Page 1

CAST 92

Boilers

Peerless

Gas

Installation,

Operation &

Maintenance

Manual

As an ENERGY STAR®Partner, PB Heat, LLC has determined that this

product meets the ENERGY STAR guidelines for energy efficiency.

Page 2

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. CODES & REGULATIONS . . . . . . . . . . . . . . .2

C. BOILER LOCATION REQUIREMENTS . . . . . .3

D. CLEARANCE REQUIREMENTS . . . . . . . . . . .4

E. COMBUSTION AIR REQUIREMENTS . . . . . .4

2. BOILER SET-UP 7

A. REMOVE THE BOILER FROM THE CRATE . .7

B. INSTALL THE RELIEF VALVE . . . . . . . . . . . . .7

C. BOILER PIPING – GENERAL . . . . . . . . . . . . .7

3. VENTING & AIR INLET PIPING 9

A. COMMON VENT SYSTEMS . . . . . . . . . . . . .9

B. VENT AND AIR PIPING, GENERAL . . . . . . .10

C. VENT PIPING . . . . . . . . . . . . . . . . . . . . . . . .10

D. AIR PIPING . . . . . . . . . . . . . . . . . . . . . . . . . .10

E. TERMINATIONS . . . . . . . . . . . . . . . . . . . . . .10

F. VENT PIPED THROUGH THE ROOF

(COMBUSTION AIR FROM THE BOILER ROOM) . .10

G. VENT PIPED THROUGH THE ROOF

(AIR PIPED THROUGH SIDE WALL) . . . . . . . . . .11

H. VENT & AIR PIPED THROUGH THE ROOF

(SEPARATE VENT AND AIR TERMINATIONS) . . . .11

I. VENT PIPED THROUGH A SIDE WALL

(SEPARATE VENT AND AIR TERMINATIONS) . . . .12

J. VENT & AIR PIPED THROUGH A

SIDE WALL (SEPARATE VENT AND AIR

TERMINATIONS)

. . . . . . . . . . . . . . . . . . . . . . .12

K. VENT & AIR PIPED THROUGH A

SIDE WALL (CONCENTRIC VENT/AIR

TERMINATION)

. . . . . . . . . . . . . . . . . . . . . . . .13

3A. VENT & AIR PIPING: THROUGH THE ROOF

(COMBUSTION AIR FROM THE BOILER ROOM) 14

A. BOILER VENT CONNECTION . . . . . . . . . . .14

B. VENT PIPING COMPONENTS . . . . . . . . . . .15

C. SUPPORT THE VENT PIPING

COMPLETELY . . . . . . . . . . . . . . . . . . . . . . . .15

D. FLOOR AND WALL PENETRATIONS . . . . .15

E. ROOF PENETRATIONS . . . . . . . . . . . . . . . .15

F. RAIN CAP TERMINATION . . . . . . . . . . . . . .15

G. COMBUSTION AIR OPENINGS . . . . . . . . . .16

H. MULTIPLE BOILER INSTALLATIONS . . . . . .16

3B. VENT & AIR PIPING: THROUGH THE ROOF

(AIR PIPED THROUGH SIDE WALL) 17

A. BOILER VENT CONNECTION . . . . . . . . . . .17

B. VENT PIPING COMPONENTS . . . . . . . . . . .18

C. SUPPORT THE VENT PIPING

COMPLETELY . . . . . . . . . . . . . . . . . . . . . . . .18

D. FLOOR AND WALL PENETRATIONS . . . . .18

E. ROOF PENETRATIONS . . . . . . . . . . . . . . . .18

F. RAIN CAP TERMINATION . . . . . . . . . . . . . .18

G. AIR PIPE CONNECTION . . . . . . . . . . . . . . . .19

H. SUPPORTING AIR PIPING . . . . . . . . . . . . . .19

I. AIR PIPE TERMINATION . . . . . . . . . . . . . . .19

J. MULTIPLE BOILER INSTALLATIONS . . . . . .21

3C. VENT PIPING: THROUGH THE ROOF

(SEPARATE TERMINATIONS) 22

A. BOILER VENT CONNECTION . . . . . . . . . . .22

B. VENT PIPING COMPONENTS . . . . . . . . . . .23

C. SUPPORT THE VENT PIPING

COMPLETELY . . . . . . . . . . . . . . . . . . . . . . . .23

D. FLOOR AND WALL PENETRATIONS . . . . .23

E. ROOF PENETRATIONS . . . . . . . . . . . . . . . .23

F. RAIN CAP TERMINATION . . . . . . . . . . . . . .23

G. AIR PIPE CONNECTION . . . . . . . . . . . . . . . .24

H. SUPPORTING AIR PIPING . . . . . . . . . . . . . .24

I. AIR PIPE TERMINATION . . . . . . . . . . . . . . .24

J. MULTIPLE BOILER INSTALLATIONS . . . . . .25

3D. VENT & AIR PIPING: THROUGH A SIDE

WALL (COMBUSTION AIR FROM THE

BOILER ROOM) 26

A. BOILER VENT CONNECTION . . . . . . . . . . .26

B. VENT PIPING COMPONENTS . . . . . . . . . . .27

C. SUPPORT THE VENT PIPING

COMPLETELY . . . . . . . . . . . . . . . . . . . . . . . .27

D. SIDEWALL TERMINATION . . . . . . . . . . . . . .27

E. COMBUSTION AIR OPENINGS . . . . . . . . . .29

F. MULTIPLE BOILER INSTALLATIONS . . . . . .29

3E. VENT & AIR PIPING: THROUGH A SIDE

WALL (SEPARATE TERMINATIONS) 30

A. BOILER VENT CONNECTION . . . . . . . . . . .30

B. VENT PIPING COMPONENTS . . . . . . . . . . .31

C. SUPPORT THE VENT PIPING

COMPLETELY . . . . . . . . . . . . . . . . . . . . . . . .31

D. AIR PIPE CONNECTION . . . . . . . . . . . . . . . .31

E. SUPPORTING AIR PIPING . . . . . . . . . . . . . .32

F. SIDEWALL TERMINATION ASSEMBLIES . .32

G. MULTIPLE BOILER INSTALLATIONS . . . . . .34

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 3

3F. VENT & AIR PIPING: THROUGH A SIDE

WALL (CONCENTRIC TERMINATION) 35

A. BOILER VENT CONNECTION . . . . . . . . . . .35

B. VENT PIPING COMPONENTS . . . . . . . . . . .36

C. SUPPORT THE VENT PIPING

COMPLETELY . . . . . . . . . . . . . . . . . . . . . . . .36

D. AIR PIPE CONNECTION . . . . . . . . . . . . . . . .36

E. SUPPORTING AIR PIPING . . . . . . . . . . . . . .37

F. SIDEWALL TERMINATION/CONCENTRIC

VENT-AIR ASSEMBLY . . . . . . . . . . . . . . . . .37

G. MULTIPLE BOILER INSTALLATIONS . . . . . .37

4. WATER PIPING & CONTROLS 39

A. BOILER PIPING CONNECTIONS . . . . . . . . .39

B. SYSTEM DESIGN . . . . . . . . . . . . . . . . . . . . .39

C. CIRCULATOR REQUIREMENTS . . . . . . . . . .39

D. ADDITIONAL CONTROLS . . . . . . . . . . . . . .40

E. EXPANSION TANK & AIR SEPARATION . . .40

F. ZONING WITH ZONE VALVES . . . . . . . . . .42

G. ZONING WITH CIRCULATORS . . . . . . . . . .43

H. MULTIPLE BOILERS,

PRIMARY/SECONDARY . . . . . . . . . . . . . . . .44

I. MULTIPLE BOILERS, PARALLEL FLOW . . .45

J. CHILLED WATER SYSTEMS . . . . . . . . . . . .46

5. FUEL PIPING 47

A. CHECK THE GAS TYPE . . . . . . . . . . . . . . . .47

B. GAS SUPPLY COMPONENTS . . . . . . . . . . .47

C. GAS PIPING JOINTS . . . . . . . . . . . . . . . . . .48

D. GAS PIPE SIZING . . . . . . . . . . . . . . . . . . . . .48

E. TEST ALL GAS PIPING FOR LEAKS . . . . . .48

6. CONDENSATE DRAIN PIPING 49

A. FILL THE CONDENSATE TRAP . . . . . . . . . .49

B. CONDENSATE LINE INSTALLATION . . . . . .49

C. CONDENSATE LINE REQUIREMENTS . . . .49

7. ELECTRICAL CONNECTIONS 50

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .50

B. POWER SUPPLY (120 VAC) . . . . . . . . . . . . .50

C. CIRCULATOR WIRING . . . . . . . . . . . . . . . . .50

D. SENSOR WIRING . . . . . . . . . . . . . . . . . . . . .51

E. IAR (INDOOR AIR RESET) WIRING,

WHEN USED . . . . . . . . . . . . . . . . . . . . . . . .52

F. DHW WIRING . . . . . . . . . . . . . . . . . . . . . . . .52

8. BOILER CONTROL: OPERATION 55

A. THE CAST 92 BOILER CONTROL . . . . . . . .55

B. BEFORE CONTROL SETUP . . . . . . . . . . . . .56

C. THE CONTROL DISPLAY . . . . . . . . . . . . . . .56

D. RECOMMENDED SETTINGS . . . . . . . . . . . .57

E. ADJUST SETPOINTS . . . . . . . . . . . . . . . . . .57

F. INDOOR AIR . . . . . . . . . . . . . . . . . . . . . . . . .58

G. OUTDOOR AIR . . . . . . . . . . . . . . . . . . . . . . .58

H. SET THE SYSTEM CLOCK . . . . . . . . . . . . . .59

9. BOILER CONTROL: MULTIPLE

BOILERS OVERVIEW 66

9A. MULTIPLE BOILERS – CAST 92 CONTROL 66

9B MULTIPLE BOILERS – (BMS) . . . . . . . . . . . .66

9C MULTIPLE BOILERS – EXTERNAL 4-20MA

CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . .66

9A. BOILER CONTROL: MULTIPLE

BOILERS (CAST 92 CONTROL) 67

A. OVERVIEW: CONTROL SETUP

SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . .67

B. POWER SUPPLY (120 VAC) . . . . . . . . . . . . .67

C. CIRCULATOR WIRING . . . . . . . . . . . . . . . . .67

D. IAR (INDOOR AIR RESET) WIRING,

WHEN USED . . . . . . . . . . . . . . . . . . . . . . . .68

E. SENSOR WIRING . . . . . . . . . . . . . . . . . . . . .69

F. DHW WIRING . . . . . . . . . . . . . . . . . . . . . . . .69

G. EXTERNAL INTERLOCKS . . . . . . . . . . . . . .72

H. OVERRIDES – CONTROL PRIORITIES . . . . .72

I. SET TERMINATION DIP SWITCHES . . . . . .72

J. SET CONTROL PARAMETERS ON

KEYPADS . . . . . . . . . . . . . . . . . . . . . . . . . . .73

K. START-UP BOILERS

L. CONNECT NETWORK CABLES . . . . . . . . . .73

M. MASTER BOILER CABLE . . . . . . . . . . . . . . .73

N. MEMBER BOILER CABLES . . . . . . . . . . . . .74

O. CHECK THE NETWORK . . . . . . . . . . . . . . . .74

P. START THE SYSTEM . . . . . . . . . . . . . . . . . .74

9B. BOILER CONTROL: MULTIPLE

BOILERS BUILDING MANAGEMENT

CONTROL (BMS) 75

A. OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . .75

B. MODBUS REGISTERS . . . . . . . . . . . . . . . . .75

C. BACNET OR LONWORKS PROTOCOLS . . .76

D. WIRING AND SET-UP . . . . . . . . . . . . . . . . .76

E. CONNECT THE BMS CABLE . . . . . . . . . . . .76

F. VERIFY BMS/HEATNET OPERATION . . . . .76

9C. BOILER CONTROL: MULTIPLE BOILERS

EXTERNAL 4–20MA CONTROL 77

A. OVERVIEW — CONTROL SETUP

SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . .77

B. CONNECT 4-20MA WIRING . . . . . . . . . . . .77

C. POWER SUPPLY (120 VAC) . . . . . . . . . . . . .77

D. CIRCULATOR WIRING . . . . . . . . . . . . . . . . .77

E. 4-20MA OPERATION . . . . . . . . . . . . . . . . . .79

F. IAR (INDOOR AIR RESET) WIRING –

APPLY ONLY IF USING SPACE HEATING

OVERRIDE MODE . . . . . . . . . . . . . . . . . . . .79

G. SENSOR WIRING . . . . . . . . . . . . . . . . . . . . .79

H. DHW WIRING – ONLY IF USING DHW

OVERRIDE MODE . . . . . . . . . . . . . . . . . . . .79

I. OVERRIDES – CONTROL PRIORITIES . . . . .79

TABLE OF CONTENTS

Page 4

J. SET CONTROL PARAMETERS ON

KEYPADS . . . . . . . . . . . . . . . . . . . . . . . . . . .82

K. START-UP BOILERS . . . . . . . . . . . . . . . . . . .82

L. START THE SYSTEM . . . . . . . . . . . . . . . . . .82

10. FILL AND TEST THE SYSTEM 83

A. CLOSED SYSTEMS ONLY . . . . . . . . . . . . . .83

B. HARD WATER CONDITIONS . . . . . . . . . . . .83

C. PREVENT OXYGEN CORROSION . . . . . . . .83

D. FLUSH AND CLEAN THE SYSTEM . . . . . . .83

E. PURGE AIR FROM THE SYSTEM . . . . . . . .83

F. ADD A CHEMICAL INHIBITOR . . . . . . . . . . .83

G. WATER PH . . . . . . . . . . . . . . . . . . . . . . . . . .84

H. ANTIFREEZE . . . . . . . . . . . . . . . . . . . . . . . . .84

I. SYSTEM PRESSURE . . . . . . . . . . . . . . . . . .84

J. FINAL CHECKS . . . . . . . . . . . . . . . . . . . . . . .85

11. START-UP PROCEDURE 86

A. START-UP CHECKLIST . . . . . . . . . . . . . . . . .86

B. LIGHTING & OPERATING PROCEDURES . .89

C. TURN THE BOILER OFF . . . . . . . . . . . . . . . .90

D. CHECK IGNITION . . . . . . . . . . . . . . . . . . . . .90

E. INSERT COMBUSTION ANALYZER

PROBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

F. CHECK HIGH FIRE OPERATION . . . . . . . . .90

G. ADJUST GAS VALVE THROTTLE

SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

H. VERIFY GAS INLET PRESSURE . . . . . . . . .91

I. TO METER GAS INPUT (NATURAL

GAS ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . .92

J. CHECK LOW FIRE OPERATION . . . . . . . . . .92

K. WHEN IS LOW FIRE ADJUSTMENT

REQUIRED? . . . . . . . . . . . . . . . . . . . . . . . . .92

L. REMOVING THE BOILER JACKET TOP . . . .92

M. ADJUSTING THE LOW-FIRE SETTING . . . .93

N. REPLACE THE BOILER JACKET TOP . . . . .93

O. MEASURE FLAME CURRENT . . . . . . . . . . .93

P. CHECK BOILER MODULATION . . . . . . . . . .93

Q. TEST FLAME FAILURE MODES . . . . . . . . .94

R. TEST CONTROL & INTERLOCK

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . .94

S. FILL OUT THE COMBUSTION TEST

RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

12. TROUBLESHOOTING 95

13. MAINTENANCE 97

A. READ BEFORE PROCEEDING . . . . . . . . . . .97

B. HANDLING CERAMIC FIBER AND

FIBERGLASS MATERIALS . . . . . . . . . . . . . .97

C. CLEANING THE AIR FILTER . . . . . . . . . . . . .97

D. ACCESSING THE ELECTRODE

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . .98

E. ACCESSING THE BURNER . . . . . . . . . . . . .99

F. ANNUAL START-UP OVERVIEW . . . . . . . .100

G. ANNUAL START-UP CHECKLIST . . . . . . . .100

14. REPAIR PARTS 102

15.BOILER RATINGS & SPECIFICATIONS 108

APPENDIX A. SUGGESTED WIRING 109

IAR (INDOOR AIR RESET) WIRING, WHEN

USED WIRING FOR 3-WIRE ZONE VALVES

WITHOUT A ZONE CONTROLLER . . . . . . . . .109

IAR (INDOOR AIR RESET) WIRING, WHEN

USED WIRING FOR CIRCULATOR RELAYS

(RELAYS MUST HAVE 24VAC COMMON

TERMINALS) . . . . . . . . . . . . . . . . . . . . . . . . . .110

IAR (INDOOR AIR RESET) WIRING, WHEN

USED WIRING FOR TYPICAL ZONE

CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . .111

APPENDIX B. COMBUSTION TEST

RECORD 113

TABLE OF CONTENTS

Page 5

1

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this manual

in the order shown. The order of these instructions has

been set in order to provide the installer with a logical

sequence of steps that will minimize potential

interferences and maximize safety during boiler

installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual special attention boxes are

provided to supplement the instructions and make special

notice of potential hazards. The definition of each of

these categories, in the judgement of PB Heat, LLC

are as follows:

USING THIS MANUAL

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

USING THIS MANUAL

Page 6

2

PREINSTALLATION

A. GENERAL

1. Cast 92 boilers are supplied completely assembled as

packaged boilers. The package should be inspected

for damage upon receipt and any damage to the unit

should be reported to the shipping company and

wholesaler. This boiler should be stored in a clean, dry

area.

