Page 1

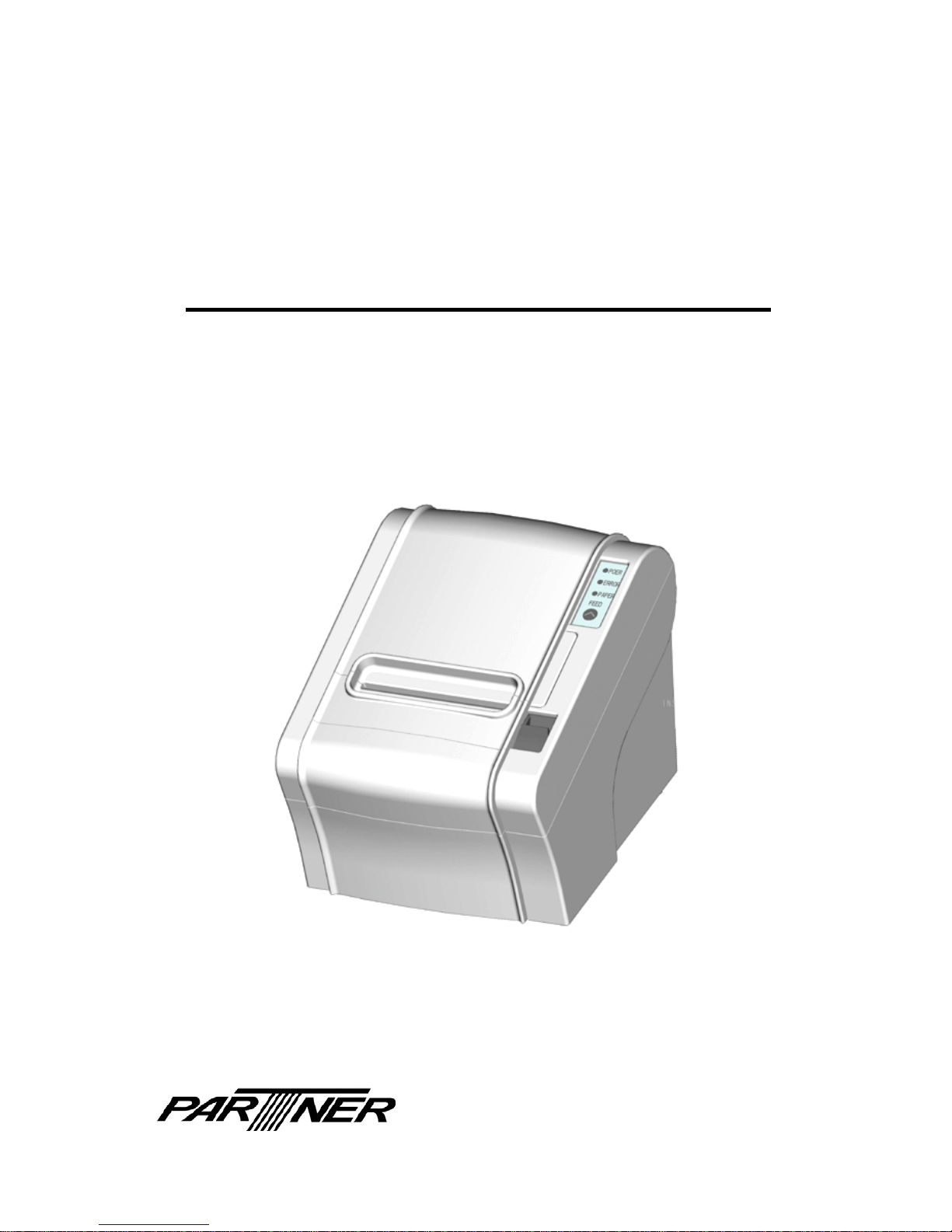

RP-300 / 310

Thermal Receipt printer

Technical manual

Partner Tech Corp.

http://www.partner.com.tw

Page 2

TITLE : RP-300/310

Page -1 -

TABLE OF CONTENTS

1. General Specifications

1.1 Printing Specifications

1.2 Character Specifications

1.3 Auto Cutter

1.4 Paper Roll Supply Device

1.5 Paper Specification

1.6 Printable Area

1.7 Printing and Cutting Positions

1.8 Internal Buffer

1.9 Electrical Characteristics

1.10 EMI and Safety Standards Applied

1.11 Reliability

1.12 Environmental Conditions

2. Configuration

2.1 Interface

2.1.1 RS-232 serial interface

2.1.2 Specifications

2.1.3 Switching between on-line and off-line

2.1.4 Interface connector terminal assignments and signal functions

2.1.5 Serial interface connection example

2.1.6 Centronics parallel interface

2.1.7 Data Receiving Timing(Compatibility Mode)

2.1.8 USB Interface

2.1.9 Interface Connector

3. Connectors

3.1 Interface Connectors

3.2 Electrical Characteristics

3.3 Drawer kick-out Connector (Modular Connector)

4. Control Command Summary

Page 3

TITLE : RP-300/310

Page -2 -

1. General Specifications

1.1 Printing Specifications

1) Printing method: Thermal line printing

2) Dot density: 180dpi x 180dpi

203dpi x 180dpi

3) Printing direction: Unidirectional with friction feed

4) Printing width: 72mm(2.83"), 576 dot positions (203dpi)

72.2mm(2.84"), 512 dot positions (180dpi)

80mm(3.15"), 640 dot positions (203dpi)

5) Characters per line(default): Font A: 42

Font B: 56

6) Printing speed: High speed mode:

35.5lines/second maximum

(1/6inch feed) (at 24V, 20℃)

Approximately 150mm/sec maximum

(approximately 5.9inchs/sec maximum)

☞ NOTE: Speeds are switched depending on the applied voltage to the printer and

head temperature conditions automatically.

☞ NOTE: There may be variations in printing after switching the mode of the

printing speed. To prevent this for logo printing with ESC* command,

using a downloaded bit image is recommended. Change in printing

speed does not occur during down loaded bit image printing.

7) Line spacing (default): 1/6 inch (4.23mm)

Programmable by control command.

Page 4

TITLE : RP-300/310

Page -3 -

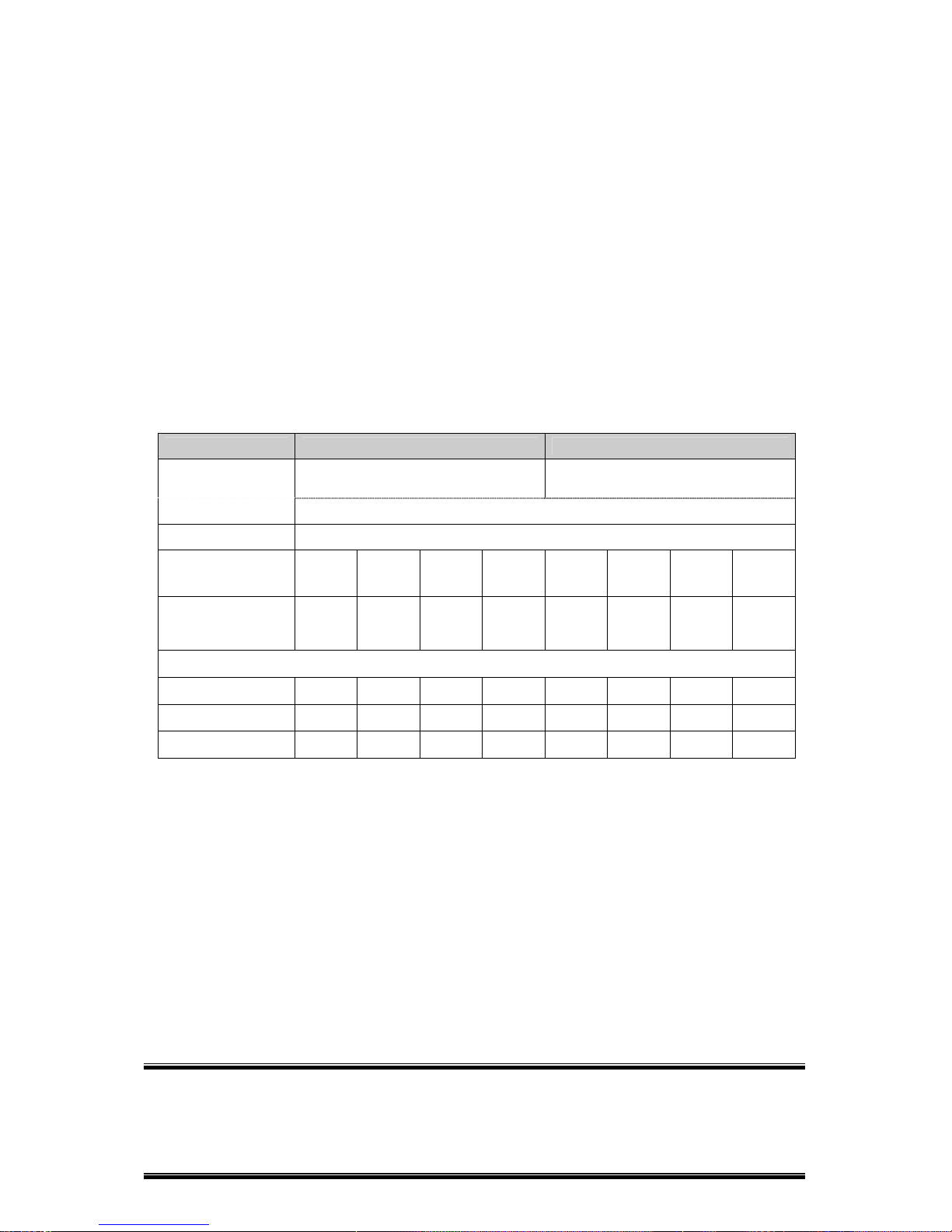

1.2 Character Specifications

1) Number of characters: Alphanumeric characters: 95

Extended graphics 128 × 7 pages

(including one space page)

International characters: 32

① English

② Hangul

③ Chinese (GB2312,Big5)

④ Kanji

2) Character structure: Font A: 12 ⅹ 24

Font B: 9 ⅹ 24

Hangul, Chinese: 24 ⅹ 24

Font A is selected as the default

3) Character size:

EPSON Emulation STAR Emulation

Dot density

0.141

ⅹ0.141mm/dot

(180*180dpi)

0.125ⅹ0.141mm/dots

(203*180dpi)

[dpi: dots per 25.4mm{1"}]

3)Printing direction Unidirectional With friction feed

4)Paper width

82.5mm

(3.25")

80mm

(3.15")

60mm

(2.36")

58mm

(2.28")

82.5mm

(3.25")

80mm

(3.15")

60mm

(2.36")

58mm

(2.28")

5)Maximum

printable area

72.2mm

(512dots)

72.2mm

(512dots)

54.1mm

(384dots)

50.8mm

(360

dots)

80mm

(640dots)

72mm

(576

dots)

54.5mm

(436

dots)

52.5mm

(420

dots)

6)Character / line

Font A (12ⅹ24) 42 42 32 30 53 48 36 35

Font B (9ⅹ24) 56 56 42 40 71 64 48 46

Kanji Font (24ⅹ24) 21 21 16 15 26 24 18 17

1.3 Auto Cutter

Partial cut: Cutting with one point center uncut

NOTE: To prevent dot displacement, after cutting, paper must be fed

approximately 1mm(14/360 inches) or more before printing.

Page 5

TITLE : RP-300/310

Page -4 -

1.4 Paper Roll Supply Device

1) Supply method: Drop-in paper roll

2) Near-end sensor:

a) Detection method: Photo Reflector

b) Paper roll spool diameter: Inside: 12mm(.47″ )

Outside: 18mm(.71″)

c) Near-end adjustment: Adjusting screw

d) Remaining amount: Fixed position #1 (approximately

23mm(0.9″ )) #2 (approximately

27mm(1.06″ ))

NOTE: You can use a command to stop printing upon detection of a paper

near-end.

1.5 Paper Specification

1) Paper type: Specified thermal paper

2) Form: Paper roll

3) Paper width:

(82.5mm paper width model)

82 ±0.5mm (3.23" ±0.02")

(80mm paper width model)

79.5 ±0.5mm (3.13" ±0.02")

(60mm paper width model)

59.5 ±0.5mm (2.34" ±0.02")

(58mm paper width model)

57.5 ±0.5mm (2.26" ±0.02")

4) Paper roll size: Roll diameter : Maximum 83mm

Take-up paper roll width:

80 ± 0.5, 1.0mm(3.15"±0.020", 0.04")

5) Paper roll spool diameter: Inside: 12mm(.47")

Outside: 18mm(.71")

NOTE: Paper must not be pasted to the paper roll spool.

Page 6

TITLE : RP-300/310

Page -5 -

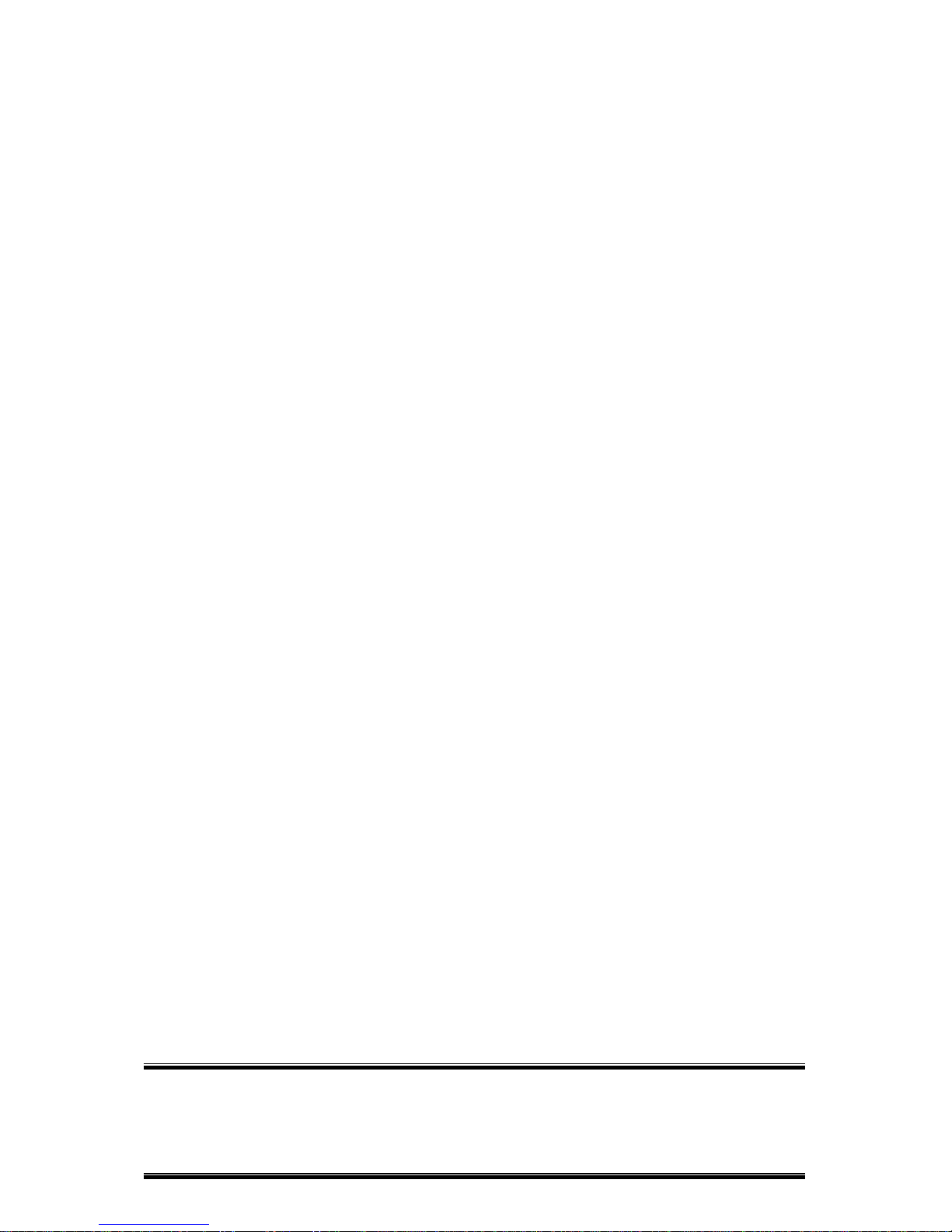

1.6 Printable Area

<EPSON Emulation>

6.8mm

0.141mm

<82.5mm {3.25"} paper width model>

82±0.5mm

3mm

512 dots

72.2mm(dot #1-#512)

