PEERLESS PT-30, PT-40, PT-60, PT-80, PT-50 Installation, Operation & Maintenance Manual

...

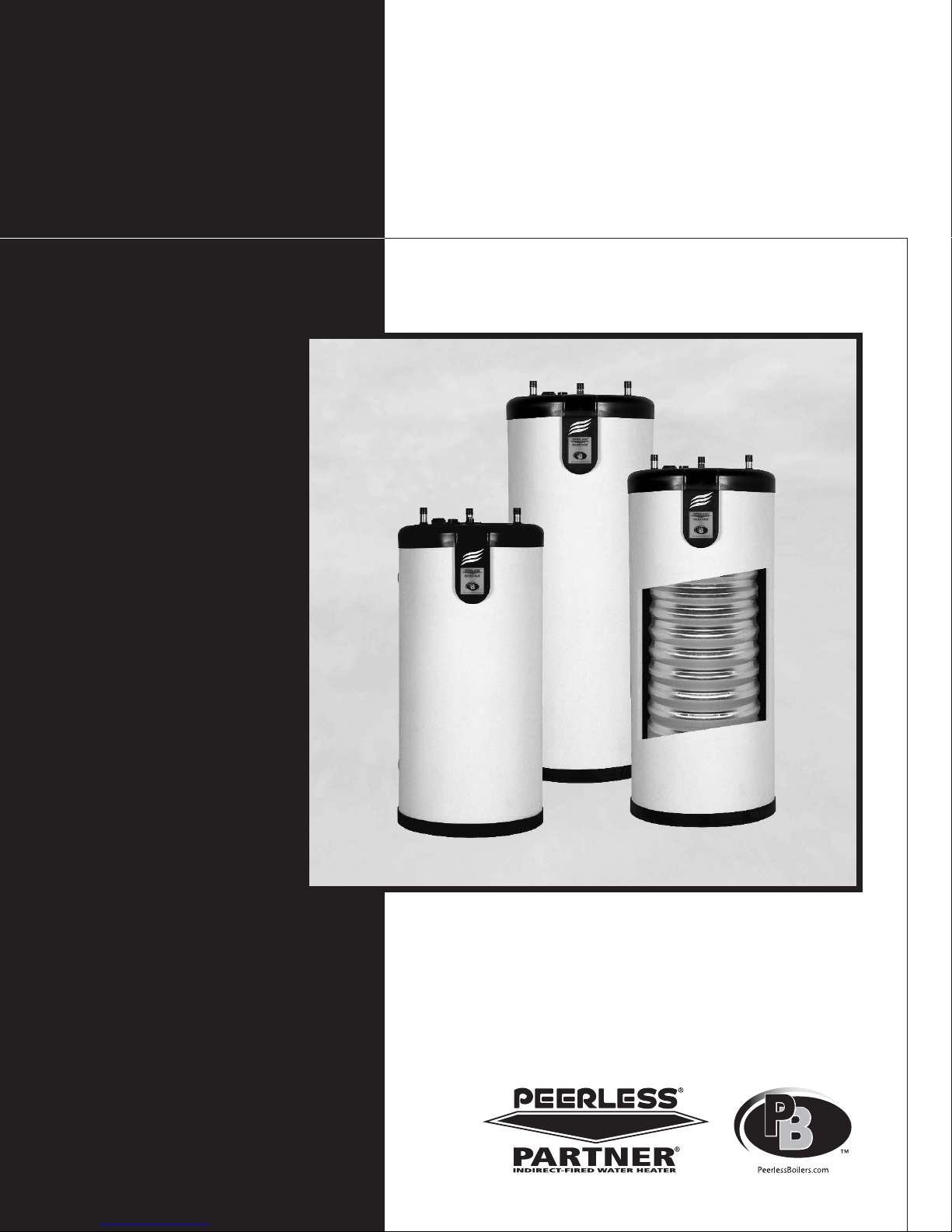

Partner

®

Water Heater

PT-30 PT-40 PT-50 PT-60 PT-80 PT-120

Peerless

®

Indirect-Fired

Installation,

Operation &

Maintenance

Manual

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . . .1

PRODUCT & SAFETY INFORMATION 2

1. PREINSTALLATION 3

A. CODES COMPLIANCE . . . . . . . . . . . . . . . . . . .3

B. CODES RESTRICTIONS . . . . . . . . . . . . . . . . . .3

C. OPERATING RESTRICTIONS . . . . . . . . . . . . . .3

D. LOCATING WATER HEATER . . . . . . . . . . . . . .3

E. PRODUCT SELECTION . . . . . . . . . . . . . . . . . .4

F. RECOMMENDED CLEARANCES . . . . . . . . . . .5

2. INSTALLATION - PIPING 6

A. TEMPERATURE & PRESSURE (T&P)

RELIEF VALVE . . . . . . . . . . . . . . . . . . . . . . . . .6

B. DRAIN VALVE . . . . . . . . . . . . . . . . . . . . . . . . . .6

C. AUTOMATIC AIR VENT . . . . . . . . . . . . . . . . . .7

D. THERMAL EXPANSION . . . . . . . . . . . . . . . . .7

E. WATER HAMMER . . . . . . . . . . . . . . . . . . . . . .7

F. VACUUM BREAKER . . . . . . . . . . . . . . . . . . . . .7

G. GENERAL PIPING . . . . . . . . . . . . . . . . . . . . . . .7

H. DOMESTIC PIPING . . . . . . . . . . . . . . . . . . . . . .7

I. THERMOSTATIC MIXING VALVE . . . . . . . . . .8

J. RECIRCULATION PIPING . . . . . . . . . . . . . . . . .8

K. MULTIPLE WATER HEATER SYSTEMS . . . . .8

L. BOILER PIPING . . . . . . . . . . . . . . . . . . . . . . . . .8

3. INSTALLATION - PIPING DRAWINGS 9

4. INSTALLATION - WIRING 16

A. WIRING REQUIREMENTS . . . . . . . . . . . . . . .16

B. CIRCULATORS . . . . . . . . . . . . . . . . . . . . . . . .16

C. ZONE VALVES . . . . . . . . . . . . . . . . . . . . . . . .16

D. SNAPSET CONNECTION . . . . . . . . . . . . . . . .16

5. INSTALLATION - WIRING DRAWINGS 17

6. WATER HEATER START-UP 22

A. FILLING THE INNER (DOMESTIC WATER)

TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

B. FILLING THE OUTER (BOILER WATER)

TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

C. GENERAL NOTES . . . . . . . . . . . . . . . . . . . . .23

D. ADJUSTING THE WATER HEATER

THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . .23

7. WATER HEATER MAINTENANCE 24

A. MAINTENANCE SCHEDULE . . . . . . . . . . . . .24

B. FILLING WATER HEATER . . . . . . . . . . . . . . .24

C. DRAINING WATER HEATER . . . . . . . . . . . . .24

D. DRAINING INNER (DOMESTIC WATER)

TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

E. DRAINING OUTER (BOILER WATER)

TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8. TROUBLESHOOTING 26

9. REPAIR PARTS 27

10. WATER HEATER DIMENSIONS &

RATINGS 29

11. PERFORMANCE RATINGS 30

TABLE OF CONTENTS

TABLE OF CONTENTS

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this manual

in the order shown. The order of these instructions has

been set in order to provide the installer with a logical

sequence of steps that will minimize potential

interferences and maximize safety during boiler

installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual special attention boxes are

provided to supplement the instructions and make special

notice of potential hazards. The definition of each of

these categories, in the judgement of PB Heat, LLC

are as follows:

