Page 1

ADDENDUM

Addendum No.: C1577M-A

Date: August 4, 2004

Manuals Affected: CM9760 Series Manuals – C538M-A, C539M-A, C540M-B, C541M-C, C542M-B,

C543M-A, C544M, C549M-A, C572M, C573M-D, C578M, C579M, C1501M, C1503M,

C1510M-QS, C1510M-A, C1520M-B, C1528M-D, C1940M, C1941M, C1942M, and

C1943M

Manual Update: The CM9760-CC1 has been replaced with the CM9700-CC1 and the CM9760-MGR manage-

ment software has been replaced with the CM9700-MGR management software.

Keep the following in mind when referring to the instructions contained in these manuals:

• The CM9700-CC1 contains the latest CC1 software (version 9.01 or higher), and is

programmed with the new CM9700-MGR management software.

• Despite the difference in model numbers, the CM9700-CC1 functions the same as the

CM9760-CC1 and most of the information in these manuals applies to version 9.01 (or

higher) CPU.

•You can add the CM9700-CC1 to an existing CM9760 system if you upgrade the existing

CM9760-CC1 units with the current software (version level 9.01 or higher).

Software version 9.01 requires a minimum of 16 MB of RAM in the CPU. If required, you

can upgrade the RAM in older CM9760-CC1 units using the software upgrade kit

appropriate for your CPU.

• Do not use the CM9760-MGR instructions contained in these manuals. Refer to the

CM9700-MGR Getting Started Software Guide, on-screen help, or Online Help for

instructions.

Pelco World Headquarters • 3500 Pelco Way, Clovis, California 93612-5699 USA • www.pelco.com

USA & Canada: Tel: 800/289-9100 • Fax: 800/289-9150

®

International: Tel: 1-559/292-1981 • Fax: 1-559/348-1120

Page 2

®

CM9760-REL

System 9760

®

Relay Interface Unit

Installation/

Operation Manual

C538M-A (3/04)

Pelco World Headquarters • 3500 Pelco Way, Clovis, CA 93612-5699 USA • www.pelco.com

USA & Canada: Tel: 800/289-9100 • Fax: 800/289-9150

International: Tel: 1-559/292-1981 • Fax: 1-559/348-1120

Page 3

CONTENTS

Section Page

1.0 GENERAL................................................................................................... 3

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ................................ 3

2.0 DESCRIPTION ........................................................................................... 4

2.1 MODELS ............................................................................................ 4

3.0 PRE-INSTALLATION INFORMATION......................................................... 5

3.1 FRONT VIEW AND DIP SWITCH ACCESS ....................................... 5

3.1.1 DIP Switches .......................................................................... 5

3.1.2 LEDs....................................................................................... 5

3.2 REAR VIEW........................................................................................ 6

3.2.1 REL Contact Pair Connections............................................... 7

3.2.2 External Relay Wiring Considerations.................................... 8

3.2.3 Communication Connectors ................................................... 8

3.2.3.1 DB-9 Connector ..................................................... 8

3.2.3.2 RJ-45 Data Cables................................................. 9

3.2.4 Power Connections ............................................................... 10

3.3 SETUP............................................................................................... 11

3.3.1 Preliminary Discussion .......................................................... 11

3.3.2 DIP Switch Settings............................................................... 13

3.3.3 Software Considerations ....................................................... 16

4.0 INSTALLATION .......................................................................................... 17

4.1 DIRECT RACK-MOUNT HOOK-UP .................................................. 17

4.2 REMOTE OPERATION ...................................................................... 17

4.3 DAISY-CHAINING .............................................................................. 18

5.0 OPERATION .............................................................................................. 19

5.1 OPERATIONAL OVERVIEW ............................................................. 19

5.2 OPERATING THE CM9760-REL FROM THE CM9760-KBD ............ 19

5.2.1 Information Retrieval ............................................................. 19

5.2.2 Keyboard Operation .............................................................. 21

6.0 SPECIFICATIONS ..................................................................................... 23

7.0 WARRANTY AND RETURN INFORMATION ............................................ 24

LIST OF ILLUSTRATIONS

Figure Page

1Front View with Panel Removal ............................................................ 5

2 Rear View of the CM9760-REL ............................................................6

3 Relay Interface Contact Configuration..................................................7

4 External Relay Wiring........................................................................... 8

5 RJ-45 Pin-outs......................................................................................9

6 RJ-45 Cable Types ............................................................................... 9

7Power Input Fuse Replacement .......................................................... 10

8 Relationship of Frame Address Space and the Relay Interface Unit...11

9 Relationship of Frame Address Space with Respect to Starting

10 DIP Switch Functions .......................................................................... 13

11 Configuring the GPI Define File for REL Operation.............................16

12 Configuring the COMMS File for REL Operation ................................ 16

13 Unit Dimensions and Rack-Mount Installation.....................................17

14 Relay Unit Daisy-Chain Configuration................................................. 18

15 Physical Representation of Figure 16 ...............................................20

16 Controlling REL Output Contacts From the CM9760-KBD ...............22

Address and the Relay Interface Units................................................ 12

LIST OF TABLES

Table Page

AFrame Address, GPI Range Association ..........................................14

2 Pelco Manual C538M-A (3/04)

Page 4

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by qualified service personnel

and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X ,6 or

6P enclosure, it is designed for indoor use only and it must not be installed

where exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C538M-A (3/04) 3

Page 5

2.0 DESCRIPTION

The CM9760-REL Relay Interface Unit is an optional accessory of the System 9760®.

The relay interface unit provides dry contact switching for direct or automatic control of peripheral equipment. The unit connects to any RS-422 COMM port on the

rear of the CM9760-CC1.

Some of the more important features of the CM9760-REL are as follows:

• Each unit provides up to 64 single-pole, single-throw (SPST) contact outputs

for operating different peripheral equipment.

• Relay output contacts may be configured for N/O (factory default) or N/C operation.

• With a handy “memory” feature , relay groups can retain or hold their pre-power

loss contact position in the event of a power failure or front panel reset.

• Multiple units may be cascaded to extend the number of rela y contact outputs

controlled from a single port on the CC1 (over 5,000 relay outputs can be

configured).

• The relay unit may be remotely placed up to 4,000 f eet (1,219.2 meters) from

the controller (RS-422 operation).