2. Carefully read these instructions and be sure to

understand the function of all connections prior to

beginning installation. Contact your PB Heat, LLC

Representative for help in answering questions.

3. This boiler must be installed by a qualified contractor.

The boiler warranty may be voided if the boiler is not

installed correctly.

4. A hot water boiler installed above radiation or as

required by the Authority having jurisdiction, must be

provided with a low water fuel cut-off device either as

part of the boiler or at the time of installation.

B. CODES & REGULATIONS

1. Installation and repairs are to be performed in strict

accordance with the requirements of state and local

regulating agencies and codes dealing with boiler and

gas appliance installation.

2. In the absence of local requirements the following

should be followed:

a. ASME Boiler and Pressure Vessel Code, Section

IV - “Heating Boilers”

b. ASME Boiler and Pressure Vessel Code, Section

VI - “Recommended Rules for the Care and

Operation of Heating Boilers”

c. ANSI Z223.1/NFPA 54 - “National Fuel Gas Code”

d. ANSI/NFPA 70 - “National Electrical Code”

e. ANSI/NFPA 211 - “Chimneys, Fireplaces, Vents

and Solid Fuel Burning Appliances”

3. Where required by the authority having jurisdiction,

the installation must conform to the Standard for

Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1.

**Please read if installing in Massachusetts**

Massachusetts requires manufacturers of Side Wall

Vented boilers to provide the following information

from the Massachusetts code:

·

A hard wired carbon monoxide detector with an

alarm and battery back-up must be installed on

the floor level where the gas equipment is to be

installed AND on each additional level of the

dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment.

·

In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be

installed on the next adjacent floor level.

·

Detector(s) must be installed by qualified licensed

professionals.

·

APPROVED CARBON MONOXIDE

DETECTORS: Each carbon monoxide detector

shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

·

SIGNAGE: A metal or plastic identification plate

shall be permanently mounted to the exterior of

the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch

in size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”.

·

EXEMPTIONS to the requirements listed above:

°

The above requirements do not apply if the

exhaust vent termination is seven (7) feet or

more above finished grade in the area of the

venting, including but not limited to decks and

porches.

°

The above requirements do not apply to a

boiler installed in a room or structure separate

from the dwelling, building or structure used in

whole or in part for residential purposes.

·

This boiler installation manual shall remain with

the boiler at the completion of the installation.

See the latest edition of Massachusetts Code 248 CMR

for complete verbage and also for additional (non-vent

related) requirements (248 CMR is available online).

If your installation is NOT in Massachusetts, please

see your authority of jurisdiction for requirements that

may be in effect in your area. In the absence of such

requirements, follow the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

1. PREINSTALLATION

Liquefied Petroleum (LP) Gas or Propane is heavier

than air and, in the event of a leak, may collect in low

areas such as basements or floor drains. The gas

may then ignite resulting in a fire or explosion.

WARNING

Page 7

3

C. BOILER LOCATION REQUIREMENTS

1. Indoor Installation Only:

a. Do not install the boiler outside or in an area that

would expose the boiler or its gas or electrical

components to rain or dripping or spraying water.

b. Do not install the boiler in a location that would

subject the boiler to freezing. Where freeze

protection is needed, follow the guidelines in this

manual.

2. Flooring:

a. The boiler can be installed on combustible

flooring, but must not be installed on carpeting.

b. The floor must be structurally sound and capable

of supporting the weight of the boiler.

c. The boiler must be leveled front to back and side

to side. Use metal shims if necessary.

3. Accessibility:

Jacket parts will have to be removed for some service

procedures. Ensure that the location provides a

reasonable means for service and operation of the

boiler.

4. System Piping, Fuel and Electrical Supply:

a. The boiler must be located such that piping for

water, gas, vent and air can reasonable be

connected.

b. There must be a reasonable means of providing

electrical supply to the boiler.

5. Adjacent Construction:

Locate the boiler in an area that will prevent water

damage to adjacent construction should a leak occur

or during routine maintenance.

6. Combustion Air:

a. Do not place the boiler in a location that would

restrict the flow of combustion air into the air

intake or subject the boiler to a negative air

pressure in the space when using air from the

boiler room.

b. Provide required combustion air openings to the

boiler room and the building (when required)

when using air from the boiler room for

combustion (see Section C, “Combustion Air

Requirements”). If air is piped to the boiler air

intake connection, combustion air openings are

not required unless other appliances share the

same room.

c. Buildings will require the installation of a fresh air

duct or other means of providing make-up air if

the intake air option isn't used. Any building

utilizing other gas burning appliances, a fireplace,

wood stove or any type of exhaust fan must be

checked for adequate combustion air when all of

these devices are in operation at one time. Sizing

of an outside air duct must be done to meet the

requirements of all such devices.

d. The boiler must be supplied with combustion air

in accordance with Section 5.3, "Air for

Combustion and Ventilation," of the latest revision

of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and all applicable local building

codes. Canadian installations must comply with

CSA B149.1 or .2 Installation Code for Gas

Burning Appliances and Equipment, or applicable

provisions of the local building codes.

7. Negative Room Pressure:

Never operate the boiler in an environment subjected

to a negative pressure unless it is Direct Vented.

Failure to comply with this warning can result in

excessive levels of carbon monoxide.

8. Combustion Air Contamination:

a. Combustion air contaminated with fluorocarbons

or other halogenated compounds such as cleaning

solvents and refrigerants will result in the

formation of acids in the combustion chamber.

These acids will cause premature failure of the

boiler.

b. Construction Dust

: If the boiler is operated while

the building is under construction it must be

protected from wood, concrete, sheet rock and

other types of dust. Failure to properly protect the

boiler from construction dust will damage the

boiler.

c. If the boiler has been operated with contaminated

air, it must be thoroughly inspected. Where

possible, boiler components must be cleaned,

following instructions provided in this manual

and/or supplementary instructions from PB Heat.

Where cleaning is not possible, the boiler may

have to be replaced.

d. Never store combustible materials, gasoline or any

product containing flammable vapors or liquids in

the vicinity of the boiler.

9. Clearances:

a. All installations must provide the minimum

clearances to combustible materials given in

Section B, “Clearance Requirements”.

b. The installation should provide the minimum

service clearances given in Section B, “Clearance

Requirements”, when possible. If these clearances

cannot be met, then:

Ensure that boiler components can be

accessed for operation/start-up/maintenance as

required in this manual.

PREINSTALLATION

Do not install the boiler unless the location meets all

of the requirements in Sections 1 through 9 below.

Failure to comply could result in severe personal

injury, death or substantial property damage.

WARNING

Page 8

4

PREINSTALLATION

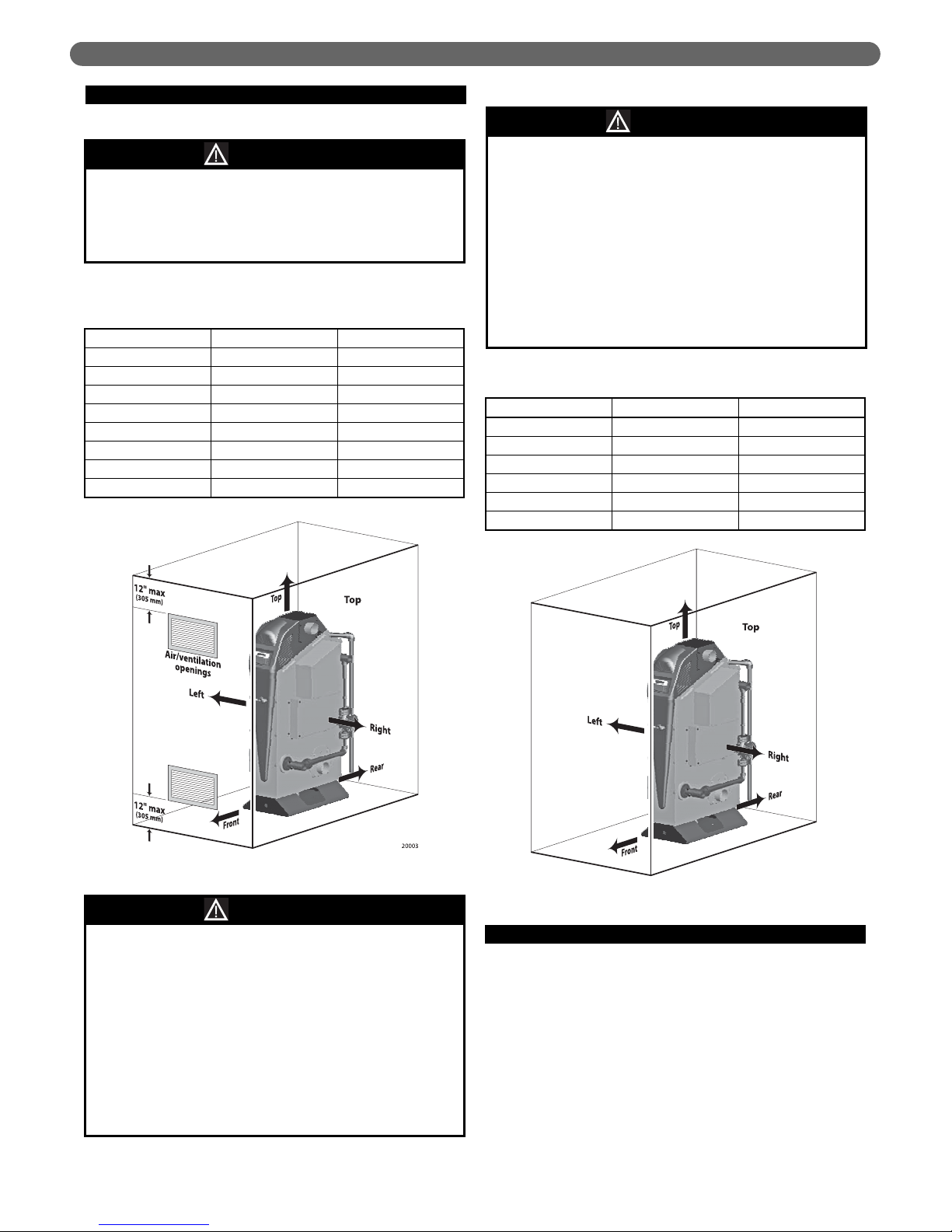

D. CLEARANCE REQUIREMENTS

1. Clearances to Combustible Surfaces:

2. Clearances for Service and Operation:

E. COMBUSTION AIR REQUIREMENTS

1. Air Ducted to Boiler Air Intake:

a. If air is ducted from outside to the boiler air

intake, follow instructions in Section 3, “Venting &

Air Inlet Piping”.

b. If the boiler is located in a small room (clearances

less than the recommended SERVICE/OPERATION

clearances given in Figure 1.2):

All installations must provide the minimum

clearances to combustible materials and surfaces

given in Table 1.1. Failure to comply could result in a

fire hazard, causing severe personal injury, death or

substantial property damage.

WARNING

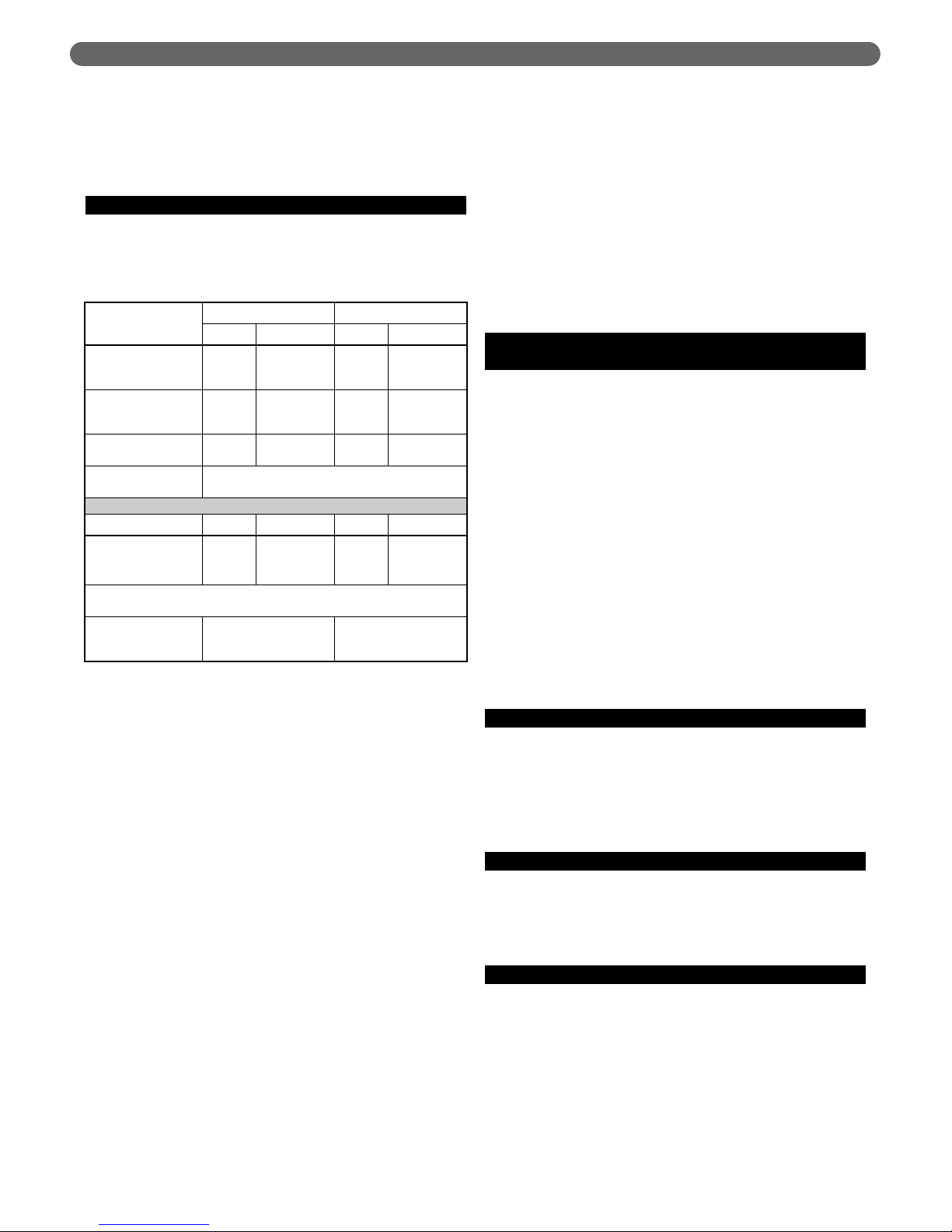

Table 1.1: Minimum Clearances to Combustible

Materials/Surfaces for ALL Installations

(Figure 1.1)

From Inches Millimeters

To p 6 153

Back 6 153

Left side 6 153

Right side 6 153

Front 6 153

Rear 6 153

Vent piping 2 51

System water piping 1 25.4

If the boiler is located in a closed room, the room

must be provided with ventilation openings even if

air is ducted to the boiler. See Figure 1.1. Size the

openings with a free area no less than 1 square inch

per BTUH input of all Cast 92 boilers in the room.

EXCEPTION: Ventilation openings are not required if

the boiler room provides at least the minimum

SERVICE/OPERATION clearances given in Table 1.2.

Failure to provide adequate ventilation could result

in overheating of the boiler components or the

room, potentially causing severe personal injury,

death or substantial property damage.

WARNING

The installation must provide reasonable access and

clearance for service and operation of the boiler. Table

2 gives recommended minimum clearances for

service and operation. The boiler may be installed in a

space that does not provide these recommended

clearances provided it is accessible for the service

and operation procedures required in this manual.

Flame observation port — The flame observation

port on the LEFT side of the boiler must be

accessible to view the combustion chamber during

boiler start-up. Make sure that the installation allows

serviceman access to the left side for this purpose.

