Page 1

V iX250IM

V iX500IM

Stepper Drives

User Guide

Part No: 1600.324.01b February, 2004 (For software revision 2.0 onwards)

Page 2

Page 3

IMPORTANT INFORMATION FOR USERS

Installation and Operation of Motion Control Equipment

It is important that motion control equipment is installed and operated in such a way that all applicable safety

requirements are met. It is your responsibility as an installer to ensure that you identify the relevant safety

standards and comply with them; failure to do so may result in damage to equipment and personal injury. In

particular, you should study the contents of this user guide carefully before installing or operating the

equipment.

The installation, set-up, test and maintenance procedures given in this User Guide should only be carried

out by competent personnel trained in the installation of electronic equipment. Such personnel should be

aware of the potential electrical and mechanical hazards associated with mains-powered motion control

equipment - please see the safety warning below. The individual or group having overall responsibility for

this equipment must ensure that operators are adequately trained.

Under no circumstances will the suppliers of the equipment be liable for any incidental, consequential or

special damages of any kind whatsoever, including but not limited to lost profits arising from or in any way

connected with the use of the equipment or this user guide.

SAFETY WARNING

High-performance motion control equipment is capable of producing rapid movement and very high forces.

Unexpected motion may occur especially during the development of controller programs. KEEP WELL

CLEAR of any machinery driven by stepper or servo motors. Never touch any part of the equipment while it

is in operation.

This product is sold as a motion control component to be installed in a complete system using good

engineering practice. Care must be taken to ensure that the product is installed and used in a safe manner

according to local safety laws and regulations. In particular, the product must be enclosed such that no part

is accessible while power may be applied.

This and other information from Parker-Hannifin Corporation, its subsidiaries and authorised distributors

provides product or system options for further investigation by users having technical expertise. Before you

select or use any product or system, it is important that you analyse all aspects of your application and

review the information concerning the product in the current product catalogue. The user, through its own

analysis and testing, is solely responsible for making the final selection of the system and components and

assuring that all performance, safety and warning requirements of the application are met.

If the equipment is used in any manner that does not conform to the instructions given in this user guide,

then the protection provided by the equipment may be impaired.

The information in this user guide, including any apparatus, methods, techniques, and concepts described

herein, are the proprietary property of Parker Electromechanical Division or its licensors, and may not be

copied, disclosed, or used for any purpose not expressly authorised by the owner thereof.

Since Parker Electromechanical constantly strives to improve all of its products, we reserve the right to

modify equipment and user guides without prior notice. No part of this user guide may be reproduced in any

form without the prior consent of Parker Electromechanical Division.

© Electromechanical Division of Parker Hannifin plc, 2003

– All Rights Reserved –

Page 4

Product Type: ViX250IM, ViX500IM

The above product is in compliance with the requirements of directives

• 73/23/EEC Low Voltage Directive

• 93/68/EEC CE Marking Directive

• 89/336/EEC Electromagnetic Compatibility Directive

Provided the installation requirements described in this user guide are met, and there are no special requirements of

the installation and operating environment so that the application may be considered typical, the ViX servo drive series

installation will conform to the protection requirements of Council Directive 89/336/EEC as amended by Directive

92/31/EEC on the approximation of the laws of the Member States relating to Electromagnetic Compatibility when

operated and maintained as intended.

In assessing the overall compliance of an installation consideration must also be given to the effects of mains

harmonics and flicker when interfacing the total supply system to the public low voltage supply system.

In accordance with IEC 61800-3:1997 (Adjustable speed electrical power drive systems) this product is of the

restricted sales distribution class which meets the needs of an industrial environment when installed as directed.

However, further measures may need to be taken for use of the product in a domestic environment.

Compliance is demonstrated by the application of the following standards:

BS EN 61800-3 Adjustable speed electrical power drive systems

(1997) including Part 3. EMC product standard including specific test methods

Amendment A11

BS EN 61000-6-2 Electromagnetic compatibility – Part 6-2: Generic standards

(2001) Immunity for industrial environments

BS EN 61000-6-4 Electromagnetic compatibility – Part 6-4: Generic standards –

(2001) Emission standard for industrial environments

BS EN 61010-1 Safety requirements for electrical equipment for measurement,

(1993) including control, and laboratory use. Part 1. General requirements

Amendment A2

WARNING – Risk of damage and/or personal injury

The ViX drives described in this user guide contain no user-serviceable parts.

Attempting to open the case of any unit, or to replace any internal component, may

result in damage to the unit and/or personal injury. This may also void the

warranty.

Page 5

Contact Addresses

For engineering For engineering

assistance in Europe: assistance in Germany

Parker Hannifin plc Parker Hannifin GmbH

Electromechanical Electromechanical

Automation

21 Balena Close P. O. Box: 77607-1720

Poole, Dorset Robert-Bosch-Str. 22

England, BH17 7DX D-77656 Offenburg, Germany

Tel: +44 (0)1202-699000 Tel: +49 (0)781 509-0

Fax: +44 (0)1202-695750 Fax: +49 (0)781 509-176

e-mail: sales.digiplan@parker.com e-mail: sales.hauser@parker.com

e-mail: support.digiplan@parker.com e-mail: techhelp_emd_OG@parker.com

Website: www.parker-eme.com Website: www.parker-eme.com

For engineering For engineering

assistance in Italy assistance in the U.S.:

Parker Hannifin SpA Parker Hannifin Corporation

Electromechanical Automation

20092 Cinisello Balsamo 5500 Business Park Drive, Suite D

Milan, Rohnert Park

Italy Via Gounod, 1 CA 94928

Tel: +39 02 6601 2478 Tel: (800) 358-9070

Fax: +39 02 6601 2808 Fax: (707) 584-3793

e-mail: sales.sbc@parker.com e-mail: emn_support@parker.com

Website: www.parker-eme.com Website: www.parkermotion.com

Automation

Electromechanical Automation

USA

FaxBack System: (800) 936-6939

Symbols used, have the following meanings:

Caution Refer to the

accompanying documentation

Protective conductor terminal

Page 6

CONTENTS i

Contents

1. Introduction.............................................................................................................1

2. Mechanical Installation...........................................................................................5

3. Electrical Installation...............................................................................................9

4. Control of ViX Drives..............................................................................................45

5. EASI-V Software ....................................................................................................95

6. Command Reference.............................................................................................115

7. ViX Maintenance and Troubleshooting ..................................................................185

8. Hardware Reference ..............................................................................................195

Appendix A/B..............................................................................................................199

Index............................................................................................................................203

The ViX250IM/500IM Microstepper Indexer Drive is UL-Recognised under file E194158.

This means it may be incorporated into end-user products that may be eligible for UL

Listing, Classification or Certification.

User Guide Issue Change Summary

This user guide, version 1600.324.01, is the first version of the ViX250IM/ViX500IM

Microstepper Indexer Drive.

When a user guide is updated, the new or changed text is differentiated with a change

bar in the outside margin (this paragraph is an example). If an entire section is changed,

the change bar is located on the outside margin of the section title. For the latest (most

up-to-date) changes required by this issue of user guide see the Latest Changes Sheet

over the page.

Page 7

ii VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Latest Changes Sheet

This page lists important changes occurring immediately before publication or between

issue updates:

Page 8

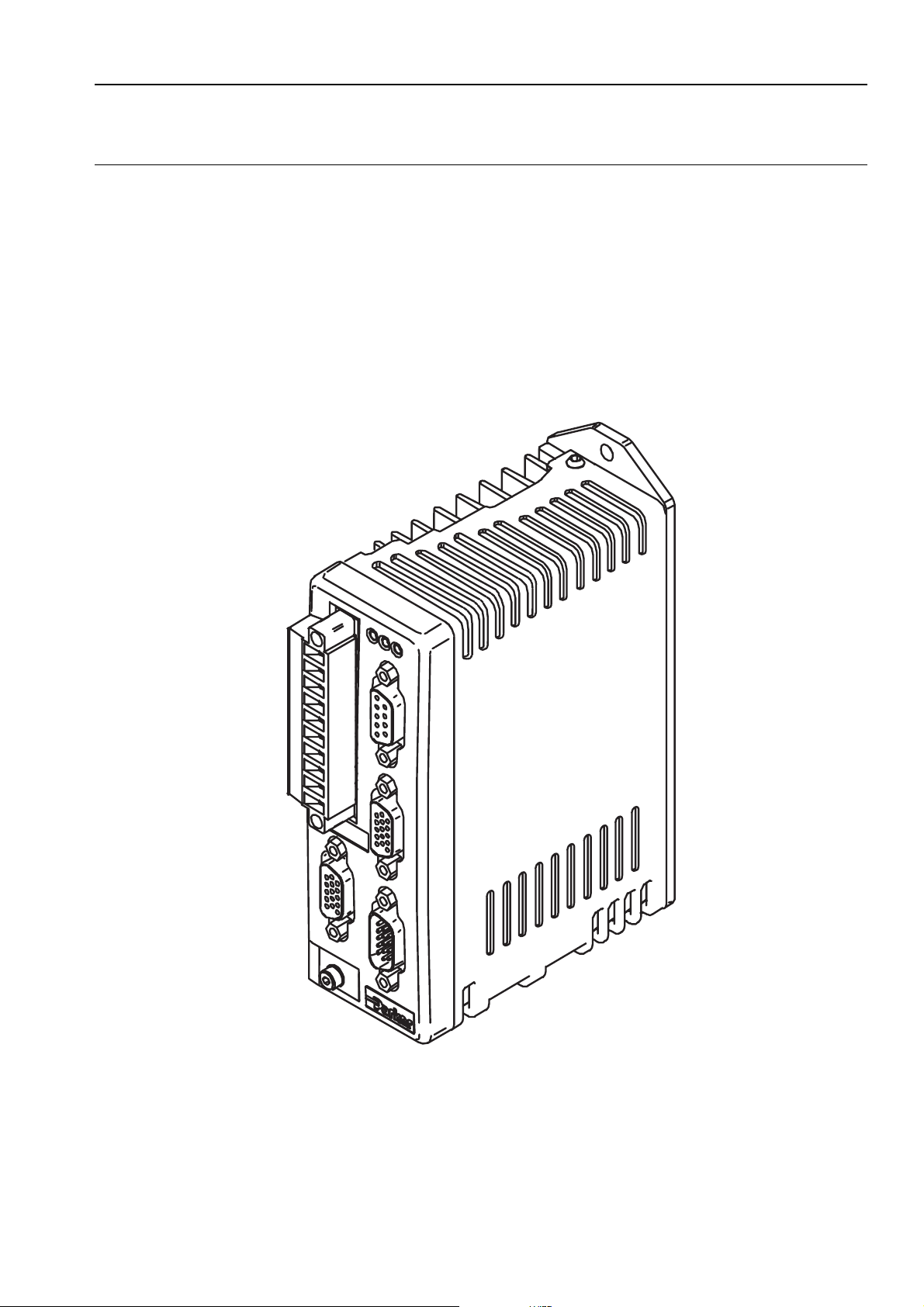

1. INTRODUCTION 1

1. Introduction

Product Description

Available in two current ratings, these microstepper indexer drives employ an optimised

digital field oriented current loop to provide low speed smoothness coupled with high speed

torque. Advanced digital techniques result in reduced settling time and reduced mid speed

instability when compared with similar competitive drive types.

The common use of EASI-V programming language and similar supply requirements make

this drive ideal for mixed technology applications when used with the ViX digital servo.

Figure 1-1. ViX250/ViX500 Microstepper Indexer Drive

Page 9

2 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

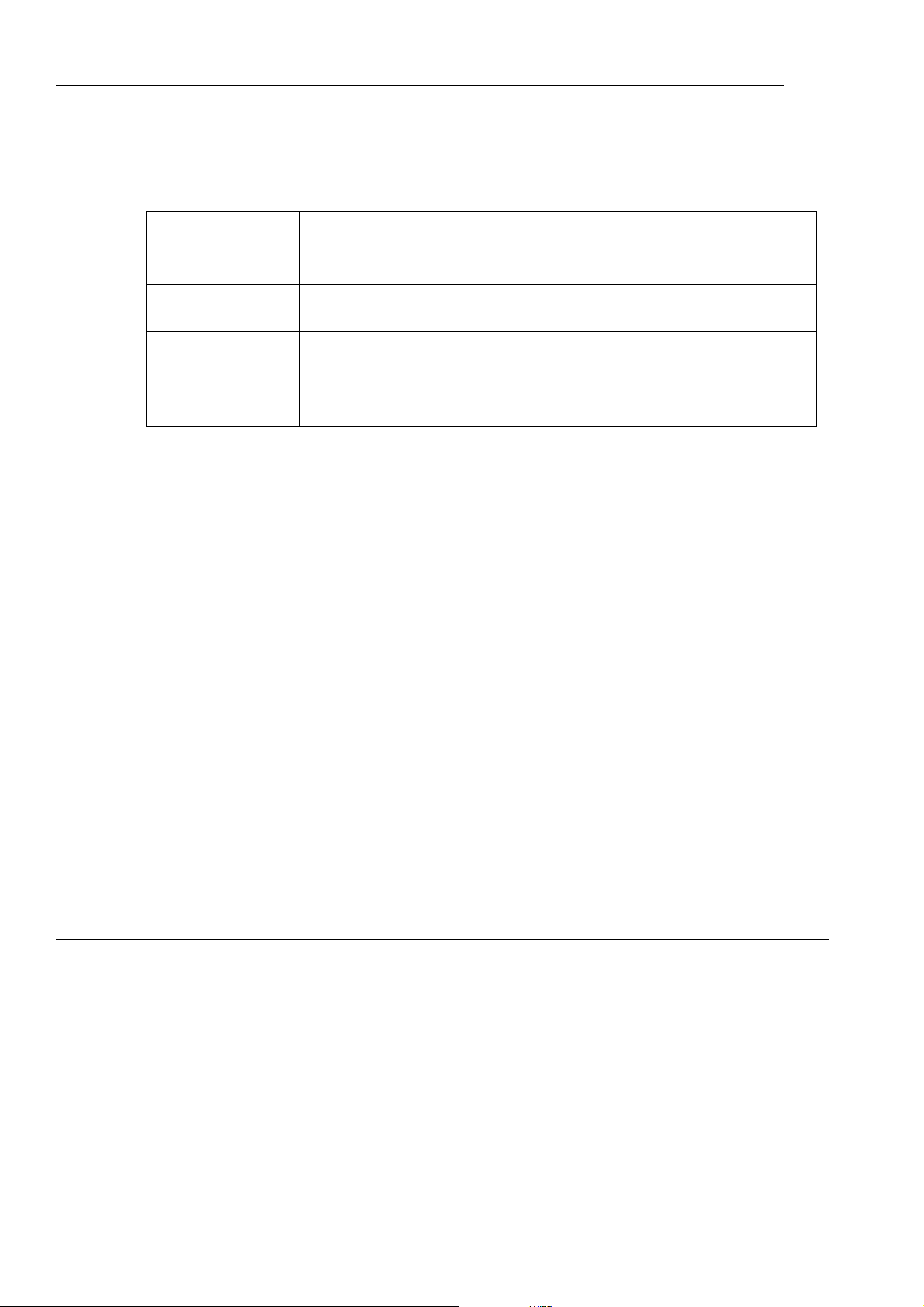

Product Variants

Digital microstepper indexer drives are available in two current ratings with two interface

