Parsun F50/60 BWL-D, F50/60 BWL-T, F50/60 FWL-T Owner's Manual

OUTBOARD MOTORS

OWNER’S MANUAL

F50/60 BWL-D

F50/60 BWL-T

F50/60 FWL-T

SUZHOU PARSUN POWER MACHINE CO., LTD.

Thank you for owning an outboard motor.

Thank you for your trust in our company and products.

The outboard motors are powerful, economic and safe, manufactured with

advanced technology.

Please read this manual carefully before operating your outboard motor. A thorough

understanding of the manual will help you to know this product for proper operation,

maintenance and care. This will ensure that your outboard motor operates well under all

conditions.

We seek continuous improvement in product quality. Therefore, while this manual

contains the most current product information available at the time of printing, there may

be minor discrepancies between your machine and this manual. If there is any question

concerning the manual, please consult your local PARSUN dealer.

Data, illustrations or explanations in this Owner’s Manual do not constitute base for

any legal claim against our company.

SUZHOU PARSUN POWER MACHINE CO., LTD

Engine Identification Numbers

Outboard motor serial number

The outboard motor serial number is marked on the label. The label can be found on the bracket left

assembly or on the upper part of the bracket swivel.

Record your outboard motor serial number in the spaces provided to assist you in ordering spare parts

from your dealer or for reference in case your outboard motor is stolen.

1. Outboard motor serial number location

Serial number as follows:

SN

1

Engine serial number

The engine serial number is carved on the aluminum casting of engine.

Engine serial number as follows:

Table of contents

1. Main components and General information ....................................................................................... 1

1.1 Main components ............................................................................................................................ 1

1.2 General information ......................................................................................................................... 5

1.2.1Specification .................................................................................................................................. 5

1.2.2 Fueling instruction ........................................................................................................................ 6

1.2.3 Propeller selection ........................................................................................................................ 7

2. Operation ........................................................................................................................................... 8

2.1 Installation ....................................................................................................................................... 8

2.1.1 Mounting height ............................................................................................................................ 9

2.1.2 Clamping the outboard motor ..................................................................................................... 10

2.2 Breaking in engine .......................................................................................................................... 11

2.3 Pre-operation checks .................................................................................................................... 12

2.4 Filling fuel ...................................................................................................................................... 14

2.5 Starting engine .............................................................................................................................. 14

2.6 Warm up engine ............................................................................................................................ 18

2.7 Shifting .......................................................................................................................................... 19

2.7.1 Forward ...................................................................................................................................... 20

2.7.2 Reverse ...................................................................................................................................... 21

2.8 Tiller ............................................................................................................................................... 22

2.9 Trim tab ......................................................................................................................................... 24

2.10 Stopping engine ........................................................................................................................... 24

2.11 Trimming outboard motor ............................................................................................................. 25

2.11.1 Tilting up ................................................................................................................................... 27

2.11.2 Tilting down ............................................................................................................................... 28

2.12 Cruising in other conditions ......................................................................................................... 29

2.12.1 Cruising in shallow water .......................................................................................................... 29

2.12.2 Cruising in salt water ................................................................................................................ 30

3. Maintenance .................................................................................................................................... 30

3.1 Greasing ........................................................................................................................................ 31

3.2 Cleaning and adjusting spark plug ................................................................................................ 32

3.3 Checking the fuel system .............................................................................................................. 33

3.3.1 Cleaning the fuel filter ................................................................................................................. 34

3.4 Inspecting idling speed .................................................................................................................. 35

3.5 Changing engine oil ....................................................................................................................... 36

3.6 Checking wiring and connectors .................................................................................................... 38

3.7 Checking for leakage ..................................................................................................................... 38

3.8 Checking propeller ........................................................................................................................ 38

3.8.1 Removing the propeller .............................................................................................................. 39

3.8.2 Installing the propeller ................................................................................................................ 40

3.9 Changing gear oil .......................................................................................................................... 41

3.10 Cleaning fuel tank ........................................................................................................................ 42

3.11 Checking and replacing anode(s) ................................................................................................ 43

3.12 Checking top cowling................................................................................................................... 43

3.13 Maintenance Table ...................................................................................................................... 44

4 Transporting and storing ................................................................................................................... 46

4.1 Transporting .................................................................................................................................. 46

4.2 Storing ........................................................................................................................................... 47

4.3 Flusher .......................................................................................................................................... 49

5. Actions in emergency ...................................................................................................................... 50

5.1 Impact damage .............................................................................................................................. 50

5.2 Power trim and tilt unit will not operate .......................................................................................... 51

5.3 Starter will not operate ................................................................................................................... 52

5.4 Replacing fuse ............................................................................................................................... 54

5.5 Treatment of submerged motor ..................................................................................................... 55

6. Troubleshooting ............................................................................................................................... 56

7. Circuit diagram ................................................................................................................................ 60