4.3mm

<80 mm {3.15"} paper width model>

0.141mm

79.5±0.5mm

3mm

512 dots

72.2mm(dot #1-#512)

Page 7

TITLE : RP-300/310

Page -6 -

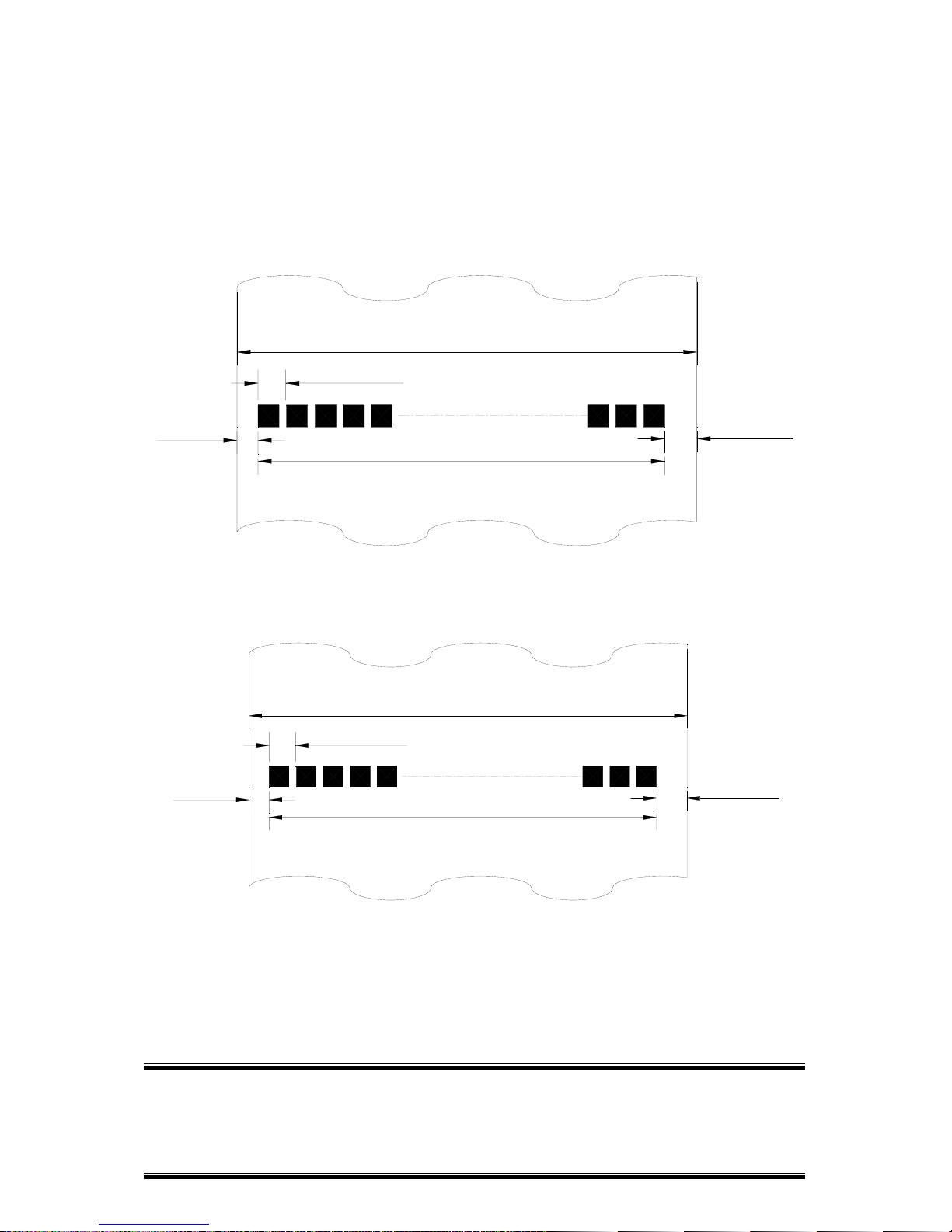

59.5±0.5mm

<60mm {2.36"} paper width model>

0.141mm

3mm

2.4mm

384 dots

54.1mm(dot #1-#384)

57.5±0.5mm

0.141mm

3mm

3.7mm

360 dots

<58mm {2.28"} paper width model>

50.8mm(dot #1-#360)

Figure 1.6.1 Printable Area for EPSON Emulation

Page 8

TITLE : RP-300/310

Page -7 -

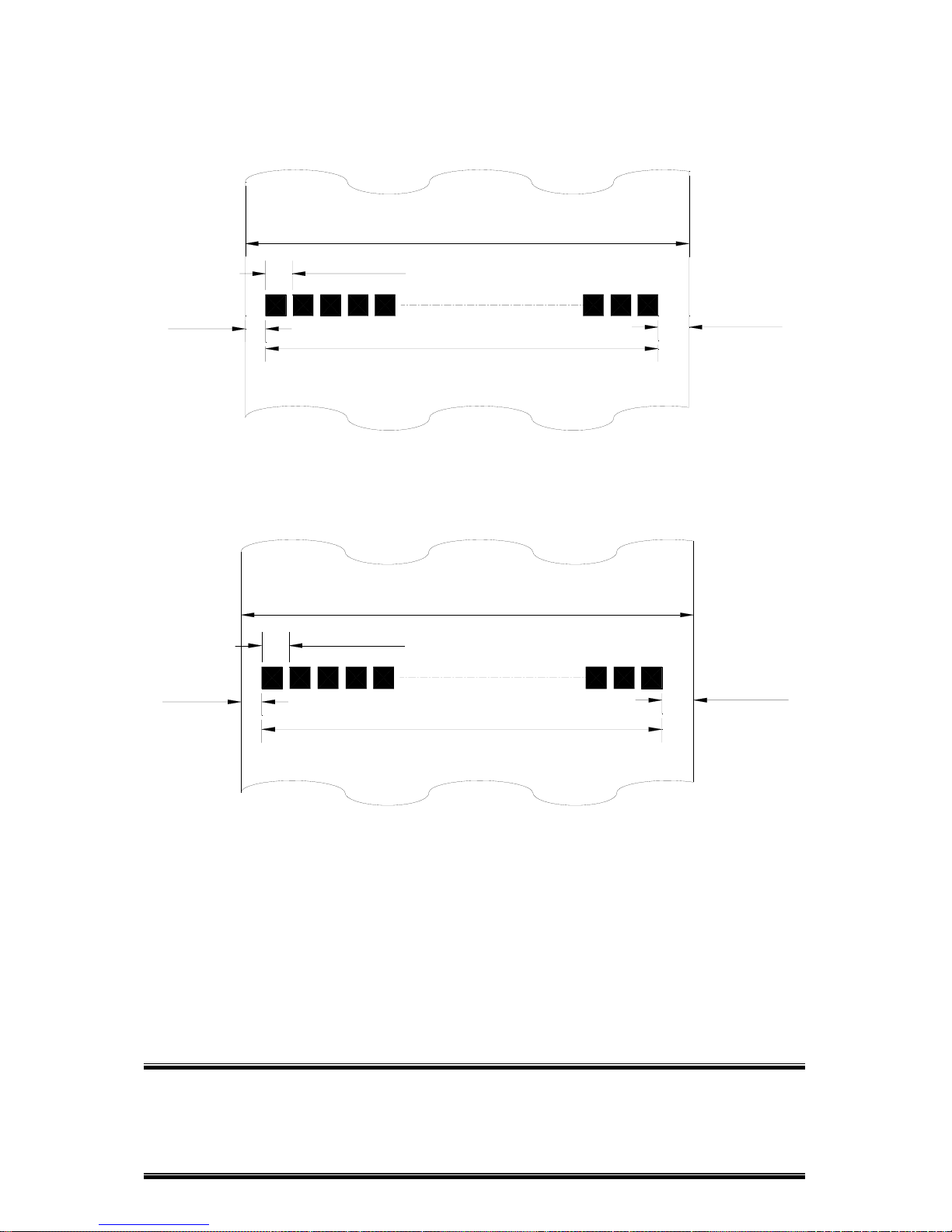

<STAR Emulation default setting>

57.5±0.5mm

<58mm {2.28"} paper width model>

0.125mm

2.65mm

420 dots

2.35mm

52.5mm(dot #1-#420)

Figure 1.6.2 Printable Area for STAR Emulation (for Default Setting)

<STAR Emulation when the paper width is changed>

82±0.5mm

<82.5 mm {3.25"} paper width model>

0.141mm

1mm

1mm

640 dots

80mm(dot #1-#640)

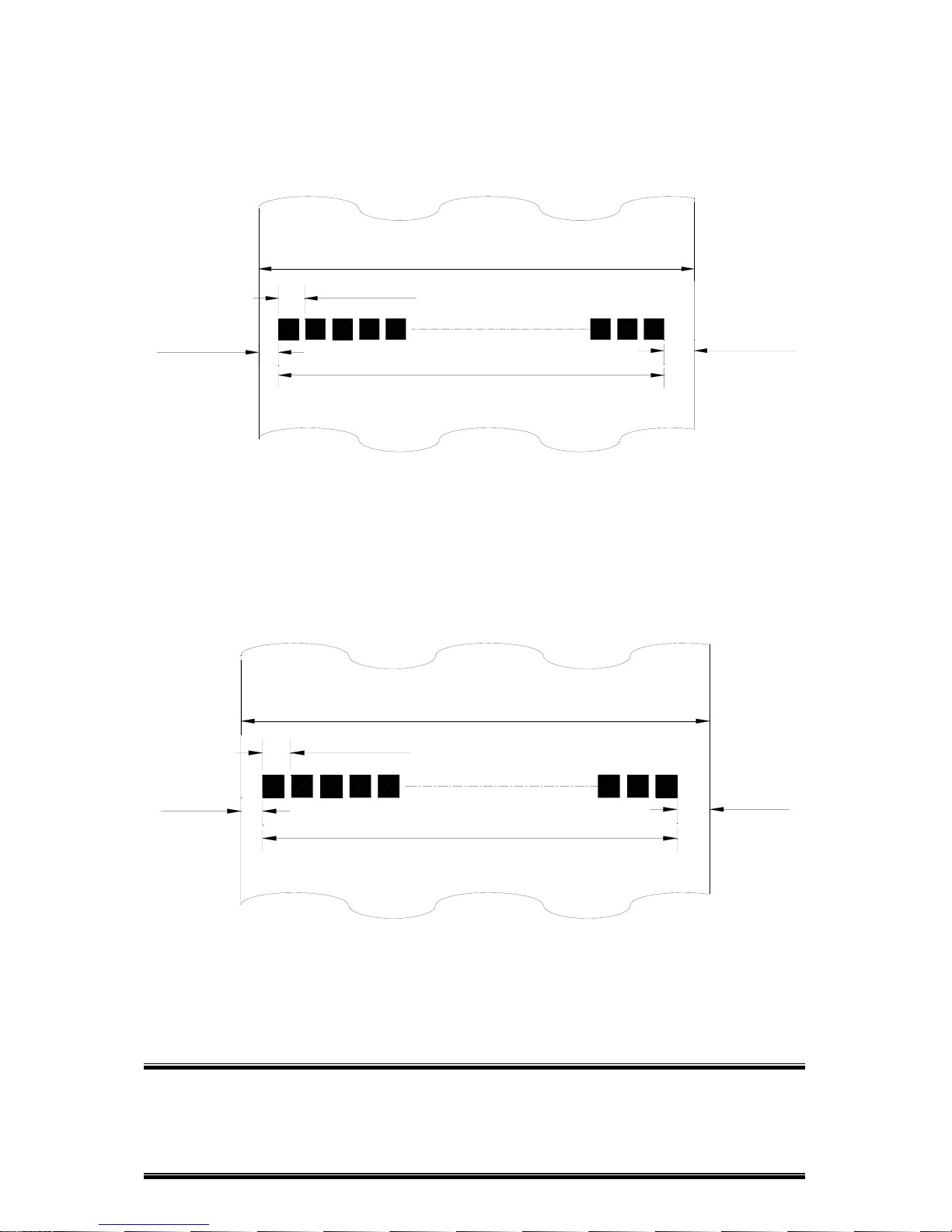

Page 9

TITLE : RP-300/310

Page -8 -

4.85mm

0.141mm

79.5±0.5mm

<80mm {3.15"} paper width model>

2.65mm

576 dots

72mm(dot #1-#576)

59.5±0.5mm

<60mm {2.36"} paper width model>

0.125mm

2.65mm

2.35mm

420 dots

54.5mm(dot #1-#436)

Figure 1.6.3 Printable Area for STAR Emulation (When the Paper Width Is Changed)

NOTE : The numeric values used here are center values to be used in designing. The

printable area may be out of alignment by 2 mm maximum to the left or right, due to the

paper position or tolerance of parts.

Page 10

TITLE : RP-300/310

Page -9 -

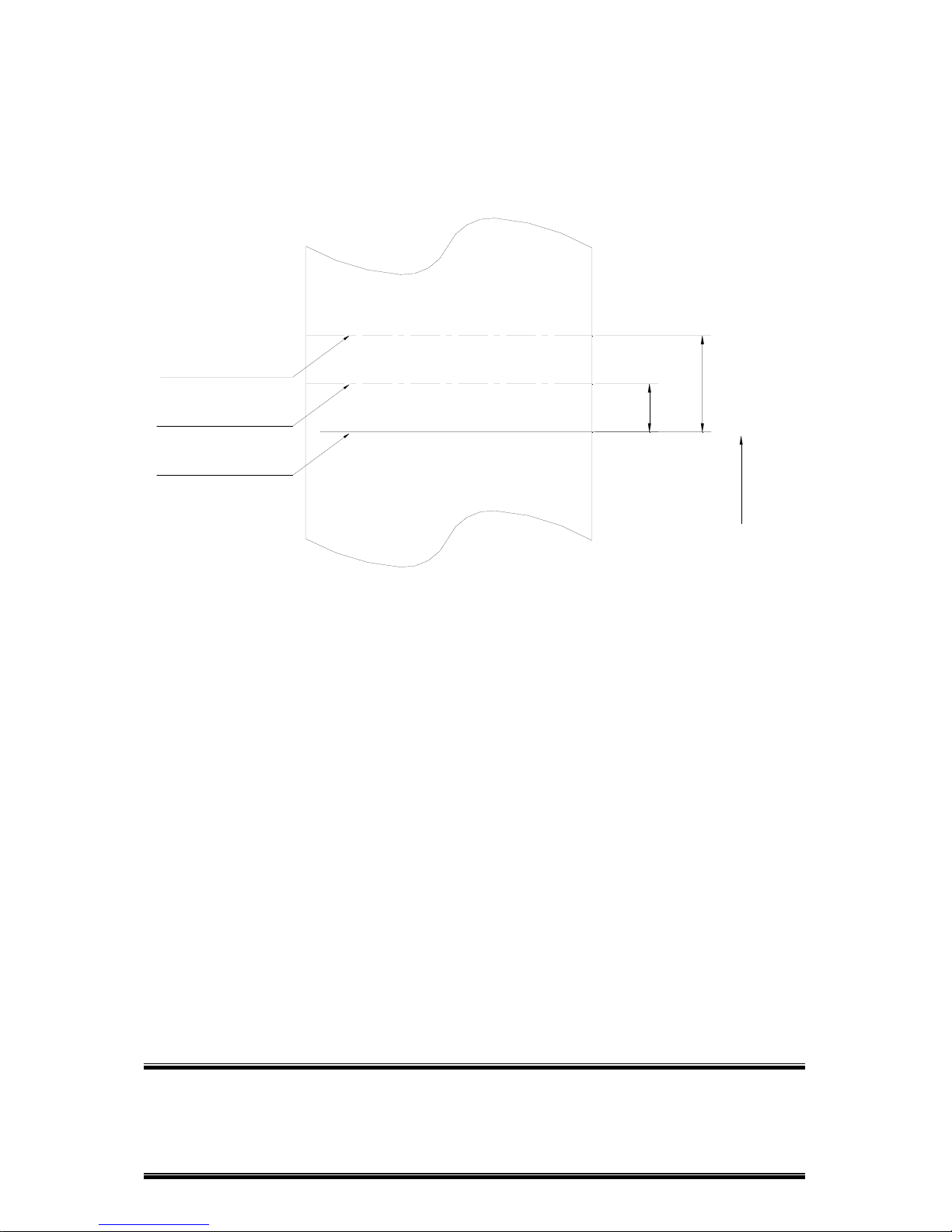

1.7 Printing and Cutting Positions

nter of the print dotline

o-cutter blade position

Manual-cutter position

[Units: mm(Al the numeric values are typical.)]

