DP/N: 4809622a v2.0 09/07/06

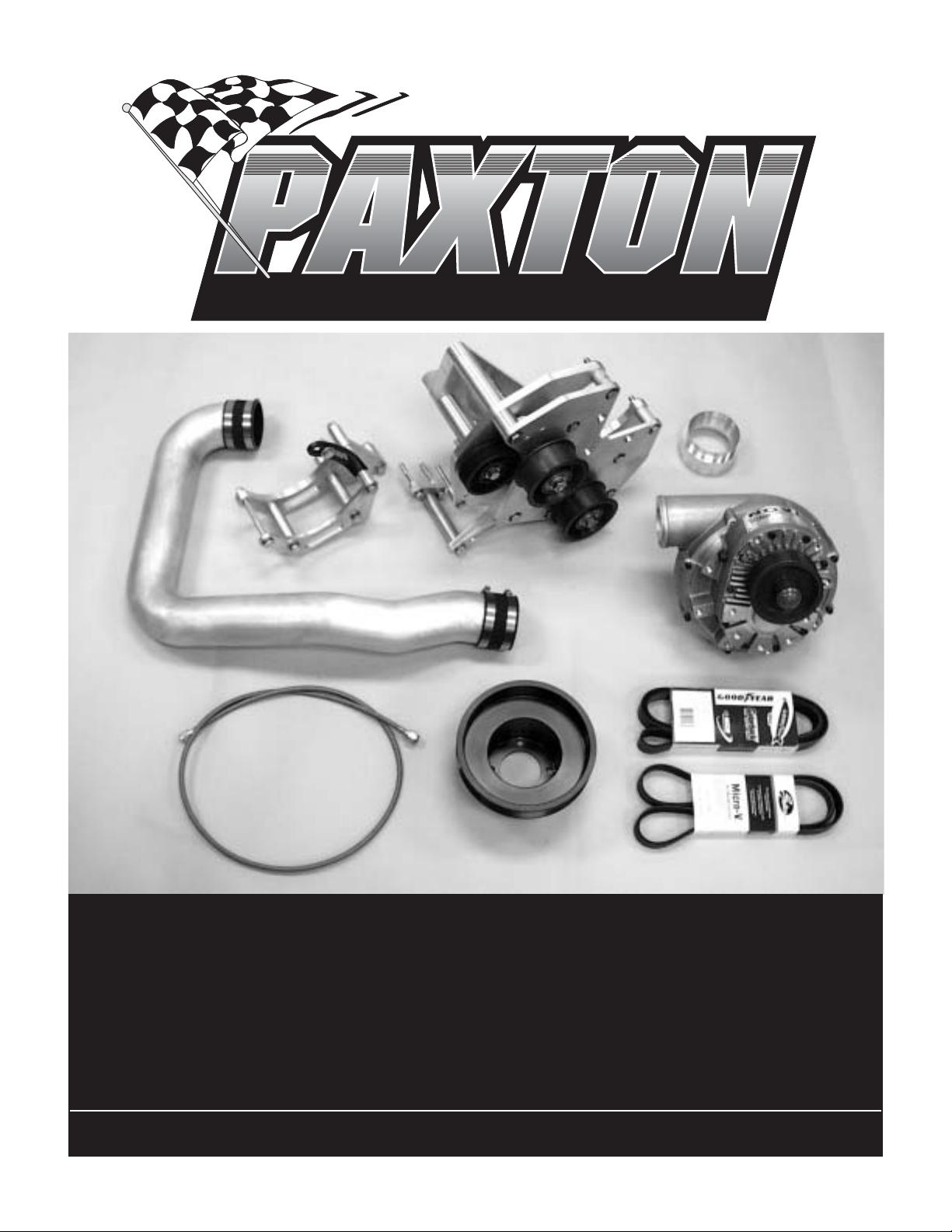

Kit # 1001824

S U P E R C H A R G E R S

Installation Manual for

Paxton Automotive

NOVI 2000

for the

Mustang 5.0L and 5.8L

Renegade Race Class

Paxton Automotive Corporation .1300 Beacon Place .Oxnard, CA 93033

(805) 604-1336 .FAX (805)604-1337

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

ii

© 2006 PAXTON AUTOMOTIVE

All rights reserved. No part of this publication may be reproduced, transmitted, transcrived, or translated into

another language in any form, by any means without written permission of Paxton Automotive.

