Page 1

IAN 43095

AIR RATCHET SET PDRS

AIR RATCHET SET

Operation and Safety Notes

Translation of original operation manual

PNEU RÁČNOVÝ UTAHOVÁK

Pokyny pro obsluhu a bezpečnostní pokyny

Překlad originálního provozního návodu

RAČNI VIJAČNIK NA STISNJEN ZRAK

Navodila za upravljanje in varnostna opozorila

Prevod originalnega navodila za uporabo

DRUCKLUFT-RATSCHENSCHRAUBER

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

43095_par_Druckluft-Ratschenschrauber PDRS_cover_SI_CZ.indd 2 28.05.14 11:13

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Pred branjem odprite stran s slikami in se nato seznanite z vsemi funkcijami naprave.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

SI Navodila za upravljanje in varnostna opozorila Stran 15

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 27

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 37

43095_par_Druckluft-Ratschenschrauber PDRS_cover_SI_CZ.indd 3 28.05.14 11:13

Page 3

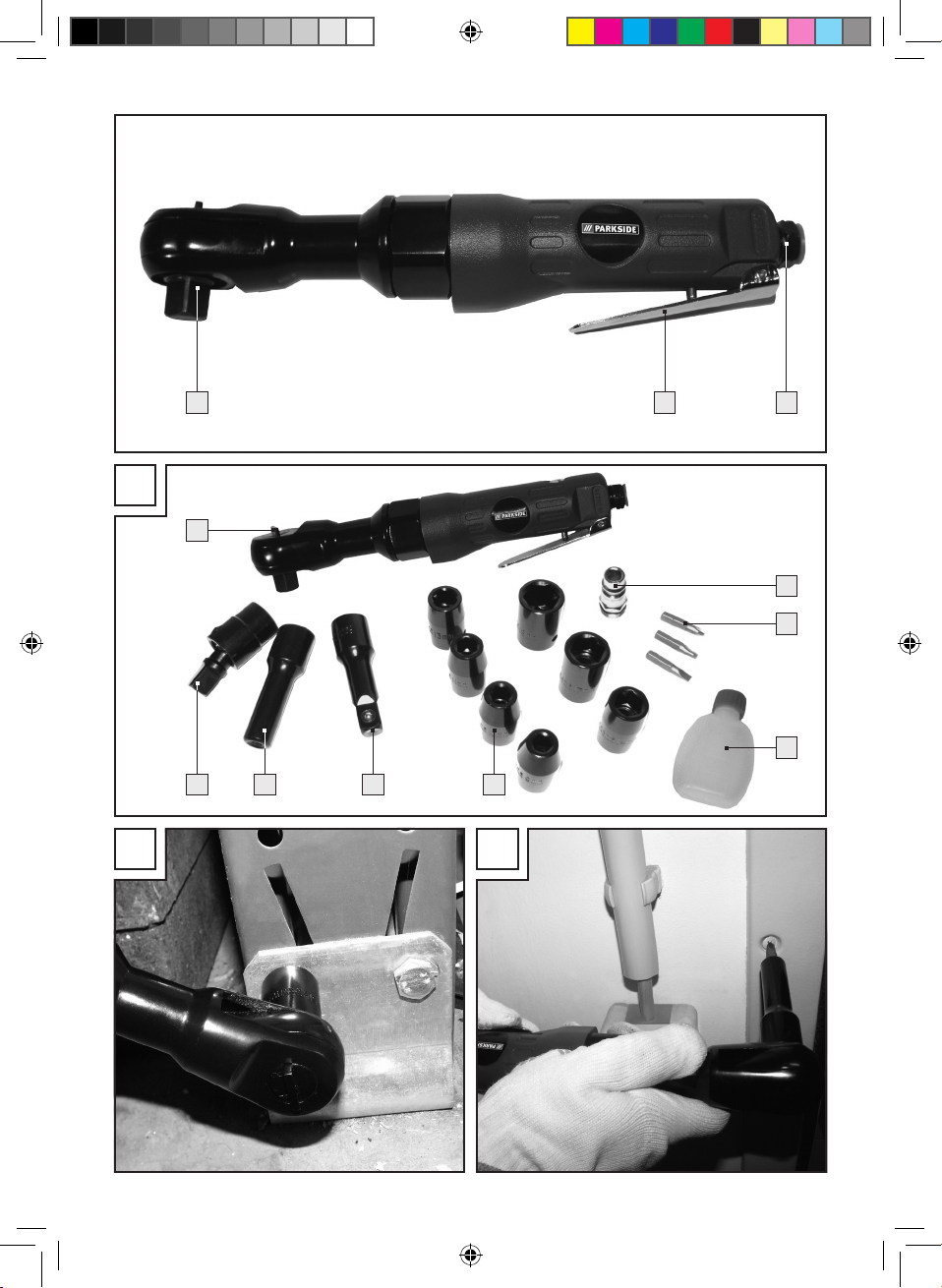

A

1 32

11

4

5

6

78910

B

43095_par_Druckluft-Ratschenschrauber PDRS_cover_SI_CZ.indd 4 28.05.14 11:13

C

Page 4

43095_par_Druckluft-Ratschenschrauber PDRS_cover_SI_CZ.indd 5 28.05.14 11:13

Page 5

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Technical Data ....................................................................................................................................Page 7

Scope of delivery ................................................................................................................................ Page 7

General safety rules ..............................................................................................................Page 7

Projectile hazards ................................................................................................................................ Page 9

Entanglement hazards ........................................................................................................................ Page 9

Operating hazards .............................................................................................................................Page 9

Repetitive motions hazards ................................................................................................................. Page 10

Accessory hazards .............................................................................................................................. Page 10

Workplace hazards ............................................................................................................................ Page 10

Dust and fume hazards ....................................................................................................................... Page 10

Noise hazards ..................................................................................................................................... Page 11

Vibration hazards................................................................................................................................Page 11

Additional safety instructions for pneumatic power tools ................................................................. Page 11

Start-up .............................................................................................................................................Page 12

After initial use ...........................................................................................................................Page 12

Maintenance ................................................................................................................................. Page 12

Cleaning and Care ................................................................................................................... Page 12

Information about warranty and service processing

Warranty terms ...................................................................................................................................Page 12

Extent of warranty ............................................................................................................................... Page 13

Processing of warranty claims ............................................................................................................ Page 13

Environmental instructions and disposal information .............................. Page 13

Declaration of Conformity ................................................................................................ Page 14

5 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 5 28.05.14 11:15

Page 6

Introduction

The following pictograms are used in these operating instructions / on the equipment:

Never use hydrogen, oxygen, carbon

Please read the operating instructions!

dioxide or other bottled gases as an

energy source.

Note

Observe the warning and safety

instructions!

Caution! Explosion hazard!

Oil daily

Air ratchet set PDRS

Introduction

Congratulations!

You have chosen high-quality device

by our company. Familiarise yourself

with the product before using it for the first time. In

addition, please carefully refer to the operating instructions and the safety advice below. Initial opera

of this tool m

ust be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

The ratcheting screwdriver is a handy, compressed-a

powered device for use by handymen and at gara

It is suitable for securing and removing screw connections in the automotive area (tyre installation,

as well as the agricultural area. Please note the to

specifications when tightening screws and nuts. If

necessary, use a torque wrench. The socket attachment is quick and easy to change. Compressed air

is connected with a plug nipple and quick connecto

Only use the product as described and for the indicated purpose. Keep these instructions in a safe place

tion

ges.

etc.)

rque

Wear ear protection, dust mask, sa

glasses and protective gloves.

Compressed air hose

Dispose of packaging and device in

an environmentally-friendly way!

When passing this product on to others, please also

include all the documents. Any use other than the

intended is prohibited and potentially dangerous.

Damages resulting from noncompliance or misuse

are not covered by the warranty and are not included

in the manufacturer‘s liability. This device has been

designed for household use and may not be used

for commercial or industrial purposes.

Features

Check that all the items are present and

that the device is in perfect condition immediately after unpacking. Do not use

the device if it is defective.

1

Ratchet head

2

ir

Trigger

3

Compressed air connection

4

Plug nipple for compressed air supply

5

Bits

6

Oil reservoir

7

Socket key

8

Extension

9

Bit holder

10

r.

U-joint

11

Pivot bolt

.

fety

6 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 6 28.05.14 11:15

Page 7

Introduction / General safety rules

Technical Data

Max. torque: 61 Nm

Operating pressure: 6.3 bar

Speed: 150 rpm

Weight: 1120 g

Noise and vibration

Noise ratings were determined according to

EN 15744. Vibration ratings were determined

according to ISO 28927-2.

Vibration

(per EN 28927-2): 2.63 m / s

Uncertainty K: 1.5 m / s

2

2

Noise level LpA: 91.9 dB(A)

Uncertainty K

Sound power level L

Uncertainty K

L

pC, peak

: 3 dB

pA

WA

: 3 dB

WA

= 105.3 dB(A)

: 102.9 dB(A)

Uncertainty K = 3 dB

Scope of delivery

1 Air ratchet set

1 Plug nipple with gasket

7 Socket key (10, 11, 13, 14, 15, 17, 19 mm)

1 Extension

3 Bits (PH 2.3, SL 5.5)

1 U-joint

1 Bit holder

1 Oil reservoir

1 Carrying case

1 Instructions for use

General safety rules

Note: When used in the following text, the terms

„compressed air unit“ or „device“ refer to the compressed air unit specified in these instructions for use.

