Page 1

P

P

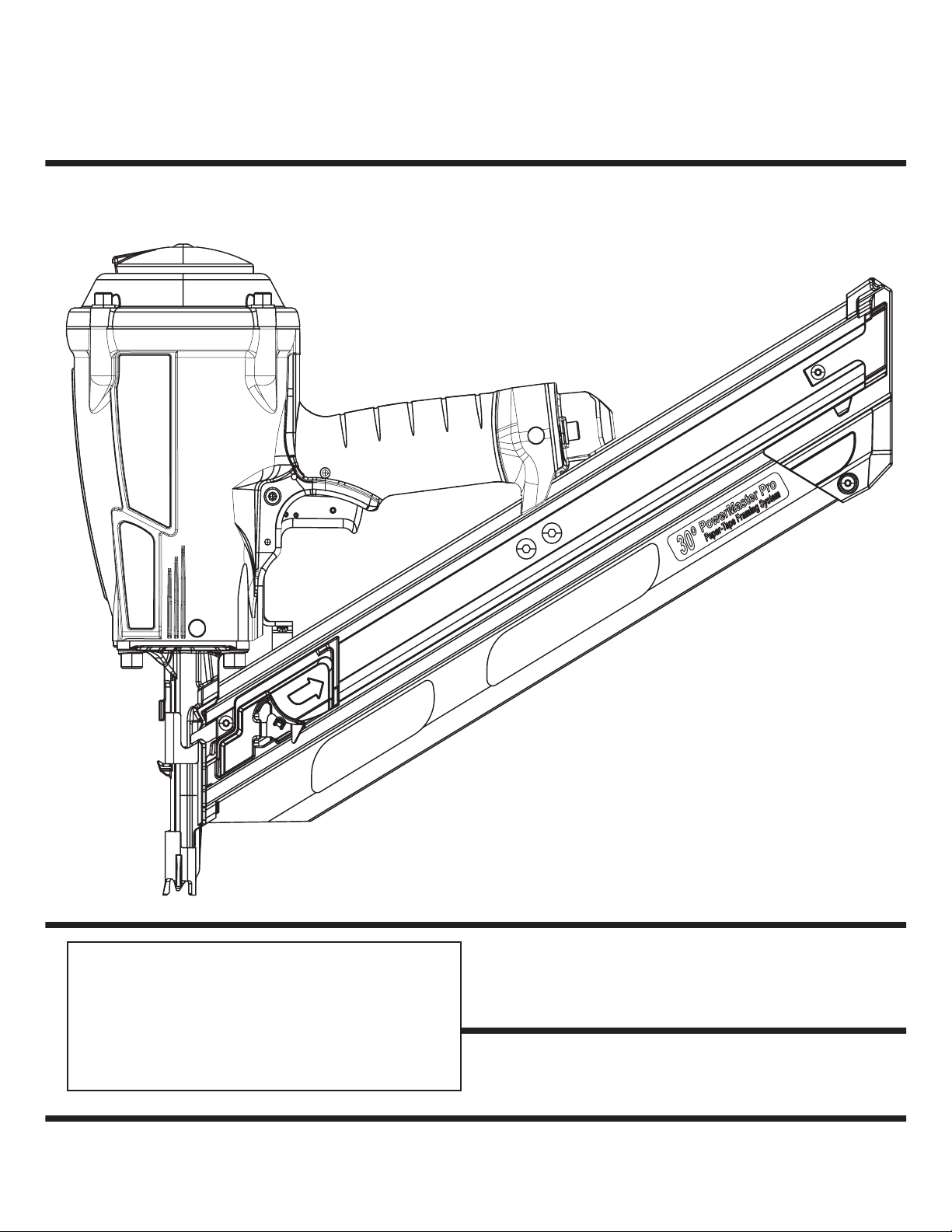

Power Master Pro

™

MODEL F-350P

Framing Nailer

IMPORTANT!

DO NOT DESTROY

It is the customers responsibility to have all

operators and service personnel read and

understand this manual.

PRINTED IN U.S.A.

© 2016, Illinois Tool Works Inc.

515022-5

11/16

OPERATING MANUAL AND

SCHEMATIC

1

Page 2

INTRODUCTION

3

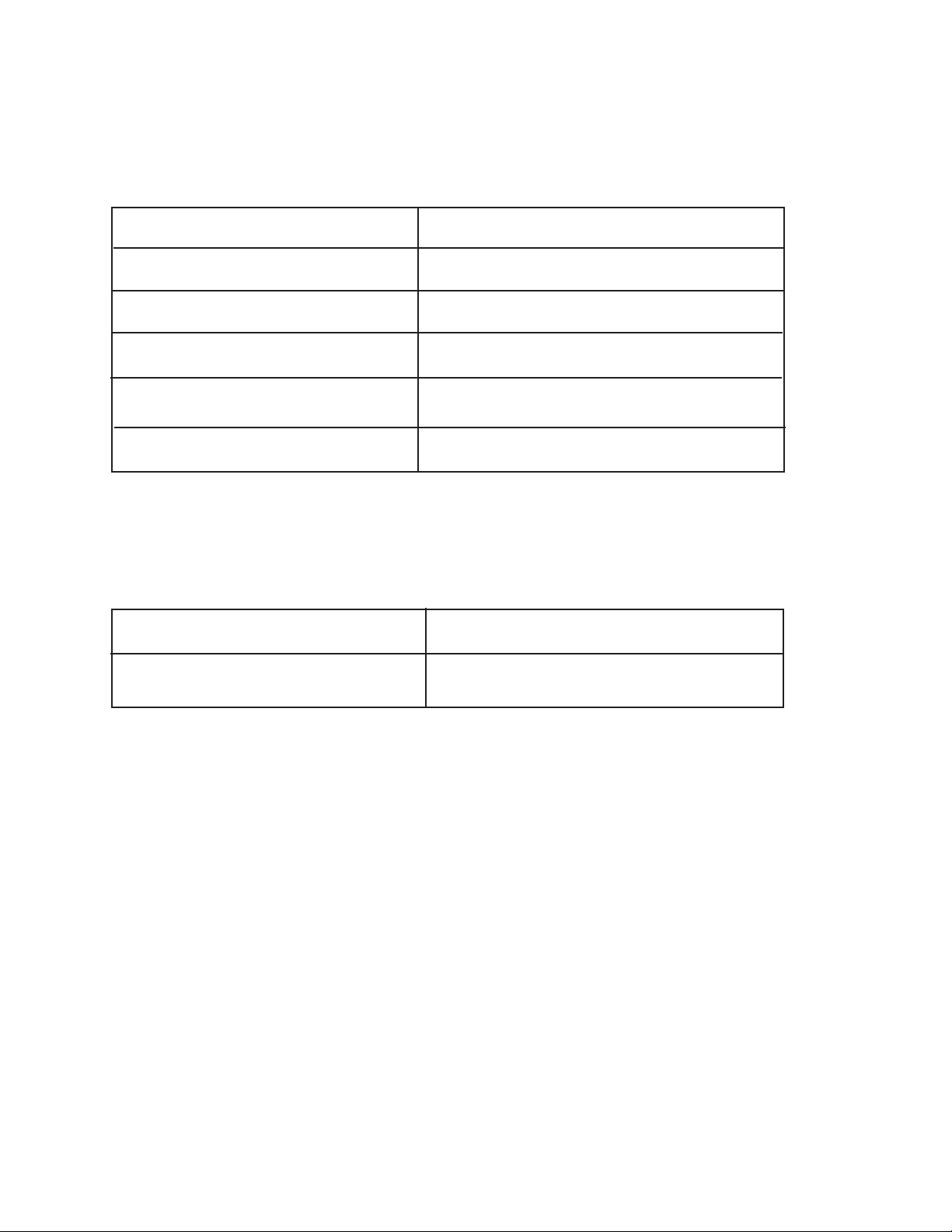

TOOL SPECIFICATIONS

MODEL NO. F-350P (Part# 515000)

HEIGHT

13.5”

WIDTH

5.5"

LENGTH

20.5"

WEIGHT 7 lbs. 13 oz.

OPERATING PRESSURE 80 to 120 p.s.i. (5.5 to 8.3 bars)

FASTENER SPECIFICATIONS

TOOL AIR FITTINGS

:

This tool uses a 3/8” N.P.T. male plug. The fitting must be capable of discharging tool air

pressure when disconnected from the air supply.

OPERATING AIR PRESSURE:

80 to120 p.s.i. (5.5 to 8.3 bars). Select the operating air pressure within this range

for best tool performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

NAIL LENGTH

2" - 3¼"

SHANK DIAMETER .113 - .131

TOOL AND FASTENER SPECIFICATIONS

The PASLODE

framing applications. This tool will deliver efficient, dependable performance when used

®

F-350P

framing nailer is a quality-built tool designed for use in residential

according to the manufactures guidelines. Please study this manual including the safety

instructions to fully understand the operation of this tool.

TOOL AND FASTENER SPECIFICATIONS ................................................................. 3

SAFETY INSTRUCTIONS ........................................................................................... 4

TOOL INSTALLATION AND OPERATION ................................................................ 5-6

AIR SYSTEMS ............................................................................................................. 7-8

FEATURES AND BENEFITS .......................................................................................... 9

EXPLODED VIEW AND SPARE PARTS LIST ....................................................... 10-11

MAINTENANCE ....................................................................................................... 12-13

TROUBLESHOOTING .................................................................................................. 14

WARRANTY .................................................................................................................. 15

ACCESSORIES ........................................................................................................... 16

2

Page 3

TOOL AND FASTENER SPECIFICATIONS

TOOL SPECIFICATIONS

MODEL NO. F-350P (Part# 515000)

HEIGHT

WIDTH

LENGTH

WEIGHT 7 lbs. 13 oz.

OPERATING PRESSURE 80 to 120 p.s.i. (5.5 to 8.3 bars)

13.5”

5.5"

20.5"

FASTENER SPECIFICATIONS

NAIL LENGTH

SHANK DIAMETER .113 - .131

2" - 3¼"

TOOL AIR FITTINGS:

This tool uses a 3/8” N.P.T. male plug. The fitting must be capable of discharging tool air

pressure when disconnected from the air supply.

OPERATING AIR PRESSURE:

80 to120 p.s.i. (5.5 to 8.3 bars). Select the operating air pressure within this range

for best tool performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

3

Page 4

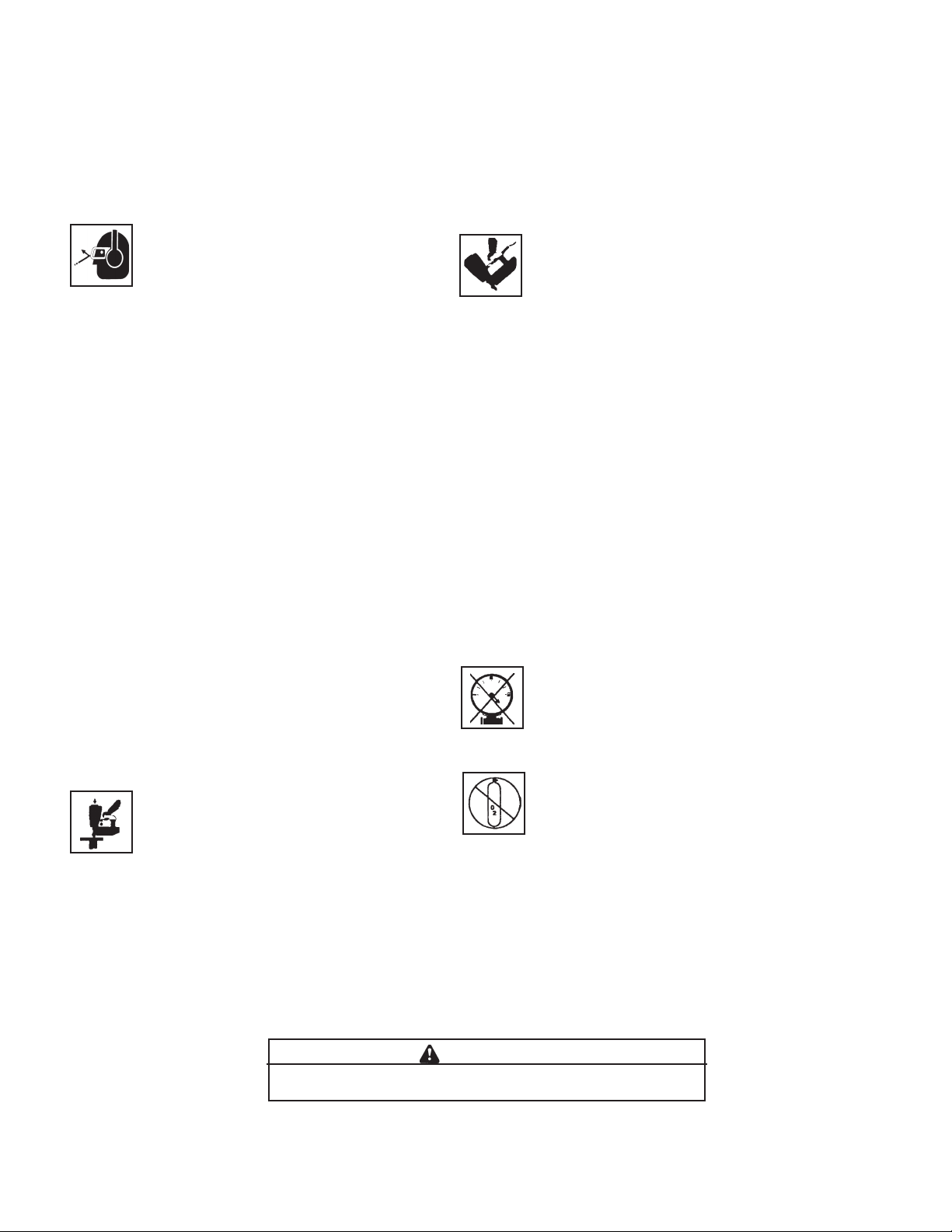

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary

for safe operation of Paslode

TO OPERATE THE TOOL UNTIL YOU READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS AND

MANUAL INSTRUCTIONS.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, that

conform to ANSI Z87.1 requirements, when operating

or working in the vicinity of a tool. As an employer you

are responsible for enforcing the use of eye protection.

