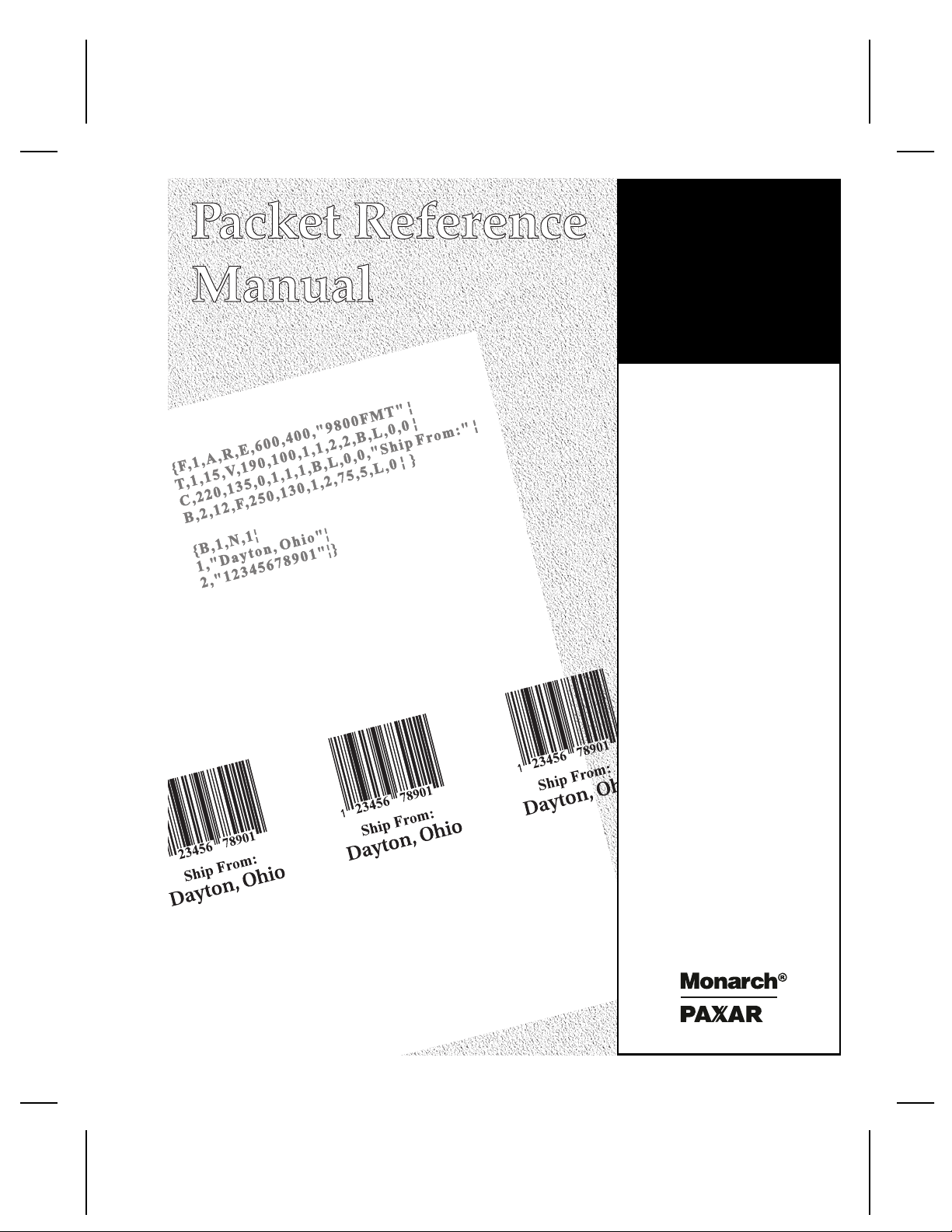

Page 1

MONARCH

DOS-based

PATHFINDER

System

Ultra

TC6035PR Rev. BA 6/01 ©2001 Monarch Marking Systems, Inc. All rights reserved.

Page 2

Each product and program carries a respective written warranty, the only

warranty on which the customer can rely. Monarch reserves the right to make

changes in the product, the programs, and their availability at any time and

without notice. Although Monarch has made every effort to provide complete

and accurate information in this manual, Monarch shall not be liable for any

omissions or inaccuracies. Any update will be incorporated in a later edition of

this manual.

©1998 Monarch Marking Systems, Inc. All rights reserved. No part of this

publication may be reproduced, transmitted, stored in a retrieval system, or

translated into any language in any form by any means, without the prior

written permission of Monarch Marking Systems, Inc.

WARNING

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

CANADIAN D.O.C. WARNING

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Réglement sur le

brouillage radioélectrique édicte par le ministère des Communications du Canada.

Trademarks

Monarch, Pathfinder, and Ultra are registered trademarks of Monarch Marking Systems, Inc.

6035 is a trademark of Monarch Marking Systems, Inc.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft in the U.S. and other countries.

TrueType is a trademark of Apple Computer, Inc.

Hewlett-Packard is a registered trademark of Hewlett-Packard Company.

CG Triumvirate and CG Triumvirate Bold are trademarks of AGFA Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated which may be registered in certain

jurisdictions.

Monarch Marking Systems

P.O. Box 608

Dayton, Ohio 45401

Page 3

TABLE OF CONTENTS

GETTING STARTED

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Creating an MPCLII Format Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using MPCLII Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

MPCLII Punctuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Standard Syntax Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

DESIGNING A FORMAT

Starting with a Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Determining Format Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Determining the Print Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Drawing Rough Sketches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

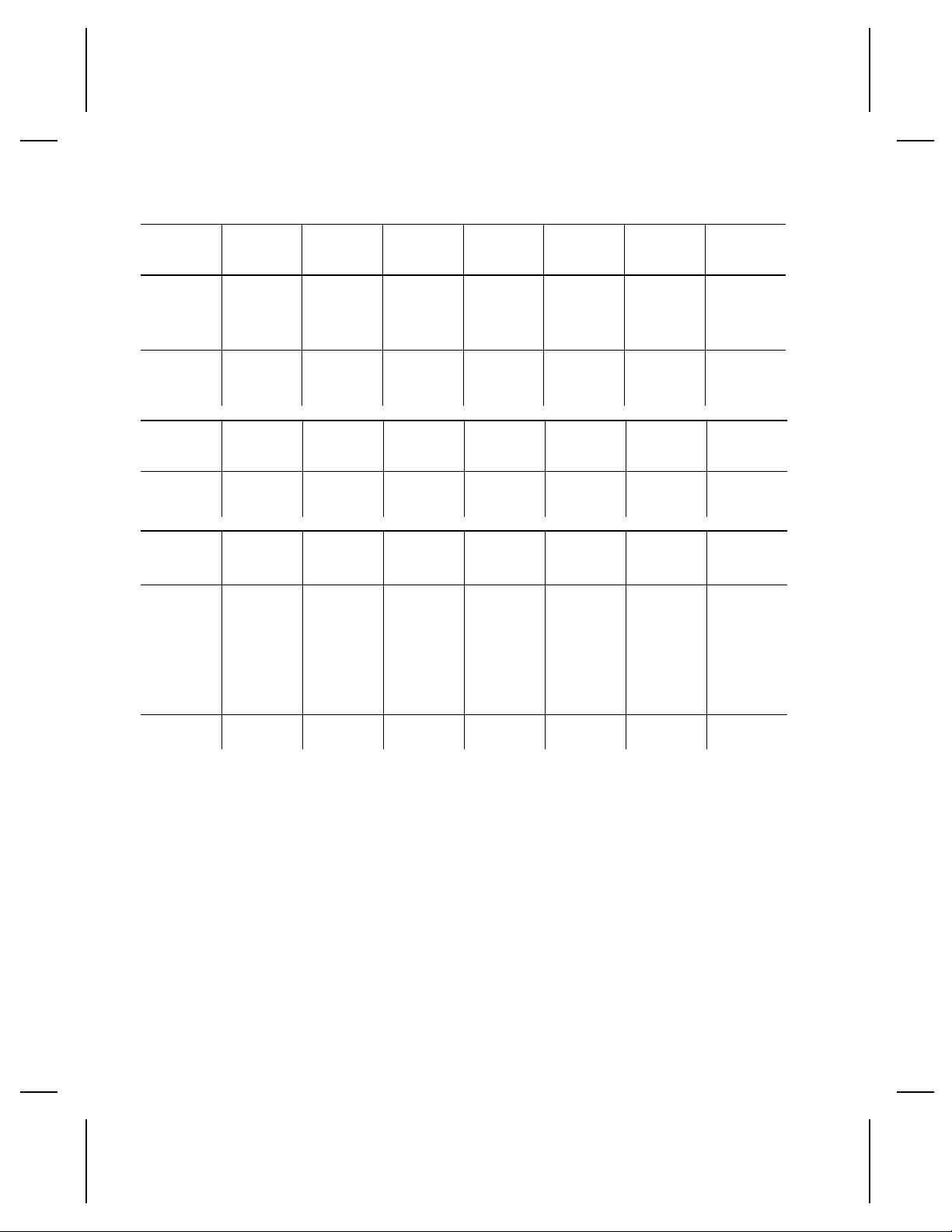

Using Supply Layout Grids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Considering Field Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Considering Fonts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Using the Format Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Filling in the Format Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

DEFINING FIELDS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Defining the Format Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Defining Text Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Defining Bar Code Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Defining Constant Text Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Defining Line Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Line Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Defining Box Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

i

Page 4

DEFINING FIELD OPTIONS

Applying Field Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Combining Field Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Option 1 (Fixed Data). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Option 4 (Copy Data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Merging Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Sub-Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Option 31 (Calculate Check Digit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Option 50 (Bar Code Density) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Option 51 (PDF417 Security/Truncation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Option 52 (PDF417 Width/Length) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Option 61 (Re-image Field) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Using Check Digits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Sum of Products Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Sum of Digits Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

PRINTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Defining the Batch Header. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Defining the Batch Control Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Defining Batch Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Merged or Sub-Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Downloading Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Sequential Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Batch Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Batch Quantity Zero Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Defining the Print Control Packet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Clearing Packets from Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

CREATING GRAPHICS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview of Bitmapped Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Determining a Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Designing Bitmapped Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

ii

Page 5

Special Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Using the Hex Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Using the Run Length Encoding Method. . . . . . . . . . . . . . . . . . . . . . . 6-5

Determining How to Store the Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Using RAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Using Temporary Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Creating a Graphic Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Positioning the Graphic Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Defining the Graphic Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Creating Bitmap Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Creating Next-Bitmap Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Creating Duplicate Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Sample Hex Graphic Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Sample Run Length Graphic Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Placing the Graphic in a Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Defining the Graphic Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Sample Bitmap Graphic Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

TROUBLESHOOTING

Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

If You Receive an Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Calling Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Data Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Format Errors (1 - 99) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Batch Errors (100 - 199) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Rule Errors (200 - 249) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Online Configuration Errors (250 - 299) . . . . . . . . . . . . . . . . . . . . . . . 7-8

Check Digit Errors (300 - 324). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Graphic Errors (325 - 399) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

General Packet Errors (300 - 324). . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Data Formatting Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Machine Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

iii

Page 6

PRINTER OPTIMIZATION

Adjusting the Print Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Reducing Imaging Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

General Format Tips and Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

SAMPLES

FONTS

SYMBOL SETS/CODE PAGES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Sample UPCA Format Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Sample Fixed Character Format Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Standard Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Monospaced Font Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Proportional Font Magnification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Using Font Numbers in Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Locating the Font Number in a Font Packet . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Supported Symbol Sets and Code Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Selecting a Symbol Set or Code Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Selecting the Internal Symbol Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Selecting the 437 Code Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Using Code 128 Function Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

ASCII Symbol Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Code Page 437 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Dot to Run Length Encoding Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

ON (Black) Dots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

OFF (White Dots) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

iv

FORMAT DESIGN TOOLS

Batch Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Check Digit Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Page 7

GETTING STARTED

Before you read this manual, review the printer information in the

Equipment Manual.

About This Manual

This manual is for the developer creating the application for the

printer.

You must develop an application that uses the packets

you create. Refer to the Programmer Manual for

information about developing an application.

Use this manual to design and print your own custom formats on

the Monarch® 6035 printer. This chapter creates a sample

MPCLII packet.

Standard Features

The following features are standard on the 6035 printer: 192 dots

per inch (DPI) printhead, 2 inch by 4 inch maximum print image,

1.8 inches per second (IPS) maximum print speed, baud rate up to

115K, center-justified printing, 4-line display, alphanumeric keypad,

scanner, and 1 Meg memory with an additional 2 Meg flash ROM.

1

Getting Started

1-1

Page 8

Creating an MPCLII Format Packet

A format defines which fields appear and where the fields are

printed on the label. The printer requires this information in a

special form, using Monarch

This section describes how to create a sample MPCLII format

packet.

Make sure supplies are loaded, you have a fully charged battery,

and you have an application in the printer. Refer your Equipment

Manual for more information.

For detailed information about the format header, text, constant

text, and bar code fields, see Chapter 3, "Defining Fields." For

information about batch packets, see Chapter 5, "Printing."

Type the following format header, in any text editor:

1.

{F,25,A,R,M,508,508,"FMT-25" p

Type the following constant text field:

2.

C,250,80,0,1,1,1,W,C,0,0,"MONARCH MARKING:",0 p

Type the following bar code field:

3.

®

Printer Control Language II (MPCL).

1-2

Getting Started

B,1,12,F,110,115,1,2,120,5,L,0 p

Type the following text field:

4.

T,2,18,V,30,30,1,1,1,1,B,C,0,0,0 p }

Page 9

You have created a format packet for your MPCLII printer. Now, a

batch packet must be created before you can print the format.

Type the following batch header, after the text field line:

5.

{B,25,N,1 p

Type the following bar code data:

6.

1,"12345678901" p

Type the following text field data:

7.

2,"DAYTON, OHIO" p }

8.

Save your file as SAMPLE.FMT.

For your application to use the format, use the

PCL library functions in

the Programmer Manual.

Getting Started

1-3

Page 10

Using MPCLII Conventions

Here are some guidelines to follow when using MPCLII.

MPCLII Punctuation

Use the following symbols when creating MPCLII packets:

{ start of header

} end of header

p field separator. Depending on the character

set you are using, this character may appear

differently, but it should always be hex 7C.

, parameter separator

"ABC" Quotation marks enclose character strings.

Empty quotes ("") identify null strings or

unused fields.

‘comment‘ Grave accents enclose comments. Any data

enclosed in grave accents is ignored. Do not

embed comments within a quoted string.

Grave accents are also used to reject

mainframe data.

1-4

Getting Started

These MPCL characters are the default.

Page 11

Standard Syntax Guidelines

When creating MPCLII packets:

N

Begin each packet with a start of header ({).

N

End each packet with an end of header (}).

N

Define no more than 50 fields in a format. Each p indicates

one field. However, options are not counted as fields.

N

The field number (0 to 999) must be unique. Monarch

recommends starting at 1, instead of 0.

N

Do not use a field number more than once per format.

N

Define all fields in the order you want to image/print them.

N

Separate all parameters with a Parameter Separator (,).

N

End each field with a Field Separator ( p ).

N

Enter all information in CAPITAL letters, except words or

phrases within quotation marks.

N

Include all parameters for a field unless documented as

optional.

N

Define non-printable text fields before the field to which they

apply.

N

Define options immediately after the field to which they apply.

N

Multiple options can be used with most fields. Options can be

used in any combination except as noted with each definition.

N

Keep in mind that proportionally spaced fonts need wider fields

than monospaced fonts. For variable field data, use a letter

"W" to determine the maximum field size.

N

Do not place a new line (return) or any other non-printing

character in a character string. However, a carriage return or

line break after each p makes your formats easier to read.

T,1,20,V,30,30,1,1,1,1,B,C,0,0,0 p

T,2,10,V,50,30,1,1,1,1,B,C,0,0,0 p

N

Spaces are ignored, except within character strings.

Getting Started

1-5

Page 12

1-6

Getting Started

Page 13

DESIGNING A FORMAT

This chapter describes how to

N

determine what kind of information to use in your format.

N

use the Supply Layout Grid and Format Worksheet.

N

categorize data into field types.

N

select fonts to use in your format.

2

Designing a Format

2-1

Page 14

Starting with a Design

Before you create a format packet, you must design your label.

There are several steps to designing a custom label:

Decide which fields should appear on your label. See

1.

"Determining Format Contents" for more information.

Determine your label size. Labels are available from Monarch

2.

in a wide variety of sizes. Your application and the amount of

data you need to print determines the supply size. Contact

Monarch Marking for more information.

Draw a rough sketch of your label. You may want to draw

3.

several variations to see what works best. See "Drawing

Rough Sketches" for more information.

Identify the field types that appear on your label. See

4.

"Considering Field Types" for more information.

Decide which fonts you want to use. See "Considering Fonts"

5.

for more information.

Fill out your Format Worksheet. See "Using the Format

6.

Worksheet" for more information.

2-2

Designing a Format

At this point, you are ready to use your format.

Create a format packet, based on how you filled out your

7.

worksheet. See Chapter 3, "Defining Fields," for more

information.

For your application to use the format, use the PCL library

8.

functions in the Programmer Manual.

Execute your application.

9.

Page 15

Determining Format Contents

Before you lay out your format, you need to make a few decisions.

For example:

N

How large is your supply?

N

Which fonts do you want to use?

N

Do you want to include a bar code?

N

Do you want to include graphics?

Determining the Print Area

The print area varies, depending on the size of your supply. Below

are the maximum and minimum print areas. Notice that the top

edge of the supply exits the printer first.

Unit of

Measure

English

(1/100")

Metric

(1/10mm)

Dots

(1/203 dots)

Maximum

Supply Size

200 x 400 183 x 365 120 x 55 109 x 46

508 x 1016 465 x 927 305 x 140 277 x 117

384 x 768 352 x 701 230 x 106 208 x 88

Maximum

Print Area

Minimum

Supply Size

Minimum

Print Area

For exact print area measurements of your

supply, see the supply layout grids in

Appendix D.

