Page 1

IAN 43095

AIR RATCHET SET PDRS

AIR RATCHET SET

Operation and Safety Notes

Translation of original operation manual

TOURNEVIS À CLIQUET À AIR COMPRIMÉ

Instructions d‘utilisation et consignes de sécurité

Traduction du mode d‘emploi d‘origine

DRUCKLUFT-RATSCHENSCHRAUBER

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

TRYKLUFT-SKRALDESKRUEMASKINE

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

PERSLUCHT-RATELSCHROEVENDRAAIER

Bedienings- en veiligheidsinstructies

Vertaling van de originele gebruiksaanwijzing

43095_par_Druckluft-Ratschenschrauber PDRS_cover_GB_IE_DK_BE.indd 2 28.05.14 11:13

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Avant de lire le mode d‘emploi, ouvrez la page contenant les illustrations et familiarisez-vous ensuite avec

toutes les fonctions de l‘appareil.

Vouw vóór het lezen de pagina met de afbeeldingen open en maak u vertrouwd met alle functies van het

apparaat.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Operation and Safety Notes Page 5

DK Brugs- og sikkerhedsanvisninger Side 15

FR / BE Instructions d‘utilisation et consignes de sécurité Page 25

NL / BE Bedienings- en veiligheidsinstructies Pagina 37

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 49

43095_par_Druckluft-Ratschenschrauber PDRS_cover_GB_IE_DK_BE.indd 3 28.05.14 11:13

Page 3

A

1 32

11

4

5

6

78910

B

43095_par_Druckluft-Ratschenschrauber PDRS_cover_GB_IE_DK_BE.indd 4 28.05.14 11:13

C

Page 4

43095_par_Druckluft-Ratschenschrauber PDRS_cover_GB_IE_DK_BE.indd 5 28.05.14 11:13

Page 5

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Technical Data ....................................................................................................................................Page 7

Scope of delivery ................................................................................................................................ Page 7

General safety rules ..............................................................................................................Page 7

Projectile hazards ................................................................................................................................ Page 9

Entanglement hazards ........................................................................................................................ Page 9

Operating hazards .............................................................................................................................Page 9

Repetitive motions hazards ................................................................................................................. Page 10

Accessory hazards .............................................................................................................................. Page 10

Workplace hazards ............................................................................................................................ Page 10

Dust and fume hazards ....................................................................................................................... Page 10

Noise hazards ..................................................................................................................................... Page 11

Vibration hazards................................................................................................................................Page 11

Additional safety instructions for pneumatic power tools ................................................................. Page 11

Start-up .............................................................................................................................................Page 12

After initial use ...........................................................................................................................Page 12

Maintenance ................................................................................................................................. Page 12

Cleaning and Care ................................................................................................................... Page 12

Information about warranty and service processing

Warranty terms ...................................................................................................................................Page 12

Extent of warranty ............................................................................................................................... Page 13

Processing of warranty claims ............................................................................................................ Page 13

Environmental instructions and disposal information .............................. Page 13

Declaration of Conformity ................................................................................................ Page 14

5 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 5 28.05.14 11:15

Page 6

Introduction

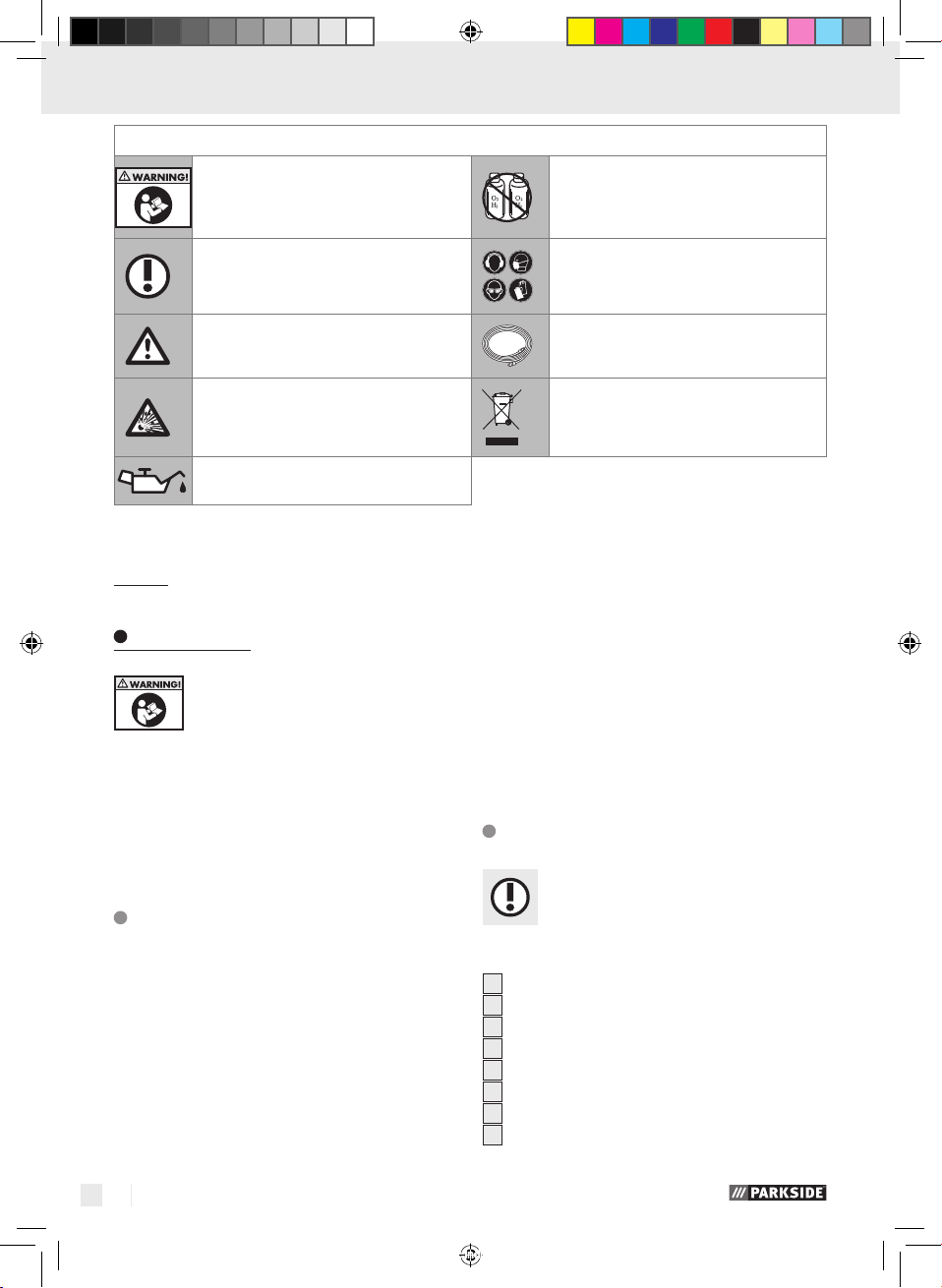

The following pictograms are used in these operating instructions / on the equipment:

Never use hydrogen, oxygen, carbon

Please read the operating instructions!

dioxide or other bottled gases as an

energy source.

Note

Observe the warning and safety

instructions!

Caution! Explosion hazard!

Oil daily

Air ratchet set PDRS

Introduction

Congratulations!

You have chosen high-quality device

by our company. Familiarise yourself

with the product before using it for the first time. In

addition, please carefully refer to the operating instructions and the safety advice below. Initial opera

of this tool m

ust be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

The ratcheting screwdriver is a handy, compressed-a

powered device for use by handymen and at gara

It is suitable for securing and removing screw connections in the automotive area (tyre installation,

as well as the agricultural area. Please note the to

specifications when tightening screws and nuts. If

necessary, use a torque wrench. The socket attachment is quick and easy to change. Compressed air

is connected with a plug nipple and quick connecto

Only use the product as described and for the indicated purpose. Keep these instructions in a safe place

tion

ges.

etc.)

rque

Wear ear protection, dust mask, sa

glasses and protective gloves.

Compressed air hose

Dispose of packaging and device in

an environmentally-friendly way!

When passing this product on to others, please also

include all the documents. Any use other than the

intended is prohibited and potentially dangerous.

Damages resulting from noncompliance or misuse

are not covered by the warranty and are not included

in the manufacturer‘s liability. This device has been

designed for household use and may not be used

for commercial or industrial purposes.

