Patterson-Kelley THERMIFIC MODU-FIRE Supplement Manual

MOD-02

©2002 Patterson-Kelley, A Harsco Company

PATTERSON-KELLEY

THERMIFIC

®

MODU-FIRE® GAS-FIRED BOILER

Supplement to the standard Installation and

Owner's Manual (TBIG - Latest Edition)

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

Installation Date: _______________________

ASME Code, Section IV

Certified by Patterson-Kelley

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

100 Burson Street, P.O. Box 458,

East Stroudsburg, PA 18301

Telephone: (877) 728-5351, Facsimile: (570) 476-7247

www.pkboilers.com

Modu-Fire® Gas-Fired Boiler Table of Contents

1.0 INTRODUCTION................................. 1

2.0 SAFETY............................................... 1

2.1 General................................................1

2.2 Training................................................1

2.3 Safety Features ...................................1

2.4 Safety Labels.......................................1

2.5 Safety Precautions...............................1

2.5.1 Electrical Hazards..........................1

2.5.2 Burn, Fire, and Explosion Hazards..1

2.5.3 Crush Hazards...............................1

2.5.4 Chemical Hazards .........................1

2.5.5 Pressure Hazards..........................1

2.5.6 Slip, Fall Hazards...........................1

3.0 INSTALLATION................................... 2

3.1 Receiving and Storage ........................2

3.1.1 Initial Inspection..............................2

3.1.2 Storage Prior to Installation ...........2

3.2 Compliance with Codes.......................2

3.3 Setup ...................................................2

3.3.1 Foundation.....................................2

3.3.2 Placement......................................2

3.3.3 Clearances.....................................2

3.4 Electrical Connections.........................2

3.5 Combustion Air....................................2

3.6 Flue Venting.........................................2

3.6.1 Vent Elbows...................................2

3.7.2 Gas Bleeds and Vents...................3

3.8 Boiler Water Piping..............................3

3.8.1 Piping Design.................................3

3.8.2 Boiler Inlet and Outlet Connections..3

3.8.3 Boiler Water Piping by Installer......3

3.8.4 Flushing and Filling........................3

3.9 Burner and Ignition System .................3

3.9.1 Inspection ......................................3

3.10 Pre-Start Check List...........................3

3.11 Safety Checks....................................3

3.11.1 Test of Ignition Safety System.....3

3.11.2 Test of Low Water Cut-off............4

3.11.3 Test of High-Limit Control............4

3.11.4 Test of Gas Pressure Switch.......4

3.12 Initial Adjustments..............................4

3.12.1A – Configuring the Controller .......4

3.12.2 Air Flow Adjustments...................9

3.12.3 Gas Pressure Adjustment............9

4.0 OPERATION......................................10

4.1 General..............................................10

4.1.1 Control Panel Front......................10

4.2 Lighting and Shut-Down Procedures.10

4.2.1 Lighting Procedures.....................11

4.2.2 Normal Shut Down Procedures...11

4.2.3 Emergency Shut Off ....................11

4.3 Typical Boiler Operating Conditions ..11

3.6.2 Barometric Damper........................2

3.6.3 Barometric Damper Location.........2

3.6.4 Flue Connection.............................2

3.6.5 Vent Termination ...........................2

3.6.6 Removing an Existing Boiler..........2

3.7 Gas Piping............................................2

3.7.1 Gas Supply Piping by Installer.......3

5.0 MAINTENANCE.................................12

5.1 Maintenance and Inspection Schedule 12

5.1.1 Daily.............................................12

5.1.2 Weekly.........................................12

5.1.3 Monthly (During Operation) .........12

5.1.4 Semi-Annually..............................12

5.1.5 Annually.......................................12

