Page 1

ADDENDUM

Addendum No.: C1577M-A

Date: August 4, 2004

Manuals Affected: CM9760 Series Manuals – C538M-A, C539M-A, C540M-B, C541M-C, C542M-B,

C543M-A, C544M, C549M-A, C572M, C573M-D, C578M, C579M, C1501M, C1503M,

C1510M-QS, C1510M-A, C1520M-B, C1528M-D, C1940M, C1941M, C1942M, and

C1943M

Manual Update: The CM9760-CC1 has been replaced with the CM9700-CC1 and the CM9760-MGR manage-

ment software has been replaced with the CM9700-MGR management software.

Keep the following in mind when referring to the instructions contained in these manuals:

• The CM9700-CC1 contains the latest CC1 software (version 9.01 or higher), and is

programmed with the new CM9700-MGR management software.

• Despite the difference in model numbers, the CM9700-CC1 functions the same as the

CM9760-CC1 and most of the information in these manuals applies to version 9.01 (or

higher) CPU.

•You can add the CM9700-CC1 to an existing CM9760 system if you upgrade the existing

CM9760-CC1 units with the current software (version level 9.01 or higher).

Software version 9.01 requires a minimum of 16 MB of RAM in the CPU. If required, you

can upgrade the RAM in older CM9760-CC1 units using the software upgrade kit

appropriate for your CPU.

• Do not use the CM9760-MGR instructions contained in these manuals. Refer to the

CM9700-MGR Getting Started Software Guide, on-screen help, or Online Help for

instructions.

Pelco World Headquarters • 3500 Pelco Way, Clovis, California 93612-5699 USA • www.pelco.com

USA & Canada: Tel: 800/289-9100 • Fax: 800/289-9150

®

International: Tel: 1-559/292-1981 • Fax: 1-559/348-1120

Page 2

®

System 9760

®

Installation Guide

C1503M (11/99)

Pelco • 300 W. Pontiac Way, Clovis • CA 93612-5699 USA • Pelco Online @ http://www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150 • DataFAX (800) 289-9108

International Customers: Tel +1 (559) 292-1981 or FAX +1 (559) 348-1120 • DataFAX +1 (559) 292-0435

Page 3

CONTENTS

Section Page

SYSTEM UNPACKING AND RACKING .............................................................................3

SYSTEM DATA CONNECTIONS .......................................................................................4

ADDITIONAL HOOKUP INFORMATION ........................................................................... 5

SYSTEM VIDEO CONNECTIONS .....................................................................................5

DEFINITIONS ............................................................................................................5

VIDEO INPUTS ..........................................................................................................5

SINGLE-BAY SYSTEMS ....................................................................................5

MULTI-BAY SYSTEMS ......................................................................................6

VIDEO OUTPUTS ......................................................................................................6

NETWORKING ..........................................................................................................6

SYSTEM PROGRAMMING................................................................................................6

CM9760-MGR ............................................................................................................6

SET 9750 ................................................................................................................... 6

DOS ...................................................................................................................................7

FILE MAINTENANCE ........................................................................................................7

TRANSFER FILES FROM CM9760-CC1 TO CM9760-MGR .................................... 7

TRANSFER FILES FROM CM9760-MGR TO 3.5-INCH FLOPPY DISK ................... 7

TRANSFER FILES FROM 3.5-INCH FLOPPY DISK TO CM9760-CC1 ....................8

RENAMING CONFIGURATION FILES ......................................................................8

VERIFYING OPERATION ..................................................................................................9

APPENDIX .........................................................................................................................9

SYSTEM PORT SETTINGS TABLE ........................................................................... 9

SETUP DRAWINGS.................................................................................................. 11

TYPICAL CONNECTIONS ............................................................................... 11

WARRANTY AND RETURN INFORMATION ................................................................... 40

LIST OF ILLUSTRATIONS

Figure Page

1 CM9760-CC1 Typical Port Layout .....................................................................11

2 CM9760-MXB Typical Connections...................................................................11

3 496 X 16 ............................................................................................................ 12

4 496 X 16 Looping ..............................................................................................13

5 736 X 16 ............................................................................................................ 14

6 736 X 16 Looping ..............................................................................................14

7 976 X 16 ............................................................................................................ 15

8 976 X 16 Looping ..............................................................................................16

9 496 X 32 ............................................................................................................ 17

10 496 X 32 Looping ..............................................................................................18

11 736 X 32 ............................................................................................................ 19

12 736 X 32 Looping ..............................................................................................20

13 976 X 32 ............................................................................................................ 21

14 976 X 32 Looping ..............................................................................................22

15 256 X 48 ............................................................................................................ 23

16 256 X 48 Looping ..............................................................................................24

17 496 X 48 ............................................................................................................ 25

18 496 X 48 Looping ..............................................................................................26

19 736 X 48 ............................................................................................................ 27

20 736 X 48 Looping ..............................................................................................28

21 976 X 48 ............................................................................................................ 29

22 976 X 48 Looping ..............................................................................................30

23 256 X 64 ............................................................................................................ 31

24 256 X 64 Looping ..............................................................................................32

25 496 X 64 ............................................................................................................ 33

26 496 X 64 Looping ..............................................................................................34

27 736 X 64 ............................................................................................................ 35

28 736 X 64 Looping ..............................................................................................36

29 976 X 64 ............................................................................................................ 37

30 976 X 64 Looping ..............................................................................................38

2 Pelco Manual C1503M (11/99)

Page 4

This guide is intended to help you with the basic installation and setup of the Pelco System

9760® Matrix Switcher and Controller. This guide is not a replacement for the system

manual, but rather a tool to help you quickly get the system up and running.

Before shipping, Pelco sets up, tests, and programs each system according to the individual

sales order. As a first step, verify that the packing slip corresponds to your sales order. Contact

us immediately if there is a discrepancy.

This guide covers the following:

1. System Packing and Racking

2. System Data Connections

• CM9760-CC1 System CPU

• CM9760-MXB Matrix Bays

• CM9760-KBD System Keyboards

• CM9760-MGR Manager Program

• Receiver Connections

• CM9760-NW1

• Peripheral Equipment

3. System Video Connections

• Definitions

• Video Inputs

• Down-Framing Interconnections

• Side-Framing Interconnections

• Video Outputs

• Networking

4. System Programming

• Manager Program

• SET 9750 Program

5. DOS

6. File Maintenance

• Transfer Files from CM9760-CC1 to CM9760-MGR

• Transfer Files from CM9760-MGR to 3.5-Inch Floppy Disk

• Transfer Files from 3.5-Inch Floppy Disk to CM9760-CC1 Hard Drive

• Renaming Configuration Files

7. Verifying Operation

8. Appendix

• System Port Settings Table

• Setup Drawings

SYSTEM UNPACKING AND RACKING

1. Unpack and inspect all equipment and verify delivery according to the packing slip.

2. Remove and save all manuals and cabling from all packages and keep them with their

associated equipment.