Appro *12.6

Paper feed direction

Appro *

30.5

Figure 1.7.1 Printing and Cutting Positions

NOTE: Numeric values used here are center values to be used in designing. The values may

vary slightly as a result of paper slack or variations in the paper. Take this into account

when setting the cutting position of the auto cutter.

Page 11

TITLE : RP-300/310

Page -10 -

1.8 Internal Buffer

1) Receive buffer: 4kbyte

1.9 Electrical Characteristics

1) Supply voltage: +24 VDC ± 7%

2) Current consumption (at 24V):

Operating: Approx. 1.5A(at ASCII Printing)

Peak:Approx. 10A(at print duty 100%, For 10 seconds or less)

Stand-by: Approx. 0.15A

1.10 EMI and Safety Standards Applied

1) Europe: EMI – EN55022 CLASS A

EMS – EN61000-3-2, EN61000-3-3, EN50082-1

Safety Standard: EN60950

2) North America: EMI - FCC Part#15 Class A

Safety Standards- UL(1950), c-UL(No.950)

1.11 Reliability

1) MCBF: 50 million lines

(based on an average printing rate of 12.5% with paper thickness

in the range 65 ㎛ to 75 ㎛).

35 million lines

(based on an average printing rate of 12.5% with paper thickness

in the range 76 ㎛ to 150 ㎛)

2) Cutter Life: 1.0 million cuttings

(if the paper thickness is between 65 and 100㎛)

1.12 Environmental Conditions

1) Temperature: Operating: 5° to 45°C

Storage: -20° to 60°C

(except for paper)

2) Humidity: Operating: 10 to 90%RH

Storage: 10 to 90%RH (except for paper)

Page 12

TITLE : RP-300/310

Page -11 -

2. Configuration

2.1 Interface

2.1.1 RS-232 serial interface

2.1.2 Specifications

Data transmission: Serial

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control

Signal levels: MARK= -3 to – 15V: Logic “ 1”

SPACE= +3 to +15V: Logic “ 0”

Baud rage: 4800, 9600, 19200, 38400 bps

Data word length: 7 or 8 bits

Parity Settings: None, even, odd

Stop bits: 1 or more

Connector (printer side): Female DSUB-25 pin connector

NOTE: The data word length, baud rate, and parity depend on the

DIP switch settings.

2.1.3 Switching between on-line and off-line

The printer does not have an on-line/off-line switch.

The printer goes off-line:

• Between when the power is turned on (including reset using the

interface) and when the printer is ready to receive data.

• During the self-test.

• When the cover is open.

• During paper feeding using the paper feed button.

• When the printer stops printing due to a paper-end (in cases when

an empty paper supply is detected by either paper roll end detector or

the paper roll near-end detector with a printing halt feature by

ESC c4).

• During macro executing stand by status.

• When a temporary abnormality occurs in the power supply voltage.

• When an error has occurred.

2.1.4 Interface connector terminal assignments and signal functions

PIN SIGNAL I/O DESCRIPTION

2 TXD - Printer transmit data line RS-232C level

3 RXD - Printer receive data line RS-232C level

4, 20 DTR Output Printer handshake to host line RS-232C level

6 DSR Input Data Send Ready

1,7 GND - System Ground

Page 13

TITLE : RP-300/310

Page -12 -

2.1.5 Serial interface connection example

Host side Printer side

TXD ………………………………… RXD

DSR ………………………………… DTR

RXD ………………………………… TXD

DTR ………………………………… DSR

FG ………………………………… FG

SG ………………………………… SG

DETAILS: ◦ Set the handshaking so that the transmit data can be

received.

◦ Transmit data to the printer after turning on the power and

initializing the printer.

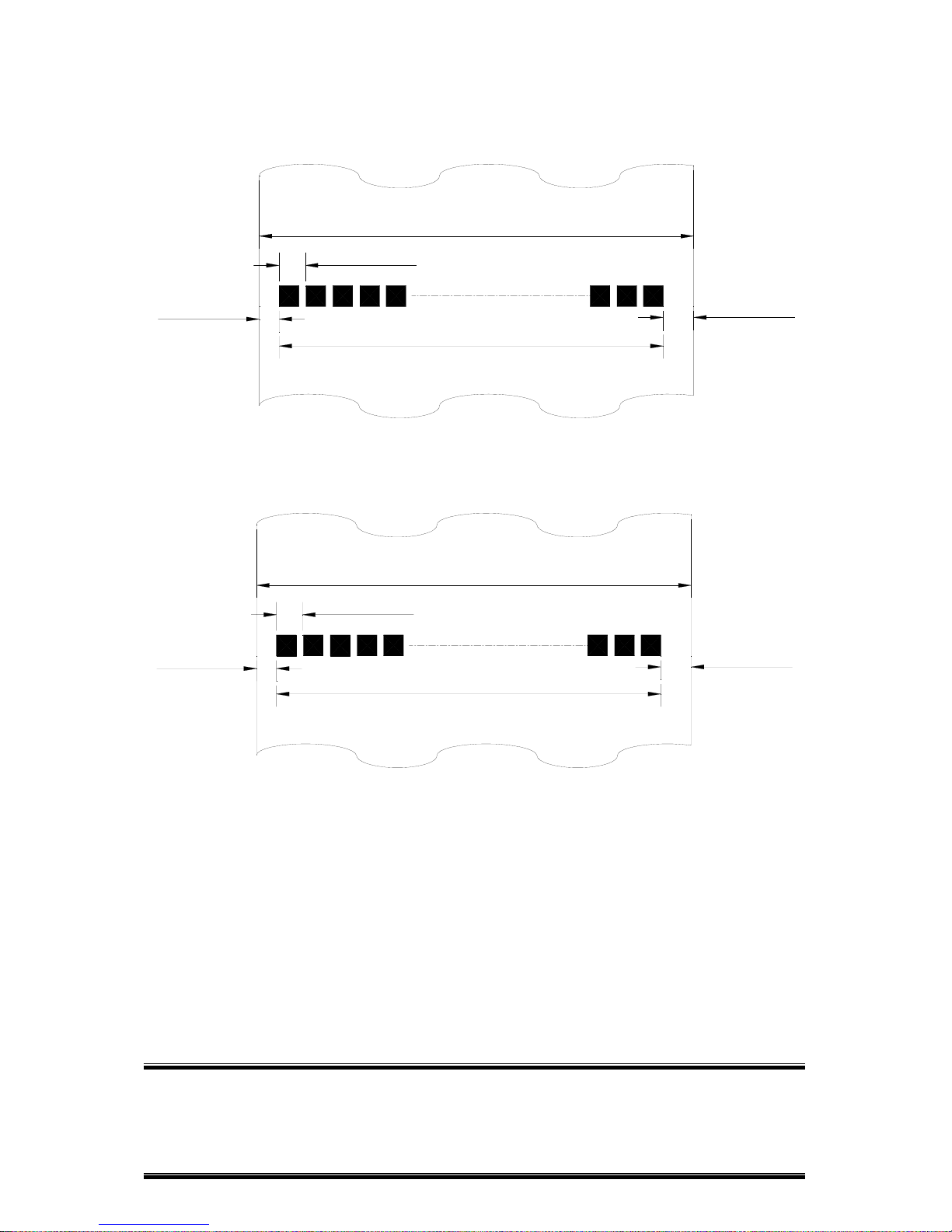

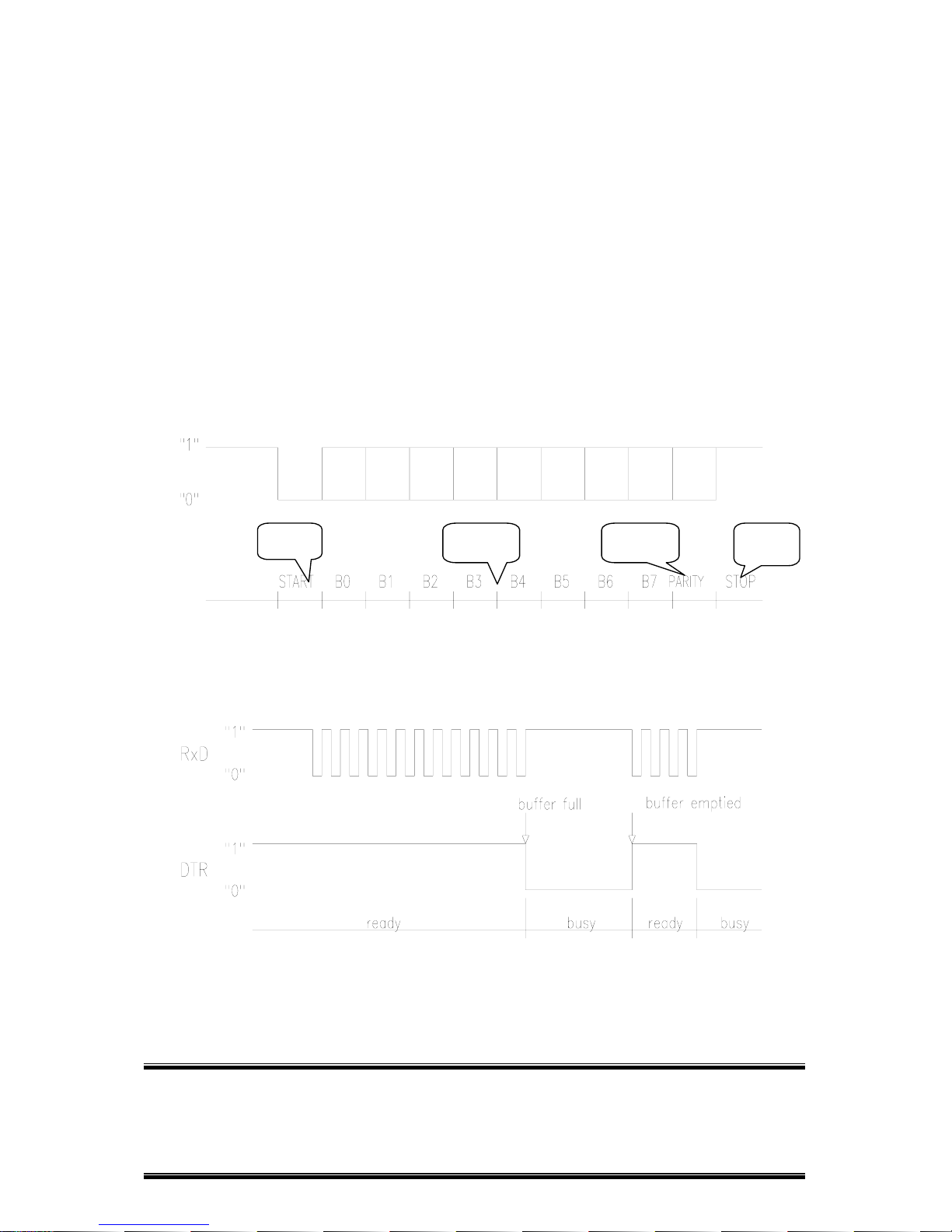

< Figure 2.1 Serial transmission bit frame >

< Figure 2.2 Line transmission with protocol >

7 or 8

Bi

t

N

one or

1 Bi

t

1 or 2

Bit

Page 14

TITLE : RP-300/310

Page -13 -

2.1.6 Centronics parallel interface

1) Specifications

Data transmission: 8-bit parallel

Synchronization: STROBE pulse supplied by host computer.

Handshaking: ACK and BUSY

Connector: D-SUB 36(female) or equivalent

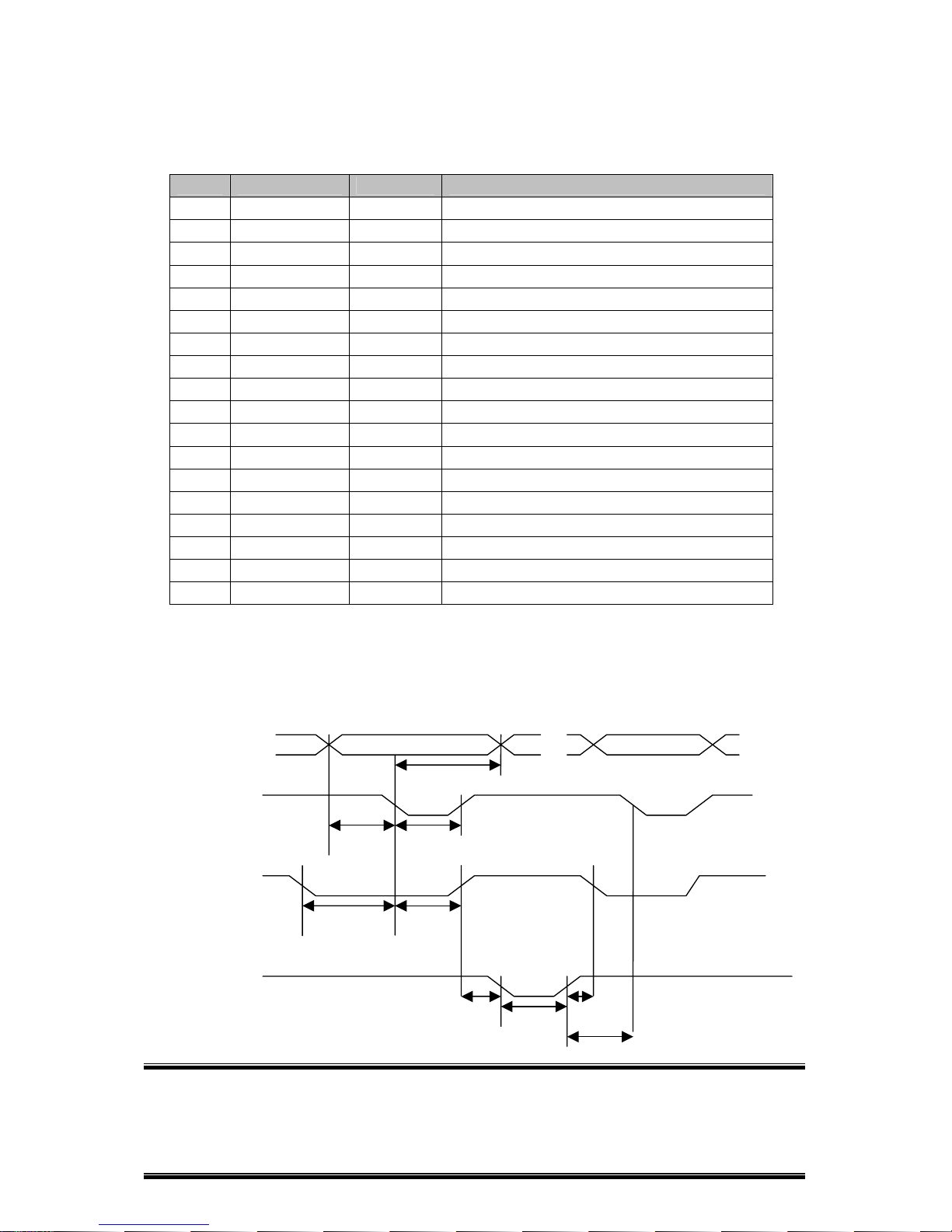

DATA Data n Data n+1

tHold

nStrobe

tSetup tSTB

Busy Peripheral Busy

tReady tBUSY

nAck

tReply tACK tnBUSY

PIN SIGNAL I/O DESCRIPTION

1 STROBE- Input Synchronize signal Data received

2-9 DATA0-7 Input Data bit Transmitted 0-7

10 ACK- Output Data receiving competed

11 BUSY Output Impossible to printer data receiving

12 PE Output Paper empty

13 SELECT Output Printer’ s status for ON/OFF line

14 AUTO FEED- Input ND

15 GROUND - System Ground

16 GROUND - System Ground

17 NC -

18 LOGIC-H - +5V

19-30 GROUND - System Ground

31 INIT- Input Initialize

32 ERROR- Output Printer Error

33 GROUND - System Ground

34 NC -

35 +5V - +5V

36 SELECT IN- Input ND

Page 15

TITLE : RP-300/310

Page -14 -

tNext

2.1.7 Data Receiving Timing (Compatibility Mode)

Specifications

Characteristics Symbol

Min [ns] Max [ns]

