Page 1

INSTALLATION

ExSite™ EHXM Series

Explosionproof

Fixed System

C1306M-B (10/06)

Page 2

Contents

List of Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Methods of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Install the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connect Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install the Enclosure and Set Pan Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Set the Tilt Angle of the Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Camera Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Protocol Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Receiver Address Settings (SW1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Termination Setting (SW2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Baud Settings (SW3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Camera/Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

List of Illustrations

1 Methods of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Attach Power Module to Mounting Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Default DIP Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Loosen Set Screw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Remove Back Cap of Camera Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Install Camera Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Center Wiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Install Wiper Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9 Factory-Installed Power Module Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10 Attach the Enclosure Unit to the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11 Set the Tilt Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Install the Sun Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13 Remove Back Cap of Camera Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

14 Remove or Instal l Camera Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

15 Install Camera Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

16 Center Wiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

List of Tables

A P Protocol Receiver Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B D Protocol Receiver Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 C1306M-B (10/06)

Page 3

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

6. To reduce the risk of ignition of hazardous atmospheres, disconnect the equipment from the supply circuit before opening. Keep assembly

tightly closed when in operation.

7. The maximum ambient temperature range is -76° to 140°F (-60° to 60°C).

8. Only use attachments/accessories specified by the manufacturer.

9. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as powersupply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or

moisture, does not operate normally, or has been dropped.

10. Installation should be done only by qualified personnel and conform to all local codes.

11. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is designed for indoor use only and it must not

be installed where exposed to rain and moisture.

12. Use only installation methods and materials capable of supporting four times the maximum specified load.

13. Use stainless steel hardware to fasten the mount to outdoor surfaces.

14. AN ALL-POLE MAINS SWITCH with a contact separation of at least 3 mm in each pole shall be incorporated in the electrical installation of

the building.

15. A readily accessible disconnect device shall be incorporated in the building installation wiring.

16. CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock do not perform

any servicing other that contained in the operating instructions unless you are qualified to do so.

17. Only use replacement parts recommended by Pelco.

The product and/or manual may bear the following marks:

WARNING: This symbol indicates that dangerous voltage constituting a risk of electric shock

is present within this unit.

This symbol indicates that there are important operating and maintenance instructions in the

literature accompanying this unit.

WARNING: HAZARDOUS MOVING PARTS. KEEP FINGERS AND OTHER BODY PARTS AWAY.

WARNING: To reduce the risk of ignition of hazardous atmospheres, disconnect the

equipment from the supply circuit before opening. Keep assembly tightly closed when

operating.

WARNING: To reduce the risk of ignition of hazardous atmospheres, conduit runs must have

a sealing fitting connected within 2 inches of the enclosure.

TO REDUCE THE RISK OF IGNITION DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE

MAY BE PRESENT.

RISK OF ELECTRIC SHOCK.

CAUTION:

DO NOT OPEN.

C1306M-B (10/06) 3

Page 4

Getting Started

Thank you for purchasing Pelco’s ExSite™ EHXM Series explosionproof system. This manual includes instructions for installing all the components

of the system. Once the system installation is complete, refer to the operation/programming manual for instructions on how to operate and

program your system.

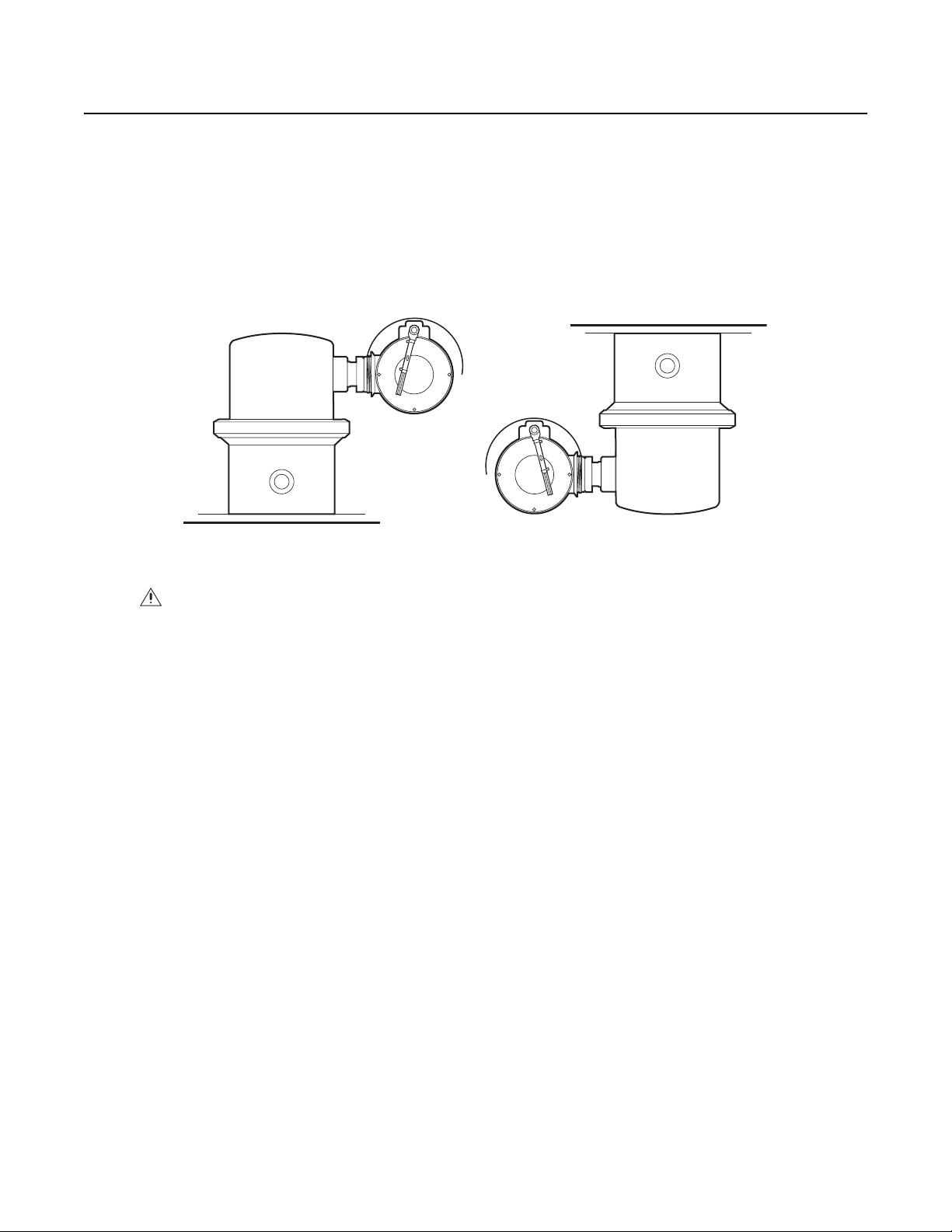

METHODS OF INSTALLATION

The system can be installed in a standard or inverted position. When installed for inverted operation, the camera orientation and controller

functions are reconfigured for normal operation through the system’s software. Hardware adjustment is not required for inverted operation.