WARNING

Table 1.2: Recommended Minimum Clearances for

Service/Operation (Figure 1.2)

From Inches Millimeters

To p 24 610

Back 24 610

Left side 24 610

Right side 24 610

Front 36 914

Rear 18 457

Figure 1.1: Clearance to Combustibles Materials

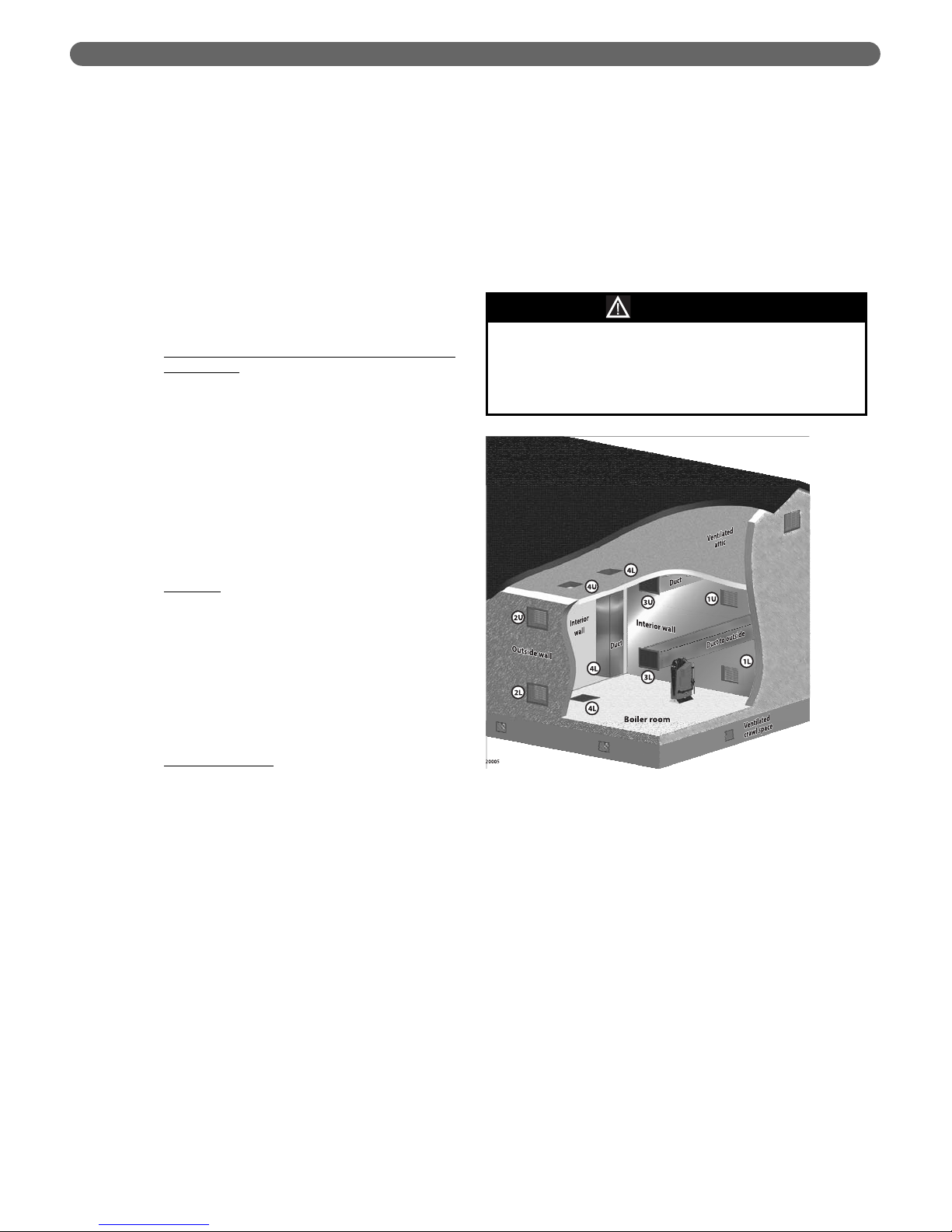

Figure 1.2: Service/Operation Clearance References

Page 9

5

PREINSTALLATION

i. No Other Appliances in the Room: Provide

two ventilation openings through one of the

enclosure walls. Each opening must be sized

for a free area of at least 1 square inch per

1,000 BTUH input of the Cast 92 boilers in

the room. One opening must be within 12

inches of the ceiling, the other within 12

inches of the floor.

ii. Other Appliances in the Same Room: The room

must have combustion air openings sized for

the other appliances. Increase the free area of

the air openings by one square inch per 1,000

BTUH of the Cast 92 boilers located in the

room.

2. Air From Boiler Room:

When the Boiler Draws Combustion Air from the

Boiler Room:

i. If the room volume is at least 50 cubic feet per

BTUH of the combined input of all appliances

in the room, no special openings are needed

UNLESS the building is of tight construction

(see definition). If the building is of tight

construction, provide openings to the building

in accordance with all applicable codes.

ii. If the boiler is in a space smaller than 50 cubic

feet volume per BTUH input, provide air

openings using one of the methods in Figure 1.3.

3. Definitions:

a. Free Area

: Louvers or grilles reduce the area of an

opening. Free area is the area remaining with the

louver or grille in place. If the free area of a louver

is unknown, use the following:

i. Metal Louver: Multiply required free area of

the opening times 1.7 to determine actual area

of the required opening.

ii. Wood Louver: Multiply required free area of

the opening times 5 to determine actual area

of the required opening.

b. Tight Construction

: When a building is extensively

sealed to prevent air infiltration, it cannot provide

enough air for combustion unless openings are

provided to the outside. The National Fuel Gas

Code defines such buildings as having all of the

following:

i. Walls and ceilings exposed to the outside

atmosphere have a continuous water vapor

retarder with a rating of 1 perm or less with

openings gasketed.

ii. Weather-stripping has been added on

openable windows and doors.

iii. Caulking or sealants are applied to areas such

as joints around windows and door frames,

between sole plates and floors, between wallceiling joints, between wall panels, at

penetrations for plumbing, electrical, and gas

lines, and in other openings.

4. Conversion Factors:

In

2

/1,000 BTUH to cm2/kw — Multiply In2/1,000

BTUH times 22

In

2

/2,000 BTUH to cm2/kw — Multiply In2/2,000

BTUH times 11

In

2

/3,000 BTUH to cm2/kw — Multiply In2/3,000

BTUH times 7.4

In

2

/4,000 BTUH to cm2/kw — Multiply In2/4,000

BTUH times 5.5

5. Air Opening Options for Combustion Air

Drawn from Boiler Room:

Upper openings (U) must be within 12 inches of the

ceiling. Lower openings (L) must be within 12 inches

of the floor.

Option 1 – Air Openings Through Interior Wall:

When air is supplied to the boiler room through

openings in an interior wall (air supply from inside the

building), size each opening to provide minimum free

area of:

1 in

2

per 1,000 BTUH of all Cast 92 boilers in the

room.

Figure 1.3: Air opening options for combustion air

drawn from boiler room

If other appliances are located in the same room as

the boiler, increase the size of air openings to

provide the free area required for the other

appliances in addition to the air required for the Cast

92 boiler(s).

WARNING

Page 10

6

PREINSTALLATION

Option 2 – Air Openings Through Outside Wall:

When air is supplied to the boiler room through

openings in an outside wall (air supply from outside

the building), size each opening to provide minimum

free area of:

1 in

2

per 4,000 BTUH of all Cast 92 boilers in the

room.

Option 3 – Horizontal Ducts to Outside Wall:

When air is supplied to the boiler room through

horizontal ducts to an outside wall (air supply from

outside the building), size each opening to provide

minimum free area of:

1 in

2

per 3,000 BTUH of all Cast 92 boilers in the

room.

Option 4 – Openings to Attic/Crawl Space:

Air openings can be connected to a ventilated attic or

crawl space. The upper opening must be to the attic.

The lower opening can be a vertical duct from the

attic or an opening in the floor from the crawl space.

Size each opening to provide minimum free area of:

1 in

2

per 3,000 BTUH of all Cast 92 boilers in the

room.

Option 5 – Single Opening (not shown):

A single opening directly connected to the outdoors

through a wall or a vertical or horizontal duct can be

used if the installation provides the clearances of

Figure 1.2, and the top of the opening is within 12

inches of the ceiling. Size the opening to provide

minimum free area of:

1 in

2

per 3,000 BTUH of all Cast 92 boilers in the

room.

Page 11

7

A. REMOVE THE BOILER FROM THE CRATE

1. Remove the crate from the skid. But leave the boiler

on the skid to move the boiler near its location.

2. Inspect the boiler thoroughly for any possible damage

that may have occurred in shipping or handling.

3. Slide the boiler off of the skid into position.

4. Use a spirit level to check whether the boiler sides and

front are vertically plumb. If not, slide metal shims

under the base until the boiler is level.

B. INSTALL THE RELIEF VALVE

Check Relief Valve Pressure Setting:

Inspect the boiler relief valve before installing to ensure it

is set at the pressure required for the system. You should

also verify that all water system components are rated for

at least the pressure setting of the relief valve to avoid

component damage due to excess pressure.

2. Connecting the Relief Valve:

Connect 3/4" NPT black iron pipe and fitting so the

relief valve as shown in Figure 2.1. Follow all

instructions provided in the relief valve manufacturer’s

instructions and labeling.

C. BOILER PIPING — GENERAL

Piping Guidelines:

• All installations must be installed by a qualified technician

in accordance with the latest revision of the ANSI/ASME

Boiler and Pressure Vessel Code, Section IV.

• Where required, the installation must comply with

ANSI/ASME CSD-1, Standard for Controls and Safety

Devices for Automatically Fired Boilers.

2. BOILER SET-UP

Never install any type of valve between the boiler and

the relief valve, or in the relief discharge piping. An

explosion could occur, causing severe personal

injury, death or substantial property damage. General

piping requirements.

WARNING

Improper piping of the boiler will void the

manufacturer’s warranty, and can cause boiler failure,

resulting in possible severe personal injury, death or

substantial property damage.

WARNING

Figure 2.1: Relief valve piping

Cold weather handling — The boiler jacket includes

plastic parts. If the boiler has been in a cold

environment (below 0°F), allow the boiler to warm to

room temperature before handling.

CAUTION

Do not drop the boiler or allow the jacket to bump

against the floor or wall when handling.

CAUTION

The boiler maximum allowable working pressure is

100 psig (700 kPa). The relief valve must never have a

setting greater than 100 psig. Using a higher pressure

relief valve could result in an explosion, causing

possible severe personal injury, death or substantial

property damage.

WARNING

Install a shut-off valve in the boiler supply and return

connections to allow isolation of the boiler for

servicing when necessary.

NOTICE

BOILER SET-UP

Page 12

8

• All applicable local codes and ordinances must also be

followed.

• A minimum clearance of 1" (25 mm) must be

maintained between heating system pipes and all

combustible construction.

• All heating system piping must be supported by

suitable hangers — not by the boiler.

• The thermal expansion of the system must be

considered when supporting the system.

• A minimum system pressure of 12 psig (84 kPa) must

be maintained.

BOILER SET-UP

Page 13

9

When a Cast 92 boiler replaces a boiler that shared a

common vent system, follow the guidelines below to

check operation of the remaining appliance(s).

A. COMMON VENT SYSTEMS

If an existing boiler is removed from a common venting

system, the common venting system may then be too

large for the proper venting of the remaining appliances

connected to it. At the time of removal of an existing

boiler, the following steps shall be followed with each

appliance remaining connected to the common venting

system placed in operation, while the other appliances

remaining connected to the common venting system are

not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and

bathroom exhaust, so they will operate at maximum

speed. Do not operate a summer exhaust fan for a

boiler installation. Close fireplace dampers.

4. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

5. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar or

pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

condition of use.

3. VENTING & AIR INLET PIPING

DO NOT install a Cast 92 boiler on a common vent

system. All Cast 92 boilers must be individually

vented. Failure to comply could result in improper

operation of any of the appliances on the vent

system, resulting in possible severe personal injury,

death or substantial property damage.

WARNING

VENTING & AIR INLET PIPING

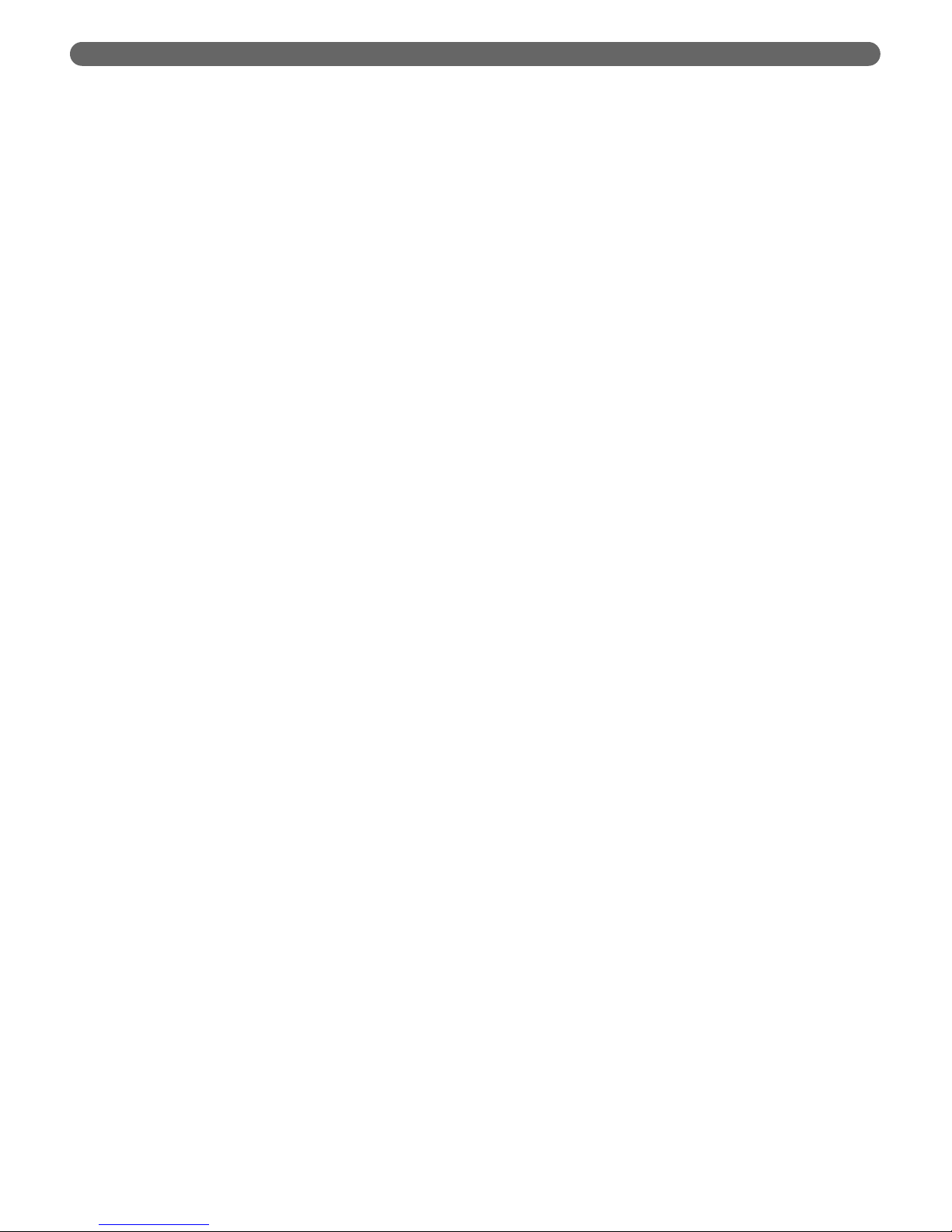

Heat-fab EZ Seal Joint Assembly

Page 14

10

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54. When resizing any portion of the

common venting system, the common venting system

should be resized to approach the minimum size as

determined using the appropriate tables in Appendix

F in the National Fuel Gas Code, ANSI Z223.1/ NFPA

54 and or CSA B149 Installation Codes.

B. VENT AND AIR PIPING, GENERAL

1. Pages 9 through 13 are a brief overview of the

options for vent and air piping configurations and give

a summary and brief list of requirements for each of

the vent/air configuration options.

2. When air is taken from the boiler room (no air pipe

connected to the boiler air inlet fitting), follow the

instructions in this manual to ensure the boiler room

has proper openings for combustion air and

ventilation.

C. VENT PIPING

1. Category II & IV Venting Only:

All Cast 92 boilers require vent piping listed for use in

pressurized, condensing operation. Use only the

materials specified in this manual. When venting

category II the flue pipe must be increased to 5 inch

for the 92-2 and 6 inch for the 92-4.

2. Vent Pipe Options:

Use only Heat-fab Saf-T Vent

®

EZ Seal or Z-Flex

®

Z-Vent vent pipe and components. You will find

specific component information for each configuration

in this manual.

3. Vent Pipe Joint Assembly:

EZ Seal and Z-Vent vent piping use a silicon rubber

ring-style gasket in each joint. Joints are secured using

metal tabs that wrap around a ring on the adjacent

piping component for Heat-fab vent pipe, or gear

clamps for Z-Flex vent pipe. Never use screws in the

vent piping. Screws are only applied to the air piping

portion of Heat-fab SC concentric vent, used for

concentric vent/air sidewall terminations.

