Page 1

®

Instruction Manual

012-10242A

Dynamics Cart Magnetic Damping

ME-6828

1

2

Included Equipment Part Number

1. Magnetic Damping Accessory ME-6828

2. Keeper plate 648-10173

Required Equipment Part Number

or

PAScar, Plunger Cart, or Collision Cart ME-6950, ME-9430,

Aluminum Dynamics Track ME-6953

For other recommended equipment, see experiments starting on page 3.

or similar

ME-9454

Introduction

Use the Magnetic Damping Accessory to add drag to a PASCO dynamics cart. When the cart moves on an aluminum track, the accessory’s magnets generate eddy currents in the track, which cause an opposing magnetic field.

The resulting drag force is proportional to the cart’s velocity. The amount of damping can be varied by changing

the size of the gap between the magnets and the track.

This manual includes set-up instructions, three experiments (starting on page 3), and sample data (page 13).

Set-up

The Magnetic Damping Accessory attaches to a cart magnetically using the magnets built into the cart’s bumper.

If your cart does not have bumper magnets, install them before using the Magnetic Damping Accessory. (See

instructions included with your cart for bumper magnet installation.)

1. Remove the keeper plate from the Magnetic Damping Accessory and put it aside.

800-772-8700 www.pasco.com

Page 2

Dynamics Cart Magnetic Damping Storage and Safety

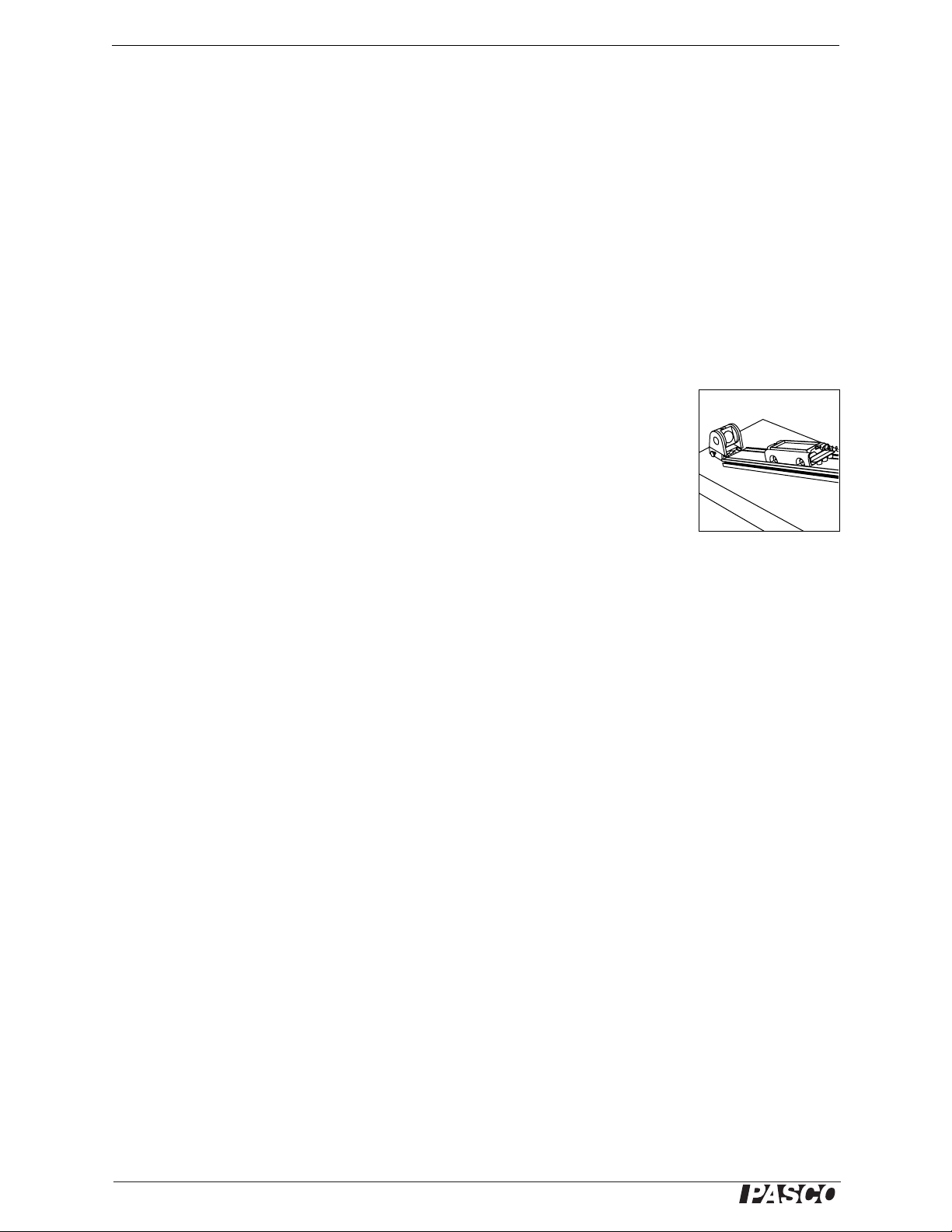

2. Place the Magnetic Damping Accessory on the magnet-equipped end of the cart

as illustrated.

3. Place the cart on an aluminum track.

4. Slide the Magnetic Damping Accessory up or down to adjust the amount of

damping. The magnets should not touch the track.

To set a gap size that can be measured or reproduced, use a stack of cards as a gauge.

Place the cards between the magnets and track as illustrated. Slide the Magnetic

Damping Accessory down until the magnets contact the top card; then remove the