Use the following formulas to convert inches to dots and metric:

Dots = inches x 192

Metric (1/10mm) = inches x 254

English (1/100 inch) = 100 x (dots/192)

Dots = Metric (1/10 mm) x 756/1000

Designing a Format

2-3

Page 16

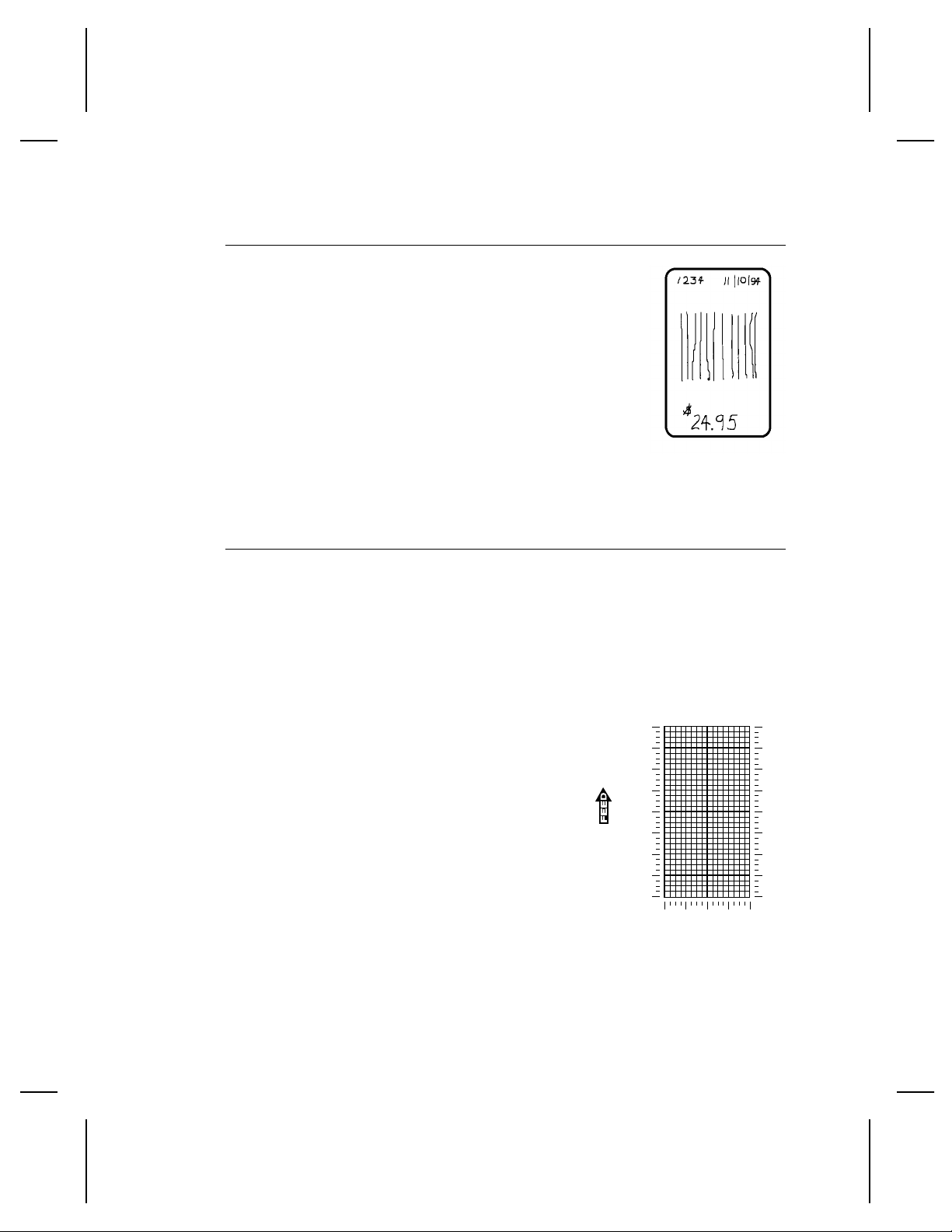

Drawing Rough Sketches

After you decide what information you want to

print, sketch how you want the information to

appear on the label. Note any areas that are

preprinted on the label, such as a logo.

As soon as you know what information to include

on the label, and you have a rough sketch, you

can use a supply layout grid to help you layout

and size your label. If you do not want to use a

grid, go to "Considering Field Types" to choose

what information you want on your label.

Using Supply Layout Grids

A supply layout grid contains measurement markers. These

markers help you accurately position information on your label.

Decide whether you want to design formats using English, Metric,

or Dot measurements. Choose from the following grids:

N

English

The English grid is measured in

1/100 inches.

N

Metric

The Metric grid is measured in 1/10

millimeters (mm).

N

Graphic

The printer uses dots to print images

on a label. The printhead has 192 dots

per inch (DPI).

Supply Layout

(dpi)

192

768

672

576

480

384

288

192

96

0.0

192

0.0

384

192

96

288

768

672

576

480

384

288

192

96

0.0

2-4

Designing a Format

If you want to use supply layout grids, a copy of each is in

Appendix D, "Format Design Tools."

Page 17

Considering Field Types

After you select a supply size, the next step in designing a format

is to decide what information you want to print on the label. For

example, you may want to print your company name, price of an

item, and a bar code that combines information from other places.

Everything you want to print falls into one of the following

categories.

Field Type Description Examples

Text Contains letters, numbers, or

symbols you want to print.

Bar Code Used for printing bar codes

that can be scanned.

Constant Text Prints fixed characters that

print without changing.

Line or Box Highlights or separates items. line marking out the regular

Graphic Contains a bitmap image or a

compliance label overlay.

item number, item

description, department

number, price, date

item or serial numbers, zip

codes, information you don’t

want to have visible to

customers

company name, company

address

price, border around the

supply

logos

All of the above field types except graphics

are discussed in Chapter 3. See Chapter 6,

"Creating Graphics" for information on

including graphics in your format.

Designing a Format

2-5

Page 18

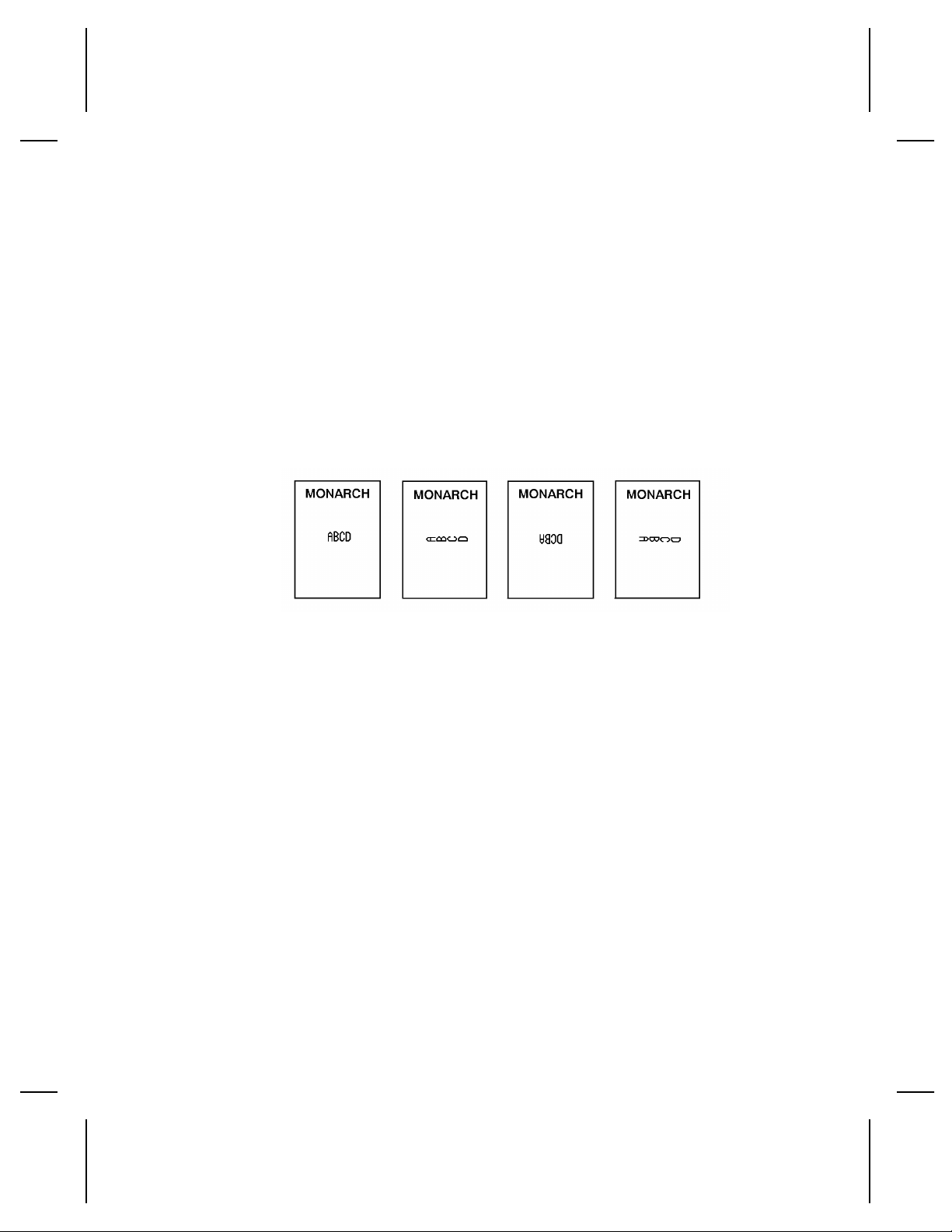

Considering Fonts

When working with fonts, you have three considerations:

N

font appearance

N

font size (bitmapped)

N

font spacing (monospaced or proportional)

See Appendix B, "Fonts," for samples of each font.

Using the Format Worksheet

The Format Worksheet is divided into sections that list the field

types. Each section has boxes to fill in with parameters that

define your format. A format worksheet is included in Appendix D,

"Format Design Tools."

Filling in the Format Worksheet

Decide what type of field to use on your label.

Make a copy of the Format Worksheet.

1.

2-6

Designing a Format

Define the Format Header.

2.

Define options as you require them. See Chapter 4, "Defining

3.

Field Options" for more information.

Page 19

DEFINING FIELDS

This chapter provides a reference for defining

N

the format header

N

text and constant text

N

bar code fields

N

line and box fields.

3

Defining Fields

3-1

Page 20

Defining the Format Header

A Format Header begins a format file.

Syntax

{F,format#,action,device,measure,length,

width,"name" p

F1. F Format Header.

F2. format# Unique number from

F3. action Enter A to add a new format to the printer.

F4. device Format storage device. R is the only valid value.

F5. measure Unit of measure. Options:

English, measured in 1/100 inches

E

Metric, measured in 1/10 mm

M

Graphic, measured in dots

G

F6. length Supply length, top to bottom, in selected units.