D. AIR PIPING

1. Air Options:

Combustion air can be piped through the side wall or

through the roof of the building. Sidewall air intake

can be done with either through-the-roof or sidewall

venting.

2. Air Piping Materials:

The best choices for air piping are PVC, CPVC or

ABS. These materials are easy to work with and yield

a clean final appearance. Joint sealing is easier than

other methods because it only requires use of the

standard joint sealant for the type of plastic pipe used.

And there are not horizontal seams requiring sealing

like on metal air piping.

Other materials suitable for combustion air venting are

galvanized pipe, aluminum pipe and flexible

aluminum pipe. All joints, including the seams, of

these piping materials must be sealed with silicone

adhesive sealant, such as Dow Corning 732.

E. TERMINATIONS

1. Through-the-roof Terminations:

Both vent and air piping must terminate with a Heatfab or Z-Flex rain cap.

2. Sidewall Terminations:

Vent and air pipes can be individually terminated

using Heat-fab or Z-Flex termination elbows with

built-in screen, or concentrically terminated using

Heat-fab type SC concentric vent/air pipe (only when

using Heat-fab vent piping) Termination components

as given in this manual.

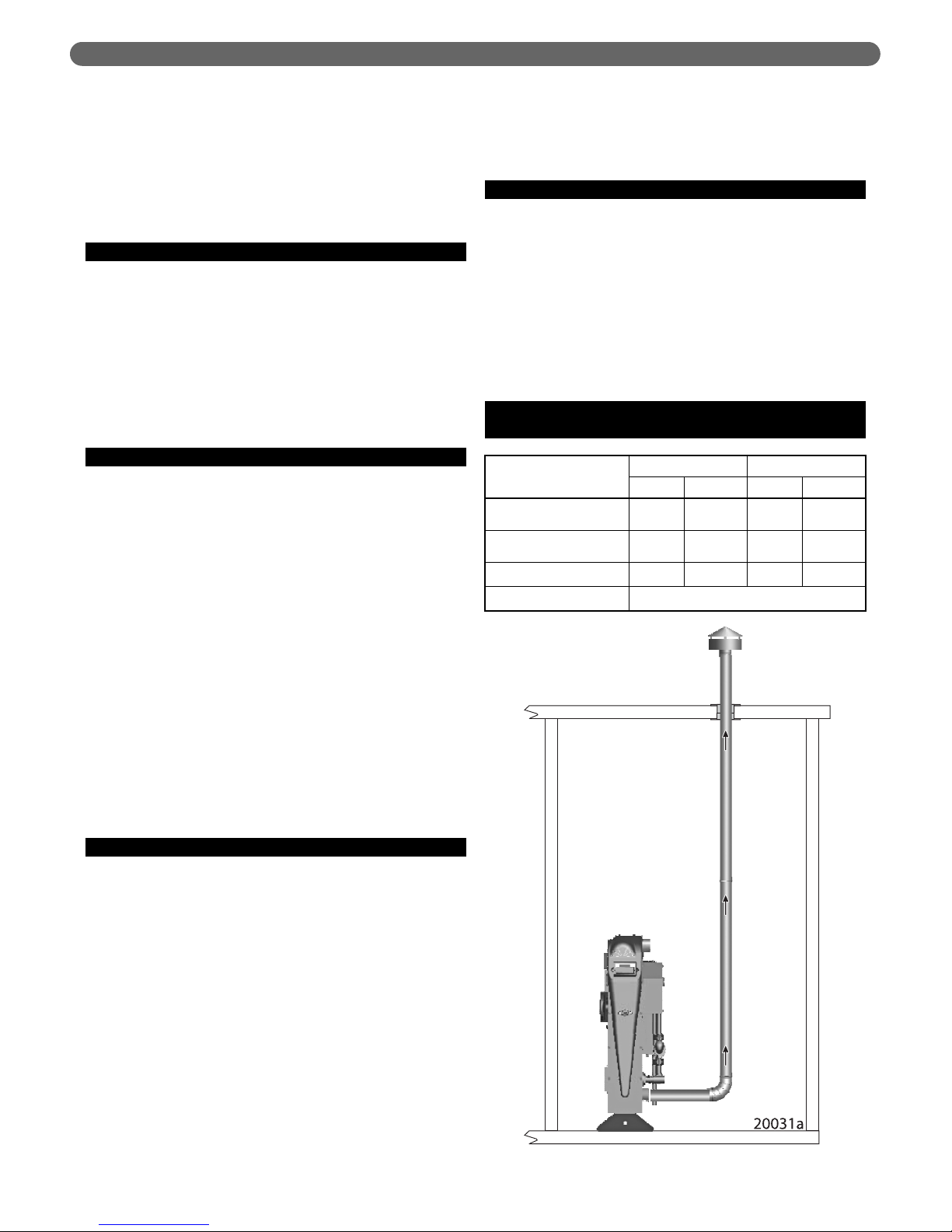

F. VENT PIPED THROUGH THE ROOF

(COMBUSTION AIR FROM THE BOILER ROOM)

VENTING & AIR INLET PIPING

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports, Thimbles, etc.)

EZ-Seal3"Z-Vent3"EZ-Seal4"Z-Vent

4"

Boiler Adapter (Adapts from

EZ-Seal to Z-Vent Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Rain Cap Vent Termination 5300CI 2SVSRCF03 5400CI 2SVSRCF04

Joint Sealant, as Needed GE RTV106 or Equivalent

Page 15

11

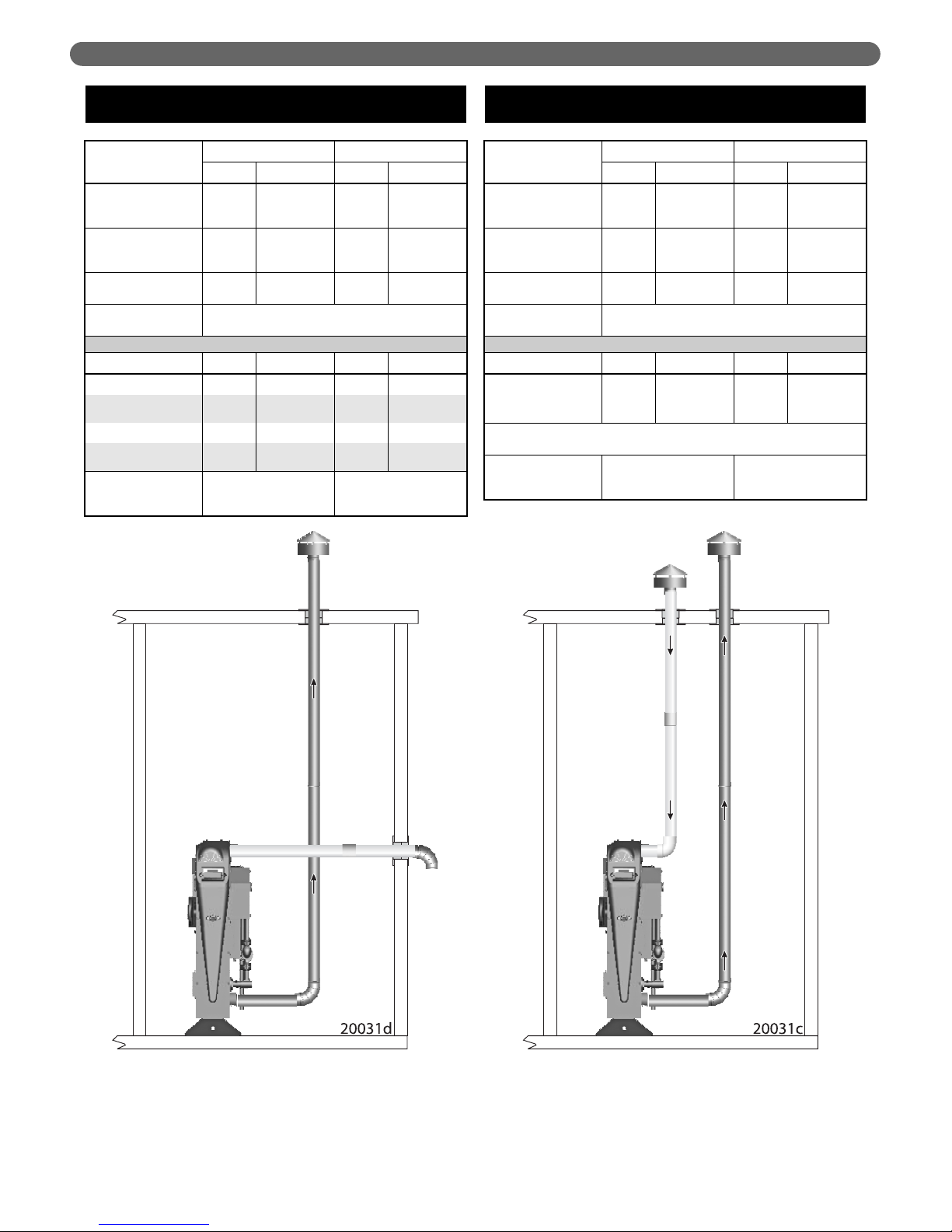

G. VENT PIPED THROUGH THE ROOF

(AIR PIPED THROUGH SIDE WALL)

H. VENT & AIR PIPED THROUGH THE ROOF

(SEPARATE VENT AND AIR TERMINATIONS)

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports,

Thimbles, etc.)

EZ-Seal

3"

Z-Vent

3"

EZ-Seal

4"

Z-Vent

4"

Boiler Adapter (Adapts

from EZ-Seal to Z-Vent

Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Rain Cap Vent

Termination

5300CI 2SVSRCF03 5400CI 2SVSRCF04

Joint Sealant,

as Needed

GE RTV106 or Equivalent

Air Components Heat-Fab Z-Flex Heat-Fab Z-Flex

Termination Elbow 9314TERM 2SVSTEX0390 9414TERM 2SVSTEX0490

Termination Pipe

Section (1 ft)

9302 2SVEPWCF0301 9402 2SVEPWCF0401

Termination Thimble 9393S 2SVSWTE03 9493S 2SVSWTE04

Gear Clamp

(Nose Clamp)

3" Clamp 7HS44XX 4" Clamp 7HS64XX

Air Piping/Components

(Incl. Supports,

Thimbles, etc.)

3" PVC, CPVC, ABS,

Galvanized or Aluminum

4" PVC, CPVC, ABS,

Galvanized or Aluminum

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports,

Thimbles, etc.)

EZ-Seal

3"

Z-Vent

3"

EZ-Seal

4"

Z-Vent

4"

Boiler Adapter (Adapts

from EZ-Seal to Z-Vent

Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Rain Cap Vent

Termination

5300CI 2SVSRCF03 5400CI 2SVSRCF04

Joint Sealant,

as Needed

GE RTV106 or Equivalent

Air Components Heat-Fab Z-Flex Heat-Fab Z-Flex

Rain Cap Termination 5300CI 2SVSRCF03 5400CI 2SVSRCF04

Termination Pipe

Section (3 ft)*

9307 2SVEPWCF0303 9407 2SVEPWCF0304

*Note: Standard air piping termination pipe section is 3 feet. A longer length can be

used if needed.

Air Piping/Components

(Incl. Supports,

Thimbles, etc.)

3" PVC, CPVC, ABS,

Galvanized or Aluminum

4" PVC, CPVC, ABS,

Galvanized or Aluminum

VENTING & AIR INLET PIPING

Page 16

12

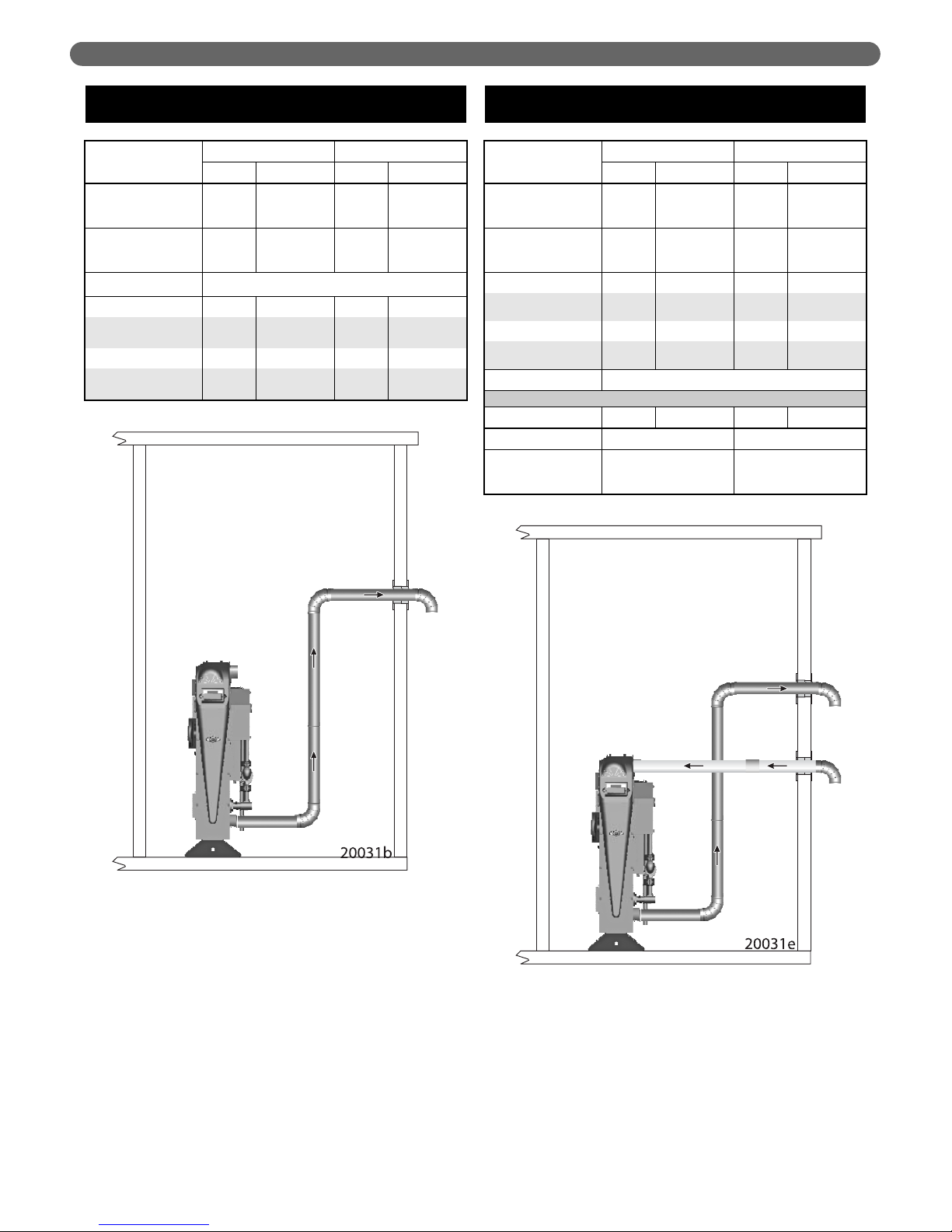

I. VENT PIPED THROUGH A SIDE WALL

(COMBUSTION AIR FROM THE BOILER ROOM)

J. VENT & AIR PIPED THROUGH A SIDE WALL

(SEPARATE VENT AND AIR TERMINATIONS)

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports,

Thimbles, etc.)

EZ-Seal

3"

Z-Vent

3"

EZ-Seal

4"

Z-Vent

4"

Boiler Adapter

(Adapts from EZ-Seal to

Z-Vent Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Joint Sealant, as Needed GE RTV106 or Equivalent

Termination Elbow 9314TERM 2SVSTEX0390 9414TERM 2SVSTEX0490

Termination Pipe Section

(1 ft)

9302 2SVEPWCF0301 9402 2SVEPWCF0401

Termination Thimble 9393S 2SVSWTE03 9493S 2SVSWTE04

Gear Clamp (Nose

Clamp)

3" Clamp 7HS44XX 4" Clamp 7HS64XX

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports,

Thimbles, etc.)

