Page 1

®

Instruction Sheet

012-10515A

Curved PAStrack

ME-6841

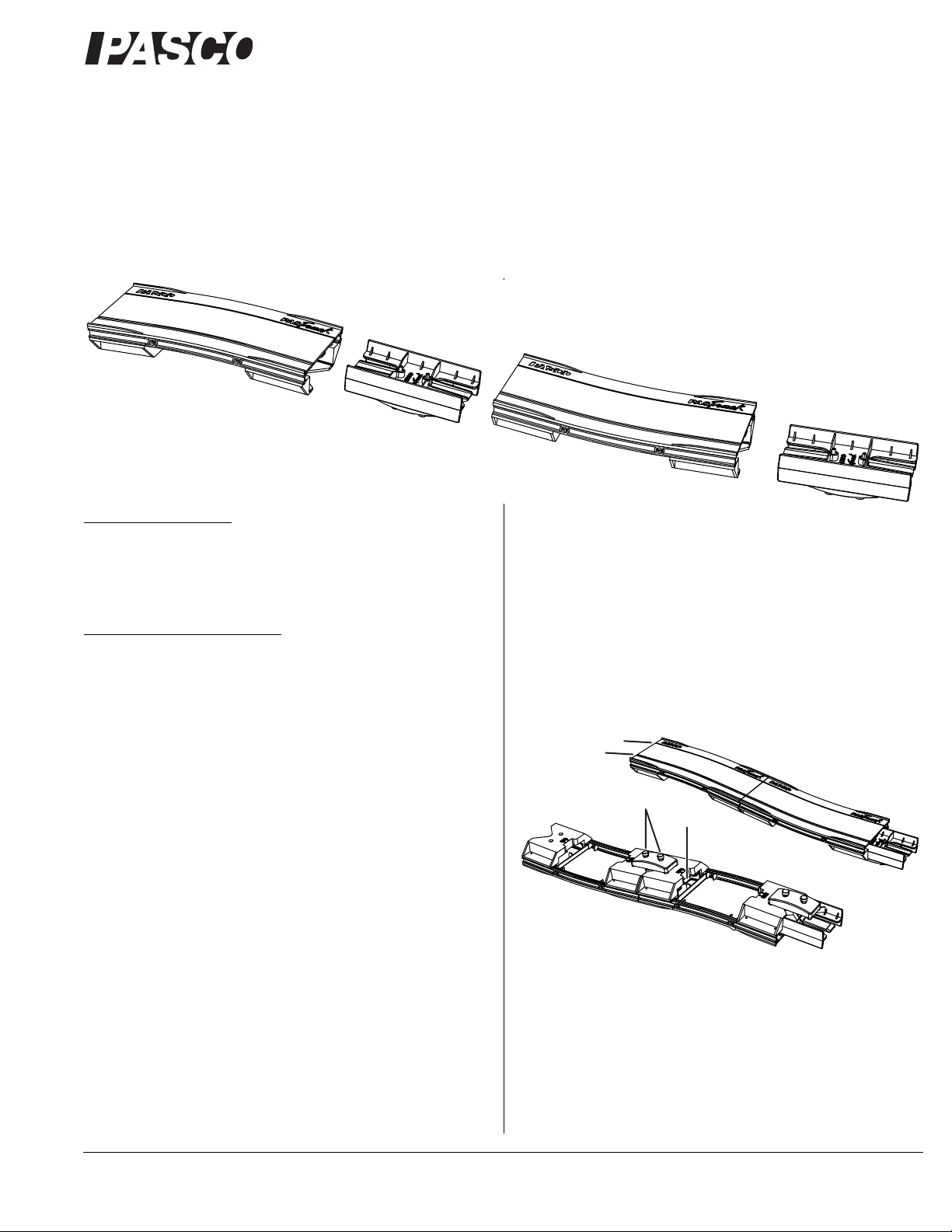

1

2

3

Included Equipment

1. Concave-down section

2. Concave-up section

3. Connectors (2 pieces)

Other Equipment Required

• Straight PAStrack (PASCO part ME-6960, which

consists of two straight sections)

• Rods, stands, and clamps for supporting elevated track

sections (see options on page 2)

• PASCO Dynamics Cart (ME-6950, ME-6951, ME-9430,

or ME-9454)

Quick Start

1. Use connector pieces to join the curved sections (part of

ME-6841) and straight sections (part of ME-6960) in any

order (see examples in figures 6 through 9).