Refer to Figure 1 for installation methods.

Figure 1. Methods of Installation

WARNINGS:

• Total weight of the system is 34.7 lb (15.71 kg). Use caution when lifting and assembling the enclosure component on the power

module. It is recommended that non-slip gloves be worn during installation.

• Do not turn the body of the enclosure more than 200° in either direction or damage to the power module cable may occur.

4 C1306M-B (10/06)

Page 5

Install the Power Module

Attach the power module to the mounting surface. Use only installation methods and materials capable of supporting four times the maximum

specified load of the system (140 lb/63.5 kg).

NOTE: If required, install the optional TXB translator, fiber module, or UTP board before installing the power module. Refer to the installation

instructions supplied with the TXB translator, fiber module, or UTP board for installation instructions.

To install the power module, refer to Figure 2 and do the following:

1. Make sure the threads of the power module and the threads of the supplied M10 x 16 mm stainless steel bolts are free of dirt and debris.

2. Apply a generous amount of thread locking compound (supplied) to the threads of the power module and the threads of the stainless steel

bolts.

3. Face the conduit fitting of the power module towards the mating conduit fitting of the installation.

4. Use the supplied 8 mm Allen wrench to secure the power module to the mounting surface with four M10 x 16 mm stainless steel bolts and

lock washers. Tighten the bolts to 25 to 27 ft-lb (34 to 37 Nm). The thread locking compound supplied must cure for one hour. Allow for this

cure period prior to completing the installation.

NOTE: Figure 2 shows the power module

being installed on a PXM100 pedestal mount

(not supplied).

Figure 2. Attach Power Module to Mounting Surface

C1306M-B (10/06) 5

Page 6

CONNECT WIRING

DANGER: Do not connect the power module to a supply circuit unless all ExSite system components (enclosure, camera module, and

power module) are installed.

Refer to the following information to connect the wires and cables as required.

WARNING: When installing this unit, provide access to the communication wires (TX+ and TX-) to allow connection to the system for

future software upgrades. Connectors must be installed so that the integrity of the hazardous location is maintained.

These communication wires are required even if the system uses Coaxitron

Maximum wire distance for RS-422 data wires is 4,000 ft (1,219 m).

NOTES:

• Relay 3 is allocated specifically for an external washer (not supplied by Pelco).

• All relays are specified for 32 VDC, 0.5 A.

• Wiring/cable for UTP and fiber optic are not provided on the wire harness. The installer must provide UTP and fiber optic connections.

®

control.

Configuration of Wire Harness

Wire Color Function

White/Orange TX+

White/Blue TX-

Red RX+

Green RX-

Violet/White Relay 3 NC (washer only)

White/Red Relay 3 COM (washer only)

Green/Black Relay 3 NO (washer only)

Gray/White Relay 2 NC

Yellow Relay 2 COM

Violet Relay 2 NO

Brown Relay 1 NC

Gray Relay 1 COM

White/Yellow/Black Relay 1 NO

White/Black/Green Alarm COM

White/Red/Black Alarm 7

White/Brown/Black Alarm 6

Orange Alarm 5

White/Orange/Black Alarm 4

White/Blue/Black Alarm 3

White/Brown Alarm 2

White/Black Alarm 1

Video Coaxial Cable Requirements

Power Connections 24 VAC

Wire Color Function

Red AC Hi

Black AC Low

Power Connections 100-240 VAC

Wire Color Function

Black AC Hi

White AC Low

Green/Yellow Earth Ground

Wiring Distances

The following are the recommended maximum distances for 24 VAC and

100-240 VAC applications and are calculated with a 10 percent voltage drop.

(Ten percent is generally the maximum allowable voltage drop for AC-powered

devices.)

Wire Gauge

Power

24 VAC

100-240

VAC

NOTE: Power consumption is 120 VA per unit. Use a power source with a

minimum of 150 VA.

18

(1.0 mm

27 ft

(8 m)

75 ft

(23 m)

2

)

16

(1.5 mm2)

43 ft

(13 m)

120 ft

(36 m)

14

(2.5 mm2)

69 ft

(21 m)

190 ft

(58 m)

12

(3.5 mm2)

110 ft

(33 m)

310 ft

(94 m)

Cable Type* Maximum Distance

RG59/U 750 ft (229 m)

RG6/U 1,000 ft (305 m)

RG11/U 1,500 ft (457 m)

*Cable requirements:

