Page 1

Includes

Teacher's Notes

and

Typical

Experiment Results

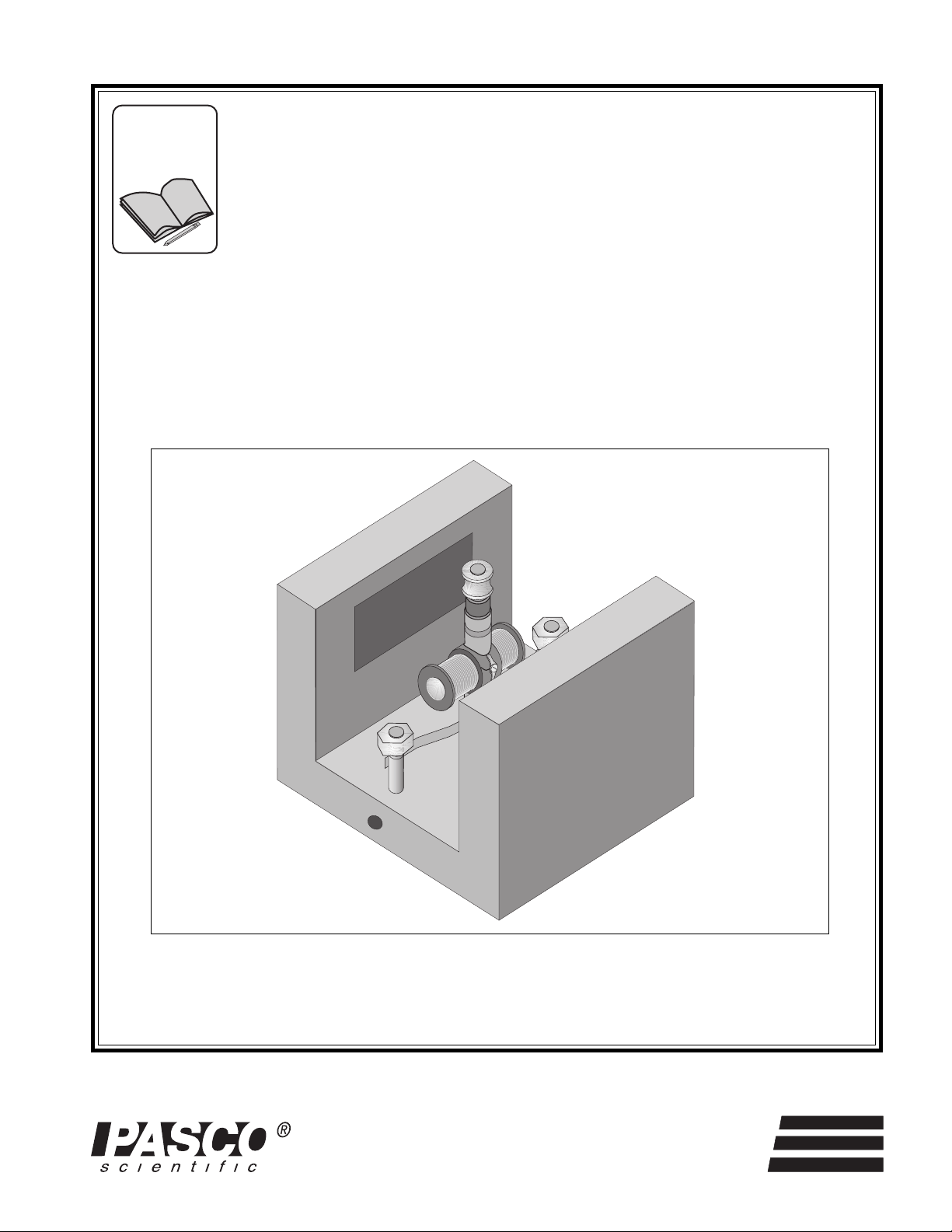

PERMANENT MAGNET

Instruction Manual and

Experiment Guide for the

PASCO scientific

Model SE-8658A

MOTOR

012-07210A

8/99

© 1999 PASCO scientific $5.00

better

10101 Foothills Blvd. • P.O. Box 619011 • Roseville, CA 95678-9011 USA

Phone (916) 786-3800 • FAX (916) 786-8905 • email: techsupp@PASCO.com

ways to

teach science

Page 2

The exclamation point within an equilateral

triangle is intended to alert the user of

important operating and safety instructions

that will help prevent damage to the

equipment or injury to the user.

Page 3

012-07210 A Permanent Magnet Motor

Table of Contents

Section ...................................................................................................... Page

Copyright and Warranty, Equipment Return ................................................. ii

Introduction .....................................................................................................1

Equipment ....................................................................................................... 1

Table 1. Equipment Options for Experiments 1 – 3 ....................................... 2

Operation .........................................................................................................3

Assembly—Permanent Magnet Motor ........................................................... 4

Suggested Uses ................................................................................................5

Experiment 1: Operation of the DC Motor ....................................................7

Experiment 2: Operation of AC and DC Generators ................................... 13

Experiment 3: Operation of an AC Synchronous Motor ............................. 19

Teacher’s Guide ............................................................................................ 25

Technical Support ........................................................................... back cover

®

i

Page 4

Permanent Magnet Motor 012-07210A

Copyright, Warranty, and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Permanent Magnet Motor

manual (012-07210A) is copyrighted and all rights

reserved. However, permission is granted to non-profit

educational institutions for reproduction of any part of

the manual providing the reproductions are used only

for their laboratories and are not sold for profit.

Reproduction under any other circumstances without

the written consent of copyright holders is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

PASCO will repair or replace at its option any part of

the product which is deemed to be defective in material

or workmanship. The warranty does not cover damage

to the product caused by abuse or improper use.

Determination of whether a product failure is the result

of a manufacturing defect or improper use by the

customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty

repair belongs to the customer. Equipment must be

properly packed to prevent damage and shipped

postage or freight prepaid. (Damage caused by

improper packing of the equipment for return shipment

will not be covered by the warranty.) Shipping costs

for returning the equipment after repair will be paid by

PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units must be

packed properly. Carriers will not accept responsibility

for damage caused by improper packing. To be certain

the unit will not be damaged in shipment, observe the

following rules:

1. The packing carton must be strong enough for the

item shipped.

2. Make certain there are at least two inches of

packing material between any point on the apparatus

and the inside walls of the carton.

3. Make certain that the packing material cannot shift

in the box or become compressed, allowing the

instrument come in contact with the packing carton.

Address: PASCO scientific

10101 Foothills Blvd.

P.O. Box 619011

Roseville, CA 95678-9011

Credits

Author: Jim Housley

Editor: Sunny Bishop

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

®

Page 5

012-07210A Permanent Magnet Motor

Introduction

The PASCO SE-8658A Permanent Magnet Motor

operates on AC or DC current, and it can be used to

generate alternating or direct current.

