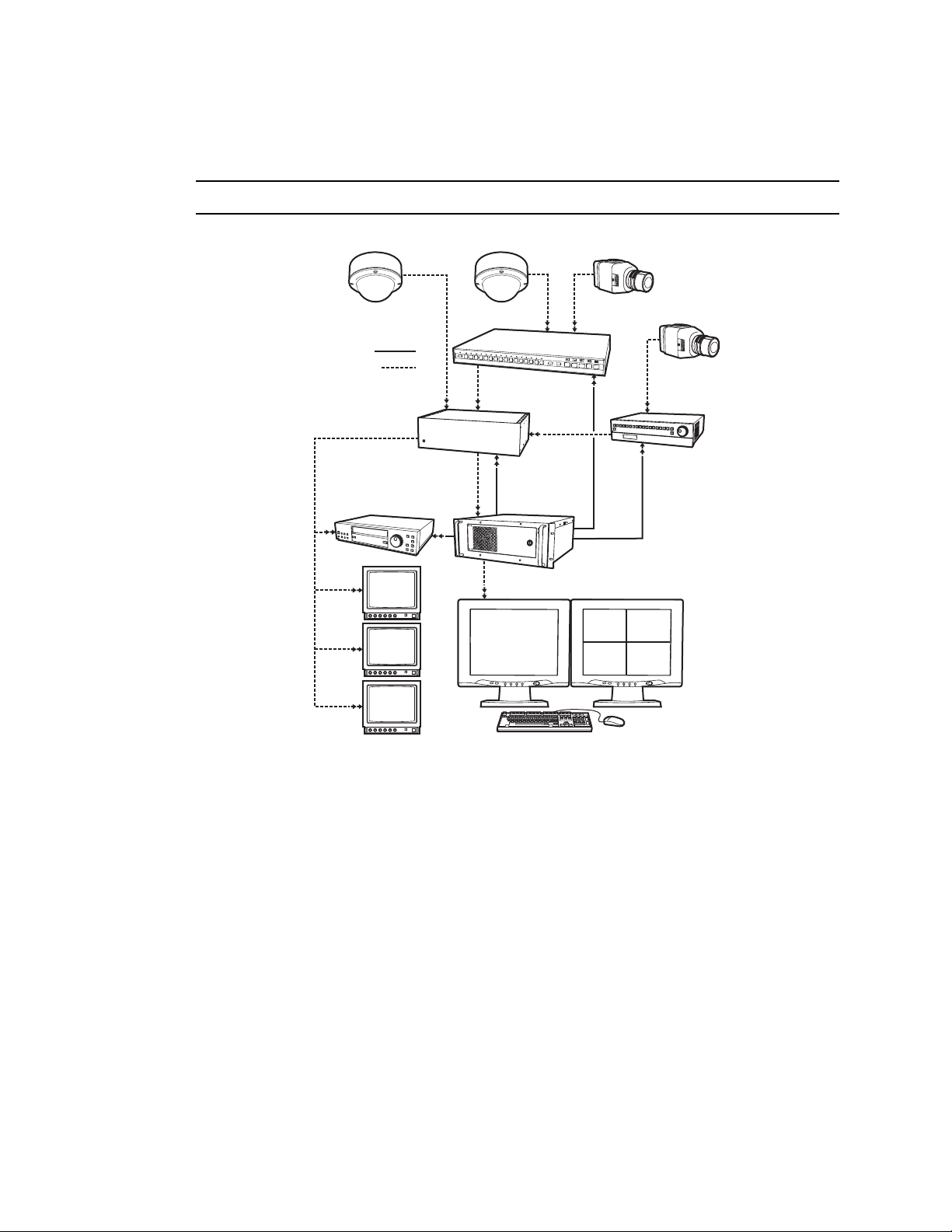

OVERVIEW

Figure 1 shows how equipment can be linked together on the VMX200 Video Management System. This illustration is only an

example. There are many ways you can link equipment together in this system.

NOTE: Each VMX200 workstation has two standard COM ports. Expansion is possible via the USB port.