Basic safety measures must be

followed when using compressed air units to eliminate

the risk of fire, electric shock and personal injury.

Be sure to read and follow the notices within these

operating instructions prior to using the equipment

and store them in a safe location.

The manufacturer assumes no liability for damages

or personal injury resulting from failure to follow these

operating instructions.

Persons (including children) who lack the knowl-

edge or experience to use the tool or whose

physical, sensory or intellectual capacities are

limited must never be allowed to use the tool

without supervision or instruction by a person

responsible for their safety.

Ensure children do not play with the device.

RISK OF INJURY! Before

performing maintenance tasks, disconnect the

compressed air supply.

EXPLOSION HAZARD! Never

use petrol or other flammable liquids

to clean the air tool! Sparks could

ignite residual vapours inside the compressed

air unit resulting in the compressed air unit exploding. Do not use the device in explosive environments with flammable liquids, gasses or dust.

Never work on materials which are or could

potentially be highly flammable or explosive.

Only use the equipment in areas of application

for which it was designed!

Do not overburden the device.

Never use hydrogen, oxygen, carbon

dioxide or other bottled gasses to

power this tool as doing so may result in an explosion and thus may cause severe

injuries.

Regularly maintain and clean the device as

specified (see chapters „Maintenance“ and

„Cleaning and care“).

Inspect the device for any damage before use.

Always make sure that the device is in perfect

condition each time before use.

Always be attentive! Unexpected movement of

the device may cause hazards.

Avoid placing your body in an unnatural position.

Keep proper footing and balance at all times.

By doing this you will be in a better position to

control the compressed air unit in unforeseen

circumstances.

7 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 7 28.05.14 11:15

Page 8

General safety rules

Do not use any device if its switch is defective.

A device that can no longer be switched on and

off is dangerous and must be repaired.

Store the device out of the reach of children

when it is not in use. Do not let anyone use the

device if he or she is not familiar with it or has not

read the instructions and advice. Compressed

air units are dangerous when they are used by

inexperienced people.

Maintain the device carefully. Check that mov-

ing device parts are working properly and move

freely. Check for any parts that are broken or

damaged enough to detrimentally affect the

functioning of the device. Have damaged parts

repaired before using the device. Many accidents have their origins in poorly maintained

devices.

Switch the device off if you do not use it anymore.

Always wear personal protective

equipment and safety glasses. Wear-

ing personal protective equipment

such as dust mask, non-slip safety shoes, safety

helmet or ear protectors, depending on the type

of air tool and its application, reduces the risk

of injuries.

Check the connections and supply lines. All

maintenance devices, couplings and hoses must

be equipped to meet the pressure and air amounts

specified in the device specific values. Pressure

that is too low influences the functioning of the

device; pressure that is too high can cause damage to property and personal injury.

Protect hoses from kinks, constrictions, solvents

and sharp edges. Keep hoses away from heat,

oil and rotating parts.

Make sure that the hose clamps are always

t

ightly fastened. If the hose clamps are not tightly

fastened or are damaged, the air could escape

uncontrollably.

R

eplace damaged hoses immediately. A damag

ed

supply line may result in the air hose flapping

about and may result in injuries.

If the power cable of the appliance is damaged,

it has to be replaced by the manufacturer or its

service department or a similarly qualified person in order to avoid hazards.

Do not use the device when tired or under the

influence of drugs, alcohol or medications. One

moment of carelessness when using the device

may result in serious injuries.

Do not directly inhale the exhaust air. Keep eyes

away from exhaust air. Exhaust air from the air

tool may contain water, oil, metal particles or

contaminants from inside the compressor. This

may damage your health.

CAREFUL WHEN PUT-

TING THE TOOL DOWN! Always put down

the device so it does not come into contact with

the trigger. This could potentially result in accidental activation of the device, which again

could result in hazards.

Only use suitable accessories. These may be

purchased from the manufacturer. Using nonOEM accessories may result in hazards.

Only use filtered and regulated compressed air.

Dust, caustic vapours and / or moisture may

damage the motor of the compressed air tool.

The hose must be designed for pres-

sures of at least 6.3 bar or 125 PSI,

but at least 150 % of the maximum

pressure generated in the system.

The tool and supply line must be

equipped with a hose coupling to

completely release pressure when

disconnecting the coupling hose.

DANGER! Avoid contact with live lines. This

device is not insulated against electric shock.

RISK OF INJURY! High

working pressures can give rise to recoil forces

that under certain conditions can result in dan

from continuous loading.

If you are inexperienced in the use of this type

of device, you should seek training on how to

handle it safely.

DANGER OF STAB

WOUNDS! Do not treat an injection as a simp

cut. A high pressure jet may inject toxins into

the body and cause serious injuries. If the spray

is injected into the skin, seek medical help immediately.

Do not modify this device in any way without t

manufacturer‘s approval.

Only use the compressed air unit with the spec-

ified pressure (6.3 bar).

Disconnect the compressed air unit from the air

supply after each use and when not in use.

ger

le

he

8 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 8 28.05.14 11:15

Page 9

General safety rules

Do not use the compressed air unit if it is not

air tight or in need of repair.

Never connect the compressed air unit to an air

hose with pressure exceeding 6.3 bar.

Keep your working area clean and well lit. Untidy

or poorly lit working areas can result in accidents.

Doing so will allow you better control of the

device, particularly under unforeseen circumstances.

Only have the device re-

paired by qualified specialist personnel using

OEM spare parts. This will maintain the safety

of the device.

Keep children and other persons away from

the device during use. Distractions can cause

you to lose control of the device.

Wear suitable clothing. Do not wear loose cloth-

ing or jewellery. Keep your hair, clothing and

gloves clear of moving parts. Loose clothing,

jewellery or long hair can become trapped in

moving parts.

Put down trigger and device in the event of un-

expected compressor failure.

If possible, use a condensate trap or regularly

drain the hoses and pipes of condensate (water)

before and whilst using compressed air units.

ATTENTION! An undersized com-

pressed air system may minimise the

efficiency of your device.

For multiple hazards, read and understand the

safety instructions before installing, operating,

repairing, maintaining, changing accessories on,

or working near the assembly power tool for

threaded fasteners. Failure to do so can result

in serious bodily injury.

Only qualified and trained operators should in-

stall, adjust or use the assembly power tool for

threaded fasteners.

Do not modify this assembly power tool for

threaded fasteners. Modifications can reduce

the effectiveness of safety measures and in

crease

the risks to the operator.

Do not discard the safety instructions; give them

to the operator.

Do not use the assembly power tool for threaded

fasteners if it has been damaged.

Tools shall be inspected periodically to verify

that the ratings and markings required by this

part of ISO 11148 are legibly marked on the

tool. The employer / user shall contact the manufacturer to obtain replacement marking labels

when necessary.

Projectile hazards

Failure of the workpiece, of accessories or even

of the inserted tool itself can generate high-velocity projectiles.

Always wear impact-resistant eye protection

during the operation of the assembly power tool

for threaded fasteners. The grade of protection

required should be assessed for each use.

Ensure that the workpiece is securely fixed.

Entanglement hazards

Entanglement hazards can result in choking,

scalping and / or lacerations if loose clothing,

personal jewellery, neckware, hair or gloves are

not kept away from the tool and accessories.

Gloves can become entangled with the rotating

drive, causing severed or broken fingers.

Rotating drive sockets and drive extensions can

easily entangle rubber-coated or metal-reinforced

gloves.

Do not wear loose-fitting gloves or gloves with

cut or frayed fingers.

Never hold the drive, socket or drive extension.

Keep hands away from rotating drives.

Operating hazards

The use of the tool can expose the operator’s

hands to hazards including crushing, impacts,

cuts and abrasions and heat. Wear suitable

gloves to protect hands.

Operators and maintenance personnel shall be

physically able to handle the bulk, weight and

power of the tool.

Hold the tool correctly; be ready to counteract

normal or sudden movements and have both

hands available.

9 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 9 28.05.14 11:15

Page 10

General safety rules

Maintain a balanced body position and secure

footing.

I

n cases where the means to absorb the reacti

on

torque are requested, it is recommended to use

a suspension arm whenever possible. If that is

not possible, side handles are recommended for

straightcase and pistol-grip tools. Reaction bars

are recommended for angle nutrunners. In any

case, it is recommended to use a means to absorb the reaction torque above 4 Nm for straight

tools, above 10 Nm for pistol-grip tools, and

above 60 Nm for angle nutrunners.

Release the start-and-stop device in the case of

an interruption of the energy supply.

Use only lubricants recommended by the manu-

facturer.

Fingers can be crushed in open-ended crow-foot

nutrunners.

Do not use in confined spaces and beware of

crushing hands between tool and workpiece,

especially when unscrewing.

Repetitive motions hazards

When using a power tool for, the operator can

experience discomfort in the hands, arms, shoulders, neck, or other parts of the body.

While using an assembly power tool for threaded

fasteners, the operator should adopt a comfortable posture while maintaining secure footing

and avoiding awkward or off-balanced postures.

