Paxton Superchargers 5.9 Dodge Ram User Manual

DP/N: 4809621 - Ram 1500 v1.0 09/18/03

Owner’s Installation Guide for the

Paxton Automotive

Novi 2000 Supercharger

for the

2002 Dodge 5.9L Ram 1500

Paxton Automotive . 1300 Beacon Place . Oxnard CA 93033

888 9-PAXTON . FAX (805) 604-1337

Kit # 1201219

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

ii

FOREWORD

T

his manual provides information on the installation, maintenance and service of the

Paxton supercharger kit expressly designed for the 2002 5.9L Dodge Ram 1500.

Contact Paxton Automotive Corporation for any additional information regarding

this kit and any of these modifications at (805) 604-1336 7:00am-3:30pm PST.

An understanding of the information contained herein will help novices, as well as experienced technicians, to correctly install and receive the greatest possible benefit from their

Paxton supercharger. When reference is made in this manual to a brand name, number, specific tool or technique, an equivalent product may be used in place of the item mentioned.

All information, illustrations and specifications contained herein are based on the latest

product information available at the time of this publication. All rights reserved to make

changes at any time without notice.

© 2004 PAXTON AUTOMOTIVE

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or translated into

another language in any form, by any means without written permission of Paxton Automotive.

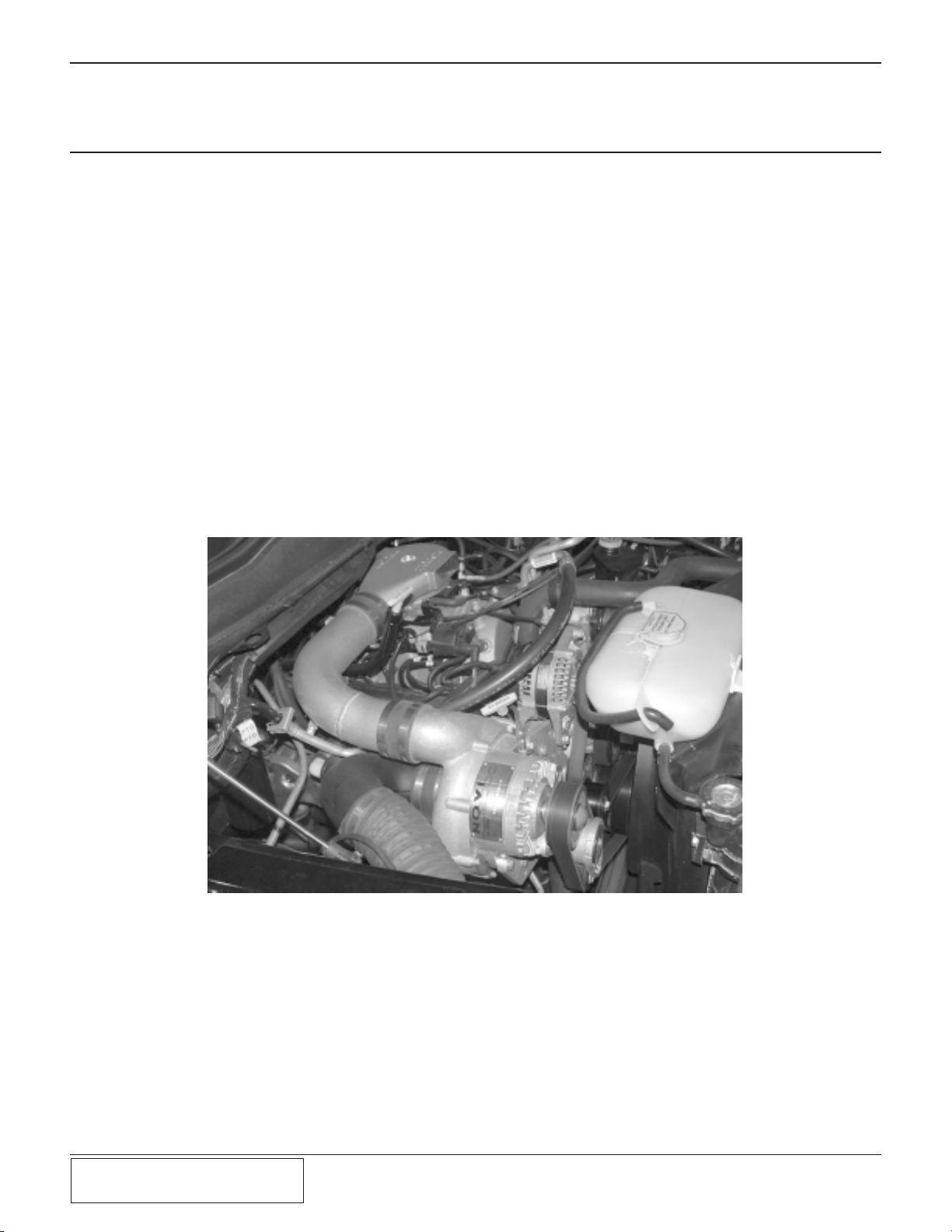

This is a typical underhood shot after installaton. Your engine compartment may

appear different.

