Page 1

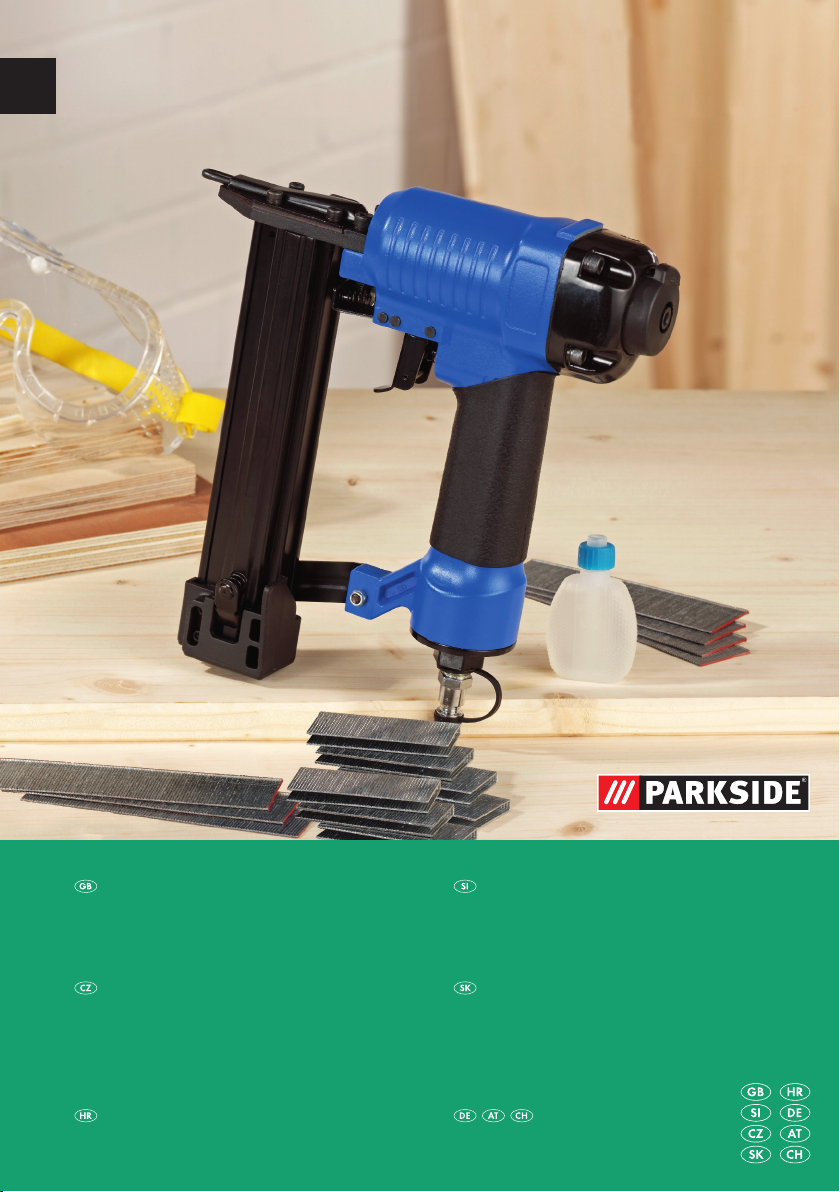

AIR STAPLER SET

aIR STaPLeR SeT

Operation and Safety Notes

SaDa PneUmaTICKŶCh

SPonKovaČŮ

Pokyny pro obsluhu a bezpečnostní pokyny

PneUmaTSKa KLameRICa SeT

Upute za posluživanje i za Vašu sigurnost

ŽebLjaLnIK na STISnjen

zRaK, KomPLeT

Navodila za upravljanje in varnostna opozorila

zoŠĺvaČKa S

PRĺSLUŠenSTvom

Pokyny pre obsluhu a bezpečnostné pokyny

DRUCKLUFT-TaCKeR-SeT

Bedienungs- und Sicherheitshinweise

Page 2

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Pred branjem obe strani s slikami odprite navzven in se nato seznanite z vsemi funkcijami naprave.

Před čtením si odklopte obě dvě strany s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte obidve strany s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Rasklopite prije čitanja obije stranice sa slikama i nakon toga se upoznajte sa svim funkcijama uređaja.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

SI Navodila za upravljanje in varnostna opozorila Stran 13

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 21

SK Pokyny pre obsluhu a bezpečnostné pokyny Strana 29

HR Upute za posluživanje i za Vašu sigurnost Stranica 37

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 45

Page 3

10

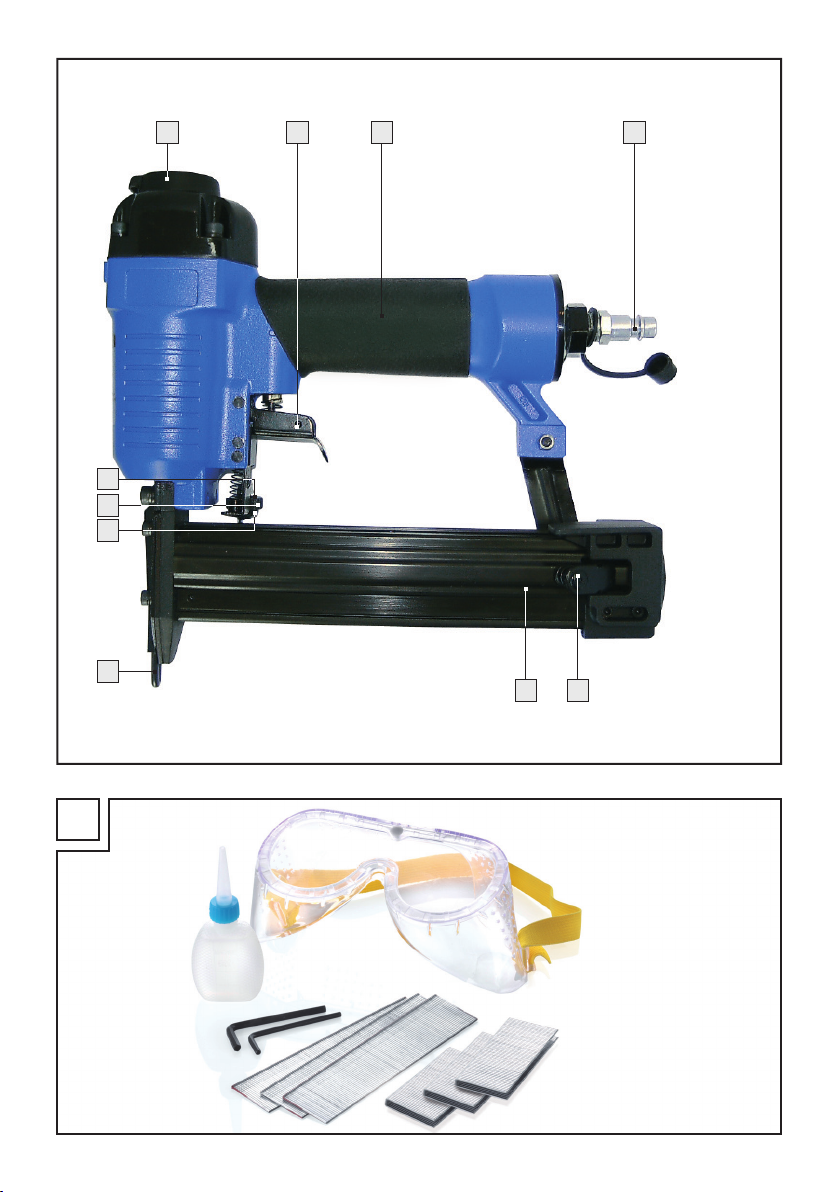

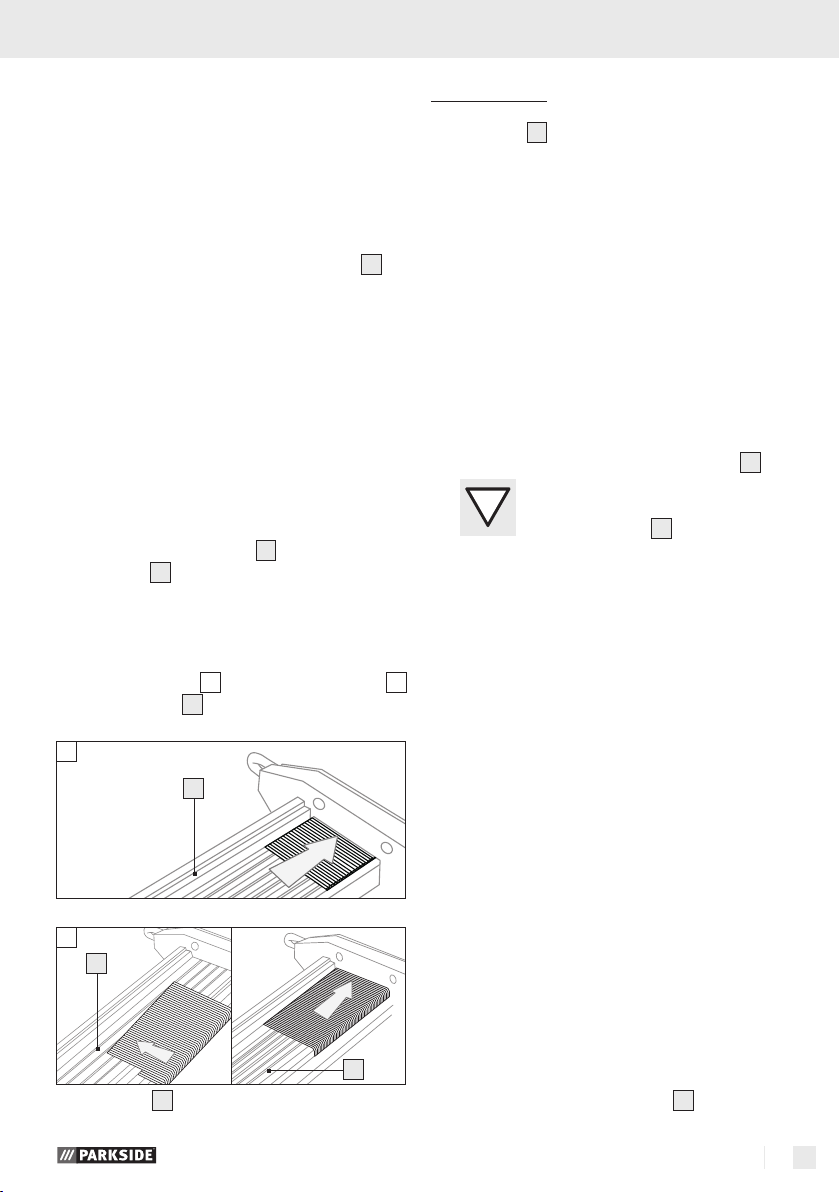

1 2 3 4

9

8

A

7

56

Page 4

B

C

D

Page 5

Table of contents

Introduction

Proper use ......................................................................................................................Page 6

Features and equipment ...............................................................................................Page 6

Included items ...............................................................................................................Page 6

Technical data ...............................................................................................................Page 6

Fastener driving tool safety

Safety at work ...............................................................................................................Page 7

Additional safety advice for compressed air tackers ..................................................Page 8

Original accessories/attachments ...............................................................................Page 8

Bringing into use

Connecting the compressed air source .......................................................................Page 8

Loading the magazine ..................................................................................................Page 9

Operation .................................................................................................................Page 9

Maintenance and cleaning

Maintenance .................................................................................................................Page 10

Cleaning ........................................................................................................................Page 10

Service .........................................................................................................................Page 10

Warranty ...................................................................................................................Page 10

Disposal ......................................................................................................................Page 11

Declaration of Conformity / Manufacturer..................................Page 11

5 GB

Page 6

Introduction

The following pictograms are used in these operating instructions / on the device:

Read the operating instructions!

