Owner’s Installation Guide for the

Paxton Automotive

Novi 1200 Supercharger

for the

Dodge Hemi

Paxton Automotive . 1300 Beacon Place . Oxnard CA 93033

(805 604-1336 . FAX (805) 604-1337

DP/N: 4809650 - v1.0 11/09/04

FOREWORD

roper installation of this supercharger kit requires general

automotive mechanic knowledge and experience. Please

P

browse through each step of this instruction manual prior to

beginning the installation to determine if you should refer the job

to a professional installer/technician. Please call Paxton Automotive

for installers in your area.

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed,

or translated into another language in any form, by any means without written permission

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

© 2005 PAXTON AUTOMOTIVE

of Paxton Automotive.

ii

TABLE OF CONTENTS

FOREWORD ..........................................................ii

TABLE OF CONTENTS ........................................................iii

RECOMMENDED TOOLS FOR INSTALLATION ................................iv

PARTS LIST ..........................................................v

1. COMPONENT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. OIL FEED ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. OIL DRAIN ASSEMBLY .................................................3-1

4. HEATER HOSE RELOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

5. COOLANT RESERVOIR RELOCATION ....................................5-1

6. SUPERCHARGER MOUNTING BRACKET .................................6-1

7. AIR INTAKE ASSEMBLY ................................................7-1

8. FUEL SYSTEM ASSEMBLY ..............................................8-1

9. ENGINE CONTROL UNIT INSTALLATION ................................. 9-1

10. CHARGE COOLER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

11. HEAT EXCHANGER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

12. SURGE AND RESERVOIR TANK INSTALLATION ..........................12-1

13. WATER HOSE ROUTING ................................................13-1

14. WATER PUMP WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

15. FINAL ASSEMBLY AND CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

iii

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

RECOMMENDED TOOLS FOR INSTALLATION

2002 Dodge Hemi

efore beginning this installation, please read

through this entire instruction booklet and

the Street Supercharger System Owner's

B

Manual which includes the Automotive Limited

Warranties Program and the Warranty Registration

form.

Paxton supercharger systems are performance

improving devices. In most cases, increases in

torque of 30-35% and horsepower of 35-45% can

be expected with the boost levels specified by

Paxton Automotive. This product is intended for

use on healthy, well maintained engines.

Installation on a worn-out or damaged engine is

not recommended and may result in failure of the

engine as well as the supercharger. Paxton

Automotive is not responsible for engine damage.

Installation on new vehicles will not harm or

adversely affect the break-in period so long as factory break-in procedures are followed.

For best performance and continued durability,

please take note of the following key points:

1. Use only premium grade fuel 91 octane or

higher (R+M/2).

2. The engine must have stock compression

ratio.

3. If the engine has been modified in any way,

check with Paxton prior to using this product.

4. Always listen for any sign of detonation

(pinging) and discontinue hard use (no

boost) until problem is resolved.

5. Perform an oil and filter change upon completion of this installation and prior to test

driving your vehicle. Thereafter, always use a

high grade SF rated engine oil or a high

quality synthetic, and change the oil and filter every 3,000 miles or less. Never attempt

to extend the oil change interval beyond

3,000 miles, regardless of oil manufacturer's

claims as potential damage to the supercharger may result.

6. Before beginning installation, replace all

spark plugs that are older than 1 year or

10,000 miles with original heat range plugs

as specified by the manufacturer and reset

timing to factory specifications (follow the

procedures indicated within the factory

repair manual and/or as indicated on the

factory underhood emissions tag). Do not

use platinum spark plugs unless they are

original equipment. Change spark plugs at

least every 15,000 miles and spark plug

wires at least every 50,000 miles.

RECOMMENDED TOOLS

FOR INSTALLATION:

1. Factory Repair Manual

2. 3/8" Socket and Drive Set: SAE & Metric

3. 1/2" Socket and Drive Set: SAE & Metric

4. 3/8" NPT Tap and Handle

5. Adjustable Wrench

6. Open End Wrenches: Metric and Standard

7. Center Punch and a 5/8" Tapered Punch

8. Springlock 3/8" and 5/8”Fuel Fitting

Disconnect Tool

9. 5 Quarts SH/CF Rated Quality Engine Oil

10. Oil Filter and Wrench

11. Flat #2 Screwdriver

12. Phillips #2 Screwdriver

13. Heavy Grease

14. Silicone Sealer

15. Drill Motor

16. 1/8", 3/16", 27/64" Drill Bits

17. Wire Strippers and Crimpers

18. Utility Knife

19. Power Steering Pulley/Puller & Installer

20. Pliers

If your vehicle has in excess of 10,000 miles

since its last spark plug change, then you will

also need:

21. Spark Plug Socket

22. NEW Spark Plugs

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

iv

2003 Dodge Hemi

Part No. 1201220

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART NO. DESCRIPTION QTY PART NO. DESCRIPTION QTY

4PCH110-044 S/C MNTG BRKT ASSY '03 HEMI 1

4PCH 010-044 SUPERCHARGER MTG PLT 1

4PCH010-010 SUPPORT S/C MOUNTING PLT 1

4PCH010-020 SUPPORT S/C MTG PLT 1

4PCH010-030 ALTERNATOR BRACE 1

4PCH017-011 COLLAR, IDLER PULLEY 1

7A312-125 5/16" x 18 x 1.25" HXHD GR5 BOLT 2

7K312-001 WASHER AN 6

7A312-100 5/16" x 18 x 1.00" HXHD GR5 BOLT 4

7C080-120 8mm x 120mm x 1.25" 1

7C010-130 10mm x 130 x 1.5" BOLT 1

7J010-002 10mm WASHER 1

7J012-092 12mm WASHER 2

7C012-100 12mm x 1.00" x 1.75" BOLT 1

7G010-175 12mm x 1.75" NUT 1

4FR016-150 SMOOTH IDLER PULLEY 1

7A437-325 7/16" x 3.25" x 14 BOLT 1

7K437-001 WASHER AN 2

7J438-072 7/16" WASHER .94"OD x .109" THICK 1"

7F437-000 7/16" x 14 NYLOC NUT 1

4PCH130-026 OIL FEED ASSY '03 HEMI

7P125-108 1/8"NPT NIPPLE 1" 1

7P125-104 1/8"NPT FEMALE TEE 1

7P125-004 1/8"NPT TO -4 x 90° JIC FITTING 1

7U250-090-240 OIL FEED HOSE -4 x 26" LONG 1

7P125-005 1/4" x -4 JIC FITTING 1

4PCH130-036 OIL DRAIN ASSY '03 HEMI

7P375-053 3/8"NPT x -8 FTG 1

7P500-500 - 8 x 90° ALUM FITTING 1

7U030-036 1/2" OIL DRAIN HOSE 48"

7R004-002 STEPLESS CLAMP 17.0-70 2

7R001-006 #6 STNL HOSE CLAMP, NARROW 2

7R004-687 CLAMP, 13/16" ONE EAR 2

7P375-055 3/8"NPT x 1/2" HOSE BARB 1

4PCH112-020 DISCHARGE ASSY '03 HEMI

4PCH012-020 DISCHARGE DUCT, '03 DODGE HEMI 1

7P156-082 5/32" TEE 2

7PS350-275 SLEEVE REDUCER 3.5"-2.75" 1

7R002-016 #16 HOSE CLAMP 5

7R002-056 #56 HOSE CLAMPS 1

7U030-046 5/32" VAC HOSE 3'

7U034-016 1" GS HOSE 2'

8D001-001 STANDARD COMPRESSOR BYPASS 1

7P100-103 1" WELD ON BUNG 1

7PS275-200 SLEEVE 2.75" x 2" 2

7R002-044 #44 HOSE CLAMP 4

4PCH212-010 AIR INTAKE ASSY

4PCH013-010 AIR BOX, WELDED, ROTO 1

4HS110-010 FLANGE ASSY, AIR BOX 1

8H040-050 AIR FILTER 3.5" FLG x 7"L 1

7R002-056 # 56 HOSE CLAMPS 4

7R002-060 #60 HOSE CLAMP 2

8H040-050 FILTER 3.50" x 7.0" LONG 1

7U035-001 FLEX HOSE 3.5" x 12" 1'

4PCH112-010 INLET DUCT, ASSY 1

7P100-103 BUNG WELD ON,

7P500-112 BUNG WELD ON, 1/2"NPT 1

7P100-578 AIR TEMP SENSOR BUNG 1

7PS275-200 SLEEVE, 2.75" x 2.00" 2

7PS350-200 SLEEVE,3.5" x 2.00" 1

7P500-026 1/2"NPT x 3/4" HOSE BARB 1

7U038-012 3/4" x 90° HOSE 4" x 12" LONG 2

7P375-075 3/4" HOSE MENDER 1

7A250-126 1/4" x 20 x 1" HXHD BOLT 4

7F250-021 1/4" NYLOC 4

7K250-001 1/4"AN WASHERS 8

4PCH101-001 FUEL PUMP ASSY '03 HEMI

7U031-018 5/16" EFI FUEL HOSE 24"

7U031018 5/16" EFI FUEL HOSE 9"

7U031018 5/16" EFI FUEL HOSE 1.8"

7U031018 5/16" EFI FUEL HOSE 1.8"

7U031018 5/16" EFI FUEL HOSE 6.5"

7U033-010 FUEL/PWR STEERING HOSE 5/8" 2.0"

