Page 1

FLUX-CORED WIRE WELDER PFDS 33 A1

FLUX-CORED WIRE WELDER

Translation of the original instructions

IAN 280331

FÜLLDRAHT-SCHWEISSGERÄT

Originalbetriebsanleitung

Page 2

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / IE/NI Translation of the original instructions Page 1

DE / AT / CH Originalbetriebsanleitung Seite 17

Page 3

A

B

Page 4

C

D E

F

Page 5

Contents

Introduction .................................2

Intended use ........................................2

Residual risk.........................................2

Features............................................2

Package contents.....................................2

Technical details .....................................3

Rating plate and explanation of symbols ..................3

Safety......................................4

Basic safety instructions ................................4

Special safety instructions ..............................5

Complementary safety instructions .......................5

Potential hazards ............................6

Risk of injury due to electric shock........................6

Confined spaces and hot rooms .........................6

Accident risks due to poor air supply in confined spaces ......6

Protective clothing ....................................6

Protection against radiation and burns ....................7

Risk of burns due to flying sparks ........................7

Risk of accidents due to spattering slag....................7

Risk of fire due to flying sparks ..........................7

Risk of explosion .....................................7

EMC appliance classification....................7

Unpacking and checking the package contents....8

Assembly ...................................8

Fitting the welding mask ...............................8

Filling with flux-cored wire ..............................8

Operation..................................11

Switching the appliance on and off......................11

Setting the welding current ............................11

Adjusting the wire feed ...............................11

Overload protection .................................11

Welding mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Welding...........................................11

Weld types.................................12

Forehand welding ...................................12

Backhand welding...................................12

Welded joints ......................................12

Butt welds .........................................12

Flat butt welds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Welds on an outer edge ..............................12

Welds on an inner edge ..............................13

Overlap welds......................................13

Cleaning and care ...........................13

Wire feed .........................................13

Cable assembly.....................................13

Welder............................................13

Troubleshooting.............................14

Disposal ...................................15

Kompernass Handels GmbH warranty..........15

Service ....................................15

Importer...................................15

Translation of the original Conformity Declaration 16

PFDS 33 A1

GB│IE│NI │ 1 ■

Page 6

FLUX-CORED WIRE WELDER PFDS 33 A1

Introduction

Congratulations on the purchase of your new appliance. You have selected

a high-quality product. The operating instructions are part of this product.

They contain important information about safety, usage and disposal.

Before using the product, please familiarise yourself with all operating and

safety instructions. Use the product only as described and for the range of

applications specified. Please also pass these operating instructions on to

any future owner.

Intended use

The appliance is suitable for self-shielded flux-core welding using an

appropriate wire. No additional gas is required. The protective gas is

contained in powdered form in the wire itself, is thus fed directly into the

arc and means that the appliance is not susceptible to wind and can be

used outside.

Only the filler wire designed for this appliance may be used.

Proper use also involves compliance with the safety instructions as well as

the assembly instruction and the operating notes in the operating instructions.

Comply exactly with the applicable accident prevention regulations.

The appliance may not be used:

▯ in rooms with insufficient ventilation,

▯ in damp or wet environments,

▯ in explosive atmospheres,

▯ for the purpose of thawing pipes,

▯ in the vicinity of people with heart pacemakers and

▯ in the vicinity of flammable materials.

Use this appliance only as described in this instruction manual. All other

uses are deemed to be improper and may result in property damage or

even in personal injury.

The manufacturer is not liable for damages caused by improper or incorrect

use.

Residual risk

Even if you operate this appliance properly, there will still be residual risks.

The following risks can occur in the context of the design and construction

of this flux-core welder:

▯ Eye injuries from flashes,

▯ Touching hot parts of the appliance or the workpiece (burns),

▯ In the case of insufficient protection, risk of accidents and burns due to

flying sparks or slag,

▯ Harmful emissions of smoke and gases in the event of poor ventilation

or insufficient extraction in closed rooms.

Reduce the residual risks by using the appliance carefully and in accordance

with all the instructions.

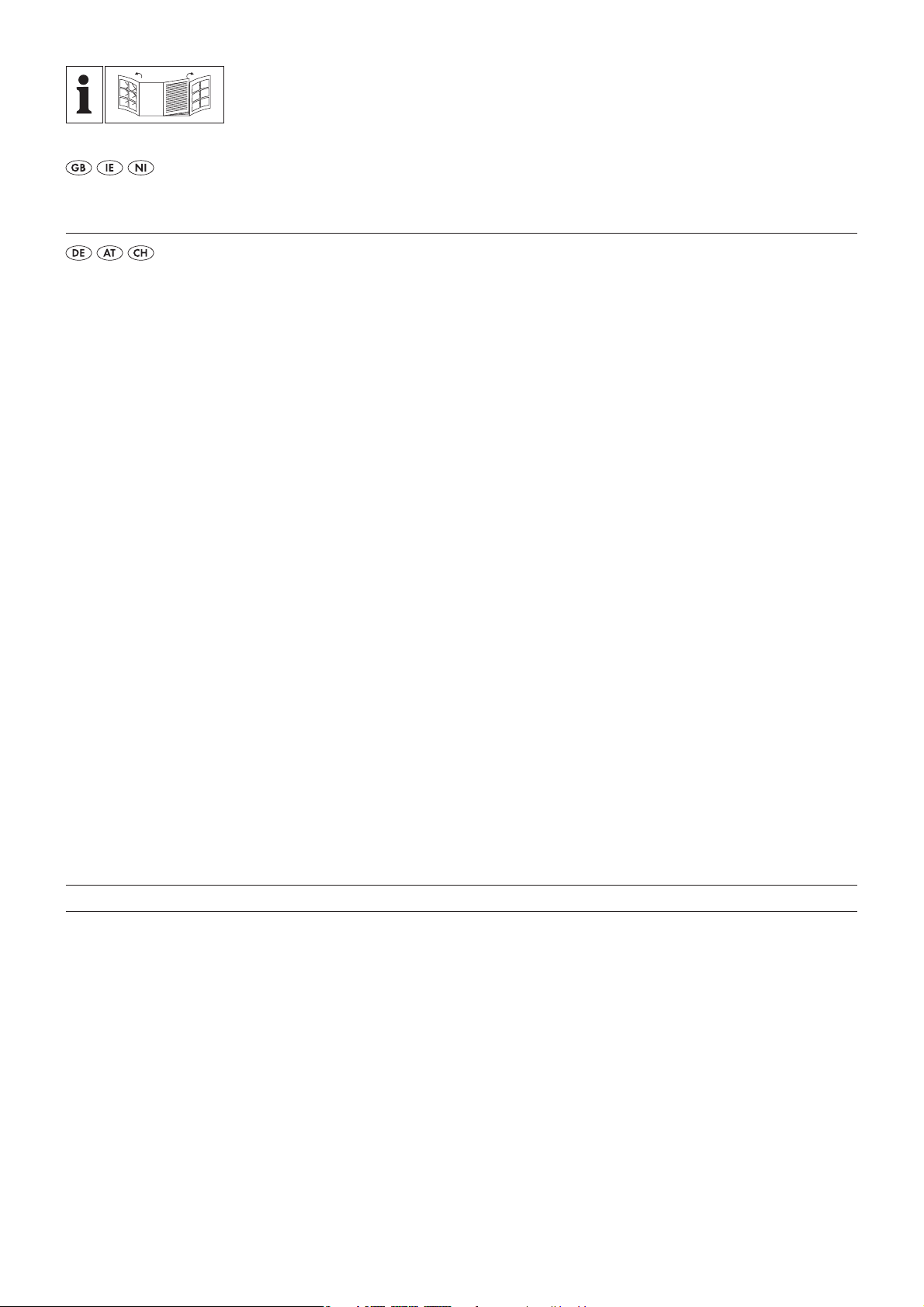

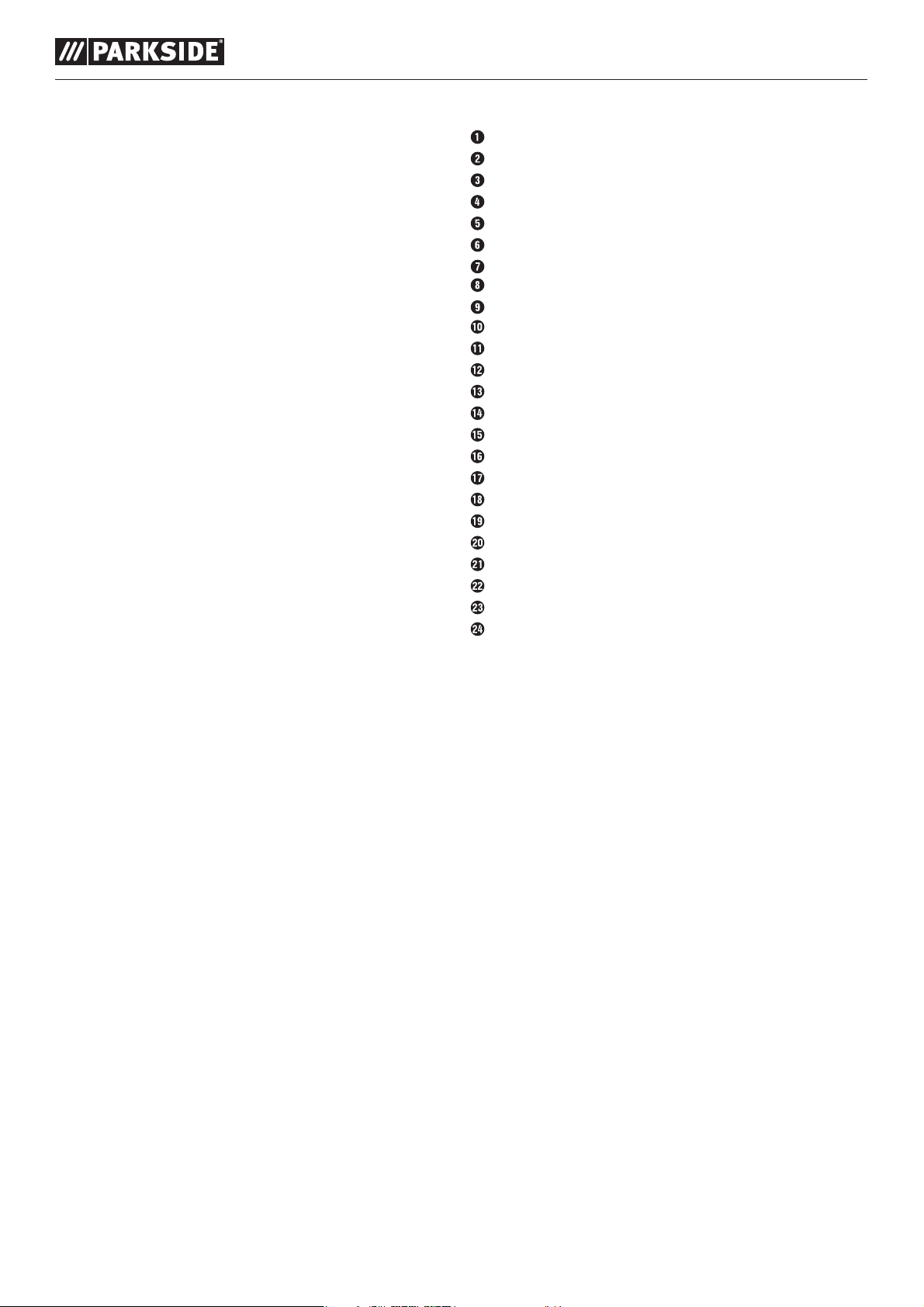

Features

Cover wire feed unit

Carrying strap

Catch

Mains plug

Earth cable with earth clamp

Cable assembly with direct connection

Torch button

Torch

Steel sleeve

Setting wheel for wire feed

MIN/MAX switch for welding current

1/2 switch for welding current

Main switch ON/OFF (incl. power indicator)

