Page 1

VO40 Open-Center

Directional Control

Valve

Catalog HY17-8505/UK

April 2007

Page 2

Catalog HY17-8505/UK

Open-Center Directional Control Valve

VO40

!

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide

product and/or system options for further investigation by users having technical expertise. It is important that you analyze all

aspects of your application, including consequences of any failure, and review the information concerning the product or system in the current product catalogue. Due to the variety of operating conditions and applications for these products or systems,

the user, through its own analysis and testing, is solely responsible for making the final selection of the products and systems

and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are

subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice.

Offer of Sale

Please contact your Parker representation for a detailed ”Offer of Sale”.

II

Parker Hannifin Corporation

Page 3

Catalog HY17-8505/UK

Contents

Introduction .............................................................................................................................................................1

Technical Information

General Description ..........................................................................................................................................3

Operation ..........................................................................................................................................................3

Benefits ............................................................................................................................................................3

Specifications ...................................................................................................................................................4

Weights .............................................................................................................................................................4

Connections .....................................................................................................................................................4

Performance Curves .........................................................................................................................................5

Environmental Characteristics ..........................................................................................................................5

Open-Center Directional Control Valve

VO40

Schematic Circuit Types ...................................................................................................................................6

Dimensions ....................................................................................................................................................7-8

Handle Actuation vs. Spool Direction ...............................................................................................................9

Ordering Information

How to Order ..................................................................................................................................................10

General Valve Assembly .................................................................................................................................11

Inlet Cover .................................................................................................................................................12-13

Outlet Cover ..............................................................................................................................................14-15

Work Sections ...........................................................................................................................................16-20

Mid-Inlet ..........................................................................................................................................................21

Assembly Configuration Form ............................................................................................................................22

III

Parker Hannifin Corporation

Page 4

Catalog HY17-8505/UK

Open-Center Directional Control Valve

VO40

Conversion factors

1 kg = 2.2046 lb

1 N = 0.22481 lbf

1 bar = 14.504 psi

1 l = 0.21997 UK gallon

1 l = 0.26417 US gallon

1 cm3 = 0.061024 in

1 m = 3.2808 feet

1 mm = 0.03937 in

9/5 °C + 32 = °F

3

IV

Parker Hannifin Corporation

Page 5

Catalog HY17-8505/UK

Introduction

Breadth of Line

Parker Hannifin is a Fortune 500

company with sales of $9 billion

and over 400,000 customers in 43

countries. Parker is the world’s

leading supplier of motion control

components and system solutions

serving the mobile, industrial

and aerospace markets.

Parker is your single source

for any hydraulic valve requirement. We provide a wide selection

of open-center and load-sense

directional control valves for any

construction, off-highway, or onhighway application. Many of our

open-center valves can be adapted

and used as closed-center, constantpressure, and constant-pressure

unloaded valves. Each of these

technologies offers unique features

for improved machine performance

over traditional, open-center control

valves.

Open-Center Directional Control Valve

VO40

When remote control is required,

Parker provides a broad line of

pilot controllers that are compact

and pressure-matched with our

control valves to provide consistent

and optimized machine control.

There are a variety of electricswitch handle options available

for additional function control by

the operator.

Parker’s premier IQAN electronics packages range from simple

stand-alone controllers to large,

multiple CAN bus systems with

color displays. For example, IQAN

interfaces with new electronic

diesel engines over the SAE J1939

CAN bus.

Package components are

designed and tested for

mobile applications to

help increase machine

uptime. The IQAN valve drivers

offer superior control of proportional hydraulic functions resulting

in increased machine productivity.

Non-programmers find IQAN’s

programming interface easy to use,

reducing development time. Furthermore, excellent diagnostic tools

and remote modem connection help

cut field service time.

Total Machine

Motion Control

You can turn to us for all your

mobile motion control solutions.

We offer stand-alone valves, as well

as custom-designed manifolds with

integrated directional control valves.

No matter what type of system you

choose, Parker solutions provide

top-notch performance and reliability. Our systems are optimized

to reduce complexity, size, cost, and

fluid leakage. Therefore, working

with Parker can significantly cut

your machine-build time.

1

Parker Hannifin Corporation

Page 6

Catalog HY17-8505/UK

Introduction

State-of-the-Art

Manufacturing

Parker is committed to using lean

manufacturing to eliminate waste

while streamlining processes.

Lean technology helps us meet

customer request dates quickly

and cost-effectively. We also rely

on state-of-the-art equipment and

technology, such as computeraided machining, to ensure

product quality.

We regularly invest in our ISO 9001

certified manufacturing facilities

because we are committed to

meeting all international standards

for safety and quality. The hydraulic

valves we manufacture comply with

relevant ISO, CSA, CE, and AMEX

standards.

In addition, Parker hydraulic valves

and valve manifolds are fully tested

and certified before being released

to the customer. You can expect

Parker hydraulic valves to work the

first time, every time.

Open-Center Directional Control Valve

VO40

Customer Service

with A Global Reach

Parker’s worldwide network of field

sales engineers and Mobile Systems

Engineers (MSEs) are the best in

the business. A field sales engineer

works closely with you, acting as a

single point of contact to evaluate

applications and design solutions.

MSEs support field sales efforts by

managing difficult design problems

and complex circuit design.

You also benefit from Parker

Mobile Technology Centers

(MTCs) that are staffed by specially

trained distributors who provide

only the highest levels of customer

service. These one-stop shops offer

complete hydraulic systems design

for mobile applications, as well as

technology services such as diagnostics, troubleshooting, computer

design, testing, and integration of

electronic controls.

Finally, our thousands of dependable distributors are strategically

located in your markets. They carry

inventory to meet specific, local

market needs, and they ensure that

products arrive when and where

they are needed. You can count on

Parker distributors to minimize

downtime.

To locate your nearest distributor

for the latest information on the

VO40 Directional Control Valve, or

our entire mobile valve line-up, visit

us at www.parker.com/eurohyd.

