PEERLESS PUREFIRE PF-850, PUREFIRE PF-1000, PureFirePF-1500 Installation, Operation & Maintenance Manual

Page 1

PUREFIRE

®

Boilers

PF-850 PF-1000

Gas

Installation,

Operation &

Maintenance

Manual

®

Page 2

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. CODES & REGULATIONS . . . . . . . . . . . . . . . . . .2

C. ACCESSIBILITY CLEARANCES . . . . . . . . . . . . . .3

D. COMBUSTION & VENTILATION AIR . . . . . . . . . .3

E. PLANNING THE LAYOUT . . . . . . . . . . . . . . . . . . .6

2. BOILER SET-UP 7

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

B. STACKING MULTIPLE BOILERS . . . . . . . . . . . . .7

3. VENTING & AIR INLET PIPING 8

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B. APPROVED MATERIALS . . . . . . . . . . . . . . . . . . .8

C. EXHAUST VENT/AIR INTAKE

PIPE LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . .8

D. EXHAUST VENT/AIR INTAKE PIPE SIZING . . . .12

E. EXHAUST VENT/AIR INTAKE PIPE

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . .12

F. TEST PORT FOR EXHAUST SAMPLING . . . . . .13

G. COMMON VENTING MULTIPLE BOILERS . . . .13

H. BOILER REMOVAL FROM COMMON

VENTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . .14

4. WATER PIPING & CONTROLS 15

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

B. OPERATING PARAMETERS . . . . . . . . . . . . . . . .15

C. SYSTEM COMPONENTS . . . . . . . . . . . . . . . . . .15

D. SYSTEM PIPING . . . . . . . . . . . . . . . . . . . . . . . . .19

E. FREEZE PROTECTION . . . . . . . . . . . . . . . . . . . .19

F. SPECIAL APPLICATIONS . . . . . . . . . . . . . . . . . .24

5. FUEL PIPING 25

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

B. FUEL LINE SIZING . . . . . . . . . . . . . . . . . . . . . . .25

C. GAS SUPPLY PIPING – INSTALLATION . . . . . .25

D. GAS SUPPLY PIPING – OPERATION . . . . . . . . .26

E. MAIN GAS VALVES – OPERATION . . . . . . . . . .27

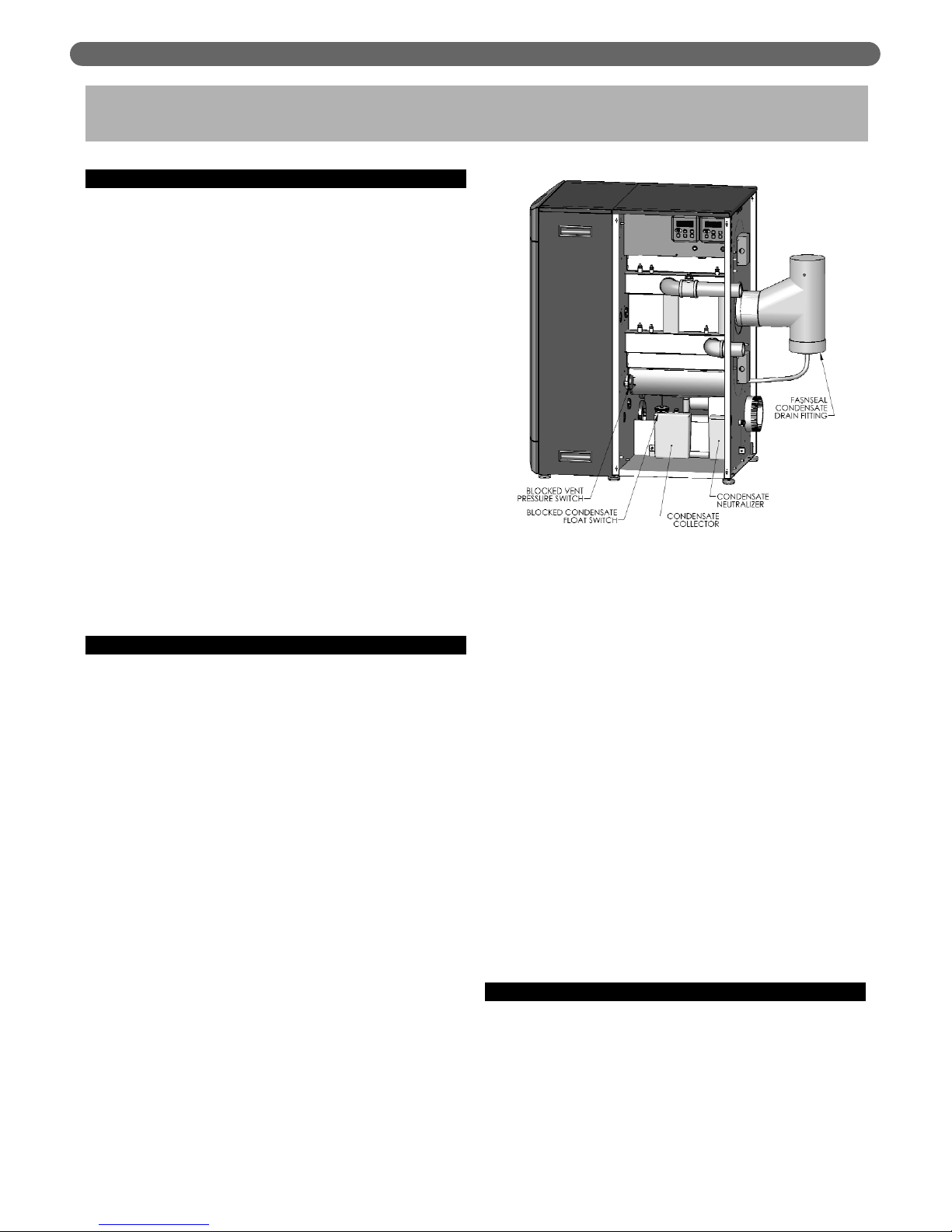

6. CONDENSATE TRAP & DRAIN SYSTEM 28

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

B. CONDENSATE SYSTEM . . . . . . . . . . . . . . . . . .28

C. CONDENSATE DRAIN PIPING . . . . . . . . . . . . . .28

7. ELECTRICAL CONNECTIONS &

INTERNAL WIRING 30

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

B. CUSTOMER CONNECTIONS . . . . . . . . . . . . . . .30

C. ZONE CIRCULATOR WIRING . . . . . . . . . . . . . . .31

D. INTERNAL WIRING . . . . . . . . . . . . . . . . . . . . . .31

8. BOILER CONTROL: OPERATION 34

A. IGNITION SEQUENCE . . . . . . . . . . . . . . . . . . . .34

B. STATUS DISPLAY . . . . . . . . . . . . . . . . . . . . . . . .36

C. USER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

D. INSTALLER MENU . . . . . . . . . . . . . . . . . . . . . . .41

E. DEFAULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

F. MULTIPLE BOILERS . . . . . . . . . . . . . . . . . . . . . .53

9. START-UP PROCEDURE 57

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

B. CHECK WATER PIPING . . . . . . . . . . . . . . . . . . .57

C. CHECK ELECTRIC POWER . . . . . . . . . . . . . . . .57

D. CHECK GAS PIPING . . . . . . . . . . . . . . . . . . . . . .57

E. CHECK OPERATION . . . . . . . . . . . . . . . . . . . . . .57

F. COMBUSTION TEST . . . . . . . . . . . . . . . . . . . . .57

G. TEST OPERATING LIMIT . . . . . . . . . . . . . . . . . .58

H. TEST HIGH LIMIT . . . . . . . . . . . . . . . . . . . . . . . .59

I. MULTIPLE BOILER SYSTEMS . . . . . . . . . . . . . .59

J. LIGHTING & OPERATING INSTRUCTIONS . . . .59

10. TROUBLESHOOTING 61

A. ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

B. BLOCKING ERRORS . . . . . . . . . . . . . . . . . . . . . .61

C. LOCKING ERRORS . . . . . . . . . . . . . . . . . . . . . . .61

D. WARNING ERRORS . . . . . . . . . . . . . . . . . . . . . .61

E. SPECIAL IGNITION/FLAME FAILURE . . . . . . . .62

F. INTERLOCKS OPEN . . . . . . . . . . . . . . . . . . . . . .62

11. MAINTENANCE 69

A. GENERAL (WITH BOILER IN USE) . . . . . . . . . .70

B. WEEKLY (WITH BOILER IN USE) . . . . . . . . . . . .70

C. ANNUALLY (BEFORE THE START OF

HEATING SEASON) . . . . . . . . . . . . . . . . . . . . . .70

D. CONDENSATE SYSTEM CLEANING

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . .70

E. COMBUSION CHAMBER COIL CLEANING

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . .71

12. BOILER DIMENSIONS & RATINGS 73

13. REPAIR PARTS 76

APPENDIX A. PIXEL DISPLAY SCREEN 86

A. STAND ALONE PIXEL DISPLAY . . . . . . . . . . . .86

B. MULTIPLE BOILER (CASCADE) PIXEL

DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

APPENDIX B. BURNER LCD STATUS

SCREENS 88

APPENDIX C. USER MENU 90

APPENDIX D. INSTALLER MENU

STRUCTURE 92

APPENDIX E. COMBUSTION TEST

RECORD 94

SERVICE LOG 95

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 3

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this manual

in the order shown. The order of these instructions has

been set in order to provide the installer with a logical

sequence of steps that will minimize potential

interferences and maximize safety during boiler

installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual special attention boxes are

provided to supplement the instructions and make special

notice of potential hazards. The definition of each of

these categories, in the judgement of PB Heat, LLC

are as follows:

USING THIS MANUAL

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

1

USING THIS MANUAL

Page 4

A. GENERAL

1. PUREFIRE®boilers are supplied completely assembled

as packaged boilers. The package should be inspected

for damage upon receipt and any damage to the unit

should be reported to the shipping company and

wholesaler. This boiler should be stored in a clean, dry

area.

2. Carefully read these instructions and be sure to

understand the function of all connections prior to

beginning installation. Contact your PB Heat, LLC

Representative for help in answering questions.

3. This boiler must be installed by a qualified contractor.

The boiler warranty may be voided if the boiler is not

installed correctly.

4. A hot water boiler installed above radiation or as

required by the Authority having jurisdiction, must be

provided with a low water fuel cut-off device either as

part of the boiler or at the time of installation.

B. CODES & REGULATIONS

1. Installation and repairs are to be performed in strict

accordance with the requirements of state and local

regulating agencies and codes dealing with boiler and

gas appliance installation.

2. In the absence of local requirements the following

should be followed:

a. ASME Boiler and Pressure Vessel Code, Section

IV - “Heating Boilers”

b. ASME Boiler and Pressure Vessel Code, Section

VI - “Recommended Rules for the Care and

Operation of Heating Boilers”

c. ANSI Z223.1/NFPA 54 - “National Fuel Gas Code”

d. ANSI/NFPA 70 - “National Electrical Code”

e. ANSI/NFPA 211 - “Chimneys, Fireplaces, Vents

and Solid Fuel Burning Appliances”

3. Where required by the authority having jurisdiction,

the installation must conform to the Standard for

Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1.

**Please read if installing in Massachusetts**

Massachusetts requires manufacturers of Side Wall

Vented boilers to provide the following information

from the Massachusetts code:

·

A hard wired carbon monoxide detector with an

alarm and battery back-up must be installed on

the floor level where the gas equipment is to be

installed AND on each additional level of the

dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment.

·

In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be

installed on the next adjacent floor level.

·

Detector(s) must be installed by qualified licensed

professionals.

·

APPROVED CARBON MONOXIDE

DETECTORS: Each carbon monoxide detector

shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

·

SIGNAGE: A metal or plastic identification plate

shall be permanently mounted to the exterior of

the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch

in size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”.

·

EXEMPTIONS to the requirements listed above:

°

The above requirements do not apply if the

exhaust vent termination is seven (7) feet or

more above finished grade in the area of the

venting, including but not limited to decks and

porches.

°

The above requirements do not apply to a

boiler installed in a room or structure separate

from the dwelling, building or structure used in

whole or in part for residential purposes.

·

This boiler installation manual shall remain with

the boiler at the completion of the installation.

See the latest edition of Massachusetts Code 248 CMR

for complete verbiage and also for additional (non-vent

related) requirements (248 CMR is available online).

If your installation is NOT in Massachusetts, please

see your authority of jurisdiction for requirements that

may be in effect in your area. In the absence of such

requirements, follow the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

2

PREINSTALLATION

1. PREINSTALLATION

Liquefied Petroleum (LP) Gas or Propane is heavier

than air and, in the event of a leak, may collect in low

areas such as basements or floor drains. The gas

may then ignite resulting in a fire or explosion.

WARNING

Page 5

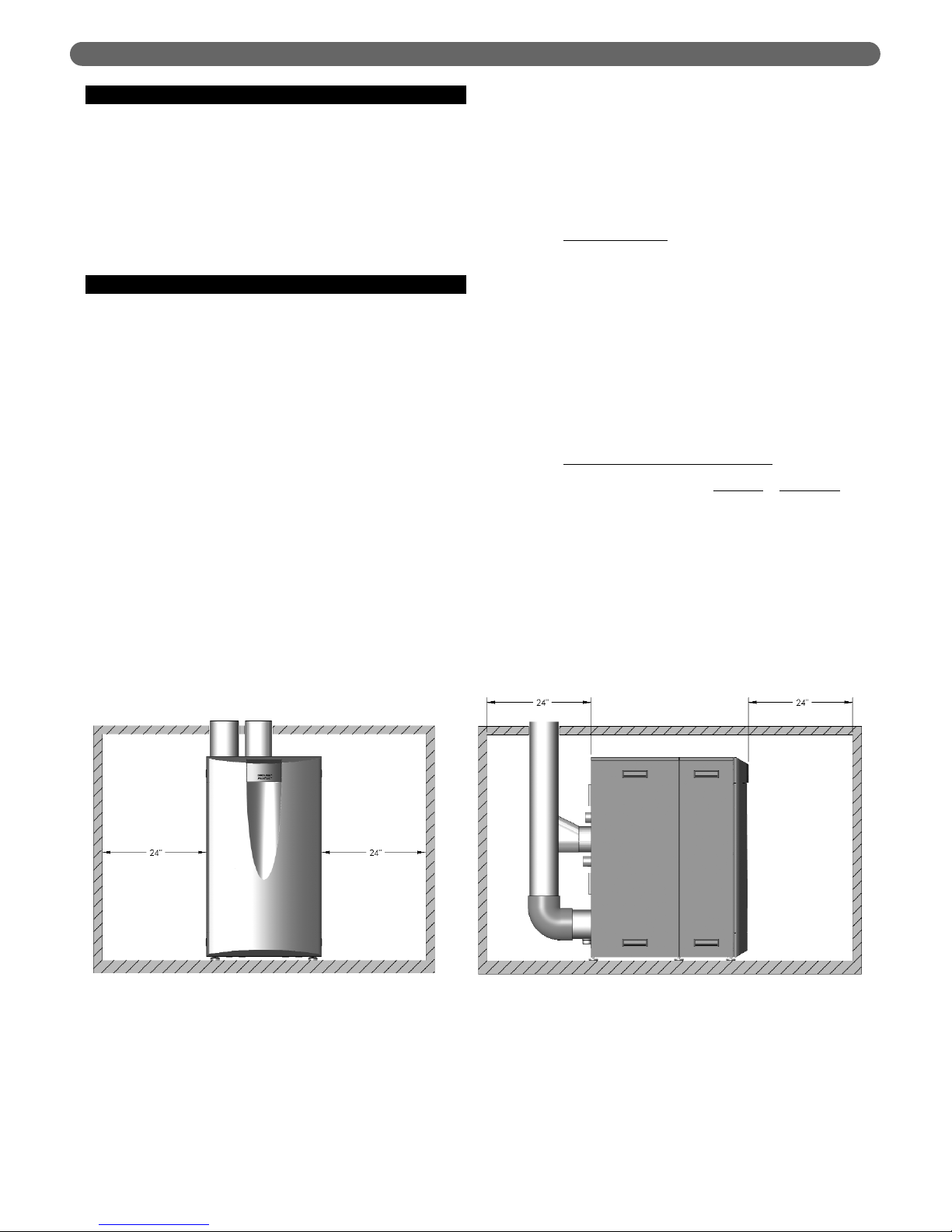

C. ACCESSIBILITY CLEARANCES

1. The PUREFIRE®boiler is certified for closet installations

with zero clearance to combustible construction. In

addition, it is design certified for use on combustible

floors. Do not install on carpeting.

2. Figure 1.1 shows the minimum recommended

clearances to allow reasonable access to the boiler for

inspection and maintenance. However, local codes or

special conditions may require greater clearances.

D. COMBUSTION AND VENTILATION AIR

1. The PUREFIRE®boiler is designed for operation with

combustion air piped directly to the boiler from

outside the building (sealed combustion). Combustion

air can be supplied from within the building only if

adequate combustion and ventilation air is provided

in accordance with the section of the National Fuel

Gas Code entitled, “Air for Combustion and

Ventilation” or applicable provisions of the local

building codes.

2. If the combustion air is piped directly to the boiler

from outside the building, no additional combustion

or ventilation air is required. Otherwise, follow the

National Fuel Gas Code recommendations

summarized in subsections 3 through 10.

3. Required Combustion Air Volume: The total required

volume of indoor air is to be the sum of the required

volumes for all appliances located within the space.

Rooms communicating directly with the space in

which the appliances are installed and through

combustion air openings sized as indicated in

Subsection 3 are considered part of the required

volume. The required volume of indoor air is to be

determined by one of two methods.

a. Standard Method

: The minimum required volume

of indoor air (room volume) shall be 50 cubic feet

per 1000 BTU/Hr (4.8 m3/kW). This method is to

be used if the air infiltration rate is unknown or if

the rate of air infiltration is known to be greater

than 0.6 air changes per hour. As an option, this

method may be used if the air infiltration rate is

known to be between 0.6 and 0.4 air changes per

hour. If the air infiltration rate is known to be

below 0.4 then the Known Air Infiltration Rate

Method must be used. If the building in which this

appliance is to be installed is unusually tight, PB

Heat recommends that the air infiltration rate be

determined.

b. Known Air Infiltration Rate Method

:

where:

I

fan

= Input of the fan assisted appliances

in Btu/hr

ACH = air change per hour (percent of the

volume of the space exchanged per

hour, expressed as a decimal)

Note: These calculations are not to be used for

infiltration rates greater than 0.60 ACH.