cards. Use calipers to measure the thickness of the stack. For maximum damping, use

a single card.

Storage and Safety

• The Magnetic Damping Accessory is shipped with a keeper plate attached to the

magnets. The keeper protects the magnets and reduces the external magnetic

field. Always store the Magnetic Damping Accessory with the keeper in

place.

• Use caution when replacing the keeper to avoid being pinched or chipping the

magnets.

• Do not remove the magnets from the body of the Magnetic Damping Acces-

sory. If the magnets are accidentally removed, replace them with caution. The

poles of all three magnets should have the same orientation.

• Keep the Magnetic Damping Accessory away from computers and magnetic

recording media.

stack of

cards

Qualitative Demonstrations

The effects of magnetic damping can be surprising. Use these demonstrations illustrate the phenomenon.

• Place a strongly damped cart on a track and ask students to move it by hand.

When the cart is moved quickly, the damping force is easily detected.

• Raise one end of the track by a few centimeters. Set the Magnetic Damping

Accessory for maximum damping and allow the cart to run down the track. With

the track inclined just enough to overcome rolling friction, the cart will creep

very slowly at a constant velocity.

2

®

Page 3

ME-6828 Experiment 1: Damped Oscillation

Experiment 1: Damped Oscillation

Equipment Part Number

Dynamics Cart Magnetic Damping ME-6828

Motion Sensor (optional for Method II) PS-2103A

1

Cart

Aluminum Track

Harmonic Springs

1

1, 2

Adjustable End Stop

IDS Pivot Clamp

1

1

ME-6950, ME-9430, or ME-9454

ME-6953

ME-9803A

ME-8971

ME-9810

or similar

or similar

or similar

or similar

Large Table Clamp ME-9472

90 cm Rod ME-8738

1

These items are components of many PASCO dynamics systems.

2

This experiment works best with a spring, or combination of springs, with a constant between 1.0 N/m and 1.5 N/m.