Always heed warning labels and

safety instructions!

Wear hearing protection and

protective glasses

Air stapler set

Q

Introduction

Please make sure that you familiarise

yourself fully with the way the fastener

driving tool works before you use it for

the first time and that you understand how to handle

fastener driving tools correctly. To help you do this,

please read the accompanying operating instructions. Keep these instructions in a safe place. If

you pass the fastener driving tool on to anyone

else, please ensure that you also pass on all the

documentation.

Q

Proper use

Keep the tacker out of the

reach of children!

Trigger lock

Dispose packaging and appliance in

an environmentally-friendly way!

8

Lower stop

9

Knurled screw

10

Upper stop

Q

Included items

1 x Compressed air tacker

1 x Carrying case

1 x Compressed air special oil

1 x Threaded plug-in nipple, ¼‘‘ ext. dia.

(factory fitted)

1 x Pack of nails, 1000 No.

1 x Pack of staples, 1000 No.

1 x Safety glasses

1 x Allen key, 3 mm

1 x Allen key, 4 mm

1 x Operating instructions

This device is intended for assembly and repair work

(see Fig. B, C, D). Any other use or modification to

the device shall be considered as improper use

and could give rise to considerable risk of accident.

We will not accept liability for loss or damage arising

from improper use. The device is intended for private,

domestic use only.

Q

Features and equipment

1

Exhaust cover (rotatable)

2

Trigger

3

Handle

4

Threaded plug-in nipple ¼“ ext. dia.

5

Magazine lever

6

Magazine

7

Trigger lock

6 GB

Q

Technical data

Working pressure: max. 7 bar

Magazine capacity: 100 No.

Nail length: 15 - 32 mm

Staple length: 16 - 32 mm

Staple width: 5.7 mm

Recommended

hose diameter: Ø 9 mm

Compressed air quality: cleaned, oiled and

condensate-free

Noise and vibration data:

The measured values are determined in accordance with EN 12549:1999, EN ISO 4871. The

A-weighted sound pressure level of the device is

typically 85.7 dB (A). Uncertainty K = 3 dB. The

Page 7

Introduction / Fastener driving tool safety

sound level while working may exceed 98.7 dB (A).

These values are device-related values and do not

represent the generation of noise at the place of use.

The noise generated at the place of use depends

e.g. on the working environment, workpiece, workpiece support, the number of tack driving cycles.

Depending on the workplace conditions and the

shape of the workpiece, it may be possible to take

job-specific noise reduction measures, such as placing the workpiece on a sound-damping substrate,

covering or clamping the workpiece to prevent vibration, setting the pressure to the lowest possible

value adequate for the job. In some cases, it may

be necessary to wear ear protection.

Wear ear protection!

Total vibration in accordance with EN ISO 8662-11:

Vibration emission value a

Uncertainty K = 1.5 m / s

Mechanical impact (vibration)

The vibration values for the fastener driving tool

were calculated in accordance with ISO 866211:1999 — Hand-held portable power tools —

Measurement of vibrations at the handle — Fastener driving tools (see Technical data). The value is a

device-related value and does not represent the

effect on the hand-arm system of using the device.

The effect on the hand-arm system of using the device depends e.g. on the tightness of your grip on

the handle, contact pressure, direction of working,

set working air pressure, workpiece, workpiece

support.

= 2.0 m / s

h,D

2

2

Fastener driving

tool safety

WARNING!

advice and instructions. Failure to observe

the safety advice and instructions could result in serious injury and/or damage to property.

Keep all the safety advice and instructions in a safe place for future

reference.

Read all the safety

J Before you start work with the

device, check that its safety features

and trigger fittings are working

properly and that all screws, bolts

and nuts are fixed tightly in place.

J Do not carry out unauthorised ad-

justments or modifications to the

fastener driving tool.

J Never disassemble or block any part

of the fastener driving tool, such as

the trigger lock.

J Do not carry out any “emergency

repairs” using unsuitable means.

J The fastener driving tool must be

regularly and properly maintained

in accordance with the manufactur-

er’s instructions.

J Do not risk weakening or damaging

the device by e.g.:

- subjecting it to impact or engraving it,

- converting it in a manner not

approved by the manufacturer,

- using templates that are made from

a hard material, e.g. steel,

- allowing it to fall or pushing it over

the floor,

- using it like a hammer, or

- using it to apply any kind of force.

Q

Safety at work

J Never point a fastener driving tool

that is ready for use directly towards

yourself or another person.

J When working, hold the fastener

driving tool in such a way that your

head and body cannot be injured

should kickback occur as a result of

an interruption of the energy supply

or striking a hard spot in the work

piece.

J Never trigger the fastener driving

tool into open space. Otherwise you risk

injury from flying fasteners and/or overloading

the device.

J Disconnect the fastener driving tool

from the air pressure network before

carrying it to a different location, es-

7 GB

Page 8

Fastener driving tool safety / Bringing into use

pecially if you are using a ladder or

moving your body in an unusual way.

J When at the workplace, always carry

the device by the handle and not

while the trigger is ready to operate.

J Pay attention to workplace conditions.

Tacks could be driven right through a thin

workpiece or shoot off and endanger people

when you are working on edges and corners.

J For your own safety, wear

suitable personal protective

equipment, such as ear and eye pro-

tection. The wearing of personal protective

equipment such as dust masks, non-slip safety

shoes, safety helmets or ear protectors, appropriate to the type of fastener driving tool used

and work undertaken, reduces the risk of injury.

Additional safety advice

for compressed air tackers

WARNING!

Never exceed the maximum allowable working

air pressure of 7 bar. Use a pressure reducer

to set the working air pressure.

WARNING!

Never use oxygen or other combustible gas as

the energy source.

J Keep your working area clean and

well lit. Untidy or poorly lit working areas

can lead to accidents.

J Keep children and other

ing tool. Distractions can cause you to lose

control of the device.

J Remain alert at all times, watch what

you are doing and always proceed

with caution when working with the

fastener driving tool. Do not use the

fastener driving tool if you are tired

or under the influence of drugs,

alcohol or medication. One moment of

carelessness when using the fastener driving

tool can lead to serious injury.

J Avoid placing your body in an unnat-

ural position. Keep proper footing

8 GB

DANGER OF INJURY!

DANGER OF INJURY!

people away while you are

operating the fastener driv-

and balance at all times. By doing this,

you will be in a better position to control the

fastener driving tool, especially in unforeseen

circumstances.

J Disconnect the device from the compressed air

source before carrying out any repairs or main-

tenance of the device or moving it to another

location.

J DANGER OF INJURY! Never use the device

if the trigger lock

removed. Otherwise you could become injured.

7

is defective or has been

J When removing the hose coupling, hold the

hose tightly in your hand to avoid injury

caused by the hose shooting backwards.

J Always use a threaded plug-in nipple ¼‘‘ and

a quick release coupling for the compressed

air connection.

J Never place your hands near the opening

while the device is ready to operate. Other-

wise you could become injured.

J Look out for damage on the device.

Check the device for damage before bringing

it into use. Do not use the device if you discover

any defects.

J Do not use pointed implements. Never

poke pointed and/or metal objects into the

interior of the device.

Q

Original accessories/

attachments

J Use only the accessories and attach-

ments detailed in the operating

instructions. The use of driven fasteners or

accessories other than those recommended in

the operating instructions could lead to you

suffering an injury.

Q

Bringing into use

Q

Connecting the

compressed air source

NOTE: Operate the compressed air tacker only

with cleaned, oiled compressed air and never exceed

the maximum working air pressure at the device of

Page 9

Bringing into use / Operation

7 bar. A pressure reducer must be fitted to the compressor to regulate the working air pressure.

j Connect the device to a suitable source of

compressed air.

1. To do this press, the quick-release coupling of

the compressed air hose (not supplied) on to

the threaded plug-in nipple ¼“ ext. dia.

4

of

the compressed air tacker. It locks itself in

place automatically.

2. Connect the other end of the compressed air

hose to the (filter) / pressure reducer at the

compressor.

Q

Loading the magazine

NOTE: Never place nails into the intermediate

opening; this opening is intended for staples. Otherwise this could lead to a blockage in the driver

and prevent the proper exit of the driven fastener.