1

1. Main components and General information

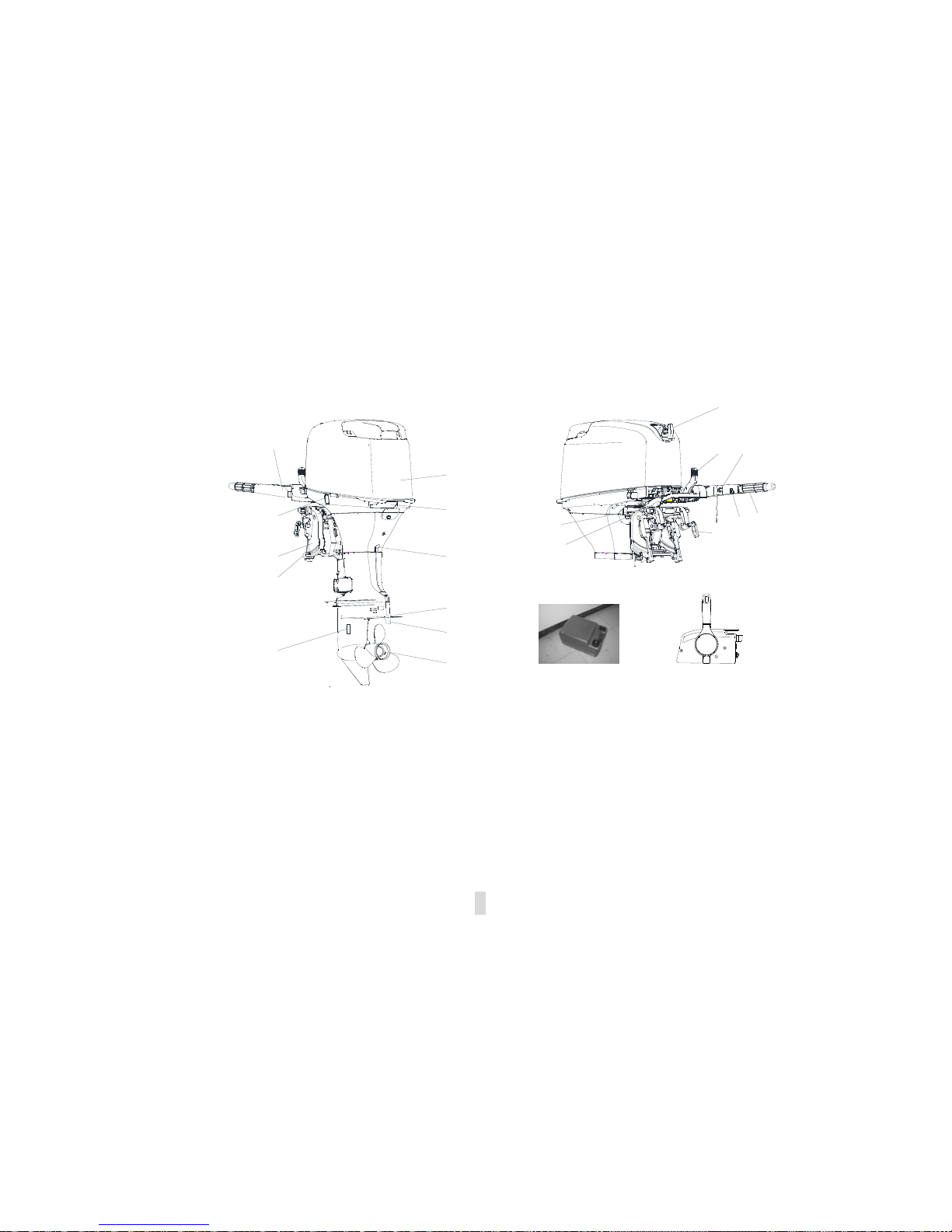

1.1 Main components

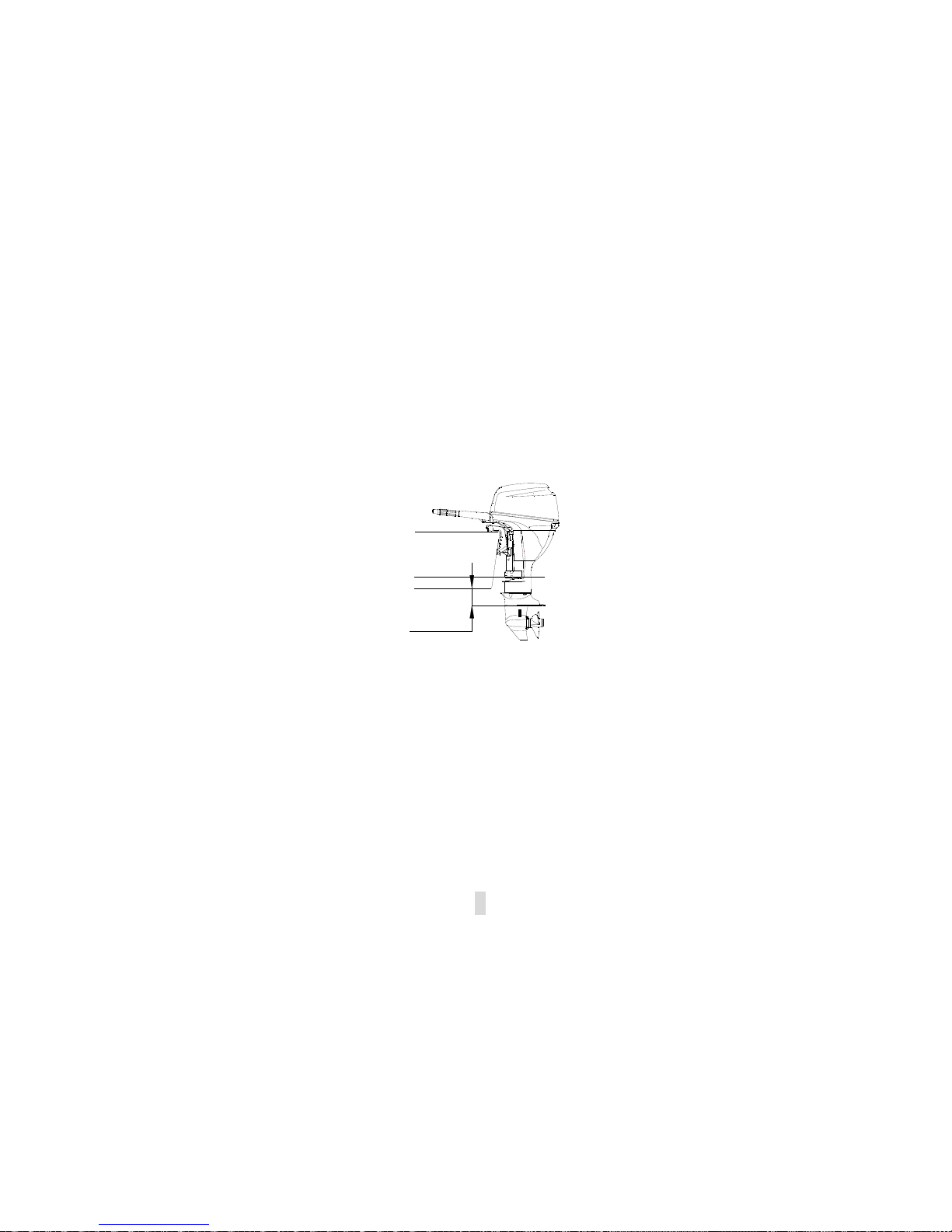

1.Top cowling 8. Tilt & trim rod 15. Throttle grip

2.Top cowling lock handle 9. Clamp bracket 16. Clam bolt

3.Drain screw 10.Tilt & trim button 17. Stand bar

4.Anti-cavitation plate 11.Tiller handle 18. Tilt lock bar

5.Trim-tab 12.Starters handle 19. Fuel tank

6.Propeller 13.Shifting handle 20. Remote control box

7.Cooling water inlet 14. Throttle frication adjuster

20