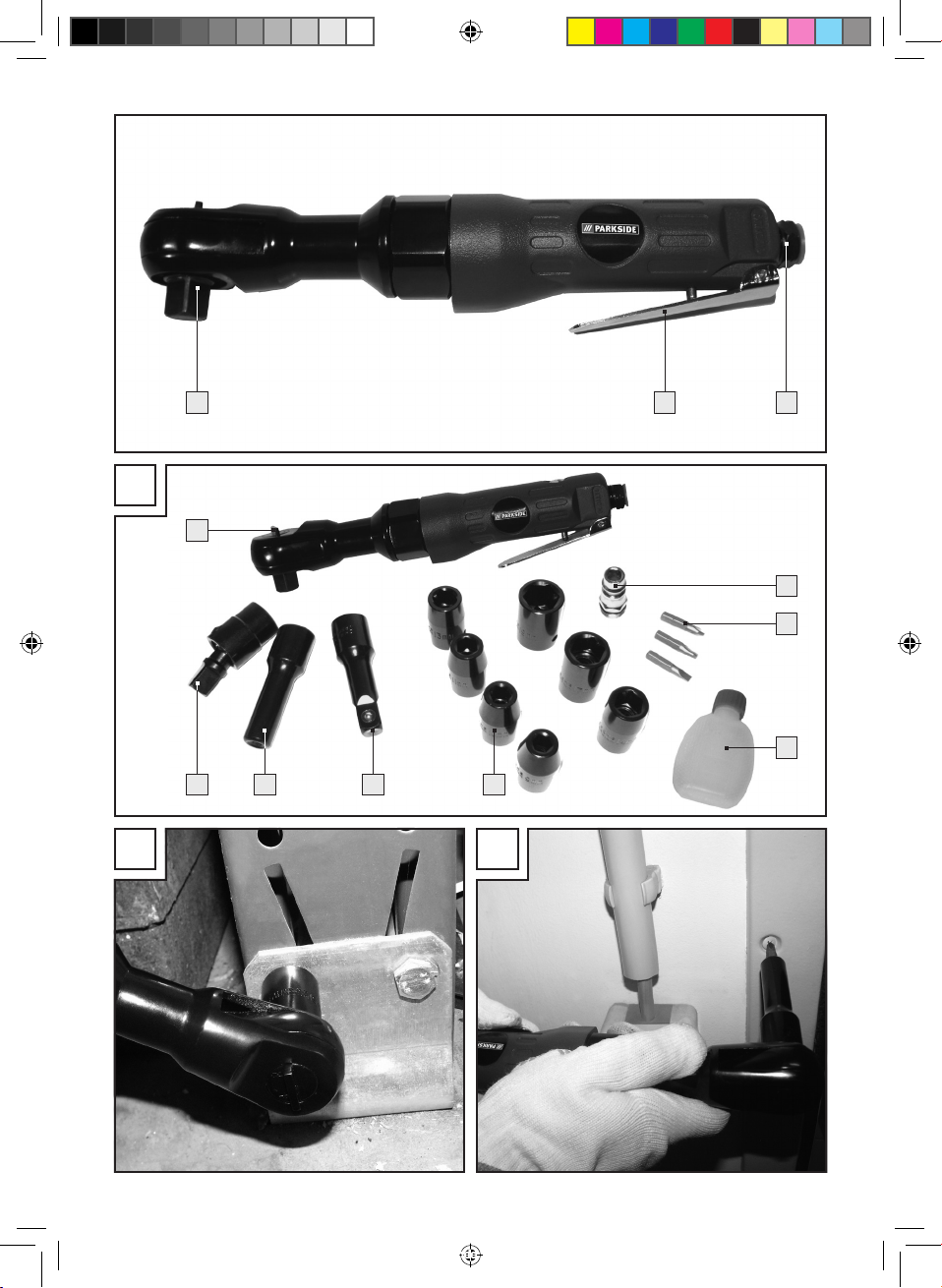

Features

Check that all the items are present and

that the device is in perfect condition immediately after unpacking. Do not use

the device if it is defective.

1

Ratchet head

2

ir

Trigger

3

Compressed air connection

4

Plug nipple for compressed air supply

5

Bits

6

Oil reservoir

7

Socket key

8

Extension

9

Bit holder

10

r.

U-joint

11

Pivot bolt

.

fety

6 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 6 28.05.14 11:15

Page 7

Introduction / General safety rules

Technical Data

Max. torque: 61 Nm

Operating pressure: 6.3 bar

Speed: 150 rpm

Weight: 1120 g

Noise and vibration

Noise ratings were determined according to

EN 15744. Vibration ratings were determined

according to ISO 28927-2.

Vibration

(per EN 28927-2): 2.63 m / s

Uncertainty K: 1.5 m / s

2

2

Noise level LpA: 91.9 dB(A)

Uncertainty K

Sound power level L

Uncertainty K

L

pC, peak

: 3 dB

pA

WA

: 3 dB

WA

= 105.3 dB(A)

: 102.9 dB(A)

Uncertainty K = 3 dB

Scope of delivery

1 Air ratchet set

1 Plug nipple with gasket

7 Socket key (10, 11, 13, 14, 15, 17, 19 mm)

1 Extension

3 Bits (PH 2.3, SL 5.5)

1 U-joint

1 Bit holder

1 Oil reservoir

1 Carrying case

1 Instructions for use

General safety rules

Note: When used in the following text, the terms

„compressed air unit“ or „device“ refer to the compressed air unit specified in these instructions for use.

Basic safety measures must be

followed when using compressed air units to eliminate

the risk of fire, electric shock and personal injury.

Be sure to read and follow the notices within these

operating instructions prior to using the equipment

and store them in a safe location.

The manufacturer assumes no liability for damages

or personal injury resulting from failure to follow these

operating instructions.

Persons (including children) who lack the knowl-

edge or experience to use the tool or whose

physical, sensory or intellectual capacities are

limited must never be allowed to use the tool

without supervision or instruction by a person

responsible for their safety.

Ensure children do not play with the device.

RISK OF INJURY! Before

performing maintenance tasks, disconnect the

compressed air supply.

EXPLOSION HAZARD! Never

use petrol or other flammable liquids

to clean the air tool! Sparks could

ignite residual vapours inside the compressed

air unit resulting in the compressed air unit exploding. Do not use the device in explosive environments with flammable liquids, gasses or dust.

Never work on materials which are or could

potentially be highly flammable or explosive.

Only use the equipment in areas of application

for which it was designed!

Do not overburden the device.

Never use hydrogen, oxygen, carbon

dioxide or other bottled gasses to

power this tool as doing so may result in an explosion and thus may cause severe

injuries.

Regularly maintain and clean the device as

specified (see chapters „Maintenance“ and

„Cleaning and care“).

Inspect the device for any damage before use.

Always make sure that the device is in perfect

condition each time before use.

Always be attentive! Unexpected movement of

the device may cause hazards.

Avoid placing your body in an unnatural position.

Keep proper footing and balance at all times.

By doing this you will be in a better position to

control the compressed air unit in unforeseen

circumstances.

7 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 7 28.05.14 11:15

Page 8

General safety rules

Do not use any device if its switch is defective.

A device that can no longer be switched on and

off is dangerous and must be repaired.

Store the device out of the reach of children

when it is not in use. Do not let anyone use the

device if he or she is not familiar with it or has not

read the instructions and advice. Compressed

air units are dangerous when they are used by

inexperienced people.

Maintain the device carefully. Check that mov-

ing device parts are working properly and move

freely. Check for any parts that are broken or

damaged enough to detrimentally affect the

functioning of the device. Have damaged parts

repaired before using the device. Many accidents have their origins in poorly maintained

devices.

Switch the device off if you do not use it anymore.

Always wear personal protective

equipment and safety glasses. Wear-

ing personal protective equipment

such as dust mask, non-slip safety shoes, safety

helmet or ear protectors, depending on the type

of air tool and its application, reduces the risk

of injuries.

Check the connections and supply lines. All

maintenance devices, couplings and hoses must

be equipped to meet the pressure and air amounts

specified in the device specific values. Pressure

that is too low influences the functioning of the

device; pressure that is too high can cause damage to property and personal injury.

Protect hoses from kinks, constrictions, solvents

and sharp edges. Keep hoses away from heat,

oil and rotating parts.

Make sure that the hose clamps are always

t

ightly fastened. If the hose clamps are not tightly

fastened or are damaged, the air could escape

uncontrollably.

R

eplace damaged hoses immediately. A damag

ed

supply line may result in the air hose flapping

about and may result in injuries.

If the power cable of the appliance is damaged,

it has to be replaced by the manufacturer or its

service department or a similarly qualified person in order to avoid hazards.

Do not use the device when tired or under the

influence of drugs, alcohol or medications. One

moment of carelessness when using the device

may result in serious injuries.

Do not directly inhale the exhaust air. Keep eyes

away from exhaust air. Exhaust air from the air

tool may contain water, oil, metal particles or

contaminants from inside the compressor. This

may damage your health.

CAREFUL WHEN PUT-

TING THE TOOL DOWN! Always put down

the device so it does not come into contact with

the trigger. This could potentially result in accidental activation of the device, which again

could result in hazards.

Only use suitable accessories. These may be

purchased from the manufacturer. Using nonOEM accessories may result in hazards.

Only use filtered and regulated compressed air.

Dust, caustic vapours and / or moisture may

damage the motor of the compressed air tool.

