Page 1

®

Parallel Spring Bracket

ME-6844

Instruction Sheet

012-09843A

Included Equipment Part Number

Suspension Bracket

ME-6844

Parallel Hook Bar

Thumbscrews (2 pieces) 617-016

Additional Equipment Recommended

Series/Parallel Spring Set ME-6842

Equal Length Spring Set ME-8970

Hooked Mass Set SE-8759

Large Table Clamp ME-9472

45 cm Rod ME-8736

Meter Stick SE-8695

800-772-8700 www.pasco.com

Introduction

The Parallel Spring Bracket allows springs to be combined in

series and parallel. Masses can be hung in offset positions to

compensate for springs of different strengths.

The Parallel Spring Bracket is ideal for:

• exploring how spring constants add when springs are

arranged in series or in parallel,

• demonstrating the analogy between combinations of springs

and combinations of capacitors, and

• exploring torque acting on the hook bar by placement of the

mass and springs at different positions.

Page 2

Parallel Spring Bracket ME-6844

Set-up

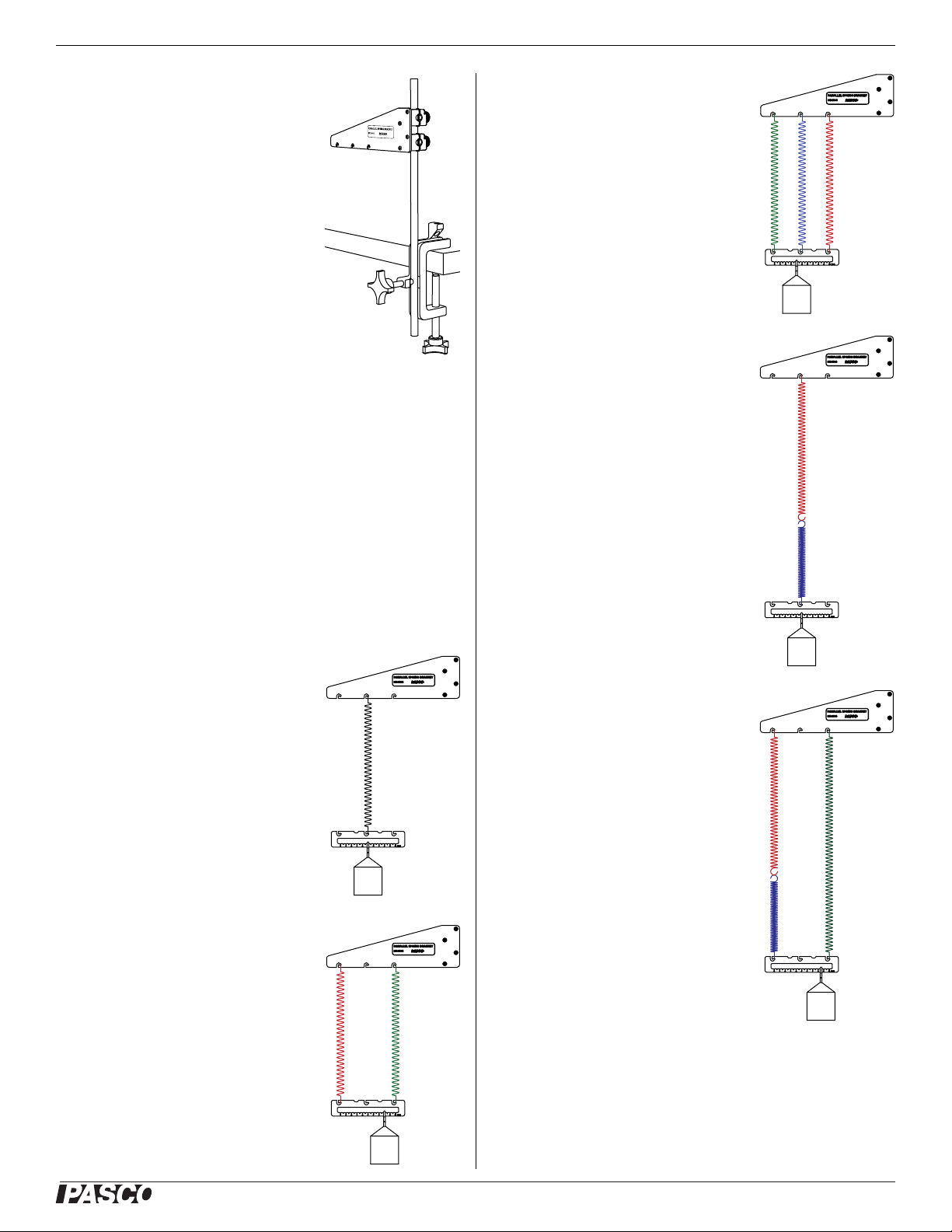

1. Assemble the suspension bracket, a

large table clamp and a rod as illustrated. The table clamp (rather than a

base) and a relatively short rod are

recommended for maximum stability.

2. Hang any combination of springs

from the suspension bracket.

3. Attach the parallel hook bar to the

bottom of the spring combination.

4. Hook a mass onto the notched slot of

the parallel hook bar. The mass should be large enough to

stretch all springs at least slightly.

5. Move the mass left or right along the notched slot to find the

position that makes the hook bar as close to horizontal as

possible.

6. Check that all springs are stretched. You should be able to

see between the coils of every spring. If one of the springs is

not stretched, increase the hanging mass.

