Page 1

®

Instruction Manual

Spring Cart Launcher

ME-6843

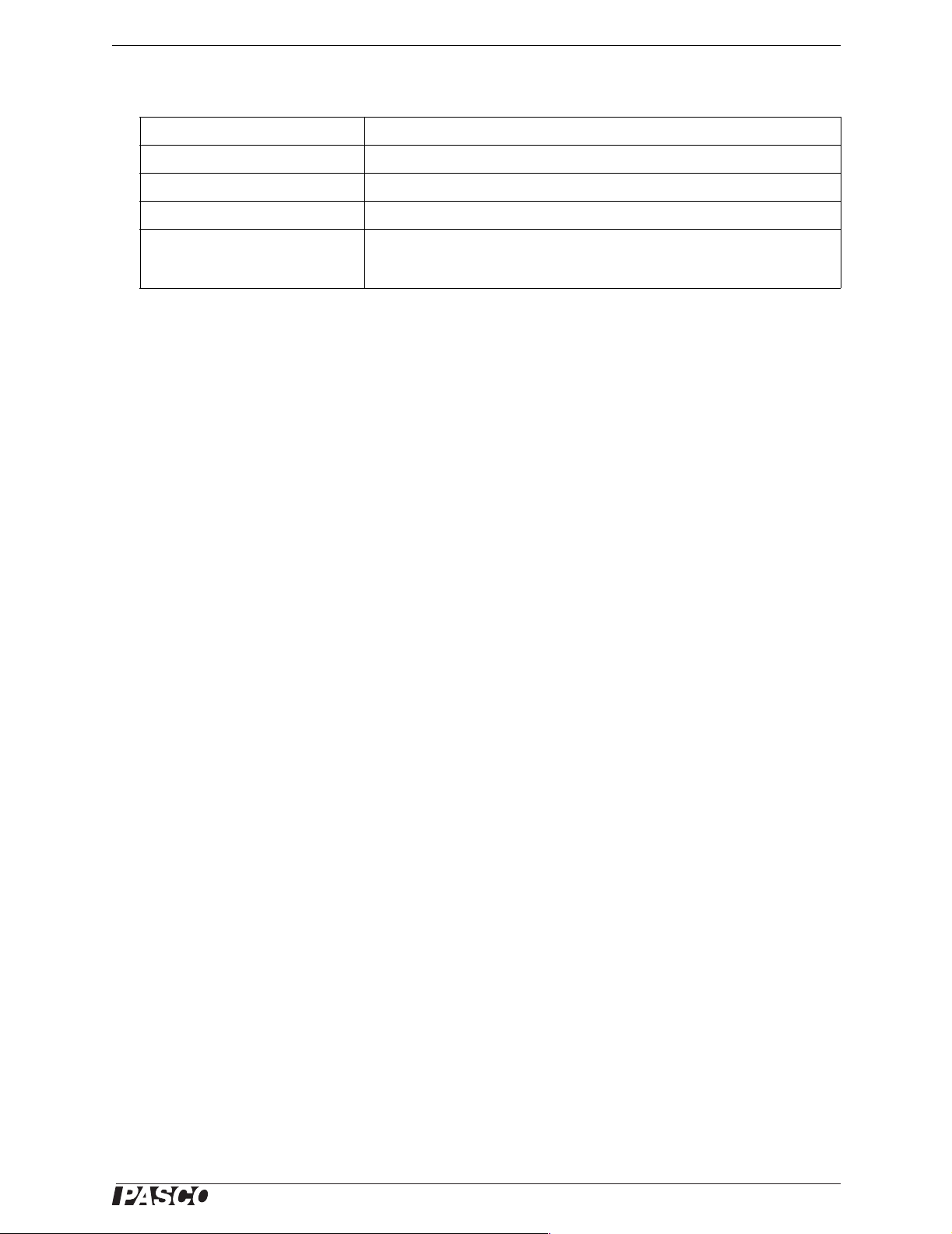

Included Equipment Quantity Replacement Part Number

012-09924A

Spring Cart Launcher 1 ME-6843

Firm Spring (black) 1

Medium Spring (blue) 1

Soft Spring (red) 1

ME-6847

1

Release Pin 2

String 1 m

Required Equipment Part Number

2

Cart

2

Tra ck

End Stops

3

1 ME-6951, ME-6950, ME-9430, or ME-9454

1 ME-6953 or similar

2 ME-9469 (2-pack)

Recommended Equipment

250 g Compact Cart Mass 2 ME-6755

For sensor-based method:

Motion Sensor

Force Sensor

4

4

1 PS-2103

1 PS-2104

For traditional method:

Super Pulley with Clamp 1 ME-9448A

Hooked Mass Set 1 SE-8759 or similar

1

ME-6847 replacement kit includes (2) of each spring and (4) release pins

2

This part is included in many of the PASCO dynamics systems. See PASCO catalog or www.pasco.com for details.

3

New-style plastic end stops required. These are included with PASCO dynamics systems starting in 2007.

4

PASPORT sensors require a PASPORT interface. See PASCO catalog or www.pasco.com for details.

800-772-8700 www.pasco.com

Page 2

Spring Cart Launcher Introduction

Introduction

The Spring Cart Launcher is designed for the study of force and motion, potential

energy, conservation of energy, the work-energy theorem, Hooke’s Law, and spring

constants. Use it to launch any PASCO dynamics cart by compressing and releasing

one of three interchangeable springs. The included release pin, in combination with

two end stops, allows you to use precisely the same spring compression for multiple

launches.

This manual includes instructions for a sensor-based experiment (page 4) using

motion and force sensors, and a traditional experiment (page 6) using hanging masses

and an inclined track.

Set-up and Launch

For this general set-up, you will need the Spring Cart

Launcher with its included springs, launch pin, and string; a

cart; a track, and two adjustable end stops.