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

iii

TABLE OF CONTENTS

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix 1201219 Kit, 2002 5.9 Dodge Ram Kit . . . . . . . . . . . . . . . . . . . .A-2

Appendix 1 1016418 Asy, S/C 2002 Dodge N2K CRV . . . . . . . . . . . . . . . . . .A-3

Appendix 2 1020220 Asy, Washer Botl Ram . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Appendix 3 1016624 Asy, S/C Mtg Brkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Appendix 4 1015938 Asy, Air Intake 02 5.9 Ram . . . . . . . . . . . . . . . . . . . . . .A-6

Appendix 5 1020119 Asy, Air Discharge 02, 5.9 Ram . . . . . . . . . . . . . . . . . .A-7

Appendix 6 1019345 Asy, S/C Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Appendix 7 1016070 Asy, S/C Oil Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Appendix 8 1017417 Asy, Belt Tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Appendix 9 1019717 Asy, Crank Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Appendix 10 1020215 Asy, Coil Reloc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Appendix 11 1015510 Asy, Compressor Bypass . . . . . . . . . . . . . . . . . . . . . . .A-13

Appendix 12 1017737 Asy, Fuel Sys 02, 5.9 Ram . . . . . . . . . . . . . . . . . . . . . .A-14

Appendix 13 1017733 Asy, Fuel Enrichment 02, 5.9 Ram . . . . . . . . . . . . . . . .A-15

Appendix 14 5A001-080 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

RECOMMENDED TOOLS FOR INSTALLATION: . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.1 INITIAL PREPARATION AND DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . .2-1

3.1 RELOCATION AND MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

4.1 SUPERCHARGER INSTALLATION AND ASSEMBLY . . . . . . . . . . . . . . . . .4-1

5.1 AIR INTAKE AND DISCHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1

6.1 FINAL CHECK OUT AND START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

iv

RECOMMENDED TOOLS

FOR INSTALLATION:

1. Metric and Standard sockets

sets

2. Metric and Standard combination

wrenches

3. Phillips and common screw drivers

4. 12" crescent wrench or 36mm

open end wrenches

5. Pliers

6. Wire cutters and wire crimping Tool

7. Hose cutters

8. 1/8" and 37/64" drill bit and hand

drill

9. 12 mm allen wrench

10. Small heat source

11. 3/8 Tap NPT

12. Ruler

13. Air compressor

14. Air hammer

1-1

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

Section 1

INTRODUCTION

C

ongratulations! You have purchased the

finest street Supercharger available for

the 2002 5.9L Dodge Ram 1500. The

centerpiece of this kit is the highly efficient

and reliable Paxton Automotive Corp. NOVI2000 supercharger. A mechanically driven (by

belt) centrifugal blower (supercharger).

This kit comes with all of the parts you’ll need

for a successful installation. The operations

required have been grouped in order of

sequence. Photos and drawings accompany the

text, allowing quick orientation and parts identification.

Installation requires a selection of tools which

is listed on page iv.

We also suggest that you obtain a Dodge shop

manual and become familiar with the details of

your cars systems. Manuals may be obtained

from your local Dodge dealer or you can order

one from Helm publications at (800)

782-4356.

For best results follow the instructions closely

and in sequence. The average installation time

for this kit is 8-10 hours. Your actual installation time will depend on skill level and working conditions. The estimate does not include

time for initial vehicle inspection, cleaning,

fine tuning or troubleshooting. Before even

picking up a wrench, read this entire manual.

We are available for technical assistance at

(805) 604-1336, 8am-4:30pm pacific time.

After reading the manual, verify that all major

assembly groups are present in the main kit

box. You should have ample space to layout

the components. As you remove a box or bag

from the main kit, note the identification label

and compare it with the parts list. Please check

the box for small parts.

Paxton makes every effort to insure that all

parts are included in the box. However, if you

discover any missing or mislabeled parts,

please contact Paxton by phone for service.

***WARNING***

DO NOT attempt installation if any part(s) are missing

from this kit. Failure to contact Paxton prior to beginning

installation will result in a charge for any missing parts.

Before starting the installation, we suggest

your engine compartment be clean. You can

clean the engine and compartment with a pressure washer (such as those used at self serve

car washes) and a safe-for-aluminum

cleaner/degreaser. Cover the distributor with a

plastic bag to prevent water from entering.