Students can not only explore properties of AC and DC

generators with this apparatus, they can also discover

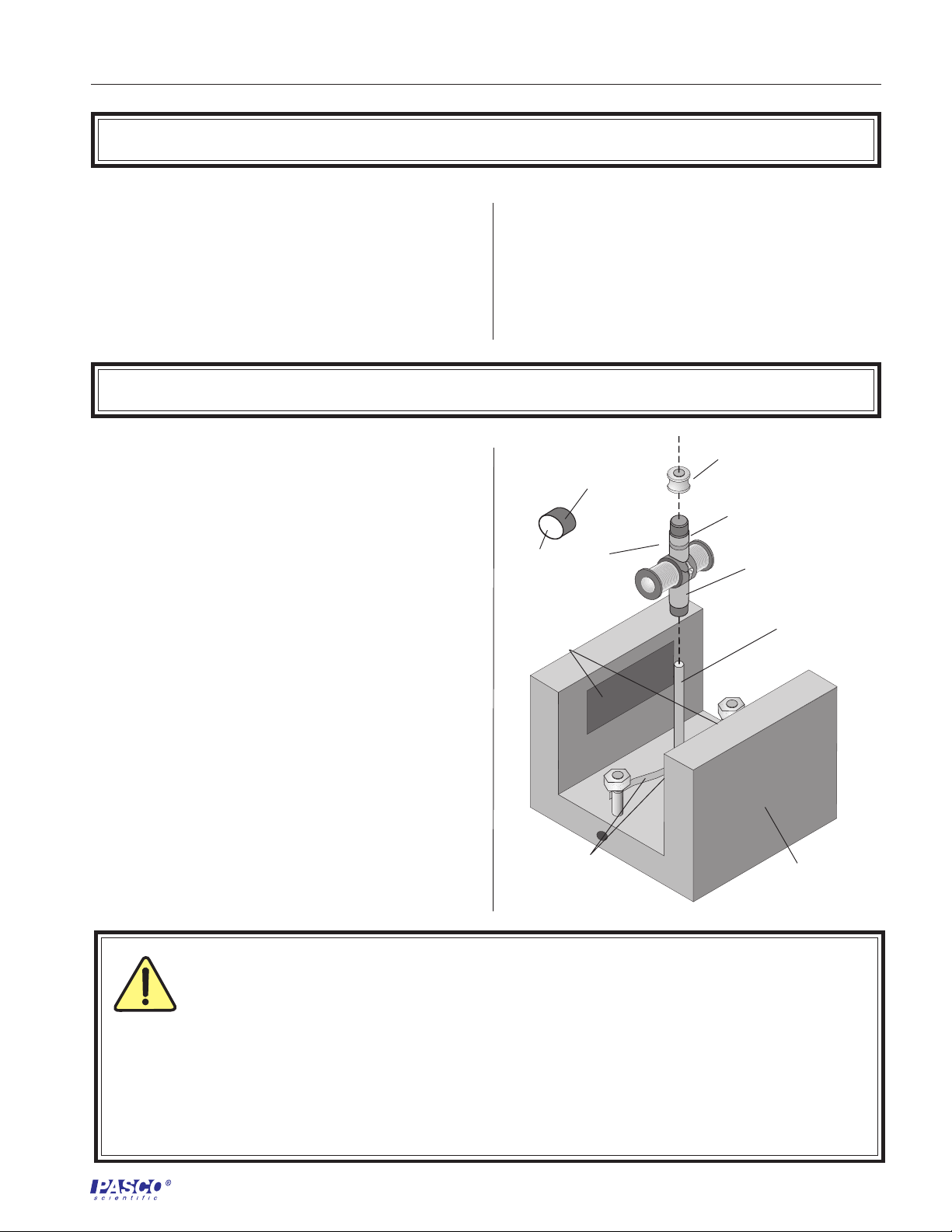

Equipment

The Permanent Magnet Motor includes

- armature with split ring commutator at one end

and a dual slip-ring commutator at the other

- field magnet, shaft and brush assembly

- maintenance items

- manual

- ceramic magnet

key concepts and relationships concerning motors and

electric current, using the Permanent Magnet Motor in

conjunction with an AC or DC power supply and

sensors for voltage, current, and rotational speed.

retaining nut

dual slip-ring

commutator

split ring

commutator

shaft

N

field

magnets

ceramic

magnet

armature

Safety precautions

brushes

shaft and

field

magnet

assembly

- Always wear safety goggles when in a room where the Permanent Magnet Motor is being used.

- Keep fingers and other objects away from the spinning armature.

- Choose power sources that limit current to not more than one ampere (1.0 A). The motor may overheat if

this current is exceeded or if power is applied continuously, especially if the armature is not rotating. The

motor is intended only for intermittent operation.

- Disconnect any power source whenever the motor is to be left unattended.

1

Page 6

Permanent Magnet Motor 012-07210A

➤ NOTE: Although the instructions for experiments in this manual are for mechanical setups with

specific PASCO equipment, the experiments in this manual may be set up in a variety of ways,

depending upon the equipment you have available. They can all be done with or without the PASCO

Science

Workshop computer interface. Table 1 lists the equipment suggested for optional experimental

setups. You may be able to substitute other equipment for the PASCO models listed in this table.

Table 1. Equipment Options for Experiments 1– 3

Experiment:

Experiment 1: DC Motor

no computer interface x x x

no computer interface x x x or x

computer interface x x x x x x

computer interface x x x or x

Experiment 2: AC/DC Generator

no computer interface x x x

computer interface x x x x or x

Experiment 3: Synchronous AC Motor

no computer interface x x x x or x

computer interface x x x x x x

Equipment:

Permanent Magnet Motor (SE-8658A)

Variable Gap Magnet (EM-8641)

Low Voltage DC Power Supply (SE-9712, 9720, or equiv.*)

Low Voltage AC/DC Power Supply (SF-9584A)

Power Amplifier (CI-6552A)

Digital Function Generator (PI-9587C)

Multimeter (SB-9623) or Ammeter (SF-9569)

Galvanometer (SF-9500) or Multimeter (SB-9623)

Voltage Sensor (CI-6503)

Science Workshop Interface (300 or 500)

Science Workshop Interface (700 or 750)

Digital Photogate Timer (SF-9215A)

Digital Stroboscope (SF-9211)

computer interface x x x x or x x

* If your power supply does not have the capability to quantify output current, you can

measure it using an ammeter. Be sure to limit the current to 1 A max. to avoid damaging

the equipment. The value can also be calculated from the voltage drop across a small value

series resistor. This option prevents damage to a potentially sensitive ammeter.

2

Page 7

012-07210A Permanent Magnet Motor

Operation

Options for electrical connections

• Banana-style plugs may be inserted into openings in

the base of the motor.

• Large alligator clips may be attached to the brass

posts that hold the brushes.

• Small alligator clips may be attached directly to the

ends of the brushes where they protrude from the

slits in the brass posts.

Power Sources Warnings

It is important to limit the current of the

power source to 1.0 A to avoid damaging

the coils of the armature. This may be

done by:

• Choosing a power supply that may be

set to limit the current to a maximum

value of 1.0 (See Table 1 for specific

suggestions for power sources);

• Using a PASCO CI-6552A Power

Amplifier, which automatically limits

current to 1.0 A;

• Carefully monitoring current with:

- The power supply’s built-in current

meter, or

- Science Workshop and the CI-6556

Current Sensor, or

- A voltmeter or multimeter, by

measuring the voltage drop across a

low-value series resistor (such as 0.51

ohm, 1 watt), and calculating the

current.

For power supplies that do not have the

capability to measure output voltage, use

a multimeter or voltmeter to insure that

the current does not exceed 1.0 A. (See

Table 1 for specific suggestions for power

sources.)

Starting the motor

• The motor is not self-starting. Immediately after

you apply the power, start the motor manually by

grasping the black plastic bushing at the top of the

armature assembly between your thumb and

forefinger and spinning the armature.

• With the Permanent Magnet Motor configured as

either a DC or universal motor, almost any

attempt you make at spinning the armature will

result in successfully starting the motor; only the

direction of the spin is important.

• When configured in an AC synchronous mode,

the motor must be spun at a speed that

approximately matches the frequency of the

power source. This is impractical at frequencies

much above 30 Hz, and some students may

require assistance even a lower frequencies.

Maintenance and Storage

• The motor may be stored in the plastic bag

furnished; this will keep it dust free and reduce

problems of corrosion that may occur in areas

having high humidity.

• The commutators and brushes will experience

wear, oxidation, and pitting and will require

attention from time to time. Rotate the armature

slowly by hand and monitor current flow or

sense the force developed to determine whether

proper contact is occurring between brushes and

commutator. To restore proper operation, clean

the contacts with emery paper or shift the

brushes somewhat to expose new surfaces.

• Careless installation of the armature onto the

shaft might bend the brushes. You can easily

bend them back into their original shape with

finger pressure.

➤ NOTE: If you are using a PASCO

CI-6502A Power Amplifier with a

CI-6500 Interface System, the distorted

waveform light will turn on during

operation of the motor, but no damage is

being done to the Power Amplifier; you

can ignore the light.

