Page 1

®

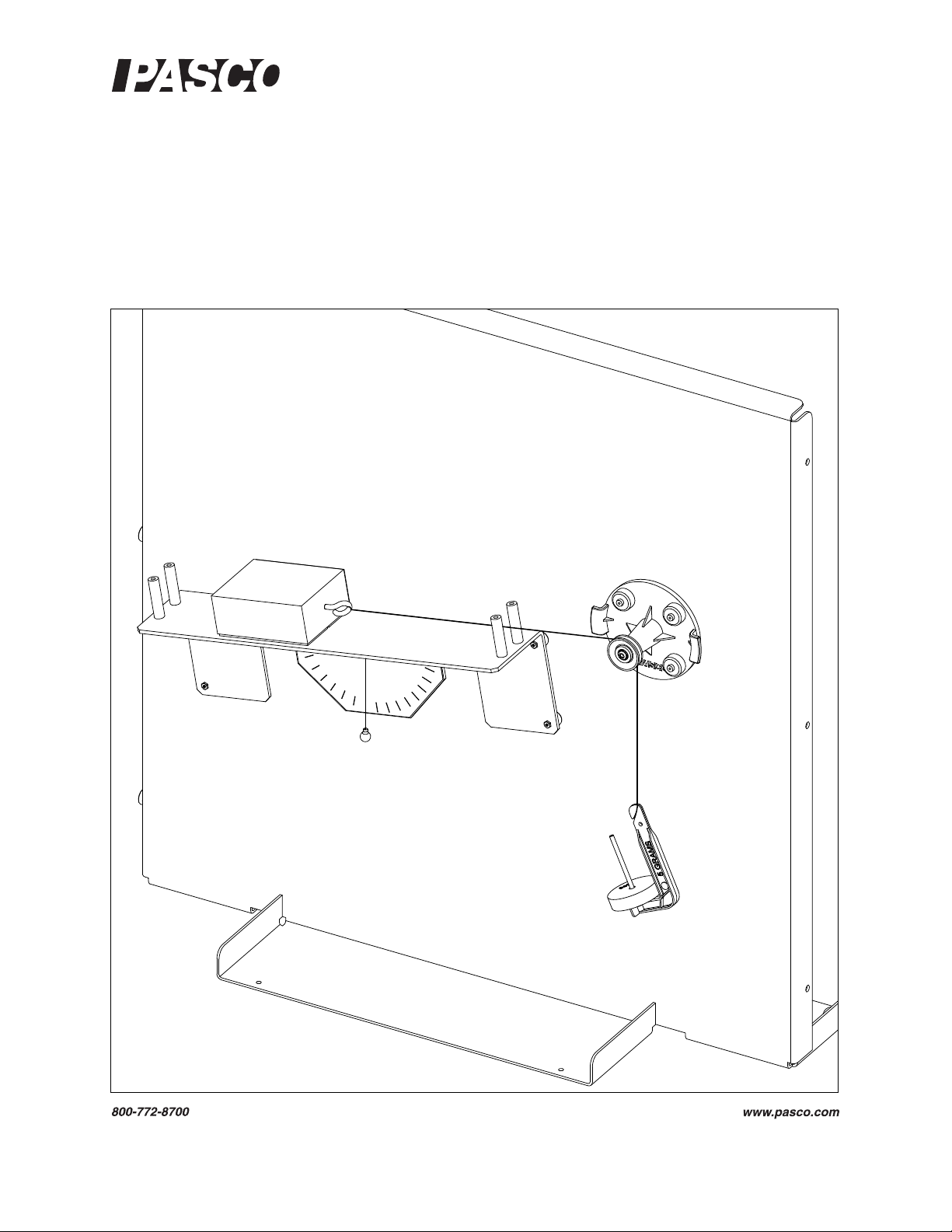

PASCO Mechanics

Statics System

ME-9502

Instruction Manual

012-12876B

*012-12876*

Page 2

®

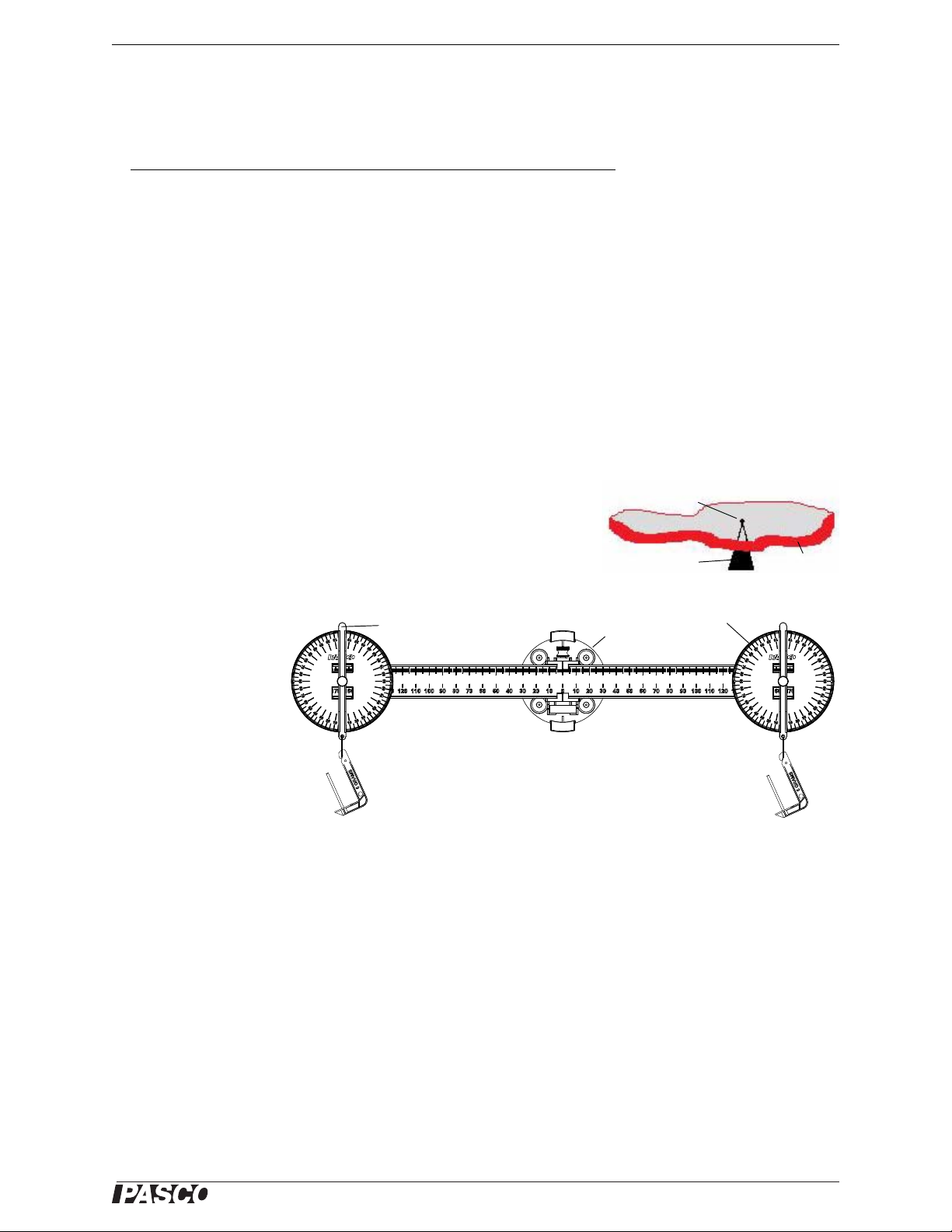

The cover page shows a a Friction Block on the Statics System Inclined Plane with a PASCO Mass Hanger from

the ME-8979 Mass and Hanger Set suspended by a thread over a Small Pulley. Most of the components of the

Statics System are held magnetically to the included workboard. This manual contains fifteen copy-ready experiments about the fundamentals of statics.

ii

Page 3

®

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Spares Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Components Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

EXPERIMENTS

1. Hooke’s Law - Measuring Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Adding Forces - Resultants and Equilibriants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Resolving Forces - Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4. Torque - Parallel Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5A. Center of Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5B. Equilibrium of Physical Bodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6. Torque - Non-Parallel Forces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7. The Inclined Plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8. Sliding Friction and Static Friction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9. Simple Harmonic Motion - Mass on a Spring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10. Simple Harmonic Motion - The Simple Pendulum . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11A: Simple Harmonic Motion - Physical Pendulum . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11B: Minimum Period for a Physical Pendulum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11C: Simple Harmonic Motion - Beam on a Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

12. Simple Machines - The Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13. Simple Machines - The Inclined Plane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14. Simple Machines - The Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

15. Forces on a Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Technical Support, Warranty, and Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

iii

Page 4

®

Statics System

iv 012-12876B

Page 5

Statics System

®

If F 0 then a = 0=

a

F

net

m

----------

=

Statics Board

ME-9502

Introduction

The study of mechanics often begins with Newton’s Laws of Motion. The first law describes the conditions for an

object to maintain its state of motion. If the net force on an object is zero, the acceleration of the object is zero.

The second law describes what happens if the net force on an object is not zero. The acceleration is directly proportional to net force, in the same direction as the net force, and inversely proportional to mass, or

Much of what is studied in an introductory course deals with the ways that forces interact with physical bodies.

The PASCO Statics System is designed to help you investigate the nature of forces for the special case in which

there is no acceleration. In other words, the vector sum of all the forces acting on the body is zero.

One reason to study the case of no acceleration is because it is easier to measure non-accelerating systems than it

is to measure accelerating systems. A great deal can be learned about the vector nature of forces by studying the

many ways in which forces can be applied to an object without causing acceleration.The second reason is that in

our everyday experience, non-accelerated systems are the rule, not the exception.

Equipment

The ME-9502 Statics System consists of the Statics Board, Spares Package, Components Package, and Mass and

Hanger Set.

ME-9503 Statics Board

The Statics Board is a ferrous metal plate approximately

45 by 45 centimeters (18 by 18 inches) with a writable

white board finish on both sides.)

The board has rubber bumpers on its base. White board

pens (or “dry erase” pens) can be used to write and draw

directly on the board. The pens are available from stationery stores and the ink can be erased with a cloth or a

white board eraser.

The Mounted Scale Assembly, Large and Small Pulley

Assemblies, Balance Arm Assembly , Force Wheel Assembly, Torque Wheel Assembly, Inclined Plane Assembly,

and Utility Mount Assembly all attach magnetically to t he

board. Components can be stored on the rear side of the

board when not in use. Except for the Inclined Plane

Assembly, all the components that can mount on the board

have a rubber ring on the base that protects the board and

the component. The round magnetic base is 6.5 centimeters (cm) in diameter.

1

Page 6

Statics System Equipment

®

No

No

Yes

Yes

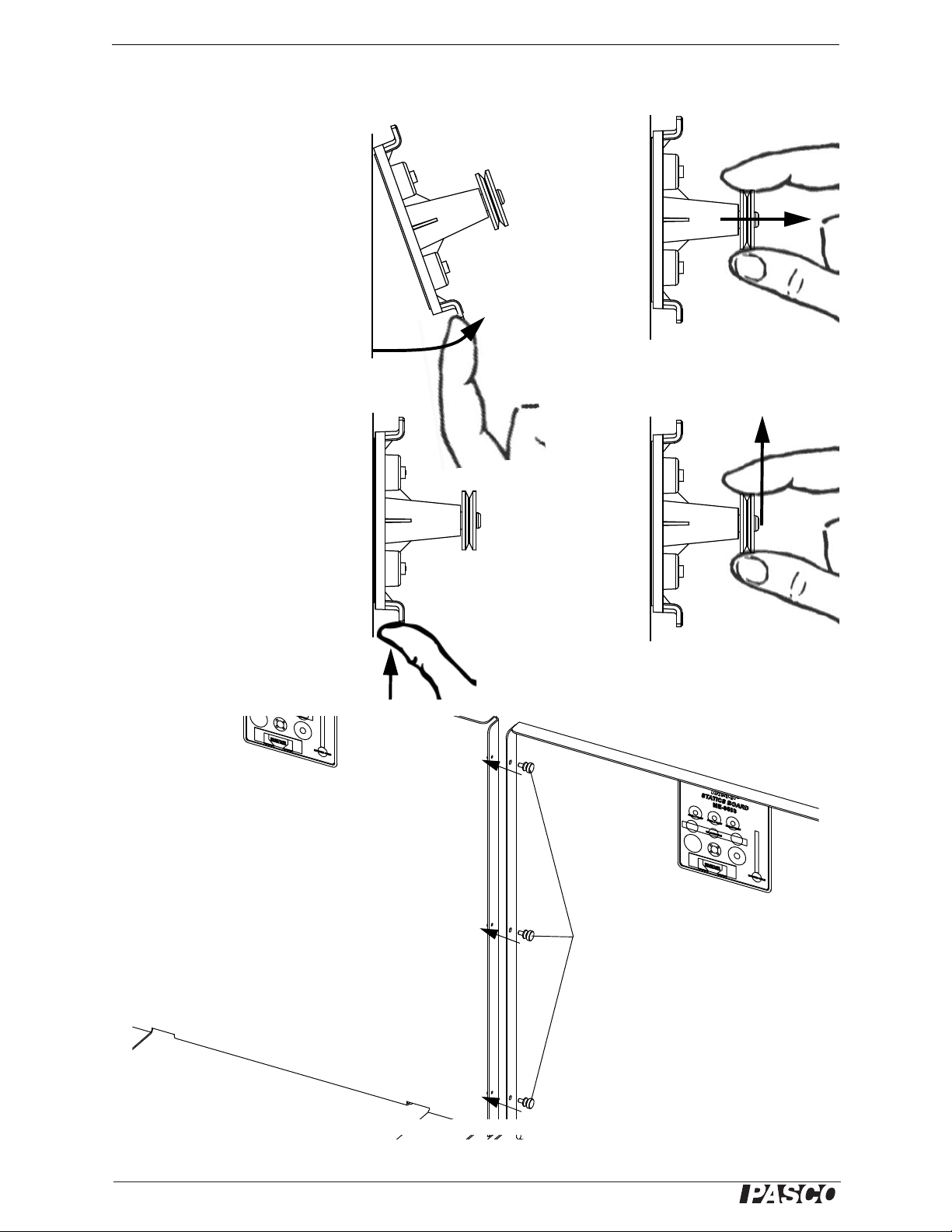

Moving Components on the Board

Rear view of Statics Boards

Connector

screws

Use the Connector

screws to join two

Statics Boards together.

Important

When moving or removing any of

the magnetically mounted components from the board, handle the

component by the magnetic base

rather than by the component itself.

This will reduce the strain on the

component.

A second board (available separately) can be attached to the first

board with the three included connector screws. To join the boards,

remove the connector screws from

the threaded holes on the side of

the first board. Put the edge of the

second board next to the first

board. Align the holes and join the

two boards with the connector

screws

.

