Page 1

Instruction Manual

Manual No. 012-08546A

Pulley Demonstration

System

Model No. SE-8685

Page 2

Pulley Demonstration System Model No. SE-8685

Table of Contents

Equipment List........................................................... 3

Introduction ............................................................. 4

Equipment Setup ........................................................ 5

I. Assembling the Frame................................................................................................................5

II. Sample Setup Options (Hanging Pulleys on the Frame)...........................................................5

A. Set up a Single Pulley on the Frame..................................................................................... 5

B. Set up a Double Pulley on the Frame....................................................................................6

C. Set up One or More Triple-Tandem Pulley(s) on the Frame ................................................6

D. Set up One or More Quadruple Pulley(s) on the Frame........................................................7

E. Set up a Four-Step Pulley on the Frame................................................................................7

Suggested Experiments ................................................. 8

Experiment 1: Mechanical and Force Differences between a Single and Double Pulley..............8

Experiment 2: Determining the Work/Energy of a Pulley System..............................................10

Experiment 3: Discovering the Mechanics of a Wheel and Axle (4-Step Pulley).......................11

Sample Data/Results................................................... 12

Appendix A: Specifications............................................ 13

Appendix B: Technical Support ....................................... 14

Appendix C: Copyright and Warranty Information .................. 14

2

®

Page 3

Model No. SE-8685 Pulley Demonstration System

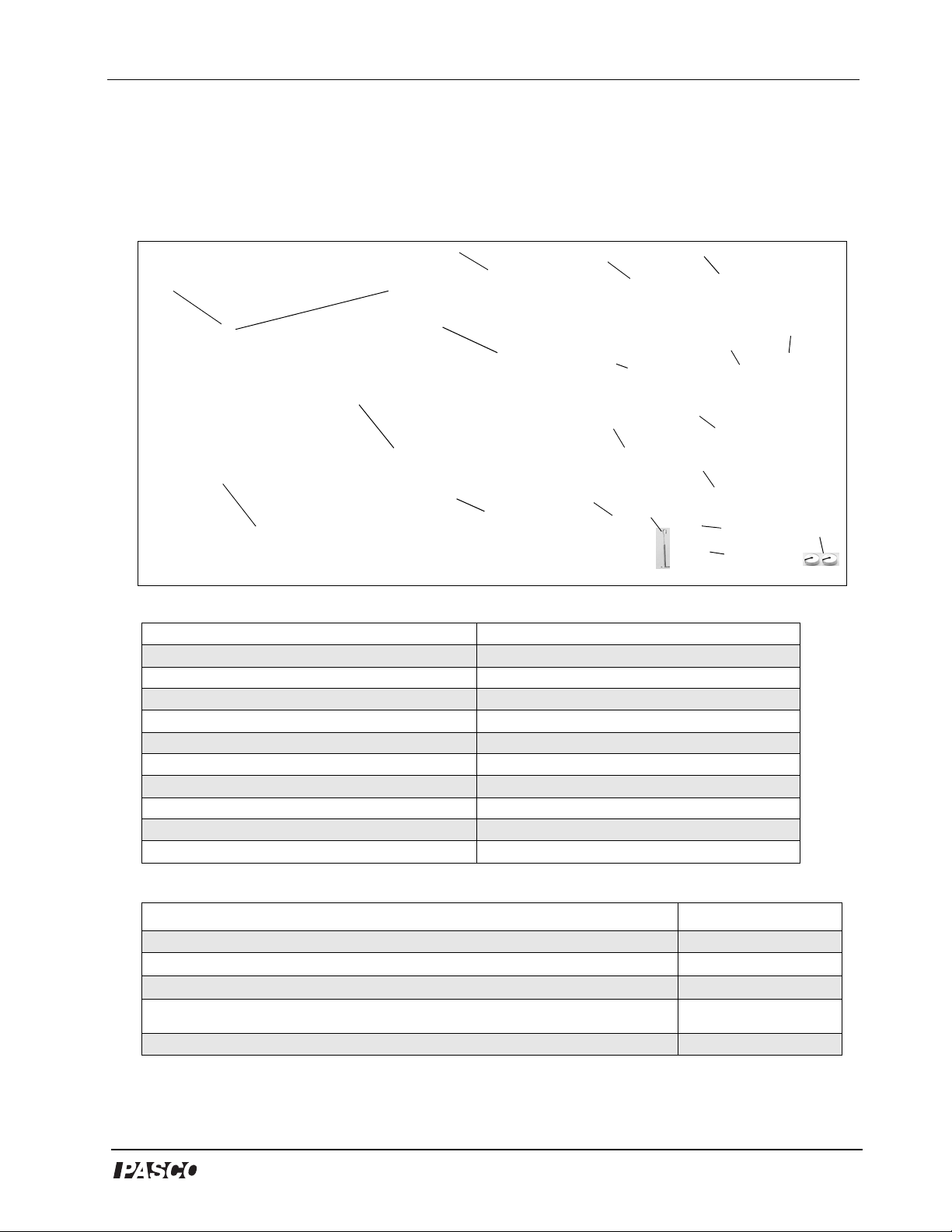

