Patterson-Kelley MOD-04 User Manual

MOD-04

PATTERSON-KELLEY

THERMIFIC®

MODU-FIRE® GAS-FIRED BOILER

Installation and Owner's Manual

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

Installation Date: _______________________

ASME Code, Section IV

Certified by Patterson-Kelley

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

100 Burson Street, P.O. Box 458,

East Stroudsburg, PA 18301

Telephone: (877) 728-5351, Facsimile: (570) 476-7247

www.pkboilers.com

Modu-Fire® Gas-Fired Boiler Table of Contents

1.0 INTRODUCTION........................................1

2.0 SAFETY......................................................1

2.1 General.......................................................1

2.2 Training....................................................... 1

2.3 Safety Features ..........................................1

2.4 Safety Labels..............................................2

2.5 Safety Precautions...................................... 2

2.5.1 Electrical Hazards.................................2

2.5.2 Burn, Fire, and Explosion Hazards.......2

2.5.3 Crush Hazards......................................3

2.5.4 Chemical Hazards................................3

2.5.5 Pressure Hazards.................................4

2.5.6 Slip, Fall Hazards ................................. 4

3.0 INSTALLATION..........................................5

3.1 Receiving and Storage ............................... 5

3.1.1 Initial Inspection....................................5

3.1.2 Storage Prior to Installation.................. 5

3.2 Compliance with Codes.............................. 5

3.3 Setup...........................................................5

3.3.1 Foundation............................................5

3.3.2 Placement............................................. 5

3.3.3 Clearances ...........................................6

3.4 Electrical Connections................................6

3.5 Combustion Air ...........................................7

3.6 Flue Venting................................................ 7

3.6.1 Vent Elbows.......................................... 8

3.6.2 Barometric Damper .............................. 8

3.6.3 Automatic Vent Damper .......................8

3.6.4 Flue Connection ................................... 8

3.6.5 Vent Termination..................................8

3.6.6 Removing an Existing Boiler ................9

3.7 Gas Piping .................................................. 9

3.7.1 Gas Supply Piping by Installer ...........11

3.7.2 Gas Bleeds and Vents by Installer.....11

3.8 Boiler Water Piping................................... 11

3.8.1 Piping Design......................................11

3.8.2 Boiler Inlet and Outlet Connections....12

3.8.3 Boiler Water Piping by Installer...........12

3.8.4 Flushing and Filling.............................13

3.8.5 Water Quality ......................................13

3.9 Burner and Ignition System.......................13

3.9.1 Inspection............................................13

3.10 Pre-Start Check List................................13

3.11 Safety Checks.........................................14

3.11.1 Test of Ignition Safety System..........14

3.11.2 Test of Low Water Cut-off.................14

3.11.3 Test of Limit Controls........................14

3.11.4 Test of Low Gas Pressure Switch.....15

3.11.5 Test of High Gas Pressure Switch....15

3.12 Initial Adjustments...................................15

3.12.1A – Configuring the Local Controller...15

3.12.1B Optional Remote Control................20

3.12.2 Air Flow Adjustments........................20

3.12.3 Gas Pressure Adjustment.................21

4.0 OPERATION ............................................22

4.1 General......................................................22

4.1.1 Control Panel Front.............................22

4.2 Lighting and Shut-Down Procedures ........22

4.2.1 Lighting Procedures............................22

4.2.2 Normal Shut Down Procedures ..........23

4.2.3 Emergency Shut Off............................23

4.3 Typical Boiler Operating Conditions..........23

5.0 MAINTENANCE ......................................24

5.1 Maintenance and Inspection Schedule.....24

5.1.1 Daily....................................................24

5.1.2 Weekly ................................................24

5.1.3 Monthly (During Operation).................24

5.1.4 Semi-Annually.....................................24

5.1.5 Annually ..............................................25

5.2 Cleaning the Burner ..................................25

Modu-Fire® Gas-Fired Boiler Table of Contents

5.3 Removing the Exchanger ......................... 26

5.4 After All Repairs or Maintenance..............26

5.5 Sequence of Operation..............................27

5.5.1 Standard Modulating ..........................27

5.5.2 IRI Modulating .................................... 28

5.6 Troubleshooting........................................ 29

6.0 PARTS/TECHNICAL SUPPORT..............31

6.1 Schematic Diagrams..................................31

Standard Unit - Local Control - Logic Diagram32

Standard Unit - Remote Control - Logic

Diagram..................................................33

Standard Unit - Local & Remote Control -

Logic Diagram........................................34

Standard Unit - Local & Remote Control w

Options - Logic Diagram........................35

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

Reorder No. 6020-V2WHPK

WARNING!

IRI Unit - Local Control - Logic Diagram.......36

IRI Unit - Remote Control - Logic Diagram...37

IRI Unit - Local & Remote Control - Logic

Diagram..................................................38

IRI Unit - Local & Remote Control w Options -

Logic Diagram ........................................39

Standard Unit – Panel Layout.......................40

IRI Unit – Panel Layout.................................41

6.2 Boiler Parts List.........................................42

6.2.1 Main Assembly....................................42

6.2.2 Control Panel......................................43

6.2.3 Gas Trains...........................................45

6.2.4 Cabinet................................................49

7.0 LIMITED WARRANTY.............................50

WARNING!

It is essential to read, understand, and follow the

recommendations of this manual before installing,

operating, or servicing this equipment. Failure to do

so could result in fire or explosion and serious injury, death, and/or property damage.

The same features which permit this boiler to

achieve high-efficiency performance make it unlike

most other boilers of this general size, so it is important to understand how this boiler operates.

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

Installation and service must be performed by a

qualified installer, service agency, or gas supplier.

What to do if you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building. Imme-

diately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier call the

fire department.

Modu-Fire® Gas-Fired Boiler Introduction/Safety

1.0 INTRODUCTION

The P-K MODU-FIRE

lutionary advance; Patterson-Kelley now combines

full-modulation burner control with our time-tested

modular hot water boiler design. The result is

“modular full-modulation”- Modu-Fire! This new

hybrid boiler combines the best of our earlier designs with a new generation of burner and control

technology. You will achieve even higher part-load

efficiencies – but without the complexity you might

expect in this type of high performance boiler. High

performance made simple and dependable for years

of trouble-free operation.

This manual covers installation of the P-K MODU-

®

FIRE

Boiler Series 1000, 1500, and 2000. The

model numbers may be followed by a prefix or suffix letter in some cases to indicate special features

or different options. While details may differ

slightly, basic operation is the same for all models.

Boilers are built to operate with natural gas or propane. Check the rating plate for the correct gas type

and flow rate.

The boiler is only a part of the complete heating

system. This boiler may be fully operational and yet

because of poor circulation, controls, or other operating characteristics, not deliver heat to the desired

location. Additional equipment such as temperature

sensors, pumps, flow switches, balancing valves and

check valves will be required for satisfactory operation of any system. Patterson-Kelley cannot be responsible for the design or operation of such systems and a qualified engineer or contractor must be

consulted.

®

Gas Fired Boiler is a revo-

2.0 SAFETY

2.1

GENERAL

The MODU-FIRE® gas-fired boiler must be:

• Installed in accordance with designs prepared

by qualified facility engineers including: structural, mechanical, electrical, and other applicable disciplines.

• Operated and serviced in accordance with a

comprehensive safety program determined and

established by the customer. Do not attempt to

operate or service until such a program has been

established.

• Operated and serviced by qualified, factory-

trained personnel in accordance with all applicable codes, laws, and regulations.

• The use of the term “factory-trained personnel”

throughout this manual indicates PattersonKelley trained on this specific piece of equipment.

2.2

TRAINING

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

Reorder No. 6020-V2WHPK

It is essential to read, understand, and follow the

recommendations of this manual before installing,

operating, or servicing this equipment. Failure to do

so could result in serious injury, death, and/or property damage.