FOREWORD

C

ongratulations! You have purchased the finest complete race-ready

supercharger kit available today. The centerpiece of this kit is the

High Efficiency PAXTON NOVI 2000 Race Supercharger, a

mechanically driven centrifugal blower.

This kit comes with all the parts you will need to install the supercharger.

Paxton Automotive assumes that you are an experienced automotive

mechanic, and have a stripped down Mustang 5.0 or 5.8 engine.

For the quickest installation time, we suggest that you read this manual

throughly before beginning. Make sure that you understand the process,

have identified the areas of the car that you will be working on, and have

the tools that you will need on hand. We estimate installation time at less

than 8 hours, not including tune-up. Once again we recommend reading

the manual before beginning the installation. We are available for tech support at 805 647-3796, Monday through Friday, 8:00 AM to 4:30 PM. PST.

After reading the manual, verify that all major assembly groups are present

in the main kit box. As you remove a box or bag, note the identification

label and compare it to the parts list.

PAXTON AUTOMOTIVE makes every effort to insure

that all parts are included in the box. If you discover that

you are missing any part, or that a part was damaged in

shipping, call PAXTON immediately. DO NOT begin

installation if a part is missing. Failure to contact PAXTON

prior to beginning installation will result in a charge for the

missing part.

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

iii

TABLE OF CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

1. RENEGADE RACE KIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1 SUPERCHARGER MOUNTING BRACKET INSTALLATION . . . . . . . . . . . . .1-1

2. MOUNTING PLATE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1 INSTALL THE S/C MOUNTING PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 PLASTIC IDLER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

3. ALTERNATOR MOUNTING BRACKET INSTALLATION . . . . . . . . . . . . . . .3-1

3.1 ALTERNATOR RELOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

4. AIR INLET / DISCHARGE TUBE INSTALLATION . . . . . . . . . . . . . . . . . . . . .4-1

4.1 INSTALL THE DISCHARGE TUBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

5. CRANK PULLEY INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 INSTALL THE CRANK PULLEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6. A FINAL WORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B. 1016039 ASY, MOUNTING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . .A-2

C. 1016106 ASY, NOVI 2000 SUPERCHARGER . . . . . . . . . . . . . . . . . . . .A-3

D. 1015612 ASY, CRANK PULLEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

E. 1016040 ASY, ALTERNATOR RELOCATION BRACKET . . . . . . . . . . .A-5

F. 1019329 ASY, OIL SUPPLY HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

G. 1016009 ASY, DISCHARGE TUBE . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

iv

Never rely solely on a floor jack when

working underneath a vehicle. Always

use jack stands that are rated for the

weight of your vehicle, use them at the

recommended lift points, and place your

vehicle in ‘PARK’ or ‘FIRST’ gear with the

parking brake set.

Always use eye protection when using power

tools, such as drills, saws, and grinders, or

when working underneath a vehicle.

Never smoke, use an open flame, or have spark

producing items around gasoline or flammable

objects. Always have a fire extinguisher that

is rated for chemical and electrical fires handy

when working on motor vehicles. Also, make sure

that the extinguisher is fully charged.

Operate engines only in a well ventilated area. Carbon

Monoxide, gasoline, and solvent vapors

are colorless and sometimes odorless, and

may asphyxiate and explode without

warning.

Always disconnect the battery from

your engine before doing work on the electrical

or fuel systems, or doing underdash work.

The chemicals used in the vehicle systems,

such as oils and coolants, are poisonous. Clean

up any spills immediately, and dispose of

waste materials properly. Pets, wild animals, and

children may die if they ingest the liquid.

PAXTON Automotive thanks you for your purchase.We welcome your com-

ments and suggestions to help us improve our products.

