Page 1

INSTALLATION

Spectra IV IP Series Dome System

In-Ceiling

Heavy-Duty In-Ceiling

Pendant (shown)

Heavy-Duty Pendant

Stainless Steel Pendant

C3461M (7/09)

Page 2

2 C3461M (7/09)

Page 3

Contents

Regulatory Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Legal Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Open Source Software Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

In-Ceiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Heavy-Duty In-Ceiling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pendant, Heavy-Duty Pendant, and Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Dome Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing the Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

In-Ceiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Heavy-Duty In-Ceiling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pendant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Heavy-Duty Pendant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

C3461M (7/09) 3

Page 4

List of Illustrations

1 Preparing the Ceiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Attaching the Conduit Fitting, Lock Nut, and Safety Chain Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Marking the Screw Hole Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Installing the Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Installing the Heavy-Duty In-Ceiling Back Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Attaching the Pendant Back Box to the Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Back Box Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Removing the TXB-IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Connect the Wiring to the Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10 Connecting Audio to the TXB-IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11 Routing the Cables in the Back Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Setting the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13 Installing the In-Ceiling Lower Dome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14 Installing the Heavy-Duty In-Ceiling Lower Dome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

15 Attaching the Leash to the Pendant Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

16 Installing the Pendant Lower Dome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

17 Installing the O-Ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

18 Installing the Heavy-Duty Pendant Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

19 Attaching the Leash to the Stainless Steel Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

20 Installing the Stainless Steel Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 C3461M (7/09)

Page 5

List of Tables

A Video Coaxial Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B 24 VAC/24 VDC Wiring Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

C Troubleshooting the Spectra IV IP Dome System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

D Switch Settings for SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

E Switch Settings for SW1, Pelco P-Type Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

F Switch Settings for SW1, Pelco D-Type Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

C3461M (7/09) 5

Page 6

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However there is no guarantee that the interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

You may also find helpful the following booklet, prepared by the FCC: “How to Identify and Resolve

Radio-TV Interference Problems.” This booklet is available from the U.S. Government Printing Office,

Washington D.C. 20402.

Changes and modifications not expressly approved by the manufacturer or registrant of this equipment can

void your authority to operate this equipment under Federal Communications Commission’s rules.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

LEGAL NOTICE

SOME PELCO EQUIPMENT CONTAINS, AND THE SOFTWARE ENABLES, AUDIO/VISUAL AND RECORDING

CAPABILITIES, THE IMPROPER USE OF WHICH MAY SUBJECT YOU TO CIVIL AND CRIMINAL PENALTIES.

APPLICABLE LAWS REGARDING THE USE OF SUCH CAPABILITIES VARY BETWEEN JURISDICTIONS AND

MAY REQUIRE, AMONG OTHER THINGS, EXPRESS WRITTEN CONSENT FROM RECORDED SUBJECTS.

YOU ARE SOLELY RESPONSIBLE FOR INSURING STRICT COMPLIANCE WITH SUCH LAWS AND FOR

STRICT ADHERENCE TO ANY/ALL RIGHTS OF PRIVACY AND PERSONALTY. USE OF THIS EQUIPMENT

AND/OR SOFTWARE FOR ILLEGAL SURVEILLANCE OR MONITORING SHALL BE DEEMED UNAUTHORIZED

USE IN VIOLATION OF THE END USER SOFTWARE AGREEMENT AND RESULT IN THE IMMEDIATE

TERMINATION OF YOUR LICENSE RIGHTS THEREUNDER.

OPEN SOURCE SOFTWARE NOTICE

This product includes certain open source or other software originated from third parties that is subject to

the GNU General Public License (GPL), GNU Library/Lesser General Public License (LGPL) and different

and/or additional copyright licenses, disclaimers and notices.

The exact terms of GPL, LGPL and some other licenses are provided to you with this product. Please refer

to the exact terms of the GPL and LGPL at www.fsf.org (Free Software Foundation) and

www.opensource.org (Open Source Initiative) regarding your rights under said license. You may obtain a

complete corresponding machine-readable copy of the source code of such software under the GPL or

LGPL by sending your request to digitalsupport@pelco.com and the subject line should read Source Code

Request. You will then receive a link in the e-mail for you to download the source code.

This offer is valid for a period of three (3) years from the date of the distribution of this product by Pelco.

6 C3461M (7/09)

Page 7

Description

Spectra® IV IP was designed with ease of installation and ease of maintenance in mind. Each dome

system consists of three components: a back box, a dome drive, and a lower dome. Spectra IV IP back box

options include the following models: environmental in-ceiling (ideal for outdoor soffits), indoor in-ceiling,

standard and environmental pendant, heavy-duty, and stainless steel. Depending on the dome drive model

with which it will be used, a back box can be ordered with or without built-in back box memory. This

memory can be used to store camera and location-specific dome settings, including labels, presets,

patterns, and zones.

MODELS

BB4N-F In-ceiling, black, with back box memory

BB4N-F-E In-ceiling, black, environmental, with back box memory

BB4N-PB Pendant mount, black, standard, with back box memory

BB4N-PG Pendant mount, gray, standard, with back box memory

BB4N-PG-E Pendant mount, gray, environmental, with back box memory

BB4NT-F In-ceiling, black

BB4NT-F-E In-ceiling, black, environmental

BB4NT-PB Pendant mount, black, standard

BB4NT-PG Pendant mount, gray, standard

BB4NT-PG-E Pendant mount, gray, environmental

BB4NHD-F Heavy-duty, in-ceiling, gray, with back box memory

BB4NHD-PG Heavy-duty, pendant, gray, with back box memory

BB4NHD-PG-E Heavy-duty, environmental pendant, gray, with back box memory

BB4N-PSG-E Stainless steel, environmental pendant, gray 316 SS, with back box memory

PARTS LIST

Qty Description

1 Back box

1 Thread compound (pendant, heavy-duty pendant, and stainless steel models only)

8 Screws, 10-32 x 3-inch, Phillips flat head (heavy-duty in-ceiling model only)

1 Important Safety Instructions manual

1 Installation manual

1 Operation/Configuration manual

1 Resource disc

C3461M (7/09) 7

Page 8

Mounting

IN-CEILING

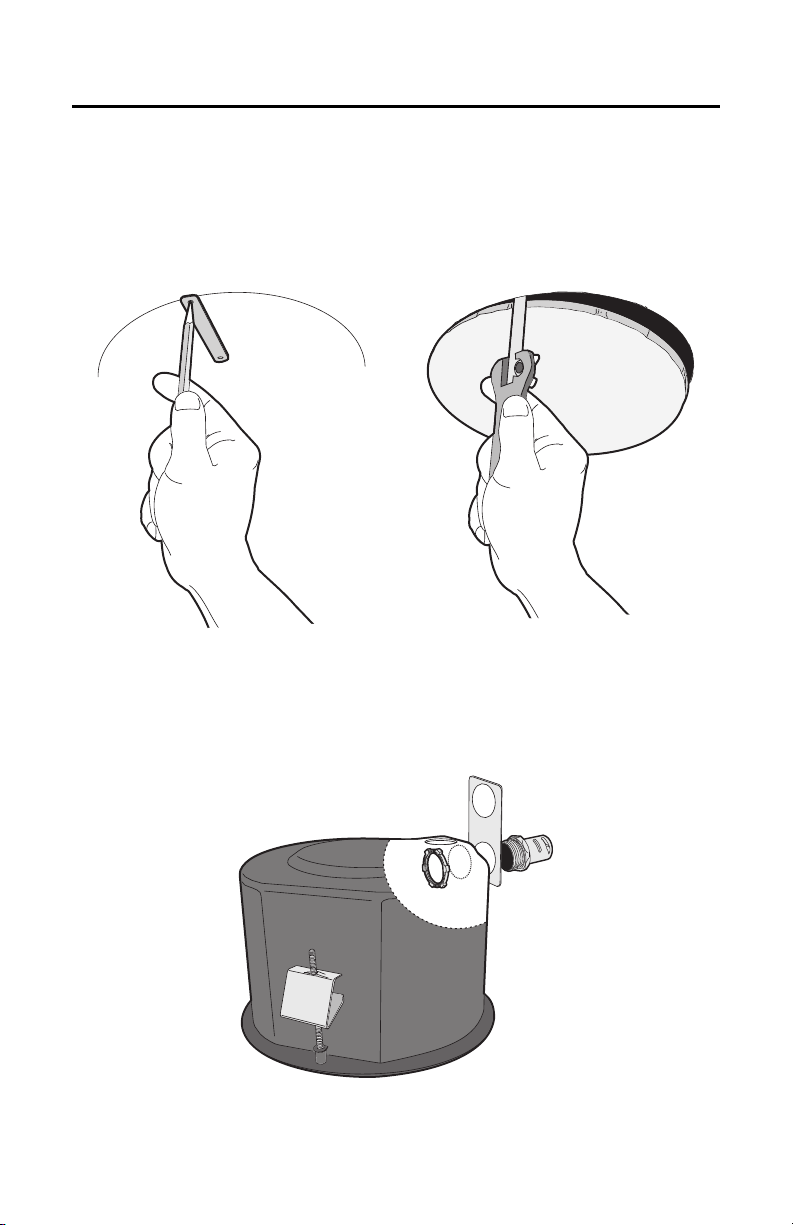

1. Prepare the ceiling (refer to Figure 1):

a. Locate the center point of the mounting location, and insert the compass tool into the ceiling.

b. Place the end of a pencil in the hole on the end of the compass tool, and draw a circle.

c. Cut out the circle.