2

Parker Hannifin Corporation

Page 7

Catalog HY17-8505/UK

Technical Information

General Description

The VO40 is an open-center directional control valve

with the flexibility of sectional construction. Consistent with this technology, it is simple in its application,

reliable, easy to troubleshoot, and cost effective. The

global design reflects the performance and quality expected by today’s machine designers. Spools have metering notches in the three critical areas – open- center,

parallel path and tank, which optimizes simultaneous

metering. Contemporary honing technology is used to

deliver low work port to tank leakage. Additionally, each

work section has a transition check to ensure that a

load does not “dip” during simultaneous operation. All

of these features, plus those listed below, were intended to take machine controllability to the next level.

Operation

The VO40 incorporates traditional open-center technology. It is usually interfaced with a constant flow pump,

whose flow is routed directly to tank when the spools

are in neutral. When one or more spools are selected,

flow is directed to the actuators. The throttling of that

flow depends upon the spool position and the design of

the metering notches. Spool notches can be designed

to accommodate resistive loads (meter-in) and negative loads (meter-out). To accommodate multiple pump

circuits, split flow and combined flow mid inlets are

available.

Open-Center Directional Control Valve

VO40

Benefits

Enhanced metering – especially during simultaneous

•

operation, this is accomplished by having notches in the

three critical areas of the spool: open center, parallel path

and tank.

Improved simultaneous metering – having a transition

•

check in each work section ensures that a load does not

“dip” downward when metering two or more work-sections.

Repeatability – consistent metering from valve to valve

•

is achieved by flycutting all of the critical cast lands. This

means that the notch position relative to the spool stroke

is controlled and predictable. The result is consistent

machine control.

Reduced operator fatigue – the open-center core is

•

a split wing or “Y” core design, which provides for a

consistent lever force when selecting the spool from

neutral to both power positions.

Reduced function drift – low internal leakage

•

accomplished thru the use of contemporary honing

technology. Also, for those functions requiring near zero

drift, pilot-operated checks are available.

Small footprint – port accessories are installed vertical

•

to the spool, allowing the handle to be positioned closer to

the valve body.

Ease of service – the bottom two stud assemblies are

•

slotted, enabling a work section to be replaced without

completely disassembling the valve assembly. This is

accomplished by loosening the top tie bolt and then lifting

the section out of the assembly. Downtime is minimized.

Easy conversion from a left-handed to a right-handed

•

section – the work section housing and spool are

symmetrical, which enables the spool to be inserted in

either end of the housing.

Improved spool seal life – the enclosed handle assembly

•

protects the spool and spool seal area from contamination

and the potential corrosion.

3

Parker Hannifin Corporation

Page 8

Catalog HY17-8505/UK

Technical Information

Open-Center Directional Control Valve

VO40

Specifications

Pressures

Flow Rates

(maximum

recommended)

Internal Pilot

Pressure

Spool Leakage

from work port

to tank

Weights

Weights are approximate due to number of variations

available.

Inlet with relief 1.92 kg (4.2 lbs)

Outlet 1.88 kg (4.1 lbs)

Work section with reliefs and

manual actuator

Work section and manual actuator

without reliefs

Work Section, PO Checks with

manual actuator

Joystick assembly 0.8 kg (1.8 lbs)

Inlet Port: 300 bar (4350 PSI)

Tank Port: 50 bar (725 PSI)

Work Ports: 300 bar (4350 PSI)

40 LPM (10.6 GPM)

Required for solenoids –

contact Parker

Max. 6 mL/min @172 bar (2500 PSI)

Oil temp. 50ºC (122ºF), and viscosity

40 cSt

1.93 kg (4.3 lbs)

1.98 kg (4.4 lbs)

2.1 kg (4.6 lbs)

Connections

Standard valves are available in 3/8" BSP (DIN 3852/2), SAE-6

or SAE-8 (J1926/1).

Connection Location SAE -8 SAE-6 BSP

P1, P2 Inlet ¾-16 UNF

T1, T2 Inlet ¾-16 UNF

P3 Outlet ¾-16 UNF

T3 Outlet ¾-16 UNF

PB1 Outlet ¾-16 UNF

Work Ports

GAGE

PORT

PC

(Hyd. Conn.)

PT

(Pneu.Conn.)