2

012-12876B

Page 7

®

Model No. ME-9502 Recommended Equipment*

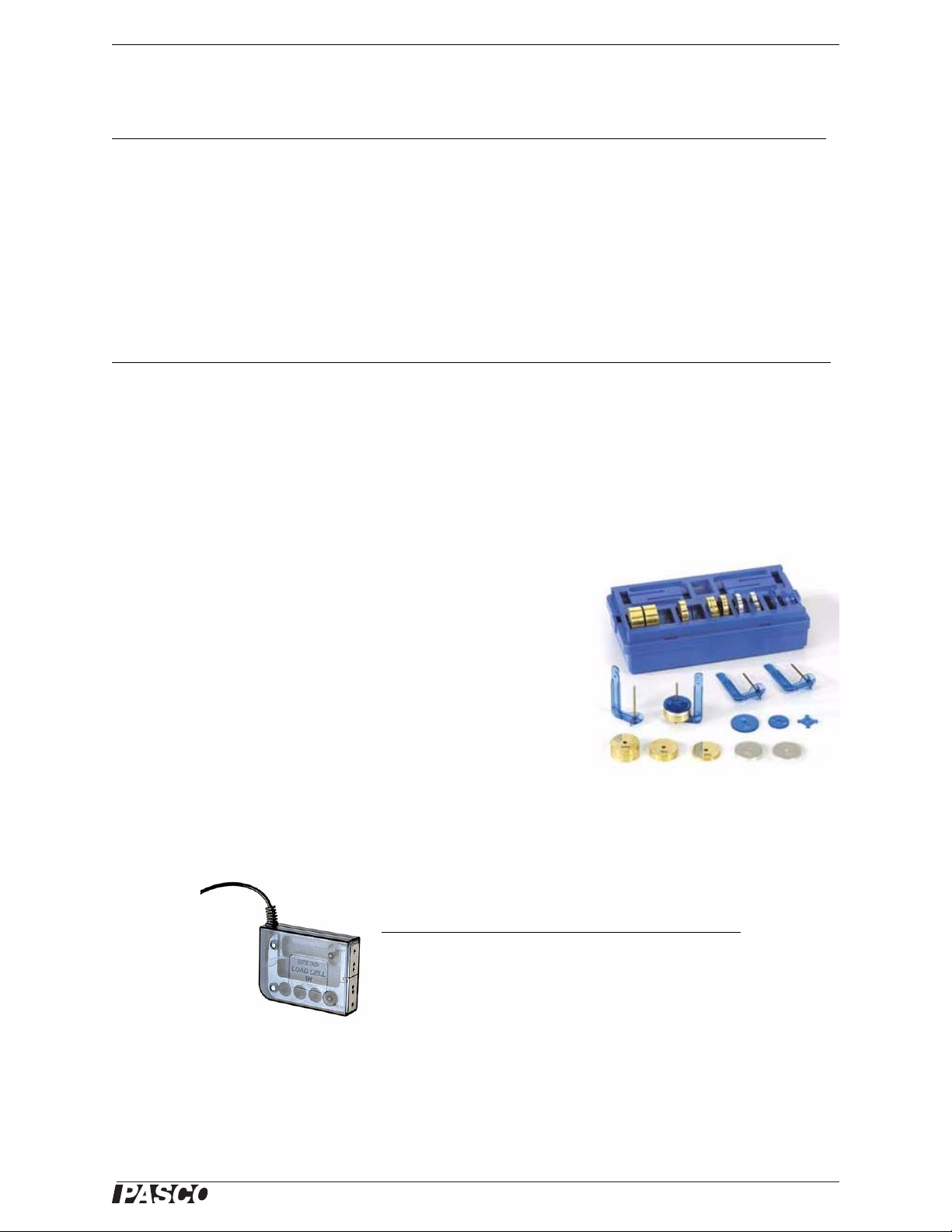

ME-8979 Mass and Hanger Set

PS-2201 5 N Load Cell

Amplifier Model

Load Cell Amplifier (PASPORT) PS-2198

Dual Load Cell Amplifier PS-2205

Load Cell Amplifier (ScienceWorkshop) CI-6464

ME-9504 Spares Package

Item Qty Item Qty

String Tie Assembly 3 Thumbscrew 6-32 by 5/8” (for Cord Clip) 2

Torque Indicator Assembly 6 Thumbscrew 4-40 by 1/2” (for balance arm protractor) 2

Nylon Thread, spool 1 Thumbscrew 6-32 by 1/4” (for balance arm pivot) 1

Cord Tensioning Clip 2 Washer 0.285” OD (for balance arm protractor) 2

Angle Indicator Arm 2 Plumb bob, brass (for inclined plane) 1

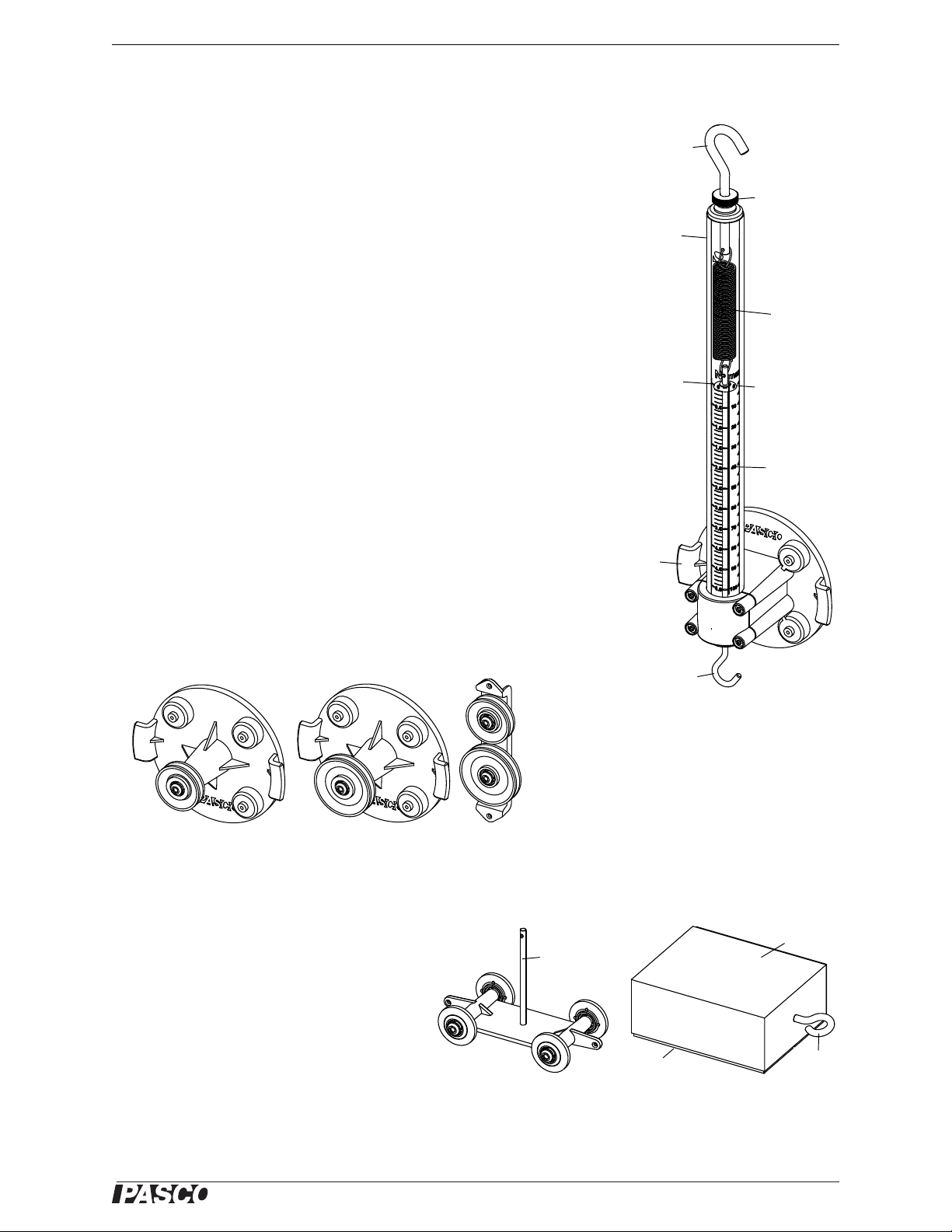

ME-9505 Components Package

Item Qty Item Qty

Large Pulley Assembly 1 Utility Mount Assembly 1

Small Pulley Assembly 2 Mass Cart Assembly 1

Mounted Scale Assembly 1 Torque Wheel Assembly 1

Balance Arm Assembly 1 Inclined Plane Assembly 1

Force Wheel Assembly 1 Friction Block Assembly 1

Double Pulley Assembly 1 Asymmetrical Plate 1

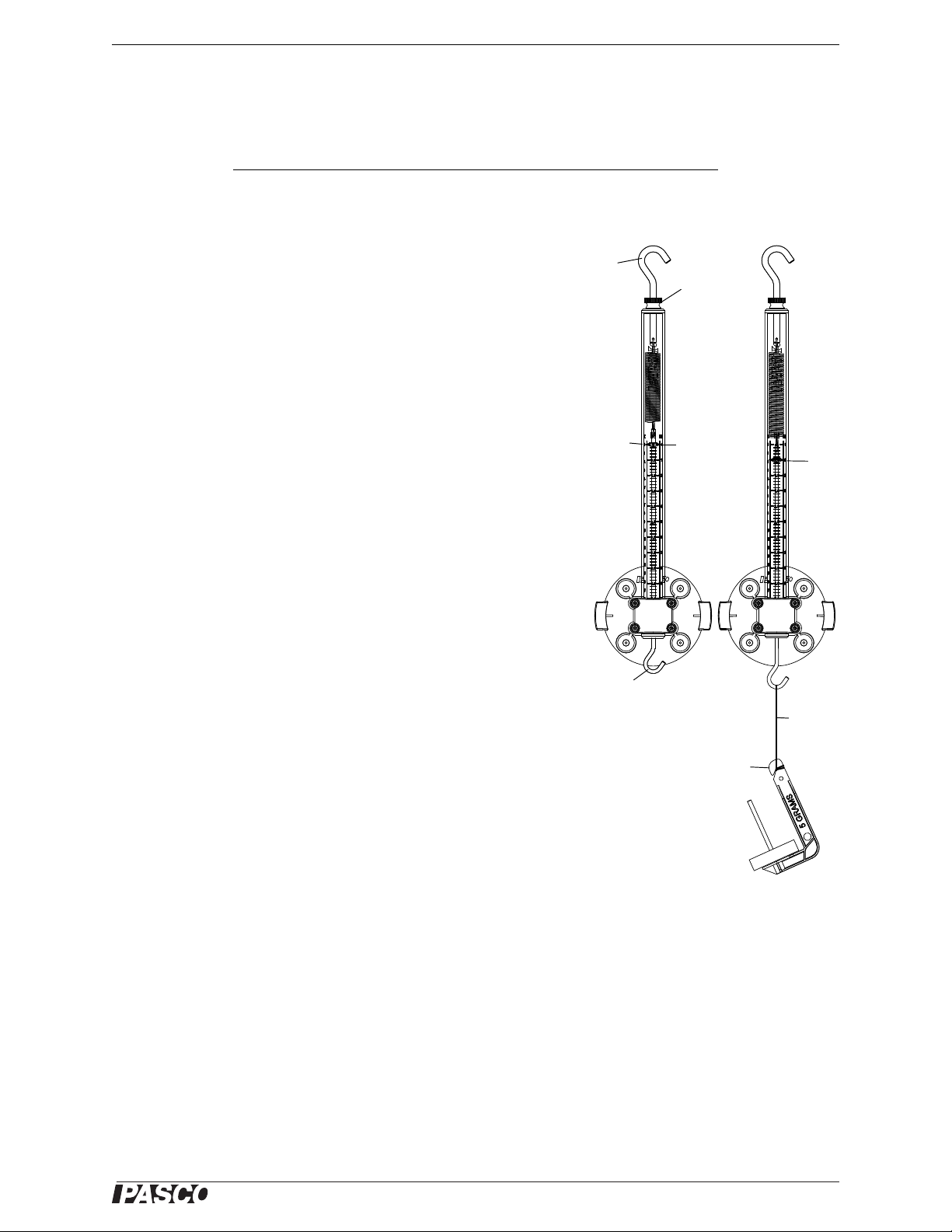

ME-8979 Mass and Hanger Set

Components from the ME-8979 P ASCO Mass and Hanger Set are used

in most of the statics experiments. The set includes four mass hangers,

a storage box, and twenty-seven masses ranging from 0.5 g to 100 g

made from brass, aluminum, or polycarbonate plastic.

Recommended Equipment*

Load Cell and Load Cell Amplifier

A PS-2201 5 N Load Cell can be used to measure force. When it is connected through an amplifier to a PASCO interface or to a PASCO

hand-held data logger, the force data from the Load Cell can be

recorded, displayed, and analyzed.

.

*See the PASCO catalog or Web site at www.pasco.com for information about PASCO load cells, load cell

amplifiers, interfaces, hand-held data loggers, and data acquisition software.

012-12876B 3

Page 8

Statics System Spares Package (ME-9504)

®

Mass Balances

Stop Watch

Inner part

(force disk)

Outer part

Tab

Put

threads

through

this hole.

String Tie Assembly

T orque Indicator Assembly

Tie a

thread to

this hole.

Snap connects

to Torque Wheel

Stopwatch (ME-1234)

The PASCO Stopwatch has a liquid crystal display (LCD) with two display modes. Its precision

is 0.01 seconds up to 3599.99 seconds, and 1 second up to 359999 seconds. Its memory holds up to

nine event times.

Mass Balance

Use a mass balance such as the OHAUS Scout

Pro Balance 2000 g (SE-8757A) or the OHAUS

Cent-O-Gram Balance (SE-8725).

Mounted Scale Assembly (ME-9824A)

The Mounted Scale Assembly (included in the ME-9505 Components Package) is also available separately as a

replacement or as an extra spring scale for experiments where measuring more than one force is required.

Spares Package (ME-9504)

The Spares Package contains some items which are used with assemblies from the Components Package. For

example, the String Tie Assembly snaps into the center of the Force Wheel Assembly and the Torque Indicator

Assembly snaps into the Torque Wheel Assembly. The Cord Tensioning Clip is used on the Utility Mount Assembly. Other items such as the Angle Indicator Arms, thumbscrews, washers, and brass weight are replacement parts.

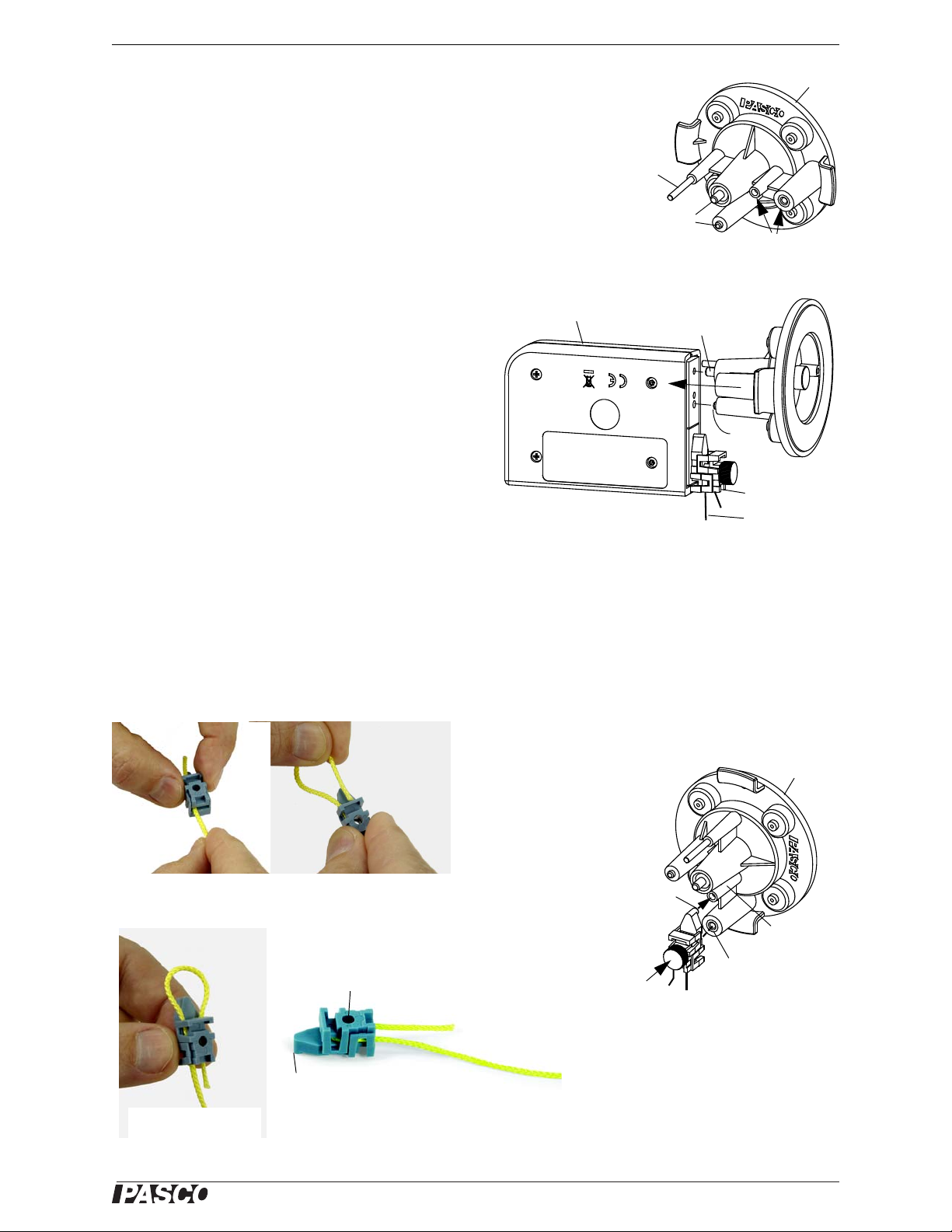

String Tie Assembly.