3

PREINSTALLATION

Figure 1.1: Minimum Accessibility Clearances – PF-850, PF-1000

15 ft

3

I

fan

ACH 1000

Btu

/

hr

Required Volume

fan

=

⎛

⎜

⎝

⎛

⎜

⎝

Page 6

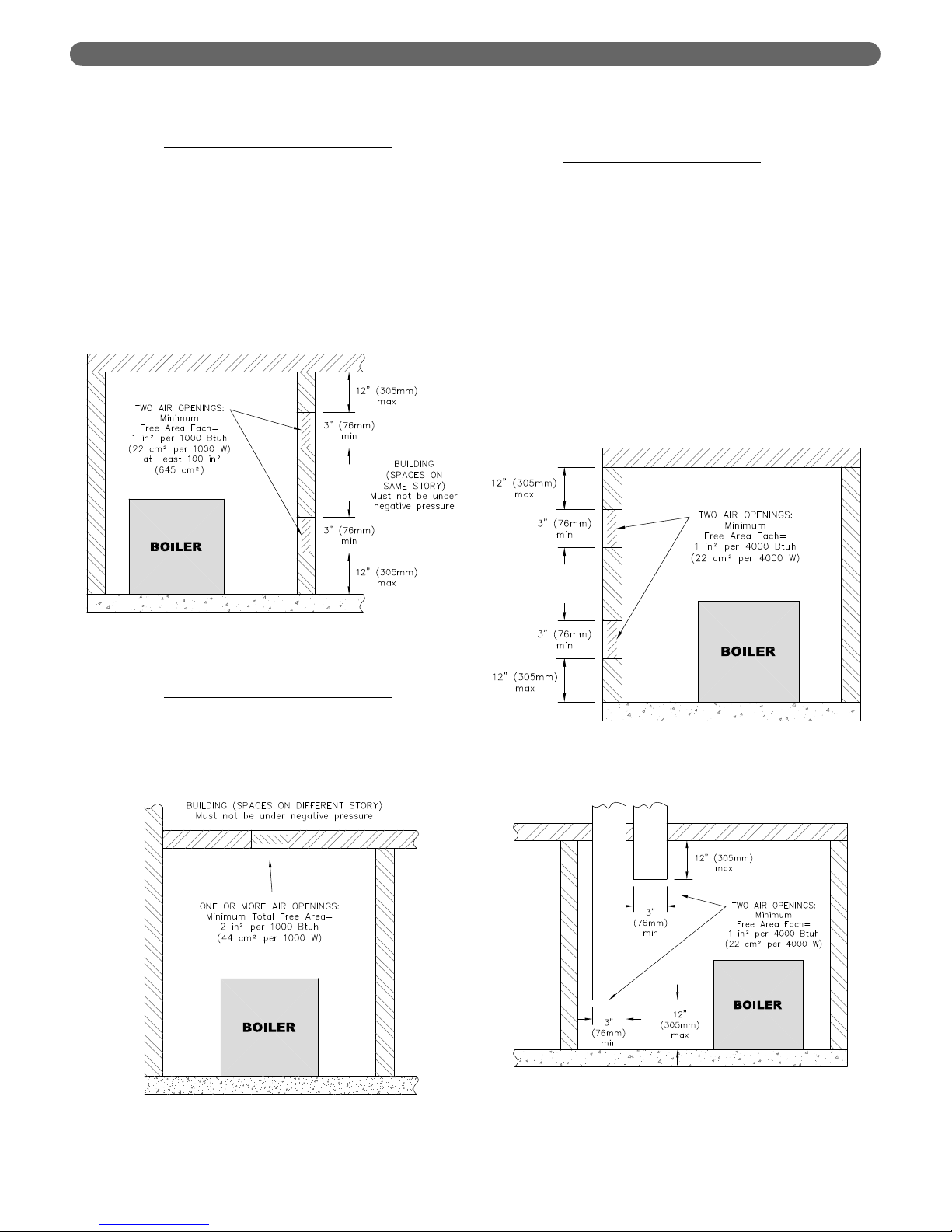

4. Indoor Air Opening Size and Location: Openings

connecting indoor spaces shall be sized and located as

follows:

a. Combining Spaces on the Same Floor

: Provide

two permanent openings communicating with

additional spaces that have a minimum free area

of 1 in

2

per 1000 Btu/hr (22 cm2per 1000 W) of

the total input rating of all gas fired equipment but

not less than 100 in

2

(645 cm2). One opening is

to begin within 12 inches (305 mm) from the top

of the space and the other is to begin within 12

inches (305 mm) from the floor. The minimum

dimension of either of these openings shall be 3

inches (76 mm). See Figure 1.2 for an illustration

of this arrangement.

b. Combining Spaces on Different Floors

: Provide

one or more permanent openings communicating

with additional spaces that have a total minimum

free area of 2 in

2

per 1000 Btu/hr (44 cm2per

1000 W) of total input rating of all equipment. See

Figure 1.3 for an illustration of this arrangement.

5. Outdoor Combustion Air: Outdoor combustion air is

to be provided through one or two permanent

openings. The minimum dimension of these air

openings is 3 inches (76 mm).

a. Two Permanent Opening Method

: Provide two

permanent openings. One opening is to begin

within 12 inches (305 mm) of the top of the

space and the other is to begin within 12 inches

(305 mm) of the floor. The openings are to

communicate directly or by ducts with the

outdoors or with spaces that freely communicate

with the outdoors. The size of the openings shall

be determined as follows:

i. Where communicating directly or through

vertical ducts with the outdoors each opening

shall have a minimum free area of 1 in

2

per

4000 Btu/hr (22 cm

2

per 4000 W) of total input

rating for all equipment in the space. See Figure

1.4 for openings directly communicating with

the outdoors or Figure 1.5 for openings

connected by ducts to the outdoors.

4

Figure 1.4: Air Openings – All Air Directly from

Outdoors

Figure 1.5: Air Openings – All Air from Outdoors

through Vertical Ducts

PREINSTALLATION

Figure 1.2: Air Openings – All Air from Indoors

on the Same Floor

Figure 1.3: Air Openings – All Air from Indoors

on Different Floors

Page 7

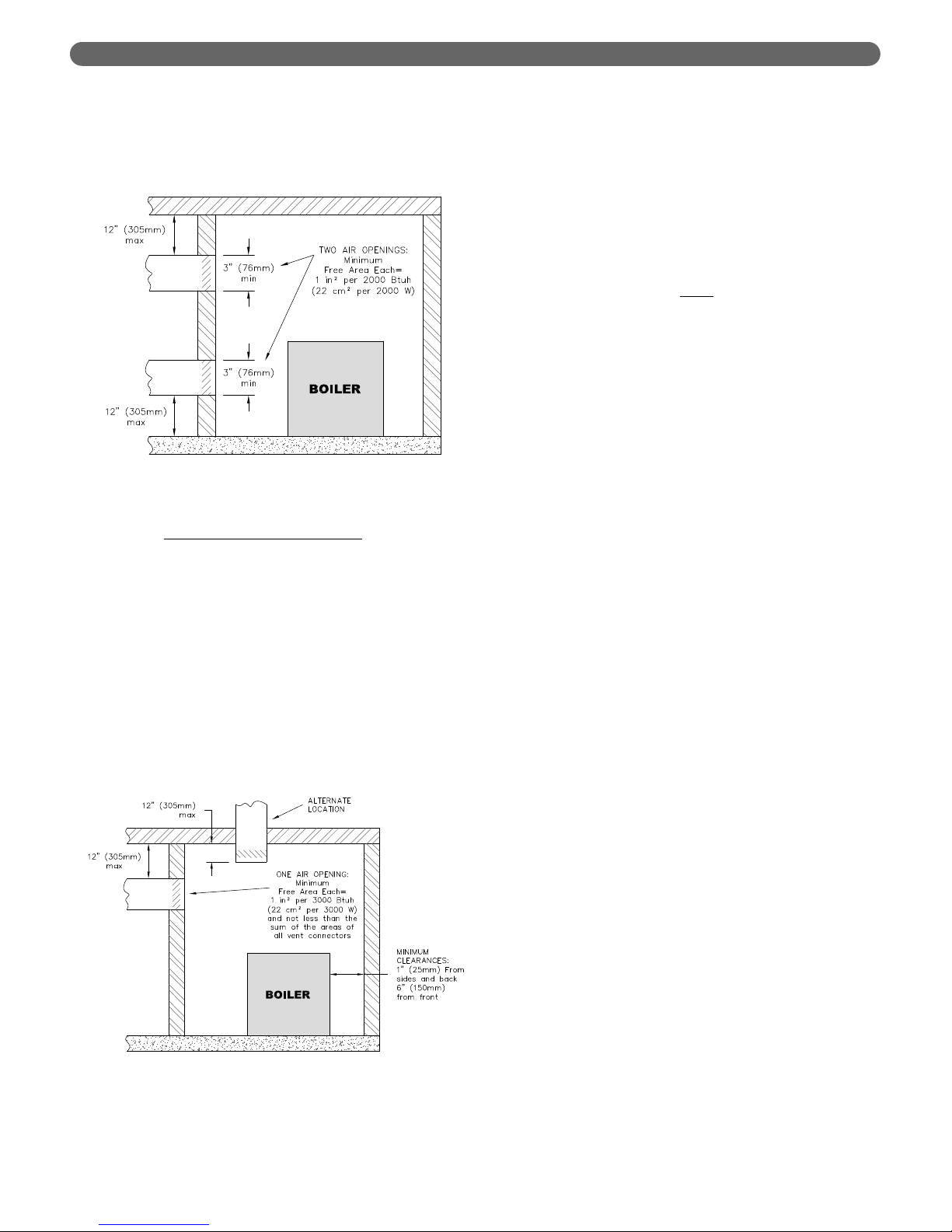

ii. Where communicating with the outdoors

through horizontal ducts, each opening shall

have a minimum free area of 1 in

2

per 2000

Btu/hr (22 cm2per 2000 W) of total rated

input for all appliances in the space. See

Figure 1.6.

b. One Permanent Opening Method

: Provide one

permanent opening beginning within 12 inches

(305 mm) of the top of the space. The opening

shall communicate directly with the outdoors,

communicate through a vertical or horizontal duct,

or communicate with a space that freely

communicates with the outdoors. The opening

shall have a minimum free area of 1 in

2

per 3000

Btu/hr of total rated input for all appliances in the

space and not less than the sum of the crosssectional areas of all vent connectors in the space.

The gas-fired equipment shall have clearances of

at least 1 inch (25 mm) from the sides and back

and 6 inches (150 mm) from the front of the

appliance. See Figure 1.7 for this arrangement.

6. Combination Indoor and Outdoor Combustion Air: If

the required volume of indoor air exceeds the

available indoor air volume, outdoor air openings or

ducts may be used to supplement the available indoor

air provided:

a. The size and location of the indoor openings

comply with Subsection 3.

b. The outdoor openings are to be located in

accordance with Subsection 4.

c. The size of the outdoor openings are to be sized

as follows:

where:

A

req

= minimum area of outdoor openings.

A

full

= full size of outdoor openings calculated

in accordance with Subsection 4.

V

avail

= available indoor air volume

V

req

= required indoor air volume

7. Engineered Installations: Engineered combustion air

installations shall provide an adequate supply of

combustion, ventilation, and dilution air and shall be

approved by the authority having jurisdiction.

8. Mechanical Combustion Air Supply:

a. In installations where all combustion air is

provided by a mechanical air supply system, the

combustion air shall be supplied from the

outdoors at the minimum rate of 0.35 ft

3

/min per

1000 Btu/hr (0.034 m

3

/min per 1000 W) of the

total rated input of all appliances in the space.

b. In installations where exhaust fans are installed,

additional air shall be provided to replace the

exhaust air.

c. Each of the appliances served shall be interlocked

to the mechanical air supply to prevent main

burner operation when the mechanical air supply

system is not in operation.

d. In buildings where the combustion air is provided

by the mechanical ventilation system, the system

shall provide the specified combustion air rate in

addition to the required ventilation air.

9. Louvers & Grills:

a. The required size of openings for combustion,

ventilation, and dilution air shall be based on the

net free area of each opening.

i. Where the free area through a louver or grille

is known, it shall be used in calculating the

opening size required to provide the free area

specified.

ii. Where the free area through a louver or grille

is not known, it shall be assumed that wooden

louvers will have 25% free area and metal

louvers and grilles will have 75% free area.

iii. Non-motorized dampers shall be fixed in the

open position.

b. Motorized dampers shall be interlocked with the

equipment so that they are proven in the full open

position prior to ignition and during operation of

the main burner.

5

Figure 1.6: Air Openings – All Air from Outdoors

through Horizontal Ducts

Figure 1.7: Air Openings – All Air from Outdoors

through One Opening

PREINSTALLATION

A

req

= A

full

x 1 –

V

avail

V

req

⎛

⎜

⎝

⎛

⎜

⎝

Page 8

i. The interlock shall prevent the main burner

from igniting if the damper fails to open during

burner startup.

ii. The interlock shall shut down the burner if the

damper closes during burner operation.

10. Combustion Air Ducts:

a. Ducts shall be constructed of galvanized steel or

an equivalent corrosion- resistant material.

b. Ducts shall terminate in an unobstructed space,

allowing free movement of combustion air to the

appliances.

c. Ducts shall serve a single space.

d. Ducts shall not serve both upper and lower

combustion air openings where both such

openings are used. The separation between ducts

serving upper and lower combustion air openings

shall be maintained to the source of combustion

air.

e. Ducts shall not be screened where terminating in

an attic space.

f. Horizontal upper combustion air ducts shall not

slope downward toward the source of the

combustion air.

g. Combustion air intake openings located on the

exterior of buildings shall have the lowest side of

the combustion air intake opening at least 12

inches (305 mm) above grade.

11. Refer to Section 3 of this manual, Venting & Air Inlet

Piping, for specific instructions for piping the exhaust

and combustion air.

E. PLANNING THE LAYOUT

1. Prepare sketches and notes showing the layout of the

boiler installation to minimize the possibility of

interferences with new or existing equipment, piping,

venting and wiring.

2. The following sections of this manual should be

reviewed for consideration of limitations with

respect to:

a. Venting and Air Inlet Piping: Section 3

b. Water Piping: Section 4

c. Fuel Piping: Section 5

d. Condensate Removal: Section 6

e. Electrical Connections: Section 7

f. Boiler Control: Section 8

g. Boiler Dimensions and Ratings: Section 12

6

PREINSTALLATION

Do not install this boiler where gasoline or other

flammable liquids or vapors are stored or are in use.

WARNING

This boiler is certified as an indoor appliance. Do not

install this boiler outdoors or locate where it will be

exposed to freezing temperatures.

WARNING

Do not install this boiler in the attic.

WARNING

Page 9

7

BOILER SET-UP

A. GENERAL

1. PUREFIRE®boilers are intended for installation in an

area with a floor drain or in a suitable drain pan. Do

not install any boiler where leaks or relief valve

discharge will cause property damage.

2. The P

UREFIRE

®

boiler is not intended to support

external piping. All venting and other piping should

be supported independently of the boiler.

3. Many jacket panels on the P

UREFIRE

®

boiler are

removable to allow inspection and maintenance. Do

not attached fixed brackets for piping or wiring on

removable jacket parts. Piping and/or wiring should

not obstruct access to removable panels.

4. Install the boiler level to prevent condensate from

backing up inside the boiler.

5. Use leveling feet to assure that the boiler is completely

level. This will prevent condensate from collecting in

the boiler and causing degradation of the heat

exchanger.