Work

Sections

Inlet

Work

Sections

Work

Sections

¾-16 UNF

M\zn-20 UNF M\zn-20 UNF

M\zn-20 UNF M\zn-20 UNF

Z\, NPT Z\, NPT Z\, NPT

>\zn-18 UNF C\,-19

>\zn-18 UNF C\,-19

>\zn-18 UNF C\,-19

>\zn-18 UNF C\,-19

>\zn-18 UNF C\,-19

>\zn-18 UNF C\,-19

¼

¼

4

Parker Hannifin Corporation

Page 9

Catalog HY17-8505/UK

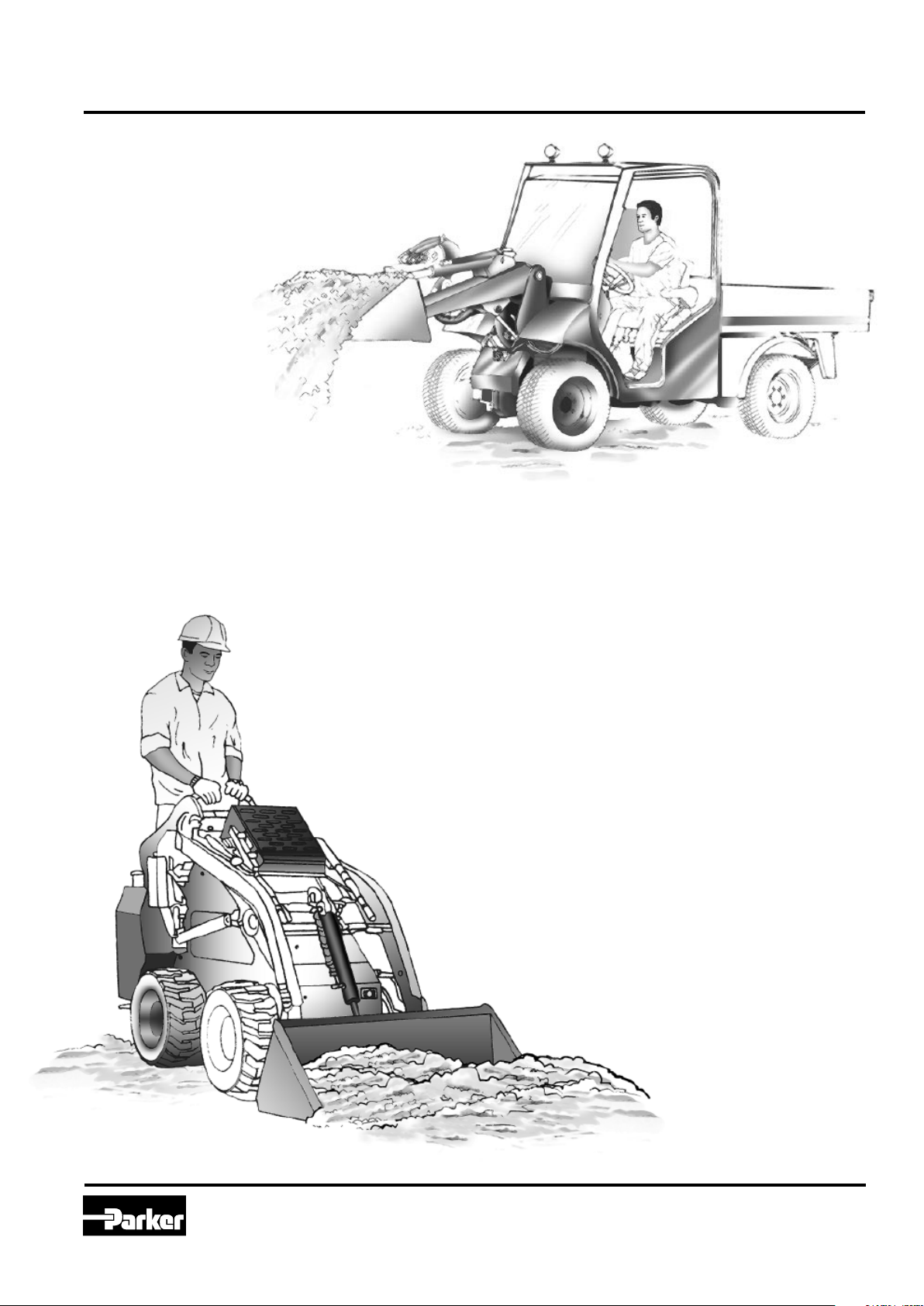

3010

20

7.92.6 5.3

50

13.2

Flow

0

LPM

GPM

0

43.5 3

87.0

6

130.5 9

174.0

217.5

PSI

12

15

Bar

Pressure

40

10.6

Pressure Drop - Open Center P T

Top Inlet to Top Outlet

→

T

P

8 Section Valve

3 Section Valve

1 Section Valve

3010

20

7.92.6 5.3

50

13.2

Flow

0

LPM

GPM

0

43.5 3

87.0

6

130.5 9

174.0

217.5

PSI

12

15

Bar

Pressure

40

10.6

Pressure Drop - Open Center P T

Side Inlet to Side Outlet

→

P

T

8 Section Valve

3 Section Valve

1 Section Valve

3010

20

7.92.6 5.3

50

13.2

Flow

0

LPM

GPM

0

43.5 3

87.0

6

130.5 9

174.0

217.5

PSI

12

15

Bar

Pressure

40

10.6

Pressure Drop - A T

Cylinder Port to Side Outlet

→

3010

20

7.92.6 5.3

50

13.2

Flow

0

LPM

GPM

0

43.5 3

87.0

6

130.5 9

174.0

217.5

PSI

12

15

Bar

Pressure

40

10.6

Pressure Drop - P A

Top Inlet to Cylinder Port

→

A

P

8 Section Valve

3 Section Valve

1 Section Valve

8 Section Valve

3 Section Valve

1 Section Valve

T

A

Technical Information

Performance Curves

Open-Center Directional Control Valve

VO40

NOTE: ISO VG 46 oil @ 50 °C

Environmental Characteristics

The valve can be mounted in all conceivable directions.

However, the mounting base should be flat and stable so

that the valve is not subjected to strain.

While the o-rings in the valve are normally of nitrile rubber, there are a number of special fluorocarbon variants.

Please contact Parker for further information.

Temperature

Oil temperature, working range:

+20°C to 90 °C (68 to 194 °F)*

Filtration

Filtration must be arranged so that Target Contamination

Class 20/18/14 according to ISO 4406 is not exceeded.

For the pilot circuit, Target Contamination Class 18/16/13

according to ISO 4406 must not be exceeded.

Hydraulic Fluids

Best performance is obtained using mineral-base oil of

high quality and cleanliness in the hydraulic system.

Hydraulic fluids of type HLP (DIN 51524), oil for automatic

gearboxes Type A and engine oil type API CD can be

used.

Viscosity, working range: 15-380 mm2/s (15-380 cST)**

Technical information in this catalog is applicable at

an oil viscosity of 30 mm2/s (30 cST) and temperature

of 50 °C (122 °F) using nitrile rubber seals.

* Product operating limits are broadly within the above range, but

satisfactory operation within the specification may not be accomplished. Leakage and response will be affected when used at temperature extremes and it is up to the user to determine acceptability

at these levels.

** Performance efficiency will be reduced if outside the ideal values.

These extreme conditions must be evaluated by the user to establish

suitability of the product’s performance.