7P312-017 FUEL PUMP FITTING 1

7P312-020 FUEL LINE FITTING 90° 1

7P312-016 5/16" x 5/16" FORD FITTING 1

8F001-500 FUEL PUMP PURBURG 1

7R003-028 ADEL CLAMP 2-3/8" .26" HOLE 2

7P312-082 TEE HOSE BARB 2

7R004-003 14.5 STEPLESS CLAMP 14

7E010-075 SHEET METAL SCREW 2

7A250-101 1/4" x 20 x 1.0" BOLT 2

7F250-021 NYLOC NUT 2

7J006-094 6mm SS WASHER 4

7F010-024 NYLOC NUT 2

7C010-075 BOLT 2

7J010-001 # 10 WASHER 4

4PCH010-070 FUEL PUMP/FMU MTG BRKT 1

4PCH238-068 FMU ASSY '03 HEMI

6PZ001-001 DECAL PAXTON FMU 1

6Z010-101 FMU HOUSING (BLUE ANODIZED) 1

6Z010-111 FMU VALVE COVER 1

6Z010-132 COVER FMU w/SPRING NO LZR, 1

6Z020-130 SML DIAPHRAM 1

6Z020-140 LRG DIAPHRAM 1

6Z030-150 BRACKET FMU 1

6Z040-160 PISTON, FMU 1

6Z050-161 FMU WASHER, 6:1/30LB PLATED 1

6Z060-181 SHIM, FMU 1

6Z070-010 FMU RING SPCER 6:1 1

6Z080-011 RETAINER,FMU SPRING 4.3 GM 2

6Z090-010 SPRING FMU 1

7C010-050 10-24 x .50" SHCS GR8 PLT 6

7C010-075 10-24 x 3/4" SHCS GR5 ZINC 4

7C024-025 10-24 x 1/4" PHIL HEAD 3

7P125-025 1/8"NPT x 5/32" HOSE 90° 1

7P125-031 1/8"NPT x 90° 5/16" HOSE BARB 1

7P125-032 1/8"NPT x 5/16" STR HOSE BARB 1

7u030-218 7/32" VAC HOSE 12"

7P157-219 5/32" x 7/32" UNION 1

7P156-082 5/32" TEE 1

7U030-046 5/32" VACUUM HOSE 10'

7U100-030 O-RING, FMU 1

8PN101-180 POWER CHARGE COOLER ASSY '03 HEMI

8N003-070 COOLER DUC T,LT1,GROUND

8N101-001 WELDED CORE, ASSY W/ENDS ONLY

8N003-011 INLET DUCT, MACH

8PN105-010 WATER TANK MTG ASSY '03 HEMI

8N055-030 RESERVOIR 1

4PCH010-110 BRKT RESERVOIR 1

7A250-050 1/4-20 SHD 1/2" LONG 3

7A250-074 1/4-20 HHD, 3/4" LONG PLTD 3

7J006-093 1/4" WASHER 8

7U038-000 3/4" HEATER HOSE CUT TO FIT 14"

7U038-012 3/4" 90° HOSE 4" x 12" 5

7U030-065 3/4" HOSE (TANK-PUMP) 1

7R007-001 NYLON CLAMP 1-1/8" 16

7P500-026 1/2" TO 3/4" 90° HOSE BARB 2

7U038-150 3/4" x 150° HOSE 2

7P375-075 3/4" HOSE MENDER 1

7F250-021 1/4" NYLOCK NUTS 3

7J250-150 1/4" FENDER WASHERS 3

v

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

2003 Dodge Hemi

Part No. 1201220-P

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART NO. DESCRIPTION QTY

8PN104-010 ASSY SURGE TANK '03 HEMI

8N056-060 SURGE TANK 1

7E010-075 #12 SHEET METAL SCREWS 2

7P500-078 1/2" x 3/4" STR HOSE BARB 2

8N055-050 PLASTIC CAP, SURGE TANK 1

7J006-093 6mm WASHER, PLATED 4

7C060-016 M6 x 1.00" x 16 HXHD 2

7U100-055 6" TIE-WRAP 10

7P500-078 1/2" x 3/4" STR HOSE BARB 3

7P500-026 1/2" x 3/4" 90° HOSE BARB 1

7U100-044 4" TIE-WRAP 5

7A250-050 1/4-20 SHCS 1/2" LONG 2

8N010-130 MTG TAB 1

8PN107-010 WATER PUMP MTG ASSY, '03 HEMI

8F001-402 PUMP, HELLA WATER 1

7R003-027 ADEL CLAMP 1

5W001-009 16-14GA MALE SLIDE INSULATED 2

5W001-010 16-14GA FEMALE INSULATED 2

5W001-019 10-12GA BUTT CON INSUL 1

5W001-042 12-10GA x 3/16" RING TERMINAL 1

5W001-017 3/8" RING TERMINAL 12GA 1

5W001-030 14GA STRD WIRE BLACK 3'

5W001-014 FUSE HOLDER 10GA WIRE 1

5W001-011 16-14GA EYELET .25" HOLE 2

5W001-015 FUSE, BLADE TYPE 20AMP 1

5WOO1-009 16-14GA MALE SLIDE INSULATED 1

7A250-050 1/4-20 x .50" SHCS ZINC PLTD 1

7J006-093 6mm WASHER, PLTD 1

5W001-022 T-TAP CONN 14-16AWG 1

8F101-510 H

8PN106-010 WATER CLR MTG ASSY, '03 HEMI

8N006-010 WATER COOLER 1

7P500-026 1/2"NPT TO 3/4" HOSE BARB 90° 2

7A250-074 1/4-20 HHD 3/4" LONG 8

7F250-021 1/4-20 NYLOCK NUT 8

7J250-001 1/4" FLAT WASHER 16

1016419 SUPERCHARGER ASSY

2A047-119 ACCESSORY DRIVE BELT

4PCH114-018 COOLANT RESV ASSY

7R002-016 # 16 HOSE CLAMPS 3

2A017-876-01 .875" x .328" x .952" LONG SPACERS 3

7C060-050 6mm x 1.0" x 50mm LONG BOLTS 3

7J006-093 6mm LARGE OD FLAT WASHERS 3

4PCH014-010 FORMED COOLANT TUBE 1

7U038-012 3/4" x 90° HOSE 4" x 12" 1

7P375-045 45° STREET ELBOW 2

7R002-012 #12 HOSE CLAMP 2

7U133-065 “J” SHAPED HOSE

7P500-001 1/2" HOSE UNION 1

5A001-110 ENGINE CONTROL UNIT

5A001-111 PROGRAMMED ENGINE CONTROL UNIT

2O PUMP WIRING ASSY 1

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

vi

2003 Dodge Hemi

Part No. 1201220-P

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART NO. DESCRIPTION QTY PART NO. DESCRIPTION QTY

4PCH110-044 S/C MNTG BRKT ASSY '03 HEMI 1

4PCH 010-044 SUPERCHARGER MTG PLT 1

4PCH010-010 SUPPORT S/C MOUNTING PLT 1

4PCH010-020 SUPPORT S/C MTG PLT 1

4PCH010-030 ALTERNATOR BRACE 1

4PCH017-011 COLLAR, IDLER PULLEY 1

7A312-125 5/16" x 18 x 1.25" HXHD GR5 BOLT 2

7K312-001 WASHER AN 6

7A312-100 5/16" x 18 x 1.00" HXHD GR5 BOLT 4

7C080-120 8mm x 120mm x 1.25" 1

7C010-130 10mm x 130mm x 1.5" BOLT 1

7J010-002 10mm WASHER 1

7J012-092 12mm WASHER 2

7C012-100 12mm x 100 x 1.75" BOLT 1

7G010-175 12mm x 1.75" NUT 1

4FR016-150 SMOOTH IDLER PULLEY 1

7A437-325 7/16" x 3.25" x 14 BOLT 1

7K437-001 WASHER AN 2

7J438-072 7/16" WASHER .94"OD x .109" THICK 1

7F437-000 7/16" x 14 NYLOC NUT 1

4PCH130-026 OIL FEED ASSY '03 HEMI

7P125-108 1/8"NPT NIPPLE 1" 1

7P125-104 1/8"NPT FEMALE TEE 1

7P125-004 1/8"NPT TO -4 x 90° JIC FITTING 1

7U250-090-240 OIL FEED HOSE -4 x 26" LONG 1

7P125-005 1/4" x -4 JIC FITTING 1

4PCH130-036 OIL DRAIN ASSY '03 HEMI

7P375-053 3/8"NPT x -8 FTG 1

7P500-500 -8 x 90° ALUM FITTING 1

7U030-036 1/2" OIL DRAIN HOSE 48"

7R004-002 STEPLESS CLAMP 17.0-70 2

7R001-006 #6 STNL HOSE CLAMP, NARROW 2

7R004-687 CLAMP, 13/16" ONE EAR 2

7P375-055 3/8"NPT x 1/2" HOSE BARB 1

4PCH112-028 DISCHARGE ASSY '03 HEMI

4PCH012-020 DISCHARGE DUCT, '03 DODGE HEMI 1

7P156-082 5/32" TEE 2

7PS350-275 SLEEVE REDUCER 3.5" - 2.75" 1

7R002-016 #16 HOSE CLAMP 5

7R002-056 #56 HOSE CLAMPS 1

7U030-046 5/32" VAC HOSE 3'

7U034-016 1" GS HOSE 2'