English

Metric

Dots

F7. width Supply width, from left to right, in selected units.

English

Metric

Dots

F8. "name" Format name (optional),

quotation marks.

55 - 400

140 - 1016

106 - 768

120 - 200

305 - 508

230 - 384

to identify the format.

0-999

characters, enclose within

0-8

3-2

Defining Fields

Example:

{F,1,A,R,E,300,200,"TEXTILES" p

Format 1 ("TEXTILES") uses a three inch long by two inch wide

label.

Page 21

Defining Text Fields

Create a separate definition for each text field. If text falls on two

lines, each line of text requires a separate definition.

Syntax

T,field#,# of char,fix/var,row,column, gap,font,hgt mag,wid

mag,color,alignment, char rot,field rot,sym set

p

T1. T Text Field.

T2. field# Unique number from

T3. # of char Maximum number of printed characters (

to identify this field.

0-99

0-2710

) in the field.

T4. fix/var Fixed or variable length field. Options:

Fixed length

F

Variable length

V

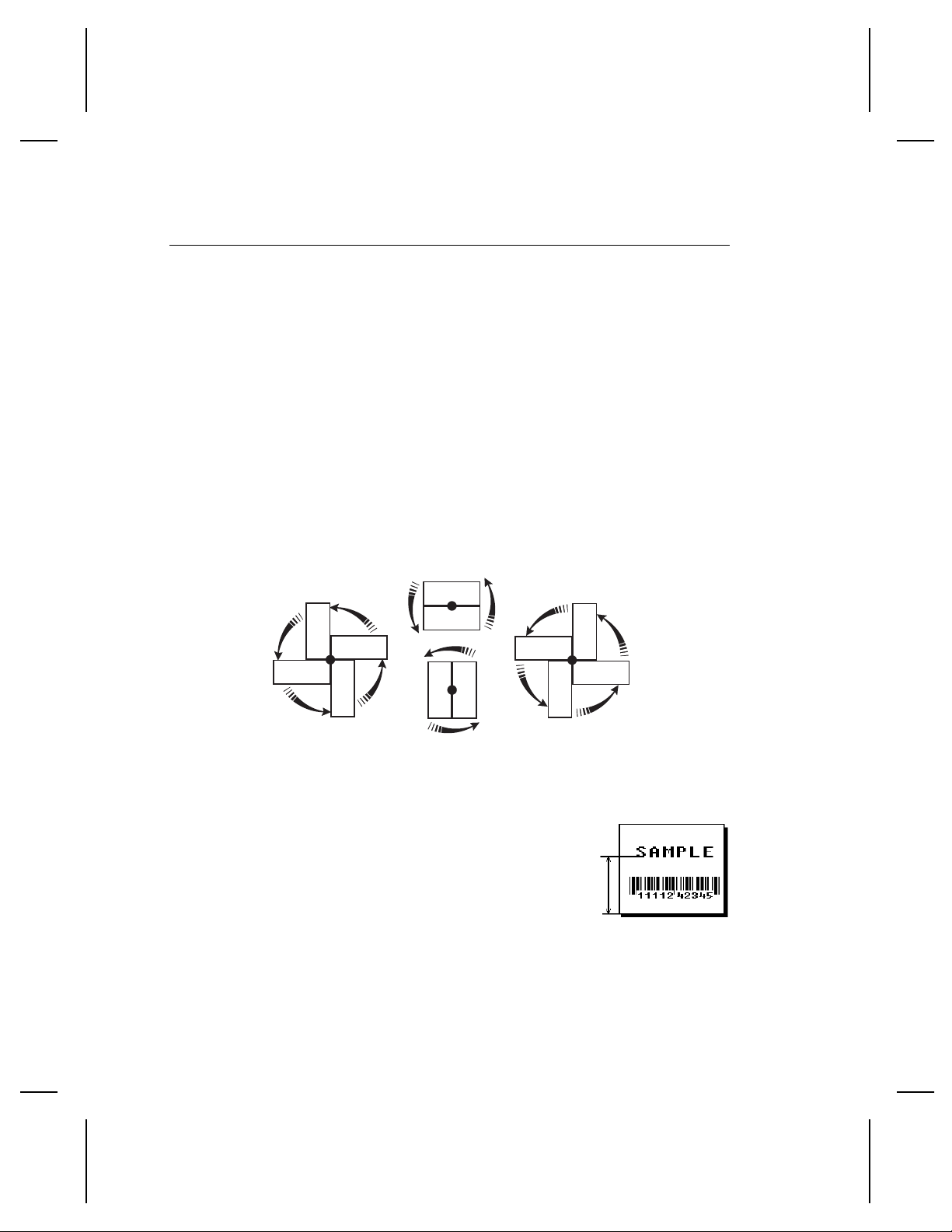

T5. row For monospaced fonts, distance from bottom of print area to

the pivot point. The pivot point varies depending on how text

is justified.

0 (TOP)

3 (RIGHT)

2 (BOTTOM)

1 (LEFT)

End-Justified

1 (LEFT)

0 (TOP)

2 (BOTTOM)

3 (RIGHT)

Left/Center/Right-Justified

2 (BOTTOM)

0 (TOP)

3 (RIGHT)

1 (LEFT)

Balanced

For proportionally spaced fonts, distance from bottom of print

area to baseline of characters in field.

English

Metric

Dot

0 - 365

0 - 927

0 - 701

Defining Fields

3-3

Page 22

T6. column Distance from the left edge of the print area to the pivot point

to find the column location.

English

Metric

Dots

T7. gap Number of dots between characters (192 dots per inch).

Range:

NOTE:

Any number other than 0 or the default number affects your

field width. Default spacing:

Letter Gothic Bold 6pt.

Letter Gothic Bold 9pt.

Reduced

All other fonts

T8. font Style of font. Options:

CG Trium Bold CG Trium Bold Cond

1000

1001

1002

1003

1004

1005

0 - 183

0 - 465

0 - 352

.

0-99

For monospaced fonts, the additional spacing is

added to the existing inter-character gap. This is

also true for proportionally spaced fonts, but

remember that the inter-character gap varies with

character combinations.

1 dot

2 dots

1 dot

varies with each letter

6.5 pt

8 pt

10 pt

12 pt

18 pt

22 pt

1006

1007

1008

1009

1010

1011

6.5 pt

8 pt

10 pt

12 pt

18 pt

22 pt

3-4

Defining Fields

Letter Gothic Bold Reduced

1012

1013

NOTE:

6 pt

9 pt

Point sizes greater than 12 include only the following

special characters:

0123456789#$%&(),./@DFKLMPS\kprö¢£¥.

All other point sizes use the whole symbol set. This

information may not apply to optional fonts.

Internal Font

2

Page 23

T9. hgt mag Height magnifier,

proportionally spaced fonts, because characters lose

smoothness at higher magnifications.

(times). Use a magnifier of 1 with

1-7

T10. wid mag Width magnifier,

not have a set width. To estimate the size of your field, use

the letter "W" for the widest field or an "L" for an average

width field. Find your selected font and the desired width in

Appendix B, "Fonts."

T11. color Options for standard printer fonts:

Opaque, Normal, Black, Normal

B

Opaque, Normal, White, Normal

D

Transparent, Normal, Black, Normal

O

Transparent, Normal, White, Normal

R

Opaque, Normal, White, Normal

W

NOTE:

There are two types of field color overlay attributes:

Transparent The overlay field (text or constant text) does

Opaque The overlay field blocks out (or "erases")

Solid black print should not exceed 30% on a given

square inch of the label, or the printhead life may be

decreased.

(times). Proportionally spaced fonts do

1-7

not block out (or "erase") existing fields.

existing fields.

Line field

blocked out by

opaque field

using attribute B

Line field not

blocked out by

transparent field

using attribute O

Field placement in the packet is an important consideration

when using field color attributes. If a line field is defined

before the overlay (text or constant text) field, the line field is

blocked out by the overlay field, depending on the overlay

field’s color attribute. If a line field is defined after the overlay

field, the line field is not blocked out by the overlay field,

regardless of the overlay field’s color attribute.

Defining Fields

3-5

Page 24

T12. alignment Options:

Align on left side of field.

L

Center text within field (monospaced fonts only)

C

Align on right side of field (monospaced fonts only)

R

Align at midpoint of field

B

Align at endpoint of the field

E

Use L, B, or E for any font.

T13. char rot Character rotation. The field or supply does not rotate, only

T14. field rot Field rotation. Field rotation rotates the whole field, not just

T15. sym set Symbol set. Use 1 (ASCII Symbol Set)

the characters do. Options:

Top of character points to top of field

0

Top of character points to left of field

1

Top of character points to bottom of field

2

Top of character points to right of field

3

the characters. Rotation is affected by the pivot point, which

varies depending on how text is justified. Lower left corner of

field is the pivot point. Options:

Top of field points to top of supply

0

Top of field points to left of supply

1

Top of field points to bottom of supply

2

Top of field points to right of supply

3

See Appendix C, "Symbol Sets/ Code Pages" for more information.

3-6

Defining Fields

Example:

T,2,10,V,250,50,0,1,1,1,B,C,0,0,0 p

Defines a text field (field #2) with a variable length of up to 10

characters. The field begins at row 250, column 50. There is no

additional gap between characters, and the Standard font is used

without any additional magnification. The printing is black on

white and centered. No field or character rotation is used. The

internal symbol set is used.

Page 25

Defining Bar Code Fields

Each bar code field requires a separate definition.

Syntax

B,field#,# of char,fix/var,row,column,

font,density,height,text,alignment,

field rot p

B1. B Bar Code Field.