• The unit is powered by an auto-ranging power supply.

• The unit is a unique, one rack unit chassis (1.75 inches or 4.45 cm) accommodating multiple types of mounting.

2.1 MODELS

CM9760-REL Single relay unit capable of controlling up to 64 relay contact

outputs per unit. (CE)

4 Pelco Manual C538M-A (3/04)

Page 6

3.0 PRE-INSTALLATION INFORMATION

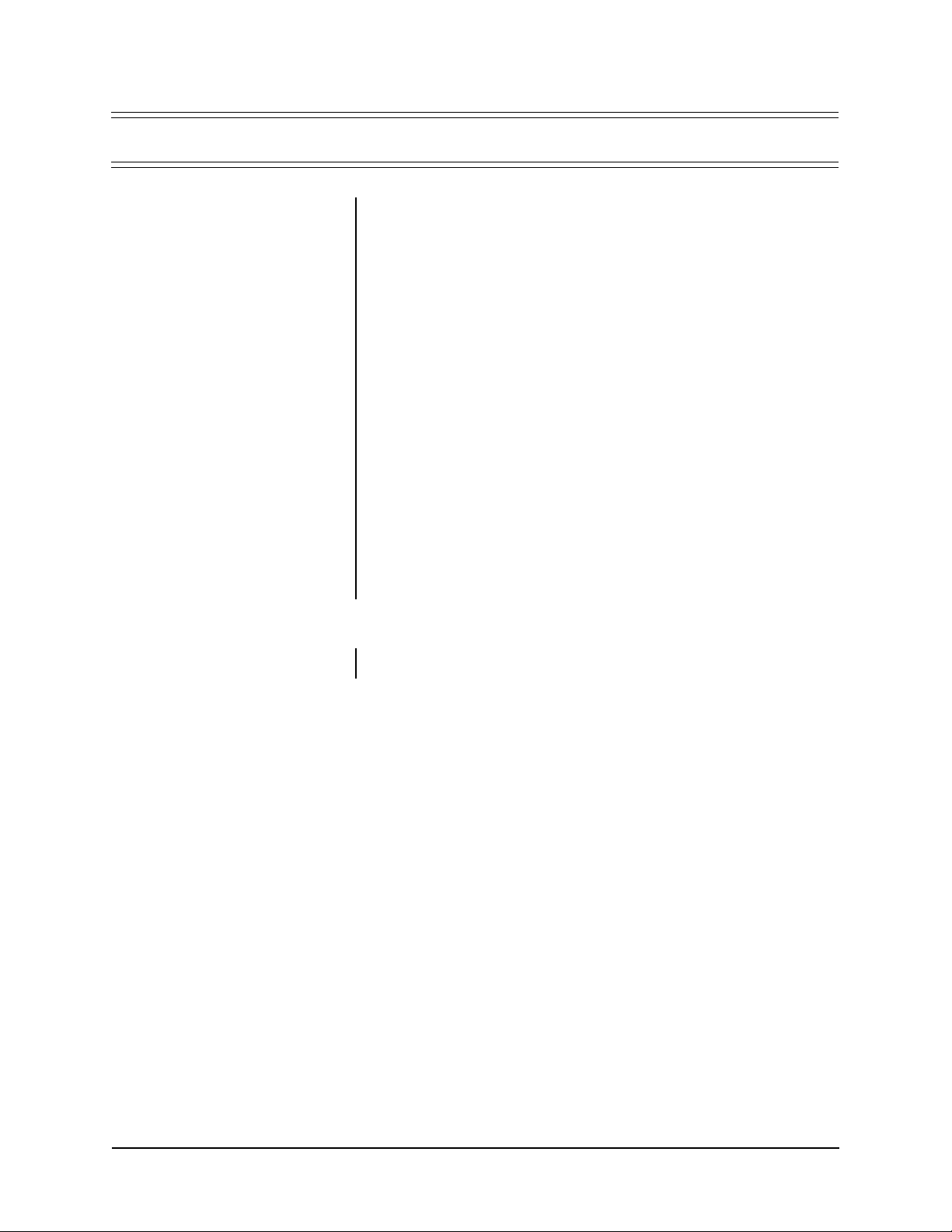

3.1 FRONT VIEW AND DIP SWITCH ACCESS

Figure 1 illustrates a front view of the unit with its front panel removed. P ower (green)

and Data (red) LEDs occupy opposite ends of the unit’s front panel. As illustrated,

the removal of the five flat-head Phillips screws that hold the front panel in place

allow access to the units three DIP switches and the reset switch. All other s witches

and connectors are on the rear of the unit.

3.1.1 DIP Switches

The relay interface unit has three 10-position DIP switches that configure the communication parameters for the unit as well setting the parameters for relay contact

output operation. DIP switch functions are discussed in Section 3.3.2, DIP Switch

Settings.

3.1.2 LEDs

The green POWER LED located on the left side of the front panel of the unit comes

ON at power up.

The red DATA LED located on the right side of the front panel continually flashes on

and off at a regular rate (about 1/2 second intervals) until the first valid command is

received. The LED will not flash again until another valid command is received. In

cascaded configurations, each relay unit only indicates receiving data when the

data has the corresponding address of the unit. In other words, LED activity is

address specific.

In addition, if power is cycled, if a DIP switch slide switch position is moved, or if a

front panel reset occurs, the LED will again flash intermittently until the first valid

command is received.