75-ohm impedance

All-copper center conductor

All-copper braided shield with 95% braid coverage

6 C1306M-B (10/06)

Page 7

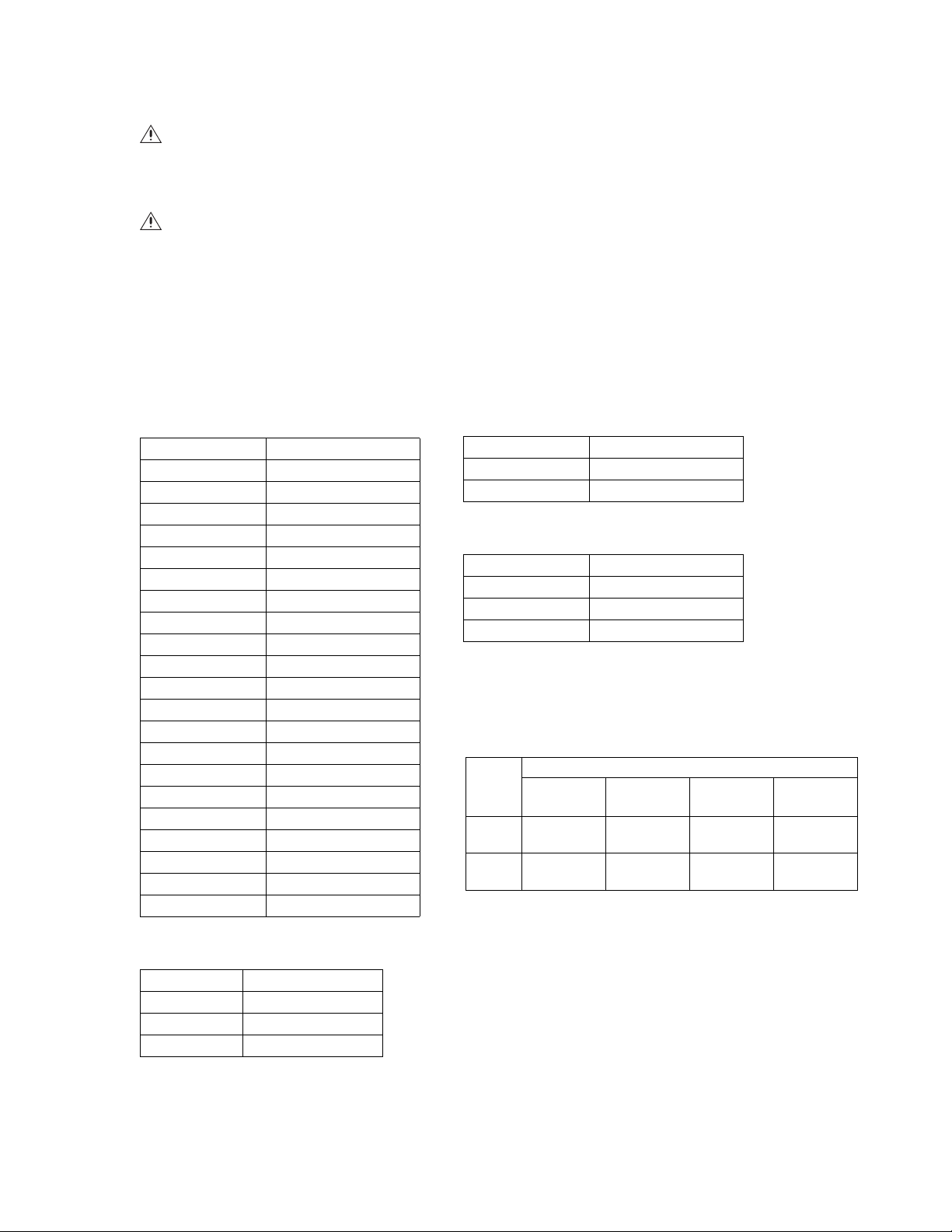

DIP SWITCH SETTINGS

Configure the receiver address, termination, and baud setting for the system. The DIP switches to configure these settings are located on the top

of the power module.

NOTE: No DIP switch settings are required for Coaxitron control.

Figure 3 shows the default settings for the DIP switches. Refer to the following to configure the ExSite system settings.

PROTOCOL SETTINGS

The ExSite system automatically detects the type of protocol. No switch settings are required to set Coaxitron or RS-422 P and D protocols.

RECEIVER ADDRESS SETTINGS (SW1)

The default address is 2 for P protocol. Refer to Table A for address settings that use P protocol. Maximum number of receivers is 32.

SW1-1 is set to the ON position.

All other switches are set to the OFF position.

45

SW1

SW2

on

1

8

7

6

5

4

3

2

1

3

2

1

SW3

on

Figure 3. Default DIP Switch Settings

8

7

6

ON

The default address is 1 for D protocol. Refer to Table B for address settings that use D protocol. Maximum number of receivers is 254.

TERMINATION SETTING (SW2)

When connecting more than one ExSite system to a single controller, terminate the unit farthest from the controller. Termination is required only

for the last unit in the series. The unit is shipped from the factory in the unterminated OFF position. To terminate the unit, set the SW2 switch to

the ON position.

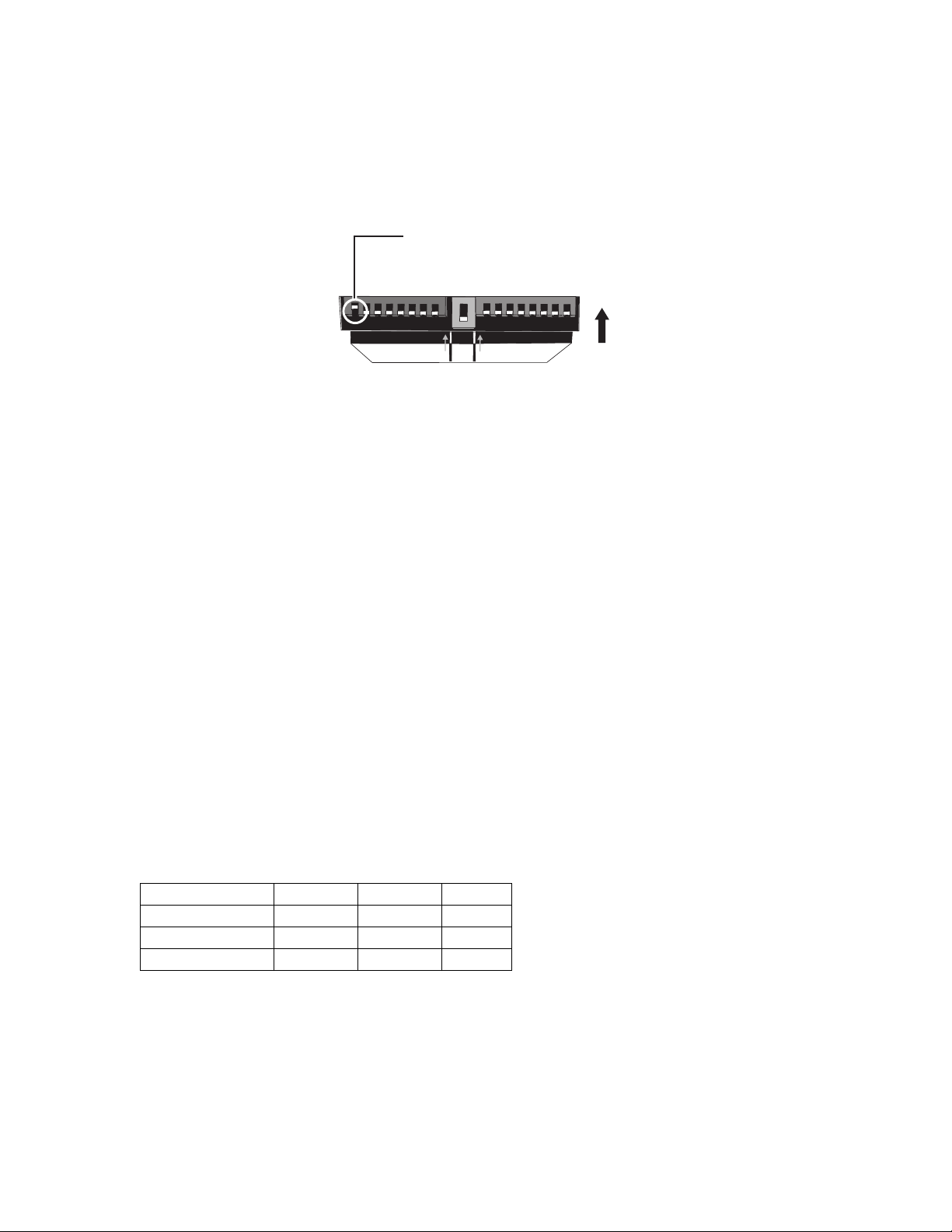

BAUD SETTINGS (SW3)

Pelco’s D-type controllers are set for 2400 baud. The default setting for the unit is 2400 baud. If you are using a Pelco D-type controller, do not

reset the SW3 switches.

