Page 1

DMXPathfinder LR

Installer’s GuideInstaller’s Guide

Version 1.2

June 2000

Gray InterfacesGray Interfaces

480C - 36 Avenue S.E.

Calgary, AB, T2G 1W4

Canada

Phone: (403) 243-8110

Fax: (403) 287-1281

E-mail: support@gray-interfaces.com

Web site: www.gray-interfaces.com

Page 2

DMXPathfinder LR Contents

CONTENTS

INTRODUCTION .............................................................. 2

WELCOME TO THE WORLD OF DMXPATHFINDER! .......................................2

CHAPTER 1: INSTALLATION AND ASSEMBLY ...................................... 3

SUMMARY................................................................... 3

BEFORE STARTING ........................................................... 3

RACK SIZING AND PLACEMENT................................................... 4

MOUNTING TERMINATION BOARDS .................................................5

I/O CABLE INSTALLATION .....................................................6

MODULE PREPARATION .........................................................6

MODULE INSTALLATION ........................................................ 7

I/O CABLE CONNECTION....................................................... 9

PC-COM CABLE CONNECTION................................................... 10

RS232/485 COMMUNICATIONS ................................................. 10

TESTING THE INSTALLATION................................................... 12

CHAPTER 2: MAINTENANCE & TESTING ......................................... 13

CARD REPLACEMENT.......................................................... 13

TEST PROCEDURES .......................................................... 13

ADVANCED TROUBLESHOOTING................................................... 15

SYSTEM RESET ............................................................. 16

1

Page 3

DMXPathfinder LR Introduction

INTRODUCTION

WELCOME TO THE WORLD OF DMXPATHFINDER!

This Installation Guide is intended to walk you through a typical installation. In

preparing the User Guide, it has been assumed that you are reasonably familiar

with the DMX512 and the various wiring methods associated with RS422/485

based protocols. Installing and configuring the PC software is covered in detail

in the Installation and User guide.

The Installer’s Guide is divided into 2 chapters:

• DMXPathfinder Installation leads you through all the steps necessary for

a “clean” installation of your hardware.

• Maintenance and Testing offers troubleshooting tips and procedures to

keep everything running smoothly.