8D001-001 STANDARD COMPRESSOR BYPASS 1

7P100-103 1" WELD ON BUNG 1

7PS275-200 SLEEVE 2.75" x 2" 2

7R002-044 #44 HOSE CLAMP 4

4PCH212-010 AIR INTAKE ASSY

4PCH013-010 AIR BOX, WELDED, ROTO 1

4HS110-010 FLANGE ASSY, AIR BOX 1

8H040-050 AIR FILTER 3.5" FLG x 7L 1

7R002-056 # 56 HOSE CLAMPS 4

7R002-060 #60 HOSE CLAMP 2

8H040-050 FILTER 3.50" x 7.0" LONG 1

7U035-001 FLEX HOSE 3.5" x 12" 1'

4PCH112-010 INLET DUCT, ASSY 1

7P100-103 BUNG WELD ON,

7P500-112 BUNG WELD ON, 1/2"NPT 1

7P100-578 AIR TEMP SENSOR BUNG 1

7PS275-200 SLEEVE, 2.75" x 2.00" 2

7PS350-200 SLEEVE,3.5" x 2.00" 1

7P500-026 1/2"NPT x 3/4" HOSE BARB 1

7U038-012 3/4" x 90° HOSE 4" x 12" LONG 2

7P375-075 3/4" HOSE MENDER 1

7A250-126 1/4" x 20 x 1" HXHD BOLT 4

7F250-021 1/4" NYLOC 4

7K250-001 1/4"AN WASHERS 8

4PCH101-001 FUEL PUMP ASSY '03 HEMI

7U031-018 5/16" EFI Fuel hose 24"

7U031-018 5/16" EFI Fuel hose 9"

7U031-018 5/16" EFI Fuel hose 1.8"

7U031-018 5/16" EFI Fuel hose 1.8"

7U031-018 5/16" EFI Fuel hose 6.5"

7U033-010 FUEL/PWR STEERING HOSE 5/8" 2.0"

7P312-017 FUEL PUMP FITTING 1

7P312-020 FUEL LINE FITTING 90° 1

7P312-016 5/16" x 5/16" FORD FITTING 1

8F001-500 FUEL PUMP PURBURG 1

7R003-028 ADEL CLAMP 2-3/8", .26" HOLE 2

7P312-082 TEE, HOSE BARB 2

7R004-003 14.5 STEPLESS CLAMP 14

7E010-075 SHEET METAL SCREW 2

7A250-101 1/4" x 20 x 1.0" BOLT 2

7F250-021 NYLOC NUT 2

7J006-094 6mm SS WASHER 4

7F010-024 NYLOC NUT 2

7C010-075 BOLT 2

7J010-001 #10 WASHER 4

4PCH010-070 FUEL PUMP/ FMU MTG BRKT 1

4PCH238-068 FMU ASSY '03 HEMI

6PZ001-001 DECAL PAXTON FMU 1

6Z010-101 FMU HOUSING (BLUE ANODIZED) 1

6Z010-111 FMU VALVE COVER 1

6Z010-132 COVER FMU w/SPRING NO LZR, 1

6Z020-130 SML DIAPHRAM 1

6Z020-140 LRG DIAPHRAM 1

6Z030-150 BRACKET FMU 1

6Z040-160 PISTON, FMU 1

6Z050-161 FMU WASHER,6:1/30LB PLATED 1

6Z060-181 SHIM, FMU 1

6Z070-010 FMU RING SPACER 6:1 1

6Z080-011 RETAINER,FMU SPRING 4.3 GM 2

6Z090-010 SPRING FMU 1

7C010-050 10-24 x .50" SHCS GR8 PLT 6

7C010-075 10-24 x 3/4" SHCS GR5 ZINC 4

7C024-025 10-24 x 1/4" PHIL HEAD 3

7P125-025 1/8"NPT x 5/32" HOSE 90° 1

7P125-031 1/8"NPT x 90° 5/16" HOSE BARB 1

7P125-032 1/8"NPT x 5/16" STR HOSE BARB 1

7u030-218 7/32" VAC HOSE 12"

7P157-219 5/32" x 7/32" UNION 1

7P156-082 5/32" TEE 1

7U030-046 5/32" VAC HOSE 10'

7U100-030 O-RING, FMU 1

8PN101-188 POWER CHARGE COOLER ASSY '03 HEMI

8N003-078 COOLER DUCT,LT1,GROUND

8N101-001 WELDED CORE, ASSY W/ENDS ONLY

8N003-018 INLET DUCT, MACH

8PN105-010 WATER TANK MTG ASSY '03 HEMI

8N055-030 RESERVOIR 1

4PCH010-110 BRKT RESERVOIR 1

7A250-050 1/4-20 SHD 1/2" LONG 3

7A250-074 1/4-20 HHD,3/4" LONG PLTD 3

7J006-093 1/4" WASHER 8

7U038-000 3/4" HEATER HOSE CUT TO FIT 14"

7U038-012 3/4" 90° HOSE 4" x 12" 5

7U030-065 3/4" HOSE (TANK-PUMP) 1

7R007-001 NYLON CLAMP 1-1/8" 16

7P500-026 1/2" TO 3/4" 90° HOSE BARB 2

7U038-150 3/4" x 150° HOSE 2

7P375-075 3/4" HOSE MENDER 1

7F250-021 1/4" NYLOCK NUTS 3

7J250-150 1/4" FENDER WASHERS 3

vii

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

2003 Dodge Hemi

Part No. 1201220

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART NO. DESCRIPTION QTY PART NO. DESCRIPTION QTY

8PN104-010 ASSY SURGE TANK '03 HEMI

8N056-060 SURGE TANK 1

7E010-075 #12 SHEET METAL SCREWS 2

7P500-078 1/2" x 3/4" STR HOSE BARB 2

8N055-050 PLASTIC CAP, SURGE TANK 1

7J006-093 6mm WASHER, PLATED 4

7C060-016 M6 x 1.00" x 16 HXHD 2

7U100-055 6" TIE-WRAP 10

7P500-078 1/2" x 3/4" STR HOSE BARB 3

7P500-026 1/2" x 3/4" 90° HOSE BARB 1

7U100-044 4" TIE-WRAP 5

7A250-050 1/4-20 SHCS 1/2" LONG 2

8N010-130 MTG TAB 1

8PN107-010 WATER PUMP MTG ASSY, '03 HEMI

8F001-402 PUMP, HELLA WATER 1

7R003-027 ADEL CLAMP 1

5W001-009 16-14GA MALE SLIDE INSULATED 2

5W001-010 16-14GA FEMALE INSULATED 2

5W001-019 10-12GA BUTT CON INSUL 1

5W001-042 12-10GA x 3/16" RING TERMINAL 1

5W001-017 3/8" RING TERMINAL 12GA 1

5W001-030 14GA STRD WIRE BLACK 3'

5W001-014 FUSE HOLDER 10GA WIRE 1

5W001-011 16-14GA EYELET .25" HOLE 2

5W001-015 FUSE, BLADE TYPE 20AMP 1

5WOO1-009 16-14GA MALE SLIDE INSULATED 1

7A250-050 1/4-20 x .50" SHCS ZINC PLTD 1

7J006-093 6mm WASHER, PLTD 1

5W001-022 T-TAP CONN 14-16AWG 1

8F101-510 H

8PN106-010 WATER CLR MTG ASSY, '03 HEMI

8N006-010 WATER COOLER 1

7P500-026 1/2"NPT TO 3/4" HOSE BARB 90° 2

7A250-074 1/4-20 HHD 3/4" LONG 8

7F250-021 1/4-20 NYLOCK NUT 8

7J250-001 1/4" FLAT WASHER 16

1016419-P SUPERCHARGER ASSY

2A047-119 ACCESSORY DRIVE BELT

4PCH114-018 COOLANT RESV ASSY

7R002-016 # 16 HOSE CLAMPS 3

2A017-876-01 .875" x .328" x .952" LONG SPACERS 3

7C060-050 6mm x 1.0" x 50mm LONG BOLTS 3

7J006-093 6mm LARGE OD FLAT WASHERS 3

4PCH014-010 FORMED COOLANT TUBE 1

7U038-012 3/4" 90° HOSE 4" x 12" 1

7P375-045 45° STREET ELBOW 2

7R002-012 #12 HOSE CLAMP 2

7U133-065 “J” SHAPED HOSE

7P500-001 1/2" HOSE UNION 1

5A001-110 ENGINE CONTROL UNIT

5A001-111 PROGRAMMED ENGINE CONTROL UNIT

2O PUMP WIRING ASSY 1

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

viii

1. COMPONENT REMOVAL

Section 1

COMPONENT REMOVAL

1. COMPONENT REMOVAL

A. Using a suitable container drain the engine

coolant. On the driver’s side of the vehicle

at the lower corner of the radiator locate the

drain petcock using a 16mm open-end

wrench rotate the petcock and drain the

coolant.