Proper training is the best protection against accidents. Operating and service personnel must be

thoroughly familiar with the basic construction of

the MODU-FIRE

®

boiler, the use and locations of

the controls, the operation of the boiler, adjustment

of its various mechanisms, and all applicable safety

precautions. If any of the provisions of this manual

are not fully and completely understood, contact the

Patterson-Kelley Sales Department.

2.3

SAFETY FEATURES

It is the responsibility of the customer to maintain

the safety features of this machine, such as: guards,

safety labels, safety controls, interlocks, lockout

devices, etc., in place and operable.

1

Modu-Fire® Gas-Fired Boiler Safety

SAFETY LABELS

2.4

NOTE

Make sure this union is

tight before closing cabinet

cover after servicing boiler.

c

1998 HCS, Inc. 800-748-0241

Reorder No. 8032-02NHAK

• Shock hazard! Properly lockout/tagout the elec-

trical service and all other energy sources before

working on or near the machine.

• Shock hazard! Boiler is not rated for wash-

down service.

NOTE

When opening leak test valves,

always follow instructions in

operation and safety manual.

c

1998 HCS, Inc. 800-748-0241

c

1998 HCS, Inc. 800-748-0241

C 1998 HCS, Inc. 800-748-0241

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

operating or servicing boiler.

Reorder No. 8032-01NHPK

!

WARNING

Reorder No. 6020-V2WHPK

!

WARNING

Electrical hazard.

Follow lockout/tagout

procedure when

servicing this boiler.

Reorder No. 5025-V1WHPK

The safety labels shown above are affixed to your

boiler. Although the labels are of high quality, they

may become dislodged or unreadable over time.

Contact Patterson-Kelley for replacement labels.

2.5

SAFETY PRECAUTIONS

Provide a suitable location for the boiler, away from

normal personnel traffic, with adequate working

space, adequate clearances, proper ventilation and

lighting, with a structure sufficiently strong and

rigid to support the weight of the boiler, all piping,

and accessories.

2.5.1 Electrical Hazards

!

WARNING

Electrical hazard.

Follow lockout/tagout

procedure when

servicing this boiler.

C 1998 HCS, Inc. 800-748-0241

Reorder No. 5025-V1WHPK

2.5.2 Burn, Fire, and Explosion Hazards

General Warning

c

1998 HCS, Inc. 800-748-0241

!

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

operating or servicing boiler.

Hot Surface

WARNING

Reorder No. 6020-V2WHPK

NOTE

Make sure this union is

tight before closing cabinet

cover after servicing boiler.

c

1998 HCS, Inc. 800-748-0241

Reorder No. 8032-02NHAK

NOTE

When opening leak test valves,

always follow instructions in

operation and safety manual.

c

1998 HCS, Inc. 800-748-0241

• Burn, fire, and explosion hazards! Installation

must be in strict conformance to all applicable

codes and standards including NFPA 54, ANSI

Z223.1 and CAN/CGA B.149. Install all required ventlines for gas devices. Refer to Section 3.7.2.

• Hazard from incorrect fuels! Possible fire, ex-

plosion, overheating, and damage. Do not use

any fuels except the design fuel for the unit.

• Overfire hazards! High pressure in gas or pro-

pane supply could result in overfiring of other

devices supplied from the same source.

• Fire and explosion hazards! Close the main gas

shutoff before servicing boiler.

Reorder No. 8032-01NHPK

2

Modu-Fire® Gas-Fired Boiler Safety

• Fire and explosion hazards! Do not store or use

gasoline or other flammable vapors or liquids in

the vicinity of this or any other gas fired appliance.

• Burn hazard! Possible hot surfaces. Do not

touch gas vent during firing operation. Use only

factory recommended vent components.

• Burn hazard! Hot fluids. Use caution when

servicing or draining boiler.

• Fire and explosion hazards! Use caution when

servicing burner. Propane (LPG) is heavier than

air and may linger in the combustion chamber,

vent lines, or elsewhere.

• Gas leak hazard! Make sure all connections to

main burner are tight when reassembling the

burner. These connections cannot be tested after the burner is assembled.

• Gas leak hazard! All threaded gas connections

must be made using a pipe compound that is resistant to liquefied petroleum. Do not use Teflon™ tape on threaded gas piping.

• Gas leak hazard! Check entire gas train for

leaks after installation. If there is a smell of gas,

shut down the boiler and obtain immediate assistance from factory-trained personnel and/or

your local fire department.

2.5.3 Crush Hazards

General Warning

• Lifting hazards! Use properly rated lifting

equipment to lift and position the boiler. The

load is unbalanced. Test balance before lifting 3

ft. above the floor. Do not allow personnel beneath the lifted load. Refer to approximate

weights in the table below:

Boiler Size Weight in Pounds

1,000,000 Btu 595

1,500,000 Btu 990

2,000,000 Btu 1,025

• Bump hazard from overhead piping. Install pip-

ing with adequate vertical clearance.

2.5.4 Chemical Hazards

• Overfire hazard! Possible fire and explosion

from excess gas pressure. Make sure that gas

inlet pressure does not exceed 14 inches w.c. to

the regulator.

• Overfire hazard! Possible fire and explosion.

Possible malfunction of regulators and/or motorized gas valves. Maintain all gas train components in good condition. Do not alter wiring

connections. Annual inspection by factorytrained personnel for proper set-up and operation is recommended.

• Environmental hazard! The motorized gas

valves may contain hydraulic oil. Use safe procedures for the disposal of all lubricants.

• Chemical hazards from cleaning products. Use

caution when cleaning the system. The use of

professional assistance is recommended. Use

safe procedures for the disposal of all cleaning

solutions.

General Warning

• Overfire and underfire hazards! Possible fire,

explosion, overheating, and component failure.

Do not attempt to adjust firing rate of the boiler.

The firing rate must be adjusted only by factory-trained personnel.

3

Modu-Fire® Gas-Fired Boiler Safety

2.5.5 Pressure Hazards

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

• Pressure hazard! Hot fluids. Install isolation

valves on boiler water inlet and outlet. Make

sure isolation valves are closed before servicing

boiler.

• Pressure hazard! Hot fluids. Annually test

safety relief valve for proper operation. Do not

operate boiler with faulty relief valve.

2.5.6 Slip, Fall Hazards

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

• Tripping hazard! Do not install piping on floor

surfaces. Maintain clear path around boiler.

• Slip and fall hazard! Use drip pan to catch wa-

ter while draining the boiler. Maintain dry floor

surfaces.

• Slip and fall hazard! Do not locate intake or

exhaust terminations directly above a walkway;

dripping of condensation can cause icing of the

walking surface.

4

Modu-Fire® Gas-Fired Boiler Installation

3.0 INSTALLATION

RECEIVING AND STORAGE

3.1

3.1.1 Initial Inspection

Upon receiving the boiler, inspect it for signs of shipping damage. Pay particular attention to the control

panel on the top of the boiler and the components

mounted on the back, which may show damage from

mishandling.

The exterior cabinet must be reasonably air-tight for

the burner to operate correctly. Leaks caused by dents

in the sheet metal or panels out of position may cause

the limit controls to show Low Air. Check to be sure

that the mixer core in the top burner is centered and

has not moved in shipment; (see Section 5.2, "Cleaning the Burner" for proper location). Verify that the

total number of pieces shown on the packing slip

agrees with those actually received.

Important: Note any damage or shortage on the

freight bill and immediately notify the carrier. File

all claims for shortage or damage with the carrier

3.1.2 Storage Prior to Installation

If the boiler is not installed immediately, it must be

stored in a location adequately protected from the

weather, preferably indoors. If this is not possible,

then it should remain in the shipping container and be

covered by a tarpaulin or other waterproof covering.

Note: Controls and other equipment that are damaged

or fail due to weather exposure are not covered by

warranty.