or similar

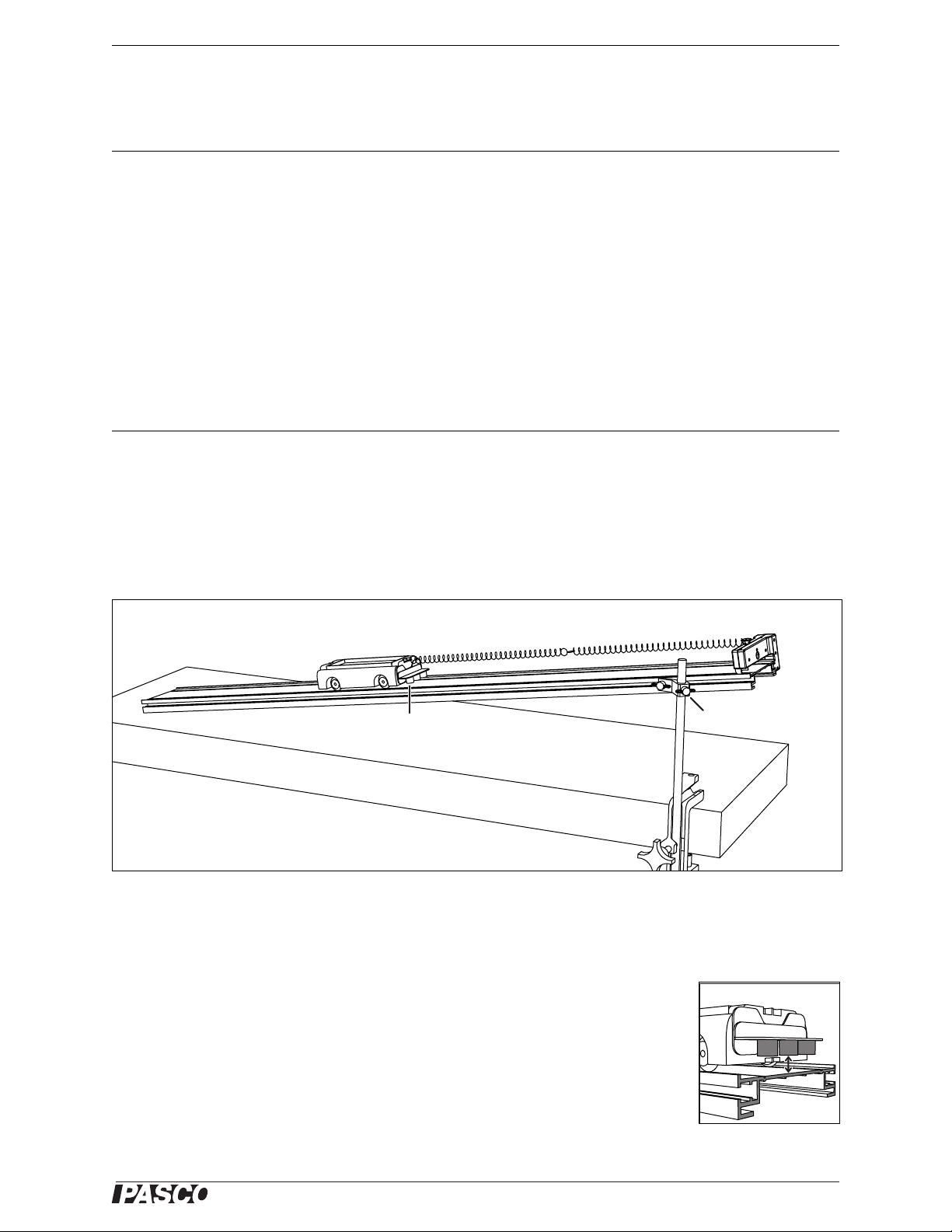

Set-up

1. Set up the equipment as illustrated. Use two or three weak springs combined

end-to-end.

cart

two or three springs end-to-end

end stop

Magnetic

Damping

Accessory

Experiment set-up for Damped Oscillation

2. Adjust the angle of the track (or the position of the end stop) so that the cart’s

equilibrium position is about 40 cm from the lower end of the track.

Method I (without sensors)

Skip to Method II if you will be using a motion sensor.

1. Place the Magnetic Damping Accessory on the end of the cart with a gap of

10 mm between the magnets and the track.

2. Tap the cart a few times so that it moves to its equilibrium position.

3. Pull the cart up the track and hold it 20.0 cm from equilibrium.

pivot clamp

rod

table clamp

Gap between magnets

and track

®

3

Page 4

Dynamics Cart Magnetic Damping Experiment 1: Damped Oscillation

4. Release the cart.

5. Allow the cart to oscillate. Count (and write down) the number of down-up cycles

that the cart completes before stopping.