3

Page 8

Permanent Magnet Motor 012-07210A

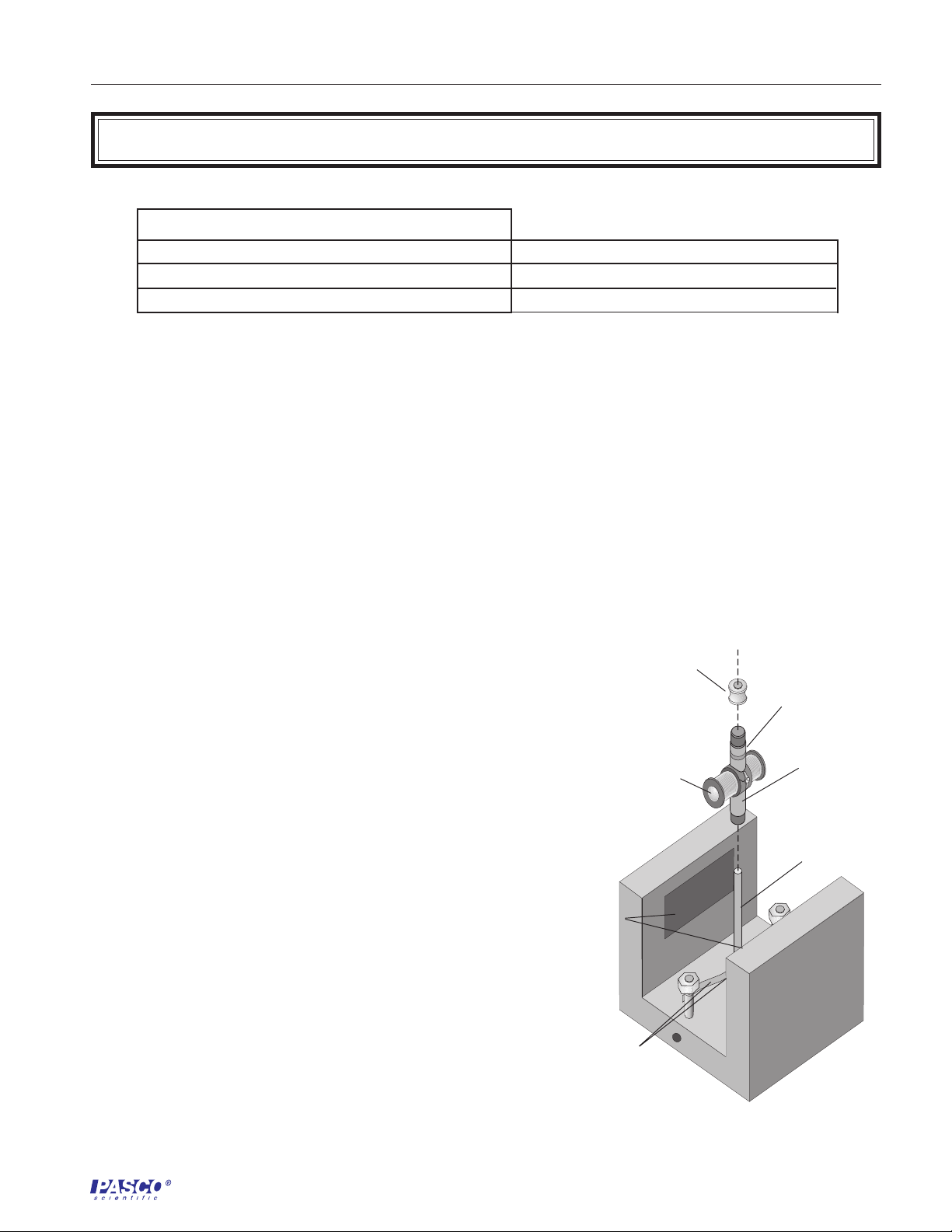

Initial Assembly

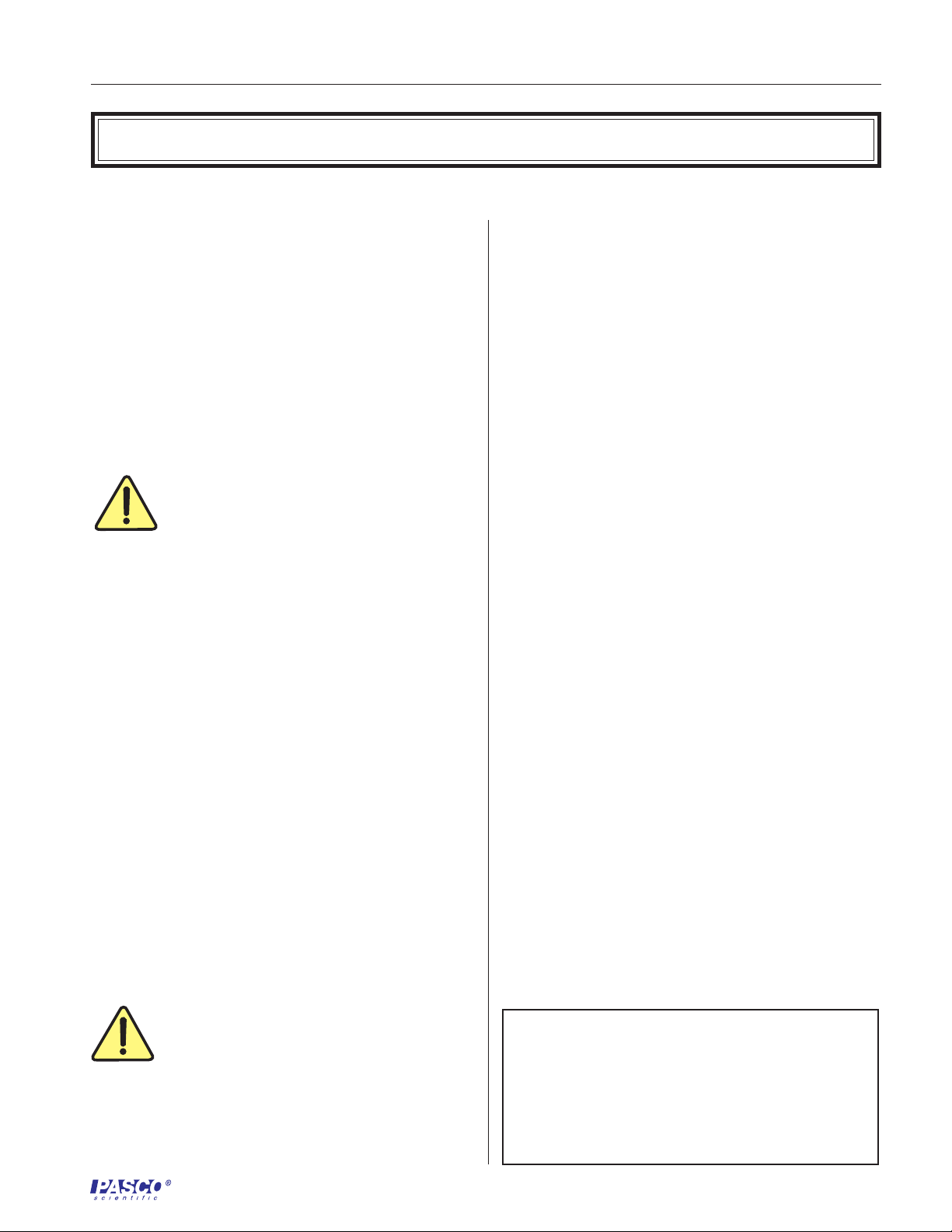

Initial Assembly of Permanent Magnet

Motor

1. Locate the part shown in the diagram below.

retaining nut

dual slip-ring

commutator

(this end down for

AC motor)

split ring

armature

field

magnets

commutator

(this end down

for DC motor)

shaft

2. Gently lower the armature onto the shaft. To make

a DC motor, the split ring commutator should be

down; for an AC motor, the dual slip-ring

commutator should be down. Carefully rotate the

armature back and forth to separate the brushes and

allow the commutator to slip down between them.

If necessary, insert a pencil or similar object down

between the brushes. Use only the most delicate

force to avoid bending the brushes and necessitating

adjustments or repairs. Screw retaining nut onto

shaft.

3. Refer to the instructions included in experiments 1–

3 for details of the electrical connections.

