PEERLESS SCT Series, SCT-05, SC-05, SC-06, SCT-06 Installation, Operation & Maintenance Manual

...Page 1

SC/SCT

Gas/Off Boilers

Installation,

Operation b

Maintenance

Manual

PEERLESS _

CAST IRON BOILERS

Page 2

6 Sizes

" Oil, Gas or Comb|nhtion G_s

Knockdown (Factory Assembled Split Block Sections)

or Packaged Hot Water or Steam Boilers

5-10 Sections 3.0 to 5.5 GPH Input Up to 83.7% Combustion Efficiency

Forced Draft Venting

• Only Requires a Three Foot Vent Above the Roof

High Efficiency Power Burners

• Choice ofBeckett, Carlin, Gordon-Piatt, Power Flame or Webster

Top Flue Outlet

• Includes Locking Damper

Large Water Content, Wet Base Section Design

• Ideal for Steam and Large Volume Hot Water Jobs

Steel Push Nipples

• Provide a Permca_cmt Water Tight S_al Belween Sections

• Unaj]'_cted by Petroleum and Other Conlaminanis

Easy to Clean

• Flueways ca_ be Cleanedj-rom Either ih__I_Ji Side or Top

Safety Controls

• Probe or Float Type Low Water Cut-OffAvailable

Tankless Coils

• For Domestic Hot Water Production on Hot Water Boilers

Deluxe Insulated Enameled Steel Jacket

• Reduces Boiler Heat Loss

• Honeywell Operating Controls

• Manual Reset High Limit Control

• LWCO on Packaged Boilers

• Tankless Coils

• Various Burner Options and Voltages

• FM and IRI Control Systems

Peerless Heal_,r Company is pleased Io offer o_lL" of lhe illosf compreh_nsiw! warranty programs

in the inda,slry. All Peerless conmlercial cast iron boilers include a fi_ll, one y_'ar warranty. A [_I_-_-_r'SS®

limited, fen year warr(mty ol_ the ca.sl troll sections is provided Jbr all commercial lint water and

steam boilers. Five cmd len-year t_xIt!llded wanantics on paris and labor are flow auailable. CAST IRON BOILERS

Ple_e Colisttll I)(,('rless [ ]_'_llt,r ColllpCllly.lbr COTil[)lt_l_! warrallly iqtbrnlalioll.

Peerless Heater Company • 231 North Walnut Street • Boyertown, PA 19512-i021 • 610-367 2153 • wv_v.peerless-heater.com

FAB SC R3 (11/02 1 5M)

Pnnted in U S A

Page 3

pr=-r=-RLESS

CAST IRON BOILERS

Series SC/SCT

Semi-Commercial

• Packaged or Knockdown

Forced Draft Venting

Power Burner

• Oil, Gas, Gas/Oil

J Steam or Hot Water Boilers

Optional Tankless Coils

Available from the factory as knockdown

split blocks or completely packaged

assembled units, with steel push nipples, for

easy installation.

The top or side clean out features allow

for easier cleaning, maintaining highest

operating efficiency.

Pressurized, forced draft firing requires

only a three foot vent above the roof,

without the need for a chimney, for

simple installations.

The SC and the SOT hot water boilers

provide optional tankless domestic hot water

openings for versatility.

The SCT designation indicates that an

optional, larger, tankless domestic hot water

coil can be installed in its specially designed

rear section for steam or hot water

boilers, insuring ample domestic hot

water production.

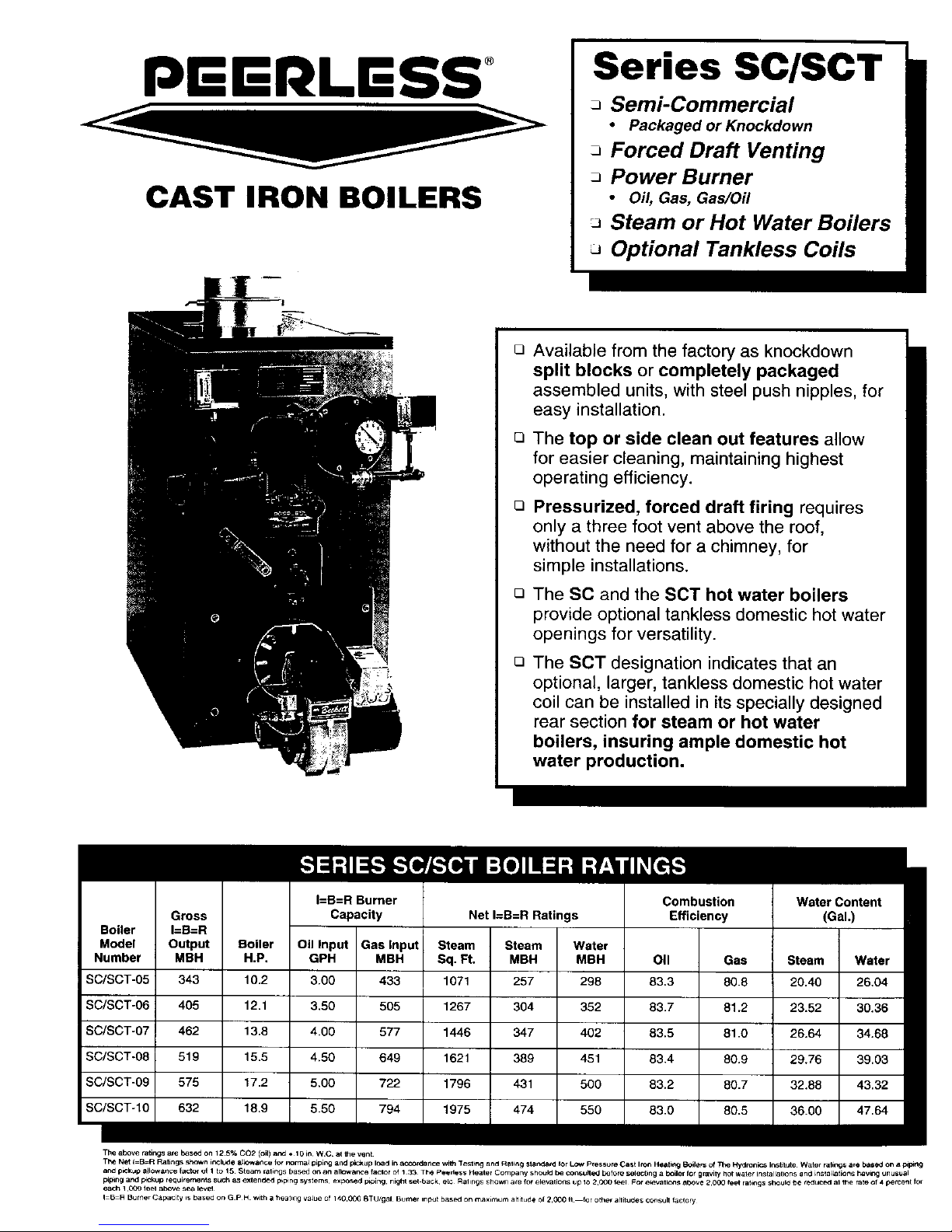

I=B=R Burner Combustion Water Content

Capacity Net I=B=R Ratings Efficiency (Gal.)

Uoiler I=B=H

Model Output Boiler Oil Input Gas Input Steam Steam Water

Number MBH H.P. GPH MBH Sq. Ft. MBH MBH Oil Gas Steam Water

SC/SCT-05 343 10.2 3.00 433 1071 257 298 83.3 80.8 20.40 26.04

SC/SCT-06 405 12.1 3,50 505 1267 304 352 83.7 81.2 23.52 30.36

SC/SCT-07 462 13.8 4.00 577 1446 347 402 83.5 81.0 26.64 34.68

SC/SCT-O8 519 15.5 4.50 649 1621 389 451 83.4 80.9 29.76 39.03

SC/SCT-09 575 17.2 5.00 722 1796 431 500 83.2 80.7 32.88 43.32

SC/SCT-10 632 18.9 5.50 794 474 550 83.0 80.5 36.00

The above catings are based on 12 5% CO2 (oil) and + 10 in W.C at Ihe vent

TPe Net I-B=R Ra_ngs shown include a_k:wance fo_ notma_ p_ping and p_c_up load in accordance w_h T_st_g and Ral_g st_e_la f d for LOW pressure Cast IrOn Heatbng Boilers of The V_/dren_s Institute Water rahngs are base_l on a p_F.ng

and p_kup a_lowan_ factor of 1 to 15 Steam ral_ngs based on aM ar_owaece factor of I 33 The Peedess Heater Company should b_ consu,ed before selectbng a boiler for grarity hot wale_ installations and _ns_a_ations havir_ unusual

F.plng and p_kup requkements such as extended p_p_ng systems¸ exposed piping¸ night set back. et¢ Rallngs shown a_e for e_evaticns up IO 2C00 lear For e_evations above 2.OO0 feet ratings sheul_ be _educed at the rate of 4 petce_t for

each 1C_O leer above sea level

I B R Burner Capacity is based on G P H with a heat,rig va_ue of 14OOOO @TU/gal Burner ,nput base_ on maximum altitude of 2¸O0O _ _or o_e_ aWtud_ ¢onsu_ _actory

Page 4

Cast Iron Block

Steam Boitar.