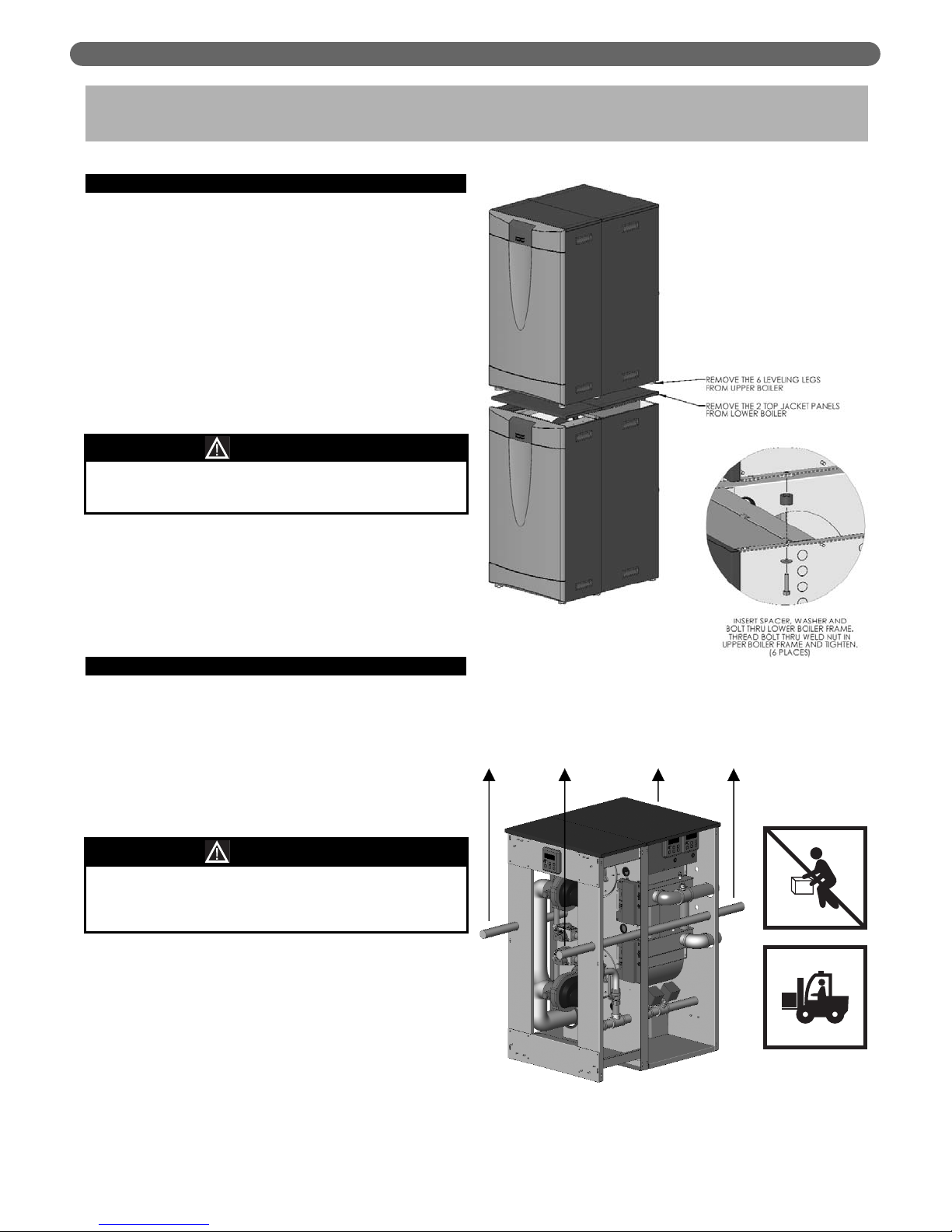

B. STACKING MULTIPLE BOILERS

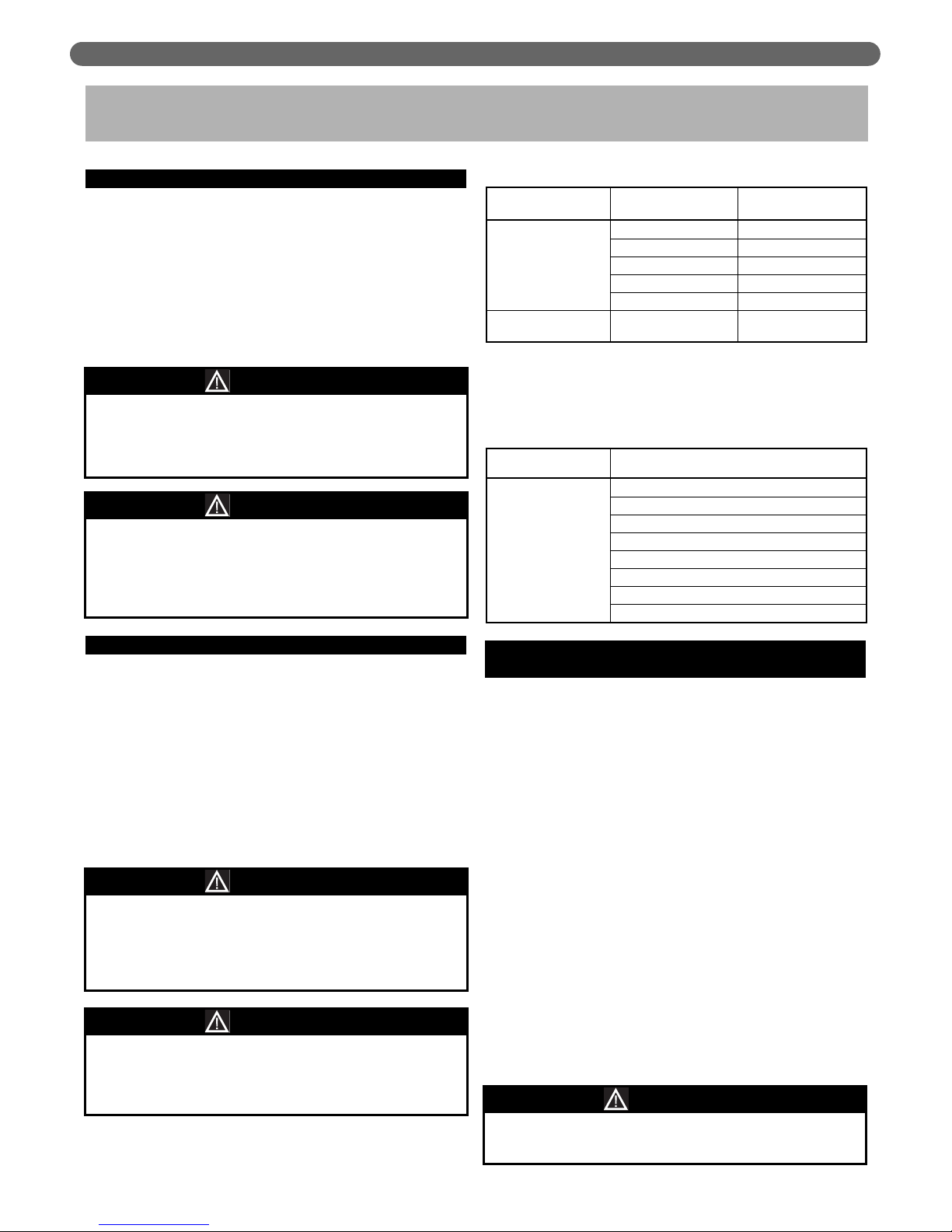

Identical PF-850 and PF-1000 boilers can be stacked to

save floor space on the installation. Figure 2.1 shows how

the upper boiler is to be attached to the lower boiler.

1. Remove all side jacket panels from the both boilers

and the top jacket panels from the lower boiler.

2. Remove the leveling legs from the boiler to be

installed on top.

3. Lift the upper boiler into place by passing 5 to 10 foot

(2-3 meter) lengths of 1" to 1-1/4" Schedule 40 or 80

steel pipe through the holes provided in the boiler

frame.

4. Insert spacers, washers and bolts (provided) through

the holes provided in the frame of the lower boiler

and thread them into the threaded inserts on the base

of the upper boiler. Figure 2.1 shows this assembly.

Tighten the bolts securely.

5. Replace all the side jacket panels and discard the top

jacket panels from the lower boiler.

2. BOILER SET-UP

Figure 2.1: Stacking and Securing Boilers

This boiler must be installed level to prevent

condensate from backing up inside the boiler.

CAUTION

Do not lift these boilers by hand. Failure to comply

may result in serious injury, death or major property

damage.

WARNING

Figure 2.2: Lifting the Upper Boiler

DO NOT LIFT

BY HAND

FORKLIFT OR

CRANE LIFT ONLY

Page 10

8

VENTING & AIR INLET PIPING

A. GENERAL

1. Install the PUREFIRE®boiler venting system in accordance

with these instructions and with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, CAN/CGA B149, and/or

applicable provisions of local building codes.

2. The P

UREFIRE

®

boiler is approved for positive pressure

exhaust venting using either indoor air or air piped

from outside. It is ETL Listed as a Category IV

(Positive Pressure, Condensing Exhaust Vent)

Appliance.

B. APPROVED MATERIALS

1. Table 3.1 lists approved materials for vent pipe (and

adhesives where applicable). Use only these materials

for exhaust vent piping.

2. PVC Pipe and fittings are not to be used for exhaust

venting in confined spaces such as closet or alcove

installations or vent pipe that passes through attics.

3. Table 3.2 lists appropriate materials for air inlet piping.

Air inlet piping is to be sealed suitably to prevent

introduction of dirt, chemicals or other contaminants

to the inlet air stream.

* PVC pipe/fittings are not to be used for venting within

confined spaces.

Notice: Installations in Canada require compliance with

ULC S636 - Standard for Type BH Gas Venting Systems.

C. EXHAUST VENT/AIR INTAKE PIPE

LOCATION

1. Install vent piping before installing water, fuel, or

condensate piping. Working from largest to smallest

diameter reduces the complexity of piping

interferences.

2. Vent and air intake piping is to be installed so that

there is sufficient access for routine inspection as

required in Section 11, of this manual.

3. The vent piping for this boiler is approved for zero

clearance to combustible construction. However, a fire

stop must be used where the vent pipe penetrates

walls or ceilings.

4. The Peerless

®

PUREFIRE®boiler, like all high efficiency,

gas-fired appliances, is likely to produce a vapor

plume due to condensation. Surfaces near the vent

termination will likely become coated with

condensation.

5. The maximum combined vent and air inlet vent

length for the Peerless

®

PUREFIRE®boiler is about 200

equivalent feet (60 m).Be sure that the boiler is

located such that the maximum vent length is not

exceeded.

3. VENTING & AIR INLET PIPING

The venting system for this product is to be installed in

strict accordance with these venting instructions.

Failure to install the vent system properly may result in

severe personal injury, death or major property damage.

WARNING

This vent system operates under positive pressure.

Vent connectors serving appliances vented by

natural draft shall not be connected into any portion

of this venting system. Failure to comply may result

in serious injury, death or major property damage.

WARNING

Only the materials listed below are approved for use

with the

P

UREFIRE

®

boiler. Use only these components

in accordance with these instructions. Failure to use

the correct material may result in serious injury,

death, or major property damage.

WARNING

Table 3.1: Approved Materials for Exhaust Vent Pipe

Use of cellular core pipe for any exhaust vent

component is prohibited. Use of cellular core pipe

may result in severe personal injury, death, or major

property damage.

WARNING

If the maximum equivalent vent length is exceeded,

the maximum burner input rate may be reduced.

NOTICE

Description Material

Conforming to

Standard

Vent Piping

& Fittings

PVC (Sch 40 or 80)*

ANSI/ASTM D1785

CPVC (Sch 40 or 80) ANSI/ASTM D1785

PVC-DWV*

ANSI/ASTM D2665

FasNSeal

®

UL-1738 & ULC-S636

MUGRO

®

ULC-S636

Pipe Cement

(PVC & CPVC Only)

PVC/CPVC Cement ANSI/ASTM D2564

Table 3.2: Approved Materials for Air Inlet Piping

Description Material

Air Inlet Pipe

& Fittings

PVC (Cellular Core or Solid)

CPVC

ABS

Smoke Pipe (Galvanized or Steel)

Dryer Vent Pipe

Flexible Duct

Stainless Steel

Polypropylene

Page 11

VENTING & AIR INLET PIPING

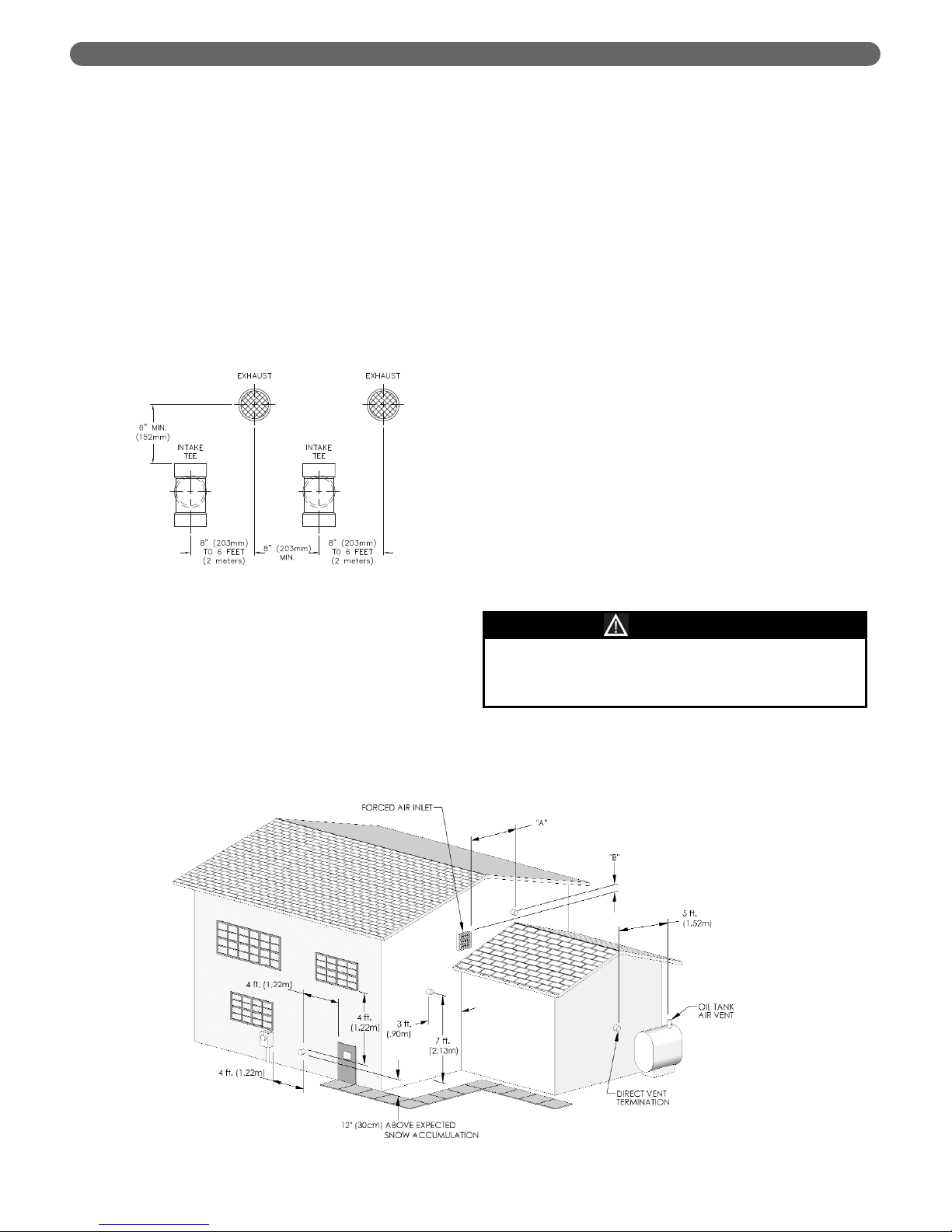

6. Air Intake Pipe Location – Sidewall Venting:

a. Provide 1 foot (30 cm) clearance from the bottom

of the air intake pipe to the level of maximum

snow accumulation. Snow removal may be

necessary to maintain clearances.

b. Do not locate air intake pipe in a parking area

where machinery may damage the pipe.

c. If the vent pipe and air inlet pipe terminations

penetrate the wall at the same level the minimum

distance between them is 8" center-to-center.

d. For multiple boiler installations, the minimum

horizontal distance between the inlet of one boiler

to the exhaust of an adjacent boiler is 8" center-tocenter. In addition, the minimum vertical distance

between the exhaust and air inlet is 6". See Figure

3.1 for an illustration.

e. The exhaust outlet of the vent pipe should not be

angled any more than 5º from horizontal.

f. Precautions should be taken to prevent

recirculation of flue gases to the air inlet pipe of

the boiler or other adjacent appliances.

7. Sidewall Venting Configuration:

a. See Figure 3.2 for an illustration of clearances for

location of exit terminals of direct-vent venting

systems.

• This boiler vent system shall terminate at least

3 feet (0.9 m) above any forced air inlet

located within 10 ft (3 m). Note: This does not

apply to the combustion air intake of a directvent appliance.

• Provide a minimum of 4 feet (1.22 m)

clearance distance from any door, operable

window, or gravity air intake into any building.

• Provide a minimum of 6 feet (1.83 m)

clearance to adjacent facing walls.

• Provide a minimum of 1 foot (30 cm)

clearance from the bottom of the exit terminal

above the expected snow accumulation level.

Snow removal may be required to maintain

clearance.

• Provide a minimum of 4 feet (1.22 m)

horizontal clearance from electrical meters, gas

meters, gas regulators, and relief equipment. In

no case shall the exit terminal be above or

below the aforementioned equipment unless

the 4 foot horizontal distance is maintained.

• Do not locate the exhaust exit terminal over

public walkways where condensate could drip

and create a hazard or nuisance.

• When adjacent to public walkways, locate the

exit terminal at least 7 feet above grade.

• Do not locate the exhaust termination directly

under roof overhangs to prevent icicles from

forming or recirculation of exhaust gases from

occurring.

• Provide 3 feet clearance from the inside corner

of adjacent walls.

Figure 3.1: Vent Pipe Spacing for Multiple

P

UREFIRE

®

Boilers

Figure 3.2: Exit Terminal Location for Mechanical Draft and Direct-Vent Venting Systems

Condensing flue gases can freeze on exterior

building surfaces which may cause discoloration and

degradation of the surfaces.