11

6

19

18

17

16

13

14

15

12

10

9

8

7

5

4

3

2

1

21

2

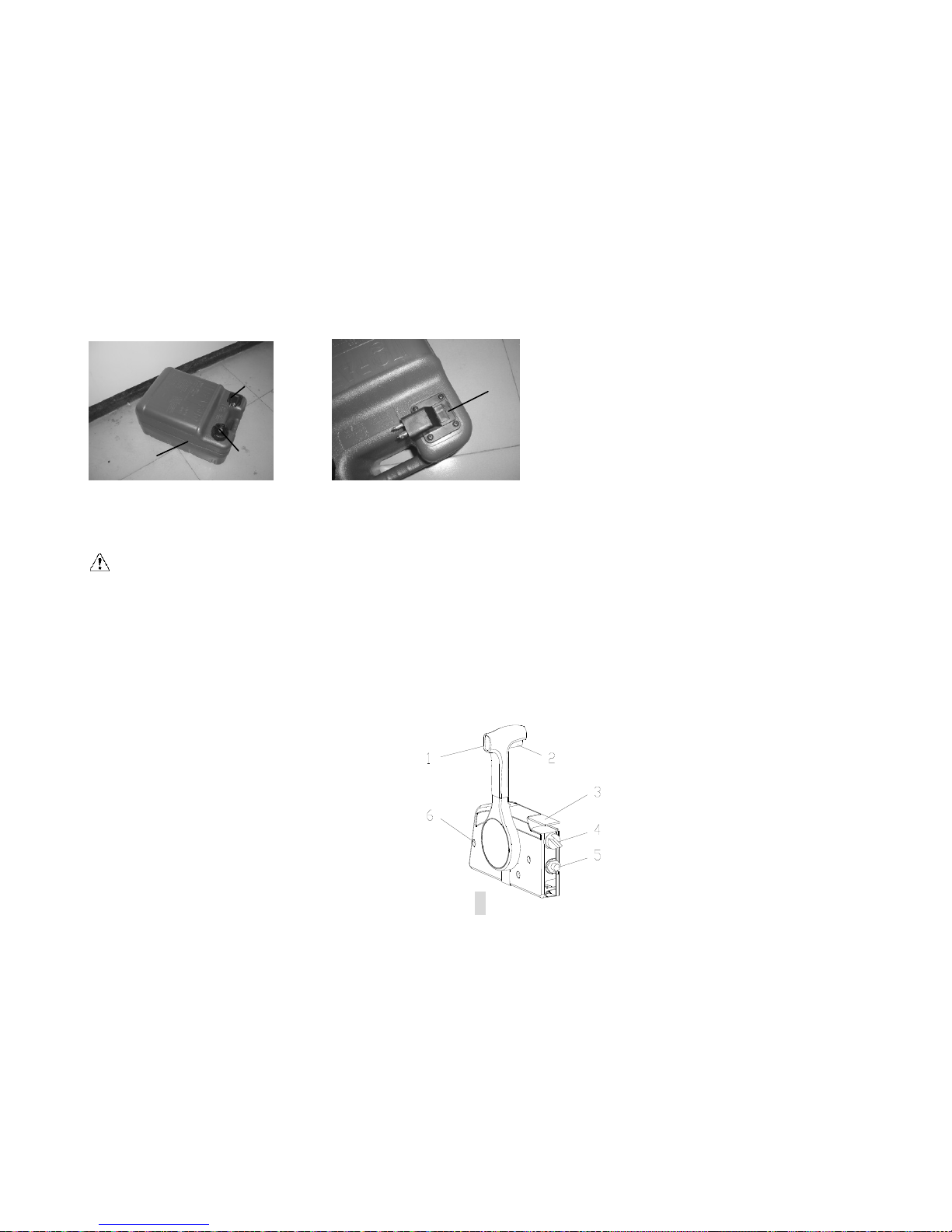

A portable fuel tank includes parts as follows:

1. Fuel tank cap 3. Air vent screw

2. Fuel joint 4. Fuel gauge

WARNING:

The fuel tank supplier with this engine could only be used as supply of fuel for it s running and

must not be as a fuel storage container.

Remote control

The remote control lever actuates both the shifter and the throttle. The electrical switches are mounted

on the remote control box.

