DP/N: 4809628 - V2.1 06/05/03

Owner’s Installation Guide for the

Paxton Automotive

Novi 1000 Supercharger

for the

2001-2003 4.6L SOHC Mustang GT

Paxton Automotive . 1300 Beacon Place . Oxnard CA 93033

805 604-1336 . FAX (805) 604-1337

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

ii

FOREWORD

Before you start the installation of your supercharger Paxton supercharger

kit, you will have to find the Paxton Computer Chip Voucher located in

your information packet. The 2001-2003 Mustang GT Supercharger Kit

requires a computer chip upgrade. You will need to fill out the chip voucher and send it and your computer to Paxton Automotive to receive your

chip upgrade. Please refer to section 7 of this manual for the procedure for

removing your engine control module.

Complete the Paxton Automotive/Ford Computer Chip Voucher and

return it to Paxton Automotive to receive the proper computer module for

your vehicle.

© 2003 PAXTON AUTOMOTIVE

All rights recerved. No parts of this publication may be reproduced, transmitted, transcrived, or translated into

another language in any form, by any means without written permission of Paxton Automotive.

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

iii

TABLE OF CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

1.1 INITIAL PREPARATION AND REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.1 SUPERCHARGER MOUNTING BRACKET ATTACHMEMT . . . . . . . . . . . . . . . . . . . . . . . .2-1

3.1 FAN RESISTOR RELOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

4.1 PREPARING TO MOUNT THE SUPERCHARGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

5.1 OIL FEED AND DRAIN LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6.1 INTAKE TRACT MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

7.1 ENGINE CONTROL COMPUTER REMOVAL AND MODIFICATION . . . . . . . . . . . . . . . . .7-1

8.1 IN-TANK FUEL PUMP INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

9.1 FINAL ASSEMBLY AND CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

List of Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Appendix A 1011816 ASY, S/C NOVI 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Appendix B 1015309 ASY, RADIATOR HOSE MODIFICATION . . . . . . . . . . . . . . . .A-4

Appendix C 1016630 ASY, S/C MOUNTING BRACKET . . . . . . . . . . . . . . . . . . . . . .A-5

Appendix D 1015933 ASY, AIR INTAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Appendix E 1017017 ASY, AIR DISCHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Appendix F 1019336 ASY, OIL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Appendix G 1019328 ASY, OIL RETURN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Appendix H 1015506 ASY, COMPRESSOR BYPASS . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Appendix I 1015530 ASY, FAN RESISTOR RELOC. . . . . . . . . . . . . . . . . . . . . . . . .A-11

Appendix J 1017734 ASY, FUEL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Appendix K 7000170 DIAGRAM, BELT ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

iv

IMPORTANT NOTES

C

ongratulations! You have purchased the

finest street supercharger available for the

Mustang GT. The centerpiece of this kit is

the High Efficiency PAXTON Supercharger, a

mechanically driven centrifugal blower.

This kit comes with all the parts you will need to

install the supercharger. The instruction manual has

been edited in order of sequence, and photographs

and drawings have been included to illustrate the

text. This will allow you quick part identification

and orientation.

The installation will require metric and SAE sockets and wrenches, a hand drill and bits, an Air

Hammer (and compressor), a 3/8” x 18 NPT tap,

screwdrivers, and a supply of buckets for the

reserve of coolant and oils.

We suggest that you obtain a copy of a Mustang

shop manual for your model of car. This may be

obtained from your dealer, or may be ordered by

mail from Helm Publications at (800) 782-4356.

Become familiar with the details of your car’s system. If it is not operating within normal parameters, we do not recommend the installation or use

of the supercharger.

For the quickest installation time, we suggest that

you read this manual thoroughly before beginning.

Make sure that you understand the process, have

identified the areas of the car that you will be

working on, and have the tools that you will need

on hand. The average installation time is 8 to 10

hours, but your time will depend on your working

conditions, experience installing superchargers,

personal skill level, and preparedness for the job.

This estimate does not include time for the initial

vehicle inspection, cleaning, fine tuning, or trouble-shooting. Once again, we recommend reading

the manual before beginning the process. We are

available for tech support at (805) 604-1336,

Monday through Friday, 7AM - 3 PM PST.

After reading the manual, verify that all major assembly groups are present in the main kit box. As you

remove a box or bag, note the identification label and compare it to the parts list.

PAXTON AUTOMOTIVE makes every effort to insure

that all parts are included in the box. If you

discover that you are missing any part,

or that a part was damaged in shipping, call PAXTON

immediately. DO NOT begin installation if a part

is missing. Failure to contact PAXTON prior to

beginning installation will result in a charge for

the missing part.

We suggest that the engine compartment be

cleaned before the installation. You can clean the

engine with a pressure washer that is found at self-

serve car washes. Use a safe-for-aluminum cleaner/degreaser, and cover the distributor and any

electronics with a plastic bag to prevent water from

entering.

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

v

Y

ou are undoubtedly eager to get started, but

please take a little more time to insure that

your safety is not in jeopardy. A moment’s

lack of attention may cause a serious injury to you,

or to someone else who happens to be standing

around. By following some simple safety precau-

PAXTON Automotive thanks you for your purchase. We welcome your

comments and suggestions to help us improve our product.

tions, you can avoid many potential dangers. The

following list is not meant to be a comprehensive

list, but rather it is meant to make you aware of

some of the risks, and encourage you to take a

safety minded approach to your work area.

• Never rely solely on a floor jack when working underneath a vehicle.Always use jack stands that are rated

for the weight of your vehicle, use them at the recommended lift points, and place your vehicle in ‘PARK’ or

‘FIRST’ gear with the parking brake set.

• Always use eye protection when using power tools, such

as drills, saws, and grinders, or when working underneath a vehicle.

• Never smoke, use an open flame, or have spark producing items around gasoline or flammable objects.Always

have a fire extinguisher that is rated for chemical and

electrical fires handy when working on motor vehicles.

Also, make sure that the extinguisher is fully charged.

• Operate engines only in a well ventilated area.Carbon

Monoxide, gasoline, and solvent vapors are colorless

and sometimes odorless, and may asphyxiate and

explode without warning.

• Always disconnect the battery from your engine before

doing work on the electrical or fuel systems, or doing

underdash work.

• The chemicals used in the vehicle systems, such as oils

and coolants, are poisonous. Clean up any spills immediately, and dispose of waste materials proper ly. Pets,

wild animals, and children may die if they ingest the liquid.

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

vi

This Page Left Intentionally Blank.