When the String Tie Assembly is snapped into the center of the Force

Wheel Assembly, you can use the apparatus to study force vectors. The

String Tie Assembly has two parts: a clear plastic inner part (the “force

disk”) that is free to move around in the center of the outer part, which

has a center hole and two tabs that snap into the Force Wheel Assembly.

(The two parts are not meant to be separated.)

Initial Setup

Get three threads that are 38 cm (15”) long. Put the threads through the

hole in the inner part of the String Tie Assembly. Tie the ends of the

threads together (for example, with an overhand knot) so that they cannot be pulled back through the inner part.

Torque Indicator Assembly

Note that the Torque Indicator Assembly has a

snap that can be connected to the Torque Wheel

Assembly . The other three assemblies are

spares.

Initial Setup

Tie a 30 cm (12”) thread to each of three Torque Indicator Assemblies.

4

012-12876B

Page 9

®

Model No. ME-9502 Components Package (ME-9505)

Spring

Indicator

disk

Scale

Base

Bottom

hook

Thumbnut

Top hook

Tab

Tube

Mounted Scale Assembly

Zero

mark

Small Pulley (2) Large Pulley Double Pulley Block

Mass Cart Friction Block

Felt

Hook

Rod for

stacking

masses

Wood

Components Package (ME-9505)

Mounted Scale Assembly

The mounted scale has four strong magnets in its base. The tube is marked in

newtons (N), ounces (oz.) and millimeters (mm). The thumbnut allows the top

hook to be raised or lowered in order to align the red indicator disk with the

zero mark on the tube.

T o zero the scale, mount the scale on the statics board. Leave the bottom hook

empty. Unscrew the thumbnut a few turns. Rotate the top hook clockwise

(left-to-right) to lower the indicator disk and counter-clockwise (right-to-left)

to raise the indicator disk. When the disk is aligned with the zero mark on the

tube label, tighten the thumbnut to hold the top hook in place.

To move the scale on the statics board, hold the scale by the tabs on the base

and push or pull the scale to the desired location. To remove the scale from the

statics board, lift one or both of the tabs on either side of the base away from

the board.

Large and Small Pulleys and Double Pulley Block

The Statics System comes with two Small Pulleys and one Large Pulley

mounted on magnetic bases. It also includes a Double Pulley Block (that does

not have a magnetic base). The Double Pulley Block is designed for

block-and-tackle experiments. A support thread can be tied to either end of the

Double Pulley Block.

All the pulleys have low friction ball bearings. The smaller pulleys are 2.41

cm (0.850”) outside diameter (OD) and 1.65 cm (0.650”) inside diameter (ID).

The larger pulleys are 2.79 cm (1.10”) OD and 2.28 cm (0.90”) ID.

Please use the tabs on the base of the components when moving them around or removing them from the statics

board.

Mass Cart and Friction Block

The Mass Cart and Friction Block are

designed to be used with the Inclined Plane

Assembly. The Mass Cart has low friction ball

bearings in each wheel and a metal rod in the

center for stacking extra masses. A thread can

be attached at either end.

The Friction Block is made of beech wood. It

has an “eye” hook at one end and is covered

with felt on the bottom and one side. Its dimensions are 2.54 cm by 5.08 cm by 6.35 cm (1.0” by 2.0” by 2.5”).

012-12876B 5

Page 10

Statics System Components Package (ME-9505)

®

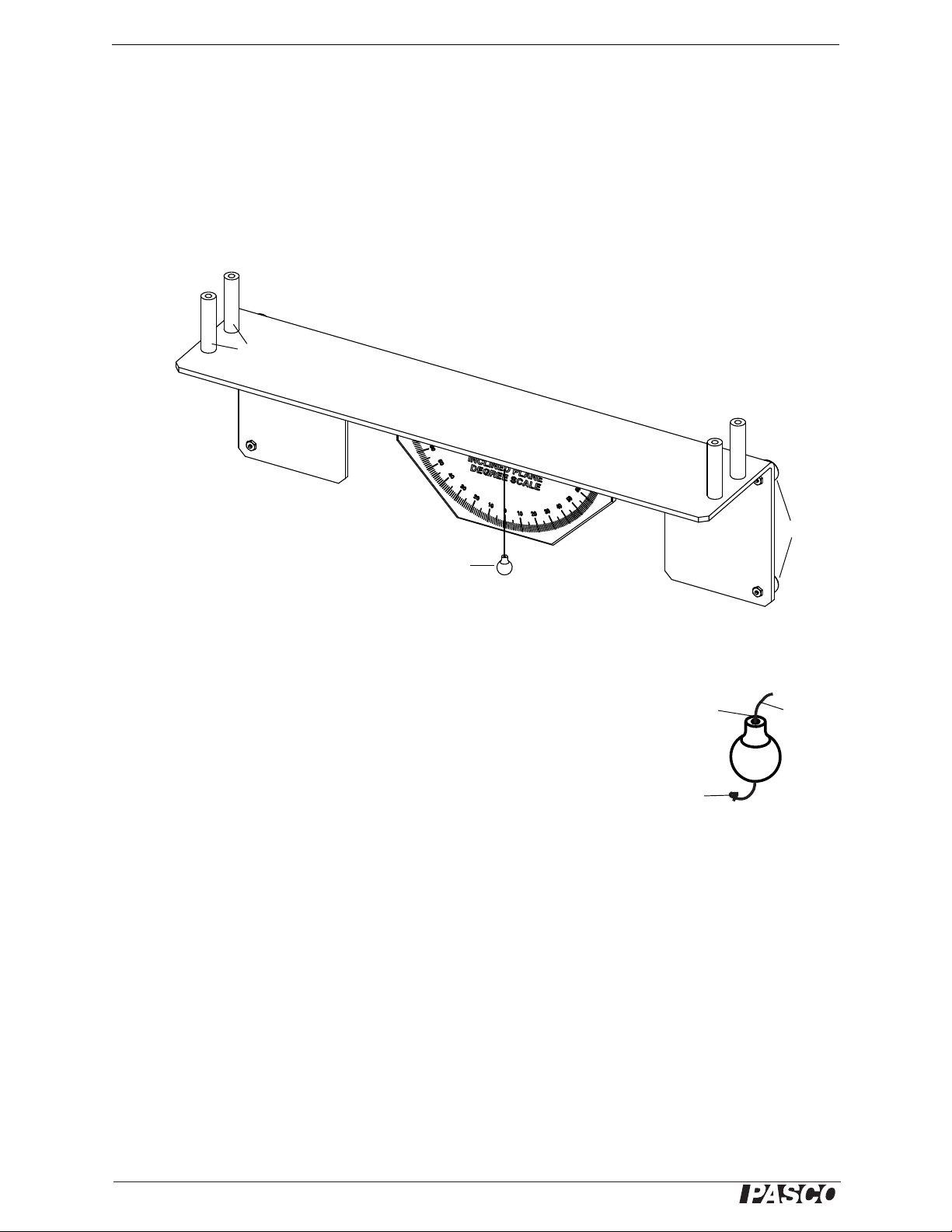

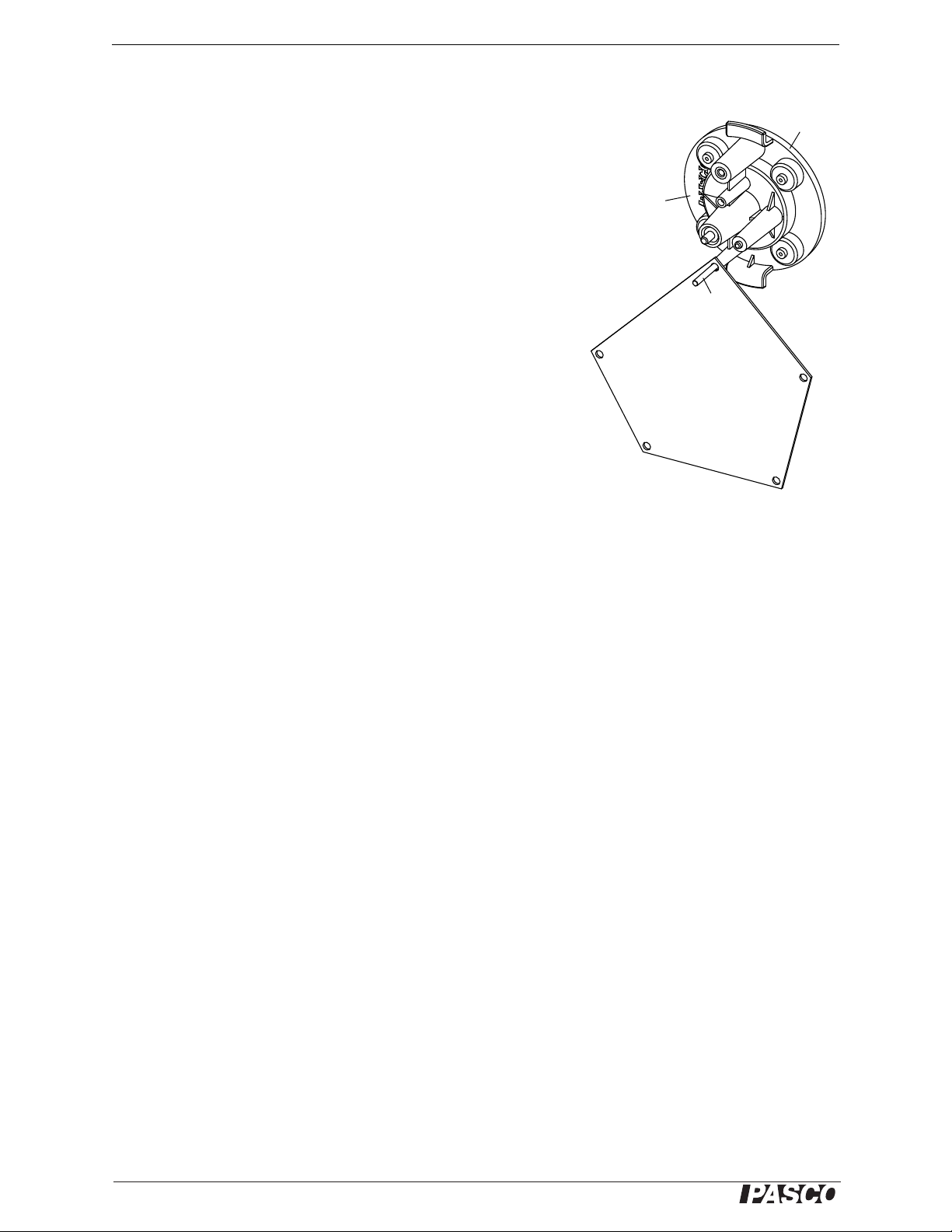

Inclined Plane Assembly

End stops

Plumb bob

Brass Weight

Put thread

through

the hole.

Tie a

knot.

Thread

Inclined Plane Assembly

The Inclined Plane Assembly has four strong magnets on its back side that hold it in position on the Statics Board.

CAUTION: The magnets on the Inclined Plane Assembly are not covered with protective material.

Be careful to firmly hold the inclined plane when placing it on the board so that the magnets are

not damaged by “snapping” against the board.

The inclined plane has end stops at each end of the plane and a degree scale with a brass plumb bob for determining the angle of the incline.

Replacing the Plumb Bob

The ME-9504 Spares package includes a spare plumb bob (brass weight). To

replace the plumb bob, use a Phillips head (“crosshead”) screwdriver to loosen

the screw on the back of the degree scale. Remove the piece of thread and get a

new piece approximately 10 cm (4”) long. Put one end of the thread through the

hole in the brass weight and tie a double knot in that end of the thread so it will

not slip back through the hole. Put the other end of the thread through the small

hole near the top of the degree scale. Adjust the length of the thread so the plumb

bob can swing freely and then wind the end of the thread around the screw on the

back. Tighten the screw to hold the thread in place.

Magnets

6

012-12876B

Page 11

®

Model No. ME-9502 Components Package (ME-9505)

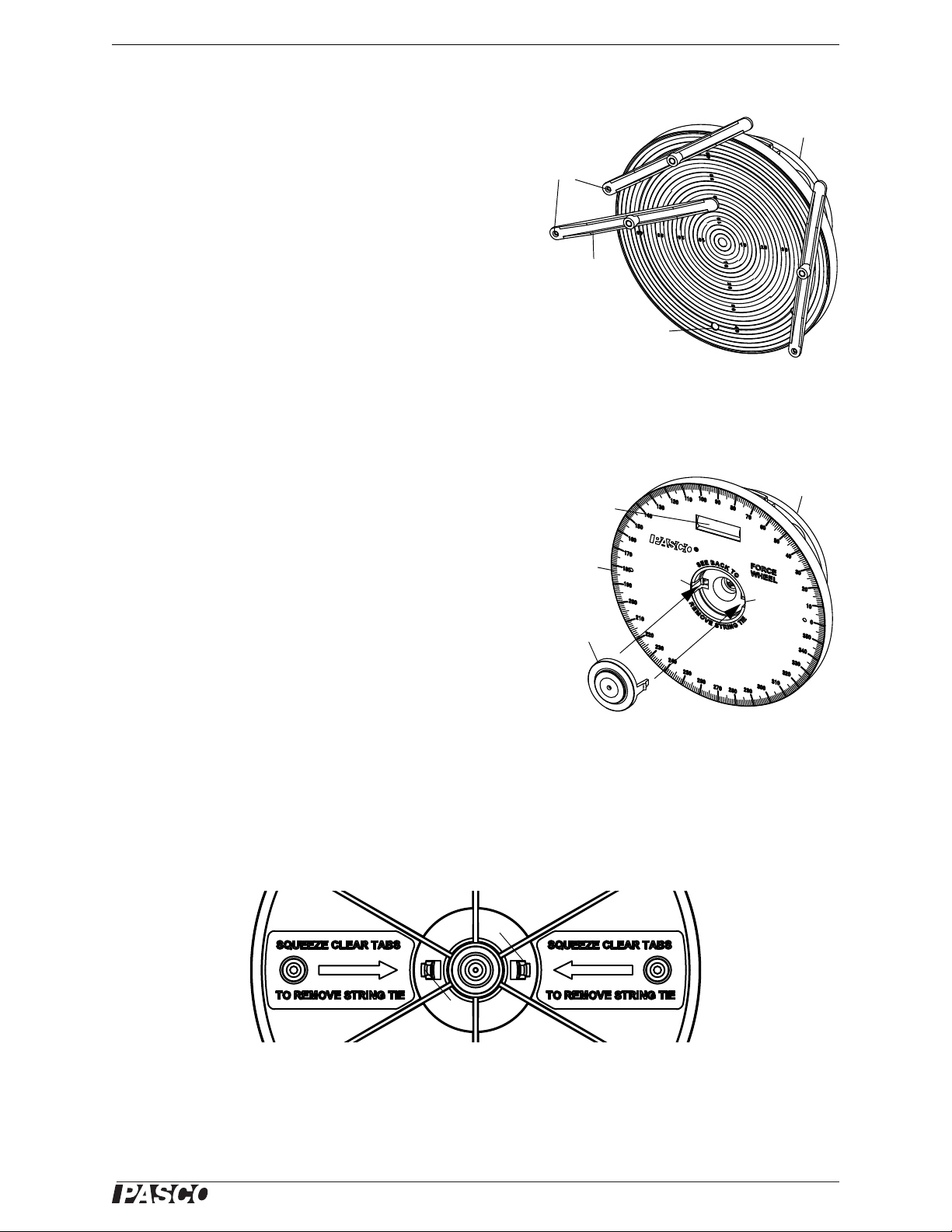

Torque Wheel Assembly

Torque Indicator Assembly

Tie a thread

to the hole.

Hole

Base

Torque

Indicator

Force Wheel Assembly

String Tie Assembly

Notch

String

Tie

Bubble

level

Base

Degree

scale

Notch

Tab

Tab

Torque Wheel Assembly and Torque Indicator Assembly

The Torque Wheel Assembly has a 5 cm radius disk with a

label that has concentric circles 2 mm apart. The disk rotates

freely on a ball bearing and has five holes for attaching a

T orque Indicator Assembly. The Torque Indicator snaps into

the hole and rotates freely. Tie a 30 cm (12”) thread to the hole

in the end of each indicator.