B2. field# Unique number from

B3. # of char Maximum number of characters. If the bar code uses a check

digit, allow an extra character for the check digit. The actual

maximum number of characters is limited by the size of the

label and bar code density. Range:

B4. fix/var Fixed (F) or variable (V) length field.

Bar Code Number of Characters Fixed or

UPCA

UPCA+2

UPCA+5

UPCA+Price CD

UPCE or LAC

UPCE+2

UPCE+5

EAN8

EAN8+2

EAN8+5

EAN13

EAN13+2

EAN13+5

EAN13+Price CD

Interleaved 2 of 5

or

Interleaved I 2 of 5 with Barrier Bar

Code 39 or MOD43

to identify this field.

0-99

0-2710

12 F

14 F

17 F

12 F

7F

9F

12 F

8F

10 F

13 F

13 F

15 F

18 F

13 F

0 to 2710 F or V

0 to 2710 F or V

.

Var iable

Defining Fields

3-7

Page 26

Bar Code Number of Characters Fixed or

Codabar (NW7)

Code 128

Code 93

Code 16K

MSI

Maxicode

PDF417

POSTNET

Var iable

0 to 26 F or V

0 to 2710 F or V

0 to 2710 V

0 to 2710 V

0 to 14 F or V

15 to 99 F

0 to 2710 F or V

0 to 11 F

B5. row Distance from bottom of the print area to the pivot point of the

field. The pivot point varies, depending on how the field is

justified. Pivot points:

Left/Center/Right-Justified Fields

Balanced Fields

Remember to include text or numbers that may appear with

the bar code for the row measurement.

English

Metric

Dots

0 - 365

0 - 927

0 - 701

End-Justified Fields

3-8

Defining Fields

Page 27

B6. column Distance from the lower left edge of the print area to the pivot

point.

English

Metric

Dots

NOTE:

B7. font Bar code. Options:

UPCA

1

UPCE

2

Interleaved 2 of 5

3

Code 39 (no check digit)

4

Codabar

5

EAN8

6

EAN13

7

Code 128

8

MSI

9

UPCA +2

10

UPCA +5

11

UPCE +2 check digit)

12

UPCE +5

13

0 - 183

0 - 465

0 - 352

Allow a minimum of

of bar code and label edges or other data.

Two-dimensional barcodes cannot be scanned

(MaxiCode, PDF417, Code 16K and POSTNET).

inch between the scan edge

1/10

14

15

16

17

21

22

23

31

32

33

40

41

44

50

EAN8 +2

EAN8 +5

EAN13 +2

EAN13 +5

LAC

POSTNET

Code 93

Code 16K

PDF417

Maxicode

Code 39 (MOD 43

UPCA & Price CD

EAN13 & Price CD

Interleaved 2 of 5 with

Barrier Bar

B8. density Bar code density. Use the following table for the bar code

density.

Defining Fields

3-9

Page 28

Barcode

Ty pe

UPCA

+2/+5

Price CD

UPCE

+2/+5 4 120% 3/15.6 9/12

EAN8

+2/+5 4 120% 3/15.6 10/13

EAN13

+2/+5

Price CD

Interleaved 1 1.0 21/109.4 1:3.0 0 to

2 of 5 2 2.0 12/62.5 1:2.5

or I 2 of 5 4 4.0 6/31.3 1:2.5

with 5 5.3 4/20.8 1:3.0

Barrier Bar 6 6.0 4/20.8 1:2.5

Code 39 1 1.3 10/52.1 1:2.5 0 to

or MOD 43 2 1.7 8/41.7 1:2.5 $%*+-./

Codabar 2 2.0 8/41.7 1:3.0 0 to

(NW7) 3 2.9 6/31.3 1:2.5 0 to 9

Code 93 3 3.6 6/31.2 N/A 0 to

Density

Selector

2

4 120% 3/15.6 14/17

2

2

2

4 120% 3/15.6 15/18

3 3.0 7/36.5 1:3.0

7 7.1 3/15.6 1:3.0

8 8.3 3/15.6 1:2.3

9 9.1 3/15.6 1:2.0

10 10.6 2/10.4 1:3.0

11 10.6 2/10.4 1:3.0

12

13 13.7 2/10.4 1:2.0

3 3.3 4/20.8 1:2.5 0 to 9

4 4.0 3/15.6 1:3.0 A to Z

6 6.0 2/10.4 1:3.0

7

11 3.7 4/20.8 1:2.0

12 12.0 1/5.2 1:3.0

20 2.8 5/26.0 1:2.2

4 4.3 4/20.8 1:2.5 :

5 4.7 4/20.8 1:2.0 a to d

7 7.7 2/10.4 1:3.0

8

9 9.6 2/10.4 1:2.0

4 4.3 5/26.0

5 5.3 4/20.8

7

10 10.7 2/10.4

Density

(% or cpi)

80% 2/10.4 N/A 11 or 12 1,5,6 0 to 9

80% 2/10.4 N/A 6 or 7 1,5,6 0 to 9

80% 2/10.4 N/A 7 or 8 1,5,6 0 to 9

80% 2/10.4 N/A 12 or 13 1,5,6 0 to 9

12.0 2/10.4 1:2.5

6.6 2/10.4 1:2.5

8.4 2/10.4 1:2.5

7.1 3/15.6

Narrow

Element

(dots/mils)

Narrow to

Wide

Ratio

Data

Length

2710

2710

26

2710

Appearance

Codes

Available

or 8

7

or 8

7

or 8

7

or 8

7

8

8

8

8

Char

0 to 9

SPACE

$%*+-./

00H to

FFH

Set

3-10

Defining Fields

Page 29

Barcode

Ty p e

Code 128 20 3.5/7.0 5/26.0 N/A 0 to

or 4 4.4/8.7 4/20.8

CODE 16K 6 5.8/11.7 3/15.6

MSI 4 4.0 4/20.8 1:2.0 0 to

Density

Selector

8

5 5.3 3/15.6 1:2.0 14

7

Density

(% or cpi)

8.7/17.5 2/10.4

6.9 2/10.4 1:2.5

Narrow

Element

(dots/mils)

Narrow

toWide

Ratio

2710

Data

Length

Appearance

Codes

Available

8

8

Char

Set

00H to

7FH

0 to 9

Barcode

Ty p e

POSTNET

Barcode

Ty p e

PDF417

(Security

Levels 1 to

8)

Maxicode 7 N/A N/A N/A 15-99 8 00H to

Density

Selector

0

(fixed at

4.3 cpi)

Density

Selector

1

2

3

4

5

6

7

8

9

Narrow

Element

(dots/mils)

24/125.0 10/52.1 4/20.8

Element

Width

(dots/mils)

2/10.4

2/10.4

2/10.4

3/15.6

3/15.6

3/15.6

4/20.8

4/20.8

4/20.8

NOTE:

Values in bold indicate the default.

Short

Element

(dots/mils)

Row

Height

(dots/mils)

2/10.4

4/20.8

6/31.3

3/15.6

6/31.3

9/46.9

4/20.8

8/41.7

12/62.5

(dots/mils)

(5 dot gap)

1:1

1:2

1:3

1:1

1:2

1:3

1:1

1:2

1:3

Element

Width

Aspect

Ratio

Data

Length

0,5,6,9

or 11

Data

Length

0 to

2710

Appearance

Codes

Available

8

Appearance

Codes

Available

8

Char

Set

0 to 9

Char Set

00H to FFH

FFH

B9. height Bar code height, in 1/100 inches, 1/10 mm, or dots. Minimum

values:

English

Metric

Dots

1

2

1

B10. text Appearance of text with bar code. For UPC and EAN only use

. For all others, use 8. Options:

1-7

No check digit or number system

1

Number system at bottom, no check digit

5

Check digit at bottom, no number system

6

Check digit and number system at bottom

7

No text, bar code only

8

Defining Fields

3-11

Page 30

B11. alignment Choose L, R, C, B or E to align the bar code data correctly in

B12. field rot Field rotation. Field rotation rotates the whole field, not just

the field. For I2 of 5, Code 39 (Mod 43), Codabar, and MSI,

you can use L, R, C, B or E. For all other bar codes, use L.

the characters. Rotation is affected by the pivot point, which

varies depending on how text is justified. Lower left corner of

field is the pivot point. Options:

Top of field points to top of supply

0

Top of field points to left of supply

1

Top of field points to bottom of supply

2

Top of field points to right of supply

3

NOTE:

Example:

Serial bar codes printed at speeds greater than 2.5

IPS may not scan properly.

B,3,12,V,150,40,1,2,80,7,L,0 p

Defines a bar code field (field #3) with 12 characters of variable

length starting at row 150, column 40. A UPCA bar code with a

density of 2 and a height of 80 is used. The check digit and

number system are shown at the bottom. The bar code is left

aligned without any field rotation.

Defining Constant Text Fields

A constant text field is a set of fixed characters that prints on all

labels. Define each constant text field separately. This field is not

assigned a field number, but is counted as a field (keep this in

mind, as the printer allows a maximum of

The characters in this field cannot be changed by batch data.

Field options do not apply to constant text fields.

Determine the height and the maximum width of the characters,

using the tables in Appendix B, "Fonts." If you’re using

proportionally spaced fonts, use the average size of the

characters. Mark the pivot point of your field. This will vary,

depending on how your field is justified.

fields per format).

100

3-12

Defining Fields

Syntax

C,row,column,gap,font,hgt mag,

wid mag,color,alignment,char rot,

field rot,"fixed char",sym set p

Page 31

C1. C Constant Text Field.