P-type controllers can operate at 2400, 4800, and 9600 baud. Set the SW3 switches (6, 7, and 8), located on the top of the power module, to the

same baud as the P-type controller.

Switch Settings for SW3

Switch Number SW3-6 SW3-7 SW3-8

2400 Baud Off Off Off

4800 Baud On Off Off

9600 Baud Off On Off

C1306M-B (10/06) 7

Page 8

Table A. P Protocol Receiver Address

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

1 OFF OFF OFF OFF OFF OFF OFF OFF

2 ON OFF OFF OFF OFF OFF OF F OFF

3 OFF ON OFF OFF OFF OFF OFF OFF

4 ON ON OF F OFF OFF OFF OFF OFF

5 OFF OFF ON OFF OFF OFF OFF OFF

6 ON OFF ON OFF OFF OFF OFF OFF

7 OFF ON ON OFF OFF OFF OFF OFF

8 ON ON ON OFF OFF OFF OFF OFF

9 OFF OFF OFF ON OFF OFF OFF OFF

10 ON OFF OFF ON OFF OFF OFF OFF

11 OFF ON OFF ON OFF OFF OFF OFF

12 ON ON OF F ON OFF OFF OFF OFF

13 OFF OFF ON ON OFF OF F OFF OFF

14 ON OFF ON ON OF F OFF OFF OFF

15 OFF ON ON ON OFF OFF OFF OFF

16 ON ON ON ON OFF OFF OFF OFF

Table B. D Protocol Receiver Address

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

1 ON OFF OFF OFF OFF OFF OFF OFF

2 OFF ON OFF OFF OFF OFF OFF OFF

3 ON ON OFF OFF OFF OFF OFF OFF

4 OFF OFF ON OFF OFF OFF OFF OFF

5 ON OFF ON OFF OFF OFF OFF OFF

6 OFF ON ON OFF OFF OFF OFF OFF

7 ON ON ON OFF OFF OFF OFF OFF

8 OFF OFF OFF ON OFF OFF OFF OFF

9 ON OFF OFF ON OFF OFF OFF OFF

10 OFF ON OFF ON OFF OFF OFF OF F

11 ON ON OFF ON OFF OFF OFF OFF

12 OFF OFF ON ON OFF OFF OFF OFF

13 ON OFF ON ON OFF OFF OFF OFF

14 OFF ON ON ON OFF OFF OFF OFF

15 ON ON ON ON OFF OFF OFF OFF

16 OFF OFF OFF OFF ON OFF OFF OFF

17 ON OFF OFF OFF ON OFF OFF OFF

18 OFF ON OFF OFF ON OFF OFF OF F

19 ON ON OFF OFF ON OFF OFF OFF

20 OFF OFF ON OFF ON OFF OFF OFF

21 ON OFF ON OFF ON OFF OFF OFF

22 OFF ON ON OFF ON OFF OFF OFF

23 ON ON ON OFF ON OFF OFF OFF

24 OFF OFF OFF ON ON OFF OFF OF F

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

17 OFF OFF OFF OFF ON OFF OFF OFF

18 ON OFF OFF OFF ON OFF OFF OFF

19 OFF ON OFF OFF ON OFF OFF OFF

20 ON ON OFF OFF ON OFF OFF OFF

21 OFF OFF ON OFF ON OFF OFF OFF

22 ON OFF ON OFF ON OFF OFF OFF

23 OFF ON ON OFF ON OFF OFF OFF

24 ON ON ON OFF ON OFF OFF OFF

25 OFF OFF OFF ON ON OFF OFF OFF

26 ON OFF OFF ON ON OFF OFF OFF

27 OFF ON OFF ON ON OFF OFF OFF

28 ON ON OFF ON ON OFF OFF OFF

29 OFF OFF ON ON ON OFF OFF OFF

30 ON OFF ON ON ON OFF OFF OFF

31 OFFONONONONOFFOFFOFF

32 ON ON ON ON ON OFF OFF OFF

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

25 ON OFF OFF ON ON OFF OFF OFF

26 OFF ON OFF ON ON OFF OFF OFF

27 ON ON OFF ON ON OFF OFF OFF

28 OFF OFF ON ON ON OFF OFF OFF

29 ON OFF ON ON ON OFF OFF OFF

30 OFF ON ON ON ON OFF OFF OFF

31 ON ON ON ON ON OFF OFF OFF

32 OFF OFF OFF OFF OFF ON OFF OF F

33 ON OFF OFF OFF OFF ON OFF OFF

34 OFF ON OFF OFF OFF ON OFF OFF

35 ON ON OFF OFF OFF ON OFF OFF

36 OFF OFF ON OFF OFF ON OFF OFF

37 ON OFF ON OFF OFF ON OFF OFF

38 OFF ON ON OFF OFF ON OFF OFF

39 ON ON ON OFF OFF ON OFF OFF

40 OFF OFF OFF ON OFF ON OFF OFF

41 ON OFF OFF ON OFF ON OFF OFF

42 OFF ON OFF ON OFF ON OFF OFF

43 ON ON OFF ON OFF ON OFF OFF

44 OFF OFF ON ON OFF ON OFF OFF

45 ON OFF ON ON OFF ON OFF OFF

46 OFF ON ON ON OFF ON OFF OFF

47 ON ON ON ON OFF ON OFF OFF

48 OFF OFF OFF OFF ON ON OFF OFF

(Continued on next page)

8 C1306M-B (10/06)

Page 9

Table B. D Protocol Receiver Address (Continued)