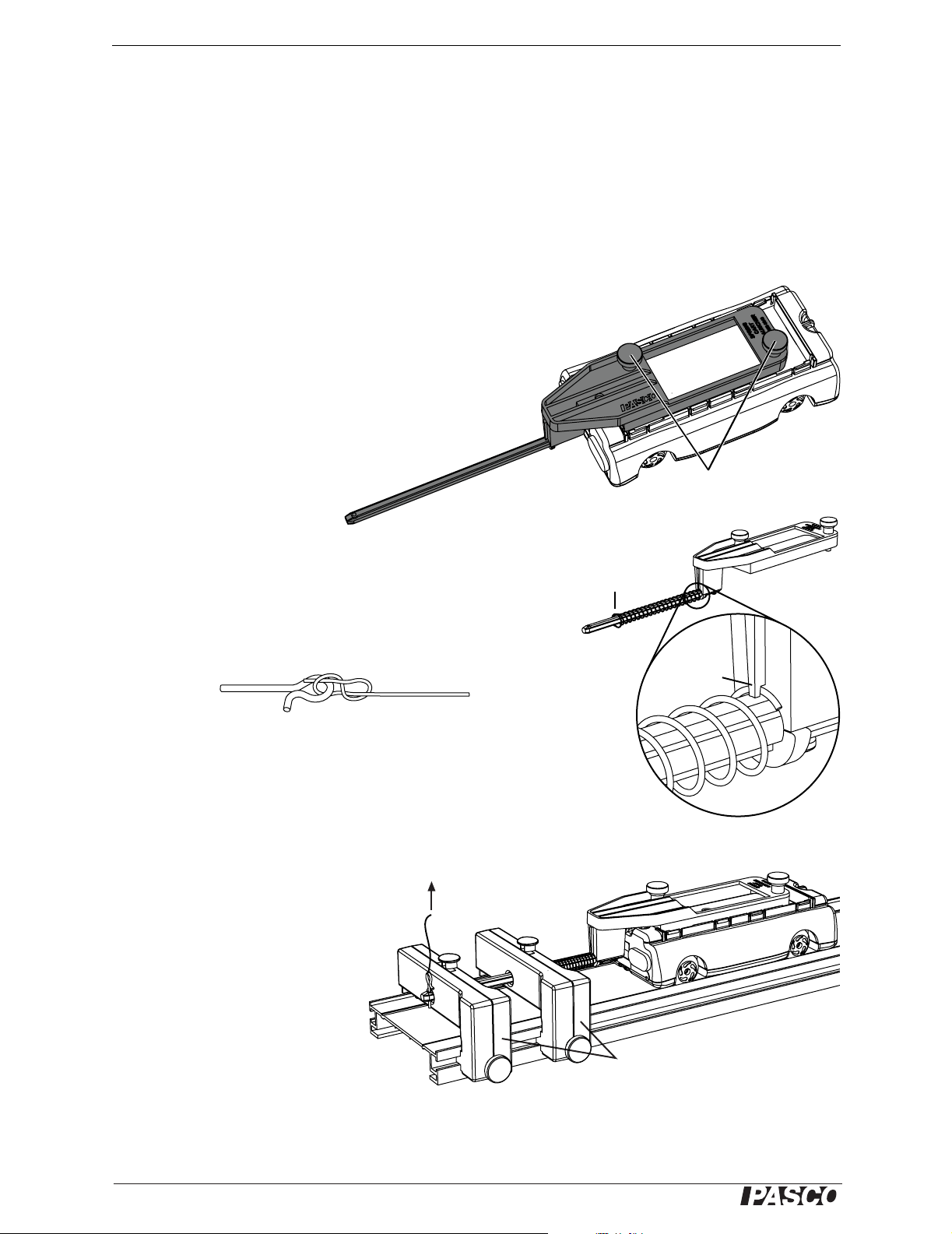

1. Fit the Spring Cart Launcher onto

the top of the cart (as illustrated). Tighten the

thumbscrews to secure it.

2. Select one of the included springs. Slide it onto the launcher

shaft with the flared end out. Turn the spring to secure the end in

the spring retention hole as illustrated.

3. Tie the string to the release pin.

Release pin String

4. Install two end stops near one end of a dynamics track between 3

cm and 10 cm apart, measured center-to-center.

5. Place the cart on the track. Push the launcher shaft through the

holes in both end stops.

6. Insert the release pin through

the hole in the end of the

launcher shaft. Allow the

Pull

up

launch pin to rest against the

end stop.

Thumbscrews

Flared

end

Spring

retention

hole

7. To launch the cart, jerk the

launch pin out by pulling

sharply up on the string.

As a simpler, but less repeatable, alternative to the above set-up, use only one end

stop and do not use the launch pin. Pull the shaft through the end stop and release it

from your hand.

2

End stops

®

Page 3

Model No. ME-6843 Cart Mass

Cart Mass

For varying the mass of the cart, the Spring Cart Launcher is designed to hold one or

two Compact Cart Masses (PASCO part ME-6755). The launcher prevents these

masses from shifting or sliding. Place the masses as illustrated.

Theory

The spring constant of a spring is

F

(eq. 1)

where F

is the force applied to the spring and x is the displacement of the end of the

x

spring from its equilibrium position.

As you push the end of a spring (or anything else) from position x

you do is equal to the area under the F

(eq. 2)

WFxxd

x

k

------=

x

versus x graph, or

x

x

2

=

∫

x

1

to x2, the work that

1

Masses

Spring constant

Work done on a spring

The potential energy stored in a spring is

1

2

(eq. 3)

U

spring

---

=

kx

2

The kinetic energy of a cart moving on a track is

1

2

(eq. 4)

where m is the mass of the cart, and

---

K

mV

=

2

V is the magnitude of velocity.

The change in gravitational potential energy of a cart moving up an inclined track is

(eq. 5)

where g = 9.8 m/s

∆U

gravity

2

, ∆s is the distance traveled along the track (in the uphill direction),

mg∆s θsin=

and θ is the track’s angle of incline.

Potential energy stored in

a spring

Kinetic energy

Potential energy of a cart

on an inclined track

®

3

Page 4

Spring Cart Launcher Sensor-based Experiment

Sensor-based Experiment

Note About Sensors and Interfaces

In this experiment, a force sensor measures the force that you apply to the spring; a

motion sensor measures the displacement of the end of the spring as it is compressed,

the position of the cart, and the velocity of the cart.

You can use the PASPORT sensors recommended on page 1 with a multiple-port

interface (such as an Xplorer GLX or Power Link) or two single-port interfaces (such

as USB Links). Most of the measurements described below can also be done with just

one single-port interface using one sensor at a time. ScienceWorkshop sensors and

interfaces would also work.