Tankless Copper Water Heater is located inthe upper front

nipple port when installed on a Hot Water Boiler.

Both Heaters may be installed on a Water Boiter when a

greater volume of Domestic Hot Water is desired.

Cast Iron Section

E

H

I

J

K

L

M _/2"

p

Q 11/4"

(05-06)

l_/z"

(07-10)

Steam Water

3/4" Low Limit Control N/A

3/4" Press• Gauge, Oper. N/A

Cont. & Limit Cont.

3/4" N/A Operating Control

3/4" N/A Limit Control

1/4" N/A Theraltimeter

Gauge Glass & N/A

Low Water Cutoff

Return Optional Return

Secondary Probe Secondary Probe

Low Water Cutoff Low Water Cutoff

Safety Valve Relief Valve

Return Return

R 3/4" Drain Cock Drain Cock

s

T

3/4" N/A Optional High Limit

3/4" Primary Probe N/A

Low Water Cutoff

Boiler

Model

Number

SC/SCT-O5

SC/SCT-06

SC/SCT-07

SC/SCT-08

SC/SCT-09

SC/SCT-IO

Width

"A"

22_/2"

22_/z"

22V2"

22_/2"

22V2"

22V2"

Length

"B"

24_/2"

28_'4"

33"

371/4"

41V2"

453/,"

Top to Floor

-C-

431/4"

43V4"

43V4"

43%"

43V4"

43%"

of Flue

"D"

10"

10"

10"

10"

10"

10"

of Flue

"E"

131/4"

15%"

171_"

19%"

21¾"

23%"

Size

-F-

7"

9"

9"

9"

10"

10"

Tappings

-G-

17%"

21-%"

257/_"

301/e"

34_'B"

38%"

Tapped Inter.

"G1"

17_/_6"

Page 5

I",11".JI_(e]lV]f_e]_F_l

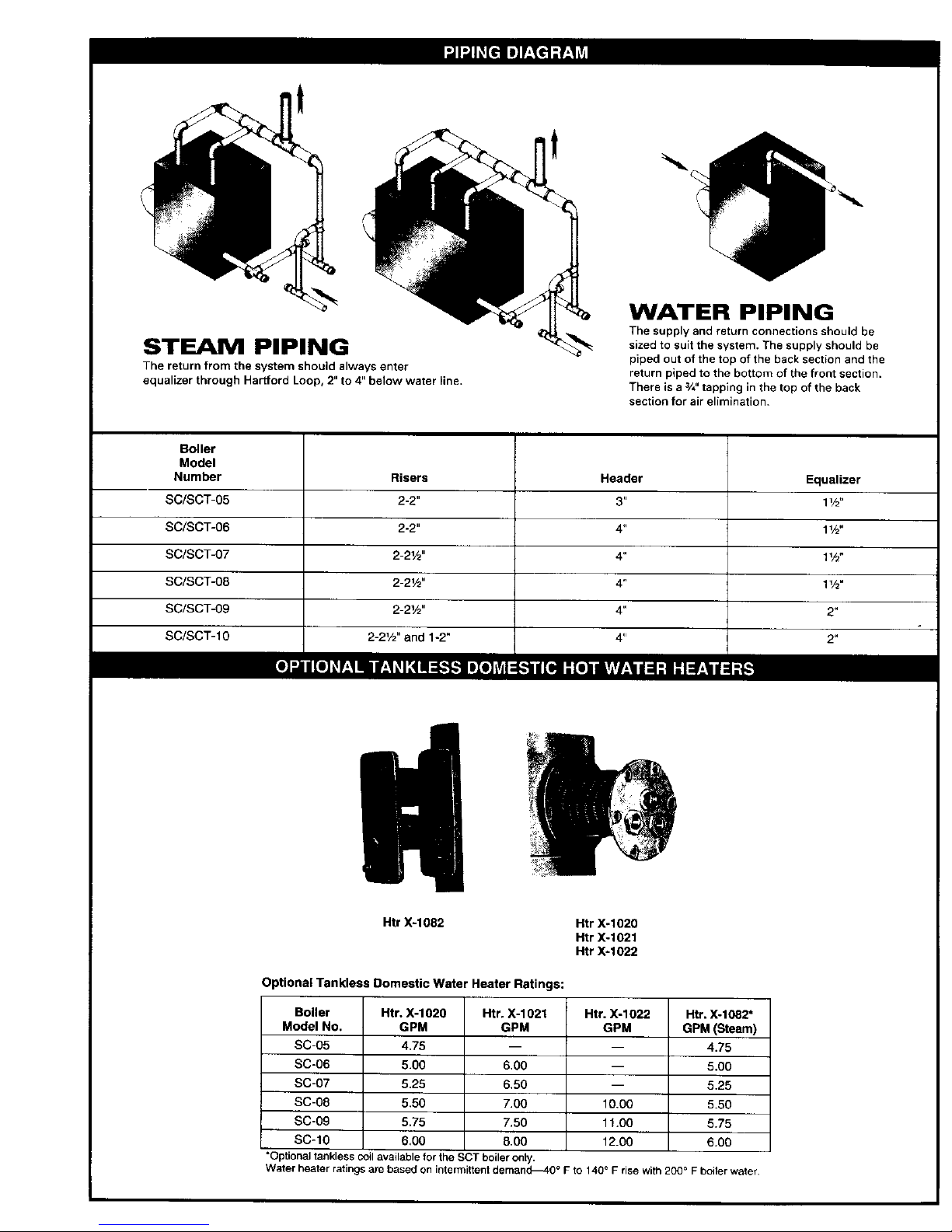

STEAM PIPING

The return from the system should always enter

equalizer through Har[ford Loop, 2" to 4" below water line.

%.

WATER PIPING

The supply and return connections should be

sized to suit the system. The supply should be

piped out of the top of the back section and the

return piped to the bottom of the front section.

There is a 3/4"tapping in the top of the back

section for air elimination.

Boiler

Model

Number

SC/SCT-05

SC/SCT-06

SC/SCT-07

SC/SCT-08

SC/SCT-09

SC/SCT-lO

Header

Htr X-1082 Htr X-1020

Htr )(-1021

Htr )(-1022

Optional Tankless Domestic Water Heater Ratings:

Boiler Htr. X-1620 Htr. X-1021 Htr. X-1022 Htr. X-1082"

Model No. GPM GPM GPM GPM (Steam)

SC-05 4.75 -- -- 4.75

SC-O6 5.00 6.00 -- 5.00

SC-07 5.25 6.50 -- 5.25

SC-08 5.50 7.00 10.00 5.50

SC-09 5.75 7.50 11.06 5.75

SC-IO 6,00 8.00 12.00 6.00

*Optionaltankless coil availablefor the SCT boiler only.

Water heater ratings are based on intermittent demands40 ° F to 140° F rise with 200 ° F boiler water.