To remove a Torque Indicator, firmly grasp the indicator at the

pivot in the middle and pull outwards while pushing on the end

of the snap from the other side of the disk.

Force Wheel Assembly and String Tie Assembly

The Force Wheel Assembly has a 5 cm radius disk with a 360°

label and a bubble level for leveling the Force Wheel. Unlike

the Torque Wheel, the Force Wheel does not rotate freely but

the disk can be turned in order to level the wheel. Once leveled,

the wheel will stay in position until moved again.

REMINDER: Be sure to put tie three threads through the hole

in the center of the String Tie before putting the String Tie into

the Force Wheel.

The String Tie Assembly snaps into the hole in the center of the

Force Wheel Assembly. Align the tabs on the String Tie with

the notches inside the hole at the center of the Force Wheel.

Push the String Tie firmly into the Force Wheel until both tabs

“snap” into place. Note that the surface of the outer part of the

String Tie will be very slightly below the surface of the Force

Wheel, but the inner part of the String Tie will be flush with the

Force Wheel.

Removing the String Tie Assembly

If you need to remove the String Tie (in order to replace the threads, for example), remove the Force Wheel from

the Statics Board. On the underside of the disk are instructions about removing the String Tie.

Remove String Tie

012-12876B 7

Page 12

Statics System Components Package (ME-9505)

®

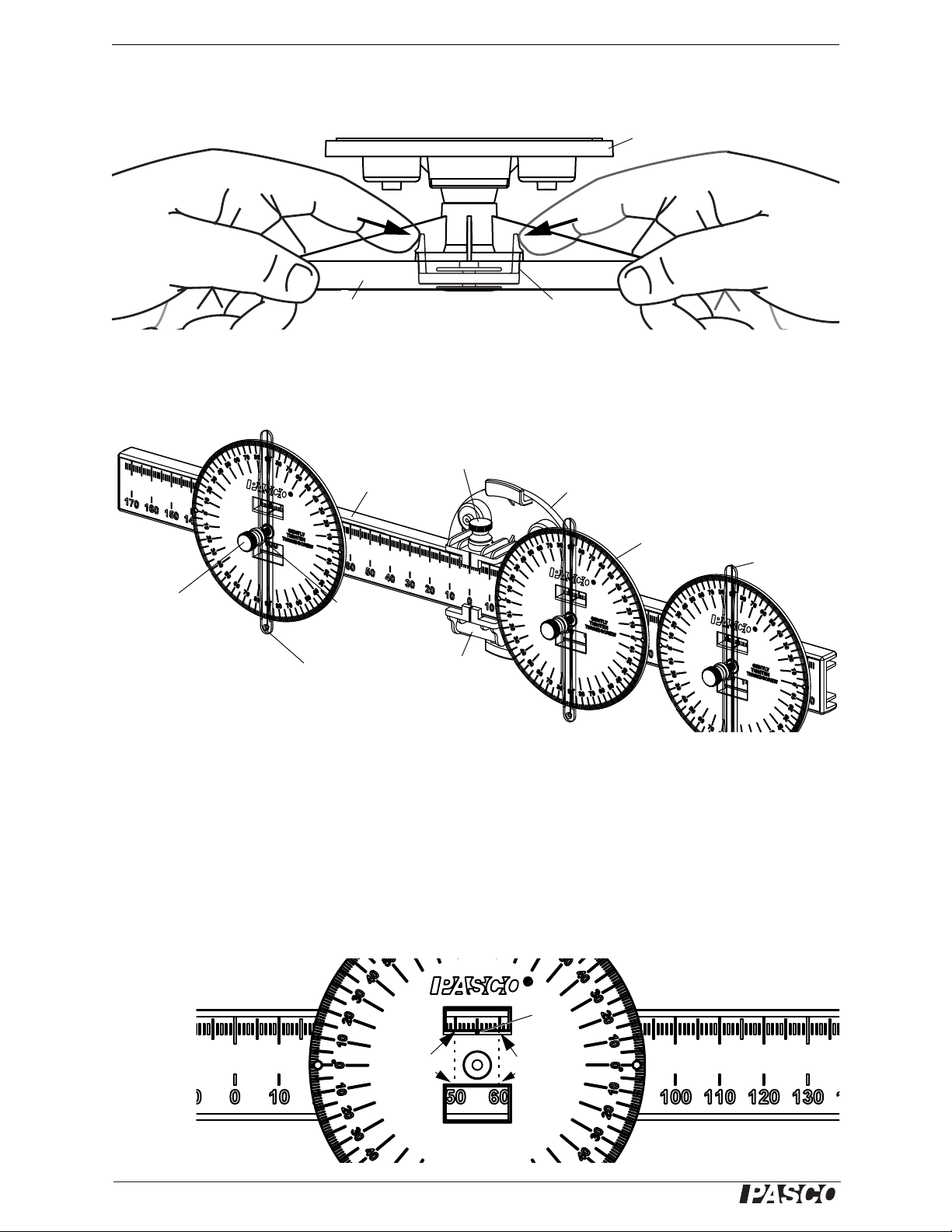

String Tie

Base

Force Wheel

Remove String Tie

Beam

Pivot

base

Bubble

level

Protractor

Tie a

thread to

the hole.

Angle Indicator

Thumbscrew

Thumbscrew

Washer

Balance Arm Assembly

Indicator

line

This tick

mark is at

50 mm.

This tick

mark is at

60 mm.

Note: The Angle Indicator is

not shown in this example.

Reading the Scale

(Imagine that the Force Wheel disk is transparent so that you can see the String Tie.) Hold the Force Wheel as

shown and push the clear plastic tabs inward with your forefingers until the String Tie pops out of the Force

Wheel.

Balance Arm Assembly

The Balance Arm Assembly consists of a Beam, a Pivot, and three Protractors that can be mounted on the beam.

Each protractor has a transparent Angle Indicator. The pivot has a bubble level for leveling the beam.

Adjust the beam by loosening the thumbscrew on the top of the pivot and sliding the beam one way or the other.

Move the protractors by loosening the thumbscrew at the center of the protractor and sliding the protractor along

the beam. Note that not all experiments need three protractors.

Reading the Scale

Read the position of the protractor relative to the midpoint through the two rectangular windows on the protractor.

The bottom window shows the position to the nearest centimeter, and the top window shows the position to the

millimeter. The top window has a small indicator line on its bottom edge. The bottom window in the example

shows the position as between 50 mm and 60 mm and the top window shows it at 55 mm.

8

012-12876B

Page 13

®

Model No. ME-9502 Components Package (ME-9505)

Utility Mount

Base

Rod for

Asymmetrical

Plate

Thumbscrew and

post for Load Cell

Attach a Cord

Clip here.

Attaching a Load Ce ll

Thumbscrew

Post

Cord Clip

Thread

Load Cell

Figure A: Hold the

cord clip so the two

parts separate

Figure B: Loop the

thread back through

the cord clip

Figure C: The thread

goes around the

screw hole

Figure D: The cord clip is ready to

be attached to a Utility Mount or a

Load Cell

Thumbscrew

hole

Peg

Threaded

post

Peg

Attaching a Cord Clip

Small

diameter

post

Base

Align the peg of the Cord

Clip with the hole in the

small diameter post.

Use the 5/8” thumbscrew

to attach the Cord Clip to

the threaded post.

Utility Mount Assembly

The Utility Mount has several functions. It can support a PS-2201 5 N

Load Cell, it has a rod from which you can hang the Asymmetrical

Plate, and the included Cord Tensioning Clip allows you to connect a

thread to the mount. The thumbscrew for the Load Cell is “captured”

by a rubber O-ring so that it will not fall out of the mount.

Attaching a Load Cell

You can use a 5N Load Cell (available separately) with

the Statics System to measure a force in much the same

way that the Mounted Scale can be used to measure a

force. (In fact, after the Load Cell is calibrated, it could be

used to calibrate the Mounted Scale.) First, loop a thread

through a Cord Clip (see below) and then attach the clip

to the “LOAD” position that is imprinted on the side of

the Load Cell. Next, attach the Load Cell’s “FIXED” end

to the thumbscrew and post on the Utility Mount.

Using a Cord Clip

The Cord Clip connects to the Utility Mount so that to a

thread and be attached to the Mount itself. Use the Clip

to attach a thread to a Load Cell (see above) that is mounted on the Utility Mount.

It is best to attach the thread through the clip before the clip is installed on the mount or on a Load Cell. The Cord

Clip has two parts but it does not come apart. Start by holding the top part of the clip so the two parts are separate

as shown in Figure A, leaving an opening through which the thread can be threaded. Insert the thread into the flat

end (not the pointed end) of the clip. Loop the thread back through the clip as shown in Figure B and Figure C.

Attach the Cord Clip to the Load Cell or the Utility Mount using the thumbscrew to tighten the clip shut.

012-12876B 9

Page 14

Statics System About the Manual

®

Rod

Asymmetrical Plate

Base

Suspend the Asymmetrical Plate

Utility

Mount

Asymmetrical Plate

The Asymmetrical Plate is a five-sided polygon with a small hole at

each corner. The Utility Mount has a slender metal rod designed to support the Asymmetrical Plate so that the plate can swing on the rod until

it reaches equilibrium.

About the Manual

The ME-9502 Statics System provides an introduction to static

mechanics. The experiments first introduce force as a vector quantity

and then build on this concept so that students will understand the equilibrium of a physical body under the application of a variety of forces

and torques. Experiments to demonstrate simple harmonic motion with

a pendulum and a spring/mass system are also included.

The experiments are presented in three groups: Basic Experiments,

Advanced Experiments, and Simple Machines. Each experiment is

copy-ready.

Basic Experiments provide the essentials for a solid introduction to

static mechanics. The concepts of vector forces, torques, and center of

mass are explored.

Advanced Experiments allow the student to combine the principles already studied to understand such phenomena as static equilibrium. Friction and simple harmonic motion are also investigated.

Simple Machines provide an opportunity for the student to investigate applications of the principles already studied and also to introduce important new concepts. Levers, inclined planes, and pulley systems are studied using the

principles of static equilibrium, work, and conservation of energy.

In addition to the equipment in the Statics System, a few common items such as pencils, rulers, protractors, paper,

a stop watch, and a mass balance will be needed for some experiments. Check the “Equipment Needed” section at

the beginning of each experiment.

NOTE: Vector quantities are designated with boldface font, such as F, W, or F

. When the same letters are used in

1

normal style font, they refer to the magnitude (size) of the vector quantity. Since the vector nature of torques is not

introduced in these experiments, boldface font is not used to designate torques.

10

012-12876B

Page 15

®

Model No. ME-9502 Exp. 1: Hooke’s Law—Measuring Force

Top

hook

Thumbnut

Indicator

Zero

mark

Bottom

hook

Figure 1.1: Setup and Procedure

Mass

hanger

10

mm

Thread

Exp. 1: Hooke’s Law—Measuring Force

Equipment Needed

Item Item

Statics Board Mounted Spring Scale

Mass and Hanger Set Thread

Introduction

At a practical level, a force is simply a push or a pull. A force is also a

vector quantity that has magnitude (size) and direction. There are different ways to apply and measure a force. One way to apply a force is to

hang a known mass, and determine the force based on the assumption

that gravity pulls the mass downward toward the center of the earth

with a magnitude F = mg, where m is the known mass and g is the

acceleration due to gravity (9.8 m/s

be expressed as 9.8 N/kg. Another way to apply a force is to pull with a

spring. A spring stretches when it is pulled, and if he amount it stretches

is directly proportional to the applied force, then the spring can be calibrated to measure unknown forces. In this experiment you will use the

known force associated with gravity pulling on calibrated masses to

investigate the properties of the Mounted Spring Scale.

2

). Note that the value of g can also

Hooke’s Law

Hooke’s Law describes the relationship between the amount of force

and the amount of stretch for an “ideal” spring. The law states that the

force and the stretch are directly proportional. In other words, the ratio

of the force divided by the stretch is a constant, k. The constant is called

the “spring constant”.

Setup

Place the Spring Scale on the Statics Board so that the spring hangs vertically in the tube. Do not hang anything on the bottom hook. The indicator must be aligned with the zero mark on the label. To zero the

Spring Scale, loosen the thumbnut at the top of the scale. Turn the top

hook clockwise to lower the indicator, and counter-clockwise to raise

the indicator. Once the indicator is aligned with the zero mark on the

label, tighten the thumbnut.

Procedure

1. Attach a thread to the bottom hook and hang a mass hanger from the thread.

2. Add mass to the mass hanger until the indicator is aligned with the 10 mm mark on the label. Adjust the mass

3. Record the total amount of mass (including the mass hanger) in the data table. Record the uncertainty.

so that the indicator is as close as possible to the mark. Estimate the uncertainty in your measurement. (If you

add or remove 0.5 g, can you see a change? What happens if you add or remove 1 g or 2 g?)

4. Add more mass to the mass hanger until the indicator is aligned with the 20 mm mark on the label and record

the total amount of mass and the uncertainty.

5. Repeat the process to move the indicator down by 10 mm each time until the indicator is aligned with the 80

mm mark. Record the total mass and the uncertainty each time.

012-12876B 11

Page 16

Statics System Exp. 1: Hooke’s Law—Measuring Force

®

Weight - Spring Scale

Weight

---------------------------------------------------- -

X100

Data Table

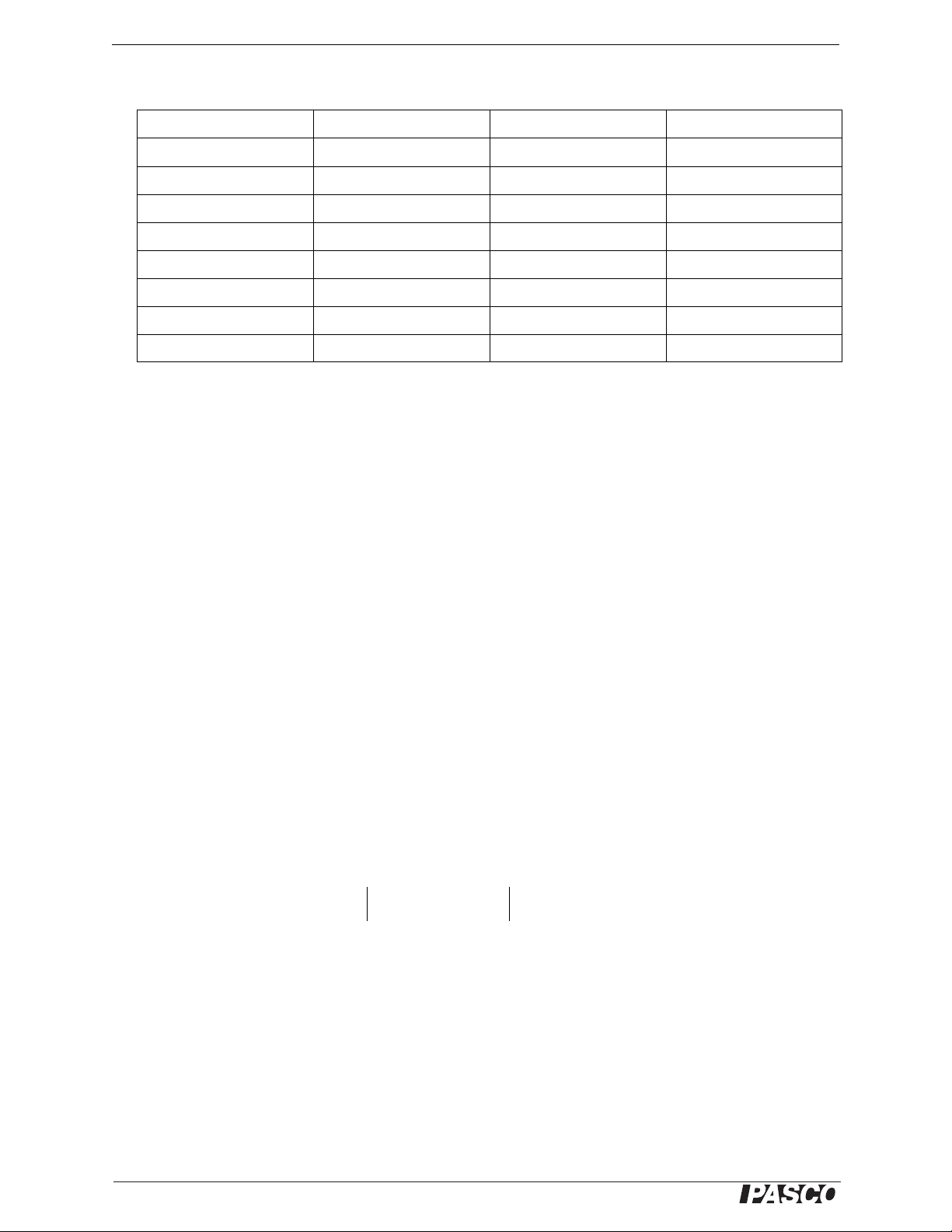

Spring Displacement (m) Mass (kg) Uncertainty Weight (N)

0.010 m (10 mm)

0.020 m (20 mm)

0.030 m (30 mm)

0.040 m (40 mm)

0.050 m (50 mm)

0.060 m (60 mm)

0.070 m (70 mm)

0.080 m (80 mm)

Calculations

1. Using the formula F = mg, where m is the mass and g is the a cceleration due to gravity, calculate the weight in

newtons for each trial. Record the weight in the data table. (To get the correct force in newtons, you must convert the mass value to kilograms.)