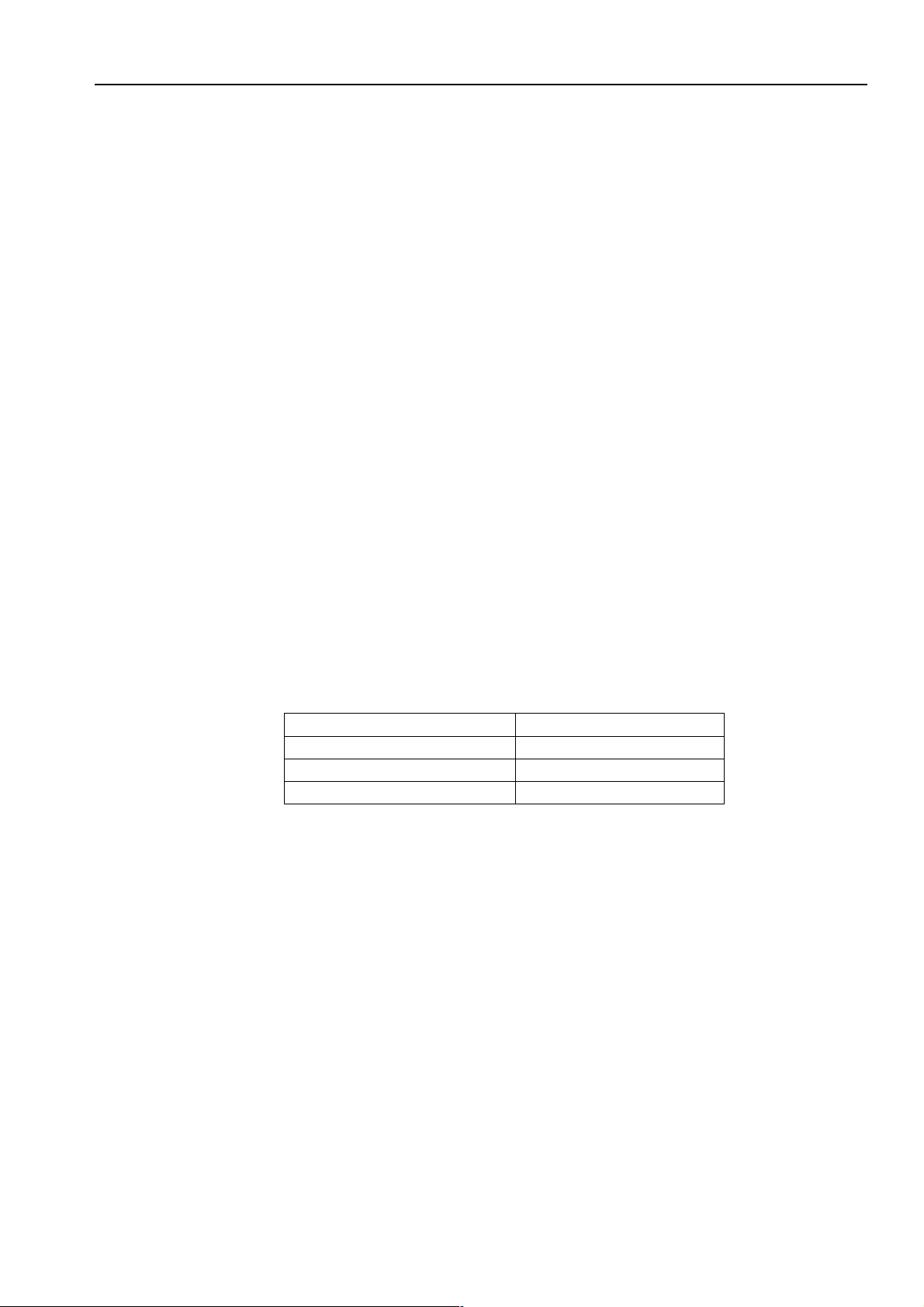

options. Table 1-1 lists the possible combinations:

Product Code Description

ViX500IM 5.6A RMS (8A peak) microstepper indexer drive with an

RS232 control interface

ViX250IM 2.8A RMS (4A peak) microstepper indexer drive with an

RS232 control interface

ViX500CM 5.6A RMS (8A peak) microstepper indexer drive with

Canbus/RS485 interface

ViX250CM 2.8A RMS (4A peak) microstepper indexer drive with

Canbus/RS485 interface

Table 1-1. ViX250/ViX500 Microstepper Indexer Drive Options

Note: RS485 serial communication is only included in the CANopen version of the drive.

Product Features

Protection Circuits

Motor short circuits, phase to phase,

phase to ground

Over-voltage trip

Under-voltage trip

Drive/motor Over-temperature

24V reverse supply protection

Function Indicators

Drive Status/Feedback Fault (HV/FB)

Drive Fault (DF)

Comms. Status (CS)

Outputs and Inputs

3 digital outputs

5 digital inputs

1 analogue input

Page 10

Fit Kits

A fit kit is available for ViXIM drives:

VIX-KIT

Part Number Quantity Description

1650.937.01 1 Information

5004.023 1 Plastic bag

5006.211 1 Product label

0405.811 1 10-way Flange

0405.961 1 9-way D-type

0405.962 2 15-way HD

0405.963 1 15-way HD

0409.530 4 9-way D-type

0313.020 1 H8FE1115NC

4005.218 1 3:1 heatshrink

4216.101 1 Closed P-clip

4216.102 1 Closed P-clip

4216.103 1 Closed P-clip

1. INTRODUCTION 3

sheet

plug strip

plug

D-type plug

D-type socket

cover

ferrite sleeve

19mm diam.

9mm ID

10.7mm ID

12.3mm ID

Page 11

4 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Further Information

This user guide contains all the necessary information for the effective use of this drive.

However, to gain a more in-depth understanding of drive applications and motion control,

consider attending one of our world-wide Customer Specific Training Workshops.

Examples of previous courses that have proved to be of benefit include:

Use and programming of the DIN rail H & L series drives

PDFX training

Using the 6K controller

EASI Tools programming

Mechanical product training for ET/ER, XR and HPLA

Page 12

2. MECHANICAL INSTALLATION 5

2. Mechanical Installation

Installation Requirements

Environment

ViX drives operate in a temperature range of 0° to 40°C with natural convection, or 50°C

Max with forced-air cooling (see Hardware Reference), at normal levels of humidity (5-95%

non-condensing). The drives can tolerate atmospheric pollution degree 2, which means only

dry, non-conductive pollution is acceptable.

Drive Cooling

Cooling of all drive types is by natural convection up to 40°C. To assist cooling, drives

should be installed vertically in an area where there is at least a 50mm (minimum) air gap

above and below the package and a 10mm (minimum) gap either side. Avoid mounting

heat-producing equipment directly below a drive.

Installers must ensure that the air temperature entering the drive or rising up to the drive is

within the ambient temperature restrictions. Under normal use the air temperature leaving

the drive and heatsink may be 25°C above ambient.

In the final installation, check that the ambient temperature specification of 40°C Max

(without forced air cooling) is not exceeded directly below the top-most drives and that any

circulating air flow is not being blocked from reaching the drives. For cabinet cooling

calculations, allow 20W per drive. For DIN rail mounting, see the thermal limitations

statement in Drive Mounting Options.

Page 13

6 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

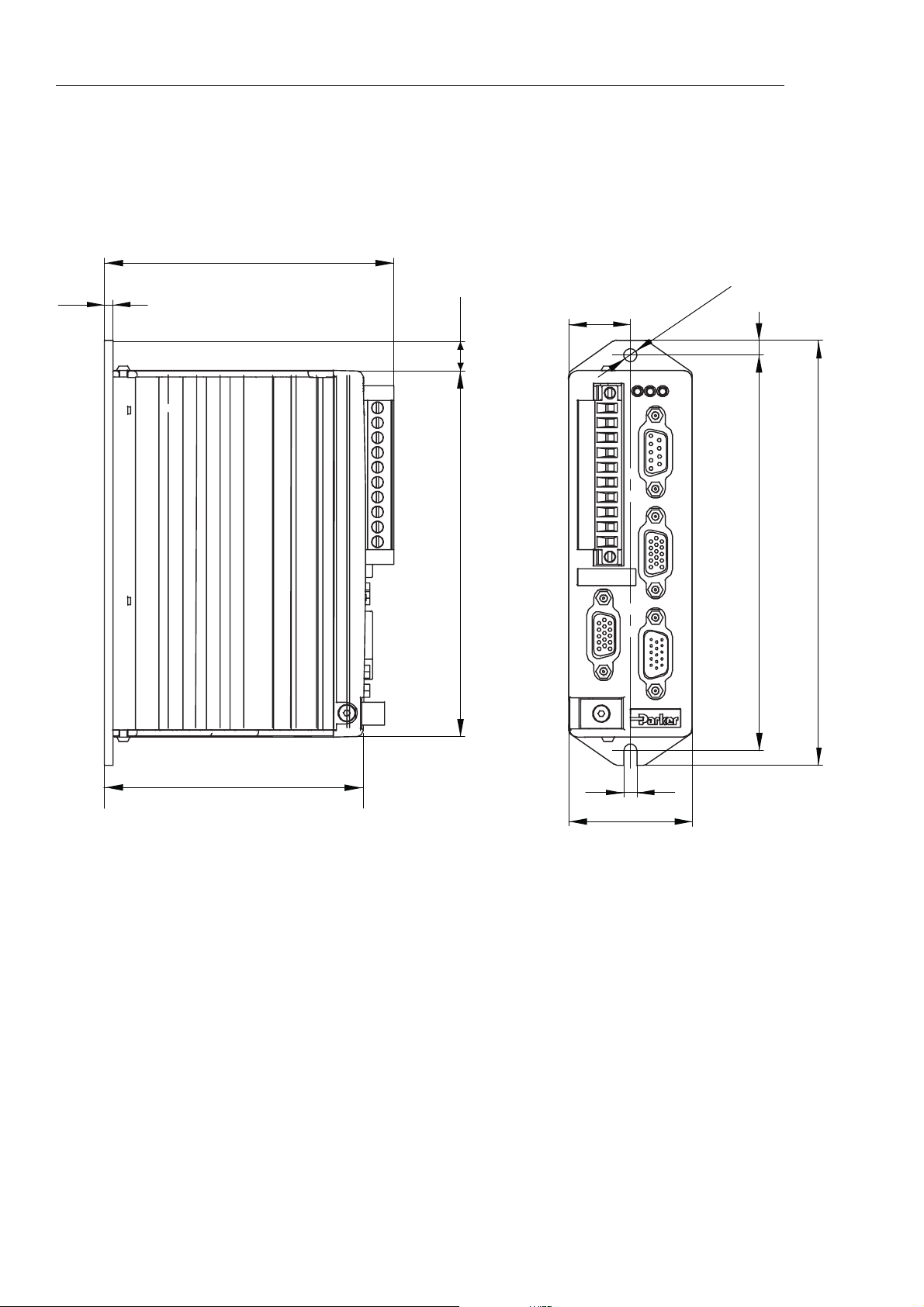

Drive Dimensions

ViX250 and ViX500 drives share the same dimensions, shown in Figure 2-1.

98.5 (with connector)

3

10.1

124.7

21

X1

X2

HVSTFB

X3

X4

X5

5

135

145

4,5

88,1

4,5

42

Figure 2-1. ViX250 & ViX500 Dimensions

Page 14

2. MECHANICAL INSTALLATION 7

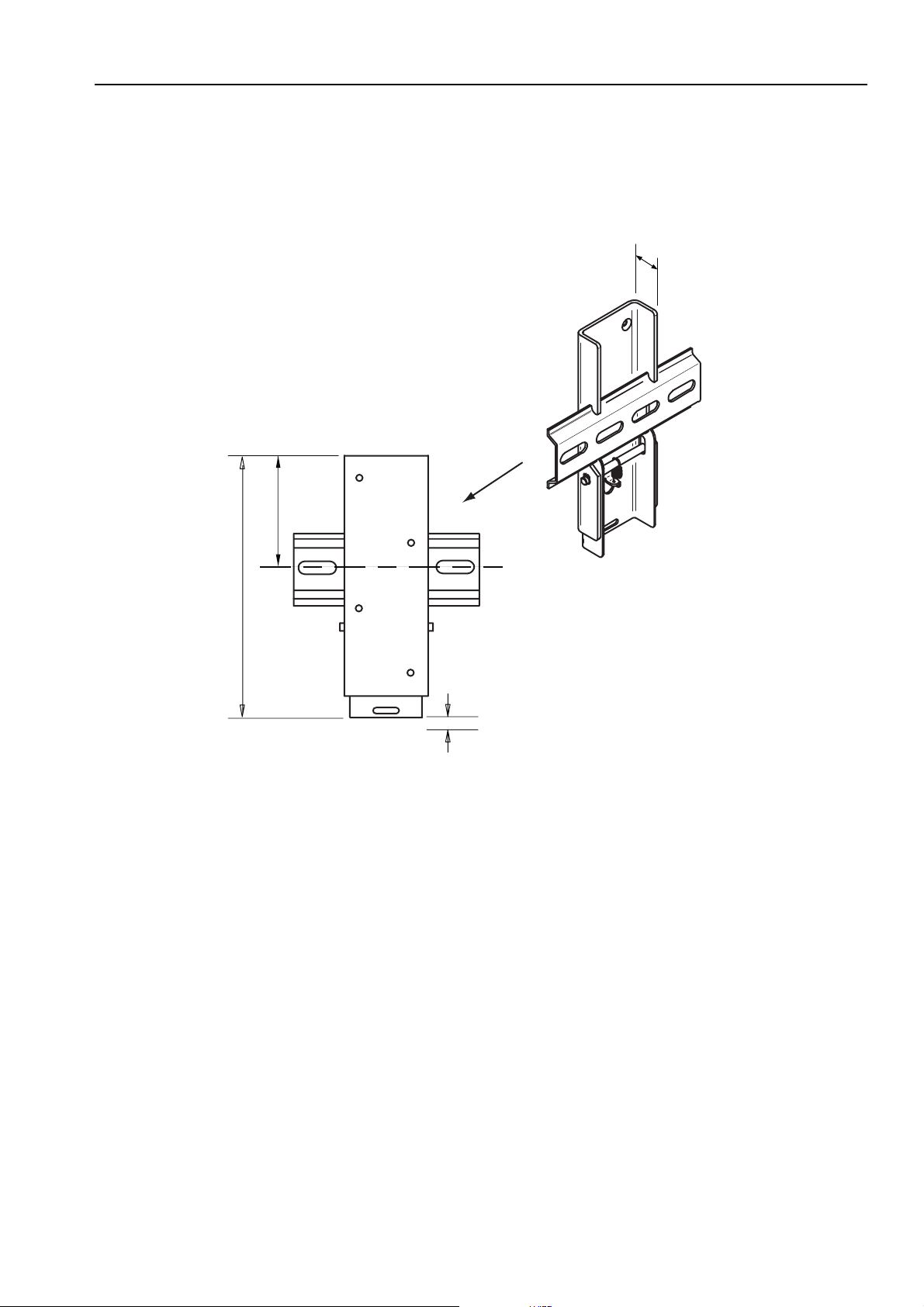

Drive Mounting Options

If you require a DIN-Rail mounting ViX drive use the optional DIN-Rail clip adapter bracket

shown in Figure 2-2.