Data Hold Time (host) tHold 750 --

Data Setup Time tSetup 750 --

STROBE Pulse Width tSTB 750 --

READY Cycle Idle Time tReady 0 --

BUSY Output Delay Time tBUSY 0 500

Data Processing Time tReply 0

∝

ACKNLG Pulse Width tACK 500 10us

BUSY Release Time tnBUSY 0

∝

ACK Cycle Idle Time tNEXT 0 --

•The printer latches data at a nStrobe ↓ timing

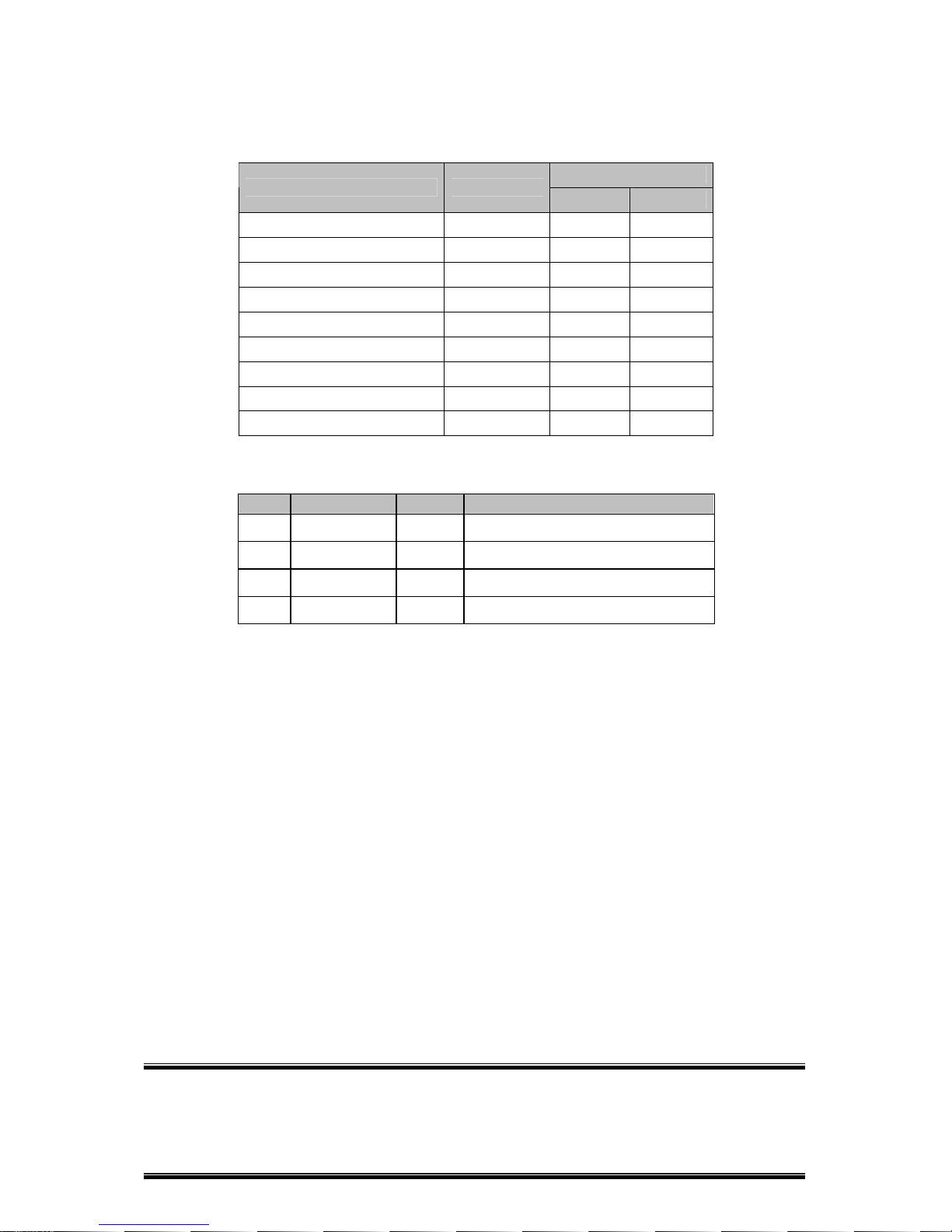

2.1.8 USB Interface

PIN SIGNAL I/O DESCRIPTION

1 +5V - +5V

2 DATA- - Printer transmit data line

3 DATA+ - Printer transmit data line

4 GND - System Ground

1) Specifications

Data transmission: USB 2.0

Connector: USB “ B” type connector

2) USB interface connection example

Host side Printer side

VCC ………………………………… VCC

DATA+ ……………………………… DATA+

DATA- ……………………………… DATA-

GND ………………………………… GND

Page 16

TITLE : RP-300/310

Page -15 -

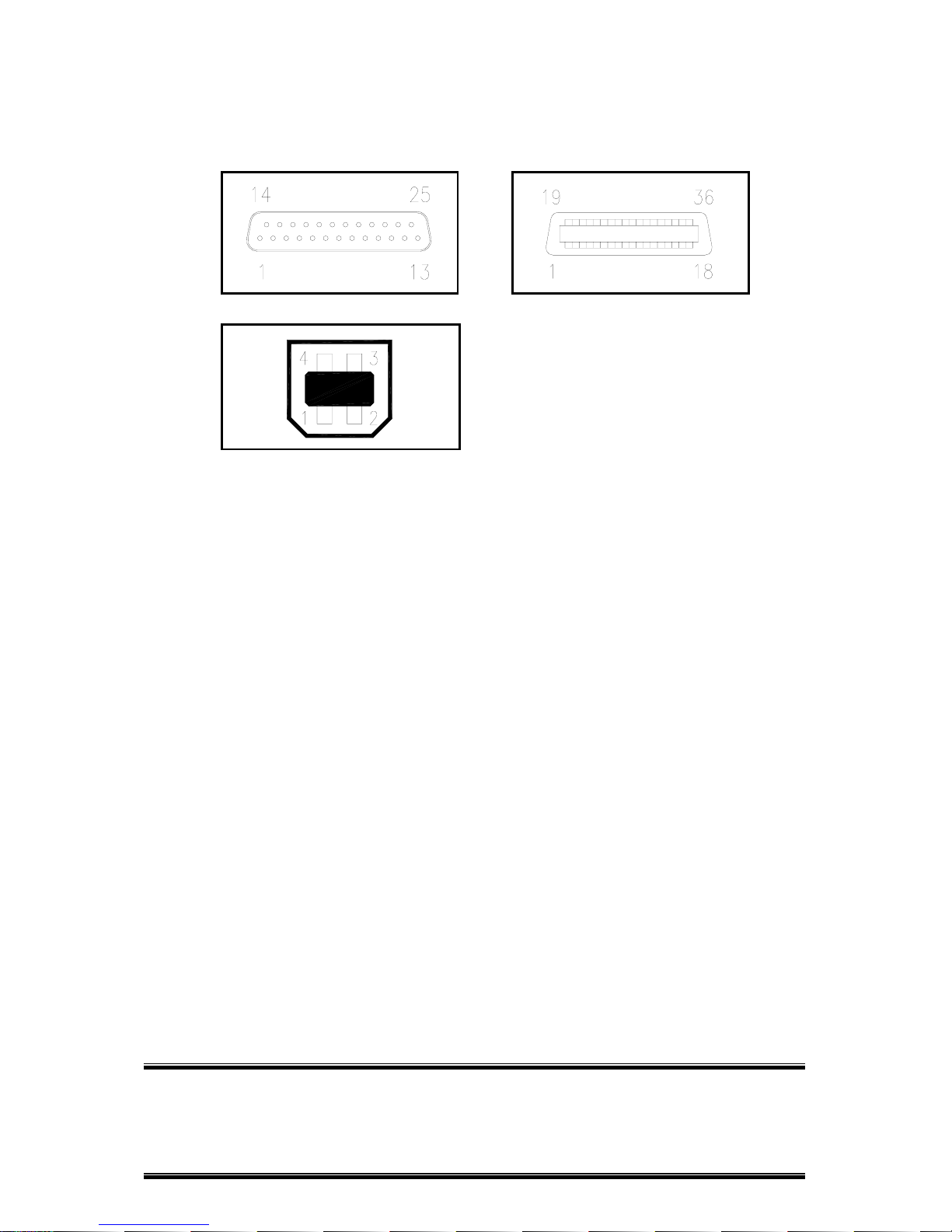

2.1.9 Interface Connector

<D-SUB 25 Female Serial Port> <D-SUB Centronics Parallel Port>

Page 17

TITLE : RP-300/310

Page -16 -

3. Connectors

3.1 Interface Connectors

Refer to Section 2.1, Interface

3.2 Electrical Characteristics

1) Input Voltage: DC 24V ± 10%

2) Current Consumption: Operating: Approx. 1.5 A (at ASC∥ printing)

Peak: Approx. 10 A (at print duty 100%, For 10 seconds or

less)

Stand-by: Approx. 0.15 A

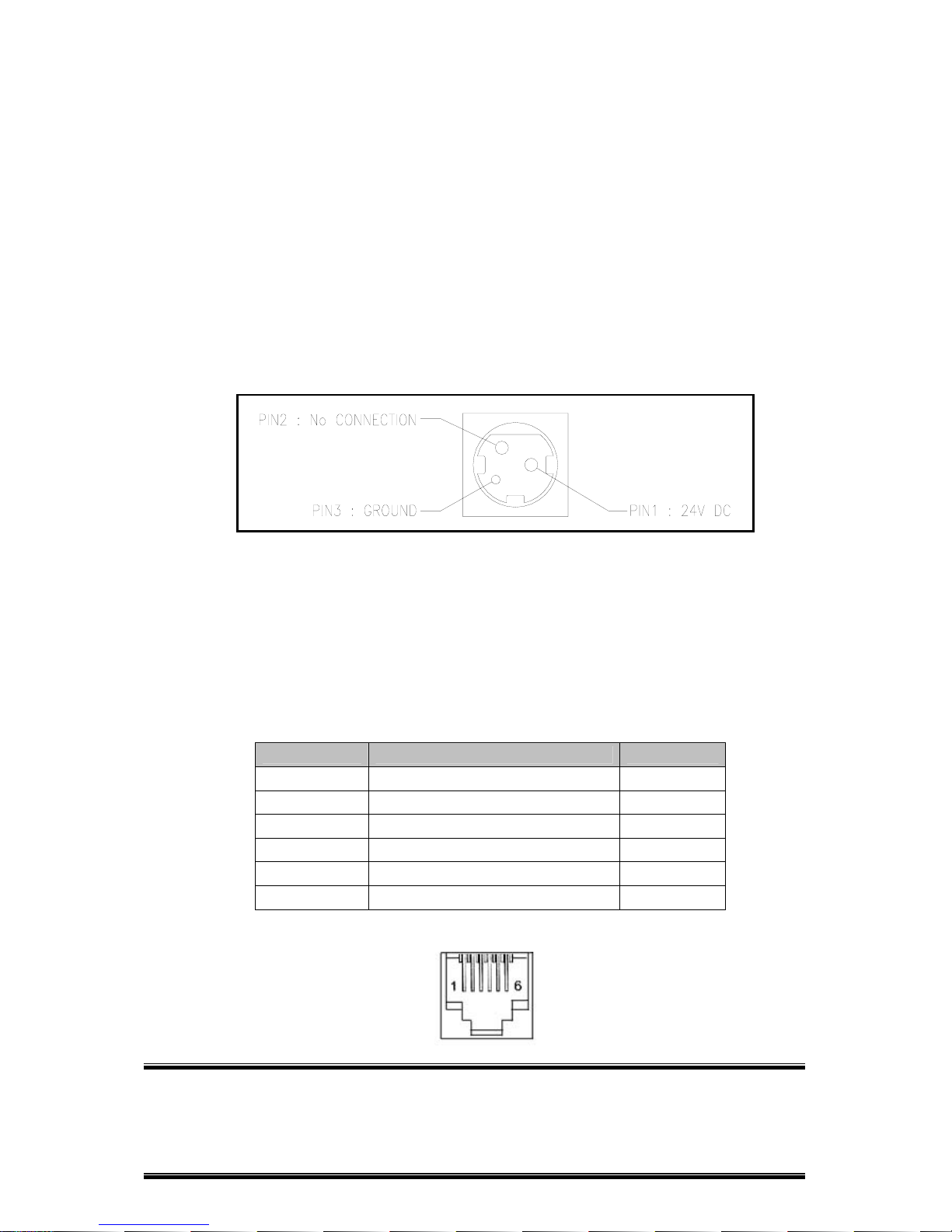

3) Power Connector

3.3 Drawer Kick-out Connector (Modular Connector)

The pulse specified by ESC p or DLE DC4 is output to this connector.

The host can confirm the status of the input signal by using the

DLE EOT, GS a, or GS r commands.