We suggest that the engine compartment be

cleaned before the installation. You can clean the

engine with a pressure washer that is found at selfserve car washes. Use a safe-for-aluminum cleaner/degreaser, and cover the distributor and any

electronics with a plastic bag to prevent water from

entering.

You are endoubtedly eager to get started, but

please take a little more time to insure that your

safely is not in jeopardy. A moments’s lack of

attention may cause a serious injury to you, or to

someone else who happens to be standing around.

By following list is not meant to be a comprehensive list, bu rather it is meant to make you aware of

some of the risks, and encourage you to take a

safety minded approach to your work area.

IMPORTANT NOTES

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

1-1

P/N 33 ATTACHES HERE

7-Bolt Points for the S/C Bracket

X

X

X

X

X

X

X

Before beginning the installation of your supercharger, the engine should have all of its accessory drive components removed.

1.1 SUPERCHARGER MOUNTING

BRACKET INSTALLATION

A. If you have not already done so, remove the

alternator.

1. Disconnect the battery

2. Relieve tension on the drive belt

3. Remove the belt

4. Remove the alternator

5. Remove the water pump pulley

B

. Install mounting bracket. (See Appendix “B”,

mounting bracket assembly.)

*** NOTE ***

We suggest that you assemble the mounting bracket

in an organized fashion, keeping the parts in order, as

is shown in Appendix “B”. It is especially critical to

keep the proper spacers and washers together with

their bolts. Refer to Appendix “B” for there locations.

*** NOTE ***

Leave out the spacers (items #11, #40, and #41) in

the initial installation of the mounting bracket. After

the complete installation of the bracket, slip the spacers into place. If the spacers do not fit snugly, the

spacers will have to be machined. This is due to the

factory variations of the engine.

Section 1

RENEGADE RACE KIT INSTALLATION

Fig. 1-a

C. Place the triangular spacer (item #12) against

the cylinder head, and attach the back plate

(item #3) to the engine block using the 2.5" x

7/16" screw and washer, (items #33, #34). The

screw passes throught the spacer and into the

cylinder head at the point shown. (See

Fig. 1-a.)

D. Slip the spacers (items #5, #6) into the counter-

bored holes in the back plate.

E. Attach the small triangular bracket (item #8) to

the lower part of the timing cover using bolts

(items #26, #27). (See Fig. 1-a.)

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

1-2

This Page Left Intentionally Blank

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

2-1

2.1 INSTALL THE S/C MOUNTING

PLATE

2.2 PLASTIC IDLER INSTALLATION

A. Attach the supercharger mounting plate,

(item #2) to the back plate using the 7-1/2" long

7/16" bolt (item #31). DO NOT fully tighten.

DO NOT install the bolts and spacers that go

into the water pump at this time. (items #40,

#41.)

B. Slide the three 7/16" bolt with washers (item

#32, #35) through the front supercharger sup-

port plate. Slide the spacers onto the bolts, and

loosely attach the bolts to the other brackets.

C. Slide the support arm (item #7) between the

two plates until the single hole at the end of the

support arm lines up with the hole at the center

of the triangular bracket. (Item #8.)

*** NOTE ***

There are two sets of holes in the support arm. This

is to accommodate the diffeent deck heights on the

302 and 351 engines. Secure the support arm using

the two 3/8" bolts (item #22). DO NOT fully tighten.

DO NOT install the spacer (item #11) at this time.

Section 2

MOUNTING PLATE INSTALLATION

C. Go back and tighten all loose bolts. Check the

fit of the remaining spacers (items #11, #40,

#41). They should fit snugly into place. Due to

the factory tolerance, after market heads, water

punps, gasket thicknesses, etc., these spacers

may need to be shortened slightly. Failure to

assure a proper fit for these spacers, either leaving them too long or too short, will cause the

bracket to sit crooked and may cause a thrown

belt. Measure as accurately as possible.

*** NOTE ***

The 351 based engines will use only one bolt and

spacer into the water pump.

D. Install the idler pulleys (item #17, #19), the

supercharger bolts (item #21) and spacers

(item #4).