USING THIS MANUAL

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

1

USING THIS MANUAL

2

PRODUCT SAFETY & INFORMATION

PRODUCT SAFETY & INFORMATION

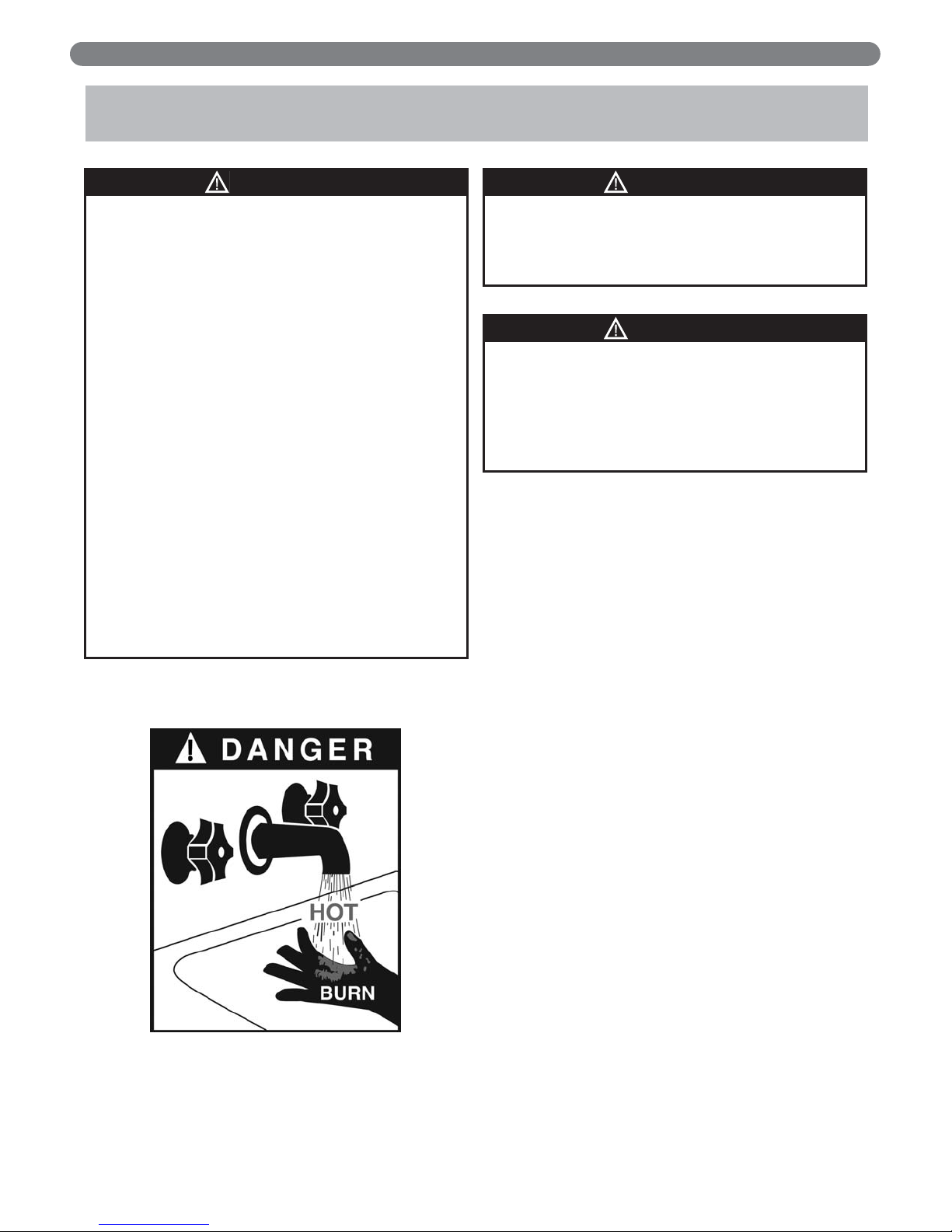

DANGER

HOT WATER CAN SCALD!

• Water temperatures over 125ºF can cause severe

burns instantly or death from scalding.

• Children, disabled and elderly are at highest risk of

being scalded.

• Never leave them unattended in or near shower,

bathtub or sink.

• Never allow small children to use a hot water faucet

or draw their own bath.

• If anyone using hot water in the building fits the

above description or if local codes or state laws

require specific water temperatures at hot water

faucet, it is recommended:

– to install a thermostatic mixing valve at this

appliance or at each water faucet.

or

– to set the thermostat knob for the lowest

temperature which satisfies your hot water

needs.

• Water drained from the system drain valves may be

extremely hot. To avoid injury:

– Make sure all connections are tight.

– Direct water flow away from any person.

Protection must be taken against excessive

temperature and pressure!

• Installation of a Temperature & Pressure (T&P) relief

valve is required.

WARNING

To prevent damage to the inner tank, the installer

must:

• Always fill inner tank prior to outer tank and always

drain outer tank prior to inner tank.

• Relieve primary system pressure below 15 psig

prior to draining inner tank.

CAUTION

3

1. PREINSTALLATION

A. CODES COMPLIANCE

Water heater installation must conform with the

instructions in this manual and where applicable:

• local, state, provincial, and national codes, laws,

regulations and ordinances.

• in Canada - CAN / CGA B149.1 or B149.2

Installation Code.

Peerless

®

Partner®water heaters are exempt from ASME

Section VIII, Division 1 Code construction per

Interpretation VIII-86-136. Check with local codes for

applicability.

Where recommendations in this manual differ from local,

or national codes, the local or national codes take

precedence.

B. CODES RESTRICTIONS

1. Single wall heat exchanger in the Peerless®Partner

®

water heater complies with National Standard

Plumbing Code, provided that:

a. boiler water (including additives) is practically

non-toxic, having toxicity rating or class of 1, as

listed in Clinical Toxicology of Commercial

Products, and

b. boiler water pressure is limited to maximum 30