1) Pin assignments: Refer to Table 2.2.2

2) Connector model:

Printer side: DAEEUN DEK-623PCB-6-B or Equivalent

User side: 6-position 6-contact (RJ12telephone jack)

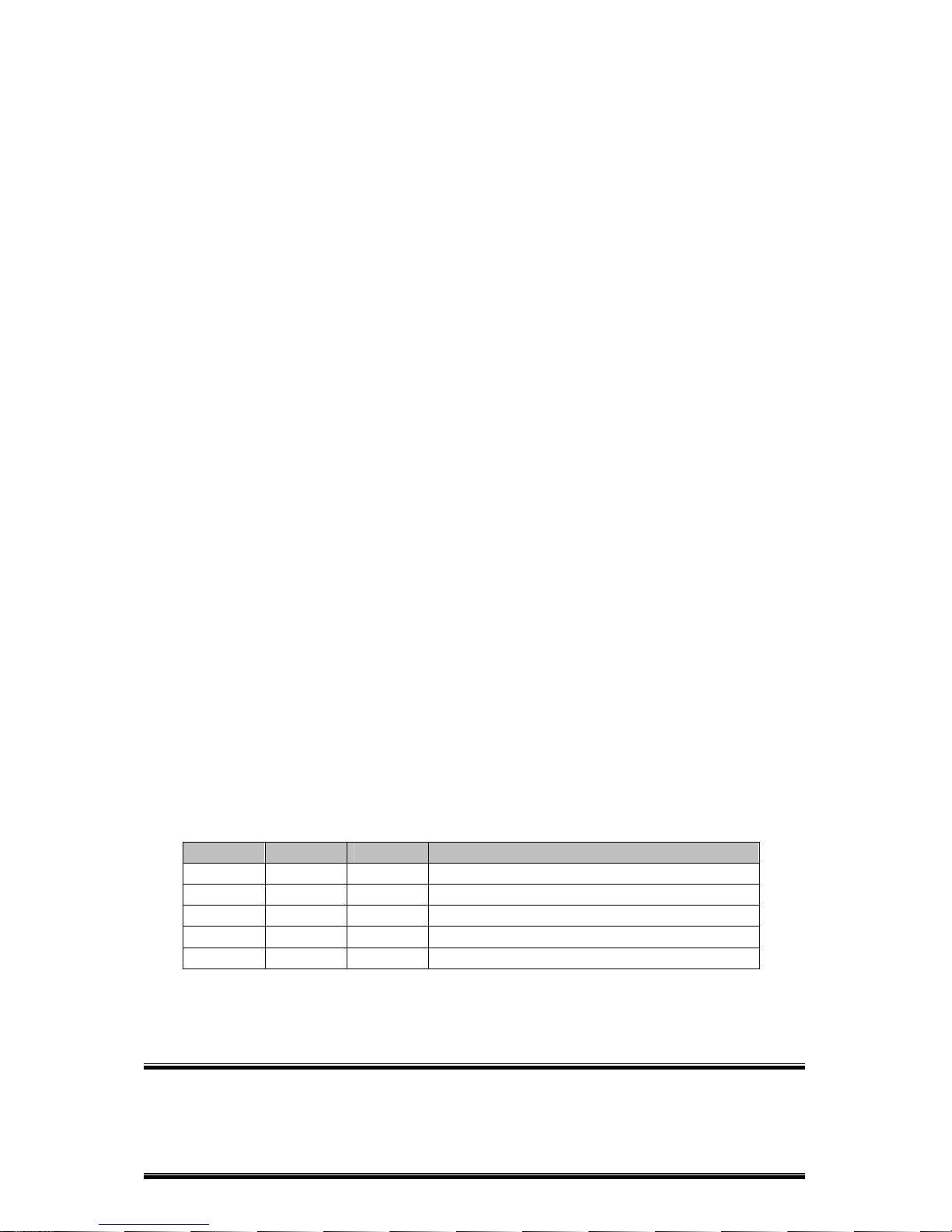

< Drawer Kick-out Connector Pin Assignments >

Pin Number Signal Name Direction

1 Frame GND -

2 Drawer kick-out drive signal 1 Output

3 Drawer open/close signal Input

4 +24V -

5 Drawer kick-out drive signal 2 Output

6 Signal GND -

+24V is output through pin 4 when the power is turned on. However, pin 4 must by

used only for the drawer.

Page 18

TITLE : RP-300/310

Page -17 -

< Figure 3.1 Drawer Kick-out Connector >

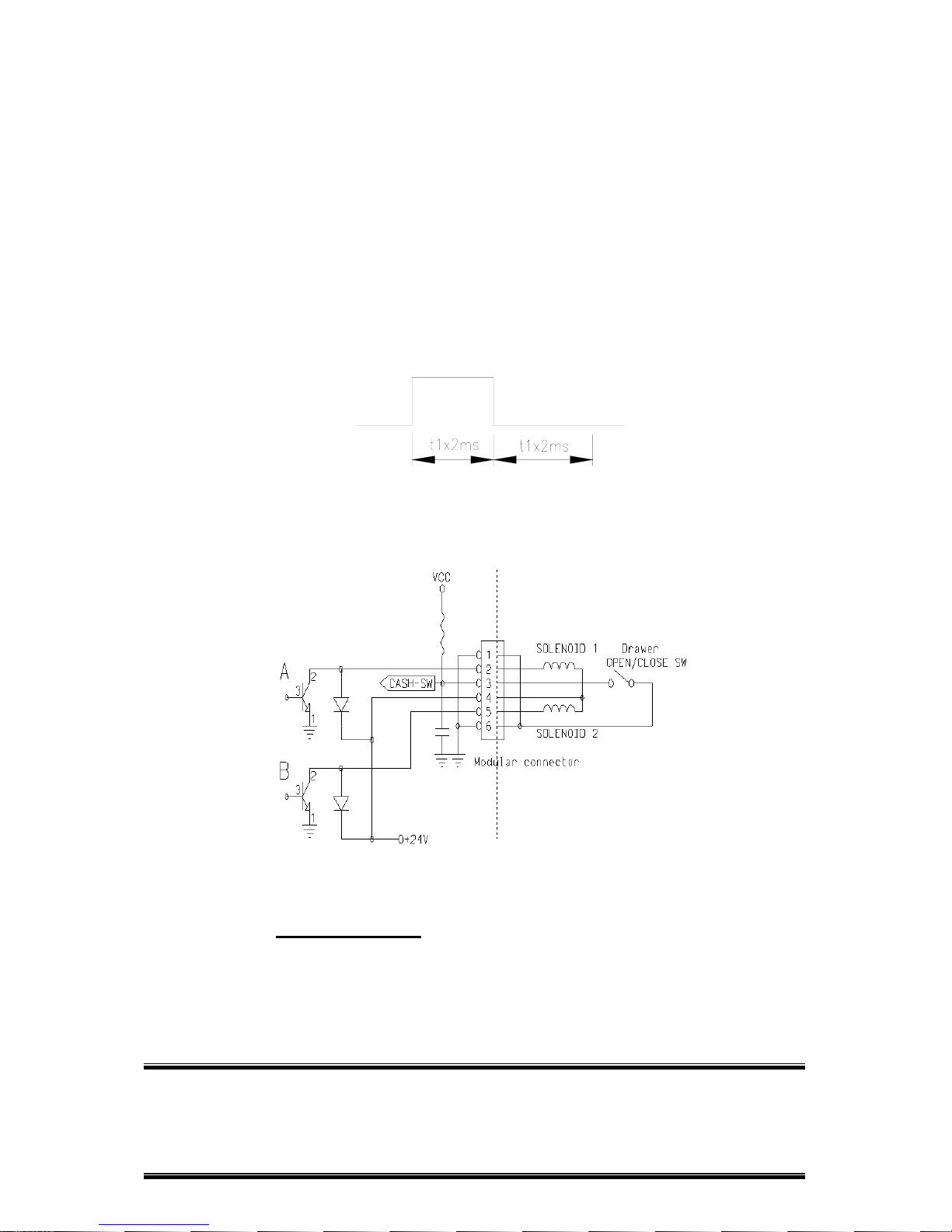

3) Drawer kick-out drive signal

Output signal: Output voltage: Approximately 24V

Output current: 1A or less

CAUTION: To avoid an overcurrent, the resistance of the drawer kick-out solenoid

must be 24 Ω or more.

Output waveform: Outputs the waveforms in Figure 3.2 to the points A and B

in Figure 3.3

t

1 (ON time) and t2 (OFF time) are specified by ESC p or

DLE DC4.

< Figure 3.2 Drawer Kick-out Drive Signal Output Waveform >

4) Drawer open/close signal

Input signal level (connector pin 3): “L”= 0 to 0.8V

“H”= 3 to 5V

< Figure 3.3 Drawer Circuitry >

NOTE: 1. Use a shielded cable for the drawer connector cable.

2. Two driver transistors cannot be energized simultaneously.

3. The drawer drive duty must by as shown below.

ON time

≤ 0.2

(ON time + OFF time)

4. Be sure to use the printer power supply (connector pin 4) for the drawer

power source.

5. The resistance of the drawer kick-out solenoid must not be less than the

specified. Otherwise, an overcurrent could damage the solenoid.

Page 19

TITLE : RP-300/310

Page -18 -

6. Do not connect telecommunication network to the drawer kick-out

connector.

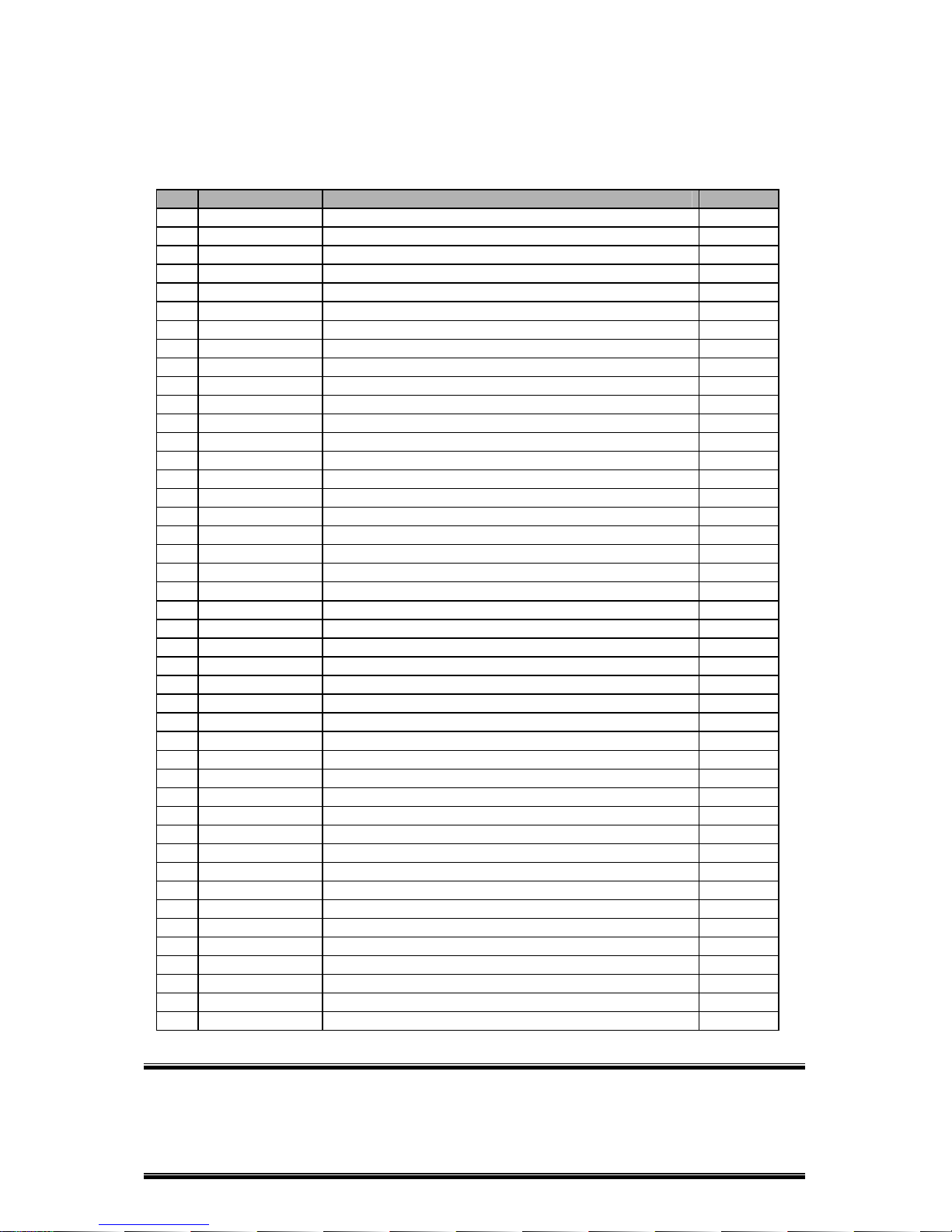

4 Controle Command summary

No. Command Function

1 HT Horizontal tab

2 LF Print and line feed

3 CR Print and carriage return

4 FF Print end position label to start printing

5 CAN Cancel print data in page mode

6 DLE EOT Real-time status transmission

7 DLE ENQ Real-time request to printer

8 DLE DC4 Generate pulse at real-time

9 ESC FF Print data in page mode

10 ESC SP Set character right-side spacing

11 ESC ! Set print mode

12 ESC $ Select/cancel user-defined character set

13 ESC % Define user-defined characters

14 ESC & Turn underline mode on/off

15 ESC * Set bit image mode

16 ESC - Turn underline mode on/off

17 ESC 2 Set 1/6 inch line spacing

18 ESC 3 Set line spacing using minimum units

19 ESC = Select peripheral device

20 ESC ? Cancel user-defined characters

21 ESC @ Initialize printer

22 ESC D Set horizontal tab positions

23 ESC E Select emphasized mode

24 ESC G Select double-strike mode

25 ESC J Print end feed paper using minimum units

26 ESC L Select page mode

27 ESC M Select character font

28 ESC R Select international character set

29 ESC S Select standard mode

30 ESC T Select print direction in page mode

31 ESC V Set/cancel 90° cw rotated character

32 ESC W Set printing area in page mode

33 ESC \ Set relative position

34 ESC a Align position

35 ESC c 3 Select paper sensor(s) to output paper-end signals

36 ESC c 4 Select paper sensor(s) to stop printing

37 ESC c 5 Enable/disable panel buttons

38 ESC d Print and feed paper n lines

39 ESC p General pulse

40 ESC t Select character code table

41 ESC { Set/cancel upside-down character printing

42 FS p Print NV bit image

43 FS q Define NV bit image

44 GS ! Select character size

Page 20

TITLE : RP-300/310

Page -19 -

45 GS $ Set absolute vertical print position in page mode

46 GS * Define downloaded bit image

47 GS / Print down-loaded bit image

48 GS : Start/end macro definition Not

avalible

49 GS B Turn white/black reverse printing mode on/off

50 GS H Select printing position of HRI characters

51 GS I Transmit printer ID

52 GS L Set left margin

53 GS P Set horizontal and vertical motion units

54 GS V Cut paper

55 GS W Set printing area width

56 GS \ Set relative vertical print position in page mode

57

GS ^

Execute macro Not

avalible

58 GS a Enable/disable Automatic Status Back(ASB)

59

GS b Turn smooting mode on/off

Not

avalible

60 GS f Select font for HRI characters

61 GS h Set bar code height

62 GS k Print bar code

63 GS r Transmit status

64 GS v 0 Print raster bit image

65 GS w Set bar code width

< Add >

1 ESC i Full cut

2 ESC m Partial cut

Page 21

TITLE : RP-300/310

Page -20 -

Command Descriptions

Command Notation

[Name] The name of the control command.

[Format] The code sequence.

In this description, < > H denotes hexadecimal numbers, < >denotes

decimal numbers and < > B denotes binary numbers.

[ ] k indicates the contents of the [ ] should be repeated k times.

[Range] The allowable range for the arguments.

[Description] Description of the command function.

[Details] If necessary provides important information on setting and using the

printer

command.

[Default] The default values for the commands.

[Reference] List related commands.

[Example] Example of using the commands.

The numbers denoted by <>H is hexadecimal.

The numbers denoted by <>B is binary.

Page 22

TITLE : RP-300/310

Page -21 -

Print Commands

The WTP series supports the following commands for printing characters and advancing

paper.

HT

[Name] Horizontal tab

[Format] ASCII HT

Hex 09

Decimal 9

[Description] Moves the print position to the next tab position.

[Details] ·This command is ignored unless the next tab position has been set.

·If the next horizontal tab position exceeds the printing area, the printer

sets the printing position to [Printing area width + 1].

·Horizontal tab positions are set using “ ESC D” .

·If this command is received when the printing position is at [printing area

width +1], the printer executes print buffer-full printing of the current

line and horizontal tab processing from the beginning of the next line.

·The default setting of the horizontal tab position for the paper roll is font

A

(12 x 24) every 8th character (9th, 17th, 25th, … column).

[Reference] ESC D

LF

[Name] Print and line feed

[Format] ASCII LF

Hex 0A

Decimal 10

[Description] ·Prints the data in the print buffer and feeds one line based on the current

line spacing.

[Details] ·This command sets the print position to the beginning of the line.

[Reference] ESC 2, ESC 3

Page 23

TITLE : RP-300/310

Page -22 -

CR

[Name] Print and carriage return.

[Format] ASCII CR

Hex 0D

Decimal 13

[Description] When automatic line feed is enabled, this command functions the same

as LF; when automatic line feed is disabled, this command is ignored.

[Details] ·Sets the print starting position to the beginning of the line.

·The automatic line feed is ignored.