The instructions below refer to operations in DataStudio software such as connecting

sensors, setting sampling rates, and setting up graphs. For information about these

tasks, press F1 to open DataStudio Help. This experiment can also be done on the

Xplorer GLX in standalone mode (without a computer).

Additional Set-up

1. Follow set-up steps 1 through 3 on page 2.

2. Install one end stop on the track. If you are using a 1.2 m track, place the end stop

near one end. If you are using a 2.2 m track, place the end stop in the middle.

3. Level the track so that the cart does not roll when release from a standstill.

4. Clip the motion sensor to the end of the track opposite from the end stop. Aim the

sensor along the track. Set the range switch to the

NEAR or cart setting.

5. Connect the motion sensor and a force sensor to your PAPORT interface (or

interfaces). If you are using a computer, connect the interfaces to it and start

DataStudio.

6. Set the sampling rate of both sensors to 20 Hz.

7. Prepare the following graphs: Position versus Time, Velocity versus Time, Posi-

tion versus Force (Pull Positive).

Spring Constant, Work, and Spring Potential Energy

In this part you will use Equation 1 to determine k for your spring. The force sensor

measures F

, and the motion measures x. The slope of the Fx versus x graph equals k.

x

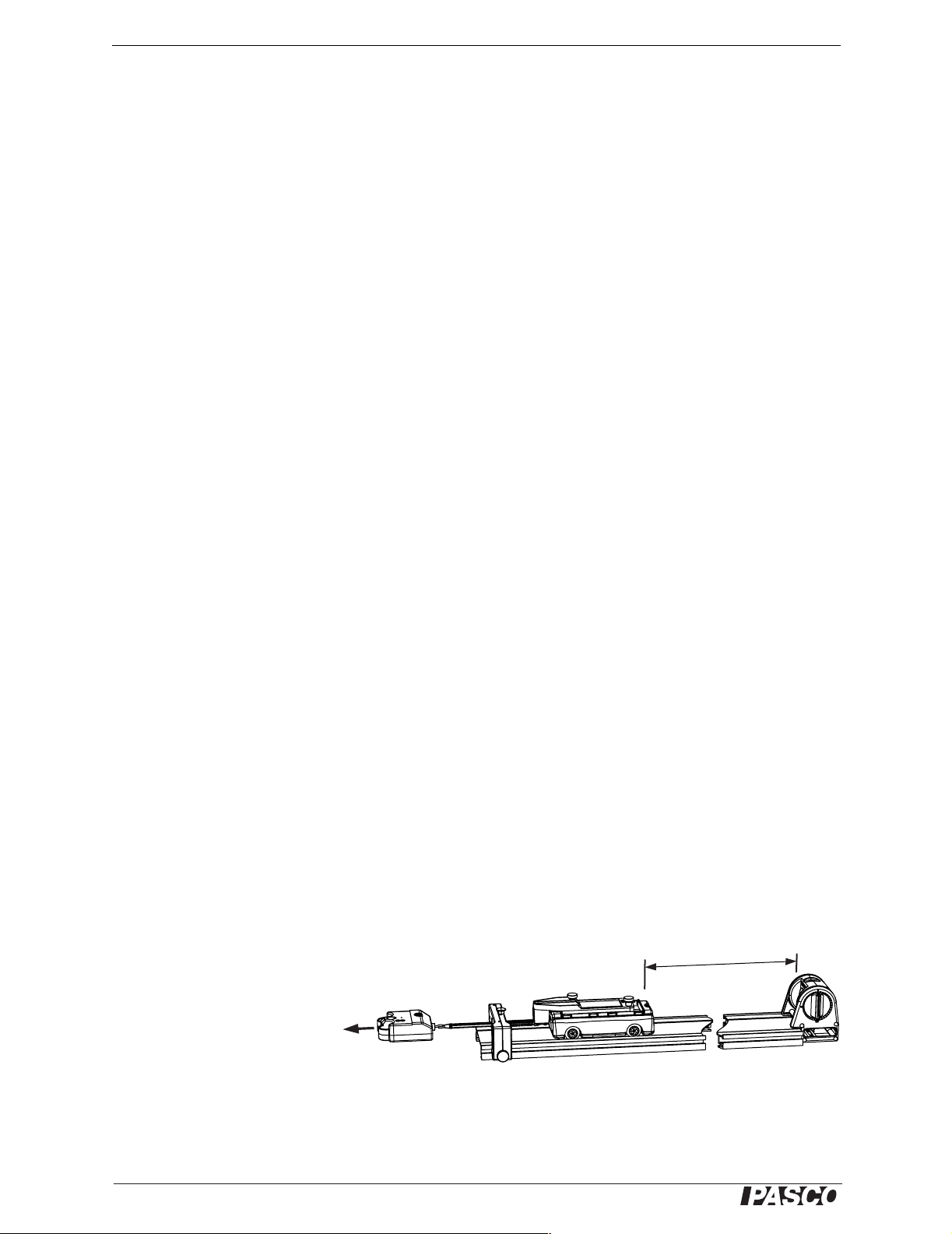

1. Place the cart on the track

with the launcher shaft

through the hole in the

end stop.

2. Use a piece of string to tie

the hook of the force sen-

Pull

Force sensor

sor to the launcher shaft.

3. Pull back with the force sensor so that the end of the spring just touches the end

stop, but do not compress the spring yet.

4

~1 m

Motion sensor

®

Page 5

Model No. ME-6843 Sensor-based Experiment

4. Press the ZERO or TARE button on the force sensor.

5. Start data recording.

6. Slowly pull back with the force sensor until the spring is almost completely com-

pressed.

Note: Have your partner hold the track to prevent it from slipping, but be careful not to block

the motion sensor.

7. Stop data recording.

8. Determine k from the slope of the F

versus x graph.

x

9. Measure the area under graph. This area equals the work, W, that you did on the

spring.

10. From the graph, determine the displacement (or change in position) of the end of

the spring.

11. Use Equation 3 to calculate U

, the potential energy stored in the spring after

spring

you compressed it.

12. Compare W to U

. Do both values have the same (or equivalent) units? What