psig by approved relief valve.

2. Single wall heat exchangers are permitted under the

Uniform Plumbing code - Paragraph L3.2. and L3.3 if

they satisfy all of the following requirements.

a. The heat transfer medium is potable water or

contains only substances which are recognized as

safe by the U.S. Food and Drug Administration.

b. The pressure of the heat transfer medium is

maintained less than the normal minimum

operating pressure of the potable water system

Exception: Steam complying with section

#1 above.

c. The equipment is permanently labeled to indicate

that only additives recognized as safe by the FDA

shall be used in the heat transfer medium.

Other heat exchanger designs may be permitted

where approved by the Administrative Authority.

C. OPERATING RESTRICTIONS

1. Maximum domestic hot water temperature is 194ºF

for commercial applications and 140ºF for residential

applications.

2. Maximum boiler water temperature is 210ºF.

3. Maximum working pressure for inner (domestic water)

tank is 150 psig.

4. Maximum working pressure for outer (boiler water)

tank is 45 psig.

5. pH and chloride limits for water heaters are:

a. chloride, less than 150 mg/l (ppm)

b. pH value min. 6 - max. 8

D. LOCATING WATER HEATER

1. This water heater is not intended for outdoor

installations.

2. Keep distance between boiler and water heater to a

minimum to:

a. reduce piping heat loss

b. provide minimal friction loss

3. Locate water heater so that any leakage from the tank

or water connections will not cause damage to the

area adjoining the water heater or to lower floors in

the structure.

When such a location is unavoidable, a suitable

drain pan with adequate drainage, should be

placed under the water heater.

4. The Peerless

®

Partner®water heaters are designed for

vertical installation only.

Peerless®Partner®water heaters will absorb less than

200,000 BTU/hr when domestic water outlet

temperature is 210°F and boiler water supply

temperature is 240°F. Listed outputs are based on

ASME Section VIII Interpretation VIII-1-86-136.

NOTICE

Do not install the water heater on any application if

the boiler piping contains non-oxygen barrier tubing

or if the boiler piping is considered an “open

system”. Exposing the outer tank of the water heater

to oxygen contamination will lead to premature tank

failure and denial of the warranty.