Figure 1. Preparing the Ceiling

2. Attach a conduit fitting (not supplied), lock nut (not supplied), and safety chain bracket (refer to

Figure 2).

3. Install a safety chain/cable (not supplied), which will support up to 16 pounds (7.3 kg).

Figure 2. Attaching the Conduit Fitting, Lock Nut, and Safety Chain Bracket

8 C3461M (7/09)

Page 9

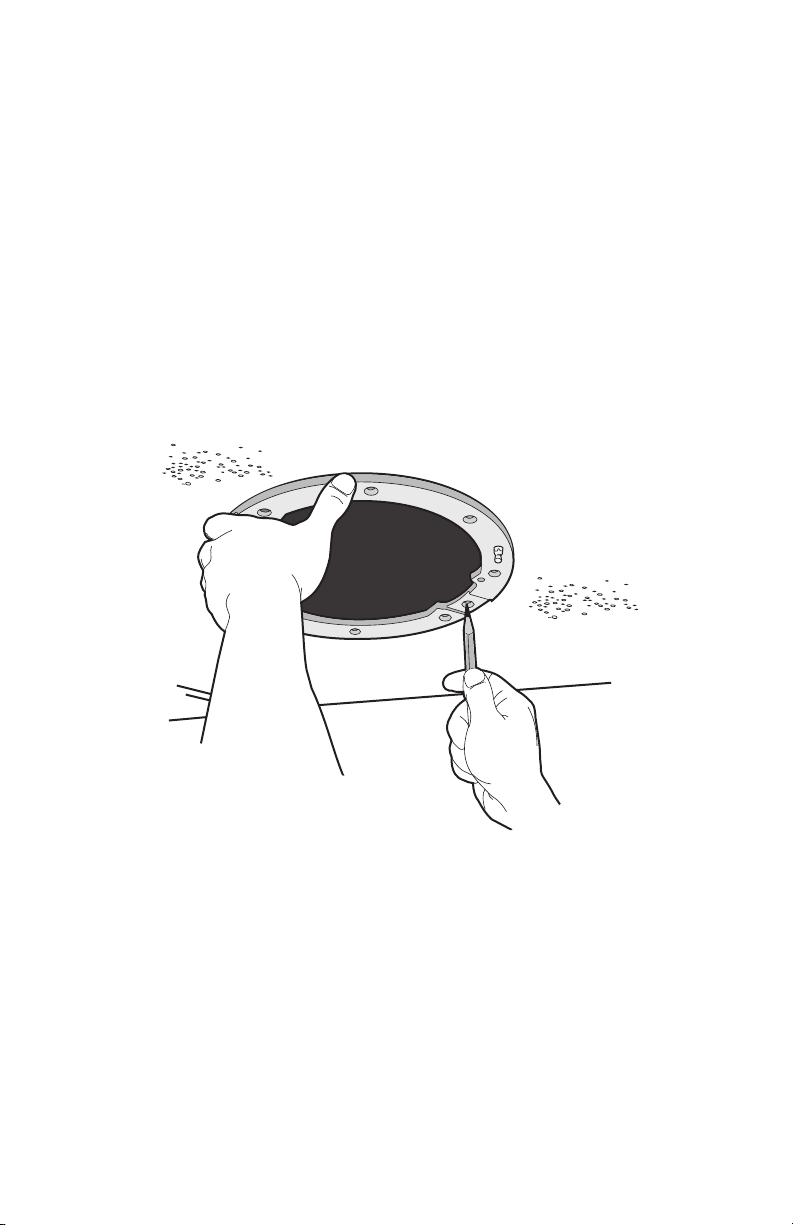

4. Open the hinged door to the back box by pushing the tab lock toward the wall of the unit and lifting

the door open.

5. Pull the wiring into the back box through the conduit fitting.

6. Connect all required wiring (refer to Wiring on page 12).

7. Install the back box by compressing the spring clips and pushing the back box through the hole.

8. Tighten the screws until you hear a clicking noise.

HEAVY-DUTY IN-CEILING

1. Prepare the ceiling (refer to Figure 1 on page 8):

a. Locate the center point of the mounting location, and insert the compass tool into the ceiling.

b. Place the end of a pencil in the hole on the end of the compass tool, and draw a circle.

c. Cut out the circle.

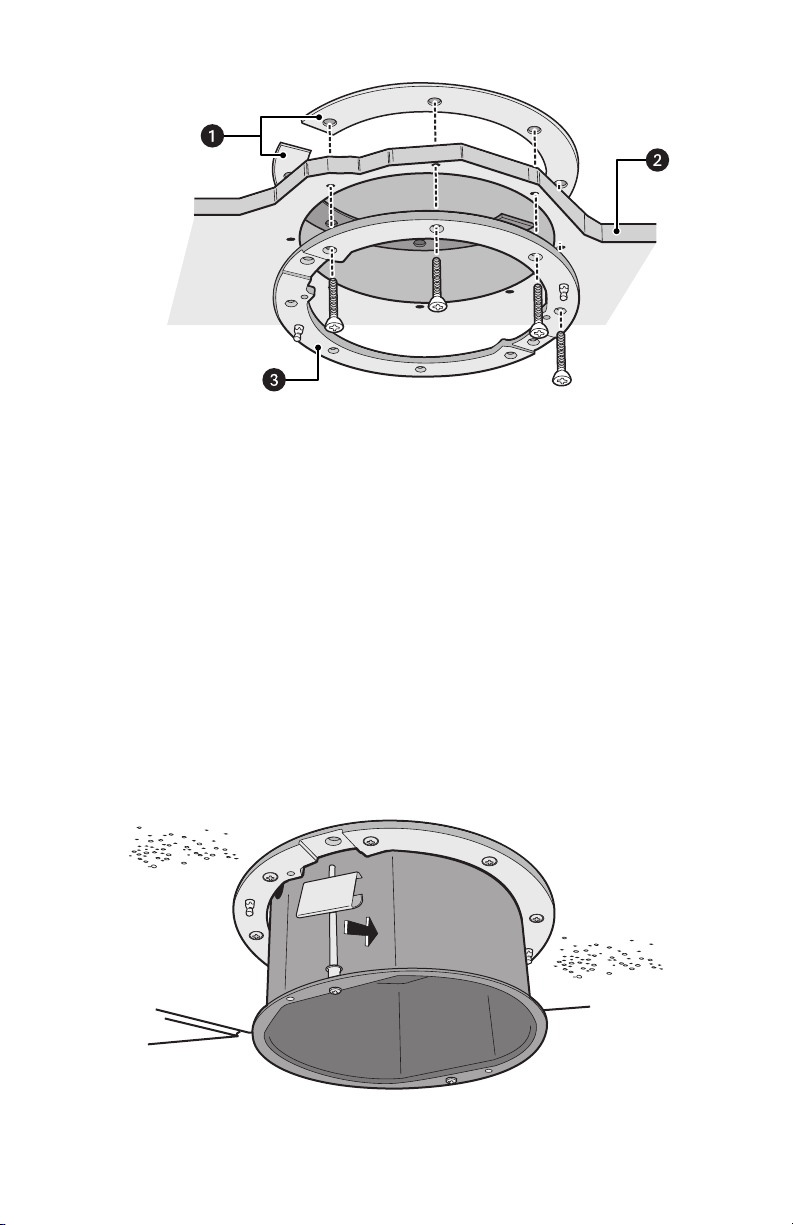

2. Use the mounting ring as a template to mark the screw hole pattern onto the mounting surface.

3. Prepare the holes.

Figure 3. Marking the Screw Hole Pattern

4. Install the mounting plates (refer to Figure 4 on page 10). Use the eight 10-32 x 3-inch screws

(supplied) to install the mounting ring and the two back mounting plates.

a. Line up the mounting ring with the eight fastener holes.

b. Feed one back mounting plate through the hole in the ceiling. Line up the plate with the four

fastener holes.

c. Install fasteners through the mounting ring, ceiling, and out the back mounting plate.

d. Install the second back mounting plate.

C3461M (7/09) 9

Page 10

Figure 4. Installing the Plates

ì

Back Mounting Plates

î

Ceiling

ï

Mounting Ring

5. Attach a conduit fitting (not supplied), lock nut (not supplied), and safety chain bracket (refer to

Figure 2 on page 8).