.

temperature. Other codes or approvals which apply

will be labeled on the boiler.

Installation of the boiler must conform to all the requirements of all national, state and local codes established by the authorities having jurisdiction or, in the

absence of such requirements, in the U.S. to the National Fuel Gas Code, ANSI Z223.1/NFPA 54, latest

edition. In Canada, the equipment shall be installed in

accordance with the current Installation Code for Gas

Burning Appliances and Equipment, CAN/CGAB.149, and applicable Provincial Regulations for the

class, which should be carefully followed in all cases.

Authorities having jurisdiction should be consulted

before installations are made.

Where required by local codes, the installation must

conform to American Society of Mechanical Engineers Safety Code for Controls and Safety Devices for

Automatically Fired Boilers (ASME CSD-1).

In the Commonwealth of Massachusetts (a) this unit

must be installed by a licensed pipe fitter / plumber,

(b) field installed gas cocks must be "T" handle type,

and (c) piping of condensate shall conform with the

State Plumbing Code.

3.3

SETUP

3.3.1 Foundation

Provide a firm, level foundation, preferably of concrete.

Note: The boiler may be installed on a combustible

floor; however, the boiler must never be installed on

carpeting.

COMPLIANCE WITH CODES

3.2

The P-K MODU-FIRE® Boiler with standard components and many options complies with American National Standard/CSA Standard ANSI Z21.13/CSA 4.9,

latest edition, Gas-Fired Low Pressure Steam and Hot

Water Boilers. The heat exchanger is constructed and

stamped in accordance with ASME Boiler and Pressure Vessel Code, Section IV for 160 psig maximum

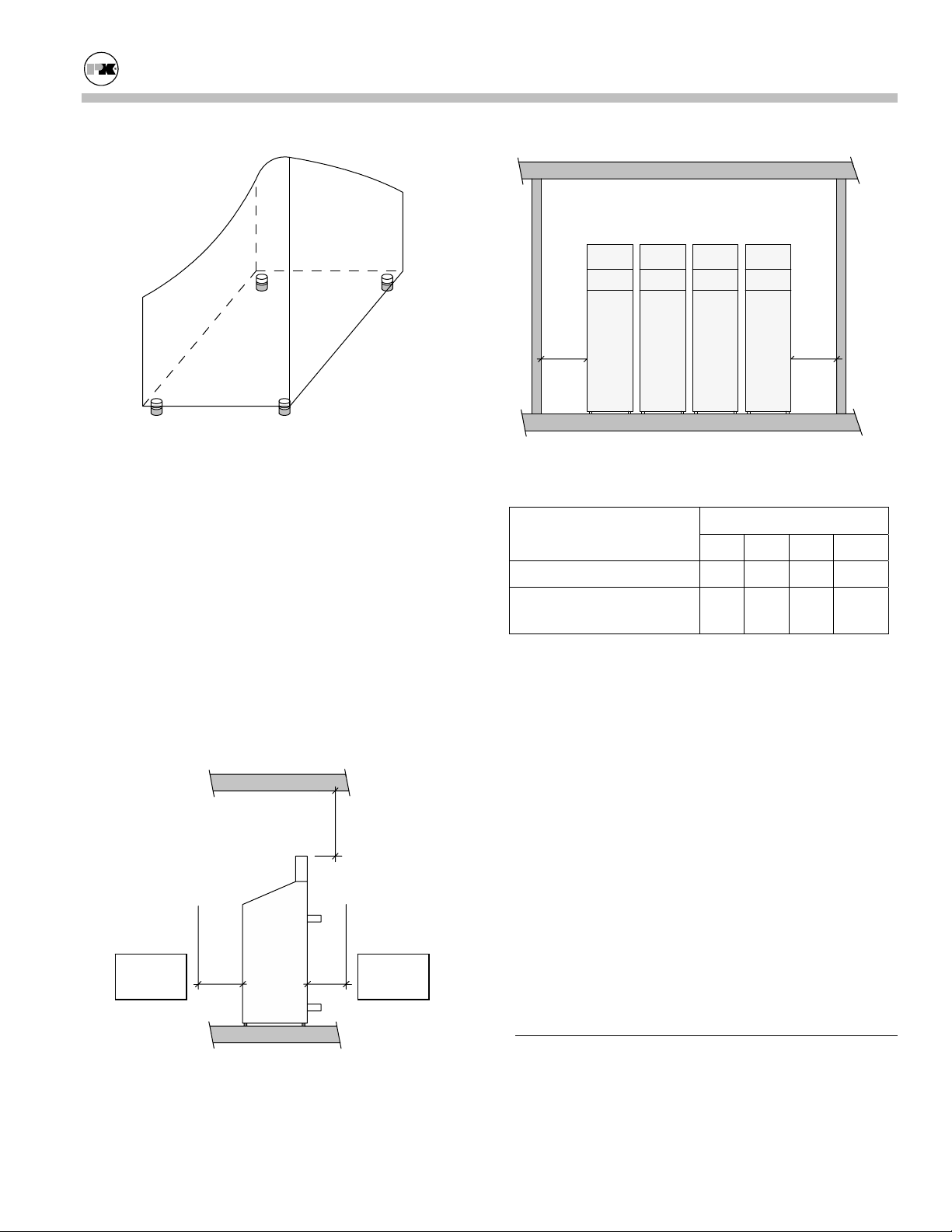

3.3.2 Placement

The boiler must be level to function properly. To assist in leveling the boiler, the four (4) leg bolts (1/2"NC) holding the boiler to the shipping skid must be

reinstalled in the threaded legs on the bottom. The

adjustable legs are also necessary to provide adequate

floor clearance and prevent distortion on the cabinet,

(twisting, etc.) in addition to leveling.

operating pressure and/or 250º F maximum operating

5

Modu-Fire® Gas-Fired Boiler Installation

DD

Adjustable Legs for Leveling and Floor Clearance

3.3.3 Clearances

If the boiler is to be installed near combustible surfaces, the minimum clearances shown in the table below must be maintained.

Failure to provide for the service access clearances,

even with non-combustible surfaces, may cause future

problems servicing the boiler.

The boiler must be installed in a space large in comparison to the boiler as described in Section 6.3 of the

National Fuel Gas Code, ANSI Z223.1, latest edition.

Minimum Clearances from Adjacent Walls, Ceiling, and

Type of Surface

Combustible Surfaces 30 24 30 24

Non-combustible Sur-

faces

† "C" dimension includes clearance to remove the

burner. Do not put pipes, ducts, etc. in this area above

the boiler.

* CSA minimum. Actual clearance depends upon

stacking requirements.

Obstructions

Dimensions (inches)

A B C† D

30 24* 30 24**

** Service access need be only on one side of a boiler

No pipes,

ducts, etc.

in this area.

C

or row of boilers. Boilers may be installed immediately adjacent to each other. However, P-K recommends this clearance between each boiler when there

is insufficient access at the rear to allow for service

and adjustment.

In Canada: The boilers are approved for installation

with zero clearance to combustible surfaces, but 24

Front of

Boiler

AB

Back of

Boiler

inch service clearances are recommended.

3.4

ELECTRICAL CONNECTIONS

All field wiring connections for power and control are

in the rear service panel on the back of the boiler.

Low voltage and high voltage terminal strips are indicated on the wiring diagram. The boiler power circuit

6

Modu-Fire® Gas-Fired Boiler Installation

is wired for 120 volts, single phase, 60 hertz. The total

operating amperage is indicated on the rating nameplate. The 1000 series require less than 9 amps; the

1500 and 2000 series less than 12 amps. Before starting the boiler, check to ensure that the proper voltage

and amperage are connected to the boiler.

An external electrical disconnect (not supplied with

the boiler) with adequate overload protection is required. The boiler must be grounded in accordance

with local codes or in the absence of such requirements, in the U.S. with National Electrical Codes,

ANSI/NFPA No. 70 latest edition and in Canada, wire

according to the current Canadian Electrical Code.