spring

is the percent difference?

13. Repeat steps 1 through 8 to determine the spring constants of all three springs.

Untie the string from the launcher shaft for the next part.

Spring Potential Energy and Kinetic Energy

In this part, you will study the relationship between the potential energy initially

stored in the spring and the kinetic energy of the cart just after launch.

1. Place a second end stop on the track about 8 cm behind the first end stop.

2. Place the cart on the track with the launcher shaft through the hole in the first end

stop. Position the cart so that the spring is touching the end stop but not compressed.

3. Start data recording.

4. Wait a few seconds (to let the sensor measure the uncom-

pressed position). Push the shaft through both and stops and

put the release pin into the shaft. Let the pin rest against the

second end stop and wait a few more seconds (to let the sensor measure the compressed position).

Important: In the next step, have your partner catch the cart before it

hits the motion sensor.

5. Pull out the release pin with a quick jerk to launch the cart

6. Stop data recording.

7. Determine the spring compression from the graph of position

versus time.

®

Release

Spring Compression

5

Page 6

Spring Cart Launcher Traditional Experiment

8. Use the value of k that you found in the previous part and Equation 3 to calculate

U

.

spring

9. Look at the graph of velocity versus time to find the velocity of the cart just after

the launch.

10. Measure the mass of the cart with the launcher and spring attached.

11. Use Equation 4 to calculate the kinetic energy of the cart.

12. Compare the initial potential energy of the spring to the kinetic energy of the cart.

Are they equal? If not, what might account for the difference?

Traditional Experiment

In this experiment (which does not require sensors), you will determine the spring

constant by using a hanging mass to apply a known force. To determine the energy

transferred to the cart, you will observe the maximum height that the cart reaches as it

runs up an inclined track.

Spring Constant

1. Follow set-up steps 1

through 3 on page 2.

2. Install an end stop about 20 cm from the end of the track.

3. Clamp a pulley to the same end of the track.

4. Position the track so that a mass hanging from the pulley is free to hang over the

edge of your lab bench.

5. Level the track so that the cart does not roll when release from a standstill.

6. Place the cart on the track with the launcher shaft through the hole in the end

stop.