Overload protection control lamp

Torch nozzle (1.0 mm)

Torch nozzle (0.8 mm)

Flux-core wire spool (wire roll) Ø 0.9 mm/510 g

Chipping hammer with

Welding mask after assembly, consisting of:

Protective plate

Protective glass catch

Mounting clip

Dark welding lens

Handle

steel brush

Package contents

1 flux-cored wire welder PFDS 33 A1

1 steel sleeve (pre-assembled)

3 weld nozzles ( 1 x 1.0mm pre-assembled; 1 x 0.8mm; 1 x 1.0mm)

1 chipping hammer with

1 flux-core wire Ø 0.9 mm/510 g

1 welding mask

1 carrying strap

1 set of operating instructions

steel brush

■ 2 │ GB│IE│NI

PFDS 33 A1

Page 7

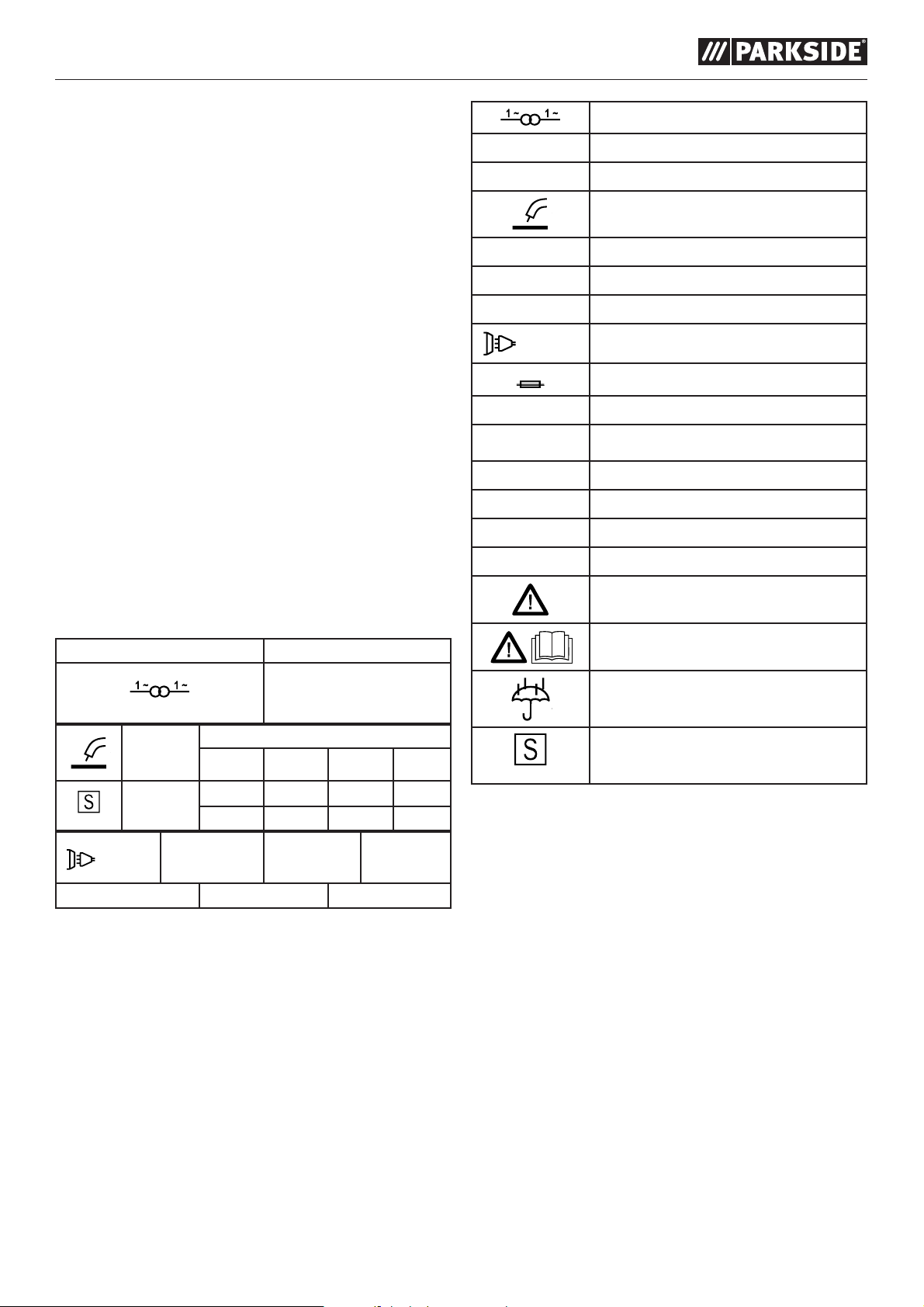

Technical details

Model: flux-cored wire welder PFDS 33 A1

Voltage U

Welding current I

No-load voltage U

Protection rating: IP 21S

Insulation class: H

Weight: 12.7 kg

Welding wire: Ø 0.7/0.8/0.9/1.0mm

Welding wire: approx. 450 g

Welding current:

▯ Material thickness

▯ Material thickness

Duty cycle X: 10% at 90 A welding current

: 230 V

1

(alternating current)

: 48 A/90 A

2

: 27.5 V

0

1.0–2.0 mm: with Ø 0.7 / 0.8 mm welding wire,

welding current 48 A – 60 A

2.0–6.0 mm: with Ø 0.8/0.9/1.0mm welding wire,

welding current 70 A – 90 A

60% at 48 A welding current

/ 50 Hz

~

Rating plate and explanation of symbols

PFDS 33 A1 S/N:

EN 60974-1:2012

EN 60974-10:2014/A1:2015

Class A

48 A / 16 V – 90 A / 18.5 V

50 Hz

~

U0 = 27.5 V

X 10 % 60 %

I

2

U

2

90 A 48 A

18.5 V 16 V

U

0

Ø mm

I

2

X

U

2

1~ 50 Hz

16A

U

1

I1 max.

I1 eff

IP21S

H

12.7 kg

Single-phase transformer

Nominal no-load voltage

Permissible flux-core wire diameter

Symbol for self-shielded flux-core welder

Rated value of the welding current

Duty cycle in %

Standardised working voltage

Mwains supply, number of phases alternating

current symbol and rated value of the frequency

Nominal value of the required mains fuse

Rated value of the mains voltage

Max. rated value of the mains current

Effective value of the max. mains current (A)

Protection class

Insulation class

Weight of the appliance

Follow the safety regulations

Read the operating instructions

Do not store or use the appliance in wet environment or in rain

Symbol for welding power sources that are suitable for welding in environments with increased

electrical risks.

1~ 50 Hz U1 = 230 V I

IP21S 12.7 kg

PFDS 33 A1

= 13 A I

1max

= 4.8 A

1eff

GB│IE│NI │ 3 ■

Page 8

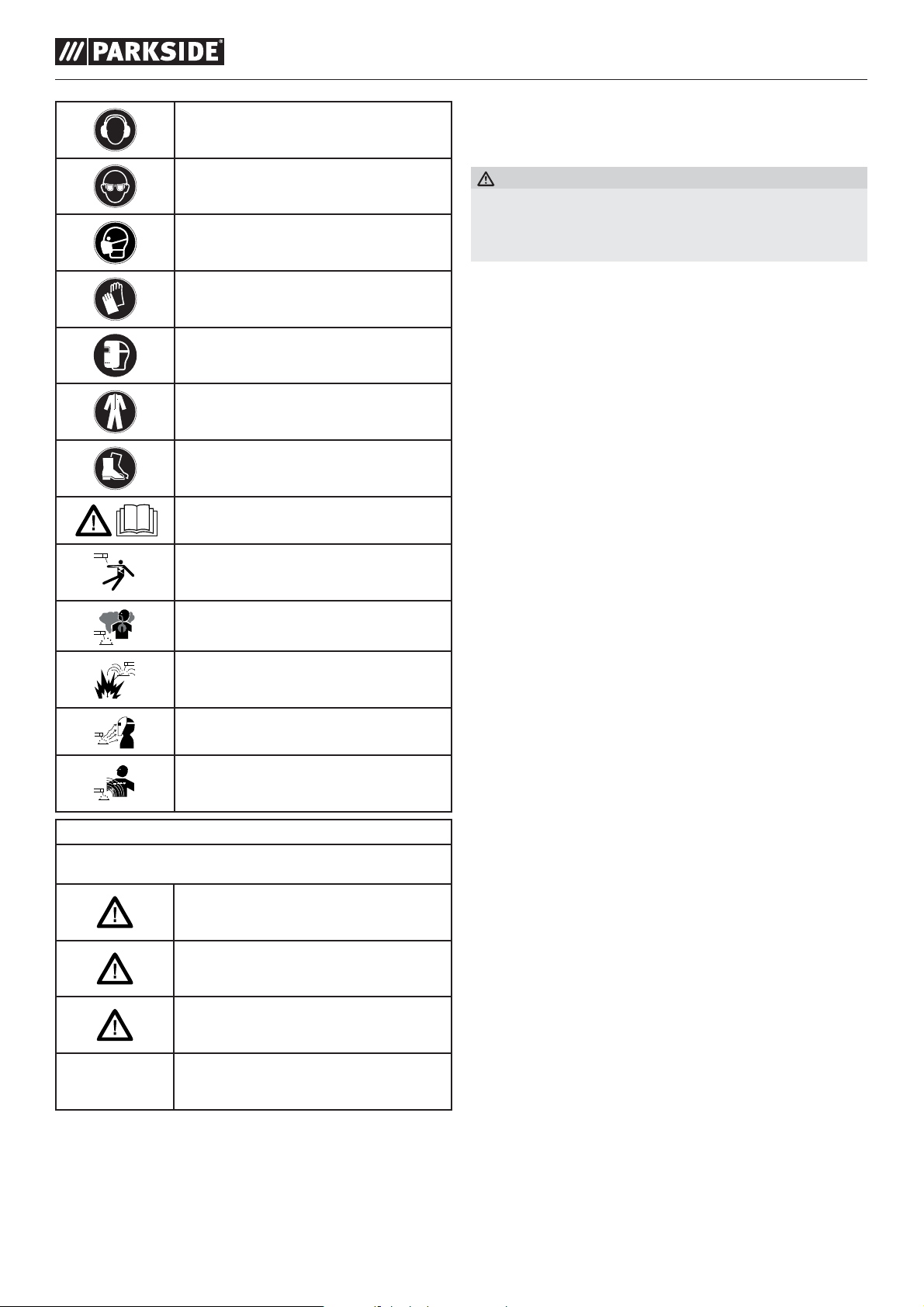

Wear ear protection!

Safety

Basic safety instructions

Wear protective goggles!

Wear a dust mask!

Wear protective gloves!

Use the welding mask!

Wear protective clothing!

Wear protective shoes!

Caution! Read instruction manual!

Electric shock from welding electrode can kill!

Breathing welding fumes can be hazardous to

your health!

Welding sparks can cause explosion or fire!

Arc rays can burn eyes and injure skin!

Electromagnetic field can cause pacemaker

malfunction!

Explanation of symbols

The following symbols and signal words are used in these instructions,

on the flux-core welder or on the packaging.

HAZARD!This signal word indicates a hazard

with a high degree of risk that will result in death

or serious injury if not prevented.

WARNING!This signal word indicates a hazard

with a medium level of risk which could lead to

death or serious injury if not prevented.

CAUTION!This signal word indicates a hazard

with a low level of risk which could result in a

minor or moderate injury if not prevented.

NOTE!This signal word warns of possible

damage to property or gives useful additional

information on assembly or operation.

WARNING! RISK OF ELECTROCUTION!

► Dangers for children and persons with limited physical, sensory or

mental capabilities (for example, partially handicapped people or

older people with limitations to their physical or mental abilities) or

lack of experience and knowledge (for example, older children).

■ The flux-core welder may only be used by adults.

■ Children should be supervised to ensure they do not play with the flux-

core welder.