1-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 1

INITIAL PREPARATION AND REMOVAL

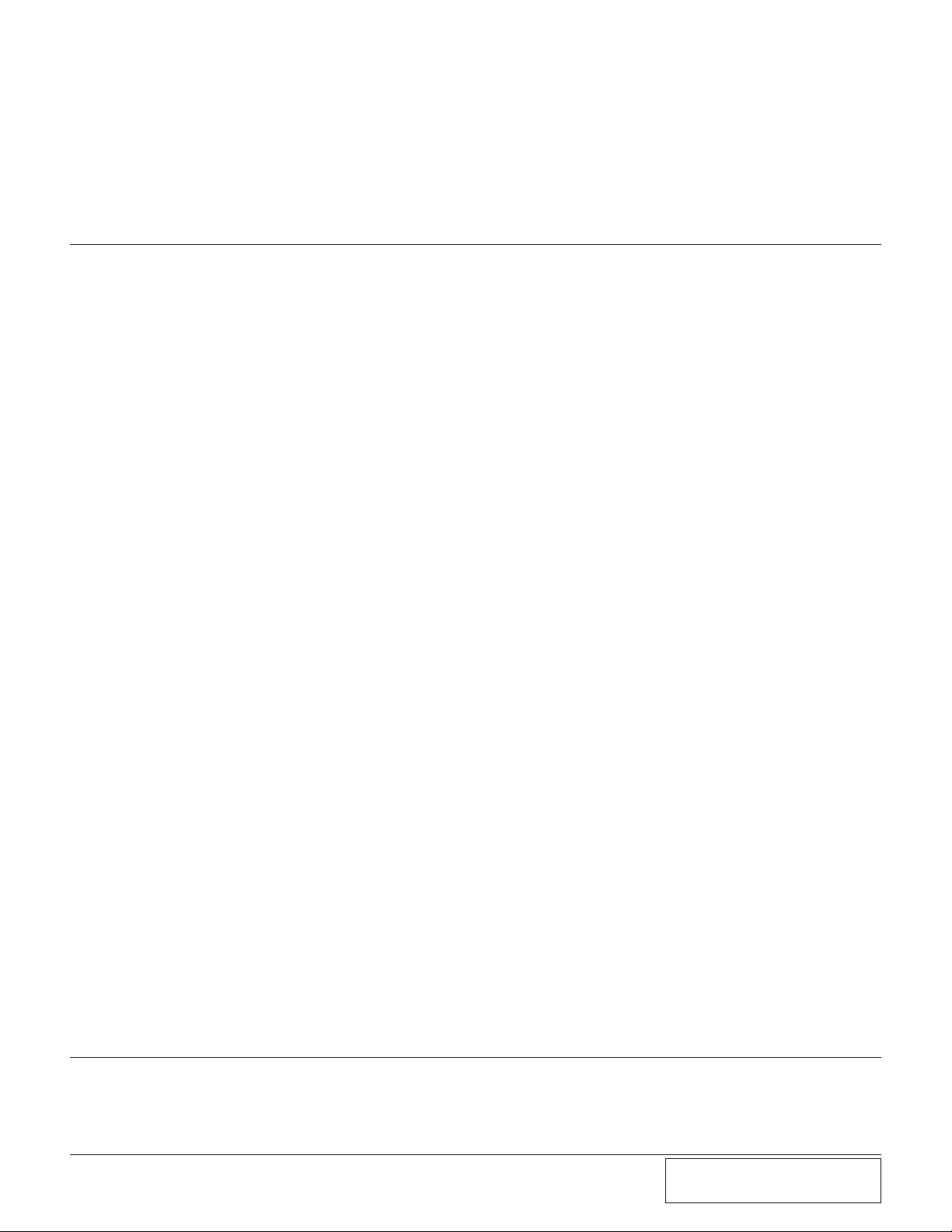

B. Before the air intake assembly can be

removed, you must first disconnect the plastic crankcase breather hose (A) and air idle

bypass hose (B). Unplug the air temperature

sensor (C) and mass air flow sensor (D).

(See Fig. 1-a.)

***NOTE***

(2002-2003 GT only) The air intake temperature sensor is now located in the MAF. (Step “C” no longer

applies.)

Fig. 1-a

A

B

C

D

1.1 INITIAL PREPARATION AND REMOVAL

A. Begin the initial preparation and disassem-

bly process by first disconnecting the negative side of the battery, and draining one gallon of coolant from the coolant reservoir. To

do this, open the valve at the bottom of the

radiator and allow to drain into a suitable

container. DO NOT allow coolant to drain

onto floor, and be sure to mop up any

coolant splatter immediately. Animals like

the taste of coolant, and if they drink it, it

will kill them.

1-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Fig. 1-b

Fig. 1-c

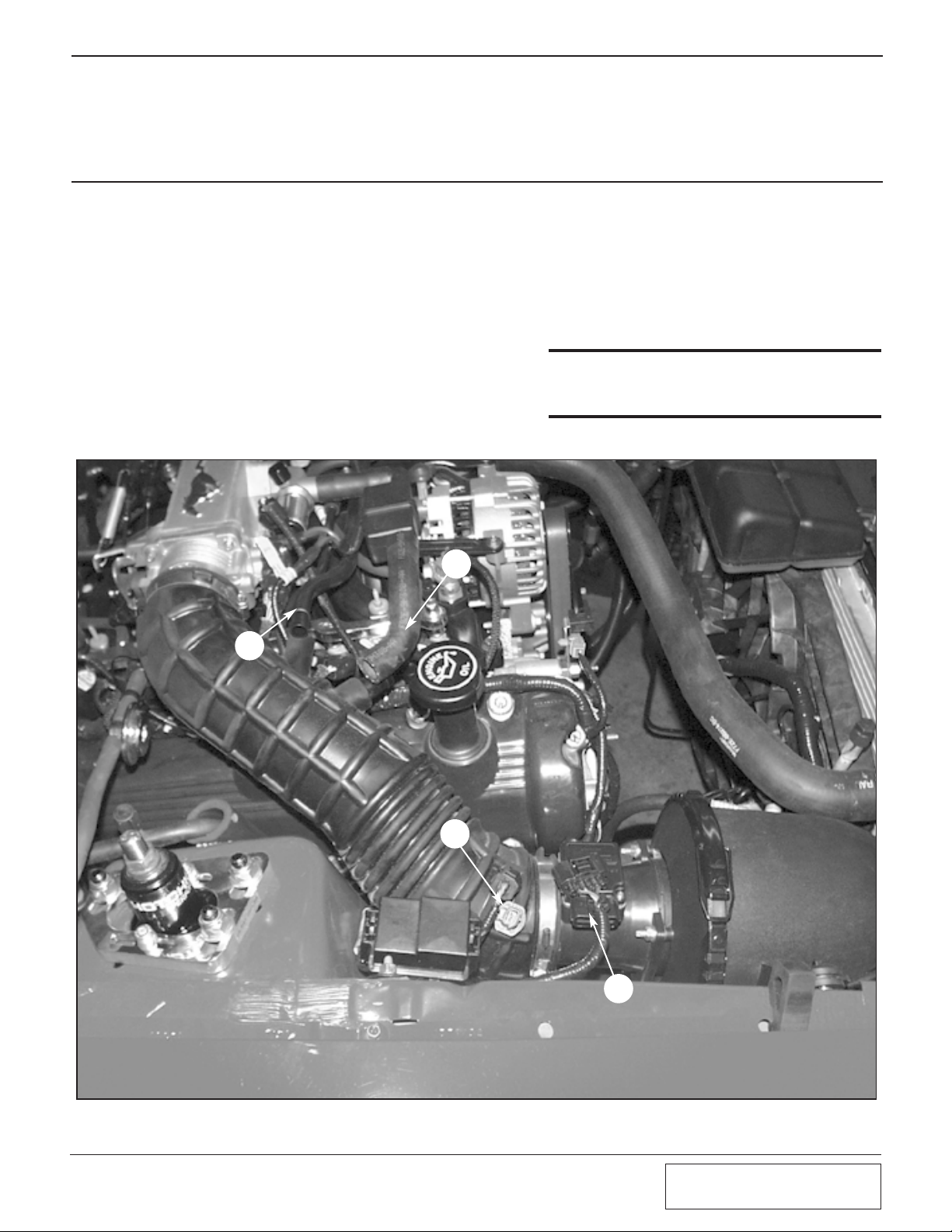

E. Once the assembly is out of the car, use a

10mm socket to remove the mass air flow

sensor and screen from the air filter housing

(see Fig 1-d). Place the mass air flow sensor

aside to be re-installed in a later step.

C. Using a flat-head screwdriver, loosen the

hose clamps at the mass air flow sensor and

the throttle body, and remove the air intake

hose (see Fig 1-b). Remove the air temperature sensor from the air intake hose and

place it aside—it will be re-installed in a

later step.

NOTE: On 2002-2003 GTs this step will not be

done.

D. Use an 8mm socket to remove the single air

filter housing retaining bolt. The air filter

and mass air sensor can then be removed as

an assembly. (See Fig 1-c.)

Fig. 1-d

E. The coolant reservoir is secured by three

nuts (see Fig 1-e). Use a 10mm socket to

remove these, and place the reservoir aside.

Remove the upper radiator hose.

