Page 1

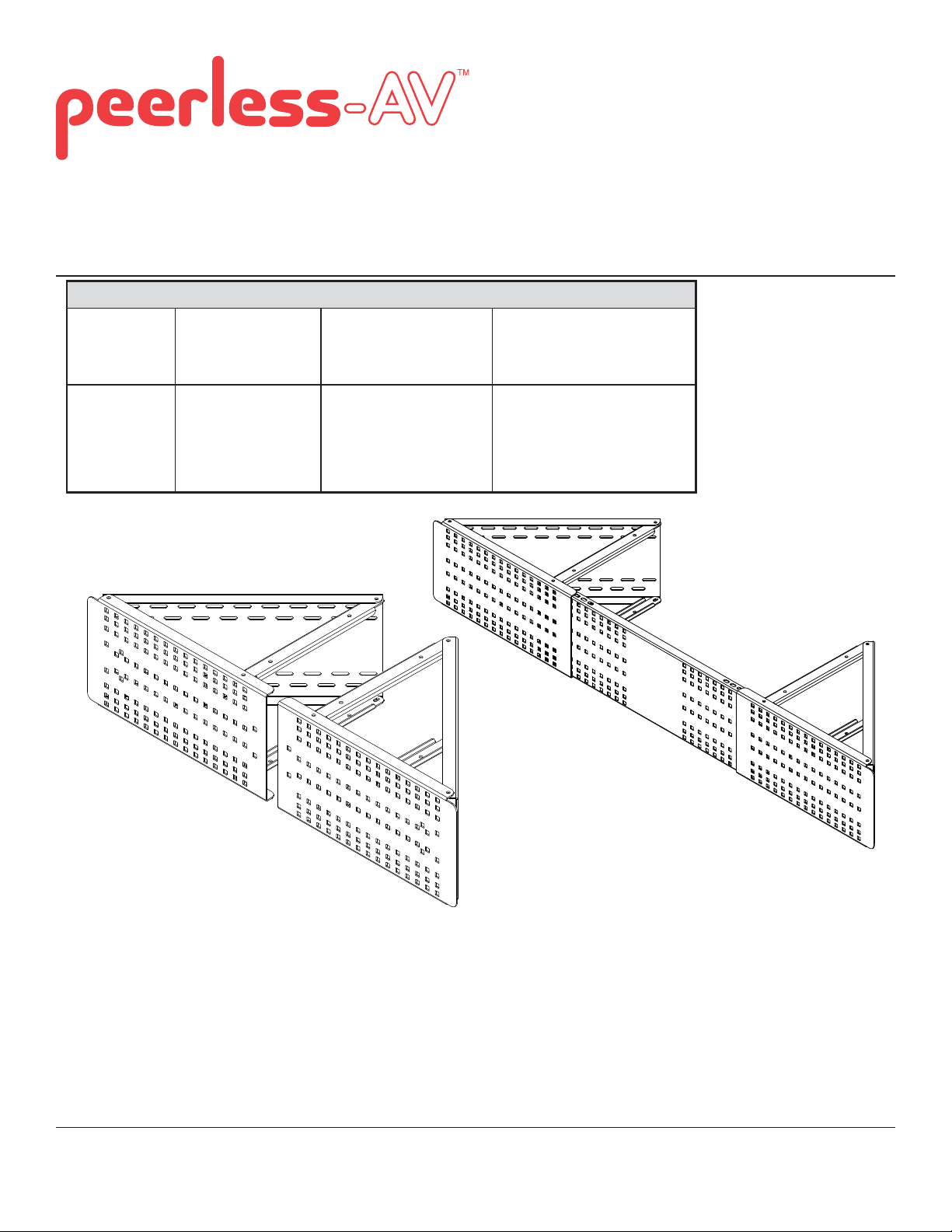

Installation and Assembly:

Flat Panel Corner Mounting Accessory

for 32" – 60" LCD and Plasma Screens

Model Screen Size Range Compatibility

CM50, CM50-S 32"-50"

CM60, CM60-S 40"-60"

Maximum Load Capacity

175 lb (79.4 kg)

200 lb (90.8 kg)

SF640/ST640

PF640/PT640

SF650/ST650

PF650/PT650

ONE-TP (2-plate configuration)

SF640/ST640

PF640/PT640

SF650/ST650

PF650/PT650

SF660/ST660

PF660/PT660

ONE-TP (3-plate configuration)

CM50, CM50-S

Features

• Allows screen to fit in corner where space is limited

• CM50(-S) wall units expand to support compatible flat/tilt wall mounts for

screens from 32" – 50"

• CM60(-S) includes additional support plate to accommodate compatible

flat/tilt wall mounts for screens from 40" – 60"

• Wall units accommodate speakers when used with smaller screens (wall

unit maybe visible with some smaller screens)

• Accessory shelf available for A/V components (sold separately)

• Mounts to wood studs, concrete, cinder block

1 of 30

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

CM60, CM60-S

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 2

Note: Read entire instruction sheet before you start installation and assembly.

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, please

call Peerless customer care at 1-800-865-2112.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Never exceed the Maximum Load Capacity. See page 1.

• If mounting to wood wall studs, make sure that mounting screws are anchored into the center of the studs. Use of

an "edge to edge" stud finder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws firmly, but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power.

• This product is intended for indoor use only. Use of this product outdoors could lead to product failure and personal

injury.

• This product was designed and intended to be mounted to the following supporting surfaces checked below with

the hardware included in this product as specified in the installation sheet. To mount this product to an alternative

supporting surface, contact Peerless customer care at 1-800-865-2112.

• This product was designed to be installed on the following wall construction only;

WALL CONSTRUCTION HARDWARE REQUIRED

• Wood Stud Included

• Wood Beam Included

• Solid Concrete Included

• Cinder Block Included

• Brick Contact Qualifi ed Professional

• Other or unsure? Contact Qualifi ed Professional

Tools Needed for Assembly

• stud fi nder (edge-to-edge stud fi nder recommended)

• phillips screwdriver

• drill

• 5/32" drill bit for wood stud wall

• 5/16" drill bit for concrete wall

• level

Accessories

• ACC324(-S) - Shelving Unit for Corner Mount

• ACC930 - Fastener pack for speaker mounts

Table of Contents

Parts List.................................................................................................................................................................................3

Installation to Interior Corner Wood Stud Walls ......................................................................................................................4

Installation to Exterior Corner Wood Stud Walls.....................................................................................................................5

Installation to Interior Concrete or Cinder Block Walls ...........................................................................................................6

Installation to Exterior Concrete or Cinder Block Walls ..........................................................................................................7

Attaching Interface Plate and Center Plate ....................................................................................................................... 8, 9

Installing Speaker Mounts ...................................................................................................................................................10

2 of 30

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 3

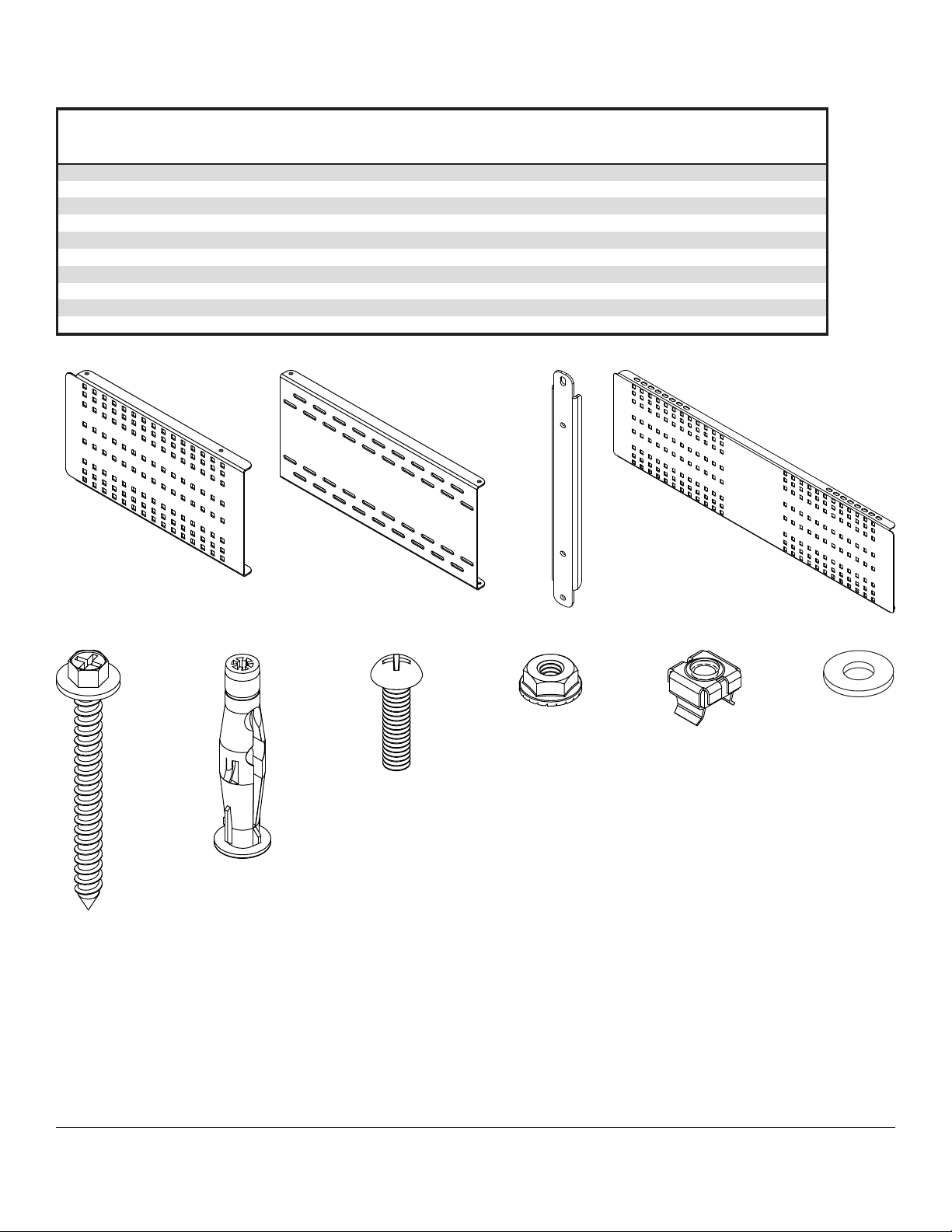

Before you begin, make sure all parts shown are included with your product.

A

Parts may appear slightly different than illustrated.