1. Remoter control lever

2. Neutral interlock trigger

3. Neutral throttle lever

4. Main switch/choke switch

5. Engine stop switch

6. Throttle friction adjuster

1

3

2

4

3

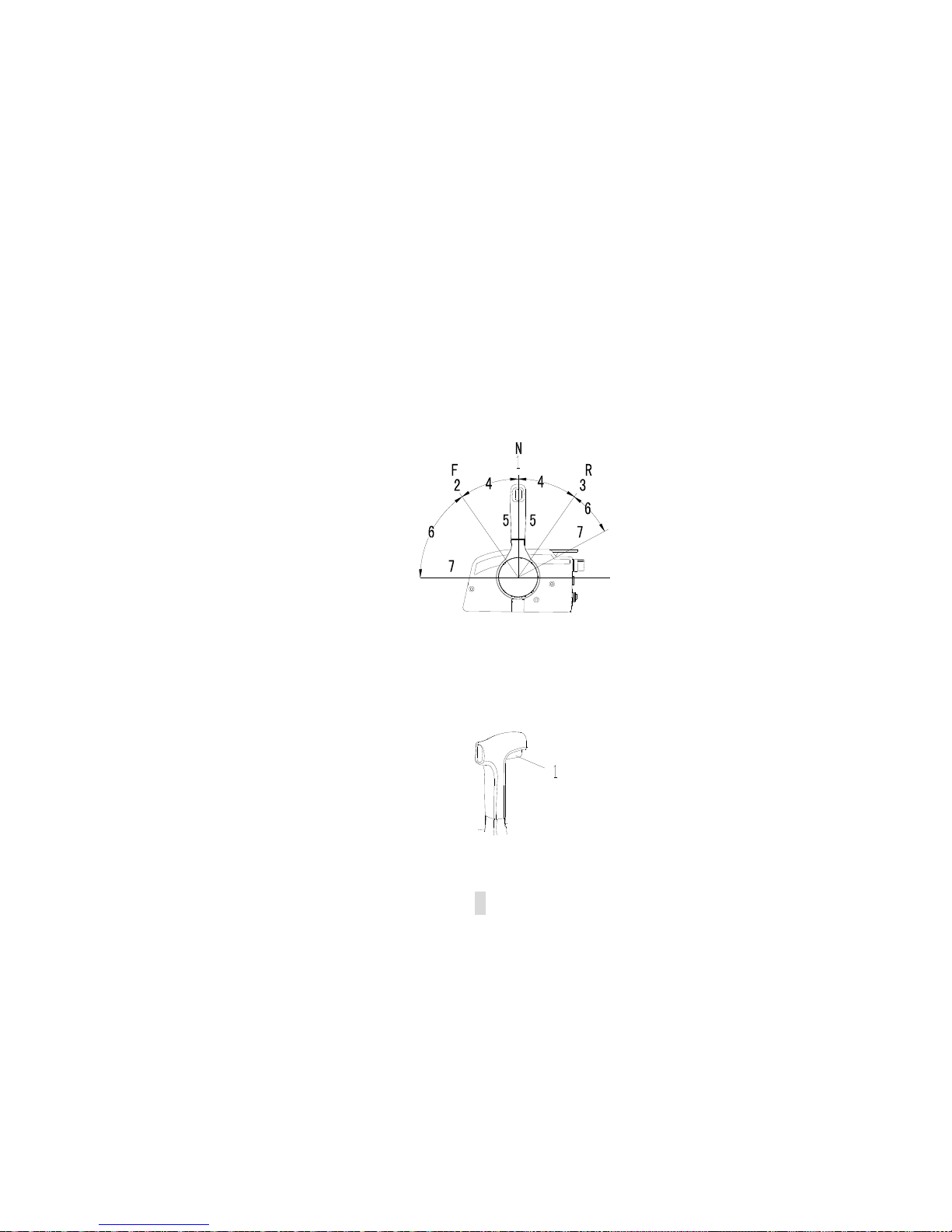

Remote control lever

Moving the lever forward from the neutral position engages forward gear. Pulling the lever back from

neutral engages reverse. The engine will continue to run at idle until the lever is moved about 35º (a

detent can be felt). Moving the lever farther opens the throttle, and the engine will begin to accelerate.

1. Neutral “N”

2. Forward “F”

3. Reverse “R”

4. Shift

5. Fully closed

6. Throttle

7. Fully open

Neutral interlock trigger

To shift out of neutral, first pull the neutral interlock trigger up.