Fig. 1-e

2-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 2

SUPERCHARGER MOUNTING BRACKET ATTACHMENT

2.1 SUPERCHARGER MOUNTING BRACKET ATTACHMENT

Fig. 2-a

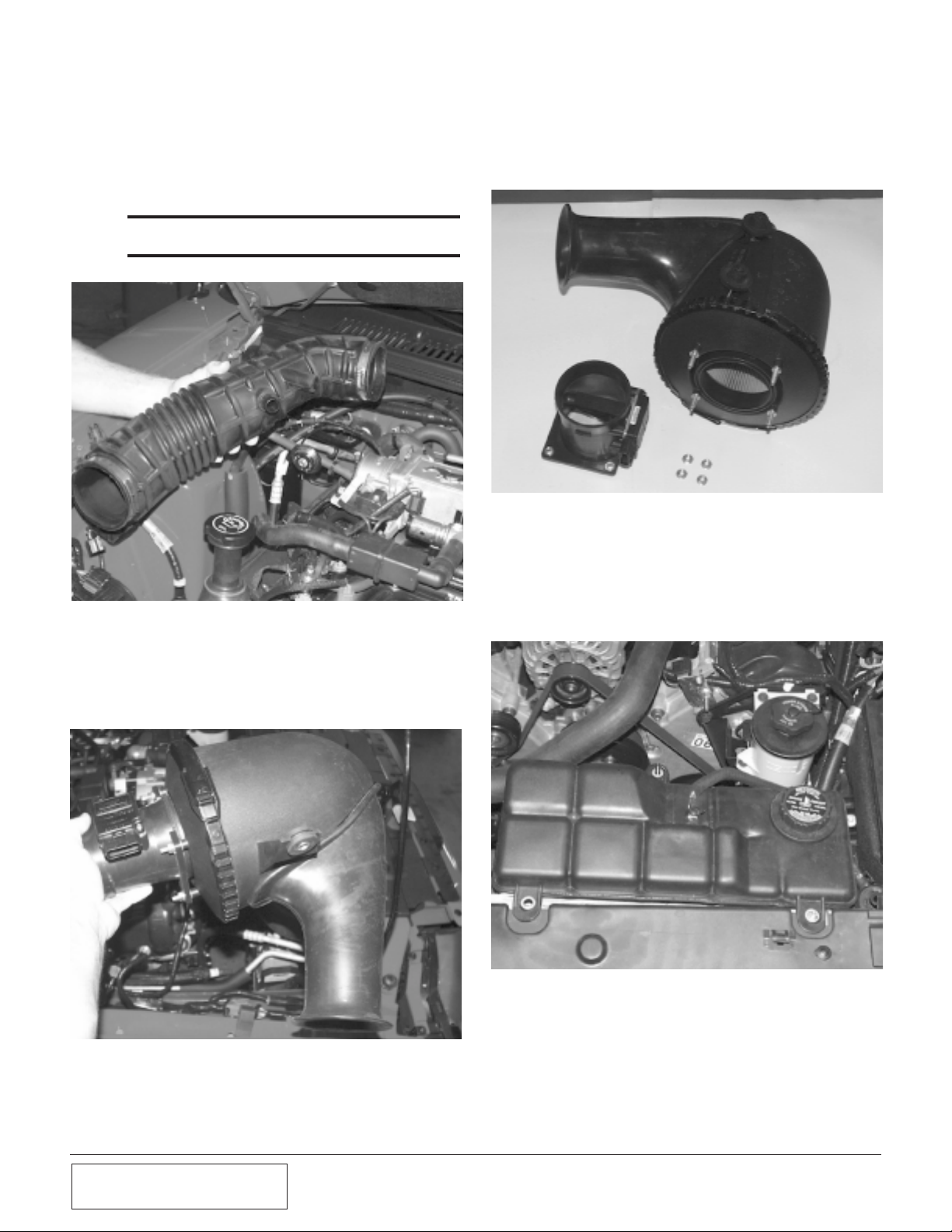

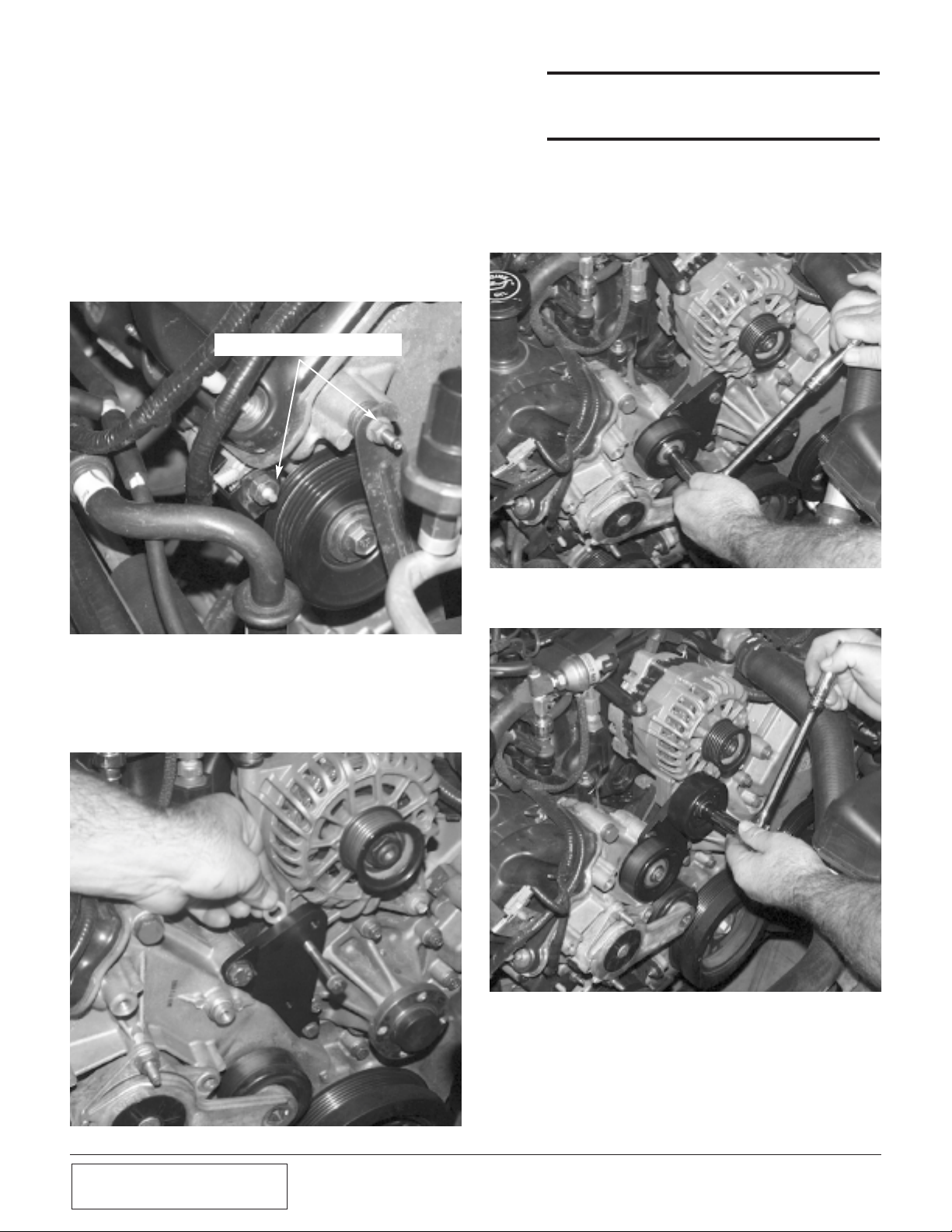

A. Loosen (but do not remove) the four 10 mm

head bolts securing the water pump pulley.

Next, remove the accessory drive belt using

a 3/8-inch drive ratchet or breaker bar into

the square at the end of the tensioner, and

rotate the tensioner clockwise. This will

relieve the tension on the belt so it can be

removed. It will not be re-used. (See

Fig. 2-a.)

B. Use a 13 mm socket to remove the idler pul-

ley, located above the belt tensioner (see Fig

2-b). Place the pulley aside to be used in a

later step. Now, you may finish removing

the four 10mm bolts securing the water

pump pulley, and place the pulley and its

fasteners aside for use in a later step.

IDLER PULLEY

Fig. 2-b

C. Next, remove three bolts at the front of the

engine (see Fig 2-c). A 10mm alternator

mounting bolt (A), and two 13 mm timing

cover bolts (B and C).