2. On a sheet of graph paper, construct a graph of Weight (N) versus Spring Displacement (m) with Spring Dis-

placement on the x-axis.

3. Draw the line that best fits your data points on the graph. The slope of this line on the graph is the ratio of the

force that stretched the spring divided by the amount of stretch. In other words, the slope is the spring constant, k, for the spring in the Spring Scale.

4. Determine the spring constant, k, from your graph and record the result. Remember to include the units (new-

tons per meter).

Spring constant = _____________________________

Using a Spring Scale to Measure Force

• Hang 160 g (0.160 kg) on the Spring Scale. Calculate the weight based on F = mg. Read the force in newtons

from the Spring Scale.

Weight = _______________ Spring Scale reading = ______________

• How does the measurement from the Spring Scale compare to the actual weight?

• Calculate the percent difference:

Percent Difference = _______________

Questions

1. Hooke’s Law states that the relationship between force and displacement in springs is a linear relationship. If

2. In what way is Hooke’s Law useful when calibrating a spring for measuring forces?

3. On your graph of Weight versus Spring Displacement, did the best fit line go through the origin (zero)? If it

12

Hooke’s Law was not valid, could a spring still be used successfully to measure forces? If so, how?

didn’t, what does that mean?

012-12876B

Page 17

®

Model No. ME-9502 Exp. 2: Adding Forces—Re sultants and Equilibriants

Figure 2.2: Setup

Force

Wheel

Bubble

level

Force

disk

Spring

Scale

Thread

Force

disk

Fg = mg

F

E

= mg

Figure 2.1: Resultant and Equilibriant

F

A

F

B

F

R

F

E

Car

Exp. 2: Adding Forces—Resultants and Equilibriants

Equipment Needed

Item Item

Statics Board Mounted Spring Scale

Force Wheel Large and Small Pulleys

Mass and Hanger Set Thread

Theory

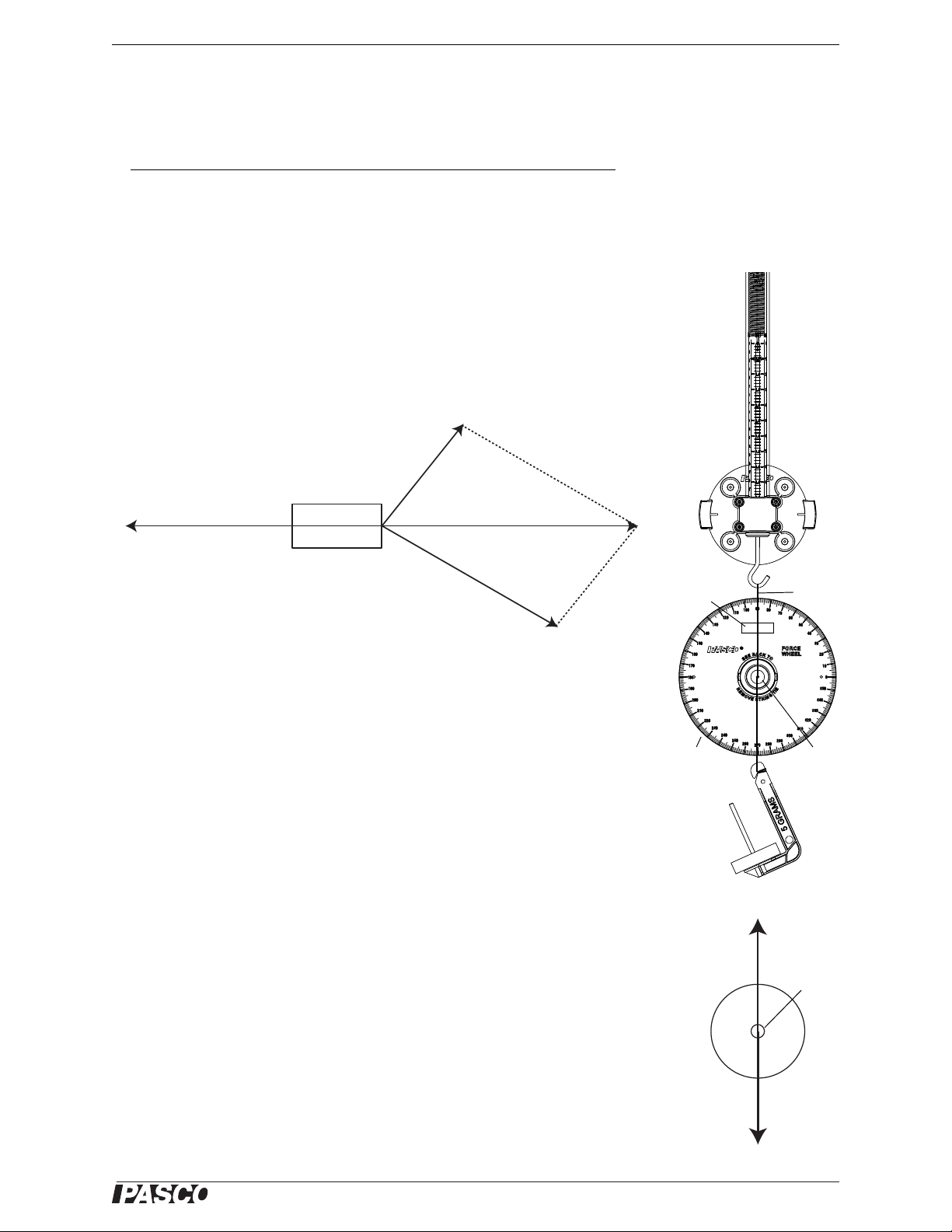

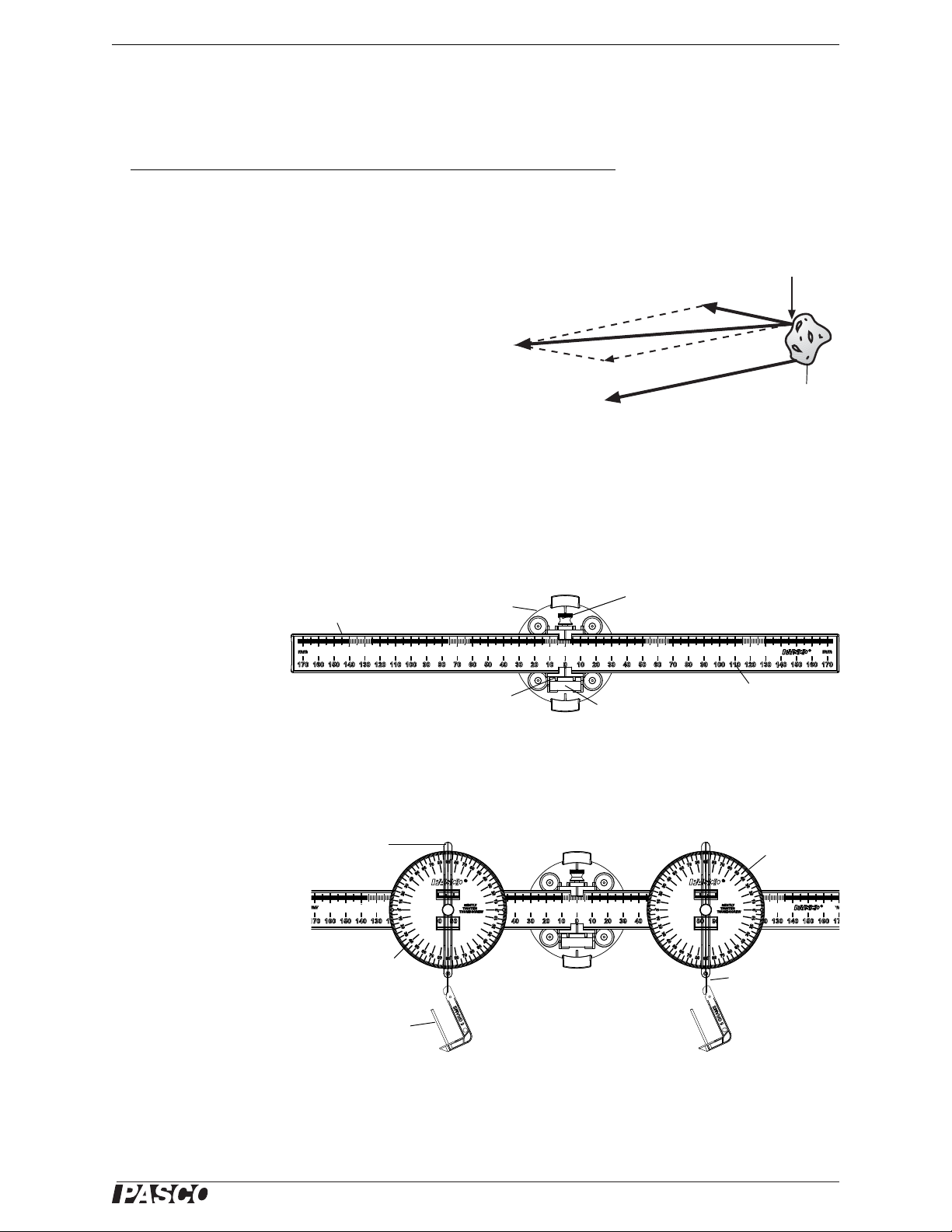

In figure 2.1, Person A and Person B are pulling with forces represented by FA and

F

on a car stuck in the mud. Since these forces are acting on the same point of the

B

car, they are called concurrent forces. Each force is defined both by is direction

(the direction of the vector arrow), and by its magnitude, which is proportional to

the length of the vector arrow. (The magnitude of the force is independent of the

length of the tow rope.)

The total force applied by the two people can be determined by adding vectors F

and F

. The parallelogram method is used in the example. The diagonal of the par-

B

allelogram is called the resultant, F

combination of F

and FB.

A

. It shows the magnitude and direction of the

R

Because the car is not moving, the net force on the car must be zero. The friction

between the car and the mud is equivalent to the resultant force, F

opposing force is called the equilibriant, F

the resultant, F

Setup

, and it has the opposite direction of the resultant.

R

. This force has the same magnitude as

E

. This equivalent

R

Set up the Spring Scale and Force Wheel on the Statics Board as shown. Twist the

Force Wheel until the bubble level shows that the Force Wheel is level. Attach one

of the threads from the force disk (inner part of the String Tie) in the center of the

Force Wheel to the bottom hook of the Spring Scale. Connect a second thread to a

mass hanger (let the third thread dangle). Add 80 g (0.080 kg) to the mass hanger.

Adjust the Spring Scale up or down so that the force disk is centered in the Force

Wheel. The mass hanger applies a force downward, F

ity, where m is the total mass of the mass hanger). When the force disk is centered,

the system is in equilibrium, so the downward force F

equal and opposite force, the equilibriant, F

F

, is applied by the Spring Scale.

E

. In this case, the equilibriant force,

E

= mg (the force due to grav-

g

must be balanced by an

g

A

012-12876B 13

Page 18

Statics System Exp. 2: Adding Forces—Resultants and Equilibriants

®

Figure 2.3: Find the Equilibriant

Small

Pulley

Small

Pulley

Large

Pulley

Force

Wheel

Force

disk

Spring

Scale

F

1

F

2

F

E

Vector diagram

1

2

E

M

2

M

1

Zero

line on

the

Force

Wheel

Procedure: Two Forces

1. Add or remove 0.5 g to the mass hanger. Did the force disk move away from the center position? How much

can you change the mass on the mass hanger without changing where the force disk is centered?

2. What are the magnitude and direction of F

• F

: Magnitude ________________ Direction ________________

g

, the gravitational force applied by the hanger, where Fg = mg?