DATA

VIDEO

MULTIPLEXER

VCR

MATRIX

SWITCHER

VMX200-SYS-Q

Figure 1. System Overview

DVR

6 C1525M-B (10/02)

Page 9

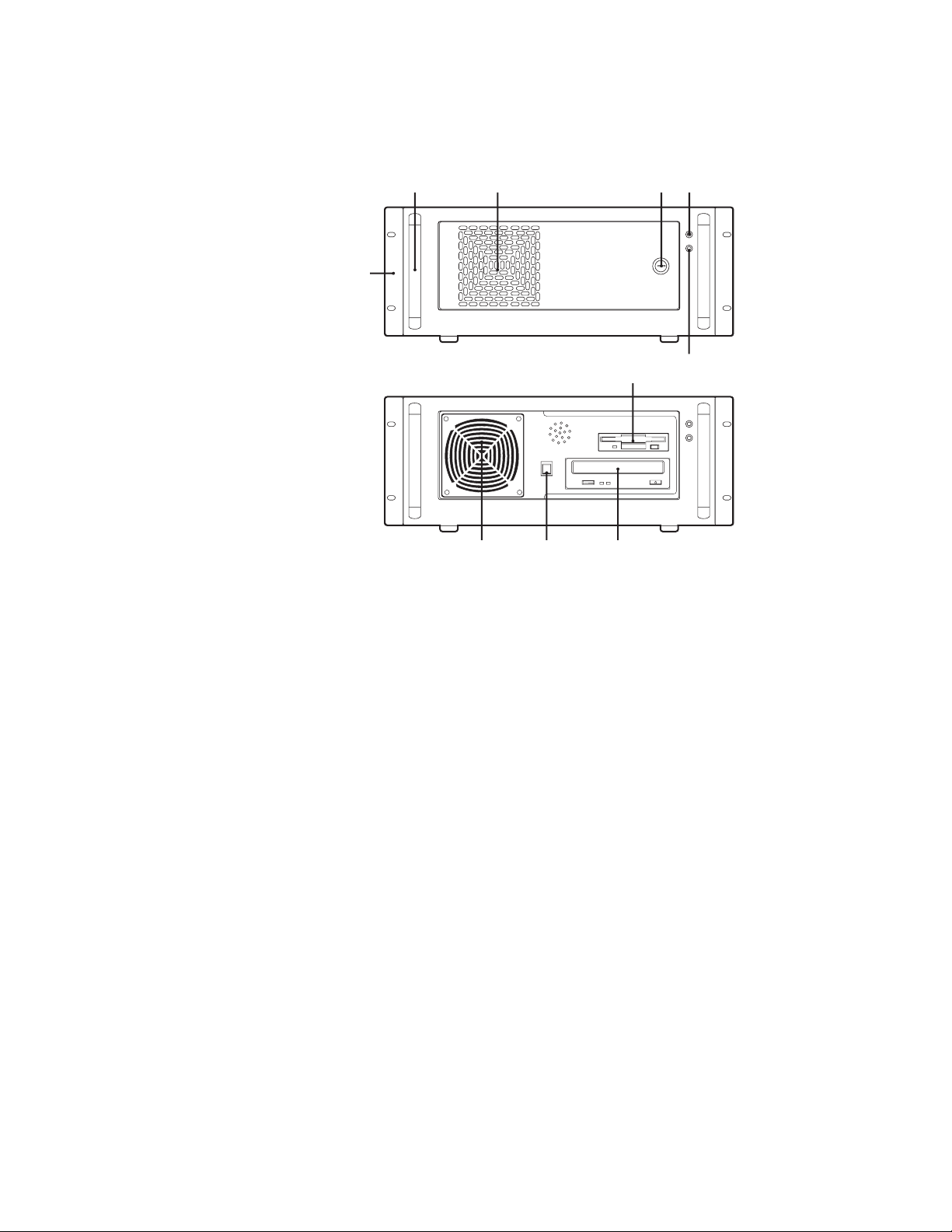

FRONT VIEW

Refer to Figure 2 to get familiarized with the front of the VMX200 workstation. The front of the unit has a door

that can be opened or locked using one of the supplied keys.