Pulley Demonstration System

Model No. SE-8685

4

3

2

1

Included Equipment

1. Base, 20 cm x 81 cm (1) 11. Slotted mass, 500 grams (1)

2. Aluminum rods, 81 cm (3) 12. Slotted mass, 200 grams (4)

3. Clamps, 90-degree angle (2) 13. Slotted mass, 100 grams (4)

4. Hook collars (8) 14. Slotted mass, 50 grams (2)

5. Single pulley (8) 15. Slotted mass, 20 grams (2)

6. Triple-tandem pulley (2) 16. Slotted mass, 10 grams (2)

7. Quadruple parallel pulley (2) 17. Slotted mass hanger, 50 grams (5)

8. Four-step differential pulley with head(1) 18. Slotted mass hanger, 20 grams (1)

9. Tightening rod (1) 19. Slotted mass hanger, 10 grams (1)

10. Nylon cord spool, 100 yards (1)

5

17

6

10

11

18

19

7

9

12

13

14

15

8

16

Additional Equipment Required

Metric Spring Scale, 20 N

Force Sensor

Rotary Motion Sens or

Any PASCO interface (

A computer

ScienceWorkshop

® or PASPORT™ interface)

Model Number

PS-2104* or CI-6746**

PS-2120* or CI-6538**

* PASCO’s PASPORT sensors (with PS- prefix) require a PASPORT interface for operation.

**PASCO’s

ScienceWorkshop

®

sensors (with CI- prefix) require a

ScienceWorkshop

interface for operation.

SE-8718

Various

(See PASCO cata log)

NA

3

Page 4

Pulley Demonstration System

Introduction

The Pulley Demonstration System (SE-8685) is designed for both the student and the teacher.

Its ease of use is suited for students learning the basics of mechanical advantage with pulley

applications. The various kinds of pulleys and accessories make it the ideal pulley

demonstration tool.

Figure 1: Pulley Demonstration System

PASCO offers a variety of sensors and equipment for measuring force, rotary motion, and

work or energy. PASCO's Metric Spring Scales (SE-8713 to SE-8718) provide an

economical way to instrument the Pulley Demonstration System for measurements of force.

For real-time data collection, and more accuracy and precision, use PASCO's Force and

Rotary Motion Sensors with a computer interface and the Pulley Demonstration System to

demonstrate work/energy theory.