Ensure that the wide and narrow grooves match from one

section to the next (see Figure 2).

2. Tighten the screws on the connectors.

3. Use rods, stands, and clamps to support the elevated straight

sections (see figures 3 through 5).

Introduction

PASCO model ME-6841 consists of two curved sections that can

be joined with straight PAStrack sections to form a single track

with different levels. The combined track can be used to study

how a change in height affects the motion of a cart. The track is

compatible with all PASCO dynamics carts (including plastic

PAScars and classic aluminum carts) and other dynamics system

accessories.

Parts of the Curved PAStrack

a

b

c

d

Figure 1

a. Narrow groove

b. Wide groove

c. Connector screws

d. Release tab

800-772-8700 www.pasco.com

Page 2

Curved PAStrack ME-6841

Assembly

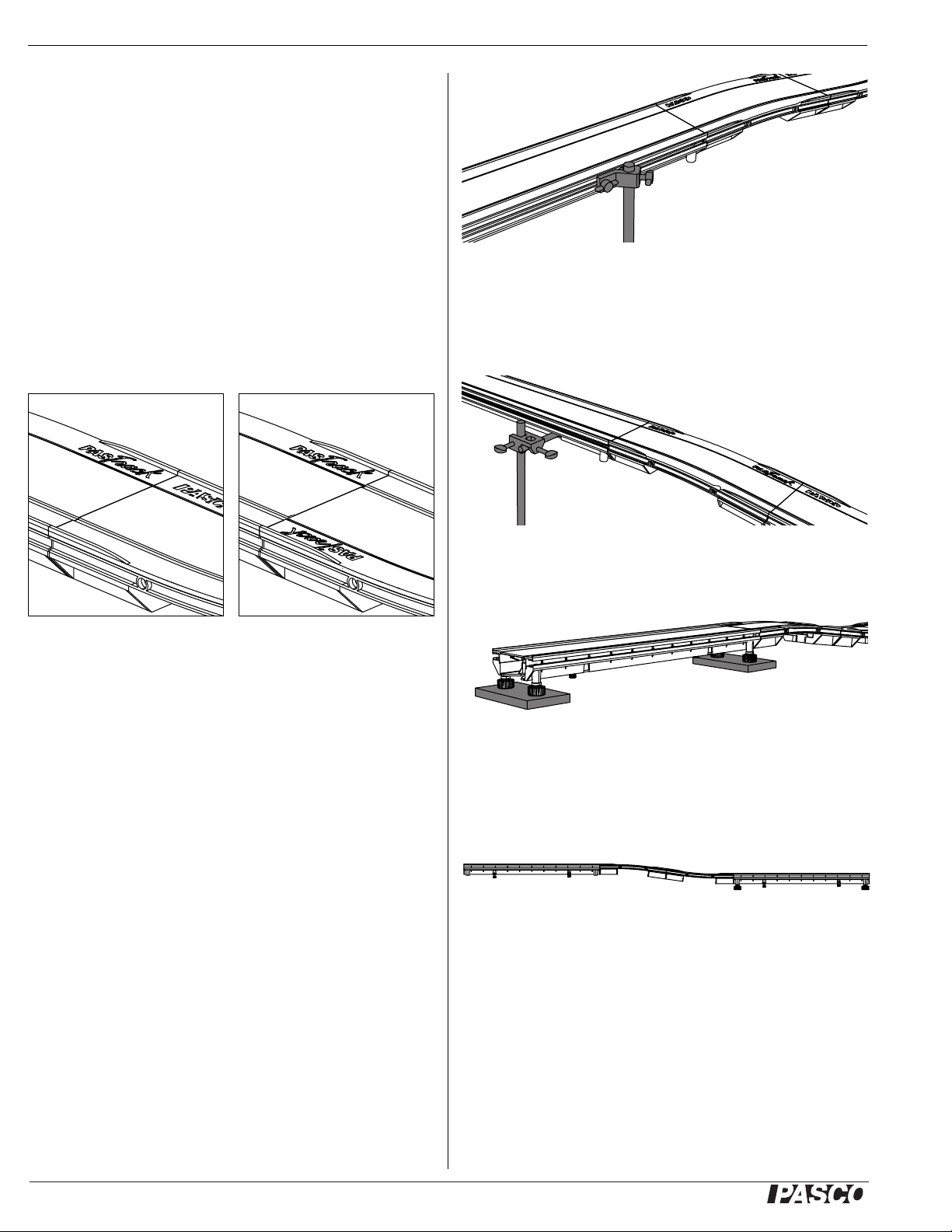

1. Slide a connector piece into a track section. Push it hard until

you hear it snap.