The hose must be designed for pres-

sures of at least 6.3 bar or 125 PSI,

but at least 150 % of the maximum

pressure generated in the system.

The tool and supply line must be

equipped with a hose coupling to

completely release pressure when

disconnecting the coupling hose.

DANGER! Avoid contact with live lines. This

device is not insulated against electric shock.

RISK OF INJURY! High

working pressures can give rise to recoil forces

that under certain conditions can result in dan

from continuous loading.

If you are inexperienced in the use of this type

of device, you should seek training on how to

handle it safely.

DANGER OF STAB

WOUNDS! Do not treat an injection as a simp

cut. A high pressure jet may inject toxins into

the body and cause serious injuries. If the spray

is injected into the skin, seek medical help immediately.

Do not modify this device in any way without t

manufacturer‘s approval.

Only use the compressed air unit with the spec-

ified pressure (6.3 bar).

Disconnect the compressed air unit from the air

supply after each use and when not in use.

ger

le

he

8 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 8 28.05.14 11:15

Page 9

General safety rules

Do not use the compressed air unit if it is not

air tight or in need of repair.

Never connect the compressed air unit to an air

hose with pressure exceeding 6.3 bar.

Keep your working area clean and well lit. Untidy

or poorly lit working areas can result in accidents.

Doing so will allow you better control of the

device, particularly under unforeseen circumstances.

Only have the device re-

paired by qualified specialist personnel using

OEM spare parts. This will maintain the safety

of the device.

Keep children and other persons away from

the device during use. Distractions can cause

you to lose control of the device.

Wear suitable clothing. Do not wear loose cloth-

ing or jewellery. Keep your hair, clothing and

gloves clear of moving parts. Loose clothing,

jewellery or long hair can become trapped in

moving parts.

Put down trigger and device in the event of un-

expected compressor failure.

If possible, use a condensate trap or regularly

drain the hoses and pipes of condensate (water)

before and whilst using compressed air units.

ATTENTION! An undersized com-

pressed air system may minimise the

efficiency of your device.

For multiple hazards, read and understand the

safety instructions before installing, operating,

repairing, maintaining, changing accessories on,

or working near the assembly power tool for

threaded fasteners. Failure to do so can result

in serious bodily injury.

Only qualified and trained operators should in-

stall, adjust or use the assembly power tool for

threaded fasteners.

Do not modify this assembly power tool for

threaded fasteners. Modifications can reduce

the effectiveness of safety measures and in

crease

the risks to the operator.

Do not discard the safety instructions; give them

to the operator.

Do not use the assembly power tool for threaded

fasteners if it has been damaged.

Tools shall be inspected periodically to verify

that the ratings and markings required by this

part of ISO 11148 are legibly marked on the

tool. The employer / user shall contact the manufacturer to obtain replacement marking labels

when necessary.

Projectile hazards

Failure of the workpiece, of accessories or even

of the inserted tool itself can generate high-velocity projectiles.

Always wear impact-resistant eye protection

during the operation of the assembly power tool

for threaded fasteners. The grade of protection

required should be assessed for each use.

Ensure that the workpiece is securely fixed.

Entanglement hazards

Entanglement hazards can result in choking,

scalping and / or lacerations if loose clothing,

personal jewellery, neckware, hair or gloves are

not kept away from the tool and accessories.

Gloves can become entangled with the rotating

drive, causing severed or broken fingers.

Rotating drive sockets and drive extensions can

easily entangle rubber-coated or metal-reinforced

gloves.

Do not wear loose-fitting gloves or gloves with

cut or frayed fingers.

Never hold the drive, socket or drive extension.

Keep hands away from rotating drives.

Operating hazards

The use of the tool can expose the operator’s

hands to hazards including crushing, impacts,

cuts and abrasions and heat. Wear suitable

gloves to protect hands.

Operators and maintenance personnel shall be

physically able to handle the bulk, weight and

power of the tool.

Hold the tool correctly; be ready to counteract

normal or sudden movements and have both

hands available.

9 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 9 28.05.14 11:15

Page 10

General safety rules

Maintain a balanced body position and secure

footing.

I

n cases where the means to absorb the reacti

on

torque are requested, it is recommended to use

a suspension arm whenever possible. If that is

not possible, side handles are recommended for

straightcase and pistol-grip tools. Reaction bars

are recommended for angle nutrunners. In any

case, it is recommended to use a means to absorb the reaction torque above 4 Nm for straight

tools, above 10 Nm for pistol-grip tools, and

above 60 Nm for angle nutrunners.

Release the start-and-stop device in the case of

an interruption of the energy supply.

Use only lubricants recommended by the manu-

facturer.

Fingers can be crushed in open-ended crow-foot

nutrunners.

Do not use in confined spaces and beware of

crushing hands between tool and workpiece,

especially when unscrewing.

Repetitive motions hazards

When using a power tool for, the operator can

experience discomfort in the hands, arms, shoulders, neck, or other parts of the body.

While using an assembly power tool for threaded

fasteners, the operator should adopt a comfortable posture while maintaining secure footing

and avoiding awkward or off-balanced postures.

The operator should change posture during extended tasks, which can help avoid discomfort

and fatigue.

If the operator experiences symptoms such as

p

ersistent or recurring discomfort, pain, throbbi

ng,

aching, tingling, numbness, burning sensations

or stiffness, these warning signs should not be

ignored. The operator should tell the employer

and consult a qualified health professional.

Accessory hazards

Disconnect the assembly power tool for threaded

fasteners from the energy supply before changing the inserted tool or accessory.

Do not touch sockets or accessories during im-

pacting, as this increases the risk of cuts, burns

or vibration injuries.

Use only sizes and types of accessories and con-

sumables that are recommended by the assembly

power tool for threaded fasteners manufacturer;

do not use other types or sizes of accessories

and consumables.

Use only impact-wrench-rated sockets in good

condition, as poor condition or hand sockets

and accessories used with impact wrenches

can shatter and become a projectile.

Workplace hazards

Slips, trips and falls are major causes of work-

p

lace injury. Be aware of slippery surfaces ca

used

by the use of the tool and also of trip hazards

caused by the air line or hydraulic hose.

Proceed with care in unfamiliar surroundings.

Hidden hazards, such as electricity or other utility lines, can exist.

The assembly power tool for threaded fasteners

is not intended for use in potentially explosive

atmospheres and is not insulated against coming into contact with electric power.

Make sure there are no electrical cables, gas

pipes, etc., that can cause a hazard if damaged

by use of the tool.

Dust and fume hazards

Dust and fumes generated when using assembly

power tools for threaded fasteners can cause

ill health (for example cancer, birth defects,

asthma and / or dermatitis); risk assessment and

implementation of appropriate controls for these

hazards are essential.

Risk assessment should include dust created by

the use of the tool and the potential for disturbing existing dust.

Direct the exhaust so as to minimize disturbance

of dust in a dust-filled environment.

Where dust or fumes are created, the priority

shall be to control them at the point of emission.

10 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 10 28.05.14 11:15

Page 11

General safety rules

All integral features or accessories for the collec-

tion, extraction or suppression of airborne dust

or fumes should be correctly used and maintained in accordance with the manufacturer’s

instructions.

Use respiratory protection in accordance with

employer’s instructions and as required by occupational health and safety regulations.

Noise hazards

Exposure to high noise levels can cause perma-

nent, disabling hearing loss and other problems,

such as tinnitus (ringing, buzzing, whistling or

humming in the ears). Therefore a risk assessment

and implementation of appropriate controls for

these hazards are essential.

Appropriate controls to reduce the risk may in-

clude actions such as damping materials to prevent workpieces from “ringing”.

Use hearing protection in accordance with em-

ployer’s instructions and as required by occupational health and safety regulations.

Operate and maintain the assembly power tool

for threaded fasteners as recommended in the

instructions handbook, to prevent an unnecessa

ry

increase in noise levels.

If the assembly power tool for threaded fasteners

has a silencer, always ensure it is in place and

in good working order when the assembly power

tool for threaded fasteners is operating.

Select, maintain and replace the consumable /

inserted tool as recommended in the instructions

handbook, to prevent an unnecessary increase

in noise.

Vibration hazards

Exposure to vibration can cause disabling dam-

age to the nerves and blood supply of the hands

and arms.

K

eep the hands away from the nutrunner socket

Wear warm clothing when working in cold con-

ditions and keep your hands warm and dry.

If you experience numbness, tingling, pain or

whitening of the skin in your fingers or hands,

stop using the assembly power tool for threaded

fasteners, tell your employer and consult a physician.

Operate and maintain the assembly power tool

for threaded fasteners as recommended in the

instructions handbook, to prevent an unnecessary increase in vibration levels.

Do not use worn or ill-fitting sockets or extensions,

as this is likely to cause a substantial increase

in vibration.

Select, maintain and replace the consumable /

inserted tool as recommended in the instructions

handbook, to prevent an unnecessary increase

in vibration levels.