6. Install a safety chain/cable (not supplied), which will support up to 16 pounds (7.3 kg).

7. Open the hinged door to the back box by pushing the tab lock toward the wall of the unit and lifting

the door open.

8. Pull the wiring into the back box through the conduit fitting.

9. Connect all required wiring (refer to Wiring on page 12).

10. Install the back box by compressing the spring clips and pushing the back box through the hole (refer

to Figure 5).

11. Tighten the screws until you hear a clicking noise.

Figure 5. Installing the Heavy-Duty In-Ceiling Back Box

10 C3461M (7/09)

Page 11

PENDANT, HEAVY-DUTY PENDANT, AND STAINLESS STEEL

1. Install the mount for the pendant dome. Refer to the instructions supplied with the mount.

NOTE: If the mount is outdoors, make sure it is properly sealed to keep moisture out.

2. Open the hinged door to the back box by pushing the tab lock towards the wall of the unit and lifting

the door open.

3. Pull the wiring into the back box.

4. Connect all required wiring (refer to Wiring on page 12).

5. Screw the back box onto the mount (refer to Figure 6). If outdoors, apply thread compound (supplied)

to the threads on the back box.

NOTE: Thread compound must be applied. Not doing so may prevent the units from being separated

in the future.

Figure 6. Attaching the Pendant Back Box to the Mount

C3461M (7/09) 11

Page 12

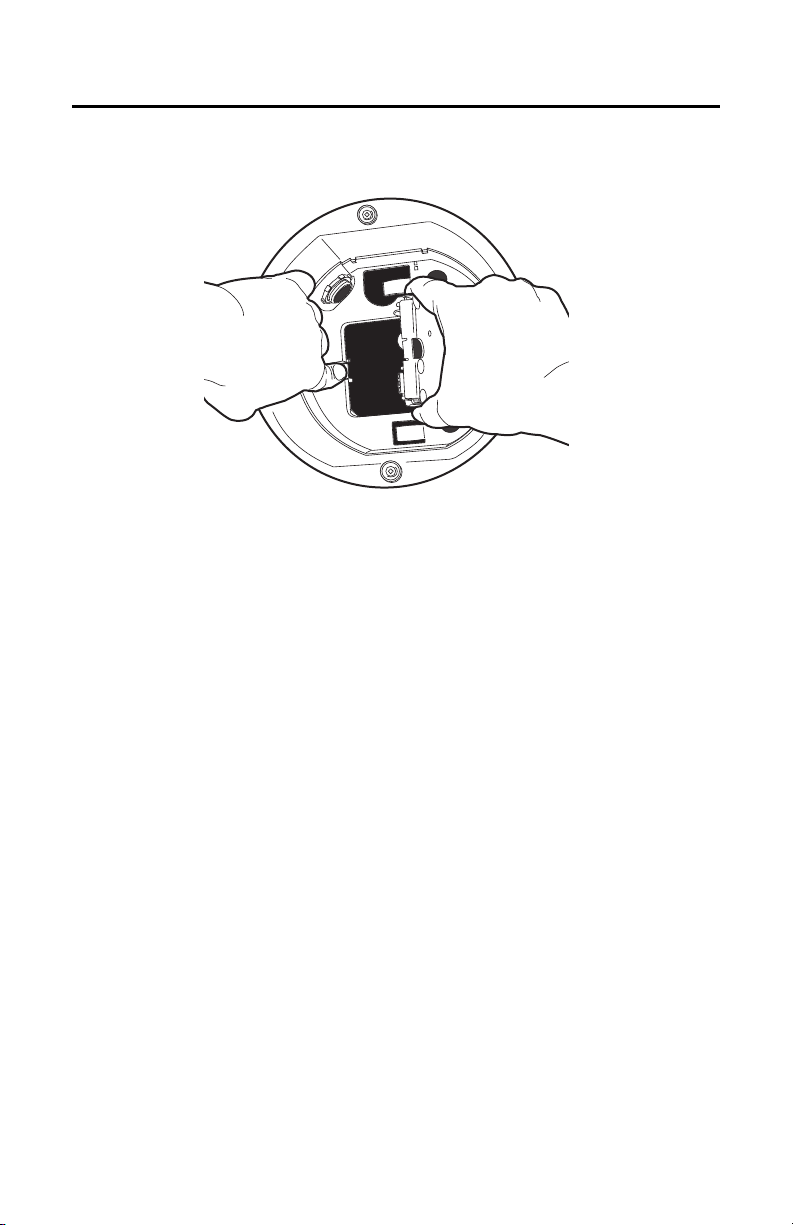

Wiring

1. Open the hinged door to the back box by pushing the tab lock toward the wall of the unit and lifting

the door open (refer to Figure 7).

Figure 7. Back Box Door

12 C3461M (7/09)

Page 13

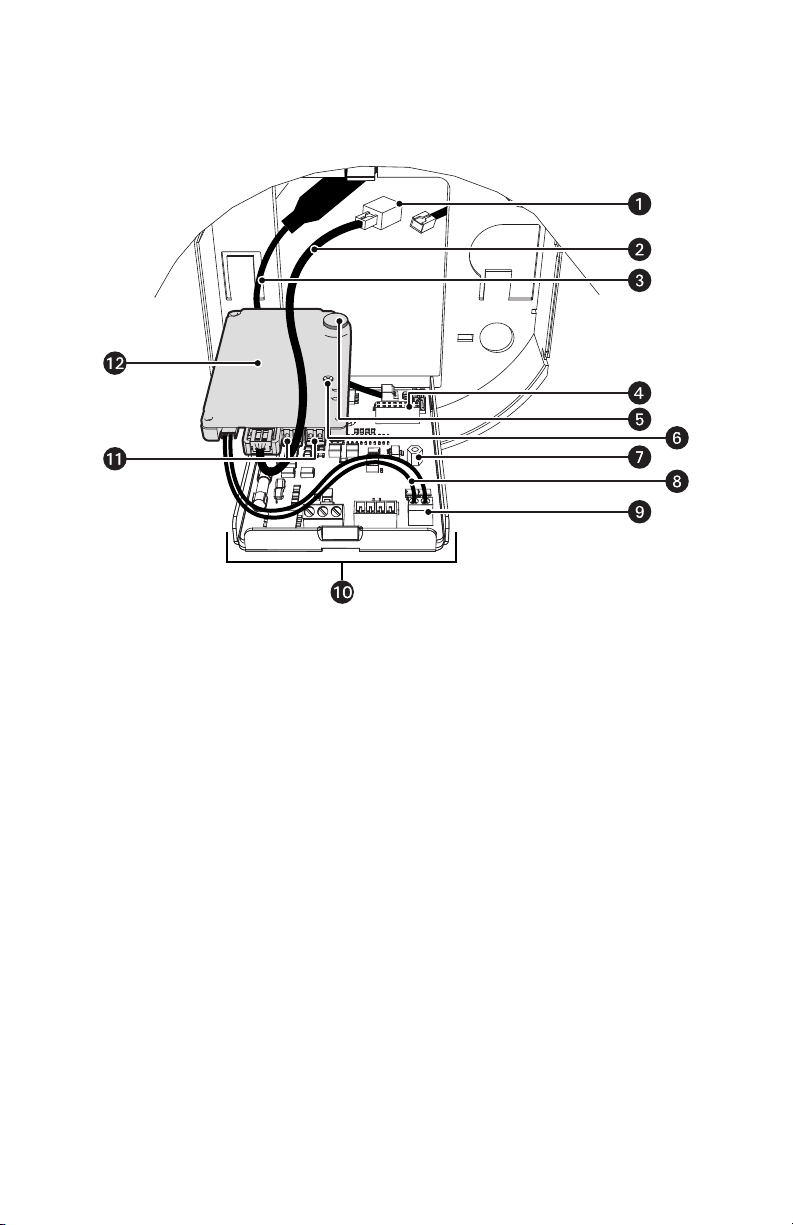

2. Remove the TXB-IP from the back box circuit board (refer to Figure 8):

a. Loosen the captive screw on the TXB-IP.

b. Carefully unplug the TXB-IP from the back box circuit board.