■ Keep children away from the packaging materials and small components.

Swallowing can lead to a risk of suffocation.

■ Ensure that the appliance is suitably maintained.

■ Maintenance and/or repairs may only be performed by qualified

persons.

■ In addition to the notices in these operating instructions, all general

safety and accident prevention legislation must also be complied with.

■ Always pay attention to what you are doing and always be alert. Do

not work with the flux-core welder if you are distracted or under the influence of drugs, alcohol or medication. Just one moment of inattention

while operating this appliance may result in an accident and serious

personal injuries.

■ Check the appliance for any possible defects before use. If the appli-

ance exhibits any faults, it must not be used under any circumstances.

■ Ensure that the welding lead, nozzle, the torch and earth connections

are all in perfect condition. Wear on the insulation and the live parts

can cause dangerous situations and reduce the quality of the welding

work.

■ Use this appliance only as described in this instruction manual.

■ Using this appliance can lead to wear on certain parts. Therefore,

check the appliance regularly for any possible damage or defects.

■ For your own safety, use only the additional equipment and acces-

sories specified in the operating instructions or recommended by the

manufacturer.

■ When setting up the appliance, ensure that it is placed on a stable and

safe working surface.

■ On heavily used supply networks and power circuits, welding work

can lead to problems for other users. If in doubt, consult your electricity

provider.

■ Comply with all national guidelines and laws when welding. This applies,

in particular, to accident prevention regulations.

■ The flux-core welder may only be used on a stable and level surface. The

flux-core welder is constructed so that it can be tilted up to a maximum

of 10° from the plane before tipping over. Secure the flux-core welder

against tipping if working on an inclined plane.

■ To avoid damage to the appliance, always transport the appliance in

an upright position.

■ 4 │ GB│IE│NI

PFDS 33 A1

Page 9

Special safety instructions

WARNING! RISK OF ELECTROCUTION!

► Incorrect electrical installation, excessive mains voltage or incorrect

handling can lead to an electric shock. Any electrical shock can be

fatal.

■ Do not connect the flux-core welder unless the mains voltage from the

socket outlet corresponds to the requirement given on the type plate.

■ Connect the flux-core welder only to an easily accessible socket, so

that it can be quickly disconnected from the mains in the event of an

accident.

■ Do not operate the flux-core welder if it has any visible damage or the

mains cable or plug are defective.

■ The mains connection cable used is a high-quality line that must not be

damaged. While working, ensure that it does not come into contact with

any hot objects. If the connecting lead is damaged it must be replaced

by a specific connecting lead that is available from the manufacturer or

its customer service. The main connecting lead may only be replaced

by the manufacturer or its customer service or a similarly qualified

person.

■ Do not open the housing except as described in these instructions.

Have all repairs carried out by qualified specialists. Contact a specialist

workshop. Unauthorised repairs, improper connection or incorrect

operation will invalidate any liability or guarantee claims.

■ Never insert any pointed and/or metallic objects into the interior of the

appliance.

■ Repairs may only be made using parts that correspond to the original

appliance specifications. This flux-core welder contains electrical and

mechanical parts that are vital as protection against sources of danger.

■ Protect the flux-core welder from damp and use it only in dry, interior

rooms.

■ Never immerse the flux-core welder, the power cable or the plug in

water or other liquids.

■ Never touch the flux-core welder or the plug with wet hands.

■ Avoid all direct contact with the welding current circuit. The no-load volt-

age between the flow nozzle and the earth clamp can be dangerous.

■ Do not pull on the mains cable to remove the plug from the socket;

always pull on the plug itself.

■ Avoid any tensile load on the mains cable.

■ Unplug the appliance before setting it up at a different location.

■ Keep the flux-core welder, mains plug and power cable away from

open flames and hot surfaces.

■ Do not kink the mains cable.

■ Protect all cables from oil, sharp edges and high temperatures.

■ If you are not using the flux-core welder, cleaning or calibrating it or if

there is a malfunction, switch off the flux-core welder and pull the plug

out of the power socket.

WARNING! RISK OF INJURY!

► Improper handling can lead to severe injuries!

■ Position the power cable so that it does not present a tripping hazard.

■ The light radiation emitted by the electric arc can cause damage to the

eyes. Protect your eyes using suitable protective glasses (DIN EN 166,

DIN EN 169/protection level 10) that you can attach to the supplied

welding mask.

■ The light radiation emitted by the electric arc can cause burns to the skin.

Use gloves and dry protective clothing that is free of oil and grease to

protect the skin from exposure to the ultraviolet radiation of the electric

arc.

■ The welded workpiece starts to glow and remains very hot for quite a

long time. Make sure that it has cooled down before touching it.

■ Arc welding can cause vapours to be released that may be hazardous

to health.

■ Ensure that there is no one within a radius of 15 m of the electric arc

who is not wearing protective clothing and eye protection. Protect

yourself and any bystanders from the possible hazardous effects of the

electric arc!

WARNING! RISK OF FIRE!

► Improper handling can lead to fires or explosions.

■ Arc welding causes sparks, melted metal parts and smoke. Therefore

ensure that you remove all flammable substances and/or materials

from the working area.

■ The welded workpiece starts to glow and remains very hot for quite a

long time. It can thus come into contact with flammable materials and

cause a fire.

■ Do not weld receptacles, containers or pipes that have been used for

flammable liquids or gases.

WARNING! ELECTROMAGNETIC FIELDS!

► The flux-core welder and the electric arc can generate electrical or

electromagnetic fields that can cause electronic systems and appliances to malfunction. These include IT systems, telecommunications

systems, electronically controlled appliances and machines. Mains and

signal lines can be interrupted. Pacemakers may also be affected.

■ Observe the maintenance instructions.

■ Unwind the earth cable

Coiled cables can enhance electromagnetic fields.

■ Provide sufficient shielding for appliances or machines sensitive to radiation.

■ If you wear a pacemaker, consult your doctor before welding.

CAUTION!

► Improper handling can lead to overheating of the flux-core welder

and property damage.

■ The flux-core welder may not be restricted or placed directly against

the wall during its functional life to ensure that enough air can always

be taken up through the ventilation slit.

■ Make sure that there is always adequate ventilation.

and the cable assembly completely.

Complementary safety instructions

■ Risk of electric shock: Electric shock from welding electrode can kill.

Do not weld in the rain or snow. Wear dry insulating gloves. Do not

touch electrode with bare hands. Do not wear wet or damaged gloves.

Protect yourself from electric shock by insulating yourself from workpiece. Do not open the equipment enclosure.

■ Risk induced by welding fumes: Breathing welding fumes can be haz-

ardous to your health. Keep your head out of the fumes. Use equipment

in an open area. Use ventilating fan to remove fumes.

■ Risk induced by welding sparks: Welding sparks can cause explo-

sion or fire. Keep flammables away from welding. Do not weld near

flammables. Welding sparks can cause fires. Have a fire extinguisher

nearby and have a watchperson ready to use it. Do not weld on drums

or any closed containers.

■ Risk induced by the arc: Arc rays can burn eyes and injure skin. Wear

hat and safety glasses. Use ear protection and button shirt collar.

Use welding helmet with correct shade of filter. Wear complete body

protection.

■ Risk induced by electromagnetic fields: Welding current produces elec-

tromagnetic field. Do not use with medical implants. Never coil welding

cables around your body. Route the welding cables together. The

safety instructions for engine driven power sources shall also include:

PFDS 33 A1

GB│IE│NI │ 5 ■

Page 10

Potential hazards

There are a number of potential hazards that can occur during arc welding.

It is therefore particularly important for the welder to comply with the

following rules to avoid endangering himself or others and prevent injuries

or damage to the appliance.

▯ Do not use this flux-core welder on a surface that is inclined by more

than 10°.

▯ Work on the voltage side, e.g. on cables, plugs, sockets, etc., may only

be carried out by qualified specialists. This applies especially to the

fitting of intermediary cables.

▯ In the event of an accident, disconnect immediately from the welding

power source.

▯ If electrical contact voltages occur, switch off the appliance immediately

and have it checked by a qualified specialist.

▯ Always ensure good electrical contacts on the welding current side.

▯ Always wear insulating gloves on both hands during welding work.

These protect the user from electric shock (no-load voltage of the welding

current circuit), harmful radiation (heat and UV radiation) as well as

from incandescent metal and splashes of slag.

▯ Wear sturdy insulating shoes (should also be waterproof). Loafers are

not suitable as falling incandescent metal droplets can cause burns.

▯ Wear suitable clothing, no synthetic fibres.

▯ Do not look into the electric arc without eye protection; always use the

welding mask with the prescribed protective glass as per DIN. In addition

to the light and heat radiation, which can dazzle and/or cause burns,

the electric arc also emits UV radiation. If not properly protected, this

invisible ultraviolet radiation can cause a very painful conjunctivitis that

is not apparent until several hours later. In addition, this UV radiation

can cause sunburn-like effects on unprotected parts of the body.

▯ Any persons in the vicinity of the electric arc or helpers must be appraised

of the dangers and be equipped with the necessary protective equipment. If necessary, put up protective walls.

▯ No welding work may be carried out on containers that have been

used for storing gases, fuels, mineral oils or similar – even if they have

been empty for a long time – as possible residues may present a risk of

explosion.

▯ Special regulations apply in rooms where there is a risk of fire or

explosion.

▯ Welded joints that are subject to heavy stress loads and are required

to comply with safety requirements may only be carried out by trained

and qualified welders. Examples of this are: pressure vessels, running

rails, tow bars, etc.

Risk of injury due to electric shock

When there is no electric arc, there is a nominal no-load voltage of U0 between the earth clamp and the flow nozzle. This voltage can be potentially

fatal if the welder touches the flow nozzle, torch nozzle, welding wire or

the workpiece with his/her bare hands.

▯ It is important to bear in mind that the protective conductor in electrical

systems or appliances can be damaged by negligence by the welding

current:

e.g. the earth clamp is placed on the welder housing which is connected to the protective conductor of the electrical system. The welding

work is carried out on a machine with a protective conductor connection. It is also possible to weld the machine without attaching the earth

clamp to it. In this case, the welding current flows from the earth clamp

via the protective conductor to the machine. The high welding current

can cause the protective conductor to melt.

▯ The supply to the mains socket must be secured as per regulations

(VDE 0100). In accordance with these regulations, only fuses or circuit

breakers with a corresponding wire cross section may be used (16 amp

circuit breaker). A too high fuse amperage can cause cable fires or

building fire damage.

Confined spaces and hot rooms

▯ When working in confined spaces or hot rooms, use insulated underlays,

filler layers and gauntlets made of leather or a different non-conductive material to insulate your body against the floor, walls, conductive

appliance parts and similar.

▯ When using welding transformers to weld in environments with in-

creased electrical risks, e.g. in confined rooms with electrically conductive walls (boilers, pipes, etc.), in hot rooms (sweating through the work

clothes), the output voltage of the flux-core welder in no-load operation

may not be higher than 48 V~ (effective value). Due to its output voltage in no-load operation, the appliance may be used in this case.

Accident risks due to poor air supply in confined

spaces

▯ Considerable quantities of smoke and gases are produced during

welding. Ensure that there is a suitable opening for the extraction of

smoke and gases. Never feed oxygen into the room. This increases the

risk of fire.

Protective clothing

▯ While working, the welder must protect all body parts from radiation

and against burns by means of clothing and the welding mask.

▯ Wear gauntlets made of a suitable material (leather) on both hands.

They must be in perfect condition.

▯ To protect your clothes from flying sparks and burns, wear a suitable

apron. If the type of work requires it, e.g. overhead welding, wear a

protective suit and, if necessary, also the corresponding headgear.

▯ The clothing worn and all accessories must comply with the guideline

“Personal protective equipment” (89/686/EEC).

■ 6 │ GB│IE│NI

PFDS 33 A1

Page 11

Protection against radiation and burns

▯ Warn of the danger to the eyes by hanging up a sign saying “Caution,

do not look into the flames!”.