EZ-Seal

3"

Z-Vent

3"

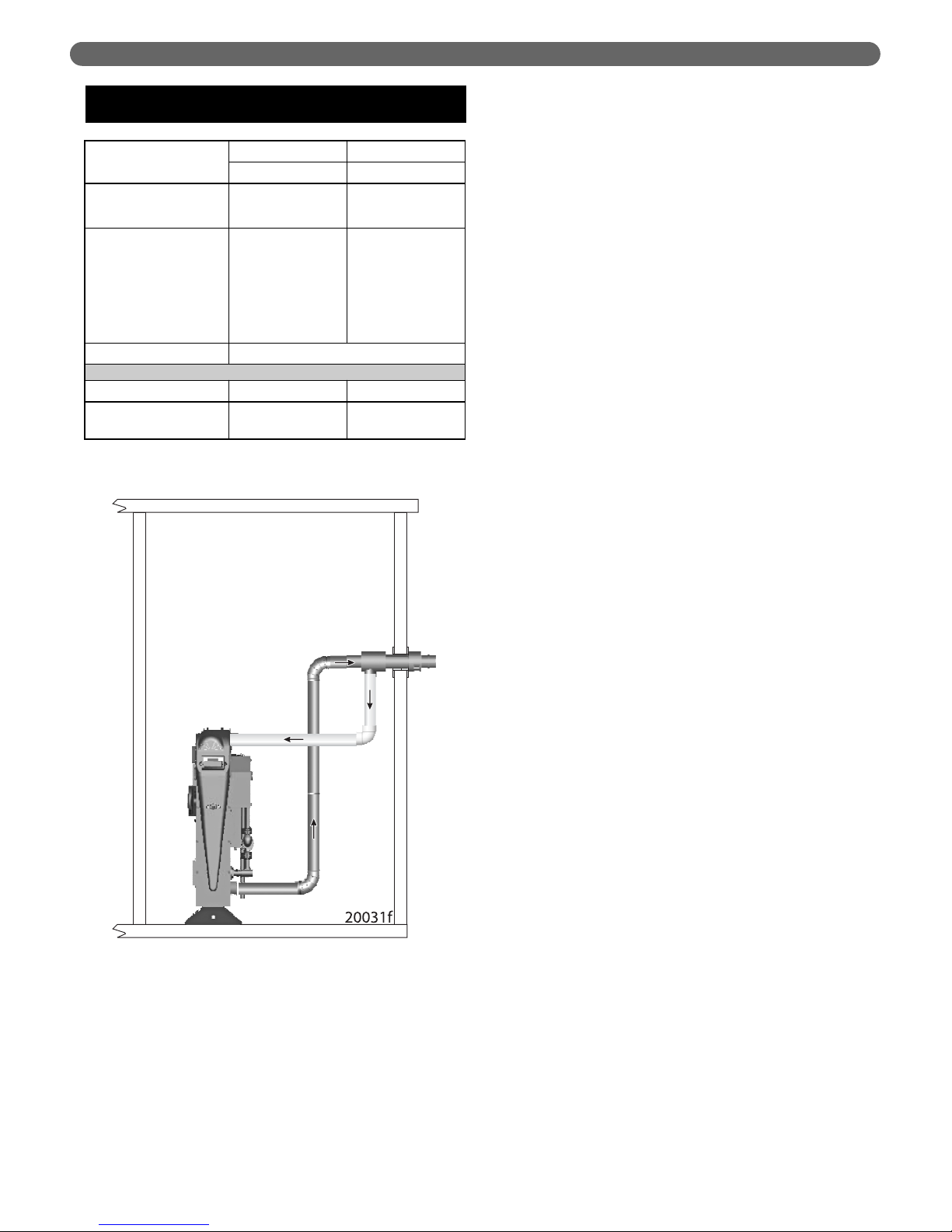

EZ-Seal

4"

Z-Vent

4"

Boiler Adapter

(Adapts from EZ-Seal to

Z-Vent Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Termination Elbow 9314TERM 2SVSTEX0390 9414TERM 2SVSTEX0490

Termination Pipe Section

(1 ft)

9302 2SVEPWCF0301 9402 2SVEPWCF0401

Termination Thimble 9393S 2SVSWTE03 9493S 2SVSWTE04

Gear Clamp (Nose

Clamp)

3" Clamp 7HS44XX 4" Clamp 7HS64XX

Joint Sealant, as Needed GE RTV106 or Equivalent

Air Components Heat-Fab Z-Flex Heat-Fab Z-Flex

Termination Elbow Same as Vent Termination Same as Vent Termination

Air Piping/Components

(Incl. Supports,

Thimbles, etc.)

3" PVC, CPVC, ABS,

Galvanized or Aluminum

4" PVC, CPVC, ABS,

Galvanized or Aluminum

VENTING & AIR INLET PIPING

Page 17

13

VENTING & AIR INLET PIPING

K. VENT & AIR PIPED THROUGH A SIDE WALL

(CONCENTRIC VENT/AIR TERMINATION)

Vent Components

92-2 92-4

Heat-Fab Heat-Fab

Vent Piping/Components

(Incl. Supports, Thimbles, etc.)

EZ-Seal, 3" Piping

Saf-T Vent SC Fittings for

Termination Assembly

EZ-Seal, 4" Piping

Saf-T Vent SC Fittings for

Termination Assembly

Termination Assembly:

• Single-wall Adapter

• Air Intake Tee

• 6" Straight Section

• 12" Straight Section

• Wall Plate (2 Required)

• Termination Adapter

• Mitered Termination

SC03ADEZ

SC03TAD3

SC0366

SC03L12

SC03FS

SC03HT

9390

SC04ADEZ

SC04TAD3

SC0466

SC04L12

SC04FS

SC04HT

9490

Joint Sealant, as Needed GE RTV106 or Equivalent

Air Components Heat-Fab Heat-Fab

Air Piping/Components

(Also Supports, Thimbles, etc.)

3" PVC, CPVC, ABS,

Galvanized or Aluminum

4" PVC, CPVC, ABS,

Galvanized or Aluminum

Page 18

14

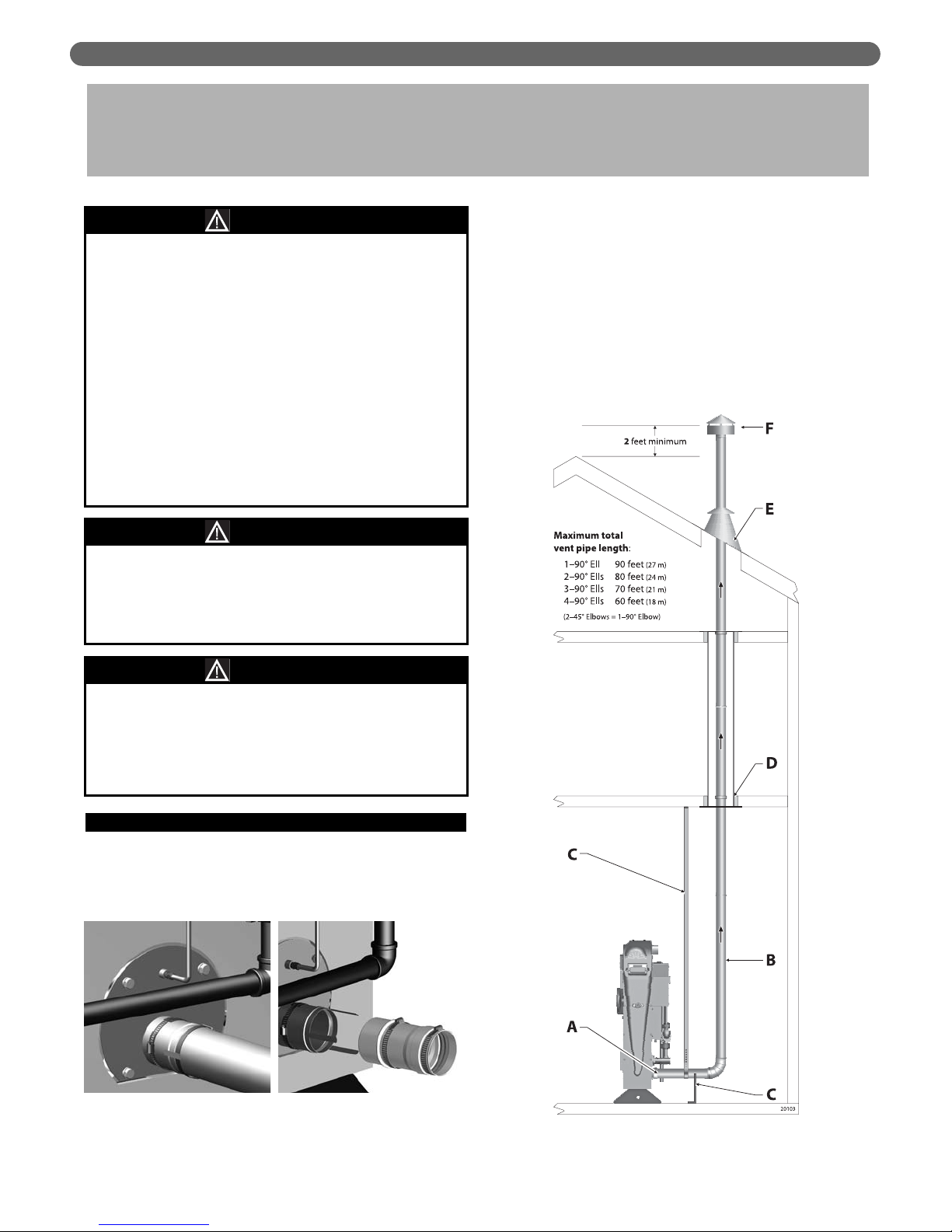

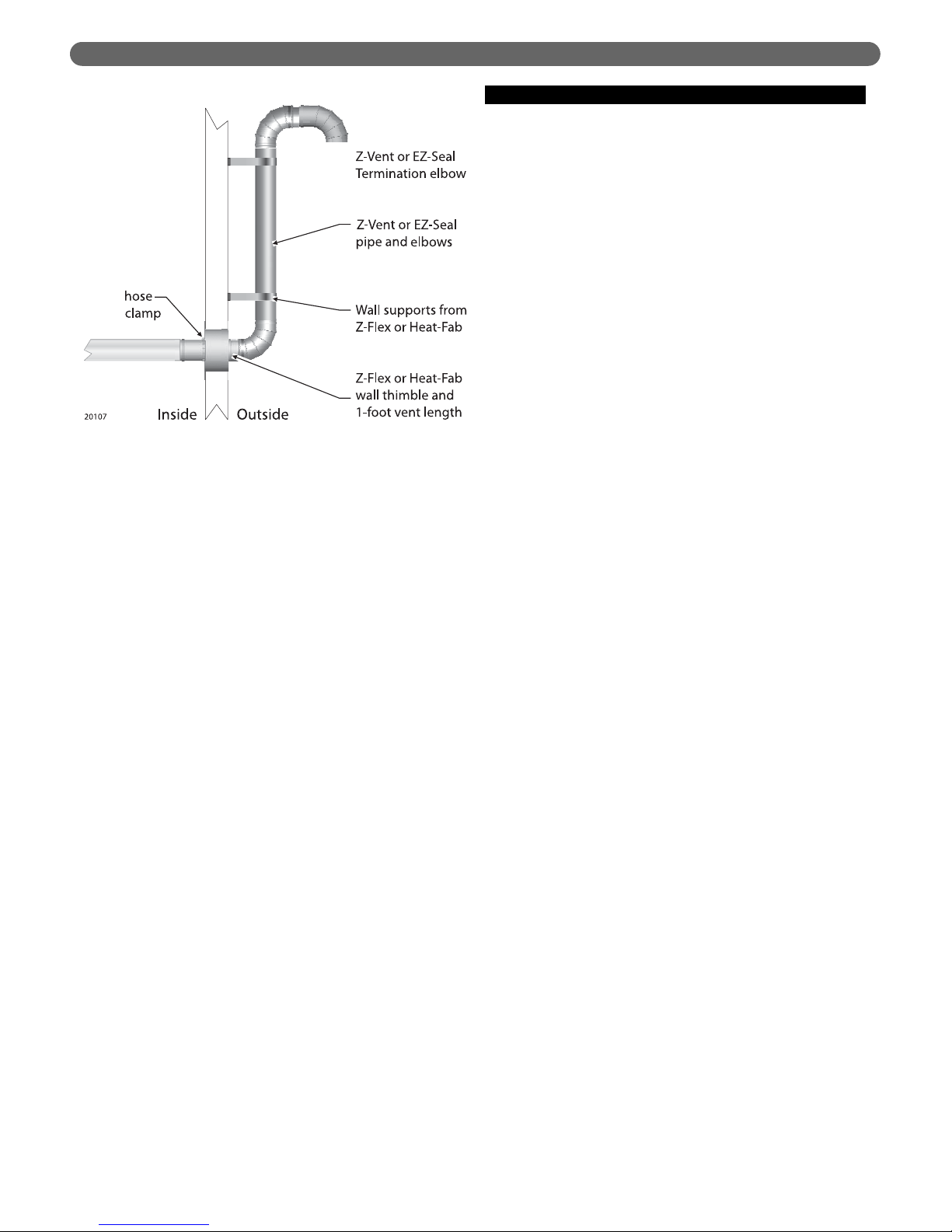

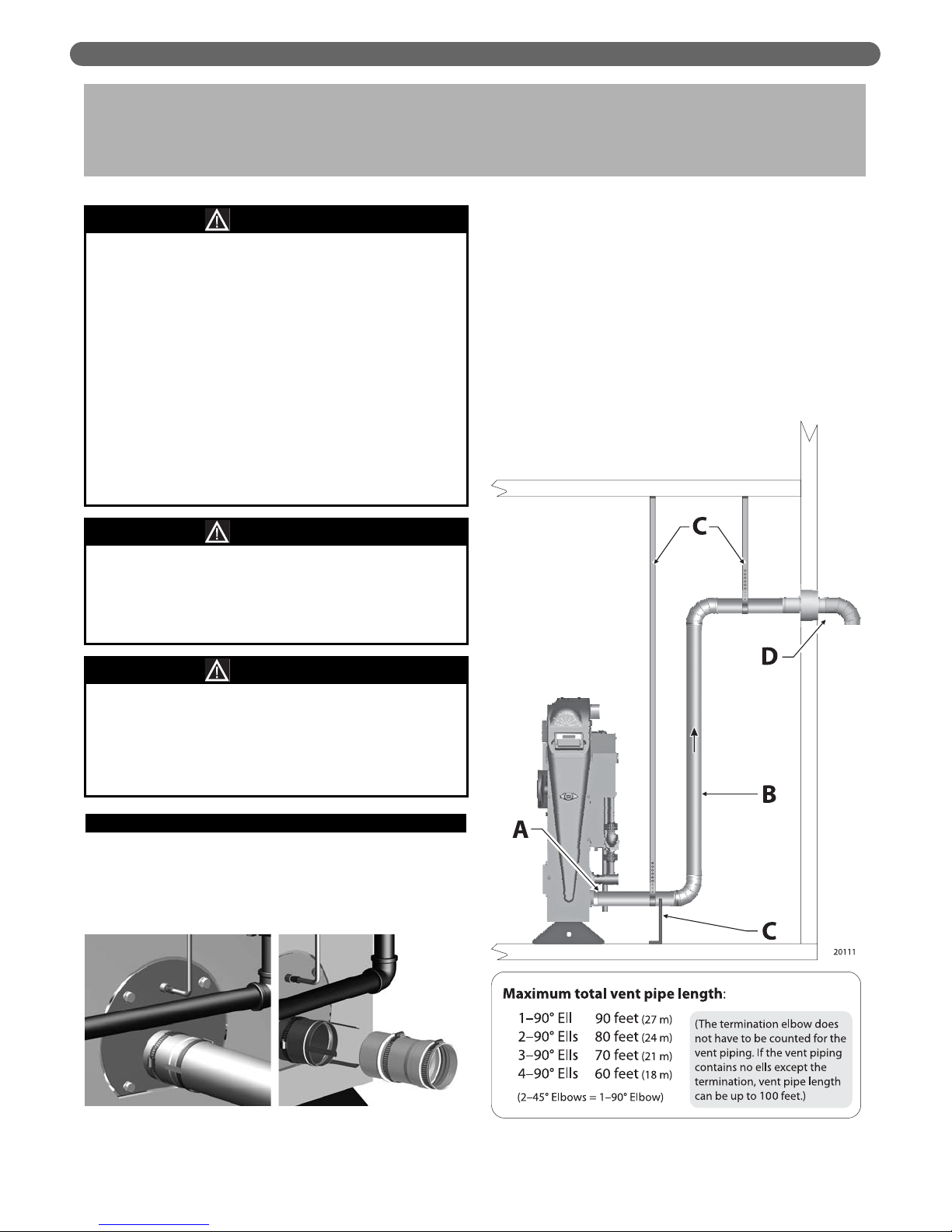

A. BOILER VENT CONNECTION

1. The vent connection at the boiler is for Heat-Fab EZSeal vent piping only. To use Z-Flex Z-Vent venting

you must install the Z-Vent adapter, part number

2SVSHTA03 (92-2) or 2SVSHTA04 (92-4).

2. EZ-Seal Connection: Insert EZ-Seal pipe male end

into the boiler connection. Make sure the locking tabs

slide under the EZ-Seal locking ring. Bend back

locking tabs to complete the joint. Follow EZ-Seal

instructions to complete the vent piping installation.