2

Page 4

DMXPathfinder LR Installation & Assembly

Chapter 1: Installation and Assembly

SUMMARY

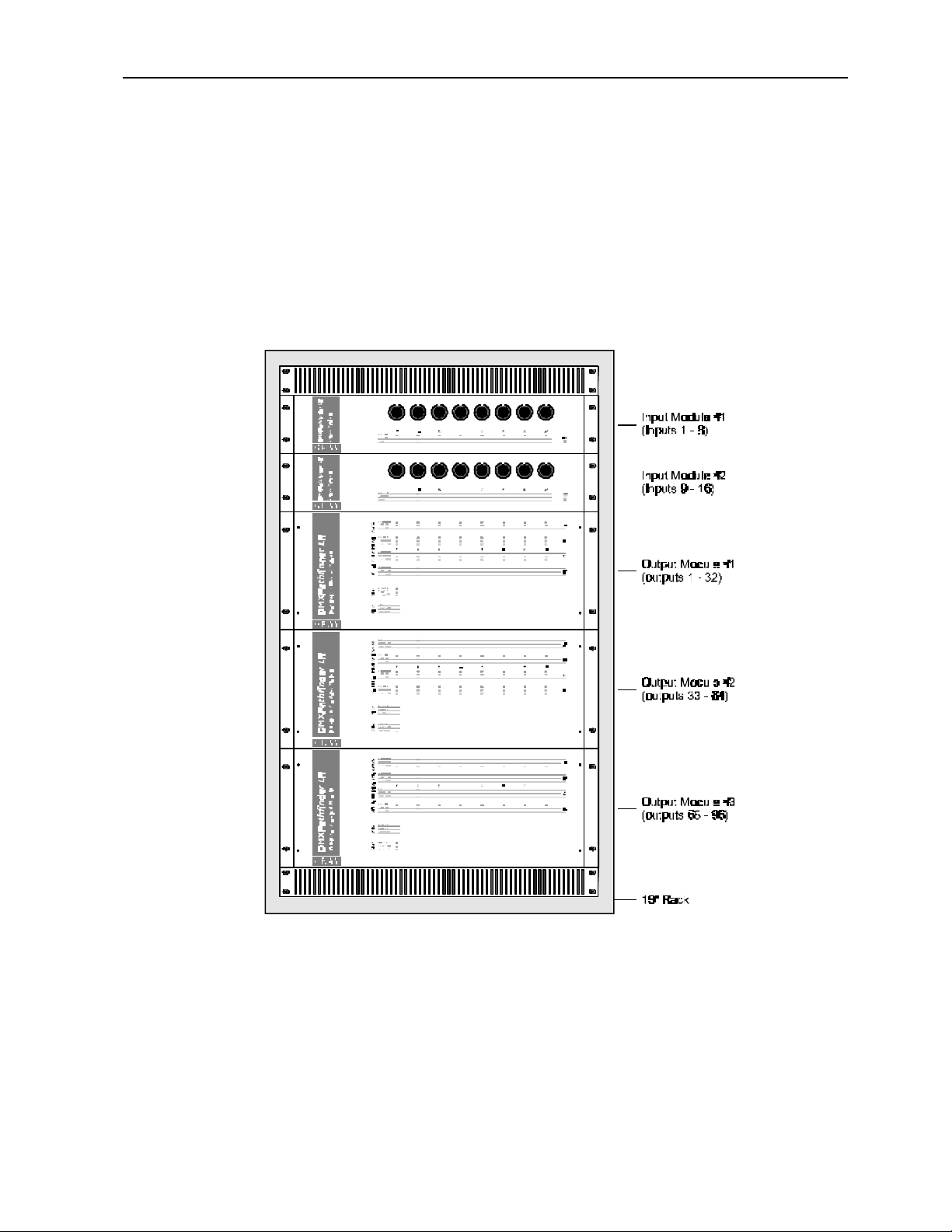

This section describes how to correctly assemble the DMXPathfinder LR

hardware into an equipment rack and connect permanently installed external

wiring.

To ensure a trouble-free installation, you should follow this sequence:

1. Install the equipment rack

2. Run conduit and pull cable

3. Install auxiliary rack equipment and power bars

4. Mount termination boards (if applicable)

5. Dress cable in the rack and terminate (if possible)

6. Unpack the DMXPathfinder LR I/O Modules and prepare

7. Install the I/O Modules in the rack

8. Connect cabling to the I/O Modules

9. Power up and test

BEFORE STARTING

Before installing the DMXPathfinder LR equipment rack, you should

carefully consider the environment in which the equipment is to be installed, the

proximity to power sources, and the required conduit and/or cable runs.

Environmental Considerations -- To maximize equipment life and minimize

the possibility of unreliable operation or failures, the following conditions should

be adhered to:

• Ambient temperature extremes: -10 to 50 degrees C

• Recommended operating temperature: +10 to +40 degrees C

• Relative humidity : 10-95% non-condensing

• General conditions: clean, dust-free environment

Fan Cooling -- Each of the DMXPathfinder LR Output Modules is provided with

an internal cooling fan. These fans draw air in on the right hand side and

exhaust air on the left. To ensure adequate air circulation, do not block the

modules at either side. If more than two or three Output Modules are installed in

3

Page 5

DMXPathfinder LR Installation & Assembly

the same rack, allow for at least a 1U vent panel at the top and bottom of the

rack.

Power Requirements -- A single phase power source (50 or 60Hz, 100-

240VAC, at 0.1A per Input Module and 0.25A per Output Module) must be

provided to the DMXPathfinder LR equipment rack. It is recommended that no

more than ten I/O modules be connected to one power circuit due to the startup

current requirements of their switch-mode power supplies.

RACK SIZING AND PLACEMENT

The system installer normally supplies the DMXPathfinder LR equipment

rack. Use only a standard E.I.A. 19" rack, at least 18" deep (24" is

recommended). To calculate minimum height, add up the number of 2U Input

4

Page 6

DMXPathfinder LR Installation & Assembly

Modules and 4U Output Modules to be installed, then add at least 2U for vent

panels and allowance for power bars, connector panels or other accessories if

required. Louvered, locking front and rear doors are recommended.

Locate the rack such that at least 3 feet of clearance is allowed at the front,

2 feet at the back, and sufficient clearance at one side (preferably the left) to

permit service access to the internal cable connections.