3. Locate in your documentation the following:

• The page entitled System 9760 Factory Default Port Settings. This im-

portant document contains specific information about your system. All System

9760s are pre-programmed based on specific criteria in the system order.

• System 9760 manual binders.

4. For best results and a clean installation, install the System 9760 using standard EIA

19-inch racks. Leave one rack unit space between each card cage for effective cooling.

5. Review the sample drawings in the appendix and select the configuration that most

closely resembles the system you are installing.

Pelco Manual C1503M (11/99) 3

Page 5

6. Install the system CM9760-CC1 CPU and CM9760-MXB matrix bays near each other.

Note that each CM9760-MXB has a unique label for identifying the bay location in the

installation. This ID information is important in ensuring correct video and data connections.

7. Install any system peripherals in a convenient location.

8. Locate the CM9760-KBD system keyboard(s), CM9505-UPS power supply(s), and the

two RJ-45 data cables supplied with each keyboard.

9. Connect all power line cords to the equipment. Do not apply power to the equip-

ment at this time.

SYSTEM DATA CONNECTIONS

1. CM9760-CC1

This is the main system controller, often called the CPU.

a. Copy the supplied system port settings from the System 9760 Factory Default

Port Settings to the System Port Settings Table in the appendix of this installation

guide.

b. Enter the label information from each matrix bay in the Description section (to

avoid confusion after completing the installation).

c. Update this table as the installation proceeds.

2. CM9760-MXB

This is the video matrix (switching) bay that contains the video input, output modules,

and bay controller module.

a. Follow the System Port Settings Table and connect the CM9760-CC1 to the

CM9760-MXB bays using the supplied RJ-45 data cables.

b. Be sure to match the matrix bay label to the CM9760-CC1’s port.

3. CM9760-KBD

This is the system keyboard for operator control commands.

a. Locate the RJ-45 data cable labeled “STRAIGHT.” Connect one end to the COM1

input on the bottom of the keyboard; connect the other end to the KEYBOARD input on the CM9505-UPS power supply.

b. Locate the cable labeled “REVERSED.” Identify the keyboard on the System Port

Settings Table. Connect one end of this cable to the appropriate data port on the

CM9760-CC1; connect the other end to the CARD CAGE input on the CM9505UPS.

4. External PC/CM9760-MGR

The CM9760-CC1 provides two 9-pin sub-miniature D connectors used for standard

RS-232 communications with the CPU. COM1 is set at the factory for use with the

CM9760-MGR program used for system programming.

a. Connect one end of a standard 9-pin sub-D cable (not supplied) to the CM9760-

CC1 and the other end to the external PC.

b. Be sure the Com port settings on the PC match the settings for COM1 on the

CM9760-CC1.

c. Refer to the

ministrative Software Manual.

Hardware Installation

section in the CM9760-MGR System 9760 Ad-

4 Pelco Manual C1503M (11/99)

Page 6

ADDITIONAL HOOKUP INFORMATION

• Comms File

The Comms Setup File contains information about the equipment that is attached to

your system. Access the Comms dialog box by clicking on the Comms tab in the Setup

9760 Configuration dialog box. Refer to the

the CM9760-MGR System 9760 Administrative Software Manual for information.

• Pan And Tilt Receivers and Domes

Each port can have up to 16 receivers or domes when using hardwired RS-422 communications connected in a daisy chain configuration.

• Ports

Use the System Port Settings Table to determine which ports are not in use. When setting up pan and tilt devices for use with the System 9760, edit the Comms file using

Pin #9 as the equipment number. Be sure the assigned port’s baud rate and parity

match that of the pan and tilt receiver. Refer to the

tion in the CM9760-MGR System 9760 Administrative Software Manual.

• Peripheral Equipment

Refer to the specific user manual for a description of each device. An RJ-45 data cable

is included with each device. Using the Factory Default Port Settings page and the

device’s interconnect cable, connect all peripheral equipment to its appropriate data

port. If the device is not shown on the Factory Default Port Settings page, refer to the

major section

CM9760-MGR System 9760 Administrative Software Manual. Also, refer to

puts

and

puts.

• CM9760-NW1

This CPU serves as a communications hub when networking two or more System

9760s. This unit includes its own Factory Default Settings table. Use both tables to determine which ports are used for data interconnection between the CM9760-CC1s and

the CM9760-NW1.

Configuring the System 9760 with the Pelco Window Set 9760

Video Outupts

sections for information on connecting video sources and out-

Comms Setup File (.SCP File)

Comms Setup File (.SCP File)

section in

sec-

in the

Video In-

SYSTEM VIDEO CONNECTIONS

For best results, use crimp-on BNCs only. Do not use screw-on BNCs–these typically do

not provide adequate ground and signal connections.

DEFINITIONS

Bay Capacity: A single CM9760-MXB can support up to 256 inputs (in increments of

Side Framing: A technique to expand the matrix video inputs beyond 256.

Down Framing: A technique to expand the matrix video outputs beyond 16.

Video Tie Lines: A method for connecting side-framed matrix bays together and networked

VIDEO INPUTS

SINGLE-BAY SYSTEMS

Refer to the sample drawings in the appendix. Connect all video sources (cameras, VCRs,

etc.) to the video input BNCs at the rear of the CM9760-MXB(s). Connect video 1 to the BNC

marked “1,” video 2 to the second BNC directly below “1,” and so on until all video cables

are connected. If the system is set up for looping, terminate the looped output at 75 ohms.

16) and 16 outputs (in increments of 4).

systems together. A video tie line is a video output from one bay connected to the video input of another. In a networked system, a tie line

provides the video path necessary to view video from a remote node.

Pelco Manual C1503M (11/99) 5

Page 7

MULTI-BAY SYSTEMS

1. Down-Framing – For systems with more than 16 monitor outputs, you must pas-

sively loop the video from the first CM9760-MXB to the second CM9760-MXB for the

next 16 monitors. The best location for the second bay is below the first bay, as shown

in the system drawing. Connect the supplied multi-coax ribbon cable from the bottom

of the first bay to the down-frame loop input of the second. Continue in this manner

connecting all down-framing bays.