Sleeve fittings should be used where practicable.

Support the weight of the tool in a stand, ten-

sioner or balancer, if possible.

Hold the tool with a light but safe grip, taking

account of the required hand reaction forces,

because the risk from vibration is generally

greater when the grip force is higher.

Additional safety instructions

for pneumatic power tools

Air under pressure can cause severe injury:

– always shut off air supply, drain hose of air

pressure and disconnect tool from air supply

when not in use, before changing accessories

or when making repairs;

– never direct air at yourself or anyone else.

Whipping hoses can cause severe injury. Always

check for damaged or loose hoses and fittings.

Cold air shall be directed away from the hands.

Do not use quick-disconnect couplings at tool

inlet for impact and air-hydraulic impulse

wrenches. Use hardened steel (or material with

comparable shock resistance) threaded hose

fittings.

Whenever universal twist couplings (claw cou-

s.

plings) are used, lock pins shall be installed

and whipcheck safety cables shall be used to

safeguard against possible hose-to-tool and

hose-and-hose connection failure.

11 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 11 28.05.14 11:15

Page 12

… / Start-up / After initial use / Maintenance / Cleaning … / Information about …

Do not exceed the maximum air pressure stated

on the tool.

For torque-control and continuous-rotation tools,

the air pressure has a safety critical effect on

performance. Therefore, requirements for length

and diameter of the hose shall be specified.

Never carry an air tool by the hose.

Start-up (see Fig. B / C)

Screw the included plug nipples 4 into the air

connection after first wrapping the thread with

2–3 layers of sealing tape (not included).

Attach the required plug-in attachment to the

square intake.

Set the correct direction of rotation on the pivot

11

bolt

:

R = counterclockwise / remove screw,

F = clockwise / tighten screw.

Attach the plug-in attachment to the screw head.

Activate the trigger 2.

Note: the connection to the compressed air source

is established through a flexible air hose with quick

connector.

The ratcheting screwdriver will perform best when

used with an LW 10 mm air hose.

After initial use

Manually

Add 3–5 drops of speciality tool oil to the compr

air connection before every use. If the compressed

air tool is not being used for several days, add 5–10

drops of oil to the compressed air connection before switching it on.

Always store your compressed air tools in dry

rooms.

essed

Cleaning and Care

Never clean with liquids such as petrol, solvents

or water.

Do not allow liquids to enter the tool.

Only clean the tool with a dry cloth.

Information about warranty

and service processing

Creative Marketing Consulting GmbH

warranty

Dear customer,

the warranty for this device is 3 years from the date

of purchase. In the event of product defects, you

have legal rights against the retailer of this product.

Your statutory rights are not limited in any way by

our warranty detailed below.

Once the task has been finished the equipment must

be disconnect from the compressed air supply

Maintenance

Following the maintenance information specified here

will ensure a long service life for the product and

trouble-free operation. Your ratchet screwdriver working properly for a long time requires daily lubrication.

You may choose from the following options:

With an oil-fog lubricator

A complete maintenance unit includes an oil-fog

lubricator and is attached to the compressor.

12 GB/IE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 12 28.05.14 11:15

3

.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This document is required as your proof of purchase.

Should this device show any fault in materials or manufacture within three years from date of purchase,

it will be repaired or replaced – at our choice – by

us free of charge. This warranty is conditional on the

defective device and the proof of purchase (receipt)

being presented within the three year warranty period, and that there is a brief written description of

the nature of the defect and of the date it arose.

If the defect is covered by our warranty, we will return the repaired device or replacement thereof. A

Page 13

Information about … / Environmental instructions and disposal information

repair or exchange of the device does not extend a

new warranty period.

Extent of warranty

The appliance has been manufactured to strict quality guidelines and meticulously examined before

delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts

subject to normal wear and tear and which can therefore be considered as wear items, or to damage

to fragile parts, e.g. switches, storage batteries or

glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All instructions provided in the operating instructions must

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. Any incorrect or improper use of the device,

use of force and changes not performed by our

authorized service branch will void the warranty.

Note:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

How to contact us:

GB, IE

Name: C. M. C. GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

service.ie@cmc-creative.de

Phone: 0-808-189-0652

(standard German landline

rates apply)

Registered office: Germany

IAN 43095

Please note that the following address is not a service address.

Please first contact the service point named above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

Processing of warranty claims

Environmental instructions

and disposal information

Please follow the instructions below to ensure quick

processing of your claim:

When inquiring about your product please have

your receipt and product number (e.g. IAN) ready

as your proof of purchase.

The product number can be found on the type plate,

an engraving, the cover page of your instructions

(bottom left) or the decal at the back or bottom.

In the event of malfunctions or other defects, please

first contact the service department below by phone

or e-mail.

A product recorded as defective, along with the proof

of purchase (sales receipt) and a description of the

defect and when it occurred, can then be returned

free of charge to you to the service address provided.

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 13 28.05.14 11:15

Do not dispose of the air tool with your household

waste, or throw into fire or water. If possible, nonoperational equipment should be recycled. Contact

your local retailer for information.

Don‘t waste, recycle!

D

evice, accessories and packaging sho

be recycled in an environmentally friendly

manner.

uld

13 GB/IE

Page 14

Declaration of Conformity

Declaration of Conformity

We,

C. M. C. GmbH

Responsible for documentation: Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

declare in our sole responsibility that the product

Air ratchet set

Serial number: 1712

Year of manufacture: 2014 / 32

IAN: 43095

Model: PARKSIDE AIR RATCHET SET PDRS

meets the basic safety requirements of European

Directives

Machinery Directive

EC Directive 2006 / 42 /EC

and its amendments.

The conformity assessment is based on the followin

harmonised standards:

EN ISO 11148-6:2012

St. Ingbert, 31.05.2014

Karl Peter Uhle

- Managing Director -

14 GB/IE

g

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 14 28.05.14 11:15

Page 15

Indholdsfortegnelse

Indledning

Formålsbestemt anvendelse ................................................................................................................Side 16

Udstyr ....................................................................................................................................................Side 16

Tekniske data........................................................................................................................................Side 17

Leverede dele .......................................................................................................................................Side 17

Generelle sikkerhedsregler .............................................................................................Side 17

Farer på grund af udslyngede dele ....................................................................................................Side 19

Farer ved berøring / indfangning ........................................................................................................Side 19

Farer under driften ...............................................................................................................................Side 20

Farer ved gentagne bevægelser .........................................................................................................Side 20

Farer ved tilbehørsdele ........................................................................................................................Side 20

Farer på arbejdspladsen .....................................................................................................................Side 20

Fare på grund af støv og dampe ........................................................................................................Side 21

Farer på grund af larm ........................................................................................................................Side 21

Farer ved svingninger ..........................................................................................................................Side 21

Yderligere sikkerheds anvisninger til pneumatiske maskiner ..............................................................Side 22

Ibrugtagning .................................................................................................................................Side 22

Efter ibrugtagningen ..............................................................................................................Side 22

Vedligeholdelse ..........................................................................................................................Side 22

Rengøring og pleje ..................................................................................................................Side 22

Henvisninger til garanti og servicering

Garantibetingelser ...............................................................................................................................Side 23

Garantiomfang .....................................................................................................................................Side 23

Afvikling af garantisager .....................................................................................................................Side 23

Miljøhenvisninger og bortskaffelsesangivelser .............................................Side 24

EG-konformitetserklæring .................................................................................................Side 24

15 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 15 28.05.14 11:15

Page 16

Indledning

Følgende piktogrammer anvendes i denne brugsanvisning / på apparatet:

Benyt aldrig hydrogen-, ilt-, kuldioxid-

Læs betjeningsvejledning!

Bemærk

eller andre gasarter i flasker som energikilde.

Bær høreværn, en åndedræts- / støvbeskyttelsesmaske, beskyttelsesbriller

og beskyttelseshandsker.

Følg advarsels- og sikkerhedsanvisningerne!

Obs! Eksplosionsfare!

Smøres dagligt

Trykluft-skraldeskruemaskine

PDRS

Indledning

Hjerteligt tillykke!

De har valgt et produkt af høj kvalitet

fra vores firma. Gør Dem fortrolig med

apparatet inden første ibrugtagning. Læs derfor den

efterfølgende betjeningsvejledning og sikkerhedsanvisningerne omhyggeligt igennem. Dette værktøj

må kun tages i brug af fagfolk.

OPBEVARES UTILGÆNGELIGT FOR BØRN!

Formålsbestemt anvendelse

Skraldenøglen er et praktisk trykluftdrevet apparat

til indsatsen hos selvbyggeren og på bilværkstedet.

Den egner sig til at fastgøre og løsne forskruninger

i personbilområdet (bildækmontering osv.) samt indenfor landbruget. Overhold ved fastspændingen af

skruer og møtrikker de nødvendige fastspændingsdrejningsmomenter. Anvend i givet fald en momentnøgle. Stiknøgleopsatserne kan De let og hurtigt skifte.