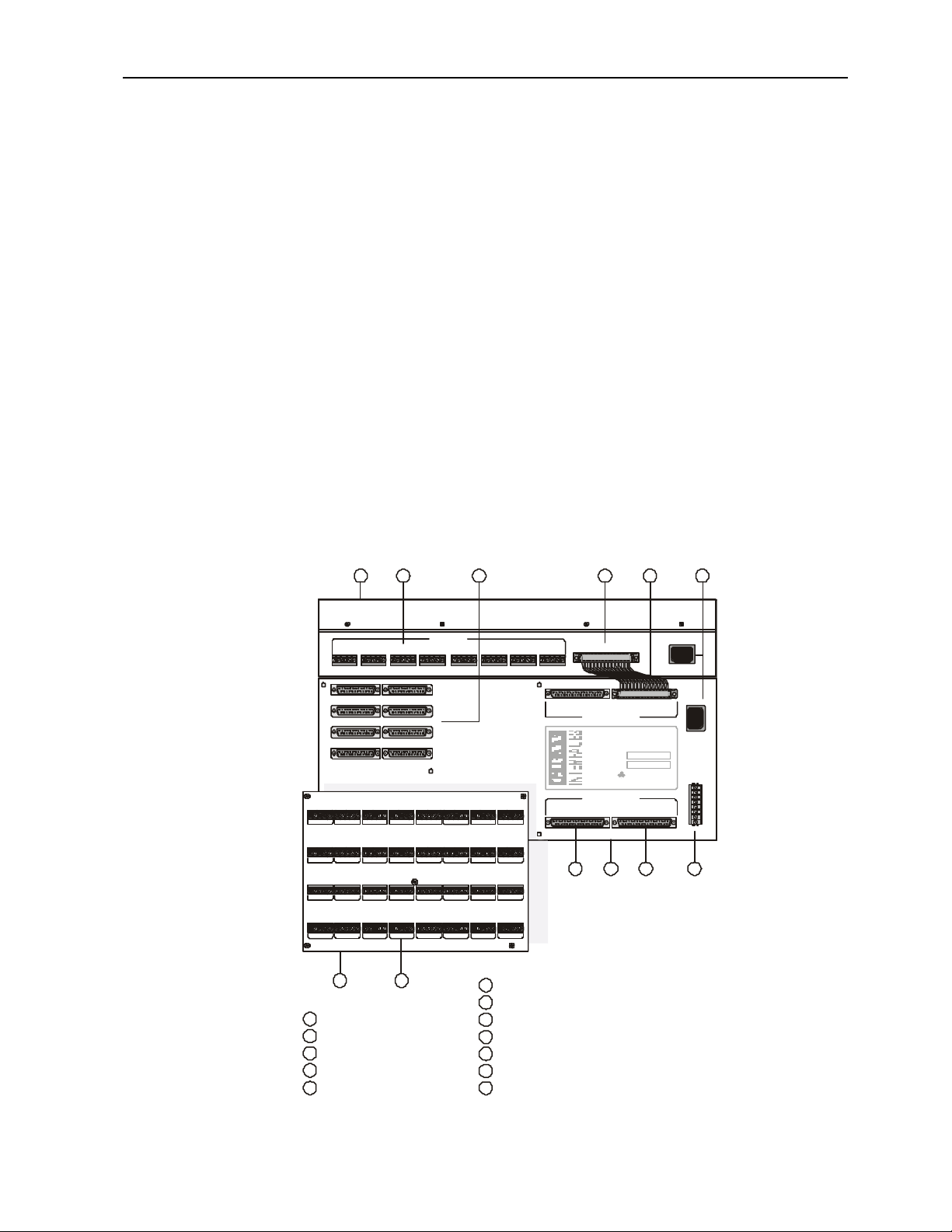

M OUNTING TERMINATION BOARDS

One of two types of cable termination boards are normally supplied with

the system to provide the physical interface between the DMXPathfinder LR

Output Modules and external station cabling.

Model P2020 32-way terminal block transition boards are the most

commonly used method of connecting the DMX output station cabling. These

A

B G C D

DMX INPUTS

PORT H

1 1 1 1 1 1 1 12 2 2 2 2 2 2 23 3 3 3 3 3 3 34 4 4 4 4 4 4 45 5 5 5 5 5 5 5

J2 J1

OUTPUT 5-8 OUTPUT 1-4

J4 J3

OUTPUT 13-16 OUTPUT 9-12

J6 J5

OUTPUT 21-24 OUTPUT 17-20

J8 J7

OUTPUT 29-32 OUTPUT 25-28

TB8

TB7

TB16

TB15

TB24

TB23

TB32

TB31

PORT FPORT G

TB6

TB5

TB4

TB3

TB2

TB14

TB13

TB12

TB11

TB10

TB22

TB21

TB20

TB19

TB18

TB30

TB29

TB28

TB27

TB26

F

G

Input Module, 8-way

A

DMX Input Terminal Blocks

B

H

J

KC

Linking Cable, 37 conductor

Mains Power Supply Input

E

LD

M

E

CABLE A THRU

POWER

100-240V 50/60Hz

J9

CABLE A IN

POWER IN

100-240V

50/60Hz

PC-COM

CPS

TxD

RxD

COM

TxD+

TxDRxD+

RxD-

J11

J13

PORT APORT BPORT CPORT DPORT E

INTER-MODULE BUS

J10

CABLE B IN

INTER-MODULE BUS

DMX Pathfinder LR

32-WAY OUTPUT MODULE

MODEL NUMBER

SERIAL NUMBER

100-240 VAC

50/60Hz 1.0A

MADE IN CANADA

INTER-MODULE BUS

TB1

TB9

TB17

TB25

CABLE B THRU

J12

JMLF H K

Processor / Output Module, 32-way

DMX Output Connectors, 4-way (DB25F)