Figure 1. Front View with Panel Removal

Pelco Manual C538M-A (3/04) 5

Page 7

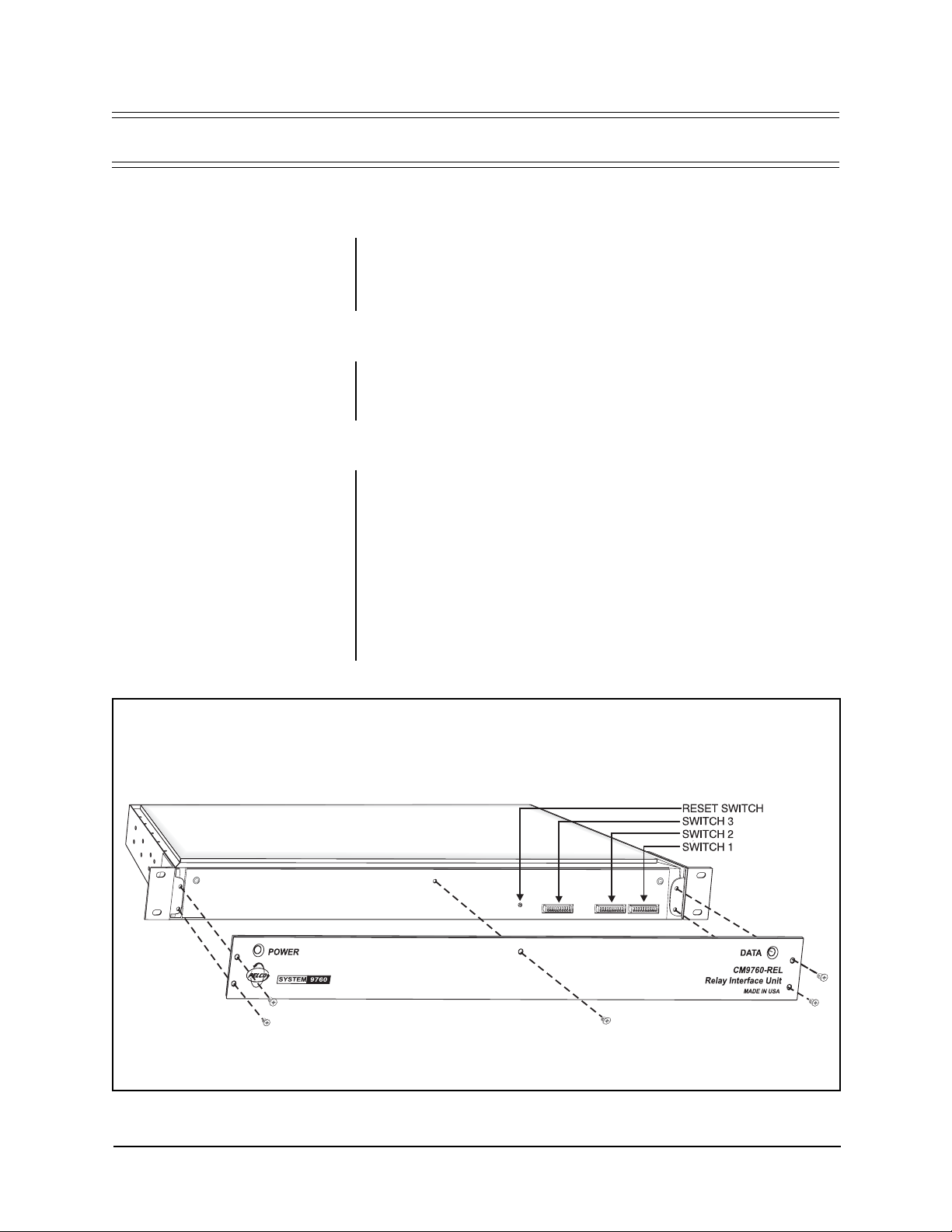

3.2 REAR VIEW

The rear of the unit is illustrated in Figure 2. From left to right are the following:

1. Four blocks consisting of 16 contact pairs, each with mating plugs for the attachment of peripheral equipment. (Only the bloc k for the first 16 contact pairs

is shown with mating plugs.)

2. RS-422 input/output communication connectors (RJ-45 type).

3. One DB-9 connector (factory use only).

4. The grouped input power functions, consisting of input power terminals, a fuse

and an ON/OFF switch.