C2. row For monospaced fonts, distance from bottom of print area to

C3. column Distance from the lower left edge of the print area to the pivot

C4. gap Number of dots between characters. Range:

C5. font Style of font. Options:

the pivot point. For proportionally spaced fonts, distance from

bottom of print area to baseline of characters in the field.

(Bottom exits the printer first.)

English

Metric

Dots

point.

English

Metric

Dots

Any number other than 0 or the default number affects your

field width. Default spacing:

Letter Gothic Bold 6pt.

Letter Gothic Bold 9pt.

All other fonts

CG Trium Bold CG Trium Bold Cond

1000

1001

1002

1003

1004

1005

6.5 pt

8 pt

10 pt

12 pt

18 pt

22 pt

0 - 365

0 - 927

0 - 701

0 - 183

0 - 465

0 - 352

1006

1007

1008

1009

1010

1011

.

0-99

1 dot

2 dots

varies with each letter

6.5 pt

8 pt

10 pt

12 pt

18 pt

22 pt

Letter Gothic Bold Reduced

1012

1013

NOTE:

C6. hgt mag Height magnifier,

proportionally spaced fonts, because characters lose

smoothness at higher magnifications for all fonts.

6 pt

9 pt

Point sizes greater than 12 include only the following

special characters:

0123456789#$%&(),./@DFKLMPS\kprö¢£¥.

All other point sizes use the whole symbol set. This

information may not apply to optional fonts.

Internal Font

2

(times). Use a magnifier of 1 with

1-7

Defining Fields

3-13

Page 32

C7. wid mag Width magnifier,

not have a set width. To estimate the size of your field, use

the letter "W" for the widest field or an "L" for an average

width field.

(times) Proportionally spaced fonts do

1-7

C8. color Options for standard printer fonts:

C9. alignment Alignment of constant text in the field. Options:

Opaque, Normal, Black, Normal

B

Opaque, Normal, White, Normal

D

Transparent, Normal, Black, Normal

O

Transparent, Normal, White, Normal

R

Opaque, Normal, White, Normal

W

NOTE:

There are two types of field color overlay attributes:

Transparent The overlay field (text or constant text) does

Opaque The overlay field blocks out (or "erases")

Field placement in the packet is an important consideration

when using field color attributes. If a line field is defined

before the overlay (text or constant text) field, the line field is

blocked out by the overlay field, depending on the overlay

field’s color attribute. If a line field is defined after the overlay

field, the line field is not blocked out by the overlay field,

regardless of the overlay field’s color attribute.

L

C

R

B

E

Solid black print should not exceed 30% on a given

square inch of the label, or the printhead life may be

decreased.

not block out (or "erase") existing fields.

existing fields.

Align on left side of field.

Center text within field (for monospaced fonts only)

Align on right side of field (for monospaced fonts only)

Align at midpoint of field

Align at end of field.

3-14

Defining Fields

Use L, B, or E for any font.

C10. char rot Character rotation. Options:

Top of character points to top of field

0

Top of character points to left of field

1

Top of character points to bottom of field

2

Top of character points to right of field

3

Page 33

C11. field rot Field rotation. Lower left corner of field is the pivot point.

Options:

Top of overlay points to top of supply

0

Top of overlay points to left of supply

1

Top of overlay points to bottom of supply

2

Top of overlay points to right of supply

3

NOTE:

C12. "fixed char" Fixed characters to appear in the field. Maximum

characters. Enclose in quotation marks.

C13. sym set Symbol set. Use 1 (ASCII Symbol Set). (0, 437).

Rotation is affected by the pivot point, which varies

depending on how text is justified.

2710

See Appendix C, "Symbol Sets/ Code Pages" for more information.

Example:

C,30,10,0,1,1,1,B,L,0,0,"MADE IN USA",0 p

Defines a constant text field starting at row 30, column 10. It does

not have any additional inter-character gap. The Standard font is

used without any additional magnification. The printing is black on

white and left justified. No field or character rotation is used.

"MADE IN USA" is printed in this field. The internal symbol set is

used.

Defining Line Fields

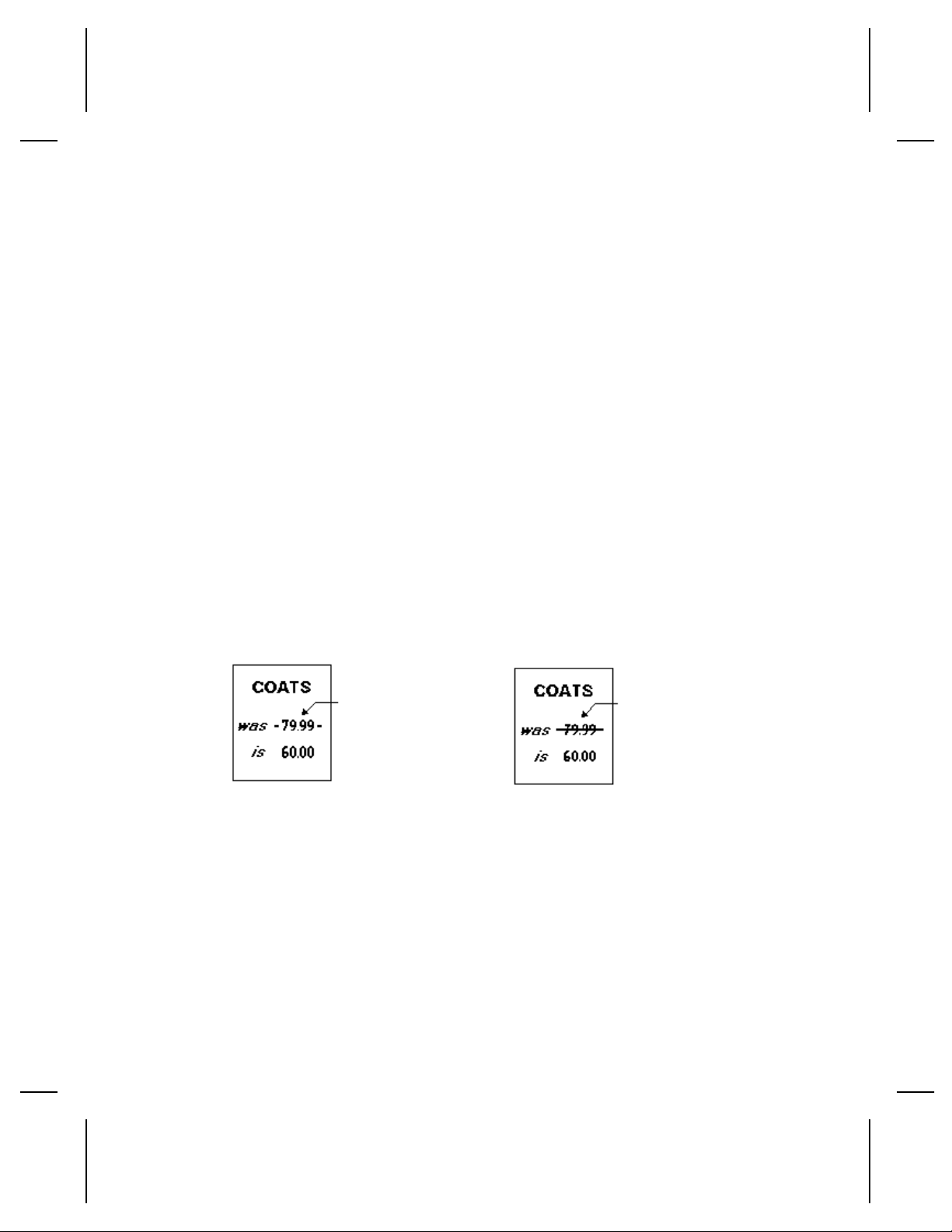

Use lines to form borders and mark out original prices. Define

each line separately. This field is not assigned a field number, but

is counted as a field (keep this in mind, as the printer allows a

maximum of 50 fields per format). You can define any line length

and a thickness up to 99 dots, as long as the solid black print does

not exceed 30 percent of any given square inch of the label.

Defining Fields

3-15

Page 34

Line Types

You can create horizontal and vertical lines. There are two ways

to define lines.

Segments

Vectors

You choose the starting point and ending point.

You choose the starting point, the angle, and

the length of the line.

Syntax

L1. L Line Field.

L2. type Type of line. Only vertical and horizontal lines are

L3. row Distance from bottom of print area to the starting point.

L4. column Distance from left edge of the print area to line origin.

L,type,row,column,angle/end row,length/

end col,thickness,"pattern" p

supported. Options:

Segment. You choose the starting point and

S

ending point.

Vector. You choose the starting point, angle,

V

and length.

English

Metric

Dots

English

Metric

Dots

0 - 365

0 - 927

0 -701

0 - 183

0 - 465

0 - 352

3-16

Defining Fields

Page 35

L5. angle/end row If Using Segments:

Row location of ending point. Measure from bottom of print

area. Ranges same as row above. On horizontal lines, this

value must match item L3.

, or

Vec tors:

.

270

Segments:

0 - 200

0 - 508

0 - 384

0 - 400

0 - 1016

0 - 768

If Using

Angle of line. Options: 0, 90,

180

L6. length/end col If Using

Column location of end point. Measure from left edge of print

area. Ranges same as column above. On vertical lines, this

value must match parameter L4.

If Using Vector s :

Length of the line in selected units.

Ranges for horizontal lines:

English

Metric

Dots

Ranges for vertical lines:

English

Metric

Dots

L7. thickness Using the chart below for reference, write the line thickness

(1 to 99) in box L7. Measured in dots.

NOTE:

Line thickness fills upward on horizontal lines, or to

the right on vertical lines.

Defining Fields

3-17

Page 36

L8. "pattern" Line pattern. Enter "".