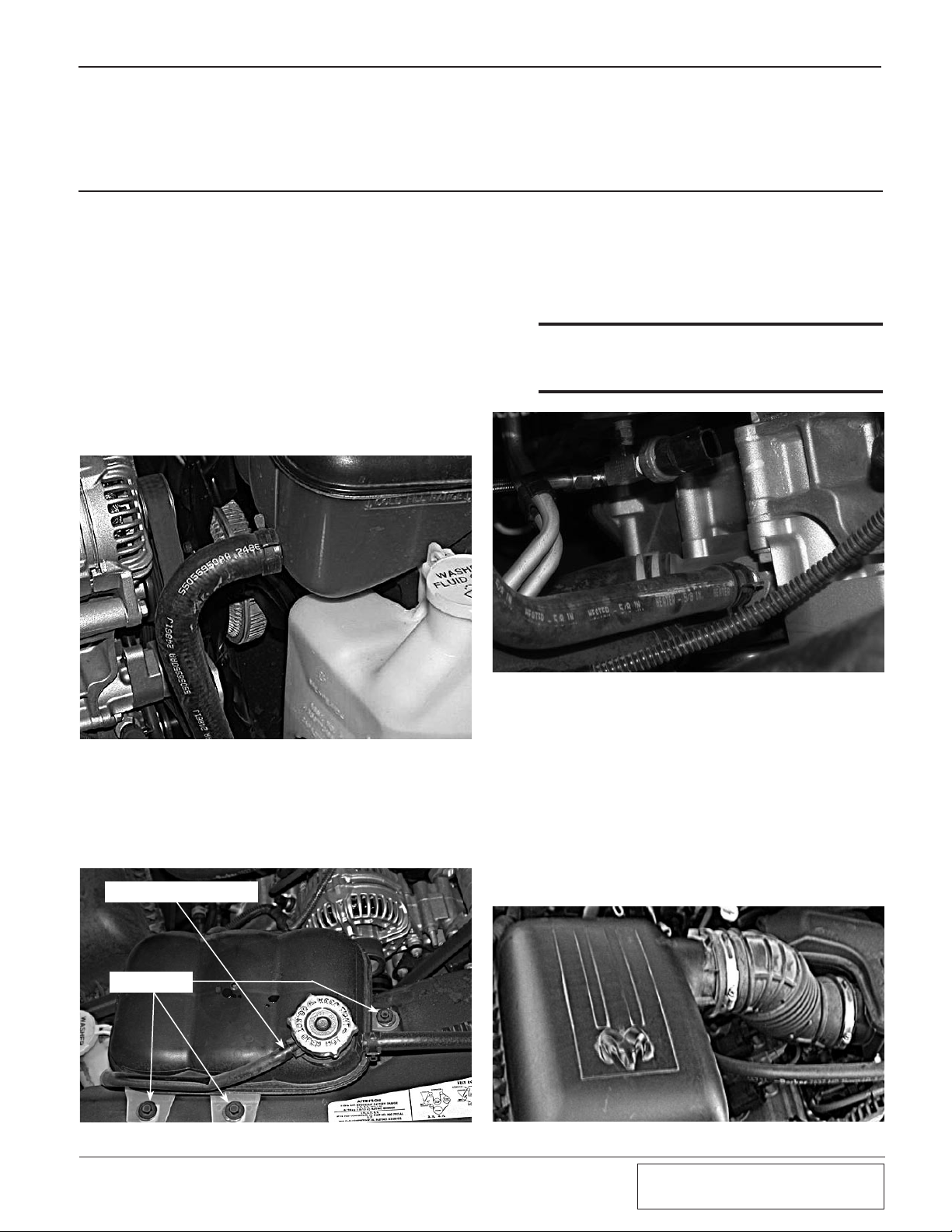

B. Locate the coolant over flow reservoir locat-

ed on the top of the radiator, loosen the hose

clamp securing the large 1" coolant hose and

remove the hose from the reservoir.

Disconnect the smaller coolant hose from

the over flow reservoir that connects to the

radiator. (See Figs. 1-a, 1-b.)

D. Using a pair of needle nose pliers or a spring

hose clamp tool remove the spring clamps

that retain the two heater hoses that are

located on the passenger side of the front

cover. Remove the hoses.

*** NOTE ***

Set the hoses aside in the engine compartment to

be modified in a later step of the installation)

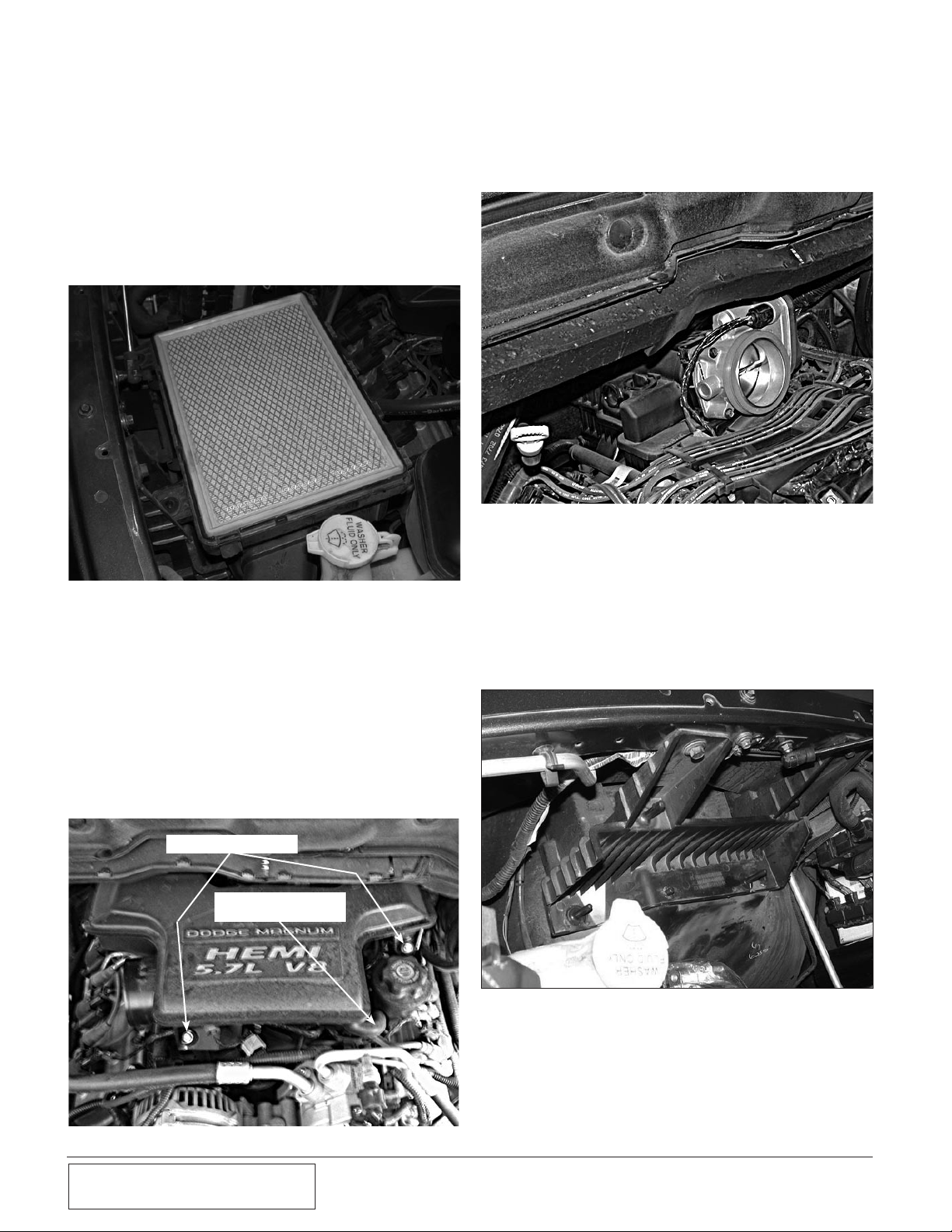

Fig. 1-a

C. Remove the three 10mm headed screws that

retain the reservoir to the top of the radiator

fan shroud and set the reservoir aside to be

reinstalled at a later stage of the installation.

(See Fig. 1-b.)

COOLANT OVERFLOW HOSE

10mm BOLTS

Fig. 1-b

Fig. 1-c

E. Using a 19mm deep socket or wrench

remove the heater hose barbed fitting at the

front cover. Set the fitting aside to be

installed in a later step of the installation.

F. Locate the hose clamp securing the factory

air ducting attached to the large plastic throttle body enclosure to the air filter cover.

Using a 8mm socket or flat blade screwdriver loosen the clamp and remove the duct

from the plastic throttle body enclosure.

(See Fig. 1-d.)

Fig. 1-d

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

G. Unclip the 4 clips that retain the top portion

of the factory air filter housing and set the

housing and rubber duct aside it will not be

reused.

H. Remove the air filter and lift up on the lower

portion of the factory air filter housing and

remove it from the air filter support bracket

set the lower portion of the housing aside it

will not be reused. (See Fig. 1-e.)

Fig. 1-e

I. Locate the intake air temperature sensor on

the passenger side of the large plastic throttle body enclosure. Disconnect the wire harness plug, remove the sensor using a twisting motion and set the sensor aside to be

reinstalled in a later step of the installation.

J. Remove the two 10mm headed bolts secur-

ing the plastic throttle body enclosure.

Remove the rubber hose going to the oil fill

neck and remove the enclosure and set aside

it will not be reused. (See Fig. 1-f.)

K. Remove the factory orange silicone ring

from the throttle body and set aside. Remove

the accessory drive belt. (See Fig. 1-g.)

Fig. 1-g

L. Using a 8mm socket, remove the eight fac-

tory screws securing the underside of the

passenger side inner fender well cover.

Remove the four 13mm head screws securing the air filter enclosure bracket to the

fender and remove the bracket it will not be

reused. Reinstall the inner fender well cover

using the factory hardware. (See Fig. 1-h.)