The operator should change posture during extended tasks, which can help avoid discomfort

and fatigue.

If the operator experiences symptoms such as

p

ersistent or recurring discomfort, pain, throbbi

ng,

aching, tingling, numbness, burning sensations

or stiffness, these warning signs should not be

ignored. The operator should tell the employer

and consult a qualified health professional.

Accessory hazards

Disconnect the assembly power tool for threaded

fasteners from the energy supply before changing the inserted tool or accessory.

Do not touch sockets or accessories during im-

pacting, as this increases the risk of cuts, burns

or vibration injuries.

Use only sizes and types of accessories and con-

sumables that are recommended by the assembly

power tool for threaded fasteners manufacturer;

do not use other types or sizes of accessories

and consumables.

Use only impact-wrench-rated sockets in good

condition, as poor condition or hand sockets

and accessories used with impact wrenches

can shatter and become a projectile.

Workplace hazards

Slips, trips and falls are major causes of work-

p

lace injury. Be aware of slippery surfaces ca

used

by the use of the tool and also of trip hazards

caused by the air line or hydraulic hose.

Proceed with care in unfamiliar surroundings.

Hidden hazards, such as electricity or other utility lines, can exist.

The assembly power tool for threaded fasteners

is not intended for use in potentially explosive

atmospheres and is not insulated against coming into contact with electric power.

Make sure there are no electrical cables, gas

pipes, etc., that can cause a hazard if damaged

by use of the tool.

Dust and fume hazards

Dust and fumes generated when using assembly

power tools for threaded fasteners can cause

ill health (for example cancer, birth defects,

asthma and / or dermatitis); risk assessment and

implementation of appropriate controls for these

hazards are essential.

Risk assessment should include dust created by

the use of the tool and the potential for disturbing existing dust.

Direct the exhaust so as to minimize disturbance

of dust in a dust-filled environment.

Where dust or fumes are created, the priority

shall be to control them at the point of emission.

10 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 10 28.05.14 11:15

Page 11

General safety rules

All integral features or accessories for the collec-

tion, extraction or suppression of airborne dust

or fumes should be correctly used and maintained in accordance with the manufacturer’s

instructions.

Use respiratory protection in accordance with

employer’s instructions and as required by occupational health and safety regulations.

Noise hazards

Exposure to high noise levels can cause perma-

nent, disabling hearing loss and other problems,

such as tinnitus (ringing, buzzing, whistling or

humming in the ears). Therefore a risk assessment

and implementation of appropriate controls for

these hazards are essential.

Appropriate controls to reduce the risk may in-

clude actions such as damping materials to prevent workpieces from “ringing”.

Use hearing protection in accordance with em-

ployer’s instructions and as required by occupational health and safety regulations.

Operate and maintain the assembly power tool

for threaded fasteners as recommended in the

instructions handbook, to prevent an unnecessa

ry

increase in noise levels.

If the assembly power tool for threaded fasteners

has a silencer, always ensure it is in place and

in good working order when the assembly power

tool for threaded fasteners is operating.

Select, maintain and replace the consumable /

inserted tool as recommended in the instructions

handbook, to prevent an unnecessary increase

in noise.

Vibration hazards

Exposure to vibration can cause disabling dam-

age to the nerves and blood supply of the hands

and arms.

K

eep the hands away from the nutrunner socket

Wear warm clothing when working in cold con-

ditions and keep your hands warm and dry.

If you experience numbness, tingling, pain or

whitening of the skin in your fingers or hands,

stop using the assembly power tool for threaded

fasteners, tell your employer and consult a physician.

Operate and maintain the assembly power tool

for threaded fasteners as recommended in the

instructions handbook, to prevent an unnecessary increase in vibration levels.

Do not use worn or ill-fitting sockets or extensions,

as this is likely to cause a substantial increase

in vibration.

Select, maintain and replace the consumable /

inserted tool as recommended in the instructions

handbook, to prevent an unnecessary increase

in vibration levels.

Sleeve fittings should be used where practicable.

Support the weight of the tool in a stand, ten-

sioner or balancer, if possible.

Hold the tool with a light but safe grip, taking

account of the required hand reaction forces,

because the risk from vibration is generally

greater when the grip force is higher.

Additional safety instructions

for pneumatic power tools

Air under pressure can cause severe injury:

– always shut off air supply, drain hose of air

pressure and disconnect tool from air supply

when not in use, before changing accessories

or when making repairs;

– never direct air at yourself or anyone else.

Whipping hoses can cause severe injury. Always

check for damaged or loose hoses and fittings.

Cold air shall be directed away from the hands.

Do not use quick-disconnect couplings at tool

inlet for impact and air-hydraulic impulse

wrenches. Use hardened steel (or material with

comparable shock resistance) threaded hose

fittings.

Whenever universal twist couplings (claw cou-

s.

plings) are used, lock pins shall be installed

and whipcheck safety cables shall be used to

safeguard against possible hose-to-tool and

hose-and-hose connection failure.

11 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 11 28.05.14 11:15

Page 12

… / Start-up / After initial use / Maintenance / Cleaning … / Information about …

Do not exceed the maximum air pressure stated

on the tool.

For torque-control and continuous-rotation tools,

the air pressure has a safety critical effect on

performance. Therefore, requirements for length

and diameter of the hose shall be specified.

Never carry an air tool by the hose.

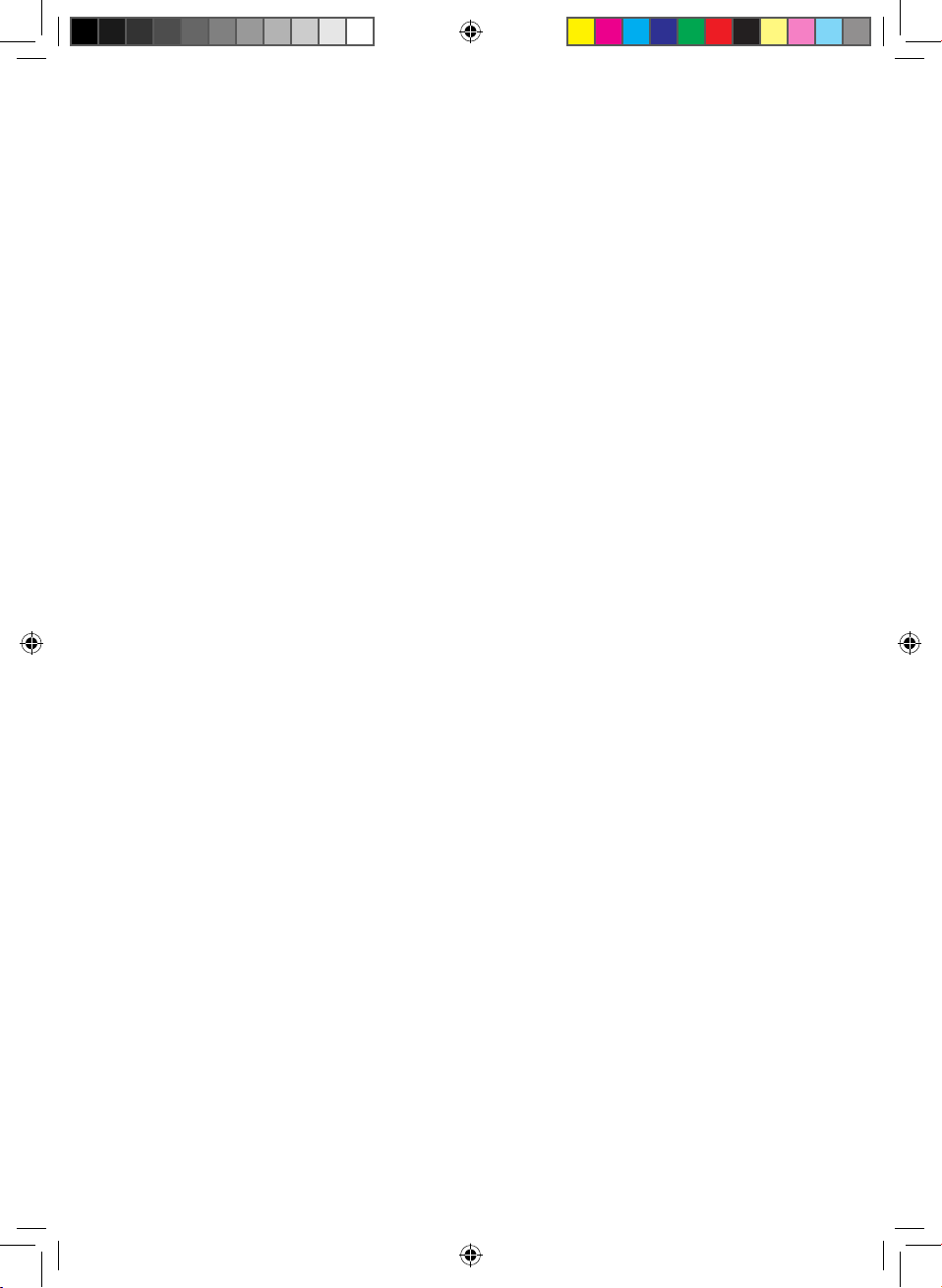

Start-up (see Fig. B / C)

Screw the included plug nipples 4 into the air

connection after first wrapping the thread with

2–3 layers of sealing tape (not included).

