Patterson-Kelley DVSCM-02 User Manual

DVSCM-02

DIRECT VENT/

SEALED

COMBUSTION

DIRECT VENT/

PATTERSON-KELLEY

THERMIFIC

DIRECT VENT/SEALED COMBUSTION

GAS-FIRED BOILER

Supplement to the standard Installation and

Owner's Manual (TBIG - Latest Edition)

®

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

ASME Code, Section IV

Certified by Patterson-Kelley

SEALED

COMBUSTION

DIRECT VENT/

SEALED

COMBUSTION

DIRECT VENT/

SEALED

COMBUSTION

DIRECT VENT/

SEALED

COMBUSTION

C.S.A Design-Certified

Complies with ANSI Z21.13/CSA 4.9

Gas-Fired Low Pressure Steam and Hot Water Boilers

Installation Date:

100 Burson Street, P.O. Box 458,

East Stroudsburg, PA 18301

Telephone: (877) 728-5351, Facsimile: (570) 476-7247

www.pkboilers.com

Patterson-Kelley

P.O. Box 458, 100 Burson Street

East Stroudsburg, PA 18301

Telephone: (570) 421-7500, Facsimile: (570) 476-7247

_______________________

DIRECT VENT/

SEALED

COMBUSTION

DIRECT VENT/

SEALED

COMBUSTION

DIRECT VENT/

SEALED

COMBUSTION

DIRECT VENT/

Thermific® Gas-Fired Boiler Table of Contents

1.0 INTRODUCTION..................................1

1.1 Code Compliance................................1

1.1.1 Direct Vent/Sealed Combustion

System..............................................1

1.1.2 Fresh Air System...........................1

1.2 Basic Inlet/Vent Configurations ...........1

1.3 Purpose and Scope of this Manual......2

2.0 SAFETY ...............................................2

3.0 INSTALLATION....................................3

3.1 Components Provided......................... 3

3.2 Combustion Air Inlet System ...............3

3.2.1 System Design - Pressure Drop....3

3.2.2 Inlet Duct.......................................3

3.2.3 Air Inlet Termination......................3

3.2.4 Inlet Duct Assembly at the Boiler... 4

3.2.5 Inlet Damper and Auxiliary Control

Panel (optional).................................5

3.3 Exhaust Venting System .....................5

3.3.1 System Design - Materials, Length,

Size, and Construction ......................5

3.3.2 Flue Gas Outlet Duct.....................5

3.3.3 Exhaust Vent Connection at the

Boiler.................................................6

3.3.4 Flue Gas Termination....................6

3.4.5 Equivalent Length of Fittings .........7

3.4 Clearances .......................................... 7

3.4.1 Sidewall Installations.....................7

3.4.2 Rooftop Installations......................8

3.4.3 Minimum Clearance for Boiler

Connections ......................................8

4.0 OPERATION ........................................9

4.1 Sequence of Operation .......................9

4.2 Combustion Operating Conditions.......9

4.2.1 Combustion Air Requirement,

SCFM............................................10

5.0 MAINTENANCE .................................10

6.0 WIRING DIAGRAMS..........................11

6.1 On-Off Series 700, 1000, 1200......... 11

6.1a On-Off IRI Series 700, 1000, 1200 .13

6.1b Lo-Hi Lo ..........................................15

6.1c Lo-Hi-Lo IRI .................................... 17

6.1d On-Off Series 1500, 1700, 2000 ..... 19

6.1e On-Off IRI Series 1500, 1700, 2000 21

6.2 Auxiliary Control Panel...................... 23

6.2.1 On-Off Auxiliary Control Panel.... 23

!

WARNING

Improper use may

result in fire or injury.

Read instructions/safety

manual before installing,

c

1998 HCS, Inc. 800-748-0241

WARNING!

essential

It is

recommendations of this manual before installing,

operating, or servicing this equipment. Failure to do

so could result in fire or explosion and serious injury,

death, and/or property damage.

to read, understand, and follow the

operating or servicing boiler.

Reorder No. 6020-V2WHPK

The same features which permit this boiler to achieve

high-efficiency performance make it unlike most other

boilers of this general size, so it is important to

understand how this boiler operates.

Do not store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

WARNING!

Installation and service must be performed by a

qualified installer, service agency, or gas supplier.

What to do if you smell gas:

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier call the fire

department.

Thermific® Gas-Fired Boiler Introduction

1.0 INTRODUCTION

Direct vent (ANSI Z21.13) is a closed system method

of ducting the combustion air directly from the outside

of the building into the inlet compartment of the

burner, and a sealed exhaust vent from the combustion

chamber to the outdoors.

The direct vent/sealed combustion option is available

on the Thermific® boilers on Series 700, 1000, 1200,

1500, 1700, and 2000.

Advantages are:

•

Savings in energy costs due to the elimination of

using conditioned air (heated and/or cooled

building air) from going back up the stack.

•

Isolation of the burner from pressure changes in

the building which can cause erratic combustion

performance.

•

Combustion air is taken from the outside which is

generally more clean than indoor air. Halide

contaminants within a building, such as chlorides,

can cause excessive corrosion in the burner, heat

exchanger and venting system.