NOTICE

Any water conditioning system must be installed

and maintained in accordance with manufacturer’s

specifications.

NOTICE

PREINSTALLATION

4

E. PRODUCT SELECTION

1. The following guidelines apply to residential systems

only. For commercial or institutional installations

contact your local PB Heat, LLC representative.

2. Determine the quantity of domestic hot water

required. Factors to consider:

a. Estimate typical peak hour demand. Determine

the general time of day (morning, noon, evening)

when the most hot water is used. Use chart below

to determine potential maximum usage.

b. Estimate unusual peak draw demand.

Whirlpool baths, hot tubs, and multiple head

showers require large quantities of hot water in a

short period of time. Contact fixture manufacturer

for quantity of water required. Generally speaking,

these circumstances can only be met with larger

storage volumes.

c. Domestic Water Temperature. Most residential

usage will be satisfied with 119°F water, the

temperature setting recommended by the

Consumer Product Safety Commission. Some

applications such as laundry and dishwashers may

require a higher temperature.

Ratings can be improved by increasing Peerless

®

Partner®thermostat setting and using a mixing

valve to temper the hot water to the proper

temperature. When temperatures greater than

119°F are required, use a mixing valve at the

outlet of the water heater or anti-scald fittings at

point of use.

d. Domestic water priority. First hour ratings may

be less than published when boiler output is

shared with space heating. Generally a consumer

will notice a drop in domestic water temperature

before a drop in space heating temperature.

Giving domestic water production priority by

directing entire boiler output to Peerless

®

Partner

®

will maximize domestic water output. However,

prioritization controls could result in an

unacceptable drop in space heating temperature

when large quantities of domestic hot water are

used, and a prioritization control malfunction

could result in loss of space heating.

3. Multiple Water Heaters. Peak domestic water

usage (first hour rating) or unusual peak draw may

not be met with a single water heater. Multiple units

can be installed as either a bank of tanks acting as a

single unit, or as multiple individual units sized and

located for specific draw situations.

PREINSTALLATION

Estimate of Peak Domestic Hot Water Usage

Average Gallons of Times Used During Gallons Used in

Use Hot Water per Usage One Hour One Hour

Shower 20 x _____________ = _____________

Bath 20 x _____________ = _____________

Shaving 2 x _____________ = _____________

Hands and Face Washing 4 x_____________ = _____________

Hair Shampoo 4 x_____________ = _____________

Hand Dish Washing 4 x _____________ = _____________

Automatic Dish Washing 14 x _____________ = _____________

Food Preparation 5 x_____________ = _____________

Wringer Clothes Washer 26 x _____________ = _____________

Automatic Clothes Washer 32 x _____________ =

Total Peak Hour Demand = __________

The Peerless®Partner®indirect-fired water heater is

deemed to be used in a "commercial setting" if at

any time the unit is operated at a temperature over

150°F. Refer to warranty for additional information.

NOTICE

DANGER

Water temperatures over 125°F

can cause severe burns instantly,

or death from scalds.

Children, disabled, and elderly are

at the highest risk of being

scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or showering.

Temperature limiting valves are available, see

manual.