1. Neutral interlock trigger

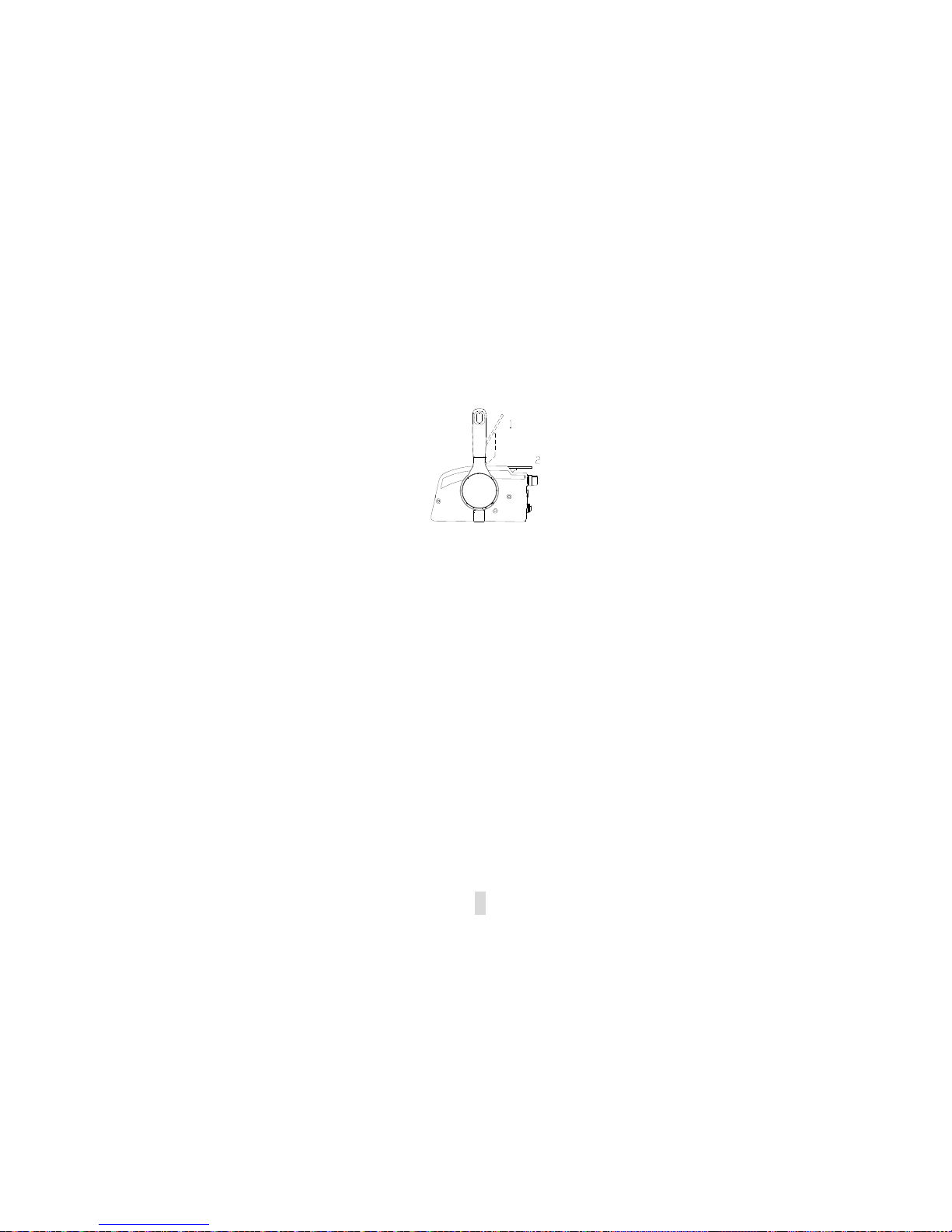

Neutral throttle lever

To open the throttle without shifting into either forward or reverse, put the remote control lever in the

neutral position and lift the neutral throttle lever.

4

NOTE:

The neutral throttle lever will operate only when the remote control lever is in neutral.

The remote control lever will operate only when the neutral throttle lever is in the closed

position.

1. Fully open

2. Fully closed

5

1.2 General information

1.2.1Specification

Main technical data:

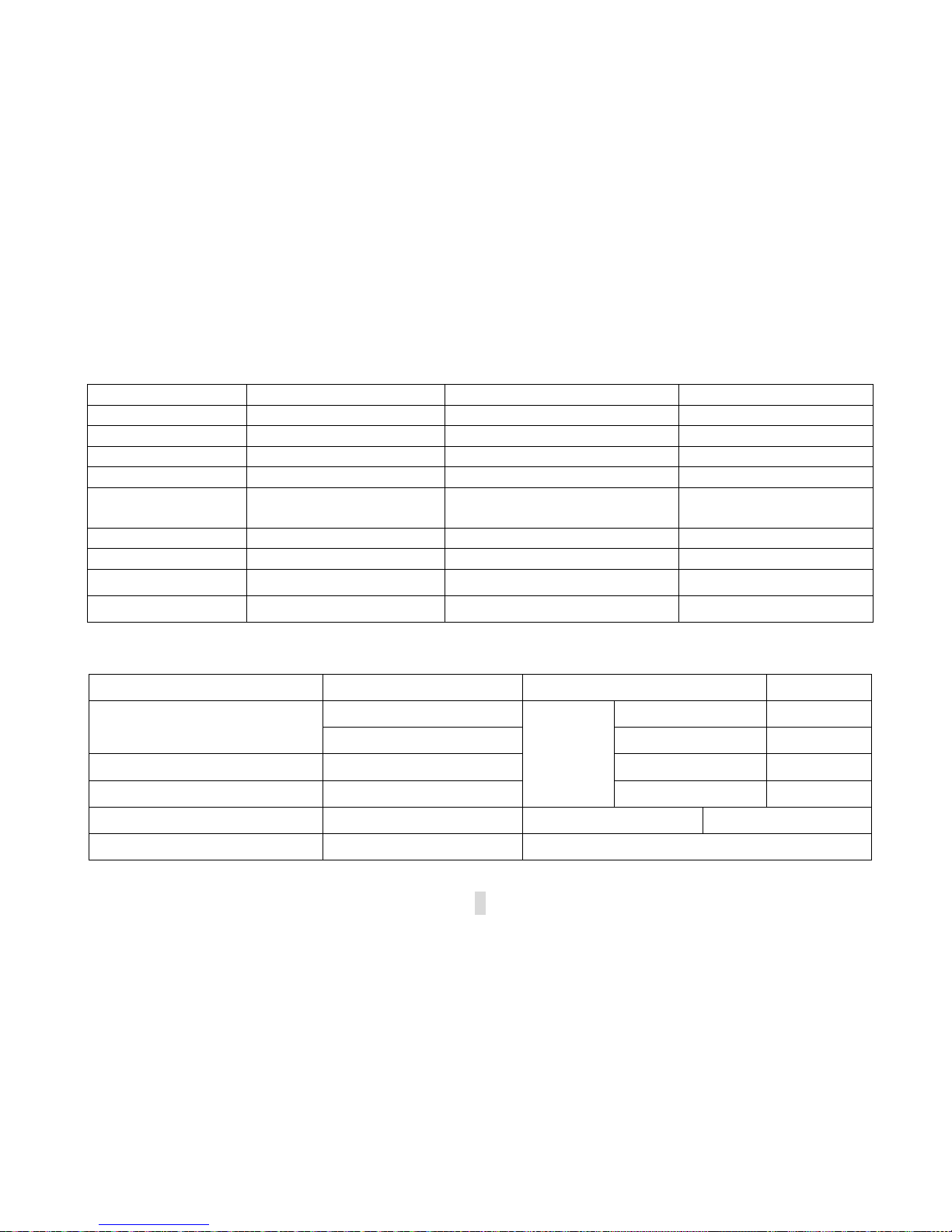

Items Data Items Data

Type of engine Four cylinders,4-stroke Weight (BWL-T) 115Kg

Displacement 996cm3 Weight (FWL-T) 110Kg

Bore X stroke 65mm×75mm Recommended fuel Unleaded regular gasoline

Gear ratio 1.85(24/13) Fuel tank capacity 24L

Overall length

1383mm(BWL-D/T)

713mm(FW-T)

Recommended engine oil SAE10W30 or SAE10W40

Overall width 427mm Engine oil quantity 2.1L(with oil filter)

Overall height 1435mm Recommended gear oil Hypoid gear oil SAE﹟90

Transom height 508mm

Gear oil quantity 430cm

3

Weight (BWL-D) 113Kg

Spark plug DPR7EA-9

Main performance:

Items Data Items Data

Maximum output

44.1Kw/5500rpm(60HP)

Tightening

torque for

engine

Spark plug 18.0Nm

36.8Kw/5500rpm(50HP) Propeller nut 35.0Nm

Idling speed (in neutral, EFI) 800±50rpm Engine oil drain bolt 18.0Nm

Full throttle operating range 5000~6000rpm Engine oil filter 18.0Nm

Valve clearance IN(cool engine) 0.15~0.25mm Spark plug gap 0.8~0.9mm

Valve clearance EX(cold engine) 0.25~0.35mm

6

1.2.2 Fueling instruction

Fueling instructions:

Recommended gasoline:

Regular unleaded gasoline,If it is not available, then premium gasoline.

