Patterson-Kelley MACH-05 User Manual

PATTERSON-KELLEY

MACH SERIES BOILER

GAS-FIRED BOILER

-

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water

Boilers

ASME Code, Section IV

Certified by Patterson-Kelley

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water

Boilers

Installation Date: _______________________

100 Burson Street, P.O. Box 458,

East Stroudsburg, PA 18301

Telephone: (877) 728-5351, Facsimile: (570) 476-7247

www.pkboilers.com

MACH® Series Gas-Fired Boiler

MACH® Series Gas-Fired Boiler Table of Contents

1.0 INTRODUCTION ........................................1

2.0 SAFETY......................................................1

2.1 General..............................................................1

2.2 Training..............................................................1

2.3 Safety Features .................................................1

2.4 Safety Labels.....................................................2

2.5 Safety Precautions ............................................2

2.5.1 Electrical Hazards....................................2

2.5.2 Burn, Fire, and Explosion Hazards..........2

2.5.3 Crush Hazards.........................................3

2.5.4 Chemical Hazards....................................3

2.5.5 Pressure Hazards ....................................4

2.5.6 Slip, Fall Hazards.....................................4

3.0 INSTALLATION..........................................5

3.1 Receiving and Storage......................................5

3.1.1 Initial Inspection .......................................5

3.1.2 Storage Prior to Installation......................5

3.2 Compliance with Codes.....................................5

3.3 Setup .................................................................5

3.3.1 Foundation...............................................5

3.3.2 Placement................................................5

3.3.3 Clearances...............................................6

3.4 Electrical Connections.......................................6

3.5 Combustion Air..................................................7

3.5.1 Air Inlet Requirements..............................7

3.6 Flue Venting.......................................................8

3.6.1 Barometric Damper..................................8

3.6.2 Flue Connection.......................................8

3.6.3 Required Clearances ...............................8

3.6.4 Vent Terminations....................................9

3.6.5 Venting for Multiple Boilers......................9

3.6.6 Sealed Combustion Air/Venting System10

3.6.7 Removing an Existing Boiler..................10

3.6.8 Intake/Exhaust Layout ...........................10

3.6.9 Intake Duct Materials and Sizes: ...........12

3.6.10 Sealing the Intake Duct........................12

3.6.11 Intake Duct Connection to Boiler .........12

3.6.12 Intake Duct Terminations.....................12

3.6.13 Vent Elbows.........................................13

3.7 Gas Piping.......................................................13

3.7.1 Gas Supply Piping by Installer...............14

3.8 Boiler Water Piping..........................................14

3.8.1 Piping Design.........................................14

3.8.2 Boiler Inlet and Outlet Connections.......15

3.8.3 Boiler Water Piping by Installer..............16

3.8.4 Flushing and Filling................................16

3.9 Burner and Ignition System.............................17

3.9.1 Inspection...............................................17

3.10 Pre-Start Check List ......................................18

3.11 Safety Checks ...............................................18

3.11.1 Test of Ignition Safety System.............18

3.11.2 Test of Low Water Cut-out...................19

3.11.3 Test of High-Limit Control....................19

3.11.4 Test of Gas Pressure Switch ...............19

3.12 Initial Adjustments .........................................20

3.12.1 Operating Temperature Controller.......20

3.12.2 Gas Pressure Adjustment....................24

3.12.3 Air Flow Adjustments...........................25

3.12.4 Gas Valve Setup and Adjustment........25

4.0 OPERATION ............................................28

4.1 General............................................................28

4.1.1 Control Panel Front................................28

4.1.2 Tests ......................................................28

4.2 Normal Lighting and Shut-Down Procedures..28

4.2.1 Lighting Procedures...............................28

4.2.2 Normal Shut Down Procedures .............28

4.2.3 Emergency Shut-Off ..............................29

4.3 Typical Boiler Operating Conditions................29

5.0 MAINTENANCE.......................................30

5.1 Maintenance and Inspection Schedule ...........30

5.1.1 Daily.......................................................30

5.1.2 Weekly ...................................................30

MACH® Series Gas-Fired Boiler Table of Contents

5.1.3 Monthly (During Operation)....................30

5.1.4 Semi-Annually (every 6 months)............31

5.1.5 Annually .................................................31

5.2 Cleaning the Burner.........................................31

5.3 After All Repairs or Maintenance.....................31

5.4 Sequence of Operation....................................32

5.5 Troubleshooting...............................................32

5.5.1 Manual Reset Service Codes ................34

5.5.2 Auto-reset Service Codes......................35

6.0 PARTS/TECHNICAL SUPPORT.............. 36

6.1 Wiring Diagrams..............................................37

6.1.1 Terminal Block Assignments – High Voltage

Circuit (TB2)...............................................37

6.1.1a Terminal Block Assignments – Low Voltage

Circuit (TB1)...............................................38

6.1.2 Wiring Series C-300...............................39

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

Reorder No. 6020-V2WHPK

6.1.3 Wiring Series C-450...............................40

6.1.4 Wiring Series C-750/900/1050...............41

6.2 Boiler Parts List ...............................................42

6.2.1 Main Assembly.......................................42

6.2.2 Control Panel.........................................43

6.2.3 Display Panel.........................................44

6.2.4 C-300/450 Heat Engine .........................45

6.2.5 C-750/900/1050 Heat Engine ................46

6.2.6 C-300 Boiler Gas Train..........................47

6.2.7 C-450 Boiler Gas Train..........................48

6.2.8 C-750/900/1050 Boiler Gas Train..........49

7.0 LIMITED WARRANTY .............................50

8.0 APPENDIX ...............................................52

WARNING!

Chemicals, fuels, or other potentially hazardous

or toxic materials must not be stored in the same

room as the boiler.

WARNING!

It is essential to read, understand, and follow the

recommendations of this manual before installing,

operating, or servicing this equipment. Failure to

do so could result in fire or explosion and serious

injury, death, and/or property damage.

WARNING!

Installation and service must be performed by a

qualified installer or service agency who has been

trained on the Patterson-Kelley MACH Boiler.

What to do if you smell gas:

The same features which permit this boiler to achieve

high-efficiency performance make it unlike most other

boilers of this general size, so it is important to

understand how this boiler operates.

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

Immediately call your gas supplier from a

WARNING

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier call the fire

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

department.

appliance.

MACH® Series Gas-Fired Boiler Safety

1.0 INTRODUCTION

The P-K MACH® Series

modulating using a variable speed combustion blower,

sophisticated microprocessor controls, modulating gas

safety shut off / control valves and a unique aluminum

alloy heat exchanger capable of operating in a fully

condensing mode to provide maximum efficiency in a

minimum amount of space. The high-quality materials

and thoroughly tested design of the boiler should

provide years of trouble-free service if the instructions

in this manual are followed carefully.

This manual covers installation of P-K MACH Series

Boilers. The model numbers may be followed by a

prefix or suffix letter in some cases to indicate special

features or different options.

While details may differ slightly, basic operation is the

same for all models. Boilers may be built to operate

with natural gas or liquefied petroleum gas (propane).

Check the rating plate for correct fuel usage and gas

pressures.

The boiler is only a part of the complete heating

system. This boiler may be fully operational and yet

because of poor circulation, control, or other operating

characteristics, not deliver heat to the desired location.

Additional equipment such as temperature sensors,

pumps, flow switches, balancing valves, and check

valves will be required for satisfactory operation of

any system. Patterson-Kelley cannot be responsible

for the design or operation of such systems and a

qualified engineer or contractor must be consulted.

Gas-Fired Boilers are fully

2.0 SAFETY

GENERAL

2.1

The MACH Series gas-fired boiler must be:

• Installed, operated, and serviced in accordance

with instructions contained in this manual.

• Installed by qualified personnel in accordance with

designs prepared by qualified facility engineers

including: structural, mechanical, electrical, and

other applicable disciplines.

• Operated and serviced in accordance with a

comprehensive safety program determined and

established by the customer. Do not attempt to

operate or service until such a program has been

established.

• Operated and serviced by qualified, properly

trained personnel in accordance with all applicable

codes, laws, and regulations.

Note: Each safety device must be maintained and

checked per the recommended schedule; refer to

Section 5.1 of this manual.

2.2

TRAINING

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

Reorder No. 6020-V2WHPK

It is essential to read, understand, and follow the

recommendations of this manual before installing,

operating, or servicing this equipment. Failure to do

so could result in property damage, serious injury, or

death.

Proper training is the best protection against accidents.

