Page 1

Includes

Teacher's Notes

and

Typical

Experiment Results

Instruction Manual and

012-06339A

Experiment Guide for the

PASCO scientific

Model ME-6694

TORSION PENDULUM

7/97

© 1997 PASCO scientific $7.50

®

10101 Foothills Blvd. • P.O. Box 619011 • Roseville, CA 95678-9011 USA

Phone (916) 786-3800 • FAX (916) 786-8905 • web: www.pasco.com

better

ways to

teach science

Page 2

Torsion Pendulum 012–06339A

Page 3

012–06339A Torsion Pendulum

Table of Contents

Section Page

Copyright, Warranty, and Equipment Return ................................................................ ii

Introduction ...................................................................................................................1

Equipment .....................................................................................................................1

Assembly with the Rotary Motion Sensor ..................................................................23

Suggested Experiment ...................................................................................................4

Experiment

Experiment 1: Determining of the Magnitude of the Moment of Inertia (I) Using

Two Methods .............................................................................. 512

Part A: Determining the Spring Constants of the Wires (κ) ...............68

Part B: Determining the Moment of Inertia (I) of a Disk Using Two

Methods ......................................................................................910

Part C: Determining the Moment of Inertia (I) of a Disk and Cylinder

Using Two Methods ................................................................. 1112

Teachers Notes............................................................ 1316

Technical Support ........................................................................................ Back Cover

i

Page 4

Copyright, Warranty , and Equipment Return

PleaseFeel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific 012-06339A manual is

copyrighted and all rights reserved. However,

permission is granted to non-profit educational

institutions for reproduction of any part of the Torsion

Pendulum manual providing the reproductions are

used only for their laboratories and are not sold for

profit. Reproduction under any other circumstances,

without the written consent of PASCO

scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

PASCO will repair or replace at its option any part of

the product which is deemed to be defective in

material or workmanship. The warranty does not

cover damage to the product caused by abuse or

improper use. Determination of whether a product

failure is the result of a manufacturing defect or

improper use by the customer shall be made solely by

PASCO scientific. Responsibility for the return of

equipment for warranty repair belongs to the

customer. Equipment must be properly packed to

prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the

equipment for return shipment will not be covered by

the warranty.) Shipping costs for returning the

equipment after repair will be paid by PASCO

scientific.

Credits

Author: Sunny Bishop

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units must

be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be damaged in

shipment, observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

➂ Make certain that the packing material cannot shift in

the box or become compressed, allowing the

instrument come in contact with the packing carton.

Address: PASCO scientific

10101 Foothills Blvd.

P.O. Box 619011

Roseville, CA 95678-9011

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 5

012–06339A Torsion Pendulum

Introduction

The PASCO ME-6694 Torsion Pendulum, an accessory for the

PASCO CI-6538 Rotary Motion Sensor (RMS), facilitates the study

of torque and the moment of inertia in a rotating body. The apparatus

uses the data acquisition capabilities of the RMS with Science

TM

Workshop

through the PASCO 500 or 700 computer interfaces.

Using the Torsion Pendulum, students can collect experimental data on

rotational acceleration, rotational position, and rotational velocity for

a variety experiments with the PASCO CI-6691 Mini-Rotational

Accessory. Three wires with different diameters supplied with the

Torsion Pendulum provide three different and repeatable torque

magnitudes.