2. Slide the next track section onto the connector piece. Push it

until it snaps.

NOTE: Every track section has one narrow groove and one wide groove.

Orient the pieces so that the grooves match from one section to the next

(see Figure 2).

Figure 3: Pivot Clamp

3. Turn the track upside down and tighten the screws on the

connector (part c in Figure 1).

4. Repeat steps 2 through 3 until all sections are assembled as

desired.

Correct Incorrect

Figure 2: Ensure that the wide and narrow grooves match from one

section to the next.

Disassembly

1. Loosen the connector screws.

Horizontal Rod Method Secure a rod (such as SA-9242) in

the built-in rod clamp of the straight section (Figure 4). Use a

right-angle clamp (such as SE-9442) to secure this rod on a vertical rod at the desired height.

Figure 4: Horizontal Rod

Block Method Place blocks, or other objects such as books or

lab jacks, under the feet of the straight section (Figure 5).

Figure 5: Block

2. Press and hold the release tabs on the bottom of the track

(part d in Figure 1).

3. Pull the track sections apart.

Options for Supporting

Elevated Track Sections

The elevated straight sections of the assembled track can be supported using one of the methods illustrated in figures 3, 4, and 5.

The number of support points needed depends on the length of

the track. In most cases, two are sufficient.

Pivot Clamp Method Attach a Pivot Clamp (ME-9810) to

the T-slot on the side of a straight section (Figure 3). Secure the

Pivot Clamp at the desired height on a vertical rod. The vertical

rod can be supported by a table clamp (such as ME-9376B) or by

a rod base (such as ME-8976).

2

Configuration Examples

Small Height Change

Figure 6: Small height change using both curved sections and two

straight sections

In this configuration, the higher level is about 34 mm above the

lower level. Use photogates or motions sensors to measure the

velocity of a cart at both levels. Calculate and compare the

changes in potential energy and kinetic energy.

The track is slightly flexible so that the higher level can be made

slightly inclined. This makes it possible to release the cart from

the top level without pushing it.

With this small height change, it is possible to launch a plastic

PAScar from the lower level to the higher level using the cart’s

built-in plunger.

®

Page 3

Curved PAStrack ME-6841

Larger Height Change

Figure 7: Larger height change using both curved sections and

three straight sections

For a larger height change, add one or more straight sections

between the curved sections. In the configuration shown in Figure 7, the height change is about 10 cm. The flexibility of the

track allows the height to be varied slightly.

Ramp

Figure 8: Ramp using the concave-up curved section and two

straight sections

In this configuration, the angle of the inclined section is about 8°.

The flexibility of the track allows the angle to be varied slightly.

Release a cart from various points on the inclined section and use

photogates or a motion sensor to measure the velocity on the

level section.

Oscillator

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

For more information about the Curved PAStrack and the latest

revision of this Instruction Sheet, visit:

www.pasco.com/go?ME-6841

Limited Warranty For a description of the product warranty, see the

PASCO catalog. Copyright The PASCO scientific 012-10515A

PAStrack Instruction Sheet

sion is granted to non-profit educational institutions for reproduction of any

part of this manual, providing the reproductions are used only in their laboratories and classrooms, and are not sold for profit. Reproduction under

any other circumstances, without the written consent of PASCO scientific,

is prohibited. Trademarks PASCO and PASCO scientific are trade-

marks or registered trademarks of PASCO scientific, in the United States

and/or in other countries. All other brands, products, or service names are

or may be trademarks or service marks of, and are used to identify, products or services of, their respective owners. For more information visit

www.pasco.com/legal.

is copyrighted with all rights reserved. Permis-

Curved

Figure 9: Oscillator using the concave-up curved section and two

straight sections

The oscillator uses the same combination of sections as the ramp,

but both straight sections are inclined. A cart released from one

end will oscillate several times before coming to rest at the center.

®

3

Loading...

Loading...