Wear hard hats in environments that require their use.

THE TOOL MUST BE USED ONLY FOR THE PURPOSE FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor, strike the housing in

any way or use the tool as a hammer to knock material

into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never

engage in horseplay with the tool or point it at yourself

or any other person, even if you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the

tool. Even if you think the tool is empty or disconnected,

never point it at anyone or yourself. Unseen fasteners

could fire from the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with,

disabled or clamped in a locked or operating position

since this will cause the tool to drive a fastener any time

the work contacting element depressed.

DO NOT LOAD FASTENERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool be sure you

disconnect the air line and that you do not depress

the trigger or work contacting element.

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact

with the workpiece. Even then you should be careful

when fastening thin material or working near the edges

and corners of the workpiece since the fasteners may

drive through or away from the workpiece.

DO NOT DISABLE OR REMOVE THE WORK

CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called a

work contacting element, to help prevent accidental

firing. Never tamper with, disable or remove the work

contacting element. Do not use the tool unless the work

contacting element is working properly. The tool could

fire unexpectedly.

®

tools.

DO NOT ATTEMPT

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it

is not in use, when you leave the work area or when

moving the tool to a new location. The tool must

never be left unattended because people who are

not familiar with the tool might handle it and injure

themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry

the tool by the air hose or with the trigger depressed

since you could drive a fastener unintentionally and

injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never

be weakened by having your companyʼs name, area of

work or anything else stamped or engraved into its

surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you

have disconnected the tool from the air line and removed

all remaining fasteners from the tool.

ALWAYS USE THE PROPER FITTING FOR THE

TOOL

Only MALE pneumatic type air connectors should be

fitted to the tool, so that high pressure air in the tool is

vented to atmosphere as soon as the air line is disconnected.

NEVER install FEMALE quick disconnect couplings on

the tool. Female couplings will trap high pressure air in

the tool when the air line is disconnected, leaving the

tool charged and able to drive at least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

.erusserp ria dednemmocer eht ta ylno loot eht etarepO

Do not exceed the maximum air pressure marked on

the tool. Be sure the air pressure gauge is operating

properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to

operate the tool since they could cause the tool to

explode. Do not operate in explosive atmospheres.

INSPECT TOOL FOR PROPER OPERATION

.deriuqer sa etacirbul dna yliad tsael ta loot eht naelC

Never operate a dirty or malfunctioning tool.

USE ONLY PASLODE RECOMMENDED PARTS AND

FASTENERS

Use only parts and fasteners specifically designed and

recommended by Paslode for use in the tool and for

work to be done. Using unauthorized parts and fasteners

or modifying the tool in any way creates dagerous

situations. Replace all missing warning labels. Refer

to tool schematic for correct placement and part number.

WARNING

Failure to follow any of the above instructions could result in severe personal

injury to tool user and bystanders or cause damage to tool and property.

Contact your local Paslode Representative for presentation of Paslodeʼs Safety Awareness Program

4

Page 5

TOOL INSTALLATION

Your Paslode tool comes ready for immediate use

and can be installed by following these steps:

1. SAFETY - All tool operators and their immediate

supervisors must become familiar with the operator

safety instructions before operating the tool. The

instructions are on page 4 of this manual.

2. Included with each tool are one copy of this

Safety and Maintenance manual and one copy of

the Tool Schematic. Keep these publications for

future reference. An ownership registration card is

also included. This card must be completed and

returned to Paslode immediately to register your

ownership.

TOOL OPERATION

Depth of Drive Adjustment

(On tools equipped with this feature)

The depth of drive adjustment is made by turning the thumbwheel on the work contact element.

If the tool is overdriving (the fastener head is

driven below the work surface), the work contact element should be moved downward. If

the fasteners stand up (the head not flush with

the surface), the work contact element should

be moved up.

3. The plastic cap in the air inlet of the tool must be

removed before the male fitting is installed. The

fitting must be a male pneumatic type that discharges

the air from the tool when the air line is disconnected.

4. Install a filter/regulator/lubricator unit, with a

gauge as close as practical to the tool, preferably

within ten feet. Refer to the Air Systems section of

this manual for air hose requirements and lengths.

In general, no other special installation is required.

5. If the operator is working at a bench or table,

it is usually best to run the air line underneath the

bench. A small tray under the benchtop can hold

the fastener supply and the tool when not in use.

6. If this tool does not work when it is first connected, do not try to make repairs. Call your Paslode

representative immediately.

Adjust the work contact element until the fastener head depth meets job requirements.

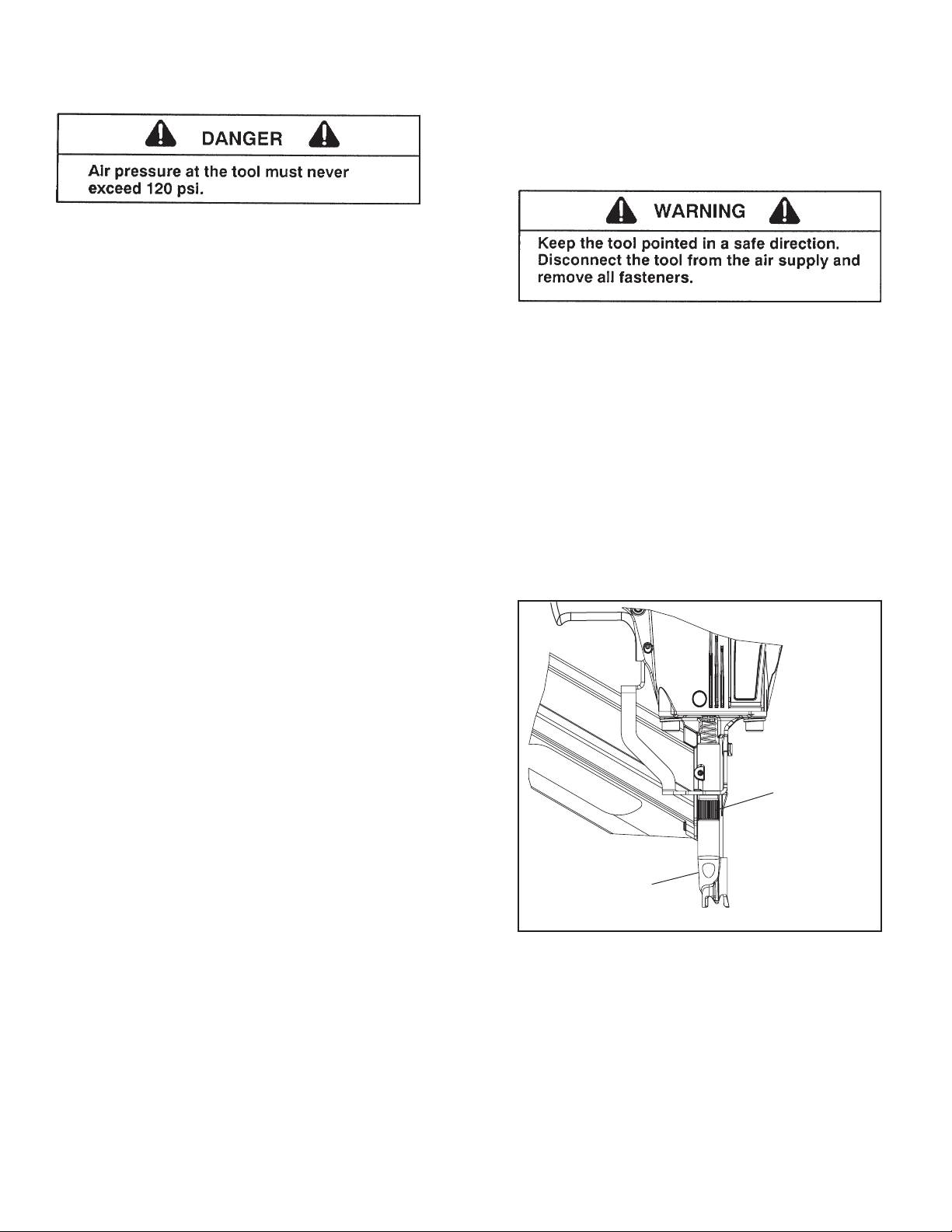

ROTATE

THUMBWHEEL

IN EITHER

DIRECTION

WORK

CONTACT

ELEMENT

5

Page 6

TOOL OPERATION continued

Loading of Nails

Step 1 - Grasp the handle firmly.

Step 2 - Insert one or two strips of nails into the rear

of the magazine.

Step 3 - Pull the follower to the rear of the magazine

until it is engaged behind the nails.

Sequential Operation - (Silver Trigger)

The tool is manufactured with a (Silver) sequential

trigger installed.

The sequential operating trigger prevents successive

or “bounce” driving.

■

Depress the work contacting element and hold it

against the work surface before pulling the trigger.

■

After each fastener is driven, completely release

the trigger and lift the tool from the work surface.

Contact Trip (Bounce) Trigger Operation

(Orange Trigger)

The trigger kit (#501048) allows successive or

“bounce” driving.

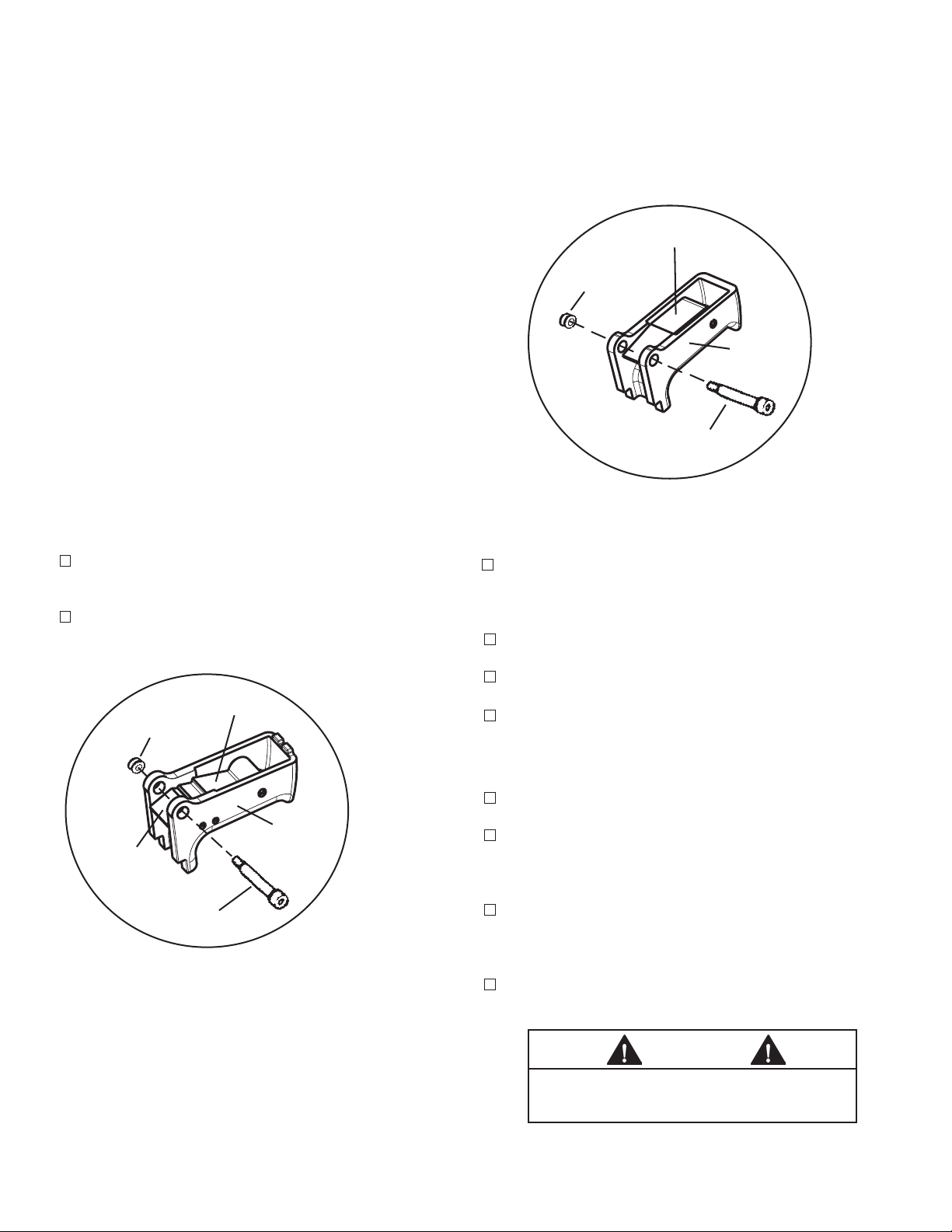

Bottom Trip Lever

Grommet

Contact

Trigger

Trigger Pin

#501048

Precision Placement Driving

■

Grasp the tool handle firmly and place the bottom of the

work contacting element firmly against the workpiece until

it is completely depressed.

■ Squeeze the trigger to drive the fastener.

Grommet

Sequential

Actuator

Sequential Lever

Trigger Pin

#501039

Sequential

Trigger

■ Lift the tool from the workpiece.

■ Repeat the procedure for the next fastener.

Successive (Bounce) Driving

■ Grasp the handle firmly.

■

Squeeze the trigger and move the tool along the workpiece with a bouncing motion, depressing the work contacting

element at the points where you want to insert a fastener.

■

Keep the trigger depressed and continue to bounce the

work contacing element against the workpiece, positioning

the tool above as carefully as possible.

■

When the desired number of fasteners have been driven,

release the tool trigger to avoid unintentional fastener discharge.

WARNING

Do not clamp or hold the trigger with

anything other than your hand.