Parts List

Description Qty. CM50 CM50-S CM60 CM60-S

interface plate 2 120-1075 120-4075 120-1075 120-4075

B wall plate 2 120-1076 120-4076 120-1076 120-4076

C support brackets 4 120-1077 120-4077 120-1077 120-4077

D center plate 1 n/a n/a 120-1078 120-4078

E #14 x 2.5" wood screws 8 5S1-015-C03 5S1-015-C03 5S1-015-C03 5S1-015-C03

F concrete anchors 8 590-0320 590-0320 590-0320 590-0320

G 1/4-20 x 1" round phillips head screw 24 510-9110 510-9110 510-9110 510-9110

H 1/4-20 flanged serrated locknut 16 530-1021 530-1021 530-1021 530-1021

I 1/4-20 Tinnerman® cage nut 12 530-2050 530-2050 530-2050 530-2050

1/4" flat washer 24 540-9440 540-9440 540-9440 540-9440

J

E

A

F

B

G

C

H

D

J

I

3 of 30

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 4

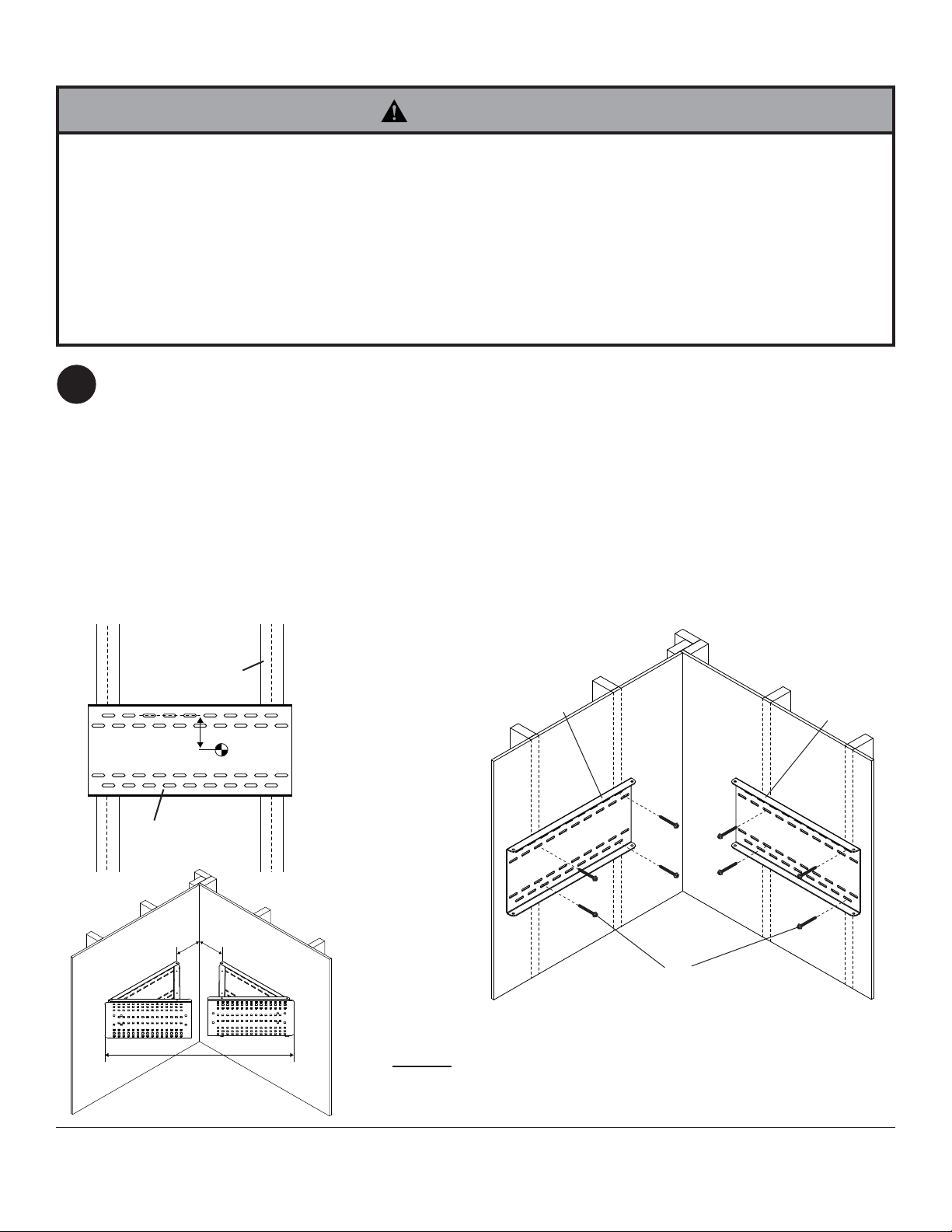

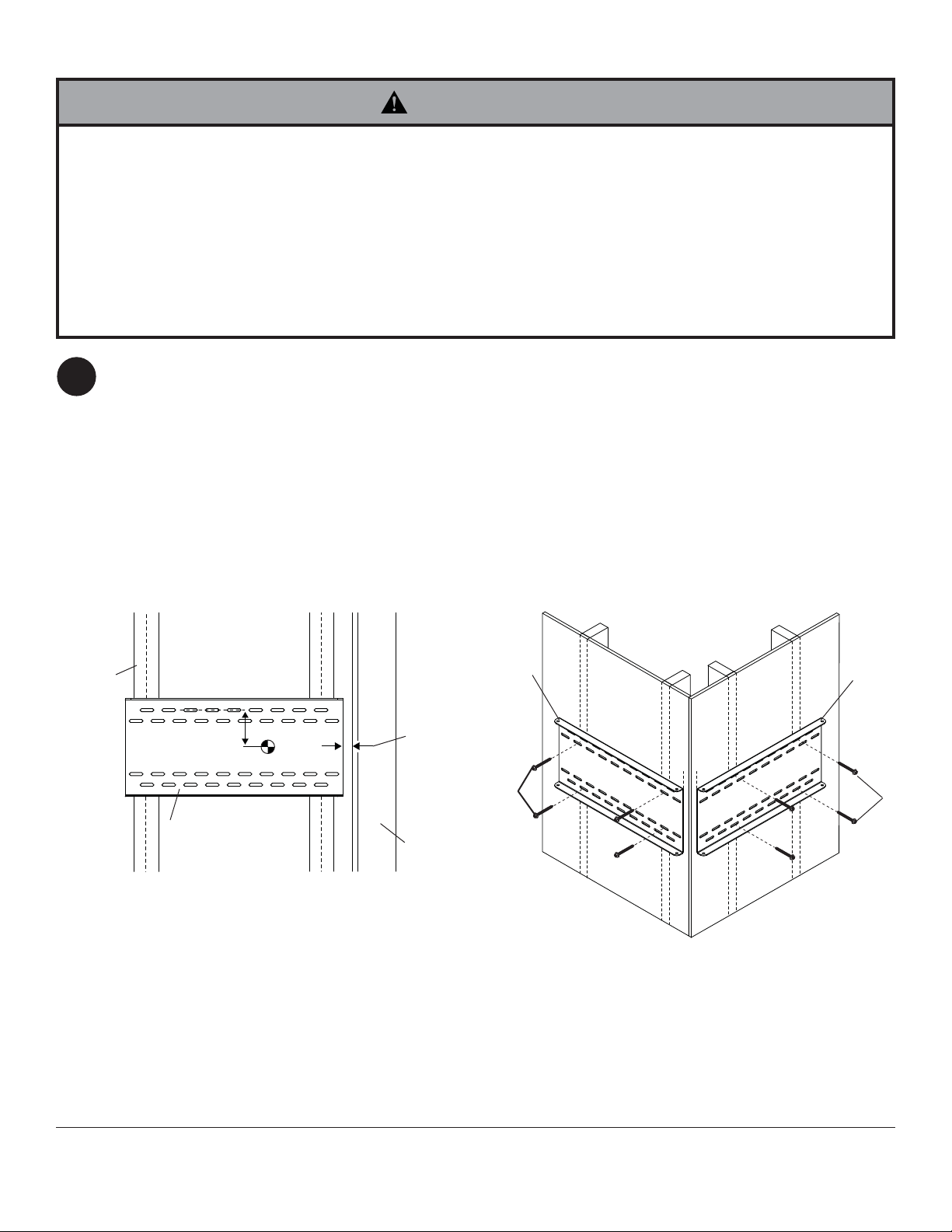

Installing to Interior Corner Wood Stud Wall

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs.

Installers are responsible to provide hardware for other types of mounting situations.

Wall plates (B) can be mounted to one or two studs that are 16" apart. Use a stud finder to locate the edges of

1

the studs. Use of an edge-to-edge stud finder is highly recommended. Based on their edges, draw a vertical line

down each stud’s center on both walls. NOTE: Depending on placement of studs on wall corners, mounting to

two studs may not be possible.

Determine the distance from the corner of the wall to the inside edge of the wall plates (B) using the equation

below and detail 1 to get distance "X". NOTE: If mounting speaker mounts to sides of corner mount, screen can

be no larger than 40". See page 10 for speaker mount installation.

Measure "X" distance from corner of wall and mark location for inside edge of wall plate. The top mounting slots

of wall plate should be located 3.44" (87 mm) above the desired screen center as shown in fig 1.1. Level wall

plate, align to location marked for inside edge of wall plate and mark four slots in alignment with center of studs.

Repeat for opposite wall plate. Drill 5/32" (4 mm) dia. holes to a minimum depth of 2.5" (64 mm). Make sure that

wall plates are level and secure using #14 x 2.5" wood screws (E).

3.44"

(87 mm)

B

X

DETAIL 1

Y

STUD

X

CS

CS = CENTER OF SCREEN

fig. 1.1

"X" =

Y

1.414

- 21.216

B

B

E

fig. 1.2

4 of 30

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 5

Installing to Exterior Corner Wood Stud Wall

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs.

Installers are responsible to provide hardware for other types of mounting situations.

Wall plates (B) can be mounted to one or two studs that are 16" apart. Use a stud fi nder to locate the edges of

1

the studs. Use of an edge-to-edge stud fi nder is highly recommended. Based on their edges, draw a vertical line

down each stud’s center on both walls. NOTE: Depending on placement of studs on wall corners, mounting to

two studs may not be possible.

NOTE: If mounting speaker mounts to sides of corner mount, screen can be no larger than 40". See page 10 for

speaker mount installation.

Measure 1" (25 mm) from corner of wall and mark location for inside edge of wall plate. The top mounting slots of

wall plate should be located 3.44" (87 mm) above the desired screen center as shown in fi g 1.3. Level wall plate,

align to location marked for inside edge of wall plate and mark four slots in alignment with center of studs. Repeat

for opposite wall plate. Drill 5/32" (4 mm) dia. holes to a minimum depth of 2.5" (64 mm). Make sure that wall

plates are level and secure using #14 x 2.5" wood screws (E).