5

Parker Hannifin Corporation

Page 10

Catalog HY17-8505/UK

B

A

P1

[26]

T1

[24]

G

B

A

B A

T4

[34]

B

A

P1

[26]

T1

[24]

T4

[34]

B

A

B

A

Technical Information

Open-Center Directional Control Valve

VO40

Circuit Types – Parallel Circuit

In the open-center parallel circuit, oil flows through the open-center passage when all of the spools are in neutral.

When spools are shifted, oil is diverted into the parallel path and available to each of the selected work-sections.

Simultaneous operation can be achieved, when two or more spools are selected. However, since oil will take the

path of least resistance the operator must meter the flow to each function to get a desired function speed.

Circuit Types – Tandem Circuit (Priority)

In the open-center tandem circuit, oil flows through the open-center passage when all of the spools are in neutral.

Tandem work-sections are fed from the open center and the parallel path is blocked. A tandem work-section will

give priority to an upstream work-section.

6

Parker Hannifin Corporation

Page 11

Catalog HY17-8505/UK

191.0 (7.51)

27.0

(1.06)

80.9

(3.19)

15.0

(0.59)

87.0 (3.42)

92.0 (3.62)

20°

A = 76.0 (3.00) + 32.0 (1.26) x No. WORK STATIONS

B = 32.0 (1.26) + 32.0 (1.26) x No. WORK STATIONS

15°

15°

132.7

(5.23)

15°

15°

207.5

(8.16)

32.0

(1.26)

32.0

(1.26)

32.0

(1.26)

9.4±0.4

(0.37±0.01)

70.0 (2.76)

40.0 (1.57)

213.6

(8.41)

70.0

(2.76)

140.0

(5.51)

161.8

(6.37)

25.0

(0.98)

A

B

B

15°

15°

10°

15°

15°

25.0

(0.98)

9.5

(0.37)

FLOAT STROKE

5.5

(0.22)

5.5

(0.22)

114.2 (4.50)

5.5

(0.22)

5.5

(0.22)

84.0 (3.31)

STROKE STROKE

STROKESTROKE

25.0

(0.98)

US

Dimensions

Inch equivalents for millimeter dimensions are shown in (**)

Assembly

Open-Center Directional Control Valve

VO40

Spool Stroke of Work Sections

3-Position Spool

7

4-Position Spool

(Float)

Parker Hannifin Corporation

Page 12

Catalog HY17-8505/UK

6.00

(0.236)

16.25

(0.640)

5.50

(0.216)

∅

4.80 (0.189)

62.0 (REF)

(2.44)

92.0

(3.62)

37.0

(1.46)

∅30.0

( 1.18)∅

16°

16°

16°

16°

20°

295

(11.6)

58

(2.3)

58

(2.3)

94

(3.7)

Float

43

(1.7)

102

(4.0)

137

(5.4)

Float

18

(0.7)

20°

R1

140

20

M8x1

Ø7,3

Ø13

Ø11

42

30

R9

Ø7,35

Dimensions

Open-Center Directional Control Valve

VO40

Mechanical Joystick

Inch equivalents for millimeter dimensions are shown in (**)

Pneumatic Actuator

Dual Actuator

Handle Rod

8

Parker Hannifin Corporation

Page 13

Catalog HY17-8505/UK

Push Handle

Pull Handle

Left-Hand Joystick

Spool OUT - Section 1

Power to “B” Port

Spool IN – Section 1

Power to “A” Port

Spool IN – Section 2

Power to “A” Port

Spool OUT – Section 2

Power to “B” Port

Right-Hand Joystick

Spool OUT - Section 2

Power to “B” Port

Spool IN – Section 2

Power to “A” Port

Spool OUT – Section 1

Power to “B” Port

Spool IN – Section 1

Power to “A” Port

A B

TANK

OPEN

CENTER

PARALLEL

PATH

TANK

OPEN

CENTER

PARALLEL

PATH

Technical Information

Handle Actuation vs. Spool Direction

• Spool Out

• Energize port “B”

• Port “A” to tank

Open-Center Directional Control Valve

VO40

• Spool In

• Energize port “A”

• Port “B” to tank

Note:

Circuit reflects spool

position, not handle

position.

9

Parker Hannifin Corporation

Page 14

Catalog HY17-8505/UK

23

23

PB

I

140

T1

T2B

P1B

P2

STATE:

FILLED BY:

# 1 # 2

pos pos description

12 47 Circuit type

15 50

Spool actuator

16 51 Lever Bracket / handle

17 51C Clevis or Handle location

17C 52 Spool pos. indication

24 60 Spool function

25 62 Piston head side

26 76A

Port A valve

27 76B

Port B valve

88A Restrictor on por t A

88B

Restrictor on port B

90 Spacer Section

93 Mid Inlet type

94 Main relief valve

98

Pressure setting (PSI)

98C Relief Flow Setting (GPM)

P/N SECTION

P/N MCH. CAST

SPACER SECTION

MID INLET

Tank connectionT2

Pump connection P1

Pump connection P2

Pressure setting (PSI)

Relief Flow Setting (GPM)

Tank connectionT1

Type of Inlet

Main relief valve

description

Max. Inlet flow (GPM)

STACK POS

INLET

WORK SECTION

[04]

CONNECTIONS

THREAD

G = ALL PORTS 3/8" BSP

U = ALL PORTS 9/16" UNF (SAE #6)

U8 = ALL PORTS 3/4" UNF (SAE #8)

U6 = P AND T 3/4" UNF AND WORK PORTS 9/16" UNF

DATE:

CITY:

CUSTOMER

U8

Customer Information

Code Position Reference

Section Number

starting with the Inlet Cover

Ordering Information

How to Order the VO40 Valve Assembly

A specification sheet is located in the back of this book, and is also available in an electronic Excel format on our

web site. This form should be used to configure a valve assembly. The layout starts from the inlet cover on the left,

work sections and mid-inlets in the middle and the outlet cover on the far right. Each field will require an entry, and

the fields are represented with a position reference [ ] to help guide you to the option codes listed in the catalog

pages 11 to 21.