Figure 2. VMX200 Front View

POWER LED

HDD (HARD DISK DRIVE) LED

KEY LOCK (2 KEYS SUPPLIED)

FAN VENTILATION

HANDLES

RACK EARS

FAN

POWER BUTTON

CD-RW DRIVE

3.5-INCH FLOPPY DRIVE

C1525M-B (10/02) 7

Page 10

REAR VIEW

Figure 3 shows the rear of each VMX200 model. This system does not require the use of all of the ports.

VMX200-SYS

VMX200-SYS-1

VMX200-SYS-Q

Figure 3. VMX200 Rear View

8 C1525M-B (10/02)

Page 11

VMX200-SYS

MOUSE PORT

KEYBOARD PORT

USB PORT (NOT USED)

COM 1

COM 2

VIDEO INPUT*

VMX200-SYS-1

MOUSE PORT

KEYBOARD PORT

USB PORT (NOT USED)

COM 1

COM 2

VIDEO INPUT*

MONITOR PORT

ETHERNET PORT (NOT USED)

S-VHS VIDEO PORT (NOT USED)

F CONNECTOR PORT (NOT USED)

PARALLEL PORT***

LEFT MONITOR PORT

ETHERNET PORT (NOT USED)

DB15 PORT (NOT USED)

S-VHS VIDEO PORT (NOT USED)

F CONNECTOR PORT (NOT USED)

PARALLEL PORT***

RIGHT MONITOR PORT

VMX200-SYS-Q

MOUSE PORT

KEYBOARD PORT

USB PORT (NOT USED)

COM 1

COM 2

RIGHT MONITOR PORT**

ETHERNET PORT (NOT USED)

VIDEO INPUT*

LEFT MONITOR PORT

PARALLEL PORT***

* Refer to the video input details in Figure 7.

** Refer to the monitor connection details in Figure 6.

*** Refer to the Windows 2000 documentation for printer installation instructions.

C1525M-B (10/02) 9

Page 12

INSTALLATION

The following items are supplied:

•1VMX200 workstation

•1Mouse

•1Keyboard

•1Video input adapter

•1Y adapter (VMX200-SYS-Q) or 1 plug adapter (VMX200-SYS-1)

•2Power cords (1 USA standard and 1 European standard)

•2Adjustable support rails with screws and nuts

•2Rack-mount ears with screws

•2Keys

•1Video input card software package

•1VMX200 system software package

•1Windows 2000 startup package

One VGA or SVGA monitor is required for the VMX200-SYS and two VGA or SVGA monitors are required for the VMX200-SYS-1

and VMX200-SYS-Q.

10 C1525M-B (10/02)

Page 13

MOUNTING

E

The VMX200 can be placed on a flat surface, such as a shelf or table, or it can be mounted in a 19-inch (48.26 cm) equipment

rack.

Follow these instructions to mount the workstation in an equipment rack:

1. Attach the two adjustable support rails to the sides of the equipment rack using the eight 10-32 x .375-inch screws. Also

2. Tighten the eight 10-32 x .250 screws.

3. Attach the two rack ears to the front side of the VMX200 using the four 10-32 x .250 screws.

4. Place the workstation on the support rails. Use the handles on the VMX200 for easier placement. Remove the rubber feet

5. Fasten the rack ears to the rack using the four 10-32 x .750 screws.

use the eight 10-32 nuts if the rack does not have threaded mounting holes.

from the VMX200 if placing it on top of another device that is already in the rack.

10-32 X .375 SCREWS

LEAVE SCREWS LOOSE UNTIL

SUPPORT RAILS ARE ATTACHED TO THE

RACK , AND THEN TIGHTEN.