Tryklufttilslutningen sker over en stiknippel og

Trykluftslange

Bortskaf emballagen og maskinen

miljøvenligt!

hurtigkobling. Benyt produktet kun som beskrevet

og til de angivne formål. Opbevar denne vejledning omhyggeligt. Hvis De giver produktet videre til

andre,

skal vejledningen også følge med. Enhver an-

ven

delse, der afviger fra den formålsbestemte anvendelse, er forbudt og indebærer potentielle farer.

Skader, der opstår på grund af manglende overholdelse eller fejlagtig anvendelse, dækkes ikke af

garantien, og hører ikke til producentens ansvarsområde. Dette apparat er beregnet til privat brug

og må ikke benyttes kommercielt eller industrielt.

Udstyr

Umiddelbart efter udpakningen skal indholdet gennemgås for fuldstændighed

og apparatets fejlfrie tilstand. Benyt ikke

produktet, når dette er defekt.

1

Skraldehoved

2

Aftrækshåndtag

3

Tryklufttilslutning

4

Stiknippel til tryklufttilslutning

5

Bits

6

Olje-beholder

7

Topnøgle

8

Forlængelsesstyk

16 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 16 28.05.14 11:15

Page 17

9

Bitholder

10

Ledstykke

11

Omskiftningsbolt

Tekniske data

Maks. drejningsmoment: 61 Nm

Arbejdstryk: 6,3 bar

Omdrejningstal: 150 min

-1

Vægt: 1120 g

Støj og vibration

Støjværdierne blev fundet iht. EN ISO 15744. Vibrationsværdierne blev fundet iht. ISO 28927-2.

Vibration

(iht. EN 28927-2): 2,63 m / s

Usikkerhed K: 1,5 m / s

2

2

Lydtryksniveau LpA: 91,9 dB(A)

Usikkerhed K

Lydeffektsniveau L

Usikkerhed K

L

, peak

pC

: 3 dB

pA

: 102,9 dB(A)

WA

: 3 dB

WA

= 105,3 dB(A)

Usikkerhed K = 3 dB

Leverede dele

1 trykluft-skraldeskruemaskine

1 stiknippel med tætningsring

7 topnøgler (10, 11, 13, 14, 15, 17, 19 mm)

1 forlængelsstyk

3 bits (PH 2,3, SL 5,5)

1 ledstykke

1 bitholder

1 olje-beholder

1 bærekuffert

1 betjeningsvejledning

Generelle

sikkerhedsregler

Henvisning: Det i følgende tekst anvendte begreb

„trykluftapparat“ eller „apparat“ relaterer sig til de

i denne betjeningsvejledning nævnte trykluftapparater.

Indledning / Generelle sikkerhedsregler

Når der anvendes trykluftsapparater, skal grundlæggende sikkerhedsforanstaltninger følges for at udelukke risici for brand, elektrisk

stød og tilskadekomst af personer. Inden den første

ibrugtagning bedes De absolut læse og overholde

henvisningerne i betjeningsvejledningen, som bør

opbevares et sikkert sted.

For materielle skader og personskader, der opstår,

fordi denne betjeningsvejledning ikke er blevet overholdt, hæfter producenten ikke.

Dette apparat er ikke egnet til anvendelse af

personer (børn indbefattet) med begrænsede

fysiske, sensoriske og mentale evner eller med

manglende erfaring og / eller viden om anvendelsen, medmindre de er under opsyn af en

person, som er ansvarlig for deres sikkerhed,

eller har fået vejledning af denne i anvendelse

af apparatet.

Sørg for at børn ikke leger med apparatet.

FARE FOR SKADE! Afbryd

trykluftforsyningen inden vedligeholdelsesarbejder.

EKSPLOSIONSFARE! Benyt aldrig

benzin eller andre brændbare væsker

til rengøring af trykluftsapparatet!

Resterende dampe i trykluftsapparatet kan antændes via gløder og forårsage en eksplosion.

Apparatet må ikke anvendes i eksplosionstruede

omgivelser, hvor der befinder sig brændbare

væsker, luftarter eller støvpartikler. Bearbejd ingen materialer, som er potentielt eller kan være

let antændelige eller eksplosive.

Anvend kun apparatet til de anvendelsesområd

som det er konciperet til!

Apparatet må ikke overbelastes.

Anvend aldrig hydrogen-, ilt, kuldioxid

eller andre gasarter i flasker som

energikilde til dette værktøj, da dette

kan medføre en eksplosion og dermed alvorlige

skader.

Apparatet skal vedligeholdes og rengøres regel-

mæssigt som foreskrevet (se kapitel „Vedligeholdelse“ og „Rengøring og pleje“).

Kontrollér apparatet for eventuelle skader inden

ibrugtagningen. Kontrollér inden hver brug, at

apparatets tilstand er upåklagelig.

Vær hele tiden koncentreret! Utilsigtede bevæ-

gelser af apparatet kan forårsage farer.

er,

17 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 17 28.05.14 11:15

Page 18

Generelle sikkerhedsregler

Undgå en unormal kropsholdning. Sørg for at

stå sikkert, og hold hele tiden ligevægten. Derved kan De bedre kontrollere trykluftsapparatet

i uventede situationer.

Brug ikke noget apparat hvis kontakt er defekt.

Et apparat, der ikke længere kan tændes eller

slukkes, er farligt og skal repareres.

Opbevar ubenyttede trykluftapparater udenfor

børns rækkevidde. Lad ikke personer benytte apparatet, hvis de ikke er fortrolige med det eller

ikke har læst disse anvisninger. Trykluftsapparater

er farlige, hvis de benyttes af uerfarne personer.

Plej apparatet med omhu. Kontrollér, om bevæ-

gelige apparatdele fungerer upåklageligt og

ikke er klemt fast, og om dele er i stykker eller

beskadiget på en sådan måde, at apparatets

funktion er forringet. Beskadigede dele skal repareres før apparatet tages i brug. Mange ulykker skyldes dårligt vedligeholdte apparater.

Sluk for apparatet når De ikke bruger det mere.

Bær personligt sikkerhedsudstyr og

altid et par sikkerhedsbriller. Personligt

sikkerhedsudstyr, som f.eks. støvma

skridsikkert fodtøj, sikkerhedshjelm eller høre

ske,

værn,

alt efter lufttrykværktøjets art og anvendelse,

nedsætter risikoen for skader.

Kontrollér tilslutninger og forsyningsledninger.

Samtlige vedligeholdelsesenheder, koblinger og

slanger skal med hensyn til tryk- og luftmængde

være dimensioneret i overensstemmelse med apparatets karakteristika. Et for lavt tryk forringer

apparatets funktion, et for højt tryk kan medføre

materielle skade og personskader.

Beskyt slangerne imod knæk, indsnævringer,

løsningsmidler og skarpe kanter. Hold slangerne

væk fra varme, olie og roterende dele.

Sørg for at slangebøjler altid er fastspændte.

Luften kan slippe ukontrolleret ud, når slangespændebånd ikke er spændt fast. eller de er

beskadigede.

Erstat øjeblikkeligt en beskadiget slange. Ein be-

skadiget forsyningsledning kan resultere i en

trykluftsslange, der slår omkring sig, hvilket dermed kan resultere i kvæstelser.

Når dette apparats tilslutningsledning beskadi-

ges, så skal den erstattes af producenten eller

dennes kundeservice eller af en lignende kvalificeret person, for at undgå farer.

Undlad at bruge apparatet hvis De er træt eller

under indflydelse af narkotika, alkohol eller medikamenter. Et øjebliks uopmærksomhed under

benyttelse af apparatet kan føre til alvorlige

kvæstelser.

Undgå direkte at indånde den brugte luft. Und

gå

at rette udblæsningsluft mod øjnene. Udblæsningsluften fra trykluftsapparatet kan indeholde

vand, olje, metalpartikler eller snavs fra kompressoren. Det kan være sundhedsfarligt.

VÆR FORSIGTIG, NÅR

DU LÆGGER APPARATET FRA DIG! Læg

altid apparatet fra dig, så det ikke kommer til

at ligge på udløseren. Det kan betyde, at apparatet aktiveres ved et uheld, hvad der ligeledes kan resultere i en fare.

Der må kun benyttes egnet tilbehør. Det kan

bestilles hos producenten. Andet tilbehør end

originaltilbehøret kan udløse en fare.

Anvend kun filtreret og reguleret trykluft. Støv,

ætsende dampe og / eller fugt kan beskadige

motoren på et trykluftsværktøj.

Slangen skal vær overdimensioneret

til et tryk af mindst 6,3 bar eller 125 psi,

dog mindst til 150 % af det i systemet

frembragte maksimaltryk.

Værktøjet og forsyningsslangen skal

være udstyret med en slangekobling,

så trykket er helt nedbrudt, når kob-

lingsslangen bliver fjernet.

RISIKO! Undgå kontakten med en strømfø-

rende ledning. Dette apparat er ikke isoleret

imod elektrisk stød.