7. Tie a piece of string (about 40 cm long) to the launcher shaft. Run the string over

the pulley and hang a 100 g mass from the string.

8. Adjust the pulley so that the string is horizontal between the pulley and the

launcher shaft.

9. In a table, record the position of the cart on the track and the total mass hanging

from the string.

10. Add 100 g to the hanging mass.

11. Repeat steps 9 and 10 up to about 500 g.

12. Calculate the force applied to the spring at each step: F

hanging mass and g = 9.8 m/s

13. Make a graph of F

versus cart position.

x

2

.

= mhg, where mh is the

x

14. Draw a best-fit line on your graph. The slope of that line equals the spring con-

stant, k.

6

®

Page 7

Model No. ME-6843 Traditional Experiment

Untie the string from the launcher shaft and remove the pulley for the next part.

Spring Potential Energy and Kinetic Energy

1. Place a second end stop on the track about 8 cm behind the first end stop.

2. Elevate one end of the track by about 20 cm.

3. Hold the cart on the track with the launcher shaft through the hole in

the first end stop, and with the spring just touching the end stop, but

not compressed. Record this position of the cart as x

.

1

4. Push the shaft through both and stops and put the release pin into the shaft. Let

the pin rest against the second end stop. Record this position of the cart as x

.

2

5. Pull out the release pin with a quick jerk.

6. Watch the cart carefully as it ascends the track. Observe the highest position

achieved. Try to read it to the nearest centimeter. Record this position as x

.

3

q

7. Calculate the spring compression: x = x

1

- x

2

8. Use x, the value of k that you found in the previous part, and Equation 3 to calcu-

late the initial potential energy of the spring.

9. Calculate the distance traveled by cart: ∆s = x

3

- x

2

10. Measure the mass, m, of the cart with the cart launcher and spring attached.

11. Measure the angle, θ, of the track.

12. Use Equation 5 to calculate the change in gravitational potential energy of the

cart.

13. Compare the initial potential energy of the spring to the maximum gravitational

potential energy of the cart. Are they equal? If not, what might account for the

difference?

®

7

Page 8

Spring Cart Launcher Other Suggested Experiments

Other Suggested Experiments

Launch from a Force Sensor

Set up an end stop, a force sensor, and the release pin as illustrated. While recording

motion- and force-sensor data, pull the force sensor to compress the spring; then jerk

out the release pin to launch the cart. In this way, you can record compression distance, spring force, and launch velocity in a single data run.