1. Attach the oil drain (not provided in this

kit) to the supercharger.

2. Attach the oil supply hose (Appendix “F”)

to the NOVI 2000.

3. Install the NOVI 2000 Race Supercharger.

4. Connect the oil supply hose to an oil sup-

ply. This can be located at the oil sender

unit.

A. Install the plastic accessory idler using the

8-3/4" long bolt and washer (items #29, #30)

and the step collar (item #18). DO NOT fully

tighten.

B. Slide the spacer (item #10) between the two

plates so it lines up with the hole that is the second from the bottom, as shown in Appendix

“B”. Slide the bolt (item #36) through both

plates and spacer to hold it in place.

*** NOTE ***

If you are using a pulley combinaztion other than

those supplied by Paxton, you may have to re-position this spacer either up or down, depending on the

pulley diameter. DO NOT install the pulley at tlhis

time.

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

2-2

This Page Left Intentionally Blank

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

3-1

3.1 ALTERNATOR RELOCATION

Section 3

ALTERNATOR MOUNTING BRACKET INSTALLATION

*** NOTE ***

The alternator Relocation kit was designed for the

factory '86-'93 style 70 AMP alternator with the stock

pulley. If you are running an underdrive pulley you

will need to acquire a longer belt. This bracket will

not accommodate the larger 140 AMP alternator. For

most racing applications, 70 AMPS is more than

enough to power the multiple fuel pumps, computers,

and ignition systems.

A. Install the alternator Relocation Bracket (See

Fig. 3-a, Appendix “E”), including the water

pump pulley, to the engine block at the points

indicated. (See Fig. 3-b.)

B. Install the alternator.

WATER PUMP

PULLEY LOCATION

Fig. 3-a

Fig. 3-b

ALTERNATOR BRACKET

LOCATIONS

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

3-2

This Page Left Intentionally Blank

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

4-1

Section 4

AIR INLET/DISCHARGE TUBE INSTALLATION

4.1 INSTALL THE DISCHARGE TUBE

RENEGADE SLEEVE ATTACHED TO

NOVI 2000 (CUTAWAY)

A. Install the discharge tube to the NOVI 2000

supercharger. (See Appendix “G”.)

B. Attach one 3.00" sleeve to the discharge of the

supercharger with two T-bolt clamps that are

provided. Leave the clamps loose.

C. Install (item #2 4PFA012-071) to the 3.00"

sleeve just installed to the discharge of the S/C.

D. Attach a 3.00" sleeve and clamps to the dis-

charge duct (item #1 4PFA012-051) and attach

duct to item #2 previously installed to the discharge of the S/C.

E. Attach two 3.00" sleeves and clamps to the dis-

charge duct (item #3, 4PFA012-061), and attach

to the previous duct that was installed.

F. Adjust ducts for alignment and tighten clamp

G. To be legal for the Renegade Race Class, install

the Renegade Venturi Sleeve at the inlet of the

supercharger. (See Fig. 4-a.)

Fig. 4-a

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

4-2

This Page Left Intentionally Blank

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

5-1

Section 5

CRANK PULLEY INSTALLATION

A. Install the crank pulley. (See Fig. 5.1-a and

Appendix “D”.)

B. Torque all bolts down to factory specs.

C. Install the drive belts. First the alternator belt

(around the 6-groove pulley), then the supercharger drive belt.

D. This completes the installation of the NOVI

2000.

5.1 INSTALL THE CRANK PULLEY

Fig. 5.1-a | Crank Pulley Location

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

5-2

This Page Left Intentionally Blank

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

6-1

Fig. 6.1-b

Thank you for purchasing this Paxton supercharger. Please understand that we are constantly improving and upgrading our product,

so there may be pictures in this manual showing parts trhat appear different than the parts

in your kit. This may be due to pictures taken

in pre-production, a change in material, or a

different engine model year for our illustrations. Rest assured that the parts will install in

the same way as described in this manual.

You have purchased the most up-to-date kit

that Paxton is selling at this time.