CAUTION

9

Page 12

VENTING & AIR INLET PIPING

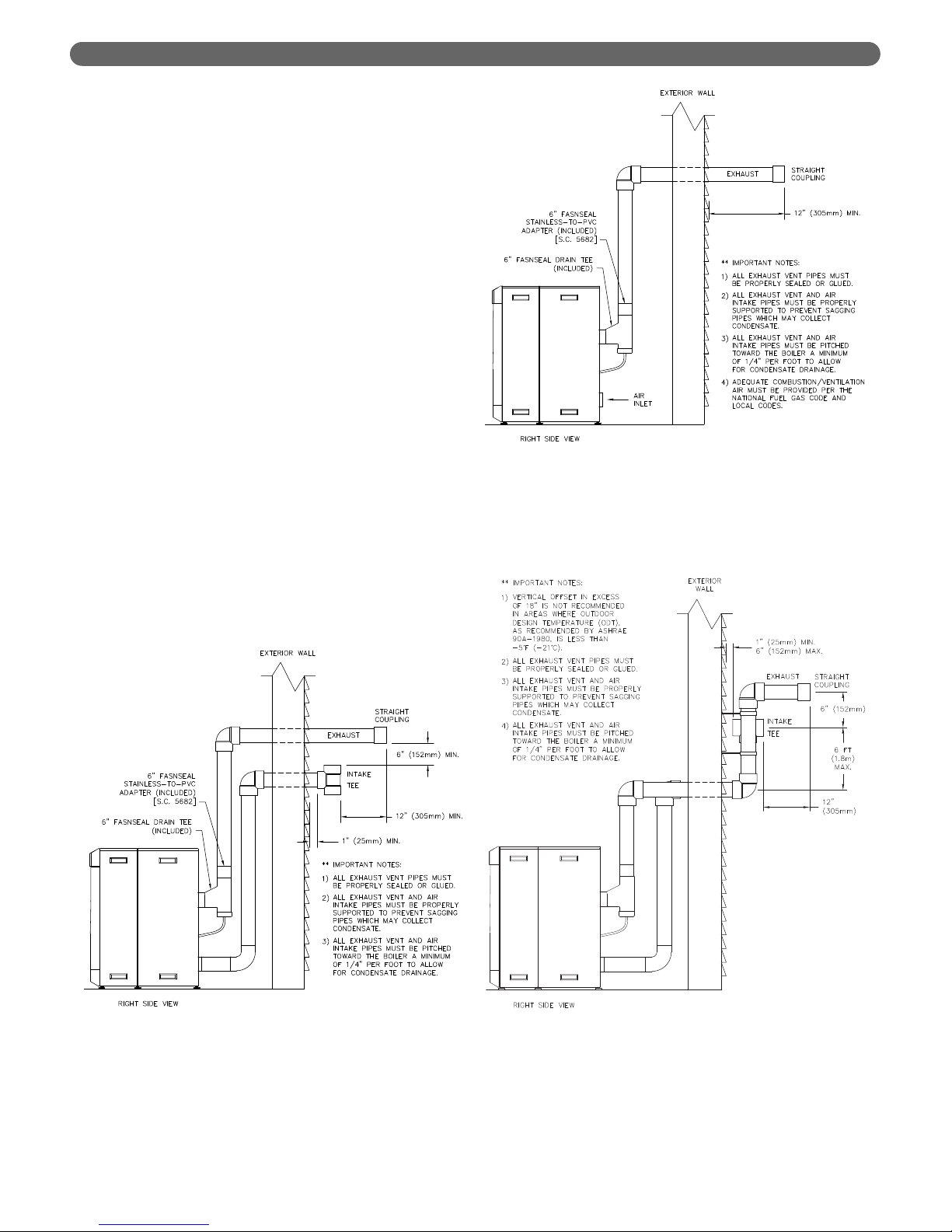

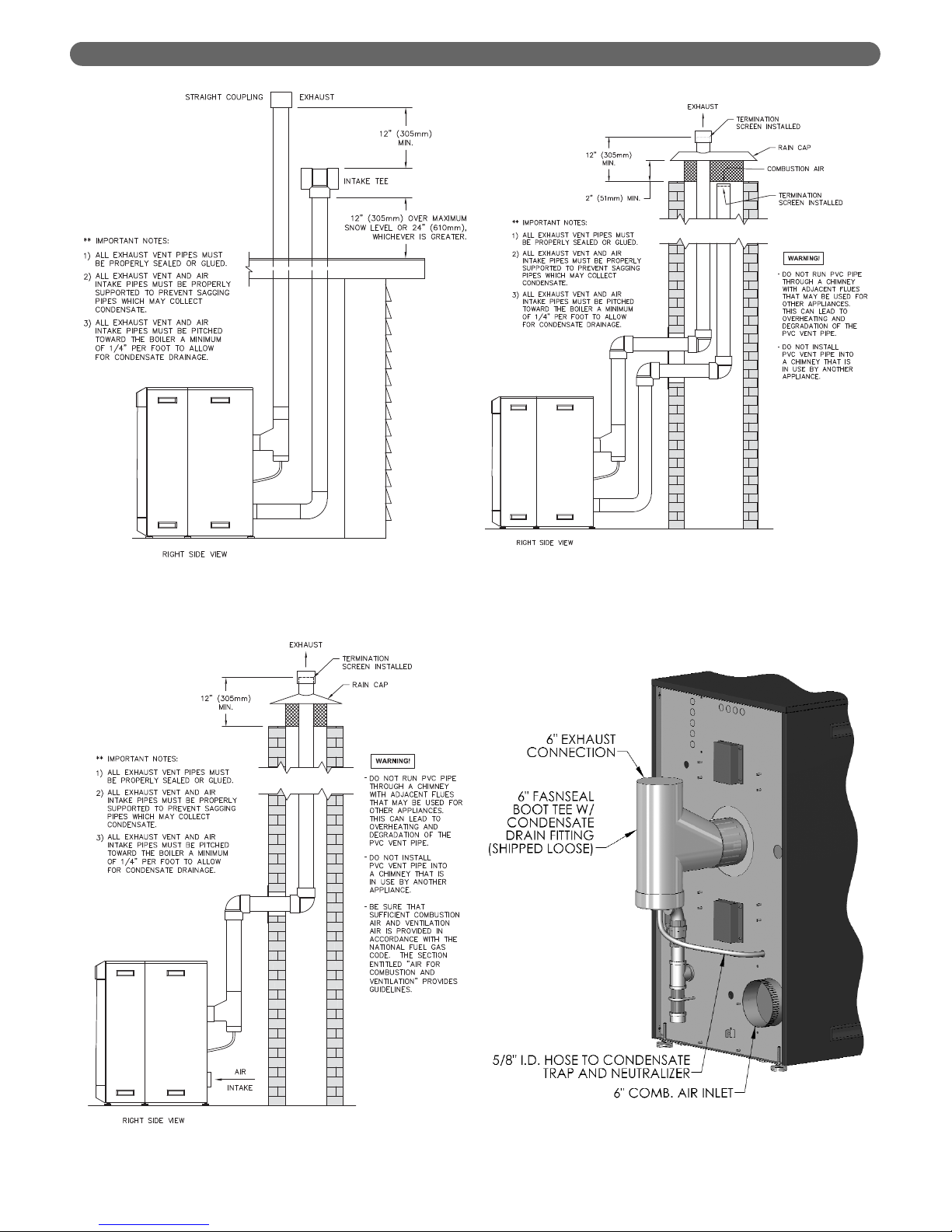

b. Figure 3.3, 3.4 and 3.5 show approved sidewall

venting configurations using standard PVC or

CPVC fittings. A similar configuration using

FasNSeal stainless steel exhaust pipe can be used

with either PVC or other approved material for the

combustion air intake piping.

8. Figures 3.6 through 3.8 show recommended vertical

venting configurations.

a. Figure 3.6 illustrates a vertical venting

configuration using PVC inlet and exhaust. A

similar configuration can be constructed using a

FasNSeal stainless steel vent termination. PVC or

other approved materials may be used for air inlet

piping.

i. The opening of the air inlet piping is to be a

minimum of 12" (300 mm) above the

expected snow accumulation on the roof

surface or 24" (600 mm) above the roof

surface, whichever is greater.

ii. Locate the opening of the exhaust vent pipe a

minimum of 12" above the air inlet opening to

prevent flue gas from recirculating to the air

inlet.

b. Figure 3.7 shows vertical exhaust venting through

an unused chimney. In this case, combustion air is

supplied from inside the building. Section 1.D

provides guidelines for determining adequate

inside air.

c. Figure 3.8 illustrates another vertical venting

configuration through an unused chimney. In this

arrangement the combustion air is supplied

through the chimney as well.

Figure 3.3: Sidewall Exhaust Vent and Air Inlet Pipe

Figure 3.5: Offset Sidewall Exhaust Vent and Air

Inlet Pipe

Figure 3.4: Sidewall Exhaust Vent with Indoor Air

10

Page 13

VENTING & AIR INLET PIPING

Figure 3.6: Vertical Exhaust and Air Inlet Pipe

Figure 3.7: Vertical Exhaust Routed Through an

Unused Chimney with Indoor Air

Figure 3.9: Drain Tee and Air Inlet Connections

Figure 3.8: Vertical Exhaust Routed Through an

Unused Chimney with Outdoor Air

11

Page 14

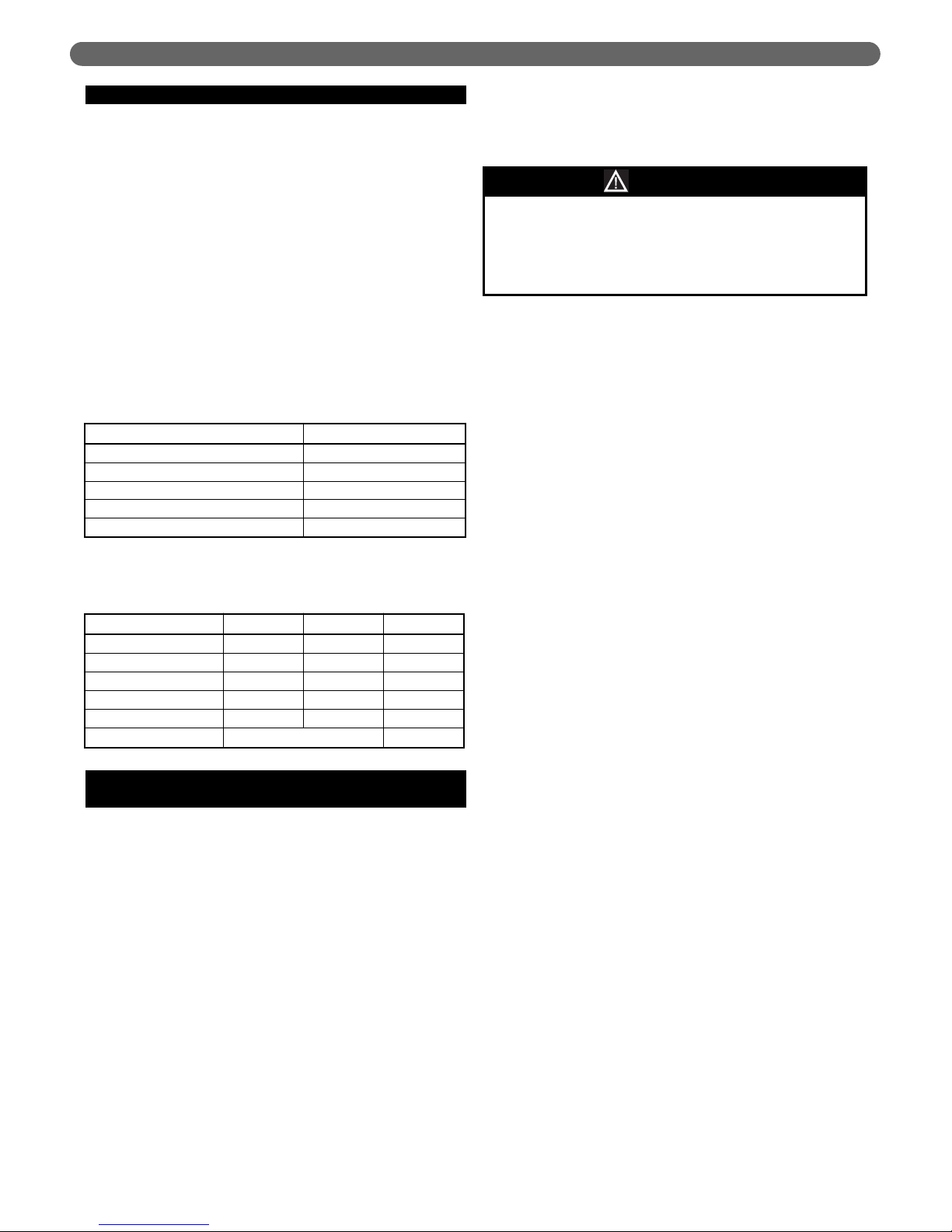

D. EXHAUST VENT/AIR INTAKE PIPE SIZING

1. PUREFIRE®boiler models PF-850 and PF-1000 are to

be installed using 6" piping for both exhaust and air

inlet. A list of approved materials for the exhaust are

in Table 3.1 and a list of approved materials for air

inlet are in Table 3.2

2. The total combined length of exhaust vent and air

intake piping is 200 equivalent feet (60 m).

a. The P

UREFIRE

®

PF-850 and PF-1000 may be

provided with room air as long as there is

adequate combustion and ventilation air provided.

See Section 1.D: Combustion and Ventilation Air

of this manual for the minimum requirements. In

this case, a maximum of 200 equivalent feet of

exhaust vent pipe can be used.

b. The equivalent length of elbows, tees and other

fittings are listed in Table 3.3.

c. The total equivalent length can be calculated as

shown in Table 3.4.

E. EXHAUST VENT/AIR INTAKE

INSTALLATION

1. Figure 3.10 shows the exhaust connection on the rear

of the boiler on the vertical centerline. The exhaust

connection is a 6" FasNSeal stainless steel connection.

2. A 6" FasNSeal stainless steel boot tee with a drain

fitting is included with each PF-850 & PF-1000 boiler.

This should be connected directly to the rear of the

boiler as shown below.

3. The Air Intake connection is a 6" galvanized collar to

the right and below the exhaust connection. This can

be connected to any of the approved air intake piping

materials.

4. The Air Intake connection should be secured with (3)

screws and sealed.

5. Remove all burrs and debris from the joints and fittings.

6. Care should be taken to prevent dirt or debris from

entering the air intake connection. A screen is

provided inside the Air Intake fitting to prevent large

objects from entering the combustion system.

7. Horizontal lengths of exhaust vent must be installed with

a slope of not less than 1/4" per foot (21mm per meter)

toward the boiler to allow condensate to drain from the

vent pipe. If the vent pipe must be piped around an

obstacle that causes a low point in the piping, a drain

with an appropriate trap must be installed.

Les sections horizontales de l’évacuation doivent être

installées avec une pente d’au moins 1/4 po au pied

(21 mm par mètre) en direction de la chaudière afin

que le condensat puisse s’évacuer du tuyau

d’évacuation. Si le tuyau d’évacuation est acheminé

autour d’un obstacle qui crée un point bas dans la

tuyauterie, il est nécessaire alors d’installer un drain

équipé d'une vidange adéquate.

8. All piping must be fully supported. Use pipe hangers

at a minimum of 4 foot (1.22 meter) intervals to

prevent sagging of the pipe.

Tous les tuyaux doivent être parfaitement soutenus.

Utiliser des attaches de tuyau tous les 4 pieds (1,22

mètres) pour éviter le fléchissement des tuyaux.

9. Exhaust and air inlet piping is to be supported

separately and should not apply force to the boiler.

Les tuyaux d’évacuation et d’arrivée d’air doivent

avoir des dispositifs de support distincts et ne pas

exercer de pression sur la chaudière.

10. Penetration openings around the vent pipe and air

intake piping are to be fully sealed to prevent exhaust

gases from entering building structures.

11. PVC & CPVC Piping:

a. Use only solid PVC or CPVC Schedule 40 or 80

pipe for exhaust venting. Cellular core PVC or

CPVC is not approved for exhaust vent.

b. All joints in vent pipe, fittings, attachment to the

boiler stub, and all vent termination joints must be

properly cleaned, primed and cemented. Use only

cement and primer approved for use with PVC or

CPVC pipe that conforms to ANSI/ASTM D2564.

c. A PVC or CPVC coupling can be used as an

outside vent termination. In this configuration,

place one of the 6" diameter screens provided

between the coupling and exhaust connection

before gluing it. This is intended to prevent birds

or rodents from entering.

d. A PVC or CPVC tee can be used as an outside air

intake termination. When using this configuration,

place one of the 6" diameter screens provided

between the tee and the air inlet connection

before gluing it. This is intended to prevent birds

or rodents from entering.

VENTING & AIR INLET PIPING

This appliance uses a positive pressure venting

system. All joints must be sealed completely to

prevent leakage of flue products into living spaces.

Failure to do this may result in severe personal injury,

death or major property damage.

WARNING

Exhaust Air Inlet Total

Straight Length of Pipe 100' 50' 150'

90° Elbows, SR 2 x 5'= 10' 1 x 5' = 5' 15'

45° Elbows, SR 2 x 3' = 6' 6'

Air Intake Tee 0' 0'

Outlet Coupling 0' 0'

Total 171'

Table 3.4: Sample Equivalent Length Calculation

Table 3.3: Equivalent Length of Fittings

Fitting Description Equivalent Length

Elbow, 90° Short Radiusz 5 feet (1.5 m)

Elbow, 90° Long Radius 4 feet (1.2 m)

Elbow, 45° Short Radius 3 feet (0.9 m)

Coupling 0 feet (0 m)

Air Intake Tee 0 feet (0 m)

12

Page 15

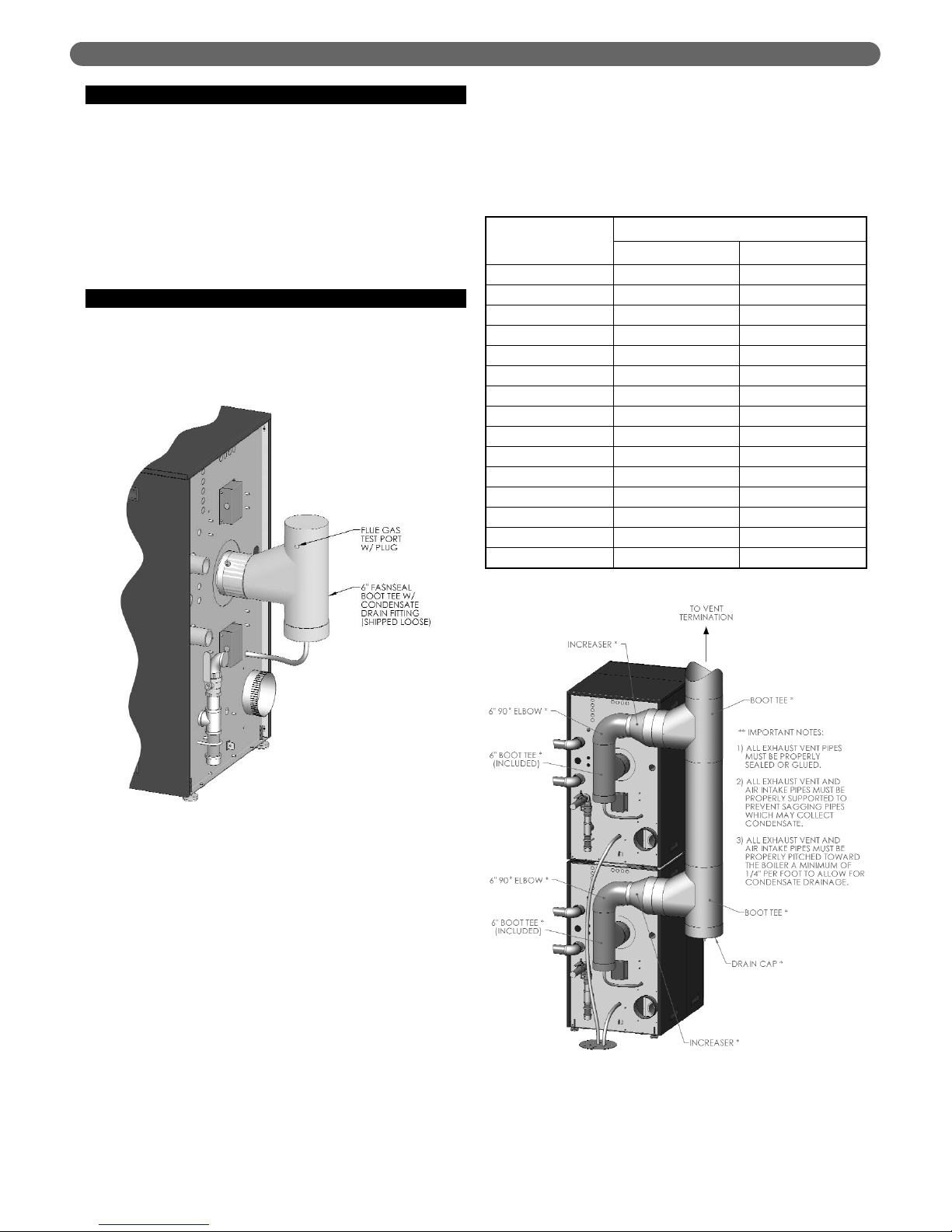

F. TEST PORT FOR EXHAUST SAMPLING

1. Figure 3.10 shows an illustration of the plugged

sample port on the outlet of the drain tee for the PF850 and PF-1000 boiler.