g

3. Use the Spring Scale and Force Wheel to determine the magnitude and direction of F

• F

: Magnitude ________________ Direction ________________

E

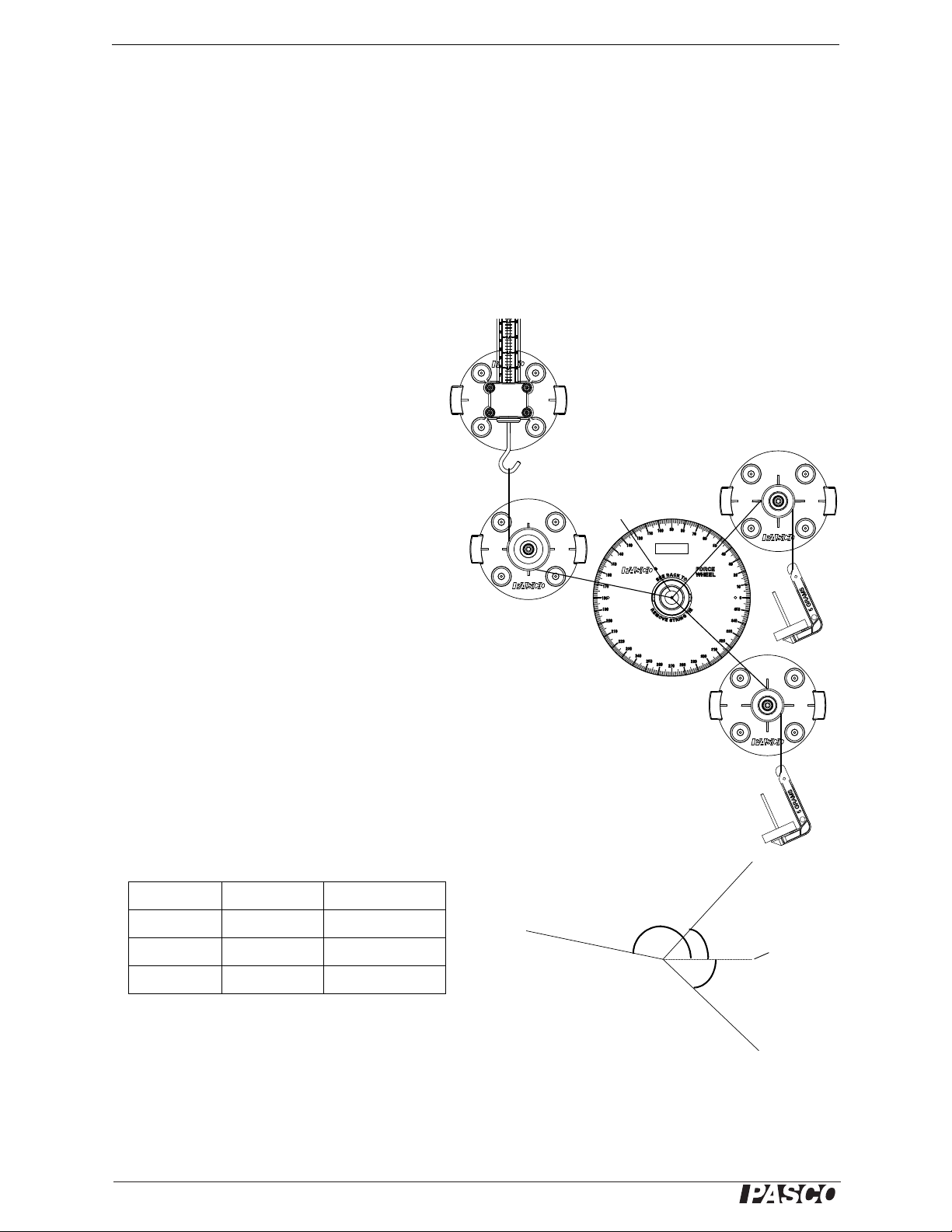

Procedure: Three Forces

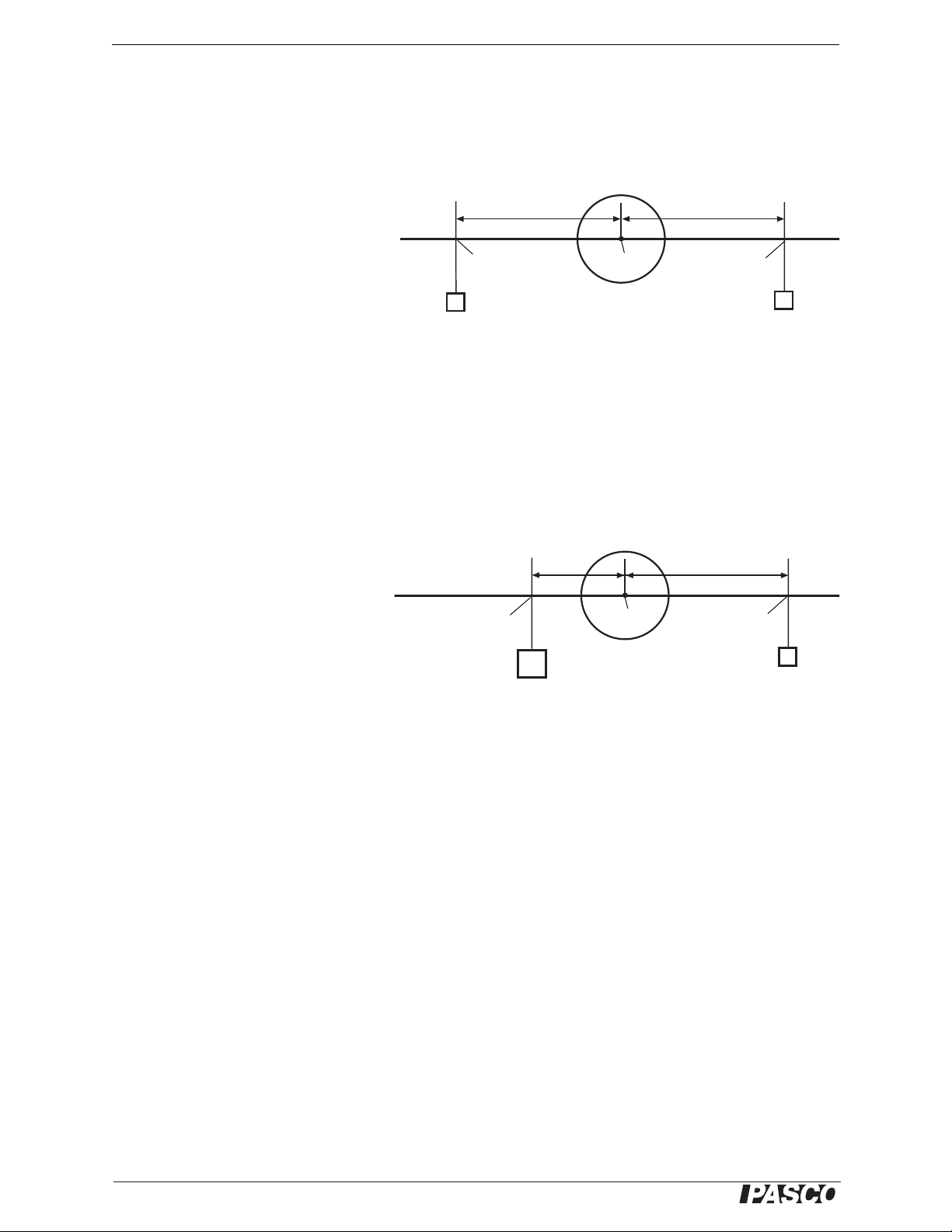

1. Attach the Large Pulley and the two Small

Pulleys to the Statics Board and move the

Spring Scale as shown in the figure.

2. Attach threads to the bottom hook of the

Spring Scale and to mass hangers over the

Small Pulleys.

3. Add 30 g (0.030 kg) to the upper mass

hanger and add 50 g (0.050 kg) to the lower

mass hanger.

4. Adjust the Large Pulley and the Spring

Scale so that the force disk is centered in the

Force Wheel.

, the equilibriant.

E

5. How much can you change the mass on the

hangers and still leave the force disk centered in the Force Wheel?

Data

Record the values of the hanging masses M1 and

M

(including the mass of the mass hangers), the

2

magnitude in newtons of the forces F

F

, and the angles 1, 2, and E with respect to

E

the zero-degree line on the Force Wheel..

Mass (kg) Force (N) Angle (°)

M

1

M

2

F

1

F

2

F

E

1

2

E

, F2, and

1

14

012-12876B

Page 19

®

Model No. ME-9502 Exp. 2: Adding Forces—Re sultants and Equilibriants

Analysis

1. On a separate piece of graph paper, use the values you recorded in the table to construct a vector diagram for

F

, F2, and FE. Choose an appropriate scale, such as 2.0 centimeters per newton, and make t he l engt h of eac h

1

vector proportional to the magnitude of the force. Label each vector and indicate the magnitude of the force it

represents.

2. On your vector diagram, use the parallelogram method to draw the resultant of F

F

. Measure the length of FR to determine the magnitude of the resultant force and record this magnitude on

R

and F2. Label the resultant

1

your vector diagram.

3. On your diagram, measure the direction of F

angle

.

R

relative to the horizontal axis of your diagram and label the

R

Questions

1. Does the magnitude of the equilibriant force vector, FE, exactly balance the magnitude of the resultant force

vector, F

2. Ho w does the dire ction of the equilibriant force vector, F

tor, F

. If not, what are some possible reasons for the difference?

R

?

R

E

, compare to the direction of the resultant force vec-

Extension

Vary the magnitudes and directions of F1 and F2 and repeat the experiments.

012-12876B 15

Page 20

Statics System Exp. 2: Adding Forces—Resultants and Equilibriants

®

16

012-12876B

Page 21

®

Model No. ME-9502 Exp. 3: Resolving Forces—Components

M

1

M

2

M

1

F

-F

x

-F

y

Spring

Scale

Pulley

Pulley

Force

Wheel

Force

disk

Figure 3.1: Setup

Exp. 3: Resolving Forces—Components

Equipment Needed

Item Item

Statics Board Mounted Spring Scale

Force Wheel Pulleys (2)

Mass and Hanger Set Thread

Theory

In experiment 2, you added concurrent forces vectorially to determine the magnitude and direction of the combined forces. In this experiment, you will do the reverse: you will find two forces which, when added together,

have the same magnitude and direction as the original force. As you will see, any force vector in the X-Y plane can

be expressed as a vector in the x-direction and a vector in the y-direction.

Setup

Set up the equipment as shown in the figure. As

shown, create a force vector F by hanging a

mass, M

center of the Force Wheel over a pulley.

, on a thread from the force disk in the

1

Set up the Spring Scale and a pulley so that the

thread from the Spring Scale is horizontal from

the bottom of the pulley to the force disk. Hang a

second mass hanger directly from the force disk

in the center of the Force Wheel.

Now pull the Spring Scale toward or away from

the pulley to adjust the horizontal or x-component of the force, F

on the vertical mass hanger , M

tical or y-component of the force, F

. Adjust the amount of mass

x

, to adjust the ver-

2

. Adjust the

y

x- and y-components in this way until the force

disk is centered in the Force Wheel.

Note: These x- and y-components are actually

the x- and y-components of the equilibriant, F

,

E

of the force F, rather than the components of F

itself.

Procedure 1

1. Calculate and record the magnitude of F (based on F = mg). Use the Force Wheel to measure the angle of F

and then record the angle.

• Magnitude, F = _________________ Angle, = ____________________

2. Record the magnitude of the x-component of the equilibriant of F and calculate and record the y-component

of the equilibriant of F.

• X-component = _________________ Y-component = ____________________

012-12876B 17

Page 22

Statics System Exp. 3: Resolving Forces—Components

®

F

Fx = F cos

F

y

= F sin

O

X

Figure 3.2: Vector components

F

R

Rx2Ry

2

+=

R

R

y

R

x

----- -

atan=

3. What are the magnitudes of F

• F

= _________________ Fy = ____________________

x

and Fy, the x- and y-components of F?

x

4. Change the magnitude and direction of the force vector F and repeat the experiment.

5. Record the magnitude and angle of the new force vector, F, and the magnitudes of F

• Magnitude, F = _________________ Angle, = ____________________

• F

= _________________ Fy = ____________________

x

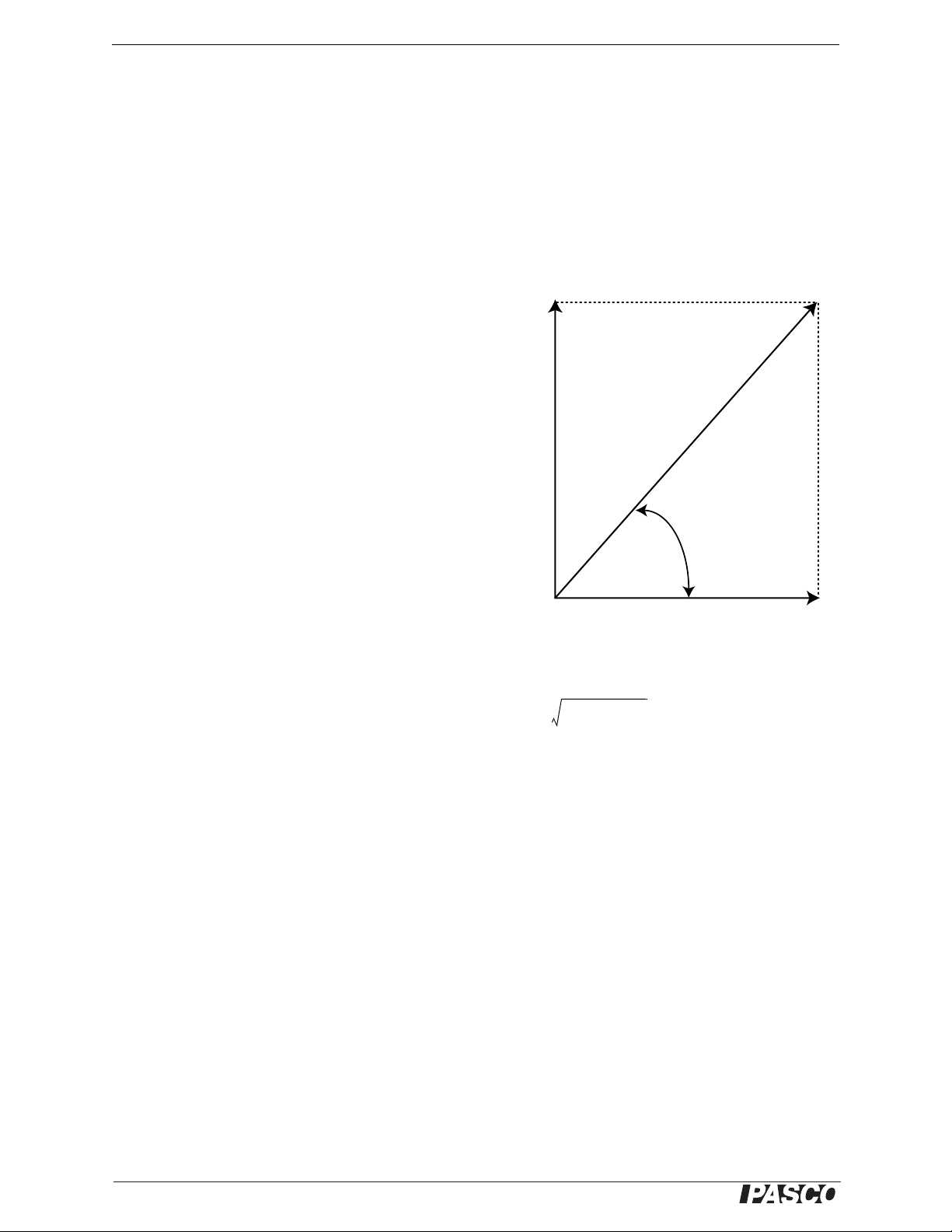

Background

Why use components to specify vectors? One

reason is that using components makes it easier

to add vectors mathematically. The figure shows

the x- and y-components of a vector of length F,

and an angle with respect to the x-axis. Since

the components are at right angles to each other,

the parallelogram used to determine their resultant is a rectangle. Using right triangle AOX, the

components of F can be calculated:

and Fy.

x

• F

, the x-component of F is F cos

x

• F

, the y-component of F is F sin

y

If you want to add several vectors, find the x- and

y-components for each vector. Add all the

x-components together and all the y-components

together. The resulting values are the x- and

y-components for the resultant. The magnitude of the resultant, F

the resultant’s x-component (R

) and the y-component (Ry).

x

, is the square root of the sum of the squares of

R

The angle of the resultant is the arctangent of the y-component divided by the x-component.

Procedure 2

Make sure that the Force Wheel is level. Set up a new force, F. Put one thread from the force disk over a pulley and

tie a mass hanger to the end of the thread. Add mass to the mass hanger.

1. Calculate and record the magnitude of the force, F, that you set up with the pulley and mass hanger. Use the

Force Wheel to determine the angle.

• Magnitude, F = _________________ Angle, = ____________________

2. Calculate the magnitudes of F

and F

• F

= _________________ Fy = ____________________

x

= F sin .)

y

3. Now, set up the Spring Scale with a pulley and a thread from the force disk so it can apply the x-component,

F

, of the new force F. Adjust the Spring Scale so that it pulls the force disk horizontally by the amount, Fx.

x

4. Next, attach a mass hanger to the third thread from the force disk so the thread hangs vertically. Add mass to

the hanger so it pulls the force disk vertically by the amount, F

18

and Fy, the x- and y-components of the new force, F. (Remember, Fx = F cos

x

.

y

012-12876B

Page 23

®

Model No. ME-9502 Exp. 3: Resolving Forces—Components

F

1

F

2

F

3

NOTE: The diagram is

not to scale.

Figure 3.3: Extension vectors

Question

1. Is the force disk at equilibrium in the center of the Force Wheel?

2. Why or why not?

Extensions

1. Generally it is most useful to find the components of a vector along perpendicular axes, as you did above.

However, it is not necessary that the axes be perpendicular. If time permits, try setting up the equipment to

find the components of a vector along non-perpendicular axes. Use pulley to redirect the component forces to

non-perpendicular directions.

2. The figure shows a classic vector combination. For the force disk to be in

equilibrium, the x-components of force

F

and force F2 must be equal and

1

opposite, and the y-components of F

and F

must add to equal the magni-

2

tude of force F

, the vertical force. Set

3

up the equipment so that the Spring

Scale applies force F

. Once the sys-

1

tem is in equilibrium, determine the xand y-components of the vectors and

compare them.

1

3. For the setup in the figure, change the

angles of F

are closer to the x-axis. Calculate the

x-components and notice the change.

What happens to the x-components as

the two forces become closer and

closer to parallel? What amount of

force would be needed if F

were both horizontal?

and F22 so that the vectors

1

and F2

1

012-12876B 19

Page 24

Statics System Exp. 3: Resolving Forces—Components

®

20

012-12876B

Page 25

®

Model No. ME-9502 Exp. 4: Torque—Parallel Forces

A

F

R

Figure 4.1: Non-concurrent forces

Object

F

1

F

1

Figure 4.2: Balance Arm

Base

Thumbscrew

Bubble level

Beam

Pivot

Scale

Figure 4.3: Setup

Angle

Indicator

Protractor 2

M

1

M

2

Protractor 1

Thread

Mass

hanger

Exp. 4: Torque—Parallel Forces

Equipment Needed

Item Item

Statics Board Balance Arm and Protractors

Mass and Hanger Set Thread

Theory

In experiment 2, you found resultants and equilibriants

for concurrent forces—forces that act upon the same

point. In the real world, forces are often not concurrent.