STUD

3.44"

(87 mm)

CS

B

CS = CENTER OF SCREEN

fig. 1.3

1"

(25 mm)

CORNER

E

B

B

E

fig. 1.4

5 of 30

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 6

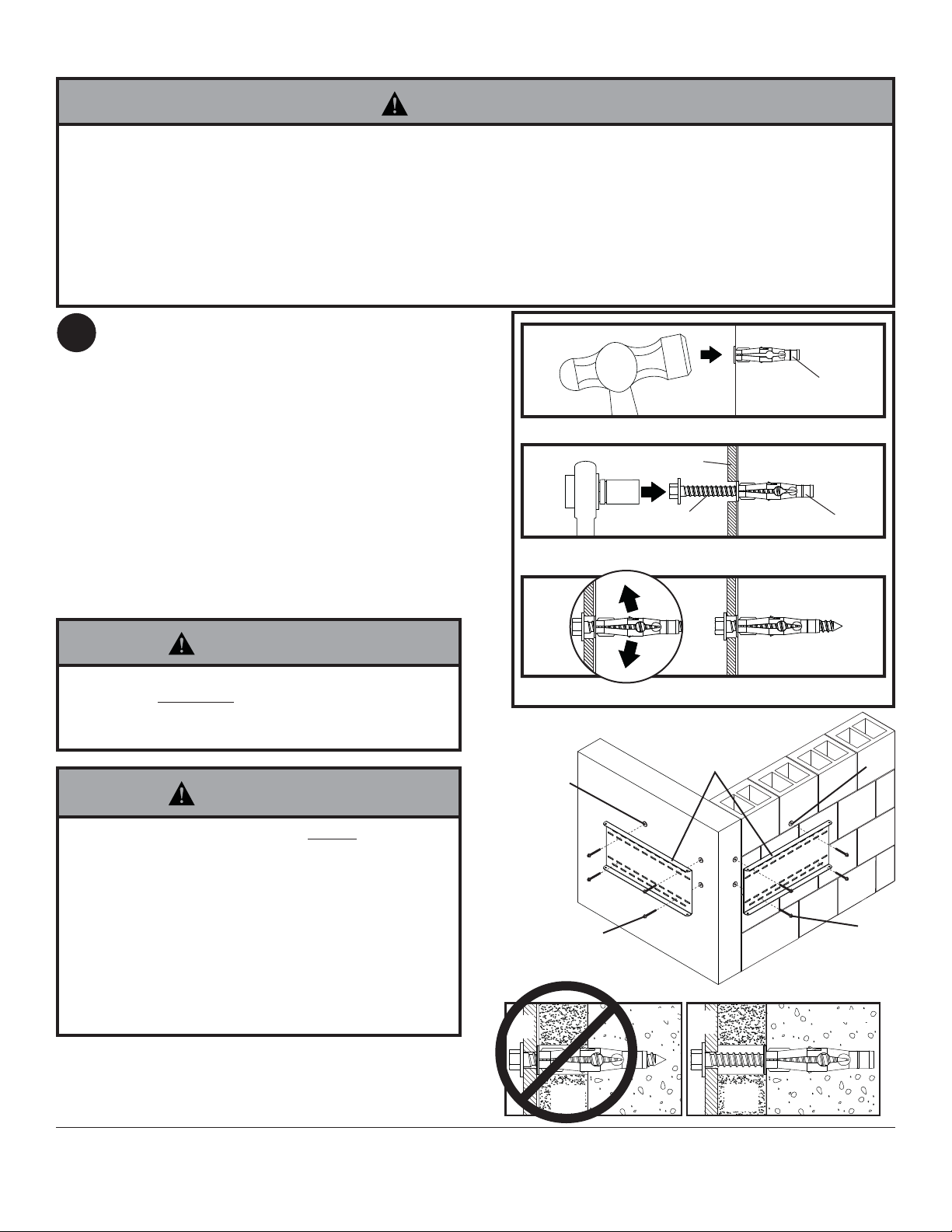

Installing to Interior Corner Concrete or Cinder Block Wall

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a

solid part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90

specifi cations. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

Determine the distance from the corner of the wall to

1

the inside edge of the wall plate (B) using the equation

and detail 1 on page 4 to get distance "X".

NOTE: If mounting speaker mounts to sides of corner

mount, screen can be no larger than 40". See page 10

for speaker mount installation.

Measure "X" distance from corner of wall and

mark location for inside edge of wall plate. The top

mounting slots of wall plate should be located 3.44"

(87 mm) above the desired screen center as shown in

fi g 1.1 on page 4. Level wall plate (B), align to location

marked for inside edge of wall plate and mark four

slots in alignment with center of studs. Repeat for

opposite wall plate. Drill 5/16" (8 mm) dia. holes to a

minimum depth of 2.5" (64 mm). Insert anchors (F) in

holes fl ush with wall as shown (right). Place wall plate

over anchors, make sure that wall plates are level and

secure using #14 x 2.5" wood screws (E).

WARNING

• Tighten screws so that wall plate is fi rmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

1

concrete

surface

F

Drill holes and insert anchors (F).

E

B

F

solid concrete

B

2

Place plate (B) over anchors (F) and secure with screws (E).

3

Tighten all fasteners.

cinder block

WARNING

• Always attach concrete anchors directly to loadbearing concrete.

• Never attach concrete anchors to concrete covered

with plaster, drywall, or other fi nishing material.

If mounting to concrete surfaces covered with

a fi nishing surface is unavoidable, the fi nishing

surface must be counterbored as shown right.

Be sure concrete anchors do not pull away from

concrete when tightening screws. If plaster/drywall

is thicker than 5/8", custom fasteners must be

supplied by installer.

6 of 30

plate

CUTAWAY VIEW

wall

F

plaster/

dry wall

E

INCORRECT CORRECT

concrete

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

wall

plate

plaster/

dry wall

F

concrete

Page 7

Installing to Exterior Corner Concrete or Cinder Block Wall

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a

solid part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90

specifi cations. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

NOTE: If mounting speaker mounts to sides of corner

1

mount, screen can be no larger than 40". See page 10

for speaker mount installation.

Measure 1" (25 mm) from corner of wall and mark

location for inside edge of wall plate. The top

mounting slots of wall plate should be located 3.44"

(87 mm) above the desired screen center as shown in

fi g 1.3 on page 5. Level wall plate (B), align to location

marked for inside edge of wall plate and mark four

slots in alignment with center of studs. Repeat for

opposite wall plate. Drill 5/16" (8 mm) dia. holes to a

minimum depth of 2.5" (64 mm). Insert anchors (F) in

holes fl ush with wall as shown (right). Place wall plate

over anchors, make sure that wall plates are level and

secure using #14 x 2.5" wood screws (E).

WARNING

• Tighten screws so that wall plate is fi rmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

WARNING

1

concrete

surface

F

Drill holes and insert anchors (F).

E

B

F

2

Place plate (B) over anchors (F) and secure with screws (E).

3

Tighten all fasteners.

solid concrete

B

cinder block

F

F

• Always attach concrete anchors directly to loadbearing concrete.

• Never attach concrete anchors to concrete covered

with plaster, drywall, or other fi nishing material.

If mounting to concrete surfaces covered with

a fi nishing surface is unavoidable, the fi nishing

surface must be counterbored as shown right.

Be sure concrete anchors do not pull away from

concrete when tightening screws. If plaster/drywall

is thicker than 5/8", custom fasteners must be

supplied by installer.

CUTAWAY VIEW

7 of 30

wall

plate

plaster/

dry wall

E

INCORRECT CORRECT

concrete

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

wall

plate

plaster/

dry wall

E

concrete

Page 8

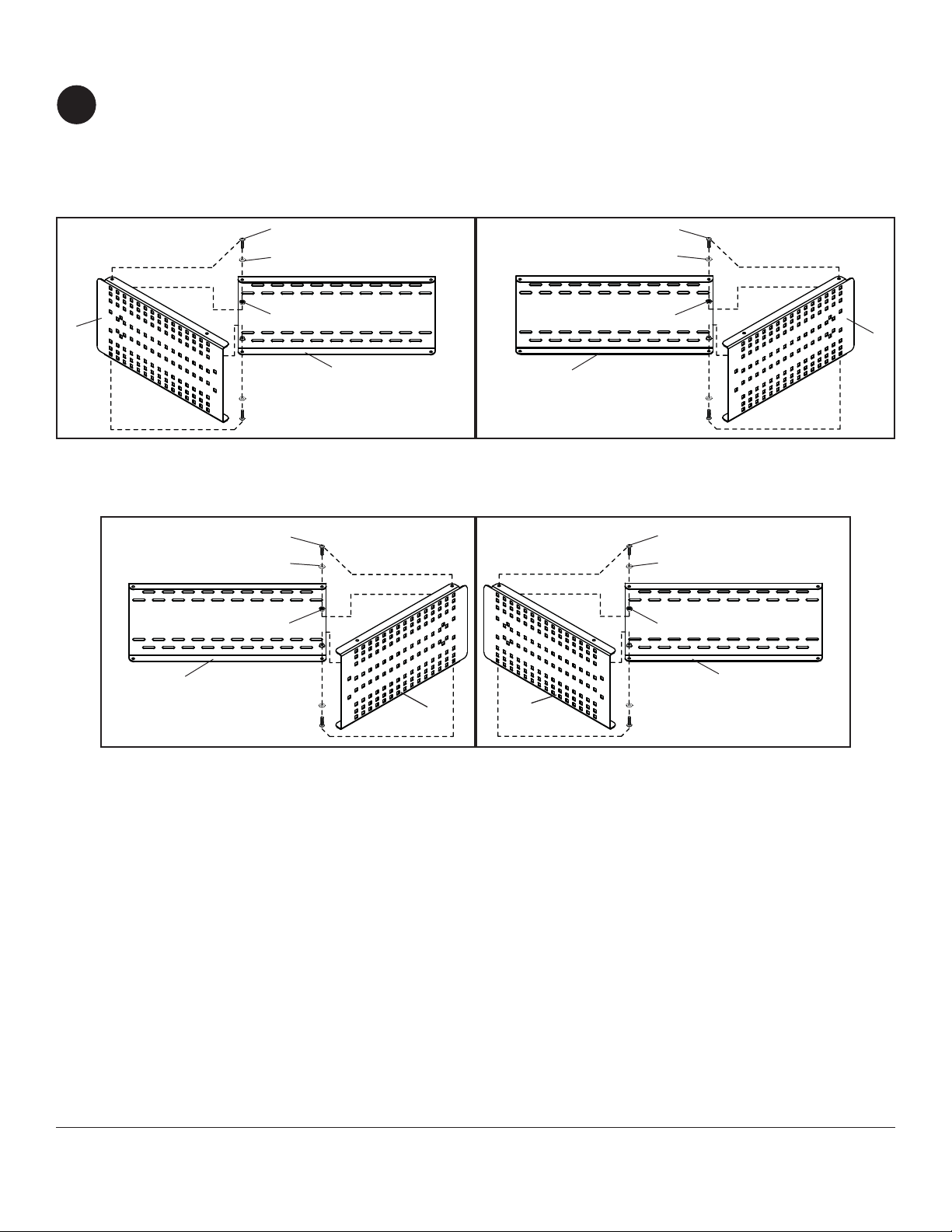

Attaching Interface Plate

Attach interface plate (A) to wall plate (B) using two sets of 1/4-20 x 1" round phillips head screws (G),

2

1/4" fl at washers (J) and 1/4-20 fl anged serrated locknuts (H) as shown in fi g 2.1 or 2.2 for interior corners

or fi g 2.3 or 2.4 for exterior corners. Repeat for opposite interface plate.