Note: A dedicated earth ground (green wire) is required to avoid nuisance shutdowns. Do not ground

through the conduit. It is also important that proper

polarity be maintained.

3.5

COMBUSTION AIR

Combustion air must be free from dust, lint, etc. The

presence of such materials in the air supplied to the

burner could cause nuisance "Low Air" shutdowns or

premature burner failure. The boiler should not be

operated during construction while the possibility of

drywall dust, demolition dust, etc. exists.

Provisions for combustion and ventilation air must be

in accordance with Section 5.3, Air for Combustion

and Ventilation, of the National Fuel Gas Code, ANSI

Z223.1, latest edition, or applicable provisions of the

local building codes. In Canada, combustion air openings shall comply with CSA 4.9. The formula is "1 sq.

in. per 1,000 Btu/hr of gas input not less than 100 sq.

in." The location shall be "neither more than 18," nor

less than 6" above the floor level."

The boiler room shall be provided with two openings

to ensure adequate combustion air and proper ventilation. One opening should be 6 to 12 inches above the

floor and the other 6 to 12 inches below the ceiling,

preferably on opposite walls. The size of each opening is determined by whether air is taken from inside

or outside the building. In Canada, ventilation air

openings shall be at least 10% of the cross sectional

area required for combustion air, but not less than 10

square inches. It is to be located at the highest practical point communicating with outdoors.

If air is taken directly from outside the building, each

opening should have a net free area of 1 square inch

for each 4,000 Btu per hour of total boiler input. For

instance, 300 square inches (2-1/12 square feet) are

required for 1,200,000 Btu per hour input.

When air is taken from the outdoors through a vertical

duct, 1 square inch per 4,000 Btu per hour is required.

If a horizontal duct is used, 1 square inch per 2,000

Btu per hour is required, i.e., 600 square inches for

1,200,000 Btu per hour input.

If air is taken from another interior space, each opening should have a net free area of 1 square inch for

each 1,000 Btu per hour of boiler input (1,200 square

inches for a 1,200,000 Btu per hour.)

WARNING!

Under no circumstances shall the boiler room ever be

under a negative pressure. Particular care should be

taken when exhaust fans, compressors, air-handling

units or other equipment may rob air from the boiler.

The combustion air supply must be completely free of

chemical fumes which may be corrosive when burned

in the boiler. Common chemicals which must be

avoided are fluorocarbons and other halogenated compounds, most commonly present as refrigerants or solvents, such as freon, trichlorethylene, perchlorethylene, chlorine, etc. These chemicals, when burned,

form acids which quickly attack the boiler tubes, tube

sheets, flue collectors and the boiler stack. The result

is improper combustion and premature boiler failure.

3.6 FLUE VENTING

This boiler requires a special vent system. Vent installations shall be in accordance with Part 7, Venting of

Equipment, of the National Fuel Gas Code, ANSI

Z223.1, CSA B149 code or applicable provisions of

the local building codes.

This boiler is Category II as it is defined in ANSI

Z21.13/CSA 4.9 latest edition. The vent material must

be listed Category II Vent pipe (316L or AL-29 4C

Stainless). Under no circumstances shall a Category I

material (e.g. B-vent) be used.

7

Modu-Fire® Gas-Fired Boiler Installation

WARNING!

This boiler should not be installed with an automatic

damper on the flue. Damper failure could create an

explosion hazard.

In Canada, the boiler is certified for installation with a

“Power Venter” by the Canadian Gas Association

when installed with the “listed accessories.” Consult

your local distributor for information on proper selection.

The venting system and the horizontal portions of the

venting system shall be supported to prevent sagging.

Consult your local vent supplier for correct vent sizing

and structural support requirements. Vent diameter is

dictated by the length and height of horizontal and vertical portions of the vent installation and the materials

of construction. It is not necessarily the same size as

the boiler connection. Correct sizing should be based

on High fire input at a nominal -.04" w.c. draft pressure at the boiler outlet with a gross stack temp of 325º

F and CO

ratings at 7.5%.

2

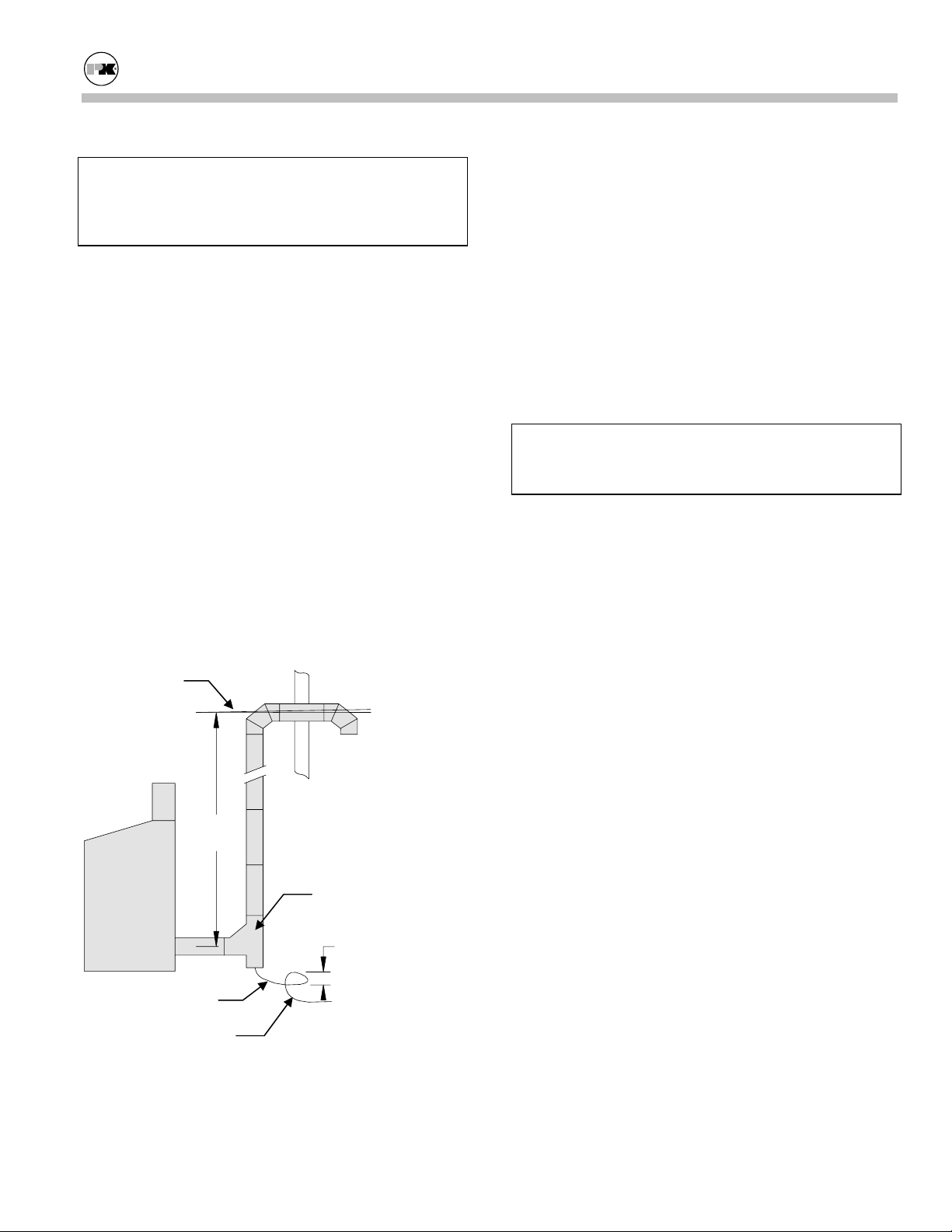

3.6.1 Vent Elbows

Pitch toward

boiler 1/4" per

foot minimum.