3. Z-Vent adapter Installation: Insert male end of adapter

into boiler vent connection. Make sure the locking

tabs slide under the gear clamp on the adapter. Bend

back the locking tabs (as in left illustration above).

Then tighten the adapter gear clamp to finish the

connection. Follow Z-Vent instructions to connect ZVent piping.

The vent piping operates with positive pressure. The

vent piping must be completely sealed and securely

supported.

Use only the vent components listed in this manual.

Use of any other materials could result in vent

system failure.

Exposed vent pipe poses a potential burn hazard to

people and pets. Insulate or shield the pipe where

necessary to prevent risk.

Never drill through, or install screws into, the vent

pipe or vent components.

Failure to properly install the vent piping could result

in flue gas leakage, causing possible severe personal

injury, death or substantial property damage.

WARNING

Terminate the vent following the guidelines in this

manual. Avoid vent termination locations likely to be

affected by winds, snowdrifts, people and pets.

Protect building materials and vegetation from

degradation caused by the flue gases and

condensation.

WARNING

Code compliance – Follow all applicable local codes

when installing the vent system. Where codes differ

from this manual, follow code requirements. Contact

PB Heat if you have any questions regarding the

installation.

NOTICE

Figure 3A.1: Vertical Venting

EZ-Seal Vent Attachment Z-Vent Adapter

Attachment

3A. VENT & AIR PIPING: THROUGH THE

ROOF

(COMBUSTION AIR FROM THE BOILER ROOM)

VENT & AIR PIPING: THROUGH THE ROOF

Page 19

15

4. Slope horizontal runs toward the boiler. All horizontal

runs of vent pipe must slope continuously at least 1/4"

per foot (21 mm per meter) to ensure condensate

drains completely back to the boiler. DO NOT install

the vent piping with any sections that could trap

condensate.

B. VENT PIPING COMPONENTS

1. See Table 3A.1 for acceptable vent components. NO

OTHER vent materials are acceptable.

2. Carefully follow the instructions supplied by the vent

piping manufacturer.

3. The vent joints seal with elastomer rings in the pipe

and fittings. Avoid damaging these seals.

4. Cutting Z-Vent Pipe (Z-Vent only — DO NOT cut EZ-

Seal Pipe): Length adjustments with Z-Vent pipe can

be made by cutting the pipe, following the Z-Vent

instructions. Be sure to cut the pipe squarely and to

file the cut edge smooth after cutting. Rough pipe

ends will damage the seals. Support the pipe when

cutting to avoid making the pipe out of round.

5. Adjustable Lengths of EZ-Seal Pipe: Length

adjustments with EZ-Seal piping are made with slip-fit

adjustable length sections, not by cutting the pipe.

Make sure the adjustable length does not jut into

elbows or terminations. This could block flue gas and

condensate flow.

6. Maximum Vent Piping Length: See the table in Figure

3A.1 for the maximum allowable length. Each elbow

causes the same pressure drop as 10 feet of vent pipe,

so the allowable length reduces 10 feet for each elbow

used in the piping. When 45° elbows are used, two

45° elbows are equivalent to one 90° elbow.

7. Insulate the vent piping where it passes through

unheated areas to prevent condensate freeze-up.

8. If the pipe passes through an occupied space, install a

chase around the pipe, following the vent pipe

instructions and applicable codes.

9. Clearance from Combustible Materials: Provide

minimum clearance to all combustible materials of at

least 2 inches (51 mm).

10. Using an Existing Chimney as a Chase: The vent

piping can be routed through an existing UNUSED

and STRAIGHT chimney. DO NOT vent directly into

the chimney. Install the vent piping so it can be

inspected after installation. Follow vent pipe

manufacturer’s instructions for chimney-as-chase

installations.

C. SUPPORT THE VENT PIPING

COMPLETELY

1. DO NOT use the boiler vent connection to support

the vent piping. Provide support straps from the

ceiling or noncombustible saddle or pedestal supports

from the floor. This is required on ALL installations,

regardless of the length of the horizontal piping

connected to the boiler.

2. Vent piping cannot be supported from above (such as

relying on roof jack sections). You must install supports

on the horizontal piping before the vent turns upward.

3. Install at least one support on every horizontal run.

For horizontal runs longer than 5 feet (1.5 m), install a

support every 3 feet (0.9 m).

4. Follow the vent pipe manufacturer’s instructions for

placement and installation of supports.

D. FLOOR AND WALL PENETRATIONS

1. Follow applicable codes and the vent pipe instructions

to install fire stops, thimbles or other devices at all

floor and wall penetrations.

2. Provide minimum 2 inches (51 mm) clearance to all

combustible construction.

E. ROOF PENETRATIONS

Follow applicable codes and the vent pipe instructions to

install a roof jack, flashing and support. Long extensions

of vent pipe above the roof may require the use of guy

supports as specified in the vent pipe instructions.

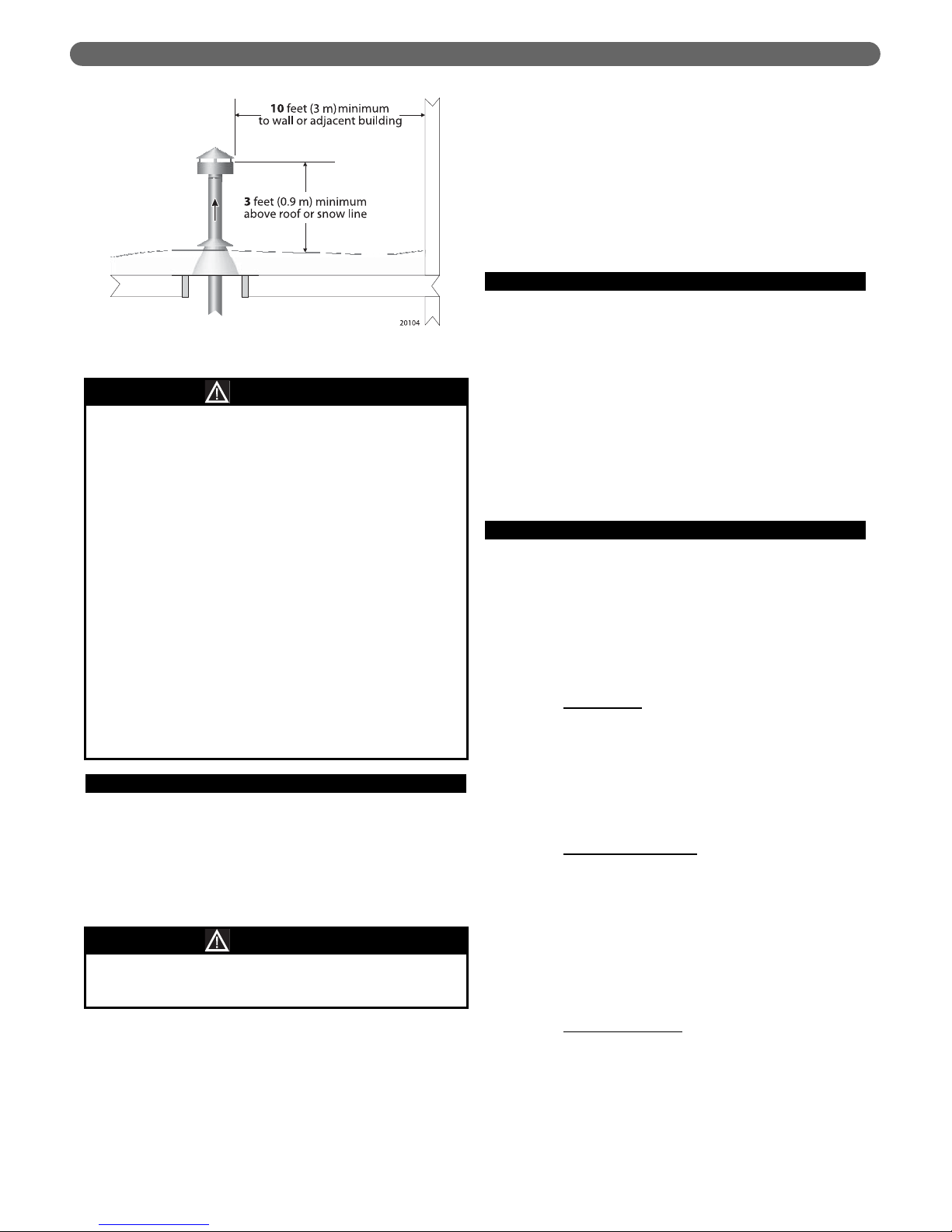

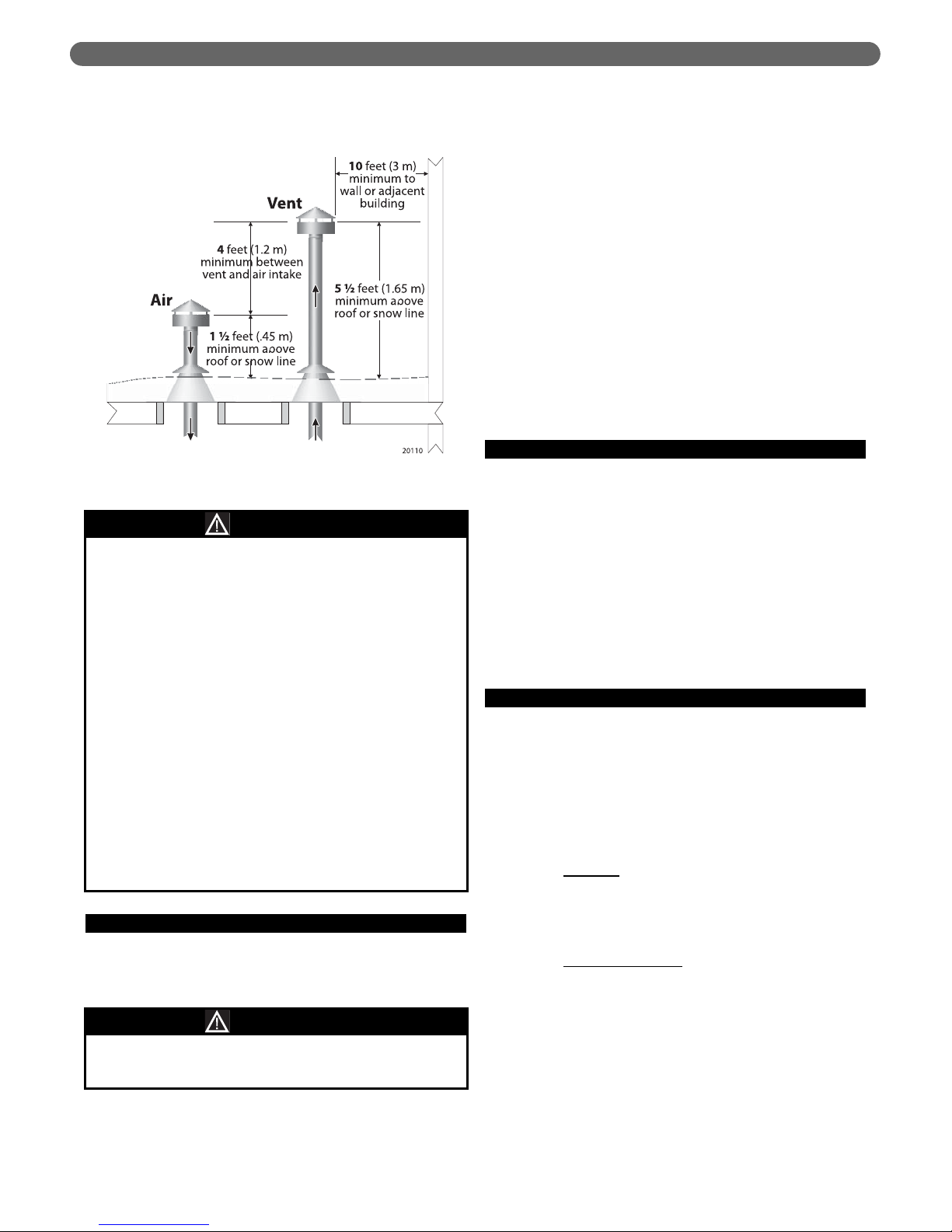

F. RAIN CAP TERMINATION

1. Use only the rain caps listed in Table 3A.1.

2. The rain cap exhaust opening must be at least 2 feet

(0.6 m) above the highest roof point within 10 feet, as

shown in Figure 3A.1. See the National Fuel Gas Code,

ANSI/NFPA 54 for details on pitched roof applications.

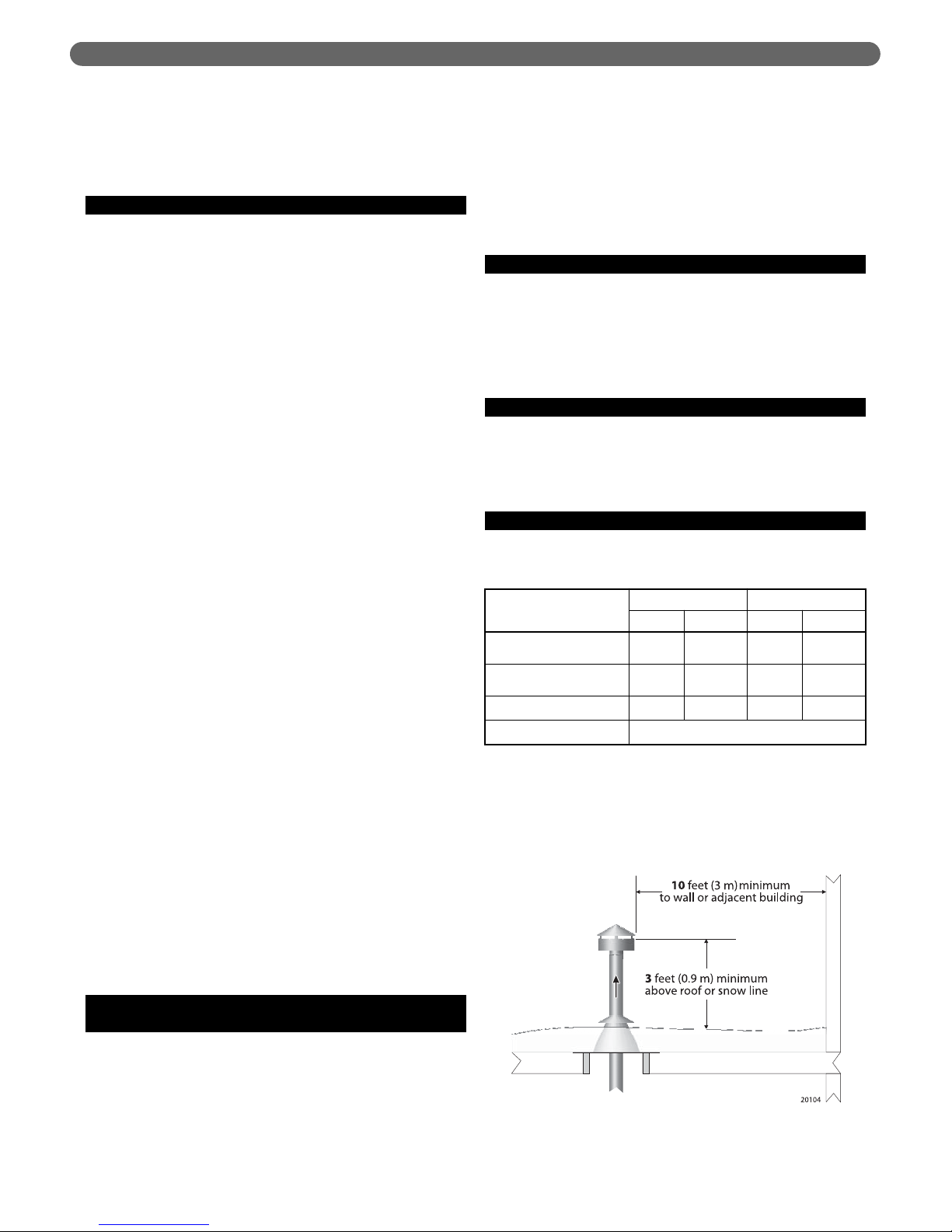

3. See Figure 3A.2 for additional minimum clearances.

VENT & AIR PIPING: THROUGH THE ROOF

Table 3A.1: Vent and Air System Components

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports, Thimbles, etc.)

EZ-Seal3"Z-Vent3"EZ-Seal4"Z-Vent

4"

Boiler Adapter (Adapts from

EZ-Seal to Z-Vent Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Rain Cap Vent Termination 5300CI 2SVSRCF03 5400CI 2SVSRCF04

Joint Sealant, as Needed GE RTV106 or Equivalent

Figure 3A.2: Vent Termination Minimum

Clearances

Page 20

16

G. COMBUSTION AIR OPENINGS

Combustion air must be supplied from the boiler room as

shown in Figure 1.1. Make sure the installation provides

air openings as required by applicable codes and this

manual.