➤ The motor may be left assembled for storage.

brushes

Figure 1

Permanent Magnet Motor Assembly

4

Page 9

012-07210A Permanent Magnet Motor

Suggested Uses

Operation as a DC motor

The Permanent Magnet Motor can be used to

demonstrate the operation of a DC motor ( Experiment

1). Students can explore relationships between motor

speed and voltage, as well as between direction of

armature rotation and polarity, learning key concepts

including: action of the split ring commutator,

dependence of speed on voltage, dependence of

direction of rotation on polarity, right-hand rule, and

direction of current flow from positive to negative.

Action of AC and DC generators

Spinning the armature by hand while it is connected to

a sensitive DC meter or to the Signal Interface II shows

the action of an AC generator, as well as the rectifying

action of the commutator in a DC generator

(Experiment 2).

Operation of a synchronous AC motor

Coupled with an AC signal supplied by the PASCO

PI-9587C Digital Function Generator/Amplifier,

Science Workshop 700 or 750 Interface and CI-6552A

Power Amplifier, or a similar function generator, the

Permanent Magnet Motor will operate in sync with 15

to 30 Hz (and often wider range) signals (Experiment

3). Students can explore the relationship between AC

voltage and motor speed, as well as between AC

current frequency and motor speed. They can conduct

detailed explorations of the precision of synchronism

of AC current and motor speed with a PASCO SF-9211

Digital Stroboscope or PASCO ME-9215A Digital

Photogate Timer with memory or by observing the

stroboscopic effect of an ordinary fluorescent lamp at

selected motor speeds. As a result, they learn key

concepts, including the independence of AC motor

speed and voltage, dependence of AC motor speed on

current frequency, and action of a dual slip-ring

commutator.

Additional possibilities

The Permanent Magnet Motor can be used to

determine the speeds of maximum power and

maximum efficiency of a DC motor by varying the load

while simultaneously measuring the speed, torque, and

armature current. In this experiment, you can measure

the motor’s speed with a photogate or stroboscope.

5

Page 10

Permanent Magnet Motor 012-07210A

6

Page 11

012-07210A Permanent Magnet Motor

Experiment 1: Operation of the DC Motor

EQUIPMENT NEEDED:

•Permanent Magnet Motor

• low voltage DC power supply, limited to 1 A • patch cords

• multimeter • small piece of masking tape

Purpose

The purpose of this experiment is to demonstrate the operation of the DC motor in terms of basic

concepts of electromagnetism.

Theory

The field magnets are permanent magnets possessing a north pole and a south pole that interact

with the north and south poles of the armature (an electromagnet when connected to an electric

current). Like poles repel, while unlike poles attract. The armature rotates until its north pole is

as close as possible to the south pole of the permanent magnet (and also as far as possible from

the north pole). Inertia carries the armature past this point. However, as the armature passes this

point, the commutator reverses the direction in the coils, so that the poles of the coils are suddenly

repelled by the nearby field magnets. Thus another half-turn occurs, and this process occurs again

and again.

Setup

A better explanation involves an understanding of fields.

The field magnets produce a magnetic field that passes

through the gap between the pole pieces. When current

passes through the turns of the armature in the presence

of the field, forces act to cause a torque that rotates the

armature. Inertia carries the armature past the position

of no torque to the point where the torque would force

the armature back in the other direction. However, at that

point the commutator reverses the direction of current in

the armature so the torque continues to act in the original

direction.

1. Gently lower the armature onto the shaft with the

split ring commutator down (Figure 1.1). Carefully

rotate the armature back and forth to separate the

brushes and allow the commutator to slip down

between them. If necessary, insert a pencil or similar

object down between the brushes. Use only the most

delicate force to avoid bending the brushes and

necessitating adjustments or repairs.

2. Connect the motor to the power source by one of

these methods ( Figure 1.2):

• Insert banana plugs into the openings in the

ends of the plastic brush older; or

retaining nut

dual slip-ring

commutator

armature

field

magnets

brushes

Figure 1.1

Assembly of the Permanent Magnet Motor

split ring

commutator

shaft

7

Page 12

Permanent Magnet Motor 012-07210A

• Grip the brass posts of the

brush holder with large

alligator clips;

or

• Attach small alligator clips to

the ends of the brass strips that

serve as brushes.

Adjust the power source to deliver 6 volts of

DC current limited to 1.0 amp. (Have your

teacher show you how if you don’t know.)

METER

PUSH FOR

CURRENT

PASCO scientific

MODEL SF-9584 LOW VOLTAGE AC/DC POWER SUPPLY

0 - 24 VOLTS DC OUTPUT

DC VOLTAGE

8 AMP MAX

DC CURENT

ADJUST

12

10

8

14

6

16

18

4

ON

AC VOLTAGE ADJUST

ADJUST

2

24

2 - 24 VOLTS AC OUTPUT

6 AMP MAX

20

22

OFF

RESET

➤ Do not turn the power on.

Procedure—Part A

1. Rotate the armature and observe how the

segments of the split ring commutator contact

Figure 1.2.

Experimental Setup

wire connected to + terminal of power supply

the brushes as the armature turns.

2. Remove the armature from the shaft by grasping it between your thumb and forefinger and rotating

it back and forth while lifting gently. If necessary, insert a pencil between the brushes to gently

separate them to remove the armature.

3. Examine the armature closely and imagine current entering one of the split rings from a brush.

Trace the path of the current through the wire to the coil, through the coil, through the wire to the

coil on the opposite side of the armature, through that coil, and through the wire to the other split

ring and into the second brush. By carefully examining the part of

the coils where the wire emerges from the coil, you can determine

the direction in which the wire is wound on the coil (Figure 1.3).

4. Holding the armature in one hand, imagine that the brush from the

+ lead is touching one of the split rings of the commutator.

Follow the wire from the split ring to the right coil of the armature

and note the direction the wire is wound in the coil. Note where

the wire enters the coil and where it exits.

5. Use the right-hand rule to determine the direction the magnetic

field will flow when you turn on the power: Grasp the coil with

your fingers wrapped around the coil in the direction of the current

(Figure 4). (Current direction is described by convention as being

from the positive to the negative lead. Note that this is opposite of

the direction of electron movement. — See note on page 10. Your

thumb will point in the direction of the field — that is, toward the

north pole of the coil.) Put a small piece of tape on the end of the

armature that will be its north pole when you turn on the power.

Figure 1.3

Direction of the Wire Winding on

the Coil

6. Follow the wire over to the left coil. Use the right-hand rule to

find the direction of the north pole.

Record your observations on Figure 1.4.

a) In this situation, is the direction of the north pole the same for the right and left coils?

b) Both coils surround a single iron core on the armature, and each coil is capable of temporarily

magnetizing the core when electric current is running through it. Do the actions of the two

coils add to create a greater effect or cancel to create a reduced effect? (Consider your answer

to 6a above.)

8

Page 13

012-07210A Permanent Magnet Motor

Draw arrows indicating the direction

of current flow.

direction of wire

Indicate whether north (N) or south (S).

N

wrapping on the coil

When you wrap

your fingers in the

direction of the

current flow in a

coil, your thumb

points towards the

north pole of the

magnetic field.

+

+

wire connected to the +

terminal of the power

supply

Figure 1.4

Determining the Direction of the Magnetic Field of the Coil Using the Right-Hand Rule

➤ Note: Here’s why the direction of conventional current is opposite to that of the

direction of electron flow: In the mid-eighteenth century, Benjamin Franklin suggested the

terms positive and negative, and conjectured that electrical current was the movement of

positive “fluid” from positive to negative regions. Although he understood that it was

equally possible that a negative fluid moves from negative to positive, there was no way to

resolve the issue for more than a century. By convention , scientists agreed to describe the

direction of current as being from positive to negative. Not until 1879 did Edwin H. Hall

show that in metals the current was a negative “fluid.” It remained for J. J. Thompson, R.

A. Millikan, and others to demonstrate the existence of electrons, which are the charge

carriers of this “fluid”. This might seem an argument for changing the convention. But

current doesn’t always travel in metals. In ionized gasses, current consists of electrons

traveling in one direction with positive ions moving simultaneously in the opposite

direction. In solutions, current consists of oppositely charged ions traveling in opposing

directions. And in certain semiconductors positive “holes” are the charge carriers.

Considering this complexity, scientists have found it most useful to continue the

convention begun by Franklin: the “direction” of current is from positive to negative.