6' min.

tee. The condensate drain must be routed to a sewer

drain trap or pump in accordance with local codes.

Refer to diagram under Vent Elbows.

3.6.2 Barometric Damper

This boiler is certified for operation without a barometric damper. P-K does not recommend the use of

one.

3.6.3 Automatic Vent Damper

WARNING!

This equipment, as manufactured, MUST NOT be

used with an automatic vent damper.

3.6.4 Flue Connection

The connection from the boiler to the vent should be

as direct as possible and the upward slope of any horizontal breaching should be at least 1/4 inch per linear

foot. This boiler should not be connected into any portion of a mechanical draft system operating under

positive pressure. Provisions must be made for supports to prevent contact of the vent with combustible

surfaces.

Note: Make sure that the weight of the vent is not

supported by the boiler vent collar. The collar is not

designed to support the weight of the vent. Structural

support and spacing from combustible surfaces must

be in accordance with the vent manufacturer's requirements.

Boot Tee /135º

Tee

Trap Loop

3" min.

3.6.5 Vent Termination

The minimum vent height above the flue outlet must

be five (5) feet and the vent should extend at least

three (3) feet above the roof / snowline, or at least two

(2) feet above the highest part of any structure within

Condensate Line

To sewer trap or

condensate drain.

ten (10) feet of the vent.

The first turn from horizontal to vertical should be

made with a 135° boot tee. A tee cover with a condensate drain shall be provided at the bottom of the boot

8

Modu-Fire® Gas-Fired Boiler Installation

(

)

4. Place the appliance being inspected in operation.

Follow the lighting instructions. Adjust the thermostat so that the appliance will operate continuously.

5. Test for spillage at the draft hood relief opening

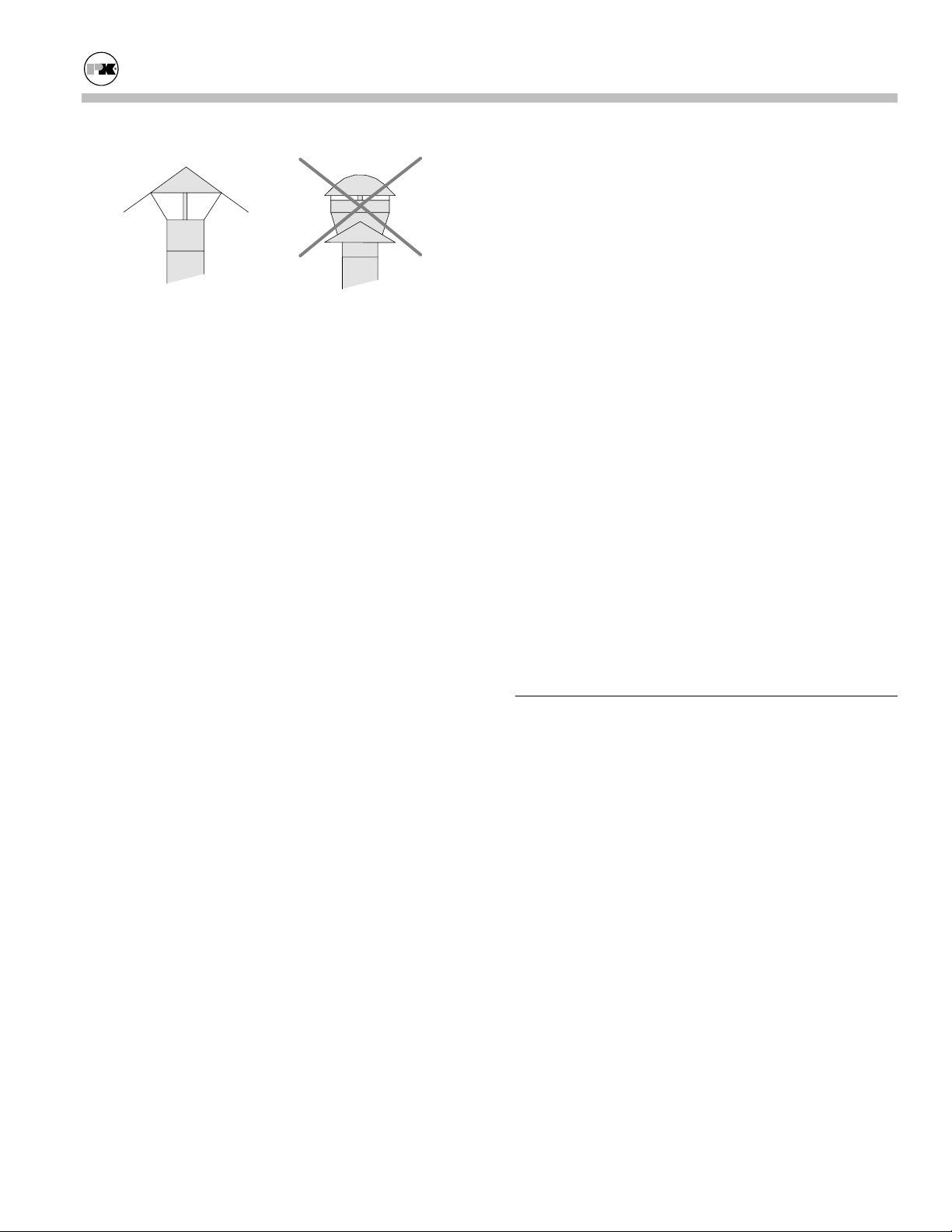

Correct Listed

Termination

Incorrect

Termination

too restrictive

Vent Termination

The vent must be provided with a weather cap of approved design and adequate capacity.

3.6.6 Removing an Existing Boiler

(from a common venting system)

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing boiler, while the

other appliances remaining connected to the common

venting system are not in operation, the following

steps should be followed with each appliance remaining connected to the common venting system placed in

operation:

after 5 minutes of main burner operation. Use the

flame of a match or candle or smoke from a cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers, and any other gas-burning appliance to

their previous conditions of use.

Any improper operation of the common venting system should be corrected so the installation conforms

with the National Fuel Gas Code, ANSI Z223.1.

When resizing any portion of the common venting system, the common venting system should be resized to

approach the minimum size as determined using the

appropriate tables in Part II in the National Fuel Gas

Code, ANSI Z223.1.

3.7

GAS PIPING

Before making the gas hook-up, make sure the boiler

is being supplied with the type of fuel shown on the

boiler nameplate.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine that there is no

blockage or restriction, leakage, corrosion or other

deficiency which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliances not connected to the common venting

The boiler shall be installed such that the gas ignition

system components are protected from water (dripping, spraying, rain, etc.) during appliance operation

and service (circulator replacement, control replacement, etc.)

The gas train components are designed to handle a

maximum inlet pressure of 14 inches water column

(1/2 psig.). If the available gas pressure exceeds 14

inch w.c., a suitable additional intermediate gas pressure regulator of the "lock up" type must be provided

to reduce the pressure to less than 14 inch w.c.

system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers.