If knocking or pinging occurs, use a different brand of gasoline or premium unleaded fuel.

If leaded gasoline is usually used, engine valves and related parts should be inspected after every 100

hours of operation.

WARNING:

Do not smoke when refueling, and keep away from sparks, flames, or other sources of

Ignition.

Stop engine before refueling.

Refuel in a well-ventilated area; refuel portable fuel tanks off the boat.

Do not overfill the fuel tank.

Take care not to spill gasoline, if gasoline spills, wipe it up immediately.

Tighten the filler cap securely after refueling.

If you should swallow some gasoline, inhale a lot of gasoline vapor, or get gasoline in your

eye, get immediate medical attentions.

If any gasoline spills onto your skin, immediately wash with soap and water. Change clothing

if gasoline spills on it.

Touch the fuel nozzle to metal components to prevent electrostatic sparks.

7

CAUTION:

Use only new clean gasoline which has been stored in clean containers and is not contaminated

with water or foreign matter.

Engine oil:

Recommended engine oil: 4-stroke outboard motor oil SAE10W30 and SAE10W40(1.7L).

WARNING:

Do not start the engine when the oil level is low. Serious damage might occur.

Always check the oil level before starting the engine.

CAUTION:

All 4-stroke engines are shipped from the factory without engine oil.

1.2.3 Propeller selection

The performance of your outboard motor will be critically affected by your choice of propeller, as an

incorrect choice could adversely affect performance. The outboard motor is fitted with propellers

chosen to perform well over a range of applications, but there may be uses where a propeller with a

different pitch would be more appropriate. Dealers stock a range of propellers and can advise you and

install a propeller on your out board that is best suited to your application.

For a greater boat load and a low engine speed, a smaller-pitch propeller is more suitable. Conversely,

a large-pitch propeller is more suitable for a smaller operating load as it enables the correct engine

speed to be maintained.

8

2. Operation

2.1 Installation

Mount the outboard motor on the center line (keel line) of the boat. For boats without a keel or which

are asymmetrical, consult your dealers.

1. Center line (keel line)

NOTE:

During water testing check the buoyancy of the boat, at rest, with its maximum load. Check that

the static water level on the exhaust housing is low enough to prevent water entry into the

power head, when water rises due to waves when the outboard is not running.

WARNING:

Overpowering a boat could cause severe instability. Do not install an outboard motor with

more horsepower than the maximum rating on the capacity plate of the boat. If the boat does

not have a capacity plate, consult the boat manufacturer.

Improper mounting of the outboard motor could result in hazardous conditions. Your dealer

or other person experienced in proper rigging should mount the motor. If you are mounting

the motor yourself, you should be trained by an experienced person.

The information presented in this section is intended as reference only. Proper mounting

depends in part on experience and the specific boat and motor combination.