16mm

57.2mm

Viewed from the back

131.2mm

of the DIN rail

Allow 10mm

for release

Figure 2-2. DIN-Rail Adapter Bracket

Remove the panel mounting plate from the back of the drive and attach the bracket to the

back of the drive using the screws provided. The drive and bracket can now be fixed to a

DIN rail by hooking the top of the bracket over the top of the DIN rail and gently pushing the

drive forward to engage the lower section of the bracket. Remove the bracket by inserting a

flat bladed screwdriver into the release slot to pull down the bottom of the bracket, releasing

it from the DIN rail.

Page 15

8 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Motor Mounting Mechanical Considerations

Keep motors securely fixed in position at all times. Do not test a motor/drive combination

without first securing the motor – see the Safety Warning at the front of this user guide.

CAUTION – risk of equipment damage

Do not back drive the motor, that is use the motor in an application that causes

mechanical rotation of the motor shaft in a manner uncontrolled by the drive.

Back driving the motor at high speed may damage the drive.

Page 16

3. ELECTRICAL INSTALLATION 9

3. Electrical Installation

Installation Safety Requirements

ViX stepper drives meet the requirements of both the European LVD & EMC directives when

installed according to the instructions given within this section. It is recommended the drive

be installed in an enclosure to protect it from atmospheric contaminants and to prevent

operator access while it has power applied. Metal equipment cabinets are ideally suited for

housing the equipment since they can provide operator protection, EMC screening, and can

be fitted with interlocks arranged to remove all hazardous motor and drive power when the

cabinet door is opened. Do not arrange interlocks to open circuit the motor phase

connections while the system is still powered, as this could cause damage to the drive.

Precautions

During installation, take the normal precautions against damage caused by electrostatic

discharges. Wear earth wrist straps. A switch or circuit breaker must be included in the

installation, which must be clearly marked as the disconnecting device and should be within

easy reach of the machine operator.

Cabinet Installation

To produce an EMC and LVD compliant installation we recommend that drives are mounted

within a steel equipment cabinet. This form of enclosure is not essential to achieving EMC

compliance, but does offer the benefits of operator protection and reduces the contamination

of the equipment from industrial processes.

A steel equipment cabinet will screen radiated emissions provided all panels are bonded to a

central earth point. Separate earth circuits are commonly used within equipment cabinets to

minimise the interaction between independent circuits. A circuit switching large currents and

sharing a common earth return with another low level signal circuit could conduct electrical

noise into the low level circuit, thereby possibly interfering with its operation. For this reason

so called ‘dirty earth’ and ‘clean earth’ circuits may be formed within the same cabinet, but all

such circuits will eventually need to be returned to the cabinet’s main star earth point.

Mount the individual drives and EMC filter on a metal earth plane. The earth plane will have

its own individual star point earth which should be hard wired (using an insulated copper

conductor) back to the cabinet’s ‘clean earth’ connection point.

LVD - Low voltage directive

EMC – Electro Magnetic Compatibility directive

Page 17

10 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Power Supply Connections

Power drives from a DC supply derived from an isolating transformer or a DC power supply

(See Power Supply Options later in this section).

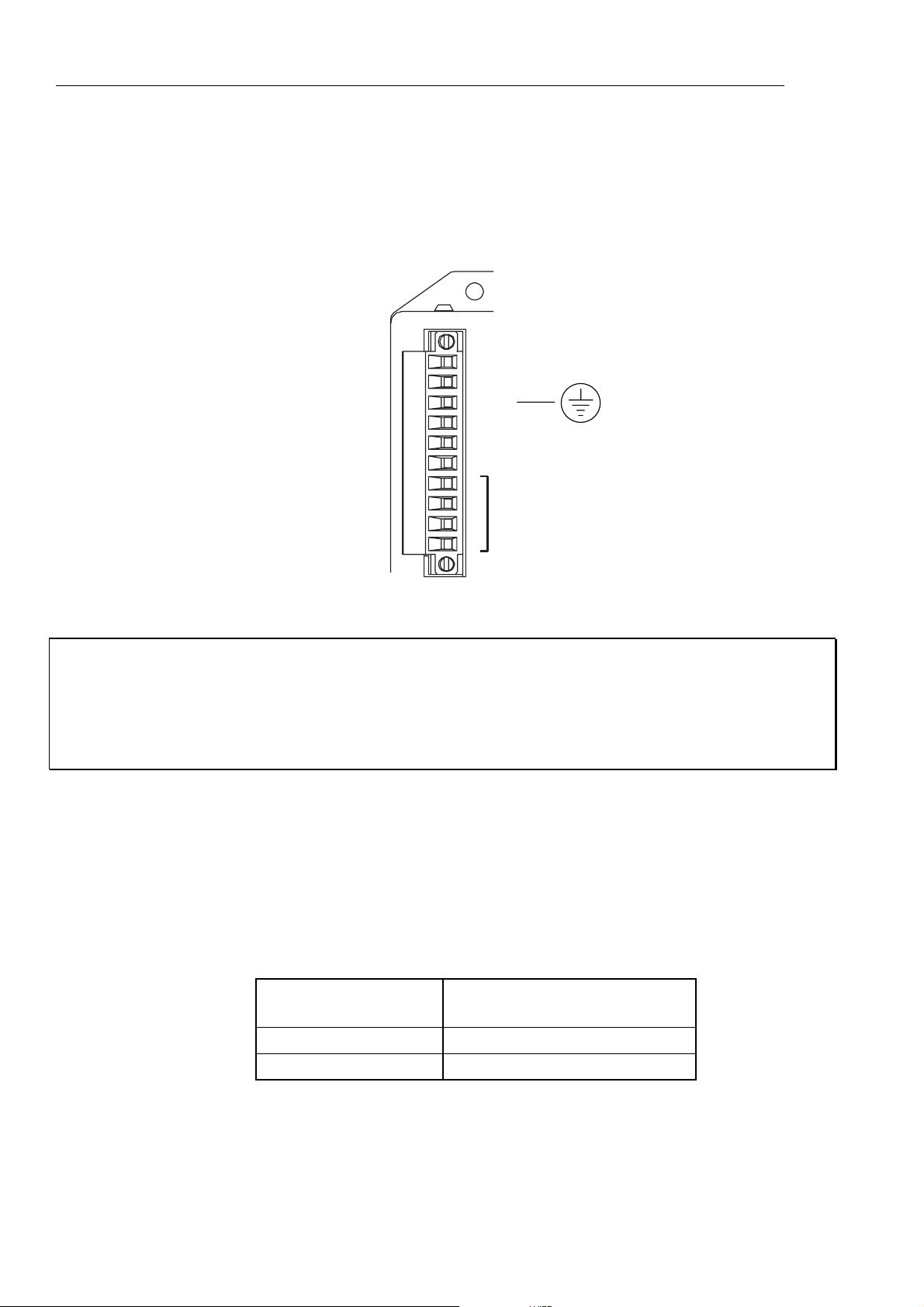

Note: Pin 10 is at the top of the connector X1 and pin 1 at the bottom.

Power & motor

10-way

connector

X1

10

+HV

9

8

7

6

5

4

3

2

1

-HV

PE

+24V DC

0V (GND 24v DC)

GND

MOTOR

CONNECTIONS

Figure 3-1. X1 Power Connections

WARNING – Possible drive damage

If you use Parker XL Series stepper drives, do not attempt to use any power wiring

harness taken from an XL drive. Although the same mating connector is used for

both an XL and a ViX, the ViX wiring is the reverse of the XL and the wrong wiring

connection will damage the drive.

Mating connector type is: Wieland 8213B/10 F OB, Part number 25.323.4053.0 (Parker part

number 0405.811).

Supply Requirements

Power the ViX drives from DC supplies as specified below:

Volts

Drive Type DC Supply Voltage

between +HV and -HV

ViX500 48V to 80V (recommended)

ViX250 24V to 80V

Table 3-1. Drive Supply Voltages

Page 18

3. ELECTRICAL INSTALLATION 11

WARNING

The drive HV supply input is not reverse polarity protected.

Reverse polarity connections will damage the drive.

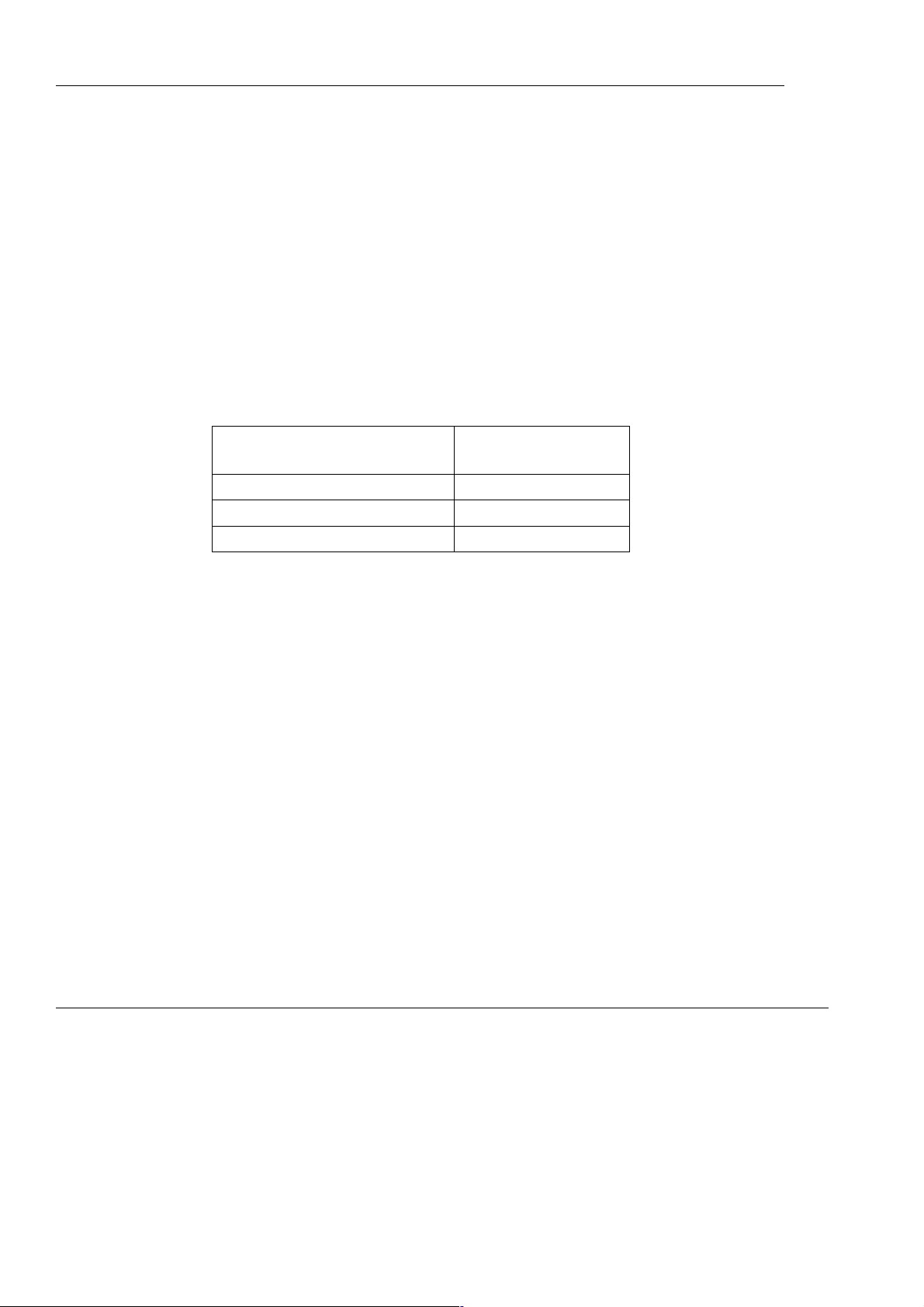

Current and Capacitance

A supply must have a minimum amount of capacitance to support a drive at peak power

draw.

Drive Type DC Supply Current Supply Capacitance

ViX500 5.6A RMS

ViX250 2.8A RMS

Table 3-2. Drive Supply Currents

6600µF

3300µF

+24V Requirements

Both drive types require a +24V controller and logic supply. The supply may also be

required for an encoder and a Fieldbus Expansion Module (FEM).

Absolute voltage range 20 to 27V

Nominal drive current 250mA (excluding encoder, & FEM)

Encoder supply loading 150mA (if required)

FEM current 50mA

Safety Earth Requirements

Earth the drive using the earth pin on X1 (pin 8).