9

Modu-Fire® Gas-Fired Boiler Installation

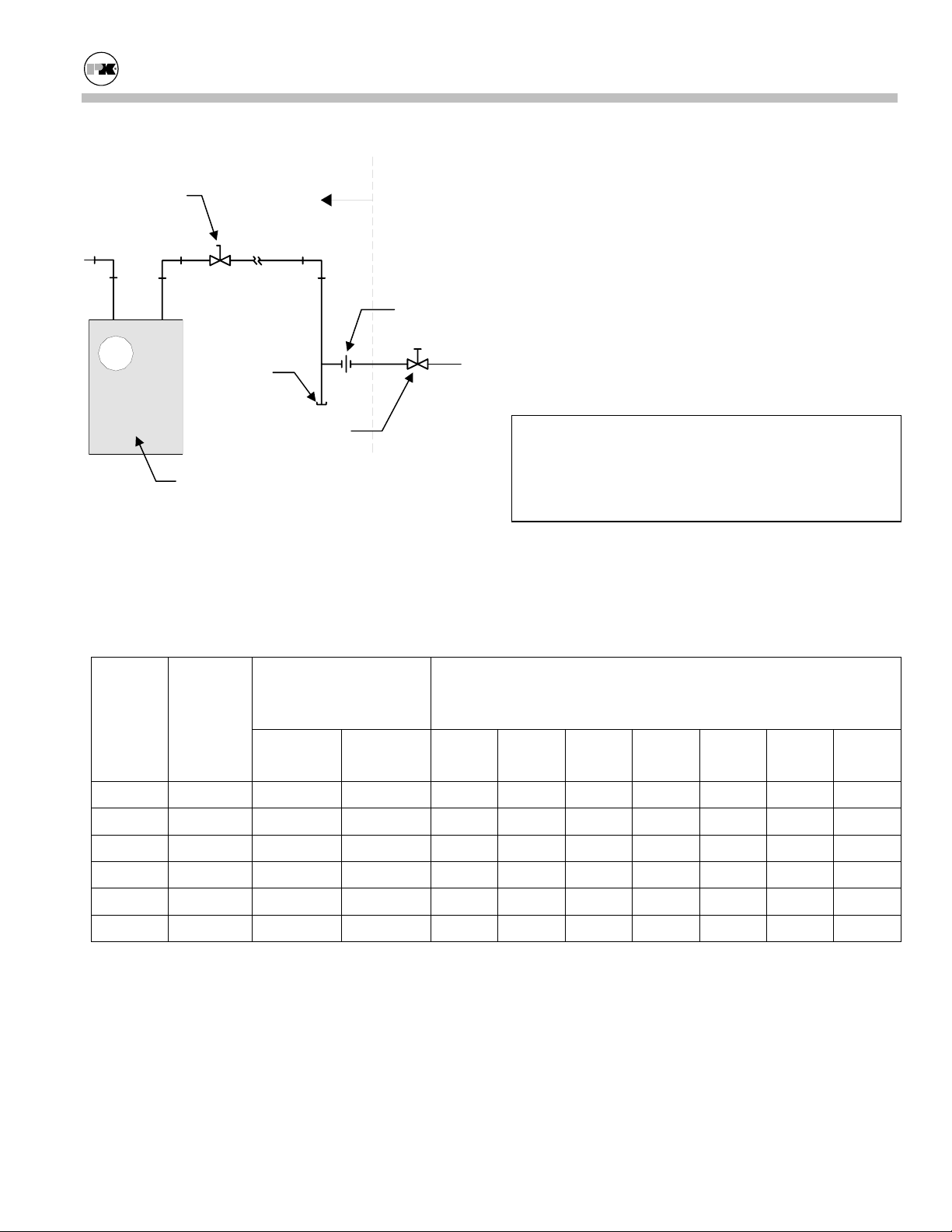

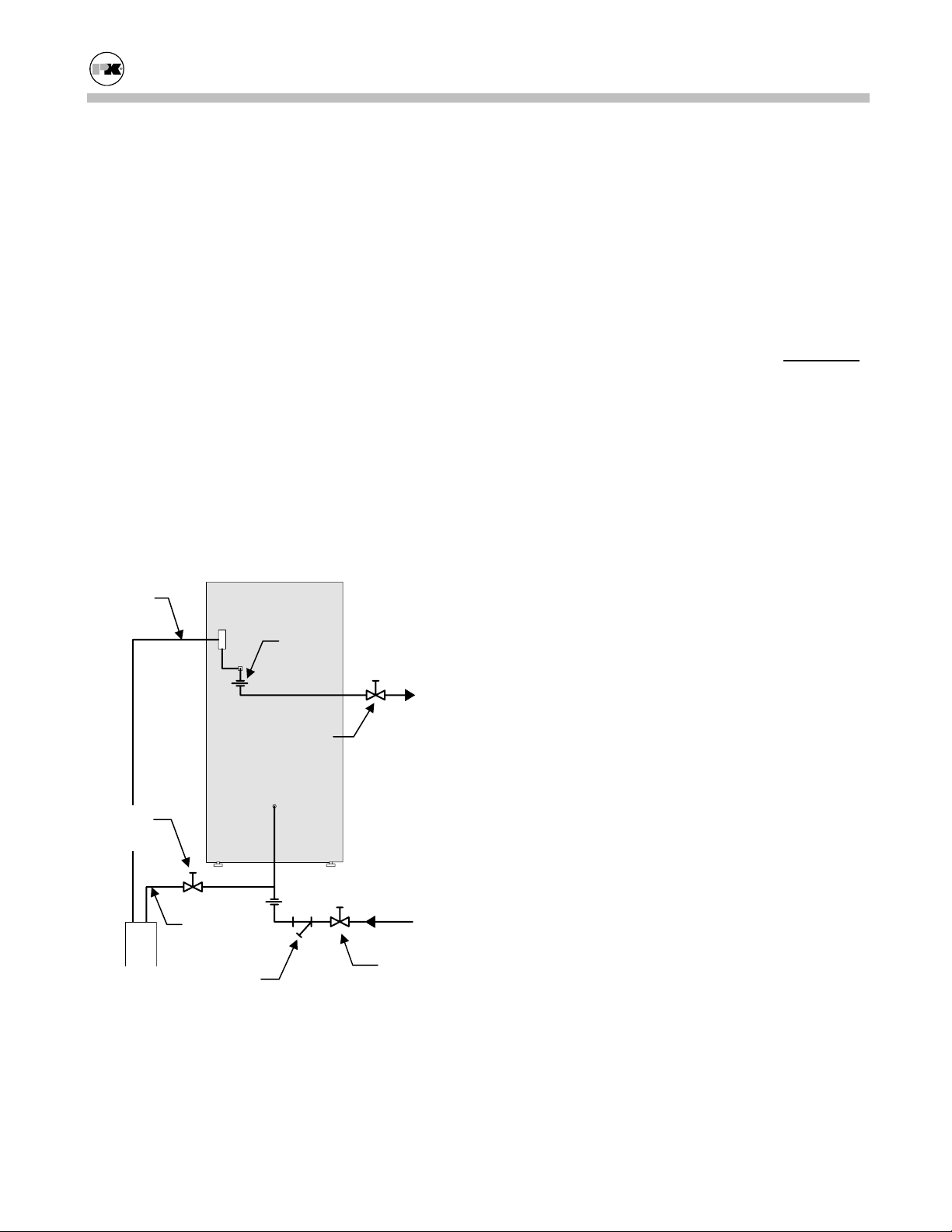

Remote Gas

Shutoff (not

supplied)

Drip Leg

Gas Meter (not

supplied)

By Installer

Union

Shutoff (on

boiler)

Gas Piping

Note: Install a sediment trap (drip leg) and a union

connection ahead of the primary manual shutoff valve

Pipe Capacity for Natural Gas

Nominal

Iron

Pipe

Size

(Inches)

Internal

Diameter

(Inches)

Equivalent Pipe Length Maximum Capacity in Cubic Feet of Natural Gas per Hour

90º Ell

(Feet)

Tee

(Feet)

on the boiler. Gas piping should be installed in accordance with National Fuel Gas Code, ANSI Z223.1,

latest edition, and any other local codes which may

apply; in Canada see CAN/CGA-B 149.

Note: See chart below for required pipe size, based on

overall length of pipe from meter plus equivalent

length of all fittings. Approximate sizing may be based

on 1 cubic foot of natural gas per 1,000 Btu per hour

input, i.e., 900,000 Btu per hour requires about 900

cubic feet per hour. (See Typical Boiler Operating

Conditions, Section 4.3, for more information.)