Figure 2. Rear View of the CM9760-REL

6 Pelco Manual C538M-A (3/04)

Page 8

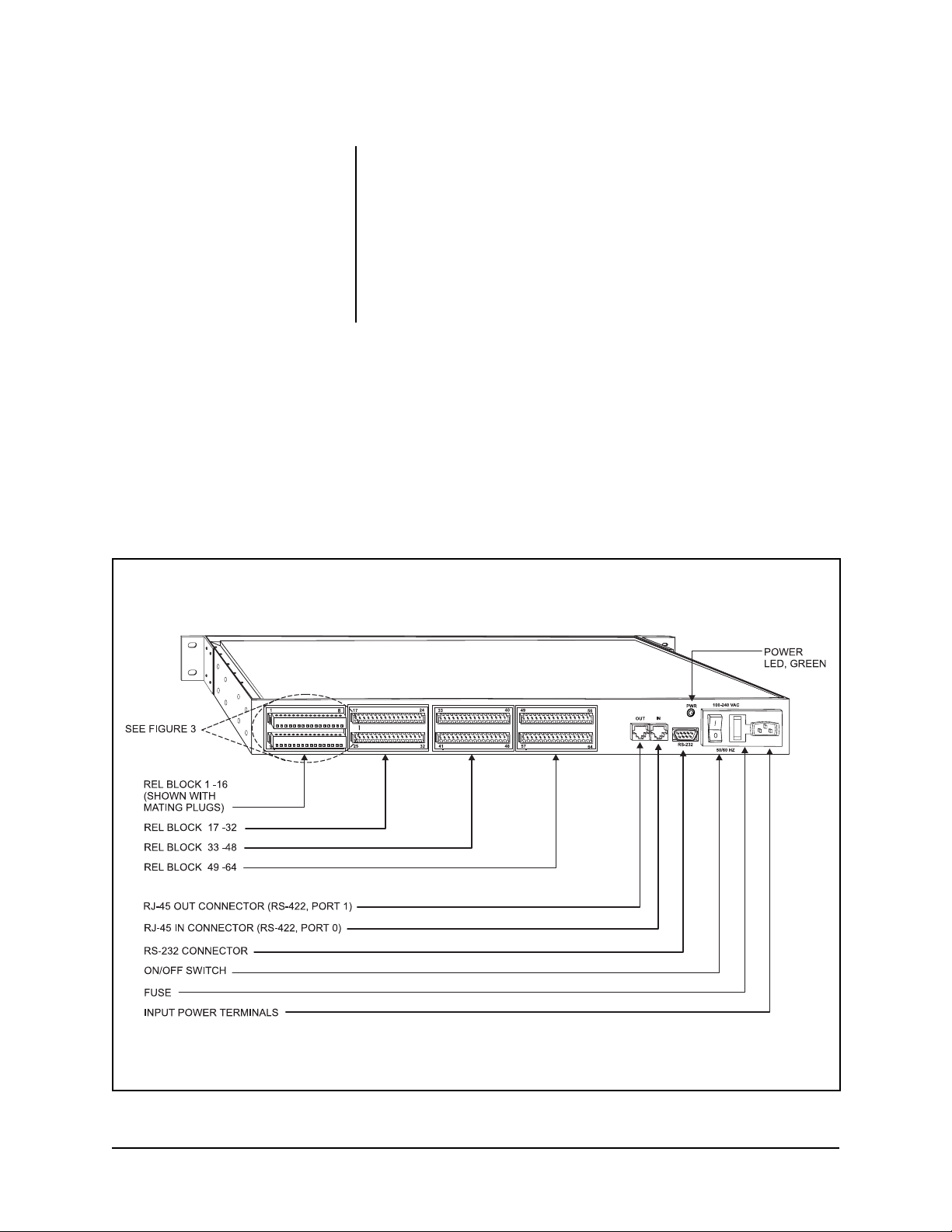

3.2.1 REL Contact Pair Connections

NOTE:

The numbers that appear

on the mating plugs in Figure 3 are

placed there for explanatory purposes only. The terminal positions

on the actual physical plugs are not

numbered.

Physically, each relay block consists of 16 relay contacts and two mating plugs.

Since a relay contact requires two terminal positions, each plug provides 8 contacts

via 16 screw terminals.

To determine the screw terminal pin numbers for a particular contact, refer to

Figure 3.

Figure 3. Relay Interf ace Contact Configur ation

Pelco Manual C538M-A (3/04) 7

Page 9

3.2.2 External Relay Wiring Considerations

Components of external relay wiring are illustrated in Figure 4.

3.2.3 Communication Connectors

Communication to and from the unit is provided through two RJ-45 ports on the

rear of the CM9760-REL. The ports are physically referenced as IN and OUT ports.

The RJ-45 IN connector allows the REL unit to be connected to an appropriate

Sercom port on the rear of a CM9760-CC1 controller. This port is factory set for

RS-422 communications.

The RJ-45 OUT female connector on the rear of the unit is always configured for

RS-422 and is used for cascading subsequent REL units.

The RJ-45 connector pin-outs are illustrated in Figure 5.

3.2.3.1 DB-9 Connector

The rear panel DB-9 connector (factory use only).

+

–

Figure 4. External Relay Wiring

32°-122°F (0°-50°C)

8 Pelco Manual C538M-A (3/04)

Page 10

3.2.3.2 RJ-45 Data Cables

NOTE:

or reverse cable for

Use the supplied “flipped”

all

data connections to the relay unit whenev er

possible.

Because both RJ-45 connectors have the same wiring pin-outs, they require the

same “flipped” cab le . In other words, the IN connector requires a “flipped” cable for

connecting the first unit to the CC1, and the OUT connector requires a “flipped”

cable for cascading other units. A “flipped” cable is as follows: Pin 1 of the cable at

one end becomes pin 8 at the other end. Refer to Figure 6.

Note that the active pin-outs are associated with the outer four pins; namely, 1, 2, 7,

and 8. All accessories on the System 9760 require that the “flipped” cable be used

to attach peripheral equipment. This includes the REL unit.

NOTE REVERSE OR “FLIPPED” CABLE

Figure 5. RJ-45 Pin-outs

Figure 6. RJ-45 Cable Types

Pelco Manual C538M-A (3/04) 9

Page 11

3.2.4 Power Connections

The CM9760-REL utilizes an auto-ranging internal transformer circuit that allows

input power to range from 100-240 VAC, 50/60Hz. Associated with the input power

is the power ON/OFF switch and the input power fuse. The fuse is easily changed

as illustrated in Figure 7.

Figure 7. Power Input Fuse Replacement

10 Pelco Manual C538M-A (3/04)

Page 12

3.3 SETUP

3.3.1 Preliminary Discussion

NOTE:

At present, 700 GPIs are

available per system node. This

limit must be kept in mind when

configuring cascaded systems.

Some devices utilize more GPIs

and therefore more F rame Address

Space than other devices.

NOTE:

Only one de vice type at a

time can utilize the same frame

start address.

FRAME ADDRESSES

The IRC, VCRC, and the CM9760-REL Relay Interface Unit, all use software GPIs

to activate control of external devices.

The number of GPIs required by each hardware device v aries. The number of GPIs

(General Purpose Interfaces) required by the REL is eight.

The address setting entered into the DIP switches, however, is based on what is

called a frame address.

There is a direct numerical relationship between GPIs and frame addressing, which

is as follows:

THE USE OF 32 GPIs SPANS ONE FRAME ADDRESS, REGARDLESS OF DEVICE TYPE USED (device types other than REL units also utilize GPI control).

Therefore a single REL, which uses eight GPIs, occupies only 1/4 of a frame address (refer to Figure 8).

This means that four relay units fit into one frame address space. T o uniquely identify and address REL units within this frame address space, two additional address

bits (sub-frame bits) are used (refer to Figure 10).

The frame address entered in the DIP switch for the REL (or any other device)

serves as a ST AR TING point f or the frame address space it needs. Once a starting

frame address is entered, the REL can be thought of as allocating for itself the next

eight GPIs or the equivalent 1/4 frame address space it needs to operate. The REL,

of course, is unique in that when you have an y grouping of REL units totaling four or

less, they will all more than likely share the SAME FRAME ADDRESS, and differ

only in their SUB-FRAME address bit settings.

Figure 8. Relationship of Frame

Address Space and

the Relay Interface

Unit

ADDITIONAL REMARKS REGARDING FRAME ADDRESSES AND GPIs

One frame address is equivalent to the use of 32 GPIs. With a total of only 700 GPIs

available, only 700/32 or 21.8 (rounded up to 22) frame addresses are needed.

Frame addressing starts at “0”, so frame addressing runs from 0 to 21, or 22 total.

The layout of all 22 frame addresses and corresponding GPI ranges can be found

in T ab le A.

THE RELAY INTERFACE MEMORY FUNCTION

SW3 DIP switch settings (SW3-3 through SW3-6) control what can be thought of

as the contact “memory” function for the REL unit.