NOTE: Be sure top flange of interface plate (A) rests on top flange of wall plate (B).

NOTE: Do not fully tighten fasteners.

LEFT INTERIOR CORNER RIGHT INTERIOR CORNER

A

G

J

H

B

fig. 2.1

LEFT EXTERIOR CORNER RIGHT EXTERIOR CORNER

B

G

J

H

B

G

J

H

fig. 2.2

G

J

H

B

A

A

fig. 2.3 fig. 2.4

8 of 30

A

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 9

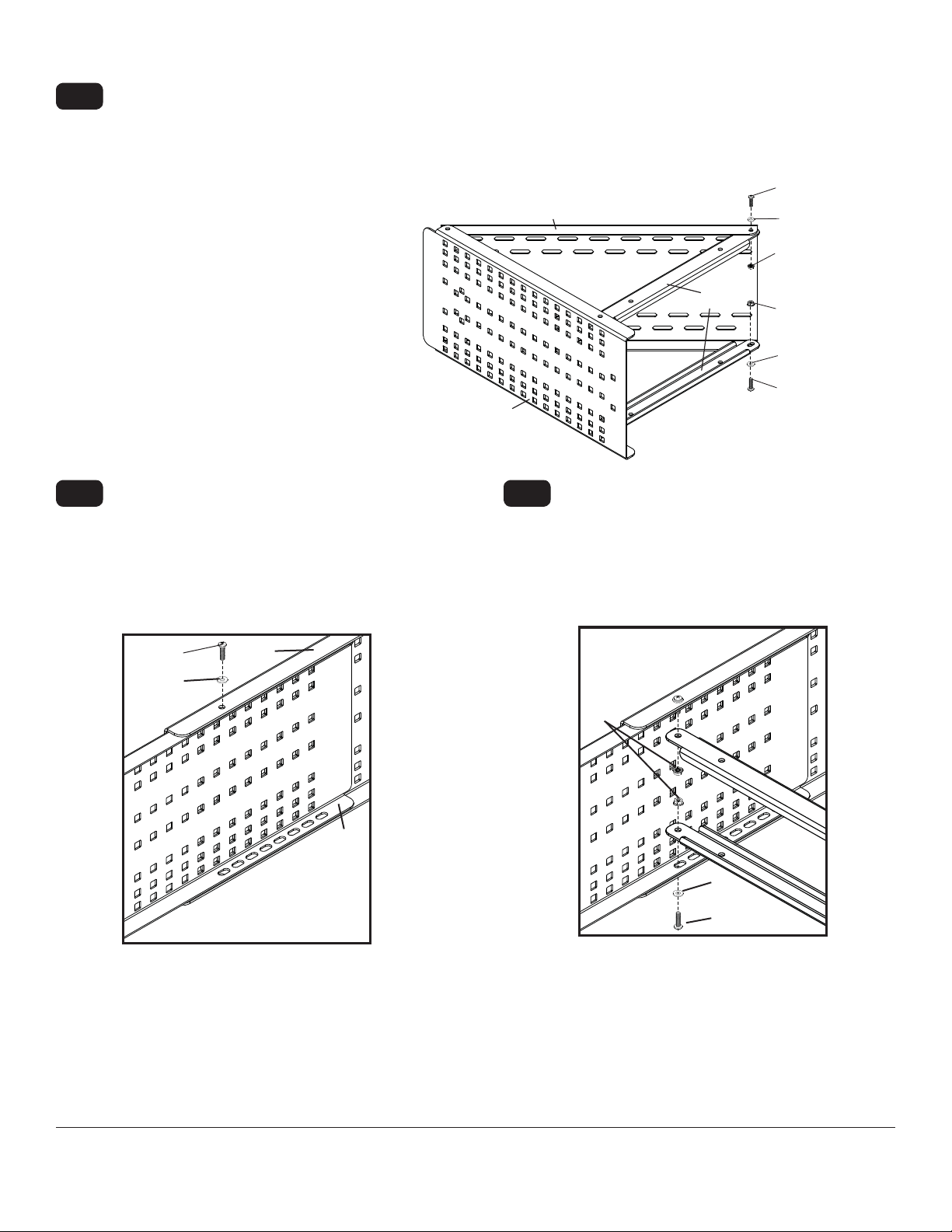

Installing Support Brackets and Center Plate

NOTE: Use center plate (D) when mounting pattern for wall plate of mount is narrower than opening

3-1

between interface plates (A).

Attach support brackets (C) to rear of wall plate (B) using 1/4-20 x 1" round phillips head screw (G),

1/4" fl at washer (J) and 1/4-20 fl anged serrated locknut (H) for each support bracket as shown below.

NOTE: Be sure fl ange of support bracket faces inside of interface plate and wall plate. NOTE: Do not

fully tighten fasteners.

Skip to step 3-3 if not installing center plate.

B

G

J

H

Swing adapter brackets (C) away from front of

3-2

mount. Slide center plate (D) behind interface

plate (A) and center between the two interface

plates. Align top and bottom holes of interface

plate with slots of center plate. Hand thread

1/4-20 x 1" round phillips head screw (G) and

1/4" fl at washer (J) through top hole only.

G

A

J

A

C

H

J

G

Swing adapter brackets (C) towards front of

3-3

mount. Guide top adapter bracket through top

screw and fasten using 1/4-20 fl anged serrated

locknut (H). Align hole of bottom adapter bracket

with bottom hole and fasten using 1/4-20 x 1"

round phillips head screw (G), 1/4" fl at washer (J)

and 1/4-20 fl anged serrated locknut (H).

H

D

9 of 30

J

G

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

Page 10

Align wall plate of wall mount with interface plates (A) to determine location of cage nuts (I) used to

4

secure wall plate to interface plates. Install cage nuts from rear side of interface plates (A) as shown

in detail 2.

NOTE: Install wall plate and remaining wall mount assembly according to instructions provided with

wall mount.

I

DETAIL 2

Installing Speaker Mounts (optional)

NOTE: Corner mount may be visible with smaller size screens.

5

NOTE: Speaker mount (sold separately) may appear different than illustrated. ACC930 (sold separately) is required

to attach speaker mount.

Using hole pattern shown below, attach speaker mount to interface plate (A) using two screws and two washers

through the front and two nuts through the rear. NOTE: Fasteners not included for installing speaker mount.

10 of 30

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 07-22-08 SHEET #: 120-9054-2 09-30-11

© 2011, Peerless Industries, Inc. All rights reserved.

Page 11

Instalación y ensamblaje:

Accesorio de instalación en esquinas para

pantallas planas de LCD o de plasma de 32" – 60"

Español

Modelo Tamaños de las Pantallas Gama de Compatibilidad

CM50, CM50-S 32"-50"

CM60, CM60-S 40"-60"

Máxima capacidad de carga

175 lb (79.4 kg)

200 lb (90.8 kg)

SF640/ST640

PF640/PT640

SF650/ST650

PF650/PT650

ONE-TP (2-placa)

SF640/ST640

PF640/PT640

SF650/ST650

PF650/PT650

SF660/ST660

PF660/PT660

ONE-TP (3-placa)

CM50, CM50-S

CARACTERÍSTICAS

• Permite que la pantalla se acomode en una esquina, donde el espacio es limitado

• Las unidades para pared CM50(-S) se expanden para sostener los soportes de pared

compatibles planos o inclinables para pantallas de 32" – 50"

• El modelo CM60(-S) incluye una placa sostenedora adicional para acomodar los soportes de

pared compatibles planos o inclinables para pantallas de 40" – 60"

• Las unidades para pared acomodan altavoces si se instala una pantalla pequeña (es posible

que se vean las unidades para pared si la pantalla es pequeña)

• Repisa de accesorios disponible para componentes de A/V (se vende por separado)

• Se instala en montantes de madera, concreto, bloques de hormigón de escorias

11 de 30

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

CM60, CM60-S

Page 12

Nota: Lea la hoja de instrucciones completa antes de comenzar la instalación y el ensamblaje.

ADVERTENCIA

• No comience a instalar el producto hasta haber leído y entendido las instrucciones y las advertencias

contenidas en la Hoja de Instalación. Si tiene alguna pregunta acerca de cualquiera de las instrucciones o las

advertencias, por favor, llame a Servicio al Cliente al 1-800-865-2112.

• Este producto sólo debe ser instalado por una persona que tenga una buena aptitud mecánica, que tenga

experiencia en

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los

fi jadores y componentes.

• Nunca sobrepase la capacidad máxima de soportar carga aceptada. Vea la página 11.

• Si va a instalar el producto en una pared con montantes de madera, asegúrese de que los tornillos de montaje

estén anclados en el centro de los montantes. Se recomienda utilizar un localizador de montantes de "borde a

borde".

• Siempre cuente con la ayuda de un asistente o utilice un equipo mecánico de izar para levantar y colocar el

equipo con más seguridad.

• Apriete los tornillos con fi rmeza, pero no en exceso. Apretarlos en exceso puede dañar los artículos y puede

disminuir signifi cativamente su fuerza de fi jación.

• Este producto está diseñado para uso en interiores solamente. Utilizar este producto en exteriores podría

causar fallas del producto y lesiones a individuos.

• Este producto fue diseñado con la intención de que se instale en las superfi cies de apoyo marcadas abajo con

los accesorios de instalación incluidos en este producto como se especifi ca en la hoja de instalación. Para

instalar este producto en otra superfi cie de apoyo, llame a Servicio al Cliente al 1-800-865-2112.