Operating and service personnel must be thoroughly

familiar with the basic construction of the P-K MACH

boiler, the use and locations of the controls, the

Series

operation of the boiler, adjustment of its various

mechanisms, and all applicable safety precautions. If

any of the provisions of this manual are not fully and

completely understood, contact the Patterson-Kelley

Sales Department toll-free at (877) 728-5351 for

assistance.

2.3

SAFETY FEATURES

It is the responsibility of the customer to maintain the

safety features, such as: guards, safety labels, safety

controls, interlocks, lockout devices, etc., in place and

operable.

Page 1

MACH® Series Gas-Fired Boiler Safety

2.4 SAFETY LABELS

NOTE

When opening leak test valves,

always follow instructions in

operation and safety manual.

c

1998 HCS, Inc. 800-748-0241

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

C 1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

The safety labels shown above are affixed to your

boiler. Although the labels are of high quality, they

may become dislodged or unreadable over time.

Contact Patterson-Kelley toll-free at (877) 728-5351

for replacement labels.

2.5

SAFETY PRECAUTIONS

Provide a suitable location for the boiler, away from

normal personnel traffic, with adequate working space,

adequate clearances, proper ventilation and lighting,

with a structure sufficiently strong and rigid to support

the weight of the boiler, all piping, and accessories.

2.5.1 Electrical Hazards

C 1998 HCS, Inc. 800-748-0241

• Shock hazard! Properly lockout/tagout the

electrical service and all other energy sources

before working on or near the boiler.

• Shock hazard! Do not spray water directly on any

electrical components.

Reorder No. 8032-01NHPK

!

WARNING

Reorder No. 6020-V2WHPK

!

WARNING

Electrical hazard.

Follow lockout/tagout

procedure when

servicing this boiler.

Reorder No. 5025-V1WHPK

!

WARNING

Electrical hazard.

Follow lockout/tagout

procedure when

servicing this boiler.

Reorder No. 5025-V1WHPK

2.5.2 Burn, Fire, and Explosion Hazards

General Warning

c

1998 HCS, Inc. 800-748-0241

!

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

operating or servicing boiler.

Hot Surface

WARNING

Reorder No. 6020-V2WHPK

NOTE

Make sure this union is

tight before closing cabinet

cover after servicing boiler.

c

1998 HCS, Inc. 800-748-0241

Reorder No. 8032-02NHAK

NOTE

When opening leak test valves,

always follow instructions in

operation and safety manual.

c

1998 HCS, Inc. 800-748-0241

• Burn, fire, and explosion hazards! Installation

must be in strict conformance to all applicable

codes and standards including NFPA 54, ANSI

Z223.1 and CAN/CGA B.149. Install all required

vent lines for gas devices. Refer to Section 3.7.1.

• Hazard from incorrect fuels! Possible fire,

explosion, overheating, and damage. Do not use

any fuels except the design fuels for the unit.

• Overfire hazards! High pressure in gas or propane

supply could result in overfiring of other devices

supplied from the same source.

• Fire and explosion hazards! Close the main gas

shutoff before servicing boiler.

• Fire and explosion hazards! Do not store or use

gasoline or other flammable vapors or liquids in

the vicinity of this or any other gas fired appliance.

• Burn hazard! Possible hot surfaces. Do not touch

gas vent during firing operation. Use only factory

recommended vent components.

• Burn hazard! Pipes, vents, and boiler components

could be hot. Do not touch piping or stack

surfaces during operation or immediately after

shutdown of the boiler.

Reorder No. 8032-01NHPK

Page 2

MACH® Series Gas-Fired Boiler Safety

• Burn hazard! Hot fluids. Use caution when

servicing or draining boiler.

• Fire and explosion hazards! Use caution when

servicing burner. Propane (LPG) is heavier than

air and may linger in the combustion chamber,

vent lines, or elsewhere.

• Gas leak hazard! Make sure the burner is installed

correctly and burner hood is securely fastened

following any maintenance performed on them.

These connections cannot be tested after the

burner is assembled.

• Gas leak hazard! All threaded gas connections

must be made using a pipe compound that is

resistant to liquefied petroleum. Do not use

Teflon™ tape on threaded gas piping.

• Gas leak hazard! Check entire gas train for leaks

after installation. If there is a smell of gas, shut

down the boiler and obtain immediate assistance

from trained service personnel and/or your local

fire department.

• Overfire hazard! Possible fire and explosion from

excess gas pressure. Make sure that gas inlet

pressure does not exceed 14 inches W.C. to the

regulator.

• Overfire hazard! Possible fire and explosion.

Possible malfunction of regulators and/or gas

safety shut off / control valves. Maintain all gas

train components in good condition. Do not alter

wiring connections. Annual inspection by factorytrained personnel for proper set-up and operation

is recommended.

2.5.3 Crush Hazards

General Warning

• Lifting hazards! Use properly rated lifting

equipment to lift and position the boiler. The load

is unbalanced. Test balance before lifting 3 ft.

above the floor. Do not allow personnel beneath

the lifted load. Refer to approximate weights in

the table below:

Boiler Size Weight in Pounds

300,000 Btu 354

450,000 Btu 440

750,000 Btu 650

900,000 Btu 700

1,050,000 Btu 750

• Bump hazard from overhead ductwork and piping.

Install components with adequate vertical

clearance.

2.5.4 Chemical Hazards

• Overfire and underfire hazards! Possible fire,

explosion, overheating, and component failure.

Do not attempt to adjust firing rate of the boiler.

The firing rate must be adjusted only by factory

trained personnel.

Page 3

General Warning

• Chemical hazards from cleaning products. Use

caution when cleaning the system. The use of

professional assistance is recommended. Use safe

procedures for the disposal of all cleaning

solutions.

• Combustion Condensate – a pH of approximately

4 to 5 can be expected. Use PVC or CPVC piping.

Collection and disposal must be in accordance

with all applicable regulations.

MACH® Series Gas-Fired Boiler Safety

2.5.5 Pressure Hazards

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

• Pressure hazard! Hot fluids. Install isolation

valves on boiler water inlet and outlet. Make sure

isolation valves are closed before servicing boiler.

• Pressure hazard! Hot fluids. Annually test safety

relief valve for proper operation. Do not operate

boiler with faulty relief valve.

2.5.6 Slip, Fall Hazards

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

operating or servicing boiler.

• Tripping hazard! Do not install piping on floor

surfaces. Maintain clear path around boiler.

• Slip and fall hazard! Use drip pan to catch water

while draining the boiler. Maintain dry floor

surfaces.

• Slip and fall hazard! Do not locate intake or

exhaust terminations directly above a walkway;

dripping of condensation can cause icing of the

walking surface.

Page 4

MACH® Series Gas-Fired Boiler Installation

3.0 INSTALLATION

RECEIVING AND STORAGE

3.1

3.1.1 Initial Inspection

Upon receiving the boiler, inspect it for signs of

shipping damage. Since some damage may be hidden,

we recommend unpacking the boiler and removing the

top cover and inspecting the boiler.

Verify that the total number of pieces shown on the

packing slip agrees with those actually received.

Important: note any damage, suspected potential

damage, or shortage of materials on the freight bill

and immediately notify the carrier. File all claims

for shortage or damage with the carrier. Claims

for hidden damages must be filed with your carrier

within 7 days. The boiler carton is equipped with a

“Tip (N) Tell”. If "Tip (N) Tell” arrow point is

blue, that indicates that the package has been on its

side or tipped over in transit.

3.1.2 Storage Prior to Installation

If the boiler is not installed immediately, it must be

stored in a location adequately protected from the

weather, preferably indoors. If this is not possible,

then it should remain in the shipping container and be

covered by a tarpaulin or other waterproof covering.

Note: controls and other equipment that are

damaged or fail due to weather exposure are not

covered by warranty.

3.2

COMPLIANCE WITH CODES

The P-K MACH Series Boiler with standard

components and with many options complies with

American National Standard/CSA Standard ANSI

Z21.13/CSA 4.9, latest edition, Gas-Fired Low

Pressure Steam and Hot Water Boilers.

The heat exchanger is constructed and stamped in

accordance with ASME Boiler and Pressure Vessel

Code, Section IV for 50 psig maximum operating

pressure and/or 200º F maximum temperature.

Other codes or approvals which apply will be labeled

on the boiler.

Installation of the boiler must conform to all the

requirements of all national, state and local codes

established by the authorities having jurisdiction or,

in the absence of such requirements, in the U.S. to the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

latest edition. In Canada, the equipment shall be

installed in accordance with the current Installation

Code for Gas Burning Appliances and Equipment,

CAN/CGA-B.149, and applicable Provincial

Regulations for the class, which should be carefully

followed in all cases. Authorities having jurisdiction

should be consulted before installations are made.