▯ Work areas are to be shielded so as to protect people in the vicinity.

▯ Keep unauthorised persons away from the welding work.

▯ Do not set up fixed welding locations in the immediate vicinity of

light-coloured or glossy walls.

▯ Windows should be blocked off to at least head height to prevent the

escape or reflection of radiation, e.g. by painting with a suitable paint.

Risk of burns due to flying sparks

The spraying welding sparks can cause painful burns. Therefore, observe

the following guidelines:

▯ Always wear a leather apron.

▯ Use leather gloves.

▯ For overhead welding, wear suitable headgear.

▯ Ensure that your trouser cuffs fall over your shoes.

▯ Wear sturdy and insulated shoes.

Risk of accidents due to spattering slag

When it sets, the slag is hard and brittle. Afterwards, it can be chipped off

using the chipping hammer – sharp-edged particles may fly up that could

seriously injure your eyes.

Therefore protect your eyes by wearing suitable protective goggles when

removing slag.

Risk of fire due to flying sparks

If molten or incandescent metal and slag particles fall onto flammable substances, these can ignite and cause a fire. Therefore, remove all flammable

objects from the working area before commencing welding work. Keep a

suitable fire extinguisher at hand.

Pay particularly close attention to the following materials.

▯ Paper

▯ Rags

▯ Textiles

▯ Wood and wood fibres

▯ Rubber

▯ Plastic

▯ Petrol

▯ Oils

▯ Tar-like substances

▯ Paints and solvent

Risk of explosion

Both the welding function and the superheated weld joint itself can cause

explosions. Therefore, do not use the appliance in a potentially explosive

environment containing combustible liquids, gases or paint mist.

Please also note:

▯ When the flux-core welder is in operation, do not lay the torch on the

flux-core welder itself or any other electrical appliance.

▯ Before finishing the welding work, do not touch the flow nozzle or any

other metal object with which the flow nozzle is in contact.

▯ Disconnect the appliance from the power immediately after completing

your welding work.

▯ Ensure that no cable is wrapped around any body part.

▯ Make sure that you are not within the welding current circuit. The welding

torch and earth must always be on the same side.

EMC appliance classification

As per the standard IEC 60974-10, this appliance is a welding unit with

class A electromagnetic compatibility. Thus it complies with the corresponding requirements for industrial and domestic use. In residential areas, it

may be connected to the low voltage electricity supply.

Even the flux-core welder complies with the emission limits of the standard,

arc welding appliances can nevertheless cause interference to sensitive

systems and appliances.

The user is responsible for any interference caused by the electric arc during

welding and must take appropriate preventive measures. The user must

pay close attention to the following:

▯ Power, control, signal and telecommunication lines

▯ Computers and microprocessor-controlled appliances

▯ TVs, radios and other playback appliances

▯ Electronic and electrical safety appliances

▯ People with pacemakers or hearing aids

▯ Measurement and calibration systems

▯ The electromagnetic immunity of other systems in the vicinity

▯ The time of the day at which the welding work is to be carried out.

To prevent possible interference radiation, we recommend:

▯ Fitting a mains filter to the mains connection or shielding it with a metal

pipe

▯ Maintaining the flux-core welder regularly and keeping it in good

condition

▯ Weld cables should be as short as possible, completely unwound and

running as close to parallel with the floor as possible

▯ An equipotential bonding should be provided

▯ The workpieces should be properly earthed

▯ Any appliances susceptible to interference radiation should moved out

of the welding area, if possible, or shielded.

PFDS 33 A1

GB│IE│NI │ 7 ■

Page 12

Unpacking and checking the package

contents

1.) Remove all components from the packaging and check whether the

flux-core welder or the individual components show any signs of

damage. If this is the case, do not use the flux-core welder. Contact the

manufacturer via the service address provided on the warranty card.

2.) Remove all protective films and other transport packaging.

3.) Check that the delivery is complete.

Assembly

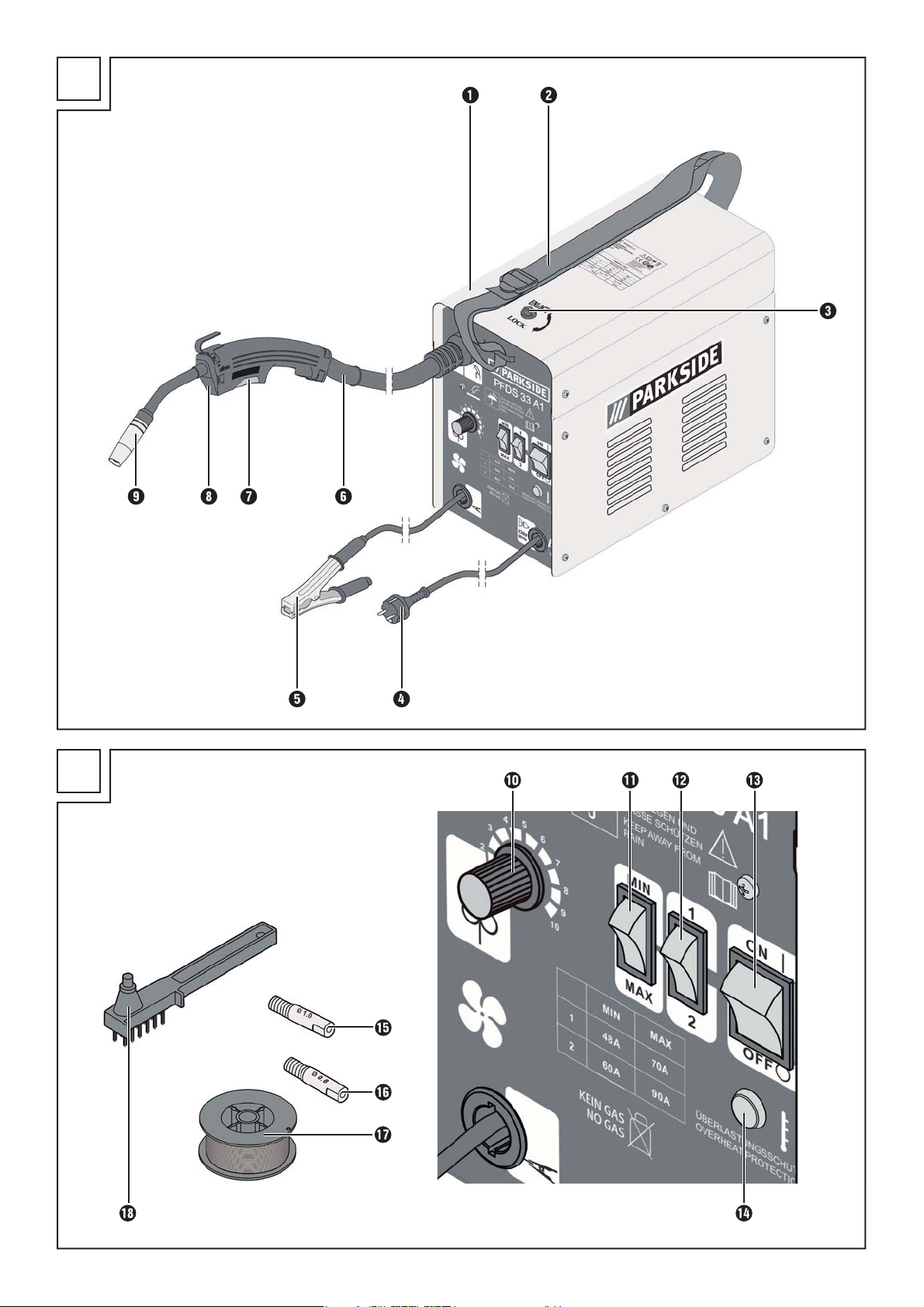

Fitting the welding mask

♦ Fold the side parts of the mask inwards.

Press the integrated clips into the corresponding holes so that they click

into each other (see fig. D).

Filling with flux-cored wire

WARNING!

► To avoid the danger of electric shock, injury or damage:

Before maintenance or pre-work preparation activity,

–

always disconnect the mains plug from the mains

power socket.

NOTE

►

Depending on the application, different types of flux-core wires will

be required. This appliance can use wires with a diameter from

0.7–1.0 mm.

► The feed roller, torch nozzle and wire diameter must always match.

► The appliance is designed for wire rolls of up to a maximum of 450 kg.

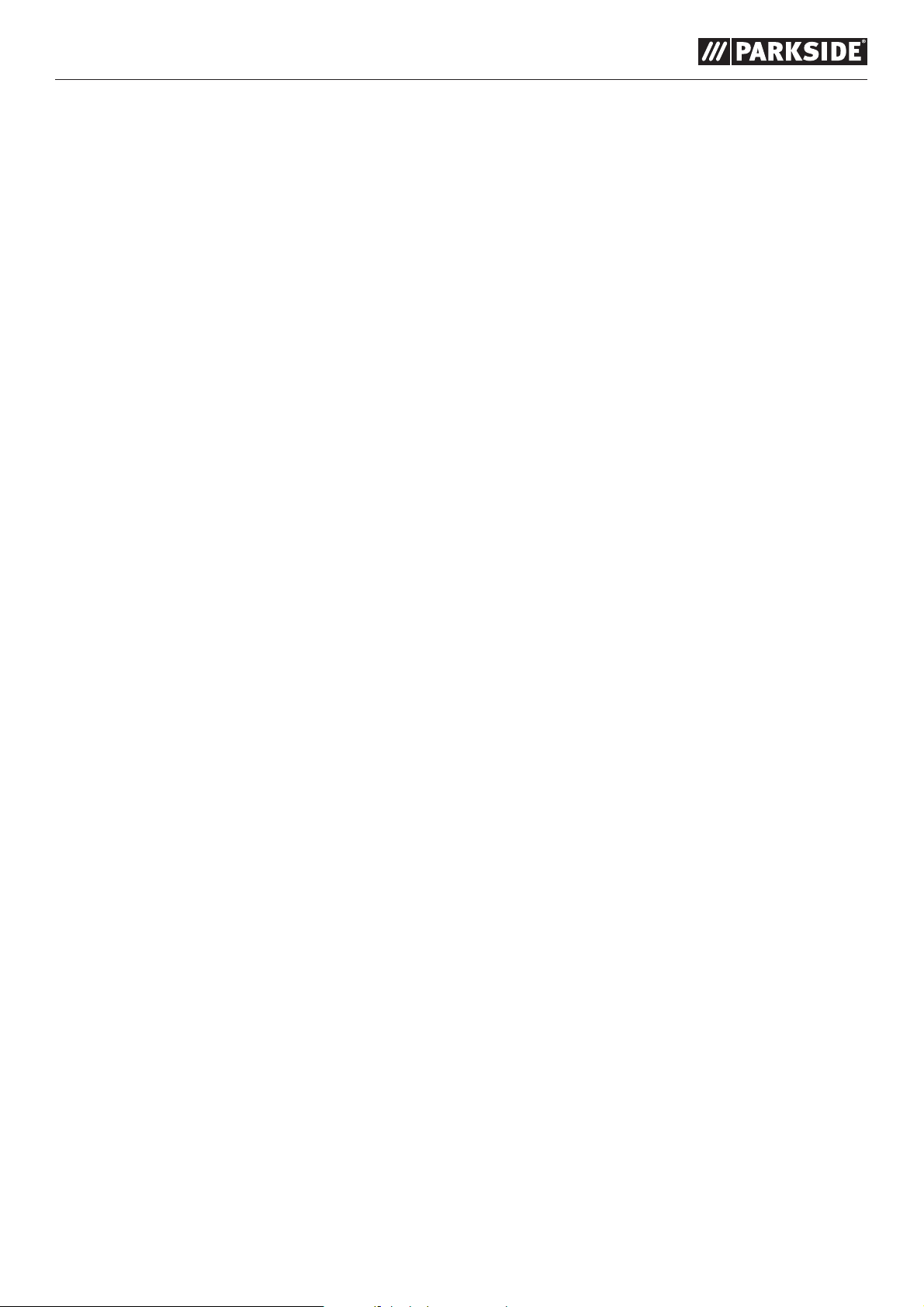

♦ Open the cover of the wire feed unit

arrow marking) to the position UNLOCK (see fig. 1).

by turning the catch (see

♦ Lay the dark welding lens

top (see fig. E).