4

®

Page 5

Equipment Setup

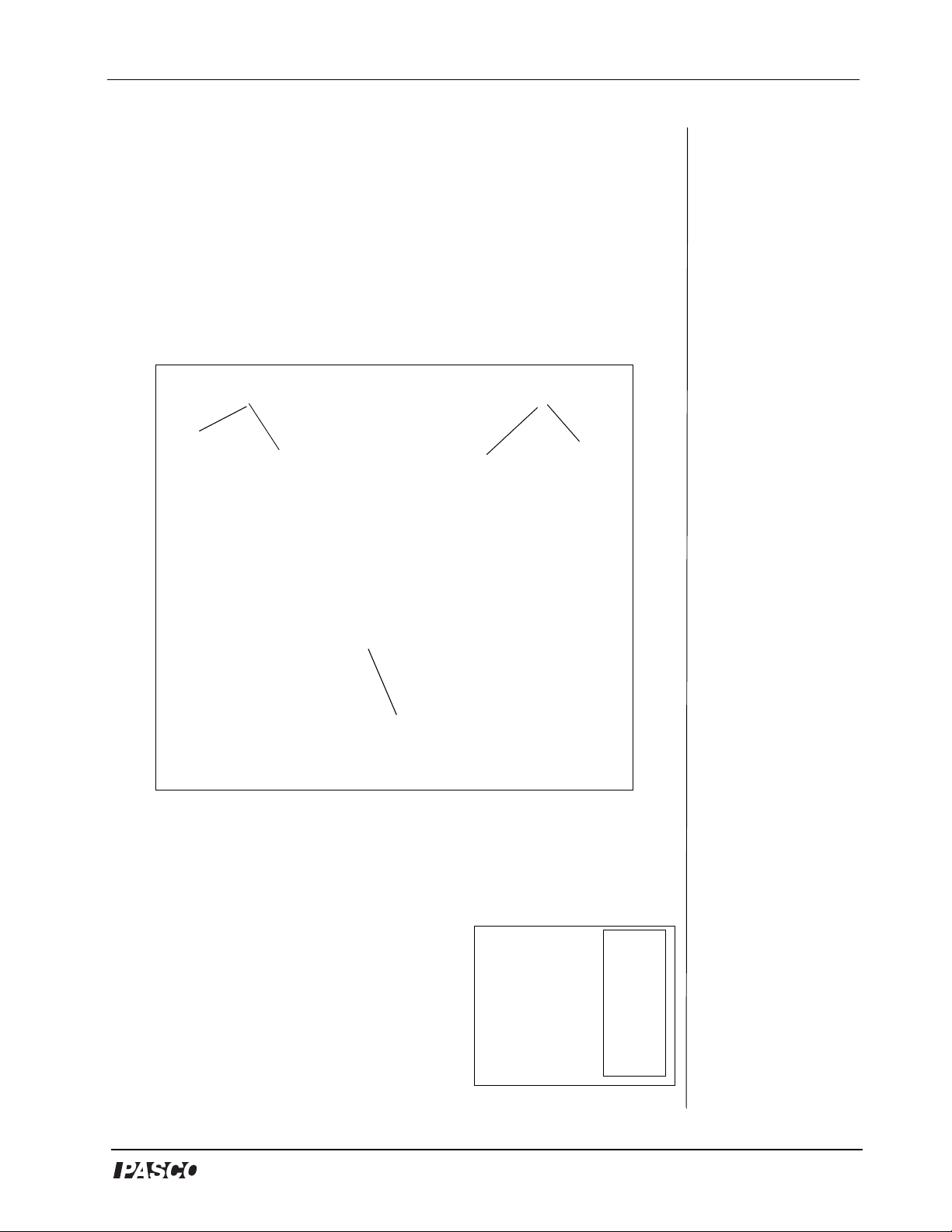

I. Assembling the Pulley Frame

a) Set the base on a sturdy, level surface. b) Thread the two support

rods to the base. c) Fasten both clamps to the top of the support rods.

d) Attach only one side of the horizontal rod to a clamp, so that one

end is free and the other is fixed. e) Slide the hook collars down the

free end of the horizontal rod. f) Secure the free end. g) Tighten the

hook collars using the top screws.