Power Supply Options

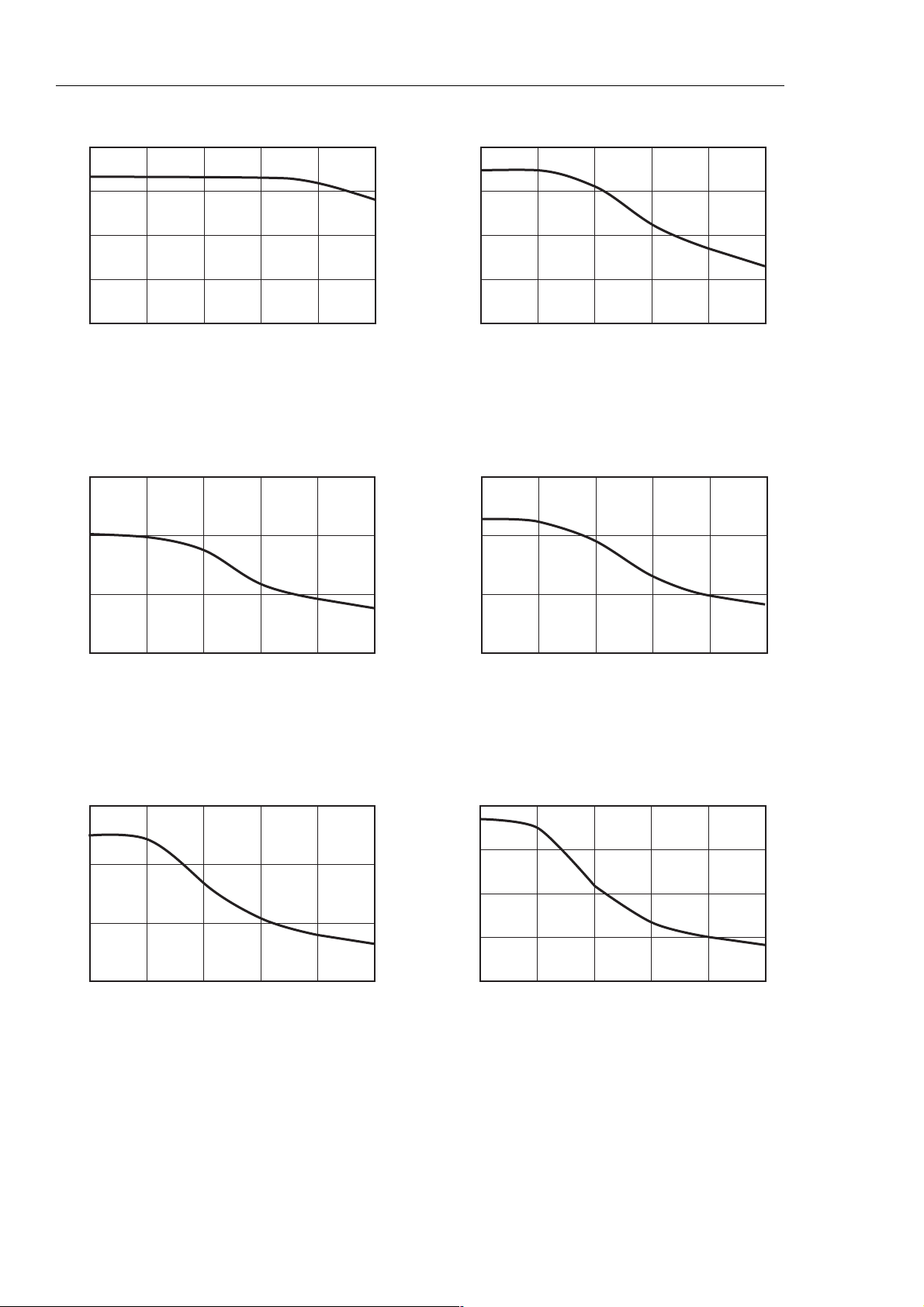

A set of torque curves (Figure 3-2) for various motor/drive combinations can be used for

calculating an applications likely power requirements.

Higher torque/current requirements will need to use the ViX500 drive and a high current

linear supply, such as the PL1100. Further power supply information is given in Appendix A.

Page 19

12 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

N

N

N

mNm

0.4

0.3

0.2

0.1

0

0

ViX250 with SY561

10 20 30 40 50

0.8

0.6

0.4

0.2

0

0

ViX250 with SY562

10 20 30 40 50

Speed, revs/sec Speed, revs/sec

mNm

1.5

1.0

ViX500 with SY563

1.5

1.0

ViX250 with SY871

0.5

0

0

10 20 30 40

50

0.5

0

0

10 20 30 40 50

Speed, revs/sec Speed, revs/sec

mNm

3.0

2.0

1.0

0

0

ViX500 with SY872

10 20 30 40 50

4.0

3.0

2.0

1.0

0

0

ViX500 with SY873

10 20 30 40 50

Speed, revs/sec Speed, revs/sec

Figure 3-2. Stepper Drive Torque/Speed Data

Page 20

3. ELECTRICAL INSTALLATION 13

XL-PSU Power Supply

The XL-PSU is a 250W, power factor corrected, switched mode power supply. Designed for

direct operation from world wide single phase AC input voltages, the supply is capable of

powering up to two ViX250 drives (see note 1) without the need for an EMC mains input filter

(see note 2). The use of the XL-PSU offers the following benefits:

• Auto-adapts to supplies between 95 and 264V AC

• No external EMC filter required

• Compact size

• Built-in +24V DC supply

Note 1: Check the application’s power requirements from the torque/speed curve of the

motor used.

Note 2: For drives with up to 30 metre motor leads.

For full installation instructions see the XL Power Supply leaflet 1600.300.XX.

Page 21

14 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

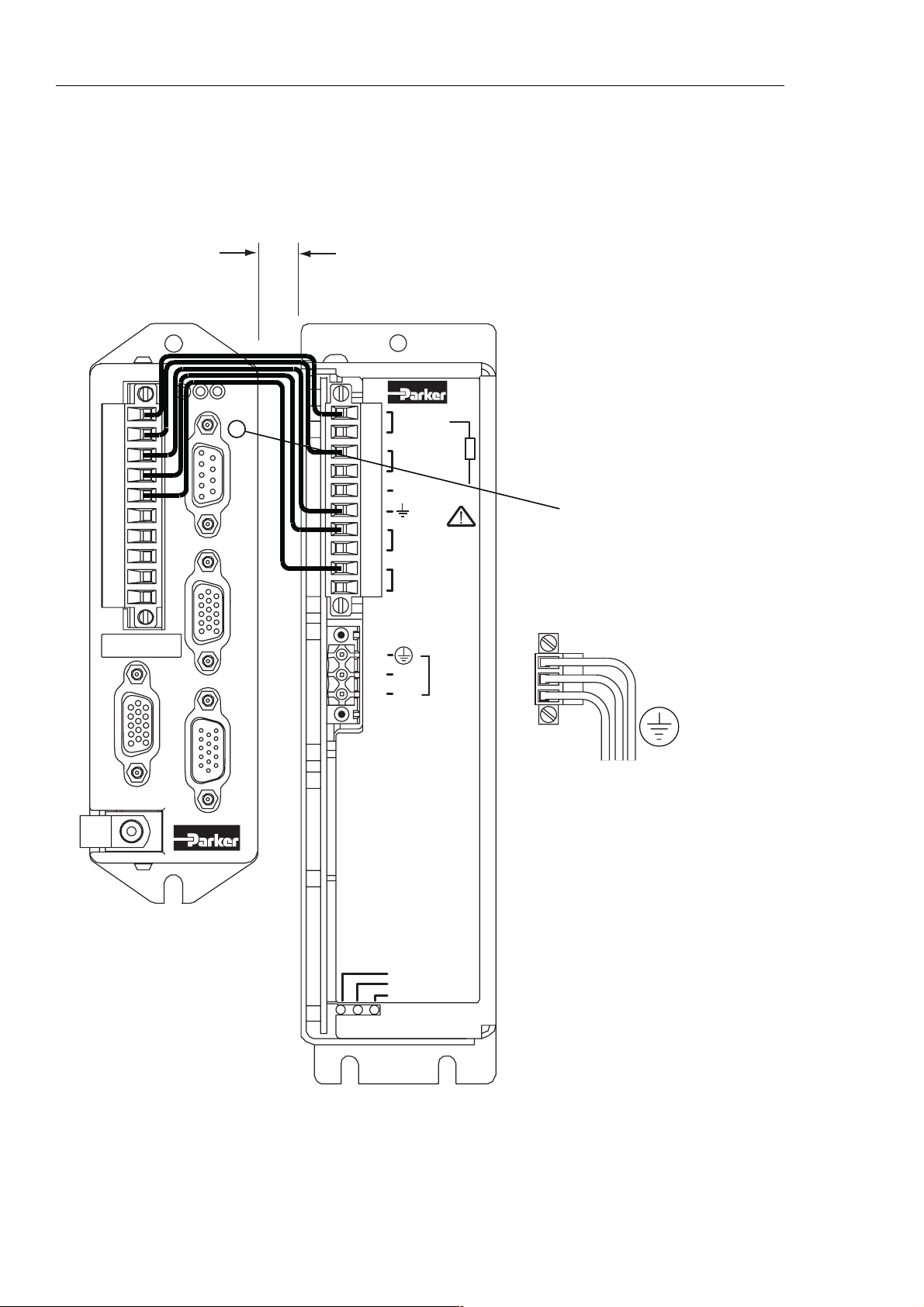

XL-PSU Supply/Drive Connections

When used to supply up to two drives the power supply can be wired as shown in Figure 3-3.

X1

10

1

ST

HV FB

X3

X4

10 mm

Mininum spacing

between drives & PSU

1

+DC (80V)

-DC

EXT. BRAKING RES.

+24V

GND

10

If the supply is positioned

this side of the drive

avoid blocking access to

D-type X3

P1

P2 mating socket

X2

MAINS

N

INPUT

X5

L

110V-230V~

50/60 Hz

250VA

P2

XL

Power

Supply

Unit

HV STATUS

BRAKING RES.

24V STATUS

Figure 3-3. XL Power Supply and Drive Connections

LN

EARTH (GND.)

The XL_PSU must

be securely earthed

Note: A kit of five connecting links is available, called ‘XL-connect’. You will need one kit for

every drive.

Page 22

3. ELECTRICAL INSTALLATION 15

XL-PSU Mounting Information

Mount the supply vertically, near the drives it will supply. Both the top 4.5mm diameter fixing

hole and the bottom two 4.5mm width fixing slots should be used.

Allow a minimum free space of 50mm both below and above its case and 10mm free space

on both sides.

Do not mount the supply above or close to other products that generate a significant amount

of heat by radiation or convection.

Page 23

16 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

PL1100 Power Supply

General Description

The PL1100 is a linear power supply with a rated output of 1120W (80V/14A) for use with

ViX and XL series drives. The supply requires a suitably rated transformer supplying 50V

AC RMS for the HV and 20V AC RMS for the +24V DC. The use of the PL1100 offers the

following benefits:

• Provides 80V HV and +24V DC output

• Single or three phase operation

• Built-in power dump switch

• Integral fusing

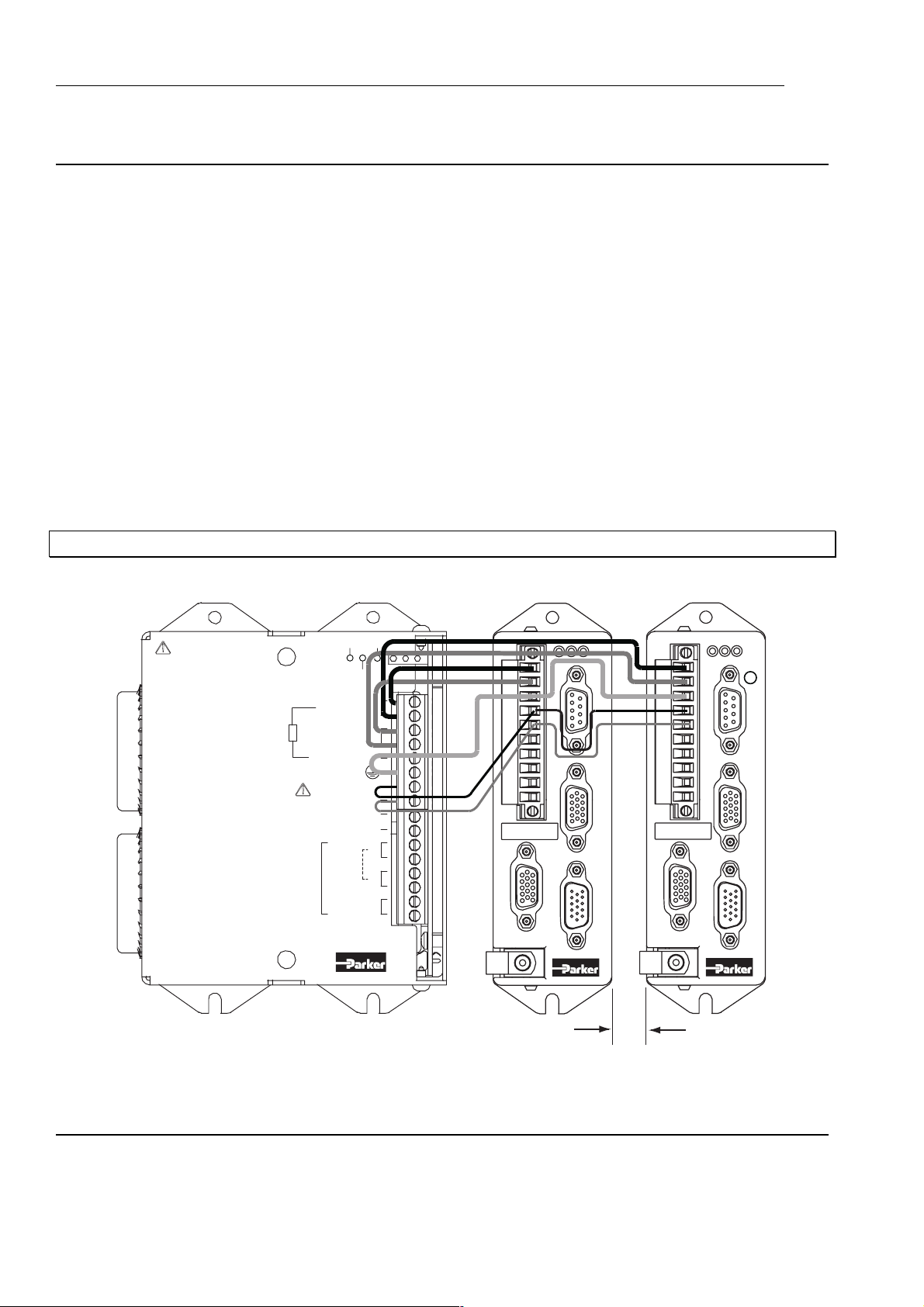

Figure 3-4 shows the PL1100 output wiring for two ViX drives. This illustrates how to route

the main HV supply separately to each drive. The lower current requirements of the +24V

logic/brake supply can allow the wiring to be linked between drives.

For full installation instructions see the PL1100 Power Supply leaflet 1600.323.XX.

ST

CAUTION

Risk of electric shock.

High voltage remains on terminals

after power is removed.

Allow 5 minutes for capacitors

to discharge.

PL1100

Power Supply

55V

AC IN

1/3 PH.