WARNING!

All threaded connections must be made using a pipe

compound that is resistant to the action of liquefied

petroleum gases. Do not use Teflon tape on gas line

threads.

Pressure Drop of 0.5 inch Water Column/Equivalent Length of

Pipe (in feet)

20

40

60

80

100

150

200

1-1/4 1.380 3.45 6.9 950

1-1/2 1.610 4.02 8.04 1,460 990 810

2 2.067 5.17 10.3 2,750 1,900 1,520 1,300 1,150 950 800

2-1/2 2.469 6.16 12.3 4,350 3,000 2,400 2,050 1,850 1,500 1,280

3 3.068 7.67 15.3 7,700 5,300 4,300 3,700 3,250 2,650 2,280

4 4.026 10.1 20.2 15,800 10,900 8,800 7,500 6,700 5,500 4,600

10

Modu-Fire® Gas-Fired Boiler Installation

3.7.1 Gas Supply Piping by Installer

The boiler and all gas piping connections should be

pressure-tested and must be checked for leaks before being placed into service. Test with compressed air or inert gas if possible.

The boiler must be disconnected at the boiler manual shut-off valve (located at the end of the supplied

gas train) from the gas supply piping system during

any pressure testing of the system at pressures in

excess of 1/2 psig (14 inch w.c.).

During any pressure testing of the gas supply piping

system at pressures equal to or less than 1/2 psig (14

inch w.c.), the boiler should be isolated from the gas

supply piping system by closing the manual shutoff.

Some leak test solutions, including soap and water,

may cause corrosion. These solutions should be

rinsed-off with water after testing.

3.7.2 Gas Bleeds and Vents by Installer

If your unit is equipped with a diaphragm gas valve,

the bleed vents on the diaphragm gas valves have

been factory-piped to terminate at the burner, as required by ANSI Z21.13. This feature provides combustion of any gas which leaks past a ruptured diaphragm during operation. Gas vents to outdoor air

must be provided for the main pressure regulator.

The pilot regulator is equipped with a vent limiting

device and does not require external venting!

• When installing per ASME CSD-1, discon-

nect factory piped bleed vents and vent the

diaphragm gas valves to outdoor air (field

piping.)

If a N.O. (normally open) vent valve is provided, it

must be vented independently of any other bleeds

and vents. Discharge of vent lines should be protected by an insect screen.

The air gas ratio control valve is equipped with a

“reference chamber vent filter” which does not require any additional venting. This connection is

labeled COMBUSTION / ATMOSPHERE.

If local conditions require venting to outdoors, the

vent line connection must be piped by the installer

in accordance with the National Fuel Gas Code

(NFPA 54), ANSI Z223.1, which states:

“In the case of vents leading outdoors, means shall

be employed to prevent water from entering this

piping and also to prevent blockage of vents by insects and foreign matter.”

The National Fuel Gas Code Handbook goes on to

say that “Insects, insect nests, ice, or freezing rain

can block outdoor vents....”

The pilot regulator is equipped with a vent limiting

device and does not require external venting!

Gas Vents by Installer

Note: Provide a drip leg in all vent/bleed lines.

All vent lines should be pitched up at all times to

prevent building a trap into the vent line.

“Vent limiters” are NOT to be installed on this

boiler.

The air gas ratio control valve is equipped with a

“reference chamber vent filter” which does not require any additional venting.

3.8

BOILER WATER PIPING

3.8.1 Piping Design

Water Flow in System

Ideal operation of the P-K MODU-FIRE® Boiler

would consist of a 20º F temperature differential

across the heat exchanger at High fire. Insufficient

flow may result in excessive short cycling of the

boiler and eventual damage or premature failure of

the equipment.

Minimum Return Water Temperature should be

greater than 130º F to avoid problems of condensation on the outside of the heat exchanger or in the

flue passages.

Proper flow rates and return water temperature may

be achieved through a combination of primary and

secondary flow loops. Multiple zones and pumps

may result in different flow rates at different times.

11

Modu-Fire® Gas-Fired Boiler Installation

Consideration must be given to all possible conditions and their consequences.

Piping With Refrigeration Machines

When used with a refrigeration system, the boiler

shall be installed so that chilled medium is piped in

parallel with the boiler. Valves should be installed

to prevent chilled water from entering the boiler

when the system is operated in the cooling mode.

Piping With Air Handling Units

The boiler piping system of a hot water heating

boiler connected to heating coils located in air handling units, where they may be exposed to refrigerated air circulation, must be equipped with flow

control valves or other automatic means to prevent

gravity circulation of the boiler water during the

cooling cycle.

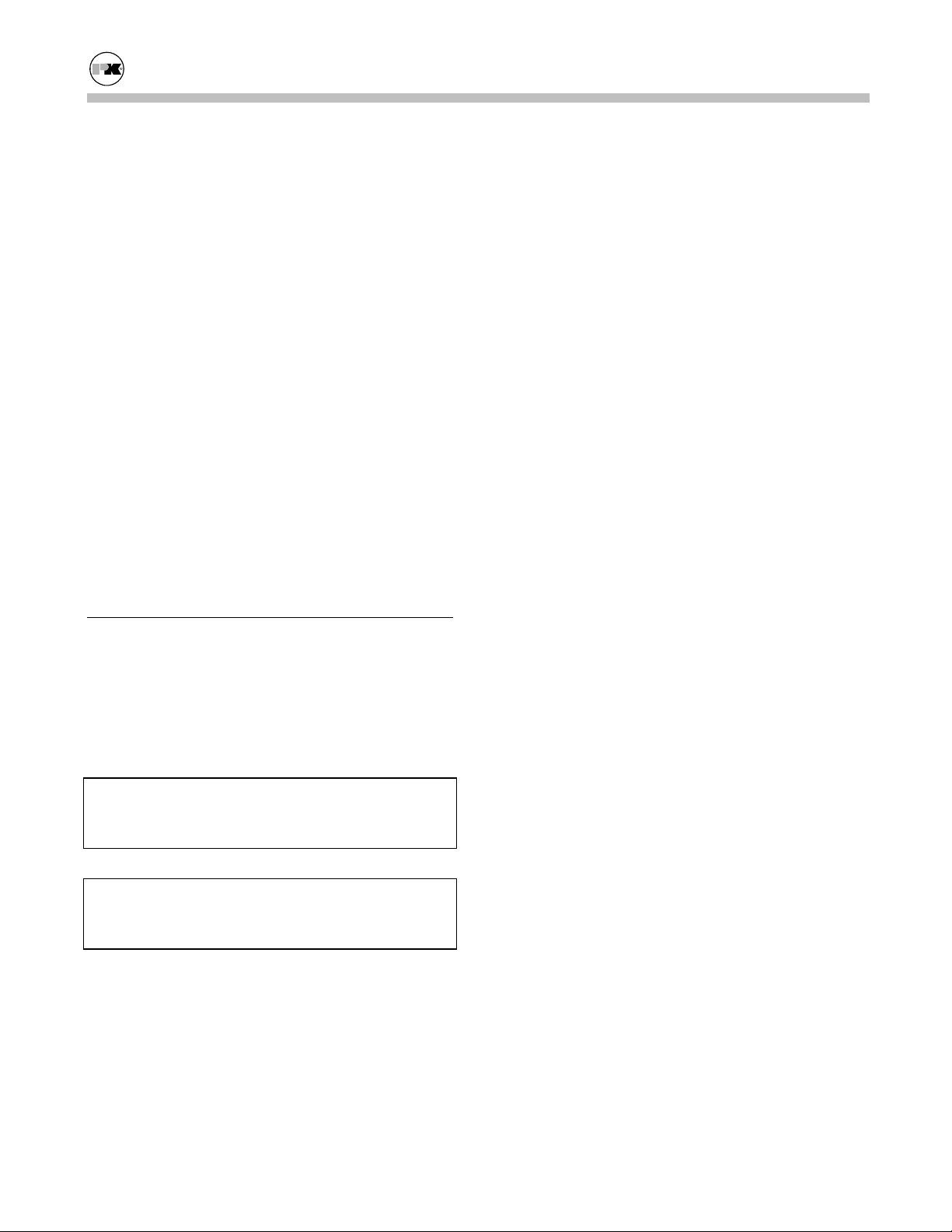

3.8.2 Boiler Inlet and Outlet Connections

Relief Valve

Drain

Union

Outlet (to

system)

Note: Pipe unions and isolating valves must be

installed in both water connections for ease of

service.