H. MULTIPLE BOILER INSTALLATIONS

1. Each boiler must be individually vented. DO NOT use

combined venting.

2. Install multiple vents through the roof following all

guidelines for single-vent installations.

3. Install the vents so they are no closer than 12 inches

on centers.

VENT & AIR PIPING: THROUGH THE ROOF

Page 21

17

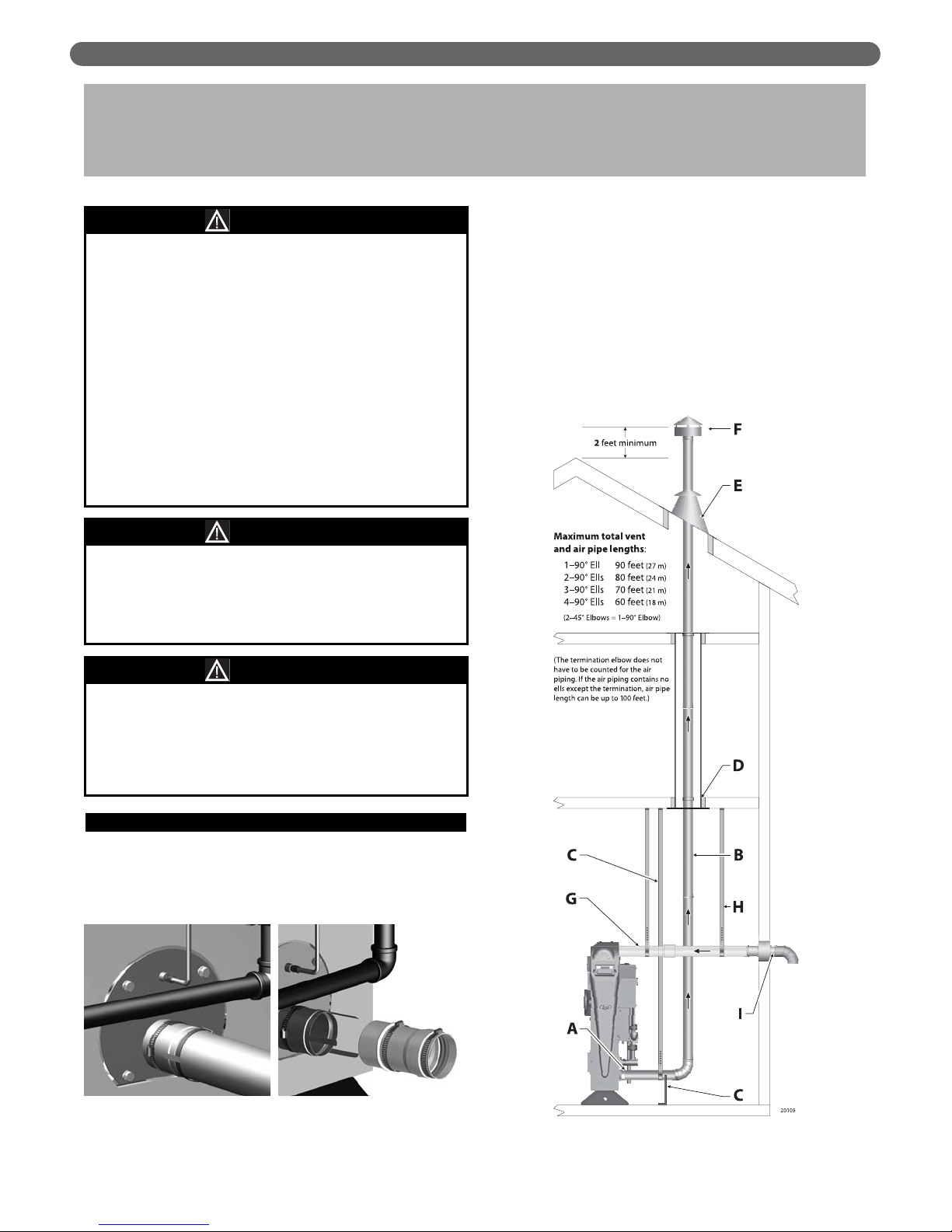

A. BOILER VENT CONNECTION

1. The vent connection at the boiler is for Heat-Fab EZSeal vent piping only. To use Z-Flex Z-Vent venting

you must install the Z-Vent adapter, part number

2SVSHTA03 (92-2) or 2SVSHTA04 (92-4).

2. EZ-Seal Connection: Insert EZ-Seal pipe male end

into the boiler connection. Make sure the locking tabs

slide under the EZ-Seal locking ring. Bend back

locking tabs to complete the joint. Follow EZ-Seal

instructions to complete the vent piping installation.

3. Z-Vent Adapter Installation: Insert male end of adapter

into boiler vent connection. Make sure the locking

tabs slide under the gear clamp on the adapter. Bend

back the locking tabs (as in left illustration above).

Then tighten the adapter gear clamp to finish the

connection. Follow Z-Vent instructions to connect ZVent piping.

VENT & AIR PIPING: THROUGH THE ROOF

The vent piping operates with positive pressure. The

vent piping must be completely sealed and securely

supported.

Use only the vent components listed in this manual.

Use of any other materials could result in vent

system failure.

Exposed vent pipe poses a potential burn hazard to

people and pets. Insulate or shield the pipe where

necessary to prevent risk.

Never drill through, or install screws into, the vent

pipe or vent components.

Failure to properly install the vent piping could result

in flue gas leakage, causing possible severe personal

injury, death or substantial property damage.

WARNING

Terminate the vent and air piping following the

guidelines in this manual. Avoid vent termination

locations likely to be affected by winds, snowdrifts,

people and pets. Protect building materials and

vegetation from degradation caused by the flue

gases and condensation.

WARNING

Code compliance – Follow all applicable local codes

when installing the vent system. Where codes differ

from this manual, follow code requirements. Contact

PB Heat if you have any questions regarding the

installation.

NOTICE

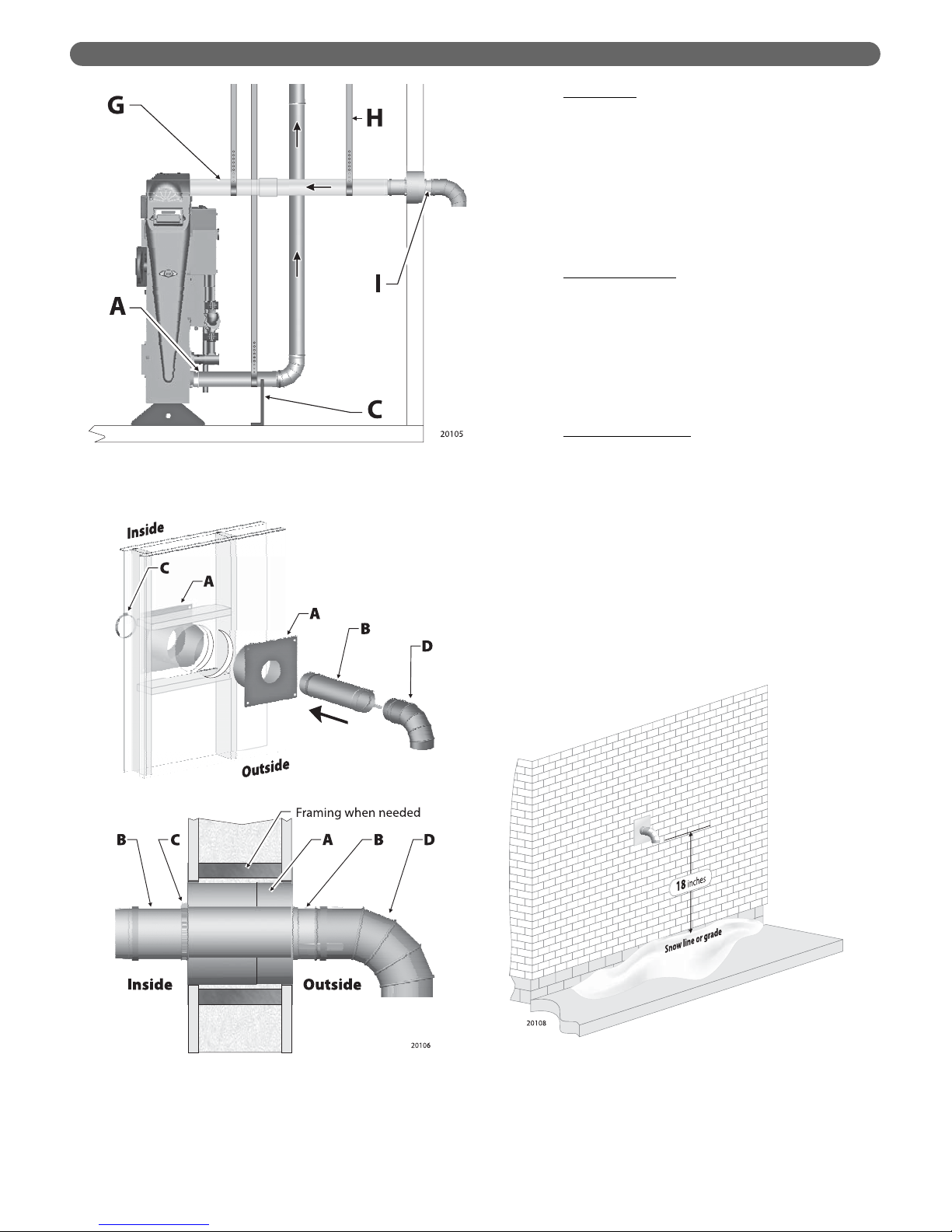

Figure 3B.1: Vertical Venting/Sidewall Air

EZ-Seal Vent Attachment Z-Vent Adapter

Attachment

3B. VENT & AIR PIPING: THROUGH THE

ROOF

(AIR PIPED THROUGH SIDE WALL)

Page 22

18

VENT & AIR PIPING: THROUGH THE ROOF

4. Slope horizontal runs toward the boiler. All horizontal

runs of vent pipe must slope continuously at least 1/4"

per foot (21 mm per meter) to ensure condensate

drains completely back to the boiler. DO NOT install

the vent piping with any sections that could trap

condensate.

B. VENT PIPING COMPONENTS

1. See Table 3B.1 for acceptable vent components. NO

OTHER vent materials are acceptable.

2. Carefully follow the instructions supplied by the vent

piping manufacturer.

3. The vent joints seal with elastomer rings in the pipe

and fittings. Avoid damaging these seals.

4. Cutting Z-Vent Pipe (Z-Vent only — DO NOT cut EZ-

Seal Pipe): Length adjustments with Z-Vent pipe can

be done by cutting the pipe, following the Z-Vent

instructions. Be sure to cut the pipe squarely and to

file the cut edge smooth after cutting. Rough pipe

ends will damage the seals. Support the pipe when

cutting to avoid making the pipe out of round.

5. Adjustable Lengths of EZ-Seal Pipe: Length

adjustments with EZ-Seal piping are done with slip-fit

adjustable length sections, not by cutting the pipe.

Make sure the adjustable length does not jut into

elbows or terminations. This could block flue gas and

condensate flow.

6. Maximum Vent Piping Length: See the table in Figure

3B.1 for the maximum allowable length. Each elbow

causes the same pressure drop as 10 feet of vent pipe,

so the allowable length reduces 10 feet for each elbow

used in the piping. When 45° elbows are used, two

45° elbows are equivalent to one 90° elbow.

7. Insulate the vent piping where it passes through

unheated areas to prevent condensate freeze-up.

8. If the pipe passes through an occupied space, install a

chase around the pipe, following the vent pipe

instructions and applicable codes.

9. Clearance from Combustible Materials: Provide

minimum clearance to all combustible materials of at

least 2 inches (51 mm).

10. Using an Existing Chimney as a Chase: The vent

piping can be routed through an existing STRAIGHT

chimney. DO NOT vent directly into the chimney.

Install the vent piping so it can be inspected after

installation. Follow vent pipe manufacturer’s

instructions for chimney-as-chase installations.

C. SUPPORT THE VENT PIPING

COMPLETELY

1. DO NOT use the boiler vent connection to support

the vent piping. Provide support straps from the

ceiling or noncombustible saddle or pedestal supports

from the floor. This is required on ALL installations,

regardless of the length of the horizontal piping

connected to the boiler.

2. Install at least one support on every horizontal run.

For horizontal runs longer than 5 feet (1.5 m), install a

support every 3 feet (0.9 m).

3. Vent piping cannot be supported from above (such as

relying on roof jack sections). You must install

supports on the horizontal piping before the vent turns

upward. Provide a support on the horizontal piping

within 6 inches of every upturned elbow to support

the vertical run.

4. Follow the vent pipe manufacturer’s instructions for

placement and installation of supports.

D. FLOOR AND WALL PENETRATIONS

1. Follow applicable codes and the vent pipe instructions

to install fire stops, thimbles or other devices at all

floor and wall penetrations.

2. Provide minimum 2 inches (51 mm) clearance to all

combustible construction.

E. ROOF PENETRATIONS

Follow applicable codes and the vent pipe instructions to

install a roof jack, flashing and support. Long extensions

of vent pipe above the roof may require the use of guy

supports as specified in the vent pipe instructions.

F. RAIN CAP TERMINATION

1. Use only the rain caps listed in Table 3B.1.

2. The rain cap exhaust opening must be at least 2 feet

(0.6 m) above the highest roof point within 10 feet, as

shown in Figure 3B.1. See the National Fuel Gas

Code, ANSI/NFPA 54 for details on pitched roof

applications.

3. See Figure 3B.2 for additional minimum clearances.

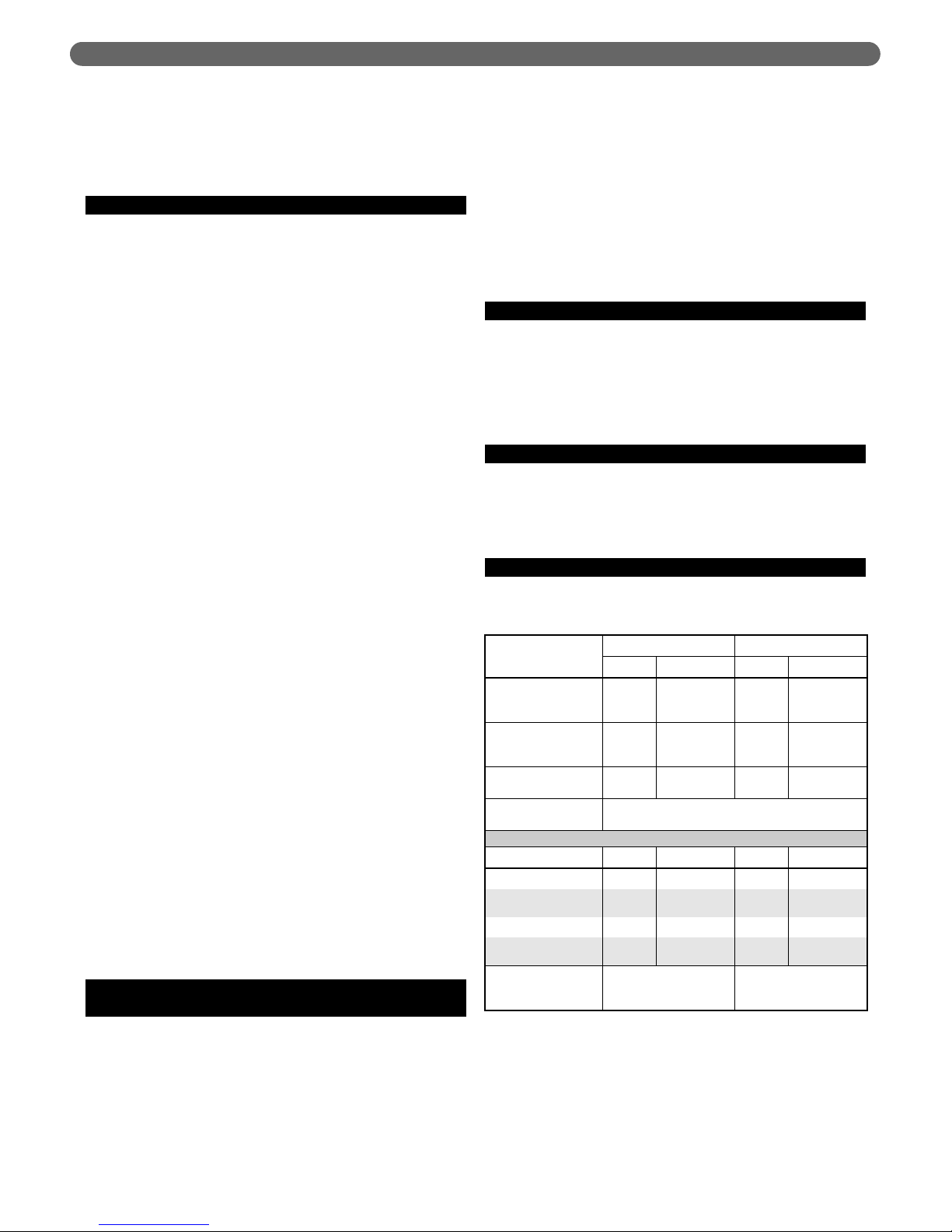

Table 3B.1: Vent and Air System Components

Vent Components

92-2 92-4

Heat-Fab Z-Flex Heat-Fab Z-Flex

Vent Piping/Components

(Incl. Supports,

Thimbles, etc.)

