Page 1

Hang for

easy reference.

â

Monarch

®

1103

®

-1110

®

Labelers

Operating Instructions

TC1000OI Rev. DF 1/08 ©2007 Paxar Americas, Inc. a subsidiary of

Avery Dennison Corp. All rights reserved.

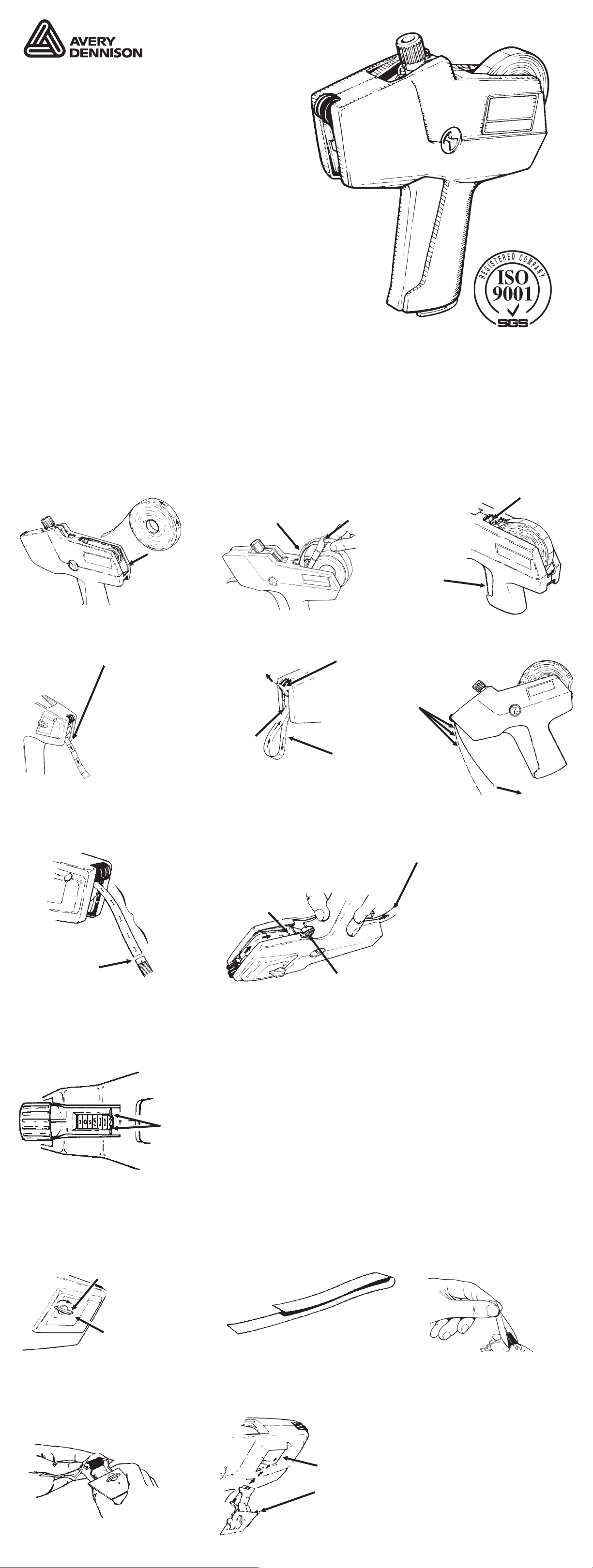

LOADING LABELS

If labeler has no label guide: Snap

label roll between hubs. Tear off

1

and discard first twelve labels and

backing paper.

If labeler has label guide: Snap

label roll between hubs. Tear off

and discard first twelve labels and

backing paper. Then, insert label

strip into guide slot as shown.

Label Guide

LOADING LABELS & SETTING PRINT BANDS

Guide Slot

Squeeze and hold

operating lever half way,

2

and feed label strip under brake

wheels.

Brake

Wheel

Continue feeding label

strip until about twelve

3

labels come out here. Release

operating lever.

Tear backing paper as

shown.

6

Backing paper

without labels

a. Feed label strip up under

4

7

Insert backing paper into slot. When

paper bows up, maintain finger

pressure and release operating

lever.

plate until two labels come

out here.

Plate

Loop

b. Squeeze operating

lever halfway and rewind

label roll until loop is

removed.

Completely squeeze operating

lever, exposing feedwheel.