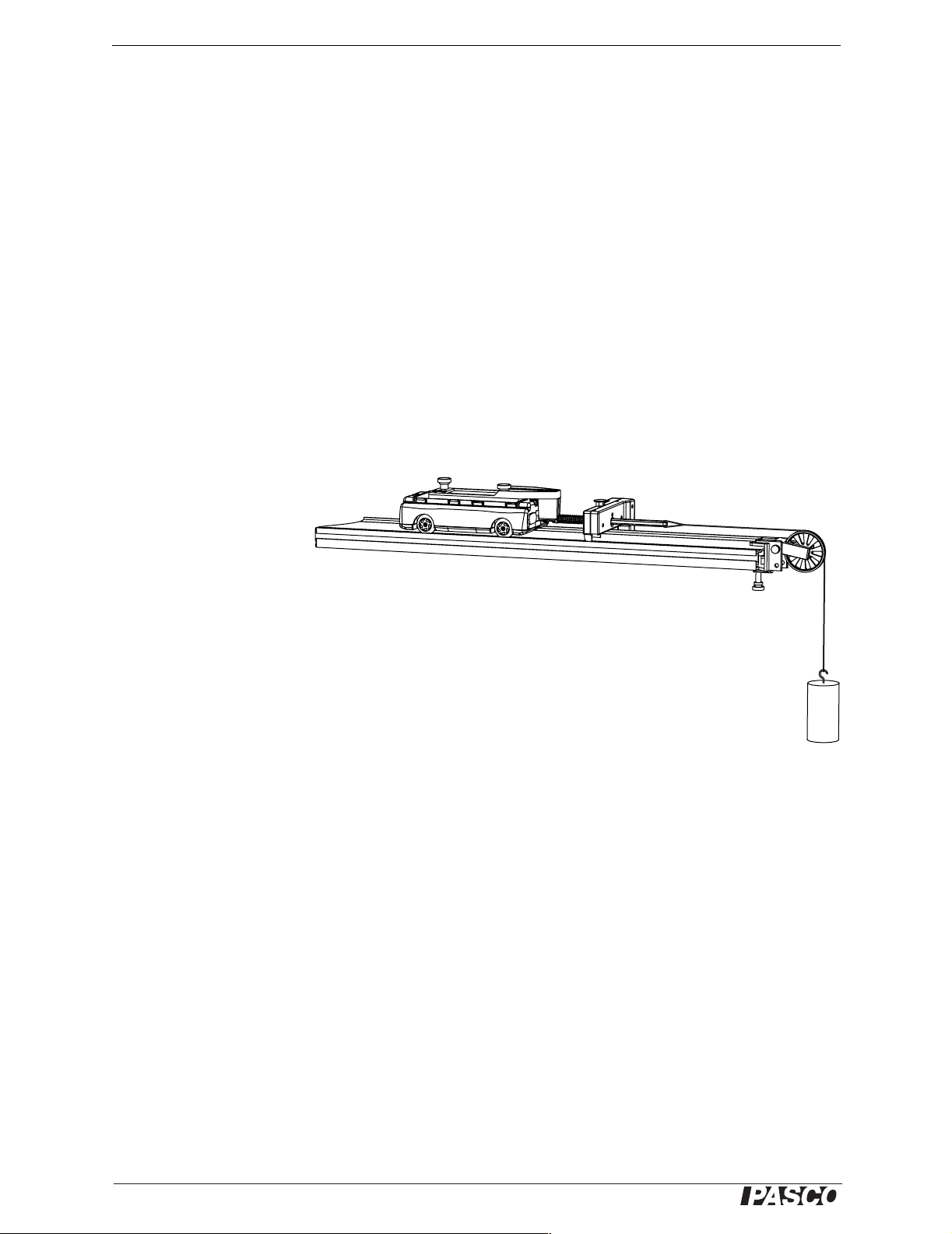

Launch from a Hanging Mass

Important: Do not use precision masses in this activity. Instead, use a small sandbag or other

object that will not be damaged when dropped.

Set up an end stop, a Super Pulley, a string, and the release pin as illustrated. Hang an

object of known mass (up to about 500 g) from the string. Jerk the pin out to launch

the cart. The spring force is equal to the weight of the hanging object.