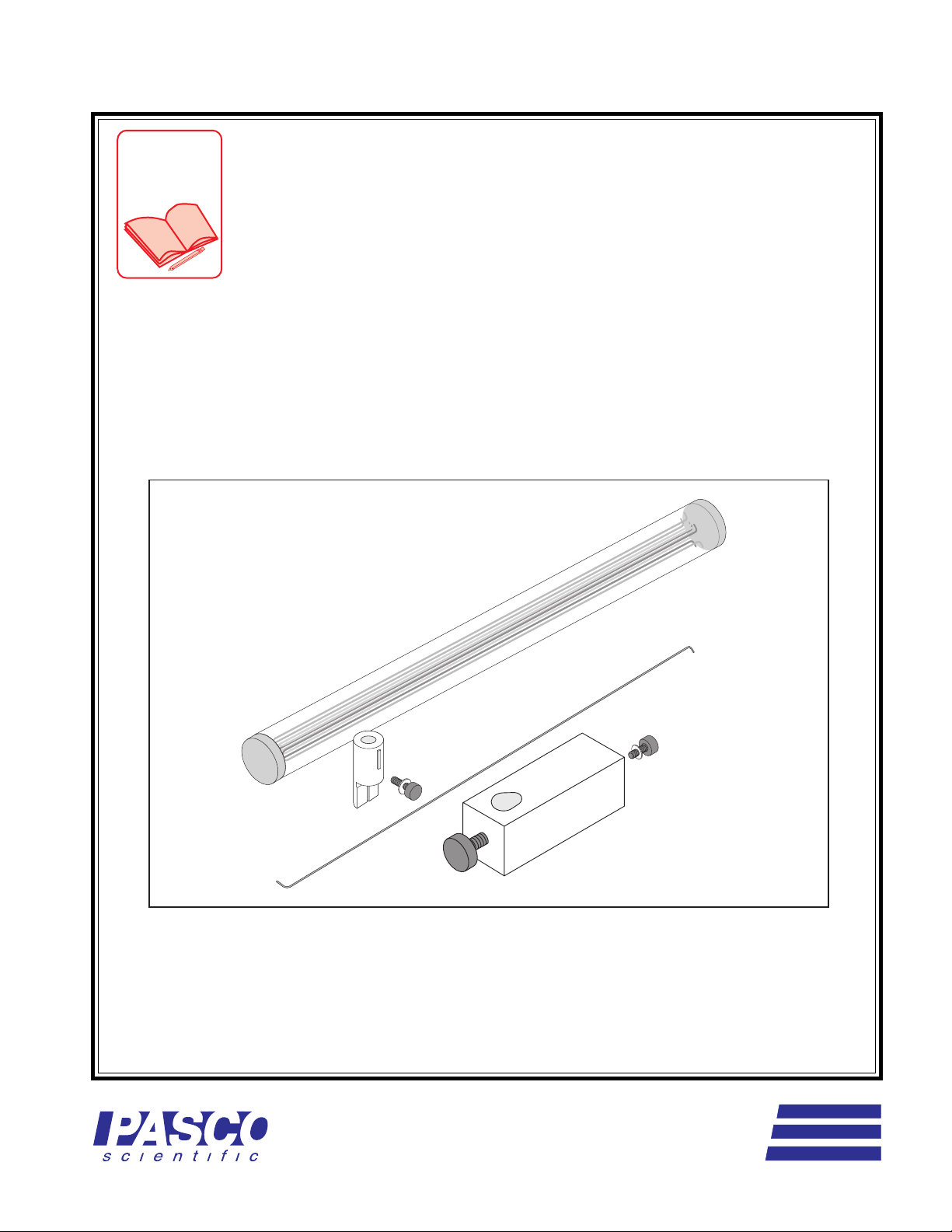

Equipment

18-inch wires, 3 each: diameters (inches): 0.032, 0.047, 0.063

upper wire clamp

lower wire clamp

18-inch wires

Additional Equipment Required:

Science Workshop

PASCO Computer Interface (500 or 700)

computer

Rotary Motion Sensor (CI-6538)

Mini-Rotational Accessory (CI-6691)

Force Sensor (CI-6537)

Additional Equipment Suggested

Table Clamp (ME-9376B) or Large Rod Stand (ME-8735)

Support Rod (90 cm) (ME-8738)

TM

version 2.1 or higher

upper wire

clamp

thumbscrew and

washer

lower wire clamp

ä

Safety Note:

Always wear safety glasses

when experimenting with the

Torsion Pendulum.

Replacement Wires

To order a set of wires, call PASCO

(800-772-8700) and order part number

003-06354.

1

Page 6

Torsion Pendulum 012–06339A

ä

Note: You will need bend the

wires as illustrated in Figure 1.