• Este producto fue diseñado para ser instalado en paredes con la siguiente construcción solamente:

CONSTRUCCIÓN DE LA PARED ACCESORIOS NECESARIOS

• Montante de madera Incluido

• Viga de madera Incluido

• Concreto macizo Incluido

• Bloque de hormigón de escorias Incluido

• Ladrillo Comuníquese con un profesional califi cado

• ¿Otra superfi cie o no está seguro? Comuníquese con un profesional califi cado

construcción básica de edifi cios y que entienda estas instrucciones en su totalidad.

Español

Herramientas necesarias para el ensamblaje

• localizador de montantes (se recomienda uno de "borde a borde")

• destornillador phillips

• taladro

• broca de 5/32" para paredes con montantes de madera

• broca de 5/16" para paredes de concreto y de bloque de

hormigón de escorias

• nivel

Accesorios

• ACC324(-S) - Unidad de repisa para el soporte de

esquina

• ACC930 - Juego de sujetadores para los soportes

para altavoces

Tabla de centenido

Lista de piezas..................................................................................................................................................................... 13

Instalación en una esquina interior de una pared con montantes de madera ..................................................................... 14

Instalación en una esquina exterior de una pared con montantes de madera .................................................................... 15

Instalación en una esquina interior de una pared concreto ................................................................................................. 16

Instalación en una esquina exterior de una pared concreto ................................................................................................ 17

Fijar la placa de interface y la placa central .................................................................................................................. 18, 19

Instalación de los soportes para altavoces.......................................................................................................................... 20

12 de 30

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

Page 13

A

Antes de comenzar, asegúrese de que su producto contiene todas las piezas que se muestran.

Las piezas podrían verse ligeramente diferentes a las ilustradas.

Lista de piezas

Descripción Cantidad

placa de interface

placa de pared

B

soportes sostenedores

C

placa central

D

tornillos para madera de 14 x 2.5"

E

Anclajes para concreto

F

tornillo phillips de cabeza redonda

G

de 1/4-20 x 1"

contratuerca dentada bridada

H

de 1/4-20

tuerca en jaula

I

de Tinnerman® 1/4-20

arandela plana de 1/4"

J

2 120-1075 120-4075 120-1075 120-4075

2 120-1076 120-4076 120-1076 120-4076

4 120-1077 120-4077 120-1077 120-4077

1 n/a n/a 120-1078 120-4078

8 5S1-015-C03 5S1-015-C03 5S1-015-C03 5S1-015-C03

8 590-0320 590-0320 590-0320 590-0320

24 510-9110 510-9110 510-9110 510-9110

16 530-1021 530-1021 530-1021 530-1021

12 530-2050 530-2050 530-2050 530-2050

24 540-9440 540-9440 540-9440 540-9440

CM50 CM50-S CM60 CM60-S

Español

E

A

F

B

G

C

H

D

J

I

13 de 30

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

Page 14

Español

Instalación en una esquina interior de una pared con montantes de madera

ADVERTENCIA

• El instalador tiene que asegurarse de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del

equipo y todos los fi jadores y componentes.

• Apriete los tornillos de madera de manera que la placa de pared se fi je fi rmemente, pero no en exceso. Apretar los

en exceso puede dañar los tornillos y puede disminuir signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

• Asegúrese de que los tornillos de montaje estén anclados en el centro del montante. Se recomienda utilizar un

localizador de montantes de "borde a borde".

• Los accesorios para la instalación que se proveen son para fi jar el soporte a montantes de madera a través de

tabique de yeso-cartón o yeso de espesor estándar. Los instaladores son responsables de suministrar los accesorios necesarios para otros tipos de instalaciones.

Las placas de pared (B) se pueden instalar en un montante o en dos montantes que tengan una separación

1

de 16". Utilice un localizador de montantes para localizar los bordes de los montantes. Se recomienda utilizar

un localizador de montantes de "borde a borde". Tomando los bordes como punto de referencia, trace una

línea vertical por el centro de cada montante en ambas paredes. NOTA: Es posible que no se pueda realizar la

instalación en dos montantes, dependiendo de la ubicación de los montantes en las esquinas de las paredes.

Determine la distancia desde la esquina de la pared hasta el borde interior de las placas de pared (B) utilizando

la ecuación que aparece abajo y el detalle 1 para conocer la distancia "X". NOTA: Si va a instalar soportes para

altavoces a los lados del soporte de esquina, la pantalla no puede medir más de 40". Vea la página 20 para saber

cómo se instalan los altavoces.

Mida la distancia "X" desde la esquina de la pared y marque la ubicación del borde interior de la placa de pared.

Las ranuras de montaje superiores de la placa de pared deben estar ubicadas a 3.44" (87 mm) encima del punto

donde quiere que quede el centro de la pantalla, como se muestra en la figura 1.1. Nivele la placa de pared,

alinéela en la ubicación que marcó del borde interior de la placa de pared y marque las cuatro ranuras alineadas

en el centro de los montantes. Haga lo mismo con la placa de pared opuesta. Taladre agujeros de 5/32" (4 mm)

de diámetro a una profundidad mínima de 2.5" (64 mm). Asegúrese de que las placas de pared estén niveladas y

fíjelas usando los tornillos para madera de 14 x 2.5" (E).

MONTANTE

3.44"

(87 mm)

CS

B

X

X

Y

DETALLE 1

CS = CENTRO DE

LA PANTALLA

fig. 1.1

"X" =

Y

1.414

14 de 30

- 21.216

B

E

fig. 1.2

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

B

Page 15

Español

Instalación en una esquina exterior de una pared con montantes de madera

ADVERTENCIA

• El instalador tiene que asegurarse de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del

equipo y todos los fi jadores y componentes.

• Apriete los tornillos de madera de manera que la placa de pared se fi je fi rmemente, pero no en exceso. Apretar los

en exceso puede dañar los tornillos y puede disminuir signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

• Asegúrese de que los tornillos de montaje estén anclados en el centro del montante. Se recomienda utilizar un

localizador de montantes de "borde a borde".

• Los accesorios para la instalación que se proveen son para fi jar el soporte a montantes de madera a través de

tabique de yeso-cartón o yeso de espesor estándar. Los instaladores son responsables de suministrar los accesorios necesarios para otros tipos de instalaciones.

Las placas de pared (B) se pueden instalar en un montante o en dos montantes que tengan una separación

1

de 16". Utilice un localizador de montantes para localizar los bordes de los montantes. Se recomienda utilizar

un localizador de montantes de "borde a borde". Tomando los bordes como punto de referencia, trace una

línea vertical por el centro de cada montante en ambas paredes. NOTA: Es posible que no se pueda realizar la

instalación en dos montantes, dependiendo de la ubicación de los montantes en las esquinas de las paredes.

NOTA: Si va a instalar soportes para altavoces a los lados del soporte de esquina, la pantalla no puede medir

más de 40". Vea la página 20 para saber cómo se instalan los altavoces.

Mida una distancia de 1" (25 mm) desde la esquina de la pared y marque la ubicación del borde interior de la

placa de pared. Las ranuras de montaje superiores de la placa de pared deben estar ubicadas a 3.44" (87 mm)

encima del punto donde quiere que quede el centro de la pantalla, como se muestra en la fi gura 1.3. Nivele la

placa de pared, alinéela en la ubicación que marcó del borde interior de la placa de pared y marque las cuatro

ranuras alineadas en el centro de los montantes. Haga lo mismo con la placa de pared opuesta. Taladre agujeros

de 5/32" (4 mm) de diámetro a una profundidad mínima de 2.5" (64 mm). Asegúrese de que las placas de pared

estén niveladas y fíjelas usando los tornillos para madera de 14 x 2.5" (E).

MONTANTE

3.44"

(87 mm)

B

CS = CENTRO DE LA

PANTALLA

CS

fig. 1.3

1"

(25 mm)

ESQUINA

15 de 30

E

B

B

E

fig. 1.4

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

Page 16

Instalación en una esquina interior de una pared concreto

Español

ADVERTENCIA

• Cuando vaya a instalar soportes de pared de Peerless en bloques de hormigón de escorias, asegúrese de que

cuente con una capa de concreto de un grosor mínimo de 1-3/8" en el agujero, que pueda usar para los anclajes

para concreto. ¡No taladre en juntas de argamasa! Asegúrese de hacer la instalación en la parte sólida del bloque,

por lo general, a un mínimo de 1" del extremo del bloque. Los bloques de hormigón de escorias tienen que cumplir

las especifi caciones de la ASTM C-90. Se sugiere utilizar un taladro eléctrico convencional a baja velocidad para

hacer el agujero en vez de un taladro percutor para no perforar el fondo del agujero al entrar en un vacío o una

cavidad.

• El concreto tiene que tener una densidad mínima de 2,000 psi. Es posible que un concreto de menos densidad no

sostenga el anclaje para concreto.

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los

fi jadores y componentes.

Determine la distancia desde la esquina de la pared

1

hasta el borde interior de la placa de pared (B) utilizando

la ecuación y el detalle 1 de la página 14 para conocer

la distancia "X". NOTA: Si va a instalar soportes para

altavoces a los lados del soporte de esquina, la pantalla

no puede medir más de 40". Vea la página 20 para

saber cómo se instalan los altavoces.Mida la distancia

"X" desde la esquina de la pared y marque la ubicación

del borde interior de la placa de pared. Las ranuras de

montaje superiores de la placa de pared deben estar

ubicadas a 3.44" (87 mm) encima del punto donde

quiere que quede el centro de la pantalla, como se

muestra en la fi gura 1.1 de la página 14. Nivele la

placa (B), alinéela en la ubicación que marcó del borde

interior de la placa de pared y marque las cuatro ranuras

alineadas en el centro de los montantes. Haga lo mismo

con la placa de pared opuesta. Taladre agujeros de

5/16" (8 mm) de diámetro a una profundidad mínima de

2.5" (64 mm). Inserte los anclajes (F) en los agujeros

a ras con la pared, como se muestra (a la derecha).

Coloque la placa de pared sobre los anclajes, asegúrese

de que las placas de pared estén niveladas y fíjelas

usando los tornillos para madera de 14 x 2.5" (E).

1

Perfore los agujeros y después inserte los anclajes (F).

2

B

E

Coloque la placa (B) sobre los anclajes (F) y fíjela con

los tornillos (E).

3

Apriete todas las fi jaciones.

superfi cie de

concreto

F

F

ADVERTENCIA

• Apriete los tornillos de manera que la placa de pared

se fi je fi rmemente, pero no en exceso. Apretarlos en

exceso puede dañar los tornillos y puede disminuir

signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

ADVERTENCIA

• Siempre fi je los anclajes para concreto directamente

en la pared que sostiene la carga.