6

Page 7

AIR SYSTEMS

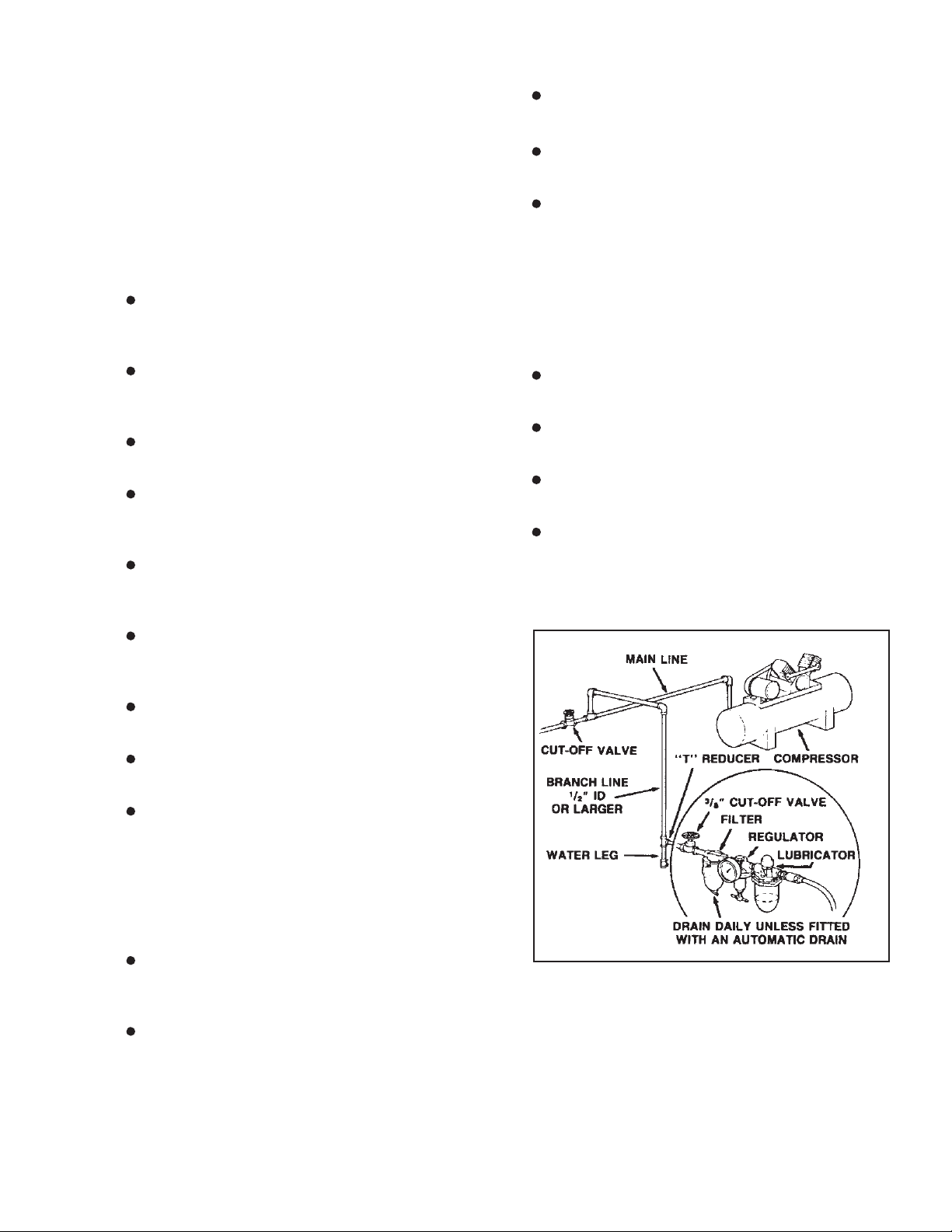

For air-powered tools to work their best, the air

supply system must be properly installed and

maintained regularly. A drawing in this section

shows a properly installed air supply system.

Handy checklists for installing and maintaining

air supply systems follow.

Indoor Air System Installation

-Be certain that:

inside diameter to ensure adequate air supply.

The main supply pipe slopes down, away from

the compressor (1/16 inch per foot).

main pipe line.

line throughout the system.

All pipes supplying air have a large enough

Air storage is provided along lengthy air lines.

Pipe line branch outlets are at the top of the

Cutoff valves are provided at each branch pipe

Air hoses are not longer than 150 feet.

The air system is lubricated regularly.

A regular maintenance program is followed.

Filter/Regulator/Lubricator Units

Filter/regulator/lubricator units that can supply

enough air and protection for Paslode tools

must meet the following specifications:

Minimum 3/8 inch NPT port size .

50 micron or fine filters.

Regulated pressure from zero to 120 psi.

Lubricators designed for low or changing

airflow.

line.

Air hoses are kept as short as practical.

Water legs extend from the bottom of each branch

A refrigerant-type dryer is installed on the system.

A regular maintenance program is followed.

Outdoor Air System Installation

-Be certain that:

are installed at the compressor.

air flow is not restricted. Minimum hose size is

3/8 inch ID with 1/2 inch ID hose used for any

application over 25 feet.

A moisture trap and a filter/regulator/lubricator

Air hoses and fittings are large enough so that

7

Page 8

AIR SYSTEMS - Continued

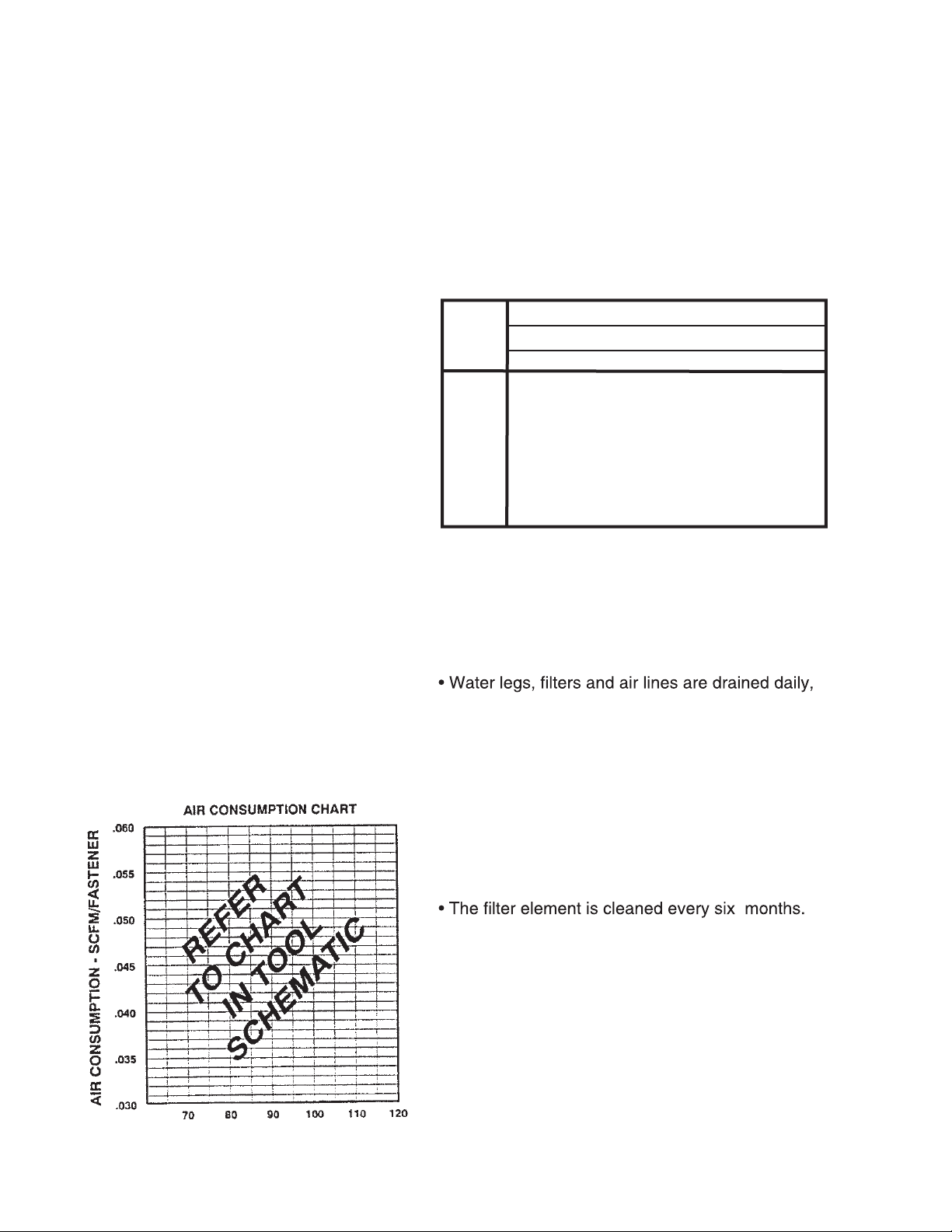

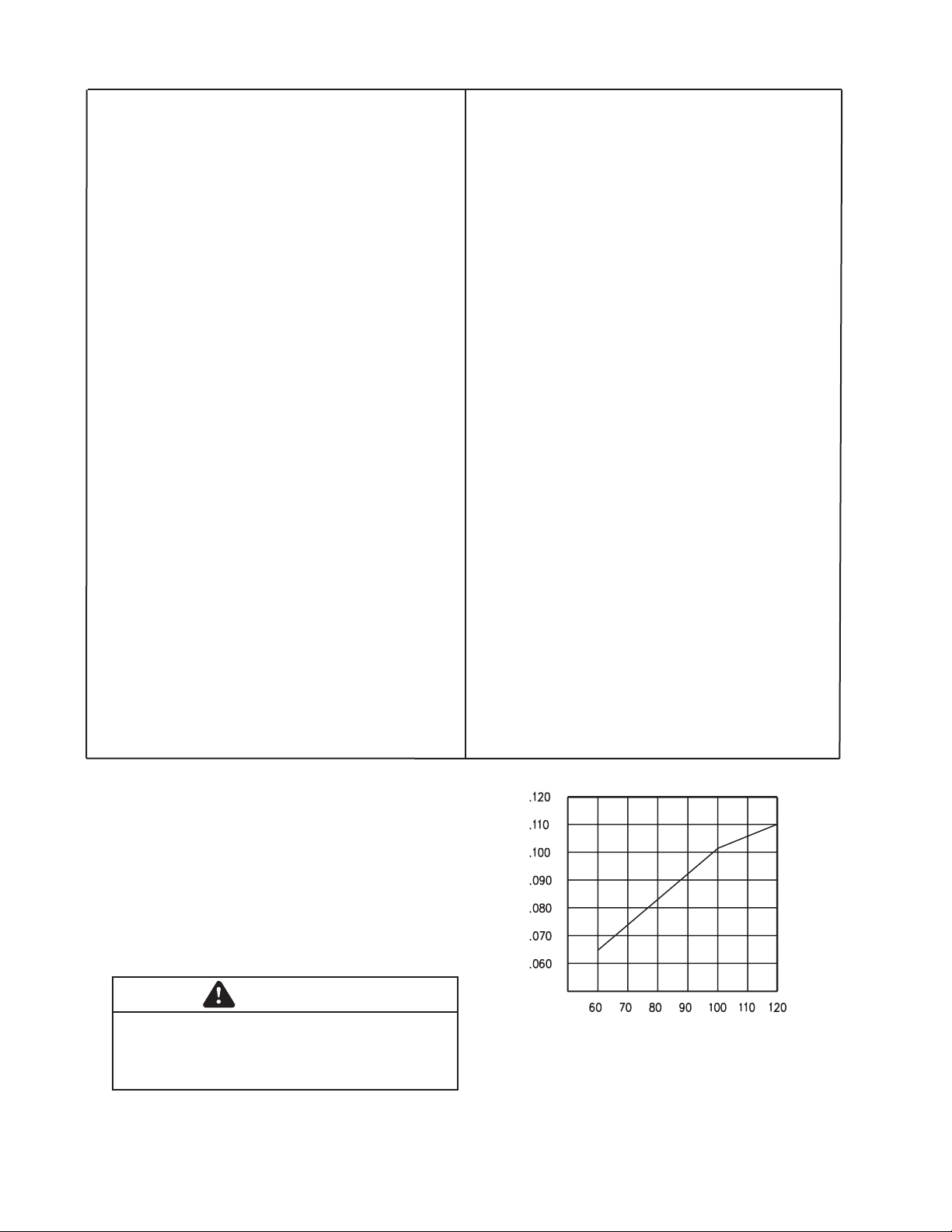

Calculating Compressor Size

Use the air consumption chart in the Tool

Schematic for each tool when calculating

the operating requirements for the tools.

Paslode tools are designed to operate effciently between 80 and 120 psi and should

never be operated at pressure greater than

120 psi.

The air consumption chart will help you find

the correct compressor size for your appli-

cation that will quickly replenish tool air pres-

sure.To use the chart you will need to know

how many tools will be used and approximately how many fasteners will be driven

each

minute by each tool onthe line.

Using the equation:

Number of tools X average fasteners/minute/

tool X 1.2 (safety factor) X air consumption

(scfm) @ pressure* (psi) = scfm required.

We can use the following example:

10 tools X 30 fasteners/minute/tool X 1.2 X

0.051scfm* (@100psi) = 18.36 scfm.

Calculated Required Piping

For example, given a 20 hp electric compressor

supplying approximately 80 cfm of air at 120 psi

and a main supply pipe length of 350 feet, we see

by the table the minimum main pipe inside diameter required for this application is 1-1/4 inch.

VOLUME

OF AIR

(CFM)

30-60

60-100

100-200

200-500

500-1000

50-200 290-500 500-1000 1000-2500 2500-5000

1 1 1¼ 1½ 1½

1 1¼ 1¼ 2 2

1¼ 1½ 2 2¼ 2½

2 2½ 3 3½ 3½

2½ 3 3½ 4 4½

LENGTH OF RUN (FT.)

NOMINAL PIPE DIAMETER (IN.)

Pneumatic System Maintenance

- Be certain that:

*This number is found in the Air Consumption

Chart

In this example, using the air consumption

chart we find that a compressor providing at

least 19 scfm of air is required. Because in

compressors approximately 1 hp is required to

produce 4 scfm, a compressor of at least 5 hp

is required.

• Pneumatic fittings are tight and do not leak.

and ensure that automatic draining systems are

operating correctly.