Fig. 2-c

C

B

A

2-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

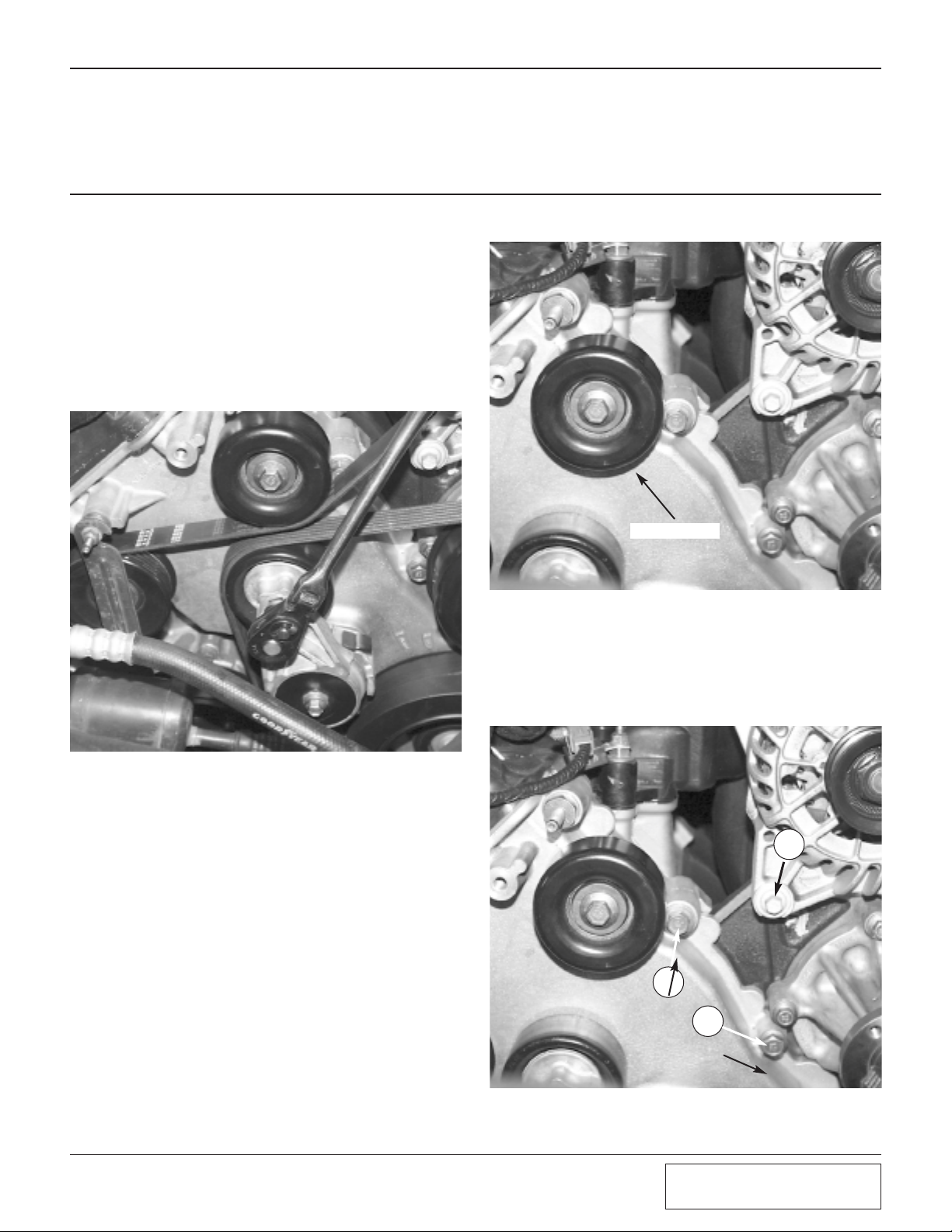

D. Remove both nuts using a 10mm and 13mm

socket. Then remove both studs using a

13mm and 18mm socket. Enlarge the hole in

the tab that held the wiring harness to the

outermost stud. Using a round file, enlarge

the hole so that it will slip over the large

diameter of the stud. This tab will get sandwiched between the cylinder head and a

spacer in a later step.(See Fig 2-d.) Note that

on some of the 2001-2003 GTs this step will

not be required and a .065 shim will go in

its place.

REMOVE THESE TWO STUD BOLTS

Fig. 2-d

E. Install the supercharger idler pulley bracket

using the supplied hardware. Be sure to

install spacer between bracket and alternator.

(See Fig 2-e)

Fig. 2-e

***NOTE***

This photo is for illustration purposes. It will be easier for you to install this bolt/spacer first, then install

the other two mounting bolts.

F. Re-install the factory idler pulley using the

factory hardware (see Fig. 2-f), followed by

the supplied supercharger idler pulley (see

Fig. 2-g).

Fig. 2-f

Fig. 2-g

2-3

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

G. Install the supercharger rear support bracket

as shown in Fig 2-h. Temporarily install the

long 10mm bolt to line up the bracket.

Leave the bolts finger tight, as it will be

necessary to move the bracket when you

install the main supercharger bracket.

(This photo is for illustration only. You will

have to install the supercharger and accessory belt before installing the bracket. There

won’t be clearance after the bracket is

installed.)

Fig. 2-h

Fig. 2-i

H. Modify the previously removed upper radia-

tor hose with supplied hose, aluminum coupler and clamps. See Appendix ‘B’

(1015309) for diagram of modification.

***NOTE***

The radiator hose assembly needs to clear the supercharger, so it is better to leave it long and trim the

assembly later than to end up short. The finished

radiator assembly is shown in Fig. 2-i.

I. Before installing the main supercharger

bracket, the A/C refrigerant refilling port

must be bent from its upright position downward, so that the cap is facing the driver’s

side fender. (See Fig 2-j.)

Fig. 2-j

***NOTE***

If possible, use a proper tubing bender for this step.

If one is not available, the line can be bent by hand,

but extreme care must be taken as the refrigerant

within the line is under very high pressure. In any

case, use a pair of heavy gloves and eye protection to

prevent injury in the event of a ruptured line.

2-4

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

This Page Left Intentionally Blank.

3-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 3

FAN RESISTOR RELOCATION

3.1 FAN RESISTOR RELOCATION

A. Disconnect the wiring harness from the fan

resistor. (See Fig. 3-a.) Remove clips holding the fan resistor to the fan shroud. Attach

the fan resistor to the supplied bracket using

the supplied hardware.

Fig. 3-a

B. Trim the fan resistor mounting tabs on the

fan shroud to provide clearance for the air

intake assembly.(See Fig. 3-b.) The fan

shroud should look like this after trimming.(See Fig. 3-c.)

Fig. 3-b

Fig. 3-c

C. Re-attach the fan resistor to the wiring har-

ness to ensure adequate wire length. (See

Fig. 3-d.) Position the fan bracket on the

passenger side of the lower fan shroud.

Mark two mounting points along the fan

shroud and drill the holes. Attach the mounting bracket with the supplied hardware.

Fig. 3-d

3-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

This Page Left Intentionally Blank.

4-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 4

PREPARING TO MOUNT THE SUPERCHARGER

A. Mount the main supercharger bracket,

installing the two 3/8 bolts and spacers in

the upper portion of the bracket. Install the

long 6mm bolt and spacer in the lower middle portion of the bracket, sandwiching the

A/C support between the spacer and rear

mounting bracket. Next, install the lower

most bolt and two spacers: one in between

the support and main brackets, one in

between the two brackets and the other

between the rear bracket and the cylinder

head. The small metal tab securing the

wiring harness gets sandwiched between the

cylinder head and the spacer. Leave everything finger tight at this point.

***NOTE***

The drive belt, shown in this picture, should be

installed at this point.(See Fig. 4-a.)

4.1 PREPARING TO MOUNT THE SUPERCHARGER

Fig. 4-a

B. Next, install the bolt and spacer at lower

right portion of the bracket. (See Fig. 4-b.)

Go back and tighten all bolts on the mounting bracket, being careful not to over torque

the small 6mm bolt. Install the supplied

drive belt as shown. (See Fig. 4-a.)

Fig. 4-b

C. Install the supercharger oil drain-back hose

on the supercharger. (See Fig. 4-c.)

***NOTE***

The hose clamp screw head should be parallel to

the supercharger mounting base.

Fig. 4-c

4-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

D. Remove the drive belt from the alternator

pulley. Install the supercharger into the main

bracket, while looping the drive belt around

the supercharger pulley. (See Fig. 4-d.)

Fig. 4-d

E. Tighten the supercharger mounting bolts.

Once the supercharger is installed, release

the belt tensioner and loop the belt back

around the alternator pulley. (See

Appendix K for a diagram of the drive belt

routing.)

***NOTE***

For maximum performance, PAXTON Automotive recommends the factory stock platinum spark plugs be

replaced with a copper spark plug (Autolite 764 or

equivalent) gapped to .035.

F. Remove the two 8mm bolts on either end of

the Fuel Injector Rail and lift the unit out.

Replace the stock injectors with the supplied

injectors. Use white lithium grease on the

O-rings to insure a smooth fit.

Fig. 4-e

5-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 5

OIL FEED AND DRAIN LINES

5.1 OIL FEED AND DRAIN LINES

A. Your Paxton Automotive NOVI 1000 super-

charger uses pressurized engine oil for lubrication. Use an oil sending unit socket (SnapOn tools; part number 6152 or equivalent) to

remove the oil sending unit on the underside

of the oil filter housing (see Fig 5-a). Install

the supplied brass junction fitting using a

small amount of Teflon paste. DO NOT

USE TEFLON TAPE. Once installed, the

junction fitting should be oriented so that

the opening faces toward the front of the car.

Fig. 5-a

B. Install the oil sending unit in the end of the

brass junction. Install the 90 degree 1/8-inch

to -4 fitting into the side of the brass junction, and orient this fitting to face towards

the driver’s side frame rail. Attach the supplied length of braided stainless steel feed

line, and route upwards to the 90 degree fitting on the supercharger.

***NOTE***

Be sure to stay clear of any moving parts or coolant

hoses (engine vibration can cause the stainless line

to chafe the rubber coolant hose, creating a leak over

time). Install the line, and tighten moderately—no

sealant is required. (See Fig. 5-b.)