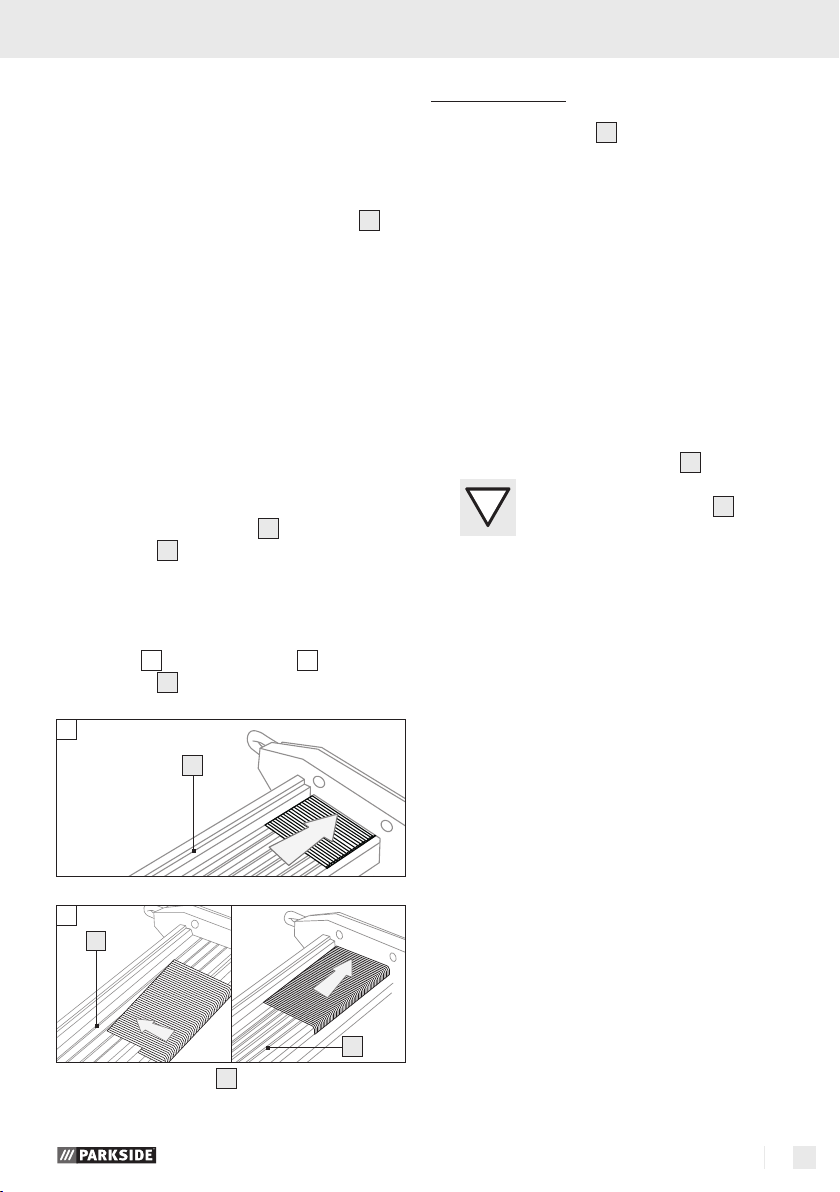

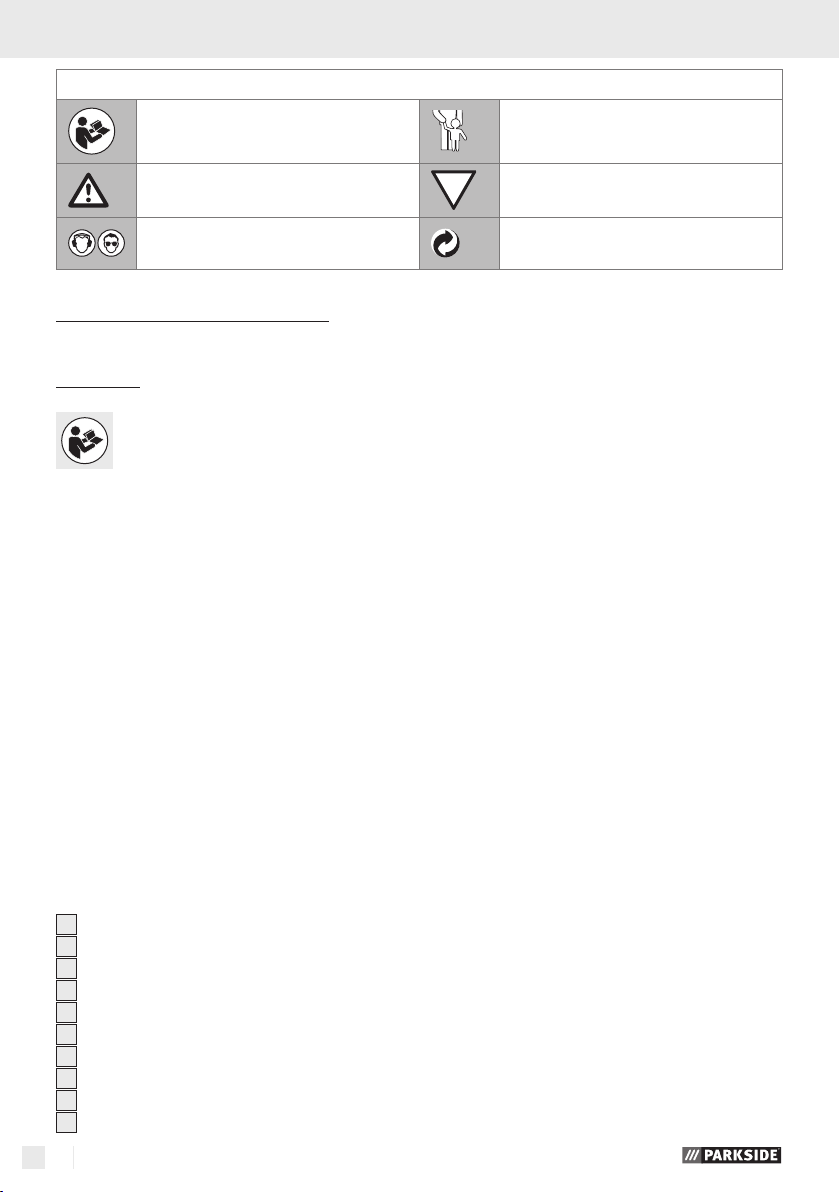

1. Press the magazine lever

magazine

6

.

5

and pull back the

NOTE: Note that only staples with a length

of 16 - 32 mm and nails with a length of

15 - 32 mm may be placed in the magazine.

2. Place some compliant driven fasteners (nails,

01

see Fig.

magazine

01

02

6

or staples, see Fig. 02) in the

6

.

6

6

3. Push the magazine 6 forward until it engages.

Q

Operation

6

j Load the magazine

of the compressed air

tacker, as described in the section about

“Loading the magazine”.

j Using the pressure reducer, set the correct

working air pressure.

j Ensure that the maximum working air pressure

at the device of 7 bar is not exceeded. An increased working air pressure does not improve

performance but only increases the consumption of compressed air and accelerates wear.

j Switch compressor on.

j Allow the compressor to run until the maximum

reservoir pressure has been reached and then

switch off the device.

j Place the compressed air tacker on to the

workpiece and press the trigger

NOTE: The compressed air tacker

is fitted with a trigger lock

2

.

7

. The

driven fastener only exits the device

if the opening of the compressed air tacker is

pressed against the workpiece and the trigger

is pressed. This safety feature ensures that

driven fasteners such as staples and nails cannot exit the device in an uncontrolled manner.

j Check whether the driven fastener is driven into

the workpiece in accordance with your requirements.

- If the driven fastener projects above the work-

piece surface, increase the compressed air

pressure in 0.5 bar steps until a satisfactory

result is achieved.

- If the driven fastener lies too far below the

workpiece surface, reduce the working

pressure in 0.5 bar steps until a satisfactory

result is achieved.

In any event, you should make every effort to work

using the lowest adequate compressed air pressure.

This brings you three important advantages:

1) You save energy,

2) You reduce the noise level,

3) You reduce the wear on the fastener driving tool.

j Avoid triggering the fastener driving tool if the

magazine is empty.

9 GB

Page 10

Operation / Maintenance and cleaning / Service / Warranty

NOTE: Fine adjustment can also be done using

the knurled screw

j Turn the knurled screw

the lower stop

9

.

9

in the direction of

8

in order to sink the fastener

more deeply into the work piece.

j Turned the knurled screw

the upper stop

10

9

in the direction of

in order to sink the fastener

less deeply into the work piece.

NOTE: The compressed air tacker can be used on

a horizontal or on a vertical workpiece.

j Turn the exhaust cover

1 to direct the escap-

ing air in the desired direction.

j After you finish work, disconnect the device

from the compressor.

NOTE: First disconnect the hose from the

compressor and only then disconnect the

compressed air supply hose from the device.

This will ensure that the compressed air supply

hose does not wave around in an uncontrolled

manner.

Q

Maintenance and cleaning

J DANGER OF BURNS! Do not start any

cleaning or maintenance work on the compressed air tacker until it has completely

cooled down.

J DANGER OF INJURY! Always disconnect

the device from the compressed air source

before you clean or maintain it.

j Install the oil mist lubricator downstream of the

(filter)/pressure reducer. To do this, insert the

plug-in nipple of the oil mist lubricator into the

quick-release coupling of the (filter)/pressure

reducer.

j Then connect the compressed air device to the

quick-release coupling provided for it.

Manual lubrication

NOTE: If you do not have an oil mist lubricator,

you must lubricate the device before each period

of use and/or after long periods of disuse.

j Place 3 - 5 drops of compresses air special oil

into the threaded plug-in nipple

4

of the

compressed air tacker.

j Then press the trigger

2

a few times.

j Introduce 5 - 10 drops after a period of

disuse of more than 5 days.

Q

Cleaning

J Do not use sharp objects for cleaning the

device. Do not allow any liquids to enter the

device. Otherwise the device could be damaged.

j Clean the device frequently; for best results, do

this immediately after you have finished using it.

j Use a dry cloth to clean the housing – under

no circumstances use petrol, solvents or cleaning agents that attack plastic.

j Pack away the compressed air tacker in the

supplied carrying case after each use to

protect it from dirt.

Q

Maintenance

j Grease the device regularly. This will ensure

that it continues to work properly and has a

long service life.

Lubrication with the oil mist lubricator

NOTE: As an air preparation stage downstream

of the pressure reducer, an oil mist lubricator provides a continuous, optimum level of lubrication to

the compressed air tacker. An oil mist lubricator

gives off fine droplets of oil into the air and thus

ensures controlled lubrication.

10 GB

Q

Service

J

WARNING!

Have your fastener

driving tool repaired only by qualified

specialist personnel using original

manufacturer parts only. This will ensure

that your fastener driving tool remains safe to use.

Q

Warranty

This appliance is guaranteed for 3 years

from the date of purchase. It has been care-

Page 11

Warranty / Disposal / Declaration of Conformity / Manufacturer

fully produced and meti-culously checked

before delivery. Please keep your receipt

as proof of purchase. Contact your service

centre by telephone in case of questions

pertaining to the warranty. Your goods

can

be transmitted free of cost only in this

manner. This warranty applies only to the

initial

purchaser and is non-transferable.

The warranty covers only material or manufacturing faults, not normal wear or damage to fragile

parts such as switches or rechargeable batteries.

The appliance is intended solely for private, not

commercial, use.

If this product has been subjected to improper or

inappropriate handling, abuse, or interventions not

carried out by one of our authorised sales and

service outlets, the warranty will be considered void.

This warranty does not affect your statutory rights.

GB

DES Ltd

Units 14-15

Bilston Industrial Estate

Oxford Street

Bilston (Great Britain)

WV14 7EG

Tel.: 0870 / 787-6177

Fax: 0870 / 787-6168

e-mail: support.uk@kompernass.com

Q

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, Burgstr. 21,

D-44867 Bochum, Germany, declare that this

product complies with the following EU directives:

Applicable harmonised standards:

EN 12100-1:2004

EN 12100-2:2004

EN 792-13:2000

Type / Device description:

Air stapler set

Bochum, 31.07.2009

Hans Kompernaß

- Managing Director -

Q

Disposal

The packaging is wholly composed of

environmentally-friendly materials that can

be disposed of at a local recycling centre.

Do not dispose of the product with

household rubbish!

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

We reserve the right to make technical modifications

in the course of further development.

11 GB

Page 12

12

Page 13

Uvod

Namen uporabe ...........................................................................................................Stran 14

Oprema .........................................................................................................................Stran 14

Obseg dobave ..............................................................................................................Stran 14

Tehnični podatki ............................................................................................................Stran 14

Varnost zabijalne naprave

Varnost pri delu .............................................................................................................Stran 15

Dopolnilna varnostna opozorila za spenjalnik na komprimiran zrak ........................Stran 16

Originalna oprema / originalne dodatne naprave .....................................................Stran 16

Začetek uporabe

Priključitev vira komprimiranega zraka ........................................................................Stran 16

Polnjenje magazina.......................................................................................................Stran 17

Uporaba .....................................................................................................................Stran 17

Kazalo

Vzdrževanje in čiščenje

Vzdrževanje ...................................................................................................................Stran 18

Čiščenje .........................................................................................................................Stran 18

Servis ............................................................................................................................Stran 18

Garancija ...................................................................................................................Stran 18

Odstranjevanje ....................................................................................................Stran 19

Izjava o skladnosti / Izdelovalec ...........................................................Stran 19

13 SI

Page 14

Uvod

V tem navodilu za upravljanje / na napravi so uporabljeni naslednji piktogrami:

Navodila za uporabo preberite!

