Parker Hannifin VIX500IM, VIX250IM User Manual

V iX250IM

V iX500IM

Stepper Drives

User Guide

Part No: 1600.324.01b February, 2004 (For software revision 2.0 onwards)

IMPORTANT INFORMATION FOR USERS

Installation and Operation of Motion Control Equipment

It is important that motion control equipment is installed and operated in such a way that all applicable safety

requirements are met. It is your responsibility as an installer to ensure that you identify the relevant safety

standards and comply with them; failure to do so may result in damage to equipment and personal injury. In

particular, you should study the contents of this user guide carefully before installing or operating the

equipment.

The installation, set-up, test and maintenance procedures given in this User Guide should only be carried

out by competent personnel trained in the installation of electronic equipment. Such personnel should be

aware of the potential electrical and mechanical hazards associated with mains-powered motion control

equipment - please see the safety warning below. The individual or group having overall responsibility for

this equipment must ensure that operators are adequately trained.

Under no circumstances will the suppliers of the equipment be liable for any incidental, consequential or

special damages of any kind whatsoever, including but not limited to lost profits arising from or in any way

connected with the use of the equipment or this user guide.

SAFETY WARNING

High-performance motion control equipment is capable of producing rapid movement and very high forces.

Unexpected motion may occur especially during the development of controller programs. KEEP WELL

CLEAR of any machinery driven by stepper or servo motors. Never touch any part of the equipment while it

is in operation.

This product is sold as a motion control component to be installed in a complete system using good

engineering practice. Care must be taken to ensure that the product is installed and used in a safe manner

according to local safety laws and regulations. In particular, the product must be enclosed such that no part

is accessible while power may be applied.

This and other information from Parker-Hannifin Corporation, its subsidiaries and authorised distributors

provides product or system options for further investigation by users having technical expertise. Before you

select or use any product or system, it is important that you analyse all aspects of your application and

review the information concerning the product in the current product catalogue. The user, through its own

analysis and testing, is solely responsible for making the final selection of the system and components and

assuring that all performance, safety and warning requirements of the application are met.

If the equipment is used in any manner that does not conform to the instructions given in this user guide,

then the protection provided by the equipment may be impaired.

The information in this user guide, including any apparatus, methods, techniques, and concepts described

herein, are the proprietary property of Parker Electromechanical Division or its licensors, and may not be

copied, disclosed, or used for any purpose not expressly authorised by the owner thereof.

Since Parker Electromechanical constantly strives to improve all of its products, we reserve the right to

modify equipment and user guides without prior notice. No part of this user guide may be reproduced in any

form without the prior consent of Parker Electromechanical Division.

© Electromechanical Division of Parker Hannifin plc, 2003

– All Rights Reserved –

Product Type: ViX250IM, ViX500IM

The above product is in compliance with the requirements of directives

• 73/23/EEC Low Voltage Directive

• 93/68/EEC CE Marking Directive

• 89/336/EEC Electromagnetic Compatibility Directive

Provided the installation requirements described in this user guide are met, and there are no special requirements of

the installation and operating environment so that the application may be considered typical, the ViX servo drive series

installation will conform to the protection requirements of Council Directive 89/336/EEC as amended by Directive

92/31/EEC on the approximation of the laws of the Member States relating to Electromagnetic Compatibility when

operated and maintained as intended.

In assessing the overall compliance of an installation consideration must also be given to the effects of mains

harmonics and flicker when interfacing the total supply system to the public low voltage supply system.

In accordance with IEC 61800-3:1997 (Adjustable speed electrical power drive systems) this product is of the

restricted sales distribution class which meets the needs of an industrial environment when installed as directed.

However, further measures may need to be taken for use of the product in a domestic environment.