6. Repeat steps 3 through 5 with the gap set to 8 mm, 6 mm, 4 mm, and 2 mm, and

with the magnets as close as possible to the track without touching.

Skip to the Questions section on page 4.

Method II (using a motion sensor)

Sensor, Interface, and Software Set-up

For detailed information about setting up your motion sensor, interface, and software, refer to the

instructions supplied with those products.

1. Place a motion sensor at the lower end of the track.

2. Adjust the angle of the track so that the cart’s equilibrium position is about 40 cm

from the sensor.

3. Connect the sensor to your interface.

4. Prepare a graph to display Position versus time.

5. Take some test data and adjust the sensor so that it can measure the cart’s position

up to a distance of about 70 cm. Delete the test data.

Leave the sample rate at the motion sensor’s default of 10 Hz.

Data Collection

1. Place the Magnetic Damping Accessory on the end of the cart with a gap of

10 mm between the magnets and the track.

2. Tap the cart a few times so that it moves to its equilibrium position.

3. Pull the cart up the track and hold it 20.0 cm from equilibrium.

4. Release the cart and start data recording at the same time.

5. Allow the cart to oscillate until it comes to a stop.

6. Stop data recording.

7. Repeat steps 3 through 6 to record data runs with the gap set to 8 mm, 6 mm,

4 mm, and 2 mm. Record a final data run with the magnets as close as possible to

the track without touching.

Motion sensor at end of

track

Question

What is the effect of moving the magnets closer to the track?

4

®

Page 5

ME-6828 Experiment 2: Critical Damping

Experiment 2: Critical Damping

Equipment Part Number

Dynamics Cart Magnetic Damping ME-6828

Stopwatch (for Method I)

ME-1234

or similar

or

Motion Sensor (for Method II)

1, 2

Cart

Aluminum Track

Harmonic Springs

Adjustable End Stop

IDS Pivot Clamp

1

1, 3

1

1

PS-2103A

or similar

ME-6950, ME-9430, or ME-9454

ME-6953

ME-9803A

ME-8971

or similar

or similar

or similar

ME-9810

Large Table Clamp ME-9472

90 cm Rod ME-8738

1

These items are components of many PASCO dynamics systems.

2

Either a plastic or aluminum cart will work; however, the lighter plastic cart allows a relatively greater amount of damping.

3

This experiment requires a spring or combination of springs with constant between 1.0 N/m and 1.5 N/m. If the spring constant is

too high, over damping will not be achievable.