+ -

Figure 8. Removing the TXB-IP

ì

RJ-45 Coupler

î

Ethernet Cable

ï

Video Coaxial Cable

ñ

16-Pin Connector

ó

Heat Sink Standoff

r

Captive Screw

C3461M (7/09) 13

s

Standoff

t

Video UTP Cable

u

UTP Connector

~í

Back Box Circuit Board

~â

Audio Connectors

~ä

TXB-IP

Page 14

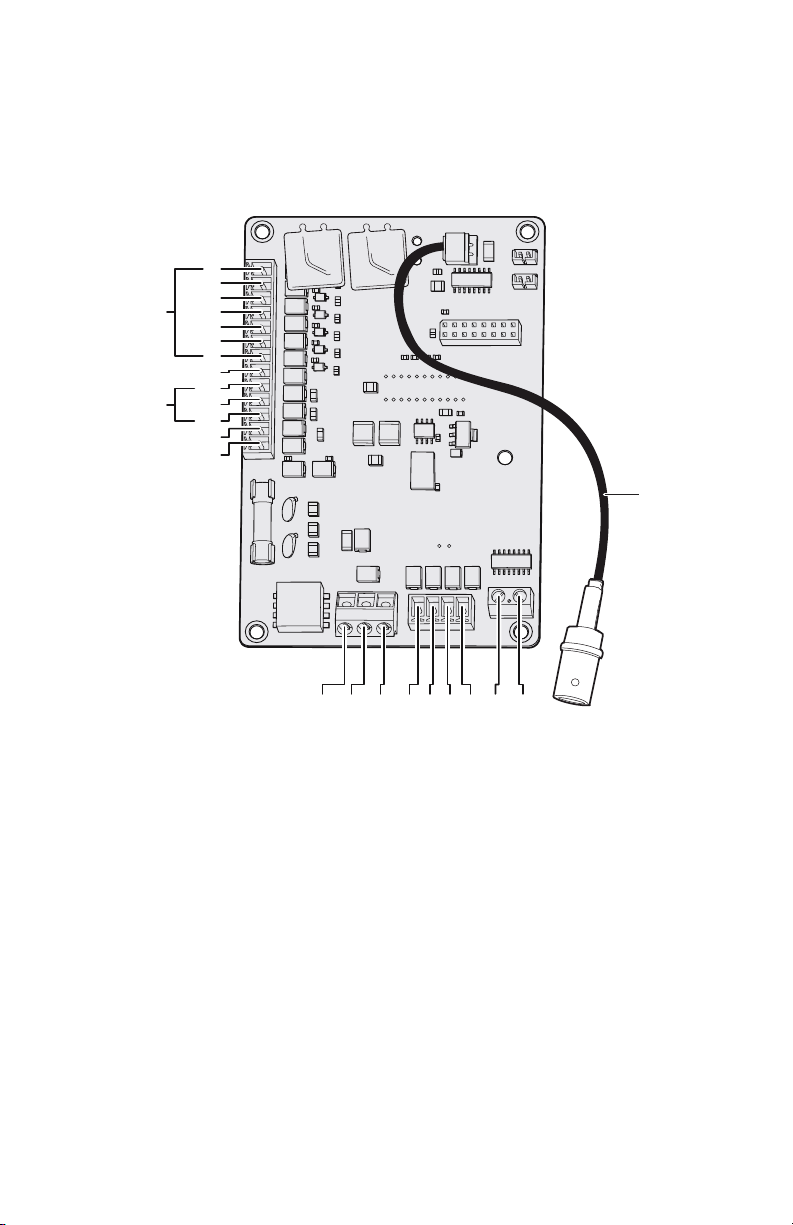

3. Connect the auxiliary, alarm, and other wiring to the back box circuit board (refer to Figure 9).

VIDEO

UTP+ UTP-RX- RX+ TX+TX-PWR- PWR+GND

AUX2

GND

GND

NO

NC

COM

7

6

5

4

3

2

1

ALARMS

AUX1

NOTES:

• Aux 1: Maximum 2 A at low voltage (<40 V)

Aux 2: Maximum 30 mA at 32 VDC

• If you are installing an environmental back box in a railway application, attach a ground wire

from the circuit board power connector to a structural ground using at least 18-gauge wire.

Figure 9. Connect the Wiring to the Circuit Board

14 C3461M (7/09)

Page 15

4. If you plan to use the audio functions, install your audio cables into the audio line-in and line-out

connectors on the TXB-IP.

NOTES:

• To take full advantage of the distance and noise immunity benefits of audio, you must use a

600-ohm impedance matching transformer and twisted pair cable (refer to Figure 10).

• A stable power supply is required for optimal audio performance.

Figure 10. Connecting Audio to the TXB-IP

ì

Microphone

î

Amplifier

ï

600-Ohm Impedance Matching TransformersAmplifier

ñ

Line-In Audio Twisted Pair Cable

C3461M (7/09) 15

ó

Line-Out Audio Twisted Pair Cable

r

600-Ohm Impedance Matching Transformer

t

Speaker

Page 16

5. Reinstall the TXB-IP:

a. Plug the TXB-IP into the 16-pin connector located on the back box circuit board.

b. Secure the TXB-IP to the standoff on the circuit board using the captive screw on the TXB-IP.

6. Plug your network Ethernet cable into the RJ-45 coupler on the TXB-IP to connect the Spectra

dome system to your existing network.

WARNING: An electrical short in the back box may occur if the metal BNC connector on the video

coaxial cable is not completely covered by the protective boot.

7. Perform one of the following options:

• View video using both analog and IP connections: Connect the video coaxial cable from

the back box circuit board to the coaxial cable coming in from the outside. Make sure that the

BNC connector is completely covered by the protective boot.

• View video using only the IP connection: Make sure that the BNC connector is

completely covered by the protective boot and is out of the way of the back box door.

8. Before closing the interconnect door, ensure that no wires are between the top of the heat sink

standoff and the back box (refer to Figure 11 on page 16). Both the video coaxial cable and the

Ethernet cable need to be routed carefully to ensure clearance for the heat sink standoff.

9. Close the interconnect door and snap the tab lock into place.

®

IV

Figure 11. Routing the Cables in the Back Box

ì

RJ-45 Coupler

î

Ethernet Cable

ï

Video Coaxial Cable

16 C3461M (7/09)

Page 17

Table A. Video Coaxial Cable Requirements

Cable Type* Maximum Distance

RG59/U 750 ft (229 m)

RG6/U 1,000 ft (305 m)

RG11/U 1,500 ft (457 m)

*Cable requirements:

• 75-ohm impedance

• All-copper center conductor

• All-copper braided shield with

95 percent braid coverage

Refer to Table B for the recommended maximum distances for 24 VAC and 24 VDC applications, which are

calculated with a 10 percent voltage drop. (Ten percent is generally the maximum allowable voltage drop

for AC- or DC-powered devices.)

Table B. 24 VAC/24 VDC Wiring Distances

18 AWG

(1.0 mm2)

196 ft

(60 m)

62 ft

(19 m)

Wire Gauge

16 AWG

(1.5 mm2)

311 ft

(95 m)

98 ft

(30 m)

14 AWG

(2.5 mm2)

495 ft

(151 m)

156 ft

(48 m)

AC/DC

Total VA/

Total Watts

23 VA/

15 W

73 VA/

65 W

20 AWG

(0.5 mm

123 ft

(38 m)

39 ft

(12 m)

2

)

NOTE: Input power for the dome is 24 VAC or 24 VDC. Using 24 VAC input power,

power consumption is 23 VA per dome for indoor models and 73 VA for outdoor models.

Using 24 VDC input power, power consumption is 0.7 A (15 W) for indoor models and

3 A (65 W) for outdoor models.

Use a 24 VAC transformer with the following minimum VA:

• 40 VA per dome: For indoor models (without heater)

• 100 VA per dome: For outdoor models (with heater)

C3461M (7/09) 17

Page 18

Installing the Dome Drive

1. Perform one of the following options:

• View video using both analog and IP connections: Set the DIP switches on the top of

the Spectra IV dome drive (refer to Figure 12). For DIP switch settings, refer to the labels

located on the top of the dome drive, or refer to Switch Settings on page 28.

• View video using the IP connection: You do not need to set the DIP switches.

NOTE: When connecting more than one Spectra dome to a single controller, terminate the unit

farthest from the controller. To terminate the dome drive set the SW2-10 switch to the ON position.

Figure 12. Setting the DIP Switches

2. Install the dome drive.

WARNING: Improper installation of the dome drive can be dangerous and can seriously damage

the equipment.

a. Align the blue and red tabs with the blue and red labels on the back box.

b. Push in the red tab and insert that side of the dome drive first.

c. Push in the blue tab and insert the dome drive into the back box the remainder of the way.

d. Continue pushing on the ends of the tabs until both sides click firmly into place.

18 C3461M (7/09)

Page 19

Installing the Lower Dome

IN-CEILING

1. Snap the clip on the end of the trim ring leash into the hole on the lip of the back box (refer to

Figure 13).

Figure 13. Installing the In-Ceiling Lower Dome

2. Snap the trim ring into the plastic snap washers on the mounting screws.

C3461M (7/09) 19

Page 20

HEAVY-DUTY IN-CEILING

1. Snap the clip of the lower trim ring leash into the hole on the lip of the back box (refer to Figure 14).

2. Insert both keys in the barrel locks. Turn the keys clockwise to the unlocked position.

NOTE: Keys cannot be removed from the lock while in the unlocked position.