Three Parallel

Three different springs (40 N/m, 20 N/m,

and 10 N/m) from the Series/Parallel

Spring Set are combined in parallel.

Series

Two springs are linked end-to-end to

form a series combination.

Sample Configurations

Single Spring

Though the hook bar is not necessary to

attach a mass to a single spring, it does

provide a convenient point from which to

measure changing displacement.

Two Parallel

Two springs (10 N/m and 40 N/m) from

the Series/Parallel Spring Set (ME-6842)

are combined in parallel. The hanging

mass is placed off center to make the

hook bar level.

Series and parallel

Two short springs from the Series/Parallel Spring Set are linked in series. That

combination is in parallel with a single

long spring from the Equal Length Spring

Set (ME-8970). When not stretched, the

long spring is twice the length of each of

the short springs.

®

2

Page 3

Parallel Spring Bracket ME-6844

Parallel Springs of Different Length

A long spring

from the Equal

Length Spring Set

and a short spring

from the

Series/Parallel

Spring Set are

combined in parallel. Both springs have

the same spring constant

(40 N/m). The initial mass

is placed off-center to make

the hook bar level; however

addition mass is added to the

center to stretch both springs

equally.

When the system oscillates, the hook

bar rocks. However, if the mass is hung

from the center (so that the hook bar is not

level) it oscillates without rocking.

A similar effect can be achieved using two identical springs with

one vertically offset using string.

3. Measure the distance from the floor to the bottom of the

hook bar again.

4. Calculate the change in force (the weight of the additional

mass), ∆F.

5. Calculate the change in position of the hook bar, ∆x.

6. Calculate the resultant spring constant using

(eq. 1)

∆F

k

-------=

∆x

The above equation lacks the negative sign usually found in

expressions of Hooke’s Law because F in this case is the applied

force rather than the force exerted by the springs.

For better precision, increase the hanging mass incrementally and

make a graph of ∆F versus ∆x. The slope of the best-fit line is k.

Addition of Spring Constants

The combination of springs is analogous to the combination of

capacitors. The equivalent spring constant of two or more springs

in parallel is

Modified Series

With this combination of springs, string, and pulleys, the balance point of the hanging mass is

always at the center of the hook bar regardless of

the spring constants or lengths.

Measurements and Calculations

Spring Constant

Use the following method to measure the spring constant of a

spring or combination of springs.

1. With the initial mass hanging from the hook bar (so that all

springs are slightly stretched), measure the distance from the

floor to the bottom of the hook bar.

2. Add some mass (typically about 500 g) to the hanging mass.

(eq. 2)

k

k1k2k3…+++=

eq

combination

For springs in series, the equivalent spring constant is

1

1

(eq. 3)

1

-------

k

-----

k

eq

1

-----

k

1

----- …+++=

k

2

3

combination

Force and Torque

The objects

attached to the

hook bar (springs

and hanging

mass) each exerts

a torque and a

force on it. When

the system is

static, the net

torque and net

force are both

zero.

When the hook

bar has two

springs and one

mass attached to

it, it is possible to

determine the

three separate

forces:

F

mg

s1

r

s2

r

m

parallel

series

F

s2

®

3

Page 4

Parallel Spring Bracket ME-6844

(eq. 4)

F

Fs1Fs2mg–+0==

net

The axis about which the torques are measured is chosen to be at

the “0 cm” mark. Spring #1 is attached at the axis, therefore its

torque is zero. The net torque is

(eq. 5)

Solving for F

(eq. 6)

τ

netrs2Fs2rm

yields:

s2

mg–0==

r

m

------

F

s2

mg=

r

s2

Combining equations 4 and 6 gives us:

r

m

1

------–

(eq. 7)

F

s1

mg=

r

s2

Period of Oscillation

The period of oscillation of a mass on a spring (or combination of

springs) is

T 2π

The mass, m , should include the hanging mass, the mass of the

hook bar, and 1/3 of the mass of the springs.

m

----=

k

Storage

To keep the bracket and hook bar together when not in use, clamp

the hook bar under the thumbscrews as illustrated.

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

To demonstrate this relationship for any combination of springs,

use a stop watch to measure the period of oscillation. Increase the

hanging mass in steps. Make a graph of T

of the best-fit line is 4π

2

/k.

2

versus ∆m. The slope

Sensor-based Measurement

To measure the spring

constant using a rotary

motion sensor (RMS)

and a force sensor, set

up the equipment as

illustrated. Pull the

force sensor to stretch

the spring combination.

Make a graph of force

(measured by the force

sensor) versus linear

position (measured by

the RMS). The slope of

the best-fit line is the

spring constant.

Limited Warranty For a description of the product warranty, see the

PASCO catalog.

Copyright The PASCO scientific 012-09843A

Instruction Sheet

granted to non-profit educational institutions for reproduction of any part of

this manual, providing the reproductions are used only in their laboratories

and classrooms, and are not sold for profit. Reproduction under any other

circumstances, without the written consent of PASCO scientific, is prohibited.

Trademarks PASCO, PASCO scientific, DataStudio, PASPORT, and

Xplorer GLX are trademarks or registered trademarks of PASCO scientific,

in the United States and/or in other countries. All other brands, products,

or service names are or may be trademarks or service marks of, and are

used to identify, products or services of, their respective owners. For more

information visit www.pasco.com/legal.

is copyrighted with all rights reser ved. Permission is

Parallel Spring Bracket

®

4

Loading...

Loading...