• Air lines are cleared to prevent freezing,

especially in winter.

• Lubricator operation is checked regularly and

ensure it has an adequate supply of lubricant.

(Paslode Part No. 403720)

• Only regulated air is being used and that each

regulator is operating properly.

8

Page 9

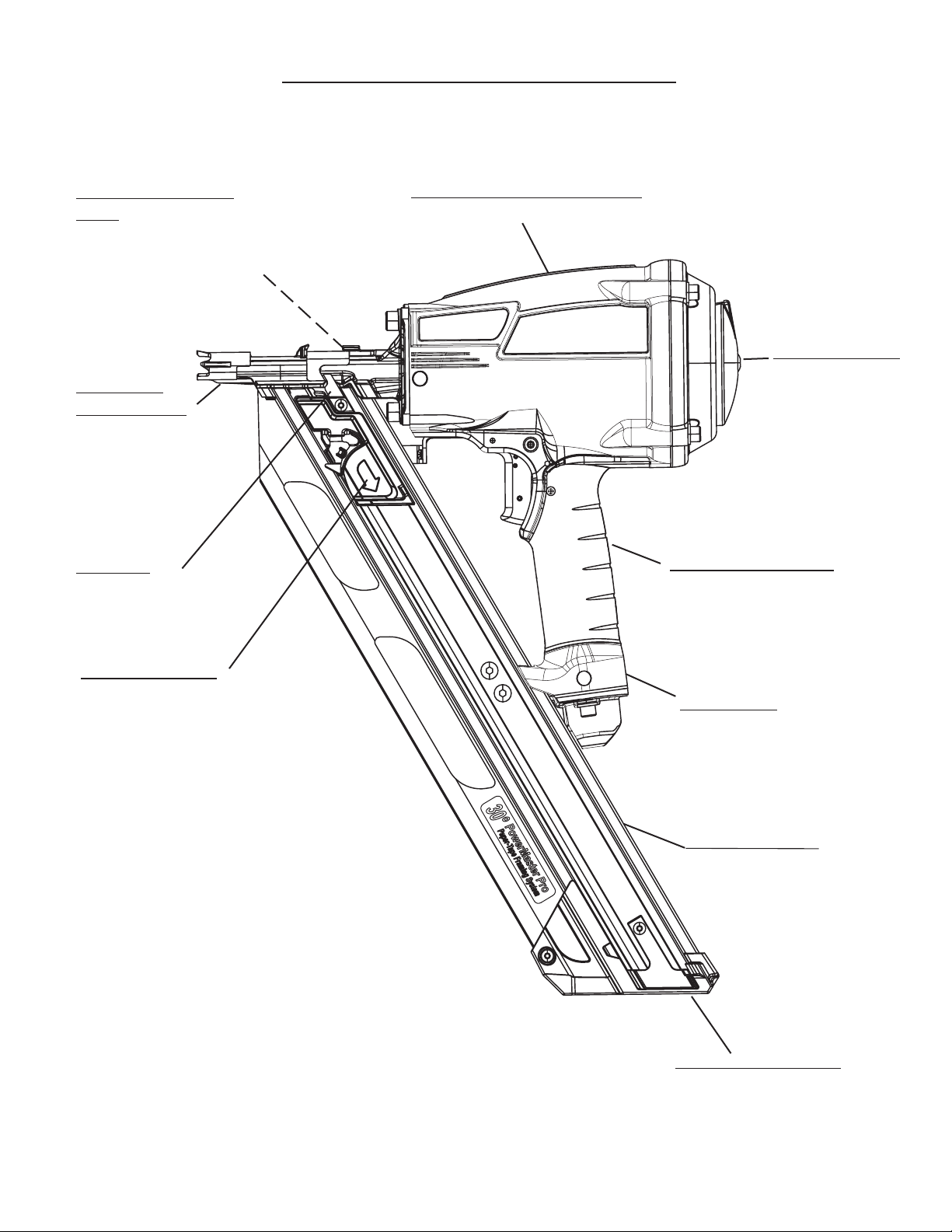

F-350P FEATURES & BENEFITS

Tool Less Depth of

Drive

Provides precise control

of nail depth without adjusting

the compressor.

(on other side)

Agressive

Work Contact

Grabs the wood

when toe nailing.

Lock Out

Eliminates blank

firing.

Durable and Reliable Engine

For shot after shot performance.

P

Easy to Service

to limit downtime.

Light Weight Design

Well balanced. Easy to

manuever with less arm

fatigue.

Bypass Follower

For fast 2-step loading.

Rafter Hook

Conveniently stowes the

tool.

In-line Magazine

for better balance

Rear Load Magazine

Holds 2 strips or 84 nails.

9

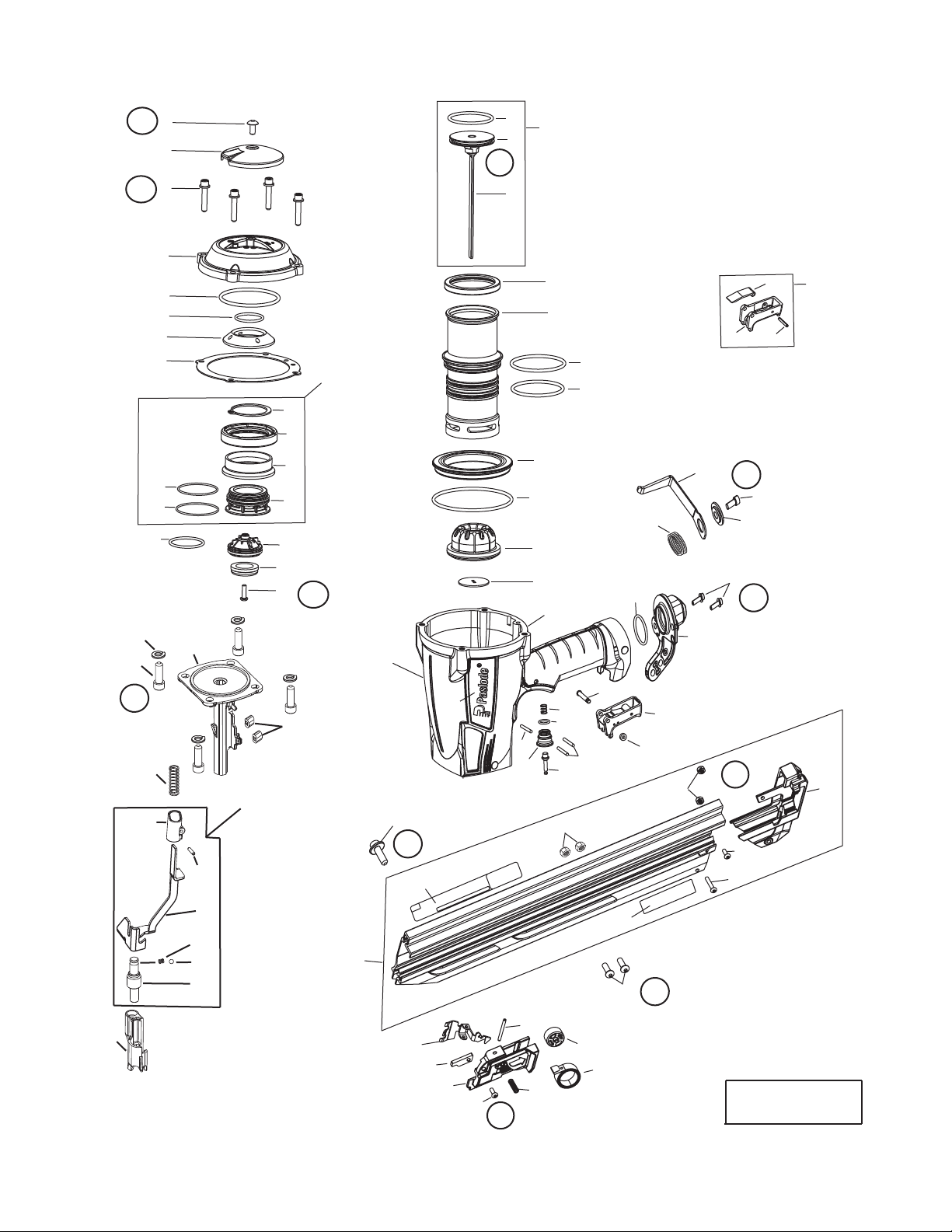

Page 10

P

PARTS LEGEND

▲

6

■ 21

501043 1 T.H.S.C.S. 1/4 -20 x 1/2”

1

2

501016 1 Air Deflector

3

501300 4 S.H.C.S. 1/4-20 x 1-1/4”

4

501017 1 Cap

*

5

500461 1 O-Ring

*

*

10

11

*

12

*13

14

15

*

16

17

18

19

*

20

*

22

*

23

24

*

25

*

26

27

*

28

*

29

30

31

32

33

*

34

*

35

*

36

*

37

38

39

** Make sure Warning Label (Part No. 515009)

is properly affixed. Replace if necessary.

➔ Denotes New Change

092042 2 O-Ring

7

500407 1 Spring, Main Valve

8

501001 1 Gasket, Cap

9

406041 1 Retaining Ring

500455 1 Upper Valve Piston

401946 1 Seal, Main Valve

091208 1 O-Ring

401950 1 O-Ring

500456 1 Lower Valve Piston

095432 1 O-Ring, Post

500454 1 Post

500453 1 Bumper, Post

402906 1 B.H.S.C.S.10-32 x 5/8"

092971 1 O-Ring, Piston

501337 1 Piston

501218 1 Driver Blade

402011 1 Seal Sleeve

501283 1 Sleeve

500249 1 O-Ring, Sleeve

092235 1 O-Ring, Sleeve

500779 1 Flange, Sleeve

501002 1 O-Ring, Midcheck

500866 1 Bumper

500729 1 Blade Seal

515017 1 Housing

071297 3

401598 1

097746 1

092174 1

097748 1

402669 1

402668

* Denotes Normal Wear Items

▲ Apply Loctite 242 (Blue) Part No. 093500

■ Apply Loctite (Green)

515013

1 Label, Housing Logo-Right

515012

1 Label, Housing Logo-Left

Roll Pin

Valve Body

Valve Pin

O-Ring, Valve Body

Spring, Valve Pin

Pin Trigger

1

Retaining Ring

owerMaster

**

40

41

42

43

44

45

46

47

48

49

50

51

▲

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

™

F-350P, 515000

1

Sequential Trigger

515003 1 End Plug

501299 2 S.H.C.S. 1/4-20 X 1”

502930 1 Spring, Rafter Hook

515005 1 Rafter Hook

515018 1 Bushing, Rafter Hook

444786 1 S.H.C.S. ,1/4-20 x 5/8”

515002 1 Nose, 30º

095417 4

009016 4 S.H.C.S. 5/16-18 x 1”

502014

515016 1 Compression Spring

502050 1 Detent Body

404361 1 Roll Pin 1/8” x 1/2”

515004 1 Upper W.C.E.

515010 1 Detent Spring

502049 1 Detent Ball

502299 1 Thumbwheel

515006 1 Lower W.C.E.

515008 1 1/4-20 x 3/8”

515009 1 Warning Label

442681 2

404325 2 Locknut #8-32

502029 1

502031 2

502038 1

515020 1

502017 2 B.H.C.S. 1/4”-20 X 3/4”

502019 1 Follower Claw

403796 1 Roll Pin

502021 1 Lockout Bar

511118 1 Follower Body

502020 1 Follower Spring

502025 1

502026 1

501008 1

501009 1

501010 1

AIR CONSUMPTION CHART

Lockwasher 5/16

2 Magazine Isolator

Locknut, 1/4-20

Magazine Cap

S.H.C.S. 8-32 x 1/2”

S.H.C.S. 8-32 x 1"

Drum Pin Assembly

Negator Spring

Lever, Bottom Trip

Spirol Pin

Bump trigger

.082

SCF

•

AIR CONSUMPTION - SCF/FASTENER

Pro

501039

Label, Magazine

WARNING

A

ll parts must be periodically inspected

and replaced if worn or broken. Failure to

do this can affect the toolʼs operation and

present a safety hazard.

AIR PRESSURE - PSIG

Note: For optimum performance Paslode

recommends the use of a 3/8” Male fitting.

10

Page 11

50

#

160

#

PowerMaster Pro

™

MODEL F-350P

19

1

2

3

4

5

6

7

8

MAIN VALVE

ASSEMBLY

500463

9

10

250

PISTON DRIVER

ASSEMBLY

20

501519

#

21

22

23

24

25

77 76

75

515000

OPTIONAL:

BUMP

TRIGGER

ASSEMBLY

501048

58

48

49

325

#

51

52

12

13

15

47

53

54

55

56

57

11

14

16

17

18

20

#

50

Upper

Work Contact

Assembly

#515011

Magaizine

Assembly

#515030

31

59

160

#

68

60

70

71

32

64

15

26

27

43

28

29

30

30

37

36

33

34

69

72

#

33

35

61

73

74

38

66

67

6

39

160

44

120

#

46

45

42

160

#

41

40

15

62

#

#

64

65

Torque Values

#

63

IN/LBS

11

Page 12

MAINTENANCE

Paslode® tools are built for ease of maintenance. A few

simple details will assure trouble-free operation and long

tool life. Anyone who uses or maintains the tool must read

the safety and maintenance instructions. Study the schematic drawing before starting any repairs on the tool.

Air-operated tools must be inspected periodically, and worn

or broken parts must be replaced to keep the tool operating

safely and efficiently. Also the items on the maintenance

chart must be checked often.

Cold Weather Care

When temperatures are below freezing, tools should be

kept warm by any convenient, safe method. If this is not

possible, the following procedure should be used to warm

up the tools.

❑ Reduce the regulated air pressure to 30 psi.

❑ Remove all fasteners from the tool.

❑

Open the drain on the air compressor tank to drain any

moisture at least daily in extremely cold or humid weather.

A few ounces of anti-freeze in the tank will keep the air

free of frost.

Testing the Tool After Servicing

After replacing any part or parts, it is important to check

the tool for proper operation. This ensures that the tool

was put together correctly, is safe to use, and will perform

the job properly.