10-32 X .750

SCREWS

10-32 X .250 SCREWS

SLIDE FRONT TO BACK TO ADJUST RAILS

TO THE CORRECT DEPTH OF RACK

RACK EARS

MAKE SURE ARROWS FACE

TOWARDS THE FRONT OF THE RACK

LEFT SIDE

10-32 X .250

SCREWS

RIGHT SID

Figure 4. Rack Mount Installation

C1525M-B (10/02) 11

Page 14

CONNECTIONS

MOUSE AND KEYBOARD

Connect the mouse and keyboard to the workstation. Figure 5 shows the VMX200-SYS model, but the connections are the

same for the other two models.

VMX200-SYS

Figure 5. Mouse and Keyboard Connections

12 C1525M-B (10/02)

Page 15

MONITOR OUTPUTS

If you have the VMX200-SYS model, you have to connect only one monitor. The VMX200-SYS-1 and VMX200-SYS-Q each

require two monitors. Refer to Figure 6.

The VMX200-SYS-Q uses an overlay. This allows a quad display.

The location of the monitors is important. The graphical map monitor must always be placed on the left and the video display

monitor must always be placed on the right.

VMX200-SYS

VGA MONITOR

VMX200-SYS-1

LEFT VGA

MONITOR

RIGHT VGA

MONITOR

LEFT VGA

MONITOR

Figure 6. Monitor Connections

VMX200-SYS-Q

DB15

RIGHT VGA

MONITOR

C1525M-B (10/02) 13

Page 16

VIDEO INPUTS

The VMX200-SYS and VMX200-SYS-1 have one video input. The VMX200-SYS-Q has six video inputs.

Follow these steps and refer to Figure 7 to connect the video:

1. Connect a spider cable to the video port on each model.

2. Connect the video input to the video source (for example, cameras or monitor output of a switch or multiplexer).

NOTE: Refer to the Installation/Operation Manual for each device you connect for further video connection information.

For the VMX200-SYS and VMX200-SYS-1, only the yellow composite (RCA) connector goes to another device. The other three

connectors are not used.

For the VMX200-SYS-Q, you can connect the six BNC connectors to other devices. For example, you can connect them to six

cameras. However, you can only drag-and-drop four of the cameras into the quad display monitor.

The six BNC connectors are as follows:

1. Input 1 (Red)

2. Input 2 (Green)

3. Input 3 (Blue)

4. Input 4 (Yellow)

5. Input 5 (Black)

6. Input 6 (White)

Although there are six video inputs, there are several applications that require only four. For example, you would normally

connect only four inputs to video outputs on a CM6800-48X8.

14 C1525M-B (10/02)

Page 17

VMX200-SYS

SPIDER

CABLE

*

REQUIRES RCA-TO-BNC ADAPTER

SPIDER

CABLE

REQUIRES RCA-TO-BNC ADAPTER

*

S-VIDEO IN (BLACK)

AUDIO IN RIGHT (RED)

AUDIO IN LEFT (WHITE)

VIDEO IN (YELLOW)

*

VMX200-SYS-1

S-VIDEO IN (BLACK)

AUDIO IN RIGHT (RED)

AUDIO IN LEFT (WHITE)

VIDEO IN (YELLOW)

*

VMX200-SYS-Q

INPUT

COLOR

1

SPIDER

CABLE

2

3

4

5

RED

GREEN

BLUE

YELLOW

BLACK

Figure 7. Video Inputs

C1525M-B (10/02) 15

Page 18

DATA CONTROL

VMX200 -SYS

The following sections provide instructions and illustrations on how to connect numerous devices to the VMX200 for data control.

Each application shows a VMX200-SYS for illustration purposes only. You can also use a VMX200-SYS-1 or VMX200-SYS-Q.

NOTE: You can use either COM 1 or COM 2 on the VMX200 for control.

SPECTRA/ESPRIT CONTROL CONNECTIONS

To connect a Spectra or Esprit to a VMX200 for direct camera control, you must use a PV130 converter to convert the RS-232

interface to an RS-422 interface.

Follow these steps and refer to Figure 8:

1. Connect the RS-232 side of the PV130 converter to either COM 1 or COM 2 on the VMX200.

2. Use twisted pair wire to connect from TX+ and TX- on the PV130 converter to RX+ and RX- on the Spectra or Esprit. You

can daisy-chain from the RX+ and RX- connections on the first Spectra or Esprit to additional units.