5

PREINSTALLATION

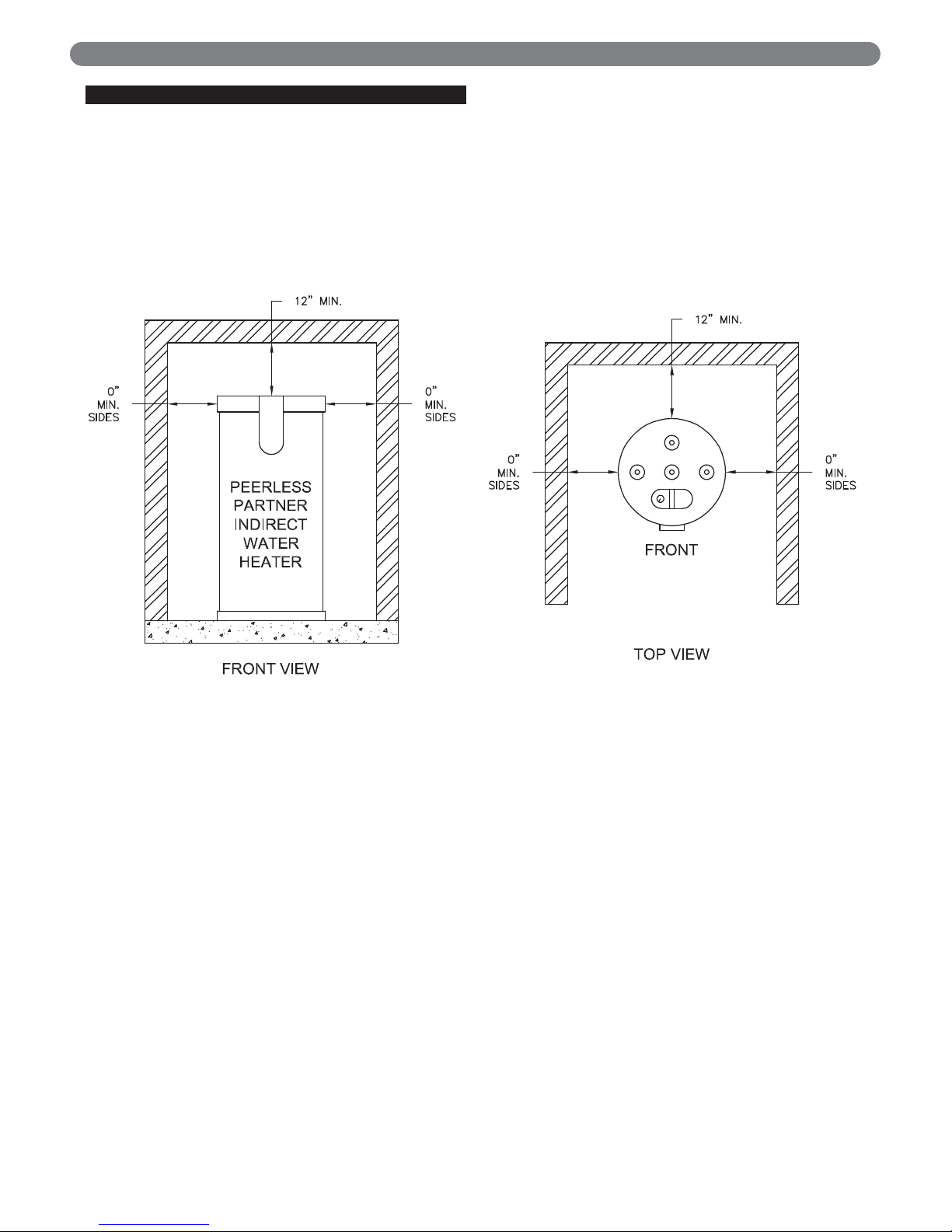

F. RECOMMENDED CLEARANCES

1. Water heater should be installed to allow adequate

clearance for servicing.

2. Zero clearance is permissible to any side of the

Peerless

®

Partner®water heater, but information labels

may be hidden.

3. Recommended top or vertical clearance is 12"

minimum.

4. Refer to boiler manual for boiler clearances.

5. See Figure 1.1 for recommended service clearances.

Figure 1.1: Recommended Clearances

6

2. INSTALLATION – PIPING

A. TEMPERATURE & PRESSURE (T&P)

RELIEF VALVE

1 Every Peerless®Partner®water heater must be

protected with a T&P relief valve.

2 Determine T&P relief valve size by the following

specifications, unless they conflict with local codes:

a. Peerless

®

Partner®30/40/50: 3/4" NPT with an

AGA Rating of 100,000 BTU/hr and a maximum

pressure rating of 150 psig. (Watts 100XL-8 or

equivalent).

b. Peerless

®

Partner®60/80/100/120: 3/4" NPT with

an AGA Rating of 200,000 BTU/hr and a

maximum pressure rating of 150 psig. (Watts

40XL-8 or equivalent).

3. Standard Installation:

Install T&P relief valve in the Auxiliary connection

located behind the air vent on the top of the water

heater (Figure 3.1).

or

Install the T&P relief valve in the run (straight through

leg) of a tee located at the domestic hot water outlet

when using the Auxiliary connection for a

recirculation return (Figure 3.2).

4. Commonwealth of Massachusetts Installation:

Follow this procedure for jurisdictions requiring a

vacuum breaker to be installed on the domestic cold

water inlet.

• Install the T&P in the run (straight through leg) of

tee located at the domestic hot water outlet. Use a

long element T&P relief valve (Fig. 3.4).

5. T&P Relief Valve Discharge Piping:

T&P relief valve discharge piping must be:

• made of material serviceable for temperatures of

250ºF or greater.

• directed so that hot water flows away from all

persons.

• directed to a suitable place for disposal.

• installed so as to allow complete draining of the

T&P relief valve and discharge line.

T&P relief valve discharge piping must not be:

• excessively long. Using more than 2 elbows or 15

feet of piping can reduce discharge capacity.

• directly connected to a drain. Terminate the

discharge piping within 6" from a drain and within

6" of the floor. Refer to local codes.

• plugged, reduced or restricted.

• subject to freezing.

B. DRAIN VALVE

Drain valve and fittings are supplied by others.

1. Standard Installation

a. Install a tee connection at the domestic cold water

inlet (Fig. 3.1 and 3.2).

b. Pipe the drain piping with drain valve from the tee

connection to:

i. a suitable place for disposal

or

ii. terminate within 12" of the floor

2. Commonwealth of Massachusetts Installation

a. Use the drain tube assembly supplied in the tank

carton.

b. Thread a 3/4" close nipple onto the Auxiliary

connection and insert an open-end dip tube into

the Auxiliary connection on top of water heater.

As shown in Fig. 3.3.

c. Install a 3/4" NPT elbow to the Auxiliary

connection, see Fig. 3.4.

d. Pipe the drain piping with drain valve from the

elbow connection to:

To reduce risk of excessive pressures and

temperatures in the water heater, install temperature

and pressure protective equipment required by local

codes, but no less than a combination temperature

and pressure relief valve certified by a nationally

recognized testing laboratory that maintains periodic

inspection of production of listed equipment or

materials, as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANSI Z21.22. This valve must

be marked with a maximum working pressure of the

water heater.