Page 6

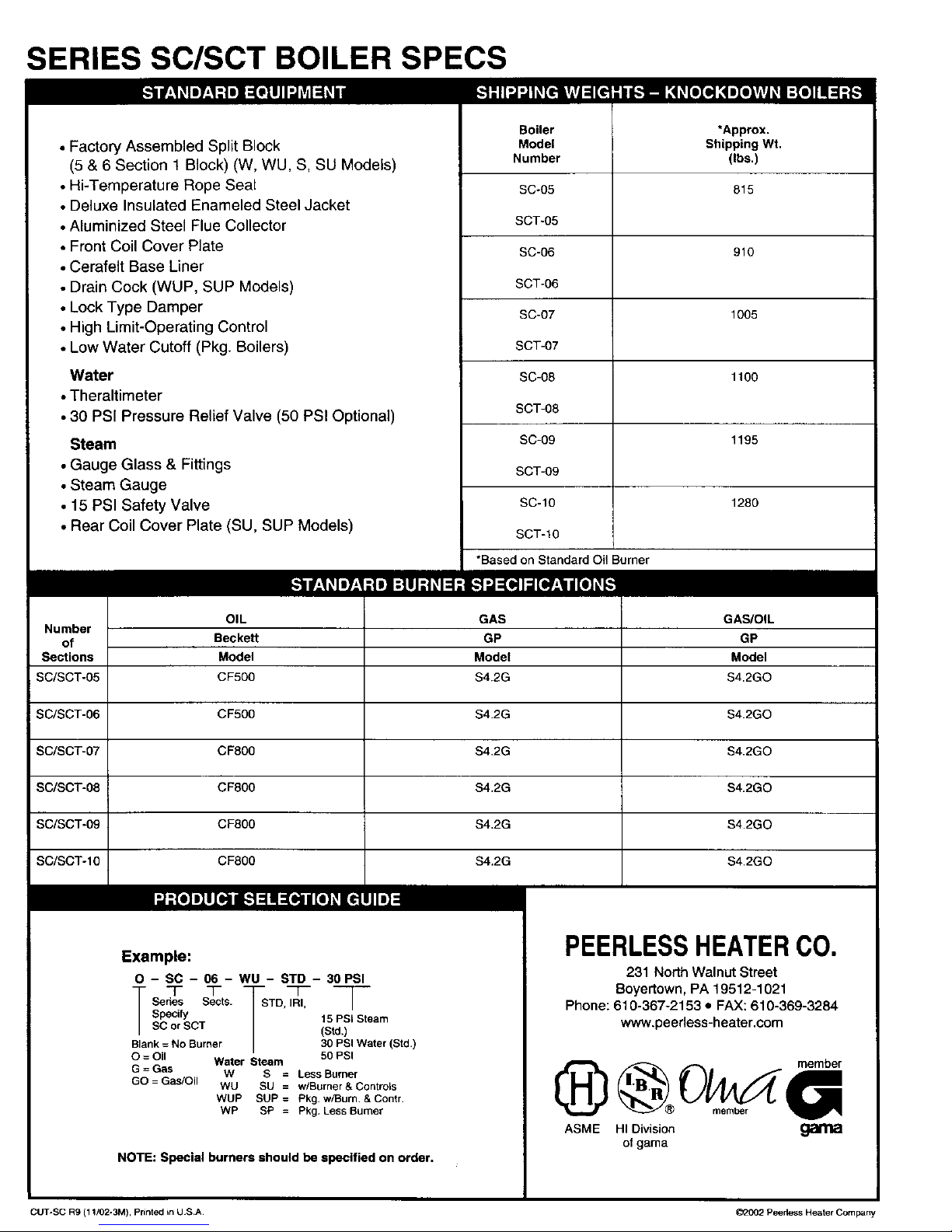

SERIES SC/SCT BOILER SPECS

_.'tl:llll41lUJl'.lll=!lli _[ 17|=l[tllltl |[!l[o[_olol

• Factory Assembled Split Block

(5 & 6 Section t Block) (W, WU, S, SU Models)

• Hi-Temperature Rope Seal

• Deluxe Insulated Enameled Steel Jacket

• Aluminized Steel Flue Collector

• Front Coil Cover Plate

• Cerafelt Base Liner

• Drain Cock (WUP, SUP Models)

• Lock Type Damper

• High Limit-Operating Control

• Low Water Cutoff (Pkg. Boilers)

Water

• Theraltimeter

• 30 PSI Pressure Relief Valve (50 PSI Optional)

Steam

• Gauge Glass & Fittings

• Steam Gauge

• 15 PSI Safety Valve

• Rear Coil Cover Plate (SU, SUP Models)

Boiler

Model

Number

SC-05

SCT-05

SC-06

SCT-06

SC-O7

SCT-07

SC-O8

SCT-08

SC-09

SCT-09

SC-10

SCT-10

*Based on Standard Oil Burner

*Approx.

Shipping Wt.

(Ibe.)

815

910

1005

1100

1195

1280

_..'L=-'il = " " " _o1117,,_

OIL GAS GAS/OiL

Number

of Beckett GP GP

Sections Model Model Model

SC/SCT-05 CF500 S4.2G S4.2GO

SC/SCT-06 CF500 $4.2G S4.2GO

SC/SCT-07 CF800 $4.2G S4.2GO

SC/SCT-08 CF800 $4.2G $4.2GO

SC/SCT-09 CF800 $4.2G $4.2GO

SC/SCT-10 CF800 $4.2G $4.2GO

Example:

O - SC - 06- WU - STD - 30PSI

-- T T -- q T

Series Sects. STD, IRI,

/

Specify 15 PSI Steam

BCor SCT (Std,)

Blank = No Burner 30 PSI Water (Std.)

O = Oil Water Steam 50 PSI

G =Gas W S = LessBurner

GO = Gas!Oil WU SU = w/Burner& Controls

WUP SUP =Pkg. w/Bum.& Contr.

WP SP = Pkg.LessBurner

NOTE: Special burners should be specified on order.

PEERLESSHEATERC0.

231 North Walnut Street

Boyertown, PA 19512-1021

Phone: 610-367-2153 ,, FAX: 610-369-3284

www.peerless-heater.com

IHD@Ou -"