FARE FOR SKADE! Højt

arbejdspres kan resultere i tilbagestødningskræfter, som under omstændigheder kan resultere i

farer på grund af varig belastning.

Når De er uerfaren i omgang med apparatet,

så bør De lade Dem skole sig i den risikoløse

omgang med apparatet.

FARE GENNEM STIKSÅR!

De må ikke behandle en indsprøjtning som et

enkelt snit. En højtryksstråle kan sprøjte giftstoffer i kroppen og resultere i alvorlige kvæstelser.

Søg omgående lægehjælp i tilfælde af indsprøjtning i huden.

Uden producentens tilladelse, så må trykluftap-

paratet på ingen måde forandres.

18 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 18 28.05.14 11:15

Page 19

Anvend trykluftapparatet kun med det foresk

tryk (6,3 bar).

Efter brug og ved ikkebrug skal trykluftappara-

tet altid skilles fra lufttilførslen.

Når trykluftapparatet ikke er lufttæt, eller hvis

det skal repareres, må det ikke anvendes.

Forbind trykluftapparatet aldrig med en trykluft-

slange, hvis tryk er højere end 6,3 bar.

Hold deres arbejdsplads rent og godt belyst.

Rod og ubelyste arbejdsomgivelser kan medføre

ulykker. På den måde kan du specielt i uventede

situationer bedre kontrollere apparatet.

Lad apparatet kun repareres

af kvalificeret fagpersonale og kun med originale reservedele. Dermed sikres at apparatets

sikkerhed bibeholdes.

Hold børn og andre personer på afstand under

benyttelsen af apparatet. Hvis De distraheres kan

De miste kontrollen over maskinen.

Ifør Dem egnet beklædning. Bær ikke smykker

og tøj, der sidder løst. Hår, tøj og handsker skal

holdes på afstand af bevægelige dele. Løst tøj,

smykker eller langt hår kan blive grebet af bevægelige dele.

Udløser og apparat skal lægges væk, hvis kom-

pressoren får et uventet svigt.

Anvend så vidt muligt en kondensatskærer eller

tøm slangerne og rørledningerne regelmæssigt

inden og under brugen af trykluftapparaterne

for kondensat.

ADVARSEL! Et underdimensioneret

lufttrykssystem kan formindske deres

apparats effektivitet.

Vedrørende de mange faremomenter, så skal

sikkerhedshenvisningerne læses og forstås inden indbygningen, driften, reparationen, vedligeholdelsen og udskiftningen af tilbehørsdele,

samt arbejdet til skrueforbindelser i nærheden af

maskinen påbegyndes. Ellers kan det resultere i

alvorlige kvæstelser.

Maskinen til skrueforbindelser bør udelukkende

installeres, indstilles eller bruges af kvalificerede

og skolede brugere.

Der må ikke foretages ændringer på maskinen

til skrueforbindelser. Ændringer kan indskrænke

sikkerhedsanvisningernes virkning og forhøje risicierne for brugeren.

revne

Generelle sikkerhedsregler

Sikkerhedsanvisningerne må ikke gå tabt – giv

dem til brugeren.

Anvend aldrig en beskadiget maskine til skrue-

forbindelser.

Maskinen skal vedligeholdes regelmæssigt for

at kontrollere, at de iht. ISO 11148 nødvendige

dimensioner og udmærkelser er kendetegnet i

læselig stand på maskinen. Den ansatte / brugeren skal opsøge producenten for at få reserveetiketter til afmærkning, hvis dette skulle være

nødvendigt.

Farer på grund

af udslyngede dele

Ved brud hos et emne eller en tilbehørsdel eller

endda ved selve maskinværktøjet, så kan dele

slynges ud med høj hastighed.

Når maskinen til skrueforbindelser er i drift, så

skal man altid bære øjenbeskyttelse. Graden af

den påkrævede beskyttelse skal altid vurderes i

hvert enkelt tilfælde.

Kontroller at emnet er fastgjort sikkert.

Farer ved berøring /

indfangning

Farer ved berøring / indfangning kan føre til

kvælning, skalpering og / eller snitsår, når løsthængende tøj, personlige smykker, halskæder,

hår eller handsker ikke holdes væk fra maskinen

og dens tilbehørsdele.

Handsker kan blive hængende i det drejende

drev, hvilket kan føre til kvæstelser eller brud

på fingrene.

Ved roterende drevfatninger og -forlængelser

kan det let føre til berøring / indfangning af

gummi- eller metalforstærkede handsker.

Bær ikke nogen løstsiddende handsker eller h

sker med afskårne eller slidte handskefingre.

Hold aldrig fast i drevet, fatningen eller drev-

forlængelsen.

Hold deres hænder væk fra det roterende drev.

and-

19 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 19 28.05.14 11:15

Page 20

Generelle sikkerhedsregler

Farer under driften

Ved indsatsen af maskinen, så kan brugerens

hænder blive udsat for farer som masning, slag,

slid og varme. Bær handsker som beskyttelse

for hænderne.

Brugerne og personalet for vedligeholdelse skal

fysisk være i stand til at kunne håndtere maskinens størrelse, vægt og ydelse.

Hold maskinen rigtigt: Vær klar til at modvirke

de normale og pludselige bevægelser – hold

begge hænder klare.

Vær opmærksom på at deres krop er i balance

og at De har et sikkert hold.

I situationer, hvor du skal bruge hjælpemidler

for at optage reaktionsdrejningsmomentet, så

anbefales det såvidt så muligt altid at anvende

en ophængningsmekanisme. Hvis dette ikke er

muligt, så anbefales sidehåndtag til maskiner

med lige håndtag eller med pistolhåndtag. Vi

anbefaler ihvertfald at anvende hælpemidler til

optagelse af reaktionsdrejningsmomentet når

det er større end 4 Nm ved maskiner med lige

håndtag, større end 10 Nm ved maskiner med

pistolhåndtag og større end 60 Nm ved vinkelskruemaskiner.

Frigiv kontrolindretningen til start og stop i til-

fælde af en afbrydelse af energitilførslen.

Anvend kun de af producenten anbefalede

smøremidler.

Fingre kan blive klemt i møtrikspændere med

åbent, fladt hoved.

Anvend ikke værktøjet i trange rum og pas på

at dine hænder ikke bliver klemt imellem maskine

og emne, især når dette skrues af.

Farer ved gentagne bevægelser

Ved anvendelsen af en maskine med skrueforbin-

delsen kan brugeren komme ud for ubehagelige

følelser i hænder, arme, skuldre, omkring halsen

eller i andre kropsdele, når der udføres arbejdsrelateret arbejde.

Indtag en behagelig stilling når du arbejder

med denne maskine, vær opmærksom på et

stabilt fodfæste og undgå ufordelagtige positioner eller sådanne, hvor det er vanskeligt at

holde balancen. Brugeren skal ændre på

kropsholdningen ved langvarigt arbejde, da

det hjælper imod ubehag og træthed.

Hvis brugeren bemærker symptomer, som f.eks.

varig utilpashed, lidelse banken, smerter, kriblen,

døvhed, brænden eller stivhed, så må disse advarselstegn ikke ignoreres. Brugeren bør (i givet

fald informere sin arbejdsgiver herom) konsultere

en kvalificeret læge.

Farer ved tilbehørsdele

Afbryd maskinen fra strømtilførslen inden ma-

skinværktøjet eller tilbehørsdelen udskiftes.

Rør ikke ved fatninger eller tilbehørsdele under

slagprocessen, da det kan forhøje faren for snitsår, forbrændinger eller kvæstelser på grund af

svingninger.

Anvend udelukkende tilbehørsdele og forbrugs-

materiale, hvis størrelse og type anbefales af

producenten for maskiner til skrueforbindelser.

Anvend udelukkende slagfatninger, som er i en

god arbejdstilstand, da en mangelfuld tilstand

af håndfatninger kan føre til, at de brækker og

bliver slynget ud, når de anvendes med slagskruetrækkere.

Farer på arbejdspladsen

Udskridning, snublen og styrt er hovedårsager

for skader på arbejdspladsen. Vær opmærksom

på overflader, som være blevet glatte efter brug

af maskinen og også på grund af luft- eller hydraulikslangen betingede farer gennem snublen.

Vær forsigtig i ukendte omgivelser. Der kan være

skjulte farer på grund af skjulte strømkabler eller

andre forsyningsledninger.

Maskinen til skrueforbindelser er ikke egnet til

brug i eksplosionsfarlige atmosfærer og ikke

isoleret imod kontakt med elektriske strømkilder.

Kontroller at der ikke er nogen elektriske lednin-

ger, gasrørledninger osv. tilstede, som i tilfælde

af beskadigelse på grund af anvendelse af maskinen kunne være farlige.