[Reference] LF

FF

[Name] Print and return to standard mode in page mode.

[Format] ASCII FF

Hex 0C

Decimal 12

[Description] Prints the data in the print buffer and returns to standard mode.

[Details] ·The buffer data is deleted after being printed.

·The printing area set by ESC W is reset to the default setting.

·The printer does not execute paper cutting.

·This command sets the print position to the beginning of the line.

·This command is enabled only in page mode.

[Reference] ESC FF, ESC L, ESC S

CAN

[Name] Cancel print data in page mode

[Format] ASCII CAN

Hex 18

Decimal 24

Page 24

TITLE : RP-300/310

Page -23 -

[Description] In page mode, delete all the print data in the current printable area.

[Details] ·This command is enabled only in page mode.

·If data that existed in the previously specified printable area also exists in

the currently specified printable area, it is deleted.

[Reference] ESC L, ESC W

DLE EOT n

[Name] Real-time status transmission.

[Format] ASCII DLE EOT

n

Hex 10 04

n

Decimal 16 4

n

[Range] 1≤n≤4

[Description] Transmits the selected printer status specified by n in real-time,

according to the following parameters:

n

=1 : Transmit printer status

n

=2 : Transmit off-line status

n

=3 : Transmit error status

n

=4 : Transmit paper roll sensor status

[Details] ·The printer transmits the current status. Each status is represented by

one-byte data.

·The printer transmits the status without confirming whether the host

computer can receive data.

·The printer executes this command upon receiving it.

·This command is executed even when the printer is offline, the receive

buffer is full, or there is an error status.

·When Auto Status Back (ASB) is enabled using the GS a command, the

status transmitted by the DLE EOT command and the ASB status must

be differentiated.

·Even though the printer is not selected using ESC = (select peripheral

device), this command is effective.

[Notes] ·The status is transmitted whenever the data sequence of

<10>H<04>H<n> (1≤ n≤ 4) is received.

Example :

In ESC *

m nL nH d1…dk

d1=<10>H, d2=<04>H, d3=<01>H

·This command should not be used within the data sequence of another

command that consists of 2 or more bytes.

Page 25

TITLE : RP-300/310

Page -24 -

Example :

If you attempt to transmit ESC 3

n

to the printer, but DTR (DSR for

the host computer) goes to MARK before

n

is transmitted and then

DLE EOT 3 interrupts before

n

is received, the code <10> H for DLE

EOT 3 is processed as the code for ESC 3 <10>H.

n

= 1: Printer status

Bit Off/On Hex Decimal Function

0 Off 00 0 Not used. Fixed to Off

1 On 02 2 Not used. Fixed to On

Off 00 0 Drawer open/close signal is LOW (connector pin 3). 2

On 04 4 Drawer open/close signal is HIGH (connector pin 3).

Off 00 0 On-line 3

On 08 8 Off-line.

4 On 10 16 Not used. Fixed to On

5,6 - - - Undefined.

7 Off 00 0 Not used. Fixed to Off.

n

= 2: Off-line status

Bit Off/On Hex Decimal Function

0 Off 00 0 Not used. Fixed to Off

1 On 02 2 Not used. Fixed to On

Off 00 0 Cover is closed 2

On 04 4 Cover is open

Off 00 0 Paper is not being fed by using the FEED button 3

On 08 8 Paper is being fed by the FEED button

4 On 10 16 Not used. Fixed to On

Off 00 0 No paper-end stop 5

On 20 32 Printing is being stopped

Off 00 0 No error 6

On 40 64 Error occurs

7 Off 00 0 Not used. Fixed to Off

Bit 5: Becomes on when the paper end sensor detects paper end and printing stops.

n

= 3: Error status

Bit Off/On Hex Decimal Function

0 Off 00 0 Not used. Fixed to Off

1 On 02 2 Not used. Fixed to On

2 - - - Undefined

Off 00 0 No auto-cutter error 3

On 08 8 Auto-cutter error occurs

4 On 10 16 Not used. Fixed to On

Off 00 0 No unrecoverable error 5

On 20 32 Unrecoverable error occurs

Off 00 0 No auto-recoverable error 6

On 40 64 Auto recoverable error occurs

7 Off 00 0 Not used. Fixed to Off

Bit 3: If these errors occur due to paper jams or the like, it is possible to recover by

Page 26

TITLE : RP-300/310

Page -25 -

correcting the cause of the error and executing DLE ENQ n (1 ≤ n ≤ 2). If an error

due to a circuit failure (e.g. wire break) occurs, it is impossible to recover.

Bit 6: When printing is stopped due to high print head temperature until the print head

temperature drops sufficiently or when the paper roll cover is open during printing,

bit 6 is On.

n

= 4: Continuous paper sensor status

Bit Off/On Hex Decimal Function

0 Off 00 0 Not used. Fixed to Off

1 On 02 2 Not used. Fixed to On

Off 00 0 Paper roll near-end sensor: paper adequate 2,3

On 0C 12 Paper near-end is detected by the paper roll near-end

sensor.

4 On 10 16 Not used. Fixed to On

Off 00 0 Paper roll sensor: Paper present 5,6

On 60 96 Paper roll end detected by paper roll sensor

7 Off 00 0 Not used. Fixed to Off

[Reference] DLE ENQ, GS a, GS r

DLE ENQ n

[Name] Real-time request to printer

[Format] ASCII DLE ENQ n

Hex 10 05 n

Decimal 16 5 n

[Range] 1≤n≤2

[Description] Responds to a request from the host computer.

n

specifies the requests as follows:

n Request

1 Recover from an error and restart printing from the line where the error occurred

2 Recover from an error aft clearing the receive and print buffers

[Details] ·When the printer is disabled with ESC = (Select peripheral device), this

command is effective.

·This command is effective only when an auto-cutter error occurs.

·The printer starts processing data upon receiving this command.

·This command is executed even when the printer is offline, the receive

buffer is full, or there is an error status with a serial interface model.

·The status is also transmitted whenever the data sequence of

<10>H<05>H< n> (1≤ n≤ 2) is received.

Example:

In ESC * ** * m

nL nH dk, d1 = <10>H, d2 = <05>H, d3 = <01>H

·This command should not be contained within another command that

consists of two or more bytes.

Page 27

TITLE : RP-300/310

Page -26 -

Example:

If you attempt to transmit ESC 3 n to the printer, but DTR (DSR

for the host computer) goes to MARK before n is transmitted, and

DLE ENQ 2 interrupts before n is received, the code <10>H for

DLE ENQ 2 is processed as the code for ESC 3 <10>H.

[Reference] DLE EOT

DLE DC4

n m t

[Name] Generate pulse at real-time

[Format] ASCII DLE DC4 n m t

Hex 10 14 n m t

Decimal 16 20 n m t

[Range] n=1

m=0,1

1≤ t≤ 8

[Description] Outputs the pulse specified by t to connector pin m as follows:

m Connector pin

0 Drawer kick-out connector pin 2.

1 Drawer kick-out connector pin 5.

The pulse ON time is [ t x 100 ms] and the OFF time is [ t x 100 ms].

[Details] ·When the printer is in an error status when this command is processed,

this command is ignored.

·When the pulse is output to the connector pin specified while ESC p or

DEL DC4 is executed while this command is processed, this command is

ignored.

·The printer executes this command upon receiving it.

·This command is executed even when the printer is off-line, the receive

buffer is full, or there is an error status.

·If print data includes the same character strings as this command, the

printer performs the same operation specified by this command. The user

must consider this.

·This command should not be used within the data sequence of another

command that consists of 2 or more bytes.

·This command is effective even when the printer is disabled with ESC =

(Select peripheral device).

[Reference] ESC p

Page 28

TITLE : RP-300/310

Page -27 -

ESC FF

[Name] Print data in page mode

[Format] ASCII ESC FF

Hex 1B 0C

Decimal 27 12

[Description] In page mode, prints all buffered data in the printable area collectively.

[Details] ·This command is enabled only in page mode.

·After printing, the printer does not clear the buffered data, setting value

for ESC T and ESC W, and the position for buffering character data.

[Reference] FF, ESC L, ESC S

ESC SP n

[Name] Set right-side character spacing

[Format] ASCII ESC SP

n

Hex 1B 20

n

Decimal 27 32

n

[Range] 0≤n ≤ 255

[Description] Sets the character spacing for the right side of the character to

[

n

x horizontal or vertical motion units].

[Details] ·The right-side character spacing for double-width mode is twice the

normal value. When characters are enlarged, the right-side character

spacing is

n

times normal value.

·This command does not affect the setting of Kanji characters.

·This command sets values independently in each mode (standard and

page modes).

·The horizontal and vertical motion units are specified by GS P.

Changing the horizontal or vertical motion units does not affect the

current right-side spacing.

Page 29

TITLE : RP-300/310

Page -28 -

·The GS P command can change the horizontal (and vertical) motion unit.

However, the value cannot be less than the minimum horizontal

movement amount, and it must be in even units of the minimum

horizontal movement amount.

·In standard mode, the horizontal motion unit is used.

·In page mode, the horizontal or vertical motion unit differs in page mode,

depending on starting position of the printable area as follows:

①When the starting position is set to the upper left or lower right of the

printable area using ESC T, the horizontal motion unit (x) is used.

②When the starting position is set to the upper right or lower left of the

printable area using ESC T, the vertical motion unit (y) is used.

·The maximum right-side spacing is 35.983 mm {255/180” }. Any setting

exceeding the maximum is converted to the maximum automatically.

[Default]

n

= 0

[Reference] GS P

ESC ! n

[Name] Select print mode(s)

[Format] ASCII ESC !

n

Hex 1B 21

n

Decimal 27 33

n

[Range]

0≤

n

≤ 255

[Description] Selects print mode(s) using

n

as follows:

Bit Off/On Hex Decimal Function

Off 00 0 Character font A (12x24) 0

On 01 1 Character font B (9x24)

1 - - - Undefined.

2 - - - Undefined.

Off 00 0 Emphasized mode not selected. 3

On 08 8 Emphasized mode selected.

Off 00 0 Double-height mode not selected. 4

On 10 16 Double-height mode selected.

Off 00 0 Double-width mode not selected. 5

On 20 32 Double-width mode selected.

6 - - - Undefined.

Off 00 0 Underline mode not selected. 7

On 80 128 Underline mode selected.

Page 30

TITLE : RP-300/310

Page -29 -

[Details] ·When both double-height and double-width modes are selected,

quadruple size characters are printed.

·The printer can underline all characters, but can not underline the space

set by HT or 90° clockwise rotated characters.

·The thickness of the underline is selected by ESC-, regardless of the

character size.

·When some characters in a line are double or more height, all the

characters on the line are aligned at the baseline.

·ESC E Can also turn on or off emphasized mode. However, the setting of

the last received command is effective.

·ESC - Can also turn on or off underline mode. However, the setting of

the last received command effective.

·GS ! Can also select character size, However, the setting of the last

received command is effective.

·Emphasized mode is effective for alphanumeric and Kanji. All print

modes except emphasized mode is effective only for alphanumeric.

[Default]

n

= 0

[Reference] ESC E, ESC -, GS !

ESC $

nL n

H

[Name] Set absolute print position

[Format] ASCII ESC $

nL n

H

Hex 1B 24

nL n

H

Decimal 27 36

nL n

H

[Range] 0≤

nL

≤ 255

0≤

nH

≤ 255

[Description] Sets the distance from the beginning of the line to the position at which

subsequent characters are to be printed.

[Details] ·The distance from the beginning of the line to the print position is

[(

n

L

+

n

H

x 256) x (vertical or horizontal motion unit)] inches.

·Settings outside the specified printable area are ignored.

·The horizontal and vertical motion units are specified by “ GS P” .

·The GS P command can change the horizontal (and vertical) motion unit.

However, the value cannot be less than the minimum horizontal

movement amount, and it must be in even units of the minimum

horizontal movement amount. In standard mode, the horizontal motion

Page 31

TITLE : RP-300/310

Page -30 -

unit is used.

·In page mode, the horizontal or vertical motion unit differs depending on

the starting position of the printable area as follows :

1. When the starting position is set to the upper left or lower right of

the printable area using ESC T, the horizontal motion unit (x) is

used.

2. When the starting position is set to the upper right or lower left of

the printable area using ESC T, the vertical motion unit (y) is used.

[Reference] ESC \, GS $, GS \, GS P

ESC % n

[Name] Select/cancel user-defined character set

[Format] ASCII ESC %

n

Hex 1B 25

n

Decimal 27 37

n

[Range] 0≤

n

≤ 255

[Description] Selects or cancels the user-defined character set

·When the LSB of n is 0, the user-defined character set is canceled.

·When the LSB of n is 1, the user-defined character set is selected.

[Details] ·When the user-defined character set is canceled, the internal character

set is automatically selected.

·

n

is available only for the least significant bit.

[Default] n = 0

[Reference] ESC &, ESC ?

ESC & y c1 c2 [x1 d1…d(y x x1)]..[ xk d1..d(y x xk)]

[Name] Define user-defined characters

[Format] ASCII ESC & y c1 c2

[x1 d1...d(y × x1)]...[xk d1...d(y × xk)]

Hex 1B 26 y c1 c2

[x1 d1...d(y × x1)]...[xk d1...d(y × xk)]

Decimal 27 38 y c1 c2

[x1 d1...d(y × x1)]...[xk d1...d(y × xk)]

[Range]

y

= 3

32

≤

c1

≤ c2 ≤ 126

0

≤ x ≤ 12 Font A (when font A (12 x 24) is selected)

0

≤ x ≤ 9 Font B (when font B (9 x 17) is selected)

0

≤ d1 ... d(

y

x xk) ≤ 255

[Description] Defines user-defined characters

·y specifies the number of bytes in the vertical direction.

Page 32

TITLE : RP-300/310

Page -31 -

·c1 specifies the beginning character code for the definition, and c2

specifies the final code.

·X specifies the number of dots in the horizontal direction.

[Details] ·The allowable character code range is from ASCII code <20>H to

<7E>(95characters).

·It is possible to define multiple characters for consecutive character

codes.

·If only one character is desired, use c1 = c2.

·d is the dot data for the characters. The dot pattern is in the horizontal

direction from the left side. Any remaining dots on the right side are

blank.

·The data to define a user-defined character is (y × x) bytes.

·Set a corresponding bit to 1 to print a dot or 0 to not print a dot.

·This command can define different user-defined character patterns by

each fonts. To select a font, use ESC !

·A user-defined character and a downloaded bit image cannot be defined

simultaneously. When this command is executed, the downloaded bit

image is cleared.

·The user-defined character definition is cleared when:

① ESC @ is executed.

② ESC ? is executed.

③ FS q is executed.

④ GS * is executed.

⑤ The printer is reset or the power is turned off.

·When the user-defined characters are defined in font B (9 x 24), only the

most significant bit of the 3rd byte of data in vertical direction is

effective.

Page 33

TITLE : RP-300/310

Page -32 -

Page 34

TITLE : RP-300/310

Page -33 -

ESC *

m nL n

H

[

d1...dk]

[Name] Select bit-image mode

[Format] ASCII ESC *

m nL n

H

d1...dk

Hex 1B 2A

m nL n

H

d1...dk

Decimal 27 42

m nL n

H

d1...dk

[Range]

m =

0, 1, 32, 33

0≤

n

L

≤ 255

0≤

n

H

≤3

0≤

d

≤ 255

Page 35

TITLE : RP-300/310

Page -34 -

[Description] Selects a bit-image mode using m for the number of dots specified by nL

and

nH

, as follows:

Vertical Direction Horizontal Direction

m

Mode

NO. of Dots Dot Density Dot Density Number of (Data(K)

0 8-dot single-density 8 60 DPI 90 DPI

nL + nH x 256

1 8-dot double-density 8 60 DPI 180 DPI

nL + nH x 256

32 24-dot single-density 24 180 DPI 90 DPI (

nL + nH x 256) x 3

33 24-dot double-density 24 180 DPI 180 DPI

(nL + nH x 256) x 3

[dpi : dots per 25.4 mm{1” }]

[Details] ·If the values of m is out of the specified range, nL and data following are

processed as normal data.