Modu-Fire® Gas-Fired Boiler Table of Contents

5.2 Cleaning the Burner...........................12

5.2.1 Semi-Annual Cleaning.................12

5.2.2 Annual Cleaning ..........................12

5.3 Removing the Exchanger ..................13

5.4 After All Repairs or Maintenance.......13

5.5 SEQUENCE OF OPERATION ...........13

5.5.1 STANDARD MODULATING........13

5.5.2 IRI MODULATING .......................14

5.6 TROUBLE SHOOTING.......................15

5.6.1 Loss of Power..............................15

5.6.2 Loss of Water Flow......................15

5.6.3 Low Gas Pressure .......................15

5.6.4 High Water Temperature .............15

5.6.5 Low Air.........................................15

5.6.6 Ignition Failure.............................15

5.6.7 Flame Failure...............................15

6.0 PARTS/TECHNICAL SUPPORT........16

6.1 Schematic Diagrams...........................16

Standard Unit w/ Siemens Control.........17

Standard Unit w/ Remote Control..........18

IRI with Siemens Control.......................19

IRI with Remote Control.........................20

6.2 Boiler Parts List..................................21

6.2.1 Main Assembly ............................21

6.2.2 Control Panel...............................22

6.2.3 Gas Train.....................................23

7.0 LIMITED WARRANTY........................ 24

REMEDY ..................................................24

EXCLUSIONS...........................................24

THIRD-PARTY WARRANTIES.................24

SEVERABILITY........................................24

NO OTHER WARRANTIES......................24

Modu-Fire® Gas-Fired Boiler Introduction/Safety

1.0 INTRODUCTION

The P-K MODU-FIRE® Gas Fired Boiler is a

revolutionary advance; Patterson-Kelley now

combines full-modulation burner control with our

time-tested modular hot water boiler design. The

result is “modular full-modulation”- Modu-Fire!

This new hybrid boiler combines the best of our

earlier designs with a generation of burner and

control technology. You will achieve even higher

part load efficiencies – but without the complexity

you might expect in this type of high performance

boiler. High performance made simple and

dependable for years of trouble-free operation.

This manual covers installation of the P-K MODU-

®

FIRE

Boiler Series 1000, 1500, and 2000. The

model numbers may be followed by a prefix or

suffix letter in some cases to indicate special

features or different options. While details may

2.0 SAFETY

(Refer To TBIG Latest Edition)

2.1

GENERAL

(Refer To TBIG Latest Edition)

2.2

TRAINING

(Refer To TBIG Latest Edition)

2.3

SAFETY FEATURES

(Refer To TBIG Latest Edition)

SAFETY LABELS

2.4

(Refer To TBIG Latest Edition)

2.5

SAFETY PRECAUTIONS

(Refer To TBIG Latest Edition)

2.5.1 Electrical Hazards

(Refer To TBIG Latest Edition)

differ slightly, basic operation is the same for all

models. Boilers are built to operate with natural

gas. Check the rating plate for the correct gas flow

rate.

The boiler is only a part of the complete heating

system. This boiler may be fully operational and yet

because of poor circulation, controls, or other

operating characteristics, not deliver heat to the

desired location. Additional equipment such as

temperature sensors, pumps, flow switches,

balancing valves and check valves will be required

for satisfactory operation of any system. PattersonKelley cannot be responsible for the design or

operation of such systems and a qualified engineer

or contractor must be consulted.

2.5.2 Burn, Fire, and Explosion Hazards

(Refer To TBIG Latest Edition)

2.5.3 Crush Hazards

(Refer To TBIG Latest Edition)

2.5.4 Chemical Hazards

(Refer To TBIG Latest Edition)

2.5.5 Pressure Hazards

(Refer To TBIG Latest Edition)

2.5.6 Slip, Fall Hazards

(Refer To TBIG Latest Edition)

1

Modu-Fire® Gas-Fired Boiler Installation

3.0 INSTALLATION

(Refer To TBIG Latest Edition)

3.1

RECEIVING AND STORAGE

(Refer To TBIG Latest Edition)