2. To obtain an exhaust sample during operation,

remove the test port plug and insert the probe from a

suitable combustion analyzer.

3. Be sure to replace the plug before leaving the boiler

unattended.

G. COMMON VENTING MULTIPLE BOILERS

1. Multiple PUREFIRE®PF-850 and PF-1000 boilers may

be connected to a common vent system if they are set

up to operate in the cascade mode described in

Section 8.

a. The boilers must communicate in a

Master/Dependent relationship provided in the

system software.

b. The backflow prevention valves supplied on the

gas/air premix inlet prevent products of

combustion from backing up through the burners

into occupied space.

c. A safety control algorithm will operate the blower

to prevent backflow in case of a backflow

prevention valve failure.

2. Figure 3.11 shows two P

UREFIRE

®

PF-850 boilers

connected with a common vent system.

a. The drain tee from the common vent section

should be trapped and neutralized separately from

the boilers.

b. The condensate drain from each boiler should be

run separately to the drain system to prevent a

clogged condensate line from shutting down

multiple boilers.

c. Table 3.5 shows recommended sizing for common

vent piping.

VENTING & AIR INLET PIPING

Figure 3.11: Multiple Boilers with Common Venting

Table 3.5: Common Exhaust Vent Sizing

Figure 3.10

Number

of Boilers

Boiler Model

PF-850 PF-1000

2 8" 9"

3 10" 12"

4 12" 12"

5 14" 14"

6 14" 16"

7 16" 16"

8 16" 18"

9 18" 18"

10 18" 20"

11 20" 20"

12 20" 22"

13 20" 22"

14 22" 24"

15 22" 24"

16 24" 24"

13

Page 16

14

VENTING & AIR INLET PIPING

H. BOILER REMOVAL FROM COMMON

VENTING SYSTEM

At the time of removal of an existing boiler, follow these

steps with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation:

Retrait de la chaudière d’un système d’évacuation

commun. Au moment de retirer une chaudière existante,

il est important de suivre les étapes suivantes pour chaque

appareil raccordé au système d’évacuation commun qui

sont en service, alors que les autres appareils demeurant

raccordés au système d’évacuation commun ne sont pas

en service :

1. Seal any unused openings in the common venting

system.

Sceller toute ouverture du système d’évacuation

commun non utilisée.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

Effectuer un contrôle visuel du système d’évacuation

pour vérifier la taille et la pente horizontale et

s’assurer qu’il n’existe aucun blocage ou obstruction,

fuite, corrosion ni tout autre problème pouvant

menacer la sécurité.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building.

Dans la mesure du possible, fermer toutes les portes

et fenêtres de l’immeuble ainsi que toutes les portes

entre l’espace dans lequel les appareils qui demeurent

raccordés au système d’évacuation commun se

trouvent et le reste de l’immeuble.

4. Turn on any clothes dryers and any appliance not

connected to common venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do

not operate a summer exhaust fan.

Mettre en marche les sécheuses et tout autre appareil

non raccordé au système d’évacuation commun.

Mettre en marche tous les ventilateurs aspirant, tels

que les hottes de cuisinière et les ventilateurs de salle

de bain, en les faisant fonctionner à vitesse maximum.

5. Close fireplace dampers.

Ne pas faire fonctionner les ventilateurs aspirant d’été.

Fermer les registres de foyers.

6. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

Mettre en service l’appareil à inspecter. Suivre les

instructions concernant l’allumage. Régler le

thermostat afin que l’appareil fonctionne sans arrêt.

7. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar, or

pipe.

Vérifier toute fuite à l’orifice de décharge du coupetirage après que le brûleur ait fonctionné pendant 5

minutes. Utiliser la flamme d’une allumette ou d’une

chandelle ou encore la fumée d’une cigarette, d’un

cigare ou d’une pipe.

8. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

conditions of use.

Après avoir établi que les résidus de combustion de

chaque appareil qui demeure raccordé au système

commun sont adéquatement évacués lorsque soumis

au test décrit ci-dessus, remettre en place les portes,

fenêtres, portes intérieures, ventilateurs aspirants,

registres de foyer et appareils fonctionnant au gaz.

9. Any improper operation of the common venting system

should be corrected so that the installation conforms

with the National Fuel Gas Code, ANSI Z223.1/NFPA

54 or CAN/CGA B149 Installation Codes.

Tout fonctionnement inadéquat du système

d’évacuation commun doit être corrigé de manière à

respecter les normes du National Fuel Gas Code,

ANSI Z223.1/NFPA 54 et/ou des Codes d’installation

CAN/ACG B149.

10. When resizing any portion of the common venting

system, the common venting system should be resized

to approach minimum size as determined using the

appropriate tables located in the chapter “Sizing of

Category I Venting Systems,” of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or CAN/CGA B149

Installation codes.

Lorsqu’il est nécessaire de modifier les dimensions de

toute portion du système d’évacuation commun, ces

dernières doivent être modifiées de manière à

respecter les dimensions minimums indiquées dans les

tableaux du chapitre « Sizing of Category I Venting

Systems » du National Fuel Gas Code, ANSI

Z223.1/NFPA 54 ou des Codes d’installation

CAN/ACG B149.

Page 17

15

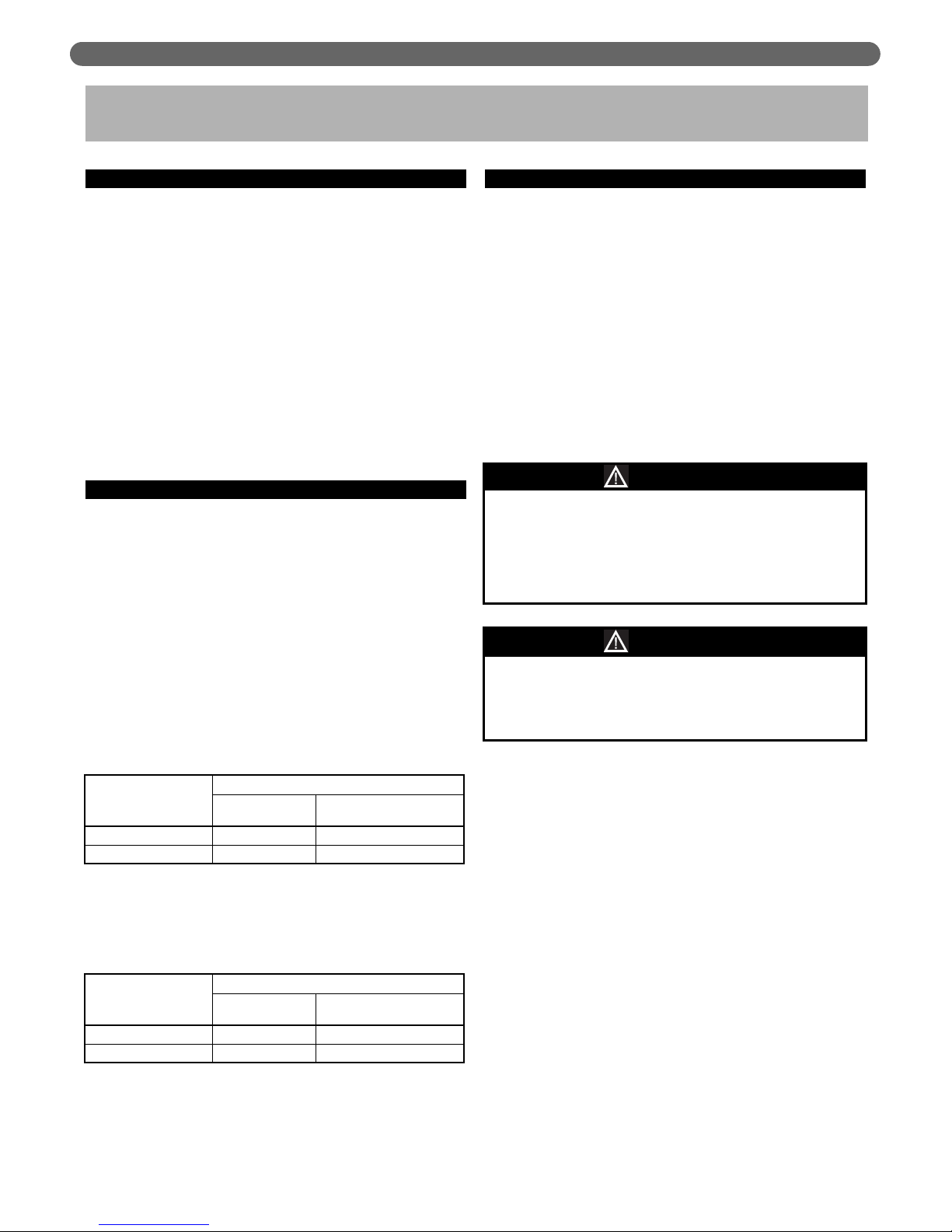

A. GENERAL

1. Size water supply and return piping in accordance

with system requirements. Do not use smaller

diameter piping than the boiler connections.

2. If the P

UREFIRE

®

boiler is used to replace an existing

boiler, make sure that the system piping is thoroughly

cleaned and free from debris before installing this boiler.

3. In hydronic systems where sediment may exist, install

a strainer in the boiler return piping to prevent large

particles and pipe scale from entering the boiler heat

exchanger. Use a large mesh screen in the strainer.

4. Install this boiler so that the gas ignition system

components are protected from water (dripping, spraying,

etc.) during operation and service (circulator replacement,

condensate trap cleaning, sensor replacement, etc.).

B. OPERATING PARAMETERS

1. The PUREFIRE®boiler is designed to operate in a

closed loop hydronic heating system under forced

circulation. This requires the system to be completely

filled with water and requires a minimum water flow

rate through the boiler to assure proper flow

distribution.

2. The minimum system operating pressure is 14.5 PSI

(69 kPa).

3. Table 4.1 lists the minimum flow rates for each

P

UREFIRE

®

model covered in this manual. Also shown

is the minimum flow rate for 50% glycol solution. For

other glycol concentrations, contact your PB Heat,

LLC representative for the minimum flow rates.

4. Section 4.E provides detailed information about using

glycol for freeze protection. Table 4.2 provides the

water volume of the heat exchangers for calculating

the system volume.

C. SYSTEM COMPONENTS

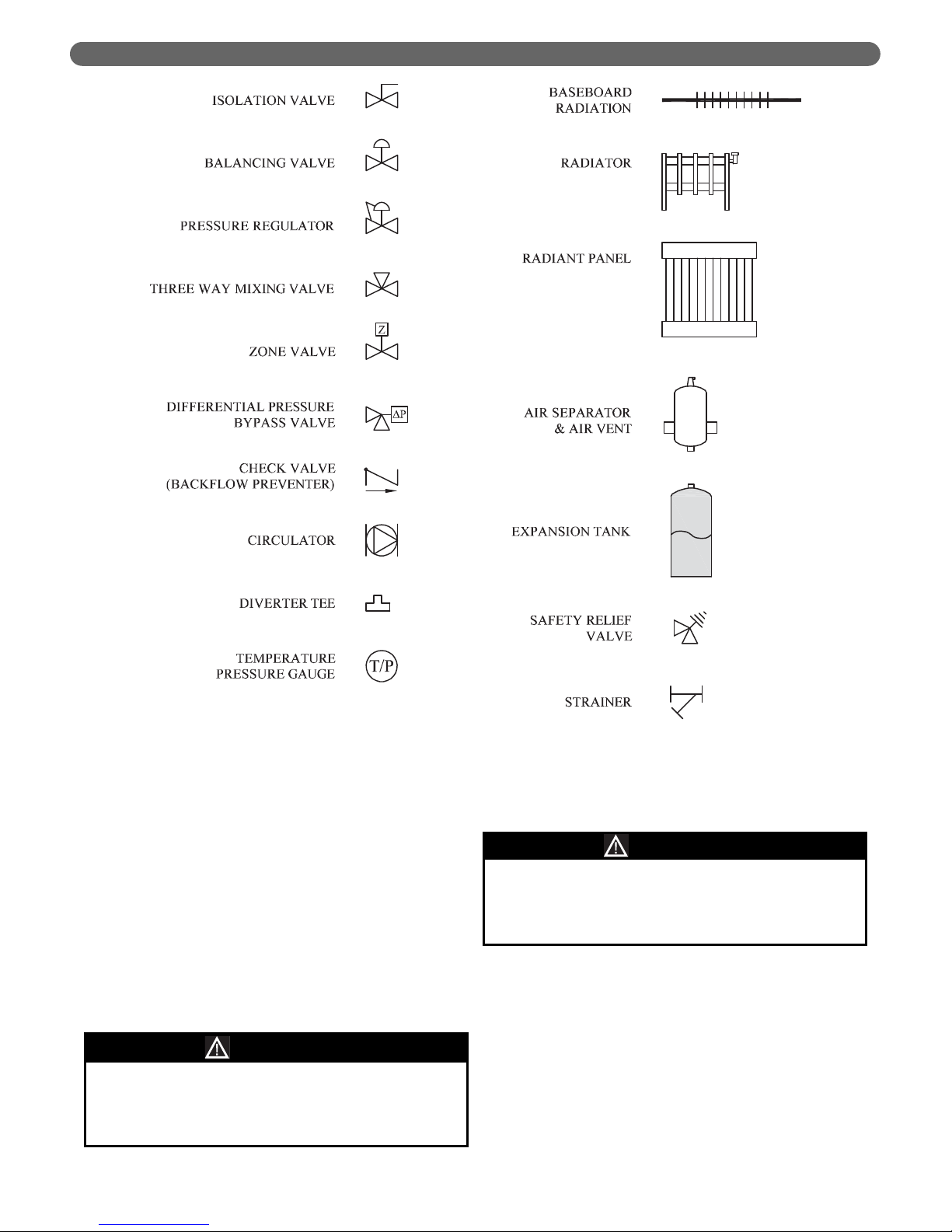

Figure 4.1 shows the symbol key for piping diagrams in

this section. The following are brief descriptions of system

components.

1. Pressure/Temperature Gauge: A combination

pressure/temperature gauge is provided with each

P

UREFIRE

®

boiler to be mounted in the piping from the

boiler supply to the system as shown in Figure 4.2.

Most local codes require this gauge.

2. Air Elimination: Closed loop hydronic systems require

air elimination devices. As the system water is heated,

dissolved oxygen and other gases will separate from

the liquid. An air elimination device (such as a TACO

Vortech

®

Air Separator) is required to remove the

dissolved gases preventing corrosion in the piping

system and eliminating noise.

3. Expansion Tank: An expansion tank (such as a Bell &

Gossett Series HFT) is required to provide room for

expansion of the heating medium (water or glycol

solution). Consult the expansion tank manufacturer's

instructions for specific information regarding

installation. The expansion tank is to be sized for the

required system volume and capacity. In addition, be

sure that the expansion tank is sized based on the

proper heating medium. Glycol solutions may expand

more than water for a similar temperature rise.

4. Y-Type Strainer or Filter Ball

®

Valve: PB Heat

recommends the use of a strainer device in the system to

prevent dirt or sediment from clogging the heat

exchanger. A 20 mesh stainless steel screen is adequate to

protect the heat exchanger. The strainer should be

cleaned often in the first several months of operation. The

Filter Ball

®

Valve from Jomar International incorporates a

strainer into a ball valve which allows the technician to

isolate the water circuit while cleaning the strainer.

5. Flow Control Valve: Flow control valves such as the

TACO Flo-Chek or Bell & Gossett Flo-Control™ are

used to prevent gravity circulation by incorporating a

check valve with a weighted disc.

4. WATER PIPING & CONTROLS

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Unlike automotive antifreeze, solutions for hydronic

applications contain corrosion inhibitors that will

protect system components from premature failure

due to corrosion.

CAUTION

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Ethylene glycol is toxic and may cause any

environmental hazard if a leak or spill occurs.

WARNING

PUREFIRE

®

Model

Minimum Flow Rate

Water

GPM (LPM)

50% Glycol Solution

GPM (LPM)

PF-850 39.5 (149.5) 49.4 (187.0)

PF-1000 46.5 (176.0) 58.2 (220.3)

Table 4.1: Minimum Boiler Flow Rates

PUREFIRE

®

Model

Total Water Capacity

Gallons Liters

PF-850 6.2 23.4

PF-1000 7.2 27.1

Table 4.2: Heat Exchanger Water Capacity

WATER PIPING & CONTROLS

Page 18

16

6. Pressure Reducing Valve: A pressure reducing valve,

such as the Bell & Gossett B-38 or a TACO #329, is

used in a hydronic system to automatically feed water

to the system whenever pressure in the system drops

below the pressure setting of the valve. These valves

should not be used on glycol systems unless close

supervision of the glycol solution is practiced.