o_, li

ASME HI Division galTia

o1gama

cLrr-sc R9 (11/02-3M), printed in USA 02002 Peedess Heater Company

Page 7

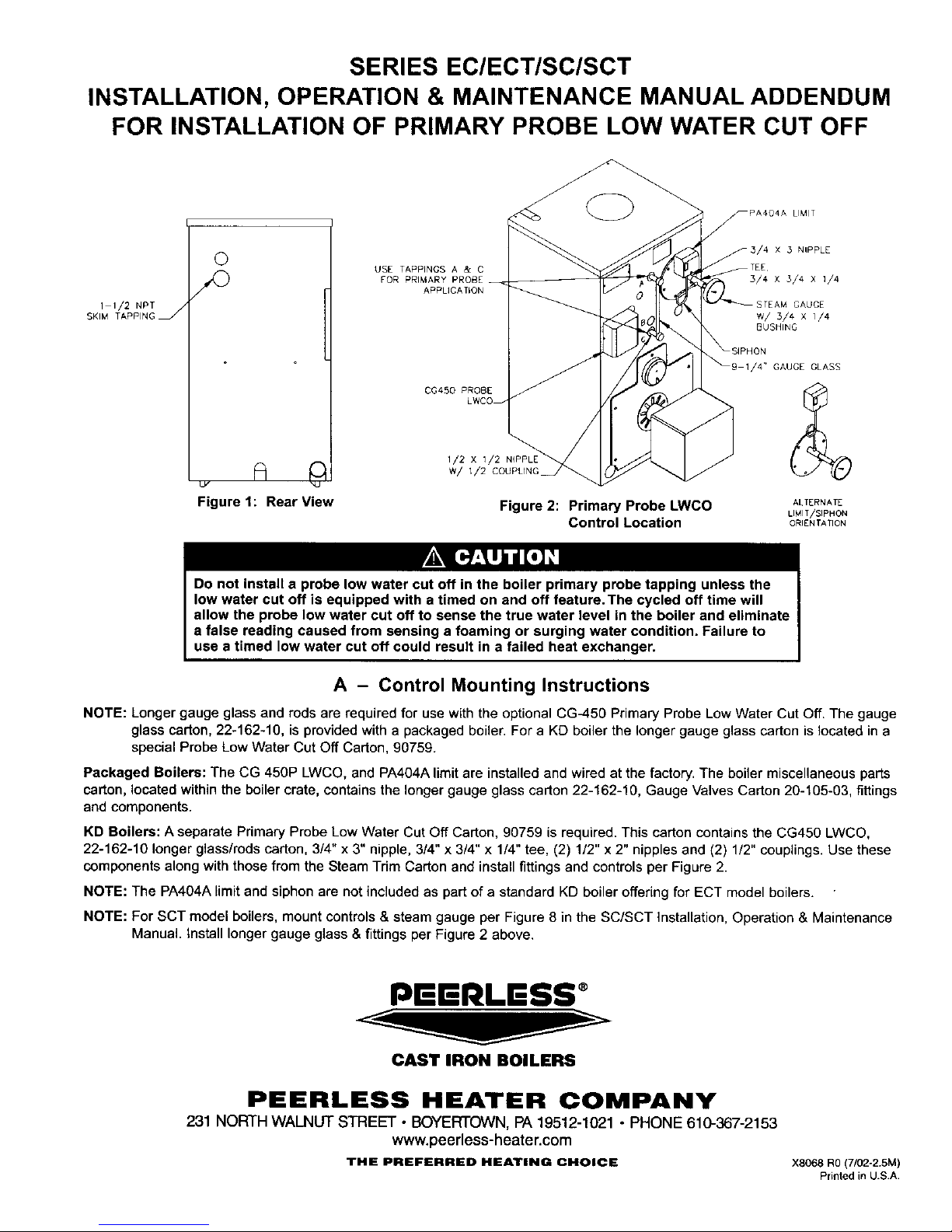

SERIES EC/ECT/SC/SCT

INSTALLATION, OPERATION & MAINTENANCE MANUAL ADDENDUM

FOR INSTALLATION OF PRIMARY PROBE LOW WATER CUT OFF

LIMIT

1 1/2 NPT/

SKIM TAPPING_

0

is

. A C

Figure 1: Rear View

USE TAPPINGS A & C

FOR

APPUCATION

CG450 PROBE

1/2 X 1/2

W/ 1/2 COUPLING

x 3 NIPPLE

TEE

3/4 x 3/4 x 1/4

STEAM GAUGE

w/ 5/4 x 1/4

BUSHINO

_9 1/4" GAUGE GLASS

g

Figure 2: Primary Probe LWCO

Control Location

ALTERNATE

LIMIT/SIPHON

ORIENTATION

IrAqi["_iJ-l[']_l

Do not install a probe low water cut off in the boiler primary probe tapping unless the

low water cut off is equipped with a timed on and off feature. The cycled off time will

allow the probe low water cut off to sense the true water level in the boiler and eliminate

a false reading caused from sensing a foaming or surging water condition. Failure to

use a timed low water cut off could result in a failed heat exchanger.

A - Control Mounting Instructions

NOTE: Longer gauge glass and rods are required for use with the optional CG-450 Primary Probe Low Water Cut Off. The gauge

glass carton, 22-162-10, is provided with a packaged boiler. For a KD boiler the longer gauge glass carton is located in a

special Probe Low Water Cut Off Carton, 90759.

Packaged Boilers: The CG 450P LWCO, and PA404A limit are installed and wired at the factory. The boiler miscellaneous parts

carton, located within the boiler crate, contains the longer gauge glass carton 22-162-10, Gauge Valves Carton 20-105-03, fittings

end components.

KD Boilers: A separate Primary Probe Low Water Cut Off Carton, 90759 is required. This carton contains the CG450 LWCO,

22-162-10 longer glass/rods carton, 3/4" x 3" nipple, 3/4" x 3/4" x 1/4" tee, (2) 1/2" x 2" nipples and (2) 1/2" couplings. Use these

components along with those from the Steam Trim Carton and install fittings and controls per Figure 2.

NOTE: The PA404A limit and siphon are not included as part of a standard KD boiler offering for ECT model boilers.

NOTE: For SCT model boilers, mount controls & steam gauge per Figure 8 in the SC/SCT Installation, Operation & Maintenance

Manual. Install longer gauge glass & fittings per Figure 2 above.

PEEI LESS ®

CAST IRON BOILERS

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET • BOYERTOWN, PA 19512-1021 • PHONE 610-367-2153

www.peerless-heater.com

THE PREFERRED HEATING CHOICE

X8068 R0 (7/02-2.5M)

Printed in U.S.A.

Page 8

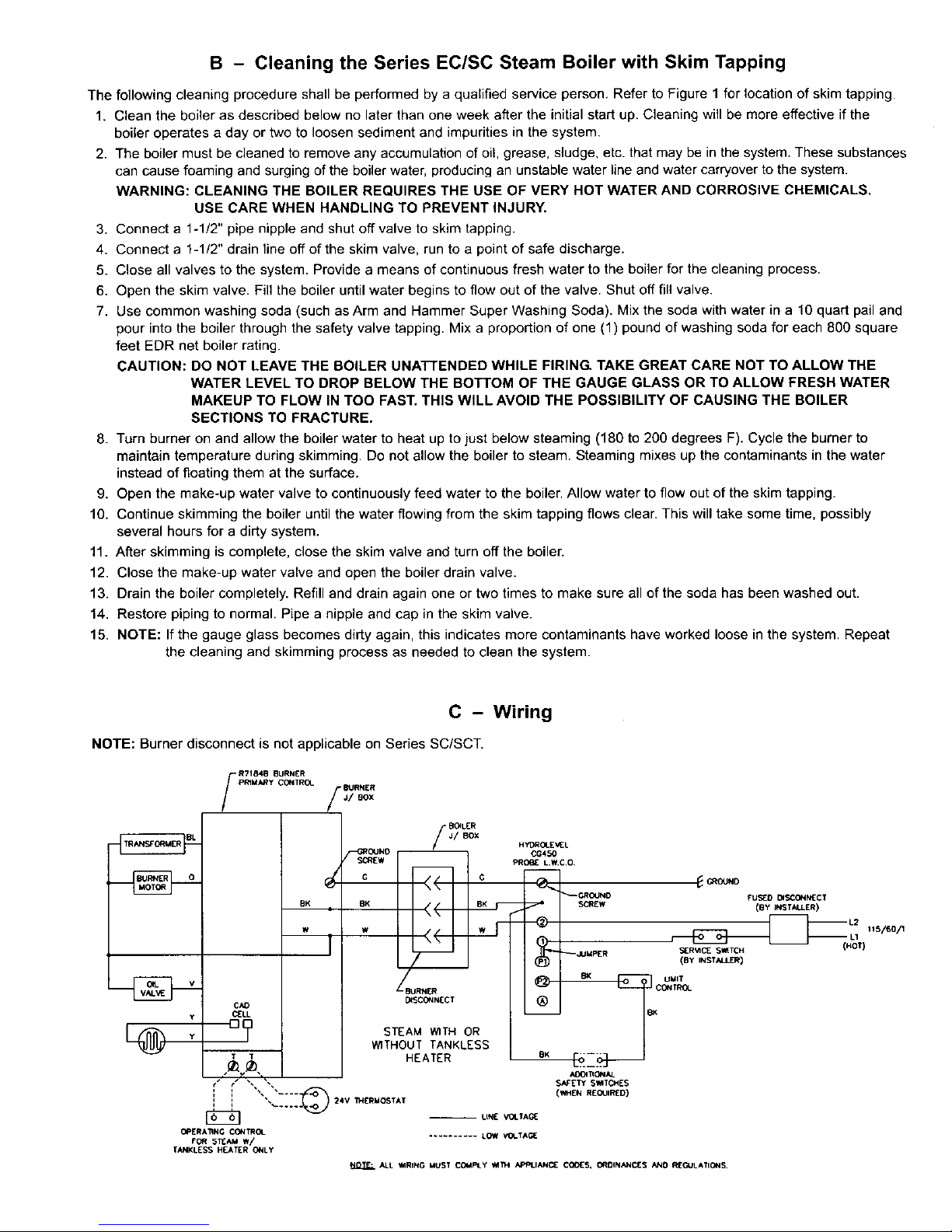

B - Cleaning the Series EC/SC Steam Boiler with Skim Tapping

The following cleaning procedure shall be performed by a qualified service person. Refer to Figure 1 for location of skim tapping.

1. Clean the boiler as described below no later than one week after the initial start up. Cleaning will be more effective if the

boiler operates a day or two to loosen sediment and impurities in the system,

2. The boiler must be cleaned to remove any accumulation of oil, grease, sludge, etc. that may be in the system. These substances

can cause foaming and surging of the boiler water, producing an unstable water line and water carryover to the system.

WARNING: CLEANING THE BOILER REQUIRES THE USE OF VERY HOT WATER AND CORROSIVE CHEMICALS,

USE CARE WHEN HANDLING TO PREVENT INJURY.

3. Connect a 1-1/2" pipe nipple and shut off valve to skim tapping.

4. Connect a 1-1/2" drain line off of the skim valve, run to a point of safe discharge.

5. Close all valves to the system. Provide a means of continuous fresh water to the boiler for the cleaning process.

6. Open the skim valve. Fill the boiler until water begins to flow out of the valve. Shut off fill valve.

7. Use common washing soda (such as Arm and Hammer Super Washing Soda). Mix the soda with water in a 10 quart pail and

pour into the boiler through the safety valve tapping. Mix a proportion of one (1) pound of washing soda for each 800 square

feet EDR net boiler rating.