Where required by local codes, the installation must

conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety

Devices for Automatically Fired Boilers (ASME

CSD-1).

In the Commonwealth of Massachusetts (a) this unit

must be installed by a licensed pipe fitter / plumber,

(b) field installed gas cocks must be “T” handle type,

and (c) piping of condensate shall conform with the

State Plumbing Code.

3.3

SETUP

3.3.1 Foundation

Provide a firm, level foundation, preferably of

concrete.

Note: The boiler may be installed on a combustible

floor; however, the boiler must never be installed on

carpeting.

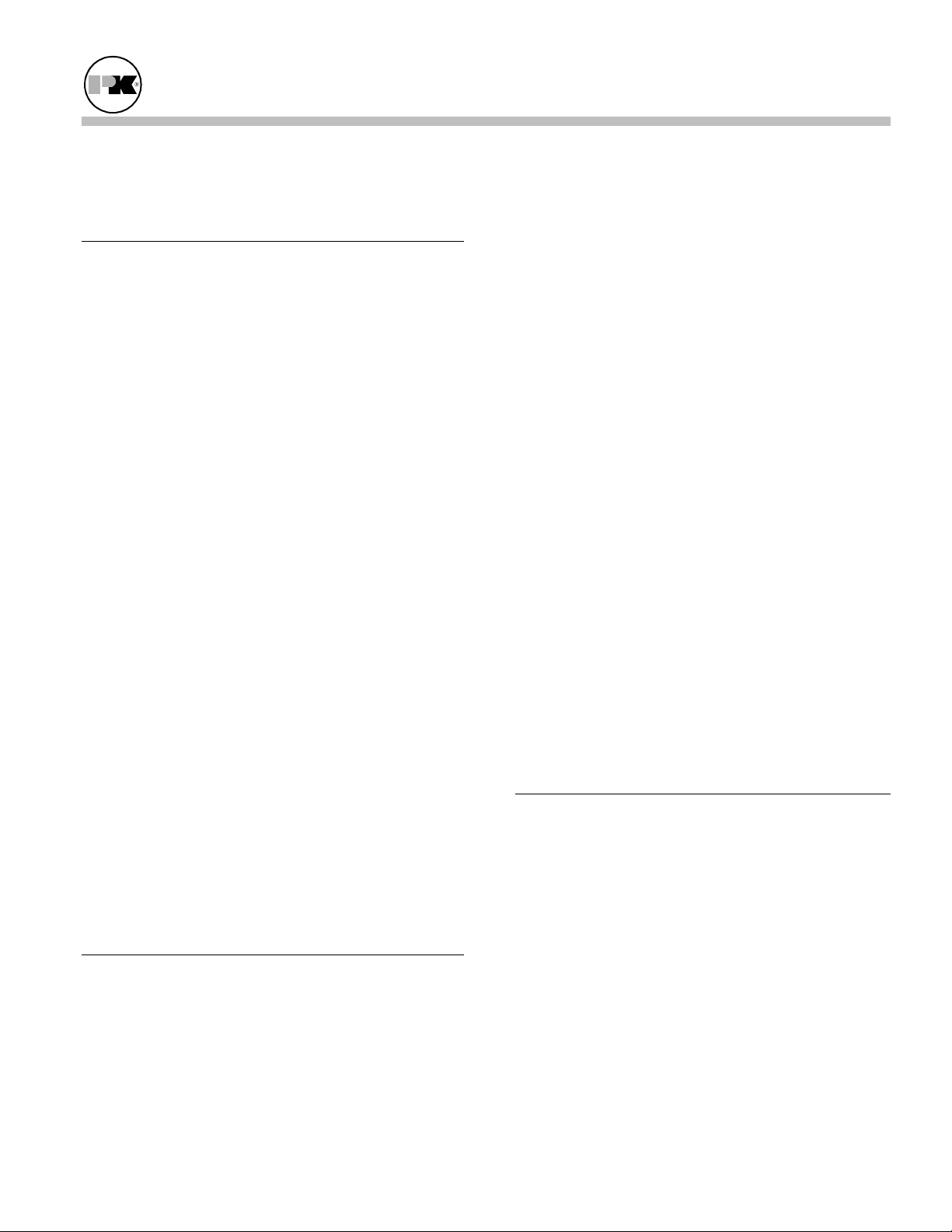

3.3.2 Placement

The boiler must be level to function properly. To

assist in leveling the boiler, the four (4) adjustable leg

bolts (1/2"- 13 NC) must be installed. The adjustable

legs are also necessary to provide adequate floor

Page 5

MACH® Series Gas-Fired Boiler Installation

clearance and prevent distortion of the cabinet,

(twisting, etc.) in addition to leveling.

Adjustable

Leg Bolts

Adjustable Legs for Leveling and Floor Clearance

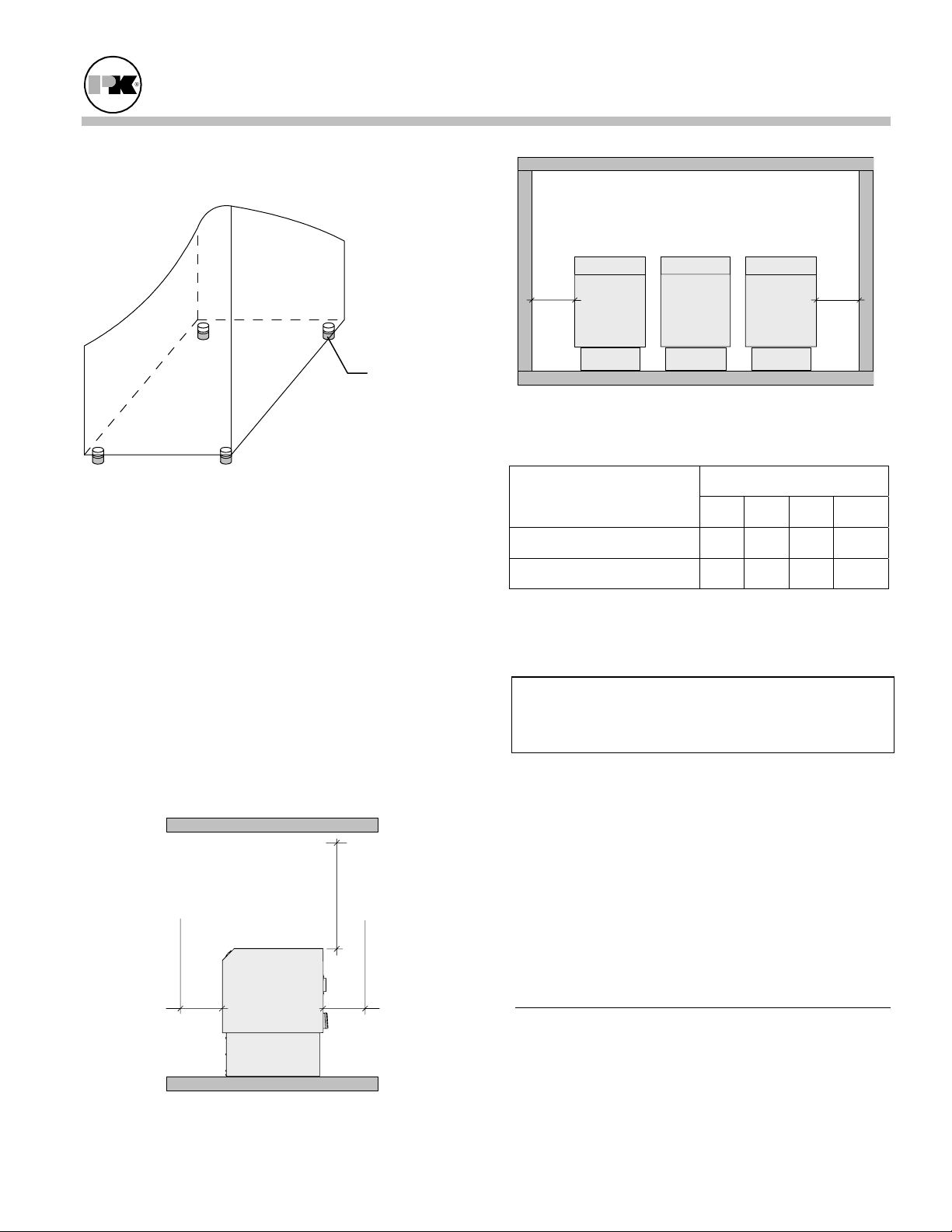

3.3.3 Clearances

If the boiler is to be installed near combustible

surfaces, the minimum clearances shown in the table

below must be maintained.

Failure to provide for the service access clearances,

even with non-combustible surfaces, may cause future

problems servicing the boiler.