One would normally expect that when power is cycled (via a power failure or front

panel reset) that the relay contacts would return to their default settings, which for

the REL, would be determined by the normally open, normally closed (N/O, N/C)

settings entered into DIP switch 2 (SW2-7 through SW2-10).

The additional DIP switch settings for the memory function allow you to ov erride the

default setting in the event power is cycled. With a switch setting of “1” (memory

enabled), the contacts (in groups of 16) will retain the contact setting they had at

the time power was cycled. For groups not enabled, the contacts will defer to their

default values (per DIP switch 2 settings) if power is cycled (refer to Figure 10).

Pelco Manual C538M-A (3/04) 11

Page 13

NOTE:

Figure 9 does not necessarily represent the order in which

REL units are

physically

connected together (for that, refer to

Figure 14).

Figure 9

does

illustrate that fr ame

address settings:

(1) Must be unique for each unit.

(2) Must follow the working rules

listed.

When setting frame addresses on the front panel switches for a group of daisychained REL units, keep in mind a few working rules:

WORKING RULES

1. Start with frame address 0, which is associated with physical GPI 1, and work

sequentially forward until all relay interf ace units are accounted for . Insure that

frame address space is contiguous (see EXAMPLE ONE and TWO of Figure 9).

2. The physical order in which relay units are connected is irrelevant. In a cascaded situation, however , leftov er REL combinations using less than one frame

address space should be placed at the tail-end of allocated frame address

space.

3. Do not overlap frame address spaces (see EXAMPLE FOUR in Figure 9).

4. Do not leave any open frame address spaces in the layout (see EXAMPLE

THREE in Figure 9).

For explanatory purposes, the setup in Figure 9 is used again in other parts of

the manual to illustrate various aspects of REL configuration and setup.

EACH BOX REPRESENTS THE

FRAME ADDRESS SPACE

(EIGHT GPIs) USED BY ONE

REL UNIT.

FRAME

ADDRESS

ADDRESS

UNIT REFERENCE:

ONE FRAME ADDRESS

SPACE SPANS 32 GPIs

SUB-

FRAME

3

2

1

0

3

2

1

0

3

2

1

0

3

2

1

0

3

2

1

0

3

2

1

0

OK

ADDRESS SPACING

GAPS NOT ALLOWED

FRAME ADDRESS

OVERLAP NOT

ALLOWED

Figure 9. Relationship of Frame Address Space with Respect to

Starting Address and the Relay Interface Units

12 Pelco Manual C538M-A (3/04)

Page 14

3.3.2 DIP Switch Settings

DIP switch settings are illustrated and discussed in Figure 10.

Figure 10. DIP Switch Functions

Pelco Manual C538M-A (3/04) 13

Page 15

Table A. Frame Address, GPI Range Association

Daisy-Chained Frame Sub-Frame Combined Associated GPI Range

Relay Units Addresses Addresses Frame/Sub-Frame Eight Required GPI #’s Associated

Running Total SW2 SW3 Addresses with a Frame/Sub-Frame Address

123456 1 2 FA/SFA 12345678

1000000 0 0 0

2000000 1 0 0

3000000 0 1 0

4000000 1 1 0

5100000 0 0 1

6100000 1 0 1

7100000 0 1 1

8100000 1 1 1

9010000 0 0 2

10 010000 1 0 2

11 010000 0 1 2

12 010000 1 1 2

13 110000 0 0 3

14 110000 1 0 3

15 110000 0 1 3

16 110000 1 1 3

17 001000 0 0 4

18 001000 1 0 4

19 001000 0 1 4

20 001000 1 1 4

21 101000 0 0 5

22 101000 1 0 5

23 101000 0 1 5

24 101000 1 1 5

25 011000 0 0 6

26 011000 1 0 6

27 011000 0 1 6

28 011000 1 1 6

29 111000 0 0 7

30 111000 1 0 7

31 111000 0 1 7

32 111000 1 1 7

33 000100 0 0 8

34 000100 1 0 8

35 000100 0 1 8

36 000100 1 1 8

37 100100 0 0 9

38 100100 1 0 9

39 100100 0 1 9

40 100100 1 1 9

41 010100 0 0 10

42 010100 1 0 10

43 010100 0 1 10

44 010100 1 1 10

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

12345678

910111213141516

17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64

65 66 67 68 69 70 71 72

73 74 75 76 77 78 79 80

81 82 83 84 85 86 87 88

89 90 91 92 93 94 95 96

97 98 99 100 101 102 103 104

105 106 107 108 109 110 111 112

113 114 115 116 117 118 119 120

121 122 123 124 125 126 127 128

129 130 131 132 133 134 135 136

137 138 139 140 141 142 143 144

145 146 147 148 149 150 151 152

153 154 155 156 157 158 159 160

161 162 163 164 165 166 167 168

169 170 171 172 173 174 175 176

177 178 179 180 181 182 183 184

185 186 187 188 189 190 191 192

193 194 195 196 197 198 199 200

201 202 203 204 205 206 207 208

209 210 211 212 213 214 215 216

217 218 219 220 221 222 223 224

225 226 227 228 229 230 231 232

233 234 235 236 237 238 239 240

241 242 243 244 245 246 247 248

249 250 251 252 253 254 255 256

257 258 259 260 261 262 263 264

265 266 267 268 269 270 271 272

273 274 275 276 277 278 279 280

281 282 283 284 285 286 287 288

289 290 291 292 293 294 295 296

297 298 299 300 301 302 303 304

305 306 307 308 309 310 311 312

313 314 315 316 317 318 319 320

321 322 323 324 325 326 327 328

329 330 331 332 333 334 335 336

337 338 339 340 341 342 343 344

345 346 347 348 349 350 351 352

(Continued on next page)

14 Pelco Manual C538M-A (3/04)

Page 16

Table A. Frame Address, GPI Range Association (Continued)

Daisy-Chained Frame Sub-Frame Combined Associated GPI Range

Relay Units Addresses Addresses Frame/Sub-Frame Eight Required GPI #’s Associated