Inlet Cover Portion of Spec Sheet

Open-Center Directional Control Valve

VO40

Example: Inlet Cover (Sect #1)

Customer has 23 l/min pump flow, requires

a pilot operated main relief set 140 bar and

wants all SAE-8 work ports.

• Reference position [4] calls out the thread

option for the entire valve assembly (SAE

or BSP) (“U8” is the code for all SAE-8

size ports).

Note: There is a separate specification

sheet which utilizes metric units.

• Reference position [12] calls out the

system flow and can be listed in LPM or

GPM depending on which spec sheet you

are using (23 is entered for flow).

• Reference position [15] gives you an

option for a standard type inlet “I” or

an unloader type inlet cover “IU” (“I” is

entered for std inlet cover).

• Reference position [16] indicates the type

of main relief valve: (“PB” is the code for

a pilot operated RV).

• Reference position [17] Enter desired

relief valve setting (140 bar is entered).

• Reference position [17C] Enter desired

flow for relief valve setting (23 l/min is

entered).

• Reference position [24-27] calls out the

inlet/outlet porting (machined/plugged)

options:

T1 is the top tank port open.

T2B is code for side tank port plugged.

P1B is code for top inlet port plugged.

P2 is code for top inlet port open.

10

Parker Hannifin Corporation

Page 15

Catalog HY17-8505/UK

Ordering Information

Open-Center Directional Control Valve

VO40

Valve Assembly – General Information

The VO40 has two basic thread versions - UNF (SAE) or BSP.

[04] – Connections Thread

G 3/8 BSP Inlet, Outlet & Work Ports.

U 9/16" UNF (SAE-6) Inlet, Outlet & Work Ports.

U6 9/16" UNF (SAE-6) Work Ports, 3/4" UNF (SAE-8) Inlet/Outlet Ports.

U8 3/4" UNF (SAE-8) Inlet, Outlet & Work Ports.

[05] – System Voltage To be determined when the solenoid option is released

[07] – Surface Treatment (Paint)

X No Paint.

P Paint valve black.

[08] – Customer Designated ID: Enter Customer Part Number

11

Parker Hannifin Corporation

Page 16

Catalog HY17-8505/UK

INLET

OUTLET

GAGE

TANK TANK

OPEN

CENTER

PARALLEL

PATH

INLET

OUTLET

TANK

OPEN

CENTER

PARALLEL

PATH

INLET

GAGE

Ordering Information – Inlet Cover

Open-Center Directional Control Valve

VO40

The inlet cover of VO40 is available in two versions. One is the standard inlet and the other is an inlet with a solenoid pump unloader (in development). The porting location options for the standard inlet are:

1) Top/side – inlet and outlet ports. Any unused ports can be plugged.

2) Top – inlet and outlet ports only.

All inlet bodies have a gage port, that comes plugged. SAE #4 (7/16"x20 UNF thread) or 1/4" BSP.

The coding to specify an inlet cover is accomplished by eight fields, as shown below:

[12] – Max Pump Flow

The pump inlet flow can be selected in LPM or GPM.

[15] – Type of Inlet

I Standard Inlet.

IU Inlet with pump unload, solenoid actuated (in development).

[24] to [27] – Inlet Porting Options

1) Standard – Top & Side Inlet/Outlet Ports 2) Standard – Top Inlet/Outlet Ports

12

Parker Hannifin Corporation

Page 17

Catalog HY17-8505/UK

Ordering Information – Inlet Cover

Open-Center Directional Control Valve

VO40

[16] - Main Relief Options

PS Adjustable main pilot-operated relief.

Adjustment range: 50 to 300 bar (725 to 4300 PSI).

PB Adjustable main pilot-operated relief

(Tamperproof aluminum cap).

Adjustment range: 50 to 300 bar (725 to 4300 PSI).

PN Adjustable main direct-acting relief.

Adjustment range: 60 to 207 bar (900 to 3000 PSI).

PA Adjustable main direct-acting relief

(Tamperproof aluminum cap).

Adjustment range: 60 to 207 bar (900 to 3000 PSI).

Y Y plug (cavity machined and plugged).

[17] – Pressure Setting – Enter pressure setting (PSI or Bar)

Note: Relief valve code PN and PA max setting is

207 bar (3000 PSI).

[17C] – Relief Flow Setting

Flow in LPM or GPM.

13

Parker Hannifin Corporation

Page 18

Catalog HY17-8505/UK

TANK

OPEN

CENTER

OUTLET

OUTLET

OUTLET

OUTLET

TANK

OPEN

CENTER

Ordering Information – Outlet Cover

Open-Center Directional Control Valve

VO40

The VO40 outlet cover is available in two versions: Standard or with pilot generation and regulation for proportional

solenoid applications.

The standard outlet has two porting configurations available:

1) Top and side outlet ports along with machining for conversion to power-beyond or closed-center.

2) Top outlet only.

The coding to specify an outlet is made by four fields as shown below:

[30] – Type of Outlet

Standard.

US

USP With pilot-pressure generation (to be used on solenoid valves) (in development).

[33] to [35] – Outlet Porting Options

1) Top and Side Oulet Ports

2) Top Oulet Port Only

14

Parker Hannifin Corporation

Page 19

Catalog HY17-8505/UK

OUTLET

OUTLET

TANK

OPEN

CENTER

POWER

BEYOND

OUTLET

OUTLET

TANK

OPEN

CENTER

CLOSED

CENTER

PLUG

Ordering Information – Outlet Cover

[33] to [35] – Outlet Porting Options

Open-Center Directional Control Valve

VO40

Power-Beyond

Closed-Center

15

Parker Hannifin Corporation

Page 20

Catalog HY17-8505/UK

Ordering Information – Work Sections

The VO40 valve can be supplied in combinations from one to ten work sections. For each work section there is

a variety of spool options, actuators, positioners and port accessories. Work sections can have parallel, series,

and/or tandem circuitry. All types can be combined in the same valve assembly.