***CAUTION***

We do not recommend proceeding with the kit installation unless your vehicle is within normal operating

parameters.

You are undoubtedly enthusiastic about getting

started on your project, but take just a little

more time to insure that your safety is not

jeopardized. A moment’s lack of attention can

result in an accident, as can failure to observe

certain simple safety precautions. The possibility of an accident will always exist, and the

following points should not be considered a

comprehensive list of all dangers. Rather, they

are intended to make you aware of the risk and

to encourage a safety conscious approach to all

work you do on your vehicle.

We look for ward to hearing from you, particularly if you

have any comments or suggestions regarding this manual at (805) 604-1336

Paxton Automotive Corporation

1300 Beacon Place

Oxnard, CA 93033

E-mail Address info@paxtonauto.com.

*** NOTE ***

Throughout these procedures the word “discard” is used

periodically in relationship to items that will no longer be

utilized in conjunction with the supercharger installation.

It is recommended that these items be saved for future

use should it become necessary.

1.1 INTRODUCTION

1-2

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

• Never rely solely on a jack when working under a vehicle. Always

use an approved set of jackstands to support the vehicle and place

them under the recommended lift points.

• When jacking a vehicle, make sure it is on a level surface, preferably concrete or asphalt. The transmission should be in “PARK” or

“FIRST”, the parking brake engaged and the wheels blocked.

• Never start the car without first verifying that the transmission is in

neutral and the parking brake is set.

• Never remove the radiator cap while the engine is hot.

• Always wear eye protection when using power tools such as drills,

saws, grinders, etc., or when working under a vehicle.

• Never smoke, use an open flame, or have spark-producing items

around gasoline or flammable solvents. Always have a fire extinguisher rated for chemical and electrical fires handy when working

on motor vehicles.

• Run engines only in well ventilated areas. Carbon monoxide, gasoline, and solvent vapors are colorless and sometimes odorless.

These can asphyxiate or explode without warning.

• Always disconnect at least the negative (-) or ground terminal of the

battery when doing any electrical, fuel system, or underdash work.

We look forward to hearing from you, particularly if you have any comments

or suggestions regarding this manual.

Paxton Automotive makes every effort to insure that all parts are

included in the box, but mistakes do occur. If you discover that you are

missing any part, or that a part is damaged in transit, please call

Paxton Automotive for service. DO NOT attempt installation if any

part(s) are missing from this kit. Failure to contact Paxton prior to

beginning installation will result in a charge for any missing parts.

2-1

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

Section 2

INITIAL PREPARATION AND DISASSEMBLY

B

egin the initial preparation and disassembly

process by disconnecting the battery cables.