Running Total SW2 SW3 Addresses with a Frame/Sub-Frame Address

123456 1 2 FA/SFA 12345678

45 110100 0 0 11

46 110100 1 0 11

47 110100 0 1 11

48 110100 1 1 11

49 001100 0 0 12

50 001100 1 0 12

51 001100 0 1 12

52 001100 1 1 12

53 101100 0 0 13

54 101100 1 0 13

55 101100 0 1 13

56 101100 1 1 13

57 011100 0 0 14

58 011100 1 0 14

59 011100 0 1 14

60 011100 1 1 14

61 111100 0 0 15

62 111100 1 0 15

63 111100 0 1 15

64 111100 1 1 15

65 000010 0 0 16

66 000010 1 0 16

67 000010 0 1 16

68 000010 1 1 16

69 100010 0 0 17

70 100010 1 0 17

71 100010 0 1 17

72 100010 1 1 17

73 010010 0 0 18

74 010010 1 0 18

75 010010 0 1 18

76 010010 1 1 18

77 110010 0 0 19

78 110010 1 0 19

79 110010 0 1 19

80 110010 1 1 19

81 001010 0 0 20

82 001010 1 0 20

83 001010 0 1 20

84 001010 1 1 20

85 101010 0 0 21

86 101010 1 0 21

87 101010 0 1 21

88 101010 1 1 21

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

353 354 355 356 357 358 359 360

361 362 363 364 365 366 367 368

369 370 371 372 373 374 375 376

377 378 379 380 381 382 383 384

385 386 387 388 389 390 391 392

393 394 395 396 397 398 399 400

401 402 403 404 405 406 407 408

409 410 411 412 413 414 415 416

417 418 419 420 421 422 423 424

425 426 427 428 429 430 431 432

433 434 435 436 437 438 439 440

441 442 443 444 445 446 447 448

449 450 451 452 453 454 455 456

457 458 459 460 461 462 463 464

465 466 467 468 469 470 471 472

473 474 475 476 477 478 479 480

481 482 483 484 485 486 487 488

489 490 491 492 493 494 495 496

497 498 499 500 501 502 503 504

505 506 507 508 509 510 511 512

513 514 515 516 517 518 519 520

521 522 523 524 525 526 527 528

529 530 531 532 533 534 535 536

537 538 539 540 541 542 543 544

545 546 547 548 549 550 551 552

553 554 555 556 557 558 559 560

561 562 563 564 565 566 567 568

569 570 571 572 573 574 575 576

577 578 579 580 581 582 583 584

585 586 587 588 589 590 591 592

593 594 595 596 597 598 599 600

601 602 603 604 605 606 607 608

609 610 611 612 613 614 615 616

617 618 619 620 621 622 623 624

625 626 627 628 629 630 631 632

633 634 635 636 637 638 639 640

641 642 643 644 645 646 647 648

649 650 651 652 653 654 655 656

657 658 659 660 661 662 663 664

665 666 667 668 669 670 671 672

673 674 675 676 677 678 679 680

681 682 683 684 685 686 687 688

689 690 691 692 693 694 695 696

697 698 699 700 701 702 703 704

Pelco Manual C538M-A (3/04) 15

Page 17

3.3.3 Software Considerations

NOTE:

When writing macros to

control REL operation, keep in

mind the following:

The macro must reflect your actual

equipment configuration; if you

change the configuration, you must

adjust the macro accordingly. For

example, if a macro were written

to control three RELs in a daisychain configuration and one of the

RELs was subsequently removed,

then any previously written macro

that included these three RELs

would have to be rewritten to reflect that change. Similarly, changing the frame address setting of

any of the RELs is essentially the

same as physically removing it

from the configuration.

Access to the operation of specific devices connected to REL units using keyboards

commands or macro operations depends on the GPI and the specific GPI ranges

each REL unit is assigned. For this to be possible, the software GPI Define File

must be configured using the MGR program. What follows is a brief introduction to

the configuration of the GPI and COMM setup files that need to be programmed for

successful REL operation. This introduction ma y not address other items that might

be needed for your particular system operation. Consult your MGR manual and

associated software for other specific or detailed information.

On a PC and monitor containing the 9760 MGR setup program, start the program

and access the GPI File (GPI file). Refer to Figure 11.

Each GPI can control up to eight relays; w e theref ore need to configure eight GPIs

to control the 64 relays on one REL unit.

1. Program the logical GPI numbers for all the physical GPI n umbers that will be

used. In most cases it is advisab le to program the logical number to be equal

to the existing physical GPI number.

2. For each associated GPI defined, configure individual relays as momentary or

latching, depending on the application.

Latching . . .

If the box is checked, it is latching; otherwise it is mometary (refer to Figure 11).

3. Define operator access, save the GPI file, return to the MGR main menu screen

and press the tab to bring up the COMMS file (.SCP file). Refer to Figure 12.

4. In the COMMs file, assign an equipment number (PIN) of 17 to the port on the

CC1 that will be used for communicating with the REL. Set the communication

settings for 9600 baud and ev en parity. Save the COMMs file, bac k out of the

MGR program and transfer all appropriate configuration files to disk and load

these files onto the CC1 to which your REL configuration is attached. You

should now be ready to operate your REL via direct control from the CM9760KBD. For manual or automatic control of REL functions under macro control,

consult the appropriate sections of the MGR manual.

R1 R2 R3 R8

✓

✓

✓

R1, R2...R8 CONFIGURED AS

MOMENTARY OR LATCHING

(DEPENDING ON APPLICATION)

Figure 11. Configuring the GPI Define File for

REL Operation

Figure 12. Configuring the COMMS File for

REL Operation

16 Pelco Manual C538M-A (3/04)

Page 18

Physical installation of the REL unit is relatively simple, although v arious configurations are possible.

4.1 DIRECT RACK-MOUNT HOOK-UP

The REL unit mounts in a standard 19-inch rack and occupies only one RU (1.75"

or 4.45 cm) of rack space (refer to Figure 13).

4.2 REMOTE OPERATION

The relay unit may be mounted to something other than a standard 19-inch rac k by

relocating the rack ears to another position. If it is desired to place the REL unit

some distance from the controller (CM9760-CC1), the RS-422 communications

from the relay unit to the controller should not exceed 4,000 feet (1,219 m).