CAUTION: DO NOT LEAVE THE BOILER UNATTENDED WHILE FIRING, TAKE GREAT CARE NOT TO ALLOW THE

WATER LEVEL TO DROP BELOW THE BOTTOM OF THE GAUGE GLASS OR TO ALLOW FRESH WATER

MAKEUP TO FLOW IN TOO FAST. THIS WILL AVOID THE POSSIBILITY OF CAUSING THE BOILER

SECTIONS TO FRACTURE.

8. Turn burner on and allow the boiler water to heat up to just below steaming (180 to 200 degrees F). Cycle the burner to

maintain temperature during skimming. Do not allow the boiler to steam. Steaming mixes up the contaminants in the water

instead of floating them at the surface.

9. Open the make-up water valve to continuously feed water to the boiler. Allow water to flow out of the skim tapping.

10. Continue skimming the boiler until the water flowing from the skim tapping flows clear. This will take some time, possibly

several hours for a dirty system.

11. After skimming is complete, close the skim valve and turn off the boiler.

12. Close the make-up water valve and open the boiler drain valve.

13. Drain the boiler completely. Refill and drain again one or two times to make sure all of the soda has been washed out.

14. Restore piping to normal. Pipe a nipple and cap in the skim valve.

15. NOTE: If the gauge glass becomes dirty again, this indicates more contaminants have worked loose in the system. Repeat

the cleaning and skimming process as needed to clean the system.

C - Wiring

NOTE: Burner disconnect is not applicable on Series SC/SCT.

Y

R7184B BURNER /

pRIMARy CONTROL BURNER

J/ BOX

BOILER

J/ BOX

G ¢

BK L BK BK

W

CA{) Ol$C_l [¢

[] STEAM WITH OR

WITHOUT TANKLESS

/ HEATER

I/" I _Y ", •

1 "_ .... o_ _4V 1M[RMOSTAT

OPERATING CONTROL

FOr( 5TEAM W/

TANKLESS H£ATER ONLY

H YDROLE _IEL

CG450

(BY INST_LU.£R)

--JUMPER )_£R'_ SIq TCH

(BY INSTALLER)

SAFETY SMTQdES

-- LIN[ VOLTAG[

.......... tOW VOLTA_

ALt _MRING MUST COMPty _T_I APPLIANOE COOLS, ORDINANCES AN0 R[GULATIONS

Page 9

INSTALLATIONINSTRUCTIONS- SERIESSCandSCT

Readcarefullybeforebeginningwork.Itwillsavetime.Studytheincludeddrawings.

Theequipmentshallbe installedinaccordancewiththoseinstallationregulationsinforceinthelocalareawheretheinstallationisto be

made.Theseshallbecarefullyfollowedin al!cases.Authoritieshavingjurisdictionshallbe consultedbeforeinstallationsare made,

A- ACCESSIBILITYCLEARANCES

1-- Toprovideforreasonableconditionsof accessibilityfor servicing,the followingminimumclearancesarerecommendedbetweenthe

boilerand adjacentwallsorotherappliances--24"onthe rightside,36"on theleftside,and30"inthefrontandrearoftheboiler.

B- AIRFORCOMBUSTIONANDVENTILATION

1-- Becertainadequatefacilitiesareavailabletoprovideairforsatisfactorycombustionandventilation,

2-- AppliancesLocatedin UnconfinedSpaces.

a. Installationsin unconfinedspaceswithconventionalconstructionandlargeareassuchasbasements,thesupplyof airfor

combustionandventilationcan usuallybeconsideredadequate.

3-- ApplianceLocatedinConfinedSpaces

a. Ifallair forcombustionandventilationistocomefromwithinthe building;twoopenings,oneneartheceilingandonenearthe

floorof the boilerroomshallbeprovidedwiththeminimumfreeareaofeachopeningequalto 140sq.in. pergallonofoilburned.

b. Ifallairfor combustionandventilationistocomefromoutsidethebuilding;twoopenings,oneneartheceilingandonenearthe

floorof the boilerroomshallbeprovidedwiththeminimumfreeareaofeachopeningequalto35sq. in.pergallonofoil burned.

Ifductsareusedtoconveytheair,areasof 35sq.in.pergallonofoilburnedforverticalductsor70sq.in.pergallonofoilburnedfor

horizontalductsaretobeprovided.Ductsshallhavethe sameareaasthefreeareaoftheopeningstowhichtheyareconnected.

C- SETrlNGUP BOILER

1-- ModelsSC/SCT-05andSC/SCT-06areshippedina singleblock.Theboilersectionson modelsSC/SCT-07thruSC/SCT-10are

shippedintwo parts.

2-- Provideagoodlevelfoundation,locatedascloseaspossibleto the centerof the heatingsystemandto the chimneyorventsystem.

TheheatingsurfaceoftheSC/SCTSeriesBoilersisdesignedtobecleanedfromeitherthetopor leftoftheunit.Allowadequate

clearanceon theleftof unit if servicingisto bedonefromthe side.

CAUTION'.THISBOILERIS NOTAPPROVEDFORUSEONCOMBUSTIBLEFLOORING.

3-- Placeeachblockofsectionson thefoundationwithnippleportsfacingeachother.RefertoFigure1.

4-- Cleannippleportswithanacceptablecleaningsolventtoremoveprotectivecoating.Makecertaintherearenoburrsaroundthe

outsideedgeoftheports.

5-- Spreada thincoatof Peerlessnipplesealerinthe nippleports.Neveron nipples.

6-- Insertthepushnipples.Makecertaintheyarecleanandfreefromburrs.

7-- Applya thin coatof nipplesealertotheropegroove.PresstheHiTempRopeintoropegroove.

8-- Arrangebothblockssothat protrudingnipplesentertheopenports.Caremustbetakento keepnipplesstraightandblocksaligned.

9-- Insertdrawrodsthroughthenippleports.Makecertainthatthe3/4"drawrodisusedonthe largenipple.Payparticularattentionto

theplacementofthedrawwashers.SeeFigure1.

10-- Beforestartingdraw,oilthethreadsandbetweenthenutsandwashers.

11-- Tightenthehexnutsanddrawboilerevenlyuntilthesmallpadson eachsectionjusttouch,

12-- Afterboileris drawn,removedrawrodsandcut5"from6!/4"threadedend.Insertrodthruthelugson eachendsectionandtighten

thehexnutshandtight.

13- Makeupwaterconnectiontoboilerandfill. Checkto makecertainthereisnoleakageatthenippleportconnection.

14-- RemovefluecollectorandHiTempRope(Items8and9,Figure4)fromcarton.Layrope(Item8)ontopof boileragainstbead

provided.Placefluecollectorontop of ropeandattachto boilerwith1/4"-20x 1-3/4"studsandnuts.Drawdownsnugly.OnModels05

and06,removecombustionchanbercoverplate(Item3)andattachflameobservationassembly(item4)to CombustionChamber

CoverPlate(item3).RemoveanddiscardroundcastironcoverdoorX-1031locatedontheinsideofthe coverplate.

15- Removeclean-outcoverplatesandinsulation(7). Eachclean-outcoverplateis attachedtotheboilerbyusingtwocarriagebolts,

nutsandwashers(6).Installthecarriageboltsintothe notchat the top andbottomof eachclean-outopening,thensecurethemwith

a flatwasherandsteelnutas shownin Figure2lockingthemintoplace.Presstheclean-outplatewithinsulationovertheprotruding

carriageboltsuntiltheboltspunchthroughtheinsulationsoa flatwasherandbrassnutcan beinstalled.Tightendownnutssnugly

compressingtheinsulationtoforma goodsealaroundthe clean-outopening.

Page 10

REAR SPLIT LARGE

BLOCK ASSEMBLY _ PUSH NIPPLE

\

HI TEMP

DRAW-UP WASHER \ ROPE

FRONT SPLIT

BLOCK ASSEMBLY

)RAW-UP WASHER

X -100t

3/4" DRAW ROD

DRAW-UP WASHER

X - 1009

SMALL

PUSH NIPPLE _

LUGS

- UP WASHER

X - 1009

I/2" DRAW ROD

FIGUREI

SIDE CLEAN-0UT

COVER PLATE

W/INSULATION

HEX.