HV

REGEN

X1

MOTOR HV OUT

MOTOR 0V.

EXT. BRAKING RES.

PE

+24V DC OUT

20V AC IN

20V AC IN

LINK

FOR

SINGLE

PHASE

X2

+24V

0V

L3

L2

L1

X1

X2

ST

HV FB

10

X3

X4

1

X5

X1

10

X2

HV FB

X3

X4

1

X5

10 mm MIN

Figure 3-4. PL1100 Power Supply and Drive Connections

Page 24

3. ELECTRICAL INSTALLATION 17

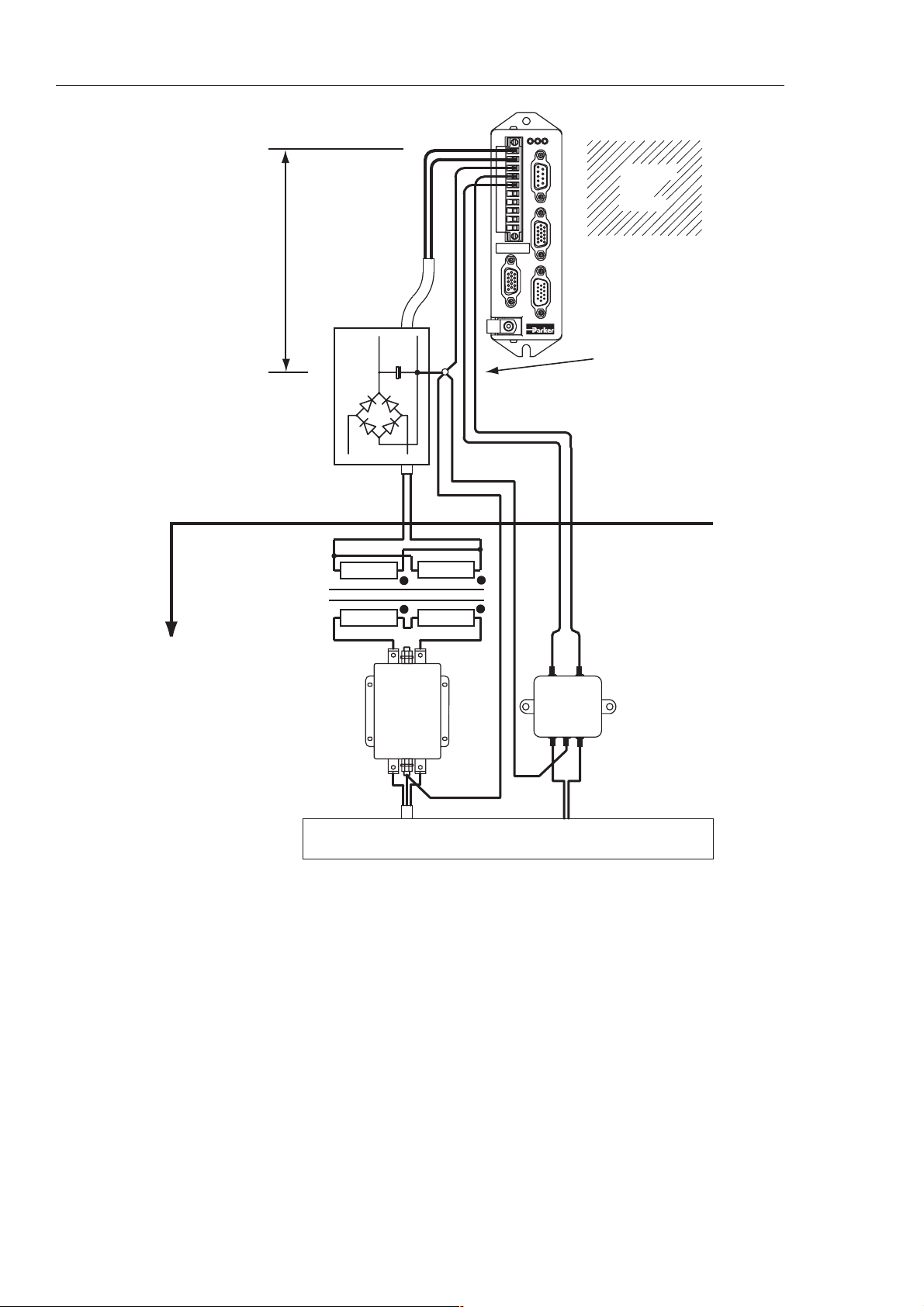

EMC Installation

These EMC installation recommendations are based on the expertise acquired during the

development of compliant applications, which Parker believes are typical of the way, a drive

or drives may be used. Provided you have no special installation requirements or untypical

operating environment requirements, ViX drives will conform to current EMC Directives, as

defined at the front of this user guide.

General Requirements

ViX mounted drives, unless used with an XL-PSU, will require an EMC supply filter to meet

EMC installation compliance requirements. Mount the drive on a conductive panel which is

shared with the EMC filters. If the panel has a paint finish, it will be necessary to remove the

paint in certain areas to ensure filters and drive make a good large-area metal to metal

contact between filter case and panel.

Mount filters close to the drive and keep the supply wiring as short as practical. Attempt to

layout the wiring in a way that minimises cross coupling between filtered and non-filtered

conductors. This means avoiding running wires from the output of a filter close to those

connected to its input. Where you wish to minimise the cross coupling between wires avoid

running them side-by-side one another, if they must cross, cross them at 90° to each other.

Keep wiring supported and close to cabinet metalwork.

Recommended EMC filter types are CORCOM 6FC10 for loads up to 6A and 3VK1 for the

+24V supply up to 3A. Multi-axis systems may require higher current rated filters.

+24V Supply Connections

ViX drives not using an XL-PSU will require a logic supply of +24V DC at 250mA (nominal)

per drive. The +24V powers the controller and I/O circuits. Keeping the +24V independent

of the drive’s internal high voltage bus supply allows the option of keeping the I/O and

controller active when no main supply is present.

Connect the +24V supply to X1 pin7 and the return to X1 pin6, the total wire length, from

supply to drive, must not exceed 10m.

Connect the +24V supply 0V line to system earth (0V) at some convenient point before the

EMC filter input, as shown in the recommended EMC layout diagram, Figure 3-5.

The 24V supply to each drive should be fitted with a time-delay fuse, rated at 3A. Note: The

+24V supply used must meet the voltage requirement specification of +24V DC +10% -15%,

ripple <1V p-p.

Page 25

18 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

ST

HV FB

X1

10

X3

Lead length

restriction

(less than 1 metre)

DC Supply

X4

1

X2

X5

CABINET

BACK

PLANE

Star earth point

to the metal

backplane

Located in

the base of

the cabinet

Transformer

AC Supply

CORCOM

Figure 3-5. ViX EMC Installation

(load)

Output

6FC10

(line)

Input

Power wiring conduit

LOAD

3VK1

LINE

+-

DC 24V Supply

Page 26

3. ELECTRICAL INSTALLATION 19

Motor Connections to the Drive

The recommended wire size for ViX250IM/500IM motor cables, of length less than 20m, is

1mm2. For motor cable lengths greater than 20m (up to a maximum of 50m) use a wire size

of 2.5mm

34805), the green wire being used to provide an earth return to the drive. Termination at the

motor must be made using a 360° bond to the motor body, and this may be achieved by

using a suitable clamp. Many stepper motors are designed to accommodate an appropriate

terminal gland which can be used for this purpose.

At the drive end of the cable, a 360° connection to the screen should be made using the

P-clip provided beneath the motor connector. The P-clip needs to be firmly clamped to the

copper braid. If the connection appears loose, fold the braid back on itself to increase the

amount of braid under the clip and re-tighten.

Custom cables will require the cable insulation to be removed to expose the braided screen.

If you are using a motor cable with 2.5mm

9mm to accommodate the increased cable diameter. A ferrite absorber, with a specification

matching that of the Chomerics H8FE-1115-NC, is also required to be positioned on the

motor cable using heat shrink sleeving or cable ties. The position of the absorber should be

within 150mm of the drive. Always secure the cable using the P-clip, as shown. Do not rely

upon the connector alone holding the motor cable in place. Avoid stress on the X1

connector by hanging cables, as this may lead to connector over-heating.

2

. Use a cable containing five conductors plus the braided screen (such as Lapp

2

conductors the size of the P-clip will need to be

Make a 360° connection to the screen using one of the stainless steel or brass P-clips

supplied within the fit kit.

Size Parker part number

9mm ID 4216.101

10.7mm ID 4216.102

12.3mm ID 4216.103

Table 3-3. P Clip sizes

Three different size ‘P’ clips allow the use of a variety of motor power cables from different

manufactures.

There must be no break in the 360° coverage that the screen provides around the cable

conductors. If a connector must be used it should retain the 360° coverage, possibly by the

use of an additional metallic casing where it passes through the bulkhead of the enclosure.

The cable screen must not be bonded to the cabinet at the point of entry. Its function is to

return high-frequency chopping current back to the drive. This may require mounting the

connector on a sub-panel insulated from the main cabinet, or using a connector having an

internal screen which is insulated from the connector housing. Within the cabinet itself, all

the motor cables should lie in the same trunking as far as possible. They must be kept

separate from any low-level control signal cables. This applies particularly where the control

cables are unscreened and run close to the drive.

Page 27

20 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Note that the motor cable routing within the equipment cabinet should be kept at least

300mm away from I/O cables carrying control signals.

All motor connections must be made using a high quality braided-screen cable. Cables

using a metallised plastic bandage for an earth screen are unsuitable and in fact provide

very little screening. Care must be taken when terminating the cable screen, the screen

itself is comparatively fragile; bending it round a tight radius can seriously affect the

screening performance. The selected cable must have a temperature rating which is

adequate for the expected operating temperature of the motor case.

Motor Cables

Motor cables may be ordered using the part numbers listed in Table 3-4.

Product code/Part

number

STC20-0300 3

STC20-0500 5

STC20-1500 15

Table 3-4. Motor Cables

Length (metres)

Motor Phase Contactors

We recommend that motor phase contactors are not used within the motor power cables. As

an alternative, make use of the drive’s power stage ‘enable’ control signal.

Ferrite absorber specifications

The absorbers described in these installation instructions use a low-grade ferrite material

that has high losses at radio frequencies. They therefore act like a high impedance in this

waveband. Produced by Parker Chomerics, the recommended component is suitable for use

with cable having an outside diameter up to 10mm. The specification is as follows:

Chomerics part number H8FE-1115-NC (Parker part number 0313.020)

Outside diameter 17.5mm

Inside diameter 10.7mm

Length 28.5mm

Impedance at 25MHz 80 ohm

Impedance at 100MHz 120ohm

Curie temperature 130°C (the device should not be operated near this temperature)

Page 28

3. ELECTRICAL INSTALLATION 21

Motor Selection

Usually optimum performance will be obtained when the current rating of the motor is

between 1 and 1.5 times the drive rating. Drives can be de-rated to accommodate motors

with lower current ratings (using variable MC within the MOTOR command), however the

high speed torque will be reduced.

Do not use a drive setting which gives an output current greater than the motor rating.

With 4 lead motors the bipolar rating is quoted and this should match the criteria stated

above.

With 8 lead motors the bipolar rating of the motor, which is normally quoted, refers to a

parallel winding connection. With the windings connected in series the current rating of the

motor connection will be 50% that of the bipolar rating, and the motor will give improved lowspeed torque, but reduced high-speed torque.

The ViX250IM/ViX500IM will drive motors having an inductance as low as 0.5mH and as

high as 20mH, but the recommended motor inductance range is between 0.8mH and 10mH.

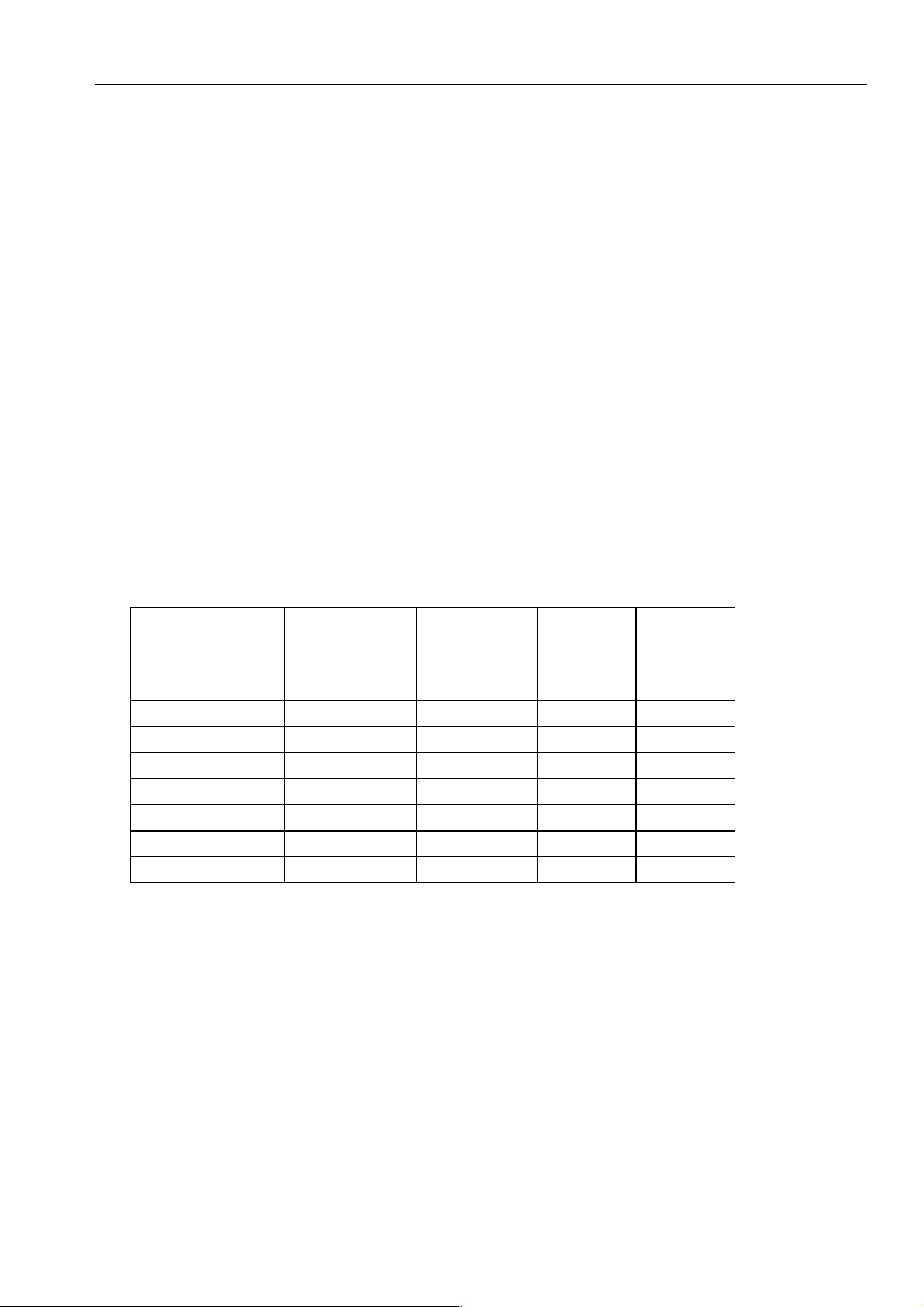

Performance of the ViX250/ViX500IM is optimised for the following motor types, listed in

Table 3-5.