Attach the required plug-in attachment to the

square intake.

Set the correct direction of rotation on the pivot

11

bolt

:

R = counterclockwise / remove screw,

F = clockwise / tighten screw.

Attach the plug-in attachment to the screw head.

Activate the trigger 2.

Note: the connection to the compressed air source

is established through a flexible air hose with quick

connector.

The ratcheting screwdriver will perform best when

used with an LW 10 mm air hose.

After initial use

Manually

Add 3–5 drops of speciality tool oil to the compr

air connection before every use. If the compressed

air tool is not being used for several days, add 5–10

drops of oil to the compressed air connection before switching it on.

Always store your compressed air tools in dry

rooms.

essed

Cleaning and Care

Never clean with liquids such as petrol, solvents

or water.

Do not allow liquids to enter the tool.

Only clean the tool with a dry cloth.

Information about warranty

and service processing

Creative Marketing Consulting GmbH

warranty

Dear customer,

the warranty for this device is 3 years from the date

of purchase. In the event of product defects, you

have legal rights against the retailer of this product.

Your statutory rights are not limited in any way by

our warranty detailed below.

Once the task has been finished the equipment must

be disconnect from the compressed air supply

Maintenance

Following the maintenance information specified here

will ensure a long service life for the product and

trouble-free operation. Your ratchet screwdriver working properly for a long time requires daily lubrication.

You may choose from the following options:

With an oil-fog lubricator

A complete maintenance unit includes an oil-fog

lubricator and is attached to the compressor.

12 GB

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 12 28.05.14 11:15

3

.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This document is required as your proof of purchase.

Should this device show any fault in materials or manufacture within three years from date of purchase,

it will be repaired or replaced – at our choice – by

us free of charge. This warranty is conditional on the

defective device and the proof of purchase (receipt)

being presented within the three year warranty period, and that there is a brief written description of

the nature of the defect and of the date it arose.

If the defect is covered by our warranty, we will return the repaired device or replacement thereof. A

Page 13

Information about … / Environmental instructions and disposal information

repair or exchange of the device does not extend a

new warranty period.

Extent of warranty

The appliance has been manufactured to strict quality guidelines and meticulously examined before

delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts

subject to normal wear and tear and which can therefore be considered as wear items, or to damage

to fragile parts, e.g. switches, storage batteries or

glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All instructions provided in the operating instructions must

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. Any incorrect or improper use of the device,

use of force and changes not performed by our

authorized service branch will void the warranty.

Note:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

How to contact us:

GB

Name: C. M. C. GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Phone: 0-808-189-0652

(standard German landline

rates apply)

Registered office: Germany

IAN 43095

Please note that the following address is not a service address.

Please first contact the service point named above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

Environmental instructions

Processing of warranty claims

Please follow the instructions below to ensure quick

processing of your claim:

When inquiring about your product please have

your receipt and product number (e.g. IAN) ready

as your proof of purchase.

The product number can be found on the type plate,

an engraving, the cover page of your instructions

(bottom left) or the decal at the back or bottom.

In the event of malfunctions or other defects, please

first contact the service department below by phone

or e-mail.

A product recorded as defective, along with the proof

of purchase (sales receipt) and a description of the

defect and when it occurred, can then be returned

free of charge to you to the service address provided.

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 13 28.05.14 11:15

and disposal information

Don‘t waste, recycle!

D

evice, accessories and packaging sho

be recycled in an environmentally friendly

manner.

Do not dispose of the air tool with your household

waste, or throw into fire or water. If possible, nonoperational equipment should be recycled. Contact

your local retailer for information.

uld

13 GB

Page 14

Declaration of Conformity

Declaration of Conformity

We,

C. M. C. GmbH

Responsible for documentation: Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

declare in our sole responsibility that the product

Air ratchet set

Serial number: 1712

Year of manufacture: 2014 / 32

IAN: 43095

Model: PARKSIDE AIR RATCHET SET PDRS

meets the basic safety requirements of European

Directives

Machinery Directive

EC Directive 2006 / 42 /EC

and its amendments.

The conformity assessment is based on the followin

harmonised standards:

EN ISO 11148-6:2012

St. Ingbert, 31.05.2014

Karl Peter Uhle

- Managing Director -

14 GB

g

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 14 28.05.14 11:15

Page 15

Kazalo

Uvod

Predvidena uporaba .......................................................................................................................... Stran 16

Oprema .............................................................................................................................................. Stran 16

Tehnični podatki ................................................................................................................................. Stran 17

Obseg dobave ................................................................................................................................... Stran 17

Splošna varnostna pravila .............................................................................................. Stran 17

Nevarnosti zaradi izvrženih delov .................................................................................................... Stran 19

Nevarnosti zaradi prijemanja / navijanja ......................................................................................... Stran 19

Nevarnosti pri delovanju ................................................................................................................... Stran 19

Nevarnosti zaradi ponavljajočih se gibov ....................................................................................... Stran 20

Nevarnosti zaradi delov dodatne opreme ....................................................................................... Stran 20

Nevarnosti na delovnem mestu ......................................................................................................... Stran 20

Nevarnosti zaradi prahu in hlapov................................................................................................... Stran 21

Nevarnosti zaradi hrupa ................................................................................................................... Stran 21

Nevarnosti zaradi tresljajev .............................................................................................................. Stran 21

Dodatna varnostna navodila za pnevmatske naprave ................................................................... Stran 21

Začetek uporabe ..................................................................................................................... Stran 22

Po začetku uporabe .............................................................................................................. Stran 22

Vzdrževanje ................................................................................................................................ Stran 22

Čiščenje in nega ........................................................................................................................ Stran 22

Napotki za garancijo in postopek servisa ........................................................ Stran 22

Garancijski pogoji .............................................................................................................................. Stran 23

Obseg garancije ................................................................................................................................ Stran 23

Postopek pri uveljavljanju garancije ................................................................................................. Stran 23

Okoljevarstveni napotki in navodila za odlaganje .................................. Stran 24

ES izjava o skladnosti .......................................................................................................... Stran 24

Garancijski list ........................................................................................................................... Stran 25

15 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 15 28.05.14 11:15

Page 16

Uvod

V tem navodilu za uporabo / na napravi se uporabljajo naslednji piktogrami:

Kot vira energije nikoli ne uporabljajte

Preberite navodilo za uporabo!

Napotek

vodikovega, kisikovega, ogljikovega

dioksida ali drugega plina v jeklenkah.

Nosite opremo za zaščito sluha,

dihalno / protiprašno zaščitno masko,

zaščitna očala in zaščitne rokavice.

Upoštevajte opozorila in varnostne

napotke!

Pozor! Nevarnost eksplozije!

Dnevno naoljite

Račni vijačnik na stisnjen zrak PDRS

Uvod

Iskrene čestitke!

Odločili ste se za kakovostno napravo

iz naše hiše. Pred prvo uporabo se seznanite z izdelkom. V ta namen pozorno preberite

naslednja navodila za uporabo in varnostne napotke.

Uporaba tega orodja je dovoljena le usposobljenim

osebam.

NE SME PRITI V ROKE OTROK!

Predvidena uporaba

Raglja je priročna, pnevmatska naprava za obrtniško

uporabo in uporabo v mehanični delavnici. Primerna

je za privijanje in odvijanje privitja na mehaničnem

področju (montaža koles itd.) in kmetijskem podro

Pri privijanju vijakov in matic pazite na nujni vrtilni

moment. Eventualno uporabite momentni ključ. Nastavke nasadnih ključev lahko preprosto in hitro zamenjate. Priključek za stisnjen zrak sestoji iz vtične

spojke in hitre spojke. Izdelek uporabljajte samo

kot je opisano, in samo za predviden namen upo

Ta navodila dobro shranite. Če izdelek odstopite

čju.

tako,

rabe.

Pnevmatska cev

Embalažo in napravo odstranite

okolju prijazno!

novemu lastniku, mu zraven izročite tudi vse doku

mente.

Vsaka uporaba, ki odstopa od predvidenega namena

uporabe, je prepovedana in potencialno nevarna.

Škode, ki nastane zaradi neupoštevanja navodil ali

napačne uporabe, garancija ne pokriva in ne spada

v področje jamstva proizvajalca. Naprava je bila

izdelana za domačo uporabo in ni dovoljena uporaba v poslovne ali industrijske namene.

Oprema

Takoj po odprtju embalaže preverite, ali

vsebuje vse spodaj naštete dele ter ali je

naprava v brezhibnem stanju. Naprave

ne uporabljajte, če je pokvarjena.

1

Glava raglje

2

Sprožilna ročka

3

Priključek za stisnjeni zrak

4

Vtična spojka za priključek stisnjenega zraka

5

Bit nastavki

6

Posoda za olje

7

Natični ključ

8

Podaljšek

9

Držalo za bit nastavke

10

Zgibni kos

11

Rotacijski svornik

16 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 16 28.05.14 11:15

Page 17

Uvod / Splošna varnostna pravila

Tehnični podatki

Maks. vrtilni moment: 61 Nm

Delovni tlak: 6,3 barov

Število obratov: 150 min

-1

Teža: 1120 g

Hrup in vibracije

Vrednosti hrupa so ugotovljene v skladu z EN ISO

15744. Vrednosti vibracij so ugotovljene v skladu

z ISO 28927-2.