2. Video-Looping – If your system is configured for video looping, properly terminate

the video cable at the last connection with 75 ohm.

3. Side-Framing – For systems with more than 256 video inputs, connect the 16 video

outputs from the second matrix bay to the first 16 video inputs of the first bay. The best

location for the second bay is next to the first bay on the same level, as shown in the

system drawing. Continue in this manner connecting all side-framing bays.

VIDEO OUTPUTS

Connect all video outputs from the CM9760-MXB to their desired device (that is, monitors,

printers, VCRs, etc.). Terminate the device at 75 ohms.

NETWORKING

For networked systems, refer to the system drawing to determine which monitor outputs

and camera inputs were assigned as video tie lines. Connect the monitor outputs assigned

as tie lines of one system to the video inputs assigned as tie lines of the other, and vice

versa.

SYSTEM PROGRAMMING

WARNING:

the Windows

manager program

(CM9760-MGR) is used to

create or edit configuration

files, the SET 9750 program

cannot be used. In other

words, the System 9760MGR flat files are not

backward compatible with

SET 9750.

After

Apply power to the CM9760-CC1, keyboard, monitor, and PC (as appropriate to the method

of programming) for system programming.

The two methods of programming the CM9760 system are as follows:

CM9760-MGR

This is the preferred programming method. It requires an external IBM-compatible PC running Windows® 95 and the supplied CM9760-MGR Manager Program. Pelco recommends

using an AT-type keyboard and VGA monitor. All system programming can be done off-site

and later downloaded (transferred) to the CM9760-CC1 by writing flat files (see the

section for an explanation of flat files). Or you can do direct “live” programming through an

RS-232 connection between the PC and the CM9760-CC1. See the

MGR Software

for details on installing the CM9760-MGR program.

The sections

CM9760-MGR to 3.5-Inch Floppy Disk

CM9760-CC1

SET 9750

This is the second programming method. The DOS-based SET 9750 program on the

CM9760-CC1 hard drive requires a VGA monitor and AT-type keyboard connected directly

to the CM9760-CC1. See the

9760

section in the CM9760-MGR System 9760 Administrative Software Manual.

DOS

section in the CM9760-MGR System 9760 Administrative Software Manual

Transfer Files from CM9760-CC1 to CM9760-MGR, Transfer Files from

that follow in this document pertain to this method.

Configuring the System 9760 with the Pelco Windows SET

, and

Transfer Files from 3.5-Inch Floppy Disk to

Installing the 9760-

6 Pelco Manual C1503M (11/99)

Page 8

DOS

The CM9760 system’s program runs in DOS. Therefore, you will need to use basic DOS

commands to transfer, overwrite, and edit data, and to maintain files on your hard drive.

The default configuration files on the CM9760-CC1 hard drive are defined at the factory and

are labeled “TEST.” These files are referred to as “flat files” and are loaded into memory

when you power up the system. (See the

dows SET 9760

for details.)

The procedures that follow show you how to copy your configuration files from the CM9760CC1 to the PC where the CM9760-MGR program is located and back again using a floppy

disk. You will need to use these procedures if you want to change these files. If you want to

rename these files, you will need to use the procedure in the

section below.

FILE MAINTENANCE

TRANSFER FILES FROM CM9760-CC1 TO CM9760-MGR

Before you can use the CM9760-MGR program to edit the pre-programmed TEST files, you

must load these files into the CM9760-MGR database.

1. Take the CM9760 offline by simultaneously pressing Ctrl and Q on the AT keyboard.

The VGA screen will display C:/9760>.

section in the CM9760-MGR System 9760 Administrative Software Manual

Configuring the System 9760 with the Pelco Win-

Renaming Configuration Files

NOTE:

The password is

case sensitive.

2. Insert a blank 3.5-inch floppy disk into the floppy drive of the CM9760-CC1.

3. Type copy test.* a: and press Enter. The flat files will be copied from the CM9760-

CC1 hard drive to the 3.5-inch floppy disk.

4. Remove the floppy disk and insert it into the PC that contains the CM9760-MGR program.

5. Start the manager program on the PC by double clicking on the Pelco 9760MGR

icon. Enter a user ID and password in the Log On dialog box (the default for both is

Admin

).

6. Click on the Read File icon on the taskbar. This opens the Flat File Utility – Read

dialog box. All the generated files have check marks to show they are selected.

7. Click Select on the Flat File Source button. This starts the standard Open dialog box.

8. Select Drive a:, then double click on the test.scp file to select. This closes the

Open dialog box and returns you to the Flat File Utility – Read dialog box.

9. Enter the number of the node you are using (number of the port on the NIU to which

the node is connected). Enter 1 if you only have a single node system.

10. Click on the Start button. Several warnings may appear indicating certain files do not

exist. This is okay. Select Continue Installation for each.

11. The message “Finished Reading Flat Files” appears when file transfer is complete.

TRANSFER FILES FROM CM9760-MGR TO 3.5-INCH FLOPPY DISK

This procedure is VERY IMPORTANT. You must copy flat files from the CM9760-

MGR program to a 3.5-inch floppy disk when modifying comms setup files and macro files.

1. Double click on the Pelco 9760MGR icon to start the CM9760-MGR program. Enter

a user ID and case sensitive password in the Log On dialog box (default for both is

Admin).

Pelco Manual C1503M (11/99) 7

Page 9

2. Insert a 3.5-inch floppy disk into the PC. Select the Write File icon on the task bar.

This opens the Flat File Utility – Write dialog box. The default for writing flat files is to

generate all files regardless of whether or not they are used. To write only specific files,

deselect the ones you do not want to generate.

3. Click Select on the Flat File Source button. This opens the standard Open dialog box.

4. Double click on the file you want to copy. This opens the Save As dialog box.

5. Select Drive a:. Click the SAVE tab. This returns you to the Flat File Utility – Write

dialog box.

6. Click on the Start button.

7. The “Finished Writing Flat Files” message appears when file copying ends.

TRANSFER FILES FROM 3.5-INCH FLOPPY DISK TO CM9760-CC1

The following example uses “test” as the default file name. If you have changed the configuration files name (refer to the

new name you selected instead of “test”.

1. Insert the 3.5-inch floppy disk containing the flat files you want to load into the

CM9760-CC1.