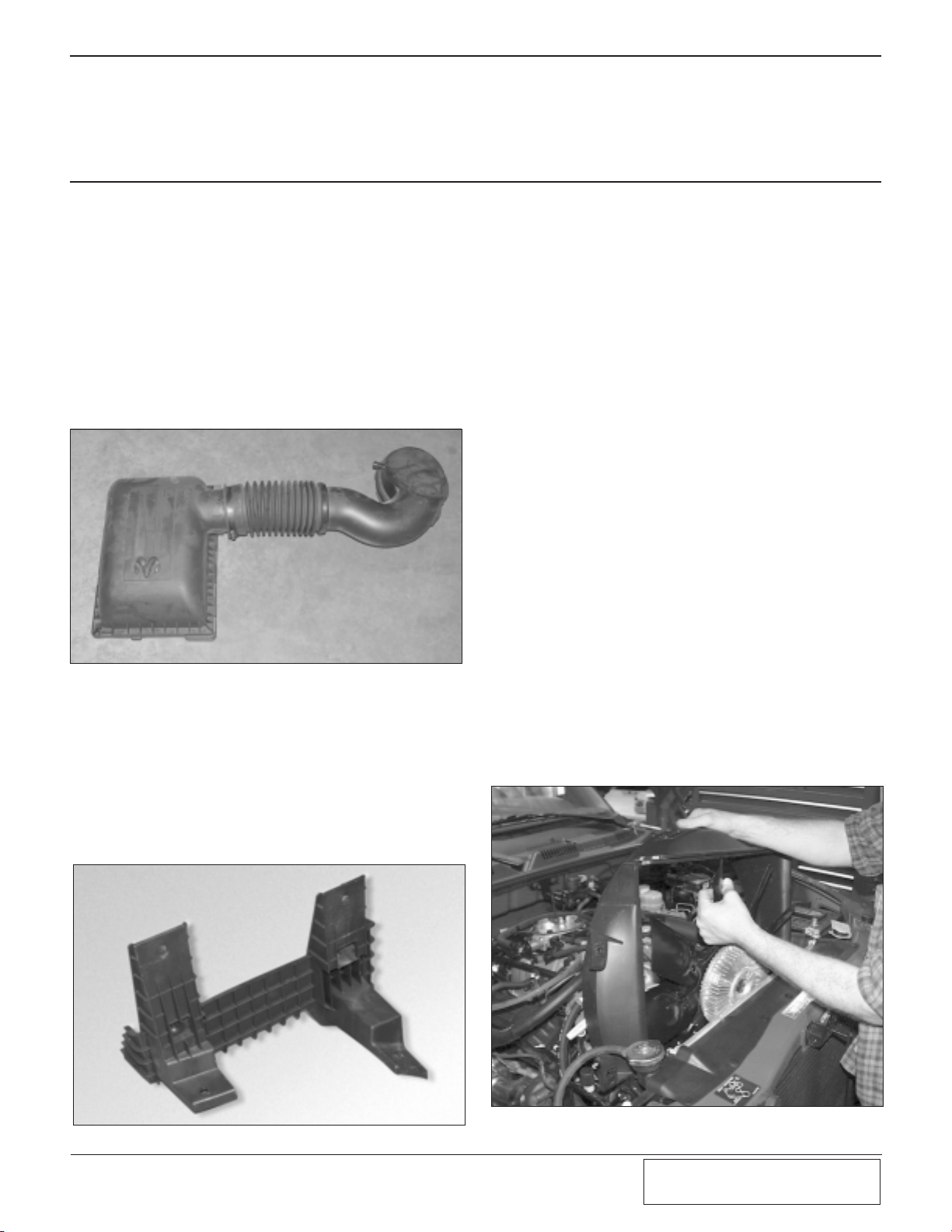

2.1 AIR INTAKE ASSEMBLY REMOVAL

A. Remove the spring clips that retain the top

cover of the air assembly. And remove the

filter.

B. Using an 8mm socket or flat blade screw

driver loosen the clamps from the Rubber

flex hose between the air box and the throttle body. Remove the cover and the flex

hose and set aside. (See Fig. 2-a.)

Fig. 2-a

Fig. 2-b

E. Reinstall the inner fender liner bolts and

clips.

2.2 FAN AND FAN SHROUD REMOVAL

A. Start by draining coolant in to a suitable

container. Locate the coolant petcock on the

drivers side of the truck attach a piece of

hose to the petcock and drain coolant.

B. Remove the 10mm bolt that attaches the

coolant over flow bottle to the fan shroud

and disconnect the overflow hose from the

radiator and set the coolant bottle to the side

to be reinstalled in a later stage of the installation.

C. Remove the windshield washer bottle hose

from the washer pump along with the connector. Drain washer fluid if necessary.

D. Remove the fan clutch nut using A factory

tool or a 1 1/16 wrench. Once you have the

nut loose allow the fan to rest in the fan

shroud.

E. Remove the two 13mm headed bolt that

attach the shroud to the radiator and remove

the fan, fan shroud and window washer bottle together. And set aside to be installed in a

later stage of the installation. (See Fig. 2-c.)

Fig. 2-c

C. Lift out the lower portion of the air cleaner

box and set aside.

D. Remove the fasteners and clips that retain

the passenger side inner fender liner. This

will aid in access to the two fasteners that

secure the air filter housing bracket to the

inner frame rail. Next remove the two bolts

that are located on the side of the frame in

the engine compartment and lift the bracket

assembly out and set a side. (See Fig 2-b.)

F. Remove the windshield washer bottle from

the fan shroud. From the backside of the

shroud you will find a flat tab. You will have

to bend this tab to remove the washer bottle

from the shroud. Set the washer bottle aside

it will not be reused.