Slot

Operating

Lever

5

lever,

separating

labels

from

backing

paper.

Discard

separated

labels.

8

paper exits labeler. If backing

paper does not become taut and

exit at rear, remove backing

paper from slot and repeat steps

6 and 7.

Grasp label strip and pull

briskly toward operating

Squeeze operating lever

several times until backing

Straight tear

between I-cuts

SETTING PRINT BANDS

Pull knob until indicators point to

desired band.

1

Indicators

INKING

Turn latch to release ink roll

door and carefully pull it

1

completely out of labeler.

Latch

Turn knob until indicators point

to desired character or blank.

2

n

2

Make sure the character you

select is not a print character

(UPSIDE DOWN). You

should be able to read the

character correctly through

the band window.

Fold a piece of scrap backing

paper.

Feedwheel

Set all bands and push

knob in all the way.

3

Insert folded backing paper

3

carrier. Pull to snap old ink roll

free.

between ink roll and

Ink Roll Door

Cut off end of new ink roll

pouch. Using pouch to protect

4

fingers, slide carrier into pouch and

snap new ink roll into carrier (one side

at a time).

Insert ink roll into ink door

opening. Tilt ink door

5

and press in...

Latch ink roll door securely.

6

Lip

to place

hinge tab

under lip.

INKING

Page 2

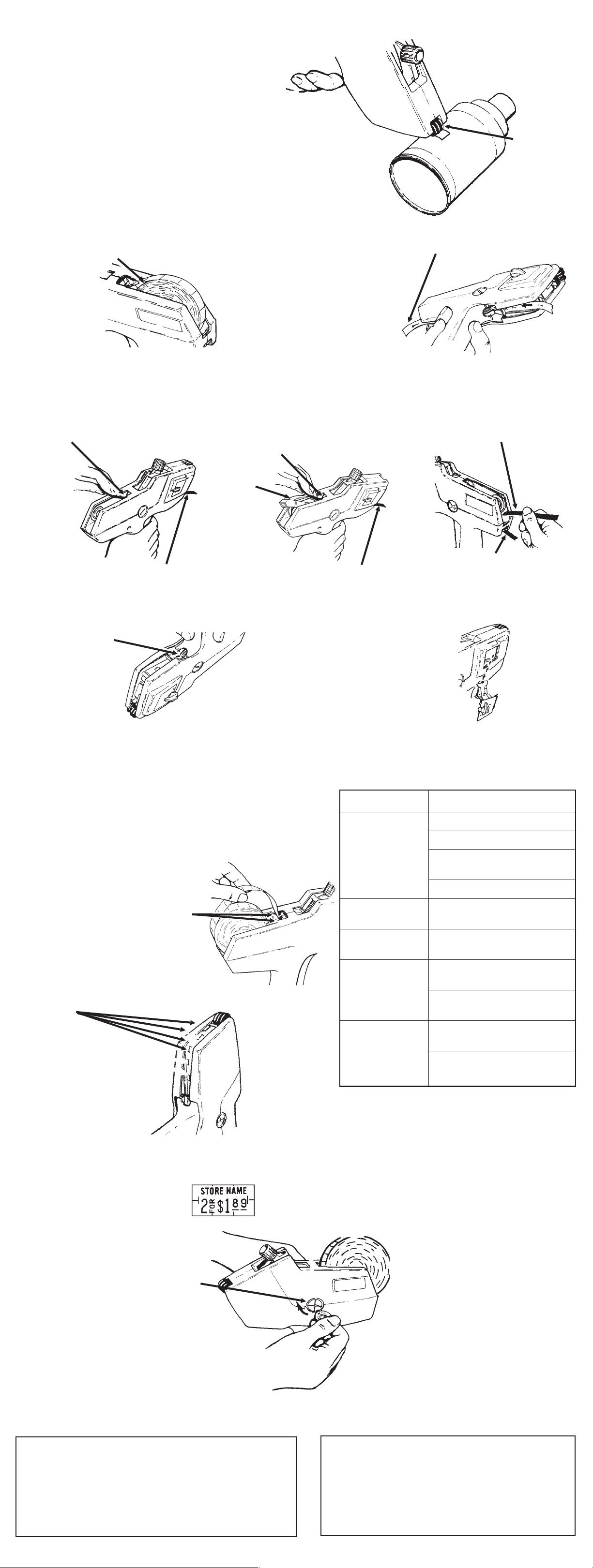

OPERATION

Squeeze operating lever completely.