Pulley Demonstration System

Fixed end

clamp

Base

Figure 1: Assembled Frame

clamp

Free end

II.Sample Setup Options (Hanging Pulleys on the Frame

A. Set up a Single Pulley on the Frame

a) Hang the metal hook on the top of the

single pulley on the hook collar. b) Tie string

to a mass hanger and loop it up and around the

pulley. c) Add weight to the mass hanger.

[Note: The free end is for pulling and

attaching measuring devices (i.e. spring scale

or Force Sensor) to measure the force.]

®

Figure 2:

Single Pulley

5

Page 6

Pulley Demonstration System

B. Set up a Double Pulley on the Frame

a) Hang a single pulley to a hook

collar. b) Tie string to another hook

collar. c) Loop the string underneath

another single pulley. d) Attach a

mass hanger to the lower pulley's

lower hook. e) Loop the string up and

over the top pulley.

[Note: The free end is for pulling and

attaching measuring devices (i.e.

spring scale or Force Sensor) to

measure the force.]

C. Set up One or More Triple-Tandem Pulley(s) on the Frame

Figure 3: Double Pulley

Set up for one triple-tandem

pulley: a) Place a hook collar on the

frame and adjust the top screw to

tighten. b) Hang the upper metal

hook of the triple-tandem pulley onto

the hook collar. c) Loop a separate

piece of string around each ring and

hook to a mass hanger. d) Add mass.

A variety of setups can be used,

depending upon your experiment.

Figure 4a: One

Triple-Tandem

Pulley

Setup for two triple-tandems

together: a) Hang one triple-tandem

on the frame and hold a second tripletandem underneath. b) Loop the

string on the lower hook of the upper

Figure 4b: Two

Triple-Tandems

pulley and continue to string in the

following direction and sequence: i) down and around the smallest ring on

the lower pulley, ii) up and around the smallest ring on the upper pulley, iii)

down and around the medium ring on the lower pulley, iv) up and around the

medium ring on the upper pulley, v) down and around the large ring on the

lower pulley, vi) up and around the large ring on the upper pulley, vii)

Attach a mass hanger to the string hanging from the upper pulley and add

mass. viii) Hook a mass hanger to the lower pulley and add weight to

balance.

6

®

Page 7

D. Set up One or More Quadruple Pulley(s) on the Frame

Set up for one quadruple

pulley: a) Attach a hook collar

to the frame and tighten. b)

Hang the quadruple pulley on

the hook collar. c) Loop a

separate piece of string around

each ring and hook to a mass

hanger. d) Add mass. e) Use

Figure 5a:

Quadruple

pulley

the free end of the string for

pulling or attaching measuring

devices. (Note: A variety of

setups can be used, depending

upon your experiment.)

Set up for two quadruple

Figure 5b:

Setup with

two quadruple

pulleys

pulleys: For this setup, have a

lab partner available to hold

the lower pulley while you

string the pulleys. To string,

tie a knot on the hook of the upper pulley and string in the following

direction and sequence (Note: Keep all strings parallel (not crossed):

Pulley Demonstration System

i) around the outside rung of the lower pulley, ii) up and around the

outside rung of the upper pulley, iii) down and around the third rung on

the lower pulley, iv) up around the third rung on the upper pulley,

v) down and around the second rung on the lower pulley, vi) up and

around the second rung on the upper pulley, vii) down and around the

inside rung on the lower pulley, vii i) down and around the first rung on

the upper pulley, viv) Hook string from the upper pulley to a mass

hanger and add weight. x) Add weight to the lower pulley.

E. Set up a Four-Step Pulley on the Frame

a) Fasten the 90° clamp to a vertical rod. b) Attach the four-step

pulley to the 90° clamp. c) String

each rung separately. d) Add mass

hangers and masses to balance.