2. Take the CM9760 offline by simultaneously pressing Ctrl and Q on the AT keyboard.

The VGA monitor will display C:/9760>.

Renaming Configuration Files

section below), substitute the

NOTE:

Before the files are

copied to the CM9760-CC1

hard drive, the message

“Files Already Exist, Over

Write? Y/N/A” (yes/no/all)

will appear.

SAVE

all

current operating flat files

that are being replaced

before selecting “yes” or “all”

at the prompt.

3. Type copy a: test.* and press Enter.

4. Type A to the prompt and press Enter. The files on the floppy disk will replace those

on the hard drive.

5. Remove the floppy disk and re-boot by simultaneously pressing Ctrl/Alt/Delete.

Changes take effect after all configuration files load.

RENAMING CONFIGURATION FILES

The

Renaming Configuration Files

name.

The system loads the flat files listed in the system’s C:/9760 subdirectory. The default

test.bat file’s command line reads

files that load when the system boots from the autoexec.bat file.

1. Take the CM9760 offline by simultaneously pressing Ctrl and Q on the CM9760 AT

keyboard. The VGA monitor will display C:/9760>.

2. Type ren test.*

you choose for the TEST files. Remember to enter a space after the first asterisk.)

3. Type cd.. to switch to the root directory.

4. Type edit autoexec.bat and press Enter. This opens the file editor and the

autoexec.bat file. The following is an example of the default autoexec.bat:

newfilename

section will show you how to give these files a new

CM9760 TEST

.* and press Enter. (

where TEST is the name of the default

“newfilename”

is any new name

echo off

path c:\dos

prompt=$t $d $p$g

uptimer /t /p /f

CD 9760

TEST

➝

(change to

newfilename

)

8 Pelco Manual C1503M (11/99)

Page 10

5. Change the command line in the autoexec.bat file to reflect the new flat files name:

from TEST to

6. Click File, then Save.

7. You also need to change the test.bat file to reflect the new flat files name, otherwise

the system will not run. Click File, then Open.

newfilename

(the name you chose in step 2 above).

8. Click on

9. Change the command line in the

from CM9760 TEST to CM9760

10. Click File, then Save.

11. Click File, then Exit to leave the file editor.

12. Re-boot the system (by simultaneously pressing Ctrl/Alt/Delete) for the changes to

take effect.

newfilename

VERIFYING OPERATION

1. Power up all the remaining equipment. After the CM9760-CC1 loads the configuration

files, the CM9760-KBD LCD should show “SYSTEM 9760.”

2. Enter 1111 (the keyboard #1 default password) on the CM9760-KBD keypad. The as-

terisks on the keyboard will move one space to the left for each number entered. The

LCD will display “ENTER MONITOR #.”

3. Enter 1 MON.

4. Press the FWD key to step through the cameras and verify switching.

The default password for keyboard 2 is 2222, keyboard 3 is 3333, etc.

APPENDIX

.bat in the 9760 directory, then Ok.

newfilename

newfilename

.bat file to reflect the new flat files name:

(the name you chose in step 2 above).

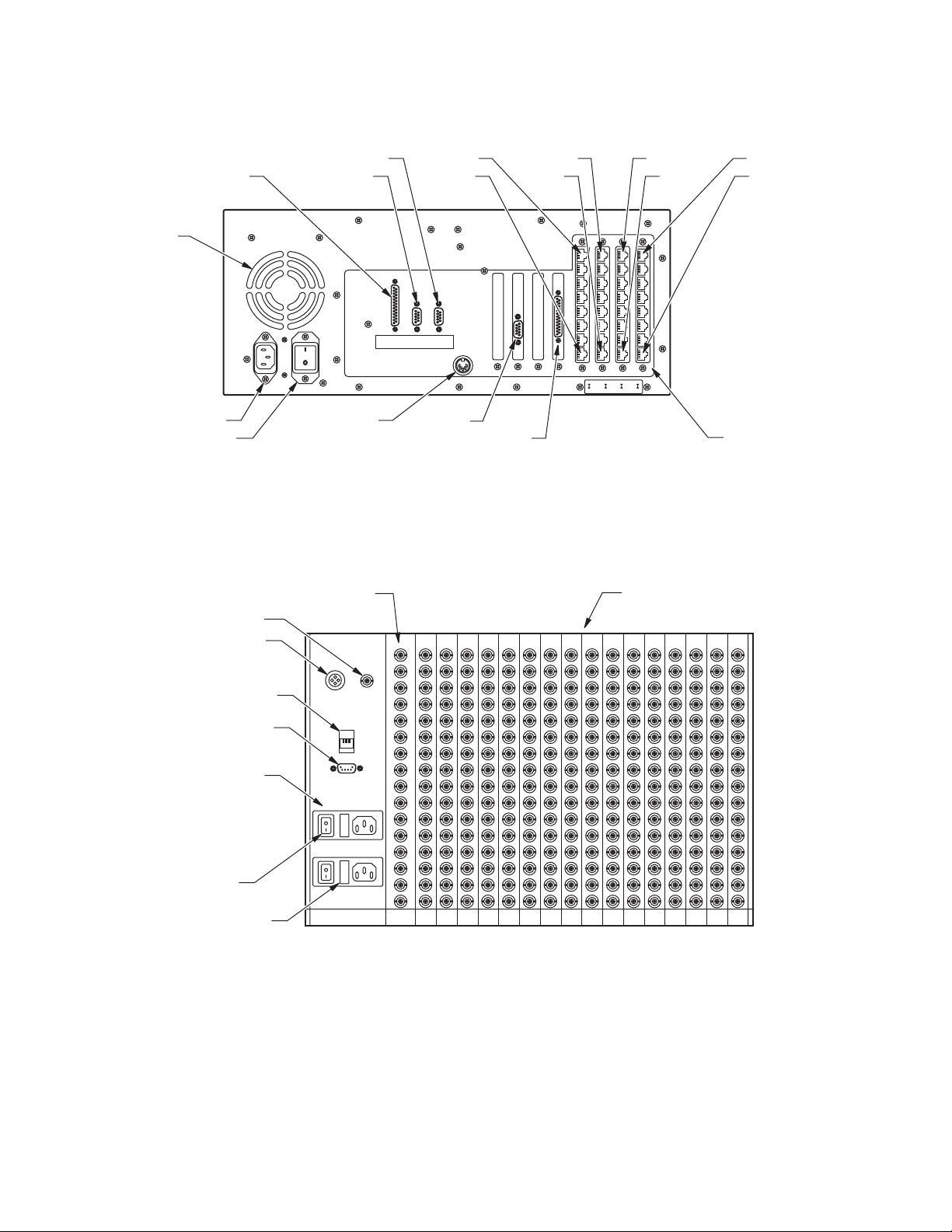

SYSTEM PORT SETTINGS TABLE

See the following page.