1.1.2 Fresh Air System

(ducted combustion air system)

In some instances compliance with ANSI Z21.13

may

not be required, in which case a "fresh air system" may

be used. Consultation with qualified professionals is

required to determine whether a "fresh air system" is

suitable for any particular application and in

compliance with all applicable codes and regulations.

All flue gas outlet (exhaust vent) material for a fresh

air system must be certified for use with a Category I

Appliance. (Standard B-vent isapproved.) The

exhaust vent may be run horizontally or vertically.

Proper vent sizing by the vent manufacturer's

recommendation must be followed.

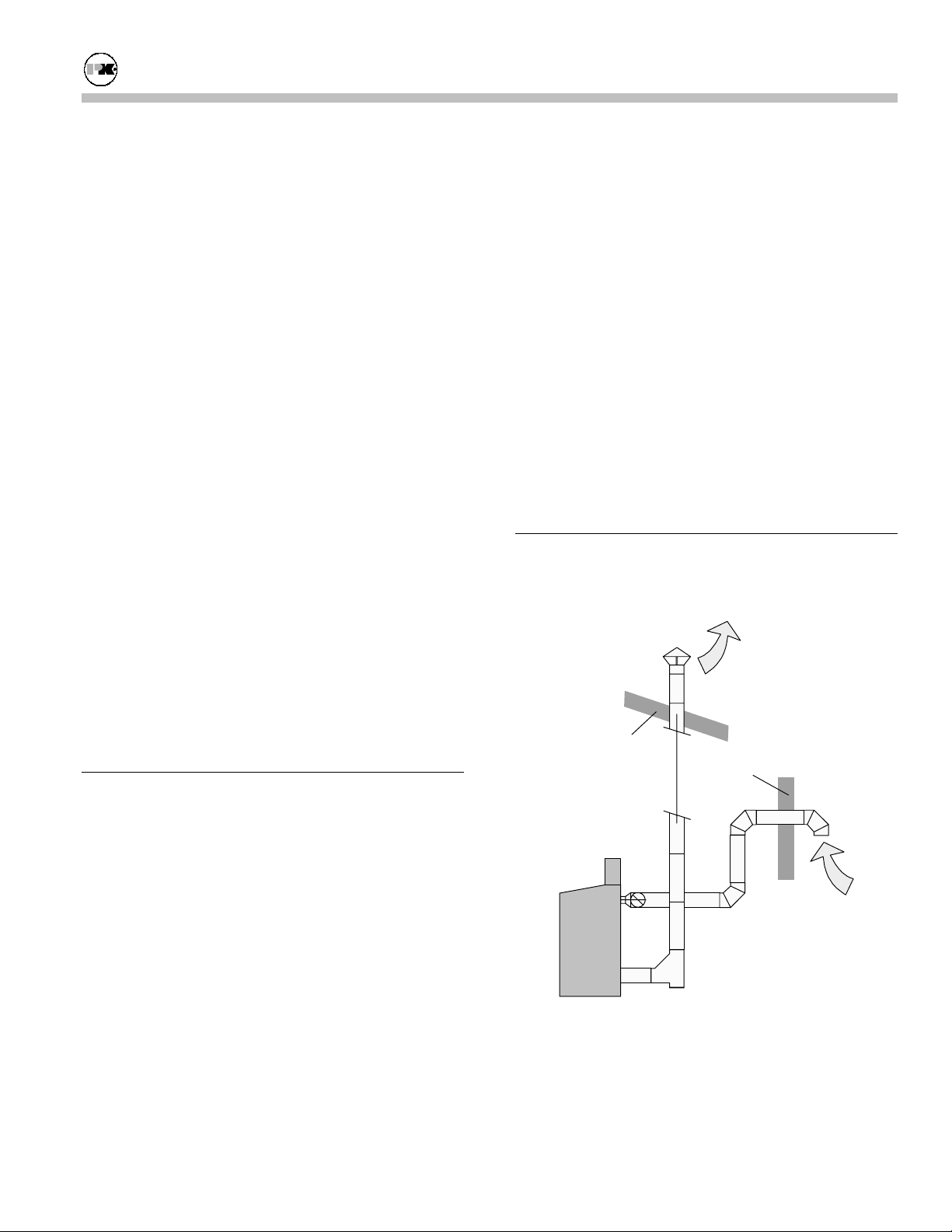

1.2 B

ASIC INLET/VENTCONFIGURATIONS

Four basic configurations are allowable for the

combustion air inlet and flue gas exhaust vent, as

follows; installation details are provided in Section 3.

•

Eliminates the need for two large combustion

air/ventilation air openings into the mechanical

space.

1.1 C

ODECOMPLIANCE

1.1.1 Direct Vent/Sealed Combustion System

(complying with ANSI Z21.13)

All flue gas outlet (exhaust vent) material must

comply with UL-1738. (Standard B-vent

is not

approved.) Proper vent sizing by the vent

manufacturer's recommendation must be followed.

The exhaust vent may be run horizontally or vertically.

The maximum allowable length of the exhaust vent for

horizontal installations, including the boot tee/135º

(not a standard tee) and the termination is

equivalent feet.