10mm HEADED BOLTS

CRANKCASE BREATHER

Fig. 1-f

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

HOSE

Fig. 1-h

2

2. OIL FEED ASSEMBLY

Section 2

OIL FEED ASSEMBLY

2. OIL FEED ASSEMBLY

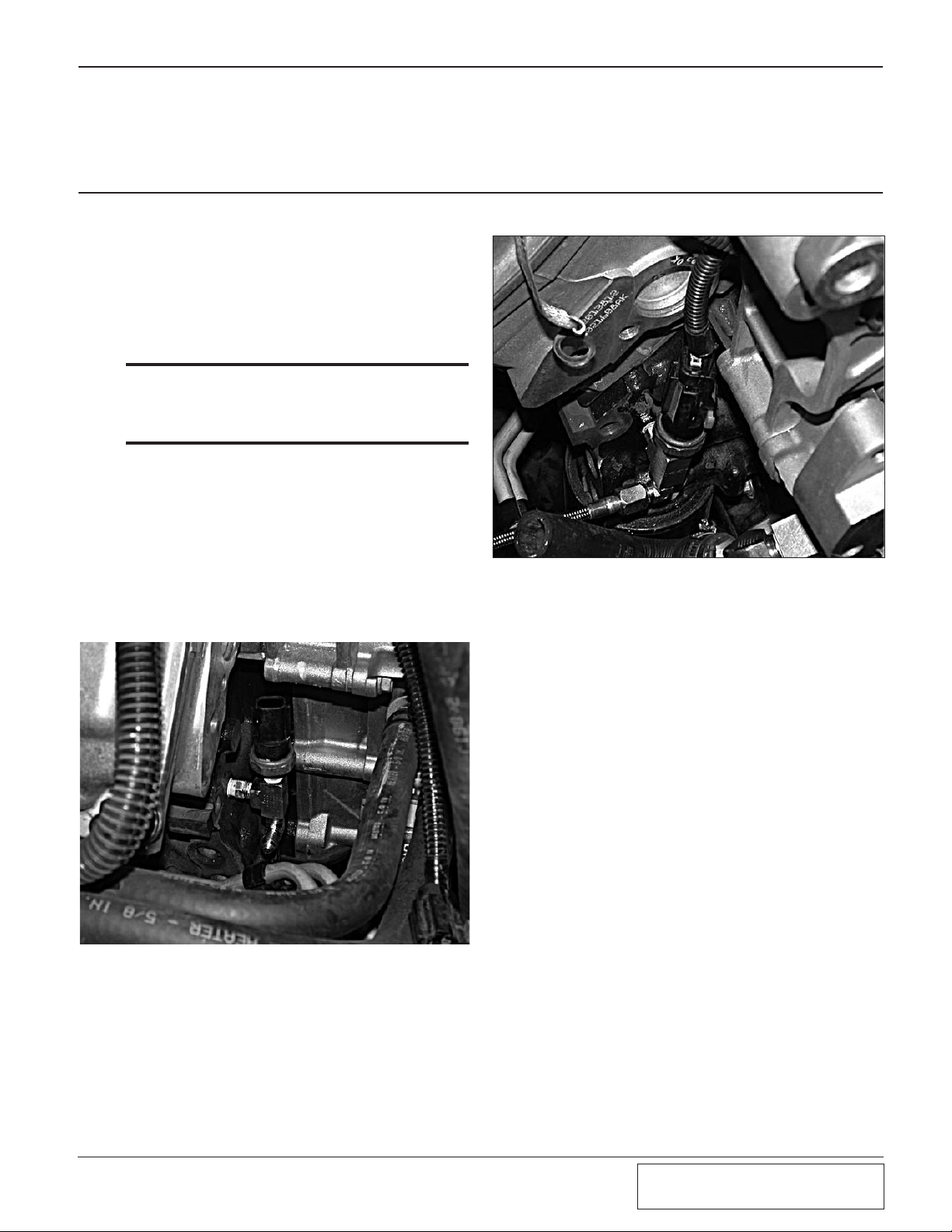

A. Disconnect the factory oil pressure sending

unit wire harness from the sending unit.

Remove and set aside the factory oil pressure sender located on the passenger of the

engine. Using the supplied fitting install the

short 1" nipple into the side of the supplied

TEE fitting.

*** NOTE ***

Do not use Teflon paste or Teflon tape on this fitting

as it may clog the supercharger oil jet and lead to

premature supercharger failure.

B. Install the supplied TEE fitting into the

location were the factory sending unit was

originally located. With the supplied TEE

fitting installed and the outlets facing up and

down install the factory sending unit into

the outlet of the tee that is facing up. Install

the supplied 1/8" NPT x –4 x 90º fitting into

the outlet that is facing down and orientate

the supplied 90º fitting to face to the passenger side of the vehicle. (See Fig. 2-a.)

Fig. 2-b

Fig. 2-a

C. Install the straight portion of the supplied

steel braided –4 hose to the 90º fitting. The

90º end will attach to the supercharger oil jet

in a later step.

D. Reattach the oil pressure sending unit wire

harness. (See Fig. 2-b.)

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

3. OIL DRAIN ASSEMBLY

Section 3

3. OIL DRAIN ASSEMBLY

OIL DRAIN ASSEMBLY

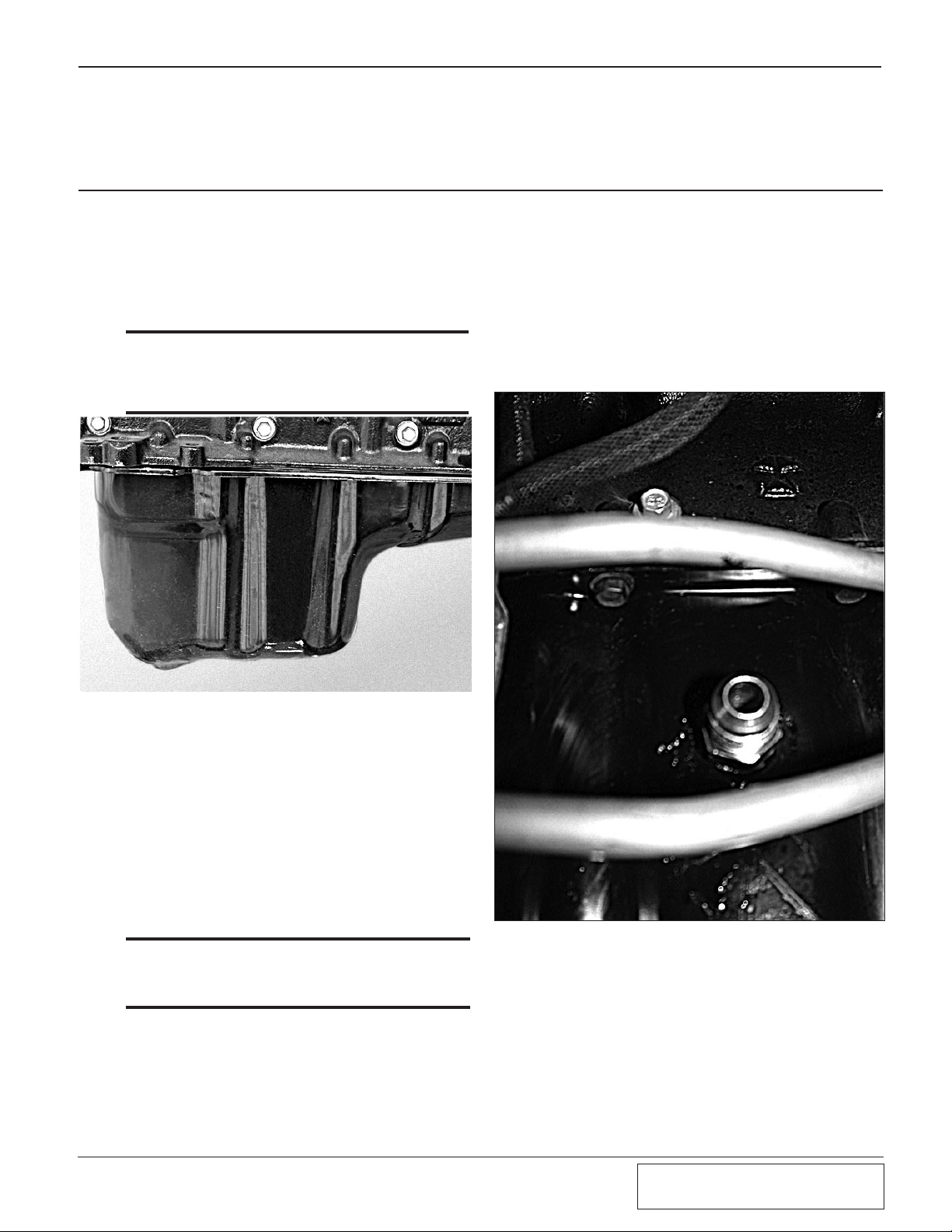

A. On the passenger side of the oil pan locate

the large hump in the oil pan measure

down1-3/4" from the lip of the oil pan and

make a mark. Center the mark between the

two oil pan retaining bolts. (See Fig 3-a.)

*** NOTE ***

It may be necessary to slightly bend the transmission cooler lines to gain access to the oil drain location.

E. Thoroughly clean the threaded area. Reach

inside the oil pan and retrieve any stray

chips. Apply a small amount of sealer to the

new threads. Apply more sealer to the supplied 3/8" x 16 x –8 fitting and secure in the

hole using a 13/16" open end wrench. Make

sure a seal is formed all around the fitting.

(See Fig. 3-b.)

Fig. 3-a

B. Using a 3/16" drill bit drill a pilot hole at the

designated mark, use grease on the drill bit

to catch any metal shavings from falling into

the oil pan. With a small piece of wire confirm that there is nothing to interfere with

the punch that is provided.

C. Using an air hammer and the supplied punch

start to enlarge the hole to 9/16" of an inch.

It is recommended to use anti seize or grease

on the punch, which will allow the punch to

role the pan correctly.

*** NOTE ***

Using a hammer can damage the oil pan, extra care

is required.)