3.1.1 Initial Inspection

(Refer To TBIG Latest Edition)

3.1.2 Storage Prior to Installation

(Refer To TBIG Latest Edition)

3.2

COMPLIANCE WITH CODES

(Refer To TBIG Latest Edition)

3.3

SETUP

(Refer To TBIG Latest Edition)

3.3.1 Foundation

(Refer To TBIG Latest Edition)

3.3.2 Placement

(Refer To TBIG Latest Edition)

3.3.3 Clearances

(Refer To TBIG Latest Edition)

3.4

ELECTRICAL CONNECTIONS

(Refer To TBIG Latest Edition)

3.5

COMBUSTION AIR

(Refer To TBIG Latest Edition)

3.6

FLUE VENTING

For boilers connected to gas vents or chimneys, vent

installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas

Code, ANSI Z223.1, or applicable provisions of the

local building codes.

In Canada, the boiler is certified for installation with

a “Power Venter” by the Canadian Gas Association

when installed with the “listed accessories.”

Consult your local distributor for information on

proper selection. The venting system and the

horizontal portions of the venting system shall be

supported to prevent sagging.

Consult your local vent supplier for correct vent

sizing and structural support requirements. Vent

diameter is dictated by the length and height of

horizontal and vertical portions of the vent

installation and the materials of construction.

Correct sizing should be based on High fire input at

a nominal -.04" W.C. draft pressure at the boiler

outlet with a gross stack temp of 325º F and CO

2

ratings at 7.5%.

3.6.1 Vent Elbows

(Refer To TBIG Latest Edition)

3.6.2 Barometric Damper

This boiler is certified for operation without a

barometric damper. However, some venting

installations may require a barometric damper for

excessive draft conditions. (Not supplied by

factory.)

3.6.3 Barometric Damper Location

(Refer To TBIG Latest Edition)

3.6.4 Flue Connection

(Refer To TBIG Latest Edition)

3.6.5 Vent Termination

(Refer To TBIG Latest Edition)

3.6.6 Removing an Existing Boiler

(Refer To TBIG Latest Edition)

This boiler is Category II as it is defined in ANSI

Z21.13/CSA 4.9 latest edition.

2

3.7

GAS PIPING

(Refer To TBIG Latest Edition)

Modu-Fire® Gas-Fired Boiler Installation

3.7.1 Gas Supply Piping by Installer

(Refer To TBIG Latest Edition)