Refer to Section 3.4.5 for equivalent

100

lengths.

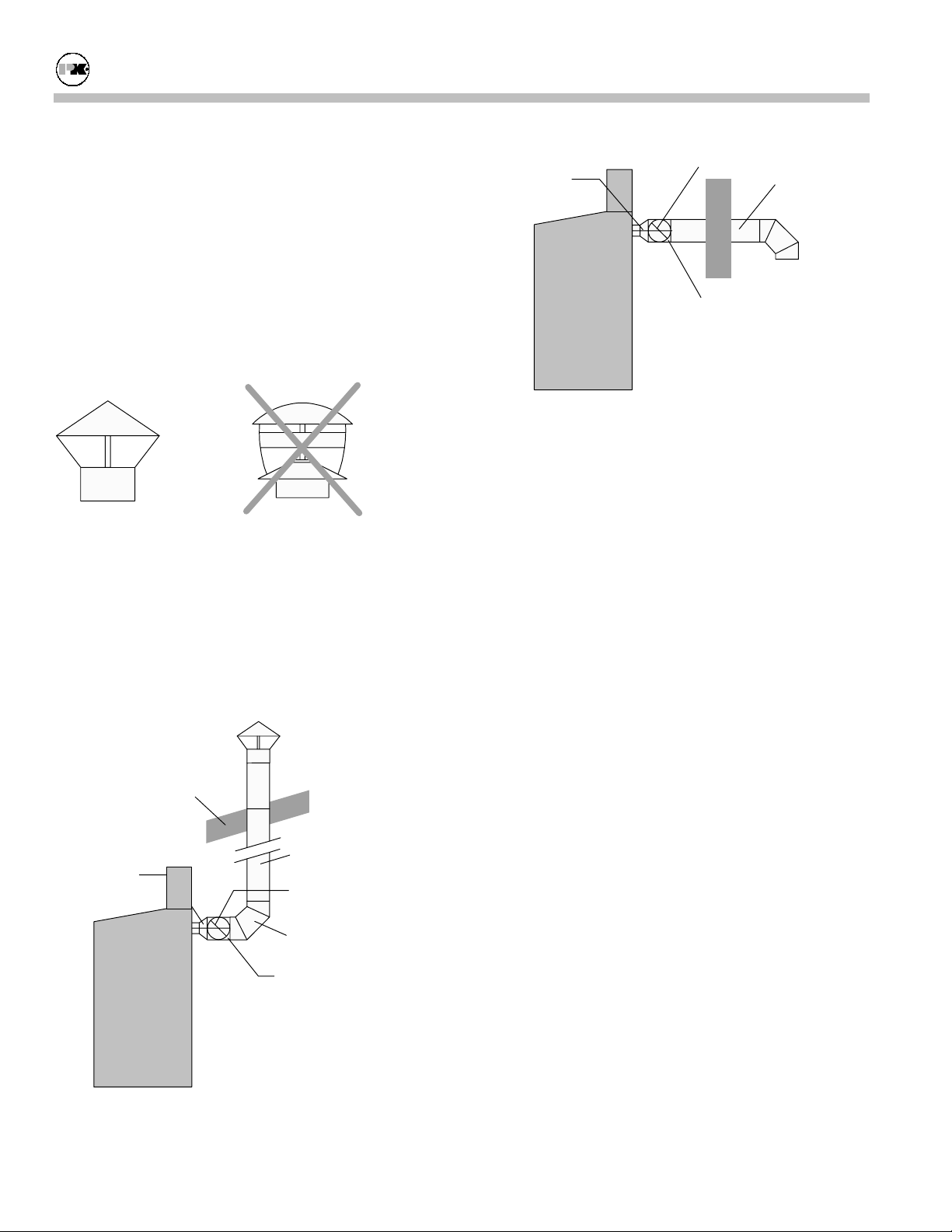

Exhaust

Vent

Roof

Sidewall

Air Inlet

1. Combustion air inlet duct through the sidewall and

the flue gas exhaust through the roof. This is the

preferred method.

Page 1

Thermific® Gas-Fired Boiler Introduction/Safety

Sidewall

Exhaust

Vent

Air Inlet

2. Both the combustion air inlet and flue gas exhaust

through the sidewall.