20 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 20 28.05.14 11:15

Page 21

Generelle sikkerhedsregler

Fare på grund af støv og dampe

Støv og dampe som opstår ved indsatsen af ma-

skinen til skrueforbindelser, kan være helbredsskadelige (som f.eks. kræft, fødselsfejl, astma

og / eller dermatitis), så er det uundgåeligt at

gennemføre en risikovurdering med henblik på

egnede reguleringsmekanismer.

I risikovurderingen bør man inddrage det støv,

der er opstået under arbejdet med maskinen

og den eksisterende støv, der derved muligvis

er blevet hvirvlet op.

Returluften skal afledes sådan, at den ophvirvlede

støv i en støvfuld omgivelse, bliver reduceret mest

muligt.

Hvis der opstår støv eller dampe, så skal den

primære opgave være den, at kontrollere denne

på stedet for deres frigivelse.

Alle maskinens tilbehørsdele eller indbyggede

dele, der er beregnet til at opfange, opsuge eller

undertrykke flyvestøv eller dampe, skal benyttes

og vedligeholdes forskriftsmæssigt iht. producentens anvisninger.

Anvend åndedrætsværn efter deres arbejdsgivers

anvisninger eller som er påkrævet iht. arbejdsog sundhedsforskrifter.

Farer på grund af larm

Indvirkningen af højt støjniveau kan føre til va-

rige høreskader, døvhed og andre problemer

som f.eks. tinnitus (ringen, susen, piben eller

summen i øret), hvis der ikke benyttes tilstrækkeligt høreværn. Det er uundgåeligt at foretage

en risikovurdering med hensyn til disse farer og

at omsætte egnede reguleringsmekanismer.

En reguleringsmekanisme, der egner sig til ri-

sikoreducering, er forholdsregler som f.eks. anvendelse af isoleringsstoffer, der kan forhindre

ringetoner som opstår på emnerne.

Brug høre værn iht. deres arbejdsgivers anvis-

ninger eller som påkrævet iht. arbejds- og sundhedsforskrifter.

Maskinen til skrueforbindelser skal drives og

vedligeholdes iht. anbefalingerne i denne vejledning for at undgå et unødigt højt støjniveau.

Råder maskinen til skrueforbindelser over en

lyddæmper, så skal du sikre at denne befinder

sig på arbejdspladsen og at den er i god tilstand, når maskinen til skrueforbindelser er i drift.

Forbrugsmaterialerne og maskinværktøjet skal

udvælges, vedligeholdes og udskiftes iht. denne

anbefalings vejledning for at undgå et unødigt

højt støjniveau.

Farer ved svingninger

Svingningers indflydelse kan forårsage beska-

digelser på nerverne og forstyrrelser i hændernes

og armenes blodcirkulation.

Hold deres hænder væk fra møtrikspænderens

fatninger.

Bær varmt tøj ved arbejdet i kolde omgivelser

og hold dine hænder varme og tørre.

Såfremt De konstaterer at huden på deres fingre

og hænder bliver følelsesløs, kribler, gør ondt

eller misfarver sig hvid, så skal De standse arbejdet med maskinen (informér i givet fald deres

arbejdsgiver) og konsultér en læge.

Maskinen til skrueforbindelser skal drives og

vedligeholdes iht. anbefalingerni denne vejledning for at undgå en unødig forstærkning af

svingningerne.

Anvend ikke slidte fatninger og forlængelse eller

sådanne, som passer dårligt, da det højst sandsynlig fører til en betydelig forstærkning af

svingningerne.

Forbrugsmaterialerne og maskinværktøjet skal

udvælges og udskiftes iht. anbefalingerne i

denne vejledning for at undgå en unødig forstærkning af svingningerne.

Såfremt muligt, så bør muffefittings anvendes.

Benyt såvidt muligt en holder, strop eller udlig-

ningsudstyr for at holde maskinens vægt.

Hold fast i maskinen med et ikke for fast men

sikkert greb i hænderne under overholdelse af

nødvendige reaktionskræfter, da svingningsrisikoen som regel bliver større med tiltagende gribekraft.

21 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 21 28.05.14 11:15

Page 22

… / Ibrugtagning / Efter … / Vedligeholdelse / Rengøring … / Henvisninger til …

Yderligere sikkerheds-

anvisninger til

pneumatiske maskiner

Trykluft kan forårsage alvorlige kvæstelser:

– Når maskinen ikke er i brug, inden udskift-

ning af tilbehørsdele eller ved reparationsarbejder så skal lufttilførslen altid lukkes, trykket

tages af slangen og maskinen skal kobles af

tryklufttilførslen.

– Ret aldrig luftstrømmen imod dig selv eller

andre personer.

Løstsiddende slanger kan forårsage alvorlige

personskader. Kontrollér derfor altid, om slangerne og deres befæstningsmateriale er ubeskadiget og ikke har løsnet sig.

Kold luft skal ledes væk fra hænderne.

Benyt ikke nogen hurtige lukningskoblinger ved

værktøjstilgangen, når du bruger slag- og impulsskruetrækkere. Til slangetilslutninger med

gevind anvendes kun nogle af hærdet stål (eller

et emne med den samme stødsikkerhed).

Såfremt der anvendes universal-drejekoblinger

(klovkoblinger), så skal du bruge låsestifte og

benytte whipcheck-slangesikringer for at beskytte

sig imod, at slangen springer af maskinen eller

i givet fald slangerne fra hinanden.

Sørg for at det på maskinen angivne maksimale

tryk ikke overskrides.

Ved drejningsmomentregulerede maskiner med

kontinuerlig rotation har lufttrykket sikkerhedsrelevante udslag på ydelsen. Derfor skal der

fastsættes krav til slangens længde og diameter.

Bær aldrig maskiner med slangen når disse ar-

bejder.

Ibrugtagning

(se afbildning. B / C)

R = venstreløb/ skrue løsnes,

F = højreløb / skrue spændes fast.

Stik stikopsatsen på nøglehovedet.

Betjen aftrækshåndtaget 2.

Henvisning: Tilslutningen til trykluftkilden sker

over en fleksibel trykluftslange med lynkobling.

Den bedste ydelse med deres skraldenøgle opnår

De med en trykluftslange LW 10 mm.

Efter ibrugtagningen

Efter udført arbejde skal apparatet skilles fra tryklufttilslutningen

3

.

Vedligeholdelse

Overholdelsen af de her angivne vedligeholdelseshenvisninger sikrer en lang levetid og en fejlfri

drift for dette produkt. Til en varig fejlfri funktion af

deres skraldenøgle forudsættes en regelmæssig

smøring.

De kan vælge mellem følgende muligheder:

over en tågesmører

En komplet vedligeholdelsesenhed indeholder en

tågesmører og er anbragt ved kompressoren.

Gennem hånd

Inden hver ibrugtagning af luftværktøjet skal du give

3–5 dråber olje til specialværktøj ned i tryklufttilslutningen. Har trykluftværktøjet ikke været benyttet i

flere dage, så skal du give 5–10 dråber olje i tryklufttilslutningen inden du tænder for det.

Opbevar deres trykluftværktøj kun i tørre rum.

Skru den medleverede stiknippel 4 i lufttilslut-

ningen, efter at De forinden har viklet 2–3 lag

tætningsbånd (ikke indeholdt i leveringen) på

gevindet.

Stik den nødvendige stikopsats på firkantopta-

gelsen.

Indstil den rigtige drejeretning ved omskiftbol-

11

ten

:

22 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 22 28.05.14 11:15

Rengøring og pleje

Anvend under ingen omstændigheder væsker

så som benzin, opløsningsmidler eller vand til

rensningen.

D

er må ikke komme væsker ind i apparatets indre

Rengør værktøjet med en tør klud.

.

Page 23

Henvisninger til garanti og servicering

Henvisninger til garanti

og servicering

Garanti fra Creative Marketing

Consulting GmbH

Kære kunde,

De får 3 års garanti fra købsdatoen af på dette apparat. Hvis der forekommer mangler ved dette produkt, har De juridiske rettigheder over for sælgeren

af dette produkt. Disse juridiske rettigheder begrænses

ikke af vores garanti, der beskrives i det følgende.

Garantibetingelser

Garantifristen begynder fra købsdatoen af. Opbevar den originale kassebon på et sikkert sted. Denne

kassebon er nødvendig som dokumentation for købet.

Hvis der inden for tre år fra købsdatoen af for dette

produkt opstår en materiale- eller fabrikationsfejl,

bliver produktet repareret eller erstattet - efter vores

valg - af os uden omkostninger for Dem. Denne garantiydelse forudsætter, at det defekte apparat og

købsbeviset (kassebon) forelægges inden udløbet

af fristen på tre år sammen med en kort beskrivelse

af, hvori manglen består, og hvornår den er opstået.

Hvis defekten dækkes af vores garanti, modtager

De derefter det reparerede eller et nyt apparat. Ved

reparation eller udskiftning af apparatet begynder

der ikke en ny garantiperiode.