VMX200 COM

PORT SETTINGS

BAUD RATE:

DATA BITS:

PARITY:

STOP BITS:

FLOW CONTROL:

9600

NONE

NONE

8

1

*12 VDC POWER SUPPLY

*IF NECESSARY

GND

+12V

RX+

RX-

TO RECEIVER(S)

ESPRIT

SPECTRA

Figure 8. Spectra/Esprit Control Connections

After you make the connections, open the Device Configuration window in the VMX200 software and add the receiver to your

system. Make sure you specify the following:

• Specify that the commands are sent via PC serial control port.

• Specify the D-Protocol driver.

• Select either “automatic” or “manual” camera addressing.

Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The receiver’s settings must match the VMX200 COM port settings. Refer to the Spectra/Esprit Installation/Operation Manuals

for instructions on setting baud rate, parity, and other settings.

16 C1525M-B (10/02)

Page 19

CM6800 CONTROL CONNECTIONS

There are two ways you can connect a CM6800 to a VMX200.

Connect a null modem cable from VMX200 COM 1 or COM 2 to the CM6800 COM 1 port.

Connect a DB9 cable from VMX200 COM 1 or COM 2 to the CM6800 ASCII Ports 2, 7, or 8. You must use a wall block to

convert the DB9 connector to an RJ-45 connector.

Figure 9. CM6800 Control Connections

Although a CM6800-48X8 is pictured above, you can use a CM6800-32X6 as long as the COM port number of the port

connection is the same. (COM ports 7 and 8 are not available on the CM6800-32X6.)

If you connect to ports 7 or 8, you must set the port for ASCII RS-232 using the CM6800 programming menus or manager

program.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM6800 to your

system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM6800 settings must match the VMX200 COM port settings. Refer to the CM6800 Installation/Operation Manual for

instructions on setting baud rate, parity, and other settings.

C1525M-B (10/02) 17

Page 20

CM6700 CONTROL CONNECTIONS

T

T

Follow these steps and refer to Figure 10:

1. Connect a DB9 cable from VMX200 COM 1 or COM 2 to the screw terminal connector on the CM6700. Note the pin-outs

on the wiring.

2. Remove the cover from the CM6700-MXB and set the SW5 DIP switch to RS-232 mode. Replace the cover when done.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM6700 to your

system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM6700 settings must match the VMX200 COM port settings. Refer to the CM6700 Installation/Operation Manual for

instructions on setting baud rate, parity, and other settings.

VMX200 -SYS

VMX200 COM

PORT SETTINGS

BAUD RATE:

DATA BITS:

STOP BITS:

PARITY:

FLOW CONTROL:

9600

1

NONE

NONE

8

RS-232

1 2 3 4 5 6 7 8 9

ALARMS

(1-9)

ALARMS

(10-18)

10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9

10

11

1213 1415 16 1718

1 2 3 4 5 6 7 8 9 10

F3NONCC

F

0123

2

COM 1 OR 2

2

3

5

VIDEO INPUTS

13579

2468101112 14

NOTE: TO PROPERLY SHIELD DATA CABLE

CONNECT GROUND ON ONE END ONLY

SW5 DIP SWITCH SETTINGS

RS-422/485

ON

1 2 3 4 5 6 7 8

RS-232

ON

1 2 3 4 5 6 7 8

KEY

ON OFF

RXD

TXD

GND

13 15

16

CM6700-MXB

COM 2

TXD

7

RXD

12

GND

9

VIDEO OUTPUTS

1

2

COM 1 (1-6)

COM 2 (7-12)

CONTROL

OUTPUTS

SET DIP SWITCH (SW5) ON CM6700-MXB TO RS-232 MODE

11

1213 14 15 16 1718

0123

LOCAL

KEYBOARD

REMOTE KEYBOARD(S)

TT RR

11

12

+ +

O

M

CM6700-MXB

F

2

11

F3NONCC

REMO

T

12

+

O

M

Figure 10. CM6700 Control Connections

18 C1525M-B (10/02)

Page 21

CM9760/9740 CONTROL CONNECTIONS

There are two ways you can make the connections:

1. Via SERCOM Ports

2. Via Data Translator

SERCOM Ports

This is called the Virtual Keyboard Method because the SERCOM ports used for the VMX200 must be programmed as keyboard

ports. Pelco recommends this method because it supports all system control functions.