CAUTION

For proper operation of the T&P and to prevent the

T&P from activating due to boiler water temperature,

use a T&P relief valve with extended element.

Recommended, an 8" minimum length.

NOTICE

Do not install any valve between T&P relief valve and

tank connection or on T&P relief valve discharge

piping. Do not plug T&P relief valve or discharge

piping. Improper placement and piping of T&P relief

valve can cause severe personal injury, death or

substantial property damage.

WARNING

INSTALLATION - PIPING

7

i. a suitable place for disposal

or

ii. terminate within 12" of the floor

C. AUTOMATIC AIR VENT

1. Remove plastic shipping cap from 1/2" NPT pipe

fitting on top center of water heater.

2. Install 1/2" x 1/8" reducer bushing provided with water

heater, using suitable pipe dope or tape.

3. Install automatic air vent provided with water heater,

using suitable pipe dope or tape.

4. Unscrew vent cap on air vent one full turn. Leave cap

unscrewed one turn for normal venting.

D. THERMAL EXPANSION

If a backflow preventer, check valve or pressure reducing

valve is piped on cold water supply piping of water

heater, install an expansion tank on cold water supply line

to prevent normal thermal expansion from repeatedly

forcing open T&P relief valve.

E. WATER HAMMER

Dishwashers, clothes washers and fast-closing positive

shut-off valves incorporated in the system all contribute to

creating water shock. Install a water hammer arrester to

prevent damage to pipes and appliances. See device

manufacturer’s instructions for application and

installation.

F. VACUUM BREAKER

Installing a vacuum breaker Watts N36-M1 or equivalent

on the domestic cold water inlet will prevent damage to

the inner tank if a negative pressure is developed in the

domestic supply line. See manufacturer’s instructions for

application and installation of the vacuum breaker.

G. GENERAL PIPING

1. For domestic water piping diagrams, see Figures 3.1

through 3.4.

2. See Figures 3.5 through 3.9 for boiler water piping

3. See Figures 3.10 and 3.11 for multiple water heater

domestic piping.

4. See Figure 3.12 for multiple water heater boiler

piping.

5. See Table 1.1 for domestic and boiler piping

connection sizes.

6. All plumbing must meet or exceed all local, state and

national plumbing codes.

7. Use pipe dope or tape suitable for potable water

systems.

8. Use isolation valves to isolate system components.

H. DOMESTIC PIPING

1. Union on domestic hot water outlet should be piped

at a higher elevation than domestic water drain valve.

This will make draining the water heater easier.

2. Install unions for easy removal of water heater. Use

dielectric unions or couplings to protect hot and cold

water fittings from corrosion when connecting

dissimilar materials such as copper and galvanized

iron pipe.

3. If copper pipe is used for domestic water connections,

first solder pipe to a threaded adapter and then screw

adapter into cold water inlet on top of water heater.

Inlet contains an internal plastic dip tube which can

be damaged by heat from soldering.

Water hammering within the domestic piping system

can cause premature failure of the inner tank of the

water heater. This type of failure is NOT covered

under warranty.

NOTICE

T&P relief valve is not intended for constant duty,

such as relief of pressure due to repeated normal

system expansion. Correct this condition by installing

a properly sized expansion tank in domestic water

system. Refer to expansion tank manufacturer’s

installation instructions for proper sizing.

