Page 1

HINxxy12BC/24BC/48BC

Basic Control Lighting P anel Interior

Installation and Setup

Installation Instructions

The HINxxy12BC/24BC/48BC is the lighting

control panel interior for the Basic Control

system.

The interior provides isolation between the line- and

low-voltage sections of the panel, as well as the

mounting frame for relays, the power supply and

optional control devices.

A complete panel assembly also includes one each of

the following:

1.Tub (HTUB series)

2.Cover (HCVR series)

3.Power Supply (HPSM115/277)

Santa Clara, CA 95050 © 2001 The Watt Stopper,® Inc.

Features

• From 12 to 48 plug-in relays

(Reliant Relay H2R series or GE RR series)

• Two color-coded, numbered switch/sensor terminations per relay

• Mounting holes for optional control devices

• Accessory power for optional occupancy sensors

Before starting, read the instructions on the next

three pages. If you have any questions, call our

Service Team at: 888-852-2778.

Retain these instructions and the completed

WIRING SCHEDULE card in the plastic sleeve

affixed to the rear of the panel cover.

Page 2

HINxxy12BC/24BC/48BC Lighting Control Panel Interior — Installation and Setup

This interior is intended for field

installation within the enclosure of

another product.

Refer to installation instructions

INHTUB and INHCVR for installation

of the Watt Stopper Tubs and Covers.

The following instructions assume

that a UL listed enclosure has been

properly installed.