Compliance is demonstrated by the application of the following standards:

BS EN 61800-3 Adjustable speed electrical power drive systems

(1997) including Part 3. EMC product standard including specific test methods

Amendment A11

BS EN 61000-6-2 Electromagnetic compatibility – Part 6-2: Generic standards

(2001) Immunity for industrial environments

BS EN 61000-6-4 Electromagnetic compatibility – Part 6-4: Generic standards –

(2001) Emission standard for industrial environments

BS EN 61010-1 Safety requirements for electrical equipment for measurement,

(1993) including control, and laboratory use. Part 1. General requirements

Amendment A2

WARNING – Risk of damage and/or personal injury

The ViX drives described in this user guide contain no user-serviceable parts.

Attempting to open the case of any unit, or to replace any internal component, may

result in damage to the unit and/or personal injury. This may also void the

warranty.

Contact Addresses

For engineering For engineering

assistance in Europe: assistance in Germany

Parker Hannifin plc Parker Hannifin GmbH

Electromechanical Electromechanical

Automation

21 Balena Close P. O. Box: 77607-1720

Poole, Dorset Robert-Bosch-Str. 22

England, BH17 7DX D-77656 Offenburg, Germany

Tel: +44 (0)1202-699000 Tel: +49 (0)781 509-0

Fax: +44 (0)1202-695750 Fax: +49 (0)781 509-176

e-mail: sales.digiplan@parker.com e-mail: sales.hauser@parker.com

e-mail: support.digiplan@parker.com e-mail: techhelp_emd_OG@parker.com

Website: www.parker-eme.com Website: www.parker-eme.com

For engineering For engineering

assistance in Italy assistance in the U.S.:

Parker Hannifin SpA Parker Hannifin Corporation

Electromechanical Automation

20092 Cinisello Balsamo 5500 Business Park Drive, Suite D

Milan, Rohnert Park

Italy Via Gounod, 1 CA 94928

Tel: +39 02 6601 2478 Tel: (800) 358-9070

Fax: +39 02 6601 2808 Fax: (707) 584-3793

e-mail: sales.sbc@parker.com e-mail: emn_support@parker.com

Website: www.parker-eme.com Website: www.parkermotion.com

Automation

Electromechanical Automation

USA

FaxBack System: (800) 936-6939

Symbols used, have the following meanings:

Caution Refer to the

accompanying documentation

Protective conductor terminal

CONTENTS i

Contents

1. Introduction.............................................................................................................1

2. Mechanical Installation...........................................................................................5

3. Electrical Installation...............................................................................................9

4. Control of ViX Drives..............................................................................................45

5. EASI-V Software ....................................................................................................95

6. Command Reference.............................................................................................115

7. ViX Maintenance and Troubleshooting ..................................................................185

8. Hardware Reference ..............................................................................................195

Appendix A/B..............................................................................................................199

Index............................................................................................................................203

The ViX250IM/500IM Microstepper Indexer Drive is UL-Recognised under file E194158.

This means it may be incorporated into end-user products that may be eligible for UL

Listing, Classification or Certification.

User Guide Issue Change Summary

This user guide, version 1600.324.01, is the first version of the ViX250IM/ViX500IM

Microstepper Indexer Drive.

When a user guide is updated, the new or changed text is differentiated with a change

bar in the outside margin (this paragraph is an example). If an entire section is changed,

the change bar is located on the outside margin of the section title. For the latest (most

up-to-date) changes required by this issue of user guide see the Latest Changes Sheet

over the page.

ii VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Latest Changes Sheet

This page lists important changes occurring immediately before publication or between

issue updates:

1. INTRODUCTION 1

1. Introduction

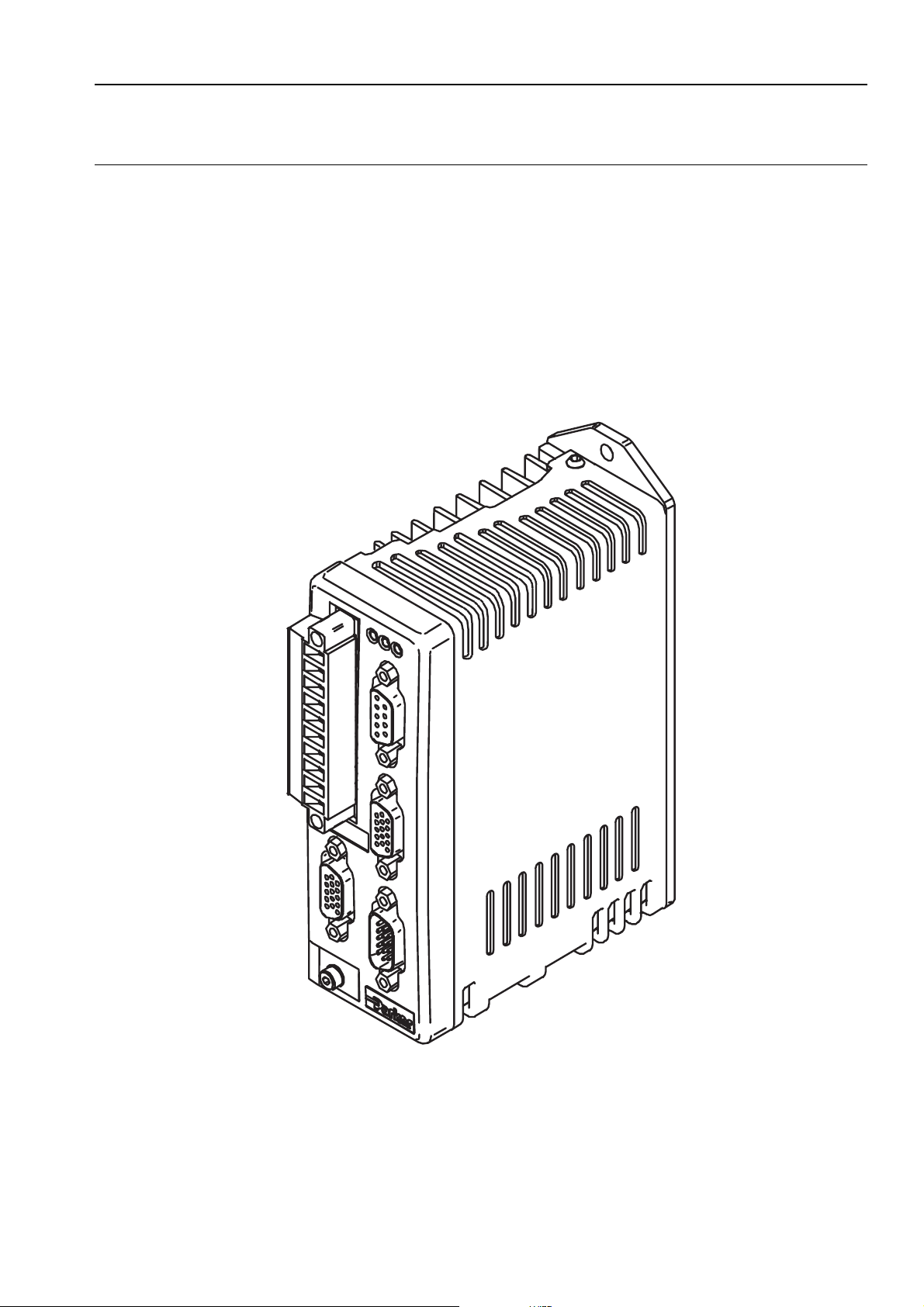

Product Description

Available in two current ratings, these microstepper indexer drives employ an optimised

digital field oriented current loop to provide low speed smoothness coupled with high speed

torque. Advanced digital techniques result in reduced settling time and reduced mid speed

instability when compared with similar competitive drive types.

The common use of EASI-V programming language and similar supply requirements make

this drive ideal for mixed technology applications when used with the ViX digital servo.