1

9

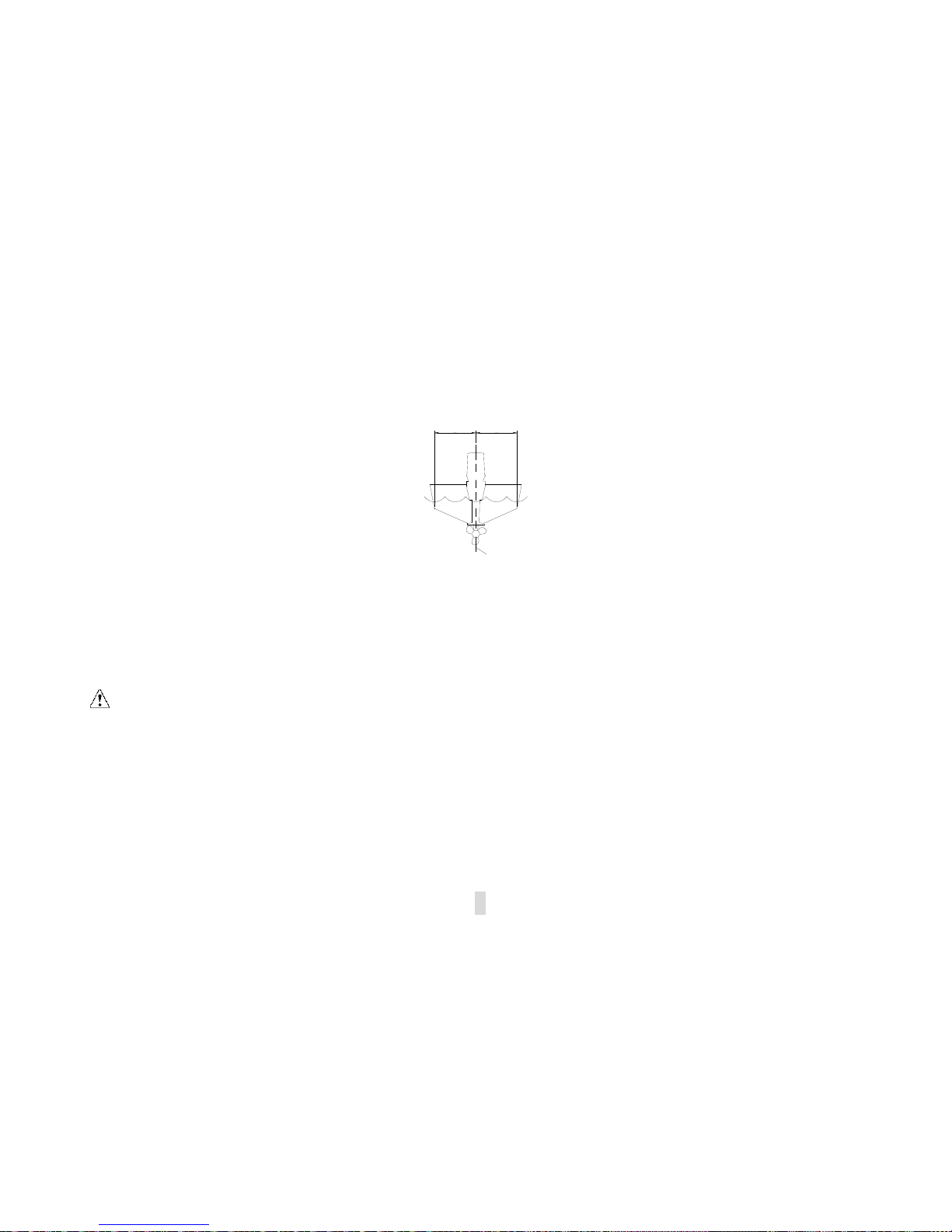

2.1.1 Mounting height

The mounting height of the outboard motor greatly affects your boat running efficiency. If the mounting

height is too high, cavitation tends to occur, thus reducing the propulsion. If the mounting height is too

low, the water resistance will increase and thereby reduce engine efficiency. Mount the outboard motor

so that the anti-cavitation plate is between the bottom of the boat and a level 25mm below it.

(0-1in)

0~25mm

NOTE:

The optimum mounting height of the outboard motor is affected by the boat and motor

combination and the desired use. Test runs at a different height can help determine the

optimum mounting height. For further information, consult your “PARSUN” dealer or boat

manufacturer.

10

2.1.2 Clamping the outboard motor

1. Tighten the transom clamp screw evenly and securely. Occasionally check the clamp screws for

tightness during operation of the outboard motor because they could become loose due to engine

vibration.

CAUTION:

Outboards that use clamp bracket screws alone are INSUFFICIENT to properly and safely

secure the outboard to the Transom. Proper installation of the outboard includes bolting the

engine to the boat through the transom.

11

WARNING:

Loose clamp screws could allow the outboard motor to fall off or move on the transom. This

could cause loss of control. Make sure the clamp screws are tightened securely,

occasionally check the screws for tightness during operation.

3. Secure the clamp bracket to the transom using the appropriate bolts. For details, consult your dealer.

WARNING:

Avoid using bolts, nuts or washers inappropriate. After tightening, test running the engine

and check their tightness.

2.2 Breaking in engine

Your new engine requires a period of breaking to allow mating surfaces of moving parts to wear in

evenly.

CAUTION

Failure to follow the break-in procedure could result in reduced engine life or even severe

engine Damage.

2. If the engine restraint cable attachment is equipped

on your engine, an engine restraint cable or chain

should be used. Attach to a secure mounting point on

the boat to avoid the engine being completely lost if it

accidentally falls off the transom.

12

1. for the first hour of operation:

Run the engine at 2000 r/min or at approximately half throttle.

2. for the second hour of operation:

Run the engine at3000 r/min or at approximately three-quarter throttle.

3. for the next eight hours of operation:

Avoid continuous operation at full throttle for more than five minutes at a time.

4. Operate the engine normally.

2.3 Pre-operation checks

Fuel

·Check to be sure you have plenty of fuel for your trip.

·Make sure there are no fuel leaks or gasoline fumes.

·Check fuel line connections to be sure they are tight.

·Be sure the fuel tank is positioned on a secure, flat surface, and that the fuel line is not twisted or

flattened, or likely to contact sharp objects.

Controls

·Check throttle, shift and steering for proper operation before starting the engine.

·The controls should work smoothly, without binding or unusual free play.

·Look for loose or damaged connections.

·Check operation of the starter and stop switches when the outboard motor is in the water.

13

CAUTION

·Do not start the engine out of water. Overheating and serious engine damage can occur.

·Check the engine and engine mounting.

·Look for loose or damaged fasteners.

·Check the propeller for damage.