CAUTION: Make sure all power is off

before wiring. Do not energize wiring

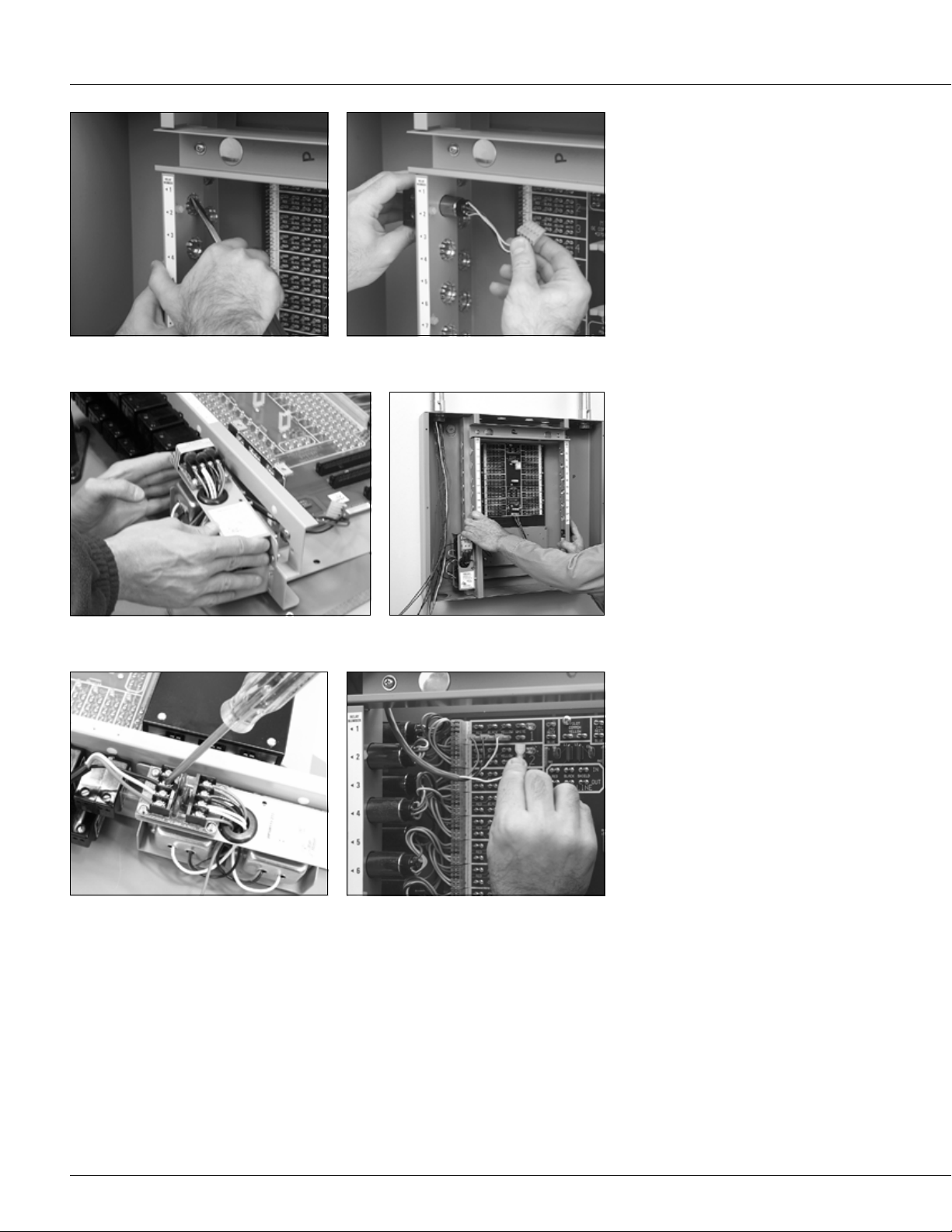

Remove knockouts as required. Install relays in the frame if necessary.

until the unit is fully assembled.

Conform to all applicable codes.

Environment

• 32° to 131°F (0° to 50°C)

• 95% relative humidity

• 15 volts/meter, 10 KHz maximum RFI

Relays

Install the power supply. Mount the interior to the studs in the tub

Making sure all power is off, connect lighting circuit

wiring to the relays and line-voltage wiring to the

power supply.

with the hardware supplied.

Connect low-voltage wiring from switches, sensors

and other input devices to the terminals on the

motherboard.

Use only Reliant Relay H2R7P/H2R9P

or GE RR7P/RR9P relays. Remove only

as many knockouts as required. From

the line-voltage side, feed the lowvoltage relay connector and leads

through the hole and plug the connector

to the appropriate relay termination on

the motherboard. Push the relay into the

hole so the retainers hold it in position.

Power Supply

Attach the HPSM115/277 power supply

to the bottom of the frame on a 12-relay

interior, or to the left side of the frame on

a 24- or 48-relay interior, and plug the

low-voltage connector to the termination

marked J1 on lower center of the

motherboard.

Mounting

Mount the interior in the tub and secure

it to the studs with the hardware supplied.

Make sure that all line- and low-voltage

wiring is confined to the appropriate areas.

2

Page 3

HINxxy12BC/24BC/48BC Lighting Control Panel Interior — Installation and Setup

Wiring

Line voltage

Before making connections to the

relays make sure that none of the

load circuits are shorted or miswired.

Connect the lighting circuits to the relay

SPST output terminals. Wire the power

supply, following the instructions which

accompany the unit. Connect the ground

wire to the stud provided in the tub.

Low voltage

Wire switches as shown in Figure 1. Wire

sensors and other low-voltage control

devices as shown in the installation

instructions accompanying the devices.

3

Use

⁄16" push-on terminals and wire ties.

Power Up and Test

Apply power to the power supply only

Figure 1 – Typical Wiring — Low-Voltage Switches

STANDARD SWITCH

LOCATION SWITCH

#20/3 AWG

1600 FEET MAXIMUM DISTANCE

HSSW3 (standard class)

HSSW3P (plenum applications)

#20/4 AWG

1600 FEET MAXIMUM DISTANCE

HOSW4 (standard class)

HOSW4P (plenum applications)

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

1

2

1

2

(

)

BLUE

ACCESSORY

POWER SUPPLY

24V 24V RECT WHITE

Using a low-voltage jumper attached to

any WHITE terminal, touch all of the

switch input RED terminals, and then

repeat for the BLACK terminals. The

relays should click on, then off. Confirm

by measuring the line-voltage terminations of the relay. Test the operation of

each low-voltage switch, sensor and

other control device according to the

individual installation instructions.

Test relays by touching each red and black switch

input terminal with a jumper connected to any white

terminal in the panel.