Section 6

A FINAL WORD

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

6-2

This Page Left Intentionally Blank

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-1

APPENDIX

Thank you for purchasing this Paxton Supercharger. Please understand

that we are constantly improving and upgrading our product, and so

there may be pictures in this manual showing parts that appear to be

different from the parts in your kit. This may be due to pictures taken in

pre-production, a change in material, or a different engine model year

for our illustrations. Rest assured that the parts will install in the same

fashion as is described in this manual, and that you have purchased the

most up-to-date kit that Paxton is selling at this time.

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-2

B

B. 1016039 ASY, MOUNTING BRACKET

REV.

DESCRIPTION

SCREW, HXHD, .312-18UNC-2A x 2.75"LG, STEEL GR8

WASHER, FLAT, .312"

SCREW, HXHD, .438-14UNC-2A x 8.75"LG, STEEL GR8

WASHER, FLAT, HEAVY, .438"

SCREW, HXHD, .438-14UNC-2A x 7.50"LG, STEEL GR8

SCREW, HXHD, .438-14UNC-2A x 7.00"LG, STEEL GR8

SCREW, HXHD, .438-14UNC-2A x 2.50"LG, STEEL GR8

WASHER, FLAT, .438"

SCREW, HXHD, MODIFIED, .438-14UNC-2A x 7.00"LG, STEEL GR8

SCREW, HXHD, .500-20UNF-2A x 5.00"LG, STEEL GR8

WASHER, FLAT, HEAVY, .500"

NUT, HEX, JAM, .500-20UNF-2B, STEEL GR5

SCREW, HXHD, .312-18UNC-2A x 6.25"LG, STEEL GR8

SPACER, .750"O.D. x .316"I.D. x 1.825"LG

PART NO.

7J312-000

7J438-072

7J438-081

7J500-001

7A312-275

7A437-875

7A437-750

7A437-700

7A437-250

141112151132211

QTY.

272829303132333435363738394041

ITEM NO.

7B500-500

7PA437-700

7F500-020

7A312-625

2A017-752-04

12

5

18

4

SPACER, .750"O.D. x .316"I.D. x .894"LG

2A017-752-02

9

3

5

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

RACE KIT, RENEGADE

33

6

41

38

34

40

15

13

14

19

29

37

2

9

4

39

28

34

31

8

10

27

26

28

28

11

7

1

21

DATE

4/19/00

A. PROCTOR

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

±1/2•

.XXX±.005

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

23

20

35

SHEET 1 OF 1

1016039

DO NOT SCALE DRAWING

ASY, MOUNTING BRACKET RENEGADE

D

1:2

SCALE:

SIZE: DWG. NO.:

5/4/00

5/4/00

5/4/00

GRE

23.8 LBS

B. WYMAN

G. COMPTON

APPR.

ENGINEERING

R&D

WEIGHT

NONE

SEE PARTS LIST

MATERIAL

FINISH

DESCRIPTION

BRKT, FRONT PLATE

ASY, S/C MOUNTING PLATE

BRKT, BACK PLATE

SPACER, .875"O.D. x .386"I.D. x 1.175"LG

SPACER, 1.250"O.D. x .438"I.D. x 3.970"LG

SPACER, SPECIAL CUT, 1.250"O.D. x .438"I.D. x 3.970"LG

SUPPORT ARM

BRKT, TRIANGULAR SUPPORT

SPACER, 1.250"O.D. x .438"I.D. x 1.175"LG

SPACER, 1.500"O.D. x .500"I.D. x 1.175"LG

SPACER, .875"O.D. x .386"I.D. x 3.782"LG

SPACER, TRIANGULAR

BRKT, IDLER ADJUSTING

SCREW, IDLER ADJUSTING

ARBOR, TENSIONER

COLLAR, STEP

ASY, PULLEY IDLER

1016071

PART NO.

4PFP010-054

4PFP010-031

4PFP017-021

4PFP017-031

4PFP010-021

4PFP010-061

4PFP017-011

4PFP017-041

2A017-879-01

1116411131111112211962132

QTY.

123456789

ITEM NO.