Upoštevajte opozorila in

varnostne napotke!

Nosite zaščitna očala in opremo

za zaščito sluha.

Žebljalnik na stisnjen

zrak, komplet

Q

Uvod

Pred prvim začetkom uporabe se obve-

zno seznanite s funkcijami zabijalne

naprave in se informirajte o pravilnem

rokovanju z zabijalnimi napravami. V ta namen

preberite naslednje navodilo za uporabo. To navodilo dobro shranite. Če zabijalno napravo odstopite

novemu lastniku, mu izročite tudi vse dokumente.

Q

Namen uporabe

Otrokom ne dovolite zadrževanja

v bližini zabijalne naprave!

Sprožilno varovalo

Embalažo in napravo odstranite

okolju prijazno!

9

narebričen vijak

10

zgornji omejevalnik

Q

Obseg dobave

1 x komplet spenjalnika na komprimiran zrak

1 x nosilni kovček

1 x specialno olje za komprimiran zrak

1 x navojna vtična spojka ¼« AG (predmontirana)

1 x paket žebljev, 1.000 kosov

1 x paket sponk, 1.000 kosov

1 x zaščitna očala

1 x inbus ključ, 3 mm

1 x inbus ključ, 4 mm

1 x navodilo za uporabo

Ta naprava je primerna za montažna dela in popravila (glejte sl. B, C, D). Kakršnakoli drugačna uporaba ali sprememba naprave ni v skladu z določili

in predstavlja znatno nevarnost nesreč. Za škodo,

nastalo pri uporabi, ki ni v skladu z določili, ne prevzamemo jamstva. Naprava je namenjena samo

za privatno uporabo.

Q

Oprema

1

zaslonka za izrabljen zrak (vrtljiva)

2

sprožilec

3

ročaj

4

navojna vtična spojka ¼« AG

5

ročica magazina

6

magazin

7

sprožilno varovalo

8

spodnji omejevalnik

14 SI

Q

Tehnični podatki

Delovni tlak: največ 7 bar

Kapaciteta polnjenja: 100 kosov

Dolžina žebljev: 15 - 32 mm

Dolžina sponk: 16 - 32 mm

Širina sponk: 5,7 mm

Priporočen premer

gibke cevi: Ø 9 mm

Kvaliteta

komprimiranega zraka: očiščen, oljno megličen

in brez kondenzata

Podatki o hrupu in vibracijah:

Izmerjene vrednosti so bile določene v skladu z

EN 12549:1999, EN ISO 4871. Nivo zvočnega

tlaka naprave po A-vrednotenju tipično znaša

85,7 dB (A). Negotovost K= 3 dB. Nivo hrupa pri

delu lahko presega 98,7 dB (A).

Page 15

Uvod / Varnost zabijalne naprave

Te vrednosti so kazatelji, ki se nanašajo na napravo,

in ne prikazujejo sproščanja hrupa na mestu uporabe.

Sproščanje hrupa na mestu uporabe je odvisno

npr. od delovnega okolja, obdelovanca, podloge

obdelovanca, števila postopkov zabijanja.

Skladno z razmerami na delovnem mestu in zgradbo obdelovanca je treba evtl. izvesti individualne

ukrepe za zmanjšanje hrupa, kot npr. položiti obdelovance na podlage, ki dušijo zvok, preprečiti vibriranje obdelovancev s pomočjo vpenjanja ali

prekrivanja, nastaviti najnižji tlak, ki je potreben za

delovni postopek. V posebnih primerih je potrebno

nošenje zaščitnih glušnikov.

Nosite zaščitne glušnike!

Skupne vrednosti nihanja v skladu z EN ISO 8662-11:

Emisijska vrednost nihanja a

Negotovost K < 1,5 m / s

Mehanski sunki (vibracija)

Za zabijalno napravo je bil vibracijski kazatelj določen v skladu ISO 8662-11:1999 — Ročno prenosno orodje na motorni pogon — Meritve mehanskih

nihanj na ročaju — Zabijalne naprave (glejte »Tehnični podatki«). Vrednost je kazatelj, ki se nanaša

na napravo, in ne predstavlja učinkovanja na sistem dlani-roke pri uporabi naprave. Učinkovanje na

sistem dlani-roke pri uporabi naprave je odvisno

npr. od oprijemalne sile, pritisne sile, smeri dela,

nastavljenega zračnega tlaka, obdelovanca, podloge obdelovanca.

h, D

2

= 2,0 m / s

2

Varnost zabijalne naprave

OPOZORILO!

stna opozorila in navodila. Neupoštevanje

varnostnih opozoril in navodil lahko povzroči hude

poškodbe in/ali materialno škodo.

vsa varnostna opoZorila in navodila

shranite Za prihodnJo uporaBo.

J Pred vsakim začetkom dela prekon-

trolirajte, če varnostne in sprožilne

Preberite vsa varno-

naprave brezhibno delujejo ter so vsi

vijaki in matice dobro pritrjeni.

J Na izvajajte nepredpisanih dejanj na

zabijalni napravi.

J Ne demontirajte in ne blokirajte delov

zabijalne naprave, kot npr. sprožilnega varovala.

J Ne izvajajte »nujnih popravil« z neu-

streznimi sredstvi.

J Zabijalno napravo je treba redno in

ustrezno vzdrževati, skladno z navedbami proizvajalca.

J Preprečite vsakršna poslabšanja in

poškodbe naprave, na primer:

- z zabijanjem ali vgraviranjem,

- s predelavami, ki jih proizvajalec

ne dopušča,

- z vodenjem vzdolž šablon, ki so izdelane iz trdega materiala, npr. jekla,

- z metanjem na tla ali potiskanjem

po tleh,

- z uporabo kot kladivo,

- z uporabo vsake vrste sile.

Q

Varnost pri delu

J Zabijalne naprave, ki je pripravljena

na obratovanje, nikoli ne usmerite

proti sebi ali drugim osebam.

J Zabijalno napravo pri delu držite

tako, da si pri morebitnem povratnem

udarcu zaradi motnje v oskrbi z energijo ali trdih mest v obdelovancu ne

morete poškodovati glave in telesa.

J Zabijalne naprave nikoli ne sprožite

v prazen prostor. Na ta način preprečite

nevarnosti zaradi prosto letečih zabijalnih

predmetov in preobremenitev naprave.

J Za transportiranje je treba zabijalno

napravo ločiti od omrežja komprimiranega zraka, še posebno, če uporabljate lestve ali se premikate z neobičajno

držo telesa.

J Na delovnem mestu zabijalno napravo

nosite samo za ročaj in ne s pritisnjenim

sprožilcem.

J Pazite na razmere na delovnem mestu.

15 SI

Page 16

Varnost zabijalne naprave / Začetek uporabe

Zabijalni predmeti lahko eventualno prebijejo

tanke obdelovance ali pri delu na kotih in robovih zdrsnejo z obdelovanca in pri tem

ogrožajo osebe.

J Za vašo osebno varnost upo-

rabljajte ustrezna sredstva

za zaščito telesa, kot npr. zaščitne

glušnike in zaščito za oči. Nošenje oseb-

ne zaščitne opreme kot so protiprašna maska,

nedrsljiva zaščitna obutev, zaščitna čelada ali

zaščitni glušniki, odvisno od vrste in načina

uporabe zabijalne naprave, zmanjšuje tveganje za povzročitev poškodb.

Dopolnilna varnostna

opozorila za spenjalnik

na komprimiran zrak

OPOZORILO!

Nikoli ne prekoračite najvišjega dovoljenega

delovnega tlaka 7 bar. Za nastavitev delovnega

tlaka uporabljajte reducirni ventil.

OPOZORILO!

Nikoli ne uporabljajte kisika ali drugih vnetljivih

plinov kot vir energije.

J Delovno območje naj bo čisto in dobro

osvetljeno. Nered in neosvetljena delovna

območja lahko vodijo do povzročitve nesreč.

J Otrok in drugih oseb med

pozorni, lahko izgubite nadzor nad napravo.

J Vedno bodite pozorni in pazite na to,

kaj delate, in delo z zabijalno napravo

opravljajte s pametjo. Zabijalne naprave ne uporabljajte, kadar ste utrujeni

ali pod vplivom drog, alkohola ali zdravil. En sam trenutek nepazljivosti pri uporabi

zabijalne naprave lahko vodi do povzročitve

resnih poškodb.

J Izogibajte se nenormalni telesni drži.

Skrbite za varno stojišče in vedno

ohranjajte ravnotežje. Na ta način lahko

zabijalno napravo v nepričakovanih situacijah

bolje kontrolirate.

16 SI

NEVARNOST POŠKODB!

NEVARNOST POŠKODB!

uporabo zabijalne naprave

ne pustite zraven. Če niste

J Pred popravili in vzdrževalnimi deli ter pred

transportom napravo odstranite z vira komprimiranega zraka.

J NEVARNOST POŠKODB! Naprave ne

uporabljajte, če je sprožilno varovalo

kvarjeno ali je bilo odstranjeno. V nasprotnem

primeru lahko pride do poškodb.

7

po-

J Pri ločevanju priključka gibke cevi gibko cev dr-

žite v roki, da preprečite poškodbe, ki bi lahko

nastale, če bi gibka cev skočila nazaj.

J Za priključitev komprimiranega zraka obvezno

uporabite navojno vtično spojko ¼« in hitri priključek.

J Z rokami se nikoli ne približajte zabijalni odpr-

tini, medtem ko je naprava pripravljena na

obratovanje. V nasprotnem primeru lahko pride

do poškodb.

J Pazite na poškodbe. Pred začetkom upo-

rabe napravo prekontrolirajte, ali kaže kakršnekoli znake poškodb. Če naprava kaže znake

okvar, se je na noben način ne sme uporabljati.

J Ne uporabljajte koničastih predmetov.

V notranjost naprave nikoli ne vtikajte koničastih

in / ali kovinskih predmetov.

Q

Originalna oprema /

originalne dodatne naprave

J Uporabljajte samo dodatno opremo

in dodatne naprave, ki so navedene v

navodilu za uporabo. Uporaba drugih

zabijalnih predmetov ali druge opreme, kot je

navedeno v navodilu za uporabo, lahko za

vas predstavlja nevarnost poškodb.

Q

Začetek uporabe

Q

Priključitev vira

komprimiranega zraka

OPOZORILO: Spenjalnik na komprimiran zrak

se sme uporabljati izključno z očiščenim, oljno megličenim komprimiranim zrakom in ne sme prekoračiti najvišjega dovoljenega delovnega tlaka 7 bar

Za reguliranje delovnega tlaka mora biti kompresor

opremljen z reducirnim ventilom.

Page 17

Začetek uporabe / Uporaba

j Napravo priključite na ustrezen vir komprimira-

nega zraka.

1. V ta namen pritisnite hitri priključek gibke cevi

za komprimiran zrak (ni vsebovan v obsegu

dobave) na navojno vtično spojko ¼« AG

spenjalnika na komprimiran zrak.

Blokada spoja poteka avtomatsko.

2. Drug konec gibke cevi za komprimiran zrak

spojite s (filtrskim) reducirnim ventilom na kompresorju.