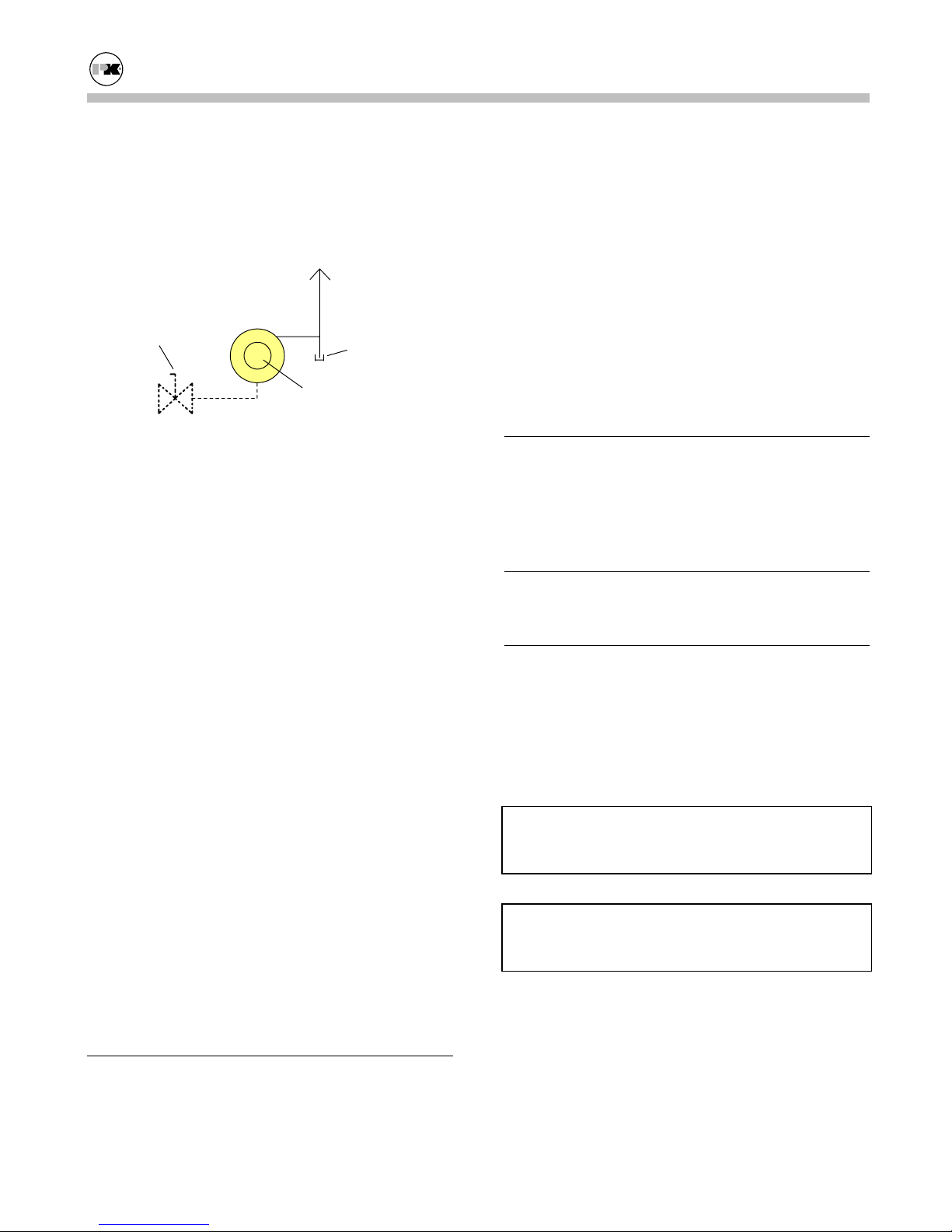

3.7.2 Gas Bleeds and Vents

Vent to

Outside Air

Gas Shutoff

(on Boiler

Gas Bleeds and Vents

Air Gas

Ratio

Control

Drip Leg

If your unit is equipped with a diaphragm gas valve,

the bleed line must be vented to the outdoors.

Maintain size of vent line consistent with vent

connection size.

Gas vents to outdoor air must be provided for the

Air Gas Ratio Control (AGRC). This connection is

labeled COMBUSTION/ATMOSPHERE. The pilot

regulator is equipped with a vent limiting device and

does not require external venting!

Gas Vents by Installer

Note: Provide a drip leg, as shown, in the vent line.

All vent lines should be pitched up at all times to

prevent building a trap into the vent line.

Note: The vent line connection on the Air Gas

Ratio Control must be piped to outdoor air by the

installer in accordance with the National Fuel Gas

Code ANSI Z223.1, latest edition, Sections 2.8.4

and 2.9.7.

If a N.O. (normally open) vent valve is provided, it

must be vented independently of any other bleeds

and vents. Discharge of vent lines should be

protected by an insect screen.

BOILER WATER PIPING

3.8

3.8.1 Piping Design

(Refer To TBIG Latest Edition)

3.8.2 Boiler Inlet and Outlet Connections

(Refer To TBIG Latest Edition)

3.8.3 Boiler Water Piping by Installer

(Refer To TBIG Latest Edition)

3.8.4 Flushing and Filling

(Refer To TBIG Latest Edition)

3.9

BURNER AND IGNITION SYSTEM

(Refer To TBIG Latest Edition)

3.9.1 Inspection

(Refer To TBIG Latest Edition)

3.10

PRE-START CHECK LIST

(Refer To TBIG Latest Edition)

SAFETY CHECKS

3.11

The following checks of safety systems must be

made before putting the boiler into normal

operation.