BRASS HEX. NUT

FLAT WASHERS

CARRIAGE BOLT

5/16 UNO X 1 3/4." Le.

FIGURE2

x

2

Page 11

D- JACKETASSEMBLY

1-- Referto Page4 forexplodedview.Attachthebackjacketpanel(19)tobossesonmiddleofbacksectionwithtwo1.4"x%"truss

headmachinescrews(20)provided.The backpanelhas two%0"dia.holescloseto the centerof the panel.

2-- Locateceramicblanketlinerandinstallincombustionchamberfloor,placingbackedgeof blanketagainstbottomedgeoftargetwall.

3-- Placethefrontjacketpanel(23)ontheblockandattachthecombustionchambercoverplateassembly(3).

4-- Attachtherightsidejacketpanel(22)tothefrontandbackpanelswithsheetmetalscrews.

NOTE:ONSERIESSCTBOILERS,THEOPTIONALWATERHEATER(17)MUSTBEINSTALLEDBEFORETHELEFTSIDE

JACKETPANELISATTACHED.

5-- Ifwaterheateris used,removeknockoutpieceinleftsidejacketpanel(21)beforeinstalling.Attachleftsidejacketpanelinthe

samemannerastherightsidepanel.

6-- Attachthetop panel.Thetopismadeintwopieces(24&25).Jointhetwopiecestogetherwithsheetmetalscrews.Securetop

paneltofront,backandsideswithsheetmetalscrews.

7-- WaterHeater

a. SeriesSCWaterBoilers- Seechartbelowforratingsandusage.

InstallWaterHeater(13)when required,inlargeopeninginfrontof boiler.SeeFigure3forsuggestedpiping.

b. SeriesSCTSteamBoilers- Seechartbelowforratings.

InstallWaterHeater(17)when requiredinlargeopeninginbacksection.SeeFigure3Aforsuggestedpiping.

TanklessWaterHeaterRatings

BOILER

MODEL HEATERNO.* HEATERNO.* HEATERNO.* HEATERNO.

NUMBER X-1020-G.PM. X-1021-G.P.M X-1022-G.P.M X-1082(Steam)

SC/SCT-05 4.75 -- -- 4.75

SC/SCT-06 5.0 6.0 -- 5.00

SC/SCT-07 5.25 6.5 -- 5.25

SC/SCT-08 5.5 7.0 10.0 5.50

SC/SCT-09 5.75 7.5 11.0 5.75

SC/SCT-10 6.0 8.0 12.0 6.00

Waterheaterratingsarebasedonintermittentdemand--40°Fto 140°Fwith200°Fboiler

watertemperature. * Usedonwaterboilersonly.

Whenwaterheaterisnotemployed,covertheheateropeningwithcoverplate(12)or (16).

BESURERUBBERGASKETISIN PLACEBETWEENCOVERPLATEOR WATERHEATERPLATEANDBOILERSECTION.

HIGH TEMPERATURE _ _M_R_U_

HOT WATER_ HEATER _T _E

MIXED TAPPING _4,,oo_moL

WATER

MIXER

CONTROL

FIGURE3 FIGURE3A

DANGER:Installmixingvalveinhotwatersupplypiping.Watertemperatureover125°Fcancauseseverebumsinstantlyordeathfromscalds.

Page 12

___.

:10

\1

2

6

26

"---22

Page 13

SERIESSC/SCT

ItemNo. Description PartNo. SCiSCT-05SCiSCT-06SCiSCT-07

1 BlockAssembly- SC-05ModelOnly X-1096 X

BlockAssembly- SC-06ModelOnly X-1096-1 X

BlockAssembly- SCT-05ModelOnly X-1097 X

BlockAssembly- SCT-06ModelOnly X-1097-1 X

FrontSplitBlockAssembly SC-1018 X

FrontSplitBlockAssembly SC-1018-1

BackSplitBlockAssembly SC-1019 X

BackSplitBlockAssembly SC-1019-1

BackSplitBlockAssembly SC-1019-2

BackSplitBlockAssembly(SCTModel) SC-1020 X

BackSplitBlockAssembly(SCTModel) SC-1021-1

BackSplitBlockAssembly(SCTModel) SC-1021-2

2 TargetWall X-3019 X X X

3 CombustionChamberCoverPlate X-1060-1 X X X

4 FlameObservationAssembly SC-1012 X X X

5 5/16"-18x 2-1/4"Studsw/Nuts- 5Req'd X-1061 X X X

6 5/16"-18x 1-3/4"CarriageBoltw/Nut X X X

7 SideClean-OutCoverPlate X-1085 X X X

8 HighTemp.Rope1/2"Dia.64"Long X

HighTemp.Rope1/2"Dia.72"Long X

HighTemp.Rope1/2"Dia.80"Long X

HighTemp.Rope1/2"Dia.88"Long

HighTemp.Rope1/2"Dia.96"Long

HighTemp.Rope1/2"Dia.104"Long

9 FlueCollectorandDamperAssembly SC-5005-5 X

FlueCollectorandDamperAssembly SC-5005 X

FlueCollectorandDamperAssembly SC-5005-1 X

FlueCollectorandDamperAssembly SC-5005-2

FlueCollectorandDamperAssembly SC-5005-3

FlueCollectorandDamperAssembly SC-5005-4 I

10 1/4"-20x 1-3/4"Studsw/Nuts- 2 Req'd X-5000 X X X

11 RubberGasket X-1023 X X ....._' X

_._ CoverPlate X-1059 X X X

TanklessCoil(OptionalWaterOnly) X-1020 X X ':, X

TanklessCoil(OptionalWaterOnly) X-1021 X ! X

t

_ TanklessCoil(OptionalWaterOnly) X-1022 i

14 3/8"-16x 3/4"HexHd.CapScrews- 6 Req'd X X X

15 RubberGasket(SCTModels) X-1083 X x , x

16 CoverPlate(SCTModels) X-1084 _ X X : X

17 I TanklessHeater(OptionalSCTModels) X-1082 X i X I X

18 [ 3/8"-16x3/4"HexHd. CapScrews -X X X

(SCTModels)- 8Req'd

19 Ba[Back------------_acke!Panel SC-6003_ X _ X _ X

ModelNo.

SC,/SCT.-_

X

X

X

X

X

X

X

x

X

X

X

X

X

X

X

X

X

X

X

X

SCiSCT..09

x

X

X

X

X

X

X

X

X

X

X

X

X

i X

! X

i

F

i X

X

; X

X

X

X

X

SC_-IO

x

x

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X

5

Page 14

SERIESSC/SCT

ModelNo.

ItemNo. PartNo. SCiSCT-05SC/SCT-06SCiSCT-07 SC/SCT-10

20 X X X X

21 X

X

X

X

22 X

X

23 X X

i

24 i X

X

i

i

X

X

ix x

X

Description

1/4"-20x3/8"TrussHd.Mach.Screws-

Cad.Plate- 2 Req'd

LeftSideJacketPanel

LeftSideJacketPanel

LeftSideJacketPanel

LeftSideJacketPanel

LeftSideJacketPanel

LeftSideJacketPanel

RightSideJacketPanel

RightSideJacketPanel

RightSideJacketPanel

RightSideJacketPanel

RightSideJacketPanel

RightSideJacketPanel

FrontJacketPanel

RightTopJacketPanel

RightTopJacketPanel

RightTopJacketPanel

RightTopJacketPanel

RightTopJacketPanel

RightTopJacketPane]

LeftTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

CeramicBlanketLiner-

SC-6001-5

SC-6001

SC-6001-1

SC-6001-2

SC-6001-3

SC-6001-4

SC-6002-5

SC-6002

SC-6002-1

SC-6002-2

SC-6002-3

SC-6002-4

SC-6000

SC-6005-5

SC-6005

SC-6005-1

SC-6005-2

SC-6005-3

SC-6005-4

SC-6004-5

SC-6004

SC-6004-1

SC-6004-2

SC-6004-3

SC-6004-4

50846

I

25 , X

i X

l

! x

26 14"x18%"! 14"x141/2"

I

I

, CeramicBlanketLiner- 51038

I Sizesmustbecattofit.

14"x23"

SCPaCT..08SOSOT..09

X X

X

X

X

X

X X

I

X

X

I

X

X

14"x271/4' 14"x311/2'

X

x

14"x35%"

* Sizemustbecutto fit.