Document Wiring

Record the circuits controlled by each

relay on the Relay Schedule card

provided with these instructions and then

place it in the plastic sleeve attached to

the inside of the panel cover.

SINGLE SWITCH WITH

PILOT INDICATION

MULTIPLE SWITCHES

CONTROLLING

SINGLE RELAY

SINGLE (OR MULTIPLE)

SWITCH CONTROL

OF A GROUP

#20/4 AWG

1600 FEET MAXIMUM DISTANCE

HPSW4 (standard class)

HPSW4P (plenum applications)

#20/4 AWG

1600 FEET MAXIMUM DISTANCE

HPSW4 (standard class)

HPSW4P (plenum applications)

#20/4 AWG

MAXIMUM DISTANCE (See below)

NUMBER

RELAYS

PARALLEL

2

4

6

8

10

MAXIMUM

DISTANCE

WITH #20/4

750 FEET

325 FEET

180 FEET

110 FEET

65 FEET

FOR MORE THAN

TWO SWITCHES,

SPLICE CONTROL

LEADS

MAXIMUM

DISTANCE

WITH #16/4

1900 FEET

825 FEET

450 FEET

275 FEET

160 FEET

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

FOR MASTER PLATE,

USE HMSW25(P

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

RED BLACK YELLOW WHITE

1

2

1

2

)

Note: Relays 1, 2 and 3

are now permanently

1

wired as a group.

You can’t control them

individually.

2

If the pilot contacts are

wired in parallel as above,

turning ON any relay in

3

the group will cause the

pilot to light.

3

Page 4

HINxxy12BC/24BC/48BC Lighting Control Panel Interior — Installation and Setup

CAUTION: When the panel cover is

open, power to the panel must be off

at all times to avoid exposure to the

line-voltage wiring. If you remove the

cover while the panel is powered up,

use extreme caution. Do not touch

any wiring, particularly outside the

interior’s low-voltage barrier.

EMERGENCY SERVICE OR SUPPORT:

888-852-2778

Troubleshooting

If no relays respond to switches …

Check the power supply LEDs. If they

are off, check:

1.the power supply plug-in connection to

the motherboard terminal J1

2.the power feed circuit to the power

supply

If they are still off …

Replace the power supply.

If an individual relay does not

respond …

Remove the switch connections and

check the relay operation directly with a

jumper.

If it still does not work …

Turn off all power to the panel and

replace the defective relay.

Check power supply LEDs. Both should be on.

Test the relay. If defective, replace.

Note: The view shown above is of a Complete

Control lighting panel interior. It is representative of

Basic Control troubleshooting.

Relay Output Ratings

Both General Electric* RR7P/RR9P and

Reliant Relay* H2R7P/H2R9P relays

may be installed in The Watt Stopper

interiors, including those listed herein.

The GE R7P/RR9P relay output power

contacts are rated as follows:

20A Tungsten, 125VAC

20A Ballast, 277VAC

20A Resistive, 277VAC

1

⁄2HP @ 110-125VAC

1

1

⁄2HP@ 220-277VAC

The Reliant Relay H2R7P/H2R9P relay

output contacts are rated as follows:

20A Tungsten

20A Ballast

20A General use

1HP @ 120VAC, 50-60Hz

Compatibility with GE Total Lighting

Control enclosures

All Watt Stopper interiors are fully

compatible with respective GE tubs,

covers and power supplies as defined in

the table below. All Watt Stopper

warranties apply whether the interior is

used in a Watt Stopper or General

Electric enclosure.

The Watt Compatible Compatible

Stopper GE Tub/Co ver GE Po wer

Cat.# Cat.# Supply Cat.#

HINxxy12BC RTUB12/RCOV12xx RPWRxxx

HINxxy24BC RTUB24/RCOV24xx RPWRxxx

HINxxy48BC RTUB48/RCOV48xx RPWRxxx

In Watt Stopper interiors, the xx stands for the number of

installed relays and the y indicates the type: G for General

Electric or R for Reliant Relay.

* All trademarks are the property of the respective parties.

Panel Division 888-852-2778 INHINBC 071301

Loading...

Loading...