4PFP017-091

2A017-879-03

1011121314151617181920212223242526

7PA375-500

7PB500-313

4PFA010-031

1210507

4PFP017-071

COLLAR, STEP

PULLEY, IDLER 6 GRV

WASHER, FLAT, .375"

SCREW, HXHD, .375-16UNC-2A x 2.75"LG, STEEL GR5

SCREW, HXHD, .375-16UNC-2A x 2.00"LG, STEEL GR5

SCREW, HXHD, .375-16UNC-2A x 4.75"LG, STEEL GR8

SCREW, FLHD, SOC, .375-16UNC-2A x .75"LG, STEEL GR8

SCREW, FLHD, SOC, .250-20UNC-2A x .75"LG, STEEL GR5

SCREW, HXHD, .312-18UNC-2A x 3.00"LG, STEEL GR8

7J375-044

7A375-276

7A375-200

7A375-475

7A375-077

7A250-077

4PFP017-081

4PFG016-150

7A312-300

1

A

30

24

24

25

21

32

20

34

8 PLACES

16

37

38

22

21

32

34

16

36

17

37

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-3

F

C. 1016106 ASY, NOVI 2000 SUPERCHARGER

REV.

.62

SHEET 1 OF 1

1016111

S/C ROTATION

DESCRIPTION

GEARCASE ASY, N2K, CW, SAT

FTG, NIPPLE, 3/8"NPT x 5/8" HOSE BARB

FTG, PLUG, 3/8"NPT WITH MAGNET

WASHER, COPPER CRUSH, 3/8"

OIL JET, LONG

SCREW, SCHD, 3/8-16UNC-2A x 1.00"LG.

CAP, SHIPPING, T2

KEY, 1/8"SQ x 1.25"LG.

SPACER, PULLEY, .125"THK.

RET, CUP BLWR PULLEY

PULLEY RETAINER S/C

CAP, TAMPER PROOF

SCREW, HXHD, 3/8-24UNF-2A x 1.00"LG.

VOLUTE, MACH, N2K, STR, CW, EXHONE

CAP, SHIPPING, 3"

CAP, SHIPPING, 4"

NAMPLATE, NOVI 2000

DRIVE SCREW, #4 x .187", GR5

WASHER, ANTI-ROTATION

CLAMP, VOLUTE

1/4-20 x .50" SHCS

CAP, SHIPPING, T5

MATING RING, .090"THK.

SHIM, IMP, .003"THK.

SHIM, IMP, .005"THK.

SHIM, IMP, .010"THK.

MATING RING, .099"THK.

MATING RING, .103"THK.

MATING RING, .112"THK.

MATING RING, .090"THK.

SHIM, IMP, .003"THK.

IMPLR, BAL, NOVI 2K, CCW

17

33 3

1

2

PART NO.

7P375-625

2H238-000

112211121111111114136100000001111

QTY

123456789

ITEM NO.

7J375-024

7P375-016

20

008704

7P375-104

7PP375-090

32 2 4

7

5

4

008718

008706

008719

7U100-075

7B375-110

2H017-125

2H040-021

2H040-011

2H018-061

2H100-035

11121314151617181920212223242526272829303127323334

3 REQD

21

6 REQD

22

2

7U100-021

2H017-021

2H100-045

23

008720

7A250-050

2H060-030

2H100-003

2H100-005

2H100-010

2

2H060-031

2H060-040

2H060-041

2H060-030

2H100-003

2H021-211

2

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

NUT, IMP 3/8"LH SL 6PT

PULLEY, S/C 8-GRV 3.75"

DEFAULT

7F375-024

1

98-00 6.9L FORD F-350

DATE

10/14/98

RV

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

±1/2•

.XXX±.005

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

ASY, S/C NOVI 2000

FORWARD ROTATION, 98-01 6.9L, SATIN

D

SIZE: DWG. NO.:

-----

-----

-----

-----

-----

-----

ENGINEERING

R&D

APPR.