CAUTION

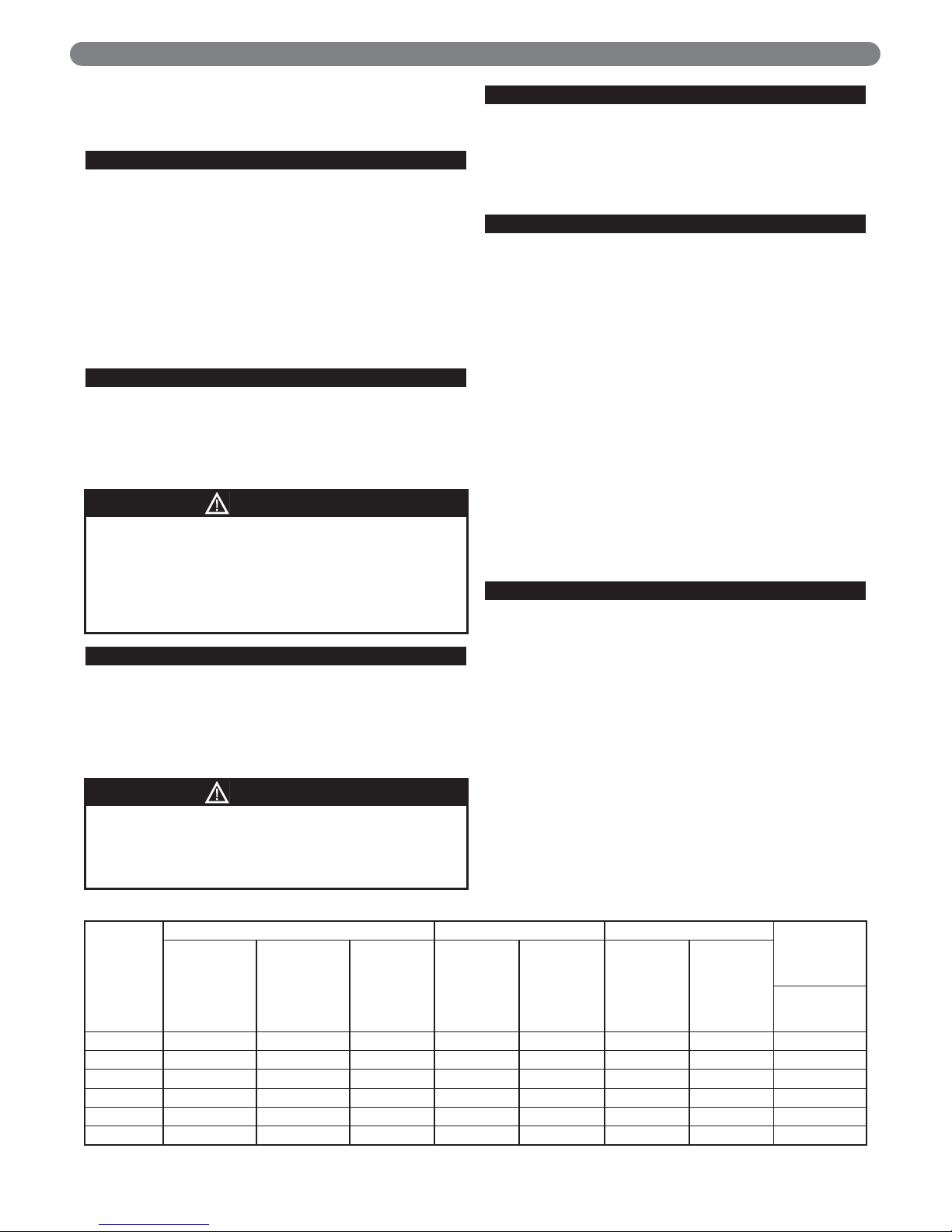

Table 1.1:

Water

Heater

Model

Number

Connections - NPT Recirculation Dip Tube Draining Dip Tube

Recommended

Minimum

Boiler Piping

Domestic

Water

Inlet/Outlet

Boiler Water

Supply/

Return

Auxiliary

Connection

Length

(inches)

Diameter

(inches)

Length

(inches)

Diameter

(inches)

Diameter

(inches)

PT-30 3/4 1 3/4 34 3/4 34 3/4 1

PT-40 3/4 1 3/4 43 3/4 43 3/4 1

PT-50 3/4 1-1/4 3/4 25 3/4 52 3/4 1-1/4

PT-60 3/4 1-1/4 3/4 34 3/4 62 3/4 1-1/4

PT-80 1-1/2 1-1/2 1-1/2 25 1-1/2 48 1-1/2 1-1/2

PP-120 1-1/2 2 1-1/2 32 1-1/2 61 1-1/2 2

INSTALLATION - PIPING

8

4. When the water supply pressure is higher than 70

psig, it is recommended to install a pressure reducing

valve on cold water supply line to prevent water loss

through T&P relief valve.

5. If water heater will replace tankless coil in boiler,

disconnect piping to coil. Allow water to drain from

coil. Do not plug tankless coil.

I. THERMOSTATIC MIXING VALVE

1. It is recommended to install an optional mixing valve

on the domestic hot water outlet.

2. Mixing valve should comply with ASSE 1017.

J. RECIRCULATION PIPING

1. T&P relief valve must be installed in run (straight

through leg) of tee located at domestic hot water

outlet of water heater.

2. It is recommended that the recirculation dip tube be

installed in auxiliary connection using a close nipple

assembly as shown Fig. 3.3, page 9. See Table 1.1

page 6 for diameter and length of dip tube.

3. A stainless steel or bronze circulator is recommended.

4. Install automatic mixing valve either at the hot water

outlet of water heater or each hot water faucet.

K. MULTIPLE WATER HEATER SYSTEMS

1. Parallel Pipe Recirculation Systems - Manifold

recirculation return to all water heaters.

2. Series Piped Systems - Piped return to the leading

(cold water inlet) water heater.

3. Install automatic mixing valve either at the hot water

outlet of water heater or each hot water faucet.

L. BOILER PIPING

1. If plastic pipe is used for boiler water piping, it must

have a maximum oxygen diffusion rate of 0.1

mg/liter-day for boiler and water heater protection.

2. Boiler water (including additives) must be practically

non-toxic, having toxicity rating or class of 1, as listed

in Clinical Toxicology of Commercial Products.

If antifreeze is used in boiler system, local codes may

require a backflow preventer on cold water supply

line. Use antifreeze specifically intended for hydronic

heating systems. Inhibited propylene glycol is

recommended at a maximum 50/50 mixture.

WARNING

Do not use automotive, ethylene glycol or petroleumbased antifreeze. Do not use any undiluted

antifreeze. This can cause severe personal injury,

death or substantial property damage.

DANGER

Plugging tankless coil inlet and outlet will result in

severe personal injury, death, or substantial property

damage.

Do not apply heat to the cold water inlet when

making sweat connections to water heater. Sweat

tubing to adapter before fitting adapter to cold water

inlet of heater. It is imperative that no heat be applied

to the cold water inlet, as it contains a non metallic

dip tube.