Inter-Module Bus Connector, 1-8 Inputs (DB37F)

Inter-Module Bus Connector, 9-16 Inputs

PC Communications Connection, RS232/RS485Inter-Module Bus Connection

Output Terminal Adapter Board, 32-way

DMX Output Terminal Blocks, 2 piece

5

Page 7

DMXPathfinder LR Installation & Assembly

boards mount directly to the rear of each output module using five 6-32

standoffs and screws. They electrically connect to each Output Module with

eight 25-pin D-style connectors, therefore a certain amount of force is required

to mate the two parts. Ensure that all 8 connectors are fully mated and that the

board is resting on the standoffs before installing the five screws.

If the DMXPathfinder LR is to be installed in a swing-out (hinged) type of

equipment rack, a different type of termination board is usually supplied, the

DMS-16LT type. These are 16-way boards, intended for mounting in the rear of

the equipment rack, on the rear service panel or on 4U rack panels supplied by

the installer or the factory, depending on project requirements. 25-conductor

twisted pair ribbon cables, 1-meter long, interconnect these boards with the rear

of the DMX Pathfinder LR Output Modules. Two termination boards should be

installed side-by-side on each panel. We recommend the use of 3/8"-1/2" 6-32

threaded standoffs and 1/4" screws to attach the boards to the mounting panels.

Insulated hardware is not necessary.

Using DMS-16LT termination boards, mounting and external station

cabling may be completed well in advance of installation of the rest of the

DMXPathfinder LR hardware.

I/O CABLE INSTALLATION

Input and Output cabling may enter the equipment rack through the top or

bottom. Bundle cables at either side of the rack, just in front of the termination

boards. Cabling installed to the rear of the rack from the panels will obscure

access to terminal blocks at the extreme edges of the termination boards.

Cables are then dressed into place for connection at the input/output

terminal blocks. Note the order of the terminal blocks. On 32-way boards they

are labeled TB1 to TB32 and are arranged right to left, top to bottom. On 16way boards they are labeled TB1 to TB16 and are arranged top to bottom, left

to right.

M ODULE PREPARATION

Unpack all of the DMX Pathfinder LR system modules and accessories

and arrange on a flat surface. First, locate the package of screws supplied with

6

Page 8

DMXPathfinder LR Installation & Assembly

each module, and use 8-32 screws to attach the rack mount ears to the sides of

each Input and Output Module.

If P2020 type termination boards are to be used, mate them to each

Output Module and fasten with 5 x 6-32 screws.

Using one power cord, power up each Input and Output Module one at a

time and verify that the main power LEDs illuminate.

Remove the four adhesive rubber feet from the bottom of each module.

M ODULE INSTALLATION

Starting with the last (bottom) Output Module , install the modules into the

equipment rack. Normally the Input Module(s) are located above the Output

Modules, but they can both be placed at the bottom or one at the top and one at

the bottom, if desired. In any case they may not be placed between Output

Modules.

7

Page 9

DMXPathfinder LR Installation & Assembly

DMX INPUTS

PORT E

PORT F

PORT G

PORT H

111111111111111

222222222222222

333333333333333

444444444444444

555555555555555

DMX INPUTS

PORT E

PORT F

PORT G

PORT H

J2

OUTPUT 5-8

J4

OUTPUT 13-16

J6

OUTPUT 21-24

J8

OUTPUT 29-32

J2

OUTPUT 5-8

J4

OUTPUT 13-16

J6

OUTPUT 21-24

J8

OUTPUT 29-32

OUTPUT 1-4

OUTPUT 9-12

OUTPUT 17-20

OUTPUT 25-28

OUTPUT 1-4

OUTPUT 9-12

OUTPUT 17-20

OUTPUT 25-28

J1

J3

J5

J7

J1

J3

J5

J7

PORT D

PORT D

PORT C

PORT C

PORT B

PORT B

Input Module #1

(inputs 1 - 8)

Input Module #2

(inputs 9 - 16)

Output Module #1

(outputs 1 - 32)

Output Module #2

(outputs 33 - 64)