9

Page 14

Permanent Magnet Motor 012-07210A

7. Turn the armature over 180° and imagine that the brush attached to the + lead is contacting the other

split ring of the commutator. Note the path of the wire from where it is attached to the split ring to

where it enters and exits from the coil on the right side of the armature. Imagine a current running

through the wire and use the right-hand rule to determine the direction the magnetic field would

flow. Is the north pole on the same end of the coil as it was in step 5?

8. Follow the wire over to the left coil. Use the right-hand rule to find the direction of the north pole.

a) In this situation, is the direction of the north pole the same for the right and left coils?

b) True or False? When the electric current is on, the two coils become electromagnets with

magnetic fields oriented in the same direction, which turns the armature into a single

electromagnet with its force oriented towards that same direction.

c) True or False? In the DC motor, you cannot determine the direction of the magnetic field of

the armature by determining the direction of the north pole of either of the two coils.

d) What happens to the location of the armature’s north pole as the brush attached to the + lead

touches the different sides of the split ring commutator?

e) Explain why the current in the armature is alternating, despite the fact that the motor is supplied

with direct current. (Hint: think about your answer to 8d.)

9. Gently replace the armature onto the shaft with the split ring commutator pointing down. Carefully

rotate the armature back and forth to separate the brushes and allow the commutator to slip down

between them. If necessary, insert a pencil or similar object between the brushes to separate them.

Use only the most delicate force to avoid bending the brushes and necessitating adjustment or

repairs.

10

Page 15

012-07210A Permanent Magnet Motor

Procedure—Part B

1. Turn on the power. Adjust the output voltage to 6 volts.

2. Use the small cylindrical ceramic magnet to check your predictions from steps 5 and 6 above.

The painted face of the magnet is its North Pole (north-seeking pole). [You can verify this by

hanging the magnet from a thread and observing that the painted face points toward the North

(toward the earth’s north magnetic pole, located in northern Canada).] With the armature and

power supply leads oriented as in Figure 1.2 and the power turned on, hold the ceramic magnet

near the ends of the armature. If both poles of the ceramic magnet attract the armature, the pole

with the stronger attraction will be the opposite pole.

➤If the motor does not start in either direction, turn off the power and ask your

teacher for help.

a) Does the result of this test agree with your predictions in steps 5 and 6?

b) Label each end of the armature in Figure 1.2 according to whether it is the north or south

pole of the electromagnet.

c) Determine the polarity of the Permanent Magnet Motor in the same way. Label its poles

“N” and “S” in Figure 1.4.

3. Predict the direction the armature will rotate when you release it from the position of Figure 1.4.

Will the motor rotate clockwise or counterclockwise?

If the motor does not start up immediately, try turning it by hand in the predicted direction. If

that fails, try turning it in the opposite direction.

4. Turn off the power and reverse the positive and negative leads to the motor. Before turning the

power on, predict the direction of rotation.

a) Will the motor rotate clockwise or counterclockwise?

Turn the power back on and immediately try spinning the motor to start it. If it doesn’t start, try

spinning it in the other direction.

b) Explain why the armature turns when you turn on the power.

11

Page 16

Permanent Magnet Motor 012-07210A

5. While the motor is running, raise the voltage to approximately 8 volts.

a) What happens to the motor’s rotational speed when you raise the voltage?

b) Does the motor’s rotational speed depend on the voltage of the DC current?

12

Page 17

012-07210A Permanent Magnet Motor

Experiment 2: Operation of AC and DC Generators

EQUIPMENT NEEDED OPTIONAL EQUIPMENT

• Permanent Magnet Motor • Voltage Sensor

• multimeter or galvanometer • computer interface

• patch cords • small strips of masking tape

Purpose

The purpose of this experiment is to detail the operation of an AC generator and a DC generator

in terms of basic concepts of electromagnetism.

Theory

Motors and generators may be regarded as devices that convert energy from one form to another

(e.g., transducers). A motor converts electrical energy into mechanical energy. Many designs of

motors work as generators as well: when mechanical energy is input by spinning the shaft,

electrical energy is produced. More than one line of reasoning may be used to predict the

magnitude and direction of the electrical current that is produced. At the most fundamental

level, electrical charges moving across a magnetic field experience a force that is at right angles

to both the direction of motion and the direction of the magnetic field, according to the vector

equation:

F=qv x B

Conductors, of course, contain charges, and moving a conductor sideways across a magnetic

field exerts a force on the charges that make the charges flow the length of the conductor if it is

part of a circuit. The force on the charges can be seen from the equation to be proportional to

both the speed and the strength of the magnetic field.

From this reasoning you can derive Faraday’s law of electromagnetic induction, which states

that a change in the magnetic flux linking a closed circuit will result in an electromotive force (or

electric current) in the circuit that is instantaneously proportional to the time rate of change of

the linking flux; however, it is easier to understand Faraday’s law by observing the action of a

generator. In a generator, an electromotive force (emf) that is proportional to the rate of change

is induced in a loop of wire that is in a field of changing magnetic flux. (The coils of the

armature may be thought of as many loops connected in series.)

Surprisingly, the direction of induced current can be determined from the law of conservation of

energy: due simply to friction, work must be done to rotate a generator. If the generator is

connected to a load and producing electric current, additional work must be done to turn the

shaft. This reasoning led to Lenz’s law: the induced current is in such a direction as to produce a

magnetic field that opposes the original magnetic field.

You can demonstrate Lenz’s law yourself by determining the direction of the magnetic field of

the permanent magnets and by detecting the direction of the induced electric current with a

galvanometer (or multimeter) as you move the armature through the magnetic field.

13

Page 18

Permanent Magnet Motor 012-07210A

Setup

1. Gently lower the armature onto the shaft with the dual slip-ring commutator pointed down.

Carefully rotate the armature back and forth to separate the brushes and allow the commutator to

slip down between them. If necessary, insert a pencil or similar object down between the brushes.

Use only the most delicate force to avoid bending the brushes and necessitating adjustments or

repairs.

2. Connect the motor to the meter by one of these

methods (Figure 2.1):

• Insert banana plugs into the openings in the

ends of the plastic brush holder;

voltmeter or

galvanometer

• Grip the brass posts of the brush holder with

large alligator clips; or

• Attach small alligator clips to the ends of the

brass strips that serve as brushes.

split ring

commutator

Procedure

Part A: AC Generator

1. During the first part of this experiment, the dual

slip-ring commutator should be pointed down,

between the brushes. If it is not, remove the

armature from the shaft by grasping it between

the thumb and forefinger and rotating it back and

forth while lifting gently. Sometimes it may be

necessary to insert a pencil between the brushes

to gently separate them so that they don’t prevent

Figure 2.1

Experimental Setup

removal of the armature.

2. The cylindrical ceramic magnet may be used to determine the polarity of other magnets. The

painted face of the magnet is its North Pole (north-seeking pole). [You can verify this by hanging

the magnet from a thread and observing that the painted face points toward magnetic North (the

earth’s north magnetic pole, located in northern Canada).] Determine the polarity of the field

magnets by holding the ceramic magnet near its rectangular poles. In the event that both poles of

the ceramic magnet attract a pole piece, the stronger attraction occurs when opposite poles are

together. Label the pole pieces N and S using small strips of tape.

3. Examine the armature closely, and imagine current entering one of the two slip rings from a brush.

Trace the path of the current through the wire to the coil, through the coil, through the wire to the

coil on the opposite side of the armature, through that coil, and through the wire to the other split ring

and into the second brush. By carefully examining the part of the coils where the leads emerge from

the coil, it should be possible to determine the direction in which the wire is wound on the coil. Can

you verify that the current maintains its same direction of rotation as it leaves one coil and enters the

other? This means that the two coils of the armature act as a single coil. Ask for help if you

cannot.

14

Page 19

012-07210A Permanent Magnet Motor

4. Label the end of the armature that connects to the upper slip ring with a small piece of tape.

5. Gently replace the armature onto the shaft. The dual slip-ring commutator should be down.

Carefully rotating the armature back and forth will often separate the brushes and allow the

commutator to slip down between them; otherwise, insert a pencil or similar object between the

brushes to separate them. Only the most delicate force should be used to avoid bending the

brushes and necessitating adjustments or repairs.