The boiler must be installed in a space large in

comparison to the boiler as described in Section 6.3 of

the National Fuel Gas Code, ANSI Z223.1, latest

edition.

No pipes,

ducts, etc. in

this area.

C

D

D

Minimum Clearances from Adjacent Walls, Ceiling, and

Dimensions (inches) Type of Surface

Combustible Surfaces 36 24 24 24

Non-combustible Surfaces 36 * 24 24**

A B C† D

Obstructions

† "C" Do not put pipes, ducts, etc. in this area above

the boiler.

CAUTION!

Bumping hazard from overhead ducts! Install all

components with adequate vertical clearances.

* Clearance depends upon vent configuration.

** Service access need be only on one side of a

boiler or row of boilers. Boilers may be installed

immediately adjacent to each other. However, P-K

recommends this clearance between each boiler

when there is insufficient access at the rear to allow

for service and adjustment.

A B

Page 6

ELECTRICAL CONNECTIONS

3.4

The boiler is wired for 120 volts, single phase, 60

hertz. The total operating amperage is indicated on

the rating nameplate. All MACH units require less

than 8 amps. Before starting the boiler, check to

ensure that the proper electrical service is connected

to the boiler.

MACH® Series Gas-Fired Boiler Installation

An external electrical disconnect (not supplied with

the boiler) with adequate overload protection is

required. The boiler must be grounded in accordance

with local codes or in the absence of such

requirements, in the U.S. with National Electrical

Codes, ANSI/NFPA No. 70 latest edition and in

Canada to the current Canadian Electrical Code, Part I,

CSA C22.1.

Note: A dedicated earth ground (green wire) is

required to avoid nuisance shutdowns. Do not ground

through the conduit. It is also important that proper

polarity be maintained.

Note: Refer to Terminal Block Assignments (Section

6.1.1).

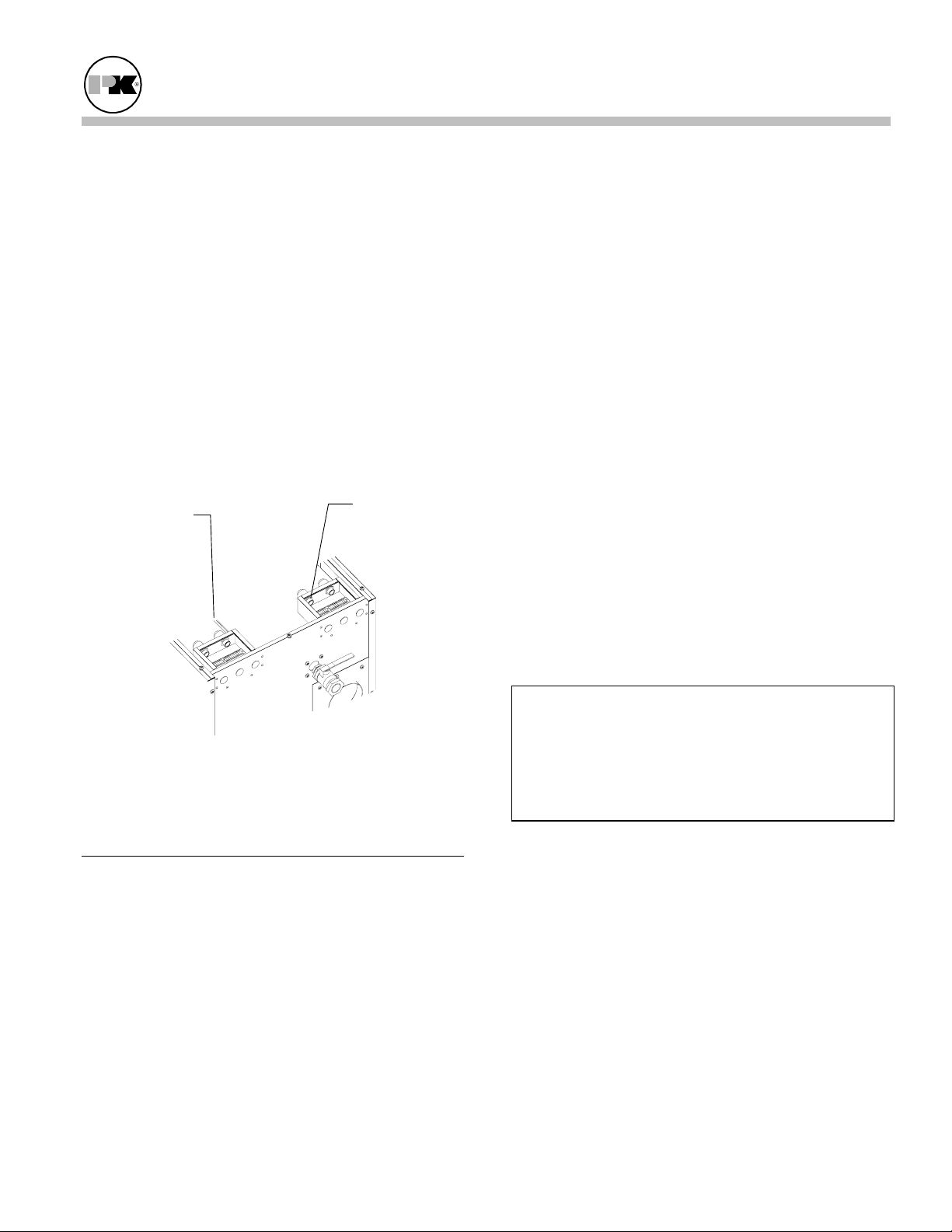

120 Volt

Electrical Control

Junction Box

Low Voltage

Control Junction

Box

when burned, form acids which quickly attack the

boiler and the boiler stack. The result is improper

combustion and premature boiler failure.

Provisions for combustion and ventilation air must be

in accordance with Section 5.3, Air for Combustion

and Ventilation, of the National Fuel Gas Code,

ANSI Z223.1, latest edition, or applicable provisions

of the local building codes. In Canada, combustion

air openings shall comply with CSA B.149

Installation Code. The formula is 1 sq. in. per 1,000

Btu/hr of gas input not less than 100 sq. in. The

location shall be neither more than 18", nor less than

6" above the floor level.

The boiler room shall be provided with two openings

to ensure adequate combustion air and proper

ventilation. One opening should be 6 to 12 inches

above the floor and the other 6 to 12 inches below the

ceiling, preferably on opposite walls. The size of

each opening is determined by whether air is taken

from inside or outside the building. In Canada,

ventilation air openings shall be at least 10% of the

cross sectional area required for combustion air, but

not less than 10 square inches. It is to be located at

the highest practical point communicating with

outdoors.

WARNING!

Electrical Connections at Rear of Boiler

3.5 COMBUSTION AIR

Combustion air must be free from dust, lint, etc. The

presence of such materials in the air supplied to the

burner could cause nuisance "Low Air" shutdowns or

premature burner failure. The boiler should not be

operated during construction while the possibility of

drywall dust, demolition dust, etc. exists.

The combustion air supply must be completely free of

chemical fumes which may be corrosive when burned

in the boiler. Common chemicals which must be

avoided are fluorocarbons and other halogenated

compounds, most commonly present as refrigerants or

solvents, such as freon, trichlorethylene,

perchlorethylene, chlorine, etc. These chemicals,

Page 7

Under no circumstances shall the boiler room

ever be under a negative pressure. Particular

care should be taken when exhaust fans,

compressors, air-handling units or other

equipment may rob air from the boiler.

3.5.1 Air Inlet Requirements

If air is taken directly from outside the building, each

opening (minimum of two) should have a net free

area of 1 square inch for each 4,000 Btu per hour of

total boiler input. For instance, 112.5 square inches

are required for 450,000 Btu per hour input.

When air is taken from the outdoors through a

vertical duct, 1 square inch per 4,000 Btu per hour is

required. If a horizontal duct is used, 1 square inch

per 2,000 Btu per hour is required, i.e., 225 square

inches for 450,000 Btu per hour input.

MACH® Series Gas-Fired Boiler Installation

If air is taken from another interior space, each

opening should have a net free area of 1 square inch

for each 1,000 Btu per hour of boiler input (450 square

inches for a 450,000 Btu per hour.)

3.6

FLUE VENTING

This boiler requires a special vent system. This boiler

is not certified for use with Type "B" vent.

This boiler is Category IV (condensing – positive

pressure) as it is defined in ANSI Z21.13/CSA 4.9,

latest edition. The vent material must be listed

Category IV vent pipe (316L or AL29-4C Stainless

Steel) and comply with UL 1738 or UL103. In

Canada it must comply with ULC-636. The exhaust

vent can be run horizontally or vertically.