CABLE A THRU

CABLE A THRU

POWER

100-240V 50/60Hz

POWER

J9

CABLE A IN

CABLE A IN

POWER IN

100-240V

50/60Hz

PC-COM

CPS

TxD

RxD

COM

TxD+

TxDRxD+

RxD-

J11

J13

J9

POWER IN

100-240V

50/60Hz

PC-COM

CPS

TxD

RxD

COM

TxD+

TxDRxD+

RxD-

J11

J13

INTER-MODULE BUS

PORT A

PORT A

1

2

3

4

5

J10

CABLE B IN

INTER-MODULE BUS

DMX Pathfinder LR

32-WAY OUTPUT MODULE

MODEL NUMBER

SERIAL NUMBER

100-250 VAC

50/60Hz 1.0A

MADE IN CANADA

INTER-MODULE BUS

CABLE B THRU

J12

J10

CABLE B IN

INTER-MODULE BUS

DMX Pathfinder LR

32-WAY OUTPUT MODULE

MODEL NUMBER

SERIAL NUMBER

100-250 VAC

50/60Hz 1.0A

MADE IN CANADA

INTER-MODULE BUS

CABLE B THRU

J12

J9

TB8

TB7

TB6

TB5

TB4

TB3

TB2

TB16

TB15

TB14

TB13

TB12

TB11

TB10

TB24

TB23

TB22

TB21

TB20

TB19

TB18

TB32

TB31

TB30

TB29

TB28

TB27

TB26

CABLE B IN

TB1

TB9

TB17

CABLE B THRU

TB25

CABLE A IN

INTER-MODULE BUS

DMX Pathfinder LR

32-WAY OUTPUT MODULE

MODEL NUMBER

SERIAL NUMBER

100-240 VAC

50/60Hz 1.0A

MADE IN CANADA

INTER-MODULE BUS

CABLE A THRU

POWER IN

100-240V

50/60Hz

Output Module #3

PC-COM

CPS

TxD

RxD

COM

TxD+

TxDRxD+

J11

RxD-

J13

(outputs 65 - 96)

Locate the 37-conductor ribbon cable jumpers and 37-pin bus

terminator(s). There should be one 7” long cable per Input Module and one or

two 3.5” short cables per Output Module. If only one Input Module is supplied,

only one bus cable set will be used.

Attach one long jumper cable from the first Input Module to the top InterModule Bus connector marked “CABLE A IN”. Attach the other from the second

Input Module (if supplied) to the connector marked “CABLE B IN”.

Install the short ribbon cable jumpers between Output Modules. The

bottom connector marked CABLE A(B) THRU on one module connects to the

top (IN) connector on the next lower module in all cases.

Install the 37-pin bus terminator plug(s) at the bottom or last unconnected

CABLE A and B THRU jacks in the system.

8

Page 10

DMXPathfinder LR Installation & Assembly

Remember that for systems with only one input module, only the CABLE A

jacks need ribbon cable jumpers and the bus terminator installed.

I/O CABLE CONNECTION

Strip back about 3 inches (8cm) of cable jacket and braid shield from each input

or output cable. Apply a 2.5" (6.5cm) piece of 1/16" heat shrink to the drain wire

and a 1" (2.5cm) piece of 3/8" heat shrink over the exposed braid ends where

each cable was stripped. These precautions are to ensure that cable shields

cannot contact each other or equipment ground.

Strip about 1/2" of insulation from the four signal wires in each cable.

Bend over 1/4" of the exposed conductors on all five wires and connect them to

the terminal block. Note that each five-position terminal block is numbered 1

thru 5 on the termination board. This corresponds to the pin numbering on XLR

5-pin connectors, that is:

Pin 1 -- Signal Common (shield)

Pin 2 – DMX Data (-)

Pin 3 – DMX Data (+)

Pin 4 – Talkback Data (-)

Pin 5 – Talkback Data (+)

Be sure to use one twisted pair for the DMX data and the other for Talkback

data. It is also good practice to label each station cable and corresponding

terminal block header position with the cable number.

Input Modules are provided with both 5-position rear mounted terminal blocks

and parallel 5-pin XLR male faceplate jacks. In some installations, the

hardwired cable terminates at female jacks mounted on an auxiliary panel. In

this case, no connection is made to the Input Module’s rear terminal blocks;

instead short XLR patch cables are used to interconnect the auxiliary panel

jacks with the Input Module’s faceplate jacks.

9

Page 11

DMXPathfinder LR Installation & Assembly

PC-COM CABLE CONNECTION

Each Output Module is provided with an 8-position rear-mounted terminal block

for connection to the system’s personal computer. Two separate ports are

provided: an RS232 port and an RS485 port. There is also a 10VDC phantom

power supply available for powering an optional RS232/485 converter. All

connections are electrically isolated from the rest of the system, so that the PC

connection can be made without concern for ground loops or common mode

voltage problems.

Two or more PCs may be connected to a DMXPathfinder LR system

simultaneously. One can be connected to the RS232 port and another to the

RS485 port on the first Output Module, and two more to the second Output

Module, and so on. For example, say three locations are needed to connect a

PC to the system, all using RS485. If there are at least 3 Output Modules, each

of the three connections can be made at a separate module.