Page 15

E- PIPING

DONOTPIPEBOILERUNTILAFTERJACKETISINSTALLED.

1-- See Figures5 and6forsuggestedpipingto theboiler.

2-- Makeupcoldwatersupplyconnectionto the boiler.

3-- Installpressuregaugeor theraltimeterintappingprovided.SeeFigure7.

4-- Plugall opentappingsintheboilerandfill withwater.Pressurizeboilerto45 PSIGfor30 PSIGsectionsand75 PSIGfor50 PSIG

sections.Checktomakecertainthat alljointsandfittingsare watertight.

5-- Afteralljointsandconnectionshavebeenprovenwatertight,removecoldwatersupplyandplugsfromalltappingsthataretobe

used.SeeFigure7fortappinglocations.

NOTE: IFTHISBOILERANDDISTRIBUTINGSYSTEMISUSEDINCONJUNCTIONWITHA REFRIGERATIONSYSTEM,THE

CHILLEDMEDIUMSHALLBEPIPEDIN PARALLELWITHTHEBOILERANDTHEPROPERVALVESAPPLIEDTO

PREVENTTHECHILLEDMEDIUMFROMENTERINGTHEBOILER.WHENTHEBOILERISCONNECTEDTOHEATING

COILSLOCATEDINAIR HANDLINGUNITSWHERETHEYMAYBEEXPOSEDTOREFRIGERATEDAIRCIRCULATION,

THEBOILERPIPINGSYSTEMMUSTBEEQUIPPEDWITHFLOWCONTROLVALVESOROTHERAUTOMATICMEANS

TO PREVENTGRAVITYCIRCULATIONOFTHEBOILERWATERDURINGTHECOOLINGCYCLE.

Boiler

ModelNo. Risers Header Equalizer

SC/SCT-05 2-2" 3" 11_"

SC/SCT-06 2-2" 4" 1W'

SC/SCT-07 2-21/2" 4" l_.&"

SC/SCT-08 2-21/2" 4" 11/2"

SC/SCT-09 2-21/2" 4" 2"

SC/SCT-IO 2-21,_' and 1-2" 4" 2"

Thereturnfromsystemshouldalwaysenterequalizerthrough

HartfordLoop,2"to 4" belownormalwaterline.

STEAM

FIGURE5

FIGURE6

Pipethesupplyandreturninoneoftwoways:

1. Pipethesupplyfromthetopoftherearsectionandreturntothe

bottomofthefrontsection.Usethe3/4"tappinginthetop of the

backsectionforairelimination.

2. Asan acceptablealternative,pipethe supplyfromthetop of the

frontsectionandreturntothe bottomoftherearsection.Provide

an aireliminationmeanswithinthesupplypiping.

HOTWATER

Page 16

F- OIL BURNERINSTALLATION

1-- Theoilburneris suppliedwitha mountingflangefixedinposition.

2-- Mounttheburnertothecombustionchambercoverplate(3)withfour5/16"-18x 1"studsandnutsprovided.BE SUREHITEMP

GASKETISBETWEENTHE BURNERMOUNTINGFLANGEANDTHECOMBUSTIONCHAMBERCOVERPLATE.

3-- OilBurnerSpecifications.

BECKE'n'BURNER CARLINBURNER

Boiler Burner *Nozzle Pressure

ModelNo. ModelNo. Size Lbs.

SC/SCT-05 CF-500 2.5060° B 140

SC/SCT-06 CF-500 3.00600B 140

SC/SCT-07 CF-800 3.25450P 150

SC/SCT-08 CF-800 3.7545° P 140

SC/SCT-09 CF-800 4.0030° P 150

SC/SCT-10 CF-800 4.5030° P 150

Boiler Burner *Nozzle Pressure

ModelNo, ModelNo, Size Lbs,

SC/SCT-05 201CRD 2.5060° B 140

SC/SCT-06 201CRD 3.00600B 140

SC/SCT-07 20t CRD 3.2545° SS 150

SC/SCT-08 201 CRD 3.7545° SS 140

SC/SCT-09 201CRD 4.0045° B 150

SC/SCT-10 301CRD 4.5045° B 150

GORDON-PIAI-rGASOR COMB.GAS-OILBURNERS POWERFLAMEGASORCOMB.GAS-OILBURNERS

Boiler GasBurner Gas-Oil *Nozzle Pressure

ModelNo. ModelNo. ModelNo. Size Lbs.

SC/SCT-05 $4.2-G-03 $4,2-GO-03 1.7590° B 300

SC/SCT-06 $4.2-G-03 $4.2-GO-03 2.2560° B 275

SC/SCT-07 $4.2-G-03 $4.2-GO-03 2.5060° B 275

SC/SCT-08 $4.2-G-03 $4.2-GO-03 2.7560° B 275

SC/SCT-09 $4.2-G-03 $4.2-GO-03 (2)1.5060°B 275

SC/SCT-10 $4.2-G-03 $4.2-GO-03 (2)1.7560°B 250

*NozzleSize: B= Delavan

Boiler GasBurner Gas-Oil *Nozzle Pressure

ModelNo. ModelNo, ModelNo. Size Lbs.

SC/SCT-05 CR1-G-10 CR1-GO-10 1.75900S 300

SC/SCT-06 CR1-G-10 CR1-GO-10 2.2590°S 275

SC/SCT-07 CR1-G-10 CR1-GO-10 2.5090°S 275

SC/SCT-08 CR1-G-10 CR1-GO-10 2.7590° S 275

SC/SCT-09 CR1-G-10 CR1-GO-10 3.0090° S 275

SC/SCT-10 CR1-G-10 CR1-GO-10 3.50900S 250

P/SS= Hago S= Steinen

4-- Forotherinformationpertinentto the oil burnerinstallation,seethe InstallationManualaccompanyingtheburner.

G-CONTROLS

1- Applycontrolsasfollows:

a. WaterBoilers:Installthelimitor operatingcontrol,temperature& pressuregaugeandthepressurereliefvalve.SeeFigure7for

properlocation.

b. SteamBoilers:Installpressuregauge,gaugeglasstrim andsafetyvalve.SeeFigures7 and8.Forapplicationoflowwater

cut-oftseeFigure11. ForpumpcontrolorfeederapplicationseeFigures9 and10.

Caution: Pipethedischargeofthepopsafetyvalveor reliefvalveto preventinjuryinthe eventof pressurerelief.Suggestdischarge

to bepipedtodrain.Pipefull sizeofoutlet.

H- CHIMNEYANDBREECHING

1- The SeriesSC/SCTboilersaredesignedforforceddraftfiringonly.Theboilerandflueoutletsizesproducethe requiredpressuresin

thecombustionchamberwhenoperatingatboilerrating.The boilerbreechingshouldbethefullsizeofthefluecollectoroutletand

maybe attachedto aconventionalchimneyora shortvent.A 3 ft. minimumheightofventabovetheroofis required.DONOT

SIDEWALLVENTBOILER.

2-- Whenattachedtoa conventionalchimneyanexcessdraftmaybeavailable.Ifsuchisthecase,adraftregulatorshouldbeinstalled

andsetto provideminimumdraft.The dampersuppliedshouldthen besetto providea maximumpressureof +0.1"watercolumnor

minimumof0"watercolumnattheoutletofthefluecollector.Lockdamperinplacebyuse of setscrews.

_ _AFT

DA_pEF I R£_ULATOR

MAX *0_ We

CC_LECT_

Iftheboilerbreechingis attachedtoa non-conventionalchimneyor shortstackthebreechingalsowill bepressurized.It shouldbepointed

outthat unsealedconventionalsmokepipemustnotbe usedas it will leakflue gasesat theseamsandjoints.

Whenconstructinga sealedorweldedbreechingfor the SeriesSC/SCTboilers,itisobviousa meansofdisconnecting(Flange)mustbe

providedtofacilitateremovalof the flue collectorfor verticalcleaningoftheboilerandchimney.

8

Page 17

FRONT

FIGURE7

DIMENSIONS

Top Length Rearof

BoilerBurner Number Jacket Jacket to Fire Jackettoc/I

UnitNumber of Width Length Floor Box ofFlue

WUorSU Sections "A .... B.... C.... D.... E"

SC/SCT-05 5 221/2" 24r/2" 431/_" 18%" 131/4"

SC/SCT-06 6 221/2" 28%" 431/4" 22%e" 15%"

SC/SCT-07 7 22!._" 327/8" 43!/4" 26¾" 171/2"

SC/SCT-08 8 221,_" 371/_" 43!/4" 301S/is' 19%"

SC/SCT-09 9 221/2" 41%" 431/4' 35Ve" 213/._'

SC/SCT-IO 10 221/2" 45%" 43";/4" 39sAe" 23Ve"

Distance Dist.Betw.