D. When you have the hole enlarged to 9/16"

pack the flutes of a 3/8" NPT tap (not supplied). Tap the hole until the fitting can be

started.

Fig. 3-b

F. Drain the engine oil, install a new oil filter,

and refill the engine with fresh oil.

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

4. HEATER HOSE RELOCATION

Section 4

HEATER HOSE RELOCATION

4. HEATER HOSE RELOCATION

A. Install a supplied 3/8" x 45° street elbow

into the front cover of the engine, install the

second supplied 3/8" x 45° street elbow into

the previously installed elbow. Install the

factory hose barb fitting that was removed

in Step 1-e and install into the open end of

the street elbow.

*** NOTE ***

Assemble the fittings using Teflon paste to aid in

sealing. Attach the “J” shaped hose to the hose barb

and secure with a supplied hose clamp. Orientate

the fittings and hose as seen in Fig 4-a.

*** NOTE ***

These fittings may need to be re-oriented to clear

the supercharger support bracket.

Fig. 4-a

B. Install the supplied 5/8" hose mender into

the open end of the “J” shaped hose and

secure with a supplied hose clamp.

C. Trim the factory coolant hose for best fit-

ment and connect to the open end of the

supplied 5/8" hose mender. Secure using a

supplied hose clamp.

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

5. COOLANT RESERVOIR RELOCATION

Section 5

COOLANT RESERVOIR RELOCATION

5. COOLANT RESERVOIR RELOCATION

A. Locate the lower radiator hose. Locate the

TEE fitting in the lower radiator hose that

the 1" hose attaches measure up approximately 2-1/2" from the TEE fitting and cut

the upper portion of the hose.

B. Locate the three spacers, screws, and wash-

ers in the coolant relocation assembly. Raise

the coolant reservoir using the spacers and

secure with the supplied 6mm screws and

washers. (See Fig. 5-a.)

Fig. 5-a

C. Locate the supplied 1" “L” shaped hose,

hose clamps and the polished formed coolant tube in the coolant reservoir assembly.

Install the straight section of the tube into

the modified 1" lower radiator hose and

secure with a supplied hose clamp. (See Fig

5-b.)

TO MODIFIED

LOWER COOLANT

HOSE

Fig. 5-b

D. Attach the “L” shaped hose to the outlet of

the coolant reservoir. Measure and trim to

the appropriate length and secure with the

supplied hose clamps. (See Fig. 5-c.)

Fig. 5-c

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

6. SUPERCHARGER MOUNTING BRACKET

Section 6

SUPERCHARGER MOUNTING BRACKET

6. SUPERCHARGER MOUNTING BRACKET

A. Locate the supplied two small supercharger

mounting plate support brackets bolts and

washers. Assemble the two brackets using

the four 5/16" x 18 x 1.0" bolts and washers

that are provided.

B. Using the supplied support bracket and the

supplied 8mm x 120 bolts and 10mm x 130

bolts confirm that the heater hose fittings

and hose previously installed clear the support bracket.

C. Remove the 15mm headed bolt closest to the

passenger side on the alternator that secures

the alternator to the front cover. (See Fig.

6-a.) This bolt will be reused to secure the

alternator in a later step.

15mm ALTERNATOR BELT

E. Loosen the remaining alternator retaining

bolt and rotate the alternator up leaving it

attached to the front cover. (See Fig. 6-c.)

Fig. 6-c

F. Remove the 13mm headed bolt just to the

left of the upper Idler pulley. Set it aside as

it will be reused in a later step. (See Fig.

6-d.)

Fig. 6-a

D. Remove and set aside the factory plate that

secures the alternator, A/C compressor, and

front cover together. (See Fig. 6-b.)

Fig. 6-b

13mm HEADED BOLT

Fig. 6-d

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

G. Remove the casting flash from the lower

mounting location using a file or small disc

sander.

*** NOTE ***

Care must be taken to not damage the machined

surface, as this surface is critical to proper mounting

bracket alignment.

CASTING FLASH TO BE REMOVED

Fig. 6-d

H. With the supplied support brackets assem-

bled using the 5/16" x 18 x 1" bolts, and

washers confirm that the support bracket sits

flush with the cylinder head and engine

block.

I. Remove the support bracket after confirming

that it sits flush with the head and block.

Using the three 5/16"- 18 x 1" bolts and

washers provided attach the support bracket

to the supercharger mounting plate leave

these bolts loose. Align the supplied support

bracket using the supplied 8mmx120 x 1.25"

bolt and 10mm x 130 x 1.5" bolt. (See Fig.

6-e.)

INSTALL THE 12mm x 100 x 1.75 BOLT

THROUGH THE ORIGINAL MOUNTING

HOLE IN THE FRONT COVER

13mm HEADED BOLT

REMOVED IN AN EARLIER

STEP

Fig. 6-e

J. Install the supplied supercharger mounting

plate as an assembly using the cylinder head

and the engine block mounting locations.

Leaving the 8mm and the 10mm bolts loose

at this time.

K. Install the supplied 12mm x 100mm x 1.75"

bolt through the supercharger mounting

plate and into the alternator-mounting boss.

Reattach the ground strap sandwiching it

between the nut and the alternator boss,

secure the bolt with the nut provided leaving

the nut loose at this time.

L. Install the factory 13mm headed bolt

removed in a previous step. (See Fig. 6-e.)

M. Locate the supplied supercharger idler pul-

ley, idler pulley stand off and the supplied

7/16" x 3.25" bolt, washers, and nut. Install

the idler pulley and standoff in the location

noted using the supplied hardware. (See Fig.

6-f.)

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

Fig. 6-f

A/C

COMPRESSOR

PULLEY

MAIN BELT

FACTORY IDLER PULLEY

ALTERNATOR

PULLEY

SUPERCHARGER

IDLER PULLEY

FACTORY IDLER

TENSIONER

FACTORY IDLER

PULLEY

CRANK

SHAFT

PULLEY

WATER

PUMP

PULLEY

POWER

STEERING

PULLEY

S/C

PULLEY

N. Attach the supplied 1/2" supercharger oil

drain line and supplied hose clamp to the

3/8" NPT barbed fitting on the supercharger,

tighten the hose clamp. Lower the supercharger into place and secure using the five

supplied 3/8" x 24 x 1.25" long bolts and

washers.

O. Tighten all mounting hardware. Route the

oil drain line down towards the fitting previously installed in the oil pan. Trim the hose

for best fitment and install the supplied 90°

push-lock fitting into the open end of the

supplied oil drain hose. Attach the 90° fitting and drain hose to the fitting previously

installed into the oil pan. Secure the hose

away from any sharp edges, sources of heat

or moving parts using the supplied wire ties.

(See Fig 6-g.)

P. Install the supercharger/accessory drive belt

using the belt routing diagram provided.

Q. Install the supplied 1/8" NPT x –4 fitting

into the supercharger oil jet, attach the open

end of the supplied braided oil feed line to

the –4 fitting previously installed. (See Fig.

6-h.)

90° -4 OIL SUPPLY HOSE

AND 1/8 NPT FITTING

Fig. 6-h

R. Reinstall the factory heater hose onto the

factory fitting on the side of the front cover

using the factory hose clamp. This hose was

removed in an earlier step of the installation.

Fig. 6-g

All Rights Reserved, Intl. Copr. Secured

3

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

4

7. AIR INTAKE ASSEMBLY

Section 7

AIR INTAKE ASSEMBLY

7. AIR INTAKE ASSEMBLY

A. Locate the supplied air filter, formed enclo-

sure, mounting flange, and 1/4"-20 mounting hardware.

B. Attach the flange to the air filter enclosure

using the 1/4"-20 nuts, bolts, and washers

provided. (See Fig. 7-a.)

*** NOTE ***

The upper mounting tab should be about 1/8" down

from the top of the fender. (See Fig 7-x.)

F. Place the supplied 3-1/2" sleeve and the sup-

plied #56 hose clamps onto the inlet of the

supercharger. Leave the hose clamps loose at

this time.

G. Locate the supplied 180º inlet duct. Install

the supplied 90º x 3/8" NPT x 1/2" hose

barb into the tapped bung on the 180° inlet

duct using Teflon paste to seal the threads.

This fitting should face straight up. (See Fig.

7-b.)

Fig. 7-a

C. Attach the supplied air filter to the air filter

mounting flange and secure with the hose

clamp provided.

D. Remove the aluminum A/C line from its

plastic clip on the passenger side inner fender. Remove the plastic clip from the vehicle

it will not be reused. Gently bend the A/C

line up for clearance for the air filter enclosure.

E. Mount the supplied air filter enclosure to the

passenger side inner fender using the supplied sheet metal fasteners provided in the

assembly.

Fig. 7-b

H. Install the supplied 180º inlet duct to the

supplied 3-1/2" sleeve previously attached to

the supercharger. Attach a 6" length of supplied flex hose to the open end of the inlet

duct and connect the opposite end to the previously mounted air filter enclosure. Secure

all connections using the hose clamps provided. (See Fig. 7-h.)

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

Fig. 7-c

I. Locate the air intake temperature sensor pre-

viously removed, install into the unthreaded

bung on the 180° inlet elbow. Locate the air

temperature sensor factory plug, strip back

the tape to expose the wires and cut the

wires approximately 3" from the connector

plug. Using the supplied 12" length of wires

extend the connector plug to reach the relocated air temperature sensor.

*** NOTE ***

It is recommended that these wire connections be

soldered and heat shrink used to insulate the connections to ensure the best contact.

J. Cut 2" off the short end of a supplied 3/4"

90° elbow hose. Attach the cut end onto the

oil fill neck breather barb. Install a supplied

3/4" hose mender into the open end of the

installed elbow hose.