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

49 ON OFF OFF OFF ON ON OFF OFF

50 OFF ON OFF OFF ON ON OFF OFF

51 ON ON OFF OFF ON ON OFF OFF

52 OFF OFF ON OFF ON ON OFF OFF

53 ON OFF ON OFF ON ON OFF OFF

54 OFF ON ON OFF ON ON OFF OFF

55 ON ON ON OFF ON ON OFF OFF

56 OFF OFF OFF ON ON ON OFF OFF

57 ON OFF OFF ON ON ON OFF OFF

58 OFF ON OFF ON ON ON OFF OFF

59 ON ON OFF ON ON ON OFF OF F

60 OFF OFF ON ON ON ON OFF OFF

61 ON OFF ON ON ON ON OFF OFF

62 OFF ON ON ON ON ON OFF OFF

63 ON ON ON ON ON ON OFF OFF

64 OFF OFF OFF OFF OFF OFF ON OFF

65 ON OFF OFF OFF OFF OFF ON OFF

66 OFF ON OFF OFF OFF OFF ON OF F

67 ON ON OFF OFF OFF OFF ON OFF

68 OFF OFF ON OFF OFF OFF ON OFF

69 ON OFF ON OFF OFF OFF ON OFF

70 OFF ON ON OFF OFF OFF ON OFF

71 ON ON ON OFF OFF OFF ON OFF

72 OFF OFF OFF ON OFF OFF ON OF F

73 ON OFF OFF ON OFF OFF ON OFF

74 OFF ON OFF ON OFF OFF ON OFF

75 ON ON OFF ON OFF OFF ON OFF

76 OFF OFF ON ON OFF OFF ON OFF

77 ON OFF ON ON OFF OFF ON OFF

78 OFF ON ON ON OFF OFF ON OFF

79 ON ON ON ON OFF O FF ON OFF

80 OFF OFF OFF OFF ON OFF ON OF F

81 ON OFF OFF OFF ON OFF ON OFF

82 OFF ON OFF OFF ON OFF ON OFF

83 ON ON OFF OFF ON OFF ON OFF

84 OFF OFF ON OFF ON OFF ON OFF

85 ON OFF ON OFF ON OFF ON OFF

86 OFF ON ON OFF ON OFF ON OFF

87 ON ON ON OFF ON OFF ON OF F

88 OFF OFF OFF ON ON OFF ON OFF

89 ON OFF OFF ON ON OFF ON OFF

90 OFF ON OFF ON ON OFF ON OFF

91 ON ON OFF ON ON OFF ON OFF

92 OFF OFF ON ON ON OFF ON OFF

93 ON OFF ON ON ON OFF ON OFF

94 OFF ON ON ON ON OFF ON OFF

95 ON ON ON ON ON OFF ON OFF

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

96 OFF OFF OFF OFF OFF ON ON OFF

97 ON OFF OFF OFF OFF ON ON OFF

98 OFF ON OFF OFF OFF ON ON OFF

99 ON ON OFF OFF OFF ON ON OFF

100 OFF OFF ON OFF OFF ON ON OFF

101 ON OFF ON OFF OFF ON ON OFF

102 OFF ON ON O FF OFF ON ON OFF

103 ON ON ON OFF OFF ON ON OFF

104 OFF OFF OFF ON OFF ON ON OFF

105 ON OFF OFF ON OFF ON ON OFF

106 OFF ON OFF ON OFF ON ON OFF

107 ON ON OFF ON OFF ON ON OFF

108 OFF OFF ON ON OFF ON ON OFF

109 ON OFF ON ON OFF ON ON OFF

110 OFF ON ON ON OFF ON ON OFF

111 ON ON ON ON OFF ON ON OFF

112 OFF OFF OFF OFF ON ON ON OFF

113 ON OFF OFF OFF ON ON ON OFF

114 OFF ON OFF OFF ON ON ON OFF

115 ON ON OFF OFF ON ON ON OFF

116 OFF OFF ON OFF ON ON ON OFF

117 ON OFF ON OFF ON ON ON OFF

118 OFF ON ON O FF ON ON ON OFF

119 ON ON ON OFF ON ON ON OFF

120 OFF OFF OFF ON ON ON ON OFF

121 ON OFF OFF ON ON ON ON OFF

122 OFF ON OFF ON ON ON ON OFF

123 ON ON OFF ON ON ON ON OFF

124 OFFOFFONONONONONOFF

125 ON OFF ON ON ON ON ON OFF

126 OFF ON ON ON ON ON ON OFF

127 ON ON ON ON ON ON ON OFF

128 OFF OFF OFF OFF OFF OFF OFF ON

129 ON OFF OFF OFF OFF OFF OFF ON

130 OFF ON OFF OFF OFF OFF OFF ON

131 ON ON OFF OFF OFF OFF OFF ON

132 OFF OFF ON OFF OFF OFF OFF ON

133 ON OFF ON OFF OFF OFF OFF ON

134 OFF ON ON O FF OFF OFF OFF ON

135 ON ON ON OFF OFF OFF OFF ON

136 OFF OFF OFF ON OFF OFF OFF ON

137 ON OFF OFF ON OFF OFF OFF ON

138 OFF ON OFF ON OFF OFF OFF ON

139 ON ON OFF ON OFF OFF OFF ON

140 OFF OFF ON ON OFF OFF OFF ON

141 ON OFF ON ON OFF OFF OFF ON

142 OFF ON ON ON OFF OFF OFF ON

(Continued on next page)

C1306M-B (10/06) 9

Page 10

Table B. D Protocol Receiver Address (Continued)