Q

Polnjenje magazina

OPOZORILO: V vmesno odprtino, ki je predvide-

na za sponke, nikoli ne vlagajte žebljev. To povzroči zastoj v gonilu in preprečuje pravilno izločanje

zabijalnega materiala.

1. Pritisnite ročico magazina

5

in magazin 6

potegnite nazaj.

OPOZORILO: Upoštevajte, da se sme v magazin vlagati samo sponke dolžine 16 - 32 mm

in žeblje dolžine 15 - 32 mm.

2. V magazin

al (žeblje, glejte sl.

01

02

6

6

vložite ustrezen zabijalni materi-

01

ali sponke, glejte sl. 02).

6

3. Magazin 6 potisnite naprej, dokler se ne

zaskoči.

4

6

Q

Uporaba

j Magazin

6

spenjalnika na komprimiran zrak

napolnite, kot je opisano v poglavju »Polnjenje

magazina«.

j S pomočjo reducirnega ventila nastavite pravilni

delovni tlak.

j Pazite na to, da na napravi ne prekoračite naj-

višjega delovnega tlaka 7 bar. Previsok delovni

tlak ne prinese prednosti v zmogljivosti, temveč

samo poviša porabo komprimiranega zraka in

pospešuje obrabo naprave.

j Vklopite kompresor.

j

Kompresor enkrat pustite teči tako dolgo, da je do-

sežen maksimalni tlak v kotlu in se naprava izklopi.

j Spenjalnik na komprimiran zrak postavite na

obdelovanec in pritisnite sprožilec

OPOZORILO: Spenjalnik na kom-

primiran zrak je opremljen s sprožilnim

varovalom

7

. Zabijalni material

zapusti napravo šele, ko je ustje spenjalnika na

komprimiran zrak pritisnjeno ob obdelovanec in

je sprožilec pritisnjen. S pomočjo te varovalne

naprave je zagotovljeno, da zabijalni predmeti

kot so sponke ali žeblji naprave ne morejo nekontrolirano zapustiti.

2

j Prekontrolirajte, ali se je zabijalni predmet

zabil skladno z zahtevami.

- Če zabijalni predmet moli ven, povišajte zračni tlak v korakih po 0,5 bar in vsakokrat ponovno prekontrolirajte konkretni rezultat.

- Če je zabijalni predmet pregloboko vtisnjen,

znižajte zračni tlak v korakih po 0,5 bar, dokler rezultat ni zadovoljiv.

Na vsak način se morate potruditi, da vedno delate

z najnižjim potrebnim zračnim tlakom. To za vas

prinaša tri bistvene prednosti:

1) Varčujte z energijo,

2) Znižate nivo hrupa,

3) Zmanjšate obrabo zabijalne naprave.

j Preprečite sproženje zabijalne naprave s

praznim magazinom.

OPOZORILO: Poleg tega je precizna nastavitev

možna s pomočjo narebričenega vijaka

j Narebričeni vijak

omejevalniku

globoko zabijete v obdelovanec.

9

zavrtite proti spodnjemu

8

, da zabijalni predmet bolj

.

9

.

17 SI

Page 18

Uporaba / Vzdrževanje in čiščenje / Servis / Garancija

j Narebričeni vijak

omejevalniku

globoko zabijete v obdelovanec.

OPOZORILO: Spenjalnik na komprimiran zrak

se lahko uporabi tako na vodoravnem kot tudi na

pravokotnem obdelovancu.

j Zavrtite zaslonko za izrabljen zrak

jajoč zrak usmerite v želeno smer.

9

zavrtite proti zgornjemu

10

, da zabijalni predmet manj

1

, da uha-

j Napravo po zaključku del ločite od kompresorja.

OPOZORILO: Najprej s kompresorja ločite

gibko cev in šele nato odstranite dovodno

gibko cev z naprave.

Tako preprečite nekontrolirano vrtinčenje

dovodne gibke cevi.

Q

Vzdrževanje in čiščenje

J NEVARNOST OPEKLIN! S čistilnimi in vzdr-

ževalnimi deli začnite šele, ko je spenjalnik na

komprimiran zrak popolnoma ohlajen.

J NEVARNOST POŠKODB! Napravo obve-

zno ločite od dovoda komprimiranega zraka,

preden jo čistite in / ali vzdržujete.

Ročno podmazovanje

OPOZORILO: Če ne razpolagate z razpršilno

mazalko, pred vsakim začetkom uporabe oz. po

daljših obratovalnih pavzah opravite podmazovanje.

j Nakapajte 3 - 5 kapljic specialnega olja za

komprimiran zrak v navojno vtično spojko

spenjalnika na komprimiran zrak.

j Nato nekajkrat pritisnite sprožilec

4

2

.

j Po obratovalni pavzi, daljši od 5 dni, nakapajte

5 - 10 kapljic.

Q

Čiščenje

J Za čiščenje naprave ne uporabljajte ostrih

predmetov. Tekočine ne smejo prodreti v notranjost naprave. V nasprotnem primeru se naprava

lahko poškoduje.

j Napravo čistite redno, najbolje vedno direktno

po zaključku del.

j Ohišje čistite s suho krpo – na noben način ne

uporabljajte bencina, topil ali čistil, ki poškodujejo plastiko.

j Spenjalnik na komprimiran zrak po vsaki upo-

rabi pospravite v zraven dobavljen nosilni

kovček, da ga zaščitite pred umazanijo.

Q

Vzdrževanje

j Napravo redno podmazujte. Na ta način ohra-

nite brezhibno delovanje in dolgo življenjsko

dobo izdelka.

Podmazovanje z razpršilno mazalko

OPOZORILO: Kot pripravljalna stopnja za redu-

cirnim ventilom razpršilna mazalka spenjalnik na

komprimiran zrak kontinuirano in optimalno podmazuje. Razpršilna mazalka odda kapljico olja v pretočni zrak in tako zagotavlja redno podmazovanje.

j Razpršilno mazalko instalirajte za (filtrskim)

reducirnim ventilom. V ta namen vtaknite vtično

spojko razpršilne mazalke v hitri priključek (filtrskega) reducirnega ventila.

j Nato priključite napravo na komprimiran zrak

na za to predviden hitri priključek.

18 SI

Q

Servis

J

Q

Za to napravo prejmete 3 leta garancije

od datuma nakupa. Naprava je bila vestno

izdelana in pred dobavo skrbno preverjena. Prosimo, shranite blagajniški račun

kot dokazilo o nakupu. Prosimo vas, da

se v primeru uveljavljanja garancije po

telefonu obrnete na svojo servisno poslo-

OPOZORILO!

pravo dajte v popravilo samo kvalificiranemu strokovnemu osebju in samo

z uporabo originalnih nadomestnih

delov. S tem se zagotovi, da varnost zabijalne

naprave ostane ohranjena.

Garancija

Vašo zabijalno na-

Page 19

Garancija / Odstranjevanje / Izjava o skladnosti / Izdelovalec

valnico. Samo tako vam lahko zagotovimo brezplačno pošiljanje vašega izdelka.

Garancijska storitev velja samo za napake v materialu

ter pri izdelavi, ne velja pa za dele, ki so podvrženi

obrabi, ali za poškodbe lomljivih delov, npr. stikal

ali akumulatorjev. Izdelek je namenjen izključno za

osebno uporabo in ne za obrtne namene.

V primerih zlorabe in nepravilne uporabe, uporabe

sile ter pri posegih, ki niso bili izvedeni v naši pooblaščeni servisni poslovalnici, garancija preneha

veljati. Vaših zakonskih pravic ta garancija ne omejuje. Ta garancija velja samo za prvega kupca in ni

prenosljiva.

SI

Birotehnika

Tkalčec Zlatko Andrija s.p.

Lendavska ulica 23

9000 Murska Sobota (Slovenija)

Phone: +386 (0) 2 522 16 66

Fax: +386 (0) 2 531 17 40

e-mail: support.si@kompernass.com

Q

Izjava o skladnosti /

Izdelovalec

Mi, podjetje Kompernaß GmbH, Burgstr. 21,

D-44867 Bochum, Nemčija, izjavljamo, da je

ta izdelek skladen s sledečimi direktivami ES:

Uporabljeni harmonizirani standardi:

EN 12100-1:2004

EN 12100-2:2004

EN 792-13:2000

Oznaka tipa / Naprave:

Žebljalnik na stisnjen zrak, komplet

Bochum, 31.07.2009

Hans Kompernaß

- direktor -

Q

Odstranjevanje

Embalaža sestoji iz naravi prijaznih materialov, ki jih lahko odvržete v lokalne

zbiralnike za recikliranje odpadkov.

Izdelka ne zavrzite med hišne odpadke!

Vse o možnostih za odstranjevanje odsluženih naprav boste izvedeli pri vaši občinski ali mestni upravi.

Pridržujemo si pravico do tehničnih sprememb.

19 SI

Page 20

20

Page 21

Sicherheit / Bedienung

Seznam obsahu

Úvod

Použití ke stanovenému účelu .......................................................................................Strana 22

Vybavení ........................................................................................................................Strana 22

Rozsah dodávky ............................................................................................................Strana 22

Technické údaje .............................................................................................................Strana 22

Bezpečnost zarážecího zařízení

Bezpečnost práce .........................................................................................................Strana 23

Doplňující bezpečnostní pokyny pro pneumatické sešívačky .....................................Strana 24

Originální příslušenství / přídavná zařízení .................................................................Strana 24

Uvedení do provozu

Připojení zdroje stlačeného tlaku .................................................................................Strana 24

Naplnění zásobníku ......................................................................................................Strana 25

Obsluha ......................................................................................................................Strana 25

Údržba a čistění

Údržba...........................................................................................................................Strana 26

Čistění ............................................................................................................................Strana 26

Servis ............................................................................................................................Strana 26

Záruka .........................................................................................................................Strana 26

Zlikvidování ............................................................................................................Strana 27

Prohlášení o shodnosti / Výrobce .........................................................Strana 27

21 CZ

Page 22

Úvod

V tomto návodu k obsluze / na zařízení jsou použity následující piktogramy:

Čtěte návod k obsluze! Zarážecí zařízení chraňte před dětmi!

Dodržujte bezpečnostní pokyny

a řiďte se upozorněními!

Noste ochranné brýle a

ochranu sluchu

Sada pneumatickŷch sponkovačů

Q

Úvod

Před prvním uvedením do provozu se

laskavě bezpodmínečně seznamte s

funkcemi zarážecího zařízení a informujte

se o správném zacházení s ním. Přečtěte si následující návod k obsluze. Tento návod si dobře uschovejte.

Všechny podklady vydejte dále s předáním zarážecího zařízení třetímu.

Q

Použití ke stanovenému účelu

Toto zařízení se hodí k montážním a opravárenským

pracím (viz obr. B, C, D). Kterékoliv jiné použití

nebo změna na zařízení neplatí jako použití ke stanovenému účelu a skrývá značná nebezpečí úrazu.

Za škody vzniklé z použití k nestanovenému účelu

nepřevezmeme ručení. Zařízení se nehodí pro průmyslové použití.