7. Back Flow Preventer: A back flow preventer (check

valve) is required by some jurisdictions to prevent water

in the hydronic system from backing up into the city

water supply. This is especially important on systems in

which glycol solution is used as the heating medium.

8. Pressure Relief Valve: The boiler pressure relief valve is

shipped in the miscellaneous parts box for field

installation. It is extremely important to install this device.

The valve is to be installed on the boiler supply pipe

as shown in Figure 4.2. Pipe the discharge of the relief

valve to within 12” of the floor and close to a floor

drain.

Provide piping that is the same size or larger than the

relief valve outlet.

9. Circulator: The boiler circulator is to be sized to

overcome the pressure drop of the system while

providing the flow required by the boiler.

a. If the boiler is piped in a secondary loop of a

primary/secondary heating system, the circulator

will need only to overcome the resistance of the

boiler and any fittings in that loop.

WATER PIPING & CONTROLS

Figure 4.1: Piping Symbol Key

Do not operate this appliance without installing the

pressure relief valve supplied with the boiler or one

with sufficient relieving capacity in accordance with

the ASME Rating Plate on the boiler heat exchanger.

WARNING

Pipe the discharge of the relief valve as close as

possible to the floor and away from high traffic areas.

Pipe the discharge to a floor drain. Failure to do so

may result in personal injury and/or property damage.

CAUTION

Page 19

17

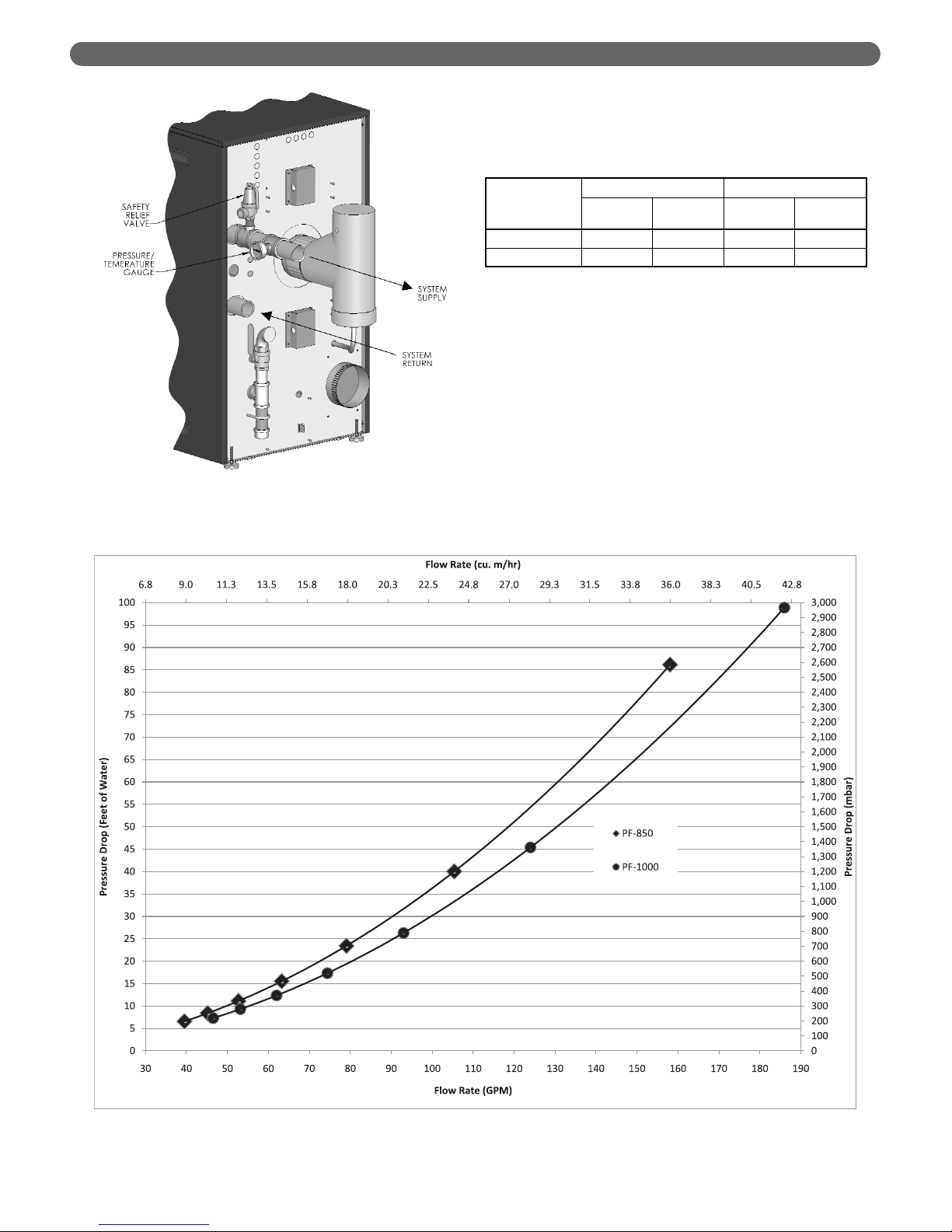

b. The circulator should be sized based on gross

output of the boiler. Table 4.3 shows the Boiler

Output as reported to the Hydronics Institute

Section of AHRI.

c. The required flow is calculated based on the design

temperature difference from the return to the supply

of the boiler. For a PF-850 with a design temperature

difference of 20°F the calculation is as follows:

Output 816,000

Required Flow =

________=_________

= 81.6 GPM

D

T x 500 20 x 500

d. The boiler pressure drop for various flow rates

can be determined using Figure 4.3, the P

UREFIRE

®

PF-850/PF-1000 Sizing Graph.

e. Table 4.4 provides the flow rate and pressure drop

information that corresponds to various boiler

temperature rise values (DT). The pressure drop

shown is for the boiler only. If there is significant

system pressure drop in the piping, this should be

considered when specifying circulators.

WATER PIPING & CONTROLS

Table 4.3: Boiler Input and Output

Figure 4.3: PUREFIRE®Circulator Sizing Graph (General Pump – Primary/Secondary)

Figure 4.2: Relief Valve and Pressure/Temperature

Gauge Installation

PUREFIRE

®

Model

Boiler Input Boiler Output

Btu/hr kW Btu/hr kW

PF-850 850,000 249 817,700 240

PF-1000 1,000,000 293 966,000 283

Page 20

18

f. Table 4.5 provides a list of recommended

circulators for boilers on a secondary loop of a

primary secondary system which uses water as a

heating medium.

g. Special consideration must be given if a glycol

based anti-freeze solution is used as a heating

medium. Propylene glycol has a higher viscosity

than water, therefore the system pressure drop will

be higher.

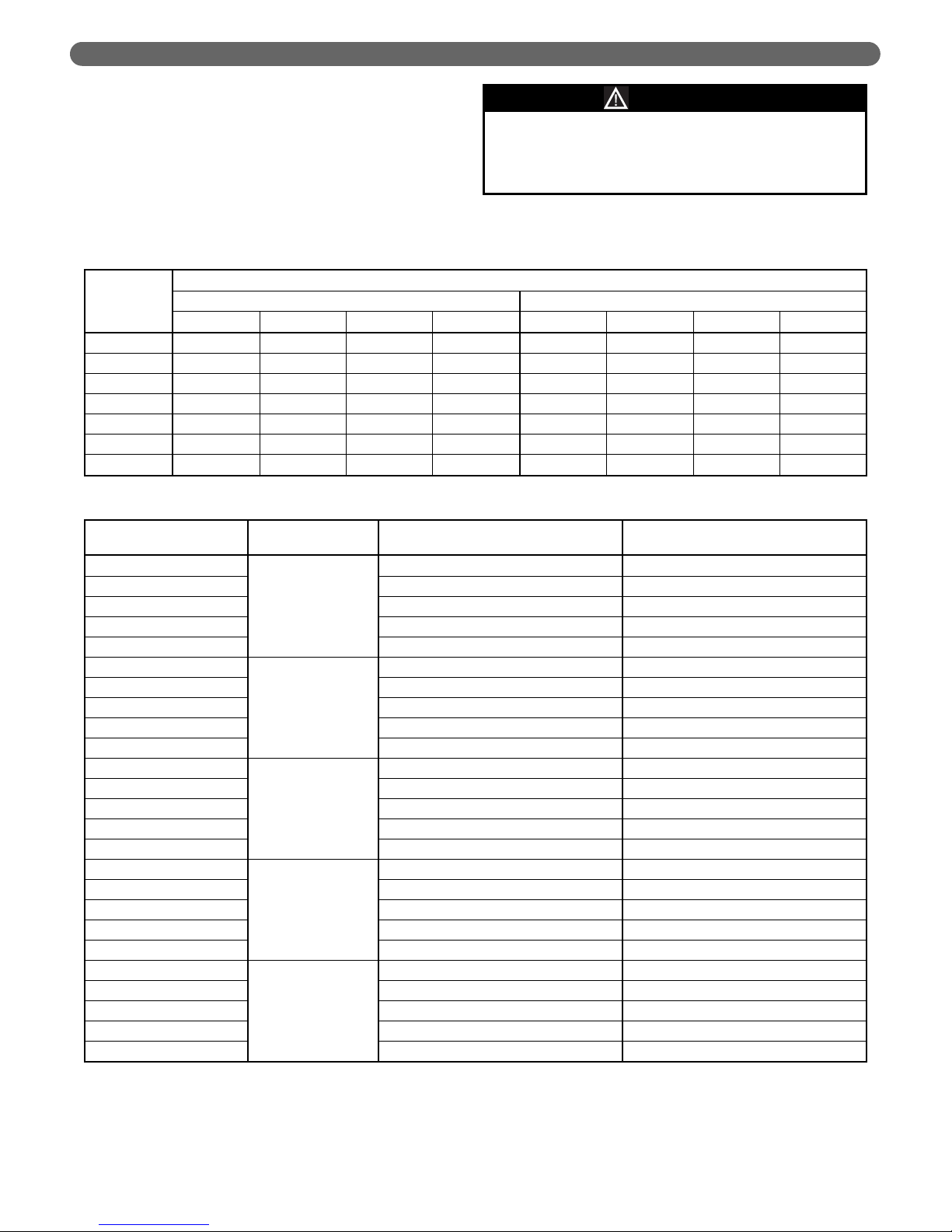

Table 4.4: Flow Rate & Pressure Drop for Various System Temperature Rise Values

DT

(°F)

Flow Rate & Pressure Drop

PF-850 PF-1000

GPM FT cu. m/hr mbar GPM FT cu. m/hr mbar

10 163.5 91.90 37.14 2747 193.2 98.87 43.88 2955

15 109.0 42.65 24.76 1275 128.8 45.37 29.25 1356

20 81.8 24.94 18.57 745 96.6 26.30 21.94 786

25 65.4 16.52 14.86 494 77.28 17.32 17.55 518

30 54.5 11.83 12.38 353 64.4 12.35 14.63 369

35 46.7 8.93 10.61 267 55.2 9.29 12.54 278

40 39.5 6.57 8.97 196 48.3 7.29 10.97 218

Table 4.5: Circulator Selection Chart (General Pump – Primary/Secondary Piping)

Circulator

Manufacturer

DT

(°F) PF-850 PF-1000

Taco

20

1635/1935, 138, 133 1635/1935

Grundfos UPS50-160/2F speed 2 UPS50-160/2F, speed 3

Bell & Gossett PD-38 PD-38

Wilo - Top S (1 Ph) 2.0 x 50 (max) 2.0 x 50 (max)

Wilo - Stratos 2.0 3 x 35 3.0 3 x 30

Taco

25

1635/1935, 132 1635/1935, 132

Grundfos UPS40-80/4F speed 3 UPS50-80/4F, speed 3

Bell & Gossett PL-130 PL-130

Wilo - Top S (1 Ph) 1.5 x 30 (max) 1.5 x 30 (min)

Wilo - Stratos 1.5 3 x 40 1.5 3 x 40

Taco

30

1611/1911, 131, 122, 121 1635/1935, 131

Grundfos UPS50-60F, speed 3 UPS40-80/4F, speed 3

Bell & Gossett 2.5" / LD3 2.5" / LD3

Wilo - Top S (1 Ph) 1.5 x 30 (min) 1.5 x 30 (min)

Wilo - Stratos 1.5 3 x 40 1.5 3 x 40

Taco

35

122, 121 122

Grundfos UPS50-60F, speed 2 UPS50-60F, speed 3

Bell & Gossett PL-75 2.5" / LD3

Wilo - Top S (1 Ph) 1.5 x 20 (max) 1.5 x 20 (max)

Wilo - Stratos 1.25 3 x 30 1.25 3 x 30

Taco

40

120 2400-60/2400-65

Grundfos UPS43-44FC, speed 3 UPS50-60F, speed 2

Bell & Gossett PL-45/NRF-45 PL-45

Wilo - Top S (1 Ph) 1.5 x 20 (min) 1.5 x 20 (min)

Wilo - Stratos 1.25 3 x 30 1.25 3 x 30

WATER PIPING & CONTROLS

The circulator sizing given is for primary/secondary

installations only. The system circulators must be

sized based on the flow and pressure drop

requirements of the system.

NOTICE

Page 21

D. SYSTEM PIPING

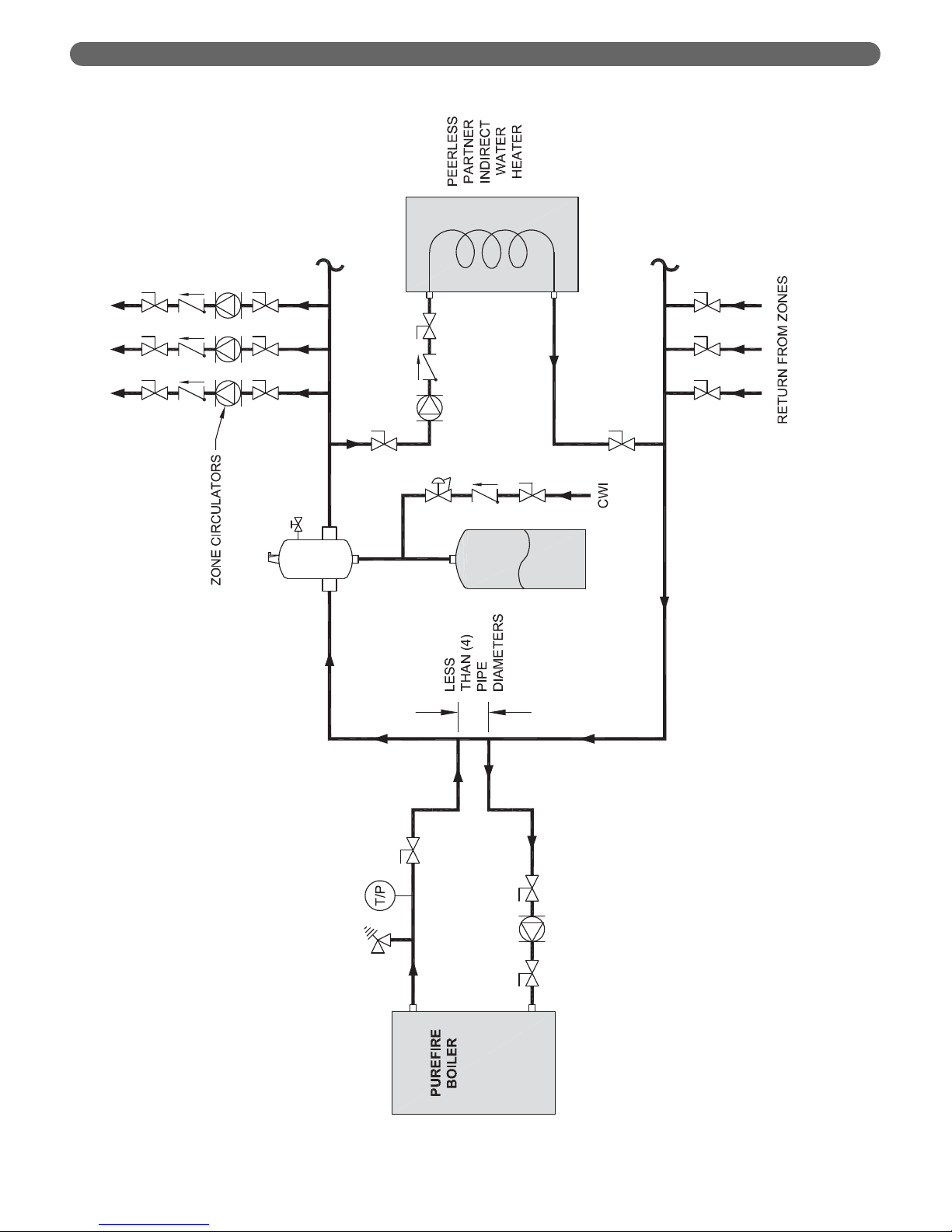

1. Figure 4.4 shows a single boiler with multiple heating

zones. In this case, the DHW zone is piped in parallel

to the heating zones on the primary loop.