Before firing the boiler refer to

Sections 4.1 and 4.2

for information on the use of the controls, lighting,

and shut-down procedures.

WARNING!

Never attempt to operate a boiler that has failed to

pass all the safety checks described below.

WARNING!

After checking controls by manual adjustment, make

sure they are always reset to their proper settings.

3.11.1 Test of Ignition Safety System

Test the ignition system safety shutoff as follows:

(Refer To TBIG Latest Edition)

3

1. Close downstream gas cock.

Modu-Fire® Gas-Fired Boiler Installation

2. With the main gas cock (inlet manual gas valve)

open and the pilot gas cock open, the burner

should be cycled on. After all the safety limits

on gas pressure, water flow and temperature are

satisfied, the blower will run and pre-purge the

boiler.

3. When air flow is established, the ignition

transformer and pilot will operate. Both

functions will be indicated by separate green

lights on the flame safeguard.

4. If a satisfactory pilot is established, the spark

will terminate and the pilot will remain on,

alone, for 10 seconds.

5. After 10 seconds, the green "Main” light on the

flame safeguard will go on; gas will not flow

since the downstream cock is closed. The

"Pilot" will remain on, along with the "Main

Gas", for another 10 seconds and then go out.

Since the gas cock is closed, at this point there

will be no main flame signal and the flame

safeguard programmer will assume a “Flame

Failure” and go to a "lockout" mode. Lockout

will require manual reset of the flame safeguard.

After completing this test, turn off the boiler and

reopen the downstream gas cock.

3.11.2 Test of Low Water Cut-off

(Refer To TBIG Latest Edition)

3.11.3 Test of High-Limit Control

Fire the boiler and test the high limit control as

follows:

With the main burner operating, turn down the

temperature setting on the "high-limit" thermostat

until the main burner shuts off. The high-limit

switch must be manually reset after testing. This

check should also be made for the "Operating

Temperature" control (the green "Heat" indicator

will go out) (see next section for Modulating Units).

Readjust thermostats to desired operating

temperature and set high-limit temperature, typically

20º F above operating temperature.

3.11.4 Test of Gas Pressure Switch

(Refer To TBIG Latest Edition)

3.12

INITIAL ADJUSTMENTS

3.12.1A – Configuring the Controller

Operating Modes:

Internal Setpoint

Night Setback

Outdoor Air Reset

Analog Input Setpoint (See Section 3.12.1B.)

Analog Input Direct Drive (Multiple boiler

Controls)

Definitions:

SP1- Setpoint 1:...................This is the primary

setpoint of the boiler.

SP2- Setpoint 2 :...................An alternate setpoint.

Available through the

night setback contact.

dSP- Differential Setpoint : ..An alternate setpoint

differential from SP1.

Available through the

night setback contact.

tA- Air temperature: ............Measurement of

outside air

temperature.

SP.E- External Setpoint:.......Measurement of the

external setpoint.

HyS1:....................................Low temperature

differential.

HyS3:....................................High temperature

differential.

Internal Setpoint

The boiler water outlet temperature is controlled to

SP1 (setpoint 1) and the boiler modulates to

maintain SP1 subject to the upper and lower

temperature differentials and the upper and lower

setpoint limit.