·The

nL

and nH indicate the number of dots of the bit image in the

horizontal direction. The number of dots is calculated

by nL + nH x 256

.

·If the bit-image data input exceeds the number of dots to be printed on a

line, the excess data is ignored.

·

d

indicates the bit-image data. Set a corresponding bit of 1 to print a dot

or to 0 to not print a dot.

·If the width of the printing area set by GS L and GS W less than the width

required by the data sent with the ESC *command the following will be

performed on the line in question (but the printing cannot exceed the

maximum printable area) :

① The width of the printing area is extended to the right to

accommodate the amount of data.

② If step ① does not provide sufficient width for the data, the left

margin is reduced to accommodate the data.

·After printing a bit image, the printer returns to normal data processing

mode.

·This command is not affected by print modes(emphasized, double-strike,

underline, character size or white/black reverse printing), except

upside-down printing mode.

·Refer to Figure 3.12.3 for the bit image development position in page

mode.

·The relationship between the image data and the dots to be printed is as

follows:

·When 8-dot bit image is selected:

Page 36

TITLE : RP-300/310

Page -35 -

ESC - n

[Name] Turn underline mode on/off

[Format] ASCII ESC -

n

Hex 1B 2D

n

Decimal 27 45

n

[Range] 0≤n ≤ 2, 48≤n ≤ 50

[Description] Turns underline mode on or off, based on the following values of

n

.

n

Function

0, 48 Turns off underline mode

1, 49 Turns on underline mode (1-dot thick)

2, 50 Turns on underline mode (2-dots thick)

[Details] ·The printer can underline all characters (including right-side character

spacing), but cannot underline the space set by HT.

·The printer cannot underline 90˚ clockwise rotated characters and

white/black inverted characters.

·When underline mode id turned off by setting the value of

n

to 0 or 48,

the following data is not underlined, and the underline thickness set

before the mode is turned off does not change. The default underline

thickness is 1 dot.

·Changing the character size does not affect the current underline

thickness.

·Underline mode can also be turned on or off by using ESC!. Note,

however, that the last received command is effective.

·This command does not affect Kanji printing.

[Default]

n

= 0

[Reference] ESC !

ESC 2

[Name] Select default line spacing

[Format] ASCII ESC 2

Hex 1B 32

Decimal 27 50

[Description] Selects approximately 4.23 mm {1/6” } spacing.

[Details] ·The line spacing can be set independently in standard mode and in

page mode.

Page 37

TITLE : RP-300/310

Page -36 -

[Reference] ESC 3

ESC 3

n

[Name] Set line spacing

[Format] ASCII ESC 3

n

Hex 1B 33

n

Decimal 27 51

n

[Range] 0≤

n

≤ 255

[Description] Sets the line spacing to [

n

x (vertical or horizontal motion unit)] inches.

[Details] ·The line spacing can be set independently in standard mode and in

page mode.

·The horizontal and vertical motion unit is specified by GS P.

Changing the horizontal or vertical motion unit does not affect the

current line spacing.

·The GS P command can change the horizontal (and vertical) motion unit.

However, the value cannot be less than the minimum vertical movement

amount, and it must be in even units of the minimum vertical movement

amount.

·In standard mode, the vertical motions until (y) is used.

·In page mode, this command function as follows, depending on the

starting position of the printable area :

①When the starting position is set to the upper left or lower right to

the printable area using ESC T, the vertical motion unit

(y)

is used.

②When the starting position is set to the upper right or lower left of

the printable area using ESC T, the horizontal motion unit

(x)

is used.

·The maximum paper feed amount is 1016 mm {40” }. Even if a paper

feed amount of more than 1016 mm{40” }is set, the printer feeds the

paper only 1016 mm{40” }

[Default] Line space is equivalent to approximately 4.23 mm{1/6” }.

[Reference] ESC 2, GS P

ESC =

n

[Name] Set peripheral device

[Format] ASCII ESC =

n

Hex 1B 3D

n

Decimal 27 61

n

Page 38

TITLE : RP-300/310

Page -37 -

[Range] 1≤n ≤ 255

[Description] Selects device to which host computer sends data, using n as follows:

Bit

Off/On Hex Decimal Function

Off 00 0 Printer disabled 0

On 01 1 Printer enabled

1-7 - - - Undefined

[Details] ·When the printer is disabled, it ignores all data except for error-recovery

commands (DLE EOT, DLE ENQ, DLE DC4) until it is enabled by this

command.

[Default] n=1

ESC ? n

[Name] Cancel user-defined characters

[Format] ASCII ESC ?

n

Hex 1B 3F

n

Decimal 27 63

n

[Range] 32 ≤

n

≤ 126

[Description] Cancels user-defined characters.

[Details] ·This command cancels the pattern defined for the character code

specified by n. After the user-defined characters is canceled, the

corresponding pattern for the internal character is printed.

·This command deletes the pattern defined for the specified code in the

font selected by ESC !.

·If a user-defined character has not been defined for the specified

character code, the printer ignores this command.

[Reference] ESC &, ESC %

ESC @

[Name] Initialize printer

[Format] ASCII ESC @

Hex 1B 40

Decimal 27 64

[Description] Clears the data in the print buffer and resets the printer mode to the mode

that was in effect when the power was turned on.

[Details] ·The DIP switch settings are not checked again.

·The data in the receive buffer is not cleared.

Page 39

TITLE : RP-300/310

Page -38 -

·The macro definition is not cleared.

·The NV bit image data is not cleared.

·The data of the NV user memory is not cleared.

ESC D [n1...nk] NUL

[Name] Set horizontal tab positions

[Format] ASCII ESC D

n1……nk NUL

Hex 1B 44

n1……nk 00

Decimal 27 68

n1……nk 0

[Range] 1≤n ≤ 255

0≤

k

≤ 32

[Description] Set is horizontal tab positions.

·

n

specifies the column number for setting a horizontal tab position from

the beginning of the line.

·

k

indicates the total number of horizontal tab positions to be set.

[Details] ·The horizontal tab position is stored as a value of [character width x

n

]

measured from the beginning of the line. The character width includes

the right-side character spacing, and double-width characters are set

with twice the width of normal characters.

·This command cancels the previous horizontal tab settings.

·When setting

n

= 8, the print position is moved to column 9 by sending

HT.

·Up to 32 tab positions (

k

=32) can be set. Data exceeding 32-tab

positions s is processed as normal data.

·Transmit [

n]k

in ascending order and place a NUL code 0 at the end.

·When [

n

]k is less than or equal to the preceding value [n]k-1, tab

setting is finished and the following data is processed as normal data,

·ESC D NUL cancels all horizontal tab positions.

·The previously specified horizontal tab positions do not change, even if

the character width changes.

·The character width is memorized for each standard and page mode.

[Default] The default tab positions are at intervals of 8 characters (columns 9, 17,

25, ...) for the font A (12 X 24).

[Reference] HT

ESC E

n

[Name] Turn emphasized mode on/off

[Format] ASCII ESC E

n

Hex 1B 45

n

Page 40

TITLE : RP-300/310

Page -39 -

Decimal 27 69

n

[Range] 0≤

n

≤ 255

[Description] Turns emphasized mode on or off.

·When the LSB of

n

is 0, emphasized mode is turned off.

·When the LSB of

n

is 1, emphasized mode is turned on.

[Details] ·Only the least significant bit of

n

is enabled.

·This command and ESC! Turn on and off emphasized mode in the same

way. Be careful when this command is used with ESC!.

[Default]

n

= 0

[Reference] ESC !

ESC G

n

[Name] Turn on/off double-strike mode

[Format] ASCII ESC G

n

Hex 1B 47

n

Decimal 27 71

n

[Range] 0≤

n

≤ 255

[Description] Turns double-strike mode on or off.

·When the LSB of

n

is 0, double-strike mode is turned off.

·When the LSB of

n

is1, double-strike mode is turned on.

[Details] ·Only the lowest bit of

n

is enabled.

·Printer output is the same in double-strike mode and in emphasized

mode.

[Default]

n

= 0

[Reference] ESC E

ESC J

n

[Name] Print and feed paper

[Format] ASCII ESC J

n

Hex 1B 4A

n

Decimal 27 74

n

[Range] 0≤

n

≤ 255

[Description] Prints the data in the print buffer and feeds the paper [

n

x vertical or

horizontal motion unit].

Page 41

TITLE : RP-300/310

Page -40 -

[Details] ·After printing is completed, this command sets the print starting position

to the beginning of the line.

·The paper feed amount set by this command does not affect the values

set by ESC 2 or ESC 3.

·The horizontal and vertical motion unit is specified by GS P.

·The GS P command can change the vertical (and horizontal) motion unit.

However, the value cannot be less than the minimum vertical movement,

and it must be in even units of the minimum vertical movement amount.

·In standard mode, the printer uses the vertical motion unit(

y

).

·In page mode, this command functions as follows, depending on the

starting position of the printable area.

①When the starting position is set to the upper left or lower right of

the printable area using ESC T, the vertical motion unit (y) is used.

②When the starting position is set to the upper right or lower left of

the printable area using ESC T, the horizontal motion unit (x) is

used.

·The maximum line spacing is 1016 mm{40” }. When the setting value

exceeds the maximum, it is converted to the maximum automatically.

[Reference] GS P

ESC L

[Name] Select page mode

[Format] ASCII ESC L

Hex 1B 4C

Decimal 27 76

[Description] Switches from standard mode to page mode.

[Details] ·This command is enabled only when input at the beginning of a line in

standard mode.

Page 42

TITLE : RP-300/310

Page -41 -

·This command has no effect in page mode.

·After printing by FF is completed or by using ESC S, the printer returns to

standard mode.

·This command sets the position where data is buffered to the position

specified by ESC T within the printing area defined by ESC W.

·This command is switches the setting for the following commands (in

which the values can be set independently in standard mode and page

mode) to those for page mode.

① Set right-side character spacing : ESC SP, FS S

② Select default line spacing : ESC 2, ESC3

·Only valve settings is possible for the following commands in page

mode; these commands are not executed.

① Turn 90° clockwise rotation mode on/off: ESC V

② Select justification: ESC a

③ Turn upside-down printing mode on/off: ESC {

④ Set left margin: GS L

⑤ Set printable area width: GS W

·The following command is ignored in page mode:

①Execute test print: GS W

·The following command is not available in page mode:

① Print NV bit image : FS p

② Define NV bit image : FS q

③ Print raster bit image : GS v 0

·The printer returns to standard mode when power is turned on, the printer

is reset, or ESC @ is used.

[Reference] FF, CAN, ESC FF, ESC S, ESC T, ESC W, GS $, GS \

ESC M n

[Name] Select character font

[Format] ASCII ESC M n

Hex 1B 4D n

Decimal 27 77 n

[Range] n= 0, 1 , 48, 49

[Description] Selects character fonts

Page 43

TITLE : RP-300/310

Page -42 -

n

Function

0, 48 Character font A (12 X 24 ) Selected

1, 49 Character font B (9 X 24 ) Selected

[Details] ·The ESC ! command can also select the character fonts. However, the

setting of the last received command is effective.

[Reference] ESC !

ESC R

n

[Name] Select an international character set

[Format] ASCII ESC R

n

Hex 1B 52

n

Decimal 27 82

n

[Range] 0≤

n

≤ 13

[Description] Selects an international character set

n

from the following table:

n

Character Set

0 U. S. A

1 France

2 Germany

3 U. K.

4 Denmark I

5 Sweden

6 Italy

7 Spain I

8 Japan

9 Norway

10 Denmark II

11 Spain II

12 Latin America

[Default]

n

= 0

[Reference] 3.2.12 International Character Set

Page 44

TITLE : RP-300/310

Page -43 -

ESC S

[Name] Select standard mode

[Format] ASCII ESC S

Hex 1B 53

Decimal 27 83

[Description] Switches from page mode to standard mode.

[Details] ·This command is effective only in page mode.

·Data buffered in page mode and the printable area developed in page

mode are cleared.

·This command is switches the setting for the following command (in

which the values can be set independently in standard mode and page

mode) to those for standard mode:

① Set right-side character spacing: ESC SP, FS S

② Select default line spacing : ESC 2, ESC 3

·The following commands are enabled only to set in standard mode.

① Set printing area in page mode : ESC W

② Set print direction in page mode : ESC T

·The following commands are ignored in standard mode.

① Set absolute vertical print position in page mode : GS $

② Set relative vertical print position in page mode : GS \

·Standard mode is selected automatically when power is turned on, the

printer is reset, or command ESC @ is used.

[Reference] FF, ESC FF, ESC L

Page 45

TITLE : RP-300/310

Page -44 -

ESC T n

[Name] Select print direction in page mode

[Format] ASCII ESC T

n

Hex 1B 54

n

Decimal 27 84

n

[Range] 0≤

n

≤3,

48≤

n

≤ 51

[Description] Select the print direction and starting position in page mode.

n

specifies the print direction and starting position as follows:

n

Print Direction Starting Position

0, 48 Left to right Upper left(A in the figure)

1, 49 Bottom to top Lower left(B in the figure)

2, 50 Right to left Lower right(C in the figure)

3, 51 Top to bottom Upper right(D in the figure)

[Details] ·When the command is input in standard mode, the printer executes only

internal flag operation. This command does not affect printing in

standard

mode.

·This command sets the position where data is buffered within the printing

area set by ESC W.

·Parameters for horizontal or vertical motion units

(x or y)

differ as

follows, depending on the starting position of the printing area:

①If the starting position is the upper left or lower right of the printing

area, data is buffered in the direction perpendicular to the paper

feed direction:

Commands using horizontal motion units: ESC SP, ESC $, ESC\

Commands using vertical motion units: ESC 3, ESC J, GS $, GS\

②If the starting position is the upper right or lower left of the printing

area, data is buffered in the paper feed direction :

Commands using horizontal motion units :

ESC 3, ESC J, GS &, GS\

Commands using vertical motion units : ESC SP, ESC $, ESC\

[Default]

n

= 0

[Reference] ESC $, ESC L, ESC W, ESC\, GS $, GS P, GS\

ESC V

n

Page 46

TITLE : RP-300/310

Page -45 -

[Name] Turn 90° clockwise rotation mode on/off

[Format] ASCII ESC V

n

Hex 1B 56

n

Decimal 27 86

n

[Range] 0≤

n

≤ 1,48≤n ≤ 49

[Description] Turns 90° clockwise rotation mode on or off.

n

is used as follows:

n Function

0, 48 Turns off 90˚ clockwise rotation mode

1, 49 Turns on 90˚ clockwise rotation mode

[Details] ·When underline mode is turned on, the printer does not underline 90°

clockwise-rotated characters.

·Double-width and double-height commands in 90° rotation mode

enlarge characters in the opposite directions from double height and

double-width commands in normal mode.

·This command affects printing in standard mode. However, the setting is

always effective.

[Default]

n

= 0

[Reference] ESC !, ESC –

ESC W

xL xH yL yH dxL dxH dyL dyH

Page 47

TITLE : RP-300/310

Page -46 -

[Name] Set printing area in page mode

[Format] ASCII ESC W

xL xH yL yH dxL dxH dyL dyH

Hex 1B 57

xL xH yL yH dxL dxH dyL dyH

Decimal 27 87

xL xH yL yH dxL dxH dyL dyH

[Range]

0≤

xL xH yL yH dxL dxH dyL dyH

≤ 255 (except

dxL=dxH=0 or dyL=dyH=0

)

[Description] ·The horizontal starting position, vertical starting position, printing area

width, and printing area height are defined as x0, y0, dx, dy,

respectively.

Each setting for the printable area is calculated as follow:

x0 = [(xL + xH x 256) x (horizontal motion unit)]

y0 = [(yL + yH x 256) x (vertical motion unit)]

dx = [(dxL + dxH x 256) x (horizontal motion unit)]

dy = [(dyL + dyH x 256) x (vertical motion unit)]

The printing area is set as shown in the figure below.