Follow these steps and refer to Figure 11.

1. Connect a PV130 converter to VMX200 COM 1 or COM 2.

2. Wire an RJ-45 reversed cable from the PV130 to the CM9760-CC1 or CM9740-CC1 RS-422 SERCOM port. For

convenience, use a wall block to connect the RJ-45 reversed cable to the SERCOM port.

3. Program the CC1's SERCOM port as a keyboard port.

Figure 11 shows two VMX200 workstations. For a single VMX200 workstation, use only one SERCOM port.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM9760/9740 to

your system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM9760/9740 settings must match the VMX200 COM port settings. Refer to the CM9760/9740 Installation/Operation

Manuals for instructions on setting baud rate, parity, and other settings.

Figure 11. CM9760/CM9740 Control Connections to SERCOM Ports

C1525M-B (10/02) 19

Page 22

Data Translator

M

You can also connect the CPU to a VMX200 via the CM9760-DT. This method does not allow complete control of cameras

connected serially to the CM9760/9740-CC1 (including presets). Therefore, Pelco recommends this method only for situations

where the Virtual Keyboard Method is not possible.

Follow these steps and refer to Figure 12:

1. Connect a null modem cable from VMX200 COM 1 or COM 2 to CM9760-DT COM A.

2. Connect another null modem cable from CM9760-DT COM B to an RS-232 COM port on either the CM9760-CC1 or

CM9740-CC1.

3. Program the CC1’s RS-232 port for ASCII protocol.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM9760/9740 to

your system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM9760/9740 settings must match the VMX200 COM port settings. Refer to the CM9760/9740 Installation/Operation

Manuals for instructions on setting baud rate, parity, and other settings.

VMX200 -SYS

NULL MODEM

CABLE

VMX200 COM

PORT SETTINGS

DATA BITS:

STOP BITS:

FLOW CONTROL:

8

1

NONE

A

B

PRINTER COM1 COM2

CM9760-DT

1 2

CM9760-CC1

OR

CM9740-CC1

12 VAC

CM9760-CC1

RS-232

CM9740-CC1

Figure 12. CM9760/CM9740 Control Connections Using Data Translator

NULL

MODE

CABLE

20 C1525M-B (10/02)

Page 23

CM8500 CONTROL CONNECTIONS

1. Connect a null modem cable from VMX200 COM 1 or COM 2 to the DB9 connector on the CM8500-DT.

2. Connect an RJ-45 straight cable from the RJ-45 connector on the CM8500-DT to one of the RJ-45 connectors on the

CM8500.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM8500 to your

system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM8500 settings must match the VMX200 COM port settings. Refer to the CM8500 Installation/Operation Manual for

instructions on setting baud rate, parity, and other settings.

Figure 13. CM8500 Control Connections

C1525M-B (10/02) 21

Page 24

GENEX MULTIPLEXER CONTROL CONNECTIONS

Follow these steps and refer to Figure 14:

1. Connect a DB9 cable from VMX200 COM 1 or COM 2 to a wall block. Note the pin-outs. Pins 1 and 8 are tied together

with Pin 5.

2. Connect an RJ-45 straight cable from the wall block to the Genex® COM OUT port.

After you make the connections, open the Device Configuration window in the VMX200 software and add the Genex Multiplexer to your system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system

configuration.

The Genex Multiplexer settings must match the VMX200 COM port settings. Refer to the Genex Multiplexer Installation/

Operation Manual for instructions on setting baud rate, parity, and other settings.