The writing on the dark welding lens

front side of the welding mask.

♦ Push the handle

mask, until it clicks into place (see fig. F).

from the inside into the corresponding recess on

into the mask with the writing at the

must now be visible from the

Fig. 1

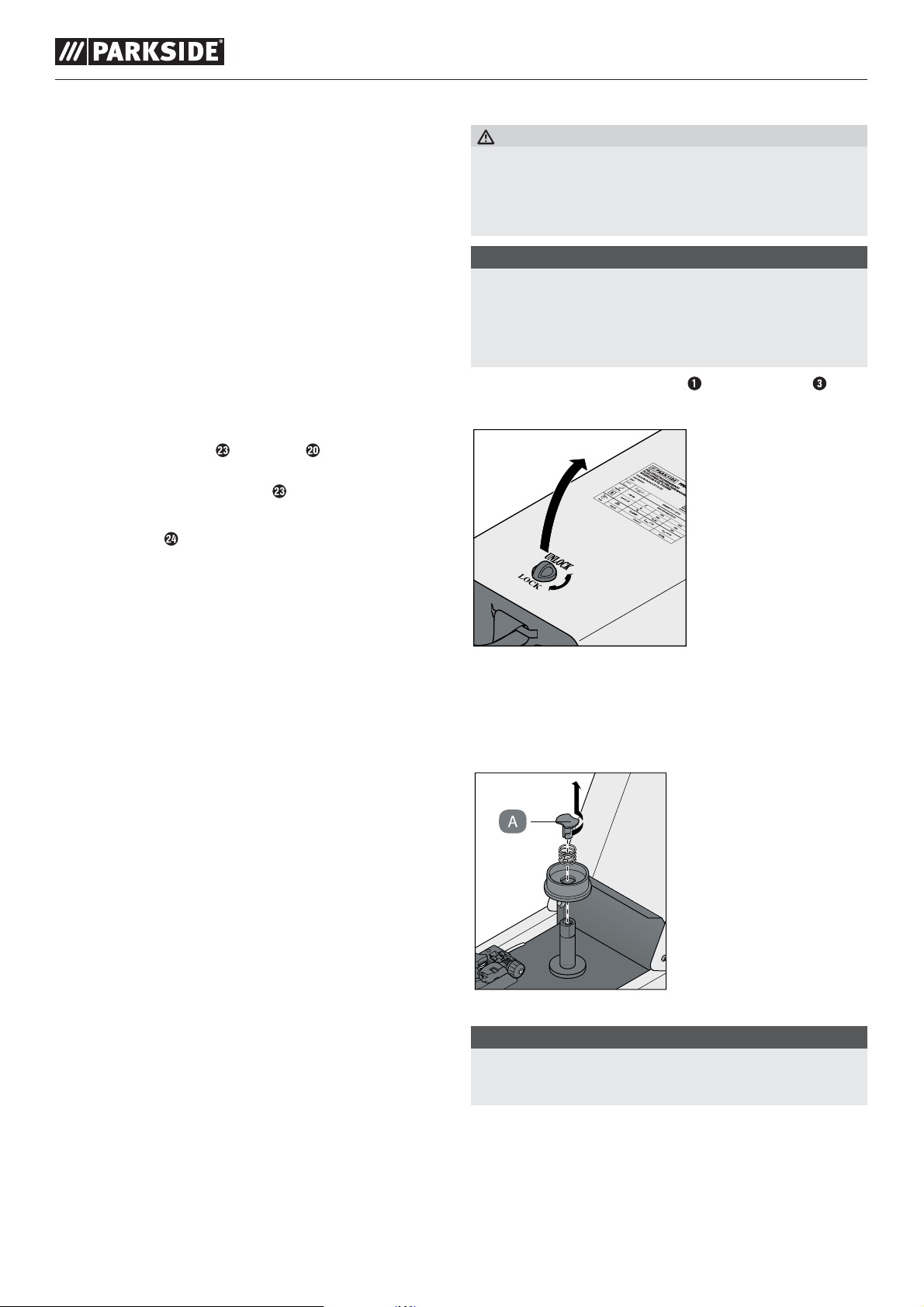

♦ Unlock the roller unit by turning the roller mount A 90° anticlockwise

(see fig. 2).

♦ Pull the roller unit from the shaft (see fig. 2).

■ 8 │ GB│IE│NI

Fig. 2

NOTE

► Make sure that the end of the wire does not come loose and cause

the roll to roll out on its own. The end of the wire may not be

released until during assembly.

PFDS 33 A1

Page 13

♦ Unpack the wire roll completely so that it can be unrolled unimpeded.

Do not release the wire end yet (see fig. 3).

♦ Place the wire roll onto the shaft. Make sure that the roll unwinds on

the same side as the wire feed guide C (see fig. 3).

♦ Put the roll mount A back on and lock it by pressing and turning it

clockwise 90° (see fig. 3).

Fig. 3

♦ Undo the adjustment screw D and swing it upwards (see fig. 4).

♦ Replace the feed roll holder F and screw it tight.

Fig. 6

♦ Remove the torch nozzle

♦ Unscrew the flow nozzle

♦ Route the cable assembly

possible (laying on the floor).

by turning it to the right (see fig. 7).

(see fig. 7).

away from the welder as straight as

Fig. 4

♦ Push the press roller unit E to the side (see fig. 5).

Fig. 5

♦ Undo the feed roll holder F by turning it anticlockwise and pulling it

upwards and off (see fig. 6).

♦ Check the upper side of the feed roll G to see if it is the correct wire

size. If required, the feed roll must be turned over or exchanged. The

supplied welding wire (Ø 0.9 mm) must be used in the feed roll G

with the next biggest specified wire thicknesses of Ø 1.0 mm.

The wire must be positioned in the upper groove!

Fig. 7

♦ Pull the wire end from the edge of the spool (see fig. 8).

♦ Trim the wire end with a wire cutter or a diagonal cutter to remove any

damaged/bent wire (see see fig. 8).

NOTE

♦ THE WIRE MUST BE HOLD ON TENSION ALL THE TIME, TO AVOID

A RELEASING AND ROLL OUT! We recommend that you always

carry out work with the help of a second person.

Fig. 8

PFDS 33 A1

GB│IE│NI │ 9 ■

Page 14

♦ Push the flux-core wire through the wire feed guide C (see fig. 9).

Fig 9

♦ Guide the wire along the feed roll G and then push it into the cable

assembly opening I (see fig. 10).

♦ As soon as the wire juts 1–2 cm out of the torch neck M, release the

torch button

Fig. 12

♦ Switch off the welder.

♦ Screw the flow nozzle back on.

Make sure that the flow nozzle

welding wire being used (see fig. 13).

With the supplied welding wire (Ø 0.9 mm) the flow nozzle

must be used with the next largest diameter of 1.0 mm .

(see fig. 12).

matches the diameter of the

Fig. 10

♦ Swivel the press roller unit E in the direction of the feed roll G

(See fig. 11).

♦ Hook the adjustment screw D into place (see fig. 11).

♦ Set the adjustment screw so that the welding wire sits firmly between

the press roller and the feed roll G in the upper guide without being

pinched (see fig. 11).

Fig. 11

♦ Switch on the welder using the main switch

♦ Press the torch button

Now the wire feed system pushes the welding wire through the cable

assembly

and the torch .

.

.

Fig. 13

♦ Push the torch nozzle

right (see fig. 14).

Fig. 14

WARNING!

► To avoid the danger of electric shock, injury or damage:

Before maintenance or pre-work preparation activity,

–

back onto the torch neck M with a turn to the

always disconnect the mains plug from the mains

power socket.

■ 10 │ GB│IE│NI

PFDS 33 A1

Page 15

Operation

Welding

Switching the appliance on and off

♦ Switch the welder on and off using the main switch .

If you do not intend to use the welder for an extended period, remove the

plug from the power socket. This is the only way to completely de-energise

the appliance.

Setting the welding current

■ Use the switches on the front of the welder to set the required

welding current.

■ If, for example, the MIN switch

up position, the welding current is 48 A and the duty cycle is at 60%.

■ If the MAX switch und the switch 2 are set to the down position,

the welding current is 90 A and the duty cycle is at 10%.

■ The required welding current is dependent on the diameter of the welding

wire being used, the material thickness and the desired penetration

depth.

1 48 A 70 A

2 60 A 90 A

und the switch 1 are set to the

MIN MAX

Adjusting the wire feed

■ To achieve a consistent weld result, you can make fine adjustments to

the wire feed using the setting wheel for the wire feed

We recommend using a setting in the middle range to start with and

then increasing or reducing the speed as required.

■ The required welding flow is dependent on the diameter of the welding

wire being used, the material thickness and the desired penetration

depth as well as the bridging distance between the two pieces being

welded.

.

Overload protection

■ The welder is protected against overheating by an automatic protection

appliance (thermostat with automatic restart) metal clad. The protection

appliance interrupts the power supply in the event of an overload and

the yellow overload protection control lamp lights up.

■ If the protection appliance activates, allow the appliance to cool down

(approx. 15 minutes). As soon as the yellow overload protection control

goes off, the appliance is again ready for use.

lamp

Welding mask

WARNING! HEALTH HAZARD!

► If you do not use the welding mask, the harmful UV radiation and the

heat coming from the electric arc can damage your eyes.

Always use the welding mask when you weld.

–

WARNING! RISK OF BURNS!

► Welded, hot workpieces are very hot so that you could burn yourself.

Always use pliers to move welded, hot workpieces.

–

After you have connected the welder to the power, proceed as follows:

♦ Connect the earth cable to the workpiece that is to be welded using

the earth clamp

Ensure that there is a good electrical connection.

♦ The workpiece should be free of rust and paint where the weld is to

made.

♦ Select the desired welding current and the wire feed depending on

the welding wire diameter, material thickness and desired penetration

depth.

♦ Switch the appliance on.

♦ Hold the welding mask

nozzle

♦ Press the torch button

Once the electric arc is burning, the appliance feeds wire into the weld

pool.

♦ Once the weld nugget is big enough, guide the torch

the desired edge.

The distance between the torch nozzle and the workpiece should be

as small as possible (never more than 10 mm).

♦ If required, oscillate a little to increase the size of the weld pool.

For inexperienced welders, it is often difficult initially to create a decent

electric arc, i.e. in terms of the correct setting of welding current and wire

feed rate.

♦ You can work out the ideal settings for the welding current and the

wire feed rate by carrying out trial welds on a test piece.

A properly set electric arc has a mild, uniform buzzing tone.

The penetration depth should be as deep as possible, the weld pool,

however, should not be able to fall through the workpiece.

If you hear a raw or hard rattle, reduce the wire feed rate and switch

up to a higher load level (increase the welding current).

If the wire feed rate is too high and/or the welding current too low, the

welding wire cannot melt properly and dips repeatedly into the weld

bed as far as the workpiece.

A quiet dull sound with a guttering electric arc indicates that the wire

feed is insufficient.

♦ Increase the wire feed rate or switch to a lower welding current.

If the welding current is too high, the wire will melt before it even

reaches the weld bed. This leads to droplet formation on the welding

wire as well as splash and an irregular electric arc.

to the position on the workpiece where you want to weld.

.

in front of your face and guide the torch

to generate an electric arc.

slowly along

PFDS 33 A1

♦ The slag may not be removed until the weld has cooled down.

To resume a weld on an interrupted joint:

♦ Start by removing the slag at the starting point.

♦ Ignite the electric arc in the groove, guide it to the continuation point,

melt properly and then continue the weld joint.