or similar

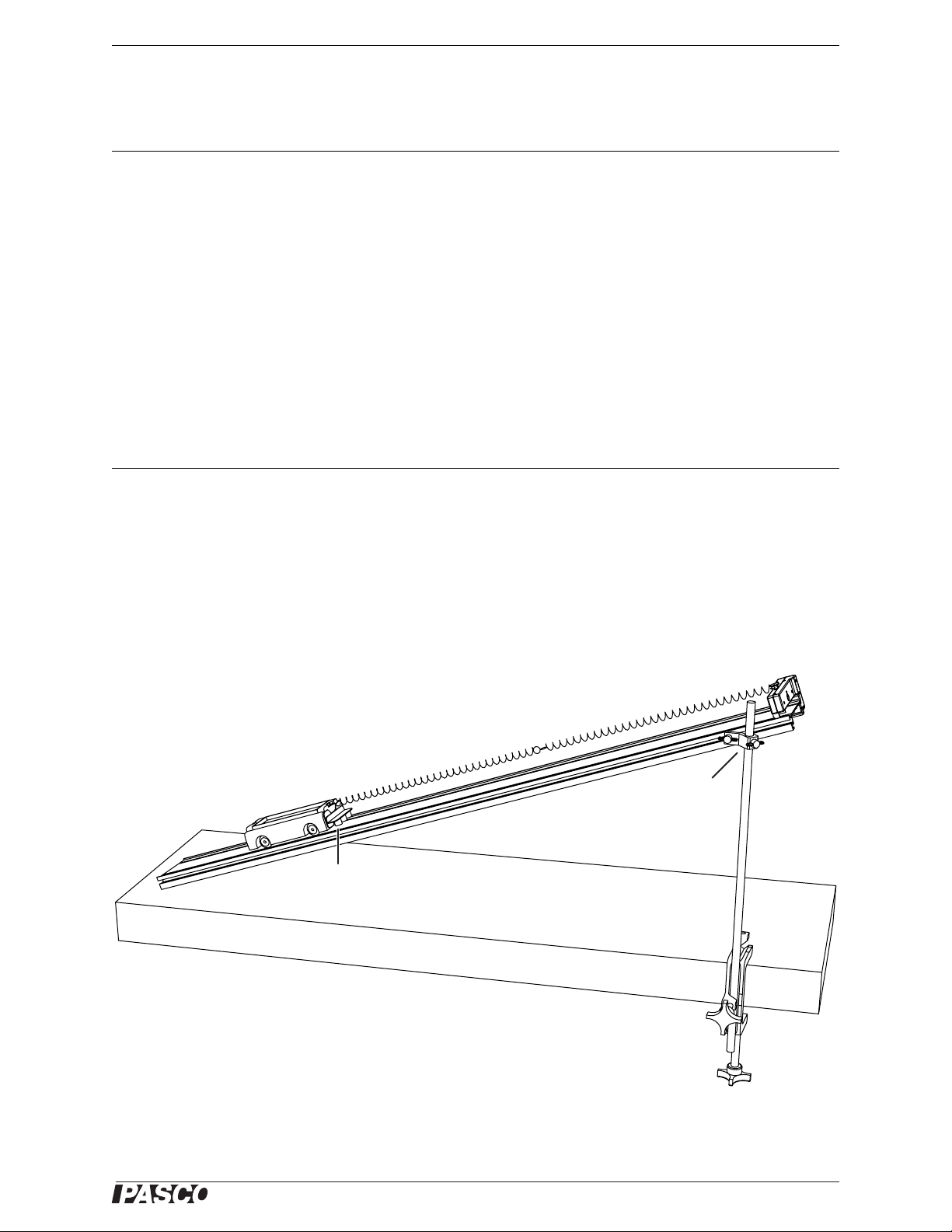

Set-up

1. Set up the equipment as illustrated. Use two or three weak springs combined

end-to-end.

end stop

two or three springs

end-to-end

cart

Magnetic

Damping

Accessory

Experiment set-up for Critical Damping

2. Adjust the angle of the track (or the position of the end stop) so that the cart’s

equilibrium position is about 20 cm from the lower end of the track.

pivot clamp

rod

table clamp

®

5

Page 6

Dynamics Cart Magnetic Damping Experiment 2: Critical Damping

3. Use tape or a pencil to mark the track about 50 cm above equilibrium.

4. Pull the cart up the track to the mark.

5. Let the cart go and carefully observe it’s movement as it comes to a stop. If the

cart overshoots equilibrium and comes back up the track, it is under-damped. If it

comes to a stop without overshooting, it is either over-damped or critically

damped.

6. Adjust the height of the magnets to reduce or increase the amount of damping.

7. Repeat steps 4 through 6 several times to find the least amount of damping (big-

gest gap) that will make the cart stop without overshooting. This is critical damping.

Method I (using a stopwatch)

Skip to Method II if you will be using a motion sensor.

1. Pull the cart up the track exactly to the mark.

2. Release the cart and start the stopwatch at the same time.

3. Stop the stopwatch when the cart stops.

4. Record the time.

5. Move the magnets up by about 1 mm to make the system under-damped.

6. Repeat steps 1 through 4.

7. Move the magnets down as close to the track as you can get them (without touch-

ing) to make the system over-damped.

8. Repeat steps 1 through 4.

Skip to the Question on page 7.

Method II (using a motion sensor)

Sensor, Interface, and Software Set-up

For detailed information about setting up your motion sensor, interface, and software, refer to the

instructions supplied with those products.