NOTICE

The Peerless®Partner®IDWH must be installed on a

closed type hydronic system. Failure to provide such

a system will result in premature failure of the outer

tank and annulment of warranty.

NOTICE

DANGER

Failure to install automatic mixing valve where

recommended will result in severe personal injury or

death.

INSTALLATION - PIPING

9

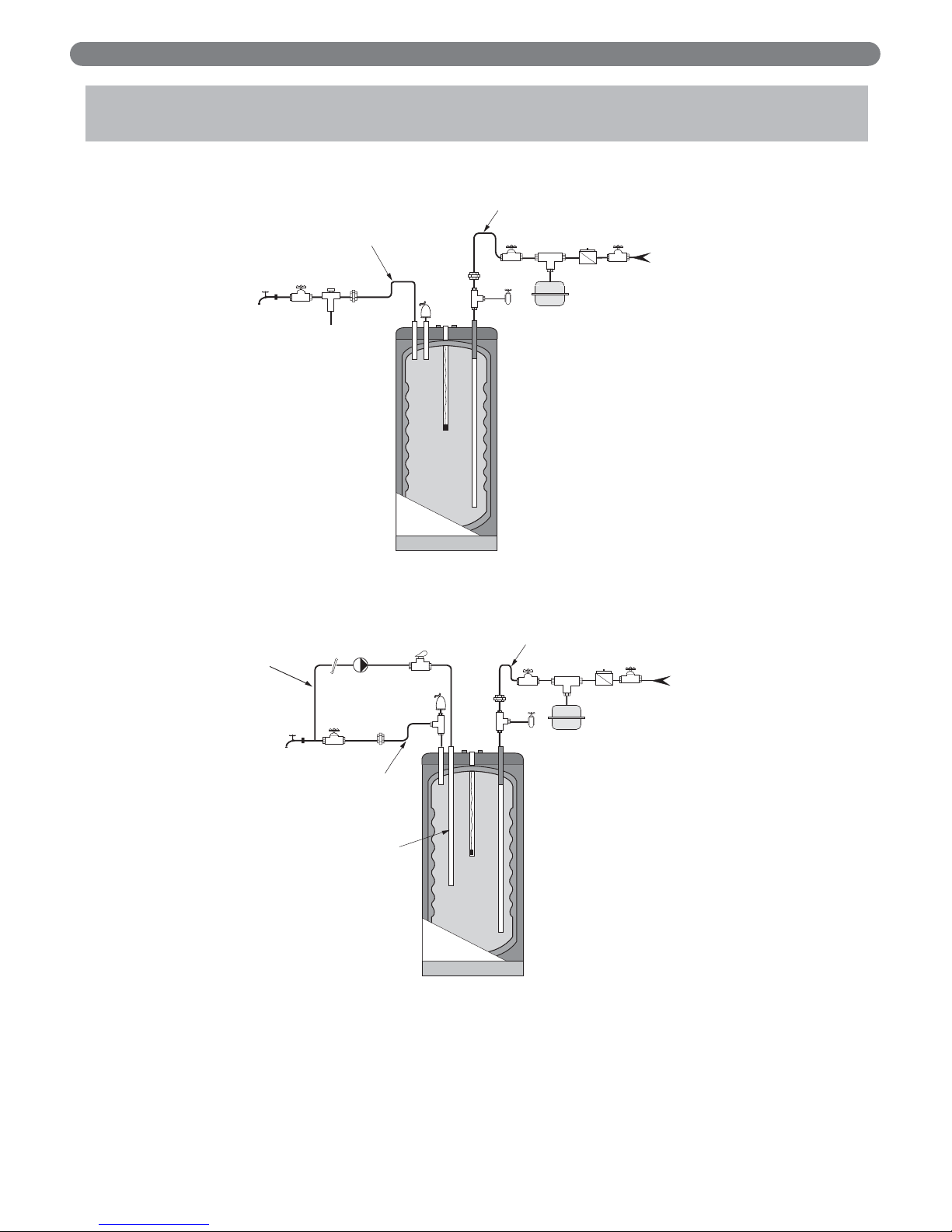

Figure 3.1: Peerless®Partner®Recommended Installation: Domestic Water Piping

Figure 3.2: Peerless®Partner®Recommended Installation: Domestic Water Piping with Recirculation

3. INSTALLATION – PIPING DRAWINGS

1. Shut-off valve

2. Recirculation Circulator

3. Flow Check Valve

4. T&P relief valve

5. Unions

6. Backflow preventer or pressure reducing valve(*)

9. Drain valve

10. Thermal expansion tank (potable)

11. Recirculation dip tube

13. Thermostatic mixing valve (*)

(*) Optional devices may be required by local codes.

INSTALLATION - PIPING DRAWINGS

5

12" min.

Heat Trap

Loop

(Optional)

1

9

Heat Trap

(Optional)

1

5

12" min.

Loop

9

10

6

10

Cold Water

1

1

6

12" min.

Heat Trap

Loop

(Optional)

13

H

M

1

Recirculating

Loop

C

1

Heat Trap

(Optional)

5

2

12" min.

Loop

4

3

4

5

11

Inlet

Cold Water

Inlet

Loading...

Loading...