Q

Vybavení

1

Kryt odpadního vzduchu (otočný)

2

Spoušť

3

Rukojeť

4

Závitová zásuvná spojka s vnějším závitem ¼“

5

Páka zásobníku

6

Zásobník

7

Spouštěcí pojistka

8

Dolní doraz

9

Rýhovaný šroub

10

Horní doraz

22 CZ

Spouštěcí pojistka

Obal i přístroj nechte zlikvidovat v

souladu s předpisy o ochraně životního prostředí!

Q

Rozsah dodávky

1 x sada pneumatické sešívačky

1 x kufřík k nošení

1 x pneumatický speciální olej

1 x závitová zásuvná spojka, s vnějším závitem ¼‘‘

(předmontována)

1 x balení hřebíků, 1000 ks.

1 x balení spon, 1000 ks.

1 x ochranné brýle

1 x klíč inbus, 3 mm

1 x klíč inbus, 4 mm

1 x návod k obsluze

Q

Technické údaje

Pracovní tlak: max. 7 barů

Nabíjecí kapacita: 100 ks.

Délka hřebíků: 15 - 32 mm

Délka spon: 16 - 32 mm

Šířka spon: 5,7 mm

Doporučený průměr

hadice: Ø 9 mm

Jakost stlačeného

vzduchu: vyčištěný, zamlžený olejem

a bez kondenzátu

Informace o hluku a vibracích:

Naměřené hodnoty vyšetřené podle EN 12549:1999

EN ISO 4871. Úroveň hluku zařízení ohodnocená

A činí podle typu 85,7 dB (A). Nejistota K = 3 dB.

Úroveň hluku může při práci překročit 98,7 dB (A).

,

Page 23

Úvod / Bezpečnost zarážecího zařízení

Tyto hodnoty jsou charakteristické hodnoty vztažené

na zařízení a nereprodukují vývoj hluku na místě

použití. Vývoj hluku na místě použití závisí např. na

pracovním okolí, obrobku, podložce obrobku, počtu

zarážecích postupů.

Podle poměrů na pracovišti a uspořádání obrobku

je třeba případně vykonat individuální opatření redukce hluku, jako je např. položení obrobků na

podložky tlumící hluk, zabránění vibracím obrobků

upnutím nebo přikrytím, nastavení nejmenšího pro

pracovní postup potřebného tlaku. Ve zvláštních

případech je zapotřebí nošení osobní ochrany sluchu.

Noste ochranu sluchu!

Celkové hodnoty vibrací podle EN ISO 8662-11:

Hodnota emisí vibrací a

Nejistota K = 1,5 m / s

Mechanické rázy (vibrace)

Pro zarážecí zařízení byla vyšetřena charakteristická hodnota vibrací podle ISO 8662-11:1999 —

Motorem poháněné stroje držené v ruce — Měření

mechanických vibrací na rukojeti — Zarážecí zařízení

(viz Technické údaje). Hodnota je charakteristickou

hodnotou pro zařízení a nepředstavuje působení

na systém ruka-paže při použití zařízení. Působení

na systém ruka-paže při použití zařízení závisí např.

na síle uchopení, přítlačné síle, pracovním směru,

nastavenému tlaku vzduchu, obrobku, podložce

obrobku.

= 2,0 m / s

h,D

2

2

Bezpečnost

zarážecího zařízení

VÝSTRAHA!

pečnostní pokyny a instrukce. Zanedbání

při dodržování bezpečnostních pokynů a instrukcí

mohou způsobit závažná poranění a / nebo poškození věcí.

vŠechny BeZpeČnostnÍ poKyny a

nÁvody uschoveJte pro Budoucnost.

Přečtěte si všechny bez-

J Před každým zahájením práce pře-

zkoušejte bezvadnou funkci pojistných

a spouštěcích zařízení, jakož i pevné

usazení všech šroubů a matic.

J Na zarážecím zařízení neprovádějte

neodborné manipulace.

J Nedemontujte nebo nezablokujte díly

zarážecího zařízení, jako je např.

spouštěcí zařízení.

J Neprovádějte „Nouzové opravy“

nevhodnými prostředky.

J Zarážecí zařízení je třeba pravidelně

a odborně udržovat podle údajů vý-

robce.

J Vyhněte se jakémukoliv oslabení

nebo poškození zařízení, např. v

důsledku:

- zarážení nebo vrytí,

- opatření k přestavbě nepovoleného

výrobcem

- vedení na šablonách, které jsou zhotoveny z tvrdého materiálu, např.

oceli,

- spadnutí nebo přesunování přes

podlahu,

- manipulace jako kladivo,

- jakéhokoliv způsobu působení násilí.

Q

Bezpečnost práce

J K provozu připravené zarážecí zaří-

zení nikdy nenasměrujte přímo proti

sobě nebo na jinou osobu.

J Zarážecí zařízení držte při práci tak,

aby se hlava a těleso nemohly při

možném zpětném rázu nebo v důsledku poruchy zásobování energií nebo

tvrdými místy v obrobku zranit.

J Nikdy neuveďte zarážecí zařízení do

záběru do volného prostoru. Tím zabráníte ohrožení volně ležícími zarážecími předměty

a přetížení zařízení.

J K přepravě je třeba zarážecí zařízení

oddělit od tlakové sítě, zejména, použijete-li žebříky nebo pohybujete-li se

v neobvyklém držení hlavy.

23 CZ

Page 24

Bezpečnost zarážecího zařízení / Uvedení do provozu

J Zarážecí zařízení nenoste na praco-

višti jen na rukojeti a ne se spuštěným

spouštěčem.

J Dbejte na poměry na pracovišti. Zará-

žené předměty mohou eventuálně prorazit slabé

obrobky nebo při práci na rozích a hranách

obrobků sklouznout a přitom poranit osoby.

J Použijte prostředky pro

ochranu těla vodné pro vaši

osobní ochranu, jako je ochrana sluchu

a očí. Nošení osobního ochranného vybavení,

jako je maska proti prachu, protiskluzná ochranná

obuv, ochranná přilba nebo ochrana sluchu,

vždy podle druhu a použití zarážecího zařízení,

snižuje riziko poranění.

Doplňující bezpečnostní

pokyny pro pneumatické

sešívačky

VÝSTRAHA!

Nikdy nepřekročte maximálně povolený pra-

covní tlak 7 barů. K nastavení pracovního tlaku

použijte redukční ventil.

VÝSTRAHA!

Nikdy nepoužívejte kyslík nebo jiné hořlavé

plyny jako zdroje energie.

J Udržujte pracovní oblast čistou a dob-

ře osvětlenou. Nepořádek a neosvětlené

pracovní oblasti přivodit úrazy.

J Během používání zarážecí

ztratit kontrolu nad zařízením.

J Buďte vždy pozorní, dbejte na to, co

děláte a konejte práci s zarážecím zařízením s rozumem. Zarážecí zařízení

nepoužívejte, jste-li unaveni nebo pod

vlivem drog, alkoholu nebo léků. Mo

nepozornosti při použití zarážecího zařízení

může vést k závažným poraněním.

J Vyhněte se neobvyklému držení hlavy.

Pečujte stabilní postoj a udržujte neustále rovnováhu. Tím můžete zarážecí zaří-

zení v neočekávaných situacích kontrolovat.

24 CZ

NEBEZPEČÍ PORANĚNÍ!

NEBEZPEČÍ PORANĚNÍ!

zařízení před dětmi a jinými

osobami. Při rozptýlení můžete

ment

J Před opravárenskými a údržbářskými pracemi,

jakož i před přepravou chraňte zařízení před

zdrojem tlaku.

J NEBEZPEČÍ PORANĚNÍ! Zařízení neuveďte

do provozu, je-li spouštěcí pojistka

nebo byla-li odstraněna. Následkem mohou

věcné škody.

7

defektní

J Při uvolnění spojky hadice držte hadici pevně v

ruce, aby se zabránilo poraněním vyvolaným

rychlým pohybem hadice zpět.

J Pro přípojku stlačeného vzduchu bezpodmíneč-

ně použijte závitovou zásuvnou spojku ¼‘‘ a

rychlospojku.

J Nikdy se nestrkejte své ruce do blízkosti výstu-

pu, zatímco je zařízení připraveno k provozu.

Následkem mohou věcné škody.

J Dbejte na poškození. Před uvedením do

provozu zkontrolujte zařízení vzhledem k poškozením. V případě, že zařízení vykazuje nedostatky, nesmí se v žádném případě uvést do

provozu.

J Nepoužívejte špičaté předměty. Nikdy

neuveďte špičaté a / nebo kovové předměty do

vnitřku zařízení.

Q

Originální příslušenství /

přídavná zařízení

J Používejte jen příslušenství a doplň-

kových zařízení, která jsou udána v

návodu k obsluze. Použití jiných než v návo-

du k obsluze doporučených zarážecích zařízení

nebo jiných doplňků může pro vás znamenat

nebezpečí úrazu.

Q

Uvedení do provozu

Q

Připojení zdroje

stlačeného tlaku

UPOZORNĚNÍ: Pneumatická sešívačka se smí

výhradně provozovat s vyčištěným, olejem zamlženým

stlačeným vzduchem a nesmí překročit maximální

pracovní tlak 7 barů na zařízení. K regulaci pracovního tlaku musí být kompresor vybaven redukčním

ventilem.

Page 25

Uvedení do provozu / Obsluha

j Zařízení připojte k vhodnému zdroji stlačeného

vzduchu.

1. K tomu stiskněte rychlospojku hadice stlačeného

vzduchu (není obsažena v rozsahu dodávky)

na závitovou zásuvnou spojku s vnějším závitem

4

¼“

pneumatické sešívačky.

Zablokování nastane automaticky.

2. Druhý konec hadice stlačeného vzduchu spojte

s redukčním ventilem (filtru) na kompresoru.

Q

Naplnění zásobníku

UPOZORNĚNÍ: Nikdy nepoložte hřebíky do

meziotvoru, který je určen pro spony. To vede ke

zpětné zácpě v hnacím mechanizmu a brání správnému výstupu zaráženého materiálu.

1. Stiskněte páku zásobníku

6

sobník

zpět.

UPOZORNĚNÍ: Mějte na paměti, že se smí

do zásobníku vložit jen spony o délce 16 - 32 mm

a hřebíky o délce 15 - 32 mm.

2.

Vložte příslušný zarážecí materiál (hřebíky, viz o

01

nebo spony, viz obr. 02) do zásobníku 6.

01

6

02

6

5

a vytáhněte zá-

br.

j Nastavte pomocí redukčního ventilu správný

pracovní tlak.

j Dbejte na to, abyste nepřekročili maximální

pracovní tlak 7 barů na zařízení. Příliš vysoký

pracovní tlak nepřinese zisk výkonu, nýbrž zvýší jen spotřebu stlačeného vzduchu a urychlí

opotřebení zařízení.

j Zapněte kompresor.

j Nechejte kompresor jednou běžet tak dlouho,

až se dosáhne maximálního tlaku kotle a zařízení se vypne.

j Posaďte pneumatickou sešívačku na obrobek a

stiskněte spouštěč

2

.

j UPOZORNĚNÍ: Pneumatická seší-

vačka je vy bavena spouštěcí pojist-

7

kou

. Zarážecí materiál opustí

zařízení teprve tehdy, je-li výstup pneumatické

sešívačky stisknut proti obrobku a je-li spouštěč

uveden v činnost. Tímto ochranným zařízením

se zajistí, že se žádné zarážené předměty, jako

jsou spony nebo hřebíky nemohou nekontrolovaně opustit zařízení.

j Přezkoušejte, je-li zarážený předmět zarážen

podle požadavků.