4.0 INSTALLATION

Figure 13. Unit Dimensions and Rack-Mount Installation

Pelco Manual C538M-A (3/04) 17

Page 19

4.3 DAISY-CHAINING

Daisy-chaining occurs when more than 64 relays are required.

More importantly, each unit must be configured to ha v e a unique address, referred

to as a Frame Address. F rame addressing with respect to REL units w as discussed

in Section 3.3.1. What follows is a discussion about the ph ysical hook-up of multiple

REL units. System software supports up to 700 GPIs or 5,600 relays. Whether

daisy-chaining two or multiple REL units, the first unit is connected from its “IN”

connector to the CC1 and connected to the second unit through its “OUT” connector. Subsequent units are chained together in the same way.

NOTE:

Since VCRC units also utilize GPI addressing, they can be

bussed together with REL units.

THE DIAGRAM BELOW DEPICTS VALID PHYSICAL HOOKUP VARIATIONS

OF THE SETUP DISCUSSED IN FIGURE 9 (MANY OTHERS ARE POSSIBLE).

SINCE EACH UNIT HAS A UNIQUE ADDRESS, IT MAKES NO DIFFERENCE

WHERE, IN THE CASCADED CHAIN, A PARTICULAR UNIT IS LOCATED.

HOOK-UP (1) AND (2) BELOW DIFFER PHYSICALLY, BUT ARE OPERATIONALLY

THE SAME (SEE NOTE).

(REFER TO SECTION ON COMMUNICATION CONNECTORS)

Figure 14 illustrates the physical hook-up of two cascaded configurations, each

containing nine REL units having the frame addresses illustrated in Figure 9.

Note that the physical order that any unit has in the configuration is independent of

its frame/sub-frame address.

Also note that the remarks made in the previous section regarding RS-422 wiring

run distances applies here when considering cables distance runs between daisychained units.

SWAPPED OR REVERSE CABLES

(1)

(2)

NOTE: PHYSICAL LOCATION OF REL 9 IN (2) IS DIFFERENT THAN REL 9 IN (1),

BUT OPERATIONALLY THE SAME BECAUSE THE FRAME ADDRESS HAS

NOT CHANGED.

Figure 14. Relay Unit Daisy-Chain Configuration

18 Pelco Manual C538M-A (3/04)

Page 20

5.0 OPERATION

5.1 OPERATIONAL OVERVIEW

The basic function of the REL unit is to allow the user/operator to control various

peripheral equipment via relay contacts. Each REL unit processes and executes

only commands with addresses that match that of the RELs (frame address). When

an REL receives a command with an inappropriate address, it passes it on to the

next unit (if applicable) via its OUT port.

When power is first applied to the unit, RAM is cleared and initialization routines

are called. The power LED is lit, operational chips are configured, interrupt priorities are set and the Data LED starts flashing on and off at about 1/2 second

intervals (refer to Section 3.1.2, LEDs). The unit is waiting for its first valid command.

5.2 OPERATING THE CM9760-REL FROM THE CM9760-KBD

Direct control operation of peripherals attached to RELs from a CM9760-KBD is

relatively straightforward once you have determined which GPI to call and AUX to

activate. In the ne xt section, we discuss two methods f or obtaining this inf ormation.

Method 1 uses Figure 16 and Table A; Method II uses the CM9760-REL GPI/AUX

CALCULATOR only (ignore VCRC references on the backside of the calculator).

5.2.1 Information Retrieval

OUR EXAMPLE: Assume you ha v e five cascaded REL units and you wish to activate the peripheral device attached to relay 39 on REL unit 5.

What information do you need to know?

Where can you find the information?

First, you need to determine two things:

1. Which GPI to call of the 704 available.

2. Which AUX, associated with the GPI, to press.

Method I – Table A and Figure 15

Figure 15 is a physical representation of OUR EXAMPLE. We will also use it to

recap the information needed to perform the steps illustrated in Figure 16.

First, the GPI range. Ev ery REL unit is associated with a range of eight GPIs. In our

sequential run of cascaded units, REL 5 has a GPI range of 33-40. (Had we instead

been interested in REL unit 1, then the GPI range we would want would be 1-8).

The GPI range can be determined in a number of ways: (1) you ma y already have a

list or (2), you can match the frame/sub-frame address on the physical REL unit

with those listed in Table A and thus find the GPI range and (3), if you already know

the frame/sub-frame address, you can use Table A alone.

Starting on the left in Figure 15, you can follow the line to the right of GPI 37 over to

where it intersects with the AUX associated with relay grouping 33-40. GPI 37,

therefore, is the specific GPI we need to accomplish our task. Of eight AUX associated with GPI 37, we can see that AUX 7 is the one we need. F ollow the vertical line

from AUX 7 up to where it intersects the associated relay n umbers and you will find

number 39.

Pelco Manual C538M-A (3/04) 19

Page 21

REL UNIT 1

REL UNIT 2

REL UNIT 3

REL UNIT 4

REL UNIT 5

PERIPHERAL

DEVICES

PERIPHERAL

DEVICES

PERIPHERAL

DEVICES

PERIPHERAL

DEVICES

GPI

RANGE

FOR

REL UNIT 5

PERIPHERAL

EQUIPMENT

ASSOCIATED

AUX

ASSOCIATED AUX

ASSOCIATED AUX

ASSOCIATED AUX

ASSOCIATED AUX

ASSOCIATED AUX

ASSOCIATED AUX

ASSOCIATED AUX

Figure 15. Physical Representation of Figure 16

20 Pelco Manual C538M-A (3/04)

Page 22

Method II – The CM9760-GPI/AUX Calculator

If we revisit the EXAMPLE just discussed and illustrated in Figures 15, we can

immediately find the information needed by direct read-off from the information

boxes on the front of the calculator.

Move the calculator wheel until the number “five” appears in the Relay Unit # box.

Go to the table to the right of that and locate relay 39 in the yellow highlighted bo x;

travel to the left along that row and read off GPI 37 on the GPI Range slot. Next,

read off the AUX needed by looking at the Associated A ux ro w and locate the Aux #

directly above 39. You no w hav e the inf ormation needed (call GPI 37, press AUX 7)

to operate the desired relay from the 9760-KBD . Once the GPI and AUX inf ormation

is at hand, control from the keyboard is easy. (Refer to Section 5.2.2, KEYBOARD

OPERATION.)