Vent installations shall be in accordance with Part 10,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1 or CSA B.149 code, or applicable

provisions of the local building codes.

The venting system and the horizontal portions of the

venting system shall be supported to prevent sagging.

The vent must be sized according to the vent

manufacturer’s recommendations. Consult your vent

supplier for correct sizing and structural support

requirements. Design calculations should be based on

a maximum of 0.22" W.C. total frictional resistance in

the stack (measured at the boiler flue gas discharge),

with a stack temperature of 210° F (gross) and a CO

2

level of 9% (natural gas) or 10.4% (propane). These

values are to be used for vent sizing calculations.

The installation of a bird screen on the vent

termination is recommended. Consult your local vent

manufacturer for proper sizing.

3.6.1 Barometric Damper

WARNING!

Do not use a barometric damper with this

boiler. (This is a positive pressure system;

combustion gas may leak into the room.)

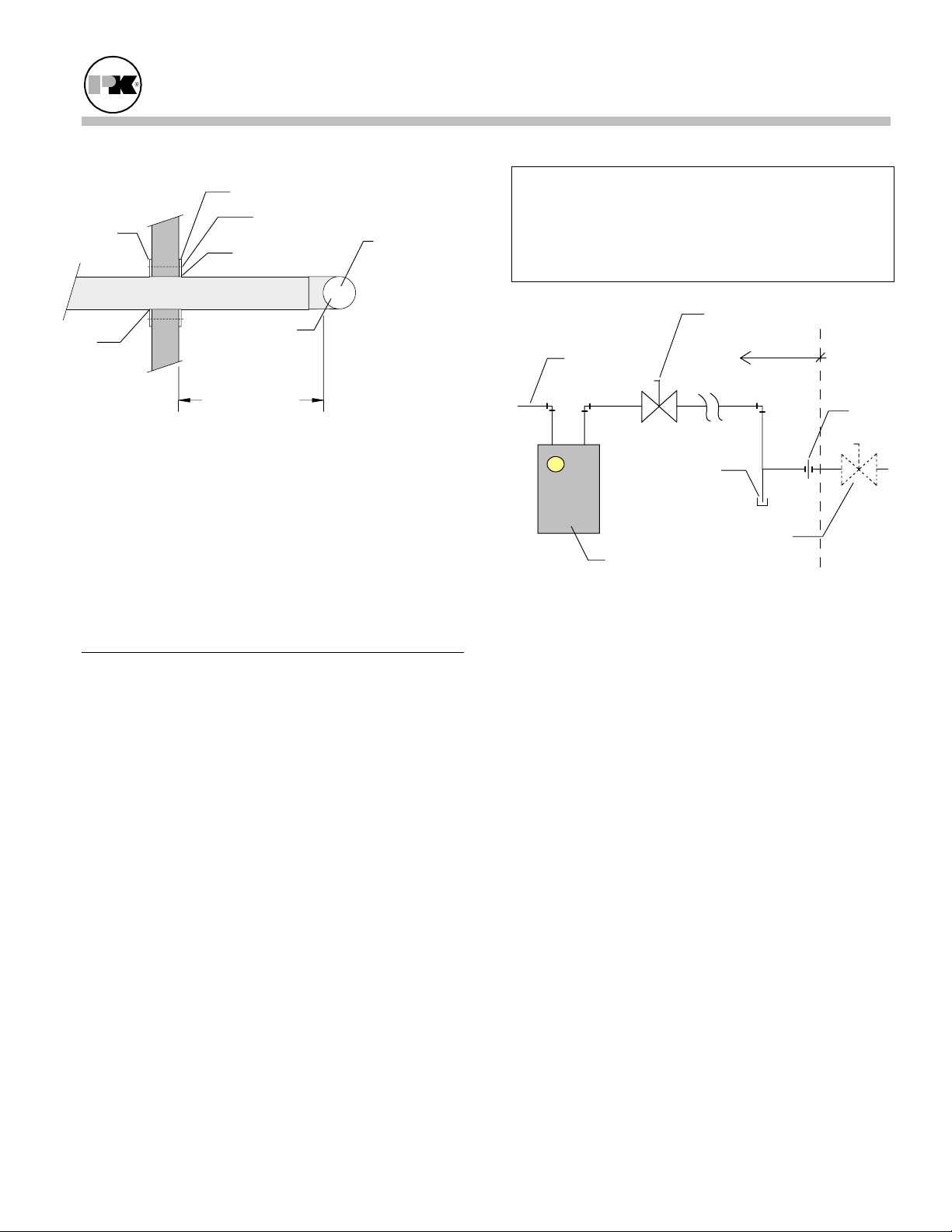

3.6.2 Flue Connection

The connection from the boiler to the vent should be

as direct as possible and the upward slope of any

horizontal breaching should be at least 1/4 inch per

linear foot. The 300 and 450 vent connection

incorporates a 4° slope toward the boiler to facilitate

pitching of the vent for condensate collection. This

boiler should not be connected into any portion of

another mechanical draft system operating under

positive pressure without consulting your local

venting representative. Provisions must be made for

supports to prevent contact of the vent with

combustible surfaces.

Note: If the vent is erected directly behind the boiler,

make sure that the weight of the vent is not

supported by the boiler vent collar. The collar is

not designed to support the weight of the vent.

Structural support and spacing from combustible

surfaces must be in accordance with the vent

manufacturer's requirements.

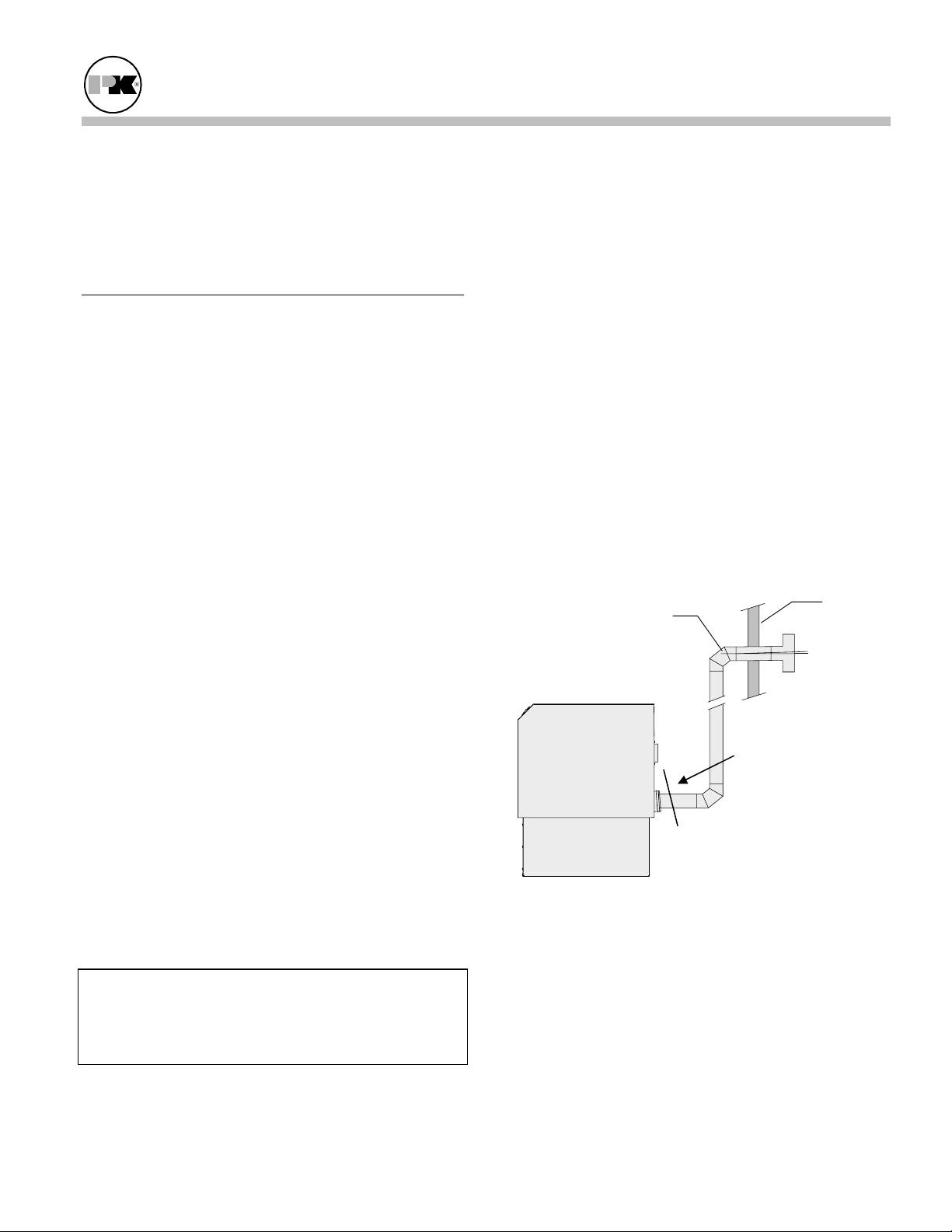

Sidewall

Pitch toward

boiler 1/4" per

foot minimum.