Figure 14. Genex Multiplexer Control Connections

22 C1525M-B (10/02)

Page 25

TLR3000 SERIES VCR CONTROL CONNECTIONS

Connect a null modem cable from VMX200 COM 1 or COM 2 to the TLR3168/TLR3096 RS-232 serial port. Refer to Figure 16.

NOTE: Pelco recommends that the null modem cable be checked with an ohmmeter to ensure that the pin connections match

those listed in the figure below.

After you make the connections, open the Device Configuration window in the VMX200 software and add the VCR to your system.

Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The TLR3000 settings must match the VMX200 COM port settings. Refer to the TLR3000 Installation/Operation Manual for

instructions on setting baud rate, parity, and other settings.

Figure 15. TLR3000 Series VCR Control Connections

C1525M-B (10/02) 23

Page 26

CM9760-ALM CONTROL CONNECTIONS

Follow these steps and refer to Figure 16:

1. Connect a PV130 converter to VMX200 COM 1 or COM 2.

2. Wire a cable from the PV130 to a wall block.

3. Connect an RJ-45 reversed cable from the wall block to the COM IN connector on the CM9760-ALM.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM9760-ALM to

your system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM9760-ALM settings must match the VMX200 COM port settings. Refer to the CM9760-ALM Installation/Operation

Manual for instructions on setting baud rate, parity, and other settings.

VMX200-SYS

TD(A)

TD(B)

RD(A)

RD(B)

GND

+12 VDC

PV130

DETAIL

5

3 4 6

2

7

8

1

WALL BLOCK

DETAIL

VMX200 COM PORT SETTINGS

RS-232 DATA

PV130

+12 VDC

GND

RD(B)

RD(A)

TD(B)

TD(A)

RS-422

DATA

REVERSED

CABLE

RJ-45

3 4 6

2

1

RS-422

5

7

8

VMX200 DB9

CONNECTOR

PIN 2

PIN 3

PIN 5

CM9760-ALM

Figure 16. CM9760-ALM Control Connections

BAUD RATE:

DATA BITS:

STOP BITS:

PARITY:

FLOW CONTROL:

RX

TX

GND

CM9760-ALM

COM IN RJ-45

CONNECTOR

PIN 1

PIN 2

PIN 7

PIN 8

4800

NONE

NONE

TX+

TXRXRX+

8

1

24 C1525M-B (10/02)

Page 27

CM9760-REL CONTROL CONNECTIONS

Follow these steps and refer to Figure 17:

1. Connect a PV130 converter to VMX200 COM 1 or COM 2.

2. Wire a cable from the PV130 to a wall block.

3. Connect an RJ-45 reversed cable from the wall block to the COM IN connector on the CM9760-REL.

After you make the connections, open the Device Configuration window in the VMX200 software and add the CM9760-REL to

your system. Refer to the VMX200 Software Installation/Operation Manual for detailed instructions on system configuration.

The CM9760-REL settings must match the VMX200 COM port settings. Refer to the CM9760-REL Installation/Operation

Manual for instructions on setting baud rate, parity, and other settings.

VMX200-SYS

TD(A)

TD(B)

RD(A)

RD(B)

GND

+12 VDC

PV130

DETAIL

5

4

3

6

2

7

1 8

WALL BLOCK

DETAIL

VMX200 COM PORT SETTINGS

RS-422 DATA

PV130

+12 VDC

GND

RD(B)

RD(A)

TD(B)

TD(A)

RS-232

CABLE

RJ-45

REVERSED

CABLE

3 4 6

2

1

RS-422

5

7

8

VMX200 DB9

CONNECTOR

PIN 2

PIN 3

PIN 5

CM9760-REL

Figure 17. CM9760-REL Control Connections

BAUD RATE:

DATA BITS:

STOP BITS:

PARITY:

FLOW CONTROL:

RX

TX

GND

COM IN RJ-45

CONNECTOR

9600

EVEN

NONE

CM9760-REL

PIN 1

TX+

PIN 2

TX-

PIN 7

RX-

PIN 8

RX+

8

1

C1525M-B (10/02) 25

Page 28

OPERATION

Refer to the VMX200 Software Installation/Operation Manual for instructions on how to operate the Video Management

System.