Flue Between FrontTap.

Size Tappings &Tap.Inter.

"F.... G.... GI"

7" 17_" --

9" 21%" --

9" 257/e" --

9" 30W' --

10" 34¾" --

10" 38%" 171,_e"

*Note:Maximum burnerlength:Beckett= 131,,_",GordonPiatt$4 = 27",Gordon PiattR =30", PowerFlameC =34", PowerFlameJ = 24', WebsterJB-1 = 30",

Size

Location N.P.T.

H ¾"

I ¾"

J ¾"

K

L

M

N

0

P

Q

R

S

T

TAPPINGLOCATIONS

Steam Water

LowLimitControl N/A

Press.Gauge,Oper. N/A

Cont.& LimitCont.

N/A OperatingControl

¾" N/A LimitControl

I,_" N/A Theraltimeter

W' GaugeGlass& N/A

LowWaterCutoff

2" Return OptionalReturn

¾" SecondaryProbe SecondaryProbe

LowWaterCutoff LowWaterCutoff

-- SafetyValve ReliefValve

1V4"on05-06 Return Return

1W' on 07-10

¾" DrainCock DrainCock

¾" N/A OptionalHighUmit

¾" PrimaryProbe N/A

LowWaterCutoff

Page 18

STEAM

3/4"

3/4" PLUGS

NOTES.'

RIGHT HAND SHOWN

LEFT HAND OPPOSITE

ALL FITTINGS MALLEABLE

314 °" 4" NIPPLE

STEAMGAUG_PRESSURETROLS

PIPINGARRANGEMENT

PLUG

REDUCING TEE

3/4", S" NIPPLE

3/4"11/4 ° HEX BUSHING

3/4 °

CROSS

314",6 ° NIPPLE

PRESSURETROL

I/4",3 ° BRASS NIPPLE

314"=3/4"°W4" REDUCING TEE

3/4" PLUG

=EDUCING TEE

STEAM GAUGE

3/4%4" NIPPLE

--3/4"° 3" NIPPLE

3/4"CR0SS

3/4"PLUG

3/_=5" NIPPLE

NOTE:

ALL FITTINGS MALLEABLE

STEAMGAUGE/PRESSURETROLS

ALTERNATEPIPINGARRANGEMENT

FIGURE8

10

Page 19

NIPPLE

I'CROSS

• . UNION

I

Illl

IIq

JACKET PANEL

,PECIAL TAPPED

INTERMEDIATE SECTION

S

"x IO" NIPPLE

INSTALL I'BLOW-OFF VALVE

I*x ,4" N _PI::'LE

UNION

NOTES:CONNECTING FITTINGS SHOWN ON THIS DRAWING

ARE TO BE SUPPLIED BY INSTALLER

ON COMB FEEDER CUT-OFF MODELS THE BURNER CUT-OFF LEVEL

IS 23/4 " BELOW NORMAL WATER LINE

FLOOR

#

FIGURE9

11

Page 20

IPPLE

LEVEL

MARA ON CASTING

r,

INSTALL I_IBLOW-OF'F VALVE

I"X 3" NIPPLE

I"G. J. UNION

I"X 4" NIPPLE

NOTE: CONN_CTING FITTINGS SHOWN ON THIS DRAWING

ARE T_ E)_ SUPPLIED BY INSTALLER

FIGURE10

12

Page 21

McD&M#67PE-2

LOWWATERCUT-OFF

B_

-CUT _F LEVEL WL

PIPE

CONNECTION

FIGURE11

I - WIRING

1-- Allalectricalwiringshallbe doneinaccordancewiththeNationalElectricalCedeandLocalRequirements.

2-- Forrecommendedwiring,See Figures12and13.

3-- Forcompleteinformationonservicingandadjustmentofcontrols,refertotheattachedcontrolspecificationsheets.

NOTE:SinglePoleSwitchesincludingthoseofSafetyControlsorProtectiveDevicesshallnotbewiredin a groundedline.

J - CLEANINGHEATINGSURFACES

NOTE:BOILERISTO BECLEANEDATLEASTONCEAYEAR.THISBOILERMAYBECLEANEDFROMTHELEFTSIDEORTOP.

1-- Turnoffallelectricalpowertoboilerbeforebeginningcleaningoperation.

2-- Ifcleaningfromtheside,removeleftjacketpanelandsideclean-outcoverplates.

3-- Ifcleaningfromthetop,removefluepipe,lefttopjacketpanelandfluecollector.

4-- Brushthefluepassageswitha wirebrushtoremoveallscaleorseatfromtheseheatingsurfaces.

5.-- Removeanyscaleorsootfromthefireboxbymeansofvacuumcleaningoranyotheravailablemoans.

NOTE:THEOILBURNERMUSTBEREMOVEDTOFACILITATETHISOPERATION.

6-- Installolean-outcoversorfluecollector,besurethegasketorropesealisingoodcondition,ifnot,replace.

7-- Installjacketpanelsandfluepipeasrequired.

13

Page 22

HY C_ EVIL. G_O'P/_0 "P

1_6C-Typ_ LWCO Ap'_._.KTK_*_

cm

r_ ..........

LOW V_L T_E ....

_ALL WIRING k_T (_fq_y TH APP_I_J_J_LE

,r--

-v--

-- q:_)

@

.__

_ WiTH TA_LESS _ATI:R

@

OR_ULA_

1::©

FORCED

HOT

WATER

Withor Without

Tankless

WaterHeater

FIGURE12

_O_" S, CRDIk_ANC£ S. ANO _-_

M(-IJO_N_t • & MILLER _Rlr_ p'_-_

_-TYF_ L_K_O r_PPLk'_ATION

HyOR_EVC,_L 650- W 5_O -p

_ LOW "/#AT T- F

W_IT[ _ X--X LI "_ V _ 5OH?. `

_ _ _ __ _

WithorWithout

TanklessWaterHeaterand

GRAV/TYHOTWATER

.k.

FIGURE13

14

Page 23

UnitNumber

BoilerBurner

WUorSU

SC/SCT-05

SC/SCT-06

SC/SCT-07

SC/SCT-08

SC/SCT-09

SC/SCT-10

Gross

I=B=R

Output

M.B.H.

343

405

462

519

575

632

Water_

K - SERIES SC AND SCT RATINGS

Net I-B-R Ratings I-B-RBurnerCapacity4

Oil Gas

Steam3 Steam G.P.H. M,B.H. Boiler

Inches

7

9

9

9

10

10

M.B.H, M.B.H,

298 257

352 304

402 347

451 389

500 431

550 474

Sq.R. Input_ Input

1071 3.00 433

1267 3.50 505

1446 4.00 577

1621 4.50 649

1796 5.00 722

1975 5.50 794

HP

10.2

12.1

13.8

15.5

17.2

18.9

VenP

Size HeightFeet

(Min.)

3

3

3

3

3

3

Apply Prefix"O" for Oil - "G"for Gas - "GO"for Gas-Oil

Ratingsbased on 121/2%CO2 Oil

1 Burner input basedon No.2 fuel oil with a heating value of 140,000 Btu per gallon.

2 Net I=B=R water ratingsbased on an allowanceof 1.15.

3 Net i=B=R steam ratingsbased on an allowanceof 1.333.

4 Consult factory beforeselecting a boiler for installationshaving unusual piping and pickup require-

ments,such as intermittent system operation,extensivepiping systems, etc.

5 A 3 foot minimum height of ventabove the roof is recommended.For any unusualventing conditions,

consult your local building code or authority.

15

Page 24

Series SC/SCT

Oil, Gas 8

Gas/Oil Boilers

Installation,

Operation r:

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and must

be affixed near the boiler for future reference.

TO THE OWNER:

This boiler should be inspected annually by a

Qualified Service Agency,

_ _ O_ Gmember

member gama

PEERLESS"

CAST IRON BOILERS

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET • BOYERTOWN, PA 19512-1021 • PHONE 610-367-2153

www.peerless-heater corn

THE PHEFEHRED HEATING CHOICE

©2002 Peerless Heater Company SC8000 R9 (6/02-2M)

Printed in U.S.A.

Loading...

Loading...