❑ Ensure that all hardware is tight.

❑

Ensure that the work contacting element is installed

correctly in relation to the trigger, and that both parts move

freely.

❑ Ensure that the magazine is properly attached.

❑

Ensure that the required safety information on the tool

is legible.

❑

Use only Paslode approved fasteners in the tool, and

ensure that they are correct for the application.

❑

Collect an air line and blank fire the tool. The reduced

air pressure will be enough to free-fire the tool. Slow speed

operation tends to warm up the moving parts. Slowing up

the piston helps the bumper and the O-rings to become

springy.

❑ Once the tool is warmed up, readjust the regulator to

the proper working pressure and reload the tool.

❑

Tool operators working outdoors or in unheated areas

in extremely cold temperatures should also:

Use Paslode pneumatic oil with antifreeze in the

lubricator, Part No. 219090 (8oz.)

Once a week, depending on the amount of tool

use, take the tool apart and wash away any sludge

with tool cleaner (Paslode Part No. 219348) to

keep the tool operating efficiently.

Cleaning the air-operated tools with solvents removes the

thin coating of grease applied to the cylinder wall and

O-rings at the factory. To replace this coating of grease,

use Chemplex grease (Paslode Part No. 403734).

12

❑

Ensure that a male air fitting is securely connected to

the tool.

❑

Test the tool by driving fasteners into a workpiece iden-

tical to the tool's application.

❑

Check the tool for air leaks during testing and for the

proper sequence of operation.

❑

Ensure that all fasteners are driven to the same depth

and that the crown of the fastener is flush with the workpiece.

Tool Lubrication

It is most important that the tool be properly lubricated by

keeping the air line lubricator filled and correctly adjusted.

Without proper lubrication the tool will not work properly

and parts will wear prematurely.

Use the proper lubricant in the air line lubricator. The

lubricator should be of low air

type, and should be kept

only Paslode recommended lubricants. Substitutes may

harm the rubber compounds in the tools O-rings and other

rubber parts. Paslode Part No. 403720 is a pneumatic

lubricating oil specially made for pneumatic applications.

If a filter/regulator/lubricator is not installed on the air system, air operated tools should be lubricated at least once

a day with 6 to 20 drops of oil, depending on the work

environment, directly through the male fitting in the tool

housing.

Most minor problems can be resolved quickly and easily

using the maintenance table that follows. If problems persist, contact your Paslode dealer for assistance.

flow or changing air flow

filled to the correct level. Use

Page 13

MAINTENANCE - Continued

CAUTION

Disconnect the tool when performing

repairs or clearing jams.

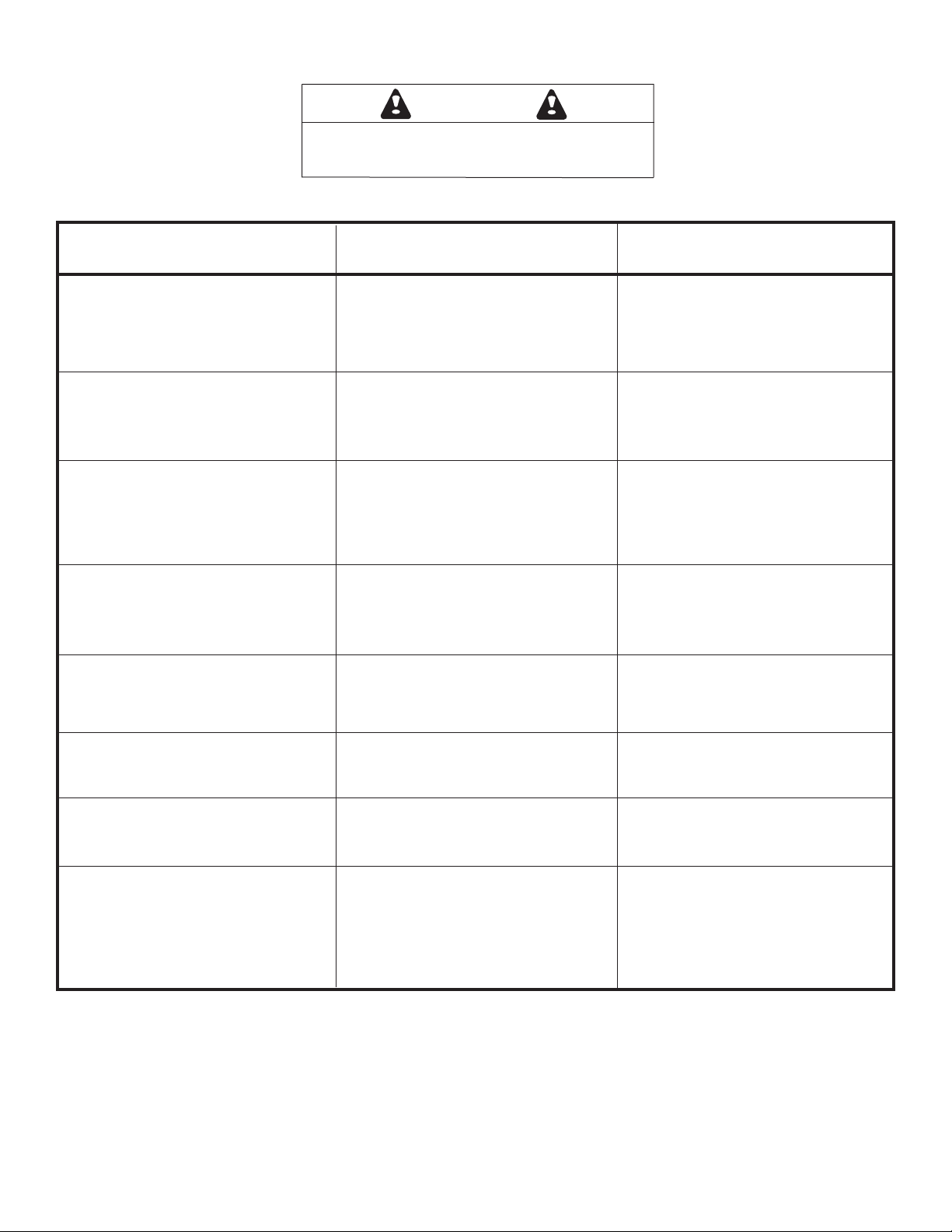

MAINTENANCE TABLE

ACTION WHY HOW

Drain air line filter(daily).

Keep lubricator

Clean filter element-then blow

air through filter in direction

opposite to normal flow.

Check that all screws on tool

are tight.

Keep work contacting elelment

working properly.

Keep magazine and feeder

mechanism clean.

filled.

Prevent accumulation of

mositure and dirt.

Keep tool lubricated.

Prevent clogging of filter with

dirt.

Prevent air leakage and promote efficient operation.

Promote operator safety and

efficient tool operation.

Prevent jamming of fasteners.

Open manual petcock (most

air supply systems have such

a valve).

Fill with Paslode pneumatic

tool lubricant. Part No.

403720.

Wash with soap and water or

follow manufacturers instructions.

Check screws daily.

Blow clean daily.

Blow clean daily.

Lubricate "O" rings that are

replaced.

Use only Paslode replacement

parts.

Assure long life and proper

operation of tool.

Keep tool operating efficiently

and maintain Paslode tool

warranty.

13

Use Chemplex grease, Part

No. 403734.

Order any repacement parts

needed from Paslode Dealer.

Page 14

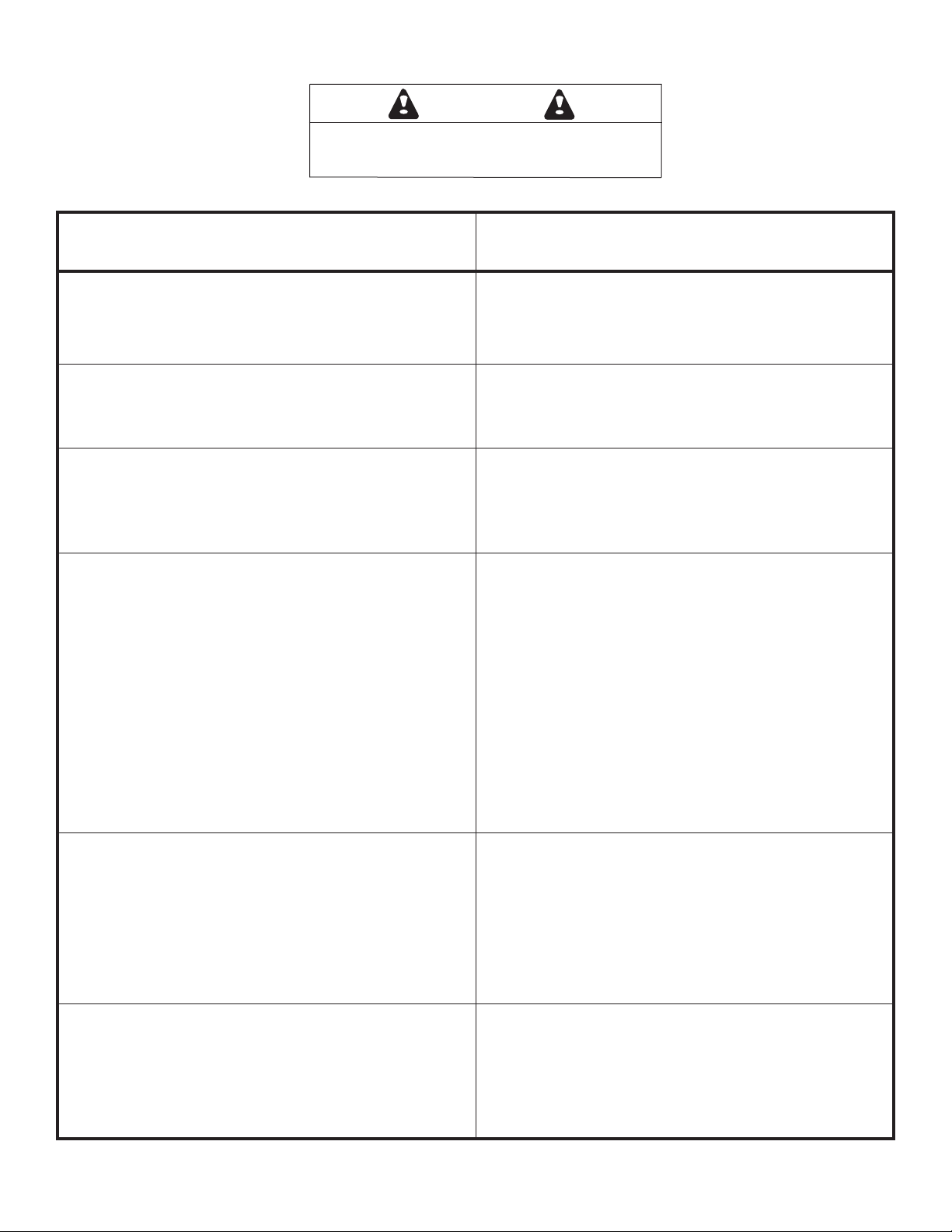

OPERATOR TROUBLESHOOTING

OPERATOR TROUBLESHOOTING

30

DETECCION Y CORRECCION DE FALLAS

PROBLEMA SOLUCIÓN

Los sujetadores no penetran completamente en la

madera.

Los sujetadores penetran bien durante las operaciones

normales, pero fallan a velocidades más altas.

Los sujetadores penetran demasiado en la madera.

Los sujetadores se acumulan en la punta de la her-

ramienta.

La herramienta “salta” mientras está funcionando; de

vez en cuando no impulsa sujetadores.

La herramienta funciona, pero no dispara sujetadores.

Hay pérdidas de aire en la cubierta cuando la herra-

mienta está conectada a la línea de aire.

Cambie la posición del elemento de contacto (Retraiga

la longitud).

Aumente la presión de aire (no debe exceder 120 psi).

Aumente el flujo de aire a la herramienta; use líneas

de aire más grandes (3/8” de diámetro como mínimo).

Cambie la posición del elemento de contacto (Extien-

da la longitud).

Reduzca la presión de aire.

Abra el seguro delantero, quite el sujetador obstruido y

cierre bien el segurro.

Compruebe si el cargador tiene los sujetadores apro-

piados. El transportador debe deslizarse sin dificultad.

Límpielo para quitar cualquier suciedad.

Verifique que se usen los sujetadores apropiados.

Use solamente sujetadores que reúnan las especifica-

ciones de Paslode.

Aumente el flujo de aire a la herramienta; use líneas

de aire más grandes (3/8” de diámetro como mínimo).

Ajuste el elemento de contacto donde sea posible.

Compruebe si el cargador tiene los sujetadores apro-

piados. Los sujetadores deben deslizarse libremente

sin presión del transportador.

Abra el seguro delantero o afloje el botón del cargador

y revise si hay suciedad o alguna obstrucción en el

área de la punta. Límpiela si es necesario.

Aumente la presión de aire (no debe exceder 120 psi).

Apriete los tornillos.

PRECAUCIÓN

Desconecte la herramienta al hacer cualquier

reparación o eliminar cualquier obstrucción.

PROBLEM CORRECTIVE ACTION

Disconnect the tool when performing

repairs or clearing jams.

CAUTION

Fasteners will not drive completely into wood.

Fasteners penetrate properly during normal

operation, but won't drive fully at faster speeds.

Fasteners drive too deeply into wood.

Tools skips during operation - no fasteners are

driven from time to time.

Adjust work contacting element (retract length).

Increase air pressure (do not exceed 120 psi).

Increase air flow to tool -- use larger air lines

(3/8 inch ID minimum).

Adjust work contacting element (extend length).

Reduce air pressure.

Check magazine for proper fasteners. Magazine follower should slide freely. Clean as needed to remove

debris.

Make sure correct fasteners are being used.

Use fasteners that meet Paslode

®

specifications only.

Tool operates, but no fasteners are driven.

Air leaks at cap when tool is connected to air.

Increase air flow to tool -- use larger air lines

(3/8 ID minimum).

Adjust work contacting element where available.

