Page 1

The Versatile AE Pump

Using the latest technology, Peerless Pump en gi neered

the AE Series pump to ac com mo date a va ri ety of

ap pli ca tions. The single stage, double suc tion, hor i zon tal

split case pump comes in forty-two dif fer ent hy drau lic

con g u ra tions and twen ty- ve pump sizes. Discharge

sizes range from two to ten inch es. The AE has a wide

se lec tion of hy drau lic per for mance en ve lopes, mul ti ple

me chan i cal con g u ra tions and sev er al ma te ri al op tions.

Series AE

Peer less Pump

HORIZONTAL SPLIT CASE

SINGLE STAGE DOUBLE

SUC TION PUMP

long er bearing and mechanical seal life. Keyed to the

shaft with an 18-8 stainless steel key, the impeller aligns

axially with threaded shaft sleeves. Grooved impeller

skirts (in combination with casing rings) extend the life

of crit i cal clearances and increase the meantime between

pre ven ta tive main te nance (MTBPM).

Peerless Pump standard mechanical seals are

mount ed over a bronze shaft sleeve and rated for

tem per a tures up to 225o F. The optional packed

stuf ng box es hold a min i mum of ve packing rings.

Split glands fa cil i tate re mov al for repacking. The gland

bolts are swing type and made of steel with 18-8 stainless

steel nuts. Water seal piping and lan tern ring are optional.

As stan dard, the upper casing features a tapped and

plugged seal ush con nec tion.

Applications

The AE S e ries pum p handl es wate r a nd othe r

non abra sive u ids. Ap pli ca tions vary from small, single

pump com mer cial in stal la tions to large, multi-pump

municipal wa ter supply systems. The Peerless Pump

AE Series gives su pe ri or per for mance in Ag ri cul ture,

Gen er al In dus try, Build ing Trade, Power In dus try, Fire

Pro tec tion, Mu nic i pal and Process ap pli ca tions.

Replaceable bronze shaft sleeves protect the carbon

steel shaft through the stuf ng box. The shaft sleeves

extend beyond the mechanical seal anges (or packing

glands) for maximum shaft protection. O-rings seal the

sleeves. Shaft and shaft sleeves are available in stain less

steel. The bear ings are single row, deep groove ball

type and grease lu bri cat ed. Average life is 100,000 hours.

Double row, outboard thrust bearings and oil lu bri ca tion

are optional.

Features

The AE Series pump uses casing material with a

min i mum of class 35 cast iron. To provide permanent

align ment of bear ings and all rotating parts, Peerless

Pump casts the bear ing bracket supports as a part of

the lower cas ing half. Re new able bronze casing rings

are doweled and shoul dered in the casing. The double

suction im pel ler is a single, cast bronze piece. Dynamic

bal anc ing gives the impeller vibration-free hy drau lic and

me chan i cal performance. The bal anc ing also provides

Speci cations

Capacities: .............. Over 8,000 gpm (1817 m3/hr)

Head: ........................ Up to 675 feet (206 meters)

Pressure: ................. Up to 510 psi (35 kg/cm2, 3,514 kPa)

Horsepower: ......... Up to 550 hp (410 kW)

Temperature: ......... Up to 250°F (121°C)

Drives: ....................... Motors, engines, steam turbines, combinations.

Liquids: ..................... Water and clear liquids.

Materials: ............... Cast iron, bronze tted as standard. Other materials avail able.

Quality Engineering

Peerless Pump designs tough, versatile prod ucts to

meet your pump ing needs. The AE Series de liv ers

va ri ety, du ra bil i ty, standardized options and

con g u ra tions unequalled in the industry. Please

con tact your local authorized Peerless Pump sales

of ce to nd out more about the AE Series, options

and prices.