[Details] ·If this command is input in standard mode, the printer executes only

internal flag operation. This command does not affect printing in

standard mode.

·If the horizontal or vertical starting position is set outside the printable

area, the printer stops command processing and processes the

following data as normal data.

·If the printing area width or height is set to 0, the printer stops command

processing and processes the following data as normal data.

·This command sets the position where data is buffered to the position

specified by ESC T within the printing area.

·If (horizontal starting position + printing area width) exceeds the printable

area, the printing area width is a automatically set to (horizontal

printable - horizontal starting position).

·If (vertical starting position + printing area height) exceeds the printable

area, the printing area height is automatically set to( vertical printable

area - vertical starting position).

·The horizontal and vertical motion units are specified by GS P.

Changing the horizontal or vertical motion unit does not affect the current

printing area.

·The GS P command can change the horizontal (and vertical) motion unit.

However, the value cannot be less than the minimum horizontal

movement amount, and it must be in even units of minimum horizontal

movement amount.

·Use the horizontal motion unit for setting the horizontal starting position

area width, and use the vertical motion unit for setting the vertical

starting position and printing area height.

·When the horizontal starting position, vertical starting position, printing

Page 48

TITLE : RP-300/310

Page -47 -

area width, and printing area height are defined as

X ,Y, Dx

, and Dy

respectively, the printing area is set as shown in the figure below.

·This printable area for this printer is approximately 72.2 mm {512/180” }

in the horizontal direction and approximately 117.3 mm {1662/360” } in

the vertical direction.

[Default]

xL = xH = yL = yH =

0

dxL = 0, dxH = 2, dyL =126, dyH =

6

[Reference] CAN, ESC L, ESC T, GS P

ESC \

nL nH

Page 49

TITLE : RP-300/310

Page -48 -

[Name] Set relative print position

[Format] ASCII ESC \

nL n

H

Hex 1B 5C

nL n

H

Decimal 27 92

nL n

H

[Range] 0≤

n

L

≤ 255

0≤

n

H

≤ 255

[Description] Sets the print starting position based on the current position by using the

horizontal or vertical motion unit.

·This command sets the distance from the current position to [(

nL+ n

H x

256

) x

(horizontal or vertical unit)].

[Details] ·Any setting that exceeds the printable area is ignored.

·When pitch

N

is specified to the right :

n

L

+

n

H

x 256 =

N

When pitch

n

is specified to the left (the negative direction), use the

complement of 65536.

When pitch

n

is specified to the left :

n

L

+

n

H

x 256 = 65536 –

n.

·The print starting position moves from the current position to [

n

x

horizontal or vertical motion unit].

·The horizontal and vertical motion units are specified by GS P.

·The GS P command can change the horizontal (and vertical) motion unit.

However, the value cannot be less than the minimum horizontal

movement amount,

and it must be in even units of the minimum horizontal movement

amount.

·In standard mode, the horizontal motion unit is used.

·In page mode, the horizontal or vertical motion unit differs as follows,

depending on the starting point of the printing area :

①When the starting position is set to the upper left or lower right of the

printable area using ESC T, the horizontal motion unit (

x

) is used.

②When the starting position is set to the upper right or lower left of the

printable area using ESC T, the vertical motion unit (

y

) is used.

[Reference] ESC $, GS P

ESC a

n

Page 50

TITLE : RP-300/310

Page -49 -

[Name] Select justification

[Format] ASCII ESC a

n

Hex 1B 61

n

Decimal 27 97

n

[Range] 0≤n ≤ 2,48 ≤n ≤ 50

[Description] Aligns all the data in one line to the specified position

n

selects the justification as follows:

n

Justification

0,48 Left justification

1,49 Centering

2,50 Right justification

[Details] ·The command is enabled only when processed at the beginning of the

line in standard mode.

·If this command is input in page mode, the printer performs only internal

flag operation.

·This command has no effect in page mode.

·This command executes justification in the printing area.

·This command justifies the space area according to

HT, ESC $ or ESC \

[Default]

n

= 0

[Example]

Left justification Centering Right justification

ABC

ABCD

ABCDE

ABC

ABCD

ABCDE

ABC

ABCD

ABCDE

ESC c 3

n

Page 51

TITLE : RP-300/310

Page -50 -

[Name] Select paper sensor(s) to output paper end signals

[Format] ASCII ESC c 3 n

Hex 1B 63 33 n

Decimal 27 99 51 n

[Range] 0≤

n

≤ 255

[Description] Selects the paper sensor(s) to output paper end signals.

·Each bit of

n

is used as follows:

Bit Off / On Hex Decimal Function

Off 00 0 Paper roll near-end sensor disabled 0

On 01 1 Paper roll near-end sensor enabled

Off 00 0 Paper roll near-end sensor disabled 1

On 02 2 Paper roll near-end sensor enabled

Off 00 0 Paper roll end sensor disabled 2

On 04 4 Paper roll end sensor enabled

Off 00 0 Paper roll end sensor disabled 3

On 08 8 Paper roll end sensor enabled

4 – 7 - - - Undefined

{Details} ·It is possible to select multiple sensors to output signals. Then, if any of

the sensors detects a paper end, the paper end signal is output.

·The command is available only with a parallel interface and is ignored

with a serial interface.

·Sensor is switched when executing this command. The paper end signal

switching be delayed depending on the receive buffer state.

·If either bit 0 or bit 1 is on, the paper roll near-end sensor is selected as

the paper sensor outputting paper-end signals

·If either bit 2 or bit 3 is on, the paper roll end sensor is selected as the

paper sensor outputting paper-end signals.

·When all the sensors are disabled, the paper end signal always outputs a

paper present status.

[Default]

n

= 15

Page 52

TITLE : RP-300/310

Page -51 -

ESC c 4 n

[Name] Select paper sensor(s) to stop printing

[Format] ASCII ESC c 4

n

Hex 1B 63 34

n

Decimal 27 99 52

n

[Range] 0≤

n

≤ 255

[Description] Selects the paper sensor(s) used to stop printing when a paper-end is

detected, using

n

as follows.

Bit Off / On Hex Decimal Function

Off 00 0 Paper roll near end sensor disabled.

0

On 01 1 Paper roll near end sensor enabled

Off 00 0 Paper roll near end sensor disabled

1

On 02 2 Paper roll near end sensor enabled

2 – 7 - - - Undefined

[Details] ·When a paper sensor is enabled with this command, printing is stopped

only when the corresponding paper is selected for printing.

·When a paper-end is detected by the paper roll sensor, the printer goes

off-line after printing stops.

·When either bit 0 or 1 is on, the printer selects the paper roll near-end

sensor for the paper sensor to stop printing.

[Default] n = 0

Page 53

TITLE : RP-300/310

Page -52 -

ESC c 5 n

[Name] Enable / disable panel buttons

[Format] ASCII ESC c 5

n

Hex 1B 63 35

n

Decimal 27 99 53

n

[Range] 0≤

n

≤ 255

[Description] Enables or disables the panel buttons.

·When the LSB of n is 0, the panel buttons are enabled.

·When the LSB of n is 1, the panel buttons are disabled.

[Details] ·Only the lowest bit of n is valid.

·When the panel buttons are disabled, none of them are usable when the

printer cover is closed.

·In this printer, the panel buttons are the FEED button.

·In the macro ready mode, the FEED button are enabled regardless of the

settings of this command; however, the paper cannot be fed by using

these buttons.

[Default]

n

= 0

ESC d

n

[Name] Print and feed

n

lines

[Format] ASCII ESC d

n

Hex 1B 64

n

Decimal 27 100

n

[Range] 0≤

n

≤ 255

[Description] Prints the data in the print buffer and feeds

n

lines.

[Details] ·This command sets the print starting position to the beginning of the line

·This command does not affect the line spacing set by ESC 2 or ESC 3.

·The maximum paper feed amount is 1016 mm{40” }. If the paper feed

amount(n x line spacing) of more than 1016 mm{40” } is specified, the

printer feeds the paper only 1016 mm{40” }.

[Reference] ESC 2, ESC 3

Page 54

TITLE : RP-300/310

Page -53 -

ESC p

m t1 t2

[Name] Generate pulse

[Format] ASCII ESC p

m t1 t2

Hex 1B 70

m t1 t2

Decimal 27 112

m t1 t2

[Range] m = 0, 1, 48, 49

0≤

t1

≤ 255, 0≤

t2

≤ 255

[Description] Outputs the pulse specified by t1 and t2 to connector pin m as follows:

m

Connector pin

0, 48 Drawer kick-out connector pin2.

1, 49 Drawer kick-out connector pin5.

[Details] ·The pulse ON time is [

t1

x 2 ms] and the OFF time is [ t2 x 2 ms].

·If

t2 < t1

, the OFF time is [ t1 x 2 ms]

[Reference] DLE DC4

Page 55

TITLE : RP-300/310

Page -54 -

ESC t

n

[Name] Select character code table

[Format] ASCII ESC t

n

Hex 1B 74

n

Decimal 27 116

n

[Range] 0≤

n

≤ 5, 16≤n≤ 26, n = 255

[Description] Selects a page

n

from the character code table.

n

Page

0 PC437 [U.S.A., Standard Europe]

1 Katakana

2 PC850 [Multilingual]

3 PC860 [Portuguese]

4 PC863 [Canadian-French]

5 PC865 [Nordic]

17 PC866 [Cyrillic #2]

255 Space page

[Default]

n

= 0

[Reference] Factory default set code page

Code page Language

CP737 Greek

CP852 Latin2

CP857

Turkish

CP862

Hebrew

CP864

Arabic

CP866

Cyrillic

CP1252

Latin1(Spanish)

CP1253

Greek

ISO8859

Latin5(Turkish)

Page 56

TITLE : RP-300/310

Page -55 -

ESC {

n

[Name] Turns on/off upside-down printing mode

[Format] ASCII ESC {

n

Hex 1B 7B

n

Decimal 27 123

n

[Range] 0 ≤ n ≤ 255

[Description] Turns upside-down printing mode on or off.

·When the LSB of

n

is 0, upside-down printing mode is turned off.

·When the LSB of

n

is 1, upside-down printing mode is turned on.

[Details] ·Only the lowest bit of

n

is valid.

·This command is enabled only when processed at the beginning of a

line in standard mode.

·When this command is input in page mode, the printer performs only

internal flag operations.

·This command does not affect printing in page mode.

·In upside-down printing mode, the printer rotates the line to be printed

by 180˚ and then prints it.

[Default]

n

= 0

[Example]

Page 57

TITLE : RP-300/310

Page -56 -

FS p

n m

[Name] Print NV bit image

[Format] ASCII FS p

n m

Hex 1C 70

n m

Decimal 28 112

n m

[Range] 1 ≤

n

≤ 255

0 ≤ m ≤ 3, 48 ≤ m ≤ 51

[Description] Prints a NV bit image

n

using the mode specified by m.

m Mode Vertical Dot Density Horizontal Dot Density

0, 48 Normal 180 dpi 180 dpi

1, 49 Double-width 180 dpi 90 dpi

2, 50 Double-height 90 dpi 180 dpi

3, 51 Quadruple 90 dpi 90 dpi

[dpi : dots per 25.4mm {1” }]

[Details] ·

n

is the number of the NV bit image (defined using the FS q command).

·

m

specifies the bit image mode.

·

NV

bit image means a bit image which is defined in a non-volatile

memory by FS q and printed by FS p.

·This command is not effective when the specified NV bit image has not

been defined.

·In standard mode, this command is effective only when there is no data

in the print buffer.

·In page mode, the command is not effective.

·This command is not affected by print modes (emphasized, double-

strike, underline, character size, white/black reverse printing, or 90°

rotated characters, etc.), except upside-down printing mode.

·If the printing area width set by GS L and GS W for the NV bit image is

less than one vertical line the following processing is performed only

on

the line in question. However, in NV bit image mode, one vertical line

means 1 dot in normal mode (m=0,48) and in double-height mode

(m=2,50), and it means 2 dots in double-width mode (m=1,49) and in

quadruple mode (m=3,51).

Page 58

TITLE : RP-300/310

Page -57 -

①The printing area width is extended to the right in NV bit image

mode

②If the printing area width cannot be extended by one line vertically,

the left margin is reduced to accommodate one line vertically.

·If the downloaded bit-image to be printed exceeds one line, the excess

data is not printed.

·This command feeds dots (for the height n of the NV bit-image) in

normal

and double-width modes, and(for the height

n

x 2 of the NV bit-image)

in

double-height and quadruple modes, regardless of the line spacing

specified by ESC 2 or ESC 3.

·After printing the bit image, this command sets the print position to the

beginning of the line and processes the data that follows as normal data.

[References] ESC *, FS q, GS/, GS v 0

Page 59

TITLE : RP-300/310

Page -58 -

FS q n [

xL xH yL yH d1...dk

] 1...[

xL xH yL yH d1...dk]n

[Name] Define NV bit image

[Format] ASCII FS q n

[xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]n

Hex 1C 71 n

[xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]n

Decimal 28 113 n

[xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]n

[Range] 1 ≤

n

≤ 255

0 ≤ xL ≤ 255

0 ≤ xH ≤ 3 (when 1 ≤ (xL + xH × 256) ≤ 1023)

0 ≤ yL ≤ 255

0 ≤ yL ≤ 1 (when 1 ≤ (yL + yH × 256) ≤ 288)

0 ≤ d ≤ 255

k = (xL + xH × 256) × (yL + yH × 256) × 8

Total defined data area = 2M bits (256K bytes)

[Description] Define the NV bit image specified by

n

.

[Details] ·

n

specifies the number of the defined NV bit image.

·xL, xH specifies (xL + xH × 256) × 8 dots in the horizontal direction for the

NV bit image you are defining.

·yL, yH specifies (yL + yH × 256) × 8 dots in the vertical direction for the

NV

bit image you are defining.

·This command cancels all NV bit image that have already been defined by

this command. The printer can not redefine only one of several data

definitions previously defined. In this case, all data needs to be sent

again.

·From the beginning of the processing of this command till the finish of

hardware reset, mechanical operations (including initializing the position

of the printer head when the cover is open, paper feeding by using the

FEED button, etc.) cannot be performed.

·During processing this command, the printer is in BUSY when writing the

data to the NV user memory and stops receiving data. Therefore it is

Page 60

TITLE : RP-300/310

Page -59 -

prohibited to transmit the data including the real-time commands during

the execution of this command.

·NV bit image means a bit image which is defined in a non-volatile memory

by FS q and printed by FS p.

·In standard mode, this command is effective only when processed at the

beginning of the line.

·In page mode, this command is not effective.

·This command is effective when 7 bytes <FS-yH> is processed as a

normal value.

·When the amount of the data exceeds the capacity left in the range

defined by xL, xH, yL, yH, the printer processes xL, xH, yL, yH out of the

defined range.

·In the first group of NV bit image, when any of the parameters xL, xH, yL,

yH, is out of the definition range, the command is disabled.

·In groups of NV bit image other than the first one, when the printer

processes xL, xH yL, yH out of the defined range, it stops processing

this

command and stars writing into the NV images. At this time, NV bit image

that haven’ t been defined are disabled (undefined), but any NV bit

images before that are enabled.

·The

d

indicates the definition data. In data (d) a 1 bit specifies a dot to be

printed and a 0 bit specifies a dot not to be printed.

·This command defines n as the number of a NV image. Number rise in

order from NV bit image 01H. Therefore, the first data group [xL xH yL

yH

d1...dk] is NV bit image 01H, and the last data group [xL xH yL yH

d1...dk] is NV bit image

n

. The total agrees with the number of NV bit

images specified by command FS p.

·A definition data of a NV bit image consists of [xL xH vL vH d1...dk].

Therefore, when only one NV bit image is defined n=1, the printer

processes a data group [xL xH yL yH d1...dk] once. The printer uses

([data:(xL + xH ×256) × (yL + yH × 256) × 8] + [header:4]) bytes of NV

memory.