6. Position the armature so that it is at right angles to the N-S orientation of the field magnets. Then

rotate it 90 degrees so that the end of the armature marked with tape is near the north pole of the

magnet. The magnetic field of the magnet may be represented by arrows passing out of the north

pole and into the south pole.

a) What happens to the amount of this magnetic field that passes through the loops of the coils

during your 90-degree rotation above? If the amount changed, did it increase or decrease?

b) What does Faraday’s induction law say about this situation?

Continue rotating the armature another 90 degrees.

7.

a) What happens to the amount of this magnetic field that passes through the loops of the coils

during your 90-degree rotation? If the amount changed, did it increase or decrease?

b) What does Faraday’s induction law say about this situation?

c) How would the induced emf during the rotation of step 6, be different from that of step 7?

The forces due to Lenz’s law in this equipment are much less than other effects and are not

8.

readily noticeable. Nonetheless, the reasoning that led to Lenz’s law allows you to predict the

direction of current. Consider the 180 degree rotation you performed above:

a) To oppose the motion during the first 90 degrees of rotation, what pole (N or S) would the

taped end of the armature need to be?

➤ To answer this question, you will need the “right-hand rule”, which can be used to

predict the direction of the magnetic field of a coil. Grasp the coil with the fingers

wrapped around the coil in the direction of the current. The thumb will point in the

direction of the field (i.e., toward the north pole of the coil). Current direction here is

described as being from the positive to the negative (conventional current). Note that

this is opposite to the direction of electron movement.

15

Page 20

Permanent Magnet Motor 012-07210A

b) To oppose the motion during the second 90 degrees of rotation, which pole (N or S) would the

taped end of the armature need to be?

9. In order to cause the armature to act as you stated in step 8 above, which direction would the

induced current need to move?

a) Must electronic current enter or leave the coil from the upper brush, in order to make the

armature act as you described in 8 (a) above?

b) Must electronic current enter or leave the coil from the upper brush, in order to make the

armature act as you described in 8 (b) above?

10.Use a voltmeter set on a DC millivolt range to test your predictions. When electronic current

enters the positive terminal of a meter, the value will be positive. If electronic current enters the

negative terminal, the needle will swing left (unless prevented by a peg in the meter) and, in a

digital meter a negative result will be displayed.

a) Test your predictions for 8 (a) and (b) above: After connecting the meter to the brushes, repeat

the two 90-degree rotations, taking about one-half second for each. Comment on your

findings.

11.

a) Using the same reasoning as before, predict the direction(s) of the current during the next 180-

degree rotation, following the one you just made.

b) Test your predictions with the meter and comment.

c) What changes if the armature is rotated in the opposite direction?

12.As the armature rotated, the current changed both in magnitude and direction. This is called

alternating current. If this generator were rotated at 3600 revolutions per minute, what would be

the frequency of the alternating current?

16

Page 21

012-07210A Permanent Magnet Motor

Part B: DC Generator

1. Review steps 1 and 5. Then remove the armature and install it with the split ring commutator

down between the brushes.

2. Connect the meter and rotate the armature slowly, at a rate of about one complete revolution in

two seconds.

a) How does the meter respond?

b) How does the meter respond when the armature is rotated in the opposite direction?

c) Why does the behavior of the split ring commutator differ in results from that of the dual slip

rings?

d) Which of the following describes the results? (a) AC (b) pulsating DC (c) steady DC

3. Spin the armature several more times, increasing the speed each time. Stop if this causes you to

exceed the range of the meter.

a) What is the effect of greater rotational speeds?

b) This result may be explained in terms of the ideas discussed above. Try to explain the effect of

greater speeds.

17

Page 22

Permanent Magnet Motor 012-07210A

4. If you have a PASCO computer interface and Voltage Sensor, try this:

a) Predict how a graph of voltage versus time would look if you put the dual slip rings down and spun the

armature rapidly and let it slow to a stop.

b) What if the split rings were down?

c) What if the split rings were down, but you spun it in the opposite direction?

d) Test these predictions if the proper equipment is available.

18

Page 23

012-07210A Permanent Magnet Motor

Experiment 3: Operation of an AC Synchronous Motor

EQUIPMENT NEEDED

• Permanent Magnet Motor • multimeter

• patch cords • corrugated cardboard

• Digital Stroboscope or • power source that will deliver both

Digital Photogate Timer DC and AC current limited to 1.0 A

Purpose

The purpose of this experiment is to demonstrate the operation of an AC synchronous motor in terms of

basic concepts of electromagnetism.

Theory

The field magnets (permanent magnets) may be

thought of as possessing north and south poles that

interact with the north and south poles of the armature

(an electromagnet). Like poles repel, while unlike

poles attract. The armature rotates until its north pole

is as close as possible to the south pole of the

permanent magnet (and also as far as possible from

the north pole). At that moment, the alternating

current reverses its direction in the armature. The

poles likewise reverse, promoting another half-turn of

the armature.

A better explanation involves an understanding of

fields. The field magnets produce a magnetic field

that passes through the gap between the poles. When

current passes through the turns of the armature in the

presence of the field, forces act to cause a torque that

rotates the armature. Inertia carries the armature past

the position of no torque to the point where the torque

would force the armature back in the other direction.

Instead, if the rotational speed of the armature matches

the frequency of the alternating current, the direction

of current in the armature will reverse at that instant,

so that the torque continues to act in the original

direction.