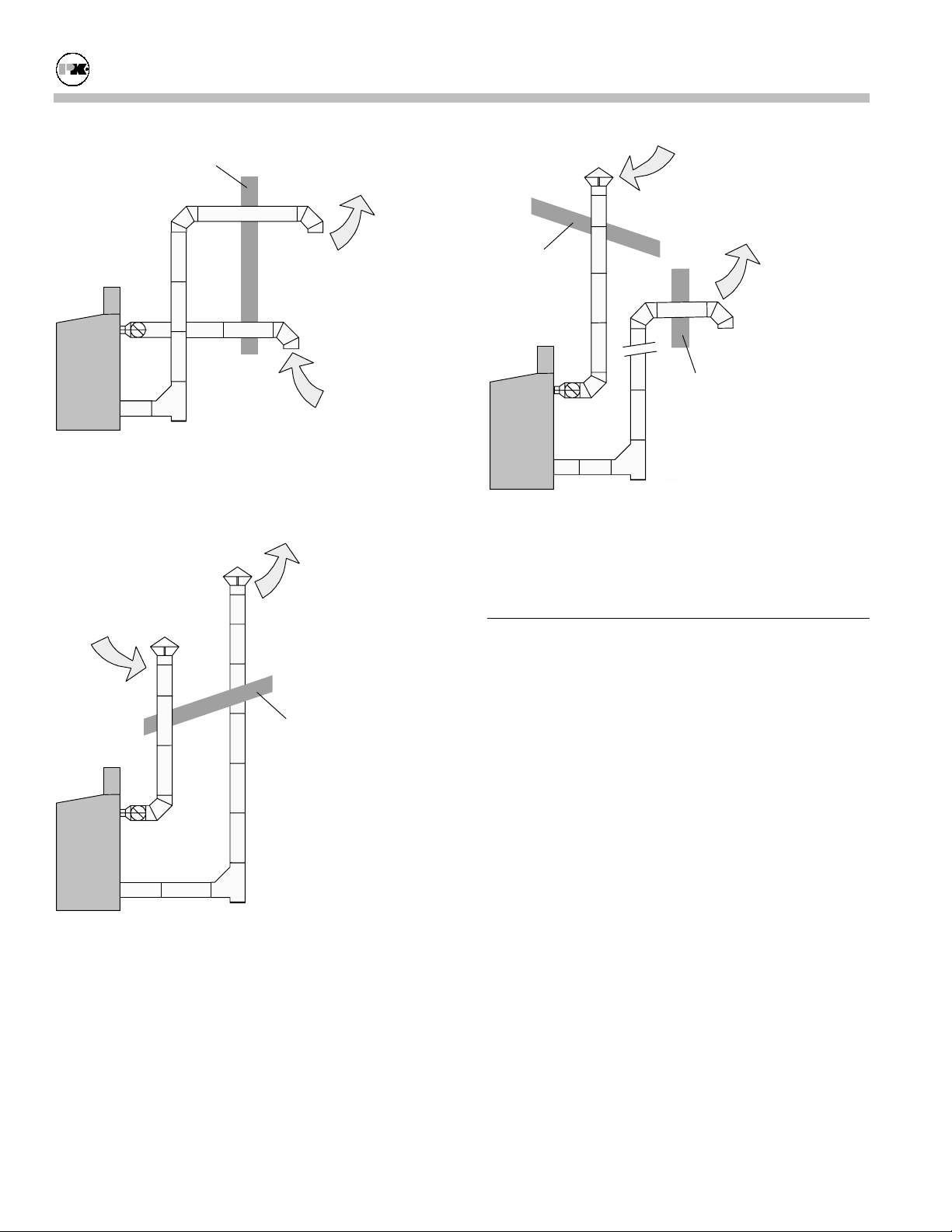

Air Inlet

Exhaust

Vent

Air Inlet

Exhaust

Vent

Roof

Sidewall

4. The combustion air inlet from the roof and the flue

gas exhaust through the sidewall.

1.3 P

URPOSE AND SCOPE OF THIS MANUAL

This manual is a supplement and companion to the

Thermific Installation and Owner's Manual. "TBIG."

Both documents must be used together.

Roof

3. The combustion air inlet from the roof and the flue

gas exhaust through the roof.

This companion document describes those safety,

installation, adjustment, and maintenance procedures

which differ from the standard model. Information

that applies to both models is found in the "TBIG"

latest edition.

2.0 SAFETY

Refer to the manual for the standard Thermific® GasFired Boiler for safety information applicable to this

equipment. Safety information applicable only to the

direct vent option appears below.

Danger!

Acceptable Venting Methods:

The only acceptable venting methods are the four

configurations shown in Section 1.2. Do not attempt

to use any other method of obtaining combustion air or

venting flue gases.

Page 2

Thermific® Gas-Fired Boiler Installation

Do not manifold two (2) or more units into a common

sidewall vent system without provisions for additional

forced draft.

3.0 INSTALLATION

3.1 C

OMPONENTS PROVIDED

The direct vent/sealed combustion option is shipped

with the following items shipped loose for field

installation:

Custom 6 inch diameter to 12 inch diameter

transition duct with extension, for attachment to

the combustion air inlet on the boiler.

A 12" inlet damper assembly with actuator and

limit switch mounted to the damper shaft.

Auxiliary Control Panel to operate the inlet

damper assembly.

The inlet damper assembly and control panel will

prevent the flow of cold air through the boiler during

the off cycle and prevent freeze up and "off cycle"

losses. The use of these two items is optional.

3.2 C

OMBUSTION AIRINLETSYSTEM

Note:

silicone sealant, or equivalent, must be used on each

circumferential and horizontal joint before joining

together. At least 24 hours must be allowed for cure

of this sealant and proper bond. Cure time can be

reduced through the application of heat (See

instructions provided with the sealant). After the cure

period, each joint must be wrapped with an aluminum

tape which is faced on the contact side with an

adhesive.