4 degree slope

toward boiler,

approx. ¾” per

foot.

Flue Connection at Boiler

3.6.3 Required Clearances

Provide clearances between combustion air intake,

exhaust vent, roof and wall surfaces, doors and

window, and snow line as shown in the following

diagrams. The exhaust vent termination must be 14

feet above grade when located adjacent to a public

walkway. It must also have a minimum 6 foot

horizontal and 6 foot vertical clearance (above or

below) any electric meters, gas meters, regulators, or

relief equipment.

Page 8

MACH® Series Gas-Fired Boiler Installation

WARNING!

Do not locate intake or exhaust terminations

directly above a walkway; dripping of condensation can cause icing of the walking surface.

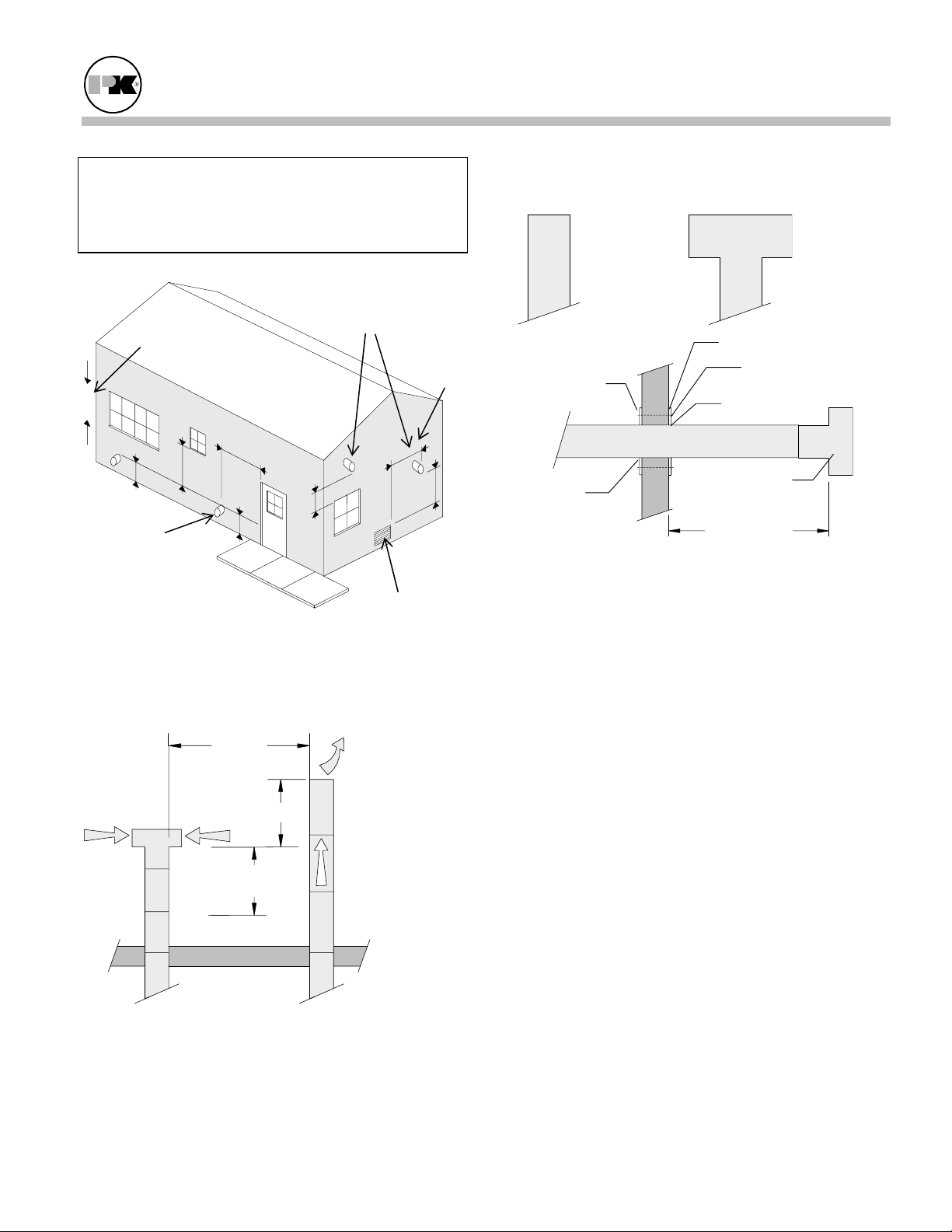

Mechanical draft vent

Direct vent terminal

clearance minimum 12 in.

12 in.

min

Mechanical draft

vent terminal

4 ft.

min.

4 ft.

min.

12 in.

min.

terminal

12 in.

min.

Forced

air inlet

Reference: ANSI Z223.1 - 2002

Sidewall Installations

Combustion

Air Inlet

10' min.

4' min.

Flue Gas

Outlet

Grade

Less

than

10 ft.

3 ft min.

3.6.4 Vent Terminations

No rain cap

required,

or Tee.

Centering

Support Plate

Sealant

(see text below)

Outside Plate

Cover Plate

Fastener

Sealant

Recommended

Termination

12" min.

Vent Termination Details

The vent should extend at least three (3) feet above

the roof, or at least two (2) feet above the highest part

of any structure within ten (10) feet of the vent.

To prevent the possible re-circulation of flue gases,

your vent designer must take into consideration such

things as prevailing winds, eddy zones, building

configurations, etc. P-K can not be responsible for

the effects such adverse conditions may have on the

operation of the boilers. Dimensions listed above or

those illustrated are minimum, and may or may not be

sufficient for conditions at a specific job site.

4' min above

snow line

Rooftop Installations

Page 9

A tee must be of approved design and adequate

capacity.

3.6.5 Venting for Multiple Boilers

The venting instructions in this manual apply to a

single boiler.

Venting systems for multiple boilers must be

designed by qualified professionals and verified by

the stack manufacturer. The venting system must

prevent backflow of exhaust gas through idle

boilers which are not operating.

MACH® Series Gas-Fired Boiler Installation

3.6.6 Sealed Combustion Air/Venting System

The MACH Series Boilers are also certified for

operation with a sealed combustion air and pressurized

venting system. Such a system employs a sealed

combustion air intake duct leading from outdoors and

a sealed exhaust vent terminating outdoors. Air flow

through the system is maintained by the fan inside the

boiler assembly.

Vent Installation Details

Installation must conform to the vent manufacturer's

instructions in all respects including joining,

clearances, fastening, fire-stopping, and other matters.

Vent ductwork may be run horizontally or vertically if

so certified.

3.6.7 Removing an Existing Boiler

(from a common venting system)

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing boiler, while the

other appliances remaining connected to the common

venting system are not in operation, the following

steps should be followed with each appliance

remaining connected to the common venting system

placed in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine that there is no

blockage or restriction, leakage, corrosion or other

deficiency which could cause an unsafe condition.

3. Insofar as is practical, close all building doors

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers

and any appliances not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Place the appliance being inspected in operation.

Follow the lighting instructions. Adjust the

thermostat so that the appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-burning

appliance to their previous conditions of use.

Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1 and CSA B149 Installation Code. When

resizing any portion of the common venting system,

the common vent system should be resized to

approach the minimum size as determined using the

appropriate tables.