4

Modu-Fire® Gas-Fired Boiler Installation

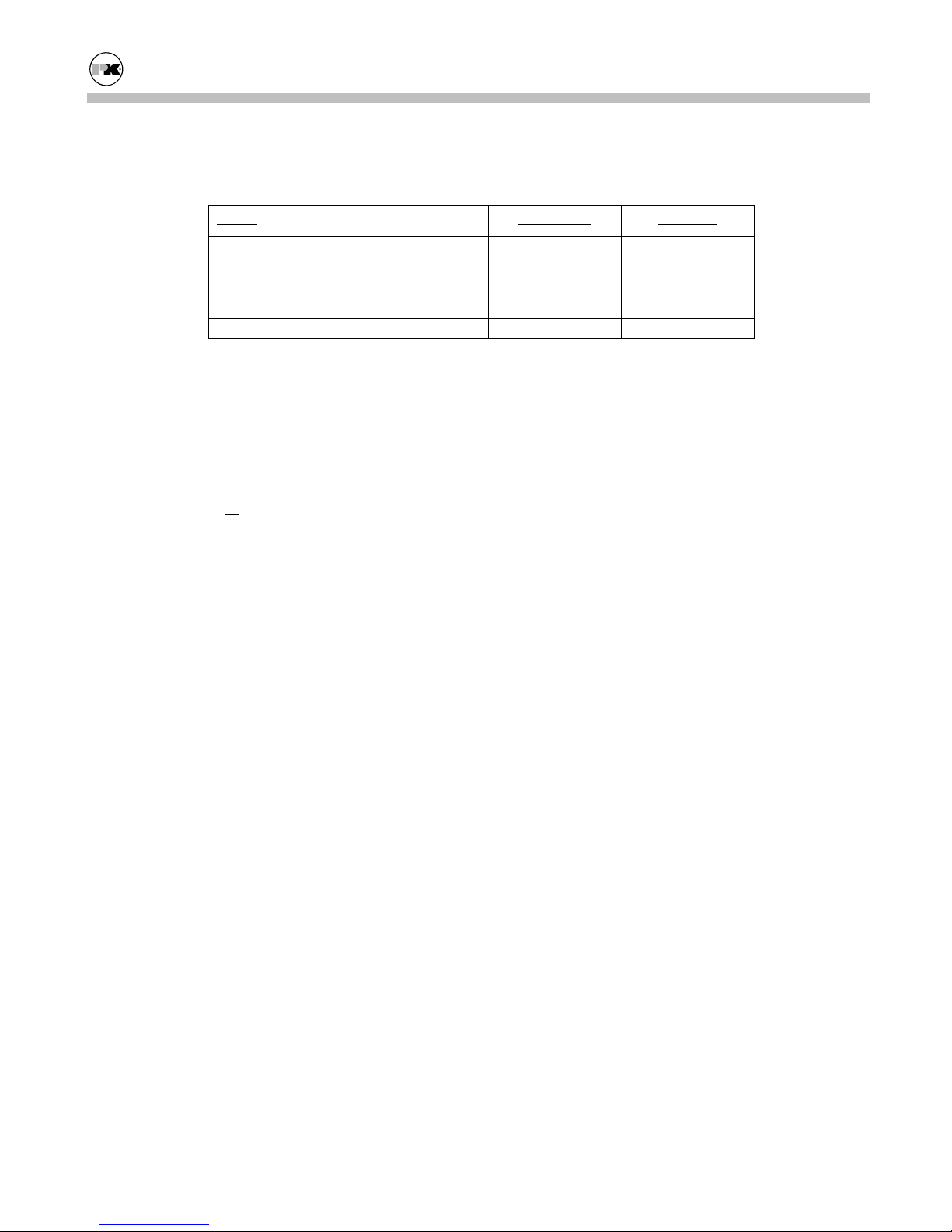

For example, assume the following settings:

ITEM DISPLAY VALUE

SETPOINT 1 SP1 160

LOW TEMP DIFFERENTIAL HyS1 -5

HIGH TEMP DIFFERENTIAL HyS3 12

LOW TEMP SETPOINT SPL 150

HIGH TEMP SETPOINT SPH 195

The boiler will modulate to try to maintain 160

If the temperature increases to 172

Setpoint 1 (SP1)

(HyS3)

12, it will shut off. Once it shuts off, it will

160 + High Temp Differential

o

F which is

not restart until the temperature drops to 155

which is Setpoint 1 (SP1)

Differential (Hys1)

160 + Low Temp

-5. The Low Temp Setpoint

o

F.

o

F

(SPL) prevents the operator from setting Setpoint 1

(SP1) lower than Low Temp Setpoint (SPL)

150.