Fig. 5-b

C. Mark the front of the oil pan 1" inch below

the pan rail and between the the two pan rail

bolts, directly in the center of the small

‘hump’. (See Appendix G.) Cover a 3/16inch drill bit with heavy grease and drill a

pilot hole (see Fig. 5-c). The grease will

help prevent metal particles from falling into

the pan. Once the hole has been drilled,

insert a straight length of welding rod or

heavy wire (such as a coat hanger) into the

hole approximately three inches to make

sure no interference is encountered. If the

path is blocked, turn the engine over until

the pathway is clear.

Fig. 5-c

5-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

D. Next, apply a small amount of anti-seize

lubricant to the tip of the punch, and insert it

into the pilot hole. Hit the punch with an air

hammer carefully using small bursts, until

the punch is inserted up to its shoulder. The

hole should measure 9/16". (See Fig 5-d.)

NO DEEPER THAN THIS

Fig. 5-d

***NOTE***

Do not use hand tools. Using an ordinary hammer

will dent the pan. Use extreme caution not to make

the hole to big, or the drain fitting will not fit and the

pan will be ruined.

E. Apply a liberal amount of heavy grease to a

3/8 inch x 16 NPT tap (not included), and

gradually thread into the hole. Clean the

threads using a clean rag and an approved

solvent, such as carburetor cleaner.

F. Apply a ample amount of silicone RTV to

the threads of the supplied 3/8-inch pipe to 8 fitting and insert into the hole, being careful not to over-tighten. (See Fig. 5-e.)

Fig. 5-e

G. Install the supercharger drain-back hose fit-

ting so that the elbow is oriented toward the

passenger side, away from the harmonic balancer/crank pulley.(See Fig 5-f.)

Fig. 5-f

6-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 6

INTAKE TRACT MODIFICATIONS

6.1 INTAKE TRACT MODIFICATIONS

A. Install the discharge tube assembly as

shown, using the supplied rubber sleeves

and stainless steel clamps. (See Fig. 6-a.)

Fig. 6-a

B. Install the supplied length of rubber hose to

the end of the hard crank case ventilation

line that runs from the driver’s side valve

cover across the engine, (see Fig 6-b). Route

the hose over the passenger side valve cover

and towards the front of the engine.

Fig. 6-b

C. Install the idle air control valve to the throt-

tle body housing with the original hose, and

to the discharge tube with the supplied

length of rubber hose and hose clamps. (See

Fig 6-c.)

Fig. 6-c

D. The supercharger bypass valve requires a

vacuum source. Remove the existing plastic

coupler in the vacuum hose that runs along

the firewall on the passenger side. Replace

with the supplied vacuum ‘T’.( See Fig 6-d.)

Attach the supplied length of vacuum hose,

and route along the passenger side frame rail

towards the supercharger. It will be connected to the bypass valve assembly in a later

step.

Fig. 6-d

6-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

E. Remove the screen from the MAF, which

was removed in step 4.(See Fig. 6-e.)

Fig. 6-e

F. Assemble the MAF, mounting bracket,

MAF/air filter adapter and air filter. The

MAF bracket assembly may look different

from what you receive in your kit, but the

assembly procedure is the same.

G. Using the supplied 1/4-20 hardware, mount

the MAF meter to the MAF bracket and

secure. Remove the factory MAF screen

before attaching the meter to the new bracket.

Fig. 6-f

Fig. 6-g

H. Attach the supplied K & N air filter, 3-1/2”

sleeve, 90° 3-1/2” elbow and #56 hose

clamps to the MAF and secure.

I. Insert the factory air temperature sensor into

the rubber grommet located on the side of

the supplied 3-1/2" x 90° elbow. Lubricate

for easier fit.

***NOTE***

2002-2003 models do not have a separate IAT sensor. Use the supplied elbow without

a hole or grom-

met for 2002-2003 models only.

J. Using a #52 hose clamp, connect the piece

of 3-1/2” flex hose to the elbow attached to

the MAF meter and route it through the

opening in the right side inner fender toward

the supercharger. Make sure the 3 1/2” flex

hose does not contact or rub on the edge of

the inner fender opening. (Eventual hose

failure will result if the hose is not properly

routed.)

K. The MAF/air filter assembly will be relocat-

ed inside the passenger fender. Remove the

two nuts that secure the passenger side

bumper cover to the inner fender. (See Fig.

6-g.) Next, locate the screw at the forward,

lower edge of the passenger side wheel

opening and remove it. This will allow the

plastic inner fender to be pulled back so the

MAF/air filter assembly can be installed.

MAF BRACKET

MOUNTING LOCATION

6-3

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Fig. 6-h

L. Place the MAF/air filter bracket over the

existing studs, then secure with the original

nuts. (See Fig. 6-h.)

M. Carefully open the main wiring harness

(runs from the passenger side inner fender

into the engine compartment) with a razor

blade, making an incision that is approximately 6-inches long. Pull the MAF wiring

upwards, until the wires are long enough to

be routed back through the opening in the

inner fender, and down to the MAF. (See

Fig. 6-i.)

Fig. 6-i

P. Connect the plastic inlet duct (with bypass

valve and hoses attached) to the supercharger inlet. This is to illustrates what the MAF

assembly should look like after assembly.

(See Fig. 6-k.)

Fig. 6-k

N. Insert the 1" x 10" rubber hose to the inlet of

the compressor bypass valve. Secure both

hoses with the supplied #16 hose clamps.

O. Install the bypass valve assembly on the

underside of the secondary intake tube. (See

Fig. 6-j.) Tighten the hose clamp to secure

the valve assembly to the intake tube.

Fig. 6-j

FACTORY AIR

TEMPERATURE SENSOR

(NOT ON 2002+ MODELS)

3-1/2" ELBOW

SLEEVE

#56 CLAMPS

FACTORY

STUDS & NUTS

INSIDE

RIGHT FRONT

PASSENGER

FENDERWELL

FRONT

6-4

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Fig. 6-l

T. Place the secondary intake tube/bypass

valve assembly on the supercharger inlet,

and attach it to the flex hose. Attach the

other end of the bypass valve to the discharge tube. Connect the hose that was previously installed on the hard plastic crank

case ventilation line to the brass fitting on

the intake tube. Tighten the clamps. The finished installation appear as in Fig. 6-m.

Fig. 6-m

Q. Join the supercharger inlet duct to the previ-

ously installed MAF hose with the supplied

#52 hose clamp.

R. Connect the opposite ends of each hose to

the crankcase breather fitting on the driver’s

side valve cover (5/8” hose) and the idle air

control resonator (3/x4” hose). Trim hose

length if required.

S. Install the 5/8” hose union into the

crankcase breather line. It may be necessary

to trim this line to ensure a proper fit. (See

Fig. 6-l.)

7-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Fig. 7-a

Section 7

ENGINE CONTROL COMPUTER REMOVAL AND MODIFICATION

7.1 ENGINE CONTROL COMPUTER

REMOVAL AND MODIFICATION

B. Pull the harnesses down and out of the way,

creating unobstructed access to the computer. Remove the 7/32 screw that secures the

retention strap (see Fig. 7-b) and pull the

computer out of the foot well.(see Fig. 7-c.)

A. Remove the passenger side door sill plate,

followed by the passenger side kick panel.

This will reveal the engine control computer

and its harnesses. The harnesses are secured

using clips, which are attached to a small

metal bracket. Pull the harnesses off the

bracket, then remove the two 7/32-inch bolts

that secure the bracket itself. Remove the

bracket.(See Fig. 7-a.)

Fig. 7-b

Fig. 7-c

7-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

D. Remove the 10mm bolt that secures the

main harness to the computer, and remove

the harness. (See Fig. 7-d.)

E. Once the computer is removed from the car,

you will need to send your computer and the

chip voucher to Paxton Automotive. The

computer will be cleaned, a computer chip

installed and returned to you, ready to be

install back into your vehicle.

Fig. 7-d

8-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 8

IN-TANK FUEL PUMP INSTALLATION

8.1 IN-TANK FUEL PUMP INSTALLATION (2001-2002 Models Only)

A. Raise the rear of the car and support it with

jack stands.

B. Open the fuel door and remove the fuel cap

and the three filler neck screws using a

10mm socket.

C. Remove the fuel filter inlet line with a 3/8"

spring-lock tool.

D. With the weight of the fuel tank supported

with a jack, remove the bolts securing the

two fuel tank straps.

E. Slowly lower the fuel tank, allowing it to

lean over with the filler side up until the

electrical connections leading to the center

mounted fuel pump are revealed. Disconnect

these two electrical connections.

F. Remove the six bolts securing the fuel pump

access cover (on top of the fuel tank) with

an 8mm wrench. Depress the two clips

securing the plastic fuel pump enclosure and

slide it out of the tank. The fuel sender float

is attached to the fuel pump enclosure and

must be handled with care. Ensure that the

tank has been lowered enough to remove the

fuel pump enclosure.