1. Place a motion sensor at the lower end of the track.

2. Connect the sensor to your interface.

3. Set the sampling rate to 50 Hz.

4. Prepare a graph to display Position versus time.

5. Take some test data and adjust the sensor so that it can measure the cart’s position

up to a distance of about 70 cm. Delete the test data.

6

Motion sensor at end of

track

®

Page 7

ME-6828 Experiment 2: Critical Damping

Data Collection

1. Pull the cart up the track exactly to the mark.

2. Release the cart and start data recording at the same time.

3. Wait until the cart stops.

4. Stop data recording.

5. Move the magnets up by about 1 mm to make the system under-damped.

6. Repeat steps 1 through 4.

7. Move the magnets down as close to the track as you can get them (without touch-

ing) to make the system over-damped.

8. Repeat steps 1 through 4.

Question

What type of damping (under, over, or critical) makes the cart stop in the shortest

time?

Further Study: What factors affect critical damping?

You have already discovered that reducing the height of the magnets can change the

system from under-damped to critically damped to over-damped. What other factors

can you adjust to change the system’s damping behavior?

Starting with a critically damped system each time, make the following changes to the

system and observe the result.

• Release the cart from a different position on the track.

• Add about 20 g of mass to the cart.

• Change the angle of the track.

• Change the spring constant (replace or remove one of the springs).

Further Study: Theoretical model

For the theoretical model of the cart’s position as a function of time, we will assume

that the spring is massless and obeys Hooke’s law; that the damping force is proportional to velocity; and that there are no forces acting on the cart other than the spring

force, the damping force, the force of gravity, and the normal force of the track. We

will also set the condition that the initial velocity at time . The

motion of the cart is determined with the following quantities:

v 0() 0= t 0=

x, the position of the cart with at the equilibrium position

x

, the initial position at time

0

x 0=

t 0=

m, the mass of the cart

k, the spring constant ( )

®

F

spring

kx–=

7

Page 8

Dynamics Cart Magnetic Damping Experiment 2: Critical Damping

b, the damping constant ( ) determined by the height of the magnets

ω

γ bm⁄=

0

, the natural frequency of the system in the absence of damping

km⁄=

, a quantity with units of frequency

F

damping

bv–=

If m and k are held constant, then the damping behavior of the system (whether it is

under-, over-, or critically damped) depends on the value of b.

Under damping

For the system to be under-damped, we must have a relatively low value of γ. Let

γ = γ

such that . Then

u

Where .

ωω

2

ω

0

xt() x

2

0

2

γ

4⁄–0>

u

γut–2⁄

e

0

2

γ

4⁄–=

u

γ

u

-------

ωt()cos

2ω

ωt()sin+=

Over damping

For over damping, the value of γ must be higher. Let γ=γ

2

ω

2

γ

0

o

4⁄–0<

. Then

such that

o

1

xt() x

Where .

βγ

0

2

4⁄ω

–=

o

--2

0

γ

γo2⁄β+()t–

o

e

------–

4β

2

x

+=

γ

1

o

---

0

2

------+

4β

e

γo2⁄β–()t–

Critical damping

2

Critical damping occurs at a specific value of γ. Let γ = γ

such that ω

c

2

−γ

/4 = 0.

0

c

Then

γ

t

γct–2⁄

c

xt() x01

=

e

-------+

2

Modeling the cart’s motion

Graph the three equations above and compare them to your actual data. Either measure or estimate your experimental values of x

, m, and k (or ω0) to put into the equa-

0

tions. Estimate values of b for under, over, and critical damping.

8

®

Page 9

ME-6828 Experiment 3: Predicting Terminal Velocity

f

f

Experiment 3: Predicting Terminal Velocity

Equipment Part Number

Dynamics Cart Magnetic Damping ME-6828

Motion Sensor PS-2103A

1

Cart

Aluminum Track

IDS Pivot Clamp

1

1

ME-6950, ME-9430, or ME-9454

ME-6953

ME-9810

or similar

or similar

Large Table Clamp ME-9472

90 cm Rod ME-8738

Angle Indicator

1

These items are components of many PASCO dynamics systems.