3. Align the ball studs, located on the mount ring, with the ball stud receivers, located on the inside of

the lower dome. Push the lower dome into the back box.

4. Hold and turn both keys to the locked position.

Figure 14. Installing the Heavy-Duty In-Ceiling Lower Dome

ì

Trim Leash

î

Ball Stud

ï

Ball Stud Receiver

ñ

Barrel Key Lock

20 C3461M (7/09)

Page 21

PENDANT

1. Attach the back box leash to the lower dome (refer to Figure 15).

Figure 15. Attaching the Leash to the Pendant Lower Dome

2. Push the lower dome into the back box.

3. Tighten the captive Phillips pan head screws to secure the lower dome.

Figure 16. Installing the Pendant Lower Dome

C3461M (7/09) 21

Page 22

HEAVY-DUTY PENDANT

1. Attach the back box leash to the lower dome (refer to Figure 15 on page 21).

2. Lightly apply O-ring lubricant (supplied with the lower dome) to the O-ring, and then install the

O-ring in the groove on the trim ring of the lower dome (refer to Figure 17).

Figure 17. Installing the O-Ring

3. Align the barrel locks in the lower dome with the holes located on each side of the back box (refer to

Figure 18 on page 23).

4. Push the lower dome into the back box.

5. Press in the pins of the barrel locks to secure the lower dome.

22 C3461M (7/09)

Page 23

Figure 18. Installing the Heavy-Duty Pendant Lower Dome

ì

Barrel Lock

î

Center Pin

C3461M (7/09) 23

Page 24

STAINLESS STEEL

1. Attach the back box leash to the lower dome using the nearest retainer screw (refer to Figure 19).

Figure 19. Attaching the Leash to the Stainless Steel Lower Dome

ì

Leash

î

Retainer Screw

2. Lightly apply O-ring lubricant (supplied with the lower dome) to the O-ring, and then install the

O-ring in the groove on the trim ring of the lower dome (refer to Figure 17).

3. Remove the two lower dome mounting screws, and apply a drop of Loctite

lower dome) to each screw.

24 C3461M (7/09)

®

222MS (supplied with

Page 25

4. Push the lower dome into the back box, line up the mounting screw holes, and install the two

mounting screws (refer to Figure 20).

Figure 20. Installing the Stainless Steel Lower Dome

C3461M (7/09) 25

Page 26

Troubleshooting

To use your dome, refer to the operation and programming manual.

If the following instructions fail to solve your problem, contact Pelco Product Support at 1-800-289-9100

(USA and Canada) or +1-559-292-1981 (international) for assistance. Be sure to have the serial number

available when calling.

Do not try to repair the unit yourself. Leave maintenance and repairs to qualified technical personnel only.

Table C. Troubleshooting the Spectra IV IP Dome System (1 of 2)

Problem Possible Causes Suggested Resolution

Dome does not start

properly after

installation.

Dome starts correctly,

but you do not have

accurate control

No video is displayed. Power is not connected. Check the power connector.

Spectra IV information

(model, firmware,

Pelco P and Pelco D

protocol addresses,

and communication

settings) does not

appear after the

configuration cycle.

The displayed video is

scrambled.

The circuit board fuse

may need to be replaced.

The back box may not be

receiving proper voltage.

Switch settings on the

dome drive are set

incorrectly.

.

Video cable is not

connected.

Video UTP cable is not

connected.

TXB-IP module is not

inserted properly.

The unit cannot complete

its configuration cycle.

Video UTP wires are

incorrectly installed.

Check the fuse on the circuit board inside the back box

for continuity. Replace the fuse if needed.

Check the wiring with a volt meter to ensure that the

back box is receiving proper voltage.

Check the signal with a volt meter or an oscilloscope.

NOTE: This step will not apply if you are using

Coaxitron control.

Ensure that the switch settings on the dome drive are

set correctly (refer to Switch Settings on page 28.)

Check the video connector.

Check the UTP connector.

Reinstall the TXB-IP module. Make sure the pins on

the module are inserted correctly.

Refer to Troubleshooting in the Installation/Operation

manual shipped with the Spectra IV dome drive.

Verify that the video UTP cable is wired correctly to

the UTP connector on the back box circuit board. The

blue wire should be connected to the positive

terminal, and the gray wire should be connected to

the negative terminal (refer to Figure 9 on page 14).

26 C3461M (7/09)

Page 27

Table C. Troubleshooting the Spectra IV IP Dome System (2 of 2)

Problem Possible Causes Suggested Resolution

The audio signal is

weak.

You are not using the

correct type of

Be sure you are using a 600-ohm impedance matching

transformer.

transformer.

The wiring distance

Test the equipment using a shorter wiring distance.

connecting the audio

equipment may be too

long.

The gain is not properly

adjusted.

If you are using an external amplifier and it has an

adjustable gain, increase the gain until the signal is

acceptable.

There is an echo when

audio is received.

The speaker volume is

too high.

The microphone and the

speaker are too close

together.

Your call station does not

Lower the speaker volume.

If your call station does not have built-in echo

cancellation, move the microphone and speaker

farther apart.

Use a call station with built-in echo cancellation.

have built-in echo

cancellation.

C3461M (7/09) 27

Page 28

Switch Settings

WARNING: If you are using Pelco D-type or Pelco P-type control, your system may not operate if

the baud rate and address switches are not set correctly. The switches are set at the factory using

the defaults for Pelco D-type control (2400 baud and address 1).

Table D. Switch Settings for SW2

Special Systems

Switch Number 12345678910

AD-32 Preset System ON

CM9502 Setting ON

™

Vicon

Serial Port Settings

Switch Number 12345678910

RS422 OFF OFF

RS485, 4-Wire OFF ON

RS485, 2-Wire ON ON

Pelco D or Pelco P Protocol Baud Rate

Switch Number 12345678910

2400 Baud

(Default for D-type Control)

4800 Baud

(Default for P-type Control)

9600 Baud OFF ON OFF

Not currently available; SW2-3 is reserved for future use.

OFF OFF OFF

ON OFF OFF

Video Cable Type

Switch Number 12345678910

Coaxial Cable OFF

Dome Termination

Switch Number 12345678910

Terminated ON

Not Terminated OFF

28 C3461M (7/09)

Page 29

Table E. Switch Settings for SW1, Pelco P-Type Control

NOTE: For Coaxitron controls, SW1 is not used; set all switches to OFF. For Pelco D-type control systems,

refer to Table F.

SPECTRA

ADDRESS

1 OFF OFF OFF OFF OFF

2 ON OFF OFF OFF OFF

3 OFF ON OFF OFF OFF

4 ON ON OFF OFF OFF

5 OFF OFF ON OFF OFF

6 ON OFF ON OFF OFF

7 OFF ON ON OFF OFF

8 ON ON ON OFF OFF

9 OFF OFF OFF ON OFF

10 ON OFF OFF ON OFF

11 OFF ON OFF ON OFF

12 ON ON OFF ON OFF

13 OFF OFF ON ON OFF

14 ON OFF ON ON OFF

15 OFF ON ON ON OFF

16 ON ON ON ON OFF

17 OFF OFF OFF OFF ON

18 ON OFF OFF OFF ON

19 OFF ON OFF OFF ON

20 ON ON OFF OFF ON

21 OFF OFF ON OFF ON

22 ON OFF ON OFF ON

23 OFF ON ON OFF ON

24 ON ON ON OFF ON

25 OFF OFF OFF ON ON

26 ON OFF OFF ON ON

27 OFF ON OFF ON ON

28 ON ON OFF ON ON

29 OFF OFF ON ON ON

30 ON OFF ON ON ON

31 OFF ON ON ON ON

32 ON ON ON ON ON

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5

SWITCH SETTING

C3461M (7/09) 29

Page 30

Table F. Switch Settings for SW1, Pelco D-Type Control

NOTE: For Coaxitron controls, SW1 is not used; set all switches to OFF. For Pelco P-type control systems,

refer to Table E.