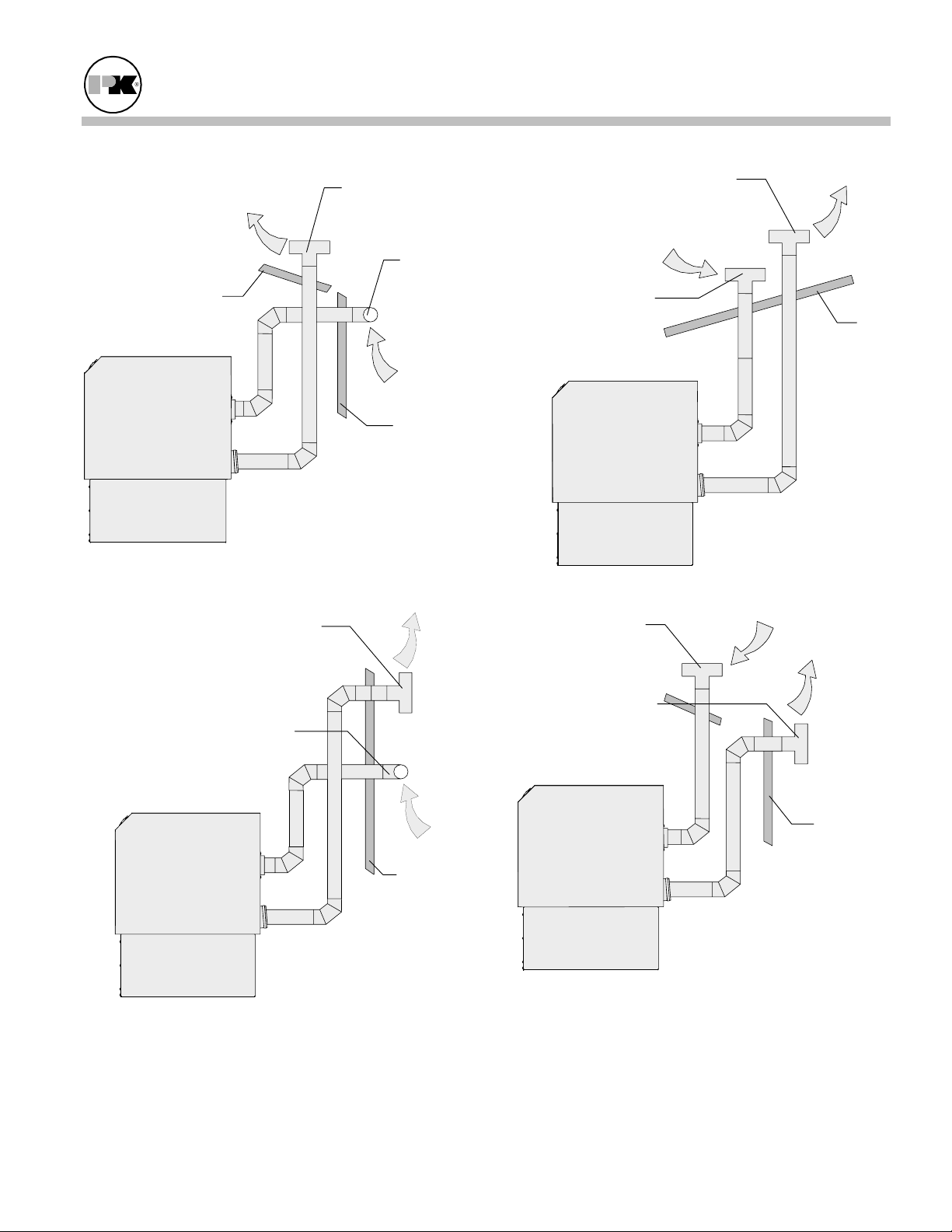

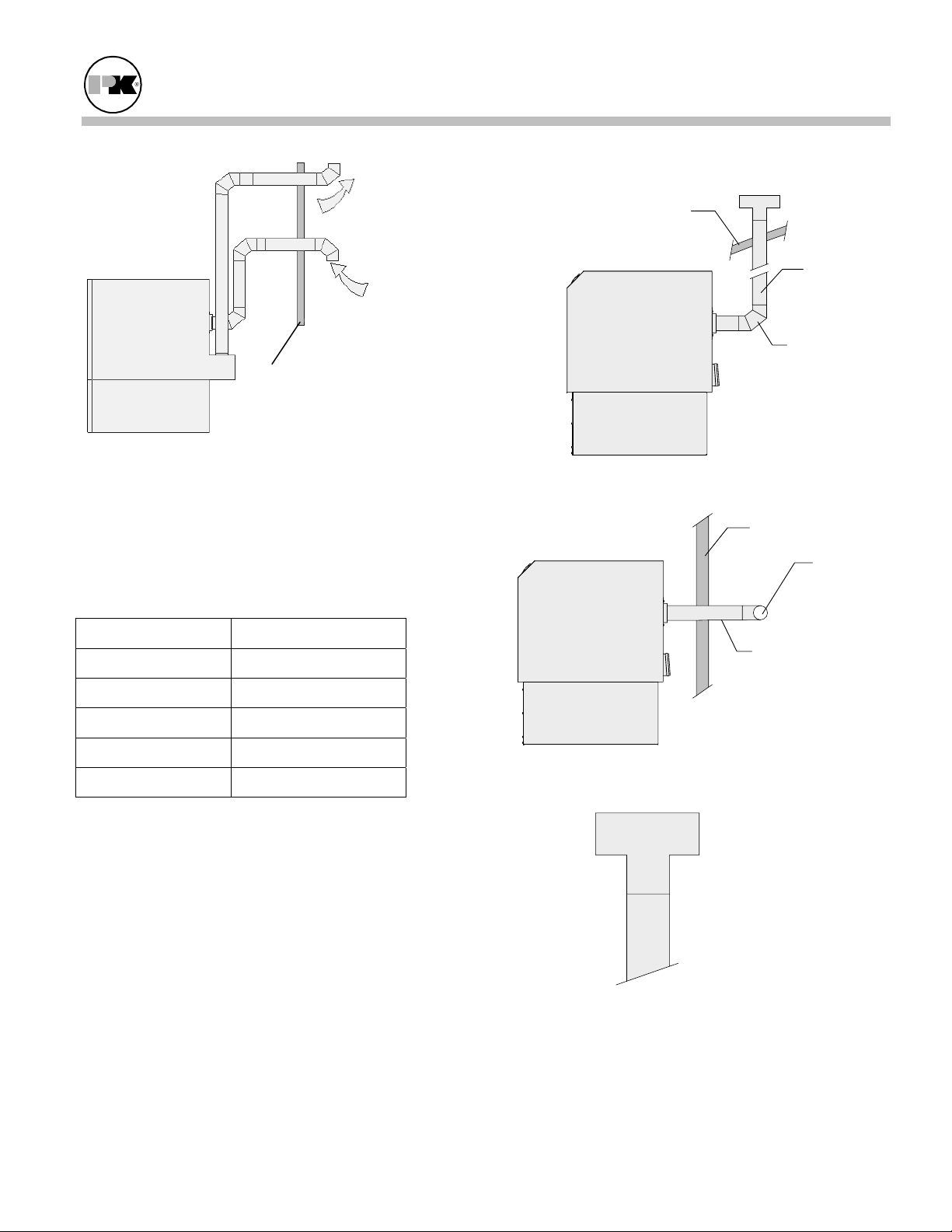

3.6.8 Intake/Exhaust Layout

Four basic configurations for the intake/exhaust may

be used. Refer to Section 3.6.3 for required

clearances for all terminations shown in the four

following figures.

Page 10

MACH® Series Gas-Fired Boiler Installation

Roof

Exhaust Vent (type of

flue termination

optional when roof

venting.)

Air Inlet (tee

mounted

horizontally.)

Sidewall

(Type of flue termination

optional when roof venting.)

(Type of flue

termination

optional.)

Exhaust Vent

Air Inlet

Roof

Sidewall Inlet, Roof Vent

Exhaust Vent

(Sidewall venting requires

vertical tee termination.)

termination optional.)

Air Inlet

(Type of flue

Roof Inlet and Vent

(Tee mounted horizontal.)

Air Inlet

Sidewall

Sidewall Inlet and Vent

Exhaust Vent

(Sidewall venting requires

vertical tee termination.)

Sidewall

Roof Inlet, Sidewall Vent

Basic Air Inlet/Vent Configurations

Page 11

MACH® Series Gas-Fired Boiler Installation

Exhaust Vent

(Sidewall

Venting

Requires Up

Elbow Mounted)

Air inlet

(Down Elbow

Mounted)

Sidewall

C750/900/1050 Sidewall Inlet and Vent

3.6.9 Intake Duct Materials and Sizes:

Material: PVC, CPVC (Schedule 40), single wall

galvanized steel, or other suitable materials.

The intake duct must be sized for a maximum pressure

drop of 0.22 inches W.C., for the SCFM as specified

below.

3.6.12 Intake Duct Terminations

Roof

Round

90° Elbow

Sidewall

Air Inlet

(tee mounted

horizontally)

Boiler Size Required SCFM

1050 245

900 210

750 175

450 105

300 70

The installation of a bird screen on the intake

termination is recommended.

3.6.10 Sealing the Intake Duct

Proper sealing of the intake ductwork is necessary to

prevent infiltration of air from conditioned space.

Joints in PVC or CPVC must be cemented. For

galvanized duct, wrap each joint and seam with

adhesive aluminum tape.