Vibracije

(skladno z EN 28927-2): 2,63 m / s

Negotovost K: 1,5 m / s

2

2

Raven zvočnega tlaka LpA: 91,9 dB(A)

Negotovost K

Raven hrupa L

Negotovost K

L

, peak

pC

: 3 dB

pA

: 102,9 dB(A)

WA

: 3 dB

WA

= 105,3 dB(A)

Negotovost K = 3 dB

Obseg dobave

1 Račni vijačnik na stisnjen zrak

1 Vtična spojka s tesnilnim obročem

7 Natični ključ (10, 11, 13, 14, 15, 17, 19 mm)

1 Podaljšek

3 Bit nastavki (PH 2,3, SL 5,5)

1 Zgibni kos

1 Držalo za bit nastavke

1 Posoda za olje

1 Kovček za nošenje

1 Navodilo za uporabo

Splošna varnostna

pravila

Napotek: Pojem, ki je v nadaljevanju besedila

uporabljen kot „pnevmatska naprava“ ali “naprava“,

se nanaša na pnevmatske naprave, ki so navedene

v teh navodilih za uporabo.

Pri uporabi pnevmatskih naprav morate slediti osnovnim varnostnim ukrepom, da

bi preprečili tveganje pred požarom, udarom električnega toka in poškodbe oseb. Pred prvo uporabo

najprej obvezno preberite in upoštevajte napotke v

teh navodilih za uporabo ter jih dobro shranite. Za

škodo in telesne poškodbe, ki so nastale zaradi neupoštevanja teh navodil za uporabo, proizvajalec

ne prevzema odgovornosti.

Ta naprava ni namenjena za to, da jo upora-

bljajo osebe (vključno z otroci), ki so omejene

v svojih telesnih, zaznavnih ali duševnih zmogljivostih ali jim primanjkuje izkušenj in / ali

znanja, razen v primeru, ko jih nadzira oseba,

odgovorna za njihovo varnost, ali pa so od te

osebe dobili navodila o tem, kako se napravo

uporablja.

Zagotovite, da se otroci ne bodo igrali z na-

pravo.

NEVARNOST

POŠKODB! Pred vzdrževalnimi deli prekinite

oskrbo s stisnjenim zrakom.

NEVARNOST EKSPLOZIJE! Za

čiščenje pnevmatske naprave nikoli

ne uporabljajte bencina ali drugih

vnetljivih tekočin! Preostala para v pnevmatski

napravi se lahko z iskricami vname in povzroči

eksplozijo naprave. Z napravo ne delajte v okolici, kjer obstaja nevarnost eksplozije in v kateri

se lahko nahajajo vnetljive tekočine, plini ali prah.

Ne obdelujte materialov, ki bi lahko bili potencialno lahko vnetljivi ali eksplozivni.

Napravo uporabljajte le na področjih uporabe,

za katera je namenjena!

Naprave ne preobremenite.

Kot vira energije za to orodje nikoli

ne uporabljajte vodikovega, kisiko-

vega ali ogljikovega dioksida ali drugega plina v steklenicah, ker to lahko privede

do eksplozije, s tem pa tudi do težkih poškodb.

Redno vzdržujte in čistite napravo kot je pred-

pisano (gl. poglavji „Vzdrževanje“ ter „Čiščenje

in nega“).

Napravo pred prvim zagonom preverite glede

morebitnih poškodb. Pred vsako uporabo se

prepričajte, da je naprava v brezhibnem stanju.

Ves čas bodite pozorni! Nepričakovani premiki

naprave lahko povzročijo nevarnost.

Izogibajte se nenaravni telesni drži. Skrbite za

varno stojišče in stalno pazite na ravnotežje.

Na ta način lahko bolje ohranite nadzor nad

17 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 17 28.05.14 11:15

Page 18

Splošna varnostna pravila

pnevmatsko napravo tudi v nepričakovanih situacijah.

Ne uporabljajte naprave s pokvarjenim stikalom.

Naprava, ki je ni več možno vklopiti ali izklopiti, je nevarna in jo je treba dati v popravilo.

Neuporabljene pnevmatske naprave shranjujte

zunaj dosega otrok. Osebam, ki z napravo niso

seznanjene ali niso prebrale teh navodil, uporabe

naprave ne dovolite. Pnevmatske naprave so

nevarne, če jih uporabljajo neizkušene osebe.

Napravo skrbno negujte. Preverite, ali premika-

joči se deli naprave brezhibno delujejo in se ne

zatikajo, ali so deli naprave odlomljeni ali poškodovani, ter ali delovanje naprave ni ovirano.

Poškodovane dele dajte pred ponovno uporabo

naprave v popravilo. Vzrok za mnoge nesreče

so slabo vzdrževane naprave.

Ko naprave več ne uporabljate, jo izklopite.

Uporabljajte osebno zaščitno opremo

in vedno nosite zaščitna očala. Upo-

raba osebne zaščitne opreme, kot

so maska za zaščito pred prahom, nedrseči delovni čevlji, zaščitna čelada ali zaščita sluha,

odvisno od načina uporabe pnevmatskega

orodja zmanjšuje tveganje nastanka poškodb.

Preverite priključke in oskrbne napeljave. Vse

vzdrževalne enote, sklopke in gibke cevi morajo

biti položene glede na tlak in količino zraka v

skladu s karakteristikami naprave. Prenizek tlak

vpliva na delovanje naprave, previsok tlak pa

lahko povzroči materialno škodo in telesne poškodbe.

Gibke cevi zavarujte pred prepogibanjem, zoži-

tvami, topili in ostrimi robovi. Gibke cevi hranite

vstran od virov vročine, od olja in vrtečih delov.

Zagotovite, da so cevne objemke vedno trdno

zategnjene. Skozi nezategnjene ali poškodovane cevne objemke lahko zrak nenadzorovano

uhaja.

Poškodovano cev takoj zamenjajte. Poškodovana

dovodna cev lahko povzroči vihtenje cevi in ta

ko

povzroči poškodbe.

Če je priključna napeljava te naprave poškodo-

vana, jo mora zamenjati proizvajalec ali njegova

servisna služba ali podobno usposobljena ose

ba,

da se preprečijo nevarnosti.

Naprave ne uporabljajte, če ste utrujeni ali če

ste pod vplivom droge, alkohola ali zdravil.

Trenutek nepozornosti med uporabo naprave

lahko povzroči resne poškodbe.

Izpušnega zraka ne vdihavajte neposredno.

Preprečite, da bi izpušni zrak prišel v oči. Izpušni zrak pnevmatske naprave lahko vsebuje vodo,

olje, kovinske delce ali nečistočo iz kompresorja.

Le-to lahko povzroči škodo za zdravje.

BODITE PREVIDNI

PRI ODLAGANJU NAPRAVE! Napravo

vedno odložite tako, da ne leži na varnostnem

vzvodu. Takšna okoliščina lahko sproži nenamerno aktiviranje naprave, kar spet lahko povzroči nevarnosti.

Uporabljate lahko le primeren pribor. Le-to lahko

kupite pri proizvajalcu. Drugo kot originalna

dodatna oprema lahko povzroči nevarnosti.

Uporabljajte le filtriran in reguliran stisnjeni zrak.

Prah, jedka para in / ali vlaga lahko poškodujejo motor pnevmatskega orodja.

Gibka cev mora biti zasnovana za

tlak najm. 6,3 bar ali 125 psi, najmanj

pa za 150 % vrednost največjega

tlaka, ki ga sistem proizvede.

Orodje in dovodni kabel morata biti

opremljena s cevno sklopko, tako

da tlaka pri ločevanju cevi sklopke

ni več.

NEVARNOST! Preprečite stik z napeljavo

pod napetostjo. Ta naprava ni izolirana proti

udaru električnega toka.

NEVARNOST PO-

ŠKODB! Pri visokih delovnih tlakih lahko pride

do pojava povratnih sil, ki morda lahko vodijo

do nevarnosti zaradi stalne obremenitve.

Če ste neizkušeni v ravnanju z napravo, se mo-

rate poučiti o nenevarnem rokovanju.

NEVARNOST VBO-

D

OV! Predrtega mesta ne zdravite kot enostav

ne

ureznine. Visokotlačni curek lahko v telo vbrizga strupene snovi in povzroči resne poškodbe.

V primeru vbrizganja v kožo, nemudoma poiščite zdravniško pomoč.

Brez privolitve proizvajalca, pnevmatske na-

prave ni dovoljeno na noben način spreminjati.

Pnevmatsko napravo uporabljajte samo s pred-

pisanim tlakom (maks. pribl. 6,3 barov).

Pnevmatsko napravo je treba po uporabi in pri

neuporabi vedno ločiti od dovoda zraka.

18 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 18 28.05.14 11:15

Page 19

Splošna varnostna pravila

Če pnevmatska naprava ni neprepustna za

zrak ali je potrebno popravilo, je ni dovoljeno

uporabljati.

Pnevmatske naprave nikoli ne priključite na tlačno

gibko cev s tlakom, višjim od 6,3 barov.