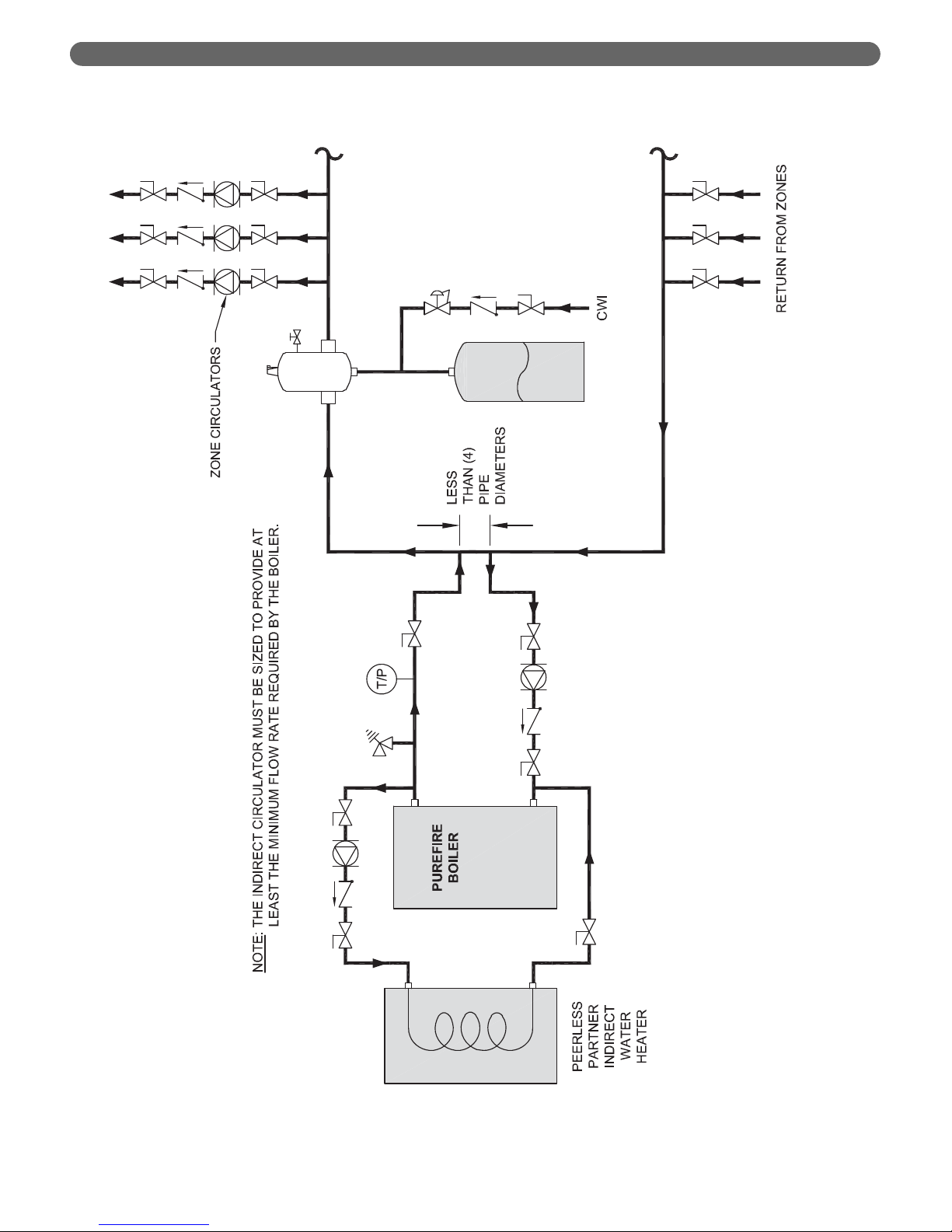

2. An alternate piping schematic for piping an indirect

water heater, such as the Peerless

®

Partner®, is

depicted in Figure 4.5. Note that, in this configuration,

the circulating pump for the indirect tank must be

sized to provide the minimum flow rate of the boiler.

In this configuration, both the GEN and CH

circulation pumps should be wired to the CH Pump

output on the terminal strip. This is required to

prevent the General (Boiler) pump from running when

a DHW demand is being satisfied. The total load of

CH and GEN pumps must not exceed 10 amps. If the

load is higher, then an isolation relay must be used.

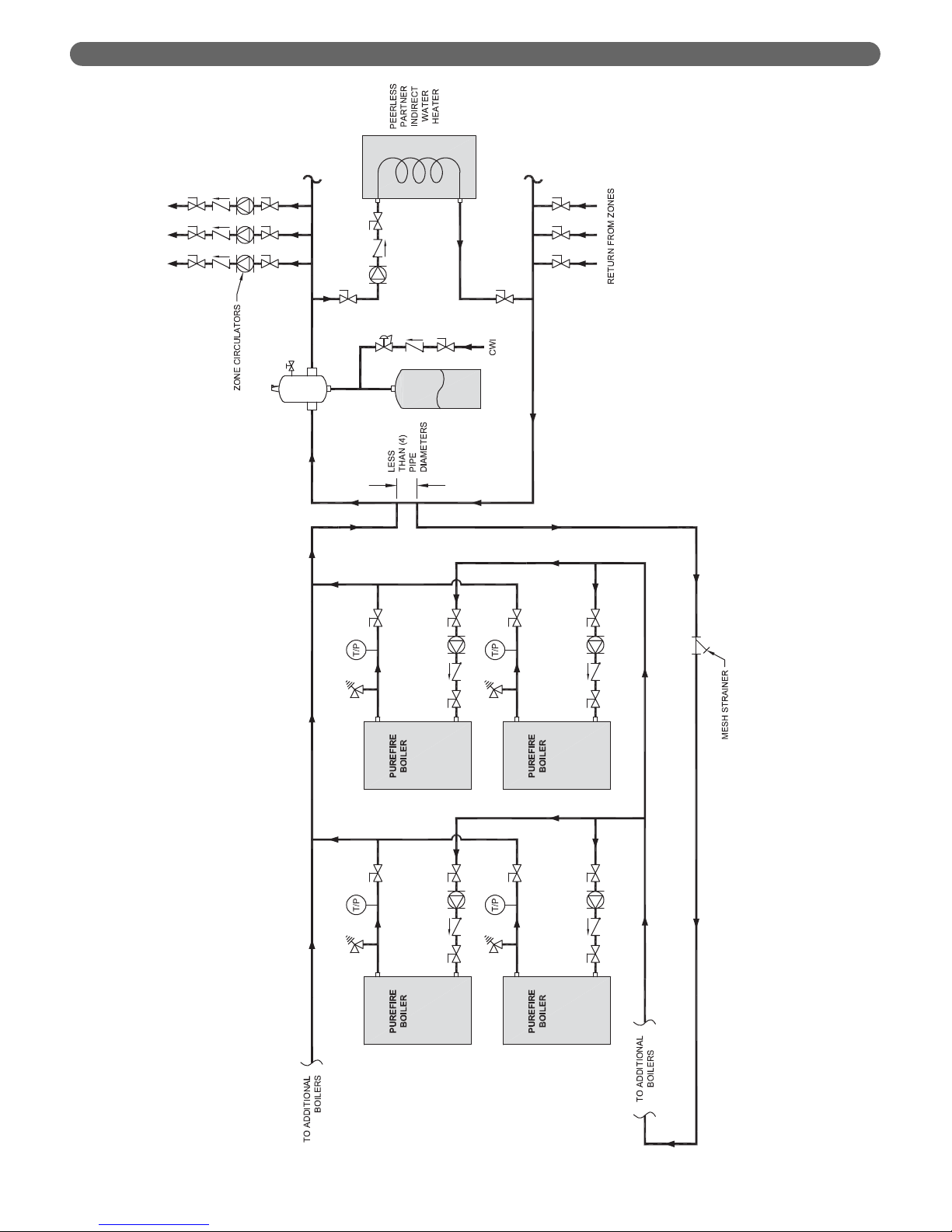

3. The configuration illustrated in Figure 4.6 is for

multiple boilers. This figure shows an indirect DHW

tank in parallel with the heating zones. Notice that the

return to the boilers from the closely spaced tees in

the primary secondary arrangement is reverse return

to provide similar lengths of piping through each

boiler. This configuration shows the boilers in groups

of two to take advantage of the P

UREFIRE

®

PF-850 or

PF-1000 stacking capability.

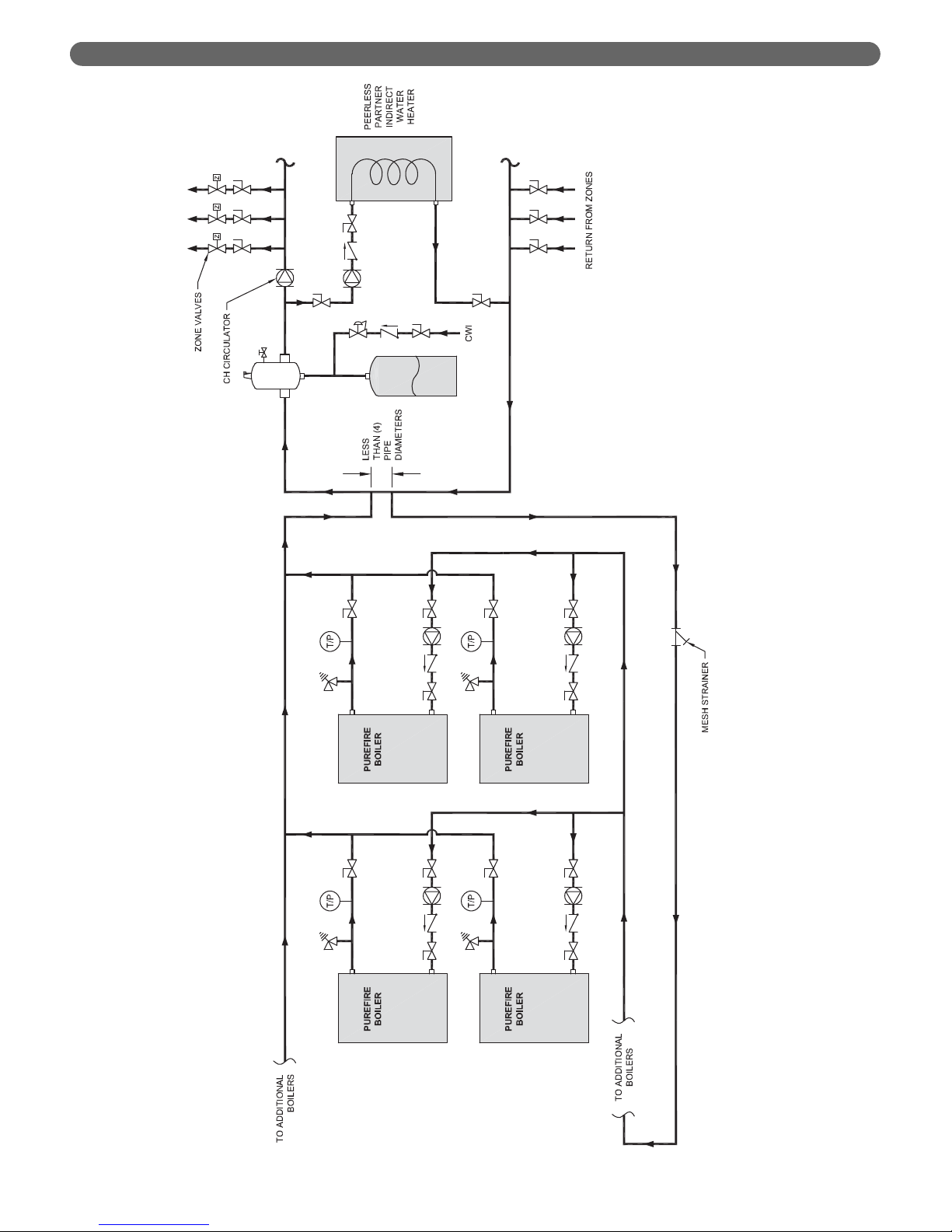

4. Figure 4.7 shows a multiple boiler configuration which

uses zone valves instead of zone circulators. Systems

which combine both zone valves and zone circulators

can help to minimize electrical loads if there are small

zones in the system. Contact your PB Heat, LLC

representative for assistance with larger systems.

E. FREEZE PROTECTION

1. Glycol for hydronic applications is specially formulated

for heating systems. It includes inhibitors which prevent

the glycol from attacking metallic system components.

Make sure that the system fluid is checked for correct

glycol concentration and inhibitor level.

2. Use only inhibited polypropylene glycol solutions of

up to 50% by volume. Ethylene glycol is toxic and

can chemically attack gaskets and seals used in

hydronic system.

3. The anti-freeze solution should be tested at least once

per year and as recommended by the manufacturer of

the product.

4. Anti-freeze solutions expand more than water. For

example, a 50% by volume solution expands 4.8%

with a 148°F temperature rise while water expands

about 3% for the same temperature increase.

Allowance for this expansion must be considered in

sizing expansion tanks and related components. Table

4.2 provides the water capacity of the heat exchanger

to help in system volume calculations.

5. The flow rate in systems utilizing glycol solutions

should be higher than in a water system to

compensate for decreased heating capacity of the fluid.

6. Due to increased flow rate and fluid viscosity, the

circulator head requirement will increase. Contact the

pump manufacturer to correctly size the circulator for

a particular application based on the glycol

concentration and heating requirements.

7. A strainer, sediment trap, or some other means for

cleaning the piping system must be provided. It

should be located in the return line upstream of the

boiler and must be cleaned frequently during the

initial operation of the system. Glycol is likely to

remove mill scale from new pipe in new installations.

8. Glycol solution is expensive and leaks should be

avoided. Weld or solder joints should be used where

possible and threaded joints should be avoided.

Make-up water should not be added to the system

automatically when glycol solution is used. Adding

make-up water will dilute the system and reduce the

ability of the solution to protect from freezing.

9. Check local regulations to see if systems containing

glycol solutions must include a back-flow preventer or

require that the glycol system be isolated from the

water supply.

10. Do not use galvanized pipe in glycol systems.

11. Use water that is low in mineral content and make

sure that there are no petroleum products in the

solution.

a. Less than 50 ppm of calcium

b. Less than 50 ppm of magnesium

c. Less than 100 ppm (5 grains/gallon) of total

hardness

d. Less than 25 ppm of chloride

e. Less than 25 ppm of sulfate

12. Check with the local water supplier for chemical

properties of the water.

13. The following test will determine if the water is of the

appropriate hardness. Collect a sample of 50% water

to 50% propylene glycol. Let the solution stand for 812 hours shaking it occasionally. If white sediment

forms, the water is too hard and should not be used

to dilute the glycol.

14. Mix the solution at room temperature.

15. Do not use a chromate treatment.

16. Refer to Technical Topics #2a published by the

Hydronics Institute for further glycol system

considerations.

WATER PIPING & CONTROLS

19

Page 22

20

WATER PIPING & CONTROLS

Figure 4.4: Recommended Piping – One Boiler with Multiple CH Zones & One DHW Tank

Page 23

21

WATER PIPING & CONTROLS

Figure 4.5: Alternate Piping – One Boiler with Multiple CH Zones & One DHW Tank

Page 24

22

WATER PIPING & CONTROLS

Figure 4.6: Recommended Piping – Multiple Boilers with Multiple CH Zones & One DHW Tank

Page 25

23

WATER PIPING & CONTROLS

Figure 4.7: Alternate Piping – Multiple Boilers with Multiple CH Zones (Zone Valves) & One DHW Tank

Page 26

24

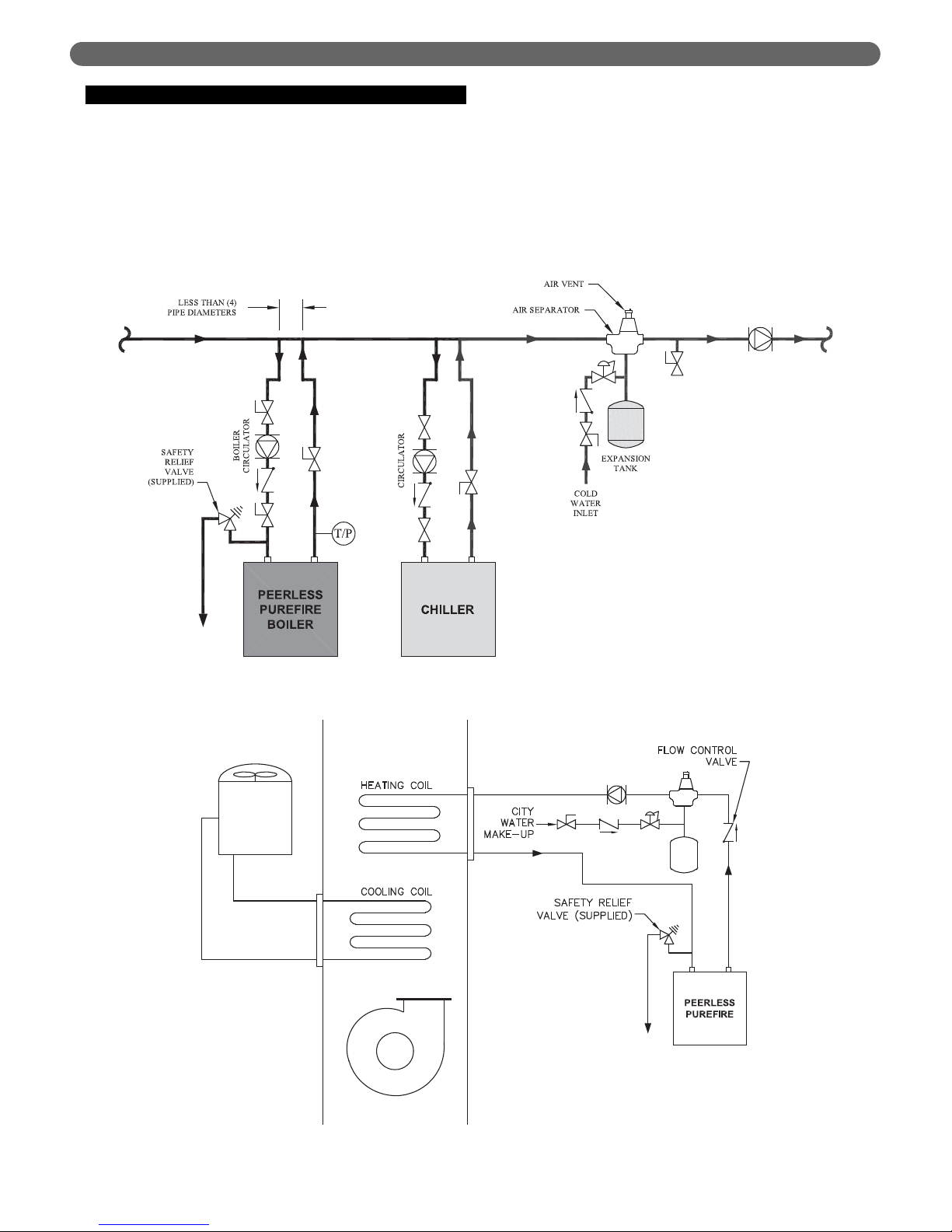

F. SPECIAL APPLICATIONS

1. If the PUREFIRE®boiler is used in conjunction with a

chilled medium system, pipe the chiller in a separate

secondary loop.

a. Assure that the boiler circulator is disabled during

chiller operation so that chilled water does not

enter the boiler.

b. Install a flow control valve (spring check valve) to

prevent gravity flow through the boiler.

c. See Figure 4.8 for recommended system piping for

chiller operation.