(The direction of the bend is not

critical.

Assembly with the Rotary Motion Sensor (RMS)

1. Use the Table Clamp to secure the Support Rod to a table in close

proximity to your computer interface (Figure 2).

RMS

to computer

interface

upper wire

clamp

wire with bent ends

Figure 1

Bend the ends of the wires to 90°

angles.

upper wire

clamp

grooves

wire

lower wire clamp

Support

Rod

Table Clamp

Figure 2

Assembly of the Torsion Pendulum and the Rotary Motion

Sensor

2. Slip the lower wire clamp onto the Support Rod.

3. Clamp the RMS at the top of the Support Rod.

4. Clamp one end of the wire under the washer of the upper wire

clamp by firmly tightening the thumbscrew, being sure to seat the

wire in the grooves (Figure 3).

Figure 3

Securing the wire to the upper wire

clamp

2

Page 7

012–06339A Torsion Pendulum

5. Clamp the other end of the wire under the washer of the lower wire

clamp by tightening the thumbscrew firmly. Be sure that the

elbow of the bend in the wire fits snugly against the axle of the

thumbscrew (Figures 4a and 4b).

a

Support Rod

thumbscrew

and washer

wire

b

thumbscrew

and washer

lower wire clamp

(front view)

wire

lower wire clamp

(side view)

Figure 4

Lateral (a) and front (b) views of attaching the bent wire to the lower clamp.

6. Adjust the height of the lower wire clamp

to about 18 inches below the shaft of the

RMS.

7. Align the guide of the upper wire clamp

with the slot of the shaft of the RMS. Slide

the upper wire clamp onto the shaft

(Figure 4).

8. Adjust height of the lower wire clamp as

necessary to position to top of the upper

wire clamp approximately half-way up

the shaft (Figure 5).

9. If necessary, adjust the lower wire clamp

so the wire is perpendicular to the table.

upper wire

clamp

slot

shaft of RMS

guide

10. Recheck all screws on the clamps to be

sure each part is firmly secured.

Support

Rod

Figure 5

Sliding the upper wire clamp onto the shaft of the Rotary

Motion Sensor

3

Page 8

Torsion Pendulum 012–06339A

➤

Note: The manual has been written with the assumption that

the user has a basic familiarity with Science Workshop and has

access to the Users Guide for Science Workshop. Users can

gain basic skills with Science Workshop by viewing the training

video and by doing the tutorial within Science Workshop. Another

useful resource is the Quick Reference Card for Science

Workshop.

Suggested Experiment

The following experiment will help students build skills in using the

Torsion Pendulum using Science Workshop for data acquisition. Students

may want to experiment further with varying lengths, thickness, or

composition of wire, or with effects of variations of temperature on the

torsional spring constant, κ.

4

Page 9

012–06339A Torsion Pendulum

I

I

Experiment 1. Determining the Magnitude of the Moment of

Inertia (I) Using Two Methods

Purpose

The purpose of the experiment is compare the magnitude of the moment of inertia (I) of a disk

and cylinder calculated by (1) using a torsional spring constant (κ) and the period of oscillation

of the Torsion Pendulum (T) and (2) with I calculated using mass and radius measurements.

Materials and Equipment Required

• Torsion Pendulum (ME-6694) • Force Sensor (CI-6537)

• Rotary Motion Sensor (CI-6538) • Table Clamp (ME-9376B)

• Mini-Rotational Accessory (CI-6691) • Support Rod (90 cm) (ME-8738)

• Science Workshop

• PASCO computer interface (500 or 700) • metric ruler

• computer • sturdy, non-stretching string—18 inches

2.1 or higher • mass balance

• pages 2 and 3 of the manual

Theory

The magnitude of the moment of inertia (I) of a disk can be determined with the Torsion

Pendulum using the following relationship:

2

T

=

where T= the time (s) for a period of oscillation of the Torsion Pendulum and κ = the torsional

spring constant of the wire.