Pelco Manual C1503M (11/99) 9

Page 11

System 9760 Factory Default Port Settings

PRINTER COM1 COM2

36

35

34

33

32

31

30

29

20

28

27

26

25

24

23

22

21

12

19

11

10

18

9

17

16

8

15

7

6

14

13

5

Note: The number of ports on your system may differ from the

above drawing. Connect System 9760 components as follows:

PORT DESCRIPTION DESCRIPTIONPORT

1 (RS-232)

2 (RS-232)

3

4

NOT PRESENT

NOT PRESENT

5

6

9

10

11

12

13

15

16

17

18

FORM 1957 REVISION B (9/23/98)

19

20

21

22

23

26

27

29

30

31

32

33

24

35

36

10 Pelco Manual C1503M (11/99)

Page 12

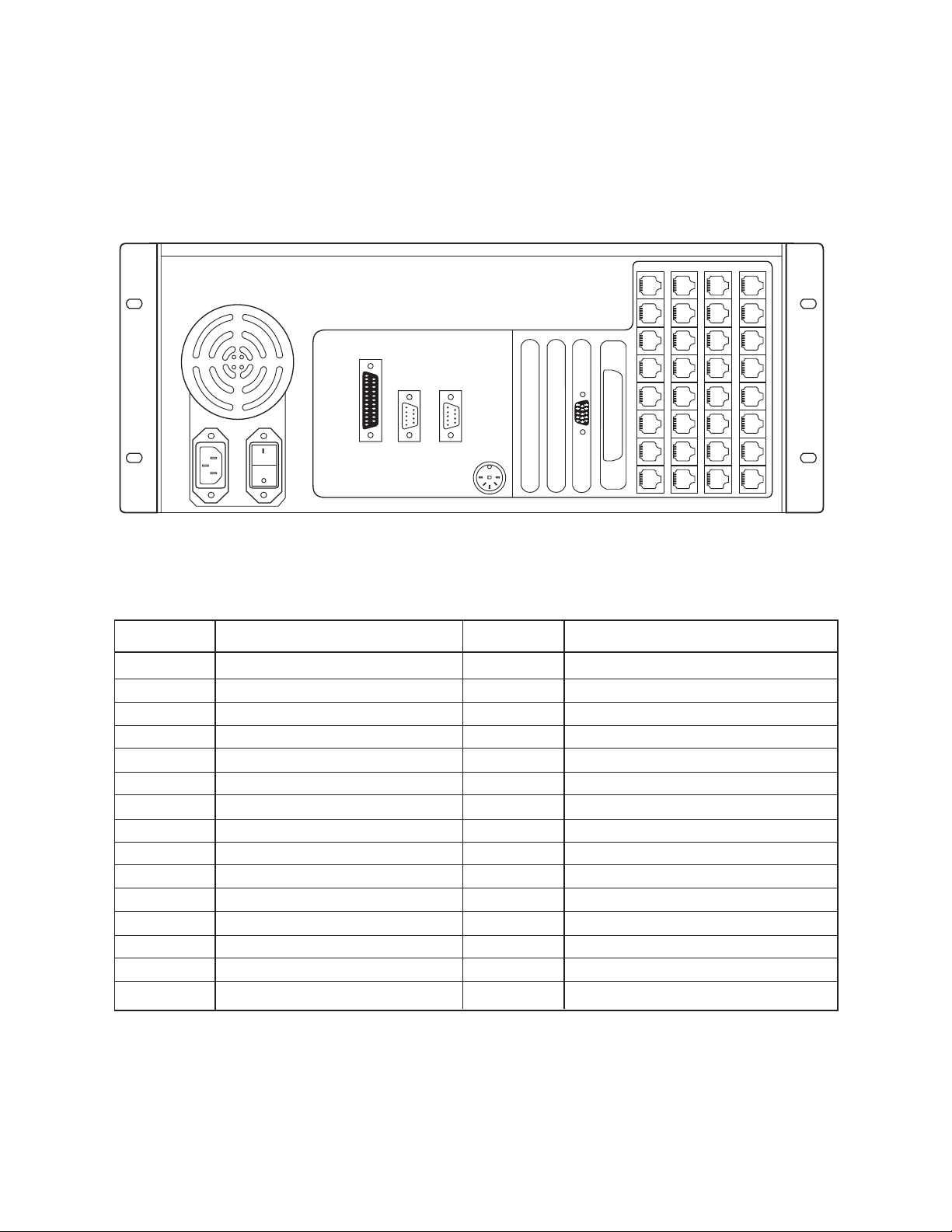

SETUP DRAWINGS

LPT PRINTER PORT

RS-232 PORT 1

FAN

POWER INPUT

AT KEYBOARD PORT

POWER SWITCH

TYPICAL CONNECTIONS

16 MONITOR OUTPUTS 256 VIDEO INPUTS

VIDEO BLACK

LEVEL OUT

ALARM PORT

RS-232 PORT 2 PORT 36

PORT 29

PRINTER COM1 COM2

PORT 28

PORT 21

VGA PORT

OPTIONAL RELAY PORT

Figure 1. CM9760-CC1 Typical Port Layout

Alarm Black

Out

35292821201312

5

PORT 20

PORT 13

PORT 12

PORT 5

RS-422 PORTS

RJ-45 DATA PORT

DB9 DATA PORT

DUAL POWER

SUPLIES

POWER

SWITCH

SUPPLY FUSES

RS-422

RS-422

Figure 2. CM9760-MXB Typical Connections

Pelco Manual C1503M (11/99) 11

Page 13

16 1

481 257 241 1

CM9760-CC1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

Figure 3. 496 X 16

CAMS

1-256

12 Pelco Manual C1503M (11/99)

Page 14

16 1

481 257 241 1

CM9760-CC1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

Alarm Black

RS-422

RS-422

Out

257-496

CM9760-MXB CM9760-MXB

Alarm Black

RS-422

RS-422

Out

CAMS

Alarm Black

RS-422

RS-422

Out

257-496

OUT

CM9760-MXBL CM9760-MXBL

CAMS

1-256

CAMS

1-256

OUT

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

Figure 4. 496 X 16 Looping

Pelco Manual C1503M (11/99) 13

Page 15

16 1

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

CAMS

513-736

CAMS

257-512

CAMS

1-256

CAMS

1-256

OUT

CAMS

257-512

OUT

CAMS

513-736

OUT

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35292821201312

5

721 497 241 1513

CM9760-MXB

CM9760-MXBL CM9760-MXBL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 1 LOOP-OUT