NONE

SEE PARTS LIST

MATERIAL

FINISH

DO NOT SCALE DRAWING

3:4

SCALE:

21.8 LBS

WEIGHT

27 22829

AS REQD

16

AS REQD

3

1

223

33

9

?

19

8

4 REQD

4

6

LONG HUB

AWAY FROM S/C

34

11

12

3

14

13

NOTES: UNLESS OTHERWISE SPECIFIED

1. ALL PARTS TO BE SUITABLY PROTECTED AT ALL TIMES TO PREVENT DAMAGE.

2. SHIM IMPELLER TO .031 WORKING HEIGHT USING ITEMS 25, 26, 27, 28,

29, 30, AND 31 (FLOOR STOCK) AS REQUIRED.

3. TORQUE TO 36 FT-LBS.

4. HEAT TO 200°F TO EASE ASSEMBLY.

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-4

1300 BEACON PLACE OXNARD, CA 93033

D. 1015612 ASY, CRANK PULLEY

TEL: (805) 604-1336 FAX: (805) 604-1337

PULLEY, CRANK

SCREW, SOC HD, .375-16UNC-2A x 1.50"LG., STEEL GR8

WASHER, FLAT, 3/8", STEEL

BELT, 8-GRV MICRO-V 56.0"LG x 28mm WIDE

DATE

4/12/00

7A375-158

7K375-040

2A048-560

4FA018-029

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

AP

APPROVALS

DRAWN

144

123

ITEM NO. QTY. PART NO. DESCRIPTION

1

4

1

A

REV.

1015612

ASY, CRANK PULLEY

5.0 - 5.8L RENEGADE

C

SIZE: DWG. NO.:

4/12/00

4/12/00

4/12/00

GRE

B. WYMAN

G. COMPTON

ENGINEERING

R&D

APPR.

SHEET 1 OF 1

DO NOT SCALE DRAWING

1:1

SCALE:

2.2 LBS

WEIGHT

4 PLACES

3

1

4 PLACES

2

.XXX±.005

±1/2•

.XX± .01

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

ANGLES: ±1/16

SEE PARTS LIST

MATERIAL

NONE

FINISH

NOTES: UNLESS OTHERWISE SPECIFIED

1. THIS PART TO BE SHIPPED SEPERATELY.

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-5

A

E. 1016040 ASY, ALTERNATOR RELOCATION BRACKET

REV.

SHEET 1 OF 1

ASY, ALTERNATOR

RACE KIT, RENEGADE

4/10/00

3/27/00

4/10/00

GRE

G. COMPTON

G. COMPTON

DRAWN

ENGINEERING

R&D

SEE PARTS LIST

ANGLES: ±1/16

MATERIAL

1016040

DO NOT SCALE DRAWING

D

1:2

SCALE:

SIZE: DWG. NO.:

4/10/00

3.5 LBS

B. WYMAN

WEIGHT

APPR.

NONE

FINISH

8

1300 BEACON PLACE OXNARD, CA 93033

8

1

7

DESCRIPTION

BRKT, ALTERNATOR REAR

BRKT, ALTERNATOR FRONT

BRKT, ALTERNATOR ADJUSTMENT

SPACER, .875"O.D. x .438"I.D. x .867"LG.

SPACER, .875"O.D. x .438"I.D. x 1.845"LG.

SPACER, .875"O.D. x .386"I.D. x 2.985"LG.

SPACER, 1.000"O.D. x .438"I.D. x 1.970"LG.

SPACER, 1.000"O.D. x .386"I.D. x 1.970"LG.

SCREW, HEX CAP, .375-16UNC-2A x 6.50"LG., STEEL, GR5

SCREW, HEX CAP, .375-16UNC-2A x 3.25"LG., STEEL, GR5

SCREW, HEX CAP, .438-14UNC-2A x 6.50"LG., STEEL, GR5

SCREW, HEX CAP, .375-16UNC-2A x 3.75"LG., STEEL, GR5

WASHER, FLAT, 7/16" x 15/16"O.D. x .06"THK, STEEL, GR5

WASHER, FLAT, 3/8" x 13/16"O.D. x .06"THK, STEEL, GR5

SCREW, HEX CAP, .375-16UNC-2A x 4.50"LG., STEEL, GR5

SCREW, HEX CAP, .375-16UNC-2A x 1.00"LG., STEEL, GR5

NUT, HEX, .375-16UNC-2B, STEEL, GR5

PULLEY, WATER PUMP

14

17

14

6

16

5

3

PART NO.