Check magazine for proper fasteners. Fasteners

should slide freely with no follower pressure.

Increase air pressure (do not exceed 120psi).

Tighten cap screws.

14

14

Page 15

TOOL WARRANTY

P

An Illinois Tool Works Company

155 Harlem Avenue

Glenview, IL 60025

MODEL F-350P

Framing Nailer

TOOL WARRANTY AND LIMITATIONS

Paslode warrants that newly purchased power

fastening tools, parts and accessories will be free

from defects in material and workmanship for the

period shown below, after the date of delivery to

the original user.

ONE-YEAR LIMITED WARRANTY

A one-year warranty will apply to all parts, except

those which are specifically covered by an extended

warranty.

FIVE-YEAR EXTENDED LIMITED WARRANTY

A

five-year warranty will apply to all housing and cap

assembly castings.

WARRANTY STATEMENT

This warranty is limited to tools sold and service requested

in the United States. To obtain information on warranty

service in the United States, refer to the Service Center

listing that was provided with your tool.

Paslode's sole liability hereunder will be to replace any part

or accessory which proves to be defective within the specific

time period. Any replacement part or accessory provided in

accordance with this warranty will carry a warranty for the

balance of the period of warranty applicable to the part it

replaces. This warranty does not apply to part replacement

required due to normal wear.

This warranty is void as to any tool which has been subjected

to misuse, abuse, accidental or intentional damage, use with

fasteners,not meeting

improperly maintained,

Paslode replacement parts,

which, in Paslode's opinion,

way that affects or detracts

Paslode specification, size, or quality,

repaired with other than genuine

damaged in transit or handling, or

has been altered or repaired in a

from the performance of the tool.

PASLODE MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, RELATING TO MERCHANTABILITY, FITNESS, OR

OTHERWISE, EXCEPT AS STATED ABOVE, and Paslode's

liability AS STATED ABOVE AND AS ASSUMED ABOVE is

in lieu of all other warranties arising out of, or in connection

with, the use and performance of the tool, except to the extent

other wise provided by applicable law. PASLODE SHALL IN

NO EVENT BE LIABLE FOR ANY DIRECT, INDIRECT, OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT

LIMITED TO, DAMAGES WHICH MAY ARISE FROM LOSS

OF ANTICIPATED PROFITS OR PRODUCTION, SPOILAGE

OF MATERIALS, INCREASED COST OF OPERATION, OR

OTHERWISE.

Paslode reserves the right to change specifications, equipment, or

designs at any time without notice and without incurring obligation.

15

Page 16

ACCESSORIES

ubricants and Loctite

L

Loctite 242 (Blue) Part No. 093500

Lubricating Oil 16 oz. Part No. 403720

Lubricaing Oil with Anitfreeze 8 oz. Part No. 219090

Chemplex 710 Lubricant 1lb. Part No. 403734

Tool Cleaner

843912 .oN traP.sloot edolsaP lla rof renaelc laedI

Safety Glasses

Clear Part No. 401382

No Mar Work Contact Part No. 502234

Pneumatic Air Fitting

Part No. 515021

For additional information on Paslode products, visit our website at

®

www.paslode.com.

For technical support call 1-800-222-6990.

To purchase parts and accessories, visit www.itwconstructionparts.com.

An Illinois Tool Works Company

155 Harlem Avenue

Glenview, IL 60025

Page 17

P

PowerMaster Pro

Clavadora Paslode

™

P

Modelo

F-350P

¡IMPORTANTE!

NO DESTRUYE ESTE MANUAL

El cliente tiene la responsibilidad de que todo

el personal de operaciones y servicio lea y

entienda este manual.

Manual de Funcionamiento y

Esquema

17

Page 18

INTRODUCCION

INTRODUCCION

La herramienta Paslode F-350P es una herramienta de calidad, diseñada para uso en aplicaciones

residencial. Esta herramienta le provera confiabilidad y eficencia cuando sea usada acorde con las

reglas del fabricante.

Lea cudadosamente este manual y las instrucciones de seguridad para comprender como usar le her-

rminienta correctamente.

CONTENIDO

SPECIFICACIONES DEL LA HERRAMINETA Y SUS SUJETADORES.............................3

INSTRUCCIONES DE SEGURIDAD................................................................................... 4

INSTALACION Y OPERACION DEL LA HERRAMINETA................................................5-6

SISTEMAS DE AIRES......................................................................................................7-8

BENEFICIOS DEL LA HERRAMIENTA.............................................................................. 9

VISTA EXPANDIDA CON LISTADO DE PIEZAS..........................................................10-11

MANTENIMIENTO.........................................................................................................12-13

DETECCION Y CORRECION DE FALLAS........................................................................14

GARANTIA.........................................................................................................................15

ACESORIOS.......................................................................................................................16

La herramienta Paslode F-350P es una herramienta de calidad, diseñada para uso en aplicaciones

residencial. Esta herramienta le provera confiabilidad y eficencia cuando sea usada acorde con las

reglas del fabricante.

Lea cudadosamente este manual y las instrucciones de seguridad para comprender como usar le herrminienta correctamente.

CONTENIDO

SPECIFICACIONES DEL LA HERRAMINETA Y SUS SUJETADORES.............................3

INSTRUCCIONES DE SEGURIDAD................................................................................... 4

INSTALACION Y OPERACION DEL LA HERRAMINETA................................................5-6

SISTEMAS DE AIRES......................................................................................................7-8

BENEFICIOS DEL LA HERRAMIENTA.............................................................................. 9

VISTA EXPANDIDA CON LISTADO DE PIEZAS..........................................................10-11

MANTENIMIENTO.........................................................................................................12-13

DETECCION Y CORRECION DE FALLAS........................................................................14

GARANTIA.........................................................................................................................15

ACESORIOS.......................................................................................................................16

2

Page 19

SPECIFICACIONES DE LA HERRAMIENTA Y LOS SUJETADORES

SPECIFICACIONES de la HERRAMIENTA

MODELO NO. F-350P (Pieza# 515000)

ALTURA

ANCHO 5.5"

LARGO

PESO

PRESION de OPERACION 80 hasta 120 p.s.i. (5.5 hasta 8.3 bars)

13.5”

20.5"

7 lbs. 13oz.

SPECIFICACIONES de los SUJETADORES

LONGITUD DEL CLAVO

2" - 3¼"

DIAMETRO .113 - .131

ACOPLAMIENTO DE AIRE

Esta herramienta utiliza un enchufie de 3/8" N.P.T. El acoplamiento debe ser capaz de

descargar la presion de aire en la herramienta cuando sea desconectado del suministro

de aire.

:

OPERACION de PRESION de AIRE:

80 hasta120 p.s.i. (5.5 hasta 8.3 bars). Para mjor funcionamiento seleccionar la presion

de aire en el rango indicado.

NO EXCEDA LA PRESIóN DE AIRE RECOMENDADA

3

Page 20

20

PELIGRO

La falta de observación de cualquiera de estas instrucciones puede ser causa de graves

lesiones personales, tanto al operador de la herramienta comoa quienes estén cerca de

ella o de daños materiales o a la herramienta

.

Comuníquese con el representante de Paslode sobre la presentación de Programa de Alerta sobre

Seguridad.

LA SEGURIDAD ESTA PRIMERO

Estas instrucciones proporcionan la información necesatia para el

funcionamiento sin peligrode las herramientas Paslode. NO trate

de usar su herramienta hasta que no haya léido y entendido

todas las precauciones de seguridad y las instrucciones de

este manual.

PROTEJASE LOS OJOS Y LOS OIDOS

Use siempre el equipo adecuado para protegerse los ojos

y los oídos que sea conforme con ANSI Z87, meintras usa

una herramienta o trabaja cerca de una herramienta en

uso. Como empleador usted es responsable de imponer el

usp del la porteccion de ojo. Lleve sombreros duros en los

ambientes que requieren su uso.

USE SU HERRAMIENTA SOLAMENTE PARA EL

PROPOSITO CON QUE FUE DISEÑADA

No arroje la herramienta al suelo; no golpee el armazón ni la use

como un martillo.

NUNCA USE LA HERRAMIENTA PARA JUGUETEAR

Esta herramienta no es un juguete; por lo tanto no la trate como

tal. Nunca juguetee con ella, ni se apunte a usted mismo ni a otra

persona, aun cuando crea que no está cargada.

NUNCA ASUMAQUE LA HERRAMIENTA ESTA VACIA

Verfique que ho haya sujetadores en elcargador. Aun cuando crea

que está vacía o desconectada, nunca se apunte ni apunte a otra

persona con la herramienta, porque podría dispararse un sujetador

que no esté a la vista.

NUNCA SUJETE EL GATILLO EN LA POSICION DE

CIERRE O DE FUNCIONAMIENTO

Nunca se debe manipular indebidamente o dejar inoperante el

gatillo, o sujetarlo en la posición de cierre o defuncionamiento,

porque se podría disparar un sujetador al oprimirse el elemento de

contacto.

NO CARGUE SUJETADORES CUANDO LA LINEA DE

AIRE COMPRIMIDO ESTE CONECTADA, O CUANDO

EL GATILLO O EL ELEMENTO DE CONTACTO ESTE

OPRIMIDO.

Antes de cargar sujetadores en la herramienta, verifique que la

línea de aire comprimido esté desconectada y que ni el gatillo ni el

elemento de contacto estén oprimidos.

USE LA HERRAMIENTA SOLAMENTE SOBRE UN MA-

TERIAL DE TRABAJO

La herramienta debe funcionar sólo cuando esté en contacto con el

material de trabajo. Debe tener mucho cuidado cuando el material

sea delagado o trabaje cerca de las aristas del mismo, porque los

sujetadores podrían atravesar o salirse del material.

NO DEJE INOPERANTE NI QUITE EL ELEMENTO DE

CONTACTO

Esta herramienta está equipada con un mecanismo de seguridad,

llamado elemento de contacto, para prevenir cualquier disparo

accidental. Nunca manipule indebidamente, deje inoperante, ni

quite el elemento de contacto. No use la herramienta a menos que

dicho elemento funcione correctamente, porque podría producirse

un disparo imprevisto.

DESCONECTE LA HERRAMIENTA CUANDO NO LA

ESTE USANDO

Siempre desconecte la herramienta de la línea de aire comprimdo

cuando no la esté usando o al dejar su lugar de trabajo. Nunca la

descuide, porque cualquier persona que no esté

familiarizada con ella podría lastimarse o lastimar otros.

TOME LA HERRAMIENTA SOLAMENTE POR EL

MANGO

Siempre tome la herramienta sólo por el mango. Nunca la tome

por la manguera o con el gatillo oprimido, porque se podría

disparar un sujetador y herirlo o herir a otra persona.

NO ALTERE EL ARMAZON DE LA HERRAMIENTA

El armazón de la herramienta es un recipiente a presión y nunca se

debe grabar en su superficie el nombre de su compañia, el del área

de trabajo, ni ningún otro detalle.

DESCONECTE LA HERRAMIENTA PARA HACER

REPARACIONES O ELIMINAR OBSTRUCCIONES

Nunca trate de eliminar obstrucciones o reparar una herramienta

sin haberla desconectado de la línea de aire compromido y quitado

todos los sujetadores.

USE SIEMPRE LOS ADAPTADORES APROPIADOS

PARA SU HERRAMIENTA

Se debe conectar a la herramienta solamente conectores neumáticos

MACHOS, para permitir que el aire de alta presíon salga tan pronto

como se desconecte la línea de aire comprimido.

NUNCA coloque enlaces HEMBRAS de desconexíon rápida en la

herramienta, porque atrapan el aire a alta presíon al desconectar

la línea de aire comprimido, dejándola cargada y lista para disparar

por lo menos un sujetador.

NO EXCEDA LA PRESION NEUMATICA MAXIMA

RECOMENDADA

La herramienta debe funcionar sólo con la presíon neumática

recomendada. No exceda la presíon neumática máxima marcada

en la herramienta. Verifique por lo menos dos veces al día que el

calibre de la presíon neumática funcione correctamente.

Nuna use aire o gases envasado, como el oxígeno, para hacer

funcionar la herramienta porque podrían hacer que explotara.

INSPECCIONE LA HERRAMIENTA PARA LA

OPERACION APROPIADA

Limpie diariamente la herramienta y lubríquela como se

recomienda. Nunca trate de hacer funcionar una herramienta sucia

o defectuosa.

USE SOLAMENTE PIEZAS Y SUJETADORES

RECOMENDADOS POR PASLODE

Use sólo piezas y sujetadores específicamente diseñados y

recomendados por Paslode para usar con esa herramienta y para

la tarea requerida. Si se usan piezas o sujetadores no autorizados

o se modifica de alguna forma la herramienta, se pueden crear

situaciones peligrosas. Vuelva a colocar todas las etiquetas de

precaucíon que flaten. Consulte el diagrama de la herramienta sobre

el número de cada parte y su ubligación correcta.

INSTRUCCIONES DE SEGURIDAD

INSTRUCCIONES DE SEGURIDAD

LA SEGURIDAD ESTA PRIMERO

Estas instrucciones proporcionan la información necesatia para el

funcionamiento sin peligrode las herramientas Paslode. NO trate

de usar su herramienta hasta que no haya léido y entendido

todas las precauciones de seguridad y las instrucciones de

este manual.

PROTEJASE LOS OJOS Y LOS OIDOS

Use siempre el equipo adecuado para protegerse los ojos

y los oídos que sea conforme con ANSI Z87, meintras usa

una herramienta o trabaja cerca de una herramienta en

uso. Como empleador usted es responsable de imponer el

usp del la porteccion de ojo. Lleve sombreros duros en los

ambientes que requieren su uso.

USE SU HERRAMIENTA SOLAMENTE PARA EL

PROPOSITO CON QUE FUE DISEÑADA

No arroje la herramienta al suelo; no golpee el armazón ni la use

como un martillo.

NUNCA USE LA HERRAMIENTA PARA JUGUETEAR

Esta herramienta no es un juguete; por lo tanto no la trate como

tal. Nunca juguetee con ella, ni se apunte a usted mismo ni a otra

persona, aun cuando crea que no está cargada.