Motor Type Motor Rated

Current in

Amps*

SY561 4.2 1.0

SY562 4.2 2.6

SY563 6.5 1.2

SY871 4.2 1.6

SY872 6.5 1.5

SY873 8.4 1.7

SY1072 8.0 2.4

*(parallel connection)

Table 3-5. SY Optimum Motor Types

Motor Voltage Ratings

Motors with a withstand voltage rating from phase to earth of 1000V AC should be used. An

insulation withstand rating of 500V AC is acceptable if an isolating transformer with earthed

screen is used to power the system, and 0V input is earthed, as specified.

Motor

Inductance

in mH per

phase*

ViX500IM ViX250IM

✔

✔✔

✔

✔✔

✔

✔

✔

Page 29

22 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Large Motors

The largest recommended motor size is a 34-frame 3-stack. Please contact Parker if

you wish to use a larger frame motor.

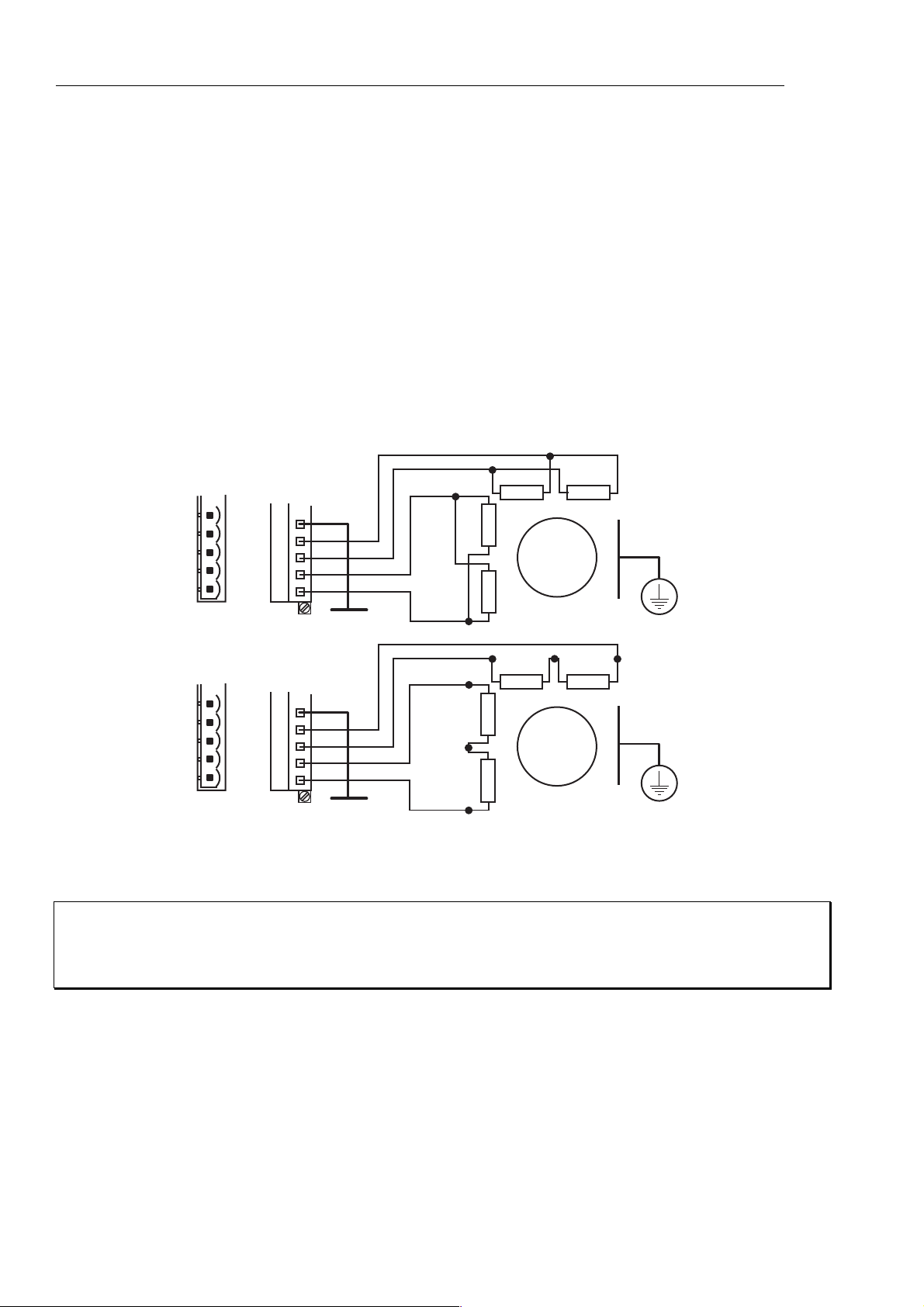

Motor Connections at the Motor

Motor connections should be made directly between the drive and motor, the use of any

switching devices, such as contactors is not recommended.

In the majority of applications the drive will be used with an eight lead motor with the

windings connected in parallel or series, as shown in Figure 3-6. Motor connections will

need to be determined from the motors data sheet or Appendix B. These are normally

identified by wire colour or terminal markings, depending upon the make of the motor.

+

-

+

MOTOR CONNECTOR

X1

5

4

3

2

1

Gnd

A+

AB+

B-

Motor case

-

+

-

+

-

MOTOR

PARALLEL

CONNECTIONS

SAFETY

EARTH

MOTOR CONNECTOR

X1

5

4

3

2

1

Gnd

A+

AB+

B-

Motor case

-

+

-

+

-

SERIES

CONNECTIONS

MOTOR

SAFETY

EARTH

+

-

+

Figure 3-6. 8 Lead Motor Connection Options

WARNING - High Temperature

The motor case temperature may exceed 70°C and should be guarded from operator

contact.

Motor Safety Earth/Ground Connection

It is recommended that the motor is independently bonded to a local safety earth point. The

safety earth lead should be at least 2.5mm

2

in area.

Page 30

3. ELECTRICAL INSTALLATION 23

Custom Motor Set Up

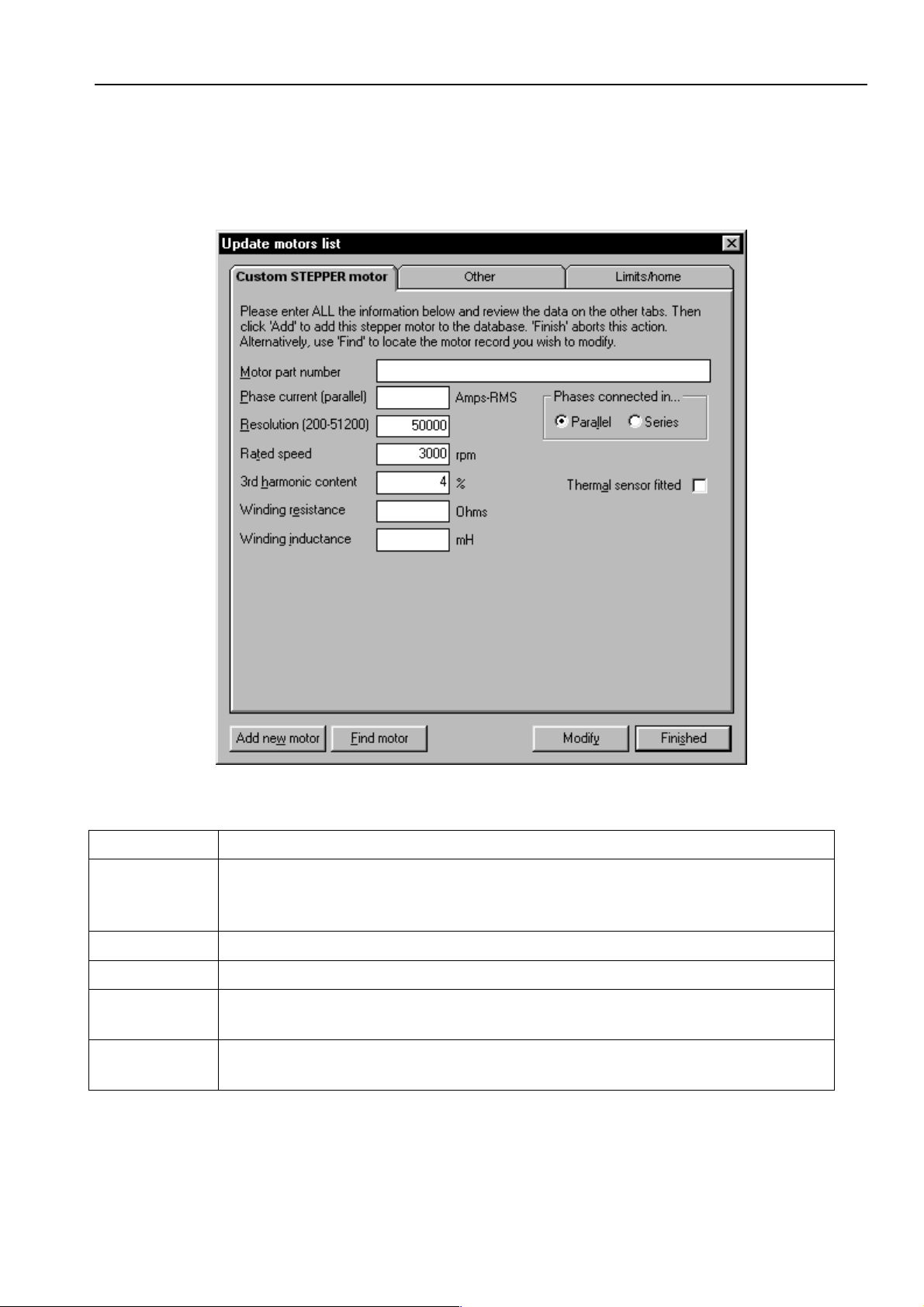

Within screen 2 of Guided stepper initialisation, clicking upon the Setup custom button will

open the window shown in Figure 3-7.

Figure 3-7. EASI-V Custom Motor Configuration Window

Motor the general name/number for the motor.

Phase

current

(parallel)

Resolution number of steps per revolution

Rated speed shaft speed in rpm for a rotary stepper.

Winding

resistance

Winding

inductance

continuous current rating of the motor in Amps RMS.

resistance of a single phase winding measured line-to-line in Ohms.

inductance of a single phase winding measured line-to-line in mH.

Page 31

24 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

The Other Parameters Tab

Selecting the Other parameters tab gives you access to the screen shown in Figure 3-8.

Figure 3-8. EASI-V Custom Motor Other Parameters

In-position

time (IT)

Digital I/O The decimal number required by the IC system variable to configure the

input/output state of the drive.

Page 32

3. ELECTRICAL INSTALLATION 25

Figure 3-9. EASI-V Custom Motor Limits/home Parameters

Limit inputs Four radio buttons used to configure the limit inputs.

Limit

switches

Home

enabled

Home

reference

edge

Home switch Defines the type of home switch used, normally open or closed.

Direction

+ velocity

Acceleration Acceleration of the motor in revs/s/s.

Homing

mode

Selection of normally closed or normally open limit switches.

Enable/disable the HOME command.

Select the required edge of the home switch where you wish the home

position to be.

Required direction and velocity. Positive direction commands must

produce movement towards the positive limit.

Homing mode selection – see sub-section on homing for an explanation

of these modes.

Page 33

26 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Motor Voltage Ratings

Motors with a withstand voltage rating from phase to earth of 1000V AC should be used. An

insulation withstand rating of 500V AC is acceptable if an isolating transformer with earthed

screen is used to power the system, and X1 pin9 (0V/GND) input is earthed, as specified.

Motor Safety Earth/Ground Connection

It is recommended that the motor is independently bonded to a local safety earth point. The

safety earth lead should be at least 2.5mm2 in area.

Short Circuit Protection

The motor outputs are protected against overload and short circuits.

Page 34

Power & Motor

X1

24-80V DC +HV

10

0V / GND -HV

9

8

Earth PE

7

24V DC

0V (GND 24v DC)

6

Motor Gnd

5

Motor phase (A+)

4

Motor phase (A-)

3

Motor phase (B+)

2

1

Motor phase (B-)

Feedback, Digital encoder

Function

X2

Feedback enc. Z+

1

Feedback enc. Z-

2

GND

3

4

Reserved

+5V output

5

GND

6

7

Feedback enc. AFeedback enc. A+

8

Reserved

9

10

Motor overtemp

Feedback enc. B-

11

12

Feedback enc. B+

Reserved

13

Reserved

14

Reserved

15

Protective Earth

PE

Power & motor

10-way

connector

Motor Earth

ME

Primary

encoder

15-way

socket

Fixing position

for motor lead

earth clip, included

in fit kit

X1

X2

1

5

10

3. ELECTRICAL INSTALLATION 27

A range of

mating connectors

are supplied, depending

upon the type of fit-kit

ordered.

ST

HV FB

X3

1

5

X4

1

1

5

6

X5

11

5

15

1

10

RS232

6

9-way

socket

9

6

11

Control/Aux I/O

15-way

socket

15

10

10

15

User I/O

15-way

plug

11

6

RJ45 connectors

8

X7 (OUT)

1

8

X6 (IN)

1

High speed

comm.

Interface

Communications

Function

X3

Rx+/Tx+ (RS485)*

1

2

Drive reset

RS232 GND

3

4

RS232 Rx

RS232 Tx

5

Rx-/Tx- (RS485)*

6

7

RS232 Tx (D loop)

8

Do not connect

+5V output

9

*requires CAN option

Control/Aux I/O

Function

X4

ANA1+ IN

1

ANA1- IN

2

0V

3

4

0V

+5V output

5

Fault output

6

Enc. A-/Step- IN

7

Enc. B-/Dir- IN

8

9

Enc. A- OUT

10

Enc. B- OUT

11

Energise/Shutdown*

12

Enc.A+/Step+ IN

13

Enc. B+/Dir+ IN

Enc. A+ OUT

14

Enc. B+ OUT

15

*Active high/low mode configurable

using system variable ES

User I/O

Function

X5

0V

1

0V

2

0V

3

4

Output 2

Output 1

5

Input 5 (limit+)

6

7

Input 4 (limit-)

Input 3 (Home)

8

9

Input 2 (Reg)

10

Input 1 (stop)

+24V

11

12

+24V

13

+24V

Output 3

14

Reserved

15

Figure 3-10. ViX Connector Pin Layout

Page 35

28 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Terminal Description

X1 Connector

X1 is the main power and motor connector. Both HV, +24V and the motor phase

connections are made to X1.