3.2.2.2 PVC Duct

Proper sealing of the tubing is necessary to prevent

flow of combustion air from conditioned space.

The installation must follow the vent manufacturer's

instructions in all respects including proper joining and

sealing of the tubing and fittings. Clearances to

combustible materials and installation of firestops

must conform to applicable codes.

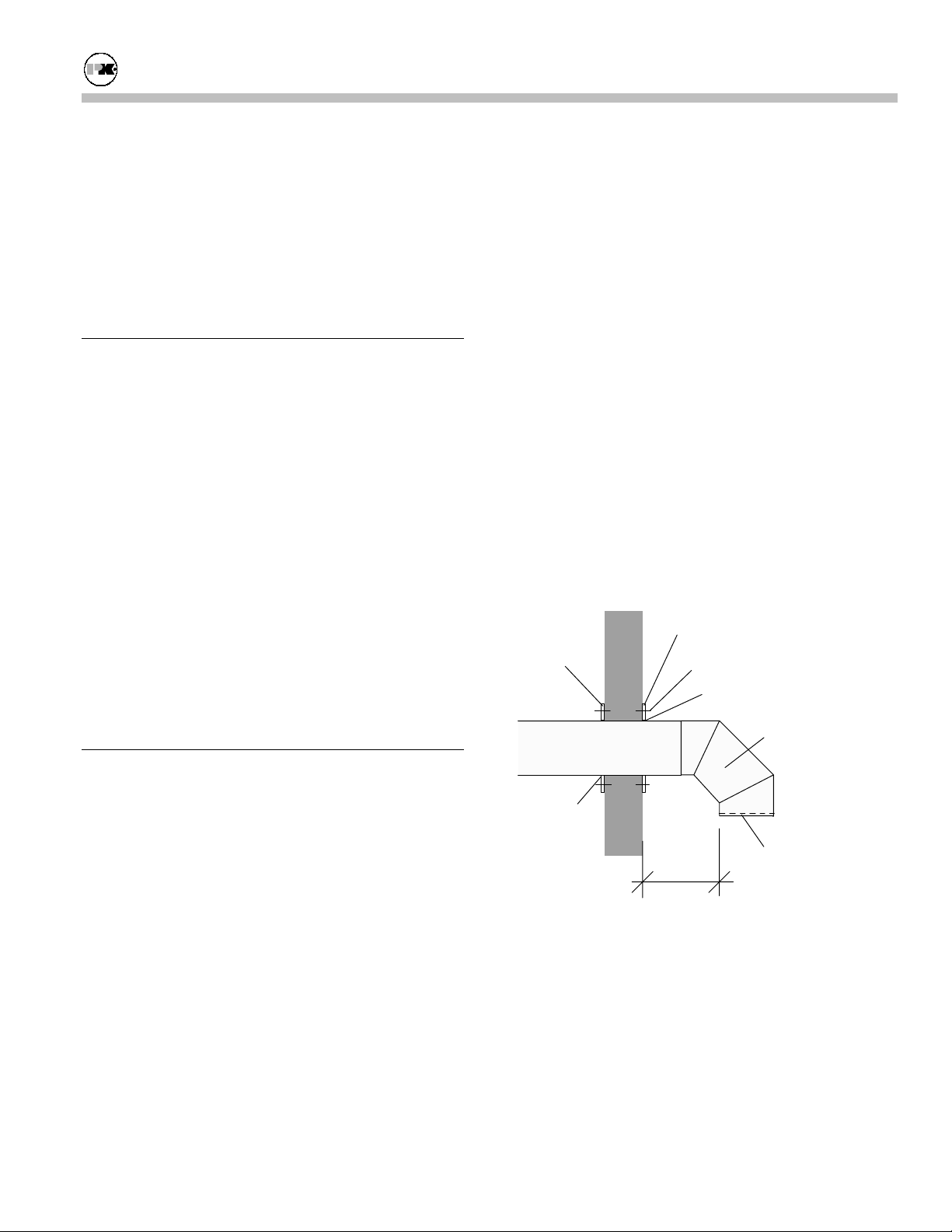

3.2.3 Air Inlet Termination

Centering

Support

Plate

Outside Plate

Cover Plate

Fastener

Sealant

Recommended

Termination

(refer to text).

3.2.1 System Design - Pressure Drop

The air inlet duct system shall be designed for a

maximum pressure drop of 0.05" W.C. taking into

account the equivalent length of all fittings. Refer to

Section 3.4.5 for equivalent length of fittings.

3.2.2 Inlet Duct

Materials shall be single wall galvanized duct

(minimum thickness 26 gauge) or PVC duct tubing

(0.187 inch wall thickness) only.

3.2.2.1 Single Wall Galvanized Duct

No substitutions.

Proper sealing of the tubing is necessary to prevent

flow of combustion air from conditioned space. If

single wall galvanized tubing is used, GE RTV 102

Page 3

Sealant

12" Min.

Field Provided

Inlet Screen

The boiler combustion air inlet duct must be fitted

with a termination device meeting the requirements of

ANSI Z21.13. There are four recommended sidewall

terminations:

•

Double wall B vent 90 degree elbow, or

•

Two double wall B vent 45 degree elbows, or

•

Schedule 40 PVC 90 degree elbow, or

•

Properly engineered intake louver screen.