Figure 6a:

Setup for a

Four-Step

Pulley

®

7

Page 8

Pulley Demonstration System

Suggested Experiments/Demonstrations

Experiment 1: Mechanical and Force Differences between a

Single Pulley and Double Pulley

Equipment required (without

computer):

Pulley Demonstration System

(SE-8685)

Two Spring Scales (SE-8718) Computer Interface (1

Measuring tape (PM-8761) DataStudio software

*PASCO’s PASPORT sensors (with PS- prefix) re quire a PASPORT interf ace fo r operation .

PASCO’s

interface for operation.

ScienceWorkshop

sensors (with CI- prefix) require a

Optional equipment (for use with

computer interface):

Two Force Sensors (CI-6746) or

(PS-2104)

ScienceWorkshop

or 1-2 PASPORT)*

ScienceWorkshop

Basic Procedure:

1. Set up a double pulley and a

single pulley each with a 200 g

mass.

2. Simultaneously, pull the string

of each from the same vertical

height down to the base.

3. Observe that the mass of the

single pulley rises twice as high

as the double pulley with twice

the effort or force.

4. Optional step: Measure the force

of each pulley using either two

Newton Spring scales or two

Force Sensors (See descriptions

a) and b) that follow).

8

Figure 1.1: Single pulley vs.

double pulley

®

Page 9

a) Measure the Pulley Force with the Newton Spring Scale

Pulley Demonstration System

Attach Newton spring scales to

spring

scale

the string on each pulley and

quantitatively discover that the

force exerted for the double

pulley decreases by a factor of

2, while the amount of string

that is pulled increases by the

same factor. Prove that the

number of pulleys relates to

this factor. Show students that

increasing the number of

pulleys increases the mechanical advantage. Discuss the fact

that the amount of work done

is the same in either pulley.

b) Measure the Pulley Force with a Force Sensor and a Computer Interface

Figure 1.2: Measuring the force

with spring scales

Instead of Newton Spring Scales, use two PASCO Force Sensors

to observe real-time force changes in DataStudio software.

1. Connect each Force Sensor to a computer interface (ScienceWorkshop or

PASPORT).

Figure 1.3: Connecting the Force Senso r to a PASPORT

interface and to a computer

2. Hang one Force Sensor from the single

pulley and the other Force Sensor from the

double pulley . (To hang, screw a hook to the

top of the Force Sensor and tie the hanging

string through the hook.)

Figure 1.4:

Pulling on

the Force

Sensor

3. In DataStudio, open a graph display and

click the Start button to collect data. As you

pull down on each pulley, force data for

both pulleys will appear in the display.

®

9

Page 10

Pulley Demonstration System

Experiment 2: Determining the Work/Energy of a Pulley System

Equipment required:

Pulley Demonstration System (SE-

8685)

Force Sensor (CI-6746 or PS-2104) Computer Interface (1

DataStudio software

*PASCO’s PASPORT sensors (with PS- prefix) re quire a PASPORT interf ace fo r operation .

PASCO’s

interface for operation.

ScienceWorkshop

sensors (with CI- prefix) require a

Rotary Motion Sensor (CI-6538 or PS-

2120)

ScienceWorkshop

or 1-2 PASPORT)*

ScienceWorkshop

Students can quantitatively find the work done on a pulley system by using

PASCO's Rotary Motion Sensor simultaneously with a Force Sensor.

1. Attach a hook collar and

clamp a Rotary Motion

Sensor to the horizontal

rod.

2. Tie one end of string to

the hook collar and loop

the string underneath a

pulley. Hang a mass

from this pulley.

Figure 2.1

3. Loop the remaining

string around the inside

groove of the Rotary

Figure 2.1-3: Setup

for Experiment 2

Figure 2.2

Motion Sensor.

Figure 2.3

4. Tie the other end of the

string to the Force Sensor.

5. In DataStudio, click the Start button and pull on the Force Sensor. The

work done can be calculated by finding the area in a Force versus Position

graph.

Alternatively , students can compare the work done on just one pulley. Hang

the same mass from just the Rotary Motion Sensor. Pull the Force Sensor

until the work done is the same as with two pulleys. Students will find that

the force applied doubles while the distance pulled is decreased by half.