Figure 1-1. ViX250/ViX500 Microstepper Indexer Drive

2 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Product Variants

Digital microstepper indexer drives are available in two current ratings with two interface

options. Table 1-1 lists the possible combinations:

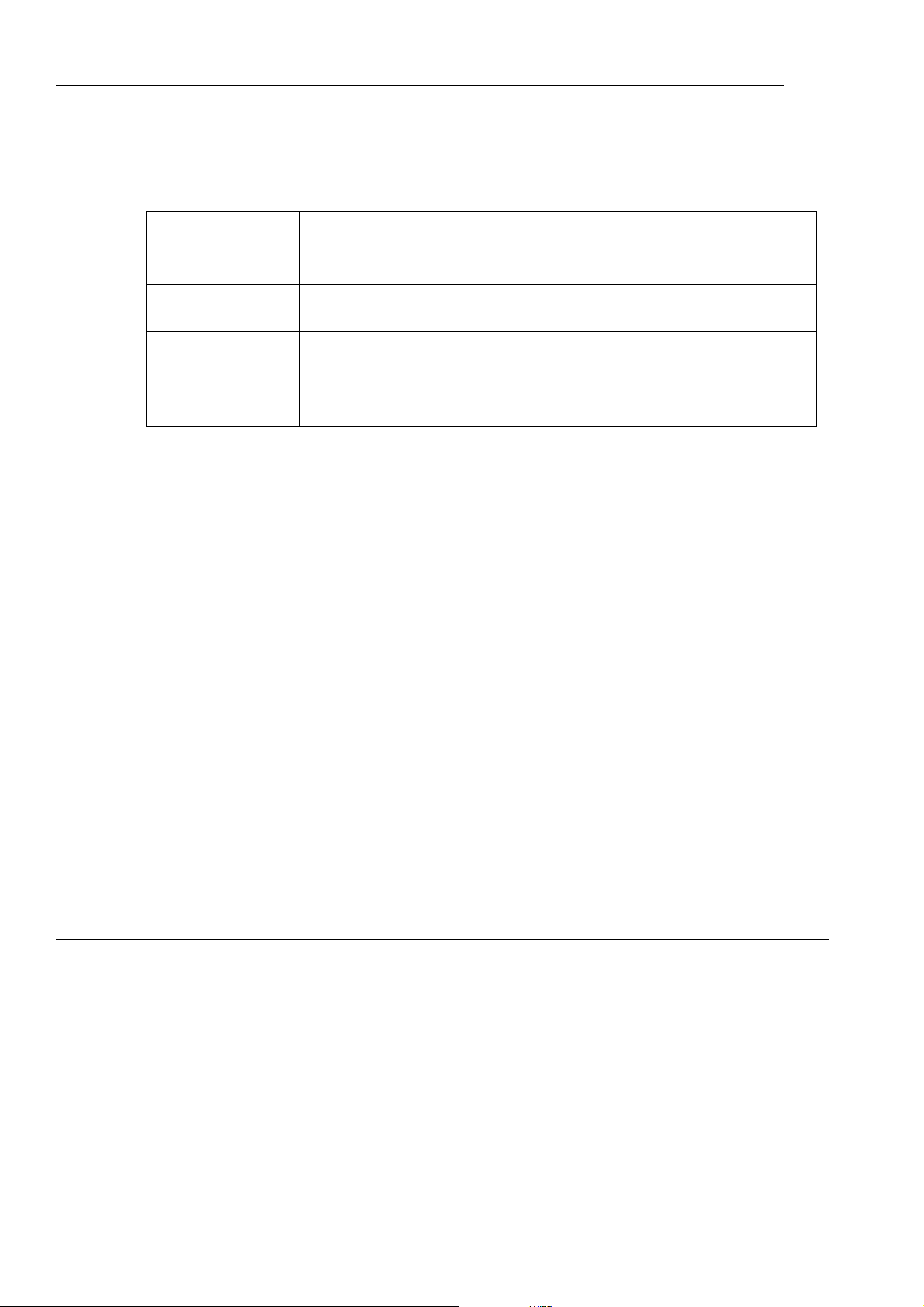

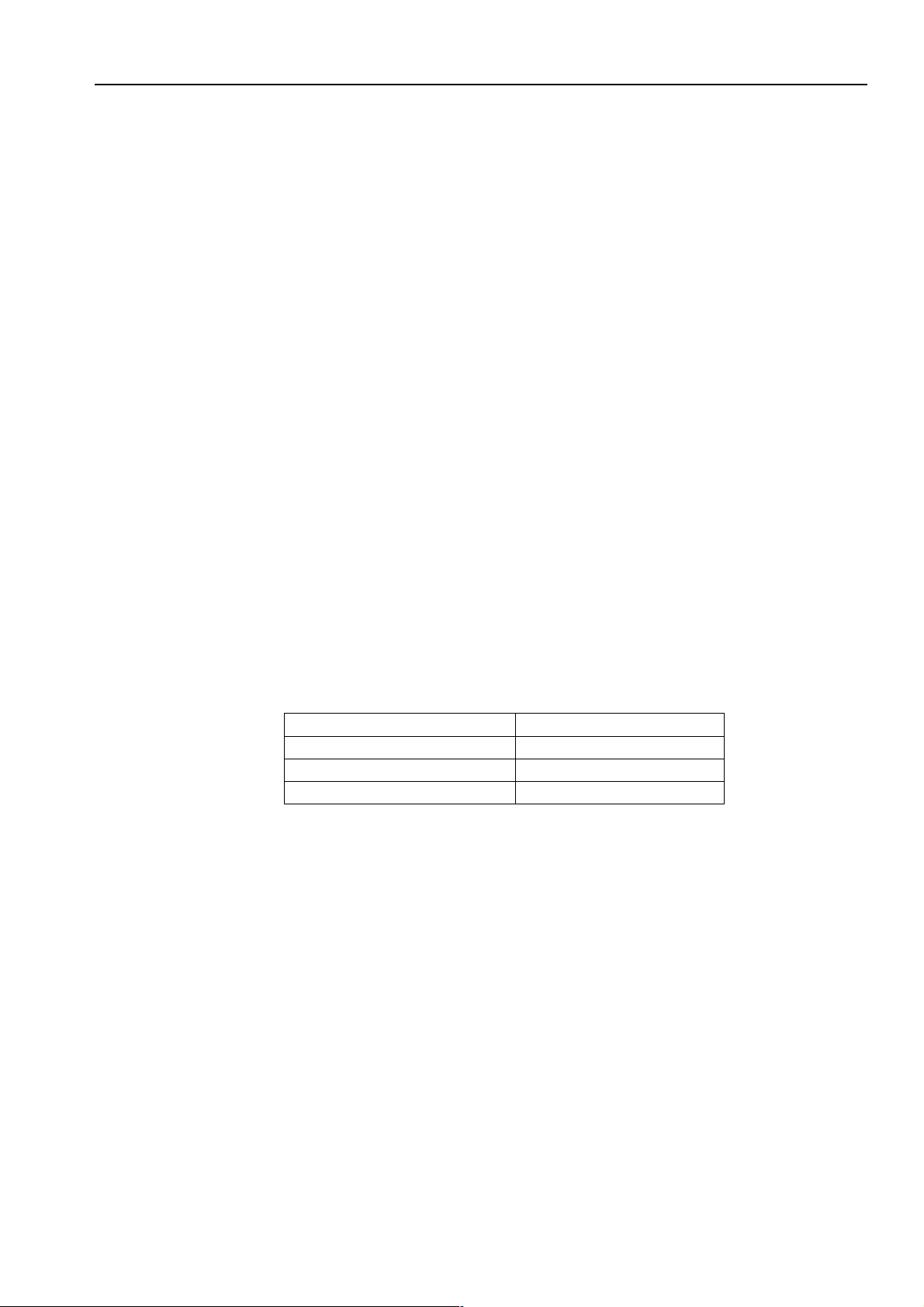

Product Code Description

ViX500IM 5.6A RMS (8A peak) microstepper indexer drive with an

RS232 control interface

ViX250IM 2.8A RMS (4A peak) microstepper indexer drive with an

RS232 control interface

ViX500CM 5.6A RMS (8A peak) microstepper indexer drive with

Canbus/RS485 interface

ViX250CM 2.8A RMS (4A peak) microstepper indexer drive with

Canbus/RS485 interface

Table 1-1. ViX250/ViX500 Microstepper Indexer Drive Options

Note: RS485 serial communication is only included in the CANopen version of the drive.

Product Features

Protection Circuits

Motor short circuits, phase to phase,

phase to ground

Over-voltage trip

Under-voltage trip

Drive/motor Over-temperature

24V reverse supply protection

Function Indicators

Drive Status/Feedback Fault (HV/FB)

Drive Fault (DF)

Comms. Status (CS)

Outputs and Inputs

3 digital outputs

5 digital inputs

1 analogue input

Fit Kits

A fit kit is available for ViXIM drives:

VIX-KIT

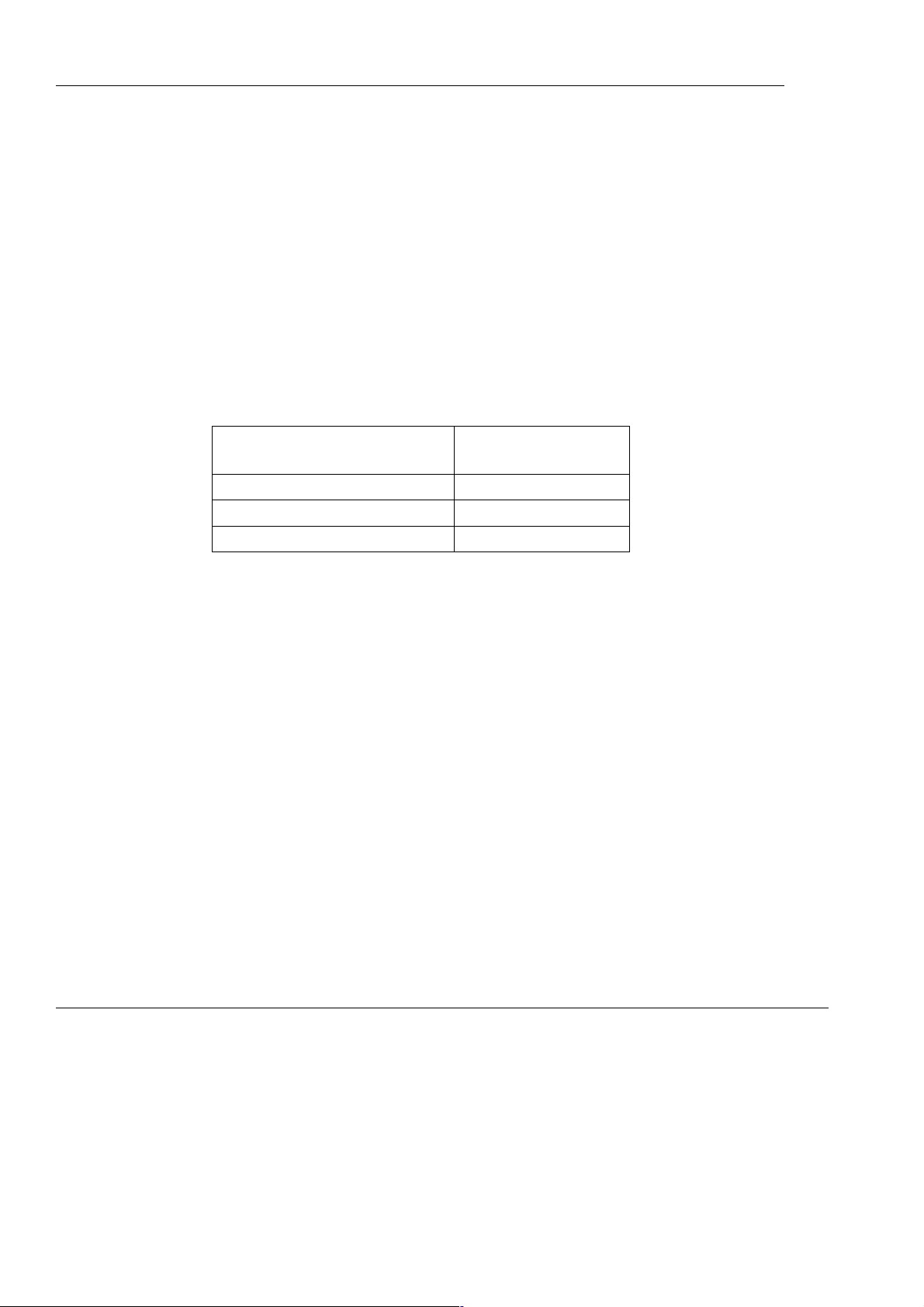

Part Number Quantity Description

1650.937.01 1 Information

5004.023 1 Plastic bag

5006.211 1 Product label

0405.811 1 10-way Flange

0405.961 1 9-way D-type

0405.962 2 15-way HD

0405.963 1 15-way HD

0409.530 4 9-way D-type

0313.020 1 H8FE1115NC

4005.218 1 3:1 heatshrink

4216.101 1 Closed P-clip

4216.102 1 Closed P-clip

4216.103 1 Closed P-clip

1. INTRODUCTION 3

sheet

plug strip

plug

D-type plug

D-type socket

cover

ferrite sleeve

19mm diam.

9mm ID

10.7mm ID

12.3mm ID

4 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Further Information

This user guide contains all the necessary information for the effective use of this drive.

However, to gain a more in-depth understanding of drive applications and motion control,

consider attending one of our world-wide Customer Specific Training Workshops.

Examples of previous courses that have proved to be of benefit include:

Use and programming of the DIN rail H & L series drives

PDFX training

Using the 6K controller

EASI Tools programming

Mechanical product training for ET/ER, XR and HPLA

2. MECHANICAL INSTALLATION 5

2. Mechanical Installation

Installation Requirements

Environment

ViX drives operate in a temperature range of 0° to 40°C with natural convection, or 50°C

Max with forced-air cooling (see Hardware Reference), at normal levels of humidity (5-95%

non-condensing). The drives can tolerate atmospheric pollution degree 2, which means only

dry, non-conductive pollution is acceptable.

Drive Cooling

Cooling of all drive types is by natural convection up to 40°C. To assist cooling, drives

should be installed vertically in an area where there is at least a 50mm (minimum) air gap

above and below the package and a 10mm (minimum) gap either side. Avoid mounting

heat-producing equipment directly below a drive.

Installers must ensure that the air temperature entering the drive or rising up to the drive is

within the ambient temperature restrictions. Under normal use the air temperature leaving

the drive and heatsink may be 25°C above ambient.

In the final installation, check that the ambient temperature specification of 40°C Max

(without forced air cooling) is not exceeded directly below the top-most drives and that any

circulating air flow is not being blocked from reaching the drives. For cabinet cooling

calculations, allow 20W per drive. For DIN rail mounting, see the thermal limitations

statement in Drive Mounting Options.