G. Remove the two screws securing the plastic

fuel pump outlet manifold to the enclosure

cap. Pull the manifold up and away from the

fuel pump.

H. Remove the three screws securing the fuel

pump enclosure's cover using a 3/16" nut

driver and remove the cover. Modify the

fuel pump cover as shown. (See Figs. 8.1-a,

8.1-b.)

I. This allows the larger O.D. pump to fit in

the cover.

J. Remove the stock fuel pump from its enclo-

sure. Separate the rubber pump support from

beneath the filter and install it on the supplied pump. Secure the support with the new

pump provided.

K. Cut the two fuel pump power wires about 1"

from the fuel pump electrical connector.

Noting the corresponding (+) and (-) connections, splice the supplied wiring harness

into place using two butt connectors.

L. Using the supplied fuel pump, reassemble

the fuel pump assembly and canister with

cap. Install the supplied 1/8" spacers beneath

the pump outlet manifold and canister cap

and install the modified pump assembly.

(See Fig. 8.1-c.)

Fig. 8.1-a

Fig. 8.1-b

TRIM TO TABS

Fig. 8.1-c

PLASTIC

FUEL PUMP

OUTLET

MANIFOLD

BYPASS

TUBE

PUMP CANISTER

VORTECH SUPPLIED

#6 x .75" SCREWS

FUEL PUMP OUTLET

SUPPLIED 1/8"

SPACERS

FUEL

OUTLET

HOSE

8-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Fig. 8.2-a

M. Remove the screen from the bottom of the

canister assembly being careful not to puncture flapper valve. (See Fig. 8.2-b.)

N. Reinstall the fuel tank, reconnect the fuel

filter inlet line, reattach the fuel filler neck,

and reinstall the fuel pump.

O. Turn the ignition key on and check for fuel

leaks.

The installation is complete.

Congratulations!

Fig. 8.2-b

A. Raise the rear of the car and support it with

jack-stands.

B. Open the fuel door and remove the fuel-cap

and the three filler neck screws using a

10mm socket.

C. Remove the fuel filter inlet line with a 3/8

springlock tool.

D.With the weight of the fuel tank supported

with a jack, remove the bolts securing the

two fuel tank straps.

E. Slowly lower the fuel tank, allowing it to

lean over with the filler side up, until the

electrical connections leading to the center

mounted fuel pump are revealed. Disconnect

these two electrical connections.

F. Remove the six bolts securing the fuel pump

access cover (on top of the fuel tank) with

an 8mm wrench. Depress the two clips

securing the plastic fuel pump enclosure and

slide it out of the tank. The fuel sender float

is attached to the fuel pump enclosure and

must be handled with care. Ensure that the

tank has been lowered enough to remove the

fuel pump enclosure.

G. Remove the two screws securing the plastic

fuel pump outlet manifold to the enclosure

cap. Pull the manifold up and away from the

fuel pump. (See Fig. 8.2-a.)

H. Remove the three screws securing the fuel

pump enclosure’s cover using a 3/16 nutdriver and remove the cover.

8.1 IN-TANK FUEL PUMP INSTALLATION (2001-2002 Models Only), cont’d.

8.2 IN-TANK FUEL PUMP INSTALLATION (2003 Models Only)

I. Remove the stock fuel pump from its enclo-

sure. Separate the rubber pump support from

beneath the filter and install it on the supplied pump. Secure the support with the new

filter provided.

J. Using the supplied fuel pump, reassemble

the fuel pump assembly and canister with

cap.

K. Reinstall the canister assembly into the fuel

tank and reattach the electrical connections.

L. Reinstall the fuel tank, reconnect the fuel fil-

ter inlet line, reattach the fuel filler neck and

reinstall the fuel cap.

M. Turn the ignition key on and check the fuel

pump for leaks.

PLASTIC

FUEL PUMP

OUTLET

MANIFOLD

BYPASS

TUBE

PUMP CANISTER

FUEL

OUTLET

HOSE

FUEL PUMP OUTLET

8-3

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Fig. 8-c / Completed Installation

8-4

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

This Page Left Intentionally Blank.

9-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Section 9

FINAL ASSEMBLY AND CHECK

W

e know that you are anxious to get out

and drive your new vehicle, but please

take a little bit more time to perform

these simple check-out steps.

A Inspect all wiring harnesses and electrical

connections. Make sure that all items are

properly routed, connected and secured. If

available, check grounds with an amp meter.

If the ground connection is suspect, connect

to the battery ground.

B. Check all hoses, lines, and fittings for prop-

erly secured connections..

C. Make certain all fasteners, brackets, and

clamps are installed and properly tightened.

D. Check serpentine accessory belt and super-

charger drive belts for proper tension and

alignment.

E. Cycle ignition key from “off” to the “on”

position 4-5 times.

F. Check the entire fuel system for possible

leaks.

G. Start engine and verify that the oil pressure

is within normal range.

H. Allow the engine to come up to normal

operating temperature.Turn the engine off.

I. Check the coolant level in the coolant recov-

ery bottle and top off as needed.

J. Check the following:

• Fluid Leaks

• Fluid Levels

• Belt Slippage

• Throttle Response

Now that the work is done, it’s time to enjoy.

PAXTON Automotive wants to thank you for

choosing our product, and wants to remind you that

the performance and response of your vehicle is

now different that what you are used to. Please

drive cautiously until you have grown accustomed

to the feel of your vehicle.

Please see the service manual included in your kit

for information on the service and maintenance of

your PAXTON Supercharger. Belt tightening,

troubleshooting, special tuning requirements, and

warranty information is also included in the

Service Manual.

9.1 FINAL ASSEMBLY AND CHECK

9-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

This Page Left Intentionally Blank.

A-1

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

APPENDIX

A-2

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Please realize that PAXTON Automotive is con-

stantly improving the performance and look of the

NOVI 1000 supercharger. Parts in your kit may

appear differently than what is pictured in this manual. This is due to photographs taken in pre-production, a change in material, costs, or an improvement

in performance.

Rest assured that you have purchased the best quality

kit that PAXTON Automotive manufactures at this

time. The installation of the materials will remain the

same.

List of Appendices

Appendix Number.... ..DWG Number............... .DWG Title

Appendix A 1011816 ASY, S/C NOVI 1000

Appendix B 1015309 ASY, RADIATOR HOSE MODIFICATION

Appendix C 1016630 ASY, S/C MOUNTING BRACKET

Appendix D 1015933 ASY, AIR INTAKE

Appendix E 1017017 ASY, AIR DISCHARGE

Appendix F 1019336 ASY, OIL SUPPLY

Appendix G 1019328 ASY, OIL RETURN

Appendix H 1015506 ASY, COMPRESSOR BYPASS

Appendix I 1015530 ASY, FAN RESISTOR RELOC.

Appendix J 1017734 ASY, FUEL PUMP

Appendix K 7000170 DIAGRAM, BELT ROUTING

A-3

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

NUT CORNER IN

Appendix A 1011816 ASY, S/C NOVI 1000

LINE WITH EDGE

B

REV.

SHEET 1 OF 1

1011816

1300 BEACON PLACE OXNARD, CA 93033

SAME ROTATION

AS 1011810

S/C ROTATION

ASY, GEARCASE, NOVI 1000, CCW

FTG, NIPPLE, 3/8NPT X 1/2 HOSE, MODIFIED

FTG, PLUG 3/8NPT WITH MAGNET

WASHER, COPPER CRUSH, 3/8

OIL JET, LG.

SCREW, SCHD, 3/8-16UNC-2A X 1.00 LG.

CAP, SHIPPING, T2

KEY, 1/8 SQ X 1.25 LG.

SPACER, PULLEY, .185 THK.

PULLEY, S/C 6 GRV 3.25

RET, CUP BLWR PULLEY

RET, PULLEY, S/C, 3/8

CAP, TAMPER PROOF

SCREW, HXHD, 3/8-24UNF-2A X 1.00 LG.

VOLUTE, NOVI 1000, CCW, STR DISCHARGE

CLAMP, VOLUTE

SCREW, HXHD, 1/4-20UNC-2A X .50 LG.

SCREW, SET, 1/4-20UNC-2A X .50 LG.

CAP, SHIPPING, 3"

CAP, SHIPPING, 4"

NAMEPLATE, NOVI 1000

SCREW, DRIVE, #4 X .187 LG.

IMPELLER, NOVI 1000, CCW, BALANCED

WASHER, ANTI-ROTATION

NUT, 3/8-24UNF-2B, FLG LOCK

MATING RING, .090 THK

MATING RING, .090 THK

SHIM, IMP, .003 THK.

SHIM, IMP, .003 THK.