• Nunca fi je los anclajes para concreto a una pared

de concreto recubierta con yeso, yeso-cartón u

otro material de acabado. Si es inevitable hacer la

instalación en una superfi cie de concreto recubierta

con una superfi cie de acabado, la superfi cie de

acabado tiene que ser escariada, como se muestra

a la derecha. Asegúrese de que los anclajes para

concreto no se separen del concreto cuando apriete

los tornillos. Si la capa de yeso o de yeso-cartón

tiene un grosor mayor que 5/8", el instalador tiene

que suministrar las fi jaciones especiales.

16 de 30

bloque de

hormigón

de escorias

F

placa

de

pared

VISTA EN CORTE

concreto macizo

B

E

INCORRECTO CORRECTO

concreto

yeso / tabique de yeso-cartón

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

placa

pared

de

F

concreto

Page 17

Instalación en una esquina exterior de una pared concreto

Español

ADVERTENCIA

• Cuando vaya a instalar soportes de pared de Peerless en bloques de hormigón de escorias, asegúrese de que

cuente con una capa de concreto de un grosor mínimo de 1-3/8" en el agujero, que pueda usar para los anclajes

para concreto. ¡No taladre en juntas de argamasa! Asegúrese de hacer la instalación en la parte sólida del bloque,

por lo general, a un mínimo de 1" del extremo del bloque. Los bloques de hormigón de escorias tienen que cumplir

las especifi caciones de la ASTM C-90. Se sugiere utilizar un taladro eléctrico convencional a baja velocidad para

hacer el agujero en vez de un taladro percutor para no perforar el fondo del agujero al entrar en un vacío o una

cavidad.

• El concreto tiene que tener una densidad mínima de 2,000 psi. Es posible que un concreto de menos densidad no

sostenga el anclaje para concreto.

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los

fi jadores y componentes.

NOTA: Si va a instalar soportes para altavoces a los

1

lados del soporte de esquina, la pantalla no puede

medir más de 40". Vea la página 20 para saber cómo

se instalan los altavoces. Mida una distancia de 1"

(25 mm) desde la esquina de la pared y marque la

ubicación del borde interior de la placa de pared.

Las ranuras de montaje superiores de la placa de

pared deben estar ubicadas a 3.44" (87 mm) encima

del punto donde quiere que quede el centro de la

pantalla, como se muestra en la fi gura 1.3 de la

página 15. Nivele la placa (B), alinéela en la ubicación

que marcó del borde interior de la placa de pared

y marque las cuatro ranuras alineadas en el centro

de los montantes. Haga lo mismo con la placa de

pared opuesta. Taladre agujeros de 5/16" (8 mm) de

diámetro a una profundidad mínima de 2.5" (64 mm).

Inserte los anclajes (F) en los agujeros a ras con la

pared, como se muestra (a la derecha). Coloque la

placa de pared sobre los anclajes, asegúrese de que

las placas de pared estén niveladas y fíjelas usando

los tornillos para madera de 14 x 2.5" (E).

1

Perfore los agujeros y después inserte los anclajes (F).

2

B

E

Coloque la placa (B) sobre los anclajes (F) y fíjela con

los tornillos (E).

3

Apriete todas las fi jaciones.

superfi cie de

concreto

F

F

ADVERTENCIA

• Apriete los tornillos de manera que la placa de pared

se fi je fi rmemente, pero no en exceso. Apretarlos en

exceso puede dañar los tornillos y puede disminuir

signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

ADVERTENCIA

• Siempre fi je los anclajes para concreto directamente

en la pared que sostiene la carga.

• Nunca fi je los anclajes para concreto a una pared

de concreto recubierta con yeso, yeso-cartón u

otro material de acabado. Si es inevitable hacer la

instalación en una superfi cie de concreto recubierta

con una superfi cie de acabado, la superfi cie de

acabado tiene que ser escariada, como se muestra

a la derecha. Asegúrese de que los anclajes para

concreto no se separen del concreto cuando apriete

los tornillos. Si la capa de yeso o de yeso-cartón

tiene un grosor mayor que 5/8", el instalador tiene

que suministrar las fi jaciones especiales.

VISTA EN CORTE

17 de 30

placa

de

pared

F

bloque de hormigón

concreto macizo

de escorias

B

E

INCORRECTO CORRECTO

concreto

yeso / tabique de yeso-cartón

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

placa

pared

de

F

E

concreto

Page 18

Fijar la placa de interface

Fije la placa de interface (A) a la placa de pared (B) usando un tornillo phillips de cabeza redonda de

2

1/4-20 x 1" (G), una arandela plana de 1/4" (J) y una contratuerca dentada bridada de 1/4-20 (H), como

se muestra en la fi gura 2.1 o en la fi gura 2.2, si se trata de una esquina interior o como se muestra

en la fi gura 2.3 o en la fi gura 2.4, si se trata de una esquina exterior. Haga lo mismo con la placa de

interface opuesta.

NOTA: Asegúrese de que la pestaña superior de la placa de interface (A) descanse sobre la pestaña

superior de la placa de pared (B).

NOTA: No apriete los sujetadores al máximo.

ESQUINA INTERIOR IZQUIERDA ESQUINA INTERIOR DERECHA

Español

A

G

J

H

B

fig. 2.1

ESQUINA EXTERIOR IZQUIERDA ESQUINA EXTERIOR DERECHA

B

G

J

H

B

G

J

H

fig. 2.2

G

J

H

B

A

A

fig. 2.3 fig. 2.4

18 de 30

A

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

Page 19

Instalación de los Soportes Sostenedores y la Placa Central

NOTA: Utilice la placa central (D) si la confi guración de montaje de la placa de pared es más estrecha

3-1

que la apertura entre las placas de interface (A). Fije los soportes sostenedores (C) a la parte trasera

de la placa de pared (B) usando un tornillo phillips de cabeza redonda de 1/4-20 x 1" (G), una arandela

plana de 1/4" (J) y una contratuerca dentada bridada de 1/4-20 (H) por cada soporte sostenedor, como

se muestra abajo.

NOTA: Asegúrese de que la pestaña del soporte sostenedor se oriente hacia el interior de la placa de

interface y de la placa de pared.

NOTA: No apriete los sujetadores al máximo.

Pase al paso 3-3 si no va a instalar la placa central.

B

Español

G

J

H

Mueva los soportes adaptadores (C) para

3-2

alejarlos de la parte delantera de la unidad del

soporte. Deslice la placa central (D) detrás

de la placa de pared (A) y centralícela entre

las dos placas de interface. Alinee el agujero

superior y el agujero inferior de la placa de

interface con las ranuras de la placa central.

Enrosque, con la mano, un tornillo phillips

de cabeza redonda de 1/4-20 x 1" (G) y una

arandela plana de 1/4" (J) por el agujero

superior solamente.`

G

A

J

C

A

Mueva los soportes adaptadores (C) para

3-3

acercarlos a la parte delantera de la unidad de

soporte. Deslice el soporte adaptador superior

por el tornillo superior y fíjelo usando una

contratuerca dentada bridada de 1/4-20 (H).

Alinee el agujero del soporte adaptador inferior

con el agujero inferior y fi je el soporte usando

un tornillo phillips de cabeza redonda de 1/4-20

x 1" (G), una arandela plana de 1/4" (J) y una

contratuerca dentada bridada de 1/4-20 (H).

H

J

G

D

19 de 30

H

J

G

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

Page 20

Alinee la placa de pared del soporte de pared con las placas de interface (A) para señalar la

4

ubicación de las tuercas en jaula (I), que se utilizan para fi jar la placa de pared a las placas de

interface. Instale las tuercas en jaula de la parte trasera de las placas de interface (A), como se

muestra en el detalle 2.

NOTA: Instale la placa de pared y los componentes restantes de la unidad del soporte de pared

según las instrucciones proporcionadas con el soporte de pared.

I

DETAIL 2

Instalación de los soportes para altavoces (opcional)

NOTA: Es posible que se vea el soporte de esquina si la pantalla es pequeña.

5

NOTA: Los soportes para altavoces (vendidos por separado) pueden verse un poco distintos a la

ilustración. Se necesita el juego ACC930 (vendido por separado) para fi jar los soportes para altavoces

al soporte de esquina.

Siguiendo la confi guración de montaje que se muestra abajo, fi je el soporte para altavoces a la placa

de interface (A) usando dos tornillos y dos arandelas por la parte delantera y dos tuercas por la parte

trasera. NOTA: No se incluyen los sujetadores para instalar los soportes para altavoces.

Español

20 de 30

Cualesquiera otras marcas y nombres de productos son marcas comerciales o registradas de sus respectivos dueños.

PUBLICADO: 07-22-08 HOJA #: 120-9054-2 09-30-11

© 2011, Peerless Industries, Inc. Todos los derechos reservados.

Page 21

Français

(2-plaque)

Installation et montage:

Accessoire de support d’encoignure pour écran plat,

pour écrans ACL et plasma de 32 à to 60 po

Plage de dimensions

Modèle

CM50, CM50-S 32"-50"

CM60, CM60-S 40"-60"

de l’écran

Capacité de charge

maximale établie

79.4 kg (175 lb)

90.8kg (200 lb)

Compatibilité

SF640/ST640

PF640/PT640

SF650/ST650

PF650/PT650

ONE-TP

SF640/ST640

PF640/PT640

SF650/ST650

PF650/PT650

SF660/ST660

PF660/PT660

ONE-TP (3-placa)

CM50, CM50-S

CARACTÉRISTIQUES

• Permet d’installer l’écran dans un coin lorsque l’espace est limité

• CM50(-S) les unités murales sont extensibles pour convenir aux supports muraux plats

inclinables compatibles pour écrans de 32 – 50 po

• CM60(-S) comprend une plaque de soutien supplémentaire pour convenir aux supports

muraux plats/inclinables compatibles pour écrans de 40 – 60 po

• les unités murales peuvent loger des haut-parleurs lorsqu’elles sont utilisées avec de plus

petits écrans (l’unité murale peut être visible avec certains écrans de petite taille)

• Étagère pour accessoires disponible pour les composants audio-vidéo (vendue séparément)

• S’installe sur des montants en bois, du béton ou du bloc de béton

21 sur 30

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

CM60, CM60-S

Page 22

Remarque : lisez entièrement la fi che d’instructions avant de commencer l’installation et l’assemblage.

Français

AVERTISSEMENT

• Ne commencez pas à installer ce produit avant d’avoir lu et assimilé les instructions et les avertissements contenus

dans cette fi che d’installation. Pour toute question concernant les instructions ou les avertissements, veuillez

appeler le service à la clientèle au 1-800-865-2112.