- Vyčnívá-li zarážený předmět, zvyšte tlak vzduchu v krocích 0,5 barů a přezkoušejte znovu

výsledek.

- Je-li zarážený předmět příliš nízko zapuštěn,

snižte tlak vzduchu po krocích 0,5 barů, až

výsledek uspokojí.

V každém případě byste se měli snažit vždy pracovat s nejnižším tlakem vzduchu. To přináší tři základní přednosti:

1) Šetříte energii,

2) Snížíte úroveň hluku,

3) Zredukujete opotřebení zarážecího zařízení.

j Vyhněte se spuštění zarážecího zařízení při

prázdném zásobníku.

3. Zásobník 6 předsuňte, až zapadne.

Q

Obsluha

j Naplňte zásobník

6

pneumatické sešívačky tak,

jak je popsáno v kapitole „Naplnění zásobníku“.

6

UPOZORNĚNÍ: Jemné nastavení je ostatně možné rýhovaným šroubem

j Otočte rýhovaný šroub

8

zu

, aby se zarážený předmět spustil níže

9

.

9

proti dolnímu dora-

do obrobku.

j Otočte rýhovaný šroub

10

zu

, aby se zarážený předmět spustil méně

9

proti hornímu dora-

nízko do obrobku.

25 CZ

Page 26

Obsluha / Údržba a čistění / Servis / Záruka

UPOZORNĚNÍ: Pneumatická sešívačka se může

přiložit jak na vodorovný, tak i na svislý obrobek.

j Otočte krytem odpadního vzduchu

vystupující vzduch odvedl požadovaným směrem.

1

, aby se

j Zařízení po ukončení práce oddělte od kom-

presoru.

UPOZORNĚNÍ: Nejprve uvolněte hadici od

kompresoru a teprve potom odstraňte zásobovací hadici od zařízení.

Tak se vyhnete nekontrolovanému víření zásobovací hadice.

Q

Údržba a čistění

J NEBEZPEČÍ POPÁLENÍ! Čisticí a údržbářské

práce zahajte teprve tehdy, je-li pneumatická

sešívačka úplně ochlazená.

J NEBEZPEČÍ PORANĚNÍ! Zařízení bezpod-

mínečně oddělte od zásobování stlačeným

vzduchem, předtím než je budete čistit a / nebo

udržovat.

Q

Údržba

j Zařízení pravidelně namažte. Tak získáte bez-

vadnou funkci a dlouhou životnost výrobku.

Mazání mazničkou olejové mlhoviny

UPOZORNĚNÍ: Jako přípravný stupeň po re-

dukčním ventilu maže maznička olejové mlhoviny

pneumatickou sešívačku spojitě a optimálně. Maznička olejové mlhoviny odevzdá jemnou kapičku

oleje proudícímu vzduchu a tak zaručí pravidelné

mazání.

j Mazničku olejové mlhoviny instalujte po redukč-

ním ventilu (filtru). K tomu zastrčte zásuvnou

spojku mazničky olejové mlhoviny do rychlospojky redukčního ventilu (filtru).

j Pak připojte zařízení stlačeného vzduchu ke k

tomu plánované rychlospojce.

Ruční mazání

UPOZORNĚNÍ: Nedisponujete-li mazničkou

olejové mlhoviny, vykonejte mazání před každým

uvedením do provozu, popř. po delších provozních

přestávkách.

26 CZ

j Nakapejte 3 - 5 kapek pneumatického speciálního

oleje do závitové zásuvné spojky

tické sešívačky

j Pak stiskněte několikrát spouštěč

4

pneuma-

2

.

j Nakapejte 5 - 10 kapek po provozní přestávce

více než 5 dní.

Q

Čistění

J Nepoužívejte ostré předměty k čištění zařízení.

Do vnitřku zařízení se nesmí dostat kapaliny.

Jinak se může výrobek poškodit.

j Zařízení pravidelně čistěte, nejlépe vždy přímo

po ukončení práce.

j Pouzdro čistěte suchou tkaninou – nikdy nepo-

užívejte benzin, rozpouštědla nebo čističe, které

působí agresivně na umělou hmotu.

j Po každém použití uschovejte pneumatickou

sešívačku v dodaném kufříku, abyste je chránili

před znečištěními.

Q

Servis

J

Q

Na přístroj dostáváte záruku v trvání

3 let od data zakoupení. Přístroj byl vyroben pečlivě a před dodáním svědomitě

vyzkoušen. Uschovejte si, prosím, pokladní lístek jako doklad o nákupu. V

případě záruky se prosím spojte telefonicky s Vaším servisním střediskem. Jen

tak můžeme zaručit bezplatné odeslání

Vašeho zboží.

Poskytnutí záruky platí pouze na závady materiálu

nebo výrobní chyby, ne však na díly podléhající

opotřebení nebo napoškození křehkých dílů, např.

VÝSTRAHA!

zařízení jen opravovat kvalifikovaným odborným personálem a jen s

originálními náhradními díly. Tím je za-

jištěno, že se dodrží bezpečnost zarážecího

zařízení.

Záruka

Nechejte své zarážecí

Page 27

Záruka / Zlikvidování / Prohlášení o shodnosti / Výrobce

vypínače nebo baterie. Výrobek je určen pouze

pro privátní použití, ne průmyslové.

Záruka zaniká v případě neúčelového a neodborného zacházení, použití násilí a v případě zásahů,

které nebudou provedeny námi autorizovanou servisní pobočkou. Vaše zákonná práva nejsou touto

zárukou omezena.

CZ

Ing. Martin Šimák, zprostředkovatel

servisu výrobků Kompernass

Malešické nám.1

108 00 Praha 10

Hotline: 800 400 235

Fax: 271 722 939

e-mail: support.cz@kompernass.com

Q

Zlikvidování

Obal se skládá z ekologicky vhodných

materiálů, které můžete zlikvidovat v

místních recyklačních střediscích.

Výrobek neodhoďte do domácího odpadu!

Q

Prohlášení o shodnosti /

Výrobce

My, Kompernaß mbH, Burgstr. 21,

D-44867 Bochum, Německo, tímto prohlašujeme pro

tento výrobek shodu s následujícími směrnicemi EU:

Použité sladěné normy:

EN 12100-1:2004

EN 12100-2:2004

EN 792-13:2000

Typ / Označení přístroje:

Sada pneumatickŷch sponkovačů

Bochum, 31.07.2009

Hans Kompernaß

- obchodní vedoucí -

O možnostech ke zlikvidování vysloužilých přístrojů

se dozvíte ve správě Vaší obce či města.

Technické změny ve smyslu dalšího vývoje

jsou vyhrazeny.

27 CZ

Page 28

28

Page 29

Sicherheit / Bedienung

Zoznam obsahu

Úvod

Používanie v súlade s určením ......................................................................................Strana 30

Vybavenie ......................................................................................................................Strana 30

Obsah dodávky ............................................................................................................Strana 30

Technické údaje .............................................................................................................Strana 30

Bezpečnosť nastreľovacieho náradia

Bezpečnosť pri práci .....................................................................................................Strana 31

Doplňujúce bezpečnostné pokyny pre pneumatickú sponkovačku / klincovačku .....Strana 32

Originálne príslušenstvo / prídavné zariadenia ..........................................................Strana 32

Uvedenie do prevádzky

Pripojenie zdroja stlačeného vzduchu .........................................................................Strana 32

Naplnenie zásobníka ...................................................................................................Strana 33

Obsluha ......................................................................................................................Strana 33

Údržba a čistenie

Údržba...........................................................................................................................Strana 34

Čistenie ..........................................................................................................................Strana 34

Servis ............................................................................................................................Strana 34

Záruśná lehota .....................................................................................................Strana 34

Likvidácia ..................................................................................................................Strana 35

Vyhlásenie o zhode / Vyhlásenie výrobcu ...................................Strana 35

29 SK

Page 30

Úvod

V tomto návode na obsluhu / na prístroji sú použité nasledujúce piktogramy:

Prečítajte si návod na používanie!

Dbajte na výstražné a

bezpečnostné pokyny!

Noste ochranné okuliare a

ochranu sluchu.

Zošĺvačka s prĺslušenstvom

Q

Úvod

Pred prvým uvedením do prevádzky sa

oboznámte s funkciami nastreľovacieho

náradia a informujte sa o správnom

zaobchádzaní s nastreľovacím náradím. Za týmto

účelom si prečítajte nasledujúci návod na obsluhu.

Tento návod dôkladne uschovajte. Ak nastreľovacie

náradie odovzdávate ďalšej osobe, priložte k

nemu aj všetky podklady.

Q

Používanie v súlade s určením

Zabráňte prístupu detí k

nastreľovaciemu náradiu!

Poistka spínača

Balenie prístroja a prístroj zlikvidujte

ekologickým spôsobom!

Q

Obsah dodávky

1 x súprava pneumatickej sponkovačky / klincovačky

1 x prenosný kufrík

1 x špeciálny olej pre pneumatické náradie

1 x závitová vsuvka s vonkajším závitom ¼‘‘

(vopred namontovaná)

1 x balík klincov, 1000 ks

1 x balík sponiek, 1000 ks

1 x ochranné okuliare

1 x inbusový kľúč, 3 mm

1 x inbusový kľúč, 4 mm

1 x návod na obsluhu

Q

Technické údaje

Toto náradie je vhodné na montážne a opravárenské

práce (pozri obr. B, C, D). Akékoľvek iné použitie alebo úprava náradia je v rozpore s určením a predstavu

značné nebezpečenstvá úrazu. Nepreberáme ruče

nie

za škody vzniknuté v dôsledku používania v rozpore

určením. Náradie je určené len na súkromné použi

Q

Vybavenie

1

záslepka odpadového vzduchu (otočná)

2

spínač

3

rukoväť

4

závitová vsuvka s vonkajším závitom ¼“

5

páčka zásobníka

6

zásobník

7

poistka spínača

8

spodný doraz

9

ryhovaná skrutka

10

horný doraz

30 SK

tie.

Pracovný tlak: max. 7 bar

Kapacita: 100 ks

Dĺžka klincov: 15 - 32 mm

je

Dĺžka sponiek: 16 - 32 mm

Šírka sponiek: 5,7 mm

s

Odporúčaný priemer

hadice: Ø 9 mm

Kvalita stlačeného

vzduchu: očistený, s rozprášeným

olejom a bez kondenzátu

Informácie o hluku a vibráciách:

Namerané hodnoty stanovené v súlade s

EN 12549:1999, EN ISO 4871. Typická hladina

akustického tlaku náradia s hodnotením A dosahuje 85,7 dB (A). Odchýlka K = 3 dB. Hladina hluku

pri práci môže prekročiť 98,7 dB (A).

Page 31

Úvod / Bezpečnosť nastreľovacieho náradia

Tieto hodnoty sú charakteristické parametre náradia

a nevyjadrujú vznik hluku na mieste použitia Vznik

hluku na mieste použitia závisí napr. od pracovného

prostredia, obrábaného predmetu, uloženia obrábaného predmetu a od počtu nastreľovacích procesov.