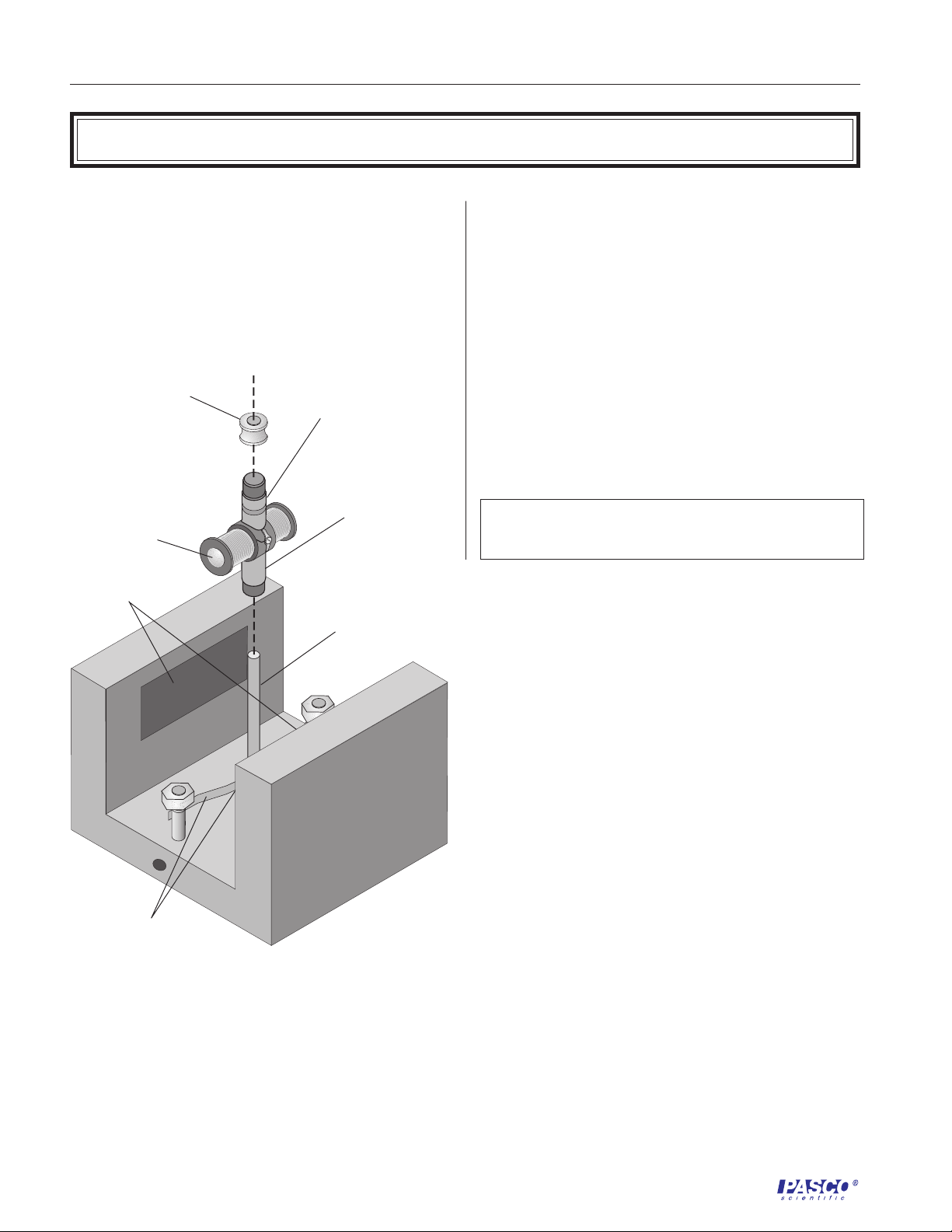

field

magnets

retaining nut

armature

brushes

split ring

commutator

dual slip-ring

commutator

shaft

Setup

Gently lower the armature onto the shaft with the dual

slip-ring commutator down. Carefully rotate the

armature back and forth to separate the brushes and

19

Figure 3.1

Installation of the Permanent Magnet Motor

onto the Field Magnets

Page 24

Permanent Magnet Motor 012-07210A

allow the commutator to slip down between them. If necessary, insert a pencil or similar

object down between the brushes. Use only the most delicate force to avoid bending the

brushes and necessitating adjustments or repairs.

Procedure—Part A

1. Remove the armature from the shaft by grasping it between your thumb and forefinger and

rotating it back and forth while lifting gently. If necessary, insert a pencil between the

brushes to gently separate them so they don’t prevent removal of the armature.

2. Examine the armature closely and imagine current entering

one of the two slip rings from a brush. Trace the path of the

current through the wire to the coil, through the coil,

through the wire to the coil on the opposite side of the

armature, through that coil, and through the wire to the

other slip ring and into the second brush. By carefully

examining the part of the coils where the leads emerge from

the coil, you should be able to determine the direction in

which the wire is wound on the coil (Figure 3.2).

3. Holding the armature in one hand, follow the wire from the

slip ring to the left coil of the armature and note the

direction the wire is wound in the coil. Note where the wire

enters and exits the coil.

4. Imagine that the AC current is in the positive half of the

waveform. This means that conventional current comes out

of the terminal marked positive of the power supply and

enters the terminal marked negative. Use the right-hand

Figure 3.2

Direction of the Wire Winding

on the Coil

rule to determine the direction the magnetic field will flow

at that instant: Grasp the coil with your fingers wrapped around the coil in the direction of the

current. (Current direction is described by convention as pointing from positive to negative.

Note that this is opposite to the direction of electron movement.) Your thumb will point in

the direction of the field (that is, toward the north pole of the coil). Put a small piece of tape

on the end of the coil that would be its north pole at that instant.

5. Follow the wire over to the right coil. Use the right-hand rule to find the direction of the

north pole.

a) In this situation, is the direction of the north pole the same for the right and left coils?

b) In that case, can you say that the north pole of either of the coils is in the same direction as

the north pole of the armature? Explain why.

c) True or False: In this AC motor, we can determine the direction of the magnetic field of

the armature at any instant by determining the direction of the north pole of either of the

two coils.

6. Imagine that the AC current is in the negative half of the waveform. This means that

conventional current comes out of the negative (black) terminal of the power supply and

enters the positive (red) terminal. Repeat step 5 to determine which end of the armature would

be its north pole at that instant.

In this case, is magnetic north on the same or opposite end of the armature?

20

Page 25

012-07210A Permanent Magnet Motor

7. Turn the armature over 180° and imagine that the AC current is in the positive half of the

waveform. Note the path of the wire from where it is attached to the slip ring to where it enters

and exits from the coil on the left side of the armature.

Use the right-hand rule to determine the direction that the magnetic field would flow.

Is the north pole on the same arm of the armature as in step 5?

8. Imagine that the AC current is in the negative half of the waveform. Use the right-hand rule to

find the armature’s north pole.

a) What can you say about the location of the armature’s north pole as the AC waveform

alternates from positive to negative?

b) What is the function of the slip-ring commutator?

9. Gently replace the armature onto the shaft. The dual slip-ring commutator should be down.

Carefully rotate the armature back and forth to separate the brushes and allow the commutator to

slip down between the brushes.

Procedure—Part B

1. Connect the motor to the power

source by one of these methods

(Figure 3.3):

• Insert banana plugs into the

openings in the ends of the

plastic brush holder;

• Grip the brass posts of the

brush holder with large

alligator clips; or

• Attach small alligator clips to

the ends of the brass strips that

serve as brushes.

Adjust the power source to

deliver 6 volts of DC current

limited to 1.0 amp. (Have your

teacher show you how if you

don’t know.)

2. Hold the armature in a position

like that shown in Figure 3.3.

Hold the ceramic magnet near the ends of the armature in order to establish which end is a north

pole and which is a south pole. The painted face of the magnet is its North Pole (north-seeking

pole). [You can verify this by hanging the magnet from a thread and observing that the painted

face points toward the North (toward the Earth’s north magnetic pole, located in northern

Canada).] If both poles of the ceramic magnet attract the armature, the pole with the stronger

attraction will be the opposite pole. Verify that the result of the tests agree with your results

from Step 3. Determine the polarity of the field magnets in the same way.

METER

Figure 3.3

Experimental Setup

PASCO scientific

PUSH FOR

CURRENT

MODEL SF-9584 LOW VOLTAGE AC/DC POWER SUPPLY

0 - 24 VOLTS DC OUTPUT

8 AMP MAX

DC VOLTAGE

ADJUST

DC CURENT

ADJUST

12

10

8

14

6

16

4

AC VOLTAGE ADJUST

2

22

24

2 - 24 VOLTS AC OUTPUT

6 AMP MAX

18

ON

20

OFF

RESET

21

Page 26

Permanent Magnet Motor 012-07210A

3. Now set the power source to furnish to the brushes on alternating current with a sinusoidal

waveform at a frequency of about 30 Hz and voltage of about 6 volts. Slowly rotate the armature

by hand through one complete revolution.

a) Describe the sensation you feel.

b) Explain why this happens.

4. Repeat this with 30 Hz and 4 volts.

a) Does this feel different? How?

b) Explain why.

➤ Troubleshooting: If there was no vibrating sensation in the previous step, either the brushes

were not contacting the slip rings, there was no AC voltage present at the brushes, or some

other defect existed. Recheck the connections and gently bend the brushes inward to make

better contact. If neither of these actions corrects the problem, get assistance. If there was a

vibrating sensation during only part of the rotation, turn off the power, remove the armature,

and examine both the split rings and brushes for corrosion and pitting. Cleaning these with

very fine (600 grit) emery paper will usually correct the problem and result in better

5. Repeat with 15 Hz and 6 volts.

a) Does this feel different? How?

b) Explain why.

6. Turn the power off.

7. Set up the photogate or stroboscope to measure the speed of rotation of the motor, following your

teacher’s instructions.

If you are using a photogate, construct a “chopper” of a 7.5 cm piece of card stock to interrupt

the beam of light from the photogate as follows:

Cut a 7.5 cm square from corrugated cardboard and punch a hole that is 1 cm in diameter in the

center (a #4 cork boring tool works well). If the square slips, you may need to secure it with

22

Page 27

012-07210A Permanent Magnet Motor

tape. Slip the square part far enough way down the split ring commutator so you can grip

the plastic bushing to spin the armature. Position the photogate so the corners of the square

interrupt the photogate’s beam 4 times per revolution.

➤ Notice that the motor is not self-starting. Immediately after you apply the AC

power, start the motor manually by grasping the black plastic bushing at the top of

the armature assembly between thumb and forefinger and spinning the armature.

It may take several attempts to successfully start the motor because you must spin

the armature at a speed that approximately matches the frequency of the power

8. Set the voltage to 8 volts and the frequency of the alternating current to 16 Hz. Start the motor

and use the stroboscope or photogate to determine the rotational speed of the motor. What is the

rotational speed of the armature? If the result is not already expressed in revolutions per second,

convert it to these units.