Connector Type

The mating connector for X1 is a Wieland 8213B/10F, part number 25.323.4053.0 (Parker

part number 0405.811). An approval marked version of this connector has the part number

25.323.1053.0.

Connector Pin Out

Connector Pin X1 Signal Name

10 24 to 80V DC +HV

9 0V/GND -HV

8 Earth PE

7 24V DC

6 0V (GND for 24V DC)

5 Motor Earth

4 Motor phase (A+)

3 Motor phase (A-)

2 Motor phase (B+)

1 Motor phase (B-)

Table 3-6. X1 Power and Motor Connections

Motor Connections at the Drive

Refer to the EMC installation information earlier in this section.

Page 36

3. ELECTRICAL INSTALLATION 29

X2 Connector

X2 provides the primary input connections for the motor feedback device. This is the input

that should be used for position maintenance and stall detection functions.

Connector Type

Connector type is a high-density 15-way D-type socket.

Connector Pin Out

Connector

Pin X2

1 Feedback enc. Z+

2 Feedback enc. Z3GND

4 reserved

5 +5V output

6GND

7 Feedback enc. A8 Feedback enc. A+

9 reserved

10 Motor overtemp+.

11 Feedback enc. B12 Feedback enc. B+

13 reserved

14 reserved

15 reserved

Primary Encoder

Table 3-7. X2 Primary Feedback Connections

Encoder Compatibility for X2 & X4

Incremental channels Input specification

Signal format quadrature 5V differential signals (A+, A-, B+, B-) index mark (Z+, Z-).

Maximum digital encoder input frequency 2.0MHz pre quad, 8.0 MHz post quadrature.

Maximum encoder supply current 350mA.

Page 37

30 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Motor Overtemperature Sensor

Standard Parker stepper motors do not use an over-temperature sensor, however when

using custom motors provision is made for the connection of either a thermal switch or

thermistor device. The following devices are supported:

• Thermik SNM130ES

• Cantherm F11 110-2-5 U106

Other ptc thermistors with a switch like characteristic are supported to DIN44081/44082.

The input requires a normally closed switch to be connected to GND on X2 pin 3 or 6.

If you use a custom motor with no overtemperature sensor fitted, make sure you leave the

‘Thermal sensor fitted’ check box un-checked in the Custom Motor Set Up screen, within

Easi-V to prevent an overtemperature fault being reported. This is the default setting in

Easi-V.

X3 Connector

X3 is the RS232/RS485 communications connector. RJ45 connectors X6 and X7 may also

be used for inter-drive communications where multi-axis systems are used.

RS485 Operation

RS485 operation is only possible on drives fitted with the appropriate FEM (Fieldbus

Expansion Module). If you require this feature please order the ViX – CM drive type.

Connector Type

Connector type is a 9-way D-type socket.

Connector Pin Out

Connector Pin X3 Function

1 Rx+/Tx+ (RS485)

2

3 RS232 GND

4 RS232 Rx

5 RS232 Tx

6 Rx-/Tx- (RS485)

7 RS232 Tx (D loop)

8 Do not connect

9 +5V output

drive reset

Table 3-8. X3 RS232/RS485 Connections

Page 38

3. ELECTRICAL INSTALLATION 31

Baud Rate

Use system variable BR to alter the baud rate of serial communications. Any change made

to the baud rate will only take effect following a save (SV) and system reset or power cycle.

Reset to RS232 Mode

To reset the drive to RS232 mode and to return to factory settings, remove power from the

drive, connect X3 pin 2 to GND and restore power.

CAUTION

This will erase ALL of your user settings and programs in volatile memory. The non-

volatile memory will not be overwritten until a save command is issued.

Terminal/PC

GND

Rx

Tx

CONN.

SHELL

Terminal RS232 socket Interface

Back of

mating plug

13

1425

PC RS232 socket Interface

Back of

mating socket

1

5

9

6

Back of

mating plug

1

Serial connector

socket

Back of

mating plug

Serial connector

plug

Drive

1

5

X3 Socket

1

5

X3 Socket

GND

Rx

Tx

CONN.

SHELL

6

9

6

9

SERIAL

2 Tx

3 Rx

7 GND

3 Tx

2 Rx

5 GND

X3

4 Rx

5 Tx

3 GND

X3SERIAL

4 Rx

5 Tx

3 GND

Figure 3-11. X3 D-type Connector RS232 Connections

Inter-drive RS232 Connections

Use the RJ45 connectors X6 and X7 to inter-connect drives, see RS232 Daisy Chain later in

this section. Always make the primary connection via D-type X3.

Page 39

32 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

RS232 Connecting Leads

RS232 cables can be ordered from Parker. Various lengths are available as listed in

Table 3-9.

Part Number Length

RS232-EASI-0250 2. 5m

RS232-EASI-0500 5.0m

RS232-EASI-0750 7.5m

RS232-EASI-1000 10.0m

RS232-EASI-1250 12.5m

RS232-EASI-1500 15.0m

Table 3-9. RS232 Connection Lead Types

X4 Connector

Connector X4 gives access to the following encoder input and output signals and the

differential analogue inputs. Certain input and output connections are dependent upon the

state of system variables EO (Encoder Output) and EI (Encoder Input). Encoder output

signals are not generated internally by the drive, they mirror the state of the feedback

encoder inputs (if present). Use encoder connection X2 for position maintenance and stall

detection feedback.

Connector Type

Connector type is a high-density 15-way D-type socket.

Connector Pin Out

Connector Pin X4 Encoder I/O

1 ANA1+ (input)

2 ANA1- (input)

30V

40V

5 +5V output

6 Fault

11 Energise/Shutdown_bar* (input)

*See system variable ES

Table 3-10. X4 Encoder I/O Connections

Page 40

3. ELECTRICAL INSTALLATION 33

Inputs Depending Upon the State of System Variable EI

Connector Pin

EI=0 EI=1 EI=2

X4

12 STEP+ CW+ A+

7 STEP- CW- A-

13 DIR+ CCW+ B+

8 DIR- CCW- B-

Outputs Depending Upon the State of System Variable EO*

Connector Pin

EO=0 EO=1 EO=2

X4

14 STEP+ CW+ A+

9 STEP- CW- A15 DIR+ CCW+ B+

10 DIR- CCW- B-

*Requires encoder feedback input on X2

Differential Analogue Input

The ViX stepper drive can accept a differential analogue input for use with the FRATE

command. The input circuit, shown in Figure 3-12, can interface to an external +/-10V

differential signal. Analogue to digital conversion (12-bit resolution) converts the analogue

input to a digital value for use within the drive. Read the value of the analogue input as a

count via system variable AI.

Drive

Input

impedance

200K

Note: both inputs must

be connected - cannot

be used as a single ended

input

ANA1+

ANA1-

0V

GND

+

A to D

-

Software offset controlled

by system variable AO

AI, analogue

input expressed

as a count

Figure 3-12. Analogue Differential Input

Page 41

34 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Figure 3-13 shows the input characteristic.

Velocity

(rps)

Commanded

velocity

Dead band

-10V

Figure 3-13. Analogue Differential Input Characteristic

An analogue deadband can be set, using system variable ‘AB’.

_________

Energise/Shutdown

Enable the drive by allowing the input pin to float high ‘1’ or by linking the pin to zero volts,

depending upon the input’s polarity. System variable ES controls the polarity of this input.

The default state of ES (Energise Sense) requires X4 input pin 11 to be connected to 0V to

enable the drive.

Volts

+10V

The function of this input differs when in mode ‘MP’, please refer to the Command

Reference section for more details.

Page 42

3. ELECTRICAL INSTALLATION 35

X5 Connector

X5 is the user Input/Output connector.

Connector Type

Connector type is a high-density 15-way D-type plug.

Connector Pin Out

Connector Pin X5 Input/Output

10V

20V

30V

4 Output 2

5 Output 1

6 Input 5 (limit+)

7 Input 4 (limit-)

8 Input 3 (home)

9 Input 2 (registration)

10 Input 1 (stop)

11 +24V

12 +24V

13 +24V

14 Output 3

15 Reserved

Table 3-11. X5 User Input/Output Connections

Page 43

36 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

User Inputs

Inputs can be configured using the Easi-V graphic interface or by writing directly to the IC

system variable. By adjusting the user input configuration, you can set the input switching

level threshold and you can set the internal input resistor to be a pull-up or a pull-down.

Figure 3-14 shows the position of software switches.

'0'

'1'

4K7

24V

'1' = Pull-up

'0' = Pull-down

(default)

82K

27K

SWC

SWB

'1' = invert

'0' = non-invert

Logic inverting

network depending

upon input pull-up

pull-down state

o/c

'0'

'1' = 24V threshold (default)

'1'

'0' = 5V threshold

0V

Logic level as

reported by IS

SWA

0V

Input

Figure 3-14. User Input Circuit

User inputs are high logic level and low level logic compatible, but must be configured

as pull-down inputs when used with low-level 5V logic, since the pull-up mode always

pulls-up to +24V.

Only one input is shown above, individual inputs can be set-up on a one-to-one basis

allowing different inputs to have different threshold switching levels or different pull-up, pulldown arrangements.

CAUTION – Unexpected motor movement

De-energise the drive before making any changes to the I/O configuration.

Page 44

3. ELECTRICAL INSTALLATION 37

User Outputs

User outputs can be configured using the Easi-V graphic interface or by writing directly to the

IC system variable. By adjusting the user output configuration, you can set the output to

source or sink current. Figure 3-15 shows the output circuit.

Common IC

housing all

top-switches

for all outputs

+24V

'1' = Current source

0V

Output

'0' = Current sink

0V

Figure 3-15. User Output Circuit

User outputs are compatible with high-level 24V logic only. Each output can source

or sink 50mA.

Note: The easiest way of configuring the drive’s inputs and outputs is to use the

Easi-V graphic user interface.

Input/Output Configuration

To set-up the input and output configuration without using the EASI-V graphic interface, you

will need to write configuration patterns to the two-byte IC parameter, as shown.

aW(IC,{4 digit decimal number equivalent to a two-byte number})

Bits 8 to 12 control the switching threshold of inputs 1 to 5 (SWC setting).

Setting a bit to a ‘1’ gives a 24V switching threshold, a ‘0’ gives a 5V switching threshold.

Bit 15141312 11 10 9 8

IC

content

not

used

not

used

not

used

in_5 in_4 in_3 in_2 in_1

Page 45

38 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Bits 0 to 4 control the input resistor pull-down/pull-up of inputs 1 to 5 (SWA setting).

Setting a bit to a ‘1’ sets the input resistor to be a pull-up to +24V, a ‘0’ sets the resistor to be

a pull-down.

Bits 5 to 7 controls the source/sink operation of outputs 1 to 3.

Setting a bit to a ‘1’ sources current from the +24V rail via the upper half of the output, while

setting a bit to a ‘0’ sinks current from a connected input through the lower output transistor

to 0V.

Bit 7 6 5 4 3 2 1 0

IC

content

Note:

[1] SWB is automatically set to ensure that the software will report ‘0’ for a closed input

switch and ‘1’ for an open input switch.

[2] sourcing outputs can only be used with 24V high level logic.

[3] 5V tolerant input connections must only be used with pull-down (sink) configuration as

the input pull-up always pulls up to 24V.

[4] Invalid combinations will report an error (*E), and the User Fault (UF) bit 1 is set (value

out of range).

out_3 out_2 out_1 in_5 in_4 in_3 in_2 in_1

User inputs are high logic level and low level logic compatible, but must be configured

as pull-down inputs when used with low-level 5V logic, since the pull-up always pullsup to +24V.

Example

Configure a drive with inputs in_1 and in_2 arranged as pull-down 5V threshold logic. In_3,

In_4 and In_5 as pull-up high threshold level logic, and all outputs as current sources. The

binary pattern required is:

(MSB) (LSB)

00011100 11111100

In hex. this becomes 1CFC, which in decimal is 7420

So the required command to (say) axis 3 is 3W(IC,7420)

IC default setting

The default setting for the drive is all inputs set to 24V threshold, all inputs pulled-down and

all outputs sourcing, which gives a binary pattern of 00011111 11100000, which in hex.

gives 1FE0, resulting in the decimal equivalent of 8160.

Page 46

3. ELECTRICAL INSTALLATION 39

N

Fault Output

The fault output is an independent NPN open-collector output which is normally ‘low’, active

‘high’. The output ratings are +30V maximum in the OFF condition and 15mA maximum in

the ON condition. Figure 3-16 shows the output circuit.

Drive

circuit

Fault

Output

0V

Figure 3-16. Fault Output Circuit

Limit Switches

The drive has two limit inputs, the positive limit input and the negative limit input. When

wiring the limit switches it is essential to check that a positive direction command produces

motion towards the positive limit switch .

+24V

C NEGATIVE

LIMIT

POSITIVE

MOTION

NC POSITIVE

LIMIT

Positive limit input

Negative limit input

Figure 3-17. Limit and Stop Switch Configuration

Page 47

40 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

RJ45 Interfaces

Positioned beneath the drive are two RJ45 communication interfaces X6 and X7. The two

interfaces provide support for Canbus, RS485 (using the Field Expansion Module) and daisy

chain ports for multi-axis RS232 connections between drives.

8

X7 RS232 daisy

1

8

1

High speed

comm.

Interface

chain output

X6 RS232 daisy

chain input

Figure 3-18. Position of Connectors X6 and X7

Page 48

3. ELECTRICAL INSTALLATION 41

FEM1 CAT5 cable colours

X6 CANopen/RS485

1 RX+/TX+ RS485 White/Orange

2 RX-/TX- RS485 Orange

3 CAN H White/Green

4 RS232 Gnd Blue

5 RS232 Gnd White/Blue

6 CAN L Green

7 RS232 Tx White/Brown

8 RS232 Rx Brown

X7

1 RX+/TX+ RS485 White/Orange

2 RX-/TX- RS485 Orange

3 CAN H White/Green

4 RS232 sense Blue

5 RS232 Gnd White/Blue

6 CAN L Green

7 RS232 Rx White/Brown

8 RS232 Tx Brown

Table 3-12. X6/X7 Input/Output Connections

CAN Bus Termination

Systems using CANopen will need to terminate the final X7 output with a 120 ohms quarter

watt resistor connected between X7 pins 3 and 6. A ready-made CAN bus RJ45 terminator

is available as shown in Figure 3-19 (Parker part number ‘ViX-RJ45-G).