Example:

L,S,110,30,110,150,10,"" p

Defines a horizontal line field as a segment starting at row 110,

column 30 and ending at row 110, column 150. The line thickness

is 10 dots.

Defining Box Fields

Use boxes to form borders or highlight items of interest. Define

each box field separately. This field is not assigned a field

number, but is counted as a field (keep this in mind, as the printer

allows a maximum of 50 fields per format). You can define any

line length and a thickness up to 99 dots, as long as the solid

black print does not exceed 30 percent of any given square inch of

the label.

Syntax

Q1. Q Box (Quadrilateral) Field.

Q2. row Distance from bottom of print area to lower left corner of box.

Q,row,column,end row,end col,thickness,

"pattern" p

English

Metric:

Dots:

0 - 365

0 - 927

0 - 701

3-18

Defining Fields

Q3. column Distance from left edge of print area to lower left corner of box.

English

Metric:

Dots:

0 - 183

0 - 465

0 - 352

Page 37

Q4. end row Distance from bottom of print area to upper right corner of

Q5. end col Distance from left edge of print area to upper right corner of

Q6. thickness Using the chart below for reference, write the desired line

box. Ranges same as row.

box. Ranges same as column.

thickness (

1 to 99

) in box Q6. Measure in dots.

NOTE:

Q7. "pattern" Line pattern. Enter "".

Example:

Line thickness fills upward on horizontal lines, or to

the right on vertical lines.

Q,240,30,270,150,3,"" p

Defines a box field starting at row 240, column 30. It ends at row

270, column 150. It has a thickness of 3 dots.

Defining Fields

3-19

Page 38

3-20

Defining Fields

Page 39

DEFINING FIELD OPTIONS

This chapter provides a reference for defining

N

field options in formats

N

check digit packets.

4

Defining Field Options

4-1

Page 40

Applying Field Options

Field options further define text and bar code fields. The text,

constant text, or bar code field must be previously defined before

you can apply any field option to it. Define options immediately

after the field to which they apply.

Combining Field Options

You can use more than one option with most fields. When you use

multiple options for the same field, you must place the options in

the order you want to apply them to your format.

Restrictions

Some options cannot be used together. See the following sections

addressing individual options for specific combinations to avoid.

Example:

Syntax

R1. R Indicates field option header.

R2. option# Option number:

R3. parameter(s) Varies per option. See the following option descriptions.

R,1,3,1,3,1,1 p

R,option#,parameter...parameter p

Define fixed characters

1

Copy data

4

Calculate check digit

31

Define bar code densities

50

Define security and truncation of PDF417 bar codes

51

Define width or length of PDF417 bar codes

52

4-2

Defining Field Options

Page 41

Option 1 (Fixed Data)

Fixed data is information (a company name or store number) you

want to print on all labels. You can define fixed characters for an

entire field or for part of a field.

Syntax

R1. R Option Header.

R2. 1 Option 1.

R3. fixed char Characters to insert. Enclose in quotation marks. If you are

R,1,"fixed char" p

defining fixed characters for part of a field, place underscores

(_) in non-fixed positions. Any spaces in the phrase are fixed

characters. Range: 0 -

2710

.

Underscore characters are stripped out and

the data is compressed if no data is supplied

by the batch and the field length is variable.

Example:

R,1,"_ _ _%$_ _ _ _ _" p

Uses fixed characters (%$) in positions four and five. The other

positions are variable.

Example:

R,1,"MONARCH" p

"MONARCH" appears as a fixed field in this example.

Defining Field Options

4-3

Page 42

Option 4 (Copy Data)

You can create a field that uses data from another field. This is

useful for creating merged fields or sub-fields. You can copy the

information from multiple fields into one field by applying the copy

procedure more than once. Copy data is the only option you can

apply to a field more than once.

The maximum number of characters defined in box T3 or B3 must

allow for the number of characters you will place in the field,

including any price, check digit, or fixed characters inserted by the

printer. The maximum number of characters in the field into which

data is copied cannot exceed

characters permitted by the

bar code

When copying from more than one field, copy

into the destination field from left to right.

or the maximum number of

2710

.

Syntax

R1. R Field Option Header.

R2. 4 Option 4.

R3. src fld Field number from which data is copied. Range: 0 to

R4. src start Position number in the source field of the first character to be

R5. # to copy Number of characters to copy. Range: 1 to

R6. dest start Position number where copied characters are to begin printing

4-4

Defining Field Options

R,4,src fld,src start,# to copy,dest

start,copy code p

copied. Character positions are numbered 1 to

from the left.

2710

in the destination field. Range: 1 to

2710.

2710

.

999

, starting

Page 43

R7. copy code Copy Method.

Copy field as is (including price symbols,

pad characters, check digits, etc.).

Copy unformatted data (without price characters,

pad characters, etc.).

Example

1

2

R,4,3,1,3,1,1 p

Copies data from field #3, starting at the first position and copying

three characters. In the destination field, the information is placed

in position 1 and copied as formatted data.

Merging Fields

You can copy data to merge the contents of fields. Use the copy

data option as many times as necessary to copy all the

appropriate fields into the merged field.

In the following example, two text and two non-printable fields are

shown. Data from these fields is merged to form field 5, and is

then printed as a bar code.

Field Data Field Type

1 203 Non-printable

2 339 Non-printable

38 Text

4BLUE Text

5 2033398BLUE Bar Code

To create this sequence:

Define fields 1, 2, 3, and 4.

1.

Define field 5 as a bar code. Allow enough characters in the

2.

bar code field to hold all the copied characters.

Apply Option 4 to field 5 once for every source field.

3.

Defining Field Options

4-5

Page 44

Sub-Fields

You can copy a segment of data from one field into a new location,

called a sub-field. For example, extract part of the data in a bar

code and display it in text form in a sub-field. Then, use the copy

data option.

Option 31 (Calculate Check Digit)

The printer generates a check digit if you apply Option 31 to the

field. You cannot use this option if the field contains a UPC, EAN,

or Code 39 (with the MOD43 check digit) bar code.

Syntax

R1. R Option Header.

R2. 31 Option 31.

R3. gen/ver Enter G to generate a check digit.

R4. check digit # Specifies a check digit scheme. Enter a number that

Example

R,31,gen/ver,check digit # p

identifies a check digit scheme that has been defined. For

more information, see "Using Check Digits." Range: 1 - 10.

R,31,G,5 p

Generates a check digit using the previously defined check digit

scheme 5.

Option 50 (Bar Code Density)

You can apply this option to bar code fields when you want to

create custom densities. When you apply this option, it overrides

the density value in the bar code field.

When using this option, set the density parameter in your bar code

field to the default value. You can only use this option once for

each bar code field. This option overrides the density selected in

the bar code field.

4-6

Defining Field Options

Page 45

Bar codes produced using Option 50 may not be scannable. The

additional character gap, narrow space, and wide space

parameters are valid

with Code 39 and Codabar. If these

only

parameters are specified for any other bar codes, they will be

ignored by the printer. Do not use Option 50 with UPC or EAN bar

codes.

Syntax

R1. R Field Option Header.

R2. 50 Option 50.

R3. narrow Dot width of the narrow element. Range:

R4. wide Dot width of the wide element. Range:

R5. gap Additional dot space between characters. Enter a value of

R6. nar_space Additional dot width of the narrow bar code space. (Code 39

R7. wide_space Additional dot width of the wide bar code space. (Code 39

Example:

R,50,narrow,wide,gap,nar_space,wide_space

p

.

1-99

.

1-99

to

. (Code 39 and Codabar only.)

99

and Codabar only). Range:

and Codabar only). Range:

R,50,4,8,5,1,1 p

1- 99

1- 99

.

.

1

Creates a custom bar code density with a narrow element of 4

dots, a wide element of 8 dots, a gap of 5 dots, and one additional

dot width for the narrow and wide bar code space (if this is a Code

39 or Codabar bar code).

Option 51 (PDF417 Security/Truncation)

You can define a security level and choose whether or not to

truncate a PDF417 bar code. Higher security levels add data to a

bar code, improving scan reliability. Some damaged bar codes

may still be scannable if the security level is high enough. You

can use this option to create standard PDF417 bar codes or use

the truncated option to create a narrower bar code. This option

can appear only once per PDF417 field, in any order, following the

bar code field.

Defining Field Options

4-7

Page 46

As the security level is increased, so is the size of your PDF417

bar code. For each level increased, the bar code will double in

size.

Syntax

R1. R Option Header.

R2. 51 Indicates Option 51.

R3. security Security level ranges from

R4. stand/def Truncation selector. Valid values:

Example

R,51,security,stand/default p

is the default).

0-8 (0

Higher security levels add data to a bar code, improving scan

reliability. Some damaged bar codes may still be scannable if

the security level is high enough.

(default) a standard PDF417 bar code

S

truncated

T

R,51,2,S p

Defines a security level of 2 for a standard PDF417 bar code.

Option 52 (PDF417 Width/Length)

This option defines the image width or length of a PDF417 bar

code. If you define a fixed number of columns (width), the bar

code expands in length. If you define a fixed number of rows

(length), the bar code expands in width.

Column value does not include start/stop or left/right indicator

columns.

If this option does not immediately follow the PDF417 bar code

field, the default settings are used. You can only use this option

once per PDF417 bar code field.

Syntax

R1. R Option Header.

R2. 52 Indicates Option 52.

4-8

Defining Field Options

R,52,row/column,dimension p

Page 47

R3. row/column Indicates if you are defining the number of rows or columns.

Row

R

Column

C

If you specify rows, the bar code expands in columns,

or vice versa.

R4. dimension The number of rows or columns defined for the bar code. The

Example:

default is 4. Valid values:

for rows

3-90

for columns

1-30

R,52,C,10 p

Defines the column width of 10, which expands the PDF417 bar

code length by 10.