The following is a description of each connection from top to bottom:

CPS – Converter Power Supply, 10VDC @ 50mA

TxD – RS232 Transmit Data

RxD – RS232 Receive Data

COM – Power Supply & Signal Common

TxD+ -- RS485 Transmit Data (+)

TxD- -- RS485 Transmit Data (-)

RxD+ -- RS485 Receive Data (+)

RxD- -- RS485 Receive Data (-)

RS232/485 COMMUNICATIONS

Each system includes an RS232-RS485 converter for optional use with the

system’s Personal Computer. The maximum cable length for RS232

connections is 50 feet (15 meters). The converter is unnecessary if the PC is

less than that distance from the Pathfinder rack. Below are the connections

required for the PC’s RS232 COM port :

Pin 1 – Carrier Detect

Pin 2 – Receive Data (connect to Pathfinder “TxD” terminal)

Pin 3 – Transmit Data (connect to Pathfinder “RxD” terminal)

Pin 4 – Data Terminal Ready

10

Page 12

DMXPathfinder LR Installation & Assembly

Pin 5 – Power & Signal Common (connect to “COM” terminal)

Pin 6 – Data Set Ready

Pin 7 – Request to Send

Pin 8 – Clear to Send

Pin 9 – Ring Indicate

Only pins 2, 3 and 5 are required to connect for RS232 communications.

If the RS232/485 converter is to be used, it is strongly recommended that a 3-

pair or 4-pair RS422/485 rated twisted pair data cable is used for the

connection to the DMXPathfinder LR. Category-5 UTP cable works well. If you

are installing Cat-5 UTP, use two pairs for data and the other two for power.

The converter has 9-pin D-style connectors at both ends. One end is marked

“PC COM”, and this end will plug directly into a 9-pin male COM port on the PC.

The following is this connector’s pinout (with respect to PC COM port):

Pin 1 – Carrier Detect (Common)

Pin 2 – Receive Data

Pin 3 – Transmit Data

Pin 4 – Data Terminal Ready

Pin 5 – Signal Common

Pin 6 – Data Set Ready (Common)

Pin 7 – Request to Send

Pin 8 – Clear to Send

Pin 9 – Ring Indicate (Common)

If the converter is accidentally plugged in backwards, no damage will result. You

will have to make up an adapter cable with a 9-pin male end to connect to the

converter from the Pathfinder. The following is this connector’s pinout:

Pin 1 – Receive Data + (connect to Pathfinder “TxD+” terminal)

Pin 2 – Receive Data - (connect to Pathfinder “TxD-” terminal)

Pin 3 – No Connection

Pin 4 – Power Supply Input (+9-12VDC – connect to “CPS” terminal)

Pin 5 – Power Supply & Signal Common (connect to “COM” terminal)

Pin 6 – No Connection

Pin 7 – No Connection

Pin 8 – Transmit Data - (connect to Pathfinder “RxD-” termin al)

Pin 9 – Transmit Data + (connect to Pathfinder “RxD+” terminal)

Note that when connecting full duplex RS232 or RS485 systems, Transmit Data at one

end connects to Receive Data at the other end.

11

Page 13

DMXPathfinder LR Installation & Assembly

T ESTING THE INSTALLATION

Once all connections are made and inspected for errors, you can power up the

DMXPathfinder LR modules in the equipment rack. With no DMX source

signals present, all eight red Isolated Power LEDs on the face of each Input

Module should be illuminated. On each Output Module, the green Processor

OK and Main 5V Power LEDs should be illuminated. If, in addition, the green

Crosspoint OK LED is on, this does not indicate a problem.

At this point, refer to DMXPathfinder LR Installation and User Guide, Chapter 2

– Communications Setup to get the PC talking to the Pathfinder. Once that has

been done, go to Chapter 5 – Diagnostics and Troubleshooting and perform the

health check and loopback tests on the installation.

12

Page 14

DMXPathfinder LR Maintenance & Testing

Chapter 2: Maintenance & Testing

CARD REPLACEMENT

Should a defective component be found in an Output Module or other

module during troubleshooting, it is best to replace the suspected defective

circuit card with a spare unit and re-test. Powering down the entire

DMXPathfinder, or at least the specific module, is recommended before

removing or inserting cards.

To replace an Output Module card, first remove loosen the four front panel

Phillips screws and the panel, then grasp the card stiffener bracket (or ejector

handles), and pull the card straight out of the module chassis. Carefully align the

replacement circuit board into the chassis' left and right card guides and slide

the unit in until it protrudes about 5mm, then push the module firmly into its

mating backplane receptacles. The card is not fully seated unless its front edge

is flush with the front of the metal chassis.

If the CPU card was replaced, check that the rotary and DIP switches have

been set the same as the replaced card.