Thermific® Gas-Fired Boiler Installation

Whichever material is used, the termination must point

down and must be backed by a metal plate secured to

the wall.

Important:

The chosen inlet termination must be

included in the calculation of the maximum allowable

equivalent length. See Section 3.4.5 for equivalent

lengths.

Correct rain cap,

unrestricted.

Typical incorrect

rain cap.

If the combustion air inlet duct is routed through the

roof, the termination must be either the same type as

described for a sidewall installation or a rain cap. The

rain cap must be unrestrictive type similar to the

illustration below.

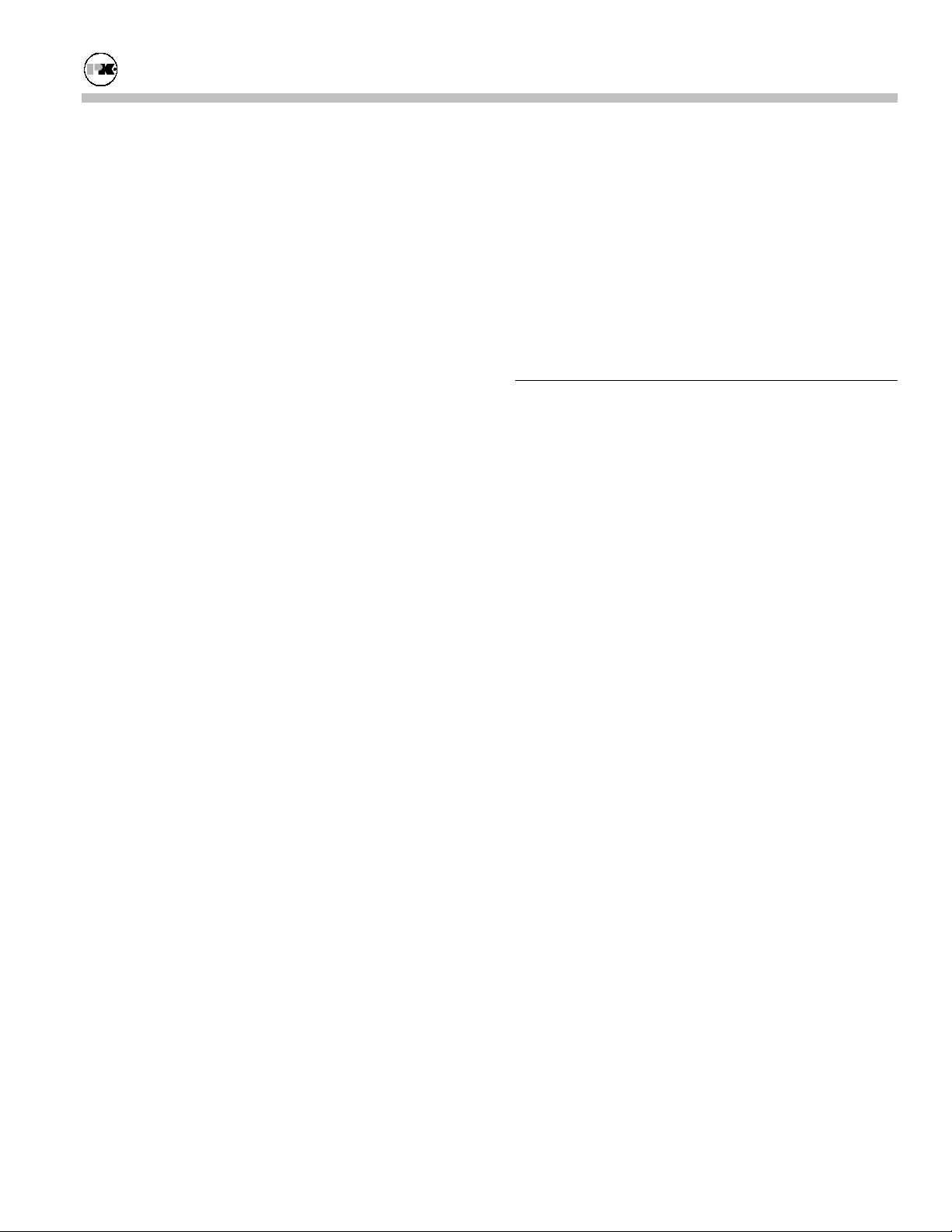

3.2.4 Inlet Duct Assembly at the Boiler

Damper

Transition

Round

Duct

Damper

Housing

(Sidewall installation shown.)

The boiler is equipped with a special collar attached to

the air inlet opening on the back of the unit (at the

blower housing on Series 700, 1000, and 1200; at the

back of the cabinet on Series 1500, 1700 and 2000.).

A separate box of accessories is sent with the boiler.

1. Attach the 6 inch diameter end of the custom

transition duct and the extension to the collar using

a minimum of 4 sheet metal screws spaced

approximately at 90 degree intervals. This joint

must then be wrapped with an aluminum tape

backed on the contact side with an adhesive. Do

not use "duct tape."