The High Temp Setpoint (SPH) prevents the

operator from setting Setpoint 1 (SP1) higher than

the High Temp Setpoint (SPH)

195.

Alternate Setpoint

The control must be configured for night setback.

(See the configuration menu.) When the Alternate

Setpoint contact is closed the boiler switches to its

alternate setpoint.

The alternate setpoint can be determined by several

different values. It can be a fixed alternate setpoint

SP2. It can be a fixed differential from SP1 called

dsP. dsP will “offset” the main setpoint SP1 by the

value of dsP. dsP can be positive or negative.

The boiler modulates to maintain this setpoint. The

boiler functions as indicated in internal setpoint;

however SP1 is determined by the outdoor air

temperature.

The setpoint SP1 is reset using a linear relationship

with outdoor air temperature. As the outdoor air

temperature drops the setpoint SP1 is increased a

proportional amount. This increase is determined

by the Heating Slope H. (See Table 1 at the end of

this section.) For example if H is set at 1 then for

every degree the outdoor air temp drops, the

setpoint SP1 will increase 1 degree.

This heating curve has a reference temperature of

68°. This reference can be offset using the Parallel

shift parameter P. (See Table 1 at the end of this

section.) If P is set to 0 the setpoint SP1 will be 68°

when the outdoor temp is 68°. If P is set to 10, the

setpoint SP1 will be 78° when the outdoor temp is

68°. The minimum setpoint of the boiler is limited

by the control. In the above example the actual

setpoint SP1 of the boiler will not go below 150°.

Analog Input Setpoint

The Alternate Setpoint can also be determined by an

external analog source such as a 4-20 mA signal.

Outdoor Air Reset

The control must be configured for outdoor air reset.

(See the configuration menu.)

The setpoint of the boiler is controlled by an

outdoor temperature sensor. As the outdoor

temperature falls the setpoint of the boiler is

increased.

5

The control must be configured for external

setpoint. (See the configuration menu.)

The setpoint of the boiler is controlled by an

external signal. The boiler functions as described

with the internal setpoint, using the value

determined by the external analog signal.

Analog Input Direct Drive

The firing rate of the boiler is controlled by an

external analog signal, usually from a multiple

Modu-Fire® Gas-Fired Boiler Installation

boiler control. The boiler turns on and off as

directed by the external control.

An operating limit control ensures that the boiler

temperature does not exceed the set value.

Refer also to Section 3.12.1B.