Before replacing the front cover, first restore power and depress the

RESET pushbutton on the first Input Module until the system resets (Processor

OK LED goes out). Then re-test the system to ensure that the fault has been

corrected. If the entire rack was powered off, it is unnecessary to press RESET

since a system-wide reset cycle always occurs automatically on power-up.

If you forget to press the RESET pushbutton after module replacement, the

function can be initiated from the DMXQConnect program at the personal

computer.

T EST PROCEDURES

System testing by maintenance personnel will usually be carried out in

response to a fault that has developed somewhere in the system. Powerful

diagnostic instruments are available to assist maintenance technicians with this

task: the Fluke Model 650 LAN Cable Meter, and Goddard Design Li'l DMX'ter,

amongst others. These will be described in more detail below. In general,

though, the procedures outlined in Chapter 5 and the troubleshooting

instructions in this Chapter are likely to help solve the vast majority of problems

encountered, especially where any system downtime cannot be tolerated.

13

Page 15

DMXPathfinder LR Maintenance & Testing

Tests using instrumentation will be performed where anomalies have

developed in the system that cannot be isolated with standard troubleshooting

procedures. Additionally, testing can establish minimum network performance

where non-DMX512 control equipment is to be connected to the system.

Fluke 650 Cable Meter -- Please refer to the manufacturer's user's

manual for detailed instructions and theory before attempting to use this

instrument. It’s not obvious to the first time user! The Fluke 650 is provided with

a battery-powered remote plug-in unit, a set of 2 adapter cables (RJ45 to 5-pin

XLR) and an AC adapter. The unit may be powered by a 9-volt alkaline battery,

but battery life tends to be rather short with the 650 so use of the AC adapter is

recommended.

When the remote unit is connected to the other end of any DMX cable run,

the 650 will verify wiring continuity on all pins except ground (pin 1). Cable

length can also be measured with the instrument, and any anomalies, e.g.

changes in line impedance will be detected. The 650 measures performance of

the cable installation at up to 10 million bits per second.

The Fluke 650's signalling is not compatible with the DMX Pathfinder LR

electronics or any other DMX generating or receiving equipment. Thus its

usage should be confined to the cable installation only.

Goddard Design Li'l DMX'ter -- This useful instrument can test most

aspects of the DMX Distribution System, from wiring continuity to signal

propagation through the Pathfinder electronics. Since the DMX'ter can both

generate and receive DMX512, it is 100% compatible with all aspects of the

distribution system, including any control system or receiving device. The

DMX'ter will directly control any receiving unit, and will verify the output of a

controller by displaying the data on an LCD readout. In addition, the instrument

will test cable continuity on all five XLR pins. Please refer to the Li'l DMX'ter

Operating Manual for more information.

Other Test Equipment -- The maintenance technician will find the

following additional test equipment useful:

.1 Oscilloscope -- for viewing data in conjunction with the

DMX'ter and its scope trigger module; for checking that both differential signals

are present on a given data line; for evaluating the performance of crosspoint

matrix and opto-repeater circuitry at higher operating speeds (greater than 250

Kbits per second).

14

Page 16

DMXPathfinder LR Maintenance & Testing

.2 Frequency Generator -- for testing crosspoint matrix and

opto-repeater high-speed performance. Useful for evaluating whether other

systems with higher data rates can be used in the network.

.3 Digital Volt/Ohm Meter -- a general purpose tool for

checking continuity, termination resistor values and power supplies.

ADVANCED T ROUBLESHOOTING

As described earlier, basic troubleshooting usually involves isolating a

troublesome or defective opto-repeater circuit, card or module and replacing it

with a known good one. It may also include checking for obvious things such as

incorrect addressing or DMX protocol incompatibility with DMX receiving

devices, absence of a line terminator, defective DMX patch cables, or even

incorrect control console configuration.

Once all basic troubleshooting checks have been completed, without the

desired resolution of the problem, more sophisticated faultfinding may be

carried out. It is recommended to use a portable computer connected to the

RS232 PC-COM port on one of the Output Module s so that test patching and

diagnostics can be done right at the DMX Pathfinder itself. First, however, try

swapping input or output cable connections on the back of the Pathfinder

modules with adjacent ones to use a different receiver and transmitter circuits.

Next, a DMX tester should be used to either transmit DMX in place of the control

console, or receive DMX in place of the receiving device(s). Check the

receiving device by connecting the DMX tester directly to it in transmit mode.

Then set the tester to receive mode and monitor the data coming to the

Pathfinder from the console, by plugging into the Input Module faceplate XLR

with a female-female cable. If this test does not point to the data source or the

receiving device as being the cause of the problem, there may be a slight

incompatibility between them as far as DMX512 is concerned. However, if the

two units had previously worked together, these tests will point to a problem in

the DMX cable installation or in one of the DMXPathfinder modules.