Other Operations Using the Calculator

The CM9760-GPI/AUX Calculator comes in handy for oper ations other than obtaining the information needed for direct keyboard control operations.

Other uses might include the following:

1. As a reference for setting frame/sub-frame address s witches when installing a

group of cascaded REL units in a system installation. J ust displa y each Rela y

Unit # in the order it is installed (1-5, say) and at each setting of the wheel,

read off the frame/sub-frame Dip Switch readings and set the corresponding

switches on the REL unit itself.

2. If you need to know the GPI range of a particular unit, move the wheel until the

unit’s DIP switch settings match those that appear in the calculator’s frame/

sub-frame address boxes. Directly read off the GPI range for the given REL

unit.

3. Check on the validity of a GPI call.

4. Use the wheel while programming GPI and other related files to double-check

the relationship of the GPIs being defined with respect to the relay actually

being set up for use on which unit.

5. As an information source in troubleshooting situations.

5.2.2 Keyboard Operation

Using the specific GPI/AUX information obtained via Method I or Method II, it is

possible to control the desired peripheral device from the CM9760-KBD.

Below are listed the steps needed to utilize this information for direct control operation from the 9760 keyboard.

Pelco Manual C538M-A (3/04) 21

Page 23

NOTE:

Figure 16 uses the setup

configuration of Figure 9 to illustrate

the steps involv ed to activate rela y

39 output on REL unit 5.

Once the system is running and a keyboard is on-line, direct control of an REL is as

follows (refer to Figure 16):

1. From the Default menu, use the keyboard keypad to enter the GPI number

that contains the relay output you wish to activate (data obtained via Method I

or Method II).

2. After entering the desired number, press the GPI button to bring up the GPI

sub-menu.

3. The GPI sub-menu shows the first six of eight auxiliary function icons, corresponding to six relays associated with the selected GPI. Press the MORE

button to see the remaining two.

4. Press the appropriate AUX function button directly below the desired A ux icon

to activate the relay and associated peripheral device.

5. Repeat steps 1 through 4 to control additional devices.

Figure 16. Controlling REL Output Contacts From the CM9760-KBD

22 Pelco Manual C538M-A (3/04)

Page 24

6.0 SPECIFICATIONS

ELECTRICAL

REL UNIT RELAY CONTACTS**

Parameters: Maximum Switching Capacity 60 Watts

Contact Resistance 75 m ohms

Rated Load

Parameters: .5A @ 125 VAC

REL UNIT

Input Voltage: Auto-ranging 100-240 VAC 50/60 Hz

Power: Consumption: 30 vA, 5 watts

Data Ports

Input: RS-422, RJ-45 connector

Maximum Operating Voltage 125V AC/DC

Maximum Current 2 Amps

2A @ 30 VDC

DIP switch selectable baud-rate.

Output: RS-422, RJ-45 connector.

Output: RS-232, DB-9 connector

Indicators: 2 power LEDs, green

Fusing: 500 mA, 250V

GENERAL

Dimensions: 17.4" W x 1.73" H x 8.54" D (44.2 cm x 4.39 cm x 21.69 cm)

Operating

Temperature: 32°F to 122°F (0°C to 50°C)

Weight: 8 lb (3.63 kg)

MECHANICAL

Connectors

REL Input: Four dual-header, 32 input connectors with mating plugs

Power: 3-wire, #18 AWG

RS422: Two RJ-45 connectors

RS-232: One DB-9 connector (factory use only)

Relay out: One 3-pin header with mating plug

** For information regarding additional specified, known parameters, refer to speci-

fication sheets for relay type G6SK-2F-H from OMRON, if necessary.

DIP switch selectable baud rate

1 data LED, red

(Design and product specifications subject to change without notice.)

Pelco Manual C538M-A (3/04) 23

Page 25

7.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or workmanship for a period of one year after the date

of shipment. Exceptions to this warranty are as noted below:

• Five years on Pelco manufactured cameras (CC3500/CC3600/CC3700

and MC3500/MC3600/MC3700 Series); two years on all other cameras.

®

• Three years on Genex

Series (multiplexers, server, and keyboard)

and 090 Series Camclosure® Camera System.

®

•Two years on 100/150, 200 and 300 Series Camclosure

Camera Sys-

tems.

•Two years on cameras and all standard motorized or fixed focal length

lenses.

®

•Two years on Legacy

, CM6700/CM6800/CM6800E/CM8500/CM9500/

CM9740/CM9760 Matrix, DF5 and DF8 Series Fixed Dome products.

®

•Two years on Spectra

, Esprit®, and PS20 Scanners, including when

used in continuous motion applications.

®

•Two years on Esprit

and WW5700 series window wiper (excluding

wiper blades).

• Eighteen months on DX Series digital video recorders.

• One year (except video heads) on video cassette recorders (VCRs).

Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications (that is, preset scan, tour and auto scan

modes).

Pelco will warrant all replacement parts and repairs for 90 days from the

date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by

reason of misuse, alteration, normal wear, or accident are not covered

under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or

loss resulting from the specific use or application made of the Products.

Pelco’ s liability f or an y claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating

to the Products shall not exceed the price paid by the Dealer to Pelco for

such Products. In no event will Pelco be liable for any special, incidental

or consequential damages (including loss of use, loss of profit and claims

of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with specific legal rights. The

Dealer may also have additional rights, which are subject to variation from

state to state.

If a warranty repair is required, the Dealer must contact Pelco at

(800) 289-9100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice

number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall

under the warranty conditions stated above, please include a written explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by

which the item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking

and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the

assigned CA or RA number and freight should be prepaid. Ship to the

appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto

Rico send the goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto

Rico and are instructed to return goods to the USA, you may do one of the

folllowing:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORW ARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

REVISION HISTORY

Manual # Date Comments

C538M 12/98 Original version.

C538M-A 3/04 Revised Figures 2 and 10 to include RS-232 information. Revised

® Pelco, the Pelco logo, Spectra, Genex, Legacy, Esprit, Camclosure, and System 9760 are registered trademarks of Pelco. © Copyright 2004, Pelco. All rights reserved.

Specifications

. Updated

Warranty and Return Information

.

24 Pelco Manual C538M-A (3/04)

Loading...

Loading...