All work sections with hold in neutral spools have transition checks (load checks). All work sections with free flow

in neutral spools (motor) do not include transition checks (load checks). Contact Parker if you require a deviation

from this configuration.

Work sections are available with or without work port option machining. Integrated pilot-operated checks (LockOut) are available in a specially machined casting (ordering code on page 20 [76 A/B]). A spacer section which

provides for more spacing between sections is also available (ordering code on page 20 [90]).

Open-Center Directional Control Valve

VO40

Examples of work port machining options:

Section without RV Cavities Section with RV Cavities

Section with PO Checks

The VO40 Pilot-Operated Check (Lock-Out) sections

provide near zero leakage and can prevent cylinder

drift when the spool is in the neutral position. When

the spool is shifted to a power position, oil is directed

to one work port. Return oil is momentarily blocked

until pilot pressure unseats the check (3.1:1 ratio). With

207 bar (3000 PSI) load, it will require 67 bar (968 PSI)

into the opposite work port to unlock.

The spool is a 4-way, 3-position free flow spool which

prevents system pressure leakage from building up

and unlocking the PO checks.

The coding to specify a work section is made by 11 fields, as shown below:

[47] – Work Section Circuitry

P Parallel Circuitry.

T Tandem Circuitry – Provides priority to upstream sections.

S Series Circuitry– (In development).

16

Parker Hannifin Corporation

Page 21

Catalog HY17-8505/UK

Ordering Information – Work Sections

Open-Center Directional Control Valve

VO40

[50] – Spool Actuators

C Spring centered to neutral position.

CD Spring centered with dual control.

CHA2 Two position detent – spool “IN”.

Detent in neutral and “A” positions.

CHB2 Two position detent – spool “OUT”.

Detent in neutral and “B” positions.

CHB3 Three position detent.

B2A Spring centered with “IN” detent.

Detent in “A” position and spring centering

to neutral position.

B2B Spring centered with “OUT” detent.

Detent in “B” position and spring centering

to neutral position.

C CD

CHA2 CHB2 CHB3

B2A B2B B2C

B2C Spring centered with detent in two

positions “A” & “B”.

CB Spring centered with detent in fourth

position, used with float spool.

PC Hydraulic Remote Actuator – Proportional.

EC Solenoid Operated – Proportional.

(in development)

ED Solenoid Operated – On/Off.

ACP Pneumatic actuator – single ended.

The pneumatic actuator for the VO40 allows the

spool to be operated by a pneumatic signal. The

pneumatic actuator is assembled onto one side

of the work section and the opposite end is open

and available for the addition of a handle. A min.

of 5.5 bar (80 PSI) is required. The threaded

ports are both 1/8" NPT.

CB

PC

17

Parker Hannifin Corporation

Page 22

Catalog HY17-8505/UK

Ordering Information – Work Sections

Open-Center Directional Control Valve

VO40

[51] – Lever Bracket Note: Handle Levers are sold separately (see PN listed below)

SH Standard enclosed handle bracket.

SR Standard enclosed handle bracket, but rotated 180 degrees.

/ No bracket, no handle, no boot (female clevis on spool).

LU No bracket, but with boot protector at spool end

(female clevis on spool).

MJL Mechanical Joystick – left side version (must be placed on two adjacent work sections).

MJR Mechanical Joystick – right side version (must be placed on two adjacent work sections).

Handle Rod Assembly is sold as a separate line item PN: K-VO40-H1.

[51C] – Spool Clevis or Handle Bracket Location

This field is used to indicate the location of the handle lever and bracket assembly –

adjacent to port “A” or port “B” side of the work section.

A Spool Clevis or Handle Bracket on port “A” side.

B Spool Clevis or Handle Bracket on port “B” side.

[52] – Spool Position Indication

/ Without spool position indicator.

SD With micro-switch on-off indicator (in development).

18

Parker Hannifin Corporation

Page 23

Catalog HY17-8505/UK

Ordering Information – Work Sections

Open-Center Directional Control Valve

VO40

[60] – Spool Function

D Double-acting (4-way) spool. Work ports blocked in the

neutral position.

EA Single-acting (3-way) spool. Port “A” blocked in neutral.

Port “A” is active and Port “B” is plugged.

EB Single-acting (3-way) spool. Port “B” blocked in neutral.

Port “B” is active and Port “A” is plugged.

M Double-acting (4-way) spool. Work ports open to tank in the

neutral position. Note: A work section with this spool does

not have a transition check (load check).

F Double-acting (4-way) spool with a 4th position in which

both work ports are connected to tank (float position).

Work ports are blocked in the neutral position.

DM Double-acting (4-way) spool. Work port pressure is bled to

tank, when the spool is in the neutral position.

Bleed notch is designed for 1.9 LPM @ 69 bar.

(0.5 GPM @1000 PSI)

DA Double-acting (4-way) spool. Work port “A” pressure is bled

to tank, when the spool is in the neutral position.

Bleed notch is designed for 0.5 GPM @1000 PSI.

(1.9 LPM @ 69 Bar)

DB Double-acting (4-way) spool. Work port “B” pressure is bled

to tank, when the spool is in the neutral position.

Bleed notch is designed for 0.5 GPM @1000 PSI.

(1.9 LPM @ 69 Bar)

19

Parker Hannifin Corporation

Page 24

Catalog HY17-8505/UK

TANK

OPEN

CENTER

PARALLEL

PATH

TANK

OPEN

CENTER

PARALLEL

PATH

ACTUATOR

METER OUT

FREE

ACTUATOR

METER IN

FREE

Ordering Information – Work Sections

Open-Center Directional Control Valve

VO40

[62] – Piston Head Side of Cylinder

The default for this field is code M. Codes A and B are only used when asymmetrical spools must be developed.