The magnitude of the moment of inertia of a disk can also be determined by measuring the

mass (m) and radius (R) of the disk and using the relationship:

=

Therefore, in the case of a uniform disk rotating about its cylinder axis, the following relationship

can be shown:

1

mR2=

2

In the case of a disk plus a cylinder (Part C of the experiment), the following relationship can

be demonstrated:

2

T

2

π

1

=

mR2+

κ

2

1

2

2

π

mR

2

κ

2

2

T

κ

π

1

2

m(R

2

2

R

)

+

1

2

where R

= the inner radius of the cylinder and R2 = the outer radius of the cylinder.

1

5

Page 10

Torsion Pendulum 012–06339A

Part A: Determining the Torsional Spring Constants of the Wires (k)

Set Up the Equipment

1. Assemble the Torsion Pendulum and the RMS as directed on pages 2 and 3 of the manual,

using the 0.032 inch (diameter) wire.

2. Securely tie the Force Sensor to the large pulley of the 3-step pulley on the RMS with a

piece of sturdy string 0.5 m in length.

Set Up Science Workshop

1. Plug the digital plugs of the RMS into digital channels 1 & 2 on the computer interface

box.

2. Plug the DIN connector of the Force Sensor into analog channel 1 of the computer interface

box.

3. Turn on the interface box and start Science Workshop.

4. In the Setup Window, set up the RMS on digital channels 1 & 2 and the Force Sensor on

analog channel 1.

➤

Note: Refer to the RMS and Force Sensor manuals for more detailed

instructions on setting them up in Science Workshop.

5. Double-click the Force Sensor icon and set the sensitivity to Med (10X).

6. Click the Sampling Options button and set the sampling rate to 50/s.

7. Click and drag a Graph icon to the Force Sensor icon. Click the Statistics button and

select

Curve Fit > Linear Fit

as is convenient.

8. Double-click the RMS icon and set Divisions/Rotation to 1440.

9. Click the x-axis input button (

Angular Position (angPos)

from the pop-up menu. Size and move the Graph display

) on the Graph display and select

(This will set the input for the x-axis).

Digital 1>

6

Page 11

012–06339A Torsion Pendulum

Collect the Data

1. Put your safety glasses on.

2. Wind the string around the large pulley in a clockwise direction.

a

90°

b

Figure 1.1

Hold the Force Sensor 90° to the pulley (a)

and 90° to the support rod (b).

90°

Force Sensor

R

A

E

T

3. Hold the Force Sensor parallel to the table at the height of large pulley and prepare to pull

it straight out (Figure 1.1).

4. Start recording data and pull the Force Sensor straight out until about 5 N of force is

exerted.

5. Stop recording data (This will be Run 1).

6. Change the wire to the 0.47 inch diameter wire.

7. Repeat steps 2-5 (Run 2).

8. Change the wire to the 0.62 inch diameter wire.

9. Repeat steps 2-5 (Run 3). Save the file.

7

Page 12

Torsion Pendulum 012–06339A

Analyze the Data

1. Use the following formula to calculate the torsional spring constant (κ) for each wire and

record in Table 1.1:

F

=

κ

θ

where l = the length of the lever arm in meters (the distance from the axis of the pulley to the

θ

groove of the pulley) and F = force in expressed in newtons, and

at a force F.

Table 1.1

Calculation of torsional spring constants of the wires (κ)

Run wire diameter slope of κ

(inches) F vs. angPos (m) (N·m)

1 0.032

2 0.047

ιn the angular displacement

ä

Note: Click the Autoscale

button on each Graph display if

necessary.

3 0.062

8

Page 13

012–06339A Torsion Pendulum

Part B: Determining the Moment of Inertia (I) of a Disk Using Two Methods

Set Up Science Workshop

1. Use the setup detailed in Part A. Save As a different file name, and delete all data sets

(Runs 1 - 3) and the Graph display.

(Note: The Force Sensor will not be used in Parts B and C.)

2. Click the Sampling Options button and set the sampling rate to 200 Hz.

3. Click and drag a Graph display to the RMS icon and choose

Pos)

from the pop-up menu. (This will set input for the y-axis.)