2. For boilers connected to heating coils in a forced air

system where they may be exposed to chilled air

circulation, install flow control valves or other

automatic means to prevent gravity circulation of the

boiler water during cooling cycles. See Figure 4.9 for

an illustration.

WATER PIPING & CONTROLS

Figure 4.8: Boiler in conjunction with a Chilled Water System

Figure 4.9: Boiler Connected to a Heating Coil in a Forced Air System

Page 27

25

A. GENERAL

1. All fuel piping to the PUREFIRE®boiler is to be in

accordance with local codes. In the absence of local

regulations refer to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

2. Size and install fuel piping to provide a supply of gas

sufficient to meet the maximum demand of all

appliances supplied by the piping.

B. FUEL LINE SIZING

1. The required flow rate of fuel gas to the boiler can be

determined by the following:

2. As an alternative, use Table 5.1 to determine the

required gas flow rate. This table uses typical heating

values for natural gas and liquefied petroleum (LP) gas.

3. Table 5.2 shows the maximum flow capacity of

several pipe sizes based on 0.3" w.c. pressure drop.

The values shown are based on a natural gas specific

gravity of 0.60.

4. Table 5.3 shows the maximum capacity of pipe sizes

for LP gas with a specific gravity of 1.50.

5. Size the fuel gas supply piping for no more than 0.5

in. w.c. pressure drop between the gas pressure

regulator and the boiler.

C. GAS SUPPLY PIPING - INSTALLATION

1. Do not install any piping directly in front of the boiler

or along either side. Always provide clearance for

removal of the front cover or side panels for

inspection and maintenance.

Boiler Input Rate

Gas Heating Value

Input Rate

(

ft

³

/

hr

)

=

(

Btu

/

hr

)

(

Btu

/

ft

³

)

FUEL PIPING

5. FUEL PIPING

PUREFIRE

®

Model

Required Input Rate

Natural Gas

(@1000 Btu/cu.ft)

LP Gas

(@ 2,500 Btu/cu.ft)

ft3/hr m3/hr ft3/hr m3/hr

PF-850 850 24.1 340 9.6

PF-1000 1000 28.3 400 11.3

Table 5.1: Required Fuel Input

Pipe

Length

1-1/4"

Pipe

1-1/2"

Pipe

2" Pipe

2-1/2"

Pipe

3" Pipe 4" Pipe 6" Pipe

ft (m)

10

(3.0)

1,050

(30)

1,600

(45)

3,050

(86)

4,800

(136)

8,500

(241)

17,500

(496)

44,000

(1246)

20

(6.1)

730

(21)

1,100

(31)

2,100

(59)

3,300

(93)

5,900

(167)

12,000

(340)

31,000

(878)

30

(9.1)

590

(17)

890

(25)

1,650

(47)

2,700

(76)

4,700

(133)

9,700

(275)

25,000

(708)

40

(12.2)

500

(14)

760

(22)

1,450

(41)

2,300

(65)

4,100

(116)

8,300

(235)

22,000

(623)

50

(15.2)

440

(12)

670

(19)

1,270

(36)

2,000

(57)

3,600

(102)

7,400

(210)

20,000

(566)

60

(18.3)

400

(11)

610

(17)

1,150

(33)

1,850

(52)

3,250

(92)

6,800

(193)

18,000

(510)

70

(21.3)

370

(10)

560

(16)

1,050

(30)

1,700

(48)

3,000

(85)

6,200

(176)

17,000

(481)

80

(24.4)

350

(10)

530

(15)

930

(26)

1,500

(42)

2,600

(74)

5,400

(153)

15,000

(425)

90

(27.4)

320

(9)

490

(14)

870

(25)

1,400

(40)

2,500

(71)

5,100

(144)

14,000

(396)

100

(30.5)

305

(9)

460

(13)

710

(20)

1,130

(32)

2,000

(57)

4,100

(116)

11,500

(326)

Table 5.2: Pipe Capacity – Natural Gas

Maximum Capacity of pipe in cubic feet per hour (cubic meters

per hour) with a pressure drop of 0.3" of water (75 Pa).

Pipe

Length

1-1/4"

Pipe

1-1/2"

Pipe

2" Pipe

2-1/2"

Pipe

3" Pipe 4" Pipe 6" Pipe

ft (m)

10

(3.0)

662

(18.7)

1,008

(28.5)

1,922

(54.4)

3,024

(85.6)

5,355

(151.6)

11,025

(312.2)

27,720

(784.9)

20

(6.1)

460

(13.0)

693

(19.6)

1,323

(37.5)

2,079

(58.9)

3,717

(105.3)

7,560

(214.1)

19,530

(553.0)

30

(9.1)

372

(10.5)

561

(15.9)

1,040

(29.4)

1,701

(48.2)

2,961

(83.8)

6,111

(173.0)

15,750

(446.0)

40

(12.2)

315

(8.9)

479

(13.6)

914

(25.9)

1,449

(41.0)

2,583

(73.1)

5,229

(148.1)

13,860

(392.5)

50

(15.2)

277

(7.8)

422

(12.0)

800

(22.7)

1,260

(35.7)

2,268

(64.2)

4,662

(132.0)

12,600

(356.8)

60

(18.3)

252

(7.1)

384

(10.9)

725

(20.5)

1,166

(33.0)

2,048

(58.0)

4,284

(121.3)

11,340

(321.1)

70

(21.3)

233

(6.6)

353

(10.0)

662

(18.7)

1,071

(30.3)

1,890

(53.5)

3,906

(110.6)

10,710

(303.3)

80

(24.4)

221

(6.2)

334

(9.5)

586

(16.6)

945

(26.8)

1,638

(46.4)

3,402

(96.3)

9,450

(267.6)

90

(27.4)

202

(5.7)

309

(8.7)

548

(15.5)

882

(25.0)

1,575

(44.6)

3,213

(91.0)

8,820

(249.8)

100

(30.5)

192

(5.4)

290

(8.2)

447

(12.7)

712

(20.2)

1,260

(35.7)

2,583

(73.1)

7,245

(205.2)

Table 5.3: Pipe Capacity – LP Gas

(1.50 Specific Gravity)

Maximum Capacity of pipe in cubic feet per hour (cubic meters

per hour) with a pressure drop of 0.3" of water (75 Pa).

Use a pipe joint sealing compound that is resistant to

liquefied petroleum gas. A non-resistant compound

may lose sealing ability in the presence of this gas,

resulting in a gas leak. Gas leaks may potentially

cause an explosion or fire.

WARNING

Page 28

26

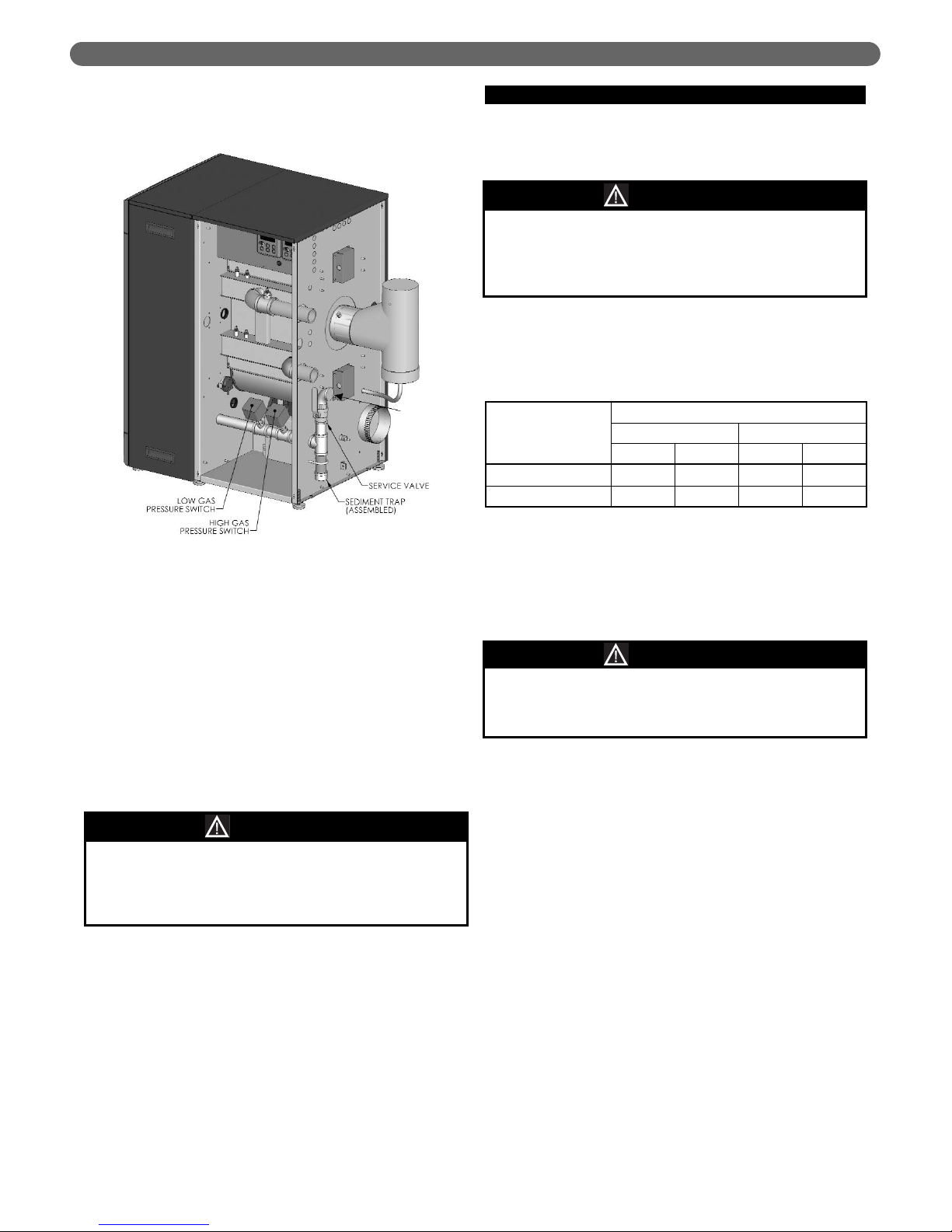

2. A sediment trap is included from the factory into the

supply piping at the boiler. Figure 5.1 shows the

sediment trap at the rear of the boiler near the base.

3. High and low gas pressure switches are provided on

the gas supply header inside the boiler cabinet. Figure

5.1 shows the pressure switch location.

4. Install the service valve, supplied by the factory, as

shown in Figure 5.1 on the inlet to the boiler gas

piping.

5. Install a ground joint union upstream of the service

valve to allow service to the appliance.

6. Maintain a minimum distance of 5 feet between the

supply gas pressure regulator and the appliance.

7. Check all gas piping for leaks prior to placing the

boiler in service. Use an approved gas detector, noncorrosive leak detection fluid, or other leak detection

method to determine if there are leaks in the system.

If leaks are found, turn off the gas flow at the service

valve and repair as necessary.

8. Gas shutoff valves, located in the blower vestibule

cabinet area, are provided for each individual burner.

These valves are to be used in addition to the gas

service valve to interrupt gas flow to the individual

burners.

D. GAS SUPPLY PIPING - OPERATION

1. The gas line must be properly purged of air to allow

the boiler to operate properly. Failure to do so may

result in burner ignition problems.

2. Table 5.4 shows the maximum and minimum fuel gas

supply pressure to the boiler.

a. Gas pressures below 3.5 in. w.c. may result in

burner ignition failures and hard ignitions. A low

gas pressure switch has been provided with the

boiler to prevent low pressure conditions.

b. Gas pressures above 26 in. w.c. may result in

damage to the automatic gas valve.

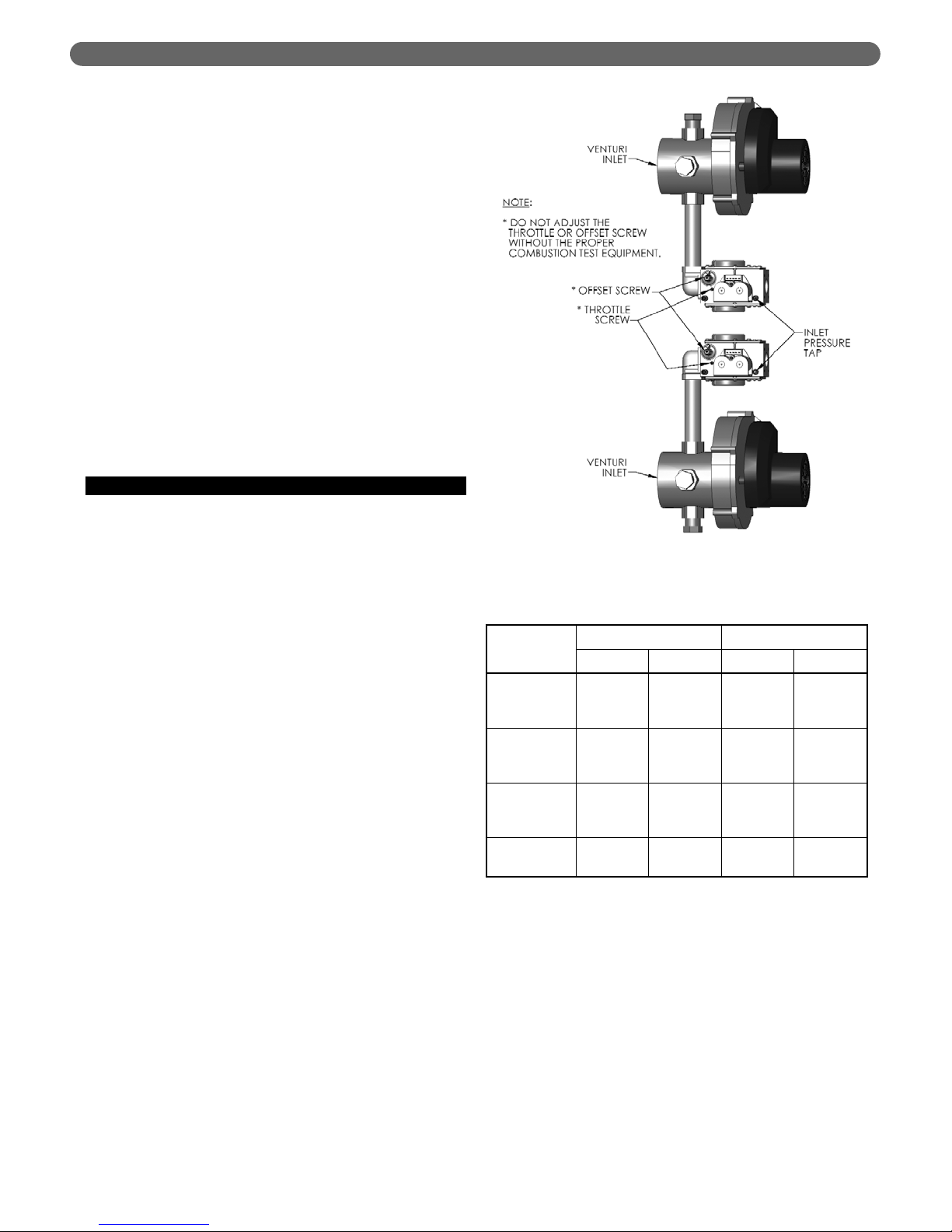

3. To check the gas supply pressure to the gas valve:

a. Turn off the power at the service switch.

b. Close the gas shutoff valve for the automatic valve

being checked.

c. Using a flat screwdriver, turn the screw inside the

inlet pressure tap fitting (see Figure 5.2) one turn

counterclockwise.

d. Attach the tube from the manometer to the inlet

pressure tap fitting.

e. Turn on the burner service switch.

f. Open the manual gas valve and start the boiler.

g. Read and record the gas pressure while the boiler

is firing.

h. Remove the call for heat and allow the burner to

shutdown normally with a full postpurge.

i. Turn off the burner service switch and close the

gas shutoff valve.

j. Remove the manometer tube from the inlet

pressure tap fitting.

FUEL PIPING

When checking for leaks, do not use matches,

candles, open flames or other methods that provide

an ignition source. This may ignite a gas leak

resulting in a fire or explosion.

WARNING

Do not subject the gas valve to more than 26 in. w.c.

(65 mbar) of gas pressure. Doing so may damage the

gas valve.

CAUTION

Fuel Type

Fuel Inlet Pressure (Main Gas Shutoff)

Minimum Maximum

in. w.c. mbar in. w.c. mbar

Natural Gas 3.5 8.5 26 65

LP Gas 3.5 8.5 26 65

Table 5.4: Maximum and Minimum Fuel Supply

Pressure

Figure 5.1: Gas Supply Pipe and Shutoff

Liquefied Petroleum (LP) Gas or Propane is heavier

than air and, in the event of a leak, may collect in low

areas such as basements or floor drains. The gas

may then ignite resulting in a fire or explosion.

WARNING

Page 29

27

k. Turn the internal screw clockwise to close the

valve.

l. Turn on the gas shutoff valve and the boiler

service switch.

m. Start the boiler and check for fuel gas odor

around the gas valve. If an odor is evident, check

to make sure that the pressure tap fitting is closed.

n. Repeat this procedure on the second gas valve.

4. All gas piping must be leak tested prior to placing the

boiler in operation.

a. If the required leak test pressure is higher than 26

in. w.c., the boiler must be isolated from the gas

supply piping by closing the service valve.

b. If the gas valve is exposed to pressure exceeding

26 in. w.c., the gas valve must be replaced.

5. Install the boiler such that the gas ignition system

components are protected from water (dropping,

spraying, rain, etc.) during operation and service