SPECTRA

ADDRESS

1 ONOFFOFFOFFOFFOFFOFFOFF

2 OFF ON OFF OFF OFF OFF OFF OFF

3 ON ON OFF OFF OFF OFF OFF OFF

4 OFF OFF ON OFF OFF OFF OFF OFF

5 ON OFF ON OFF OFF OFF OFF OFF

6 OFF ON ON OFF OFF OFF OFF OFF

7 ONONONOFFOFFOFFOFFOFF

8 OFF OFF OFF ON OFF OFF OFF OFF

9 ON OFF OFF ON OFF OFF OFF OFF

10 OFF ON OFF ON OFF OFF OFF OFF

11 ON ON OFF ON OFF OFF OFF OFF

12 OFF OFF ON ON OFF OFF OFF OFF

13 ON OFF ON ON OFF OFF OFF OFF

14 OFF ON ON ON OFF OFF OFF OFF

15 ON ON ON ON OFF OFF OFF OFF

16 OFF OFF OFF OFF ON OFF OFF OFF

17 ON OFF OFF OFF ON OFF OFF OFF

18 OFF ON OFF OFF ON OFF OFF OFF

19 ON ON OFF OFF ON OFF OFF OFF

20 OFF OFF ON OFF ON OFF OFF OFF

21 ON OFF ON OFF ON OFF OFF OFF

22 OFF ON ON OFF ON OFF OFF OFF

23 ON ON ON OFF ON OFF OFF OFF

24 OFF OFF OFF ON ON OFF OFF OFF

25 ON OFF OFF ON ON OFF OFF OFF

26 OFF ON OFF ON ON OFF OFF OFF

27 ON ON OFF ON ON OFF OFF OFF

28 OFF OFF ON ON ON OFF OFF OFF

29 ON OFF ON ON ON OFF OFF OFF

30 OFF ON ON ON ON OFF OFF OFF

31 ON ON ON ON ON OFF OFF OFF

32 OFF OFF OFF OFF OFF ON OFF OFF

33 ON OFF OFF OFF OFF ON OFF OFF

34 OFF ON OFF OFF OFF ON OFF OFF

35 ON ON OFF OFF OFF ON OFF OFF

36 OFF OFF ON OFF OFF ON OFF OFF

37 ON OFF ON OFF OFF ON OFF OFF

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

30 C3461M (7/09)

Page 31

SPECTRA

ADDRESS

38 OFF ON ON OFF OFF ON OFF OFF

39 ON ON ON OFF OFF ON OFF OFF

40 OFF OFF OFF ON OFF ON OFF OFF

41 ON OFF OFF ON OFF ON OFF OFF

42 OFF ON OFF ON OFF ON OFF OFF

43 ON ON OFF ON OFF ON OFF OFF

44 OFF OFF ON ON OFF ON OFF OFF

45 ON OFF ON ON OFF ON OFF OFF

46 OFF ON ON ON OFF ON OFF OFF

47 ON ON ON ON OFF ON OFF OFF

48 OFF OFF OFF OFF ON ON OFF OFF

49 ON OFF OFF OFF ON ON OFF OFF

50 OFF ON OFF OFF ON ON OFF OFF

51 ON ON OFF OFF ON ON OFF OFF

52 OFF OFF ON OFF ON ON OFF OFF

53 ON OFF ON OFF ON ON OFF OFF

54 OFF ON ON OFF ON ON OFF OFF

55 ON ON ON OFF ON ON OFF OFF

56 OFF OFF OFF ON ON ON OFF OFF

57 ON OFF OFF ON ON ON OFF OFF

58 OFF ON OFF ON ON ON OFF OFF

59 ON ON OFF ON ON ON OFF OFF

60 OFF OFF ON ON ON ON OFF OFF

61 ON OFF ON ON ON ON OFF OFF

62 OFF ON ON ON ON ON OFF OFF

63 ON ON ON ON ON ON OFF OFF

64 OFF OFF OFF OFF OFF OFF ON OFF

65 ON OFF OFF OFF OFF OFF ON OFF

66 OFF ON OFF OFF OFF OFF ON OFF

67 ON ON OFF OFF OFF OFF ON OFF

68 OFF OFF ON OFF OFF OFF ON OFF

69 ON OFF ON OFF OFF OFF ON OFF

70 OFF ON ON OFF OFF OFF ON OFF

71 ON ON ON OFF OFF OFF ON OFF

72 OFF OFF OFF ON OFF OFF ON OFF

73 ON OFF OFF ON OFF OFF ON OFF

74 OFF ON OFF ON OFF OFF ON OFF

75 ON ON OFF ON OFF OFF ON OFF

76 OFF OFF ON ON OFF OFF ON OFF

77 ON OFF ON ON OFF OFF ON OFF

78 OFF ON ON ON OFF OFF ON OFF

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

C3461M (7/09) 31

Page 32

SPECTRA

ADDRESS

79 ON ON ON ON OFF OFF ON OFF

80 OFF OFF OFF OFF ON OFF ON OFF

81 ON OFF OFF OFF ON OFF ON OFF

82 OFF ON OFF OFF ON OFF ON OFF

83 ON ON OFF OFF ON OFF ON OFF

84 OFF OFF ON OFF ON OFF ON OFF

85 ON OFF ON OFF ON OFF ON OFF

86 OFF ON ON OFF ON OFF ON OFF

87 ON ON ON OFF ON OFF ON OFF

88 OFF OFF OFF ON ON OFF ON OFF

89 ON OFF OFF ON ON OFF ON OFF

90 OFF ON OFF ON ON OFF ON OFF

91 ON ON OFF ON ON OFF ON OFF

92 OFF OFF ON ON ON OFF ON OFF

93 ON OFF ON ON ON OFF ON OFF

94 OFF ON ON ON ON OFF ON OFF

95 ON ON ON ON ON OFF ON OFF

96 OFF OFF OFF OFF OFF ON ON OFF

97 ON OFF OFF OFF OFF ON ON OFF

98 OFF ON OFF OFF OFF ON ON OFF

99 ON ON OFF OFF OFF ON ON OFF

100 OFF OFF ON OFF OFF ON ON OFF

101 ON OFF ON OFF OFF ON ON OFF

102 OFF ON ON OFF OFF ON ON OFF

103 ONONONOFFOFFONONOFF

104 OFF OFF OFF ON OFF ON ON OFF

105 ON OFF OFF ON OFF ON ON OFF

106 OFF ON OFF ON OFF ON ON OFF

107 ON ON OFF ON OFF ON ON OFF

108 OFF OFF ON ON OFF ON ON OFF

109 ON OFF ON ON OFF ON ON OFF

110 OFF ON ON ON OFF ON ON OFF

111 ON ON ON ON OFF ON ON OFF

112 OFF OFF OFF OFF ON ON ON OFF

113 ON OFF OFF OFF ON ON ON OFF

114 OFF ON OFF OFF ON ON ON OFF

115 ONONOFFOFFONONONOFF

116 OFF OFF ON OFF ON ON ON OFF

117 ON OFF ON OFF ON ON ON OFF

118 OFF ON ON OFF ON ON ON OFF

119 ON ON ON OFF ON ON ON OFF

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

32 C3461M (7/09)

Page 33

SPECTRA

ADDRESS

120 OFF OFF OFF ON ON ON ON OFF

121 ONOFFOFFONONONONOFF

122 OFF ON OFF ON ON ON ON OFF

123 ON ON OFF ON ON ON ON OFF

124 OFF OFF ON ON ON ON ON OFF

125 ON OFF ON ON ON ON ON OFF

126 OFF ON ON ON ON ON ON OFF

127 ONONONONONONONOFF

128 OFF OFF OFF OFF OFF OFF OFF ON

129 ON OFF OFF OFF OFF OFF OFF ON

130 OFF ON OFF OFF OFF OFF OFF ON

131 ON ON OFF OFF OFF OFF OFF ON

132 OFF OFF ON OFF OFF OFF OFF ON

133 ON OFF ON OFF OFF OFF OFF ON

134 OFF ON ON OFF OFF OFF OFF ON

135 ONONONOFFOFFOFFOFFON

136 OFF OFF OFF ON OFF OFF OFF ON

137 ON OFF OFF ON OFF OFF OFF ON

138 OFF ON OFF ON OFF OFF OFF ON

139 ON ON OFF ON OFF OFF OFF ON

140 OFF OFF ON ON OFF OFF OFF ON

141 ON OFF ON ON OFF OFF OFF ON

142 OFF ON ON ON OFF OFF OFF ON

143 ONONONONOFFOFFOFFON

144 OFF OFF OFF OFF ON OFF OFF ON

145 ON OFF OFF OFF ON OFF OFF ON

146 OFF ON OFF OFF ON OFF OFF ON

147 ON ON OFF OFF ON OFF OFF ON

148 OFF OFF ON OFF ON OFF OFF ON

149 ON OFF ON OFF ON OFF OFF ON

150 OFF ON ON OFF ON OFF OFF ON

151 ON ON ON OFF ON OFF OFF ON

152 OFF OFF OFF ON ON OFF OFF ON

153 ONOFFOFFON ONOFFOFFON

154 OFF ON OFF ON ON OFF OFF ON

155 ON ON OFF ON ON OFF OFF ON

156 OFF OFF ON ON ON OFF OFF ON

157 ON OFF ON ON ON OFF OFF ON

158 OFF ON ON ON ON OFF OFF ON

159 ONONONONONOFFOFFON

160 OFF OFF OFF OFF OFF ON OFF ON

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

C3461M (7/09) 33

Page 34

SPECTRA

ADDRESS

161 ON OFF OFF OFF OFF ON OFF ON

162 OFF ON OFF OFF OFF ON OFF ON

163 ON ON OFF OFF OFF ON OFF ON

164 OFF OFF ON OFF OFF ON OFF ON

165 ON OFF ON OFF OFF ON OFF ON

166 OFF ON ON OFF OFF ON OFF ON

167 ONONONOFFOFFONOFFON

168 OFF OFF OFF ON OFF ON OFF ON

169 ON OFF OFF ON OFF ON OFF ON

170 OFF ON OFF ON OFF ON OFF ON