Set Up the Equipment

1. Attach the disk from the Mini-Rotational

Accessory to the 3-step pulley with the

thumbscrew (Figure 1.2).

2. Check the thumbscrews holding the wire to be

sure they are tight.

Collect the Data

1. Put your safety glasses on.

2. Twist the disk 1/4 turn clockwise.

3. Begin recording data, release the disk, and record

for about 3 5 seconds.

4. Stop recording data.

Angular Position (ang

disk from Mini-Rotational

Accessory

3-step pulley

5. Click on the Autoscale button to resize the graph,

if necessary.

6. Use the Smart Cursor to determine the time for

each period of oscillation (T) of the pendulum

(measure the time between adjacent maxima of

the angular position vs. time graph). Record in

Table 1.2.

7. Change the wire to the 0.047 inch diameter wire

and repeat steps 26.

Figure 1.2

Experimental setup

9

Page 14

Torsion Pendulum 012–06339A

I

I

8. Change the wire to the 0.062 inch diameter wire and repeat steps 26.

9. Determine the mass and radius of the disk and record below.

mass of disk (kg)_________

radius of disk (m)_________

Table 1.2

Calculation of I from torsional spring constants of wires (κ)

Run wire diameter κ (N·m) T I

(inches) (from pt.A) (s) (kg/m2)

1 0.032

2 0.047

3 0.062

I (using mass and radius measurements) _____________

Compare the values of calculated I

1. Calculate I using both formulas:

above.

=

T

2

π

2

κ

and

1

=

2

mR

and record

2

10

Page 15

012–06339A Torsion Pendulum

R

2

R

1

I

I

I

Part C: Determining the Moment of Inertia (I) of a Disk and Cylinder Using Two Methods

1. Place the ring of the Mini-Rotational

Accessory on the disk (Figure 1.3).

2. Repeat steps 26 of Part B. Record your

data in Table 1.3.

3. Change the wire to the 0.047 inch

diameter wire and repeat steps 26.

4. Change the wire to the 0.032 inch

diameter wire and repeat steps 26.

5. Measure the mass and R

and R2 of the

1

cylinder and record below.

mass of cylinder (kg) ____________

R

(m) ____________________

1

R

(m) ____________________

2

cylinder from MiniRotational Accessory

3-step pulley

Figure 1.3

Experimental setup for Part C

disk from MiniRotational

Accessory

Table 1.3

Calculation of I

disk and cylinder

from the torsional spring constants

of wires (κ)

wire diameter κ (N·m) T I

disk and cylinder

(inches) (from part A) (s) (kg/m2)

0.032

0.047

0.062

I

disk and cylinder

(using mass and radius measurements) _____________

Compare the values of calculated I

1. Calculate I using both formulas:

2

T

=

and record above.

κ

2

π

and

=

1

mR2+

2

1

2

m(R

2

2

R

)

+

1

2

1

2

=

m(R

2

2

R

)

+

1

2

11

Page 16

Torsion Pendulum 012–06339A

Questions

1. How closely did the calculations of I match?

2. What are some possible sources of experimental error?

12

Page 17

012–06339A Torsion Pendulum

Teachers Notes:

General

➤ Safety Note: Use safety glasses when operating the Torsion

Pendulum

Experimental data will vary somewhat from the typical data included here due to the

differences in wire lengths and other variables, but the overall data patterns will be the

same.