They act upon different points on an object. In the figure, for example, two forces are pulling on different

points of an object. Two questions can be asked:

1. In which direction will the object be accelerated?

2. Will the object rotate?

If the two forces were both applied at point A, the resultant would be the force vector shown, F

. In fact, FR points

R

in the direction in which the object will be accelerated. (This idea will be investigated further in later experiments,)

What about question 2? Will the object rotate? In this experiment you will begin to investigate the types of forces

that cause rotation in physical bodies. In doing so, you will encounter a new concept—torque.

Setup

Mount the Balance

Arm near the center of

the Statics Board.

Level the Beam

Loosen the thumbscrew and adjust the beam so that the zero mark on the beam is aligned with the indicator marks

on the pivot. When the beam is level, the bubble in the bubble level will be midway between the two lines on the

level.

Add the Protractors

First, find the mass of two

of the protractors and

record the masses. (Note

that you can use the Spring

Scale to measure the mass.)

• Protractor 1 =

__________

• Protractor 2 =

__________

Loosen the thumbscrews on the two protractors and slide one onto each end of the beam. Tie a mass hanger to the

thread on the angle indicator of each protractor.

012-12876B 21

Page 26

Statics System Exp. 4: Torque—Parallel Forces

®

d

1

d

2

M

1

M

2

Figure 4.4: Measuring Torques

center of

protractor 1

center of

protractor 2

pivot

M

1

M

2

d

1

d

2

Figure 4.5: More Torques

center of

protractor 1

pivot

center of

protractor 2

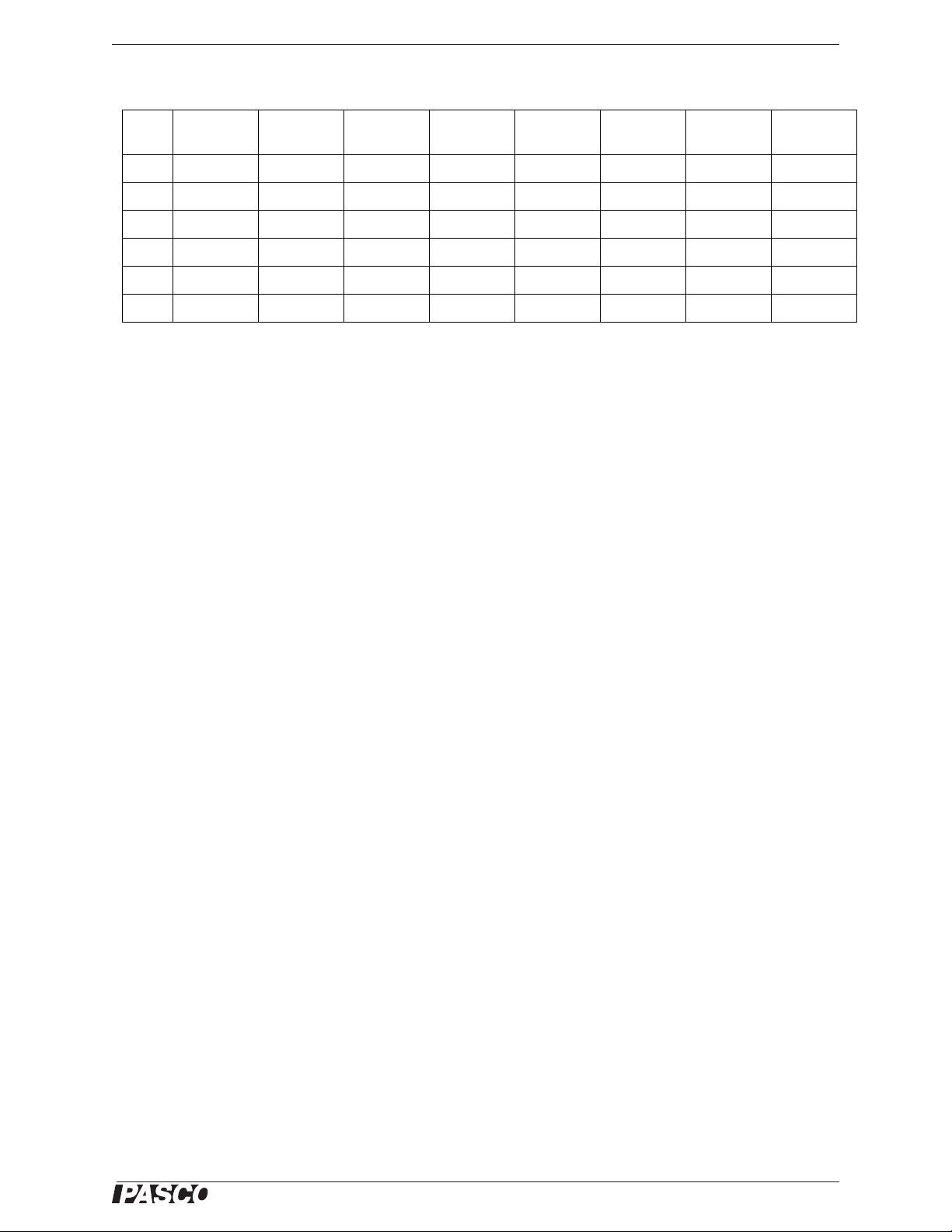

Procedure: Equal Distance, Equal Mass

Position one of the protractors near one end the beam and tighten its thumbscrew to hold it in place. Adjust the

position of the other protractor until the beam is perfectly balanced, and then tighten its thumbscrew to hold it in

place.

1. Measure d

and d2, the distances

1

from the pivot to the center of each

protractor.

•d

= _______________

1

•d

= _______________

2

2. Add a 50-gram mass to each mass

hanger.

• Is the beam still balanced?

3. Add an ad ditional 20-gram to one of the mass hangers.

• Can you restore the balance of the beam by repositioning the other protractor and mass hanger?

Procedure: Unequal Distance, Unequal Mass

Position one of the protractors approximately halfway between the pivot point

and the end of the beam and tighten its

thumbscrew to hold it in place. Add 75

grams of mass to the mass hanger, M

.

1

Place various masses on the other mass

hanger (M

) and slide it along the beam

2

as needed to rebalance the beam.

1. At the first balanced position, measure the total mass, M

and M2, on each side of the pivot (protractor, mass

1

hanger, added masses) and record the masses in the data table.

2. Measure the distances, d

and d2, between the centers of the protractors and the pivot and record the values in

1

the data table.

3. Take measurements for five more different valu es of M

and record your results in the data table. Be sure to

2

include the units of your measurements.

4. If there is time, vary M

and repeat the procedure.

1

• Reminder: For accurate results, include the mass of the protractor, mass hanger, and added masses when measuring M

and M2.

1

Calculations

Calculate the gravitational force (weight = mg) produced by the total mass on each side of the beam for each case.

Calculate the torques,

of the net force and the lever arm. Since the distance and the direction of the force are at right angles in this experiment, the torque, , is F d (where F

balanced position of the beam.

22

and 2, on each side of the beam for each case. Remember, torque, , is the cross product

1

= mg). Record your calculated values of weight, Fg, and torque, , for each

g

012-12876B

Page 27

®

Model No. ME-9502 Exp. 4: Torque—Parallel Forces

Data Table

Case Total Mass

M

(kg)

1

1

2

3

4

5

6

Weight

F1 (N)

Distance

d1 (m)

Torque

1 = F1 d

1

Total Mass

M

(kg)

2

Weight

F2 (N)

Distance

d2 (m)

2 = F2 d

Questions

1. From your results, what mathematical relationship must there be between 1 and 2 in order for the beam to be

balanced?

2. What torque is exerted on the balance beam by the upward pull of the pivot point?

Extension

If you have time, try adding a third Protractor and Mass Hanger to the beam on the same side of the beam as the

second Protractor.

Torque

2

Question

What relationship must there be between

protractors and mass hangers?

, 2, and 3 in order for the beam to be balanced when there are three

1

012-12876B 23

Page 28

Statics System Exp. 4: Torque—Parallel Forces

®

24

012-12876B

Page 29

®

Model No. ME-9502 Exp. 5A: Center of Mass

Support

Center of mass

Object

Figure 5.1: Equipment Setup

M

1

M

2

Pivot

base

Protractor

Angle

Indicator

Exp. 5A: Center of Mass

Equipment Needed

Item Item

Statics Board Balance Arm and Protractors

Asymmetrical Plate Thread

Mass and Hanger Set

Theory

Gravity is a universal force; every bit of matter in the universe is attracted to every other bit of matter. Therefore,

when the Balance Arm is supported by the pivot, every bit of matter in the Balance Arm is attracted to every bit of

matter in the Earth.

Fortunately , the sum of all these individual gravitational forces produces a single resultant. This resultant acts as if

it were pulling between the center of the Earth and the center of mass of the Balance Arm. The magnitude of the

force is the same as if all the matter of the Earth were located at the center of the Earth, and all the matter of the

Balance Arm were located at the center of mass of the Balance Arm.

An object thrown so that it rotates tends to rotate about its center of mass,

and the center of mass follows a parabolic path. An object whose center of

mass is above a support tends to remain in rotational equilibrium (balanced on the support). In this experiment you will use your knowledge of

torque to understand and locate the center of mass of an object.

Setup

Measure and record the

mass of the beam.

Next, find the mass of

two of the protractors

and record the masses.

(Note that you can use

the Spring Scale to

measure the mass.)

• Beam = ________

• Protractor 1 = __________

• Protractor 2 = __________

Loosen the thumbscrews on the two protractors and slide one onto each end of the beam so each protractor is at the

165 mm mark. Tie a mass hanger to the thread on the angle indicator of each protractor

Mount the Balance Arm near the center of the Statics Board.

Record the total mass of the beam plus protractors plus mass hangers (5 grams each).

• Mass of system = _____________

012-12876B 25

Page 30

Statics System Exp. 5A: Center of Mass

®

Pivot

Center of mass

of the beam

F

2

F

3

F

1

Figure 5.2: Torques and the Center of Mass

Level the Beam and Mark the Center of Mass

Loosen the thumbscrew and adjust the beam so that the indicator marks on the pivot are aligned with the zero mark

on the beam. If necessary, adjust the positions of the two protractors until the bubble in the bubble level is midway

between the two lines on the level. Once the beam is balanced and level, tighten the thumbscrews to hold the protractors and beam in place.

Put a pencil mark on the beam to indicate the center of mass of the system. All of the mass of the system (beam,

protractors, mass hangers) acts as if it is concentrated at the center of mass.

Once the beam is in balance, the force at the pivot point must be the equilibriant of the total gravitational force acting on the beam. Since the beam does not rotate, the gravitational force and its equilibriant must be concurrent

forces.

Experiment

1. Why would the Balance Arm necessarily rotate if the resultant of the gravitational forces and the force provided by the pivot were not concurrent forces?

• Think of the Balance Arm as a collection of many small hanging masses. Each hanging mass is pulled down

by gravity and therefore produces a torque about the pivot point of the Balance Arm.

2. What is the relationship between the sum of the clockwise torques about the center of the mass and the sum of

the counterclockwise torques about the center of mass? Explain.

• Add 50 grams to one mass hanger and 100 grams to the other mass hanger. Loosen the thumbscrew on the

beam and slide the beam through the pivot until the beam and masses are balanced. Tighten the thumbscrew.

• The pivot is still supporting everything (beam, protractors, mass hangers, and hanging masses), but at the new

center of mass of the system–the pivot point.

3. Calculate the three torques,

and

provided by the three forces

3

F

, F2, and F3 acting about the new

1

, 2,

1

pivot point position. Be sure to indicate whether each torque is clockwise (cw) or counterclockwise (ccw).

Position Mass (kg) Force (F = mg) Distance (m) Torque ( = F d)

1 0.050

2 0.100

3

4. Are the clockwise and counte rclockwise torques balanced?

• Remove the 50 gram mass from the left hand mass hanger, but leave the hanger and protractor in place.

(Removing the mass effectively removes F

balances the torque provided by F

26

and the beam is level again.

2

). Reposition the beam in the pivot until the torque provided by F3

1

012-12876B

Page 31

®

Model No. ME-9502 Exp. 5A: Center of Mass

Mass

hanger

Asymmetrical

Plate

Force Sensor

Mount

Thread

Rod

Figure 5.3: Finding the

Center of Mass

• Recalculate the torques about the pivot point.

Position Force (F = mg) Torque ( = F d)

2

3

5. Are the torques balanced?

Asymmetrical Plate

Replace the Balance Arm with the Force Sensor Mount. Hang the Asymmetrical Plate from the rod on the Force Sensor Mount.

Since the force of the rod acting on the plate is the equilibriant to the sum of the

gravitational forces acting on the plate, the line of force exerted by the rod must

pass through the center of the mass of the plate. Loop a piece of thread over the

rod and attach a mass hanger to the end of the thread.

Use a pencil or a “dry erase” pen to draw a line on the Asymmetrical Plate that

marks the position of the thread on the plate.

Remove the thread and mass hanger. Hang the plate from a different hole. Put

the thread and mass hanger back on the rod. Draw a new line on the plate that

marks the position of the thread.

Repeat the process for a third different hole. Draw a third line on the plate.

6. Does the line showing where the thread is hanging pass through the center

of mass of the plate?

7. Would this method work for a three dimensional object? Why or why not?

Extension

Remove the thread and plate from the rod. Try to balance the Asymmetrical Plate on your finger by placing the tip

of you finger under the point where the three drawn lines intersect. What happens?

012-12876B 27

Page 32

Statics System Exp. 5A: Center of Mass

®

28

012-12876B

Page 33

®

Model No. ME-9502 Exp. 5B: Equilibrium of Physical Bodies

Figure 5.4: Non-concurrent,

non-parallel forces

Object

F

1

F

2

F

3

M

1

M

2

F

1

F

2

F

3

F

4

Spring

Scale

Force

diagram

Point of

suspension

Center of mass

of the beam

C.O.M.

Figure 5.5: Equipment Setup

Exp. 5B: Equilibrium of Physical Bodies

Equipment Needed

Item Item

Statics Board Balance Arm and Protractors

Pulley (1) Mounted Spring Scale

Mass and Hanger Set Thread

Theory

Any force acting on a body may produce both translational motion

(movement of the center of mass of the body in the direction of the force)

and rotational motion (rotation about a pivot point).

In this part of the experiment you will investigate the interplay between

forces and torques by examining all the forces acting on a body in physical equilibrium.

Setup

Find the center of mass of the balance beam and mark it with a pencil. Use the Spring Scale, mass hangers, and

three protractors on the Balance Arm to set up the equipment as shown.

By supporting

the Balance

Arm from the

Spring Scale,

you can now

determine all

the forces acting on the Balance Arm.

As shown in

the diagram,

these forces

include F

weight of the

mass, M

the weight of

the mass M

F

, the weight

3

1

, F2,

1

, the

,

2

of the balance

beam acting

through its center of mass, and

F

, the upward pull of the Spring Scale.

4

Experiment

Fill in the data table listing M (in kilograms), F (in newtons), d (the distance in meters from the applied force to the

suspension point), and (the torque acting about the point of suspension in newton • meters. Indicate whether each

torque is clockwise (cw) or counterclockwise (ccw)

012-12876B 29

Page 34

Statics System Exp. 5B: Equilibrium of Physical Bodies

®

F

1

F

2

F

3

F

4

d

1

d

2

d

3

d

4

Figure 5.6: Change the Origin

Origin

Data Table.

Position mass (M) force (F) distance (d) torque ()

1

2

3

4—

Calculations

1. Calculate and record the sum of the clockwise and counterclockwise torques.

= _________________________

cw

• Are the torques balanced?

2. Calculate and record the sum of the upward and downward forces.

F

= _________________________ F

up

= _______________________

ccw

= _______________________

down

• Are the translational forces balanced?

3. On the basis of your answers to the questions, what conditions must be met for a physical body to be in equilibrium (no acceleration)?

Change the Origin

In measuring the torques the first time, all the distances were measured from the point of suspension of the Balance Arm. This measures the tendency of the beam to rotate about this point of suspension. You can also measure

the torques about any other point, on or off the beam. Using the same forces as you used before, re-measure the

distances, measuring from the left end of the balance beam as shown in the diagram.

Recalculate the

torques to

determine the

tendency of the

beam to rotate

about the left

end of the

beam.

Record your

data in the second table. As

before, indicate whether each torque is clockwise (cw) or counterclockwise (ccw).