For example, a cylinder that requires meter-in for one direction and meter-out for the other.

M Standard symmetrical spool- cylinder or motor.

A Piston head connected with port “A”.

B Piston head connected with port “B”.

[76 A/B] – Work Port Valves

Anti-Cavitation

This pertains to the work port accessory options.

/ Port not machined.

Y2 Relief Valve cavity plugged.

N2 Anti-cavitation valve.

( ) RV/AC Non-Adjustable: Enter Pressure setting (PSI or Bar).

Note: RV Set at 10 LPM (2.6 GPM).

C2 Pilot-Operated Checks (Lock-out valve).

Refer to page 16.

[88 A/B] – Work Port Option

/ No Restrictor.

Work port restrictors restrict flow in one direction

and are free flow in the opposite direction.

Restrict flow “out” of actuator “into” work port.

P1 = 1mm (0.040")

P2 = 2mm (0.080")

P3 = 3mm (0.120")

P4 = 4mm (0.160")

Restrict flow “out” of work port “into” actuator.

N1 = 1mm (0.040")

N2 = 1mm (0.080")

N3 = 1mm (0.120")

N4 = 1mm (0.160")

RV/AC Non-Adjustable

Check

Y plug for blocking

RV cavity

[90] – Spacer Section

N Spacer Section.

This section connects the open center, parallel path

and tank cores between two adjacent work sections.

This section is used to provide additional spacing

between two work sections. All other fields in the

work section code can be left blank. (Contact Parker

for size options available.)

20

Parker Hannifin Corporation

Page 25

Catalog HY17-8505/UK

INLET

TANK

OPEN

CENTER

PARALLEL

PATH

TANK

OPEN

CENTER

PARALLEL

PATH

OUTLET

INLET

TANK

OPEN

CENTER

TANK

OPEN

CENTER

PARALLEL

PATH

Ordering Information – Mid-Inlet

Open-Center Directional Control Valve

VO40

The VO40 mid-inlet options are split or combined flow. They are available with a main RV option. There is also a

provision for an outlet port on the split flow version only.

The coding to specify a mid-inlet is made by three fields as shown below:

Mid-Inlet

Optional

Outlet Port

C5 Only

Relief Valve

Mid-Inlet

Pump Port

Split Flow, C5Combined Flow, C3

[93] – Mid Inlet Options

Combined Flow (Port “A” inlet - Port “B” is plugged and not available to tank).

C3

C5 Split Flow (Port “A” inlet - Port “B” is optional tank port).

[94] – Main Pressure Relief

Y Without pressure relief (cavity machined and plugged).

PA Direct-acting relief valve non-adjustable.

[98] – Pressure Setting - Enter pressure (PSI or Bar)

[98C] – Mid-Inlet Relief Flow Setting

Flow in GPM or LPM.

21

Parker Hannifin Corporation

Page 26

Catalog HY17-8505/UK

PARKER HANNIFIN CORPORATION - HYDRAULICS GROUP SHEET 1 DE 1

VO40 - DIRECTIONAL STACK VALVE - DATA SHEET

REVISION

Date

STATE:

App.

FILLED BY:

11#01

#

9#8#7#

6

#5

#4

#3

#2

#

1#

noitpi

r

cs

e

dsop

so

p pos

7

421 Circuit type 30

0

5

5

1 Spool actuator

33

1

5

61

Lever Bracket / handle 34

C

1

571 Clevis or Handle location 35 Tank connection T5

2

5

C

7

1 Spool pos. indication

0

6

42

Spool function

2

6

5

2 Piston head side

A

6

7

6

2 Port A valve

B

6

7

72 Port B valve

rev. date doc app

88A

Restrictor on port A

A

88B

Restrictor on port B B

C

90

Spacer Section D

E

RESTRICTORS

93

Mid Inlet type

F

94

Main relief valve G

98 Pressure setting (PSI)

98C Relief Flow Setting (GPM)

REMARKS:

CONNECTION PORT A

CONNECTION PORT B

ASSEMBLING KIT

TEST STANDARD:

P/N SECTION

P/N MACH. CAST

(Leave blank if not sure)

P/N ACCESSORIES

P/N SECTION

P/N MCH. CAST

SPACER SECTION

MID INLET

Tank connection T2

Pump connection P1 REVISIONS

Pump connection P2

Pressure setting (PSI)

Relief Flow Setting (GPM) P/N SECTION

Tank connection T1 P/N MCH CAST

Type of Inlet Tank connection T3

Main relief valve Tank connection T4

description

description

Max. Inlet flow (GPM)

Type

STACK POS

# last

INLET WORK SECTION OUTLET

12

= 12 VCC

24 = 24 VCC

[07]

PAINTING

P = BLACK BASE

X = NO PAINTING

[08]

CUSTOMER DESIGNATED ID:

[04]

CONNECTIONS

THREAD

G = ALL PORTS 3/8" BSP

U

= ALL PORTS 9/16" UNF (SAE #6)

U8 = ALL PORTS 3/4" UNF (SAE #8)

U6

= P AND T 3/4" UNF AND WORK PORTS 9/16" UNF

[05]

SYSTEM VOLTAGE

Replace

DATE: )IS

P

(

E

RUS

S

ERPMU

M

I

X

A

M

)MPG(WO

L

FM

U

M

I

X

A

M

CITY:

CUSTOMER NUMBER:

P/N

CUSTOMER

APPLICATION

A

B

1.0 P1

2.0 P2

3.0 P3

4.0 P4

1.0 N1

2.0 N2

3.0 N3

4.0 N4

CODE

[88]

CODE

[88]

DIA.

(MM)

DIA.

(MM)

METER OUT

FREE

METER OUT

FREE

METER IN

FREE

METER IN

FREE

1.0 P1

2.0 P2

3.0 P3

4.0 P4

1.0 N1

2.0 N2

3.0 N3

4.0 N4

CODE

[88]

CODE

[88]

DIA.