2-2

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

Fig. 2-f

Fig. 2-d

Fig. 2-e

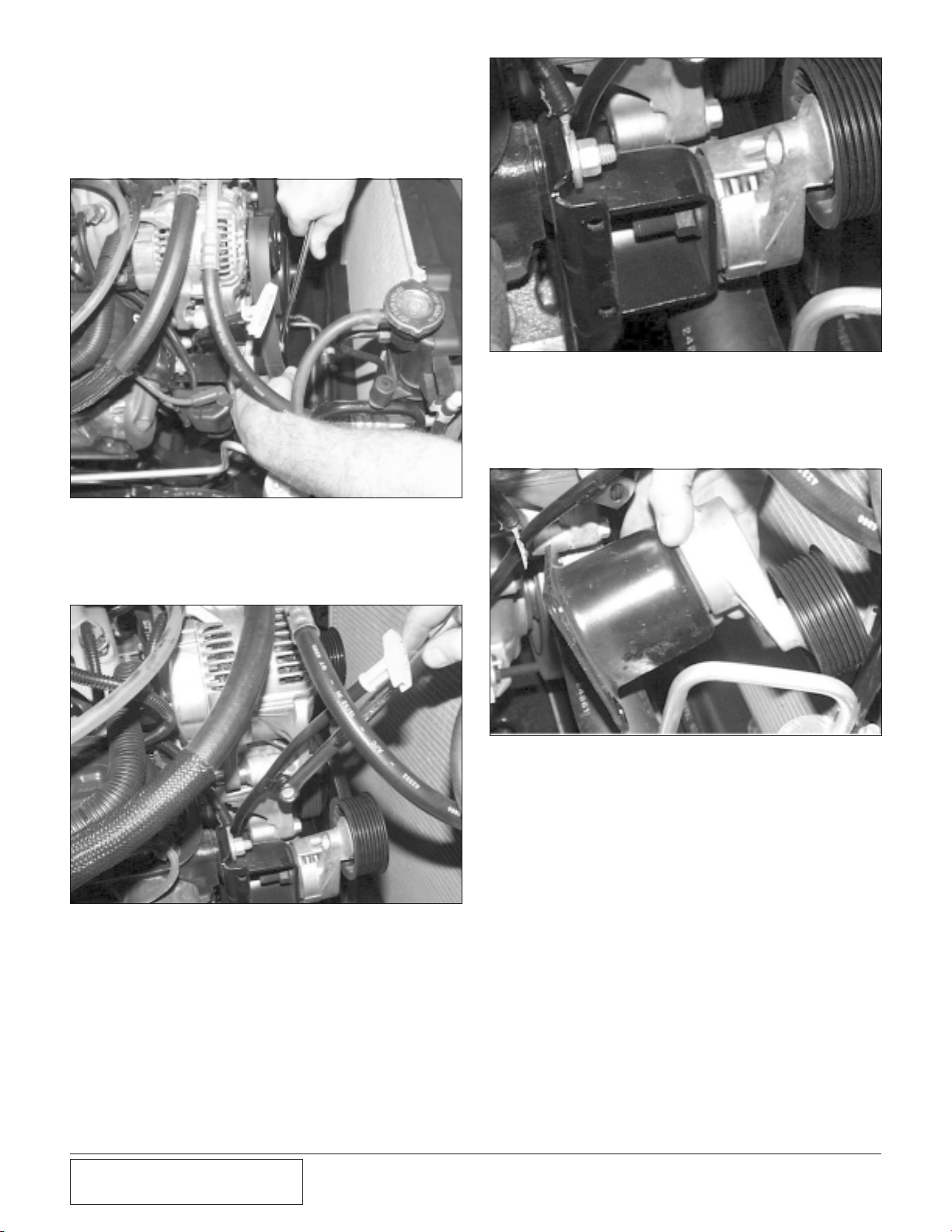

B. Remove the bolt attaching the dipstick to the

alternator bracket and set the bolt aside to be

reinstalled in a later step. (See Fig. 2-e.)

C. Remove the nut that attaches the factory ten-

sioner and set the tensioner aside to be reinstalled in a later step. (See Fig. 2-f.)

D. Remove the three bolts and nuts that retain

the tensioner bracket and set aside to be

reused in a later step of the installation. (See

Fig. 2-g.)

Fig. 2-g

2.3 ACCESSORY BELT, AND BELT

TENSIONER REMOVAL

A. Remove the Accessory belt by detensioning

the Factory tensioner rotate the tensioner in

a clock wise direction using a 15 mm

wrench (See Fig. 2-d.)

3-1

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

Section 3

CRANK PULLEY AND COIL REMOVAL AND INSTALLATION

3.1 CRANK PULLEY REMOVAL AND

INSTALLATION

A. Loosen the large crank pulley-retaining bolt.

B. Using a three jaw puller slowly remove the

pulley you will have to use the retaining bolt

to back up the puller so there will not be

damage to the crank threads.

C. Once you have the pulley removed set aside

it will not be reused.

D. With the supplied Crank pulley reinstall the

crank pulley. Using the factory-retaining

bolt or a crank pulley installation tool, slowly pull the new pulley in to place take time

with this as to not damage the threads.

E. Once the supplied pulley has been installed

remove the factory-retaining bolt. Install the

supplied dowel pins and supplied supercharger pulley spacer. Reinstall the factory

crank pulley retaining bolt using lock tight

and torque to factory specs.

***NOTE***

This spacer fits tight. Take care in installing it so as not

to damage it or the new crank pulley.