Garantiomfang

overholdes nøjagtigt. Anvendelsesformål og handlinger, der frarådes eller advares imod i betjeningsvejledningen, skal ubetinget undgås.

Produktet er kun beregnet til privat og ikke til erh

vervsmæssig brug. Ved misbrug og uhensigtsmæssig behandling, anvendelse af vold og ved indgreb, som

ikke er foretaget af vores autoriserede service-afdeling, ophører garantien.

Afvikling af garantisager

For at kunne sikre en hurtig behandling af dit anliggende skal følgende henvisninger følges:

Opbevar kassebon og artikelnummer (f.eks. IAN)

som købsdokumentation, så disse kan fremlægges

på forespørgsel.

Artikelnumrene er angivet på typeskiltet, ved en indgravering, på forsiden af vejledningen (nederst til

venstre) eller på et mærkat på bag- eller undersiden.

Hvis der forekommer funktionsfejl eller andre mangler, skal De først kontakte nedenstående serviceafdeling telefonisk eller via e-mail.

Et produkt, der er registreret som defekt, kan De derefter sende portofrit til den meddelte serviceadresse

med vedlæggelse af købsbeviset (kassebon) og angivelsen af, hvori manglen består, og hvornår den

er opstået.

Henvisning:

På www.lidl-service.com kan De down loade denne og mange yderligere håndbøger, produktvideoer og software.

Køleboksen er produceret omhyggeligt efter strenge

Kontaktinformationer:

kvalitetskrav og inden levering afprøvet samvittighedsfuldt.

Garantien gælder for materiale- eller fabrikationsfejl.

Garantien omfatter ikke produktdele, der udsættes

for normal slitage og dermed kan betragtes som sliddele, eller beskadigelser af følsomme komponenter

som f.eks. kontakter, batterier eller dele af glas.

DK

Navn: C. M. C. GmbH

Internetadresse: www.cmc-creative.de

E-mail: service.dk@cmc-creative.de

Telefon: +49 (0) 6894 9989752

(normal takst fra det tyske fastnet)

Hovedsæde: Tyskland

Garantien bortfalder, hvis apparatet bliver beskadiget eller ikke anvendes eller vedligeholdes korrekt.

IAN 43095

Til en korrekt anvendelse af produktet skal alle henvisninger, der er opført i betjeningsvejledningen,

23 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 23 28.05.14 11:15

Page 24

… / Miljøhenvisninger og bortskaffelsesangivelser / EG-konformitetserklæring

Bemærk, at følgende adresse ikke er en serviceadresse.

Kontakt først ovenforstående serviceafdeling.

Adresse:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Tyskland

Miljøhenvisninger og

bortskaffelsesangivelser

Råstofgenindvinding i stedet

for bortskaffelse af affald!

Apparat, tilbehør og emballage skal

afleveres til miljøvenlig genbrug.

Kast ikke trykluftsværktøjet i husholdningsaffaldet,

ild eller vand. Hvis det er muligt, skal ikke mere

funktionsdygtige apparater genbruges. Spørg om

råd hos deres lokale forhandler.

EG-konformitetserklæring

Maskindirektiv

EU-direktiv 2006 / 42 / EF

og de senere vedtagne ændringer.

Følgende harmoniserede normer blev taget i betragtning i forbindelse med evalueringen af konformitetserklæringen:

EN ISO 11148-6:2012

St. Ingbert, 31.05.2014

Karl Peter Uhle

- Direktør -

Vi, virksomheden

C. M. C. GmbH

Dokumentansvarlig: Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

erklærer på eget ansvar, at produktet

Trykluft-skraldeskruemaskine

Serienummer: 1712

Produktionsår: 2014 / 32

IAN: 43095

Model: PARKSIDE TRYKLUFT-SKRALDESKRU-

EMASKINE PDRS

opfylder de væsentlige sikkerhedskrav, som er fastlagt i de europæiske retningslinjer

24 DK

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 24 28.05.14 11:15

Page 25

Table des matières

Introduction

Utilisation conforme ............................................................................................................................Page 26

Équipement .......................................................................................................................................... Page 26

Caractéristiques techniques ................................................................................................................ Page 27

Contenu de la livraison ....................................................................................................................... Page 27

Règles de sécurité générales .......................................................................................... Page 27

Phénomènes dangereux dus aux projections ....................................................................................Page 30

Phénomènes dangereux de happement ............................................................................................ Page 30

Phénomènes dangereux dus au fonctionnement ..............................................................................Page 30

Phénomènes dangereux dus aux mouvements répétitifs .................................................................. Page 30

Phénomènes dangereux dus aux accessoires ................................................................................... Page 31

Phénomène dangereux dus au lieu de travail ................................................................................... Page 31

Phénomènes dangereux dus à la poussière et à la fumée ............................................................... Page 31

Phénomènes dangereux dus au bruit ................................................................................................Page 32

Phénomènes dangereux dus aux vibrations ...................................................................................... Page 32

Instructions de sécurité supplémentaires pour les machines pneumatiques .................................... Page 32

Mise en marche .......................................................................................................................... Page 33

Après la mise en marche .................................................................................................... Page 33

Maintenance ................................................................................................................................. Page 33

Nettoyage et entretien ........................................................................................................ Page 33

Remarques sur la garantie et le service après-vente ................................ Page 33

Conditions de garantie ....................................................................................................................... Page 34

Étendue de la garantie ....................................................................................................................... Page 34

Faire valoir sa garantie ....................................................................................................................... Page 34

Indications relatives à l‘environnement et à la mise au rebut .......... Page 35

Déclaration de conformité ................................................................................................ Page 35

25 FR/BE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 25 28.05.14 11:15

Page 26

Introduction

Les pictogrammes suivants sont utilisés dans le présent mode d’emploi / sur l‘appareil :

Lire la notice d'utilisation !

Remarque

Respectez les avertissements et les

consignes de sécurité !

Attention ! Risque d'explosion !

Graissage quotidiennement

Tournevis à cliquet à air comprimé

PDRS

Introduction

Félicitations !

Vous avez opté pour un produit de

grande qualité conçu par notre entreprise. Avant la première mise en marche du produit,

vous devez vous familiariser avec toutes ses fonc

Veuillez lire attentivement la notice d‘utilisation ci-dessous ainsi que les consignes de sécurité. Seules les

personnes initiées à cet outil doivent le mettre en

marche.

À TENIR HORS DE LA PORTÉE DES ENFANTS !

tions.

N'utilisez jamais d'hydrogène, d'oxygène,

de dioxyde de carbone ou d'autres gaz

en bouteille comme source d'énergie.

Portez une protection auditive, un

masque de protection respiratoire /

antipoussière, ainsi que des lunettes

et des gants de protection.

Tuyau à air comprimé

Mettez l’emballage et l’appareil au

rebut de manière écologique.

Respectez les couples de serrage prescrits lors du

serrage des vis et des écrous. Utilisez si nécessaire

une clé dynamométrique. Vous pouvez changer facilement et rapidement d‘élément sur votre clé à tube.

L‘arrivée d‘air comprimé se fait à l‘aide d‘un raccord

mâle et d‘un raccord rapide. Utilisez ce produit en

vous conformant uniquement à ces instructions et

dans les domaines d’application spécifiés. Veuillez

conserver soigneusement ces instructions. Si vous

prêtez ce produit à une autre personne, veuillez lui

remettre tous les documents s‘y rapportant. Tout usage

divergeant de l‘utilisation prévue est interdite et potentiellement dangereuse. Les dommages résultant

du non-respect des consignes ou d‘une utilisation

incorrecte ne sont pas couverts par la garantie et

ne relèvent pas de la responsabilité du fabricant.

L‘appareil est conçu pour un usage à domicile et

ne doit pas être utilisé à des fins commerciales ou

industrielles.

Utilisation conforme

Équipement

Le cliquet réversible est un appareil pneumatique

manuel conçu afin d‘être manipulé par les amateurs

de bricolage et les personnes disposant d‘un garage.

Il se destine à fixer et desserrer les raccords filetés

dans le domaine de l‘automobile (montage des pneus

etc.) mais également dans le domaine agricole.

26 FR/BE

43095_par_Druckluft-Ratschenschrauber PDRS_content_GB_IE_DK_BE.indd 26 28.05.14 11:15

état. N‘utilisez pas l‘appareil dès lors qu‘il présente

,

des défauts.

Dès l‘ouverture de l‘emballage, veuillez

vérifier que le contenu de la livraison est

complet et que l‘appareil est en parfait

Page 27

1

Tête de la clé à cliquet

2

Levier de détente

3

Raccord d‘air comprimé

4

Raccord mâle pour raccord d‘air comprimé

5

Embouts

6

Flacon d‘huile

7

Clé à douille

8

Rallonge

9

Porte-embout

10

Charnière

11

Tourillon de renvoi

Caractéristiques techniques

Couple max. : 61 Nm

Pression de travail : 6,3 bar

Nombre de rotations : 150 min

-1

Poids : 1120 g