171 ON ON OFF ON OFF ON OFF ON

172 OFF OFF ON ON OFF ON OFF ON

173 ON OFF ON ON OFF ON OFF ON

174 OFF ON ON ON OFF ON OFF ON

175 ONONONONOFFONOFFON

176 OFF OFF OFF OFF ON ON OFF ON

177 ON OFF OFF OFF ON ON OFF ON

178 OFF ON OFF OFF ON ON OFF ON

179 ON ON OFF OFF ON ON OFF ON

180 OFF OFF ON OFF ON ON OFF ON

181 ON OFF ON OFF ON ON OFF ON

182 OFF ON ON OFF ON ON OFF ON

183 ON ON ON OFF ON ON OFF ON

184 OFF OFF OFF ON ON ON OFF ON

185 ONOFFOFFON ON ONOFFON

186 OFF ON OFF ON ON ON OFF ON

187 ON ON OFF ON ON ON OFF ON

188 OFF OFF ON ON ON ON OFF ON

189 ON OFF ON ON ON ON OFF ON

190 OFF ON ON ON ON ON OFF ON

191 ONONONONONONOFFON

192 OFF OFF OFF OFF OFF OFF ON ON

193 ON OFF OFF OFF OFF OFF ON ON

194 OFF ON OFF OFF OFF OFF ON ON

195 ON ON OFF OFF OFF OFF ON ON

196 OFF OFF ON OFF OFF OFF ON ON

197 ON OFF ON OFF OFF OFF ON ON

198 OFF ON ON OFF OFF OFF ON ON

199 ON ON ON OFF OFF OFF ON ON

200 OFF OFF OFF ON OFF OFF ON ON

201 ON OFF OFF ON OFF OFF ON ON

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

34 C3461M (7/09)

Page 35

SPECTRA

ADDRESS

202 OFF ON OFF ON OFF OFF ON ON

203 ON ON OFF ON OFF OFF ON ON

204 OFF OFF ON ON OFF OFF ON ON

205 ON OFF ON ON OFF OFF ON ON

206 OFF ON ON ON OFF OFF ON ON

207 ONONONONOFFOFFONON

208 OFF OFF OFF OFF ON OFF ON ON

209 ON OFF OFF OFF ON OFF ON ON

210 OFF ON OFF OFF ON OFF ON ON

211 ON ON OFF OFF ON OFF ON ON

212 OFF OFF ON OFF ON OFF ON ON

213 ON OFF ON OFF ON OFF ON ON

214 OFF ON ON OFF ON OFF ON ON

215 ONONONOFFONOFFONON

216 OFF OFF OFF ON ON OFF ON ON

217 ONOFFOFFON ONOFFON ON

218 OFF ON OFF ON ON OFF ON ON

219 ON ON OFF ON ON OFF ON ON

220 OFF OFF ON ON ON OFF ON ON

221 ON OFF ON ON ON OFF ON ON

222 OFF ON ON ON ON OFF ON ON

223 ONONONONONOFFONON

224 OFF OFF OFF OFF OFF ON ON ON

225 ON OFF OFF OFF OFF ON ON ON

226 OFF ON OFF OFF OFF ON ON ON

227 ON ON OFF OFF OFF ON ON ON

228 OFF OFF ON OFF OFF ON ON ON

229 ON OFF ON OFF OFF ON ON ON

230 OFF ON ON OFF OFF ON ON ON

231 ONONONOFFOFFONONON

232 OFF OFF OFF ON OFF ON ON ON

233 ON OFF OFF ON OFF ON ON ON

234 OFF ON OFF ON OFF ON ON ON

235 ONONOFFONOFFONONON

236 OFF OFF ON ON OFF ON ON ON

237 ON OFF ON ON OFF ON ON ON

238 OFF ON ON ON OFF ON ON ON

239 ON ON ON ON OFF ON ON ON

240 OFF OFF OFF OFF ON ON ON ON

241 ON OFF OFF OFF ON ON ON ON

242 OFF ON OFF OFF ON ON ON ON

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

C3461M (7/09) 35

Page 36

SPECTRA

ADDRESS

243 ONONOFFOFFONONONON

244 OFF OFF ON OFF ON ON ON ON

245 ONOFFONOFFONONONON

246 OFF ON ON OFF ON ON ON ON

247 ON ON ON OFF ON ON ON ON

248 OFF OFF OFF ON ON ON ON ON

249 ONOFFOFFONONONONON

250 OFF ON OFF ON ON ON ON ON

251 ON ON OFF ON ON ON ON ON

252 OFF OFF ON ON ON ON ON ON

253 ON OFF ON ON ON ON ON ON

254 OFF ON ON ON ON ON ON ON

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

SWITCH SETTING

36 C3461M (7/09)

Page 37

Specifications

ELECTRICAL

(Dome Drive Only)

Input Voltage 18 to 32 VAC; 24 VAC nominal

Input Power

24 VAC 23 VA nominal (indoor, without heater)

24 VDC 0.7 A nominal (indoor, without heater)

Fuse 1.25 A

Auxiliary Outputs 2

Alarm Inputs 7

Relay Contacts AUX 1

Type Form C Open collector transistor output

Voltage Low voltage (<40 V) 32 VDC maximum

Current 2 A maximum 150 mA maximum

AUDIO

Streaming Bidirectional: full or half duplex

Input/Output Terminal block, analog for microphone and speaker;

Compression G.711 PCM 8 bit, 8 kHz mono at 64 kbit/s

22 to 27 VDC; 24 VDC nominal

73 VA nominal (outdoor, with heater)

3 A nominal (outdoor, without heater)

AUX 2 Output

600-ohm differential; 1 Vp-p maximum signal level

C3461M (7/09) 37

Page 38

IN-CEILING

Construction

Back Box Plastic

Dome Drive Aluminum, thermoplastic

Lower Dome Acrylic

Cable Entry (Back Box) 0.75-inch conduit fitting

Pan Movement 360° continuous pan rotation

Vertical Tilt Unobstructed +2° to -92°

Manual Pan/Tilt Speeds*

Pan 0.1° to 80°/sec manual operation, 150°/sec turbo

Tilt 0.1° to 40°/sec manual operation

Preset Speeds

Pan 400°/sec

Tilt 200°/sec

Environment

In-Ceiling Indoor

Environmental In-Ceiling Outdoor

Operating Temperature

In-Ceiling Indoor 32° to 122°F (0° to 50°C)

Environmental In-Ceiling (Assumes no wind chill factor)

Maximum 140°F (60°C) absolute maximum; 122°F (50°C) sustained

Minimum -60°F (-51.1°C) absolute minimum; prevents icing at sustained

Weight (approximate)

Back Box

In-Ceiling Indoor 1.50 lb (0.68 kg)

Environmental In-Ceiling 2.10 lb (0.95 kg)

Dome Drive 3.30 lb (1.48 kg)

Lower Dome

In-Ceiling Indoor 0.20 lb (0.09 kg)

Environmental In-Ceiling 0.60 lb (0.27 kg)

*For variable-speed operation, an appropriate controller is required. With fixed-speed controllers, pan/tilt

speed is 20°/sec. The CM6700/CM6800 controller with the KBD200A keyboard has programmable fixed

speeds.

maximum

minimum of -50°F (-45°C); de-ices 0.1 inch (2.5 mm) within

3 hours after power-up

38 C3461M (7/09)

Page 39

HEAVY-DUTY IN-CEILING

Construction

Back Box Aluminum

Dome Drive Aluminum, thermoplastic

Lower Dome Clear polycarbonate, 0.090-inch thick

Cage Thickness 0.12 x 0.30-inch cast stainless steel

Cage Color Black, for maximum discreetness

Cable Entry (Back Box) 0.75-inch conduit fitting

Pan Movement 360° continuous pan rotation

Vertical Tilt +2° to -92°

Manual Pan/Tilt Speeds*

Pan 0.1° to 80°/sec manual operation, 150°/sec turbo

Tilt 0.1° to 40°/sec

Preset Speeds

Pan 400°/sec

Tilt 200°/sec

Environment Indoor only

Operating Temperature 32° to 122°F (0° to 50°C)

Weight (approximate)

Back Box 2.17 lb (0.98 kg)

Dome Drive 3.30 lb (1.48 kg)

Lower Dome 0.20 lb (0.09 kg)

In-Ceiling 1.60 lb (0.73 kg)

In-Ceiling with Cage 3.60 lb (1.63 kg)

*For variable-speed operation, an appropriate controller is required. With fixed-speed controllers, pan/tilt

speed is 20°/sec. The CM6700/CM6800 controller with the KBD200A keyboard has programmable fixed

speeds.