2

Or other way to measure track angle

2

ME-9495

or similar

Introduction

In this experiment, you will study the motion of a magnetically damped cart. First,

you will discover the relationship between the velocity and acceleration as it comes to

a stop after being pushed on a level track. Using this relationship, you will predict the

cart’s terminal velocity on a inclined track. Finally, you will test your prediction.

Part I: Acceleration versus Velocity

Theory

The magnetic drag force, f

, is proportional to (and in the opposite direction of)

m

velocity v

(eq. 1)

bv–=

m

where b is a positive constant.

On a level track, assuming no other sources of friction, f

is the only force (along the

m

axis of movement) acting on the cart. Therefore, by Newton’s second law

(eq. 2)

ma=

m

where m is the mass of the cart and a is the acceleration. (Note that f

necessarily constant over time.)

The combination of equations 1 and 2 gives the relationship between a and v

m

(eq. 3)

In a graph of v versus a, the slope will equal .

-----

v

a–=

b

mb⁄–

and a are not

m

®

9

Page 10

Dynamics Cart Magnetic Damping Experiment 3: Predicting Terminal Velocity

Equation 3 assumes that magnetic drag is the only source of friction. A real cart is

also affected by friction that is not proportional velocity, but is constant as long as the

cart is moving. If this additional frictional force is f

, then the net force on the cart is

0

(eq. 4)

F

ma bv– f0–= = for v 0>()

net

and

f

m

0

-----

(eq. 5)

The addition of f

does affect the slope of the v versus a graph, but it does add a ver-

0

v

tical offset (or “Y-intercept’) equal to .

----–=

a–

b

b

b⁄–

f

0

In this part of the experiment, you will use the motion sensor to record v and a as the

cart slows down after you push it on a level track.

Set-up

1. Make the track level.

2. Attach a motion sensor to the left end of the track.

3. Attach the Magnetic Damping Accessory to the cart.

4. If you are using a plastic cart, add about 250 g of mass, so that the total mass is

about 500 g. (Additional mass is not necessary with a metal cart.)

5. Place the cart on the track with the Magnetic Damping Accessory away from the

motion sensor.

6. Adjust the magnets to be about 1 mm above the track. Check to make sure that

the magnets do not touch the track when you push the cart swiftly.

Important: After you have adjusted the magnets, do not readjust them for the remainder of the

experiment.

Experiment set-up for Terminal Velocity, Part I

Sensor, Interface, and Software Set-up

For detailed information about setting up your motion sensor, interface, and software, refer to the

instructions supplied with those products.

1. Connect the sensor to your interface.

2. Prepare a graph (or graphs) to display Position, Velocity, and Acceleration versus

time.

3. Take some test data and adjust the sensor so that it can measure the cart’s position

up to a distance of about 1 m. Delete the test data.

Leave the sample rate at the motion sensor’s default of 10 Hz.

10

®

Page 11

ME-6828 Experiment 3: Predicting Terminal Velocity

Data Collection

You may need to try several times to complete the following steps successfully. If you

do not get it right, delete your data and try again. The recorded data should show the

motion of the cart only after you release it and before it comes to a complete stop.

There should be about 1 s of recorded data. Use one hand to push the cart and the

other hand to start and stop data recording.

1. Using a smooth, sweeping motion, push the cart away from the motion sensor

and release it. Make sure that your hand does not prevent the motion sensor from

detecting the cart.

2. About 0.1 s after releasing the cart, start data recording.

3. Just before the cart stops, stop data recording.

Analysis

1. Create a graph showing velocity (on the vertical axis) versus acceleration (on the

horizontal axis).

2. Apply a linear fit to the data.

According to equation 5, the slope of the best-fit line equals and the Y-intercept equals .

f0b⁄–

mb⁄–

Part II: Predicting Terminal Velocity

Theory

If a cart is allowed to roll down an inclined track, its velocity will increase until the

frictional forces acting against the direction of movement equal the gravitational force

acting in the direction of movement. At that point, the net force on the cart is zero, the

acceleration is zero, and the velocity remains constant. This velocity is known as the

terminal velocity, v

The gravitational force acting on the cart (in the direction of movement) is ,

where g =9.81m/s

(eq. 6)

The values of b and f

Solving equation 6 gives

(eq. 7)

.