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

143 ON ON ON ON OFF OFF OFF ON

144 OFF OFF OFF OFF ON OFF OFF ON

145 ON OFF OFF OFF ON OFF OFF ON

146 OFF ON OFF OFF ON OFF OFF ON

147 ONONOFFOFFONOFFOFFON

148 OFF OFF ON OFF ON OFF OFF ON

149 ON OFF ON OFF ON OFF OFF ON

150 OFF ON ON OFF ON OFF OFF ON

151 ON ON ON OFF ON OFF OFF ON

152 OFF OFF OFF ON ON OFF OFF ON

153 ON OFF OFF ON ON OFF OFF ON

154 OFF ON OFF ON ON OFF OFF ON

155 ON ON OFF ON ON OFF OFF ON

156 OFF OFF ON ON ON OFF OFF ON

157 ON OFF ON ON ON OFF OFF ON

158 OFF ON ON ON ON OFF OFF ON

159 ONONONONONOFFOFFON

160 OFF OFF OFF OFF OFF ON OFF ON

161 ON OFF OFF OFF OFF ON OFF ON

162 OFF ON OFF OFF OFF ON OFF ON

163 ON ON OFF OFF OFF ON OFF ON

164 OFF OFF ON OFF OFF ON OFF ON

165 ON OFF ON OFF OFF ON OFF ON

166 OFF ON ON OFF OFF ON OFF ON

167 O N ON O N OFF OFF ON OFF ON

168 OFF OFF OFF ON OFF ON OFF ON

169 ON OFF OFF ON OFF ON OFF ON

170 OFF ON OFF ON OFF ON OFF ON

171 ON ON OFF ON OFF ON OFF ON

172 OFF OFF ON ON OFF ON OFF ON

173 ON OFF ON ON OFF ON OFF ON

174 OFF ON ON ON OFF ON OFF ON

175 ONONONONOFFONOFFON

176 OFF OFF OFF OFF ON ON OFF ON

177 ON OFF OFF OFF ON ON OFF ON

178 OFF ON OFF OFF ON ON OFF ON

179 ON ON OFF OFF ON ON OFF ON

180 OFF OFF ON OFF ON ON OFF ON

181 ON OFF ON OFF ON ON OFF ON

182 OFF ON ON OFF ON ON OFF ON

183 ON ON ON OFF ON ON OFF ON

184 OFF OFF OFF ON ON ON OFF ON

185 ON OFF OFF ON ON ON O FF ON

186 OFF ON OFF ON ON ON OFF ON

187 ON ON OFF ON ON ON OFF ON

188 OFF OFF ON ON ON ON OFF ON

189 ON OFF ON ON ON ON OFF ON

190 OFF ON ON ON ON ON OFF ON

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

191 ONONONONONONOFFON

192 OFF OFF OFF OFF OFF OFF ON ON

193 ON OFF OFF OFF OFF OFF ON ON

194 OFF ON OFF OFF OFF OFF ON ON

195 ON ON OFF OFF OFF OFF ON ON

196 OFF OFF ON OFF OFF OFF ON ON

197 ON OFF ON OFF OFF OFF ON ON

198 OFF ON ON OFF OF F OFF ON ON

199 ON ON ON OFF OFF OFF ON ON

200 OFF OFF OFF ON OFF OFF ON ON

201 ON OFF OFF ON OFF OFF ON ON

202 OFF ON OFF ON OFF OFF ON ON

203 ON ON OFF ON OFF OFF ON ON

204 OFF OFF ON ON OFF OFF ON ON

205 ON OFF ON ON OFF OFF ON ON

206 OFF ON ON ON OFF OFF ON ON

207 ONONONONOFFOFFONON

208 OFF OFF OFF OFF ON OFF ON ON

209 ON OFF OFF OFF ON OFF ON ON

210 OFF ON OFF OFF ON OFF ON ON

211 ON ON OFF OFF ON OFF ON ON

212 OFF OFF ON OFF ON OFF ON ON

213 ON OFF ON OFF ON OFF ON ON

214 OFF ON ON OFF ON OFF ON ON

215 ON ON ON OFF ON OFF ON ON

216 OFF OFF OFF ON ON OFF ON ON

217 ON OFF OFF ON ON OFF ON ON

218 OFF ON OFF ON ON OFF ON ON

219 ON ON OFF ON ON OFF ON ON

220 OFF OFF ON ON ON OFF ON ON

221 ON OFF ON ON ON OFF ON ON

222 OFF ON ON ON ON OFF ON ON

223 ONONONONONOFFONON

224 OFF OFF OFF OFF OFF ON ON ON

225 ON OFF OFF OFF OFF ON ON ON

226 OFF ON OFF OFF OFF ON ON ON

227 ON ON OFF OFF OF F ON ON ON

228 OFF OFF ON OFF OFF ON ON ON

229 ON OFF ON OFF OFF ON ON ON

230 OFF ON ON OFF OF F ON ON ON

231 ONONONOFFOFFONONON

232 OFF OFF OFF ON OFF ON ON ON

233 ON OFF OFF ON OFF ON ON ON

234 OFF ON OFF ON OFF ON ON ON

235 ON ON OFF ON OFF ON ON ON

236 OFF OFF ON ON OFF ON ON ON

237 ON OFF ON ON OFF ON ON ON

238 OFF ON ON ON OFF ON ON ON

(Continued on next page)

10 C1306M-B (10/06)

Page 11

Table B. D Protocol Receiver Address (Continued)

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

239 ONONONONOFFONONON

240 OFF OFF OFF OFF ON ON ON ON

241 ON OFF OFF OFF ON ON ON ON

242 OFF ON OFF OFF ON ON ON ON

243 ONONOFFOFFONONONON

244 OFF OFF ON OFF ON ON ON ON

245 ONOFFONOFFONONONON

246 OFF ON ON OFF ON ON ON ON

SWITCH SETTING

ADDRESS

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

247 ON ON ON OFF ON ON ON ON

248 OFF OFF OFF ON ON ON ON ON

249 ONOFFOFFONONONONON

250 OFF ON OFF ON ON ON ON ON

251 ON ON OFF ON ON ON ON ON

252 OFF OFF ON ON ON ON ON ON

253 ON OFF ON ON ON ON ON ON

254 OFF ON ON ON ON ON ON ON

C1306M-B (10/06) 11

Page 12

Install the Camera Module

To install the camera module, do the following:

1. Refer to Figure 4. Loosen the set screw at the back of the camera enclosure with the provided 1.5 mm Allen wrench.

SET SCREW

Figure 4. Loosen Set Screw

WARNING: To avoid thread damage carefully remove the back of the camera enclosure. Never use force to remove the back of the camera

enclosure.

2. Use the supplied spanner wrench to loosen the back of the camera enclosure (refer to Figure 5). Once the back is loose, use your hands to

continue to loosen it until it can be removed.

CAMERA

ENCLOSURE

BACK

SPANNER

WRENCH

Figure 5. Remove Back Cap of Camera Enclosure

12 C1306M-B (10/06)

Page 13

WARNING: Do not force the camera module into the camera enclosure.

3. Slide the camera module into the camera enclosure. Refer to Figure 6 to position the camera module properly in the camera enclosure.

Carefully mate the camera’s power connector to the mating connector located inside the camera enclosure.

Models with a wiper: The tab located inside the camera enclosure must be pointing down before installing the camera module (refer to

Figure 6). To position the tab, place the wiper, located at the front of the camera enclosure, in the center of the viewing window (refer to

Figure 7).

TAB

CENTER

NOTCHES

CAMERA

MODULE

CAMERA

ENCLOSURE

Figure 6. Install Camera Module

Figure 7. Center Wiper

CENTER WIPER

C1306M-B (10/06) 13

Page 14

4. Models with a wiper: Refer to Figure 8 and do the following to install the arm of the wiper:

a. Place the supplied green bushing on the stud located behind the handle of the camera module. The bushing should be in the same

orientation as shown in Figure 8.

b. Install the wiper arm. Place the ridge of the arm in the notch of the camera enclosure tab and the slot of the arm over the green

bushing.