GB│IE│NI │ 11 ■

Page 16

CAUTION!

► Please note that the torch must always be put down on an insulated

surface after welding.

♦ Always switch off the welder after completing welding work and

during breaks and pull the plug out of the mains socket.

Weld types

Forehand welding

The torch is pushed forwards.

Result: lower penetration depth, broader weld, flatter weld bead and

greater fusion error tolerance.

Backhand welding

The torch is dragged from the weld joint.

Result: higher penetration depth, narrower weld, higher weld bead and

lower fusion error tolerance.

Flat butt welds

Welds should be made without interruption and with a sufficient penetration depth. Therefore, good preparation is extremely important.

■ The factors that influence the quality of the weld result are: the amper-

age, the distance between weld edges, the inclination of the torch and

the corresponding diameter of the welding wire.

■ The steeper you hold the torch against the workpiece, the higher the

penetration depth and vice versa.

Welded joints

There are two basic types of joint types in welding: Butt welds and angle

welding (outer edge, inner edge and overlapping).

Butt welds

With butt welds of up to 2 mm, the weld edges are moved completely

together.

For greater thicknesses, see the table below:

d

S

S= 1–3 mm 3–4 mm 4–6 mm

Area d= 0.5–1.5 mm 1.5–2.5 mm 2–3 mm

Fusion face

d=

Vertical

d=

1–2 mm 2–3 mm 3–4 mm

1–1.5 mm 1.5–2.5 mm 2–3 mm

■ To forestall or reduce deformations that can happen during the material

hardening process, it is good to fix the workpiece, where possible,

using a clamp that counteracts the contraction and deformation of the

material.

■ Avoid stiffening the welded structure to prevent cracks in the weld.

These problems can be avoided if there is a possibility of turning the

workpiece so that the weld can be carried out in two passes running in

opposite directions.

Welds on an outer edge

The preparation for this is very simple.

■ 12 │ GB│IE│NI

For thicker materials, however, it is no longer expedient. In this case, it is

better to prepare a joint as shown opposite in which the edge of a plate is

angled.

45°

PFDS 33 A1

Page 17

Welds on an inner edge

The preparation for this weld joint is very simple and is carried out for thicknesses of 5 mm. The dimension “d” needs to be reduced to a minimum

and should always be less than 2 mm.

Wire feed

■ Regular cleaning of the wire feed drive and replacement of worn wire

feed rolls.

■ Blow out the steel core with compressed air.

■ Do not tighten the tension spring on the pressure roller too tightly. Ex-

cessive pressure lead to higher abrasion of the steel wire. The dust thus

created deposits in the guide spring and causes an uneven discharge

of the welding wire making it impossible to create an even weld.

d

For thicker materials, however, it is no longer expedient. In this case, it is better

to prepare a joint as shown opposite in which the edge of a plate is angled.

45°45°

Overlap welds

The most usual preparation is that with straight weld edges. The weld can

be undone using a standard angle weld seam. Both workpieces must be

brought as close to each other as possible.

Cable assembly

■ Protect the cable assembly from external damage.

■ Never pull it over sharp edges or other objects.

■ Never drive a vehicle over it.

■ Clean the cable assembly regularly.

■ The steel sleeve and torch nozzle are wearing parts.

■ The torch nozzle is exposed to heat radiation and friction from the wire

and must be checked and replaced regularly.

■ Weld splatter collects on the torch nozzle. This must be removed

regularly.

■ For overhead welding, frequent cleaning is necessary.

■ Use nozzle grease or nozzle spray before and after welding. This

prevents too much splatter from accumulating.

Welder

■ The transformer of the welder must be freed of accumulated dust to

ensure that the cooling works properly. In especially dirty air, a monthly

cleaning using compressed air is necessary.

■ Protect the welder from metal dust.

Cleaning and care

WARNING!

► To avoid the danger of electric shock, injury or damage:

Before cleaning, always disconnect the mains plug

–

from the mains power socket.

– Never immerse the flux-core welder or the accessories

in water.

– Allow the flux-core welder and accessories to cool

down before cleaning them.

– Never use abrasive, caustic or scratching cleaning

agents. These can damage the appliance.

■ Keep the flux-core welder clean. Welding equipment must be kept free

of dust to ensure adequate cooling. In especially dirty air, a monthly

cleaning using compressed air is necessary.

■ Protect the flux-core welder from metal dust.

■ Store the flux-core welder in a dry room, secured from access by un-

authorised persons or children.

■ Ensure that the welding lead, the torch and earth clamp are all in

perfect condition.

■ Cables and current-carrying parts of the flux-core welder with dam-

aged insulation are dangerous and can impair the proper functioning

of the appliance.

■ Repairs may only be carried out by authorised repair shops or similarly

qualified persons.

■ Always disconnect the appliance from the mains power supply before

all maintenance and repair work.

PFDS 33 A1

GB│IE│NI │ 13 ■

Page 18

Troubleshooting

Malfunction Possible cause Remedy

No function. Incorrect mains connection. Check mains fuse or have the mains supply checked by a technician.

The overload protection has

activated.

Irregular wire feed. Not enough pressure on the

feed roll.

Wire not lying correctly in the

groove of the feed roll or the

groove is too big or the wire

feed roll is worn.

Poorly wound wire; crossed

wires.

No wire feed. Torch switch or control line in

cable assembly defective.

Wire feed not adjustable. Adjusting wheel or control circuit

defective.

No welding current with

normally functioning wire

feed.

Torch is getting too hot. Flow nozzle loose or too large. Tighten or replace flow nozzle.

Welding current too low. Bad earth contact. Check the earth clamp and cable as well as the cable assembly.

Cable assembly or earth cable

defective.

Control circuit defective.

Allow the appliance to cool down.

Increase pressure.

Place wire correctly in the groove of the feed roll or, if necessary, replace the

feed roll.

Replace wire roll.

Please contact our service department.

Please contact our service department.

Check cable assembly and earth cable and, if necessary, contact the service

department.

If necessary, contact our service department.

■ 14 │ GB│IE│NI

PFDS 33 A1

Page 19

Disposal

The packaging is made from environmentally friendly material

and can be disposed of at your local recycling plant.

Do not dispose of power tools in your normal

household waste!

European Directive 2012/19/EU requires that worn-out power tools

be collected separately and recycled in an environmentally compatible

manner.

Take the appliance to a nearby collection facility.

Please consult your local authorities regarding suitable disposal of wornout power tools.

Warranty claim procedure

To ensure quick processing of your case, please observe the following

instructions:

■ Please have the till receipt and the item number (e.g. IAN 12345)

available as proof of purchase.

■ You will find the item number on the type plate, an engraving on the

front page of the instructions (bottom left), or as a sticker on the rear or

bottom of the appliance.

■ If functional or other defects occur, please contact the service depart-

ment listed either by telephone or by e-mail.

■ You can return a defective product to us free of charge to the service

address that will be provided to you. Ensure that you enclose the proof

of purchase (till receipt) and information about what the defect is and

when it occurred.

Kompernass Handels GmbH warranty

Dear Customer,

This appliance has a 3-year warranty valid from the date of purchase. If this

product has any faults, you, the buyer, have certain statutory rights. Your statutory rights are not restricted in any way by the warranty described below.

Warranty conditions

The validity period of the warranty starts from the date of purchase. Please

keep your original receipt in a safe place. This document will be required

as proof of purchase.

If any material or production fault occurs within three years of the date of

purchase of the product, we will either repair or replace the product for

you at our discretion. This warranty service is dependent on you presenting

the defective appliance and the proof of purchase (receipt) and a short

written description of the fault and its time of occurrence.

If the defect is covered by the warranty, your product will either be repaired

or replaced by us. The repair or replacement of a product does not signify

the beginning of a new warranty period.

Warranty period and statutory claims for defects

The warranty period is not prolonged by repairs effected under the

warranty. This also applies to replaced and repaired components. Any

damage and defects present at the time of purchase must be reported immediately after unpacking. Repairs carried out after expiry of the warranty

period shall be subject to a fee.

Scope of the warranty

This appliance has been manufactured in accordance with strict quality

guidelines and inspected meticulously prior to delivery.

The warranty covers material faults or production faults. The warranty does

not extend to product parts subject to normal wear and tear or fragile parts

such as switches, batteries, baking moulds or parts made of glass.

The warranty does not apply if the product has been damaged, improperly

used or improperly maintained. The directions in the operating instructions

for the product regarding proper use of the product are to be strictly followed. Uses and actions that are discouraged in the operating instructions

or which are warned against must be avoided.

This product is intended solely for private use and not for commercial

purposes. The warranty shall be deemed void in cases of misuse or improper

handling, use of force and modifications/repairs which have not been

carried out by one of our authorised Service centres.

You can download these instructions along with many other

manuals, product videos and software on

www.lidl-service.com.

Service

WARNING!

► Have the power tool repaired by the service centre or a qualified

electrician and only using genuine replacement parts.

This will ensure that the safety of the appliance is maintained.

► Always ensure that the power plug or the mains cable is replaced

only by the manufacturer of the appliance or by an approved

customer service provider. This will ensure that the safety of the

appliance is maintained.

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

IAN 280331

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

IAN 280331

Importer

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

44867 BOCHUM

GERMANY

www.kompernass.com

PFDS 33 A1

GB│IE│NI │ 15 ■

Page 20

Translation of the original Conformity

Declaration

We, KOMPERNASS HANDELS GMBH, documents officer:

Mr. Semi Uguzlu, BURGSTR. 21, 44867 BOCHUM, GERMANY, hereby

declare that this product complies with the following standards, normative

documents and EC directives:

EC Low Voltage Directive

(2014/35/EU)

EMC (Electromagnetic Compatibility)

(2014/30/EU)

RoHS Directive

(2011/65/EU)*

*The manufacturer bears the full responsibility for compliance with this

conformity declaration. The object of the declaration described above

complies with the requirements of the Directive 2011/65/EU of the European Parliament and Council of 8 June 2011 on the limitations of use of

certain dangerous substances in electrical and electronic appliances.

Applied harmonised standards:

EN 60974-1: 2012

EN 60974-10: 2014/A1: 2015

EN 50581: 2012

Type/appliance designation:

Flux-cored wire welder PFDS 33 A1

Year of manufacture: 08 - 2016

Serial number: IAN 280331

Bochum, 29/07/2016

Semi Uguzlu

- Quality Manager -

The right to effect technical changes in the context of further development

is reserved.

■ 16 │ GB│IE│NI

PFDS 33 A1

Page 21

Inhaltsverzeichnis

Einleitung ..................................18

Bestimmungsgemäßer Gebrauch .......................18

Restrisiko ..........................................18

Ausstattung ........................................18

Lieferumfang .......................................18

Technische Daten....................................19

Leistungsschild und Symbolerklärung ....................19

Sicherheit ..................................20

Grundsätzliche

Sicherheitshinweise ..................................20

Besondere Sicherheitshinweise .........................21

Ergänzende Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . 21

Gefahrenquellen ............................22

Unfallgefahr durch elektrischen Schlag...................22

Enge und heiße Räume ...............................22

Unfallgefahr durch Luftmangel in engen Räumen ...........22

Schutzkleidung .....................................22

Schutz gegen Strahlen und Verbrennungen ...............23

Unfallgefahr durch sprühende Funken....................23

Unfallgefahr durch spritzende Schlacketeilchen ............23

Brandgefahr durch sprühende Funken....................23

Explosionsgefahr ....................................23

EMV-Geräteklassifizierung....................23

Auspacken und Lieferumfang prüfen ...........24

Montage...................................24

Schweißschutzschild montieren .........................24

Fülldraht einsetzen...................................24

Betrieb ....................................27

Gerät ein- und ausschalten ............................27

Schweißstrom einstellen...............................27

Drahtvorschub einstellen ..............................27

Überlastschutz ......................................27

Schweißschutzschild .................................27

Schweißen.........................................27

Schweißnaht ...............................28

Stechnaht oder stoßendes Schweißen....................28

Schleppnaht oder ziehendes Schweißen .................28

Schweißverbindungen................................28

Stumpfschweißverbindungen...........................28

Flache Stumpfschweißverbindungen .....................28

Schweißverbindungen an der Außenecke.................28

Schweißverbindungen in der Innenecke ..................29

Überlappungsschweißverbindungen.....................29

Reinigung und Pflege ........................29

Drahtvorschub ......................................29

Schlauchpaket......................................29

Schweißgerät.......................................29

Fehlersuche ................................30

Entsorgung.................................31

Garantie der Kompernaß Handels GmbH .......31

Service ....................................31

Importeur..................................31

Original-Konformitätserklärung ...............32

PFDS 33 A1

DE│AT│CH │ 17 ■

Page 22

FÜLLDRAHT-SCHWEISSGERÄT

PFDS 33 A1

Einleitung

Wir beglückwünschen Sie zum Kauf Ihres neuen Gerätes. Sie haben sich

damit für ein hochwertiges Produkt entschieden. Die Bedienungsanleitung ist

Teil dieses Produkts. Sie enthält wichtige Hinweise für Sicherheit, Gebrauch und

Entsorgung. Machen Sie sich vor der Benutzung des Produkts mit allen Bedienund Sicherheitshinweisen vertraut. Benutzen Sie das Produkt nur wie beschrieben und für die angegebenen Einsatzbereiche. Händigen Sie alle Unterlagen

bei Weitergabe des Produkts an Dritte mit aus.