C3461M (7/09) 39

Page 40

PENDANT

Construction

Back Box Aluminum

Dome Drive Aluminum, thermoplastic

Lower Dome Acrylic

Cable Entry (Back Box) Through 1.5-inch NPT pendant mount

Pan Movement 360° continuous pan rotation

Vertical Tilt Unobstructed +2° to -92°

Manual Pan/Tilt Speeds*

Pan 0.1° to 80°/sec manual operation, 150°/sec turbo

Tilt 0.1° to 40°/sec manual operation

Preset Speeds

Pan 400°/sec

Tilt 200°/sec

Environment Indoor/outdoor

Operating Temperature

Standard Pendant (Assumes no wind chill factor)

Maximum 140°F (60°C) absolute maximum in shade; 122°F (50°C) sustained

Minimum 25°F (-4°C) sustained minimum

Environmental Pendant (Assumes no wind chill factor)

Maximum 140°F (60°C) absolute maximum; 122°F (50°C) sustained

Minimum -60°F (-51.1°C) absolute minimum; prevents icing at sustained

Weight (approximate)

Back Box

Standard Pendant 2.40 lb (1.09 kg)

Environmental Pendant 3.50 lb (1.59 kg)

Dome Drive 3.30 lb (1.48 kg)

Lower Dome 0.20 lb (0.09 kg)

*For variable-speed operation, an appropriate controller is required. With fixed-speed controllers, pan/tilt

speed is 20°/sec. The CM6700/CM6800 controller with the KBD200A keyboard has programmable fixed

speeds.

maximum in shade; 113°F (45°C) absolute maximum in direct

sunlight; 95°F (35°C) sustained maximum in direct sunlight

maximum

minimum of -50°F (-45°C); de-ices 0.1 inch (2.5 mm) within 3

hours after power-up

40 C3461M (7/09)

Page 41

HEAVY-DUTY PENDANT

Construction

Back Box Aluminum

Dome Drive Aluminum, thermoplastic

Lower Dome Clear polycarbonate, 0.09-inch thick

Cage Thickness 0.12 x 0.30-inch cast stainless steel

Cage Color Black, for maximum discreetness

Cable Entry (Back Box) Through 1.5-inch NPT pendant mount

Pan Movement 360° continuous pan rotation

Vertical Tilt +2° to -92°

Manual Pan/Tilt Speeds*

Pan 0.1° to 80°/sec manual operation, 150°/sec turbo

Tilt 0.1° to 40°/sec

Preset Speeds

Pan 400°/sec

Tilt 200°/sec

Environment Indoor/outdoor

Operating Temperature

Pendant 32° to 140°F (0° to 60°C) absolute maximum; 32° to 122°F (0° to

Environmental Pendant (Assumes no wind chill factor)

Maximum 140°F (60°C) absolute maximum; 122°F (50°C) sustained

Minimum -60°F (-51.1°C) absolute minimum; minimal icing at sustained

Weight (approximate)

Back Box

Pendant 4.45 lb (2.02 kg)

Environmental Pendant 4.75 lb (2.15 kg)

Dome Drive3.3 lb (1.48 kg)

Lower Dome

Pendant 1.83 lb (0.83 kg)

Pendant with Cage 3.83 lb (1.74 kg)

*For variable-speed operation, an appropriate controller is required. With fixed-speed controllers, pan/tilt

speed is 20°/sec. The CM6700/CM6800 controller with the KBD200A keyboard has programmable fixed

speeds.

50°C) sustained maximum

maximum

minimum of -50°F (-45°C); prevents icing at sustained minimum

of -40°F (-40°C); de-ices 0.1 inch (2.5 mm) within 3 hours after

power-up

C3461M (7/09) 41

Page 42

STAINLESS STEEL

REVISION HISTORY

Manual # Date Comments

C3461M 7/09 Original version.

Pelco, the Pelco logo, Camclosure, Digital Sent ry, Endura, Esprit, ExSite, Genex, Intelli-M, Legacy, and Spectra are registered trademarks of Pelco, Inc.

Spectra III is a trademark of Pelco, Inc.

DLP is a registered trademark of Texas Instruments Incorporated.

All product names and services identified t hroughout this document are trademarks or registered trademarks of their respective companies.

The absence of a trademark or registered trad emark from this document does not constitute a waiver of intellectual property rights.

© Copyright 2009, Pelco, Inc. All rights reserve d.

Construction

Back Box 316 stainless steel; gray, polyurethane powder-coated finish

Dome Drive Aluminum, thermoplastic

Lower Dome Trim Ring 316 stainless steel; black, polyurethane powder-coated finish

Bubble Acrylic, clear or smoked

Cable Entry (Back Box) Through 1.5-inch NPT pendant mount

Pan Movement 360° continuous pan rotation

Vertical Tilt Unobstructed +2° to -92°

Manual Pan/Tilt Speeds*

Pan 0.1° to 80°/sec manual operation, 150°/sec turbo

Tilt 0.1° to 40°/sec manual operation

Preset Speeds

Pan 400°/sec

Tilt 200°/sec

Environment Indoor/outdoor

Operating Temperature Assumes no wind chill factor; for detailed test conditions, contact

Maximum 140°F (60°C) absolute maximum; 122°F (50°C) sustained

Minimum -60°F (-51.1°C) absolute minimum; minimal icing at sustained

Weight (approximate)

Back Box 4.75 lb (2.15 kg)

Dome Drive 3.3 lb (1.48 kg)

Lower Dome 1.83 lb (0.83 kg)

*For variable-speed operation, an appropriate controller is required. With fixed-speed controllers, pan/tilt

speed is 20°/sec. The CM6700/CM6800 controller with the KBD200A keyboard has programmable fixed

speeds.

Pelco.)

maximum

minimum of -50°F (-45°C); prevents icing at sustained minimum

of -40°F (-40°C); de-ices 0.1 inch (2.5 mm) within 3 hours after

power-up

42 C3461M (7/09)

Page 43

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, an y merchandise proved defective in material or workmanship for a period of one year after the date of

shipment.

Exceptions to this warranty are as noted below:

• Five years:

– Fiber optic products

– TW3 000 Series unshielded twisted pair (UTP) transmission products

– CC370 1H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models

• Three years:

– Pe lco-branded fixed camera models (CCC1390H Series, C10DN Series, C10CH Series, IP3701H Series, and IX Series)

– EH150 0 Series enclosures

®

– Spectra

IV products (including Spectra IV IP)

– Cam closure

– DX Se ries digital video recorders, DVR5100 Series digital video recorders, Digital Sentry

– En dura

– Ge nex® Series products (multiplexers, server, and keyboard)

– PMCL200/300/400 Series LCD monitors

• Two years:

– S tandard varifocal, fixed focal, and motorized zoom lenses.

– DF5/DF8 Series fixed dom e products

– Lega cy® Series integrated positioning systems

– Spectra III™, Spectra Mini, Spectra Mini IP, Esprit®, ExSite®, and PS20 scanners, including when u sed in continuous motion applications.

– Espr it Ti and TI2500 Series thermal imaging products

– Espr it and WW5700 Series window wiper (excluding wiper blades).

– CM 6700/CM6800/CM9700 Series matrix

– Di gital Light Processing (DLP®) displays (except lamp and color wheel). The lamp and color wheel will be covered for a period of 90 days.

– Inte lli-M

•One year:

– Video cassette record ers (VCRs), except video heads. Video heads will be covered for a period of six months.

• Six months:

– Al l pan and tilts, scanners, or preset lenses used in continuous motion applicatio ns (preset scan, tour, and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to a Pelco designated locatio n. Repairs made necessary by reason of misuse, alteration, normal wear, or accident are no t covered under

this warranty.

Pelco assumes no risk and shall be subject to no li ability for damages or loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to

the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event will Pelco be liable for any special, incidental, or

consequential damages (including loss of use, loss of profit, and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with spe cific legal rights. The Dealer may also have additional right s, which are subject to variation from state

to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall un der the warranty conditions stated above, please include a written

explanation with the product wh en returned.

Method of return shipment shall be the same or equal to the method by which the item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if

returned for credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and freight should be prepaid

®

Series (IS, ICS, IP) integrated camera systems

recorders, and NVR300 Series network video r ecorders

®

Series distributed network-based video pro ducts

The air filter is not covered under warranty.

®

eIDC controllers

®

Series hardware products, DVX Series digital vide o

12-23-08

Page 44

www.pelco.com

Pelco, Inc. Worldwide Headquarters 3500 Pelco Way Clovis, California 93612 USA

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

Loading...

Loading...