5. Secure the camera module (and wiper) with the supplied 8-32 Phillips flat head screw (refer to Figure 8).

SET TAB IN

CENTER POSITION

8-32 PHILLIPS FLAT

HEAD SCREW

ARM

CAMERA

MODULE

STUD

BUSHING

HANDLE

Figure 8. Install Wiper Arm

WARNINGS:

• To avoid thread damage carefully install the back cap to the camera enclosure.

• Never force the back cap onto the end of the camera enclosure.

• When installation is completed there should be no gap between the back cap and the camera enclosure.

6. Reinstall the back cap on the enclosure by doing the following:

a. Use your hands to turn the back cap clockwise until you can no longer turn it with your hands. The back cap should turn easily until it

comes in contact with the O-ring. If it does not turn easily the threads are not aligned and thread damage will occur.

b. Continue tightening the back cap with the supplied spanner wrench. There should be no gap between the back cap and the enclosure

when the back cap is tightened and properly installed.

c. Once the back cap is installed, secure the back cap with the set screw using the supplied 1.5 mm Allen wrench.

14 C1306M-B (10/06)

Page 15

Install the Enclosure and Set Pan Position

1. Check for proper seating of the power module seal. Make sure the seal is fully seated in the groove on the top of the power module.

POWER MODULE SEAL

POWER MODULE

Figure 9. Factory-Installed Power Module Seal

WARNING: Use caution when attaching the enclosure unit to the power module. If the grooves on the top of the power module are

damaged, the integrity of the unit could be compromised.

2. Refer to Figure 10 and attach the enclosure unit to the power module. Align the pins of the enclosure unit with the holes of the power

module. Carefully mate the enclosure connector to the power module connector.

LOCKING

RING

PIN

HOLE

Figure 10. Attach the Enclosure Unit to the Power Module

WARNINGS:

• Total weight of the enclosure component is 34.7 lb (15.71 kg). Use caution when lifting and assembling the pan and tilt component on

the power module.

• The weight of the enclosure unit must be safely supported during installation.

• It is recommended that non-slip gloves be worn during installation.

• Avoid thread damage. Never use force when assembling and tightening the threaded components of the system.

3. Turn the body of the enclosure to the left or right to set the pan position of the unit.

WARNING: Do not turn the body of the enclosure more than 200° in either direction or damage to the internal power module cable may occur.

4. With your hands carefully thread the enclosure’s locking ring on the threads of the power module until the threads are completely engaged.

5. Use the supplied spanner wrench to tighten the locking ring and fix the position of the enclosure. After the locking ring has been tightened,

tap the end of the handle of the wrench with a hammer or the palm of your hand to ensure a secure fit. Make sure that the pan position is

maintained when tightening the locking ring. Tighten the set screw of the locking ring with the supplied 2 mm Allen wrench to secure the

locking ring.

C1306M-B (10/06) 15

Page 16

Set the Tilt Angle of the Camera Module

1. Place a 41 mm open end or crescent wrench on the tilt locking nut and a 21 mm open end wrench on the tilt shaft (refer to Figure 11).

SET SCREW

TILT LOCK

NUT

TILT SHAFT

Figure 11. Set the Tilt Position

2. Hold the tilt shaft in position with the 21 mm wrench, and then turn the 41 mm wrench to loosen the tilt locking nut.

3. Adjust the tilt position of the camera module by moving the camera module up or down.

4. Continue to hold the tilt shaft with the 21 mm wrench and then tighten the tilt locking nut to set the tilt position of the camera module.

Make sure the tilt position is maintained when tightening the locking ring. Tighten the set screw of the locking nut with the supplied 2 mm

Allen wrench to secure the locking nut.

16 C1306M-B (10/06)

Page 17

Install the Sun Shroud

1. Place the supplied nylon washers on the 6-32 Phillips pan head screws. Refer to Figure 12.

2. Align the mounting holes of the sun shroud with the holes on top of the camera enclosure.

3. Use the supplied nylon washers and screws to secure the sun shroud to the camera enclosure.

6-32 PHILLIPS PAN

HEAD SCREW

SUN SHROUD

NYLON

WASHER

Figure 12. Install the Sun Shroud

C1306M-B (10/06) 17

Page 18

Maintenance

CAMERA MODULE REPLACEMENT

DANGER: To reduce the risk of ignition of hazardous atmospheres, disconnect the equipment from the power supply before opening.

Keep assembly tightly closed when operating.

To replace the camera module, do the following:

1. Remove the back cap of the camera enclosure. Refer to Figure 13 and do the following:

a. Loosen the set screw with a 1.5 mm Allen wrench.

b. Use the supplied spanner wrench to loosen the back cap of the camera enclosure. Once the back is loose, use your hands to continue

to loosen it until it can be removed.

CAMERA

ENCLOSURE

BACK

SET SCREW

SPANNER

WRENCH

Figure 13. Remove Back Cap of Camera Enclosure

2. Remove the 8-32 Phillips flat head screw that secures the camera module inside the camera enclosure (refer to Figure 14).

SET TAB IN

CENTER POSITION

8-32 PHILLIPS FLAT

HEAD SCREW

ARM

CAMERA

MODULE

STUD

BUSHING

HANDLE

Figure 14. Remove or Install Camera Module

18 C1306M-B (10/06)

Page 19

3. Models with a wiper: Remove the wiper arm and the green bushing from the unit (refer to Figure 14).

4. Slide the camera module out of the enclosure.

WARNING: Never force the camera module into the enclosure.

5. Install the new camera module by doing the following:

Slide the camera module into the camera enclosure. Refer to Figure 15 to position the camera module properly in the camera enclosure.

Carefully mate the camera’s power connector to the mating connector located inside the camera enclosure.

Models with a wiper: The tab located inside the enclosure must be pointing down before installing the camera module (refer to

Figure 15). To position the tab, place the wiper, located at the front of the camera enclosure, in the center of the viewing window (refer to

Figure 16).

TAB

CENTER

NOTCHES

CAMERA

MODULE

Figure 15. Install Camera Module

CAMERA

ENCLOSURE

CENTER WIPER

Figure 16. Center Wiper

C1306M-B (10/06) 19

Page 20

6. Models with a wiper: Refer to Figure 14 and do the following to reinstall the arm of the wiper:

a. Reinstall the green bushing on the stud located behind the handle of the camera module.

b. Reinstall the wiper arm. Place the ridge of the arm in the notch of the camera enclosure tab and the slot of the arm over the green

bushing.

7. Secure the camera module and the wiper arm with the 8-32 Phillips flat head screw (refer to Figure 14).

WARNINGS:

• To avoid thread damage, carefully install the back cap to the enclosure.

• Never force the back cap onto the end of the enclosure.