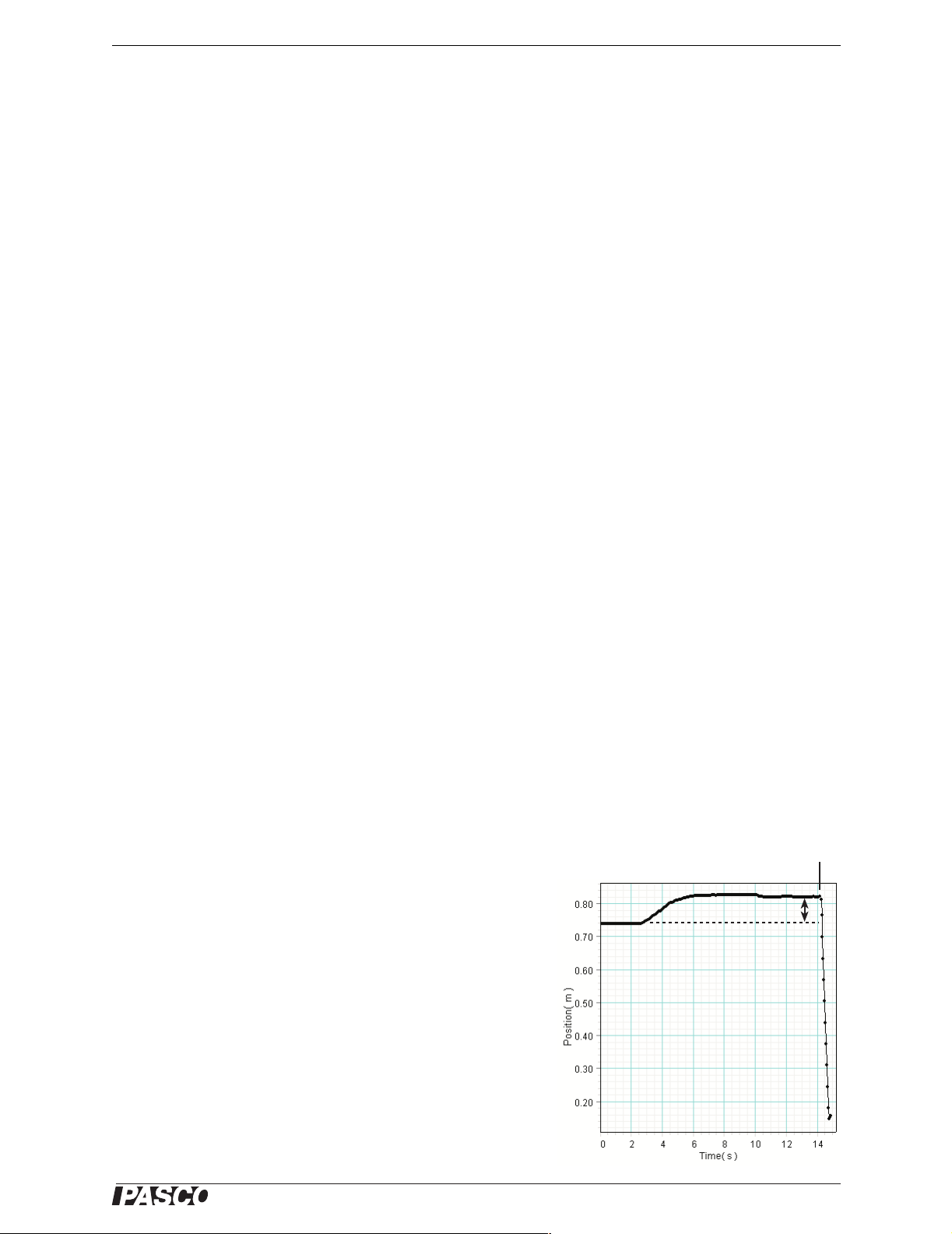

Collision with a Fixed Object

Set up a track with an end stop at one end and a motion sensor at the other end. Set the

sampling rate to 50 Hz. Start data recording. Give the cart a push to make it roll along

the track and bounce off the end stop. Stop data recording.

Hold the cart stationary with the spring just touching the end stop and record a second

data run to measure the “zero-compression” position.

Use the velocity data to determine the kinetic energy of the cart before and after the

collision. Use the position data to determine the maximum spring compression (that

is, the maximum position measured during the collision minus the position measured

when the spring was just touching the end stop). From the compression distance, calculate the maximum potential energy stored in the spring.

In this collision, energy is transferred from kinetic energy to potential energy and

back to kinetic energy. At each step, how much energy is “lost?” Where does it go?

Zero-compression

Maximum

compression

position

Velocity before

Velocity after

8

®

Page 9

Model No. ME-6843 Specifications

Specifications

Launcher dimensions 31 cm × 5 cm × 4 cm

Shaft length 14 cm

Spring length 10 cm

Spring diameter 1 cm

Spring constants 142 ± 14 N/m (black)

112 ± 11 N/m (blue)

84 ± 8 N/m (red)

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

Limited Warranty

For a description of the product warranty, see the PASCO catalog.

Copyright

The PASCO scientific 012-09924A

granted to non-profit educational institutions for reproduction of any part of this manual, providing the reproductions are used only in

their laboratories and classrooms, and are not sold for profit. Reproduction under any other circumstances, without the written consent of PASCO scientific, is prohibited.

Spring Cart Launcher Instruction Manual

is copyrighted with all rights reserved. Permission is

Trademarks

PASCO, PASCO scientific, DataStudio, PASPORT, and ScienceWorkshop are trademarks or registered trademarks of PASCO scientific, in the United States and/or in other countries. All other brands, products, or service names are or may be trademarks or service

marks of, and are used to identify, products or services of, their respective owners. For more information visit www.pasco.com/legal.

®

9

Loading...

Loading...