Option 61 (Re-image Field)

If you have a constant field that appears on top of a non-constant

field, apply this option to the constant field. For example, you may

create a tag for an item on sale. The tag shows both the old and

the new prices, but has a line drawn through the old price.

The constant field can be a line, a box, a graphic, or constant text.

This option redraws the constant field when the other field

changes. If you do not use this option, the field may appear

broken.

Syntax

R,61 p

Using Check Digits

Check digits are typically used to ensure that a text or bar code

field scans correctly. If you apply Option 31, the printer calculates

a check digit. A check digit scheme determines how the printer

calculates a check digit. When you define a check digit scheme,

you assign a number to identify it. This number is later entered in

box R4 when you apply Option 31 to a field. You can use check

digits with text or bar code fields. Check digit calculations are

performed on numeric data only.

Defining Field Options

4-9

Page 48

Do not use check digits with price fields. Do not define a check

digit scheme for these bar codes, because they have predefined

check digits: UPC, EAN, Code 39 (with the MOD43 check digit),

and Code 93.

Syntax

{A,selector,action,device,modulus,

fld_length,D/P,"weights" p }

A1. A Check Digit Header.

A2. selector Assign a number from

A3. action Adds a check digit scheme. Enter A.

A4. device Device. Use R.

A5. modulus Number from

A6. fld_length The maximum number of characters the field will contain.

A7. D/P Algorithm. The algorithm determines how the check digit is

A8. "weights

Example:

products or the sum of digits.

Range:

calculated.Options:

D

P

String of digits used for calculation. A weight string is a group

"

of two or more numbers that is applied to a field. The number

of digits in this string should equal the number in fld_length.

Enclose in quotation marks. Range:

0 - 2710

sum of digits

sum of products

{A,1,A,R,10,5,P,"65432" p }

. The modulus is used to divide the sum of

2-11

.

to this check digit formula.

1-10

0 - 2710

.

Adds check digit scheme number 1 to the printer’s memory. The

modulus is 10, the maximum number of characters in the field is 5.

The check digit is calculated by using the Sum of Products and the

string of digits used in the calculation is "65432."

Sum of Products Calculation

This is an example of how the printer uses Sum of Products to

calculate a check digit for this data:

4-10

Defining Field Options

5 2 3 2 4 5 2 1 9

Page 49

Weights are applied to each digit, starting with the last digit in

1.

the weight string. They are applied right to left, beginning at

the right-most position of the field. Remember, a weight string

must contain at least two different numbers. This example has

a weight string of

1,2,3,4

:

field:

weight string:

Each digit in the field is multiplied by the weight assigned to it:

2.

field:

weight string:

products:

Next, the product of each digit is added together. This is the

3.

5 2 3 2 4 5 2 1 9

4 1 2 3 4 1 2 3 4

5 2 3 2 4 5 2 1 9

4 1 2 3 4 1 2 3 4

20 2 6 6 16 5 4 3 36

sum of the products.

20 + 2 + 6 + 6 + 16 + 5 + 4 + 3 + 36 = 98

Divide the sum of the products by the modulus (10 in this

4.

case), only to the whole number. The balance is called the

remainder.

9

10 98

90

8

Subtract the remainder from the modulus.

5.

The result becomes the check digit. In this case, the check

digit is 2.

10 - 8 = 2

Defining Field Options

4-11

Page 50

Sum of Digits Calculation

This is an example of how the printer uses Sum of Digits to

calculate a check digit for this data:

5 2 3 2 4 5 2 1 9

Weights are applied to each digit, starting with the last digit in

1.

the weight string. They are applied right to left, beginning at

the right-most position of the field. Remember, a weight string

must contain at least two different numbers. This example has

a weight string of

1,2,3,4

:

field:

weight string:

Each digit in the field is multiplied by the weight assigned to it:

2.

field:

weight string:

products:

Next, the digits of the products are added together. Two-digit

3.

products are treated as two separate digits.

This is the sum of the digits.

2 + 0 + 2 + 6 + 6 + 1 + 6 + 5 + 4 + 3 + 3 + 6 = 44

Divide the sum of the digits by the modulus (10 in this case),

4.

only to the whole number. The balance is called the

remainder.

4

10 44

40

4

5 2 3 2 4 5 2 1 9

4 1 2 3 4 1 2 3 4

5 2 3 2 4 5 2 1 9

4 1 2 3 4 1 2 3 4

20 2 6 6 16 5 4 3 36

4-12

Defining Field Options

Page 51

Subtract the remainder from the modulus.

5.

The result becomes the check digit. In this case, the check

digit is 6.

10 - 4 = 6

Defining Field Options

4-13

Page 52

4-14

Defining Field Options

Page 53

PRINTING

This chapter describes how to

N

define the batch header, batch control, and batch data files

N

create a Print Control Packet.

5

Printing

5-1

Page 54

Defining the Batch Header

Batch data is the actual information printed on the supply. Batch

data fills in the format’s text, bar code, and non-printable text

fields.

A batch packet contains three parts:

batch header identifies the format and how many labels to

print.

batch control defines the print job.

batch data

(optional)

defines the actual information printed on the

label.

A batch header begins the file. It tells which format the batch uses

and how many labels to print. To record batch data, make a copy

of the worksheet in Appendix D, "Format Design Tools."

Syntax

B1. B Batch Header.

B2. format# Format number (0-999) to use.

B3. N/U Controls how image is generated.

{B,format#,N/U,quantity p

N New. Erase image and re-image all fields using

online data. Any missing fields will be blank.

U Update last image with 1 or more fields.

All other fields remain the same as the last

queued batch.

5-2

Printing

Page 55

B4. quantity Quantity to print (0-24).

Using 0 pre-images the field to reduce the

imaging time for labels. See "Batch Quantity

Zero Method" for more information.

Example:

{B,1,N,1 p

Defines a batch header that uses format #1 and reimages all fields

using the online data. One label is printed with this batch.

Defining the Batch Control Field

The batch header must precede this field. The batch control field

defines the print job and applies only to the batch that immediately

follows.

Syntax

E1. E Batch Control Field.

E2. feed_mode Feed Mode. Options:

E3. batch_sep Batch Separator. Use 0.

E4. print_mult Number of tags with the same image. Use 1.

E5. multi_part Number of identical parts on one tag. Use 1.

Example:

E,feed_mode,batch_sep,print_mult,

multi_part p

0 Continuous Feed (default)

1 On-Demand

E,0,0,1,1 p

Defines a batch control field. Continuous feed mode is used and

no separator prints between batches.

Printing

5-3

Page 56

Defining Batch Data Fields

Batch data fields should be sent in field number order. Use

continuation fields for large amounts of data. If you are using N

(New) in the batch header, you must list all fields with your data in

sequence. If you are using U, you need to list only those fields

and data that changes from the last printed batch.

Syntax

field# Identifies the text, bar code, or non-printable text field in

"data string" Provides the actual information to appear in fields. Enclose in

C Identifies information to be appended to the data string. (This

"continuation" Provides the actual information to be added to the batch

Example:

field#,"data string" p

C,"continuation" p

which to insert the following data. Range: 0 - 999.

quotation marks. Range: 0 - 2710.

parameter is optional.)

packet. Enclose in quotation marks. Use this option to break

up longer fields. (This parameter is optional.)

1,"Size 12" p

2,"" p

3,"Blue" p

C,"and this would be appended." p

Defines a batch data field. "Size 12" prints in field #1, a blank line

appears in field #2, "Blue and this would be appended" prints in

field #3.

Merged or Sub-Fields

5-4

If a field is completely filled by data copied from other fields, use

quotation marks without spaces between them for the "data string"

parameter.

Printing

Page 57

Downloading Methods

You can use pclOpen or pclWrite to write the packet to the printer,

or you can download the format and batch data using one of three

methods: sequential method, batch method, batch quantity zero

method. Refer to the Programmer Manual for more information.

Sequential Method

Using the sequential method, you send all your format and batch

data at one time. Use this method when your application does not

require operator intervention to input data. All data is sent down

at one time, and the printer then images each field. As soon as

the last field is imaged, your labels begin to print.

Example:

{Format}

{Batch Packet}

Batch Method

This is similar to the sequential method, but it is used when you

want to send multiple batches. All data for the first batch is sent at

one time, and the printer then images each field. As soon as the

last field for the first batch is imaged, labels begin to print. This

process is repeated for each subsequent batch.

Example:

{Format}

{Batch Packet}

{Batch Packet}

Batch Quantity Zero Method

You may use the batch quantity zero method when your

application requires operator intervention to enter data. While the

operator is entering data, the previous field is sent with a batch

quantity of zero. The printer images the field, but does not print it.

After the operator enters the data for the last field, the batch

quantity can be specified. The last remaining field is imaged, and

the label prints almost immediately.

Printing

5-5

Page 58

To use the batch quantity zero method:

Send the format and a batch header in one file. The first time

1.

you send the batch header, use the parameter N (new batch),

and the parameter 0 for (zero quantity). This ensures the

label is properly positioned.

The printer images constant text, line, and box fields, but does

not print them.

Input data for each field, and send it with a batch header using

2.

the parameter U (batch update) and a quantity of zero. When

the printer receives the data, it immediately images the field,

but does not print it.

At this time, the printer is imaging all associated fields,

including fields that copy from other fields.

Repeat step 2 for each field except the last one.

3.

For the last field, input data and send a batch header with the

4.

quantity of labels you want printed. When the printer receives

input for the last field, it immediately prints the labels. See

"Reducing Imaging Time" in Chapter 8 for an example using

the batch quantity zero method.

5-6

Printing