NUNCA ASUMAQUE LA HERRAMIENTA ESTA VACIA

Verfique que ho haya sujetadores en elcargador. Aun cuando crea

que está vacía o desconectada, nunca se apunte ni apunte a otra

persona con la herramienta, porque podría dispararse un sujetador

que no esté a la vista.

NUNCA SUJETE EL GATILLO EN LA POSICION DE

CIERRE O DE FUNCIONAMIENTO

Nunca se debe manipular indebidamente o dejar inoperante el

gatillo, o sujetarlo en la posición de cierre o defuncionamiento,

porque se podría disparar un sujetador al oprimirse el elemento de

contacto.

NO CARGUE SUJETADORES CUANDO LA LINEA DE

AIRE COMPRIMIDO ESTE CONECTADA, O CUANDO

EL GATILLO O EL ELEMENTO DE CONTACTO ESTE

OPRIMIDO.

Antes de cargar sujetadores en la herramienta, verifique que la

línea de aire comprimido esté desconectada y que ni el gatillo ni el

elemento de contacto estén oprimidos.

USE LA HERRAMIENTA SOLAMENTE SOBRE UN MATERIAL DE TRABAJO

La herramienta debe funcionar sólo cuando esté en contacto con el

material de trabajo. Debe tener mucho cuidado cuando el material

sea delagado o trabaje cerca de las aristas del mismo, porque los

sujetadores podrían atravesar o salirse del material.

NO DEJE INOPERANTE NI QUITE EL ELEMENTO DE

CONTACTO

Esta herramienta está equipada con un mecanismo de seguridad,

llamado elemento de contacto, para prevenir cualquier disparo

accidental. Nunca manipule indebidamente, deje inoperante, ni

quite el elemento de contacto. No use la herramienta a menos que

dicho elemento funcione correctamente, porque podría producirse

un disparo imprevisto.

La falta de observación de cualquiera de estas instrucciones puede ser causa de graves

lesiones personales, tanto al operador de la herramienta comoa quienes estén cerca de

ella o de daños materiales o a la herramienta

Comuníquese con el representante de Paslode sobre la presentación de Programa de Alerta sobre

Seguridad.

PELIGRO

.

DESCONECTE LA HERRAMIENTA CUANDO NO LA

ESTE USANDO

Siempre desconecte la herramienta de la línea de aire comprimdo

cuando no la esté usando o al dejar su lugar de trabajo. Nunca la

descuide, porque cualquier persona que no esté

familiarizada con ella podría lastimarse o lastimar otros.

TOME LA HERRAMIENTA SOLAMENTE POR EL

MANGO

Siempre tome la herramienta sólo por el mango. Nunca la tome

por la manguera o con el gatillo oprimido, porque se podría

disparar un sujetador y herirlo o herir a otra persona.

NO ALTERE EL ARMAZON DE LA HERRAMIENTA

El armazón de la herramienta es un recipiente a presión y nunca se

debe grabar en su superficie el nombre de su compañia, el del área

de trabajo, ni ningún otro detalle.

DESCONECTE LA HERRAMIENTA PARA HACER

REPARACIONES O ELIMINAR OBSTRUCCIONES

Nunca trate de eliminar obstrucciones o reparar una herramienta

sin haberla desconectado de la línea de aire compromido y quitado

todos los sujetadores.

USE SIEMPRE LOS ADAPTADORES APROPIADOS

PARA SU HERRAMIENTA

Se debe conectar a la herramienta solamente conectores neumáticos

MACHOS, para permitir que el aire de alta presíon salga tan pronto

como se desconecte la línea de aire comprimido.

NUNCA coloque enlaces HEMBRAS de desconexíon rápida en la

herramienta, porque atrapan el aire a alta presíon al desconectar

la línea de aire comprimido, dejándola cargada y lista para disparar

por lo menos un sujetador.

NO EXCEDA LA PRESION NEUMATICA MAXIMA

RECOMENDADA

La herramienta debe funcionar sólo con la presíon neumática

recomendada. No exceda la presíon neumática máxima marcada

en la herramienta. Verifique por lo menos dos veces al día que el

calibre de la presíon neumática funcione correctamente.

Nuna use aire o gases envasado, como el oxígeno, para hacer

funcionar la herramienta porque podrían hacer que explotara.

No haga funcionar en atmósferas explosivas.

INSPECCIONE LA HERRAMIENTA PARA LA

OPERACION APROPIADA

Limpie diariamente la herramienta y lubríquela como se

recomienda. Nunca trate de hacer funcionar una herramienta sucia

o defectuosa.

USE SOLAMENTE PIEZAS Y SUJETADORES

RECOMENDADOS POR PASLODE

Use sólo piezas y sujetadores específicamente diseñados y

recomendados por Paslode para

la tarea requerida. Si se usan piezas o sujetadores no autorizados

o se modifica de alguna forma la herramienta, se pueden crear

situaciones peligrosas. Vuelva a colocar todas las etiquetas de

precaucíon que flaten. Consulte el diagrama de la herramienta sobre

el número de cada parte y su ubligación correcta.

usar con esa herramienta y para

4

Page 21

INSTALACION DE LA

HERRAMIENTA

FUNCIONAMIENTO DE LA

HERRAMIENTA

Su herramienta Paslode está lista para usarse y

se puede unstalar siguiendo estos pasos:

1. SEGURIDAD:

Antes de usar la herramienta, todos

los operadores y sus supervisores inmediatos deben

familiarizarse con las instrucciobnes de seguridad de

la página 4 de este manual.

2. Con cada herramienta se entrega una copia de este

manual. Conserve este manual para cualquiera consulta

futura. Además, se incluye una targeta de rehistro, que

debe llenarse y devolverse inmediatamente a Paslode

para que su herramienta quede registrada.

3. Quite la cubierta plástica en la entrada del aire de la

herrmienta antes de instalar el adaptador macho. Se

requiere un adaptador neumático tipo macho, que desc-

argue el aire de la herramienta cuando se desconecte

la línea de aire comprimido.

4. Instale una unidad de filtro/regulador/lubricador con

un calibre, tan cercano al de la herramienta como sea

posible, de preferencia a menos de tres metros. Con-

sulte le sección Sustemas Neumáticos de este manual

sobre la longitud y los requisitos de las mangueras de

aire comprimido. En general, no se exige ninguna otra

instalación especial.

5. Si el operador usa una mesa para trabajar. se acon-

seja colocar la línea de aire comprimido debajo de la

misma. Se puede colocar una pequeña bandeja en la

parte inferior de la mesa para quardar los sujetadores

y la herramienta cuando no están un uso.

6. Si la herramienta no funciona cuando se conecta por

primera vez, no trate de repararla; llame de inmediato

al representate de Paslode.

PELIGRO

La presión de aire en la herramienta nunca

debe exceder 120 psi.

Regulación de la profundida de colocación

(en herramientas que tienen esta característica)

La profundidad de colocaión se logra regulando la tuerca

de ajuste a sea el elemento de contacto.

Si la herramienta excede la profundidad deseada (la cabeza

del sujetador es impulsada por debajo de la superfice de

trabajo), baje el elemento de contacto. Si los sujetadores

sobresalen (la cabeza del sujetador no está al mismo nivel

que la superficie de trabajo), suba el elemento de contacto.

Mueva el elemento de contacto hasta que la cabeza del

sujetador quede a la profundidad deseada.

PELIGRO

Apunte la herramienta en alguna dirección en

que no haya peligro. Deconéctela de la fuente

de aire comprimido y quítele todos los

sujetadores.

Elemento de

contacto

Tuerca de

ajuste

INSTALACION DE LA

HERRAMIENTA

La presión de aire en la herramienta nunca

debe exceder 120 psi.

Su herramienta Paslode está lista para usarse y

se puede unstalar siguiendo estos pasos:

1. SEGURIDAD:

los operadores y sus supervisores inmediatos deben

familiarizarse con las instrucciobnes de seguridad de

la página 4 de este manual.

2. Con cada herramienta se entrega una copia de este

manual. Conserve este manual para cualquiera consulta

futura. Además, se incluye una targeta de rehistro, que

debe llenarse y devolverse inmediatamente a Paslode

para que su herramienta quede registrada.

3. Quite la cubierta plástica en la entrada del aire de la

herrmienta antes de instalar el adaptador macho. Se

requiere un adaptador neumático tipo macho, que descargue el aire de la herramienta cuando se desconecte

la línea de aire comprimido.

4. Instale una unidad de filtro/regulador/lubricador con

un calibre, tan cercano al de la herramienta como sea

posible, de preferencia a menos de tres metros. Consulte le sección Sustemas Neumáticos de este manual

sobre la longitud y los requisitos de las mangueras de

aire comprimido. En general, no se exige ninguna otra

instalación especial.

5. Si el operador usa una mesa para trabajar. se aconseja colocar la línea de aire comprimido debajo de la

misma. Se puede colocar una pequeña bandeja en la

parte inferior de la mesa para quardar los sujetadores

y la herramienta cuando no están un uso.

6. Si la herramienta no funciona cuando se conecta por

primera vez, no trate de repararla; llame de inmediato

al representate de Paslode.

Antes de usar la herramienta, todos

PELIGRO

FUNCIONAMIENTO DE LA

HERRAMIENTA

Regulación de la profundida de colocación

(en herramientas que tienen esta característica)

Apunte la herramienta en alguna dirección en

que no haya peligro. Deconéctela de la fuente

de aire comprimido y quítele todos los

sujetadores.

La profundidad de colocaión se logra regulando la tuerca

de ajuste a sea el elemento de contacto.

Si la herramienta excede la profundidad deseada (la cabeza

del sujetador es impulsada por debajo de la superfice de

trabajo), baje el elemento de contacto. Si los sujetadores

sobresalen (la cabeza del sujetador no está al mismo nivel

que la superficie de trabajo), suba el elemento de contacto.

Mueva el elemento de contacto hasta que la cabeza del

sujetador quede a la profundidad deseada.

Elemento de

contacto

PELIGRO

Tuerca de

ajuste

5

Page 22

FUNCIONAMIENTO DE LA

HERRAMIENTA

(continuación)

Funcionamiento en secuencia

El juego de funcionamiento en secuencia

evita los impulsos sucesivos o "de rebote".

■

Oprima el elemento de contacto y

manténgalo apoyado contra el material

de trabajo antes de apreter el gatillo.

■

Después de haber impulsado cada

sujetador, suelte completamente el gatillo

y levante la herramienta del material de

trabajo.

Colocación precisa

■

Tome firmamente la herramienta por el

mango y sosténgala de modo que el base del

elemento de contacto quede bien apoyada en

el material de trabajo.

■ Apriete el gatillo para disparar el sujetador.

■ Separe la herramienta del material de

trabajo.

■ Repita el mismo procedimiento con el

próximo sujetador.

Impulsos sucesivos (de rebote)

■ Tome la herramienta firmemente por

el mango.

■ Apriete el gatillo y mueva la

herramienta a lo largo del material de

trabajo con un movimiento de rebote,

oprimiendo el elemento de contacto

en los lugares donde quiera colocar

un sujetador.

■

Manteniendo apretado el gatillo,

continúe haciendo rebotar el elemento

de contacto contra el material de trabajo,

colocando cuidadosamente la herramienta.

■

Una vez que haya colocado todos los

sujetadores necesarios, deje de oprimir el

gatillo para

evitar que salgan más.

PELIGRO

No sujete ni sostenga el gatillo con ninguna

otra cosa que no sea la mano.

Sujetadores

Paso 1 Tome firmamente el mango.

Paso 2 Insertar uno o dos tiras de

clavos en parte atras del

cargador.

Paso 3 Hale el seguidor hasta que

conecte con la oparte trasera

del cargador.

Arandela

Pasador

del Gatillo

Palanca Secuencial

Gatillo

Secuencial

Actuador

Secuencial

#501039

#501048

Arandela

Pasador

del Gatillo

Bottom de la

palanca de viaje

Contacto

de activación

Gatillo de Color Gris

Naranja Gatillo

FUNCIONAMIENTO DE LA

HERRAMIENTA

(continuación)

Sujetadores

Paso 1 Tome firmamente el mango.

Paso 2 Insertar uno o dos tiras de

clavos en parte atras del

cargador.

Paso 3 Hale el seguidor hasta que

conecte con la oparte trasera

del cargador.

Funcionamiento en secuencia

El juego de funcionamiento en secuencia

evita los impulsos sucesivos o "de rebote".

■

Oprima el elemento de contacto y

manténgalo apoyado contra el material

de trabajo antes de apreter el gatillo.

■

Después de haber impulsado cada

sujetador, suelte completamente el gatillo

y levante la herramienta del material de

trabajo.

Gatillo de Color Gris

Palanca Secuencial

Arandela

Gatillo

Secuencial

Actuador

Secuencial

Pasador

del Gatillo

#501039

Colocación precisa

■

Tome firmamente la herramienta por el

mango y sosténgala de modo que el base del

elemento de contacto quede bien apoyada en

el material de trabajo.

■ Apriete el gatillo para disparar el sujetador.

■ Separe la herramienta del material de

trabajo.

■ Repita el mismo procedimiento con el

próximo sujetador.

Naranja Gatillo

Bottom de la

palanca de viaje

Arandela

Contacto

de activación

Pasador

del Gatillo

#501048

Impulsos sucesivos (de rebote)

■ Tome la herramienta firmemente por

el mango.

■ Apriete el gatillo y mueva la

herramienta a lo largo del material de

trabajo con un movimiento de rebote,

oprimiendo el elemento de contacto

en los lugares donde quiera colocar

un sujetador.

■

Manteniendo apretado el gatillo,

continúe haciendo rebotar el elemento

de contacto contra el material de trabajo,

colocando cuidadosamente la herramienta.

■

Una vez que haya colocado todos los

sujetadores necesarios, deje de oprimir el

gatillo para

evitar que salgan más.

PELIGRO

No sujete ni sostenga el gatillo con ninguna

otra cosa que no sea la mano.