4PFP015-031

4PFP015-021

4PFP015-011

4PFP017-061

4PFP017-051

2A017-880-01

2A017-880-03

2A017-879-05

1111121211111611111

QTY.

123456789

ITEM NO.

10

6

2

7J438-081

7A375-650

7J375-044

7A375-324

7A437-650

7A375-375

7A375-451

101112131415161718

7F375-016

7A375-100

4PFP016-081

1

TEL: (805) 604-1336 FAX: (805) 604-1337

BELT, 6-GRV, 56.0"LG. x 21mm WIDE

DATE

2A046-560

19

APPROVALS

1

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

±1/2•

.XXX±.005

.XX± .01

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

14

4

14

9

13

11

14

15

14

12

NOTES: UNLESS OTHERWISE SPECIFIED

1. SHIP THESE ITEMS LOOSE.

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-6

DESCRIPTION

F. 1019329 ASY, OIL SUPPLY HOSE

HOSE, OIL, AN4 x AN4 x 24.0"LG.

FTG, ELBOW, AN4 x 1/8"NPT

FTG, STREET TEE, 1/4"NPT

FTG, NIPPLE, AN4 x 1/4"NPT

C

REV.

SHEET 1 OF 1

1019329

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

ASY, OIL SUPPLY

RACE KIT, RENEGADE

DO NOT SCALE DRAWING

C

1:1

3

TO STOCK OIL SENDER

PART NO.

7P125-004

7P250-034

7P250-031

7U250-090-240

111

1

QTY.

123

4

ITEM NO.

4

DATE

6/15/99

JFC

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

.XXX±.005

±1/2•

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

SIZE: DWG. NO.:

-----

-----

-----

-----

-----

-----

ENGINEERING

R&D

APPR.

SEE PARTS LIST

MATERIAL

FINISH

SCALE:

0.8 LBS

WEIGHT

NONE

TO STOCK OIL

SENDER LOCATION

1

2

TO S/C ASY

P/N: 4809622a

©2006 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

07SEP06 v2.0 MusRenegade(4809622a v2.0)

A-7

C

G. 1016009 ASY, DISCHARGE TUBE

REV.

SHEET 1 OF 1

1016009

1

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

RACE KIT, RENEGADE

DESCRIPTION

TUBE, DISCHARGE

TUBE, DISCHARGE

TUBE, DISCHARGE

HOSE, TURBO 3.00" x 3.00"LG

CLAMP, T-BOLT BAND

PAD, BLWR BYPASS

ASY, DISCHARGE TUBE

DO NOT SCALE DRAWING

C

1:1

PART NO.

4PFA012-051

4PFA012-071

11148

5

4

5

3

5

4

5

2

QTY.

12345

ITEM NO

7PS300-300

4PFA012-061

A

7R005-002

8D004-054

2

6

A

1

DATE

5/01/00

A. PROCTOR

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

.XXX±.005

±1/2•

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

SIZE: DWG. NO.:

5/02/00

5/02/00

5/02/00

GRE

B. WYMAN

G. COMPTON

ENGINEERING

R&D

APPR.

SEE PARTS LIST

MATERIAL

FINISH

SCALE:

3.7 LBS

WEIGHT

NONE

TO THROTTLE BODY

5

4

5

5

4

5

TO S/C ASY

NOTES: UNLESS OTHERWISE SPECIFIED

1. TO BE SHIPPED SEPERATELY.

DP/N: 4809622a v2.0 09/07/06

1300 Beacon Place • Oxnard, CA 93033-9901 • (805) 604-1336

FAX (805) 604-1337 • paxtonautomotive.com • M-F 8:00 AM - 4:30 PM PST

Loading...

Loading...