Bestimmungsgemäßer Gebrauch

Das Gerät ist zum selbstschützenden Fülldrahtschweißen unter Verwendung des entsprechenden Drahtes geeignet. Es wird kein zusätzliches Gas

benötigt. Das Schutzgas ist in pulverisierter Form im Draht enthalten, wird

somit direkt in den Lichtbogen geleitet und macht das Gerät bei Arbeiten

im Freien unempfindlich gegen Wind.

Es dürfen nur für das Gerät geeignete Drahtelektroden verwendet werden.

Bestandteil der bestimmungsgemäßen Verwendung ist auch die Beachtung

der Sicherheitshinweise sowie der Montageanleitung und der Betriebshinweise in der Bedienungsanleitung.

Die geltenden Unfallverhütungsvorschriften sind genauestens einzuhalten.

Das Gerät darf nicht verwendet werden:

▯ in nicht ausreichend belüfteten Räumen,

▯ in feuchter oder nasser Umgebung,

▯ in explosionsgefährdeter Umgebung,

▯ zum Auftauen von Rohren,

▯ in der Nähe von Menschen mit Herzschrittmacher und

▯ in der Nähe von leicht entflammbaren Materialien.

Verwenden Sie das Gerät nur wie in dieser Bedienungsanleitung beschrieben. Jede andere Verwendung gilt als nicht bestimmungsgemäß und kann

zu Sachschäden oder sogar zu Personenschäden führen.

Der Hersteller oder Händler übernimmt keine Haftung für Schäden, die

durch nicht bestimmungsgemäßen oder falschen Gebrauch entstanden

sind.

Ausstattung

Abdeckung Drahtvorschubeinheit

Tragegurt

Verriegelung

Netzstecker

Massekabel mit Masseklemme

Schlauchpaket mit Direktanschluss

Brennertaste

Brenner

Brennerdüse

Einstellrad für Drahtvorschub

MIN/MAX Schalter für Schweißstromeinstellung

1/2 Schalter für Schweißstromeinstellung

Hauptschalter EIN/AUS

(inkl. Netzkontrolllampe)

Kontrolllampe Überlastschutz

Schweißdüse (1,0 mm)

Schweißdüse (0,8 mm)

Fülldraht-Schweißspule (Drahtrolle) Ø 0,9 mm/510 g

Schlackenhammer mit Drahtbürste

Schweißschutzschild nach Montage,

bestehend aus:

Schildkörper

Schutzglasverriegelung

Montageclip

Dunkles Schweißglas

Handgriff

Lieferumfang

1 Fülldraht-Schweißgerät PFDS 33 A1

1 Brennerdüse (vormontiert)

3 Schweißdüsen ( 1x 1,0 mm vormontiert ; 1x 0,8 mm ; 1x 1,0 mm)

1 Schlackenhammer mit Drahtbürste

1 Fülldraht Ø 0,9 mm/510 g

1 Schweißschutzschild

1 Tragegurt

1 Bedienungsanleitung

Restrisiko

Auch wenn Sie das Gerät vorschriftsmäßig bedienen, bleiben immer Restrisiken bestehen. Folgende Gefahren können im Zusammenhang mit der

Bauweise und Ausführung dieses Fülldrahtschweißgerätes auftreten:

▯ Augenverletzungen durch Blendung,

▯ Berühren heißer Teile des Gerätes oder des Werkstückes (Brandverlet-

zungen),

▯ Bei unsachgemäßer Absicherung Unfall- und Brandgefahr durch sprü-

hende Funken oder Schlacketeilchen,

▯ Gesundheitsschädliche Emissionen von Rauchen und Gasen, bei Luft-

mangel bzw. ungenügender Absaugung in geschlossenen Räumen.

Vermindern Sie das Restrisiko, indem Sie das Gerät sorgfältig und vorschriftsmäßig benutzen und alle Anweisungen befolgen.

■ 18 │ DE│AT│CH

PFDS 33 A1

Page 23

Technische Daten

Typ: Fülldraht-Schweißgerät

PFDS 33 A1

Netzspannung U

Schweißstrom I

Leerlaufspannung U

Schutzart: IP 21S

Isolationsklasse: H

Gewicht: 12,7 kg

Schweißdraht: Ø 0,7 / 0,8 / 0,9 / 1,0 mm

Schweißdrahttrommel: ca. 450 g

Schweißstrom:

▯ Materialstärke

1,0 – 2,0 mm: Mit Ø 0,7 / 0,8 mm Schweißdraht,

▯ Materialstärke

2,0 – 6,0 mm: Mit Ø 0,8/0,9/1,0 mm Schweißdraht,

Einschaltdauer X: 10 % bei 90 A Schweißstrom

: 230 V ~ / 50 Hz

1

(Wechselstrom)

: 48 A / 90 A

2

: 27,5 V

0

Schweißstrom 48 A – 60 A

Schweißstrom 70 A – 90 A

60 % bei 48 A Schweißstrom

U

0

Ø mm

I

2

X

U

2

1~ 50 Hz

U

1

I1 max

I1 eff

IP21S

H

12,7 kg

Einphasen-Transformator

Nennleerlaufspannung

zulässiger Fülldrahtdurchmesser

Symbol für selbstschützendes Fülldrahtschweißgerät

Bemessungswert des Schweißstroms

Einschaltdauer in %

genormte Arbeitsspannung

Netzanschluss, Anzahl der Phasen Wechselstromsymbol und Bemessungswert der Frequenz

Bemessungswert der Netzspannung

größter Bemessungswert des Netzstroms

Effektivwert des größten

Netzstroms (A)

Schutzart

Isolationsklasse

Gewicht des Gerätes

Sicherheitsbestimmungen beachten

Leistungsschild und Symbolerklärung

PFDS 33 A1 S/N:

EN 60974-1:2012

EN 60974-10:2014/A1:2015

Class A

48 A / 16 V – 90 A / 18.5 V

50 Hz

~

U0 = 27.5 V

1~ 50 Hz U1 = 230 V I

IP21S 12.7 kg

X 10 % 60 %

I

2

U

2

90 A 48 A

18.5 V 16 V

= 13 A I

1max

= 4.8 A

1eff

Gefahr! Betriebsanleitung lesen!

Lagern oder verwenden Sie das Gerät nicht in

nasser Umgebung oder Regen

Symbol für Schweißstromquellen, die zum Schweißen

in Umgebungen mit erhöhter elektrischer Gefährdung

geeignet sind.

Nennwert der erforderlichen Netzsicherung: 16 A

PFDS 33 A1

DE│AT│CH │ 19 ■

Page 24

Gehörschutz tragen!

Schutzbrille tragen!

Staubmaske tragen!

Schutzhandschuhe tragen!

Schutzschild verwenden!

Schutzkleidung tragen!

Schutzschuhe tragen!

Gefahr! Betriebsanleitung lesen!

Elektrischer Schlag von der Schweißelektrode

kann tödlich sein!

Einatmen von Schweißrauchen kann Ihre

Gesundheit gefährden!

Schweißfunken können eine Explosion oder einen

Brand verursachen!

Lichtbogenstrahlen können die Augen schädigen

und die Haut verletzen!

Elektromagnetische Felder können die Funktion

von Herzschrittmachern stören!

Zeichenerklärung

Die folgenden Symbole und Signalworte werden in dieser Bedienungsanleitung, am Fülldrahtschweißgerät oder auf der Verpackung verwendet.

GEFAHR! Dieses Signalwort bezeichnet eine

Gefährdung mit einem hohen Risikograd, die,

wenn sie nicht vermieden wird den Tod oder eine

schwere Verletzung zur Folge hat.

WARNUNG! Dieses Signalwort bezeichnet eine

Gefährdung mit einem mittleren Risikograd, die,

wenn sie nicht vermieden wird, den Tod oder eine

schwere Verletzung zur Folge haben kann.

VORSICHT! Dieses Signalwort bezeichnet eine

Gefährdung mit einem niedrigen Risikograd, die,

wenn sie nicht vermieden wird, eine geringfügige

oder mäßige Verletzung zur Folge haben kann.

HINWEIS! Dieses Signalwort warnt vor möglichen

Sachschäden oder gibt Ihnen nützliche Zusatzinformationen zum Zusammenbau oder zum Betrieb.

Sicherheit

Grundsätzliche

Sicherheitshinweise

WARNUNG! STROMSCHLAGGEFAHR!

► Gefahren für Kinder und Personen mit verringerten physischen,

sensorischen oder mentalen Fähigkeiten (beispielsweise teilweise

Behinderte, ältere Personen mit Einschränkung ihrer physischen und

mentalen Fähigkeiten) oder Mangel an Erfahrung und Wissen (beispielsweise ältere Kinder).

■ Das Fülldrahtschweißgerät darf ausschließlich von Erwachsenen

benutzt werden.

■ Kinder müssen beaufsichtigt werden, um sicherzustellen, dass sie nicht

mit dem Fülldrahtschweißgerät spielen.

■ Halten Sie Kinder von Verpackungsmaterial und Kleinteilen fern. Bei

Verschlucken besteht Erstickungsgefahr.

■ Sorgen Sie für eine angemessene Pflege des Gerätes.

■ Reparaturen und/oder Wartungsarbeiten dürfen nur von qualifizierten

Personen durchgeführt werden.

■ Zusätzlich zu den Hinweisen in dieser

Bedienungsanleitung müssen die allgemeinen Sicherheits- und Unfallverhütungsvorschriften des Gesetzgebers berücksichtigt werden.

■ Seien Sie stets aufmerksam und achten Sie immer darauf, was Sie tun.

Führen Sie keine Arbeiten mit dem Fülldrahtschweißgerät durch, wenn Sie

unaufmerksam sind bzw. unter Einfluss von Drogen, Alkohol oder Medikamenten stehen. Bereits ein Moment der Unachtsamkeit beim Gebrauch

dieses Gerätes kann zu ernsthaften Unfällen und Verletzungen führen.

■ Kontrollieren Sie das Gerät vor Inbetriebnahme auf etwaige Beschädi-

gungen. Sollte das Gerät Mängel aufweisen, darf es auf keinen Fall in

Betrieb genommen werden.

■ Achten Sie auf einen einwandfreien Zustand der Schweißkabel, Düse,

des Brenners sowie der Masseklemmen. Abnutzungen an der Isolierung

und an den stromführenden Teilen können eine gefährliche Situation

hervorrufen und die Qualität der Schweißarbeit mindern.