• Ce produit doit être installé uniquement par quelqu’un possédant une bonne aptitude à la mécanique, une

expérience de la construction immobilière et ayant bien compris ces instructions.

• Assurez-vous que la surface de support puisse soutenir sans danger la charge totale de l’équipement ainsi que des

pièces et composants qui y sont attachés.

• Ne dépassez jamais la capacité de charge maximum établie. Reportez-vous à la page 21.

• Lors d’une installation sur un mur à montants en bois, assurez-vous que les vis de montage sont ancrées au centre

des montants. L’utilisation d’un localisateur de montants « bord à bord » est fortement recommandée.

• Pour lever et positionner l’équipement en toute sécurité, faites-vous toujours aider par une autre personne ou

utilisez un dispositif de levage mécanique.

• Serrez fermement les vis, mais sans excès. Un serrage excessif peut endommager les composants et en réduire

considérablement la capacité de support.

• Ce produit est conçu uniquement pour un usage intérieur. L’utilisation de ce produit à l’extérieur peut causer une

défaillance du produit et des blessures corporelles.

• Ce produit a été conçu pour une installation aux surfaces de support marquées d’une croix ci-dessous avec les

pièces de fi xation incluses tel qu’indiqué sur la fi che d’installation. Pour monter ce produit sur un autre type de

surface de support, contactez le service à la clientèle au 1 800 865-2112.

• Ce produit a été conçu uniquement pour une installation sur les types de murs ci-dessous :

TYPE DE MUR PIÈCES DE FIXATION REQUISES

• Montant en bois Incluses

• Poutre en bois Incluses

• Béton plein Incluses

• Bloc de béton de mâchefer Incluses

• Brique Contacter un professionnel qualifi é

• Autre, ou vous n’êtes pas sûr ? Contacter un professionnel qualifi é

Outils nécessaires au montage

• localisateur de montants (un localisateur de montants

« bord à bord » est recommandé)

• tournevis Phillips

• perceuse

• foret de 5/32 po pour les murs à montants en bois

• foret de 5/16 po pour les murs en béton et en bloc de

béton

• niveau

Accesorios

• ACC324(-S) – Étagère pour support d’encoignure

• ACC930 – Jeu de fixations pour supports de hautparleurs

Table des matières

Liste des pièces ................................................................................................................................................................... 23

Installation au coin intérieur de murs à montants en bois ................................................................................................... 24

Installation au coin extérieur de murs à montants en bois .................................................................................................. 25

Installation au coin intérieur de murs en béton .................................................................................................................... 26

Installation au coin extérieur de murs en béton ................................................................................................................... 27

Fixation de la plaque d’interconnexion et de la plaque centrale .................................................................................... 28, 29

Installation des supports de haut-parleurs........................................................................................................................... 30

22 sur 30

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

Page 23

Avant de commencer, assurez-vous que toutes les pièces indiquées sont incluses avec le produit.

Il est possible que les pièces semblent légèrement différentes de l’illustration.

Liste des pièces

Descripción Qté

plaque d’interconnexion 2 120-1075 120-4075 120-1075 120-4075

A

plaque murale 2 120-1076 120-4076 120-1076 120-4076

B

pattes de support 4 120-1077 120-4077 120-1077 120-4077

C

Plaque centrale 1 n/a n/a 120-1078 120-4078

D

E

vis à bois n

ancrages pour béton 8 590-0320 590-0320 590-0320 590-0320

F

vis phillips à tête ronde 1/4-20 x 1 po 24 510-9110 510-9110 510-9110 510-9110

G

écrou de blocage à embase crantée 1/4-20 16 530-1021 530-1021 530-1021 530-1021

H

écrou prisonnier Tinnerman® 1/4-20 12 530-2050 530-2050 530-2050 530-2050

I

rondelle plate de 1/4 po

J

o

14 x 2,5 po

8 5S1-015-C03 5S1-015-C03 5S1-015-C03 5S1-015-C03

24 540-9440 540-9440 540-9440 540-9440

CM50 CM50-S CM60 CM60-S

Français

E

A

F

B

G

C

H

D

J

I

23 sur 30

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

Page 24

Installation au coin intérieur de murs à montants en bois

AVERTISSEMENT

• L’installateur doit s’assurer que la surface de support pourra soutenir sans danger la charge combinée de

l’équipement, de toute sa visserie et de tous ses composants.

• Serrez les vis à bois de manière que la plaque murale soit fermement fi xée, mais sans excès. Un serrage ex-

cessif peut endommager les vis et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Assurez-vous que les vis de montage sont ancrées au centre des montants. L’usage d’un localisateur de montants « bord à bord » est fortement conseillé.

• La visserie est fournie pour fi xer la monture à travers une cloison sèche ou du plâtre d’épaisseur standard et

dans des montants en bois. Il appartient aux installateurs de fournir la visserie nécessaire pour d’autres types

de situations.

Les plaques murales (B) peuvent être installées à un montant ou à deux montants espacés de 16 po. Repérez le

1

bord des montants à l’aide d’un localisateur de montants. L’utilisation d’un localisateur de montants « bord à bord

» est fortement recommandée. Après avoir repéré les bords, tracez une ligne verticale le long du centre des deux

murs. REMARQUE : Selon la position des montants sur les coins du mur, il pourrait être impossible de procéder à

une installation sur deux montants.

Déterminez la distance entre le coin du mur et le bord intérieur des plaques murales (B) à l’aide de l’équation

ci-dessous et du dessin de détail 1 pour obtenir la distance « X ». REMARQUE : Si les supports de haut-parleurs

sont installés sur les côtés du support d’encoignure, la taille de l’écran ne peut excéder 40 po. Voir page 30 pour

l’installation du support de haut-parleurs.

Mesurez la distance « X » à partir du coin du mur et marquez l’emplacement du bord intérieur de la plaque

murale. Les fentes de montage supérieures de la plaque murale doivent être situées à 3,44 po (87 mm) au-dessus

de l’endroit souhaité pour le centre de l’écran comme illustré à la fi gure 1.1. Mettez la plaque murale à niveau,

alignez-la sur l’emplacement que vous avez marqué pour le bord intérieur de la plaque murale, et marquez quatre

fentes alignées sur le centre des montants. Répétez l’opération pour la plaque murale du mur opposé. Percez

des trous de 5/32 po (4 mm) de dia. à une profondeur minimale de 2,5 po (64 mm). Veillez à ce que les plaques

murales soient de niveau et fi xez-les à l’aide de vis à bois #14 x 2,5 po (E).

Français

MONTANT

3.44"

(87 mm)

B

X

X

Y

DÉTAIL 1

CE

CE = CENTRE DE L’ÉCRAN

fig. 1.1

"X" =

Y

1.414

24 sur 30

- 21.216

B

B

E

fig. 1.2

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

Page 25

Installation au coin extérieur de murs à montants en bois

AVERTISSEMENT

• L’installateur doit s’assurer que la surface de support pourra soutenir sans danger la charge combinée de

l’équipement, de toute sa visserie et de tous ses composants.

• Serrez les vis à bois de manière que la plaque murale soit fermement fi xée, mais sans excès. Un serrage ex-

cessif peut endommager les vis et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Assurez-vous que les vis de montage sont ancrées au centre des montants. L’usage d’un localisateur de montants « bord à bord » est fortement conseillé.

• La visserie est fournie pour fi xer la monture à travers une cloison sèche ou du plâtre d’épaisseur standard et

dans des montants en bois. Il appartient aux installateurs de fournir la visserie nécessaire pour d’autres types

de situations.

Les plaques murales (B) peuvent être installées à un montant ou à deux montants espacés de 16 po. Repérez le

1

bord des montants à l’aide d’un localisateur de montants. L’utilisation d’un localisateur de montants « bord à bord

» est fortement recommandée. Après avoir repéré les bords, tracez une ligne verticale le long du centre des deux

murs. REMARQUE : Selon la position des montants sur les coins du mur, il pourrait être impossible de procéder

à une installation sur deux montants.

REMARQUE : Si les supports de haut-parleurs sont installés sur les côtés du support d’encoignure, la taille de

l’écran ne peut excéder 40 po. Voir page 30 pour l’installation du support de haut-parleurs.

Mesurez 1 po (25 mm) à partir du coin du mur et marquez l’emplacement du bord intérieur de la plaque murale.

Les fentes de montage supérieures de la plaque murale doivent être situées à 3,44 po (87 mm) au-dessus de

l’endroit souhaité pour le centre de l’écran comme illustré à la fi gure 1,3. Mettez la plaque murale à niveau,

alignez-la sur l’emplacement que vous avez marqué pour le bord intérieur de la plaque murale, et marquez quatre

fentes alignées sur le centre des montants. Répétez l’opération pour la plaque murale du mur opposé. Percez

des trous de 5/32 po (4 mm) de dia. à une profondeur minimale de 2,5 po (64 mm). Veillez à ce que les plaques

murales soient de niveau et fi xez-les à l’aide de vis à bois #14 x 2,5 po (E).

Français

MONTANT

3.44"

(87 mm)

CE

B

CE = CENTRE DE L’ÉCRAN

fig. 1.3

1"

(25 mm)

COIN

E

25 sur 30

B

B

E

fig. 1.4

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

Page 26

Installation au coin intérieur de murs en béton

Français

AVERTISSEMENT

• Si vous installez des montures murales Peerless sur un bloc de béton de mâchefer, vérifi ez que vous disposez

d’une épaisseur de béton d’au moins 0,34 cm (1 3/8 po) dans le trou destiné aux ancrages de béton. Ne percez pas

dans les joints de mortier ! Veillez à effectuer le montage dans une partie pleine du bloc, généralement à au moins

2,5 cm (1 po) du côté du bloc. Le bloc de béton de mâchefer doit être conforme aux spécifi cations de l’ASTM C-90.

Pour percer le trou, il est conseillé d’utiliser une perceuse électrique standard sur un réglage bas au lieu d’un marteau perforateur, afi n d’éviter de briser la partie arrière du trou lorsque vous pénétrez un vide ou une cavité.

• Le béton doit avoir une densité minimale de 2000 psi. Un béton de densité moindre risquerait de ne pas retenir un

ancrage de béton.

• Assurez-vous que la surface de support pourra soutenir sans danger la charge combinée de l’équipement, de toute

sa visserie et de tous ses composants.