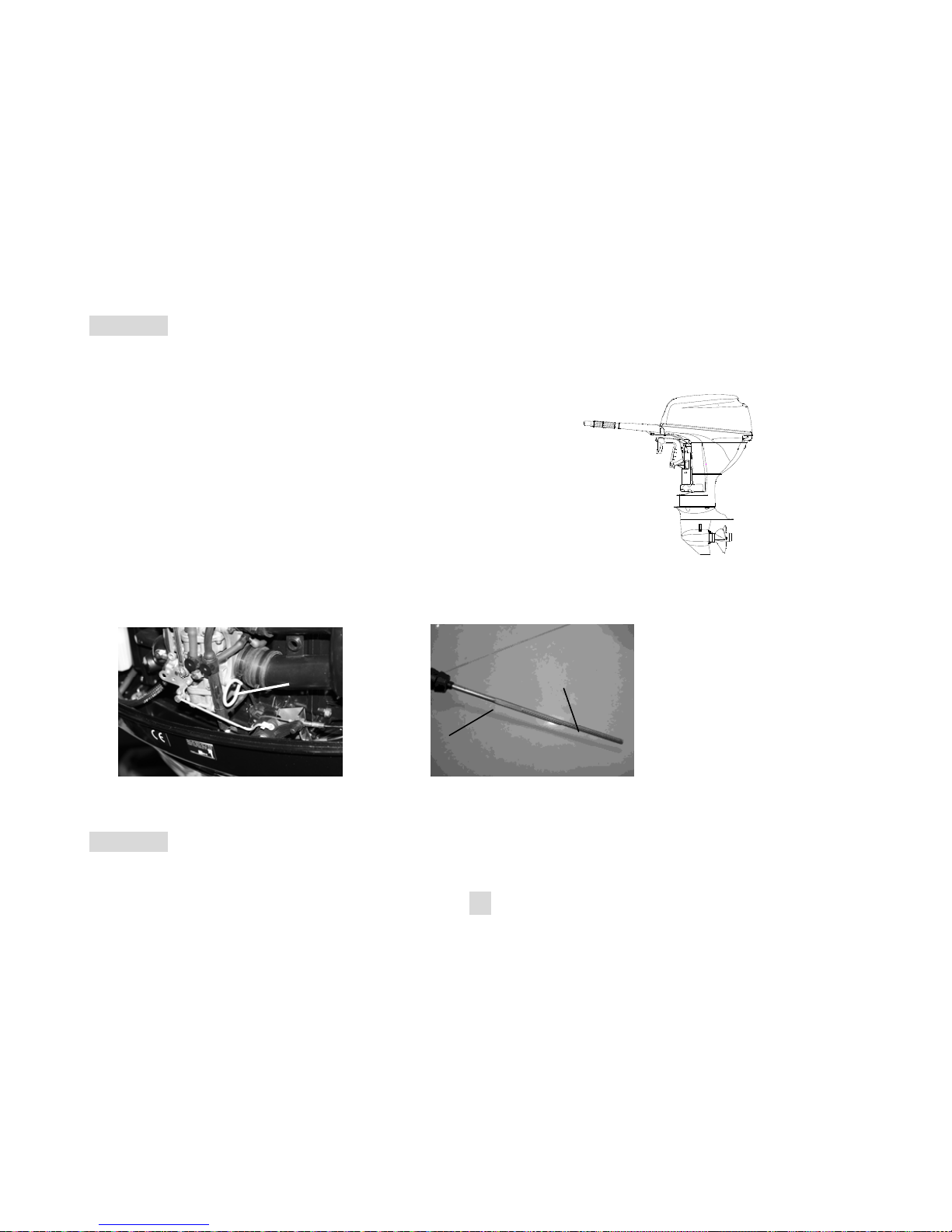

Checking the engine oil level

1. Put the outboard motor in an upright position (not tilted).

2. Check the oil level using the dipstick to be sure the level falls between the upper and lower marks.

Fill with oil if it is below the lower mark, or drain to the specified level if it is above the upper mark.

1. Oil dipstick 2 Upper level mark 3.Lower level mark

CAUTION

Be sure to completely insert the dipstick into the dipstick guide.

1

2

3

14

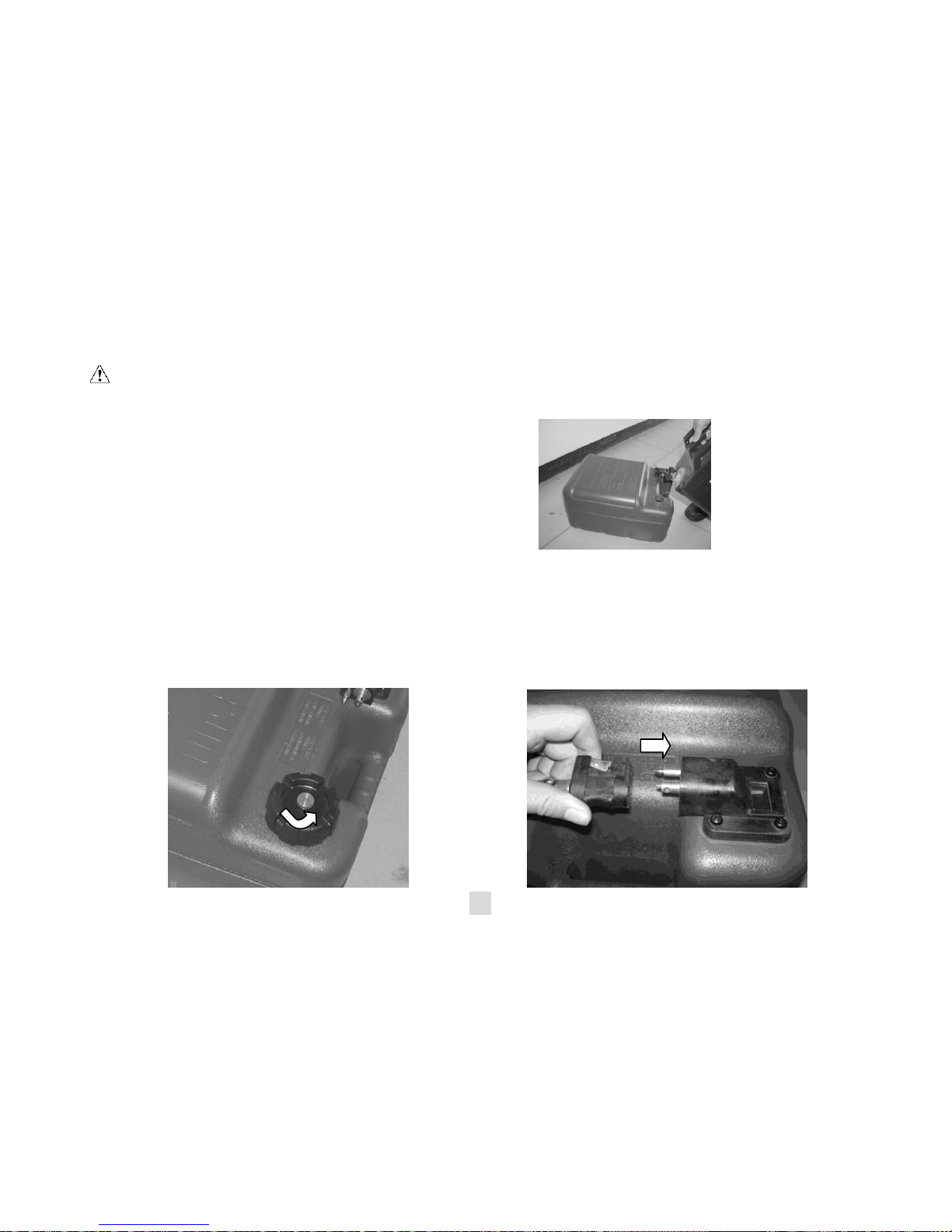

2.4 Filling fuel

WARNING:

Gasoline and its vapors are highly flammable and explosive. Keep away from sparks,

cigarettes, flames, or other sources of ignition.

1. Remove the fuel tank cap.

2. Carefully fill the fuel tank.

3

. Securely close the cap after filling the tank. Wipe up any spilled fuel.

2.5 Starting engine

1. Connect fuel joints securely after loosing the air vent screw on the fuel tank cap (2 or 3 turns).

Loading...

Loading...