10

Note: T o cr eate a For ce

vs. Position graph: In

DataStudio’s Experiment

Setup window , go to the

Rotary Motion Sensor and

click the Linear Position

option. From the Data

list, drag the position icon

over the x-axis in the

Graph display.

®

Page 11

Pulley Demonstration System

Experiment 3: Discovering the Mechanics of a Wheel and Axle

(4-Step Pulley)

Equipment required:

Pulley Demonst ration System

(SE-8685)

Calipers (SF-8711) or measuring

tape (PM-8761)

1. Have students measure the diameters of the grooves of the pulley. (If

calipers or a meauring tape is not available, see the Specifications in

Appendix A.)

2. Loop string counterclockwise

around the smallest groove of

the 4-step pulley until there is

enough friction for the string to

support a large mass.

3. Choose one of the other

grooves and loop enough

string clockwise until it can

support some mass.

4. Have the students experiment

with the amount of mass that

balances the system.

5. Ask students to calculate the

ratio between the masses and

compare this value to the ratio

of the diameters of the

grooves. Students should find

Figure 3: Setup with Wheel and

Axle

that the ratio of the diameters

of the grooves is identical to the ratio of the masses.

®

11

Page 12

Pulley Demonstration System

Sample Data/Results

Experiment 1 Results: Mechanical Force Differences in Single Pulley vs.

Double Pulley

Force for single pulley

Force for double pulley

Experiment 2 Results:Measuring the Work/Energy of a Pulley System

Work for one pulley

Work for two pulleys

Experiment 3 Results: Discovering the Mechanics of a Wheel and Axle (4Step Pulley)

Groove 1: diameter = 2.0 cm; mass = 10 g

Groove 4: diameter = 6.0 cm; mass = 30 g

Ratios: diameters=1/3; masses=1/3

12

®

Page 13

Appendix A: Specifications

Pulleys Specifications:

Single pulley: circumference: 15.4 cm; diameter: 4.9 cm

Triple-tandem pulley: small pulley: circumference: 7.9 cm ;

diameter: 2.5 cm

medium pulley: circumference: 11.6 cm;

diameter: 3.7 cm

large pulley: circumference: 15.4 cm;

diameter: 4.9 cm

Quadruple pulley: pulley circumference: 15.4 cm;

diameter: 4.9 cm

Four-step pulley: step 1 groove: 6.28 cm circumference;

2.0 cm diameter

step 2 groove: 9.42 cm circumference;

3.0 cm diameter

step 3 groove: 12.56 circumference;

4.0 cm diameter

step 4 groove: 18.84 circumference:

6.0 cm diameter

Pulley Demonstration System

Slotted masses: 10 g, 20 g, 50 g, 100 g, 200 g, 500 g

®

13

Page 14

Pulley Demonstration System

Appendix B: Technical Support

For assistance with the SE-8685 or any other PASC O products, contact

PASCO as follows:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

Web: www.pasco.com

Email: techsupp@pasco.com

Appendix C: Copyright and Warranty Information

Copyright Notice

The PASCO scientific 012-08546A Pulley Demonstration System Manual is copyrighted and

all rights reserved. However, permission is granted to non-profit educational institutions for

reproduction of any part of the 012-08546A Pulley Demonstration System Manual, providing

the reproductions are used only for their laboratories and are not sold for profit. Reproduction

under any other circumstances, without the written consent of PASCO scientific, is

prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from defects in materials and workmanship

for a period of one year from the date of shipment to the customer. PASCO will repair or

replace, at its option, any part of the product which is deemed to be defective in material or

workmanship. The warranty does not cover damage to the product caused by abuse or

improper use. Determination of whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the equipment for return shipment will not

be covered by the warranty.) Shipping costs for returning the equipment after repair will be

paid by PASCO scientific.

14

®

Loading...

Loading...