EZ-Seal

3"

Z-Vent

3"

EZ-Seal

4"

Z-Vent

4"

Boiler Adapter (Adapts

from EZ-Seal to Z-Vent

Piping)

Not

Required

2SVSHTA03

Not

Required

2SVSHTA04

Rain Cap Vent

Termination

5300CI 2SVSRCF03 5400CI 2SVSRCF04

Joint Sealant,

as Needed

GE RTV106 or Equivalent

Air Components Heat-Fab Z-Flex Heat-Fab Z-Flex

Termination Elbow 9314TERM 2SVSTEX0390 9414TERM 2SVSTEX0490

Termination Pipe

Section (1 ft)

9302 2SVEPWCF0301 9402 2SVEPWCF0401

Termination Thimble 9393S 2SVSWTE03 9493S 2SVSWTE04

Gear Clamp

(Nose Clamp)

3" Clamp 7HS44XX 4" Clamp 7HS64XX

Air Piping/Components

(Incl. Supports,

Thimbles, etc.)

3" PVC, CPVC, ABS,

Galvanized or Aluminum

4" PVC, CPVC, ABS,

Galvanized or Aluminum

Page 23

19

G. AIR PIPE CONNECTION

1. Before installing the air piping, install the air pipe

sidewall termination assembly (Item D, Figure 3B.1).

See instructions following.

2. Construct the air piping from PVC, CPVC or ABS

plastic, or galvanized or aluminum metallic pipe

(including flexible aluminum duct if desired).

3. Attach the air piping to the boiler air connection,

preferably using silicone RTV to seal the connection. If

the boiler room air is free of contaminants you can

use metallic duct tape to seal the joints. With age,

however, duct tape adhesives can loosen, so duct tape

is not as reliable as silicone RTV.

4. If the installation is required to meet direct vent

(sealed combustion) requirements, seal all joints withe

silicone RTV. The air pipe installation must be air-tight

and water-tight.

5. Maximum air piping length: See the table in Figure

3B.1, for the maximum allowable length. Each elbow

causes the same pressure drop as 10 feet of vent pipe,

so the allowable length reduces 10 feet for each elbow

used in the piping. When 45° elbows are used, two

45° elbows are equivalent to one 90° elbow.

H. SUPPORTING AIR PIPING

1. DO NOT use the boiler air connection to support the

air piping. Provide support straps from the ceiling or

install wall brackets.

2. Provide at least one support on all air pipe

installations.

3. Provide a support every 3 feet for air pipe lengths

greater than 5 feet horizontally.

4. Provide a support on the horizontal piping within 6

inches of every upturned elbow to support the vertical

run.

I. AIR PIPE TERMINATION

1. See Table 3B.1 for part numbers of the sidewall

termination components required for Z-Vent and EZSeal air pipe installations. The air piping termination

must be constructed using the stainless steel vent

materials listed in Table 3B.1 to ensure the

configuration is correct. DO NOT terminate the air

piping with any other method.

2. Termination Assembly Components:

a. Wall Thimble

: Use only the thimble listed in Table

3B.1. The hole in the thimble will prevent the pipe

length (B) from being pushed inward. The raised

portion of the pipe female end is too large to pass

through the hole in the thimble. Follow the vent

pipe manufacturer’s instructions supplied with the

thimble. If the wall thimble isn’t long enough for

the application, follow the vent manufacturer’s

instructions to add an extension.

Alternate Construction

: The air pipe can be

inserted through a hole without using a thimble.

For this option, attach a storm collar on both the

inside and outside walls at the penetration. Before

attaching the collars, seal around the air pipe

thoroughly with silicone RTV to prevent air

leakage or insect access. The storm collar tightens

around the vent pipe with a gear clamp. This

prevents movement of the finished assembly. You

will still need to use the length of vent pipe and

the termination elbow described below.

b. Length of Vent Pipe

: Use a 1-foot length of vent

pipe as listed in Table 3B.1 unless the wall

penetration requires a longer length. If a longer

length is required, use a length of EZ-Seal or ZVent long enough for the application.

Insert the pipe from OUTSIDE, male end first. The

pipe will stop at the raised section of the female end.

VENT & AIR PIPING: THROUGH THE ROOF

COMBUSTION AIR MUST BE UNCONTAMINATED

Construction dust: If the boiler is operated while the

building is under construction it must be protected

from wood, concrete, sheet rock and other types of

dust. Failure to properly protect the boiler from

construction dust will damage the boiler.

Combustion air contaminated with fluorocarbons or

other halogenated compounds, such as laundry

products, cleaning solvents and refrigerants will

result in the formation of acids in the combustion

chamber and vent piping. These acids will cause

premature failure of the boiler and vent, causing

possible severe personal injury, death or substantial

property damage.

If the boiler room, or any room through which the air

piping travels, may contain contaminants as listed

above, you MUST seal air pipe joints with silicone

RTV to prevent contaminants from entering the

boiler combustion air. The finished air piping

installation must be air-tight and water-tight.

WARNING

Figure 3B.2: Termination Minimum Clearances

When using metallic piping, seal all of the longitudinal

seam joints in addition to the component joints.

NOTICE

Page 24

20

VENT & AIR PIPING: THROUGH THE ROOF

c. Gear Clamp: Use a hose clamp or a gear clamp

manufactured by the vent manufacturer (see Table

3B.2).

Slide the clamp over the male end of the pipe

after the pipe has been inserted from outside.

From the inside, pull the pipe so it is firmly against

the outside plate.

Push the gear clamp against the inside plate and

tighten securely. This will prevent the termination

assembly from being pushed outward.

d. Termination Elbow

: Use only the termination

elbow listed in Table 3B.2. The elbow must be

pointed downward.

Before inserting the male end of the elbow into

the pipe, apply a bead of silicone RTV and spread

around the end.

Insert the termination elbow and secure using the

vent pipe manufacturer’s joint assembly

procedure.

Termination Location

: Install the air pipe

termination where it meets the minimum

clearances shown in Figure 3B.4.

Appliance exhaust outlets: Install the air intake at

least 2 feet below and 5 feet horizontally from any

appliance vent outlet.

Exiting below grade or minimum height: See

Figure 3B.5. When the air pipe must exit the

building below grade or below the minimum

height for the termination elbow, install vertical

piping as necessary for the termination elbow to

be high enough to meet the minimum clearances

of Figure 3B.4. Make sure to support the piping

using wall brackets available from the vent pipe

manufacturer.

Figure 3B.1: Vertical Venting/Sidewall Air

(Partially Repeated from Page 17)

Figure 3B.4: Minimum Clearances to Air

Termination

Figure 3B.2: Sidewall Air Pipe Termination

Assembly

Page 25

21

J. MULTIPLE BOILER INSTALLATIONS

1. Venting Multiple Boilers:

a. Each boiler must be individually vented. DO NOT

use combined venting.

b. Install multiple vents through the roof following all

guidelines for single-vent installations.

c. Install the vents so they are no closer than 12

inches on centers.

2. Air Piping for Multiple Boilers:

a. Air for each boiler must be individually piped. DO

NOT use combined air piping.

b. Install multiple air pipes through the side wall

following all guidelines for single-air pipe

installations.

c. Install the terminations so they are no closer than

12 inches on centers.

VENT & AIR PIPING: THROUGH THE ROOF

Figure 3B.2: Using External Piping to Raise the

Termination

Page 26

22

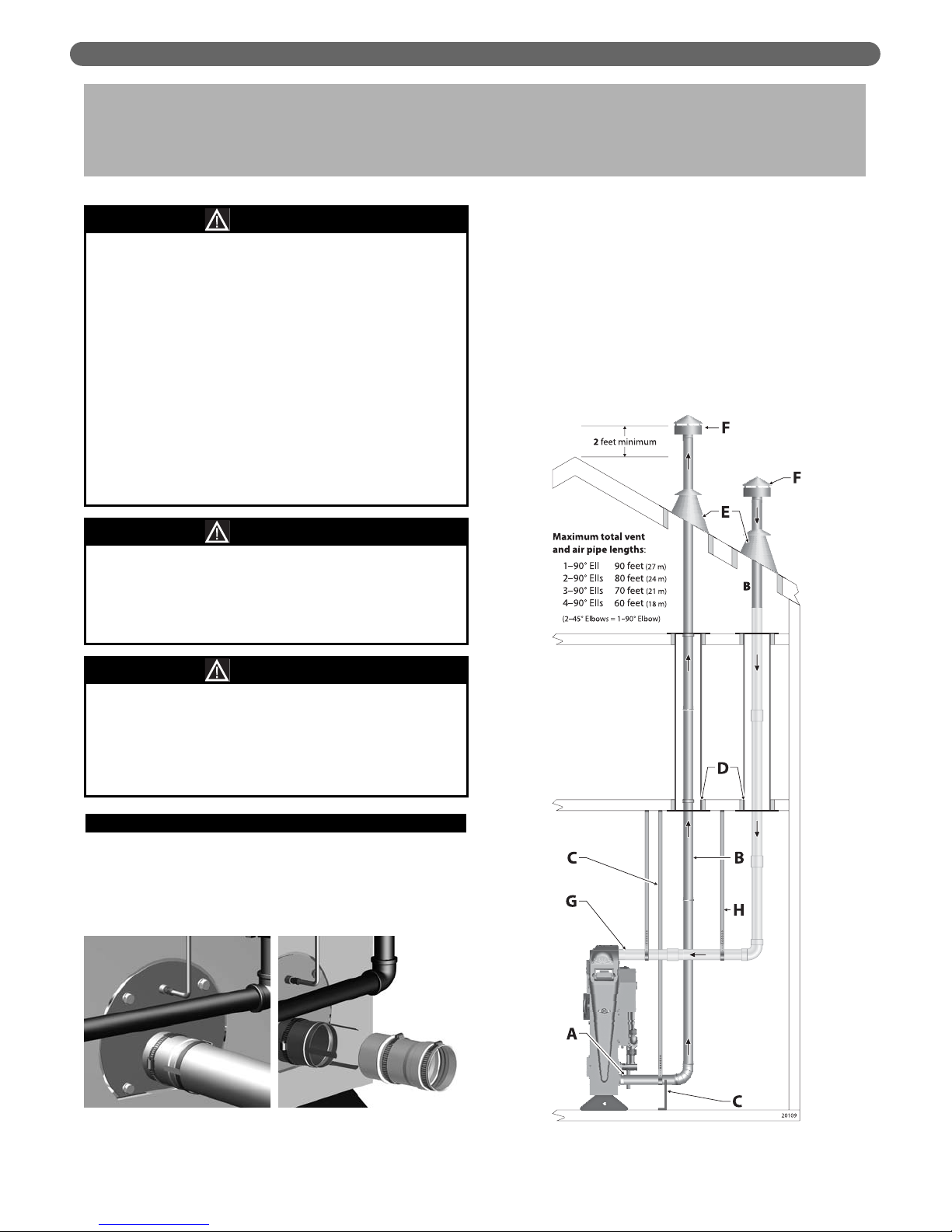

A. BOILER VENT CONNECTION

1. The vent connection at the boiler is for Heat-Fab EZSeal vent piping only. To use Z-Flex Z-Vent venting

you must install the Z-Vent adapter, part number

2SVSHTA03 (92-2) or 2SVSHTA04 (92-4).

2. EZ-Seal Connection: Insert EZ-Seal pipe male end

into the boiler connection. Make sure the locking tabs

slide under the EZ-Seal locking ring. Bend back

locking tabs to complete the joint. Follow EZ-Seal

instructions to complete the vent piping installation.

3. Z-Vent Adapter Installation: Insert male end of adapter

into boiler vent connection. Make sure the locking

tabs slide under the gear clamp on the adapter. Bend

back the locking tabs (as in left illustration above).

Then tighten the adapter gear clamp to finish the

connection. Follow Z-Vent instructions to connect

Z-Vent piping.

The vent piping operates with positive pressure. The

vent piping must be completely sealed and securely

supported.

Use only the vent components listed in this manual.

Use of any other materials could result in vent

system failure.

Exposed vent pipe poses a potential burn hazard to

people and pets. Insulate or shield the pipe where

necessary to prevent risk.

Never drill through, or install screws into, the vent

pipe or vent components.

Failure to properly install the vent piping could result

in flue gas leakage, causing possible severe personal

injury, death or substantial property damage.

WARNING

Terminate the vent and air piping following the

guidelines in this manual. Avoid vent termination

locations likely to be affected by winds, snowdrifts,

people and pets. Protect building materials and

vegetation from degradation caused by the flue

gases and condensation.

WARNING

Code compliance – Follow all applicable local codes

when installing the vent system. Where codes differ

from this manual, follow code requirements. Contact

PB Heat if you have any questions regarding the

installation.

NOTICE

Figure 3C.1: Vertical Venting

VENT & AIR PIPING: THROUGH THE ROOF

3C. VENT PIPING: THROUGH THE ROOF

(SEPARATE TERMINATIONS)

EZ-Seal Vent Attachment Z-Vent Adapter

Attachment

Page 27

23

4. Slope horizontal runs toward the boiler. All horizontal

runs of vent pipe must slope continuously at least 1/4"

per foot (21 mm per meter) to ensure condensate

drains completely back to the boiler. DO NOT install

the vent piping with any sections that could trap

condensate.

B. VENT PIPING COMPONENTS

1. See Table 3C.1 for acceptable vent components. NO

OTHER vent materials are acceptable.

2. Carefully follow the instructions supplied by the vent

piping manufacturer.

3. The vent joints seal with elastomer rings in the pipe

and fittings. Avoid damaging these seals.

4. Cutting Z-Vent Pipe (Z-Vent only — DO NOT cut EZ-

Seal Pipe): Length adjustments with Z-Vent pipe can

be done by cutting the pipe, following the Z-Vent

instructions. Be sure to cut the pipe squarely and to

file the cut edge smooth after cutting. Rough pipe

ends will damage the seals. Support the pipe when

cutting to avoid making the pipe out of round.

5. Adjustable Lengths of EZ-Seal Pipe: Length

adjustments with EZ-Seal piping are done with slip-fit

adjustable length sections, not by cutting the pipe.

Make sure the adjustable length does not jut into

elbows or terminations. This could block flue gas and

condensate flow.

6. Maximum Vent Piping Length: See the table in Figure

3C.1 for the maximum allowable length. Each elbow

causes the same pressure drop as 10 feet of vent pipe,

so the allowable length reduces 10 feet for each elbow

used in the piping. When 45° elbows are used, two

45° elbows are equivalent to one 90° elbow.

7. Insulate the vent piping where it passes through

unheated areas to prevent condensate freeze-up.

8. If the pipe passes through an occupied space, install a

chase around the pipe, following the vent pipe

instructions and applicable codes.

9. Clearance from combustible materials: Provide

minimum clearance to all combustible materials of at

least 2 inches (51 mm).

10. Using an existing chimney as a chase: The vent piping

and air piping can be routed through an existing

UNUSED and STRAIGHT chimney. DO NOT vent

directly into the chimney. Install the vent piping so it

can be inspected after installation. Follow vent pipe

manufacturer’s instructions for chimney-as-chase

installations.

C. SUPPORT THE VENT PIPING

COMPLETELY

1. DO NOT use the boiler vent connection to support

the vent piping. Provide support straps from the

ceiling or noncombustible saddle or pedestal supports

from the floor. This is required on ALL installations,

regardless of the length of the horizontal piping

connected to the boiler.

2. Install at least one support on every horizontal run.

For horizontal runs longer than 5 feet (1.5 m), install a

support every 3 feet (0.9 m).

3. Vent piping cannot be supported from above (such as

relying on roof jack sections). You must install

supports on the horizontal piping before the vent turns

upward. Provide a support on the horizontal piping

within 6 inches of every upturned elbow to support

the vertical run.

4. Follow the vent pipe manufacturer’s instructions for

placement and installation of supports.

D. FLOOR AND WALL PENETRATIONS

1. Follow applicable codes and the vent pipe instructions

to install fire stops, thimbles or other devices at all

floor and wall penetrations.

2. Provide minimum 2 inches (51 mm) clearance to all

combustible construction.

E. ROOF PENETRATIONS

Follow applicable codes and the vent pipe instructions to

install a roof jack, flashing and support. Long extensions

of vent pipe above the roof may require the use of guy