Linear Fit

y = a1 + a2 x

a1 = -0.16328

a2 = -1.42996

chi^2 = 0.03058

iterations = 20

R un # 6

F orce (N)

slope of

the fitted

line

-6.0 -4.0 -2.0 0

0 1.0 2.0 3.0 4.0 5.0 6.0

Ru n #6

Angular Position (rad)

Figure TN1.1

Typical data for determining the torsional spring constant (κ) (0.047 inch diameter

wire)

Table TN1.1

Calculation of torsional spring constants of the wires (κ),

typical data

Run wire diameter slope of l κ

(inches) F vs. angPos (m) (N·m)

1 0.032 -0.3162 0.0254 0.008

2 0.047 -1.4300 0.0254 0.036

3 0.062 -4.4465 0.0254 0.113

13

Page 18

Torsion Pendulum 012–06339A

Part B

Run #1, 2, 3

Angular Position (rad)

0.032 in. wire

-5.0 -4.0 -3.0 -2.0 -1.0 0 1.0

2.5 3.0 3.5 4.0 4.5 5.0 5.5

Time (s)

0.047 in. wire

0.062 in. wire

Figure TN1.2

Typical data for determining the period of rotation (T) for the three wire diameters (disk accessory)

Table TN1.2

Calculation of I from torsional spring constants (κ) of wires

Run wire diameter κ* T I

(inches) (N·m) (s) (kg/m2)

1 0.032 0.008 0.861 1.5 x 10

2 0.047 0.036 0.408 1.5 x 10

3 0.062 0.113 0.239 1.6 x 10

-4

-4

-4

mass of disk 0.126 kg*

radius of disk 0.047 m*

*may vary somewhat

14

*from part A

I (using mass and radius measurements) 1.4 x 10

-4

Page 19

012–06339A Torsion Pendulum

Part C

Run #4, 5, 6

Angular Position (rad)

-5.0 -4.0 -3.0 -2.0 -1.0 0 1.0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

0.032 in. wire

Time (s)

0.047 in. wire0.062 in. wire

Figure TN1.3

Typical data for determining the period of rotation (T) for the three wire diameters (disk plus cylinder)

Table TN1.3

Calculation of I

disk plus cylinder

from torsional spring constants

(κ) of wires

mass of cylinder 0.468 kg*

Run wire diameter κ* T I

(inches) (N·m) (s) (kg/m2)

1 0.032 0.008 1.826 6.8 x 10

2 0.047 0.036 0.861 6.8 x 10

3 0.062 0.113 0.500 7.2 x 10

*from part A

-4

-4

-4

of cylinder 0.027 m*

R

1

of cylinder 0.039 m*

R

2

*may vary somewhat

I

disk plus cylinder

I = 1.4 x 10

I = 6.7 x 10

(using mass and radius measurements) 6.7 x 10

-4

-4

**from Part B

2

kg/m

(disk)** + 5.3 x 10

2

kg/m

-4

kg/m2 (cylinder)

-4

kg/m

2

15

Page 20

Torsion Pendulum 012–06339A

I

I

Questions

1. The experiment demonstrated that the magnitude of the moment of inertia of a disk can be

determined two ways: using the torsional spring constant of a wire (κ) and the period of

2

T

oscillation of the Torsion Pendulum (T), applying the relationship

=

measuring the mass and diameter of the disk and applying the relationship

2. The calculated magnitude of I is approximately the same using either method. However,

some experimental error is to be expected, particularly since some portions contributing to

I (the pulley, axle, etc.) were not included in the calculation of I from using mass and radius

measurements, but were included in the calculation of I using the torsional spring constant

of the wire and period of oscillation of the Torsion Pendulum.

2

π

=

κ

and by

1

mR

2

2

.

The same comments apply to Part C.

16

Page 21

012–06339A Torsion Pendulum

T echnical Support

Feedback

If you have any comments about the product or manual,

please let us know. If you have any suggestions on

alternate experiments or find a problem in the manual,

please tell us. PASCO appreciates any customer

feedback. Your input helps us evaluate and improve our

product.

To Reach PASCO

For technical support, call us at 1-800-772-8700

(toll-free within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@pasco.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

➤ If your problem is with the PASCO apparatus, note:

Title and model number (usually listed on the

label);

Approximate age of apparatus;

A detailed description of the problem/sequence of

events (in case you cant call PASCO right away, you

wont lose valuable data);

If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

➤ If your problem relates to the instruction manual,

note:

Part number and revision (listed by month and year

on the front cover);

Have the manual at hand to discuss your

questions.

17

Page 22

Loading...

Loading...