30

012-12876B

Page 35

®

Model No. ME-9502 Exp. 5B: Equilibrium of Physical Bodies

Data Table: Change the Origin.

Position force (F) distance (d) torque ()

1

2

3

4

Calculations

1. Calculate and record the sum of the clockwise and counterclockwise torques.

= _________________________

cw

= _______________________

ccw

• Are the torques balanced?

Extension

Use a pulley, hanging mass, and a thread to produce an additional upward force at one end of the beam. You may

need to use tape to secure the thread to the beam.) Adjust the positions of the remaining hanging masses and the

Spring Scale to bring the beam back into balance so it is level horizontally.

• Are all the forces balanced, both for translational and rotations motion?

• Diagram your setup and show your calculations on a separate sheet of paper.

012-12876B 31

Page 36

Statics System Exp. 5B: Equilibrium of Physical Bodies

®

32

012-12876B

Page 37

®

Model No. ME-9502 Exp. 6: Torque—Non-Paralle l Forces

Figure 6.1: Torque

F

d

F

Pivot

point

Lever

arm

d

Fd sin=

Exp. 6: Torque—Non-Parallel Forces

Equipment Needed

Item Item

Statics Board Balance Arm and Protractors

Pulley Mounted Spring Scale

Mass and Hanger Set Thread

Theory

In a previous experiment, you investigated torques

appled to the Balance Arm and discovered that when

the torques about the point of rotation are balanced, the

beam remains balanced. All the forces in that experiment were perpendicular to the beam and parallel to

each other. What happens when one or more of the

forces is not perpendicular to the beam?

It turns out that the formula for torque can be generalized to account for this case. Torque is the cross product of the force vector and the lever arm where the lever arm

is the distance from the pivot point to where the force is applied. The generalized formula is:

where F is the magnitude of the force vector, d is the distance from the pivot point to the point at which the force

is applied (that is, the “lever arm”), and is the angle between the force vector, F, and the lever arm, d. Note that

F sin is F

is d

perpendicular distance, d

, the component of the force vector, F, that is perpendicular to the lever arm, d. Note also that d sin

the component of the lever arm, d, that is perpendicular to the force vector, F. In other words, d sin is the

, from the pivot point to the line of force.

Setup

Mount the Balance Arm on the left half of the Statics Board. Adjust the beam so that the zero marks on the beam

align with the indicator marks on the pivot.

Put a protractor on each end of the beam (for example, between 130 and 140 mm from the pivot). Adjust the position of the protractors if necessary so that the beam is balanced and level.

012-12876B 33

Page 38

Statics System Exp. 6: Torque—Non-Parallel Forces

®

M

2

Figure 6.2: Equipment Setup

Spring

Scale

Pulley

Protractor

Beam

M

2

F

2

F

1

d

2

d

1

Pivot point

Figure 6.3: Schematic

12–12+2

Suspend a mass, M

, from one protractor. Mount the Spring Scale on the Statics Board and connect it to the other

2

protractor using a thread and a Pulley as shown.

Procedure

1. Measure d1 and d2 and record the values.

2. Record the total mass, M

tude of the force, F

, and the magni-

2

(weight of the hanging

2

mass). Use your measured values to calculate the torque,

, produced by the force, F2.

2

Be sure to include the units for each value.

d1 (m) d2 (m) M2 (kg) F2 (N) (N•m)

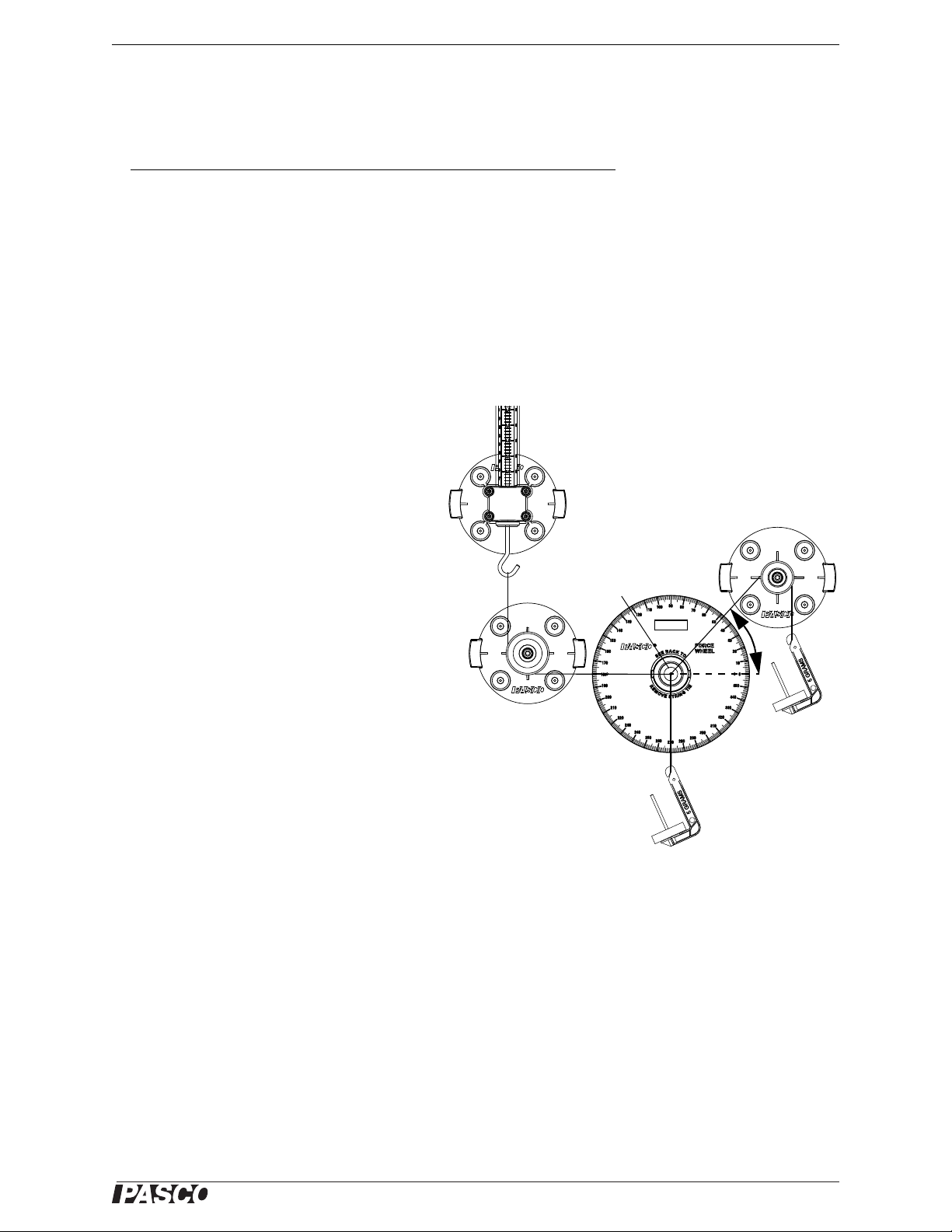

• By moving the pulley, you can adjust the angle of the force, F

. Note that when you move the pulley, you also

1

need to move the Spring Scale in order to keep the thread perfectly vertical between the Spring Scale and the

pulley.

3. Set the angle of F

toward or away from the pulley as needed so that the magnitude of F

to each of the values shown in the table below. At each angle, move the Spring Scale

1

is sufficient to balance the beam.

1

Record the force reading on the Spring Scale in newtons.

Angle F

30°

40°

50°

60°

(N) 1 = F1d1 sin

1

34

70°

80°

012-12876B

Page 39

®

Model No. ME-9502 Exp. 6: Torque—Non-Paralle l Forces

F

1

F

2

O

F

1

O

O

F

2

d

2

d

1

d

d

d

1

d

2

Line of force

Line of

force

Pivot

point

Figure 6.4: Non-Parallel Forces

Figure 6.5: Using the Torque Wheel

O

d

1

d

1

F

1

Line of

force

4. Perform the calculations to determine the torque, 1, provided by the Spring Scale, and the percent difference

between

and 2. [The percent difference is the difference of the two torques divided by the average of the

1

two torques.]

• T o provide a consistent mathematical definition of torque,

and 2 must be determined according to the same

1

formula.

5. Apply the generalized definition of torque ( = F d sin ) to the calculation of

What is the angle between the force, F

, and the lever arm, d2?] Does the calculated value using the general-

2

ized definition change the results?

Analyzing Non-Parallel Forces

Imagine two non-parallel forces acting on an object at different distances

from its pivot point. The figure shows a diagram for a calculation of

torque provided by two non-parallel forces. The force F

torque

produces a torque

about the point O with a magnitude of F1 d1 sin 1. The force F2

1

about the point O with a magnitude of F2 d2 sin 2.

2

However, it would be misleading to simply add the two torques together

to determine the total torque because

and 2 cause rotation about point

1

O in opposite directions. When adding two or more torques, add together

the magnitudes of all the torques that tend to cause clockwise rotation,

then add together the magnitudes of all the torques that tend to cause

counterclockwise rotation. For the system to be balanced, the sum of the

clockwise torques must equal the sum of the counterclockwise torques.

Remember that the perpendicular distance, d

, from the pivot point to the

force is equal to d sin and that the angle is measured between the lever

arm, d, and the line of force.

produces a

1

in step 2 previously. [Hint:

2

Torque Wheel

A Torque Wheel provides an easy method for creating an equilibrium

among several non parallel forces. Figure 6.5 shows a force F applied at

an angle to the line from the center of the Torque Wheel to the point of

application of the force. The torque can be calculated as = F d sin .

However, as shown, d sin is just the perpendicular distance, d

between the center of the Torque Wheel and the line of force, when that

line is extended far enough.

Imagine a To rque Wheel with tw o non-parallel forces. The angle

between the force F

tance d

fore, the torque

The radial scale on the Torque Wheel label allows you to measure the

perpendicular distance from the pivot point to the line of force. Each

concentric circle on the label is 2 mm larger in radius. Each Torque

Indicator Arm is transparent and has a centerline that shows the line

of force.

and the lever arm d1 is . The perpendicular dis-

from the pivot point O to the line of force is d1 sin . There-

1

1

produced by F1 is F1 d1

,

012-12876B 35

Page 40

Statics System Exp. 6: Torque—Non-Parallel Forces

®

F

1

F

2

F

3

d

1

d

2

d

3

Pivot

point

Torque

Indicator

Arm

Figure 6.6: Set up the Torque Wheel

Torque

Wheel

Radial

scale

Set Up the Torque Wheel

Remove the Balance Arm and set up the

Torque Wheel on the Statics Board as shown

in the diagram. Use pulleys, thread, and hanging masses to apply three torques to the wheel.

Use the radial scale on the T orque Wheel label

to measure the perpendicular distance from

each line of force to the pivot point. Record

the distances in the data table. Calculate and

record the forces. Calculate and record the

torque for each force using = F d

. Be sure

to indicate whether the torque is clockwise or

counterclockwise.

Subtract the sum of the clockwise torques

from the sum of the counterclockwise torques

to determine the total net torque.

Data Table

Force, F (N) Perpendicular Distance, d

1

2

3

(m) Torque,

= F d

(N•m)

Total Torque = ________________

Question

Within the limits of your experimental error, is the total net torque equal to zero when the Torque Wheel is in equilibrium.

Extension

Repeat the procedure with different forces and angles.

36

012-12876B

Page 41

®

Model No. ME-9502 Exp. 7: The Inclined Plane

Figure 7.1: The Inclined Plane

F

F

Object

Inclined

plane

F

Figure 7.2: Equipment Setup

Inclined

Plane

Pulley

Spring

Scale

Cart

100-g

mass

Keep the thread

parallel to the plane.

Exp. 7: The Inclined Plane

Equipment Needed

Item Item

Statics Board Inclined Plane and Cart

Pulley (2) Mounted Spring Scale

Mass and Hanger Set Thread

Introduction

Suppose you must design a ramp with a cable to hold a

heavy object on an inclined ramp. For a given angle of

inclination of the ramp, how much force must the

cable deliver to hold the object on the ramp? How

much force must the ramp be able to support?

You could solve this problem by building ramps and

cable and testing them, or by testing scale models.

Alternatively, you could use your knowledge of forces

and vectors to solve the problem mathematically. In

the diagram, for example, the weight, F, of the object

on the inclined plane can be resolved into two components: one perpendicular to the plane, F

the plane, F

. The angle, , is the angle of inclination of the inclined plane. In this experiment, you will compare

the mathematical solution with data taken directly from a scale model.

, and one parallel to

Experiment

1. Add a 100-g mass to the cart and measure and record the total mass of the cart. Calculate and record the

weight of the cart-plus-mass.

• total mass of cart = _______________ weight of cart = _________________

2. Set up the Inclined Plane on the Statics Board. Start with the plane at 15°. Put the cart on the Inclined Plane

and use thread connected under a pulley to the Spring Scale to hold the cart in place on the ramp.

012-12876B 37

Page 42

Statics System Exp. 7: The Inclined Plane

®

measured - calculatedmeasured + calculated2 x 100%

Figure 7.3: Normal Force Equipment Setup

The force provided by the Spring Scale, F

the Inclined Plane, F

The calculated component of force that is parallel to the Inclined Plane, F

measured

, equals the component of the force of gravity that is parallel to

calculated

, is F sin

, where is the angle of the plane.

3. Adjust the angle of inclination of the Inclined Plane to each of the values shown in the table. For accurate values, adjust the pulley and Spring Scale so that the thread remains parallel to the plane. At each value, record

the measured value, F

measured

4. At each value, calculate the magnitude of the force parallel to the plane, F

, of the force parallel to the plane.

calculated

= F sin and record the

calculated value.

5. Calculate the percent difference between the measured and calculated values of the force parallel to the plane.

Angle F

15°

30°

45°

60°

75°

*The Percent Difference is the absolulte value of the ratio of the difference of the measured and calculated values, divided by the

average of the measured plus calculated values, converted to a percentage.

measured

F

calculated

= F sin Percent Difference*

Question

How well does the calculated force based on the vector model compare to your measured force?

Normal Force

The force that the Inclined Plane provides to support the cart is called the normal force (a force perpendicular –

“normal” – to the surface.) In the vector model of the force, the component of force that is perpendicular to the

plane, F

surface.

To measure the force of the cart on the Inclined Plane, reset the Inclined Plane to 15°. Replace the Spring Scale

with a mass hanger connected by a thread over the pulley to the cart. Add masses to the mass hanger until the cart

and the hanging mass are in equilibrium. (In other words, the force provided by the tension in the thread equals the

component of the cart’s weight that is parallel to the plane.)

, is F cos . The normal force is equal to the force of the cart on the Inclined Plane, perpendicular to its

38

012-12876B

Page 43

®

Model No. ME-9502 Exp. 7: The Inclined Plane

Figure 7.4: Measure the Normal Force

Tie the thread to the

hole in the post.

Record the total mass of the mass hanger and calculate and record the weight.

• total mass of mass hanger = _______________ weight of mass hanger = _________________

• How does the weight of the mass hanger compare to value of F

calculated

, the component of the cart’s weight

that is parallel to the plane? (See the data table for the value at 15°.)

Add a second pulley to the Statics Board and set up the Spring Balance above the pulley. Tie a thread to the hole at

the top of the post of the cart. Arrange the pulley so the thread from the post is in line with the post, and therefore

is perpendicular to the plane. Arrange the Spring Scale so that the angle of the thread from the pulley up to the

scale is vertical.

Pull the Spring Scale up until the force just barely lifts the mass cart off the Inclined Plane.

Record the value of the Spring Scale as the perpendicular force, F

F

Calculate the value of the perpendicular force as predicted by the vector model, F

value

F

Question

How well does the calculated force based on the vector model compare to your measured force?

measured

calculated

= __________________

= __________________

calculated

= F cos Record the

012-12876B 39

Page 44

Statics System Exp. 7: The Inclined Plane

®

40

012-12876B

Page 45

®

Model No. ME-9502 Exp. 8: Slidin g Fr iction

Plumb bob

Figure 8.1: Equipment Setup

Friction

Block

The thread must

be parallel to the

Inclined Plane.

Level the

Inclined Plane

Mass

Pulley

Mass

Hanger

Exp. 8: Sliding Friction

Equipment Needed

Item Item

Statics Board Inclined Plane and Friction Block

Pulley Mounted Spring Scale

Mass and Hanger Set Thread

Theory