K. Cut a 13" long section of the supplied

straight 3/4" hose and connect one end onto

the hose mender previously installed, connect the opposite end onto the 3/4" 90° hose

barb previously installed into the supplied

180° air inlet duct.

L. Tighten all hose clamps.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

8. FUEL SYSTEM ASSEMBLY

Section 8

FUEL SYSTEM ASSEMBLY

8. FUEL SYSTEM ASSEMBLY

A. Locate the supplied supplemental fuel sup-

ply assembly 4PCH101-001. Assemble the

supplied fuel pump to the supplied fuel

pump/FMU mounting bracket using the provided adel clamps and 1/4"-20 bolts, nuts,

washers as shown in Fig. 8-a.

*** NOTE ***

Verify that the fuel pump outlet fitting is a 5/16"

brass barbed fitting and that a copper washer is

installed and the fitting is tight, if the fitting 5/16"

brass barbed fitting has not been installed it will be

necessary to remove the existing fitting from the

fuel pump and install the supplied 5/16" brass

barbed fitting with a copper washer.

B. Mount the supplied FMU to the fuel pump/

FMU mounting bracket using supplied

10-24 bolts, nuts, and washers. Assemble

per Fig 8-a.

Fig. 8-a

C. From beneath the vehicle mark two mount-

ing locations on the inner driver’s side frame

rail near the factory fuel lines for the fuel

pump/FMU bracket assembly to mount. Use

the bracket as a template and mount the

bracket using the supplied self-tapping sheet

metal screws to mount the bracket to the

inner frame rail. (See Fig. 8-b.)

FUEL OUTLET

D. Using a 5/16" spring lock disconnect tool

disconnect the flexible fuel line from the

hard line. Attach a length of 5/16" fuel hose

to the outlet of the fuel pump and secure

with a supplied clamp, route the hose to the

open end of the fuel line leading to the

engine. Trim the hose for best fit, install the

supplied male 5/16" fuel line adapter fitting

into the open end of the hose and secure

with a supplied clamp. Attach the male

adapter fitting to the factory fuel line.

E. Attach a 2-1/2" length of supplied 5/8" fuel

line onto the inlet of the fuel pump, two of

the supplied clamps must be used to secure

this hose onto the fuel pump. Install the supplied 5/8" to 5/16" barbed reducer into the

open end of the previously installed 5/8"

hose, secure using the supplied clamp.

Install a section of 5/16" fuel hose onto the

previously installed barb and secure the end

with a supplied clamp. Route the open end

of the hose to the open end of the fuel line

leading to the vehicle’s gas tank, trim the

hose for best fitment and install a provided

5/16" plastic female fitting into the hose and

secure with a supplied hose clamp. Attach

the supplied female adapter fitting to the

factory fuel line.

F. Cut the 5/16" fuel hose previously installed

from the supplied fuel pump inlet to the factory fuel line, install the supplied TEE fitting

at this connection and secure it using two

supplied hose clamps. Attach a length of

FUEL PUMP

Fig. 8-b

FUEL INLET

FMU

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

5/16" fuel hose to the inlet of the FMU and

secure using a supplied clamp. Route the

open end of the 5/16" fuel hose to the open

barb of the TEE fitting, trim the hose for

best fitment and secure using a supplied

hose clamp.

G. Cut the 5/16" fuel hose previously installed

from the supplied fuel pump outlet to the

factory fuel line, install the supplied TEE fitting at this connection and secure it using

two supplied hose clamps. Attach a length of

5/16" fuel hose to the outlet of the FMU and

secure using a supplied clamp. Route the

open end of the 5/16" fuel hose to the open

barb of the TEE fitting, trim the hose for

best fitment and secure using a supplied

hose clamp.

H. Route the hoses away from sharp or hot

objects and secure using the supplied wire

ties.

I. Attach an open end of the supplied 5/32"

vacuum line onto the vacuum port of the

previously installed FMU. Route the vacuum line along the frame rail and into the

engine compartment near the factory brake

booster mounted on the vehicle’s firewall.

Secure the hose line away from any sharp,

hot, or moving objects using the supplied

wire ties. The vacuum line with be attached

to a vacuum source at a later step.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

MAP SENSOR

CAM/SENSOR

CRANK/SENSOR

GREEN/RED

TAN/YELLOW

GREY/BLACK

GREEN/RED

TAN/YELLOW

GREY/BLACK

EC U PL UG /B LA CK

P/ N #3 5 P/ N #34 P /N #23

CRANK IN CAM IN MAP/S ENSO R

TO MANIFOLD

VACUUM/BOOST

G RE Y/ BL AC K

TAN /Y ELL OW

GR EE N/ RE D

GR EE N

TA N

G RE Y

B LA CK

R ED

CR A NK O UT

C AM O UT

MAP/ SEN SO R

OU T

CR AN K IN

C AM I N

MAP/ SEN SO R

IN

PAXTON ENGINE CONTROL UNIT

9. ENGINE CONTROL UNIT INSTALLATION

Section 9

ENGINE CONTROL UNIT INSTALLATION

9. ENGINE CONTROL UNIT INSTALLATION

A. Using a T-15 torx bit remove the two factory

screws securing the panel below the steering

column on the driver’s side of the vehicle

and remove the panel. In a suitable location

in the driver’s compartment under the dash

secure the PECU with the Velcro hook/latch

that is provided.

B. Locate the two 15mm headed bolts that

retain the cover that the clutch actuating

cable would pass through, remove the cover

and drill a 9/16" hole that will allow the

PECU harness and the 5/32" vacuum line to

pass through. Reinstall the cover and route

the PECU wire harnesses and vacuum hose

through the 9/16" opening. (See Fig. 9-a.)

E. Locate pin 34 at the C2 plug on the Factory

ECU. Cut the tan/yellow wire (Cam Sensor).

Connect the tan wire from the PECU to the

tan/yellow wire leading to the cam sensor on

the factory ECU. Connect the tan/yellow

wire from the PECU to the tan/yellow wire

leading to the factory ECU plug.

F. Locate pin 23 at the C2 plug on the factory

ECU. Cut the green/red wire (Map Sensor).

Connect the green wire from the PECU to

the green/red wire leading to the map sensor.

Connect the green/red wire from the PECU

to the wire leading to the factory ECU plug.

G. Tape up the violet wire, as it will not be

used. Tap the small red wire coming from

the PECU to the C1 plug pin 11. Tap the

small black wire coming from the PECU to

the C1 plug pin 18.

H. Route the supplied 5/32" vacuum line into

the engine compartment near the brake

booster, it will be connected at a later step.

C. Run the PCEU harness across the firewall

thru the factory wire harness cover to the

Factory engine control unit.

D. Locate the C2 plug at the factory ECU pin

35, cut the gray/black wire (crank sensor).

Using the connectors provided connect the

gray wire from the PECU to the gray/black

wire leading to the crank sensor. Connect

the gray/black wire from the PECU to the

gray/black wire going to factory ECU plug.

*** NOTE ***

that it is recommended that these and all other connections be soldered.

Fig. 9-a

Fig. 9-b

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

10. CHARGE COOLER INSTALLATION

Section 10

CHARGE COOLER INSTALLATION

10. CHARGE COOLER INSTALLATION

A. Install a supplied reducer sleeve onto the

throttle body, install the aftercooler core into

the reducer sleeve and secure with the supplied hose clamps. Install the supplied 2.75"

x 2" sleeve onto the discharge of the supercharger and another on the open end of the

aftercooler core previously installed.

B. Install the supplied discharge duct between

the supercharger and the aftercooler core

with the welded bung facing the vehicle’s

firewall, secure all connections using the

supplied hose clamps.

E. Attach an end of the supplied 5/32" vacuum

hose onto the vacuum nipple on the previously installed bypass valve. Route the

length of supplied vacuum hose to the brake

booster mounted on the driver’s side firewall

and secure the hose as necessary using the

supplied wire ties.

F. Remove the small vacuum cap from the fac-

tory fitting on the vehicle’s brake booster.

Attach the supplied vacuum hose onto the

open port on the brake booster, install a supplied 5/32" brass reducer into the vacuum

line previously installed. Trim the supplied

5/32" vacuum line connected to the bypass

valve for the best fitment and install onto the

open port of the previously installed reducer.

G. Install a supplied 5/32" brass vacuum TEE

fitting into the bypass valve vacuum line

previously installed and attach the vacuum

line from the FMU to the supplied TEE.

Install another supplied 5/32" brass TEE into

the bypass valve vacuum line; attach the

vacuum hose from the PECU to the previously installed TEE.

Fig. 10-a

*** NOTE ***

It may be necessary to gently bend the air conditioning line to gain clearance between it and the supercharger discharge.

C. Install the supplied 3/4" NPT x 90° brass fit-

ting into the lower threaded opening of the

aftercooler core; the fitting must face

towards the firewall of the vehicle. Install

the supplied 1/2" x 3/4" straight brass fitting

into the upper threaded opening in the aftercooler core.

D. Install the short end of the supplied 1" 90°

elbow hose onto the bung on the 180° air

inlet duct. Attach a 6" section of 1" hose

onto the bung on the supercharger discharge

duct. Install the supplied bypass valve into

the hose lines per Fig. 10-c.

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

11. HEAT EXCHANGER INSTALLATION

Section 11

HEAT EXCHANGER INSTALLATION

11. HEAT EXCHANGER INSTALLATION

A. Install the two supplied ?" 90° brass fittings

into the supplied heat exchanger, both must

be pointing in the same direction to the side.