The bottom connection to the boiler is the INLET

and must be used for the return from the system.

The top connection to the boiler is the OUTLET and

must be connected as the supply to the system.

Piping must be installed such that no piping stresses

are transmitted to the boiler. The boiler should not

be used as a pipe anchor.

3.8.3 Boiler Water Piping by Installer

Strainer

To avoid possible contamination of the boiler with

dirt, rust or sediment from the system, a strainer

near the boiler inlet is strongly recommended. Even

new systems may contain sufficient foreign material

to eventually reduce the performance of the heat

exchanger. Adequate circulation of good clean water is essential to maximum efficiency and long life

of the boiler.

Relief Valve and Piping

Isolating

Valve

Isolating

Valve

Inlet (from

Boiler

Drain

Strainer

Boiler Inlet and Outlet Connections

system)

Isolating

Valve

Make water connections as the application warrants,

or at a minimum, as shown, but always in compliance with the local requirements.

Each boiler is supplied with a pressure-relief valve

sized in accordance with ASME requirements. The

relief valve should be piped to a suitable floor drain.

Reducing couplings or other restrictions are not

permitted in the discharge line.

Low Water Cut-off

The boiler is furnished with a flow-switch-type low

water cut-off as required by Section IV ASME

Code; no field piping is required. If the flow switch

does not sense water flow, the boiler will shut down

and a red indicator will be illuminated on the control

panel. This flow switch only proves that flow is

present. It does not prove adequate flow as required

by this boiler.

Installation of an external low water cutoff or manual reset low-water switch may be required by certain codes or in certain installations. Consult your

local code for details.

12

Modu-Fire® Gas-Fired Boiler Installation

WARNING!

Never install a valve that can isolate the low water

cutoff from the boiler.

Drain Valve and Piping

The boiler is not provided with external drain connections. A drain valve should be installed near the

inlet (system return) connection to the boiler and

piped to a suitable floor drain. The boiler can be

completely drained through the bottom header by

removing the flush plug in the bottom end plate.

This plug may also be used to flush accumulated

sediment from the bottom of the boiler.

3.8.4 Flushing and Filling

Flushing the System

Before filling the boiler, flush the system to remove

the debris. Clean and flush old piping thoroughly

before installing the boiler as recommended by your

water conditioning or chemical treatment supplier.

Under no circumstances should the hydronic system

be flushed while the boiler is attached to the system

since the debris or corrosion products could accumulate in the boiler and plug the boiler heat exchanger.

If the piping system attached to this unit will be

chemically cleaned, the boiler must be disconnected

from the system and a bypass installed so that the

chemical cleaning solution does not circulate

through the boiler.

Filling

To be sure that the boiler is not air-bound, open the

pressure-relief valve located at the rear of the boiler.

Leave the relief valve open until a steady flow of

water is observed. Close the valve and finish filling

the system.

treated make-up water can cause premature failure

due to buildup of scale. Such failure is not covered

by warranty.

Scale can also reduce efficiency. For example, a

scale thickness of 1/16" will result in a 12.5% loss

of efficiency.

The water quality should be within the guidelines

established by the American Boiler Manufacturers

Association, as follows:

• Total solids: 2,500 ppm

• Total alkalinity: 500 ppm

• Total hardness: 150 ppm

The amount of oils, fats, grease, and other organic

matter should be limited to 10 ppm.

Consult your water conditioning or chemical treatment supplier for analysis and recommendations.

If antifreeze is to be used in the system, the customer should perform a hazard analysis to determine

the use and disposal of the antifreeze.

3.9

BURNER AND IGNITION SYSTEM

3.9.1 Inspection

Inspect the burners to be sure nothing was damaged

or knocked loose during shipment. Make sure that

the mixer core in the top of the burner is centered in

the burner head; (see burner photo in section on

"Cleaning the Burner" Section 5.2). Inspect the pilot line, main gas train and ignition electrode to be

sure they were not damaged during shipment or installation. Check to see that the pilot is securely

attached and that it is properly positioned to ignite

the main burner.

3.10

PRE-START CHECK LIST

3.8.5 Water Quality

The boiler is designed to operate in a closed-loop

system. As such, the system should be tight and not

Before attempting to start the boiler, make sure the

following items have been completed.

1. Flue gas from the boiler is properly vented.

require make-up water. A high percentage of un-

13

Modu-Fire® Gas-Fired Boiler Installation

2. Gas connection has been made, pressure tested

for leakage, and the line purged of air. Make

sure all required bleeds and vents have been installed.

3. Water connections are complete, and the boiler

and system have been filled and purged of air.

4. The boiler must be connected to a 120 volt / 60

Hz power source with proper polarity and dedicated machinery ground. Provide a disconnect

having adequate overload protection.

5. Combustion air openings are not obstructed in

any way and have adequate capacity. (See Section 3.5)

6. The boiler is placed the proper distance from

any combustible walls or substances, in accordance with Section 3.3.3.

7. Relief valves have been properly piped to floor

drains.

SAFETY CHECKS

3.11

The following checks of safety systems must be

made before putting the boiler into normal operation.

Before firing the boiler refer to Sections 4.1 and 4.2

for information on the use of the controls, lighting,

and shut-down procedures.

WARNING!

Never attempt to operate a boiler that has failed to

pass all the safety checks described below.

WARNING!

After checking controls by manual adjustment, make

sure they are always reset to their proper settings.

3.11.1 Test of Ignition Safety System

Test the ignition system safety shutoff as follows:

1. Close the gas cock which is downstream from

the two safety shut off valves (in the vertical

line).

2. With the main gas cock (inlet manual gas valve)

open and the pilot gas cock open, the burner

should be cycled on. After all the safety limits

on gas pressure, water flow and temperature are

satisfied, the blower will run and pre-purge the

boiler.

3. When air flow is established, the ignition transformer and pilot will operate. Both functions

will be indicated by separate indicator lights on

the flame safeguard.

4. If a satisfactory pilot is established, the spark

will terminate and the pilot will remain on,

alone, for 10 seconds.

5. After 10 seconds, the "Main” light on the flame

safeguard will go on; gas will not flow since the

downstream cock is closed. The "Pilot" will

remain on, along with the "Main Gas", for another 10 - 15 seconds and then go out. Since the

gas cock is closed, at this point there will be no

main flame signal and the flame safeguard programmer will assume a “Flame Failure” and go

to a "lockout" mode. Lockout will require manual reset of the flame safeguard.

After completing this test, turn off the boiler and

reopen the downstream gas cock.

3.11.2 Test of Low Water Cut-off

The boiler is furnished with a flow-switch-type low

water cutoff in the outlet nozzle. Test as follows:

Operation of the switch can be checked by first turning the boiler off and then turning the system pump

off, stopping water flow in the system. After turning off the pump, turn the boiler back on. It should

not operate, and a red indicator for "Low Water" or

"Water Flow" should be illuminated. Do not shut

the pump off while the boiler is operating.

Perform appropriate tests on any external probe-type

low water cutoff.

3.11.3 Test of Limit Controls

Fire the boiler and test the high limit control as follows:

With the main burner operating, turn down the temperature setting on the "high-limit" thermostat until

14

Loading...

Loading...