9. While the motor is running, lower the voltage to 6 volts. Does the rotational speed of the

armature change when you change the voltage?

➤Note: with the PASCO 6500 Series Power Amplifier, the motor may stop and

need to be restarted manually.

10.Return the voltage to 8 volts and change the frequency of the alternating current to 20 Hz, and

then 24 Hz, determining the rotational speed each time. (Manually restart the motor each time if

needed.)

Does the rotational speed of the armature change when you change the current frequency?

11. If the room is lit with fluorescent lights, you can also see the effect changing the current

frequency on the motor’s speed. Fluorescent lamps flash twice during each cycle of the AC

power that supplies them. When the motor operates at a submultiple of this rate, multiple

images will appear to be stationary, so the armature will appear to be stationary. Observe the

armature at current frequencies of 15, 20, 24, and 30 Hz (or at 16.67, 20, and 25 Hz in locations

with 50 Hz AC power).

23

Page 28

Permanent Magnet Motor 012-07210A

24

Page 29

012-07210A Permanent Magnet Motor

Teacher’s Guide

Experiment 1:

Remind students not to prolong situations when the armature is not spinning and the power

is connected—the coils will overheat.

Figure 1. 4, labeled

Draw arrows indicating the direction of

current flow.

Indicate which pole is north (N) or south (S).

N

S

+

wire connected to the +

terminal of the power

supply

Answers To Questions:

Part A

6. a) Yes.

b) They add together to create a greater effect.

N

S

N

+

direction of wire

wrapping on the coil

When you wrap

your fingers in the

direction of the flow

of the electric

current, your

thumb points

towards the north

pole of the

magnetic field.

7. No.

8. a) Yes.

b) True.

c) False.

d) The location of the armature’s north pole alternates between ends of the armature as the + lead

touches the alternate sides of the split ring commutator.

e) The current is alternating in the coils because one side of the split ring commutator sends the

current in one direction in the wire, while the other side sends it in the opposite direction in the

wire.

25

Page 30

Permanent Magnet Motor 012-07210A

Part B

3. Results of the test should agree with predictions.

4. Clockwise, if the leads are connected exactly as shown in Figure 2 and the north pole of the field

magnets are on the left.

5. a) It should rotate in the counter-clockwise direction.

b) Answers will vary. If students explain using the concept of “opposite magnetic poles attract and

same poles repel,” they will say something like, “As the opposite sides of the split-ring commutator come in contact with the + lead of the DC power supply, the location of the north pole

of the electromagnet alternates, causing it to seek alternating poles on the permanent magnet.”

If students respond using the concept of torque they might say, “The flux lines of the permanent magnet extend from its north to south pole and interact with the flux lines of the electromagnet, producing a torque that spins the armature. Inertia carries the armature past the position of no torque to the point where the torque would force the armature back in the other direction. However, at that point, the commutator reverses the direction of current in the armature so the torque continues to act in the original direction.”

6. a) The motor speeds up.

b) The motor’s speed is directly dependent on the voltage of the DC current.

Experiment 2

Answers To Questions:

Part A: AC Generator

6. a) It increased.

b) An emf (electromotive force or voltage) will be induced in the coil.

7. a) It decreased.

b) An emf will be induced.

c) The emf will be opposite in sign (or direction) in the two steps because the change in flux within

the turns is opposite in the two cases. (In one case it is increasing, in the other case, decreasing.)

8. a) It should be a north pole, to repel the N pole of the field magnets opposing the motion.

b) a south pole

a) It must enter the coil from the upper brush.

9.

b) It must leave the coil and pass into the upper brush.

10. If the negative lead of the meter is connected to the upper brush and the positive lead is connected

to the lower brush, then the meter value will show positive during the first quarter turn, and negative during the second quarter turn.

11.a) During the 3rd quarter turn, the current will leave the coil and pass into the upper brush; dur-

ing the 4th quarter turn, the current will enter the coil from the upper brush.

b) Assuming as before that the negative lead of the meter is connected to the upper brush and the

positive lead is connected to the lower brush, during the 3rd quarter turn, the meter will show

negative (or move left); during the 4th quarter turn, the meter will show positive (or move right).

c) Every result will be reversed.

12. 3600 cycles per minute, or 60 cycles per second, more properly termed 60 Hertz, or 60 Hz

26

Page 31

012-07210A Permanent Magnet Motor

Part B: DC Generator

1. a) The voltage and current produced is always in the same direction (direct current) but is pul-

sating, not steady. (The pulsating nature will be difficult to note with a digital meter.) Assuming as before that the negative lead of the meter is connected to the upper brush and the

positive lead is connected to the lower brush, then if armature is rotated clockwise (as

viewed from above) the meter will read positive.

b) It responds similarly to a but in the opposite direction.

c) Just as the current is about to reverse direction (as, for example, between steps 10 a and b),

the commutator reverses the connections between the coil and the brushes in order to maintain the direction of the current.

d) pulsating DC

2. a) The effect would be greater voltage and current.

b) Answers will vary. Two possible explanations include: (1) The free electrons present in the

wire of the coil move through the wire as a current due to the force given by

F=qV x B, where the force is seen as being proportional to the velocity of the wire, and thus

the electrons contained in it. At greater rotational speeds, the velocity of the wire would be

greater, and thus the force causing electron movement would also be greater. (2) Faraday’s

law states that the emf induced is proportional to the rate at which the flux in the loops of

the coils is changing. At higher rotational speeds, the rate of change of the flux is greater,

and thus so is the emf.

3. a) The graph of voltage versus time would be a “sine wave” whose amplitude and “wave-

length”, or

period, is decreasing to zero.

b) It would be the same as a except all portions that would be below the horizontal (time) axis are

instead reflected above it.

c) It would be the same as b except everything is below the axis.

Experiment 3

Notes concerning the setup:

• If the power source does not limit the current to 1 A, use an appropriate resistor in series

to limit the current.

• If the AC power source does not quantify the current, use an appropriate ammeter, or

calculate the current by measuring the voltage drop across a resistor of 0.51 ohm and a

power rating of 1 watt wired in series.

• Remind students not to prolong situations when the armature is not spinning and the

power is connected—the coils will overheat.

Answer To Questions:

Part A

5. a) Yes.

b) Yes. Since the coils are wound such that the north poles of each are in the same direction,

they work together to produce a net magnetic flux for the armature that is the sum of the

magnetic flux of each of the coils.

c) True

27

Page 32

Permanent Magnet Motor 012-07210A

6. Opposite

7. Yes

8. a) The armature’s north pole alternates from end to end as the AC waveform alternates from posi-

tive to negative.

b) The slip-ring commutator connects the armature to the power source by way of the brushes and

enables the current to travel in an unbroken stream from the positive to the negative terminals of

the power supply.

Part B

3. a) The armature vibrates or pulses.

b) This happens because the alternating current causes the polarity of the armature to reverse with

each AC cycle.

4. a) It vibrates or pulses at the same frequency, but with less force.

b) This happens because the rate at which the polarity reverses is the same, but the force of the in-

duced magnetic flux of the armature decreases with decreasing voltage.

5. a) The rate of vibration is lessened, and the strength of the pulsation is increased.

b) The halving of the cycle rate of the AC results in halving the rate of reversal of polarity in the

armature, while the increase in voltage results in the increase in strength of the pulsations.

9. The rotational speed of the armature does not change when you change the voltage.

10.The speed varies directly with the AC frequency.

28

Page 33

Technical Support

Feedback

If you have any comments about the product or

manual, please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual, please tell us. PASCO appreciates any

customer feedback. Your input helps us evaluate and

improve our product.

To Reach PASCO

For technical support, call us at 1-800-772-8700

(toll-free within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@PASCO.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

If your problem is computer/software related, note:

- Title and revision date of software.

- Type of computer (make, model, speed).

- Type of external cables/peripherals.

If your problem is with the PASCO apparatus, note:

- Title and model number (usually listed on the la-

bel).

- Approximate age of apparatus.

- A detailed description of the problem/sequence of

events.

If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

If your problem relates to the instruction manual,

note:

- Part number and revision (listed by month and

year on the front cover), and

- Have the manual at hand to discuss your ques-

tions.

Page 34

Loading...

Loading...