V závislosti od pomerov na pracovisku a tvaru obrábaného predmetu treba poprípade prijať individuálne opatrenia na redukciu hluku, napr. uložiť

obrábané predmety na podložky tlmiace hluk, zabrániť vibráciám obrábaných predmetov ich upnutím

alebo zakrytím, nastaviť najnižší tlak potrebný pre

pracovný postup. V osobitných prípadoch je potrebné nosiť osobnú ochranu sluchu.

Noste ochranu sluchu!

Celkové hodnoty vibrácií podľa EN ISO 8662-11:

Emisná hodnota vibrácií a

Odchýlka K = 1,5 m / s

Mechanické otrasy (vibrácia)

Pre nastreľovacie náradie bola charakteristická hodnota vibrácií stanovená podľa ISO 8662-11:1999 —

ručné stroje poháňané motorom — meranie mechanických vibrácií na rukoväti — nastreľovacie náradie

(pozri technické údaje). Hodnota je charakteristickým

parametrom náradia a nepredstavuje pôsobenie na

systém rameno/ruka pri použití náradia. Pôsobenie

na systém rameno/ruka pri použití náradia závisí

napr. od uchopovacej sily, prítlačnej sily, pracovného smeru, nastaveného tlaku vzduchu, obrábaného

predmetu a od uloženia obrábaného predmetu.

h,D

2

= 2,0 m / s

2

Bezpečnosť

nastreľovacieho náradia

VAROVANIE!

pečnostné upozornenia a pokyny. Zanedba-

nie dodržiavania bezpečnostných upozornení a

pokynov môže spôsobiť závažné poranenia a /

alebo hmotné škody.

vŠetKy BeZpeČnostnÉ upoZornenia

a poKyny uschovaJte pre nesKorŠie

pouŽitie.

Prečítajte si všetky bez-

J Pred každým začiatkom prác skontro-

lujte bezchybné fungovanie bezpečnostných a spínacích zariadení, ako aj

upevnenie všetkých skrutiek a matíc.

J Nevykonávajte žiadne manipulácie

na nastreľovacom náradí, ktoré sú v

rozpore s predpismi.

J Nedemontujte ani neblokujte žiadne

časti nastreľovacieho náradia, napr.

poistku spínača.

J Nevykonávajte žiadne „núdzové

opravy“ pomocou nevhodných

prostriedkov.

J Nastreľovacie náradie treba pravidel-

ne a odborne udržiavať podľa údajov

výrobcu.

J Zabráňte akémukoľvek oslabeniu a

poškodeniu náradia, napr.:

- zatĺkaním a vyrývaním,

- prerábaním bez schválenia výrobcu

- presúvaním po šablónach vyrobených

z tvrdého materiálu, napr. z ocele,

- pádom na podlahu alebo posúvaním

po podlahe,

- používaním vo funkcii kladiva,

- akýmkoľvek silovým pôsobením.

Q

Bezpečnosť pri práci

J Nastreľovacím náradím pripraveným

na prevádzku nikdy nemierte na

seba samého alebo na iné osoby.

J Nastreľovacie náradie držte pri práci

tak, aby pri možnom spätnom náraze

nemohlo dôjsť k poraneniu hlavy a

tela v dôsledku prerušenia dodávky

energie alebo tvrdými miestami v obrábanom predmete.

J Nastreľovacie náradie nikdy neakti-

vujte na voľnom priestranstve. Zabránite tým ohrozeniu v dôsledku voľne poletujúcich

nastreľovacích predmetov a preťaženia náradia.

J Pri prepravovaní treba nastreľovacie

náradie odpojiť zo siete stlačeného

vzduchu, najmä ak používate rebríky,

alebo ak sa presúvate v neobvyklej

polohe.

31 SK

Page 32

Bezpečnosť nastreľovacieho náradia / Uvedenie do prevádzky

J

Na pracovisku prenášajte nastreľovaci

náradie len za rukoväť, nie so stlačeným spínačom.

J Všímajte si pomery na pracovisku.

Nastreľovacie náradie môže prípadne preraziť

tenké obrábané predmety alebo pri práci skĺznuť po rohoch a hranách obrábaných predmetov

a pritom ohroziť osoby.

J Pre svoju osobnú ochranu

používajte vhodné ochranné

pomôcky, napr. ochranu sluchu a očí.

Nosenie osobného ochranného výstroja, ako

je protiprachová maska, protišmyková bezpečnostná obuv, ochranná prilba alebo ochrana

sluchu, v závislosti od druhu a použitia nastreľovacieho náradia, znižuje riziko poranení.

Doplňujúce bezpečnostné

pokyny pre pneumatickú

sponkovačku / klincovačku

VAROVANIE!

PORANENIA! Nikdy neprekračujte maximál-

ny povolený pracovný tlak 7 bar. Na nastavenie

pracovného tlaku používajte reduktor tlaku.

VAROVANIE!

PORANENIA! Nikdy nepoužívajte kyslík ale-

bo iné horľavé plyny ako zdroj energie.

J Pracovnú oblasť udržiavajte čistú a

riadne osvetlenú. Neporiadok a neosvetlené pracovné oblasti môžu viesť k úrazom.

J Deti a ďalšie osoby nepúšťajte

blízkosti. Pri odvedení pozornosti môžete

stratiť kontrolu nad náradím.

J Buďte vždy sústredený, dávajte pozor

na to, čo robíte a k práci s nastreľovacím náradím pristupujte s rozvahou.

Nastreľovacie náradie nepoužívajte

vtedy, ak ste unavený, alebo ak ste

pod vplyvom drog, alkoholu či liekov.

Jediná chvíľka nepozornosti pri používaní nastreľovacieho náradia môže viesť k vážnym

poraneniam.

J Vyhýbajte sa neobvyklému držaniu

tela. Zabezpečte si stabilný postoj a

32 SK

NEBEZPEČENSTVO

NEBEZPEČENSTVO

počas používania nastreľovacieho náradia do jeho

e

vždy udržiavajte rovnováhu. Vďaka

tomu budete môcť nastreľovacie náradie v neočakávaných situáciách lepšie kontrolovať.

J Náradie odpojte pre opravárenskými a údrž-

bovými prácami i pred prepravou od zdroja

stlačeného vzduchu.

J NEBEZPEČENSTVO PORANENIA! Náradie

neuvádzajte do prevádzky vtedy, ak je poistka

spínača

Inak môže dôjsť k poraneniam.

7

chybná alebo bola odstránená.

J Pri uvoľňovaní hadicovej spojky držte hadicu

pevne v ruke, aby ste zabránili poraneniam

spôsobeným vymrštenou hadicou.

J

Na pripojenie stlačeného vzduchu používajte bezpodmienečne závitovú vsuvku ¼‘‘ a rýchlospoj

J Ruky sa nesmú nikdy dostať do blízkosti ústia,

keď je náradie pripravené na prevádzku. Inak

môže dôjsť k poraneniam.

J Dávajte pozor na poškodenie. Pred

uvedením do prevádzky skontrolujte prípadné

poškodenia náradia. Ak sa na náradí vyskytnú

poruchy, nesmie sa v žiadnom prípade uvádzať

do prevádzky.

J Nepoužívajte ostré predmety. Ostré

a / alebo kovové predmety nikdy nezavádzajte

do vnútra náradia.

Q

Originálne príslušenstvo /

prídavné zariadenia

J Používajte iba také príslušenstvo a

prídavné zariadenia, ktoré sú uvedené v návode na obsluhu. Používanie iných

nastreľovacích predmetov, ako tých, ktoré sú

odporúčané v návode na obsluhu, alebo iného

príslušenstva môže pre vás znamenať nebezpečenstvo poranenia.

Q

Uvedenie do prevádzky

Q

Pripojenie zdroja

stlačeného vzduchu

UPOZORNENIE: Pneumatická sponkovačka /

klincovačka sa smie prevádzkovať výlučne s očisteným stlačeným vzduchom s rozprášeným olejom,

ku.

Page 33

Uvedenie do prevádzky / Obsluha

pričom sa nesmie prekročiť maximálny pracovný tlak

náradia 7 bar. Kvôli regulovaniu pracovného tlaku

musí byť kompresor vybavený reduktorom tlaku.

j Náradie pripojte k vhodnému zdroju stlačené-

ho vzduchu.

1. Za týmto účelom nasuňte rýchlospojku pneumatickej hadice (nie je súčasťou dodávky) na

závitovú vsuvku s vonkajším závitom ¼“

pneumatickej sponkovačky/klincovačky.

Zablokovanie nastane automaticky.

2. Spojte druhý koniec pneumatickej hadice s

(filtračným) reduktorom tlaku na kompresore.

Q

Naplnenie zásobníka

UPOZORNENIE: Nikdy nevkladajte klince do

otvoru, ktorý je určený pre sponky. Vedie to k vzpriečeniu v posúvači a zabraňuje správnemu výstupu

nastreľovacieho materiálu.

1. Stlačte páčku zásobníka

zásobník

6

.

5

a odsuňte

UPOZORNENIE: Nezabúdajte, že do zásobníka sa smú vkladať len sponky s dĺžkou

16 - 32 mm a klince s dĺžkou 15 - 32 mm.

2. Vložte zodpovedajúci nastreľovací materiál

(klince, pozri obr.

do zásobníka

01

02

6

01

alebo sponky, pozri obr. 02

6

.

6

4

Q

Obsluha

j Zásobník

6

pneumatickej sponkovačky /

klincovačky naplňte podľa opisu v kapitole

„Naplnenie zásobníka“.

j Pomocou reduktora tlaku nastavte správny

pracovný tlak.

j Dbajte na to, aby ste neprekročili maximálny

pracovný tlak náradia 7 bar. Nadmerný pracovný tlak nevylepšuje výkon, ale len zvyšuje

spotrebu stlačeného vzduchu a urýchľuje opotrebovanie náradia.

j Zapnite kompresor.

j Kompresor nechajte bežať dovtedy, kým sa

nedosiahne maximálny tlak v kotle a náradie

sa nevypne.

j Pneumatickú sponkovačku / klincovačku priložte

k obrábaného predmetu a stlačte spínač

UPOZORNENIE: Pneumatická

sponkovačka / klincovačka je vybavená

poistkou spínača

7

. Nastreľovací

materiál opustí náradie až vtedy, keď ústie

pneumatickej sponkovačky / klincovačky pritlačíte k obrábanému predmetu a stlačíte spínač.

Vďaka tomuto ochrannému zariadeniu sa zabezpečí, aby náradie nemohli nekontrolovane

opúšťať žiadne nastreľovacie predmety, ako sú

sponky alebo klince.

2

.

j Skontrolujte, či je nastreľovací predmet nastre-

lený v súlade s požiadavkami.

- Ak nastreľovací predmet vyčnieva, zvyšujte tlak

vzduchu v krokoch po 0,5 bar a zakaždým

znovu skontrolujte výsledok.

- Ak je nastreľovací predmet zapustený príliš

hlboko, znižujte tlak vzduchu v krokoch po

0,5 bar, kým nebude výsledok uspokojivý.

Každopádne by ste sa mali snažiť o prácu s čo

najnižším tlakom vzduchu. Prinesie vám to tri podstatné výhody:

1) ušetríte energiu,

2) znížite hladinu hluku,