(MM)

DIA.

(MM)

METER OUT

FREE

METER OUT

FREE

METER OUT

FREE

METER OUT

FREE

METER IN

FREE

METER IN

FREEFREEFREE

Assembly Configuration Form

Open-Center Directional Control Valve

VO40

22

Parker Hannifin Corporation

Page 27

Extensive Hydraulic Product Offering

Accumulators

Piston, bladder and diaphragm type accumulators,

gas bottles and KleenVent

reservoir isolators.

Filtration

Pressure and return line

filters enhances machine life,

reduces maintenance and

lowers costs.

Compact Hydraulics Cylinders

Self-contained with a motor,

gear pump, reservoir, internal valving, load hold checks

and relief valves.

Integrated Hydrau-

Standard and custom

hydraulic cylinders for

industrial and mobile

applications.

Motors

lic Circuits

Solutions for complex circuits that include threaded

cartridge valves integrated

into a single manifold.

Full line of high and low

speed motors provides power

up to 1700 Nm of torque.

Electronics/Remote

Controls

Parker’s unique IQAN approach combines sturdy,

well-tested hardware with

intelligent, flexible computing power.

Power Take Off

Parker Chelsea leads the

industry for engineering,

innovation and performance

in auxiliary power systems.

The most complete line of

standard, pre-engineered,

cataloged hydraulic power

units in the industry.

PumpsPower Units Valves and Controls

Broad line of energy- efficient hydraulic pumps that

includes piston, vane and

gear pumps.

Covering the Industrial, Mobile

and Truck markets, each catalog

is paired with an interactive CD.

Call for your comprehensive

guides today. 00800 27 27 5374

(from AU,BE,CH,DE,EI,FR,UK

only) All other countries should

call one of the following:

+44 1442 358 429

(English speaking service)

+44 1442 358 428

(German speaking service)

+44 1442 358 427

(French speaking service)

Rotary Actuator

Industry leader in the design

and manufacture of hydraulic rack and pinion, and

vane style rotary actuators.

Industrial Bulletin

HY02-8022

Mobile Bulletin

HY02-8023

Hydraulic valves for virtually every hydraulic equipment

application, from simple to

precise control.

Truck Bulletin

HY02-8020

www.parker.com/eurohyd

Page 28

Hydraulics Group

Sales Offices

InternationalEurope

Austria

Wiener Neustadt

Tel.: +43 (0)2622 23501

Fax: +43 (0) 2622 66212

Austria

Wiener Neustadt

(Resp for East Europe)

Tel.: +43 (0)2622 23501 970

Fax: +43 (0) 2622 23501 977

Belgium

Nivelles

Tel.: +32 (0)67 280 900

Fax: +32 (0)67 280 999

Czech Republic

Klecany

Tel.: +420 284 083 111

Fax: +420 284 083 112

Denmark

Ballerup

Tel.: +45 43 56 04 00

Fax: +45 43 73 31 07

Finland

Vantaa

Tel.: +358 20 753 2500

Fax: +358 20 753 2200

France

Contamine-sur-Arve

Tel.: +33 (0)4 50 25 80 25

Fax: +33 (0)4 50 25 24 25

Germany

Kaarst

Tel.: +49 (0)2131 4016 0

Fax: +49 (0)2131 4016 9199

Ireland

Dublin

Tel.: +353 (0)1 466 6370

Fax: +353 (0)1 466 6376

Italy

Corsico (MI)

Tel.: +39 02 45 19 21

Fax: +39 02 4 47 93 40

The Netherlands

Oldenzaal

Tel.: +31 (0)541 585 000

Fax: +31 (0)541 585 459

Norway

Ski

Tel.: +47 64 91 10 00

Fax: +47 64 91 10 90

Poland

Warsaw

Tel.: +48 (0)22 573 24 00

Fax: +48 (0)22 573 24 03

Portugal

Leca da Palmeira

Tel.: +351 22 999 7360

Fax: +351 22 996 1527

Slovakia

Ref. Czech Republic

Spain

Madrid

Tel.: +34 91 675 73 00

Fax: +34 91 675 77 11

Sweden

Spånga

Tel.: +46 (0)8 59 79 50 00

Fax: +46 (0)8 59 79 51 10

United Kingdom

Warwick

Tel.: +44 (0)1926 317 878

Fax: +44 (0)1926 317 855

Australia

Castle Hill

Tel.: +61 (0)2 9634 7777

Fax: +61 (0)2 9842 5111

Canada

Milton, Ontario

Tel.: +1 905 693 3000

Fax: +1 905 876 0788

China

Shanghai

Tel.: +86 21 5031 2525

Fax: +86 21 5834 8975

Asia Pacific Group

Hong Kong

Tel.: +852 2428 8008

Fax: +852 2425 6896

India

Mumbai

Tel.: +91 22 5613 7081/82-85

Fax: +91 22 2768 6841/6618

Japan

Tokyo

Tel.: +81 3 6408 3900

Fax: +81 3 5449 7201

Latin America Group

Brazil

Tel.: +55 51 3470 9144

Fax: +55 51 3470 9281

South Africa

Kempton Park

Tel.: +27 (0)11 961 0700

Fax: +27 (0)11 392 7213

USA

Cleveland (industrial)

Tel.: +1 216 896 3000

Fax: +1 216 896 4031

Lincolnshire (mobile)

Tel.: +1 847 821 1500

Fax: +1 847 821 7600

Parker Hannifin is the world’s premier supplier of motion and control systems and

solutions, with sales and manufacturing facilities throughout the world. For product

information and details of your nearest Parker sales office, visit us at www.parker.com

or call free on 00800 2727 5374.

Catalogue HY17-8505/UK

POD 04/2007 PC

© Copyright 2007

Parker Hannifin Corporation

All rights reserved

Loading...

Loading...