T

2

and θ is the angle of incline. At terminal velocity, the net force is

F

0 mg θsin bvTf0––== for vT0>()

net

are the same as they were on the level track.

0

m

-----

v

g θsin

T

b

f

0

----–=

b

mg θsin

Analysis

In Part 1, you found the values of and . Use these values and equation

mb⁄– f0b⁄–

7 to predict the terminal velocity of your cart on a track inclined at θ =3.0°.

At θ =3.0°, v

= _________________, prediction

T

®

11

Page 12

Dynamics Cart Magnetic Damping Experiment 3: Predicting Terminal Velocity

Part III: Measuring Terminal Velocity

Set-up

1. Take the cart off the track and set it aside. (Be careful not to let the Magnetic

Damping Accessory shift on the cart.)

2. Use a table clamp, rod and pivot clamp to raise the left end of the track (with the

motion sensor attached). Adjust the incline to 3.0°.

Experiment set-up for Terminal Velocity, Part III

Data Collection

1. Place the cart back on the track and hold it about 15 cm from the motion sensor

with the magnets away from the sensor.

Note: Before releasing the cart, be prepared to stop it so that the Magnetic Damping Accessory is

not knocked out of position.

2. Start data recording.

3. Release the cart, stop it after it has rolled about 1 m.

4. Stop data recording.

Analysis

From your recorded data, determine the terminal velocity.

At θ =3.0°, v

= _________________, measured

T

Questions

1. How close was your prediction to your measured value of vT? If they were not

exactly equal, what might account for the difference?

2. Would the terminal velocity change if you changed the mass of the cart?

3. Did you have to measure the mass of the cart to predict the terminal velocity?

12

®

Page 13

ME-6828 Sample Data

Sample Data

Experiment 1: Damped Oscillation

Damping

increases as

the magnets

are moved

closer to the

track.

Experiment 2: Critical Damping

Critical damping makes the

cart stop in

the shortest

time.

Note that, due

to static friction, the

under-damped

cart stops at a

slightly different position.

®

13

Page 14

Dynamics Cart Magnetic Damping Sample Data

Experiment 3: Predicting Terminal Velocity

The graph below shows position versus time as the cart is coming to a stop on a level track.

The graph below shows velocity versus acceleration for the cart on the level track.

From the slope and intercept of the best-fit line: and . From these values and equation 7, the predicted terminal velocity is .

mb⁄–0.52 s–= f0b⁄– 0.033 m/s–=

v

0.23 m/s=

T

The graph below shows position versus time for the cart running down a 3° incline. The slope of the linear portion is the measured terminal velocity: .

v

0.2225 m/s=

T

In this case the predicted and measured values differ by about 0.01 m/s, or 4%. The

difference may be due to uncertainty in the values of , , and the angle of

mb⁄ f0b⁄

the inclined track.

The terminal velocity would be different if the cart’s mass were changed. In this

experiment, it is not necessary to know the mass of the cart to predict the terminal

velocity.

14

®

Page 15

ME-6828 Technical Support

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

Limited Warranty

For a description of the product warranty, see the PASCO catalog.

Copyright

The PASCO scientific 012-10242A

mission is granted to non-profit educational institutions for reproduction of any part of this manual, providing the reproductions are

used only in their laboratories and classrooms, and are not sold for profit. Reproduction under any other circumstances, without the

written consent of PASCO scientific, is prohibited.

Dynamics Cart Magnetic Damping Instruction Manual

is copyrighted with all rights reserved. Per-

Trademarks

PASCO, PASCO scientific, DataStudio, PASPORT, and ScienceWorkshop are trademarks or registered trademarks of PASCO scientific, in the United States and/or in other countries. All other brands, products, or service names are or may be trademarks or service

marks of, and are used to identify, products or services of, their respective owners. For more information visit www.pasco.com/legal.

®

15

Loading...

Loading...