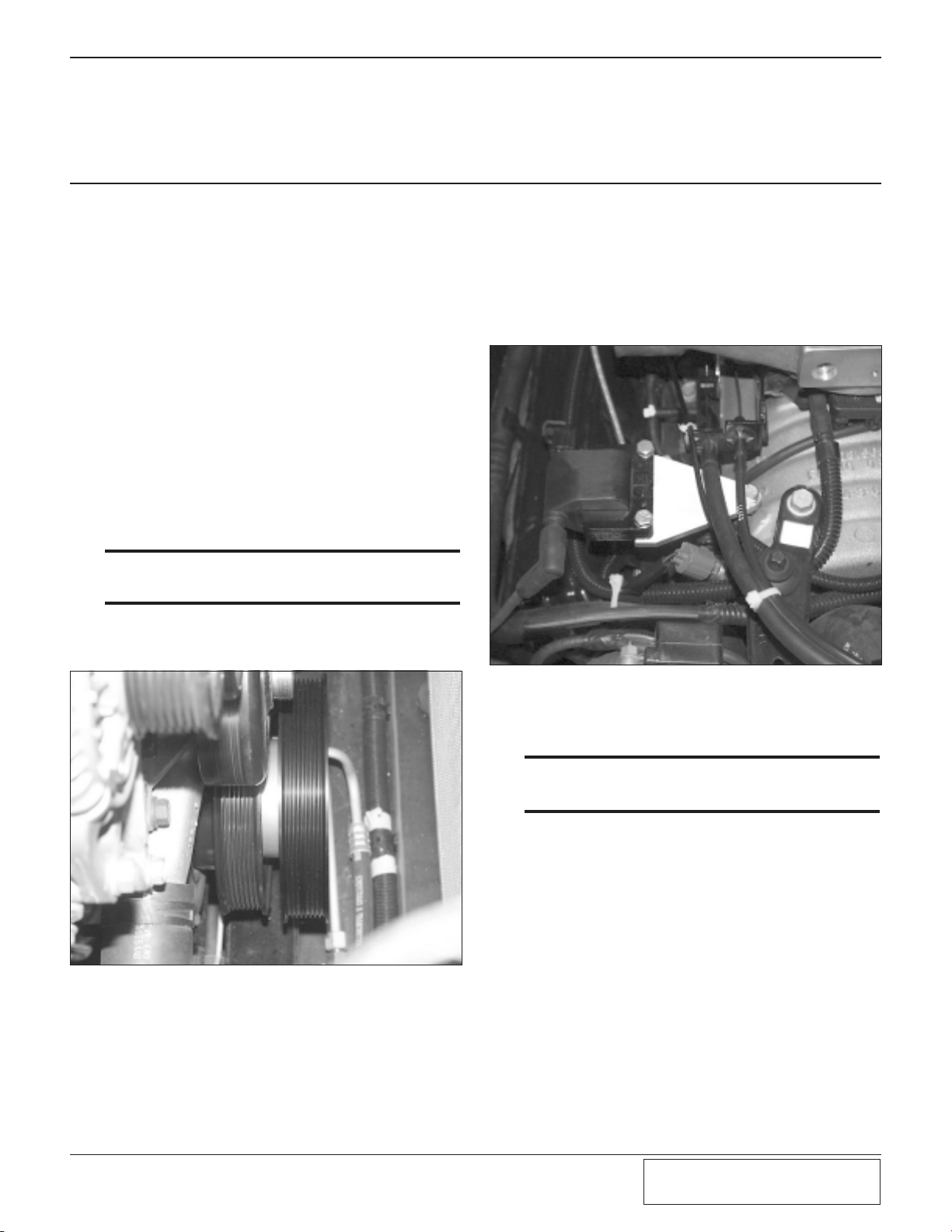

F. Install the supplied supercharge pulley using

the supplied fasteners and lock tight. (See

Fig. 3-a.)

Fig. 3-a

coil from the existing coil bracket. Remove

the factory coil bracket from the cylinder

head and set aside the coil bracket will be

replaced with a supplied coil bracket.

B. Attach the supplied coil bracket to the coil

with the supplied fasteners and install the

coil and bracket in its new location using the

supplied-retaining bolt. (See Fig. 3-b.)

Fig. 3-b

G. Check factory crank pulley belt for align-

ment with accessories. To assure that the

new crank pulley is properly installed and

seated.

3.2 COIL REMOVAL AND INSTALLATION.

A. Remove the 10mm nuts and bolt that retain

the coil disconnect the plug. And remove the

C. You may need to extend the wires on the

factory coil plug using the supplied wire and

but connectors.

***NOTE***

This may not be necessary on all vehicles check length

first and modify if necessary)

3-2

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

This Page Left Intentionally Blank.

4-1

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

4.1 SUPERCHARGER MOUNTING

BRACKET

A. Remove the pulley from the stock accessory

belt tensioner and the tensioner from the

stock bracket for re-installation.