1

Release operating lever completely.

2

Apply label to item being marked as shown.

3

Rollers

n

A wiping motion works best, DO NOT POUND

labeler when applying labels.

REMOVING SUPPLIES

Tear label strip and carefully remove label roll.

1

Tear

MAINTENANCE

If labeler has no label guide:

Remove label roll. Squeeze

1

operating lever half way and feed label

removal strip under brake wheels...

Squeeze and release operating lever until

2

backing paper exits here.

If labeler has label guide:

Remove label roll. Squeeze

operating lever half way and feed

label removal strip over label guide,

under brake wheels...

To clear backing paper

track, insert label removal

2

strip here, using corner to

remove stray labels.

and out the front of labeler.

Squeeze operating lever to turn feedwheel

for inspection. Remove stray labels with corner

3

of label removal strip.

Feedwheel

Label

Guide

Insert label removal strip here

and out the front of labeler.

Remove ink door and inspect door opening for

4

stray labels. Remove stray labels with corner of

label removal strip.

to loosen labels.

OPERATION, REMOVING SUPPLIES & MAINTENANCE

LUBRICATION TROUBLESHOOTING

Monarch Lubricant 086989 is recommended.

Lubricate as shown below with labeler loaded

when:

a. slow or hesitant feeding occurs.

b. adhesive buildup is seen.

c. feedwheel tears backing paper.

d. ink roll is changed.

LUBRICATE:

One drop

each side of

label chute.

LUBRICATE:

One drop each spot on

backing paper. Spread

with finger.

Problem Solution

Labels will not

feed.

Print incorrectly

located.

Printing smeared

or distorted.

Printing too light

(all over).

Slow hesitant

feeding. Labeler

tends to ‘hang up’

when operating

lever is released.

Reload per instructions.

Check for correct supplies.

Follow MAINTENANCE

instructions.

Check for correct print location.

Adjust per PRINT LOCATION

ADJUSTMENT instructions.

Print several labels (15-20) until

excess ink is used up.

Install new ink roll per INKING

instructions.

Squeeze operating lever harder

during operation.

Follow MAINTENANCE

instructions.

Lubricate per instructions.

DO

NOT OVER

LUBRICATE!

If none of the above eliminates the problem, return

labeler to an Authorized Paxar Service Center.

PRINT LOCATION ADJUSTMENT AVAILABLE SUPPLIES

Print location is correct when

all characters are fully visible on

the printed label. Dial characters

for every position when testing

location.

Place small coin in slot of each

disk (one on each side of labeler)

1

as shown.

Hold coin steady in slot labeled

HOLD, and turn other coin very

2

slowly clockwise until one click is heard.

Print sample label and check for

correct print location.

3

Repeat steps 1, 2, and 3 until print

is correctly located. If correct print

4

location is passed, continue adjustment

until correct print location reappears.

000940 Holster (Vinyl)

000935 Label Scraper

(w/ handle, Pkg of 20)

M00PLS01 Label Scraper

(w/o handle Pkg of 10)

119919 Maintenance Kit

08394601 Black Ink Roll

Visit www.paxar.com for sales, service, supplies, information,

and telephone numbers of our locations throughout the world.

TOLL FREE:

1-800-543-6650 (In the U.S.A.)

1-800-363-7525 (In Canada)

LUBRICATION, TROUBLESHOOTING & PRINT LOCATION

Warranties

PRODUCT WARRANTY STATEMENTS MAY

VARY FROM COUNTRY TO COUNTRY.

PLEASE CONTACT THE AUTHORIZED PAXAR

REPRESENTATIVE IN YOUR COUNTRY

FOR DETAILS.

Page 3

Suspendre pour

une consultation plus pratique.

â

Monarch

®

1103

®

-1110

®

Etiqueteuses

Mode d’emploi

TC1000OI Rev. DF 1/08 ©2007 Paxar Americas, Inc. a subsidiary of Avery Dennison Corp.

Tous droits réservés.

CHARGEMENT DES ETIQUETTES

Si l’étiqueteuse ne possède pas de

1

guide pour charger les étiquettes: faites

glisser le rouleau d’étiquettes entre les axes.

Déchirez et jetez les douze premières étiquettes

et le papier support.

Si l’étiqueteuse a un guide d’étiquettes :

placez le rouleau d’étiquettes entre les

axes. Déchirez et jetez les douze

premières étiquettes et le papier support.