Delovno območje naj bo vedno čisto in dobro

osvetljeno. Nered in neosvetljena delovna področja so lahko vzrok za nezgode. Na ta način lahko bolje ohranite nadzor nad napravo

tudi v nepričakovanih situacijah.

Napravo dajte v popra-

vilo samo kvalificiranemu strokovnemu osebju

in samo z uporabo originalnih nadomestnih

delov. S tem se zagotovi, da varnost naprave

ostane ohranjena.

Otrok in drugih oseb med uporabo naprave ne

pustite blizu. Če niste pozorni, lahko izgubite

nadzor nad napravo.

Nosite primerna oblačila. Ne nosite širokih obla-

čil ali nakita. Poskrbite, da lasje, oblačila in rokavice ne pridejo v bližino vrtečih se delov stroja.

Ohlapna oblačila, nakit ali dolgi lasje bi se

lahko ujeli v premikajoče se dele.

V primeru nepričakovanega izpada kompreso

sprožilec in napravo odložite.

Po možnosti uporabite prestreznik kondenzata

ali redno praznite cevi in cevne napeljave od

kondenzata (vode) pred in med uporabo pnevmatskih naprav.

POZOR! Nezadostno dimenzioni-

ran sistem stisnjenega zraka lahko

zmanjša učinkovitost vaše naprave.

Zaradi večkratnih nevarnosti je potrebno prebrati

in razumeti varnostne napotke pred vgradnjo,

uporabo, popravilom, vzdrževanjem in zamenjavo delov dodatne opreme kot tudi pred

delom v bližini naprav za vijačne spoje. V nasprotnem primeru lahko pride do težkih telesnih

poškodb.

Napravo za vijačne spoje lahko pripravijo, na-

stavijo ali uporabljajo le kvalificirani in šolani

uporabniki.

Naprave za vijačne spoje ni dovoljeno spremi-

njati. Spremembe lahko zmanjšajo učinkovitost

varnostnih ukrepov in povečajo tveganje za

uporabnike.

Varnostnih napotkov ne smete izgubiti - izročite

jih uporabniku.

rja,

Nikoli ne uporabljajte pokvarjene naprave za

vijačne spoje.

Naprave je potrebno redno vzdrževati zaradi

preverbe, da so vse razpoložljive vrednosti izračunov in oznake od ISO 11148, na napravi

berljivo označene. Zaposleni / uporabnik se

mora obrniti na proizvajalca, v kolikor potrebuje nadomestne nalepke za označbo.

Nevarnosti zaradi

izvrženih delov

Pri zlomu obdelovanca ali dela dodatne opreme

ali celo dela orodja naprave same, se lahko

deli z veliko hitrostjo izvržejo.

Pri uporabi naprave za navojne spoje, vedno

nosite zaščito za oči, odporno proti udarcem.

Stopnjo potrebne zaščite je potrebno oceniti

za vsako uporabo posebej.

Potrebno je zagotoviti, da je obdelovanec

varno pritrjen.

Nevarnosti zaradi prijemanja /

navijanja

Nevarnosti zaradi prijemanja / navijanja lahko

povzročijo zadušitev, skalpiranje in / ali ureznine,

če od naprave in njenih dodatnih delov ne držite

stran oblek, osebnega nakita, ogrlic, las ali rokavic.

Rokavice se lahko zapletejo v vrteči pogon, kar

lahko povzroči poškodbe na prstih ali zlom.

Pri vrtečem se pogonu okovja in podaljškov

lahko pride do prijema / navijanja gumiranih ali

s kovino ojačanih rokavic.

Ne nosite ohlapnih rokavic ali rokavice z odre-

zanimi ali zaprtimi vrhi prstov.

Nikoli ne držite pogona, okovja ali pogonskega

podaljška.

Roke držite stran od vrtečega pogona.

Nevarnosti pri delovanju

Pri uporabi naprave so roke uporabnika lahko

izpostavljene nevarnosti zaradi zmečkanin,

19 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 19 28.05.14 11:15

Page 20

Splošna varnostna pravila

udarcev, ureznin, odrgnin in toplote. Za zaščito

rok nosite ustrezne rokavice.

Uporabniki naprave in vzdrževalci morajo biti

fizično v stanju rokovati s težo in zmogljivostmi

naprave.

Pravilno držite napravo: Bodite pripravljeni se

odzvati na običajne in nenadne gibe - držite obe

roki v pripravljenosti.

Pazite, da je vaše telo v ravnotežju in da stojite

stabilno.

V primerih, ko so na razpolago pomožna sred-

stva za sprejem reakcijskega vrtilnega momenta

priporočamo, da uporabite napravo za obešanje kadarkoli je to mogoče. V kolikor to ni mogoče, priporočamo stranske ročaje za naprave

z ravnim ročajem in naprave z ročajem pištole.

V vsakem primeru priporočamo, da uporabite

pripomočke za sprejem reakcijskega vrtilnega

momenta, če je večji od 4 Nm pri napravah z

ravnim ročajem, večji od 10 Nm pri napravah

zročajem pištole in večji od 60 Nm pri vogalnih

vijačnikih.

Upravljalna naprava za zagon ali zaustavitev se

v primeru prekinitve oskrbe z električnim tokom

zaustavi.

Uporabljajte samo maziva, ki jih priporoča pro-

izvajalec.

Prsti se lahko stisnejo v navojih matic z odprto

plosko glavo.

Orodja ne uporabljajte v ozkih prostorih in pa-

zite, da ne stisnete rok med napravo in obdelovanca, posebej pri odvijanju.

Nevarnosti zaradi

ponavljajočih se gibov

Pri uporabi naprave za vijačne povezave, upo-

rabnik pri izvedbi z delom povezanih dejavnosti

lahko začuti neprijetne občutke v dlaneh, rokah,

ramenih, na področju vratu ali na drugih delih

telesa.

Pri delu s to napravo zavzemite udoben polo-

žaj, pazite na varno postavitev in se izogibajte

neugodnim ter takšnih položajev, pri katerih je

težko držati ravnotežje. Uporabnik naj med dlje

časa trajajočim delom zamenja držo, kar lahko

pomaga preprečiti neprijetnosti in utrujenost.

V kolikor uporabnik kaže znake kot so npr. daljše

slabo počutje, tegobe, hitrejše bitje srca, bolečine, mravljinčenje, gluhost, skelenje ali togost,

teh opozorilnih znakov ne ignorirajte. Uporabnik naj le-to sporoči svojemu delodajalcu in se

posvetuje s kvalificiranim zdravnikom.

Nevarnosti zaradi delov

dodatne opreme

Pred menjavo orodja naprave ali delov dodatne

opreme, ločite napravo od oskrbe z električnim

tokom.

Okovja ali delov dodatne opreme se ne dotikajte

med udarnim postopkom, saj le-to lahko poveča

nevarnost ureznin, opeklin ali poškodb zaradi

tresljajev.

Uporabljajte izključno dele dodatne opreme in

potrošni material velikosti in tipov, ki jih priporoča

proizvajalec stroja za vijačne spoje; ne uporabljajte drugih tipov ali velikosti dodatne opreme

in potrošnih materialov.

Uporabljajte izključno udarno okovje v dobrem

stanju, saj pomanjkljivo stanje ročnega okovja

in delov dodatne opreme lahko povzroči, da

le-to pri uporabi z udarnimi vijačniki poči in jih

izvrže.

Nevarnosti na delovnem mestu

Najpogostejši vzroki za poškodbe na delovnem

m

estu so da spodrsnete, se spotaknete in pade

Bodite pozorni na površine, ki z uporabo naprave

lahko postanejo spolzke ter na nevarnosti zaradi spotikanja čez zračno ali hidravlično cev.

V neznani okolici bodite previdni. Skrite nevar-

nosti lahko nastanejo zaradi električnega kabla

ali druge dovodne napeljave.

Naprava za vijačne spoje ni namenjena za

uporabo v ozračju, kjer grozi nevarnost eksplozije in ni izolirana proti kontaktu z viri elektrike.

Prepričajte se, da na razpolago ni električnih

vodov, napeljav plinskih cevi itd., ki v primeru

poškodbe zaradi uporabe naprave lahko povzročijo nevarnost.

te.

20 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 20 28.05.14 11:15

Page 21

Splošna varnostna pravila

Nevarnosti zaradi

prahu in hlapov

Pri uporabi naprave za vijačne spoje nastali pra

in hlapi, lahko povzročijo škodo za zdravje (npr.

rak, prirojena napaka, astma in / ali dermatitis);

nujno potrebna je izvedba ocene tveganja v

zvezi s temi nevarnostmi in uresničevanje ustreznih regulacijskih mehanizmov.

V oceni tveganja pri uporabi naprave bi moral

biti upoštevan nastajajoči prah in pri tem možen

vrtinčeni prah.

Izpušni zrak je potrebno odvajati tako, da se

vrtinčenje prahu v prašni okolici zmanjša na

najmanjšo možno mero.

V kolikor nastajajo prah ali hlapi je glavna na-

loga, le-te nadzorovati na mestu izločanja.

Vse dele naprave za vgradnjo ali dodatne dele

naprave, ki so namenjeni sprejemanju, sesanju

ali izločanju letečega prahu ali hlapov, je potrebno uporabljati in vzdrževati skladno z navodili proizvajalca.