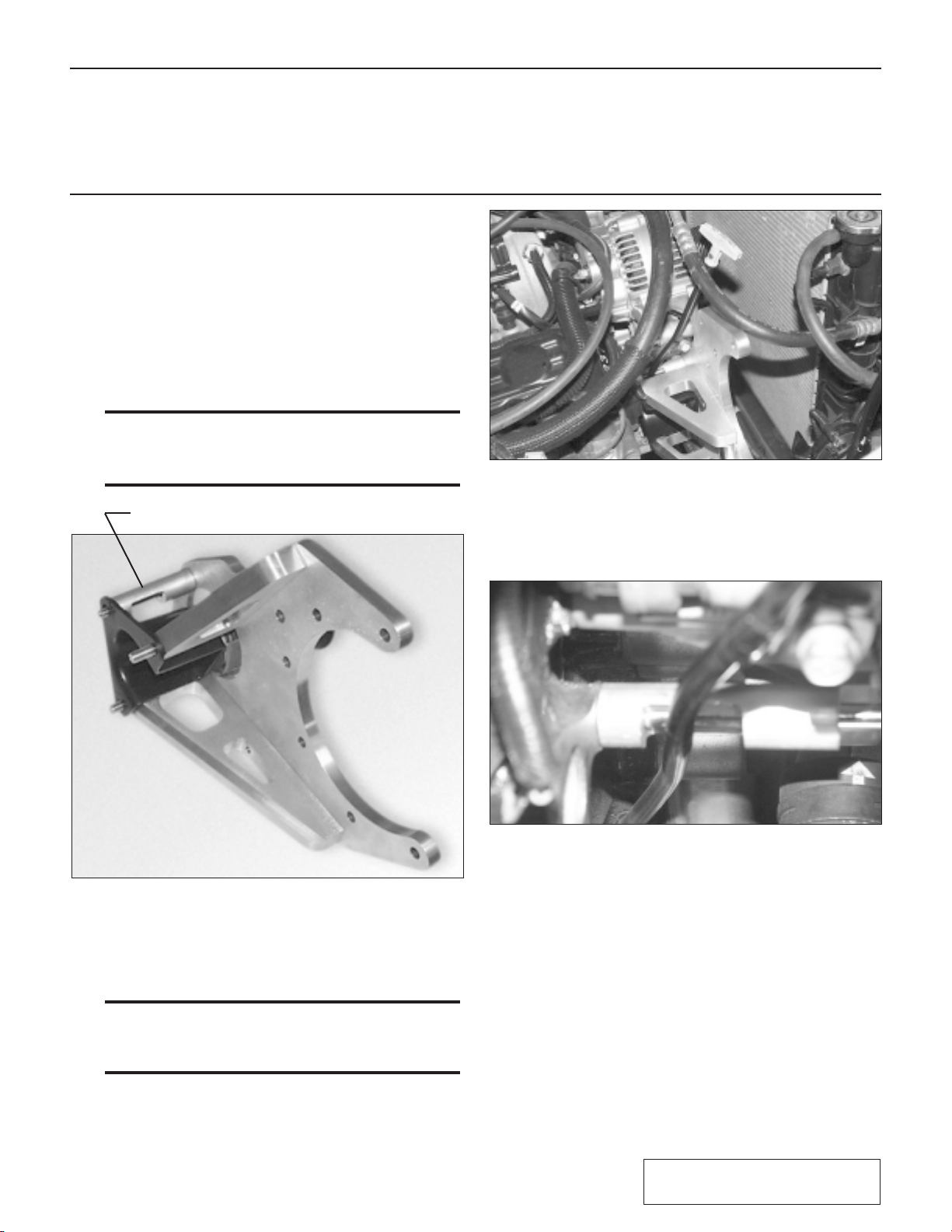

B. This is how the bracket should look prior to

installation. (See Fig. 4-a.) Note the accessory belt tensioner bracket. This spacer will

have to be removed before you install the

bracket. The dipstick goes between the tensioner and spacer.

***NOTE***

The idler pulley and pulley stand-off have been removed.

They will be installed once the supercharger bracket has

been installed.

Fig. 4-a

C. Mount the bracket in the holes at the stock

accessory belt tensioner location. Remove

the two countersunk allen head bolts and

lower this arm to gain access to the dip-stick

bolt. (See Fig. 4-b.)

***NOTE***

When installing the spacer, you may have to bend the

dipstick. Do not bend it excessively as it will become

harder to get in and out.

D. Re-install the countersunk bolts.

E. This is how the spacer should look installed.

Short portion toward the engine block. (See

Fig. 4-c.)