Puis, insérez la bande d’étiquettes dans la

fente de guidage, selon les instructions.

Guide

d’étiquettes

Fente de

guidage

Appuyer et maintenir la gâchette

2

à mi-chemin et faites passer la

bande d’étiquettes sous les roues de

freinage.

Roues

de

freinage

Continuez à faire avancer la

3

bande d’étiquettes jusqu’à ce qu’environ

douze étiquettes sortent par ici. Relâchez

la gâchette.

Déchirez le papier support selon

6

l’illustration.

Faites avancer la bande

4

d’étiquettes sous la plaque jusqu’à ce

que deux étiquettes sortent par ici.

Plaque

Boucle

Appuyer et maintenir la gâchette

à mi-chemin. Ré-embobinez la bande

d’étiquettes jusqu’à ce que la boucle

disparaisse.

Appuyez complètement sur la

7

gâchette, laissant apparaître ainsi le

rouleau d’alimentation. Insérez le papier dans

la fente. Lorsque le papier se courbe vers le

haut, maintenez une pression de vos doigts,

puis relâchez la gâchette.

Gâchette

Prenez la bande d’étiquettes

5

et tirez d’un coup sec en direction

de la gâchette,

séparant les

étiquettes du

papier support

Jetez les

étiquettes

décollées.

Appuyez plusieurs fois sur la

8

gâchette, jusqu’à ce que le papier

support soit sorti de l’étiqueteuse. Si le

papier support n’est pas assez tendu et

sort par l’arrière, retirez le papier

support et répétez les étapes 6 et 7.

Papier

support sans

Déchirez en ligne

droite entre les

découpures en I

Fente

RÉGLAGE DES BANDES D’IMPRESSION

Tirez sur le bouton jusqu’à ce que les

1

indicateurs soient pointés vers la bande

voulue.

Indicateur

Tournez le bouton jusqu’à ce que les

2

indicateurs soient pointés vers le

caractère voulu.

n

Veillez à ce que le caractère

choisi ne soit pas un caractère

d’impression (RENVERSE). Vous

devriez pouvoir lire correctement le

caractère par la fenêtre de la bande.

Rouleau d’alimentation

3

bout.

Réglez toutes les bandes et

appuyez sur le bouton jusqu’au

MISE EN PLACE DU ROULEAU D’ENCRE

Tournez la fermeture pour

1

dégager la porte du rouleau d’encre,

celle-ci doit être soigneusement et

entièrement sortie de l’étiqueteuse.

Fermeture

Porte du rouleau

d’encre

Coupez l’extrémité du sachet du rouleau

4

d’encre neuf. En protégeant vos doigts à

l’aide sachet, faites glisser le logement

dans le sachet et insérez le rouleau d’encre

neuf dans son logement (un côté à la fois).

Pliez un bout de papier support qui

2

ne sera pas utilisé.

Insérez le rouleau d’encre dans

5

l’ouverture de la porte pour l’encre.

Faites incliner cette porte et appuyez vers

l’intérieur...

Languett

pour placer

l’onglet articulé

sous la languette.

Insérez le papier support plié

3

entre le rouleau d’encre et le

porte-rouleau.Tirez pour libérer le

rouleau d’encre usagé.

Refermez bien la porte du

6

rouleau d’encre.

ENCRAGE

Page 4

FONCTIONNEMENT

Appuyez complètement sur la gâchette.

1

Relâchez complètement la gâchette.

2

Appliquez l’étiquette sur le produit à marquer

3

selon l’illustration.

n

Pour une efficacité optimale, procédez par mouvements

de balayage. NE DONNEZ PAS DE COUPS violents avec

l’étiqueteuse lors de la pose d’étiquettes.

RETRAIT DES ETIQUETTES

Déchirez la bande d’étiquettes et retirez soigneusement

1

le rouleau d’étiquettes.

Déchire

ENTRETIEN

Si l’étiqueteuse n’a pas de guide

1

d’étiquettes : retirez le rouleau

d’étiquettes. Appuyez sur et faites passer la

bande de retrait des étiquettes sous les roues

de freinage. . .

Appuyez sur la gâchette, puis relâchez-la jusqu’à

2

ce que le papier support sorte par ici.

Si l’étiqueteuse a un guide d’étiquette :

retirez le rouleau d’étiquettes. Appuyez

sur la gâchette jusqu’à mi-parcours et

faites passer la bande de retrait

d’étiquettes sur le guide de l’étiqueteuse,

sous les roues de freinage. . .