Uporabljajte zaščitno opremo za dihanje po

navodilih vašega delodajalca ali kot zahtevajo

delovni predpisi in predpisi za varovanje zdravja.

Nevarnosti zaradi hrupa

Vpliv visoke stopnje hrupa lahko pri nezadostni

zaščiti sluha povzroči trajne poškodbe sluha,

izgubo sluha in druge težave, kot npr. tinitus

(zvonjenje, žvižganje ali brenčanje v ušesih).

Nujno potrebna je izvedba ocene tveganja v

zvezi s temi nevarnostmi in uresničevanje ustreznih regulacijskih mehanizmov.

K ustreznim regulacijskim mehanizmom za

zmanjšanje tveganja spadajo ukrepi, kot je

uporaba izolacijskih sredstev za preprečitev

hrupa zvonjenja na obdelovancih.

Uporabljajte zaščitno opremo za sluh po navo-

dilih vašega delodajalca ali kot zahtevajo delovni predpisi in predpisi za varovanje zdravja.

Napravo za vijačne spoje je potrebno upravljati

in vzdrževati po priporočilih vsebovanih v teh

navodilih, da bi preprečili nepotrebno povišanje stopnje hrupa.

V kolikor naprava za vijačne spoje razpolaga

z dušilcem zvoka se vedno prepričajte, da je

le-ta na razpolago pri uporabi naprave in da

h

je v dobrem delovnem stanju.

Potrošni material in orodje naprave izberite, vzdr-

žujte in nadomestite v skladu s priporočili v navodilih, da bi preprečili nepotrebno povišanje

stopnje hrupa.

Nevarnosti zaradi tresljajev

Vpliv tresljajev lahko povzroči okvaro živcev in

motnje cirkulacije krvi v dlaneh in rokah.

Držite roke stran od okovja v navojih matic.

Pri delu v mrzli okolici nosite topla oblačila in

ohranjajte roke tople in suhe.

Če ugotovite, da koža na vaših prstih ali dlaneh

dreveni, srbi, boli ali se belo obarva, prenehajte

z delom z napravo, obvestite vašega delodajalca in se posvetujte z zdravnikom.

Napravo za vijačne spoje je potrebno upravljati

in vzdrževati po priporočilih vsebovanih v teh

navodilih, da bi preprečili nepotrebno povečanje tresljajev.

Ne uporabljajte zaprtih ali slabo prilegajočih se

okovij ali podaljškov, saj le-to z veliko verjetnostjo močno poveča tresljaje.

Potrošni material in orodje naprave izberite, vzdr-

žujte in nadomestite v skladu s priporočili v navodilih, da bi preprečili nepotrebno povečanje

tresljajev.

Kadar je mogoče, uporabite fitinge objemk.

Za držanje teže naprave uporabite stojalo, na-

penjalo ali izravnalno napravo, kadarkoli je to

mogoče.

Napravo držite ne premočno, vendar čvrsto z

upoštevanjem potrebne moči dlani, saj se s tveganjem tresljajev praviloma poveča moč oprijema.

Dodatna varnostna navodila

za pnevmatske naprave

Stisnjeni zrak lahko povzroči resne poškodbe:

– Ko naprava ni v uporabi, pri zamenjavi de-

lov dodatne opreme ali pri izvedbi popravil,

21 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 21 28.05.14 11:15

Page 22

… / … / Po začetku … / Vzdrževanje / Čiščenje … / Napotki za garancijo in …

vedno zaprite dovod zraka, zračna cev naj

bo brez pritiska in napravo ločite od dovoda

stisnjenega zraka.

– Zračnega toka nikoli ne usmerite proti sebi

ali proti drugim osebam.

Vihteče cevi lahko povzročijo resne poškodbe.

Zato vedno preverite, ali so cevi in pritrdilna

sredstva nepoškodovana ter se niso razrahljala.

Mrzel zrak odvajajte stran od rok.

Pri udarnih in impulznih vijačnikih ne uporabljajte

sklopk s hitrim zapiralom na vhodu obdelovanca.

Za cevne priključke z navojem uporabite samo

takšne iz kaljenega jekla (ali obdelovanec s

primerljivo odpornostjo proti udarcem).

V kolikor uporabite univerzalne vrtljive sklopke

(zobate sklopke), morate vstaviti zatike, uporabite tudi varovalo cevi whipcheck, da zagotovite

zaščito v primeru zatajitve spoja cevi z napravo

ali spoja med cevmi.

Poskrbite, da najvišji tlak, ki je naveden na na-

pravi, ni presežen.

Pri napravah s stalno rotacijo, krmiljene z vrtilnim

momentom, ima zračni tlak varnostne učinke

na zmogljivost. Zato je potrebno določiti zahteve glede dolžine in premera cevi.

Naprav, ki delujejo na zrak, pri nošenju nikoli

ne nosite za cev.

Začetek uporabe (glej sliko B / C)

Po začetku uporabe

Po opravljenem delu morate napravo ločiti od priključka stisnjenega zraka

3

.

Vzdrževanje

Ob upoštevanju tukaj navedenih napotkov za vzdrževanje sta dolga življenjska doba in nemoteno obratovanje tega kakovostnega izdelka zagotovljena.

Za dolgotrajno brezhibno delovanje Vaše raglje je

obvezno dnevno mazanje.

Na razpolago imate naslednje možnosti:

O razpršilniku olja

Kompletna enota za vzdrževanje vsebuje razpršilnik

olja in je pritrjen na kompresor.

Ročno

Pred vsakim zagonom pnevmatskega orodja dajte

3–5 kapljic olja v priključek stisnjenega zraka. Če

pnevmatskega orodja nekaj dni niste uporabljali,

pred vklopom nakapajte 5–10 kapljic olja v prevmatski priključek.

Hranite Vaše pnevmatsko orodje v suhem

prostoru.

Privijte priloženo vtično spojko 4 v zračni

priključek, potem ko ste prej navili 2–3 sloje

tesnilnega traku (ni priložen) na navoj.

Nataknite potrebni nastavek na štirirobo vpe-

njalno napravo.

Nastavite pravo smer vrtenja na rotacijskem

svorniku

R = vrtenje v levo / odvijanje vijaka,

F = vrtenje v desno / privijanje vijaka.

Nataknite nastavek na glavo vijaka.

Pritisnite sprožilno ročko 2.

Napotek: Za priključitev na vir stisnjenega zraka

je potrebna pnevmatska cev s hitro spojko.

Najboljšo zmogljivost Vaše raglje boste dosegli z

pnevmatsko cevjo LW 10 mm.

22 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 22 28.05.14 11:15

11

:

Čiščenje in nega

Za čiščenje v nobenem primeru ne uporabljajte

tekočin, kot so bencin, razredčilo ali voda.

V notranjost naprave ne smejo vdreti tekočine.

Orodje čistite samo s suho krpo.

Napotki za garancijo in

postopek servisa

Garancija podjetja Creative Marketing

Consulting GmbH

Spoštovana stranka,

za to napravo prejmete 3 leta garancije od datuma

nakupa. V primeru pomanjkljivosti tega izdelka,

lahko

Page 23

Napotki za garancijo in postopek servisa

do prodajalca izdelka uveljavljate svoje zakonsko

določene pravice. Teh zakonskih pravic pa naša

garancija, navedena spodaj, ne omejuje.

Garancijski pogoji

Garancijski rok začne veljati od datuma nakupa. Prosimo, da originalni blagajniški račun skrbno shranite.

Ta dokument potrebujete kot dokazilo o nakupu.

Če se v roku treh let od datuma nakupa izdelka pojavi napaka pri materialu ali izdelavi, bomo vaš izdelek ‒ po svoji lastni izbiri ‒ brezplačno popravili

ali ga zamenjali. Pogoj za uveljavljanje te garancijsk

storitve je, da nam pred potekom teh treh let predložite

okvarjeno napravo in blagajniški račun (blagajniški

izpisek) ter nam pisno na kratko opišete, katere pomanjkljivosti naprava ima in kdaj so se pojavile.

Če naša garancija vašo okvaro pokriva, boste od

nas prejeli popravljen ali nov izdelek. S popravilom

ali zamenjavo izdelka pa ne začne teči novo garancijsko obdobje.

Obseg garancije

Naprava je bila izdelana skrbno, v skladu s strogimi pravili o kakovosti in pred dobavo natančno

preverjena.

Garancijska storitev velja za napake pri materialu

ali izdelavi. Ta garancija ne zajema delov izdelka, ki

so izpostavljeni normalni obrabi in ki se zato lahko

dojemajo kot obrabni deli, ali za poškodbe lomljivih

delov, npr. stikal, baterij ali delov, ki so izdelani iz

stekla.

Garancija preneha veljati, če je bil izdelek poškodovan

ali ni bil strokovno uporabljen ali vzdrževan. Za

ustrezno uporabo izdelka je potrebno natančno

upoštevati vse napotke v navodilih za uporabo.

Obvezno se je potrebno izogibati namenom uporabe

in načinom ravnanja, od katerih navodila za uporabo

odsvetujejo ali pred katerimi svarijo.

jih ni izvedla naša pooblaščena servisna poslovalnica, garancija preneha veljati.