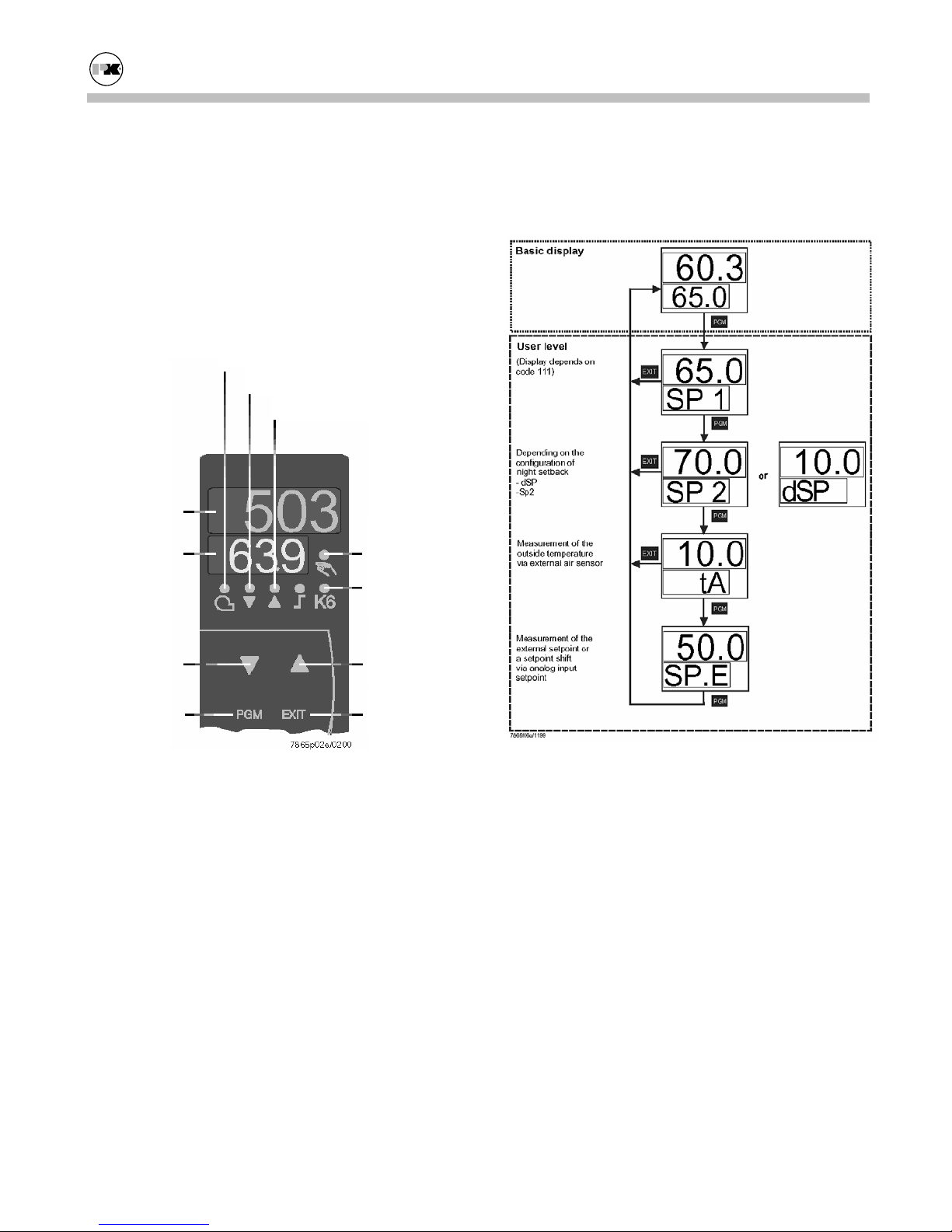

Use of the Controller

Actual Value

Display (red)

Setpoint

Display

(green)

Operating Limit Closed

Firing Rate Decreasing

Firing Rate Increasing

Manual

Operation

Alarm Relay

Energized

The following table indicates the menu options

available from each level. The options available

depend on the operating mode of the boiler.

Decrease

Value

PROGRAM

Button

Increase

Value

EXIT

Button

The diagram shows the RWF40 after switching on

power. This condition is called the basic display.

The actual value and the currently active setpoint

are shown here. Manual operation, self-setting, and

the user, parameter, and configuration levels can be

activated from here.

Operation of the Control:

The temperature control has three levels of

cascading menus. They are:

USER level,

PARAMETER level, and the

CONFIGURATION level.

User Level:

To access the User level from the basic display

press PGM.

Change the setpoint

SP1 with or .

Change to setpoint SP2 or dSP with PGM.

Change the setpoint SP2 or dSP with or .

Return to the basic display with

EXIT.

Manual Operation of the Boiler

The boiler firing rate can be controlled manually.

To change to manual operation press

EXIT for

5 seconds.

The LED above the hand symbol lights up.

6

Loading...

Loading...