SHIM, IMP, .005 THK.

SHIM, IMP, .010 THK.

MATING RING, .099 THK

7P375-016

7J375-024

7PP375-017

008704

7P375-104

7PP375-090

2H229-000

20

112211221111111662111411110010000

123456789

ITEM NO. QTY. PART NO. DESCRIPTION

19

3

25

24

008718

7U100-075

2H017-185

2H036-325

2H040-021

2H040-011

10111213141516171819202122232425262627272829303132

7B375-110

2H019-021

2H100-040

008706

7A250-051

7A250-052

008719

2H100-030

7U100-021

2H021-201

2H017-021

7G010-155

2H060-030

2H060-030

2

2H100-003

2H100-003

2H100-005

2H100-010

2H060-031

2

TEL: (805) 604-1336 FAX: (805) 604-1337

MATING RING, .103 THK

MATING RING, .112 THK

2H060-040

2H060-041

0

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

98-03 4.6L MUSTANG GT

DATE

12/04/01

A. PROCTOR

APPROVALS

DRAWN

4.6L 2V, 2000-2001, SATIN

ASY, S/C NOVI 1000 REVERSE ROTATION,

D

SIZE DWG. NO.

----10/4/01

12/04/01

----------

G. COMPTON

G. COMPTON

ENGINEERING

R&D

APPR.

DO NOT SCALE DRAWING

3:4

SCALE:

20.8 LBS

WEIGHT

18

7

5

4

15

2

23

4

2

29

28

32

27

AS REQD.

31

2

30

26

AS REQD.

2

21

22

4

4 REQD

6

9

8

6 REQD.

17

16

1

3

3

2

7

10

.XXX±.005

±1/2•

.XX± .01

NONE

SEE PARTS LIST

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

FINISH

SHORT HUB AWAY

FROM S/C

11

12

14

13

A-4

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

A

Appendix B 1015309 ASY, RADIATOR HOSE MODIFICATION

REV.

1015309

SHEET 1 OF 1

TO MODIFIED STOCK RADIATOR HOSE

1.25" INTERNAL DIAMETER

CUT HERE

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

99-03 4.6L MUSTANG GT

237R002-024 CLAMP, HOSE #24

314PFH014-011 REDUCER, RADIATOR HOSE

414PFH014-020-1

ITEM NO. QTY. PART NO. DESCRIPTION

1

DATE

9/18/00

AP

1.50" INTERNAL DIAMETER

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

ENGINEERING

±1/2•

.XXX±.005

.XX± .01

ASY, RADIATOR HOSE MODIFICATION

R&D

DO NOT SCALE DRAWING

D

1:1.25

SCALE:

SIZE DWG. NO.

?.? LBS

APPR.

WEIGHT

NONE

SEE PARTS LIST

ANGLES: ±1/16

CUT HERE (1" FROM END)

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

FINISH

2

MODIFIED

4

3

2

TO RADIATOR

2

A-5

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

TO STOCK

Appendix C 1016630 ASY, S/C MOUNTING BRACKET

B

REV.

SHEET 1 OF 1

1016630

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

99-03 4.6L MUSTANG GT

PLATE, FRONT, S/C MTG BRKT

WASHER, FLAT, 3/8

SCREW, HXHD, 3/8-16UNC-2A x 1.25 LG.

SCREW, HXHD, 3/8-16UNC-2A x 2.75 LG.

SPACER, .875 x .404 x 1.565 LG.

SPACER, .875 x .328 x 1.500

SPACER, FLARED, 3/8

PLATE, IDLER MTG

SPACER, .750 x .328 x .130 LG.

PLATE, REAR, S/C MTG BRKT

SCREW, HXHD, M8 x 1.25 x 30mm

COLLAR, IDLER

PULLEY, IDLER

RET, PULLEY, 3/8

SPACER, .875 HEX x 1.275 LG.

SPACER, .875 x .404 x 1.235 LG.

WASHER, FLAT, 6mm

SCREW, SCHD, M6 x 1.00 x 80mm

SCREW, HXHD, 3/8-16UNC-2A x 4.75 LG.

STUD, M8 x 1.25 X 3.35" LG.

SCREW, HXHD, M8 x 1.25 x 65mm

WASHER, FLAT, 5/16

SCREW, HXHD, M8 x 1.25 x 50mm

WASHER, FLAT, 10mm

SCREW, HXHD, M10 x 1.50 x 60mm

SCREW, HXHD, M8 x 1.25 x 55mm

SCREW, HXHD, 3/8-16UNC-2A x 1.75 LG.

SCREW, HXHD, M8 x 1.25 x 160mm

SCREW, FHSH, M8 x 1.25 x 20mm

9

BELT, 6 GRV

DO NOT SCALE DRAWING

ASY, S/C NOVI 1000 FOWARD ROTATION

PROWLER, POLISHED WITH UPGRADE

D

1:1.5

SIZE DWG. NO.

11/6/00

12/11/00

12/11/00

L. KECK

G. COMPTON

G. COMPTON

ENGINEERING

R&D

APPR.

SCALE:

7.3 LBS

WEIGHT

TO ENGINE

8

2221

20

7J375-044

7A375-124

7A375-276

4PFL010-034

110623111111111111111161112111

123456789

ITEM NO. QTY. PART NO. DESCRIPTION

4PFL017-011

2A017-875-02

2A017-876-02

26 22

15

26 22

12

10

13

1210517

7J006-093

7C060-080

7A375-475

7C080-066

7K312-001

7C080-051

7J010-002

7C080-030

4PFL010-021

2H040-011

4PFL010-044

4PFH017-021

2A017-750-03

4PFL017-021

2A017-875-06

101112131415161718192021222324252627282930

7PC080-335

1

1

7C010-060

1

1

1

2223

REPLACE STOCK FLANGE-HEAD

7C080-056

7A375-178

7C080-160

7C080-023

2A046-073

1

1

A

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DATE

10/25/00

A. PROCTOR

APPROVALS

DRAWN

29

16

2211

5

5

6

TO S/C

5

2

3

1

24

25

TO STOCK

TO S/C

23

ON TIMING COVER

REPLACE STOCK STUD

14

±1/2•

.XXX±.005

2

27

.XX± .01

NONE

SEE PARTS LIST

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

FINISH

7

1

TO ENGINE

2

19

17

18

4 2

TO ENGINE

22

28

TO ENGINE

NOTES: UNLESS OTHERWISE SPECIFIED:

A-6

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

TO S/C INLET

Appendix D 1015933 ASY, AIR INTAKE

SLEEVE, 3.50" ID x 2.00"L

CLAMP, HOSE, #56

FILTER, AIR w/CLAMP

CLAMP, HOSE, #64

INTAKE ELBOW, 90°

GROMMET, RUBBER 7/16"

8H040-090

7R002-064

4FH012-012

1

17

SCREW, 1/4-20 x 3/4", ZINC

7A250-075

7U100-052

9

MAF BRACKET

7R002-056

7PS350-200

Mustang MAF

4FH010-050-BENT

11213114442111111

1

1245678

3

ITEM NO. QTY. PART NO. DESCRIPTION

TO STOCK

PVC HOSE

WASHER, 1/4" SAE

NUT, 1/4-20 w/NYLOCK

CLAMP, HOSE, #52

HOSE, FLEX, 3.50" ID x 9.0"L

TUBE, AIR INTAKE, MODIFIED

FTG, ELBOW, 90°, 1/2" HOSE BARB x 3/8 NPT

ELBOW, RUBBER, 4" ID x 90°

1/2" OIL DRAIN HOSE

7J250-001

7F250-021

7P375-055

7S400-001

7R002-052

7U035-001

4PFK012-011

7U030-036 x 45

111213141516171819

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

COUPLING, INLINE HOSE, 1/2"

7P500-001

1

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

99-03 4.6L MUSTANG/MUSTANG GT

DATE

10/23/00

A. PROCTOR

APPROVALS

DRAWN

10/30/00

G. COMPTON

ENGINEERING

REV.

ASY, AIR INTAKE

SIZE DWG. NO.

10/30/00

10/30/00

L. KECK

G. COMPTON

APPR.