Postopek pri

uveljavljanju garancije

Za zagotovitev hitre obdelave vašega primera vas

prosimo, da sledite naslednjim napotkom:

Prosimo, da za vsa vprašanja pripravite blagajniški

račun in številko izdelka (npr. IAN) kot dokazilo o

nakupu.

Številko artikla poiščite na tipski tablici, na gravuri,

na prvi strani vaših navodil (levo spodaj) ali na na-

e

lepki na zadnji ali spodnji strani.

Če bi prišlo do napak v delovanju ali drugih pomanjkljivosti, se najprej po telefonu ali po elektronski

pošti obrnite na spodaj navedeni oddelek servisne

službe.

Izdelek, za katerega se ugotovi, da je okvarjen, lahko

potem skupaj z dokazilom o nakupu (blagajniškim

računom) in navedbo o tem, katero pomanjkljivost

ima in kdaj je do nje prišlo, z brezplačno pošiljko

pošljete na naslov servisa, ki ga boste prejeli.

Opozorilo:

S strani www.lidl-service.com si lahko

naložite ta in mnoge druge priročnike,

videoposnetke izdelkov in programsko

opremo.

Dosegljivi smo tako:

SI

Ime: C.M.C. Creative Marketing &

Consulting GmbH

Servis in informacije

Media-Impeks d.o.o

Spletna stran: www.cmc-creative.de

E-pošta: service.si@cmc-creative.de

Telefon: 00386 2 796 3511

(normalna tarifa nem. tel. omrežja)

Sedež: Nemčija

Izdelek je namenjen izključno za zasebno in ne za

IAN 43095

poslovno uporabo. V primeru zlorabe ali nepravilnega ravnanja, pri uporabi sile ter pri posegih, ki

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 23 28.05.14 11:15

Upoštevajte, da spodnji naslov ni naslov servisa.

23 SI

Page 24

… / Okoljevarstveni napotki in navodila za odlaganje / ES izjava o skladnosti

Najprej se obrnite na zgoraj navedeno servisno

službo.

Naslov:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Nemčija

Okoljevarstveni napotki in

navodila za odlaganje

Recikliranje surovin namesto

odlaganja smeti!

Napravo, dodatno opremo in embalažo

oddajte na okolju prijazno mesto za recikliranje.

Pnevmatskega orodja ne odvrzite med gospodinjske

odpadke, v ogenj ali v vodo. V kolikor mogoče, je

potrebno nedelujoče naprave reciklirati. Vprašajte

vašega lokalnega prodajalca za pomoč.

ES izjava o skladnosti

Direktiva o napravah

2006 / 42 / ES Direktiva ES

in njihovih spremembah.

Za ocenitev konformnosti so bile uporabljene naslednje harmonizirane norme:

EN ISO 11148-6:2012

St. Ingbert, 31.05.2014

Karl Peter Uhle

- Direktor -

Mi,

C. M. C. GmbH

Odgovorni za dokumentacijo: Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

z izključno odgovornostjo izjavljamo, da izdelek

Račni vijačnik na stisnjen zrak

Serijska številka: 1712

Leto izdelave: 2014 / 32

IAN: 43095

Model: PARKSIDE RAČNI VIJAČNIK NA

STISNJEN ZRAK PDRS

zadovoljuje bistvene varnostne zahteve, ki so

določene v evropskih direktivah

24 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 24 28.05.14 11:15

Page 25

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

00386 (0) 80 28 60

Garancijski list

Garancijski list

1. S tem garancijskim listom jamčimo C.M.C.

GmbH, da bo izdelek v garancijskem roku ob

normalni in pravilni uporabi brezhibno deloval

in se zavezujemo, da bomo ob izpolnjenih spodaj navedenih pogojih odpravili morebitne pomanjkljivosti in okvare zaradi napak v materialu

ali izdelavi oz. po svoji presoji izdelek zamenjali

ali vrnili kupnino.

2. Garancija je veljavna na ozemlju Republike

Slovenije.

3. Garancijski rok za proizvod je 3 leta od dneva

izročitve balga. Dan izročitve blaga je enak

dnevom prodaje, ki je razviden iz računa.

4. Kupec je dolžan okvaro javiti pooblaščenemu

servisu oz. se informirati o nadaljnjih postopkih

na zgoraj navedeni telefonski številki. Svetujem

vam, da pred tem natančno preberete navodila

o sestavi in uporabi izdelka.

5. Kupec je dolžan pooblaščenemu servisu predložiti garancijski list in račun, kot potrdilo in

dokazilo o nakupu.

6. V primeru, da proizvod popravlja nepooblaščeni servis ali oseba, kupec ne more uveljavljati

zahtevkov iz te garancije.

7. Vzroki za okvaro oz. nedelovanje izdelka morajo biti lastnosti stvari same, in ne vzroki, ki so

zunaj proizvajalčeve oz. prodajalčeve sfere. Kupe

c ne more uveljavljati zahtevkov iz te garancije

če se ni držal priloženih navodil za sestavo in

uporabo izdelka ali, če je izdelek kakorkoli

spremenjen ali nepravilno vzdrževan.

8. Jamčimo servisiranje in rezervne dele za minimalno dobo, ki je zahtevana s strani zakonodaje.

9. Obrabni deli oz. potrošni material so izvzeti iz

garancije.

10. Vsi potrebni podatki za uveljavljanje garancije

o

se nahajajo na dveh ločenih dokumentih (gar

cijski list, račun).

11. Ta garancija proizvajalca ne izključuje pravic

potrošnika, ki izhajajo iz odgovornosti prodajalca za napake na blagu.

,

an-

Prodajalec:

Lidl d.o.o.k.d., Pod lipami 1, SI-1218 Komenda

25 SI

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 25 28.05.14 11:15

Page 26

26

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 26 28.05.14 11:15

Page 27

Seznam obsahu

Úvod

Použití ke stanovenému účelu..........................................................................................................Strana 28

Vybavení ...........................................................................................................................................Strana 28

Technické údaje ............................................................................................................................... Strana 29

Obsah dodávky ............................................................................................................................... Strana 29

Všeobecná bezpečnostní pravidla ......................................................................... Strana 29

Ohrožení vymrštěnými díly .............................................................................................................. Strana 31

Ohrožení zachycením nebo navinutím ........................................................................................... Strana 31

Ohrožení za provozu ...................................................................................................................... Strana 31

Ohrožení opakovanými pohyby ..................................................................................................... Strana 32

Ohrožení příslušenstvím ................................................................................................................... Strana 32

Ohrožení na pracovišti .................................................................................................................... Strana 32

Ohrožení prachem a výpary ...........................................................................................................Strana 32

Ohrožení hlukem ..............................................................................................................................Strana 33

Ohrožení vibracemi ......................................................................................................................... Strana 33

Přídavné bezpečnostní pokyny pro pneumatické výrobky ............................................................Strana 33

Uvedení do provozu ...........................................................................................................Strana 34

Po použití ..................................................................................................................................... Strana 34

Údržba ............................................................................................................................................Strana 34

Čistění a ošetřování ............................................................................................................. Strana 34

Pokyny k záruce a provádění servisu

Záruční podmínky ............................................................................................................................ Strana 34

Rozsah záruky .................................................................................................................................. Strana 35

Postup v případě uplatňování záruky ............................................................................................. Strana 35

Ekologické pokyny a informace pro odstranění do odpadu .......... Strana 35

Prohlášení o konformitě .................................................................................................Strana 36

27 CZ

43095_par_Druckluft-Ratschenschrauber PDRS_content_SI_CZ.indd 27 28.05.14 11:15

Page 28

Úvod

V tomto návodu k obsluze / na zařízení jsou použity následující piktogramy:

Nikdy nepoužívejte jako zdroj ener-

Přečtěte si návod kobsluze!

Upozornění

gie vodík, kyslík, oxid uhličitý nebo

jiný plyn vláhvi.

Noste ochranu sluchu, protiprachovou

masku, ochranné brýle a ochranné

rukavice.

Dbejte na výstrahy a řiďte se

bezpečnostními pokyny!

Pozor! Nebezpečí výbuchu!

Denně mazat

Pneu ráčnový utahovák PDRS

Úvod

Srdečně blahopřejeme!

Rozhodli jste se pro kvalitní výrobek

naší firmy. Před prvním uvedením do

provozu se seznamte s výrobkem. Ktomu si pozorně

přečtěte následující návod kobsluze a bezpečnostní

pokyny. Toto nářadí mohou uvádět do provozu pouze

zaškolené osoby.

VÝROBEK SE NESMÍ DOSTAT DO

RUKOU DĚTÍ!

Použití ke stanovenému účelu

Vzduchová tlaková hadice

Obal i výrobek odstraňujte do odpadu

ekologicky!

vzduch se provádí přes vsuvku a rychlospojku. Používejte výrobek jen podle popisu a jen v udaných

oblastech. Tento návod si dobře uschovejte. Při předávání výrobku třetí osobě předávejte současně i

všechny jeho podklady. Jakékoliv použití, které se liší

od použití ke stanovenému účelu, je zakázané a hrozí

potenciálním nebezpečím. Na škody způsobené

nerespektováním pokynů nebo chybným použitím