6

Page 23

23

SISTEMAS NEUMÁTICOS

El sistema neumático debe estar correctamente

instalado y recibir mantenimiento periódicamente para

que todas las herramientas de potencia neumática

funcionen bien. El diagrama de más abajo muestra

un sistema neumático correctamente instalado. A

continuación se detallan las revisiones necesarias

para la instalación y el mantenimiento de los sistemas

neumáticos.

Instalación de Un Sistema Neumático

para Interiores

- Asegure Que:

■ El diámetro interior de todas las líneas que

suministran aire sea bastante grande como para

garantizar un suministro de aire adecuado.

■ La línea principal tenga una inclinación de (1/16

de pulgada por pie) a partir del compressor.

■ Existen almacenamientos de aire a lo largo de las

líneas muy largas.

■ Las salidas de aire en las líneas secundarias

estén en la parte superior de la línea principal.

■ Existen válvulas de cierre en cada una de las

líneas secundarias de todo el sistema.

■ Las columnas de agua se extiendan desde el

extremo inferior de cada línea secundaria.

■ Se haya instalado en el sistema un secador tipo

refrigerante.

■ Las mangueras de aire sean tan cortas como sea

posible.

■ Se siga un programa regular de mantenimiento.

Instalación de Un Sistema Neumático

para Exteriores

- Asegure Que:

■ Se hayan instalado en el compresor un colector

de humedad y un filtro/regulador/lubricador.

■ Las mangueras de aire y los adaptadores tengan

la longitud suficiente para que el aire circule sin

problemas. El diámetro mínimo de una manguera

de aire es de 3/8 de pulgada y de 1/2 pulgada

para cualquier apalicación de más de 7.60 m.

■ Las mangueras de aire no midan más de 45.70 m

de longitud.

■ El sistema neumático sea lubricado

periódicamente.

■ Se siga un programa regular de mantenimiento.

Unidades de Filtro/Regulador/Lubricador

Las unidades de filtro/regulador/lubricador capaces

de proporcionar aire y proetección suficientes a las

herramientas Paslode deben tener las siguientes

características:

■ Tamaño mínimo del orificio a presión y tempera

tura normales de 3/8 de pulgada

■ Filtros de 50 micrones o más finos

■ Presión regulada de 0 a 120 psi

■ Lubricadores diseñados para corriente de aire

baja o variable

SISTEMAS NEUMÁTICOS

El sistema neumático debe estar correctamente

instalado y recibir mantenimiento periódicamente para

que todas las herramientas de potencia neumática

funcionen bien. El diagrama de más abajo muestra

un sistema neumático correctamente instalado. A

continuación se detallan las revisiones necesarias

para la instalación y el mantenimiento de los sistemas

neumáticos.

Instalación de Un Sistema Neumático

para Interiores

- Asegure Que:

■ El diámetro interior de todas las líneas que

suministran aire sea bastante grande como para

garantizar un suministro de aire adecuado.

■ La línea principal tenga una inclinación de (1/16

de pulgada por pie) a partir del compressor.

■ Existen almacenamientos de aire a lo largo de las

líneas muy largas.

■ Las salidas de aire en las líneas secundarias

estén en la parte superior de la línea principal.

■ Existen válvulas de cierre en cada una de las

líneas secundarias de todo el sistema.

■ Las columnas de agua se extiendan desde el

extremo inferior de cada línea secundaria.

■ Se haya instalado en el sistema un secador tipo

refrigerante.

■ Las mangueras de aire sean tan cortas como sea

posible.

■ Se siga un programa regular de mantenimiento.

■ Las mangueras de aire no midan más de 45.70 m

de longitud.

■ El sistema neumático sea lubricado

periódicamente.

■ Se siga un programa regular de mantenimiento.

Unidades de Filtro/Regulador/Lubricador

Las unidades de filtro/regulador/lubricador capaces

de proporcionar aire y proetección suficientes a las

herramientas Paslode deben tener las siguientes

características:

■ Tamaño mínimo del orificio a presión y tempera

tura normales de 3/8 de pulgada

■ Filtros de 50 micrones o más finos

■ Presión regulada de 0 a 120 psi

■ Lubricadores diseñados para corriente de aire

baja o variable

Instalación de Un Sistema Neumático

para Exteriores

- Asegure Que:

■ Se hayan instalado en el compresor un colector

de humedad y un filtro/regulador/lubricador.

■ Las mangueras de aire y los adaptadores tengan

la longitud suficiente para que el aire circule sin

problemas. El diámetro mínimo de una manguera

de aire es de 3/8 de pulgada y de 1/2 pulgada

para cualquier apalicación de más de 7.60 m.

7

Page 24

24

Cómo Calcular la Tubería Necesaria

Por ejemplo, si un compresor eléctrico de 20 hp

proporciona aproximadamente 80 pies³/min. de aire a

120 psi y la longitud de la línea principal es de 106.70

m, la tabla indica que el diámetro interior de la línea

principal necesario para esta aplicación debe ser de

1-1/4 pulgadas como mínimo.

Importante: Presión de Aire (80-100 psi)

Mantenimiento del Sistema Neumático

- Asegure Que:

■ Los adaptadores neumáticos estén apretados y

no haya pérdidas.

■ Las columnas de agua, o los filtros y las líneas

de aire se drenen diariamente, y que los

sistemas de drenaje automáticos funcionen

correctamente.

■ Las líneas de aire estén limpias para evitar que

se congelen, especialmente en invierno.

■ El funcionamineto del lubricador se examine

periódicamente y que el suministro de lubricante

sea adecuado (Pieza N° 403720).

■ Se limpie el filtro cada seis meses.

■ Sólo se use aire regulado y que cada regulador

funcione correctamente.

SISTEMAS NEUMATICOS (continuación)

Cómo Calcular el Tamaño del Compresor

Use la tabla de consumo de aire en el esquema de

cada herramienta para calcular los requisitos de funcionamiento de las herramientas. Las herramientas

Paslode han sido diseñadas para funcionar eficientemente entre 80 y 120 psi, y nunca se deben usar a

presiones superiores a 120 psi. La tabla de consumo

de aire le permitirá encontrar el tamaño correcto del

compresor para reponer rápidamente la presión del

aire en su herramienta.

Para usar la tabla necesita saber cuántas herramientas se usarán y aproximadamente cuántos sujetadores aplicará, por minuto, cada herramienta de la línea.

Use esta ecuación:

Número de herramientas X promedio de

sujetadores/minuto/herramienta X 1.2 (factor

de seguridad) X consumo de aire (pies³/min./

estándar) @ presión* (psi) = pies³/min./

estándar requeridos

Por ejemplo:

10 herramientas X 30 sujetadores/minuto/

herramienta X 1.2 X 0.051 pies³/min./

estándar* (@ 100 psi) = 18.36 pies³/min./

estándar.

* Esta cifra aparece en la tabla de Consumo de Aire.

Usando la tabla de consumo de aire, este ejemplo

demuestra que se necesita un compresor que proporcione 19 pies³/min./estándar de aire, por lo menos.

Como en compresores se necesita aproximadamente

1 hp para proporcionar 4 pies³/min./estándar, se requiere, por lo menos, un compresor de 5 hp.

Cómo Calcular la Tubería Necesaria

Por ejemplo, si un compresor eléctrico de 20 hp

proporciona aproximadamente 80 pies³/min. de aire a

120 psi y la longitud de la línea principal es de 106.70

m, la tabla indica que el diámetro interior de la línea

principal necesario para esta aplicación debe ser de

1-1/4 pulgadas como mínimo.

Importante: Presión de Aire (80-100 psi)

Mantenimiento del Sistema Neumático

- Asegure Que:

■ Los adaptadores neumáticos estén apretados y

no haya pérdidas.

■ Las columnas de agua, o los filtros y las líneas

de aire se drenen diariamente, y que los

sistemas de drenaje automáticos funcionen

correctamente.

■ Las líneas de aire estén limpias para evitar que

se congelen, especialmente en invierno.

■ El funcionamineto del lubricador se examine

periódicamente y que el suministro de lubricante

sea adecuado (Pieza N° 403720).

■ Se limpie el filtro cada seis meses.

■ Sólo se use aire regulado y que cada regulador

funcione correctamente.

8

Page 25

F350-P Características y Beneficios

F350-P Características y Beneficios

Facil de Mantener

Para minimizar tiempo

de Inactividad

Ajuste de Profundidad Sin

Uso de Herramienta

Proporciona control preciso

de la profundidad de clavo sin

ajustar el compresor

(sobre lado opuesto)

Diseño Ligero

Fácil de manejar con menos

cansancio del brazo.

Motor Potente

Impulsa consistentemente

en toda madera

procesada

Diseño Compacto

Puede entrar en

lugares apretados

Desvío del Seguidor de

Clavos

Para carga rápida en dos

pasos

Cierre de Disparo

Elimina disparos en

blanco

Carrillera de Carga

Trasera

Sostiene dos tiras o 84

clavos

Gancho de Vigas

Sitúa la herramienta a

mano

Contacto

Agresivo

Agarra la

madera cuando

sujeta clavos

oblicuos

P

Ajuste de Profundidad Sin

Uso de Herramienta

Proporciona control preciso

de la profundidad de clavo sin

ajustar el compresor

(sobre lado opuesto)

Contacto

Agresivo

Agarra la

madera cuando

sujeta clavos

oblicuos

Diseño Compacto

Puede entrar en

lugares apretados

P

Motor Potente

Impulsa consistentemente

en toda madera

procesada

Facil de Mantener

Para minimizar tiempo

de Inactividad

Cierre de Disparo

Elimina disparos en

blanco

Desvío del Seguidor de

Clavos

Para carga rápida en dos

pasos

Diseño Ligero

Fácil de manejar con menos

cansancio del brazo.

Gancho de Vigas

Sitúa la herramienta a

mano

Carrillera de Carga

Trasera

Sostiene dos tiras o 84

clavos

9

Page 26

Siempre use protección para oídos y equipo de segu-

ridad para los ojos, incluyendo protectores laterales

cuando este manejando o trabajando en los alred-

edores de una herramienta.

Solo opere la herramienta usando la presión de aire

recomendada. No

sobre pase la maxima presión de

aire marcada sobre la herramienta. Asegure que el

indicador de presión de aire este trabajando bien y

reviselo por lo menos dos veces al día.

Nunca use algún aire o gas embotellado tal como el

oxígeno para funcionar la herramienta ya que pueden

causar que la herramienta explote.

INSTRUCCIONES DE SEGURIDAD

USE PROTECCIÓN PARA OJOS Y OÍDOS.

NO SOBRE PASE LA MAXIMA PRESIÓN DE

AIRE RECOMEND

ADA

M

aster

Pro

™

F-350P, 515000

41

42

515003 1 End Plug

43

501299 2 S.H.C.S. 1/4-20 X 1”

44

45

502390 1 Spring, Rafter Hook

46

515005 1 Rafter Hook

47

515018 1 Bushing, Rafter Hook

▲

48

444786 1 S.H.C.S. ,1/4-20 x 5/8”

49

515002 1 Nose, 30º

50

095417 4

Lockwasher 5/16

51

009016 4 S.H.C.S. 5/16-18 x 1”

52

502014 2 Magazine Isolator

53

515016 1 Compression Spring

54

502050 1 Detent Body

55

404361 1 Roll Pin 1/8” x 1/2”

56

515004 1 Upper W.C.E.

57

515010 1 Detent Spring

58

502049 1 Detent Ball

59

502299 1 Thumbwheel

60

515006 1 Lower W.C.E.

61

515008 1 1/4-20 x 3/8”

62

515009 1 Warning Label

63

442681 2

64

502038 1

65

502029 1

Magazine Cap

66

501031 2

S.H.C.S. 8-32 x 1"

67

68

515020 1

S.H.C.S. 8-32 x 3/4”

Label, Magazine

69

502017 2 B.H.C.S. 1/4”-20 X 3/4”

**

70

502019 1 Follower Claw

72

502021 1 Lockout Bar

75

502025 1

Locknut, 1/4-20

404325 2 Locknut #8-32

71

403796 1 Roll Pin

73

511118 1 Follower Body

74

502020 1 Follower Spring

Drum Pin Assembly

77

501008 1

501009 1

76

502026 1

Lever, Bottom Trip

40

Spirol Pin

501010 1

Bump trigger

Negator Spring

501039

1

Sequential Trigger

LISTA DE PIEZAS

▲

6

■ 21

35

* Indica piezas de desgaste normal

** Asegure que la Etiqueta de Advertencia (502192) este bien

pegada. Reemplaze si es necesario.

▲

■

Aplique Loctite (Rojo) No. de Pieza 093422

•

➔

501043 1 T.H.S.C.S. 1/4 -20 x 1/2”

1

2

501016 1 Air Deflector

3

*

*

*

10

11

*

12

*13

14

15

*

16

17

18

19

*

20

*

22

*

23

24

*

25

*

26

27

*

28

*

29

30

31

32

33

*

34

*

*

36

*

37

38

39

501300 4 S.H.C.S. 1/4-20 x 1-1/4”

4

501017 1 Cap

5

500461 1 O-Ring

092042 2 O-Ring

7

500407 1 Spring, Main Valve

8

501001 1 Gasket, Cap

9

406041 1 Retaining Ring

500455 1 Upper Valve Piston

401946 1 Seal, Main Valve

091208 1 O-Ring

401950 1 O-Ring

500456 1 Lower Valve Piston

095432 1 O-Ring, Post

500454 1 Post

500453 1 Bumper, Post

402906 1 B.H.S.C.S.10-32 x 5/8"

092971 1 O-Ring, Piston

501337 1 Piston

501218 1 Driver Blade

402011 1 Seal Sleeve

501283 1 Sleeve

500249 1 O-Ring, Sleeve

092235 1 O-Ring, Sleeve

500779 1 Flange, Sleeve

501002 1 O-Ring, Midcheck

500866 1 Bumper

500729 1 Blade Seal

515017 1 Housing

515013

071297 3

401598 1

097746 1

092174 1

097748 1

402669 1

402668

1 Label, Housing Logo-Right

515012

1 Label, Housing Logo-Left

Roll Pin

Valve Body

Valve Pin

O-Ring, Valve Body