Roof

Transition

Duct

(Roof installation shown.)

Round

Damper

o

90 Elbow

Damper

Housing

Page 4

Important:

do not insulate the transition duct or

extension.

Refer to Section 3.2 for instructions for installing and

wiring the auxiliary control panel; it is required if the

optional inlet damper is used.

3.2.4.1 Sealing PVC Duct Tubing to the Inlet Duct

Apply a 3/4" wide x 1/8" thick gasket to the outside

surface edge of the entire circumference of the

transition duct (or extension). A closed cell foam

rubber gasket with pressure sensitive adhesive works

very well. Insert 3/4" of the transition duct into the

PVC duct tubing so that the gasket lines up with the

edge of the PVC tubing. Lay an approximate 3/8"

wide bead of GE RTV-102 silicone sealant, or

equivalent, along the gap between the gasket and

inside wall of the tubing. Allow the silicone sealant to

cure for 24 hours. The cure time can be shortened

Thermific® Gas-Fired Boiler Installation

with the application of heat. Refer to the

manufacturer's instructions. Wrap the joint with

aluminum tape which is backed with an adhesive on

the contact side.

3.2.5 Inlet Damper and Auxiliary Control

Panel (optional)

Note:

The inlet damper assembly and control panel will

prevent the flow of cold air through the boiler during

the off cycle and prevent freeze up. These two items

optional

are

in all installations.

Refer to Section 4.1 for a description of the control

sequence applicable to the inlet damper.

The damper must be field installed into a section of

horizontal or vertical inlet ductwork. Orient the

damper such that the arrow points towards the boiler.

3.2.5.1 Field Wiring to Auxiliary Control Panel

The auxiliary control panel controls the inlet damper

(if used). The auxiliary control panel does not have to

be mounted on or near the boiler; it can be remotely

mounted.

Use 16GA MTW Wire for all field wiring. See

Section 6 for the logic and wiring diagrams of this

auxiliary control panel and the sealed combustion

boilers.

There are five (5) field run wires between the boiler

and its auxiliary control panel; three (3) for main

power supply and two (2) wires for boiler

interconnect.

1. The main power supply (G/H/N) must come from

the same boiler that the damper is connected to.

2. Remove the blue jumper wire in the terminal block

on the boiler when wiring.

There are also five (5) field run wires between the

auxiliary control panel and the inlet damper assembly;

three (3) to the damper actuator and two (2) to the

limit switch.

1. Terminals for the damper actuator:

DO = Damper Open (CW)

DC = Damper Closed (CCW)

DN = Neutral/Common

2. Terminals for the limit (end) switch

SI = N.O. (Normally Open)

S2 = Common

3.3 E

XHAUST VENTINGSYSTEM

3.3.1 System Design - Materials, Length, Size,

and Construction

The flue gas outlet (exhaust vent) must be designed to

comply with UL 1738 and ULC-636. (Refer to

Section 1.1.2 for situations where alternate compliance

may be permitted.) The exhaust vent can be run

horizontally or vertically.

The vent must be sized according to the vent

manufacture's recommendations. Consult the vent

supplier for correct sizing and structural support

requirements. Vent diameter is dictated by the length

and height of horizontal and vertical portions of the

vent installation and materials of construction. Design

calculations should be based on a negative 0.03 W.C.

with a stack temperature of 325º F (gross) and a CO

2

level of 7.6%; (these values are to be used for vent

sizing calculations.) The

maximum

allowable length

of the vent duct, including the boot tee/135º tee (not a

standard tee) and the termination is 100 equivalent

feet. See Section 3.4.5 for the equivalent length of the

fittings.

3.3.2 Flue Gas Outlet Duct

The installation must follow the vent manufacturer's

instructions in all respects including proper joining and

sealing of the tubing and fittings, clearances to

combustible materials and installation of firestops.