Rouleaux

Appuyez sur le levier de

2

fonctionnement pour faire tourner

le rouleau d’alimentation et procéder à

son inspection. Retirez les étiquettes

dispersées avec le coin de la bande de

retrait des étiquettes.

Guide

d’étiquettes

et par l’avant de l’étiqueteuse.

Appuyez sur la gâchette pour faire tourner le rouleau

3

d’alimentation et procéder à son inspection. Retirez les

étiquettes dispersées avec le coin de la bande de retrait des

étiquettes.

Rouleau

d’alimentation

et par l’avant de l’étiqueteuse.

FONCTIONNEMENT, RETRAIT DES ETIQUETTES & ENTRETIEN

Insérez ici la bande de retrait des

étiquettes pour dégager les étiquettes.

Retirez la porte du rouleau d’encre et inspectez

4

son ouverture pour vérifier qu’il n’y a pas d’étiquettes

égarées. Retirez les étiquettes dispersées avec le coin de la

bande de retrait des étiquettes.

LUBRIFICATION RESOLUTION DES PROBLEMES

Le lubrifiant Monarch est conseillé. Lubrifiez selon

les instructions figurant ci-dessous (lorsque

l’étiqueteuse est chargée) si :

a. l’alimentation des étiquettes est lente et incertaine.

b. une accumulation de colle est constatée.

c. le rouleau d’alimentation déchire le papier de support.

d. le rouleau d’encre est changé.

LUBRIFICATION

: une goutte de

chaque côté de

la glissière.

LUBRIFICATION : une

goutte à chaque

endroit sur le papier.

NE PAS LUBRIFIER

DE MANIERE

EXCESSIVE !

Problème Remède

Les étiquettes ne passent

pas.

Impression située de

manière incorrecte.

Impression tachée ou

déformée.

Impression trop pâle

(partout).

Alimentation lente et

incertaine. L’étiqueteuse à

tendance à “raccrocher”

lorsque la gâchette est

relâchéz.

Impossible d’imprimer. Retirez la porte du rouleau d’encre et

Rechargez selon les instructions.

Vérifiez que les étiquettes utilisées

soient adéquates.

Suivez les instructions d’ENTRETIEN.

Vérifiez le bon emplacement de

l’impression.

Réglez selon les instructions

d’AJUSTEMENT DE

L’EMPLACEMENT D’IMPRESSION.

Imprimez plusieurs étiquettes (15-20)

jusqu’à ce que l’excédent d’encre soit

épuisé.

Installez un nouveau rouleau d’encre

selon les instructions concernant

l’ENCRAGE.

Appuyez plus fortement sur la

gâchette de l’utilisation.

Suivez les instructions d’ENTRETIEN.

Lubrifiez selon les instructions.

vérifiez qu’il n’y a pas d’étiquettes

dispersées selon les instructions

d’ENTRETIEN.

AJUSTEMENT DE L’EMPLACEMENT DE L’IMPRESSION

L’emplacement choisi pour l’impression

est correct quand tous les caractères

sont entièrement visibles sur l’étiquette

imprimée. Composez l’impression des

caractères pour chaque position quand

vous testez l’emplacement.

Placez une petite pièce de monnaie

1

dans la fente de chaque disque (un de

chaque côté de l’étiqueteuse) selon les

instructions.

Gardez la pièce de monnaie en place

2

dans la fente portant l’inscription HOLD et

tournez doucement l’autre pièce dans le sens

des aiguilles d’une montre jusqu’à ce que vous

entendiez un déclic.

Imprimez l’étiquette d’essai et vérifiez

3

que l’emplacement de l’impression est

correct.

Répétez les étapes 1, 2 et 3 jusqu’à ce

4

que l’impression soit correctement située.

Si vous avez dépassé le bon emplacement de

l’impression, continuez le réglage jusqu’à ce

que l’emplacement correct réapparaisse.

Paxar propose un service de maintenance

dans le monde entier. Pour toute information

concernant les accessoires, les

consommables ou les conditions de garantie,

contactez votre revendeur local ou visitez:

www.paxar.com

LUBRIFICATION, RESOLUTION DES PROBLEMES, EMPLACEMENT

DE L’IMPRESSION ET ETIQUETTES

Loading...

Loading...