Déterminez la distance entre le coin du mur et le bord

intérieur de la plaque murale (B) à l’aide de l’équation et

1

du dessin de détail 1 en page 24 pour obtenir la distance

« X ». REMARQUE : Si les supports de haut-parleurs

sont installés sur les côtés du support d’encoignure, la

taille de l’écran ne peut excéder 40 po. Voir page 30

pour l’installation du support de haut-parleurs. Mesurez

la distance « X » à partir du coin du mur et marquez

l’emplacement du bord intérieur de la plaque murale. Les

fentes de montage supérieures de la plaque murale doivent

être situées à 3,44 po (87 mm) au-dessus de l’endroit

souhaité pour le centre de l’écran comme illustré à la fi g 1.1

en page 24. Mettez la plaque murale à niveau (B), alignezla sur l’endroit que vous avez marqué pour le bord intérieur

de la plaque murale et marquez quatre fentes alignées sur

le centre des montants. Répétez l’opération pour la plaque

murale du mur opposé. Percez des trous de

5/16 po (8 mm) de dia. à une profondeur minimale de 2,5

po (64 mm). Insérez les chevilles d’ancrage (F) dans les

trous au ras du mur comme illustré (à droite). Posez la

plaque murale sur les chevilles d’ancrage, veillez à ce que

les plaques murales soient de niveau et fi xez-les à l’aide de

vis à bois #14 x 2,5 po (E).

AVERTISSEMENT

• Serrez les vis de manière que la plaque murale

soit fermement fi xée, mais sans excès. Un ser-

rage excessif peut endommager les vis et en

réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

1

Percez des trous et insérez les ancrages (F).

2

B

E

Placez la plaque (B) sur les ancrages (F) et fi xez avec

des vis (E).

3

Serrez toutes les fi xations.

béton plein

bloc de béton de

mâchefer

B

surface en

béton

F

F

AVERTISSEMENT

• Fixez toujours des ancrages de béton directement

sur du béton porteur.

• Ne fi xez jamais des chevilles d’ancrage pour béton

à du béton recouvert d’une couche de plâtre, d’une

cloison sèche ou de tout autre matériau de fi nition.

Si vous devez absolument effectuer l’installation sur

du béton recouvert d’une surface de fi nition, celle-ci

doit être chambrée, comme indiqué à droite. Veillez

à ce que les chevilles d’ancrage ne s’éloignent pas

du béton lorsque vous serrez les vis. Si l’épaisseur

du plâtre ou de la cloison sèche dépasse 5/8 po,

l’installateur devra fournir des pièces de fi xation sur

mesure.

26 sur 30

F

plaque

mural

plâtre /

VUE EN COUPE

cloison sèche

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

E

INCORRECT

béton

plaque

mural

plâtre /

cloison sèche

F

CORRECT

béton

Page 27

Installation au coin extérieur de murs en béton

Français

AVERTISSEMENT

• Si vous installez des montures murales Peerless sur un bloc de béton de mâchefer, vérifi ez que vous disposez

d’une épaisseur de béton d’au moins 0,34 cm (1 3/8 po) dans le trou destiné aux ancrages de béton. Ne percez pas

dans les joints de mortier ! Veillez à effectuer le montage dans une partie pleine du bloc, généralement à au moins

2,5 cm (1 po) du côté du bloc. Le bloc de béton de mâchefer doit être conforme aux spécifi cations de l’ASTM C-90.

Pour percer le trou, il est conseillé d’utiliser une perceuse électrique standard sur un réglage bas au lieu d’un marteau perforateur, afi n d’éviter de briser la partie arrière du trou lorsque vous pénétrez un vide ou une cavité.

• Le béton doit avoir une densité minimale de 2000 psi. Un béton de densité moindre risquerait de ne pas retenir un

ancrage de béton.

• Assurez-vous que la surface de support pourra soutenir sans danger la charge combinée de l’équipement, de toute

sa visserie et de tous ses composants.

REMARQUE : Si les supports de haut-parleurs sont

1

installés sur les côtés du support d’encoignure, la taille

de l’écran ne peut excéder 40 po. Voir page 30 pour

l’installation du support de haut-parleurs.

Mesurez 1 po (25 mm) à partir du coin du mur et

marquez l’emplacement du bord intérieur de la plaque

murale. Les fentes de montage supérieures de la plaque

murale doivent être situées à 3,44 po (87 mm) audessus de l’endroit souhaité pour le centre de l’écran

comme illustré à la fi g. 1.3 en page 25. Mettez la plaque

murale à niveau (B), alignez-la sur l’endroit que vous

avez marqué pour le bord intérieur de la plaque murale

et marquez quatre fentes alignées sur le centre des

montants. Répétez l’opération pour la plaque murale du

mur opposé. Percez des trous de 5/16 po (8 mm) de dia.

à une profondeur minimale de 2,5 po (64 mm). Insérez

les chevilles d’ancrage (F) dans les trous au ras du mur

comme illustré (à droite). Posez la plaque murale sur

les chevilles d’ancrage, en veillant à ce que les plaques

murales soient de niveau, et fi xez-les à l’aide de vis à

bois #14 x 2,5 po (E).

AVERTISSEMENT

• Serrez les vis de manière que la plaque murale

soit fermement fi xée, mais sans excès. Un serrage

excessif peut endommager les vis et en réduire

considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

1

Percez des trous et insérez les ancrages (F).

2

B

E

Placez la plaque (B) sur les ancrages (F) et fi xez avec

des vis (E).

3

Serrez toutes les fi xations.

béton plein

B

bloc de béton

de mâchefer

F

surface en

béton

F

F

F

AVERTISSEMENT

• Fixez toujours des ancrages de béton directement

sur du béton porteur.

• Ne fi xez jamais des chevilles d’ancrage pour béton

à du béton recouvert d’une couche de plâtre, d’une

cloison sèche ou de tout autre matériau de fi nition.

Si vous devez absolument effectuer l’installation sur

du béton recouvert d’une surface de fi nition, celle-ci

doit être chambrée, comme indiqué à droite. Veillez

à ce que les chevilles d’ancrage ne s’éloignent pas

du béton lorsque vous serrez les vis. Si l’épaisseur

du plâtre ou de la cloison sèche dépasse 5/8 po,

l’installateur devra fournir des pièces de fi xation sur

mesure.

27 sur 30

E

plaque

mural

plâtre /

VUE EN COUPE

cloison sèche

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

INCORRECT

béton

plaque

mural

plâtre /

cloison sèche

E

CORRECT

béton

Page 28

Fixation de la plaque d’interconnexion

Fixez la plaque d’interconnexion (A) à la plaque murale (B) à l’aide d’une vis Phillips à tête ronde 1/4-20 x 1 po (G),

2

d’une rondelle plate 1/4 po (J) et d’un écrou de blocage à embase crantée 1/4-20 (H) comme illustré à la fi g 2.1

ou 2.2 pour les coins intérieurs ou aux fi g 2.3 et 2.4 pour les coins extérieurs. Répétez l’opération pour la plaque

d’interconnexion du mur opposé.

REMARQUE : Assurez-vous que la bride supérieure de la plaque d’interconnexion (A) repose sur la bride

supérieure de la plaque murale (B).

REMARQUE : Ne pas serrer complètement les fi xations.

COIN GAUCHE INTÉRIEUR COIN DROIT INTÉRIEUR

Français

A

G

J

H

B

fig. 2.1

COIN GAUCHE EXTÉRIEUR COIN DROIT EXTÉRIEUR

B

G

J

H

B

G

J

H

fig. 2.2

G

J

H

B

A

A

fig. 2.3 fig. 2.4

28 sur 30

A

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

Page 29

Installation des pattes de support et de la Plaque Centrale

REMARQUE : Utilisez la plaque centrale (D) lorsque la confi guration de montage de la plaque murale

3-1

est plus étroite que l’ouverture entre les plaques d’interconnexion (A). Fixez les pattes de support (C)

à l’arrière de la plaque murale (B) à l’aide de vis Phillips à tête ronde 1/4-20 x 1 po (G), d’une rondelle

plate 1/4 po (J) et d’un écrou de blocage à embase crantée 1/4-20 (H) pour chaque patte de support

comme illustré ci-dessous.

REMARQUE : Veillez à ce que la bride de la patte de support soit orientée vers l’intérieur de la plaque

d’interconnexion et de la plaque murale.

REMARQUE : Ne pas serrer complètement les fi xations.

Passez à l’étape 3-3 si vous n’installez pas de plaque centrale.

B

Français

G

J

H

C

H

J

Faites pivoter les supports adaptateurs (C)

3-2

hors de l’avant du support. Faites glisser

la plaque centrale (D) derrière la plaque

d’interconnexion (A) et centrez-la entre les

deux plaques d’interconnexion. Alignez les

trous supérieurs et inférieurs de la plaque

d’interconnexion sur les fentes de la plaque

centrale. Vissez manuellement la vis Phillips à

tête ronde 1/4-20 x 1 po (G) et la rondelle plate

1/4 po (J) dans le trou supérieur uniquement.

G

A

J

A

G

Faites pivoter les supports adaptateurs (C) vers

3-3

l’avant du support. Guidez le support adaptateur

supérieur dans la vis supérieure et fi xez-le à

l’aide d’un écrou à embase crantée 1/4-20 (H).

Alignez le trou du support adaptateur inférieur

sur le trou inférieur et fi xez-le à l’aide d’une vis

Phillips à tête ronde 1/4-20 x 1 po (G), d’une

rondelle plate 1/4 po (J) et d’un écrou de blocage

à embase crantée 1/4-20 (H).

H

D

29 sur 30

J

G

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

Page 30

Alignez la plaque murale sur les plaques d’interconnexion (A) pour déterminer l’emplacement des

4

écrous prisonniers (I) servant à fi xer la plaque murale aux plaques d’interconnexion. Installez les

écrous prisonniers à l’arrière des plaques d’interconnexion (A) comme illustré dans le dessin de

détail 2.

REMARQUE : Installez la plaque murale et le reste du support mural selon les instructions fournies

avec le support mural.

I

DETAIL 2

Installation des supports de haut-parleurs (facultatif)

REMARQUE : Le support d’encoignure peut être visible avec des écrans de petite taille.

5

REMARQUE : Le support de haut-parleurs (vendu séparément) peut différer de l’illustration. ACC930 (vendu

séparément) est nécessaire à l’installation du support de haut-parleurs au support d’encoignure.À l’aide de la

confi guration de trous ci-dessous, fi xez le support de haut-parleurs à la plaque d’interconnexion (A) à l’aide de

deux vis et de deux rondelles à l’avant et de deux écrous à l’arrière. REMARQUE : Les fi xations nécessaires à

l’installation du support de haut-parleurs ne sont pas comprises

Français

30 sur 30

Tous les autres noms de marques et de produits sont des marques de commerce ou déposées de leurs propriétaires respectifs.

PUBLIÉ LE : 07-22-08 FEUILLE no : 120-9054-2 09-30-11

© 2011, Peerless Industries, Inc. Tous droits réservés.

Loading...

Loading...