CAM 16 LOOP-OUT

VIDEO TIE LINES X16

16 1

CM9760-MXBL

CM9760-CC1

PRINTER COM1 COM2

VIDEO TIE LINES X16

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

CM9760-MXB CM9760-MXB

721 497 241 1513

Out

CAMS

513-736

Alarm Black

RS-422

RS-422

Out

CAMS

257-512

257

Alarm Black

RS-422

RS-422

Out

CAMS

1-256

CM9760-MXB

Figure 5. 736 X 16

14 Pelco Manual C1503M (11/99)

Figure 6. 736 X 16 Looping

Page 16

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

CAMS

513-768

CAMS

1-256

16 1

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

CM9760-MXB

VIDEO TIE LINES X16

CM9760-MXB

961

769

753

513

497

257

241

1

Figure 7. 976 X 16

Pelco Manual C1503M (11/99) 15

Page 17

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

961

769

753

513

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

CAMS

513-768

CAMS

1-256

CAMS

257-512

OUT

CAMS

1-256

OUT

CAMS

513-768

OUT

CAMS

769-976

OUT

CAMS

257-512

497

257

241

1

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

CM9760-MXB

VIDEO TIE LINES X16

CM9760-MXB

CM9760-MXBL CM9760-MXBL

CM9760-MXBL

CM9760-MXBL

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

16 1

Figure 8. 976 X 16 Looping

16 Pelco Manual C1503M (11/99)

Page 18

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

481 257 241 1

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35292821201312

5

CM9760-MXB CM9760-MXB

16 1

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

32 17

CAMS

257-496

CAMS

1-256

Pelco Manual C1503M (11/99) 17

Figure 9. 496 X 32

Page 19

16 1

481 257 241 1

CM9760-CC1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

Alarm Black

RS-422

RS-422

Out

257-496

CM9760-MXB CM9760-MXB

32 17

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

OUT

Alarm Black

RS-422

RS-422

Out

CAMS

1-256

CAMS

1-256

OUT

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

CM9760-MXB

CM9760-MXB

Figure 10. 496 X 32 Looping

18 Pelco Manual C1503M (11/99)

Page 20

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

721

513

497

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

241

1

Alarm Black

Out

RS-422

RS-422

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

16 1

CM9760-MXB

CM9760-MXB

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

32 17

CAMS

513-736

CAMS

257-512

CAMS

1-256

VIDEO TIE LINES X16

Figure 11. 736 X 32

Pelco Manual C1503M (11/99) 19

Page 21

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

721

513

497

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

241

1

Alarm Black

Out

RS-422

RS-422

CAMS

513-736

OUT

CAMS

257-512

OUT

CAMS

1-256

OUT

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

16 1

CM9760-MXB

CM9760-MXB

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

32 17

CAMS

513-736

CAMS

257-512

CAMS

1-256

VIDEO TIE LINES X16

Figure 12. 736 X 32 Looping

20 Pelco Manual C1503M (11/99)

Page 22

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

961

769

753

513

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

497

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

241

1

Alarm Black

Out

RS-422

RS-422

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

16 1

CM9760-MXB

CM9760-MXB

CM9760-MXB

CM9760-MXB

32 17

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

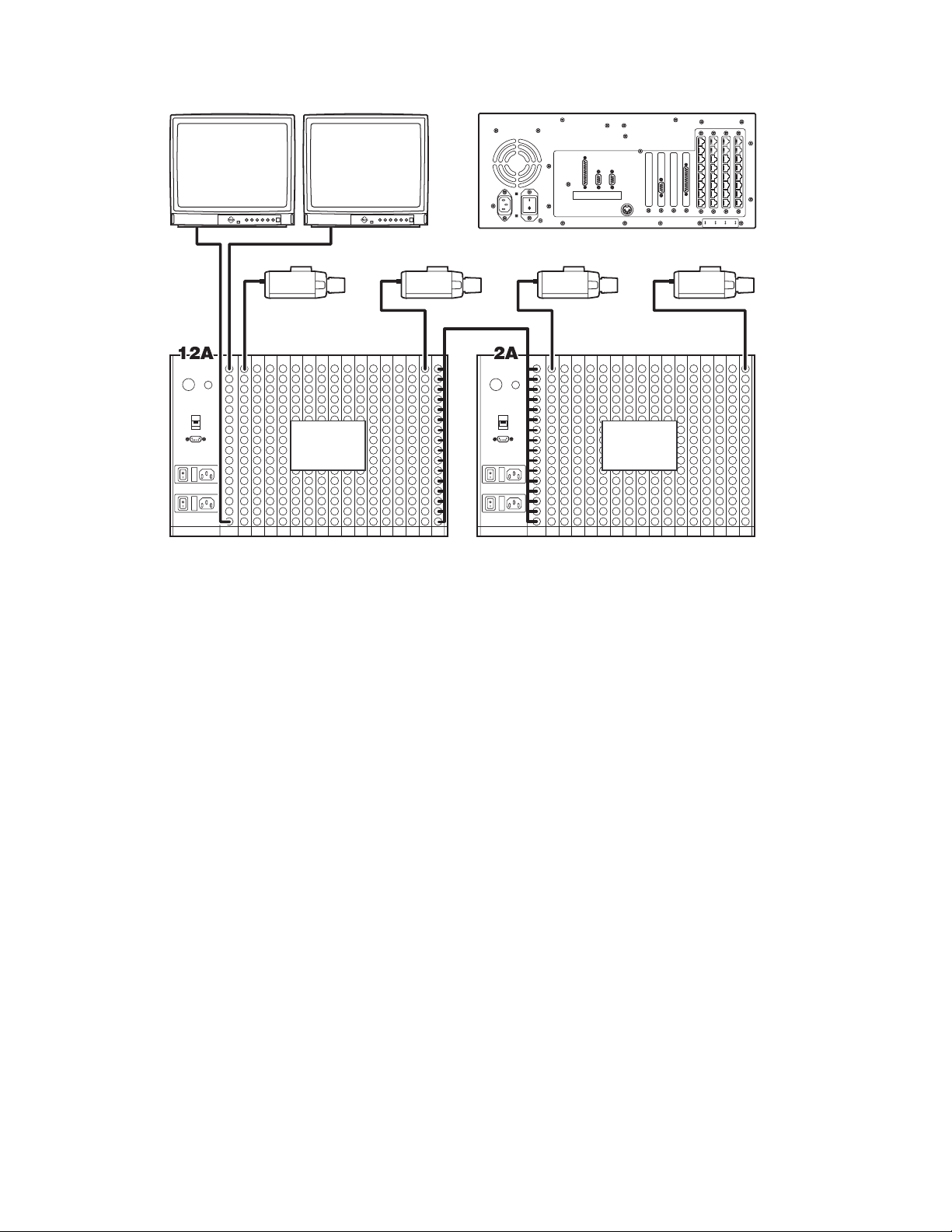

2A

2B

12A22A32A

12B22B32B

CAMS

769-976

CAMS

513-768

CAMS

257-512

VIDEO TIE LINES X16

CAMS

1-256

Figure 13. 976 X 32

Pelco Manual C1503M (11/99) 21

Page 23

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

961

769

753

513

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

497

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

241

1

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

OUT

CAMS

513-768

OUT

CAMS

257-512

OUT

CAMS

1-256

OUT