3.6.11 Intake Duct Connection to Boiler

Connect the air supply duct to the collar on the back of

the boiler. Fasten the duct to the collar with sheet

metal screws at 90º angles. Seal the joint.

Round

No rain cap -

Unrestricted

The roof intake termination must be an

unrestrictive type, as shown above.

Page 12

MACH® Series Gas-Fired Boiler Installation

Centering

Support Plate

Sealant

3.6.13 Vent Elbows

The turn from horizontal to vertical should be made

with two 45º ells or with one long radius 90º ell for

best operation. Do not use "short radius" ells.

3.7

Before making the gas hook-up, make sure the boiler

is being supplied with the type of fuel shown on the

boiler nameplate.

The boiler shall be installed such that the gas ignition

system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement, control

replacement, etc.)

The boiler is factory fire-tested and adjusted for proper

combustion with natural gas supply pressure of 7”

W.C. Typical gas pressure supply for natural gas is

7" W.C. (11" W.C. for propane). The gas train

components are certified to handle a maximum inlet

pressure of 14" W.C. (1/2 psig.). If the available gas

pressure exceeds 14" W.C., a suitable additional

intermediate gas pressure regulator of the "lock up"

type must be provided to reduce the pressure to less

than 14" W.C.

Recommended

GAS PIPING

Outside Plate

Cover Plate

Fastener

Sealant

Termination

12" min.

Field Provided

Inlet Screens

Intake Termination Details

WARNING!

All threaded connections must be made using a

pipe compound that is resistant to the action of

liquefied petroleum gases. Do not use Teflon

tape on gas line threads.

Natural Gas

Supply

Drip Leg

Meter

(not supplied)

Remote Gas Shutoff

(not supplied)

By Installer

Union

Shutoff

(on boiler)

Gas Piping

In the Commonwealth of Massachusetts, the gas cock

must be a “T-handle type.”

Note: Install a sediment trap (drip leg) and a union

connection ahead of the primary manual shutoff valve

on the boiler. Gas piping should be installed in

accordance with National Fuel Gas Code, ANSI

Z223.1, latest edition, and any other local codes

which may apply; in Canada see CAN/CGA-B.149.

Note: See Pipe Capacity for Natural Gas chart on the

following page for required pipe size, based on

overall length of pipe from meter plus equivalent

length of all fittings. Approximate sizing may be

based on 1 cubic foot of natural gas per 1,000 Btu per

hour input, i.e., 500,000 Btu per hour requires about

500 cubic feet per hour. (See "Typical Boiler

Operating Conditions," Section 4.3, for more

information.)

Page 13

MACH® Series Gas-Fired Boiler Installation

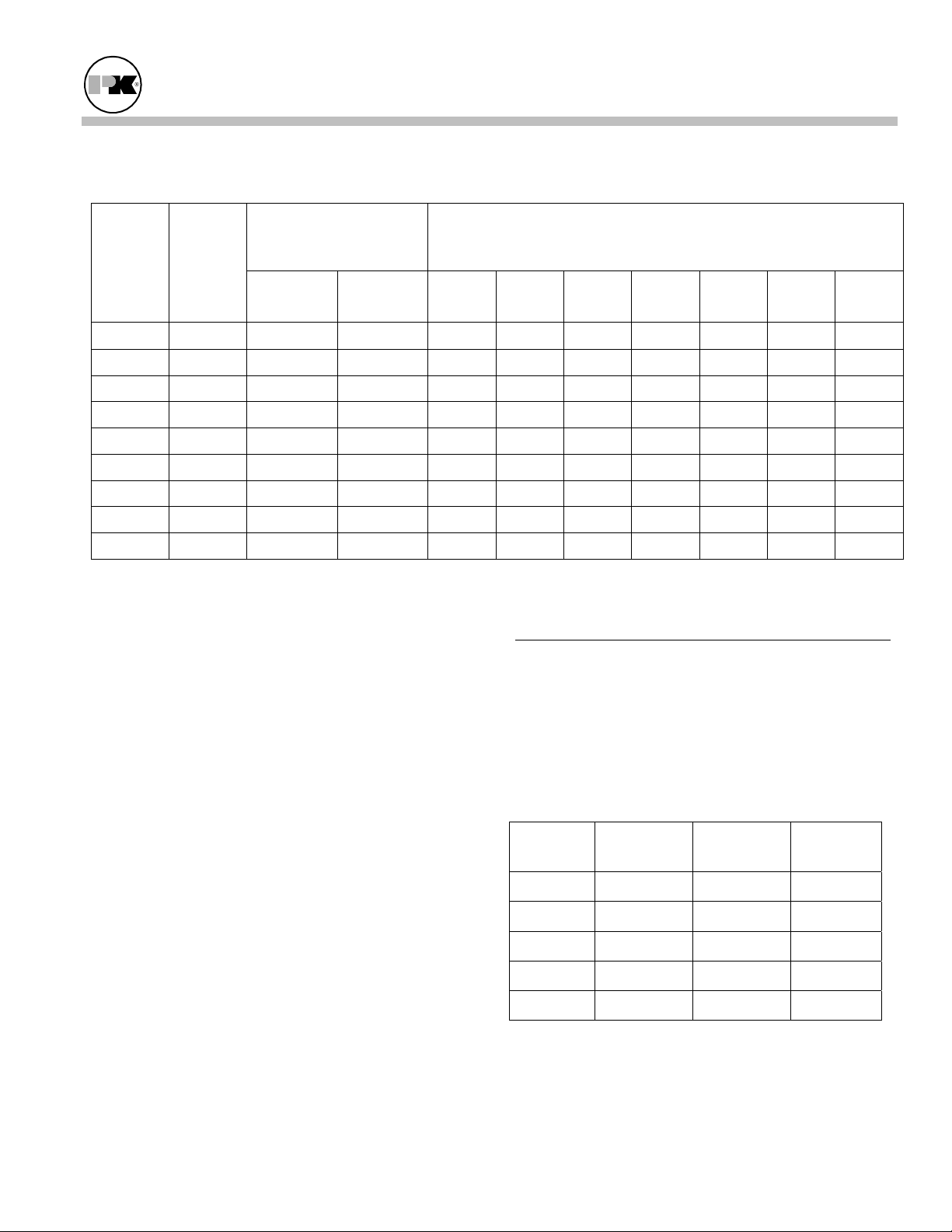

Pipe Capacity for Natural Gas

Nominal

Iron Pipe

Size

(Inches)

1/2 0.622 1.55 3.1 120 82 66 57 50 40 35

3/4 0.824 2.06 4.12 250 170 138 118 103 84 72

1 1.049 2.62 5.24 465 320 260 220 195 160 135

1- 1/4 1.380 3.45 6.9 950 660 530 460 400 325 280

1- 1/2 1.610 4.02 8.04 1460 990 810 690 620 500 430

2 2.067 5.17 10.3 2750 1900 1520 1300 1150 950 800

2- 1/2 2.469 6.16 12.3 4350 3000 2400 2050 1850 1500 1280

3 3.068 7.67 15.3 7700 5300 4300 3700 3250 2650 2280

4 4.026 10.1 20.2 15800 10900 8800 7500 6700 5500 4600

Internal

Diameter

(Inches)

Equivalent Pipe Length

90º Ell

(Feet)

Tee

(Feet)

Maximum Capacity in Cubic Feet of Natural Gas per Hour

Pressure Drop of 0.5 inch Water Column/Equivalent Length of Pipe

(in feet)

20

40

60

80

100

150

3.7.1 Gas Supply Piping by Installer

3.8

BOILER WATER PIPING

200

The boiler and all gas piping connections should be

pressure-tested and must be checked for leaks before

being placed into service. Test with compressed air or

inert gas if possible.

The boiler must be disconnected at the boiler manual

shut-off valve (located at the end of the supplied gas

train) from the gas supply piping system during any

pressure testing of the system at pressures in excess of

1/2 psig (14" W.C.).

During any pressure testing of the gas supply piping

system at pressures equal to or less than 1/2 psig (14"

W.C.), the boiler should be isolated from the gas

supply piping system by closing the manual shut-off.

Some leak test solutions, including soap and water,

may cause corrosion. These solutions should be

rinsed-off with water after testing.

3.8.1 Piping Design

Water Flow in System

For proper water flow requirements see below.

Incorrect flow may result in eventual damage or

premature failure of the equipment.

Model Max Flow

GPM

Min Flow

GPM

DP ft. at

max flow

1050 105 52 12

900 90 45 12

750 75 37 12

450 45 22 8.5

300 30 15 8.5

Contact factory for minimum flow at other than

maximum firing rate.

Page 14

Loading...

Loading...