SPECIFICATIONS

ELECTRICAL

Input Voltage: 100-240 VAC, 50/60 Hz, auto-ranging

Signal System (NTSC/PAL)

VMX200-SYS: VMX200 software-selectable

VMX200-SYS-1: VMX200 software-selectable

VMX200-SYS-Q: Auto-sensing

Video Outputs

Single Monitor Systems: 1 SVGA

Dual Monitor Systems: 2 SVGA

Power Consumption: 180W maximum

MECHANICAL

Connectors

Video Inputs: BNC

PS/2 Mouse and Keyboard: 6-pin mini-DIN

SVGA Monitor Port: 15-pin D-type

Printer Port: 25-pin D-type

10/100 TCP/IP Port: RJ-45

COM 1 and 2: 9-pin D-type

GENERAL

Operating Temperature: 41° to 104°F (5° to 40°C)

Relative Humidity: Maximum 80% non-condensing

Dimensions

Desktop: 7.3 (H) x 17.0 (W) x 19.6 (D) inches (18.5 x 43.2 x 49.8 cm)

Rack Mount: 7.0 (H) x 19.0 (W) x 19.6 (D) inches (17.8 x 48.3 x 49.8 cm)

Unit Weight: 27 lb (12.27 kg)

Shipping Weight: 55 lb (24.9 kg) maximum

(Design and product specifications subject to change without notice.)

26 C1525M-B (10/02)

Page 29

REGULATORY NOTICES

This equipment has been tested and found to comply with the limits of a Class B digital device, pursuant to part 15 of the FCC

rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However there is no guarantee that the interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try and correct the interference by one

or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment. Exceptions to this warranty are

as noted below:

• Five years on Pelco manufactured cameras (CC3500/CC3600/CC3700 and MC3500/MC3600

Series); two years on all other cameras.

• Three years on Genex® Series (multiplexers, server, and keyboard).

•Two years on all standard motorized or fixed focal length lenses.

•Two years on Legacy®, Camclosure™ Camera Systems, CM6700/CM6800/CM8500/CM9500/

CM9740/CM9760 Matrix, DF5 and DF8 Series Fixed Dome products.

•Two years on Spectra®, Esprit™, and PS20 Scanners, including when used in continuous

motion applications.

•Two years on Esprit and WW5700 series window wiper (excluding wiper blades).

• Eighteen months on DX Series digital video recorders.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the

specific use or application made of the Products. Pelco’s liability for any claim, whether based on

breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no

event will Pelco be liable for any special, incidental or consequential damages (including loss of

use, loss of profit and claims of third parties) however caused, whether by the negligence of

Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to

obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty conditions

stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received by

Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800) 2899100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA

number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and

freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico:

Intermediate Consignee Ultimate Consignee

American Overseas Air Freight Pelco

320 Beach Road 3500 Pelco Way

Burlingame, CA 94010 Clovis, CA 93612-5699

USA USA

REVISION HISTORY

Manual # Date Comments

C1525M 5/02 Original version.

C1525M-A 8/02 Changed Left VGA Monitor connection on the VMX200-SYS-1 model on Figure 6. Switched call-out 8 with call-out 10 on the VMX200-SYS-1 on page 9. Revised

C1525M-B 10/02 Added CM8500 section. Revised Figure 11.

® Pelco, the Pelco logo, Spectra, Genex, and Legacy Coaxitron are registered trademarks of Pelco. ® Windows is a registered trademark of Microsoft Corporation.

™ Esprit and Camclosure are trademarks of Pelco. © Copyright 2002, Pelco. All rights reserved.

C1525M-B (10/02) 27

COM Port Settings on Figure 10. Wall block pin outs changed on Figure 13. Removed DX3000 and PelcoNet sections. Added CM9760-ALM and CM9760-REL

sections.

Page 30

®

World Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

Orangeburg, New York Las Vegas, Nevada Eindhoven, The Netherlands Wokingham, United Kingdom Montreal, Canada

Loading...

Loading...