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

16 1

CM9760-MXB

CM9760-MXB

CM9760-MXB

CM9760-MXB

32 17

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

2A

2B

12A22A32A

12B22B32B

CAMS

769-976

CAMS

513-768

CAMS

257-512

VIDEO TIE LINES X16

CAMS

1-256

Figure 14. 976 X 32 Looping

22 Pelco Manual C1503M (11/99)

Page 24

16 1

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

32 17

241 1

CAMS

1-256

CM9760-CC1

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

2C

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

Figure 15. 256 X 48

Pelco Manual C1503M (11/99) 23

Page 25

16 1

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

32 17

241 1

CAMS

1-256

CM9760-CC1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

2C

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

OUT

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

CM9760-MXB

Figure 16. 256 X 48 Looping

24 Pelco Manual C1503M (11/99)

Page 26

16 1

481 257 241 1

CM9760-CC1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

RS-422

RS-422

Out

Alarm Black

RS-422

RS-422

Out

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

48 33

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

12C 2C

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Figure 17. 496 X 48

Pelco Manual C1503M (11/99) 25

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Page 27

16 1

481 257 241 1

CM9760-CC1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

48 33

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

12C 2C

Alarm Black

Out

RS-422

RS-422

CAMS

257-496

OUT

CM9760-MXB

Figure 18. 496 X 48 Looping

26 Pelco Manual C1503M (11/99)

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

CAMS

1-256

OUT

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

Page 28

16 1

PRINTER COM1 COM2

CM9760-CC1

VIDEO TIE LINES X16

721 513 497 257

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

241 1

Alarm Black

RS-422

RS-422

Out

CAMS

513-736

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

Alarm Black

RS-422

RS-422

Out

12C22C 2C

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

CM9760-MXB

Figure 19. 736 X 48

Pelco Manual C1503M (11/99) 27

Page 29

16 1

PRINTER COM1 COM2

CM9760-CC1

VIDEO TIE LINES X16

721 513 497 257

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

241 1

Alarm Black

RS-422

RS-422

Out

CAMS

513-736

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

Alarm Black

RS-422

RS-422

Out

CAMS

513-736

OUT

12C22C 2C

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

CAMS

257-512

OUT

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

CAMS

1-256

OUT

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

CM9760-MXB

CM9760-MXB

CM9760-MXB

Figure 20. 736 X 48 Looping

28 Pelco Manual C1503M (11/99)

Page 30

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

961

769

753

513

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

497

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

241

1

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

16 1

CM9760-MXB

CM9760-MXB

CM9760-MXB

CM9760-MXB

32 17

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

12A22A32A

12B22B32B

CM9760-MXB

CM9760-MXB CM9760-MXB

48 33

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

2B

2A

12C22C32C 2C

CAMS

769-976

CAMS

513-768

CAMS

257-512

VIDEO TIE LINES X16

CAMS

1-256

Figure 21. 976 X 48

Pelco Manual C1503M (11/99) 29

Page 31

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

961

769

753

513

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

497

257

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

241

1

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

OUT

CAMS

513-768

OUT

CAMS

257-512

OUT

CAMS

1-256

OUT

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM

’