■ Verwenden Sie das Gerät nur wie in dieser Bedienungsanleitung

beschrieben.

■ Der Gebrauch dieses Gerätes kann bei bestimmten Teilen zu Verschleiß

führen. Kontrollieren Sie deshalb das Gerät regelmäßig auf etwaige Beschädigungen und Mängel.

■ Benutzen Sie zu Ihrer eigenen Sicherheit nur Zubehör und Zusatzgerä-

te, die ausdrücklich in der Bedienungsanleitung angegeben oder vom

Hersteller empfohlen werden.

■ Achten Sie bei der Aufstellung des Gerätes auf eine feste und sichere

Standfläche.

■ Bei überlasteten Versorgungsnetzen und Stromkreisen können während

des Schweißens für andere Verbraucher Störungen verursacht werden.

Im Zweifelsfalle ist das Stromversorgungsunternehmen zu Rate zu

ziehen.

■ Beim Schweißen sind die jeweiligen nationalen Richtlinien und Gesetze

zu beachten. Dies betrifft insbesondere die jeweiligen Unfallverhütungsvorschriften.

■ Das Fülldrahtschweißgerät darf ausschließlich auf einem ebenen und

flachen Untergrund aufgestellt werden. Das Fülldrahtschweißgerät ist

so konstruiert, dass es bis zu einem Winkel von 10° Abweichung von

der Ebene kippsicher ist. Sichern Sie das Fülldrahtschweißgerät gegen

Umstürzen, falls sie es auf eine geneigte Ebene stellen.

■ Um Geräteschäden vorzubeugen, darf das

Gerät ausschließlich aufrecht transportiert werden.

■ 20 │ DE│AT│CH

PFDS 33 A1

Page 25

Besondere Sicherheitshinweise

WARNUNG! STROMSCHLAGGEFAHR!

► Fehlerhafte Elektroinstallation, zu hohe Netzspannung oder falsche

Handhabung können zu elektrischem Stromschlag führen. Jeder

Elektroschock kann tödlich sein.

■ Schließen Sie das Fülldrahtschweißgerät nur an, wenn die Netzspannung

der Steckdose mit der Angabe auf dem Typenschild übereinstimmt.

■ Schließen Sie das Fülldrahtschweißgerät nur an eine gut zugängliche

Steckdose an, damit Sie es bei einem Störfall schnell vom Stromnetz

trennen können.

■ Betreiben Sie das Fülldrahtschweißgerät nicht, wenn es sichtbare Schä-

den aufweist oder das Netzkabel bzw. der Netzstecker defekt sind.

■ Das verwendete Netzanschlusskabel ist eine hochwertige Leitung, welche

nicht beschädigt werden darf. Achten Sie bei Ihrer Arbeit darauf, diese

nicht mit heissen Gegenständen zu berühren. Wenn die Anschlussleitung

beschädigt wird, muss diese durch eine besondere Anschlussleitung ersetzt

werden, die vom Hersteller oder seinem Kundendienst erhältlich ist. Das

Auswechseln der Anschlussleitung darf nur durch den Hersteller oder seinen Kundendienst oder ähnlich qualifizierte Personen durchgeführt werden.

■ Öffnen Sie das Gehäuse nur soweit, wie es in dieser Anleitung

beschrieben ist. Überlassen Sie die Reparatur Fachkräften. Wenden

Sie sich dazu an eine Fachwerkstatt. Bei eigenständig durchgeführten

Reparaturen, unsachgemäßem Anschluss oder falscher Bedienung sind

Haftungs- und Garantieansprüche ausgeschlossen.

■ Führen Sie niemals spitze und/oder metallische Gegenstände in das

Innere des Gerätes ein.

■ Bei Reparaturen dürfen nur Teile verwendet werden, die den ursprüng-

lichen Gerätedaten entsprechen. In diesem Fülldrahtschweißgerät

befinden sich elektrische und mechanische Teile, die zum Schutz gegen

Gefahrenquellen unerlässlich sind.

■ Schützen Sie das Fülldrahtschweißgerät vor Feuchtigkeit und verwen-

den Sie es ausschließlich in trockenen Innenräumen.

■ Tauchen Sie weder das Fülldrahtschweißgerät noch Netzkabel oder

-stecker in Wasser oder andere Flüssigkeiten.

■ Fassen Sie das Fülldrahtschweißgerät oder den Netzstecker niemals mit

feuchten Händen an.

■ Vermeiden Sie jeden direkten Kontakt mit dem Schweißstromkreis. Die

Leerlaufspannung, die zwischen Stromdüse und Masseklemme auftritt,

kann gefährlich sein.

■ Ziehen Sie den Netzstecker nie am Netzkabel aus der Steckdose,

sondern fassen Sie immer den Netzstecker an.

■ Vermeiden Sie jede Zugbeanspruchung des Netzkabels.

■ Stecken Sie das Gerät aus, bevor Sie es andernorts aufstellen wollen.

■ Halten Sie das Fülldrahtschweißgerät, den Netzstecker und das Netz-

kabel von offenem Feuer und heißen Flächen fern.

■ Knicken Sie das Netzkabel nicht.

■ Schützen Sie sämtliche Kabel vor Öl, scharfen Kanten und hohen

Temperaturen.

■ Wenn Sie das Fülldrahtschweißgerät nicht benutzen, es reinigen, Einstellarbei-

ten vornehmen oder wenn eine Störung auftritt, schalten Sie das Fülldrahtschweißgerät immer aus und ziehen Sie den Stecker aus der Steckdose.

WARNUNG! VERLETZUNGSGEFAHR!

► Unsachgemäße Handhabung kann zu schweren Verletzungen führen.

■ Verlegen Sie das Netzkabel so, dass es nicht zur Stolperfalle wird.

■ Die Lichtstrahlung des Lichtbogens kann die Augen schädigen. Schützen

Sie die Augen mit dafür bestimmten Schutzgläsern (EN 166, EN 169 /

Schutzgrad 10), die Sie auf dem beigelegten Schutzschild befestigen.

■ Die Lichtstrahlung des Lichtbogens kann Verbrennungen auf der Haut

hervorrufen. Verwenden Sie Handschuhe und trockene Schutzkleidung,

die frei von Öl und Fett ist, um die Haut nicht den ultravioletten Strahlungen des Lichtbogens auszusetzen.

■ Das geschweißte Arbeitsstück beginnt zu glühen und bleibt relativ lange

sehr heiß. Achten Sie darauf, dass es abgekühlt ist, bevor Sie es anfassen.

■ Beim Lichtbogenschweißen werden Dämpfe frei, die möglicherweise

schädlich sind.

■ Achten Sie darauf, dass sich keine Personen ohne Schutzkleidung und

Augenschutz im Umkreis von 15 m um den Lichtbogen befinden. Schützen Sie sich und umstehende Personen gegen die eventuell gefährlichen Effekte des Lichtbogens!

WARNUNG! BRANDGEFAHR!

► Unsachgemäße Handhabung kann zu Bränden oder Explosionen führen.

■ Lichtbogenschweißen erzeugt Funken, geschmolzene Metallteile und

Rauch. Achten Sie daher darauf, alle brennbaren Substanzen und/

oder Materialien vom Arbeitsplatz zu entfernen.

■ Das geschweißte Arbeitsstück beginnt zu glühen und bleibt relativ

lange sehr heiß. Es kann daher im Kontakt mit brennbaren Materialien

einen Brand erzeugen.

■ Schweißen Sie nicht auf Behältern, Gefäßen oder Rohren, die brennba-

re Flüssigkeit oder Gase enthalten haben.

WARNUNG! ELEKTROMAGNETISCHE FELDER!

► Durch das Fülldrahtschweißgerät und den Lichtbogen können elektrische

oder elektromagnetische Felder entstehen, die elektronische Anlagen

und Geräte stören können. Dazu gehören z.B. EDV-Anlagen, Telekommunikationseinrichtungen, elektronisch gesteuerte Geräte und Maschinen. Auch Netz- und Signalleitungen können gestört werden.Herzschrittmacher können gestört werden.

■ Beachten Sie die Wartungsvorschriften.

■ Wickeln Sie das Massekabel

ab. Aufgewickelt können sich elektromagnetische Felder verstärken.

■ Schirmen Sie strahlungsempfindliche Geräte oder Maschinen ausreichend ab.

■ Halten Sie vor dem Schweißen Rücksprache mit Ihrem Arzt, wenn Sie einen

Herzschrittmacher tragen.

VORSICHT!

► Unsachgemäße Handhabung kann zur Überhitzung des Fülldraht-

schweißgerät oder Sachschäden führen.

■ Das Fülldrahtschweißgerät darf während der Funktionsdauer nicht

eingeengt oder direkt an der Wand stehen, damit immer genügend Luft

durch die Öffnungsschlitze aufgenommen werden kann.

■ Überzeugen Sie sich, dass ausreichend Luftzufuhr zur Verfügung steht.

sowie das Schlauchpaket vollständig

Ergänzende Sicherheitshinweise

■ Gefährdung durch elektrischen Schlag. Elektrischer Schlag von einer

Schweißelektrode kann tödlich sein. Nicht bei Regen oder Schnee

schweißen. Trockene Isolierhandschuhe tragen. Die Elektrode nicht mit

bloßen Händen anfassen. Keine nassen oder beschädigten Handschuhe

tragen. Sich selbst vor einem elektrischen Schlag durch Isolierungen gegen

das Werkstück schützen. Das Gehäuse der Einrichtung nicht öffnen.

■ Gefährdung durch Schweißrauch. Das Einatmen von Schweißrauchen kann die

Gesundheit gefährden. Den Kopf nicht in die Rauche halten. Einrichtungen in offenen Bereichen verwenden. Entlüftung zum Entfernen der Rauche verwenden.

■ Gefährdung durch Schweißfunken. Schweißfunken können eine Explo-

sion oder einen Brand verursachen. Brennbare Stoffe vom Schweißen

fernhalten. Nicht neben brennbaren Stoffen schweißen. Schweißfunken

können Brände verursachen. Einen Feuerlöscherin der Nähe bereithalten und einen Beobachter, der ihn sofort benutzen kann. Nicht auf

Trommeln oder irgendwelchen geschlossenen Behältern schweißen.

■ Gefährdung durch Lichtbogenstrahlen. Lichtbogenstrahlen können die Augen

schädigen und die Haut verletzen. Hut und Sicherheitsbrille tragen. Gehörschutz und hoch geschlossen Hemdkragen tragen. Schweißerschutzhelme

und einwandfreie Filtergrößen tragen. Vollständigen Körperschutz tragen.

■ Gefährdung durch elektromagnetische Felder. Schweißstrom erzeugt

elektromagnetische Felder. Nicht zusammen mit medizinischen Implantaten

verwenden. Niemals die Schweißleitungen um den Körper wickeln. Schweißleitungen zusammenführen.

PFDS 33 A1

DE│AT│CH │ 21 ■

Page 26

Gefahrenquellen

Beim Lichtbogenschweißen ergeben sich eine Reihe von Gefahrenquellen.

Es ist daher für den Schweißer besonders wichtig, nachfolgende Regeln

zu beachten, um sich und andere nicht zu gefährden und Schäden für

Mensch und Gerät zu vermeiden.

▯ Verwenden Sie dieses Fülldrahtschweißgerät nicht auf Ebenen mit einer

Neigung größer als 10°.

▯ Arbeiten auf der Netzspannungsseite, z.B. an Kabeln, Steckern, Steck-

dosen usw. nur vom Fachmann ausführen lassen. Dies gilt insbesondere

für das Erstellen von Zwischenkabeln.

▯ Bei Unfällen Schweißstromquelle sofort vom Netz trennen.

▯ Wenn elektrische Berührungsspannungen auftreten, Gerät sofort ab-

schalten und vom Fachmann überprüfen lassen.

▯ Auf der Schweißstromseite immer auf gute elektrische Kontakte achten.

▯ Beim Schweißen immer an beiden Händen isolierende Handschuhe