• When installation is completed, there should be no gap between the back cap and the camera enclosure.

8. Reinstall the back cap on the camera enclosure by doing the following:

a. Use your hands to turn the back cap clockwise until you can no longer turn it with your hands. The back cap should turn easily until it

comes in contact with the O-ring. If it does not turn easily, the threads are not aligned and thread damage will occur.

b. Continue tightening the back cap with the supplied spanner wrench. There should be no gap between the back cap and the camera

enclosure when the back cap is tightened and properly installed.

c. After the back cap is installed, secure the back cap with the set screw using a 1.5 mm Allen wrench.

20 C1306M-B (10/06)

Page 21

Specifications

ELECTRICAL

Input Voltage 24 VAC or 100-240 VAC

Input Voltage Range ±10%

Power Consumption Maximum 60 W (120 VA) per system

Heater and Defroster Microprocessor controlled

Electrical Connections 6-foot wire harness with connections for power, video, data control, alarm inputs, and auxiliary outputs

MECHANICAL

Cable Entry One 0.75-inch (1.91 cm) NPT threaded opening

GENERAL

Construction 316L stainless steel

Finish Electropolish

Viewing Window 0.50-inch (12.7 mm) thick, soda-lime tempered glass

Operating Temperature -76° to 140°F (-60° to 60°C)

Unit Weight 34.7 lb (15.71 kg)

Effective Projected Area (EPA) 97.3 square inches

13.1 (33.27)

5.13

(13.03)

4.91

(12.47)

0.75 NPT

(1.91)

4 PLCS. TYP.

10MM - 1.5MM X 14MM

ON A 4.75-INCH DIA. B.C.

EQUALLY SPACED

11.5 (29.21)

3.354

(8.52)

10.5

(26.8)

NOTE: Values in parentheses are centimeters; all others are inches.

C1306M-B (10/06) 21

Page 22

CAMERA/OPTICS

Camera Day/Night (23X) Color LowLight™ (22X) Color

Signal Format NTSC, PAL NTSC, PAL

Scanning System 2:1 Interlace 2:1 Interlace

™

Image Sensor 1/4-inch CCD 1/4-inch EXview HAD

Effective Pixels

NTSC

PAL

Horizontal Resolution

NTSC

PAL

724 (H) x 494 (V)

724 (H) x 582 (V)

>470 TV lines

>470 TV lines

768 (H) x 494 (V)

752 (H) x 582 (V)

>470 TV lines

>460 TV lines

Lens F1.6 (f = 3.6~82.8 mm optical) F1.6 (f = 4~88 mm optical)

Zoom 23X optical, 10X digital 22X optical, 12X digital

Zoom Speed 2.9/4.2/5.8 seconds 2.4/3.9/6.3 seconds

Horizontal Angle of

View

54° at 3.6 mm wide zoom

2.5° at 82.8 mm telephoto zoom

47° at 4.0 mm wide zoom

2.2° at 88 mm telephoto zoom

Focus Automatic with manual override Automatic with manual override

Maximum Sensitivity

at 35 IRE

NTSC

0.08 lux at 1/2 sec shutter (color)

0.02 lux at 1/2 sec shutter

0.3 lux at 1/60 sec shutter (B-W)

0.013 lux at 1/2 sec shutter (B-W)

PAL

0.08 lux at 1/1.5 sec shutter (color)

0.02 lux at 1/1.5 sec shutter

0.3 lux at 1/50 sec shutter (B-W)

0.013 lux at 1/1.5 sec shutter (B-W)

Sync System Internal/AC line lock, phase adjustable via

remote control, V-Sync*

Internal/AC line lock, phase adjustable via remote

control, V-Sync*

White Balance Automatic with manual override* Automatic with manual override*

Shutter Speed

NTSC

PAL

Automatic (electronic iris)/Manual

1/2~1/30,000*

1/1.5~1/30,000*

Automatic (electronic iris)/Manual

1/2~1/30,000*

1/1.5~1/30,000*

Iris Control Automatic Iris Control with manual override* Automatic Iris Control with manual override*

Gain Control Automatic/OFF* Automatic/OFF*

Video Output 1 Vp-p, 75 ohms 1 Vp-p, 75 ohms

Video Signal to Noise >50 dB >50 dB

*Manual control of camera setup functions can be done with CM6700, CM6800, CM8500, CM9500, CM9740, CM9760, CM9770,

CM9780, KBD200A, KBD300A, and MPT9500 controllers, but not with CM7500, MPT9000, or KBD9000 controllers.

CCD

22 C1306M-B (10/06)

Page 23

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FR/FT/FS Series fiber optic products and TW3000 Series unshielded twisted

pair transmission products.

• Three years on Genex

• Three years on Camclosure

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models,

which have a five-year warranty.

• Three years on PMCL200/300/400 Series LCD monitors.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy

dome products.

• Two years on Spectra

continuous motion applications.

• Two years on Esprit

• Two years (except lamp and color wheel) on Digital Light Processing (DLP

The lamp and color wheel will be covered for a period of 90 days. The air filter is not

covered under warranty.

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from

the specific use or application made of the Products. Pelco’s liability for any claim, whether

based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for such

Products. In no event will Pelco be liable for any special, incidental or consequential damages

(including loss of use, loss of profit and claims of third parties) however caused, whether by

the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

®

Series products (multiplexers, server, and keyboard).

®

and fixed camera models, except the CC3701H-2,

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

®

) displays.

If a warranty repair is required, the Dealer must contact Pelco at (800)þ289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product when

returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at

(800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned for

credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

The materials used in the manufacture of this document and its components are compliant to the requirements of Directive 2002/95/EC.

This equipment contains electrical or electronic components that must be recycled properly to comply with Directive 2002/96/EC of the European Union

regarding the disposal of waste electrical and electronic equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

REVISION HISTORY

Manual # Date Comments

C1306M 8/05 Original version.

C1306M-A 7/06 Updated for the new factory-installed power module seal (ECO 06-1400). Revised power module installation instructions. Removed Figure 9.

C1306M-B 10/06 Removed color reference to power module seal (ECO 06-14300). Added power module warning. Added Figure 9.

Pelco, the Pelco logo, Spectra, Genex, Esprit, Cam closure, Coaxitron, and Legacy are registered trademarks of Pelco. ©Copyright 2006, Pelco. All rights reserved.

Endura, ExSite, and LowLight are trademar ks of Pelco.

EXview HAD is a trademark of Sony Corporation.

Page 24

Worldwide Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

Australia|Canada|Finland|France|Italy|Russia|Singapore|Spain|Sweden|The Netherlands|United Arab Emirates|United Kingdom|United States

Loading...

Loading...