(See Fig 11-a.)

Fig. 11-a

B. Using the supplied heat exchanger as a tem-

plate mark two mounting locations on the

radiator core support, the heat exchanger

should be mounted towards the passenger

side.

C. Mount the supplied heat exchanger with the

previously installed ?" x 90° brass fittings

pointing toward the passenger side of the

vehicle, use the supplied 1/4"-20 nuts, bolts,

and washers to secure to the radiator core

support. (See Fig. 11-b.)

Fig. 11-b

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

12. SURGE AND RESERVOIR TANK INSTALLATION

Section 12

SURGE AND RESERVOIR TANK INSTALLATION

12. SURGE AND RESERVOIR TANK INSTALLATION

A. Screw two supplied 3/4" x 1/2" NPT straight

brass fittings into the plastic surge tank.

B. Using the supplied 1/4"-20 x .50" SHCS

screw and washers attach the supplied surge

tank to the supplied surge tank-mounting

bracket. (See Fig 12-a.)

Fig. 12-a

C. The factory ground wire located on the pas-

senger side of the firewall will need to be

relocated. Using a 10mm socket remove the

nut securing the ground strap to the stud as

well as the nut secured on the stud to the

right of it. Secure the ground strap to the

second stud using the factory hardware.

D. Attach the surge tank to the stud the ground

strap had been originally secured to using

the factory 10mm headed nut.

E. Mark and drill a hole using the supplied

sheet metal screw to secure the open mounting location on the bracket. See Fig 12-b.)

Fig. 12-b

F. Mount the supplied water pump to the side

of the supplied triangle water reservoir using

the supplied 1/4"-20 hardware and adel

clamp.

G. Install the supplied 3/4" x 1/2" NPT 90°

brass fittings into the water reservoir. Mount

the supplied triangle water reservoir to the

supplied reservoir mounting bracket using

the 1/4"-20 hardware provided. (See Fig.

12-c.)

Fig. 12-c

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

H. Attach the supplied 3/4" short 90° hose to

the inlet of the water pump and connect to

the previously installed brass fitting at the

bottom of the reservoir. Secure the hose

using the supplied nylon ratchet clamps.

I. Mark two mounting locations using the

water pump reservoir assembly bracket as a

template on the passenger side inner frame

rail. Drill and secure the water pump reservoir assembly to the frame rail using the

supplied sheet metal screws.

Fig. 12-d

J. Cut the harness for the water pump leaving

as much of the wires intact from the pump.

Install a supplied ring terminal onto the

brown (negative) wire and secure to one of

the water pump reservoir assembly mounting screws.

Fig. 12-e

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

7E010-075 SHEET METAL SCREWS (SECURES

SURGE TANK BRACKET TO FIEWALL)

1/4 x 20 x 1/2 BOLTS 7A250-051

6mm WASHER 7J006-093

3/4 HOSE UNION

BARDED 7P375-075

3/4" HOSE

(7U038-000)

CUT TO FIT

90° 1/2 NPT TO

4" HOSE BARB

(7P500-026)

SURGE TANK

(8N156-050)

AIR CHARGE COOLER ???

(8PN101-180)

90° 1/2 NPT TO

4" HOSE BARB

(7P500-026)

3/4" HOSE (7U038-000)

CUT TO FIT

WATERCOOLER (8N006-010)

WATERCOOLER (8N006-010)

90° MOLDED HOSE ELBOW (7U030-065) CONNECTS FITTING ON BOTTOM

TANK TO INLET OF WATER PUMP

WATER PUMP

(8F001-402)

1/2" SOCKET HEAD CAP SCREW (7A250-050)

INSTALL THROUGH ADEL CLAMP AND INTO

WATER TANK TO HOLD WATER PUMP

WATER PUMP CLAMP (8N010-080)

WATER

RESERVOIR

(8N055-030)

1" NPT HOLE

NOT USEDHOLE SHOULD

BE BLIND OR

PLUGGED

13. WATER HOSE ROUTING

Section 13

WATER HOSE ROUTING

13. WATER HOSE ROUTING

*** NOTE ***

Make sure to leave the hose slightly long to allow for

engine movement.

A. Using a 3/4" 90° molded hose, trim 2" off

from the short hose leg, attach the cut end

onto the 3/4" x 1/2" NPT 90° brass fitting on

the passenger side of the supplied heat

exchanger previously installed. Install a supplied 3/4" brass hose mender into the long

end of the hose.

B. Using a supplied 3/4" 90° molded hose, trim

2" off of the short end, install the short end

onto the 3/4" 90° brass fitting previously

installed in the aftercooler core. Install a

supplied 3/4" brass hose mender into the

long end of the molded hose.

C. Cut a 55" section of 3/4" hose, connect one

end onto the 3/4" hose mender previously

installed in the molded hose attached to the

aftercooler. Route the hose along the passenger side inner fender, under the radiator, and

connect to the open end of the 3/4" brass

hose mender/elbow hose connected to the

heat exchanger.

D. Using another 3/4" 90° molded hose trim

2-1/2" off of the short end of the hose,

install the short end onto the outlet of the

previously installed water pump. Install a

3/4" brass hose mender into the open end of

the hose.

E. Cut a 27" long section of the supplied 3/4"

hose, attach an end to the open end of the

previously installed brass hose mender.

Attach the open end of the hose to the open

fitting on the supplied heat exchanger, trim

the hose for best fitment.

F. Cut a 14" long section of the supplied 3/4"

hose, attach one end to the straight fitting on

the aftercooler core, connect the open hose

end to the fitting on the side of the surge

tank, trim the hose length for best fitment.

G. Cut a 60" long section of the supplied 3/4"

hose, attach one end to the 3/4" x 1/2" NPT

brass fitting previously installed in the bottom of the supplied surge tank. Route the

hose along the passenger side inner fender

and connect the open end of the hose to the

3/4" x 1/2" NPT 90° brass fitting on the top

of the water reservoir, trim the hose for best

fitment.

H. Secure all hose connections using the sup-

plied nylon hose clamps. Check to ensure all

hose lines are free of kinks, secure hose

lines as needed away from sharp, hot, or

moving objects using the supplied wire ties.

Fig. 13-a

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

14. WATER PUMP WIRING

Section 14

14. WATER PUMP WIRING

WATER PUMP WIRING

A. Using a supplied sheet metal screw, attach

the supplied relay to the driver’s side radiator core support per Fig. 14-a.

Fig. 14-a

B. Attach a supplied ring terminal to the

ground wire (black) on terminal 86 of the

supplied relay; attach a supplied ring terminal to the relay mounting screw.

C. Route the red wire on terminal 87 down and

along the backside of the front bumper and

connect to the green wire using the supplied

butt connector at the previously installed

water pump. Use the supplied wire ties to

secure as necessary.

D. Route the yellow wire from terminal 85 and

the ???

E. Route the red wire from terminal 30 on the

relay into the engine compartment and

attach a supplied ring terminal to the wire

end. The ring terminal must be connected to

a constant battery power source. Remove the

cover from the remote battery lug next to the

engine compartment’s fuse/relay center.

Secure the ring terminal to this lug using

factory hardware and use wire ties to secure

the wire as needed away from sharp or hot

objects.

F. With the key on, make sure the charge cool-

er water pump is operating and that water is

flowing through the surge tank. Fill the

surge tank if necessary with a 50/50 coolant/

water mix. If the water is not flowing,

remove the charge cooler supply hose and

lower until water flows out of the hose. If

necessary, provide light suction to the hose

to help prime the pump. Verify water flow.

Do not let the pump run for extended periods (30 seconds or more) without water

flow. Fill the charge cooler tank until the

level stabilizes.

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

15. FINAL ASSEMBLY AND CHECK

Section 15

FINAL ASSEMBLY AND CHECK

15. FINAL ASSEMBLY AND CHECK

A. If your battery was disconnected, reconnect

it.

B. If your vehicle has gone over 10,000 miles

since its last spark plug change, you will

need to change the spark plugs now before

test driving the vehicle.

C. Check all fittings, nuts, bolts and clamps for

tightness. Pay particular attention to oil and

fuel lines around moving parts, sharp edges

and exhaust system parts. Make sure all

wires and lines are properly secured with

clamps or wire ties.

D. Check all fluid levels, making sure that your

tank(s) is/are filled with 91 octane or higher

fuel before commencing test drive.

E. Start the engine and allow to idle for a few

minutes.

F. Recheck to be sure no hoses, wires, etc. are

near exhaust headers or moving parts and

check for any signs of fluid leakage.

Recheck all fluid levels.

G. PLEASE TAKE SPECIAL NOTE:

Operating the vehicle without ALL subassemblies completely and properly installed

may cause FAILURE OF MAJOR

COMPONENTS.

H. Test drive the vehicle.

I. Read the Street Supercharger System

Owner’s Manual and RETURN THE

Warranty REGISTRATION FORM within

thirty (30) days of purchasing your supercharger system to qualify for the 3-year limited warranty.

1

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

This Page Left Intentionally Blank.

P/N: 4809650

©2004 Paxton Automotive

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

2

This Page Left Intentionally Blank.

3

All Rights Reserved, Intl. Copr. Secured

11NOV04 v1.0 03DodgeHemi(4809650v1.0)

©2004 Paxton Automotive

P/N: 4809650

1300 Beacon Place • Oxnard, CA 93033-9901 • (805) 604-1336

FAX (805) 604-1337 • paxtonautomotive.com • M-F 8:00 AM - 4:30 PM PST

DP/N: 4809650 - v1.0 11/09/04

Loading...

Loading...