R&D

D

SHEET 1 OF 1

1015933

DO NOT SCALE DRAWING

D

1:2

SCALE:

10.3 LBS

WEIGHT

STOCK AIR SENSOR

11

7

5

.XX± .01

.XXX±.005

±1/2•

NONE

SEE PARTS LIST

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

15

13

4

8

TO COMPRESSOR

16

4

11

12

14

4

10

9

FINISH

6

3

3

2

1

NOTES: UNLESS OTHERWISE SPECIFIED

A-7

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

TO THROTTLE BODY

Appendix E 1017017 ASY, AIR DISCHARGE

5

9

TO ANTI-REVERSION

5

SLV, BLK, 3.00D x 2.00

HOSE CLAMP,

CLAMP, HOSE #10

7R002-048

7R002-010

7PS300-200

4PFH012-020

23

46

52

71

ITEM NO. QTY. PART NO. DESCRIPTION

4PFH012-020

4PFH012-048

111

131

1017017-P

ASY ITEM QT PART

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

99-03 4.6L MUSTANG GT

7U038-000-9

4PFH012-041

81

91

DATE

10/20/00

A. PROCTOR

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

4PFH012-028

TEST1

1

1017018

DRAWN

.XXX±.005

±1/2•

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

A

REV.

1017017

ASY, AIR DISCHARGE

D

SIZE DWG. NO.

10/30/00

10/23/00

10/30/00

L. KECK

G. COMPTON

G. COMPTON

APPR.

ENGINEERING

R&D

NONE

SEE PARTS LIST

MATERIAL

FINISH

SHEET 1 OF 1

DO NOT SCALE DRAWING

1:1.75

SCALE:

3.6 LBS

WEIGHT

7

TO S/C OUTLET

6

4

3

2

NIPPLE ON P/N 4810127-6

8

A-8

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

B

Appendix F 1019336 ASY, OIL SUPPLY

REV.

SHEET 1 OF 1

1019336

1300 BEACON PLACE OXNARD, CA 93033

TO S/C ASY

3

TEL: (805) 604-1336 FAX: (805) 604-1337

ASY, S/C OIL SUPPLY

99-03 4.6L MUSTANG GT

DATE

6/14/99

DO NOT SCALE DRAWING

C

3:4

SCALE:

SIZE DWG. NO.

HOSE, OIL SS BRAID, AN4 x AN4, 46.5" LG.

OIL FEED HOSE, 46.5" -4 STRT

FTG, STREET TEE, 1/4NPT

FTG, 90° ELBOW, AN4 x 1/8NPT

FTG, 90° ELBOW, AN4 x 1/4NPT

2

7U250-000-465

7P250-034

7P125-004

7P250-082

4

STOCK OIL SENDER LOCATION

1

111

123

ITEM NO. QTY. PART NO. DESCRIPTION

1

4

JFC

.2 LBS

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

APPR.

ENGINEERING

R&D

SEE PARTS LIST

ANGLES: ±1/16

MATERIAL

WEIGHT

NONE

FINISH

DRAWN

.XXX±.005

±1/2•

.XX± .01

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

A-9

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

TO S/C ASY

Appendix G 1019328 ASY, OIL RETURN

C

REV.

SHEET 1 OF 1

1019328

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

ASY, OIL RETURN

99-03 4.6L MUSTANG

5

7

FTG, HOSE END, AN8 X 1/2 BARB

FTG, 90^ SWIVEL, AN8 MALE X AN8 FEM

FTG, STR, AN8 X 3/8 NPT

CLAMP, HOSE, #10

PUNCH, OIL PAN

7P500-063

7P500-052

7P375-053

7R002-010

7T640-011

7U030-036x13

11121

23456

ITEM NO. QTY. PART NO. DESCRIPTION

1

7

1

DATE

4/5/00

JFC

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

.XXX±.005

±1/2•

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

C

SIZE DWG. NO.

ENGINEERING

R&D

APPR.

SEE PARTS LIST

MATERIAL

FINISH

DO NOT SCALE DRAWING

3:4

SCALE:

.8 LBS

WEIGHT

NONE

1.00

1.75

OIL PAN

PUNCH HOLE

WITH ITEM 6

LOCATION FOR ITEM 5

5

2

3

(FRONT OF OIL PAN)

TO OIL PAN

4

NOTES: UNLESS OTHERWISE SPECIFIED

1. SHIP THIS ITEM LOOSE.

A-10

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

D

Appendix H 1015506 ASY, COMPRESSOR BYPASS

REV.

SHEET 1 OF 1

1015506

1300 BEACON PLACE OXNARD, CA 93033

CLAMP, HOSE #16

TEE, VACUUM, 1/4"

VALVE, BY-PASS

TO EXISTING VACUUM LINE

6

10

2.50±.06

-02

5

8D001-001

7R002-016

7P156-082

14111

146

ITEM NO. QTY. PART NO. DESCRIPTION

7U030-046 x 36"

7U133-100-02

7U133-100-01

1

101112

D

TEL: (805) 604-1336 FAX: (805) 604-1337

99-03 4.6L MUSTANG

ASY, COMPRESSOR BY-PASS

DATE

8/22/99

JFC

DO NOT SCALE DRAWING

D

3:4

SCALE:

SIZE DWG. NO.

2.8 LBS

APPROVALS

CAD GENERATED DRAWING,

5

DO NOT MANUALLY UPDATE

DRAWN

ENGINEERING

R&D

WEIGHT

APPR.

.XXX±.005

±1/2•

-01

5

DISCARD

5.25±.06

3.25±.06

DISCARD

ITEM 5 MODIFICATION DETAIL

TO AIR DISCHARGE ASY

TO AIR INTAKE ASY

1

4

4

5

-01

-02

5

4

4

.XX± .01

NONE

SEE PARTS LIST

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

FINISH

A-11

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

2 REQD

Appendix I 1015530 ASY, FAN RESISTOR RELOC.

3

4

BRKT, FAN RESISTOR RELOCATION

SCREW, #14 X .75 LG, SELF TAPPING

WASHER, FLAT, #10

NUT, HEX, 10-24UNC-2B, STEEL WITH NYLOK

SCREW, SHCS, 10-24UNC-2A X .75 LG, STEEL GR5

7J010-001

7F010-024

7E014-075

4PFL010-041

7C010-075

A

REV.

SHEET 1 OF 1

1015530

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

2001 4.6L MUSTANG GT

DATE

11/7/00

G. COMPTON

APPROVALS

DRAWN

ASY, FAN RESISTOR RELOCATION

C

SIZE DWG. NO.

11/7/00

12/11/00

12/11/00

L. KECK

G. COMPTON

G. COMPTON

APPR.

ENGINEERING

R&D

DO NOT SCALE DRAWING

2:1

SCALE:

.2 LBS

WEIGHT

2

2 REQD

2 REQD

3 5

12422

1

12345

ITEM NO. QTY. PART NO. DESCRIPTION

.XXX±.005

±1/2•

.XX± .01

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

ANGLES: ±1/16

MATERIAL

SEE PARTS LIST

NONE

FINISH

A-12

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

NC

Appendix J 1017734 ASY, FUEL PUMP

REV.

SHEET 1 OF 1

1017734

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

ASY, FUEL PUMP

99-02 4.6L MUSTANG GT

DATE

5/3/01

DO NOT SCALE DRAWING

B

1:1

SCALE:

SIZE DWG. NO.

PIGTAIL CONNCTR, FUEL PUMP

SPACER, .312 OD/.14 ID

2A017-048

5W001-052

1

2

2

3

ITEM NO. QTY. PART NO. DESCRIPTION

14-16AWG SOLDERLESS CONNECTOR

SCREW, SHTMTL, HXHD, #6 x .75 LG.

7E006-075

5W001-013

2

2

4

5

APPR.

ENGINEERING

R&D

SEE PARTS LIST

MATERIAL

FINISH

2 LBS

WEIGHT

NONE

G. COMPTON

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

DRAWN

.XXX±.005

±1/2•

.XX± .01

ANGLES: ±1/16

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

NOTES: UNLESS OTHERWISE SPECIFIED

1. ALL ITEMS SHIPPED LOOSE.

A-13

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

ALTERN

Appendix K 7000170 DIAGRAM, BELT ROUTING

WATER PUMP

POWER STEERING

NC

REV.

SHEET 1 OF 1

7000170

1300 BEACON PLACE OXNARD, CA 93033

TEL: (805) 604-1336 FAX: (805) 604-1337

1999-2003 MUSTANG GT

DIAGRAM, BELT ROUTING

DO NOT SCALE DRAWING

B

1:1

SCALE:

SIZE DWG. NO.

DATE

7/10/00

A. PROCTOR

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

APPR.

ENGINEERING

R&D

SEE PARTS LIST

ANGLES: ±1/16

MATERIAL

WEIGHT

NONE

FINISH

DRAWN

.XXX±.005

±1/2•

.XX± .01

DECIMALS:

FRACTIONS:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

SUPERCHARG

CRANK

A/C

P/N: 4809628

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr.Secured

05JUN03 v2.1 MusGT(4809628 v2.1)

Paxton Automotive . 1300 Beacon Place . Oxnard CA 93033

805 604-1336 . FAX (805) 604-1337

Loading...

Loading...