Page 2

Series AE

400

300

200

100

70

50

40

30

20

15

50 80 100 200 400 7001000 2000 4000 7000 10000

5

6

10

60

20

30

40

100

300020001000500300200100503020

150 200 300 400 500 700 1000 2000 3000 4000

700 90050040030020010080605040

600

500

400

300

200

100

90

80

70

70

80

90

100

200

60

50

40

30

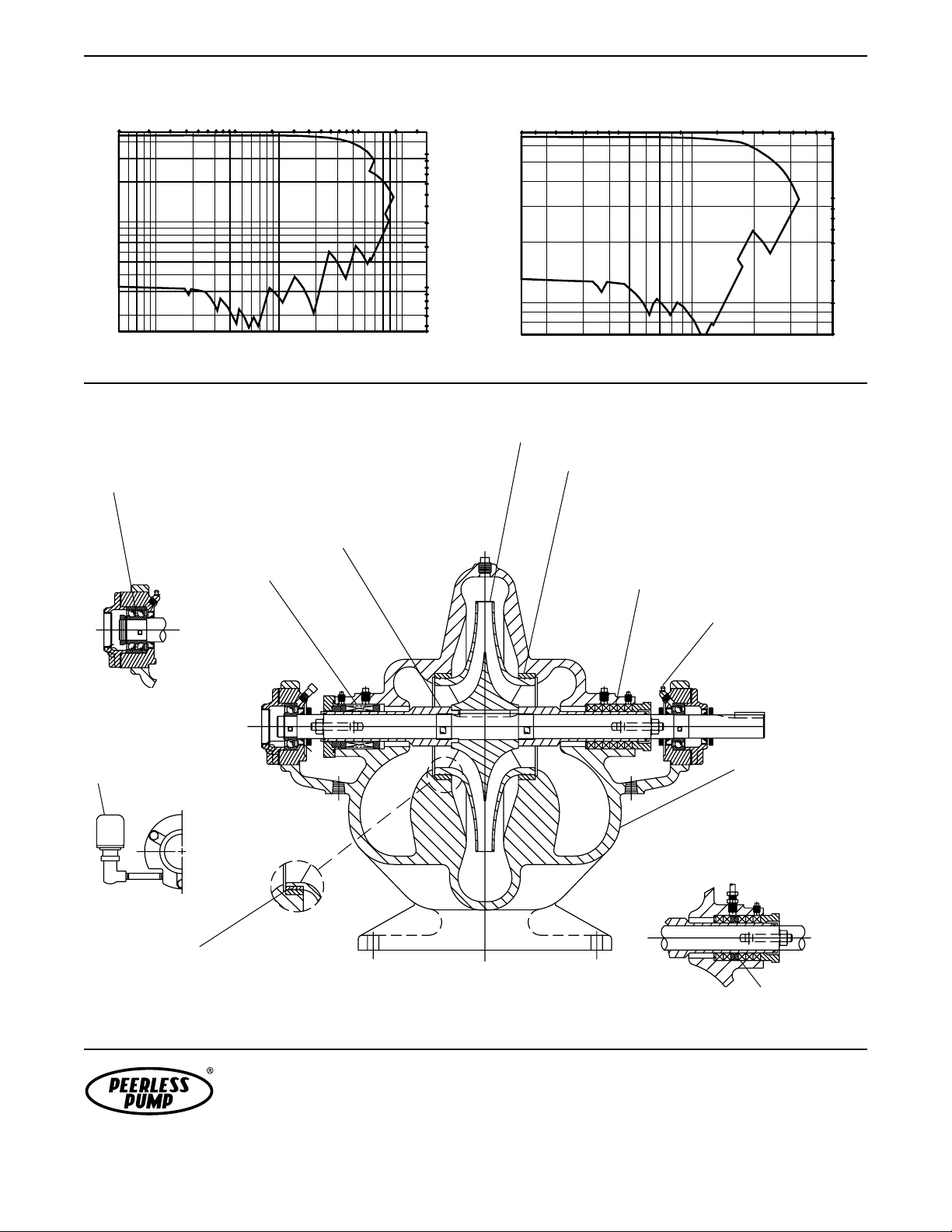

AE Series Range Chart - 1750 RPM AE Series Range Chart - 3550 RPM

FLOW (M3/HR)

FLOW (M3/HR)

HEAD (Feet)

FLOW (GPM)

Bearings

Grease lubrication is standard. Oil lubrication is optional. Can

be converted in the eld with minimal effort. Average bearing

life of 100,000 hours for long trouble free bearing operation

with proper maintenance. Available with double row outboard

thrust bearings.

Socket Seal Assembly

Tested and approved to provide positive shaft sealing at

all operation conditions. (Optional)

Mechanical Seal

(Standard)

HEAD (Feet)

HEAD (Meters)

Impeller

Dynamic balancing extends operation life of the pump.

Shouldered Case Rings

Provides positive position control to reduce recirculation losses for improved

efciencies. Pump can usually be returned to original hydraulic design

through replacement of wear rings.

HEAD (Meters)

FLOW (GPM)

Stufng boxes

Mechanical seals are standard. Packing is optional.

Field conversion can be made with minimal effort.

Grease Lubrication

(Standard)

Oil Lubrication

(Optional)

Grooved Impeller Rings

Grooved impeller ring (optional construction) or

grooved impeller skirt (standard). Reduces recirculation

losses better than standard impeller skirts. Maintains

maximum pump efciency for extended time periods.

The content of this brochure is subject to change without notice. Copyright 2003 by Peerless Pump Company. Printed in U.S.A. 4/03. Brochure B-1200

Peerless Pump Company

P.O. Box 7026

Indianapolis, IN 46207-7026

(317)925-9661, Fax: (317)924-7388

www.peerlesspump.com

Case Assembly

Higher quality pump castings

with 35,000 PSI or better tensile

strength cast iron are standard.

250# ange thickness and diameter with 125# of 250# drilling

standard on most models.

Packing

(Optional) With or without

lantern ring.

Loading...

Loading...