S

SPECIFIC DATA

CONNECTIONS

CM9760-CC1

CM9760-MXB CM9760-MXB

PRINTER COM1 COM2

35

29

28

21

20

13

12

5

16 1

CM9760-MXB

CM9760-MXB

CM9760-MXB

CM9760-MXB

32 17

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

12A22A32A

12B22B32B

CM9760-MXB

CM9760-MXB CM9760-MXB

48 33

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

SUPPLIED DOWN-

FRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

2B

2A

12C22C32C 2C

CAMS

769-976

CAMS

513-768

CAMS

257-512

VIDEO TIE LINES X16

CAMS

1-256

Figure 22. 976 X 48 Looping

30 Pelco Manual C1503M (11/99)

Page 32

16 1

2A

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

32 17

2B

Alarm Black

Out

RS-422

RS-422

241 1

CAMS

1-256

CM9760-CC1

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

CM9760-MXB

48 33

2C

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

64 49

2D

Alarm Black

Out

RS-422

RS-422

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

Figure 23. 256 X 64

Pelco Manual C1503M (11/99) 31

Page 33

16 1

2A

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

32 17

2B

Alarm Black

Out

RS-422

RS-422

241 1

CAMS

1-256

CM9760-CC1

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

CM9760-MXB

48 33

2C

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

64 49

2D

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CAM 1 LOOP-OUT

CAMS

1-256

OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

Figure 24. 256 X 64 Looping

32 Pelco Manual C1503M (11/99)

Page 34

16 1

CM9760-CC1

481 257 241 1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

12C

Alarm Black

RS-422

RS-422

Out

2C

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

64 49

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

12D 2D

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Figure 25. 496 X 64

Pelco Manual C1503M (11/99) 33

Page 35

16 1

CM9760-CC1

481 257 241 1

PRINTER COM1 COM2

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

12C

Alarm Black

RS-422

RS-422

Out

2C

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

64 49

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

12D 2D

Alarm Black

RS-422

RS-422

Out

CAMS

257-496

OUT

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

OUT

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

CM9760-MXB

CM9760-MXB

Figure 26. 496 X 64 Looping

34 Pelco Manual C1503M (11/99)

Page 36

16 1

PRINTER COM1 COM2

CM9760-CC1

VIDEO TIE LINES X16

721 513 497 257

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

241 1

Alarm Black

RS-422

RS-422

Out

CAMS

513-736

Alarm Black

RS-422

RS-422

Out

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

Alarm Black

RS-422

RS-422

Out

12C22C

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

2C

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

CM9760-MXB

64 49

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

12D22D

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

2D

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Figure 27. 736 X 64

Pelco Manual C1503M (11/99) 35

Page 37

16 1

PRINTER COM1 COM2

CM9760-CC1

VIDEO TIE LINES X16

721 513 497 257

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

241 1

Alarm Black

RS-422

RS-422

Out

CAMS

513-736

Alarm Black

Out

RS-422

RS-422

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

48 33

Alarm Black

RS-422

RS-422

Out

12C22C

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

2C

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB

CM9760-MXB

64 49

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

Alarm Black

RS-422

RS-422

12D22D

Out

CAMS

513-736

OUT

Alarm Black

RS-422

RS-422

Out

CAMS

257-512

OUT

2D

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

OUT

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

CM9760-MXB

CM9760-MXB

CM9760-MXB

Figure 28. 736 X 64 Looping

36 Pelco Manual C1503M (11/99)

Page 38

16 1

PRINTER COM1 COM2

CM9760-CC1

VIDEO TIE LINES X16

961 769 753 513

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

497 257

241 1

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

Alarm Black

Out

RS-422

RS-422

CM9760-MXB CM9760-MXB

32 17

Alarm Black

RS-422

RS-422

CM9760-MXB

Out

Alarm Black

RS-422

RS-422

CM9760-MXB

Out

48 33

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

CAMS

513-768

12A22A32A

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

CM9760-MXB

12B22B32B

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

12C22C32C 2C

Alarm Black

Out

RS-422

RS-422

2A

CM9760-MXB

2B

CM9760-MXB

Alarm Black

Alarm Black

Alarm Black

Out

RS-422

RS-422

Out

RS-422

RS-422

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB CM9760-MXB

CM9760-MXB

64 49

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

Alarm Black

RS-422

RS-422

CM9760-MXB

Out

Alarm Black

Out

RS-422

RS-422

CM9760-MXB CM9760-MXB

12D22D32D 2D

Alarm Black

Out

RS-422

RS-422

Alarm Black

CM9760-MXB

Out

RS-422

RS-422

Figure 29. 976 X 64

Pelco Manual C1503M (11/99) 37

Page 39

16 1

PRINTER COM1 COM2

CM9760-CC1

VIDEO TIE LINES X16

961 769 753 513

35292821201312

REFER TO PORT

ASSIGNMENT PAGE

FOR YOUR SYSTEM’S

SPECIFIC DATA

CONNECTIONS

5

497 257

241 1

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

Alarm Black

Out

RS-422

RS-422

CM9760-MXB CM9760-MXB

32 17

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

Alarm Black

RS-422

RS-422

CM9760-MXB

Out

48 33

Alarm Black

Out

RS-422

RS-422

Alarm Black

Out

RS-422

RS-422

CAMS

513-768

12A22A32A

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

12B22B32B

Alarm Black

Out

RS-422

RS-422

CM9760-MXB

12C22C32C 2C

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

CM9760-MXB

CM9760-MXB

2A

Alarm Black

2B

Alarm Black

Alarm Black

Out

RS-422

RS-422

Out

RS-422

RS-422

Out

RS-422

RS-422

CAMS

1-256

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

CM9760-MXB

CM9760-MXB CM9760-MXB

CM9760-MXB

64 49

SUPPLIED DOWNFRAMING CABLES

16X RIBBON COAXIAL

Alarm Black

Out

RS-422

RS-422

CAMS

769-976

OUT

Alarm Black

Out

RS-422

RS-422

CAMS

513-768

OUT

12D22D32D 2D

Alarm Black

Out

RS-422

RS-422

CAMS

257-512

OUT

Alarm Black

Out

RS-422

RS-422

CAMS

1-256

OUT

CAM 1 LOOP-OUT

SYSTEM LOOPED

OUTPUTS ARE NOT

TERMINATED

CAM 16 LOOP-OUT

CM9760-MXB

CM9760-MXB CM9760-MXB

CM9760-MXB

Figure 30. 976 X 64 Looping

38 Pelco Manual C1503M (11/99)

Page 40

NOTES

Pelco Manual C1503M (11/99) 39

Page 41

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or workmanship for a period of one year after the date of

shipment. Exceptions to this warranty are as noted below:

• Three years on Genex™ Series (multiplexers, server, and keyboard).

• Two years on all standard motorized and fixed focal length lenses.

• Two years on Esprit™, Legacy®, Intercept®, PV1000 Series, CM6700/

CM8500/CM9500/CM9750/CM9760 Matrix, Spectra®, DF5 Series and DF8

Fixed Dome products.

• Two years on WW5700 series window wiper (excluding wiper blades).

• Two years on cameras.

• Six months on all pan and tilts, scanners or preset lenses used in continuous

motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date

of Pelco shipment. All goods requiring warranty repair shall be sent freight

prepaid to Pelco, Clovis, California. Repairs made necessary by reason of

misuse, alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s

liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for such Products.

In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused, whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

REVISION HISTORY

Manual # Date Comments

C1503M 11/99 Original version.

If a warranty repair is required, the Dealer must contact Pelco at (800) 2899100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall

under the warranty conditions stated above, please include a written explanation with the product when returned.

Ship freight prepaid to: Pelco

Method of return shipment shall be the same or equal to the method by which

the item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please

call the factory at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for credit, and RA number if returned for

repair). Goods returned for repair or credit should be clearly identified with

the assigned CA/RA number and freight should be prepaid. All merchandise

returned for credit may be subject to a 20% restocking and refurbishing charge.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

300 West Pontiac Way

Clovis, CA 93612-5699

® Pelco, the Pelco logo, and System 9760 are registered trademarks of Pelco. © Copyright 1999, Pelco. All rights reserved.

40 Pelco Manual C1503M (11/99)

Loading...

Loading...