Page 5

Thermific® Gas-Fired Boiler Installation

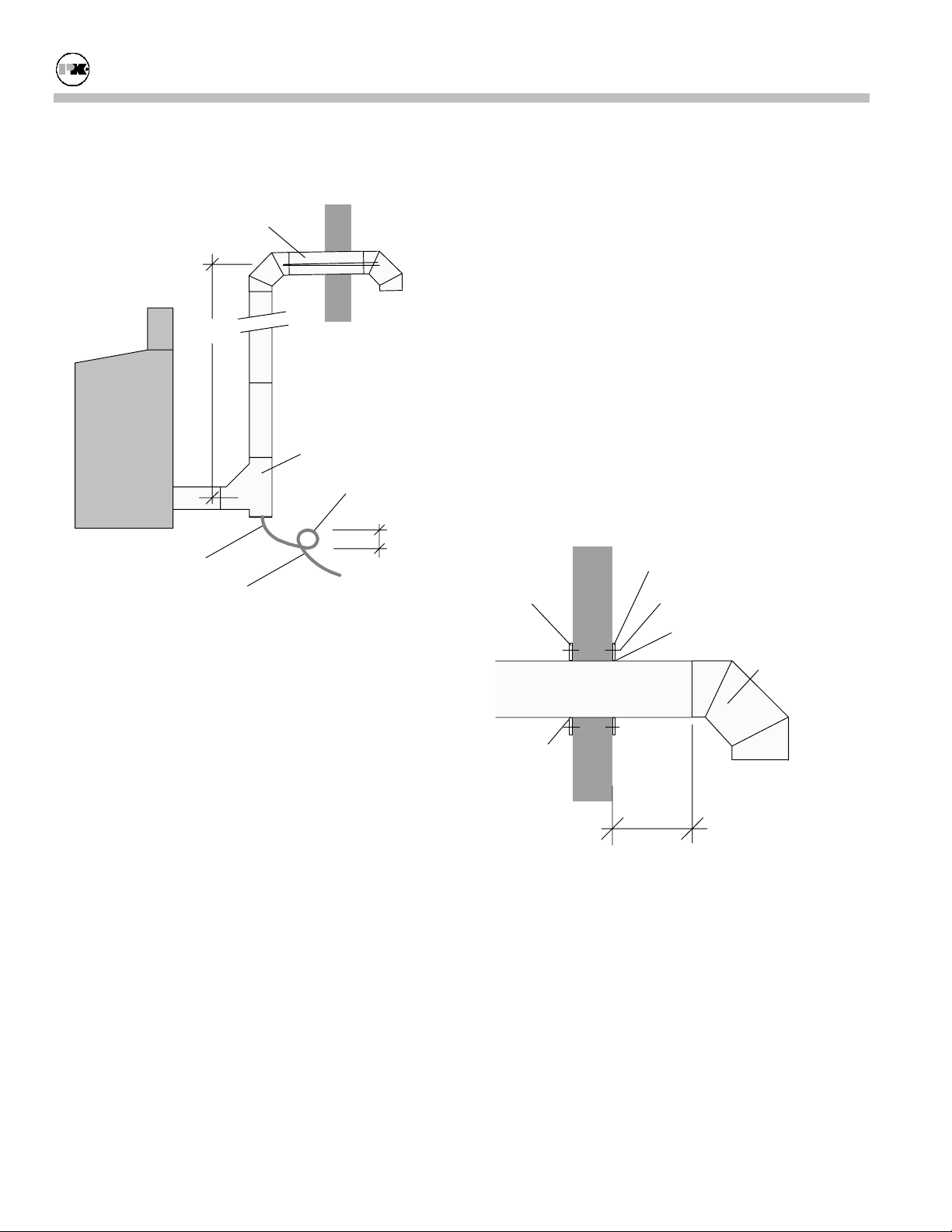

3.3.3 Exhaust Vent Connection at the Boiler

Pitch toward boiler

1/4" per foot min.

6' Min.

Boot Tee/

o

135 Tee

Trap Loop

3" Min.

Condensate Drain

To s ewe r t rap

or condensate pump.

At the outlet of the boiler, an adjustable or fixed length

(minimum 2 feet for clearance from inlet duct;

maximum 3 feet for proper lift) section may be

utilized. This section must be secured to the outlet

collar by a minimum of 4 sheet metal screws spaced at

approximately 90 degree intervals.

from the outlet of the boot tee/ 135º tee to the inlet of

the elbow. In addition, for sidewall venting, it is

important

to provide a downward pitch of at least 1/4

very

inch per foot of run from the termination at the wall

toward the boiler for proper drainage of the condensate

and for buoyancy assist of the flue gas. Furthermore,

do not

locate sidewall terminations over area of

pedestrian or vehicular traffic due to potential

condensate drippage and ice build-up. See Section 3.4

Clearances for more information.

When joining the double wall tubing and fittings, it is

important to orient the male end of the section toward

the boiler. The female end is positioned away from

the boiler towards the vent terminal. Follow the vent

manufacturer's instructions for proper installation.

3.3.4 Flue Gas Termination

Centering

Support

Plate

Sealant

Outside Plate

Cover Plate

Fastener

Sealant

Recommended

termination

(refer to text).

Even though the unit is classified as a Category I

boiler (Non-pressurized-non condensing), there are

certain abnormal conditions which may cause

condensation in the flue vent. Therefore, it is

recommended that a tee cover with a drain be provided

at the bottom of the boot tee/135º tee. For proper

disposal of the condensate, corrosion resistant tubing

or plastic tubing should be connected to the drain

nipple. Before connecting the tubing to the tee cover

nipple, the trap loop must be primed by pouring a

small quantity of water into the drain line. The

condensate drain line can be routed to a sewer drain

trap or pump. Consult the vent manufacturer's

instructions for proper installation of drain line.

In transitioning from horizontal to vertical, a double

wall boot tee/135º tee must be installed (not a standard

tee). If the flue gas exhaust is to be routed through the

sidewall, a minimum vertical rise of 6 feet is required

Page 6

12" Min.

The exhaust vent termination must be a P-K

recommended device. There are four approved

sidewall terminations:

90º elbow pointing down, or

Two 45º elbows pointing down, or

45º elbow pointing down, or

Standard tee pointing up/down.

Important:

The equivalent length of the chosen

termination must be included in the calculation of the

maximum allowable equivalent length. See Section

3.4.5 for equivalent lengths.

Loading...

Loading...