At this point, the suspect Output Module’s output card or should be

withdrawn from its chassis and the spare unit inserted in its place (remember to

power down before withdrawing or inserting any cards). If this proves that the

original unit is defective, inspect the card for signs of damage or any other

obvious cause. Return the defective card to the factory for repair unless you

have the facilities to carry out your own service. For more serious defects, such

as power supply or fan failure, disconnect the entire module and take it to the

test bench for repair, or return it to the factory. DMXPathfinder LR modules are

not difficult to service with basic tools and test equipment. If the suspect module

15

Page 17

DMXPathfinder LR Maintenance & Testing

proves to be good, test the DMX cable installation for open or shorted lines

using the DMX QConnect loopback test diagnostic (see Chapter 5). A similar

test can be done for input cabling.

If the above tests yield passing results and the problem persists, it may be

necessary to use the Fluke LAN Cable Meter to do a high-frequency analysis of

the suspect cable runs. This test will quickly indicate any anomalies having to

do with cable impedance and capacitance that would result in excessive signal

distortion or attenuation. This test will help to locate less-obvious problems such

as pinched or over-heated cabling that cannot be found with simple continuity

checks.

DMXPathfinder LR Installation and User Guide, Chapter 5 covers the

easy to use diagnostic features of the DMXQConnect software. The

diagnostics can be used to check for defective Pathfinder internal hardware and

to carry out system maintenance procedures such as cable and termination

integrity checks. Please take the time to familiarize yourself with the capabilities

of these diagnostics as they have the potential for helping to save a great deal

of effort and system downtime.

SYSTEM RESET

Under normal conditions, the user never needs to interact with any part of

the DMXPathfinder LR module installation. Exceptions to this might include

checking the LED status as described previously, or having to recover from a

temporary component failure or when service and card replacement is being

carried out.

A “System Reset” pushbutton has been provided on the face of each Input

Module for the latter purpose. It’s important to remember that only the reset

button on the first Input Module is active. If you depress either one, however, you

will assume that both are inactive as nothing will happen. You will need to

depress and hold the correct one for at least two seconds to initiate a reset

cycle. The external reset function was designed this way to help prevent anyone

from accidentally resetting the DMX Pathfinder and momentarily interrupting the

flow of DMX data through it.

16

Page 18

DMXPathfinder LR Index

INDEX

9

9-pin D-style connectors · 10

A

Advanced Troubleshooting · 14

Ambient temperature · 3

Assembly · 3

B

bus terminator · 8

C

CABLE A IN · 8

CABLE A(B) THRU · 8

CABLE B IN · 8

cabling · 6

Card Replacement · 12

Cat-5 UTP cable · 10

COM · 10

COM port · 10

control console · 14

Cooling · 3

CPS · 10

CPU · 12

Crosspoint OK LED · 11

D

diagnostic instruments · 12

diagnostics · 14

Digital Volt/Ohm Meter · 14

DIP switches · 12

DMS-16LT · 6

DMX · 2, 11

DMX Data · 9

DMX distribution system · 13

DMX'ter · 13

E

Environmental Considerations

· 3

equipment rack · 3, 4, 6, 7, 11

F

Fan · 3

Frequency Generator · 14

G

Goddard Design · 13

ground loops · 10

H

humidity · 3

I

I/O Cable Connection · 9

I/O Cable Installation · 6

Input Module · 5, 7, 11

Installation · 3

installer · 4

Inter-Module Bus connector · 8

Isolated Power LED · 11

L

LAN Cable Meter · 12, 13, 15

LED status · 15

Li'l DMX'ter · 12, 13

Loopback Test · 15

M

Main 5V Power LED · 11

Module Installation · 7

Module Preparation · 6

O

opto-repeater · 14

Oscilloscope · 13

output card · 14

Output Module · 5, 6, 7, 9, 10,

11, 12, 14

P

P2020 · 5, 7

PC COM · 10

PC-COM Cable Connection · 9

PC-COM port · 14

personal computer · 9, 10

pinout · 10

Power Requirements · 4

Processor OK LED · 11, 12

R

Rack Placement · 4

Rack Sizing · 4

Relative humidity · 3

RESET · 12

ribbon cable · 6, 8

RS232 · 9, 14

RS232/485 converter · 10

RS485 · 9

rubber feet · 7

RxD · 10

S

Signal common · 9

System Reset · 15

System testing · 12

T

Talkback · 9

temperature · 3

terminal block · 5, 6, 9

termination boards · 3, 5

Test Procedures · 12

TESTING · 12

Testing the Installation · 11

transition boards · 5

troubleshooting · 12, 14

TxD · 10

U

UTP cable · 10

17

Page 19

DMXPathfinder LR Index

V

vent · 4

X

XLR · 9, 14

18

Loading...

Loading...