Fig. 4-b

Fig. 4-c

Section 4

SUPERCHARGER BRACKET ASSEMBLY

REMOVE THIS SPACER BEFORE INSTALLING THE S/C BRACKET

4-2

P/N: 4809621

©2003 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

18SEP03 v1.0 Dodge Ram 1500(4809621v1.0)

Fig. 4-d

Fig. 4-h

Fig. 4-g

Fig. 4-f

Fig. 4-e

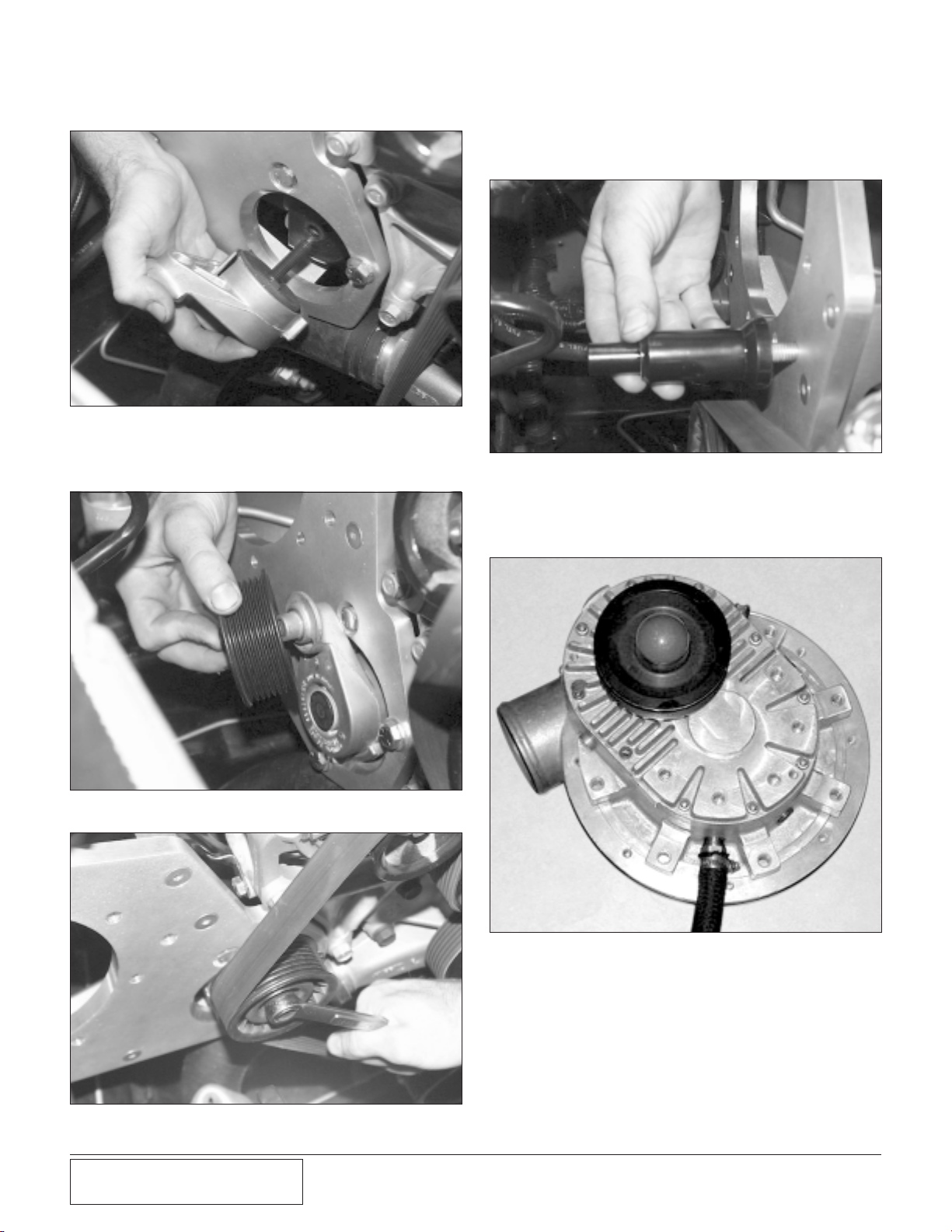

C. Attach the supercharger to the mounting

bracket using the six 3/8-16 x 1-1/4" bolts

and washers provided.

4.3 IDLER PULLEY STAND-OFF

A. Install the idler pulley stand-off. (See Fig.

4-g.)

B. Install the idler pulley on the idler pulley

stand-off and tighten to approximately

35 ft/lbs.

C. Install the oil drain hose to the supercharger

using the hose and hose clamp provided.

(See Fig. 4-h.)

4.2 ACCESSORY BELT TENSIONER

A. Install the tensioner using the factory nut

and washer. (See Fig. 4-d.)

B. Reinstall the factory tensioner pulley and

factory accessory belt. (See Figs. 4-e, 4-f.)

Loading...

Loading...