50mm

pin 1

Figure 3-19. CAN Bus Terminator

Page 49

42 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Communication Daisy Chain

Drives can be ‘daisy-chained’ for RS232/RS485* operation as shown below. Using this

arrangement the drive connected to the controlling PC, via its front panel D-type connector,

becomes axis #1. To automatically assign addresses, connect all power, motor, feedback

and communication cables then power-up all the drives, see ‘#’ command for more details.

At the controlling PC, type the following commands:

#1 ;cause the 1st drive to establish the daisy chain

in a 3-axis system the response will be #4

0SV ;save the address configuration

0Z ;reset

response should be a single check sum from axis 1

more than one check sum indicates a problem, possibly no save command

Final drive

terminates

the daisy chain

Figure 3-20. RJ45 RS232 Daisy Chain Connections

X6 rear

X7 front & X6 rear

RS232 Input from PC

X7 front

*Note for RS485 operation, the drive will need to be fitted with a FEM CAN & RS485

interface. Using the command #1(485) will switch all drives to 485 operation, which is

automatically saved.

Using the X6/X7 connections on the underside of the drive will allow the last drive in the

chain to detect that there are no more connections made to X7 which will close the daisy

chain loop back internally.

Page 50

3. ELECTRICAL INSTALLATION 43

To maintain the integrity of the EMC screening, all RS232 and RS485 connections must be

made via the drive’s X3 D-type connector.

RJ45 Connecting Leads

RJ45 link cables can be ordered from Parker. Various lengths are available as listed in

Table 3-13.

Part Number Length

VIX-RJ45-0025 0.25m

VIX-RJ45-0050 0.5m

VIX-RJ45-0075 0.75m

VIX-RJ45-0100 1.0m

VIX-RJ45-0200 2.0m

Table 3-13. RJ45 Connection Lead Types

Note: Individual cables that are within the RJ45 daisy chain system must not exceed a length

of 2m. Where a cable length greater than 2m is required between axes, a fully screened

connection should be made via connector X3.

Page 51

44 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Page 52

4. CONTROL OF VIX DRIVES 45

4. Control of ViX Drives

Overview

This section introduces you to the operation of the ViX stepper drive, the implementation of

motion control moves and the way commands are used. Basic controller operation is

described together with the code structure. How system information is signalled via system

variables and the use of various flag registers for status and fault reporting are described.

Both basic and advanced motion control functions are covered including elements of event

driven code used for fault reporting and registration.

Controller Operation

ViX intelligent drives have an integrated controller which can be driven directly by a PC over

a serial link, or programmed to respond to code selected by event triggers or user

instructions.

Direct Mode

Direct operation of the controller over a serial link can be used for program

development/downloading purposes or direct on-line control from an industrial PC or PLC.

When used directly the controller will accept commands prefixed with the drive’s address

and will action the commands as they are received. In direct mode any controlling

application program is stored in a remote location and is only downloaded to the drive when

required.

Programmed Mode

This mode allows a program stored within the drive to control operations. The program can

be written off-line on a PC and then downloaded to the drive via a serial link. The application

program is stored within the drive and is automatically invoked at power up provided it is

enabled by the <a>ARM1X command and the program has a START label. Alternatively,

you could directly issue a <a>GOTO(START) command.

Code Structure

You write program code as a series of blocks. Each code block has a unique label at the

beginning and is terminated with an END label (block delimiter). The use of labels allows the

code structure of the form illustrated in Figure 4-1, which shows the block nature together

with an example of code.

Declare

Declare every label used in a program, apart from START, REG, NOREG and FAULT that

have been pre-declared. If a label is declared, but not defined, a runtime error will be

signalled when it is called.

Note: START, REG, NOREG and FAULT are all reserved labels.

You can only declare labels in the command line at the start of a program or within the

START code. The choice is between memory efficiency and the retention of declared labels

Page 53

46

during up-loading/down-loading of programs. Declaring labels in the command line, before

any START code, makes the most efficient use of the available memory. If you then up-load

the program to a PC and later down-load the same program the declarations will have been

lost. To retain declared labels you must declare them in the START code, this allows a

program to be up-loaded and down-loaded without loss of declared labels, although more

memory will be used. Despite the greater amount of memory being used, it is safer to make

the declarations within the START label as there is less chance of forgetting to declare parts

of the code.

Example of DECLARE being used in the command line:

VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

1K ;Kill or stop any program currently running

1CLEAR(ALL) ;Erase all existing programs

1DECLARE(MAIN) ;Declare labels

1DECLARE(MOVE1)

1DECLARE(MOVE2)

.

.

Example of DECLARE being used following the START label:

1K ;Kill or stop any program currently running

1CLEAR(ALL) ;Erase all programs

1START:

1DECLARE(MAIN) ;Declare labels

1DECLARE(MOVE1)

1DECLARE(MOVE2)

.

1END

Labels

Labels consist of up to 5 upper case alphanumeric characters terminated with a colon (:), but

a label must begin with an alpha character. Choose a name that is relevant to the operation

being performed, or a system label name.

To terminate a code block use ‘END’ (no colon).

You can use up to 20 labels, although four of these have already been allocated to START,

REG, NOREG and FAULT, leaving sixteen for general use.

Label Execution

By using the label select command (LSEL), labelled code blocks can be triggered by a digital

pattern appearing on certain user inputs. The command defines the user inputs to be used,

the style of code detected (BCD or binary) and the manner in which the code is executed

(continuous or re-trigger).

Enable the LSEL command using its on/off parameter to allow input selection of labels.

Page 54

4. CONTROL OF VIX DRIVES 47

Structure

The code example of an absolute positioning move shown in Figure 4-1 demonstrates how

to write code that follows the block structure. Use the start code to initialise the drive:

Start code and

Initialisation

Main

Program

Block 1

Example:

1START: ; start label definition

1DECLARE(MAIN) ; declare labels

1DECLARE(MOVE2) ; declare move 2

1LIMITS(3,0,0) ; configure limits.

1GOTO(MAIN) ; goto main program

1END

Block 2

Block 3

Figure 4-1. Program Structure

1START:

1DECLARE(MAIN)

1DECLARE(MOVE2)

1LIMITS(3,0,0)

1GOTO(MAIN)

1END

1MAIN:

1PROFILE2(40,10,-48000,25)

1GOSUB(MOVE2)

1END

1MOVE2:

1W(PA,0)

1MA

1USE(2)

1G

1END

Use the MAIN part of the program to define profiles and to control the order of moves:

1MAIN: ; main label definition

1PROFILE2(40,10,-48000,25) ; define move parameters

1GOSUB(MOVE2) ; jump to label move 2

1END ; end of label definition

Page 55

48

Finally, call individual moves from the main part of the program:

Note: PROFILE2 defined in the main part of the program has the following characteristics:

ACCELERATION 40rps² , DECELERATION 10rps², DISTANCE 48000 steps (12 REVS

MOVE), NEGATIVE DIRECTION , VELOCITY 25 rps.

In small programs, the start code can be combined with the main part of the program. For

experienced X-code users, the shorter blocks of code in the example above, accessed via

subroutines, is the equivalent of a sequence.

A second example illustrates the code required for an incremental move. Here the START

and MAIN code blocks have been combined within the START block:

VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

1MOVE2: ; define program label “move2”

1W(PA,0) ; zero position absolute

1MA ; absolute positioning move

1USE(2) ; use motion profile 2

1G ; execute move

1END ; end of program move 2 definition

1START: ; start label definition

1DECLARE(MOVE1) ; declare move1 label

1LIMITS(3,0,0) ; configure limits (disable, n/c).

1PROFILE1(80,20,24000,20) ; define move parameters

1GOTO(MOVE1) ; transfer to label move 1

1END ; end of label definition

1MOVE1: ; define program label.

1MI ; incremental positioning move

1USE(1) ; use motion profile 1

1G ; execute move

1END ; end of program move 1 definition.

Note: [1] DEVICE ADDRESSING IS REQUIRED FOR ALL COMMANDS

[2] PROFILE1 has the following characteristics:

ACCELERATION 80rps² , DECELERATION 20rps², DISTANCE 24000 steps (6 REVS

MOVE), POSITIVE DIRECTION , VELOCITY 20 rps.

Page 56

4. CONTROL OF VIX DRIVES 49

LOOP Command

The block structure of the code lends itself to performing repetitive operations, using the

LOOP command. The command can be used to call a particular labelled block of code for

either a specified number of times or continuously.

An example using the LOOP command is given below, again the START and MAIN code

blocks have been combined within the START block:

1START: ; start label definition

1DECLARE(LOAD) ; declare label

1LIMITS(3,0,0) ; disable limits

1PROFILE3(100,50,4000,35) ; define move parameters

1MI ; set mode to incremental

1LOOP(LOAD,6) ; repeat the load unload 6 times

1END ; end of label definition

1LOAD: ; define program label load

1USE(3) ; use motion profile 3

1O(XX0) ; ensure o/p 3 is off

1T1 ; wait for 1 sec delay

1G ; execute move

1O(XX1) ; turn on o/p 3

1T1 ; wait for 1 sec delay

1END ; end of label definition

Page 57

50

Reserved System Labels

Certain pre-defined labels are recognised by the controller as containing code used for

common operations. If event triggered code is enabled (ARM1), the code entered for these

common operations will be automatically run when the event occurs.

System labels have the following names:

START: specifies the power on code, run using the ARM1 command

FAULT: specifies the code that is to be run when a fault occurs

REG: specifies the code to be run when a registration mark is detected within the

NOREG: specifies the code to be run when a registration mark is not detected within the

Note: If necessary, these labels can be used for other purposes, but cannot be re-named.

VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

registration window

registration window

Fault Label

Use the pre-declared label named FAULT to identify a block of code that is executed when a

particular problem (fault) has been detected. The code following the FAULT label needs to

change the state of an output, to indicate a fault has occurred and then go on to possibly

diagnose the problem. Once the problem has been corrected, the FAULT code will need to

detect an external ‘reset’, by monitoring a designated input and then execute an ON

command to clear the FAULT. At the end of the FAULT code a GOTO(START) can be

issued to restart the program. This style of programming will always ensure that once a

fault is detected the drive will stop and will not start again until commanded to do so.

Before the code following a FAULT label can be executed certain conditions must be met,

these are:

• FAULT must be defined

• ARM must be set to enable a FAULT label

This means FAULT label code must be present and the ARMX1 command exists at the

beginning of the code.

Page 58

4. CONTROL OF VIX DRIVES 51

The conditions under which the FAULT label is called will vary depending upon the fault itself

and the condition of various other commands and command parameters. An exact

description is presented in Table 4-1. However, in general, a FAULT label will be called

given any one of the following conditions:

• An attempt to go home further onto a limit is made and the limit is enabled.

• An attempt to go further onto a limit is made with no fault label currently

running, the limit configuration is stop on limit and the limit is enabled.

• A limit is hit during motion and the move is not a go home, a fault label is not being

run, the limit configuration is stop on limit and the limit is enabled.

• A drive fault has occurred, but no drive programming is taking place.

• When it is called from a GOTO, GOSUB or LOOP command*.

*Note: in this case a FAULT has not actually occurred, consequently the FAULT label will be

called irrespective of the state of the ARM command.

Table 4-1 summarises the conditions necessary for the FAULT label to be called. The

FAULT label will not be called when any one of the following conditions occur:

• There is an error whilst sending a command

• There is a general run time error with the program

• The program memory area becomes full

• A label is attempted to be run when it does not exist

• The transmit buffer or receive buffer suffer an overflow

Command & parameter conditions

Fault

Condition

G onto a limit Y N/A Y Y Y Y N/A

Hit limit Y Y Y Y Y Y N/A

Drive fault Y N/A Y N/A N/A N/A Y

GOTO Y N/A N/A N/A N/A N/A Y

GOSUB Y N/A N/A N/A N/A N/A Y

LOOP Y N/A N/A N/A N/A N/A Y

FAULT

label

defined

NotGHFault

ARM

bit

Limit is

enabled

Not

running

fault

label

Limit

decision

is stop

program

execution

Not

program

-ming

the drive

Table 4-1. Conditions Required to Call a Fault Label

Page 59

52

Example

The following example shows the use of a FAULT label within a program.

VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

1ARM11 ;enable auto-run on power-up & enable fault routine

1SV ;save the settings

1START: ;start of program

1ARM11 ;re-enable auto-run & fault in case ‘K’ command sent

.

<initialisation commands>

.

1O(1XX) ;turn on output 1 - drive OK

.

<main process commands>

.

1END

1FAULT: ;fault routine

1O(0XX) ;turn off output 1 - drive fault

.

<diagnostic code - if required>*

.

1TR(IN,=,1XXXX) ;wait for input 1 to become active (RESET)

1ON ;clear fault

1GOTO(START) ;run from start of program again

1END

*Note: An example of diagnostic code is given in the sub-section entitled Conditional Code

later within this section.

Page 60

4. CONTROL OF VIX DRIVES 53

Start Label

The system label START: introduces the drive’s setup and initialisation code. With ARM

enabled the code is automatically executed at system start-up*. Consequently the code

needs to be saved with ARM1X set. If you save a program with ARM0X set, the start-up

code will not run and the controller will only respond to serial input commands.

*Unless a drive fault is pending and a fault routine is defined and armed.

Start Label Example:

1START:

1”RUNNING”

-

-

1END

1FAULT:

1”FAULT”

1TR(IN,=,1XXXX)

1GOTO(START)

1END

1ARM01 ;enable fault routine only

1SV ;save all settings

If you cycle the power to the drive the “START” routine will not automatically run. To start it

you would have to type in 1GOTO(START). However, the “FAULT” routine will run if a fault

occurs

Entering the following code:

1ARM11 ;enable auto run on “START”

1SV ;save all settings

The “START” routine should automatically run on the next power-up.

Page 61

54

VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Use of the LSEL Command

You can let user inputs call programmed routines by the use of special label names and

associated user input numbers. By including the code you wish to action, following a predefined input label, will enable your code to be run when the defined user input is activated.

For example, to select one of three labels using two user inputs, the code would be:

1START:

1CLEAR(ALL) ;clear memory

1DECLARE(L1) ;declare label 1

1DECLARE(L2) ;declare label 2

1DECLARE(L3) ;declare label 3

1LSEL1(0,2,1) ;define inputs and code

1A20 ;set acceleration

1V5 ;set velocity

1O(000) ;set all outputs low

1END