6 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Drive Dimensions

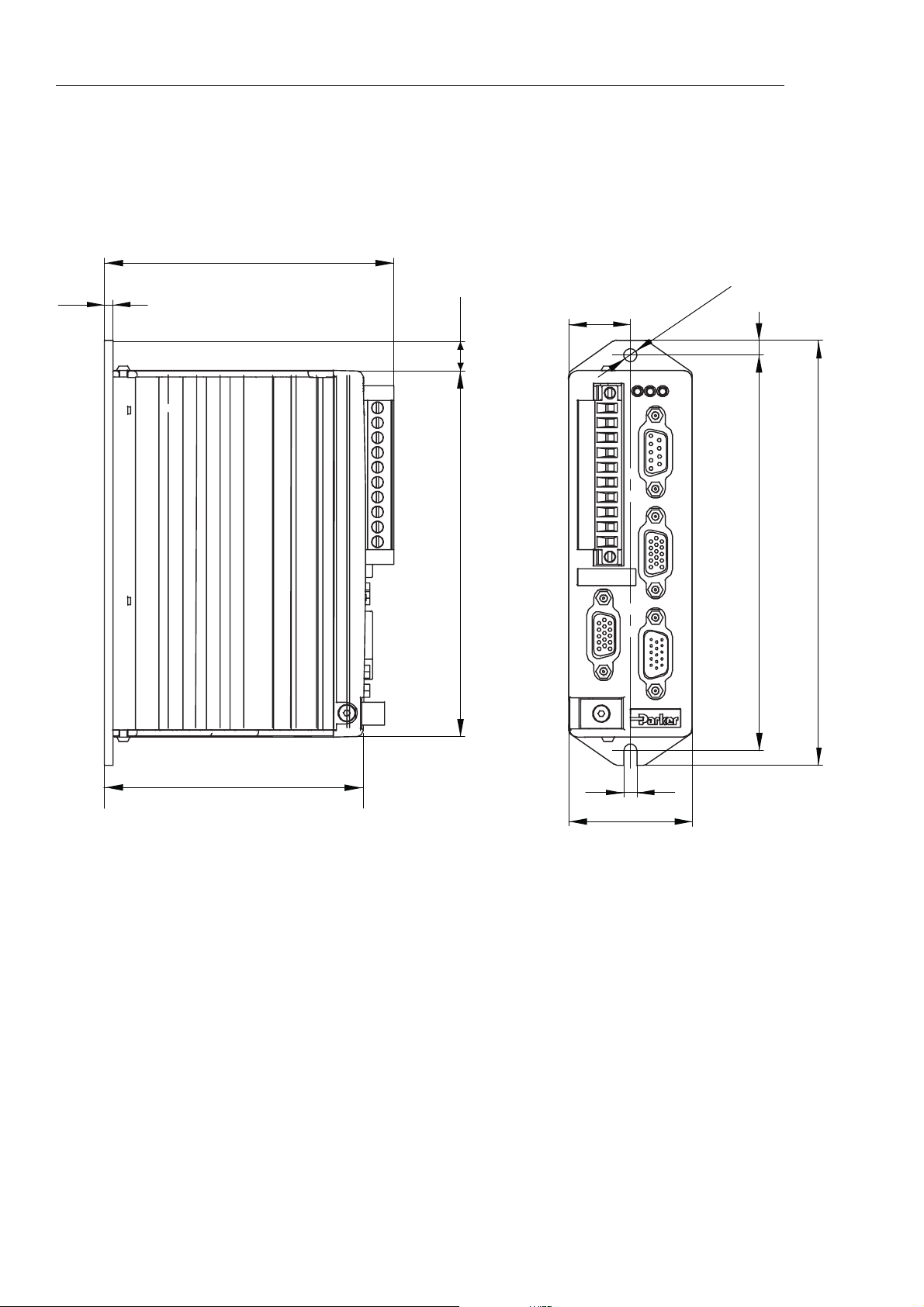

ViX250 and ViX500 drives share the same dimensions, shown in Figure 2-1.

98.5 (with connector)

3

10.1

124.7

21

X1

X2

HVSTFB

X3

X4

X5

5

135

145

4,5

88,1

4,5

42

Figure 2-1. ViX250 & ViX500 Dimensions

2. MECHANICAL INSTALLATION 7

Drive Mounting Options

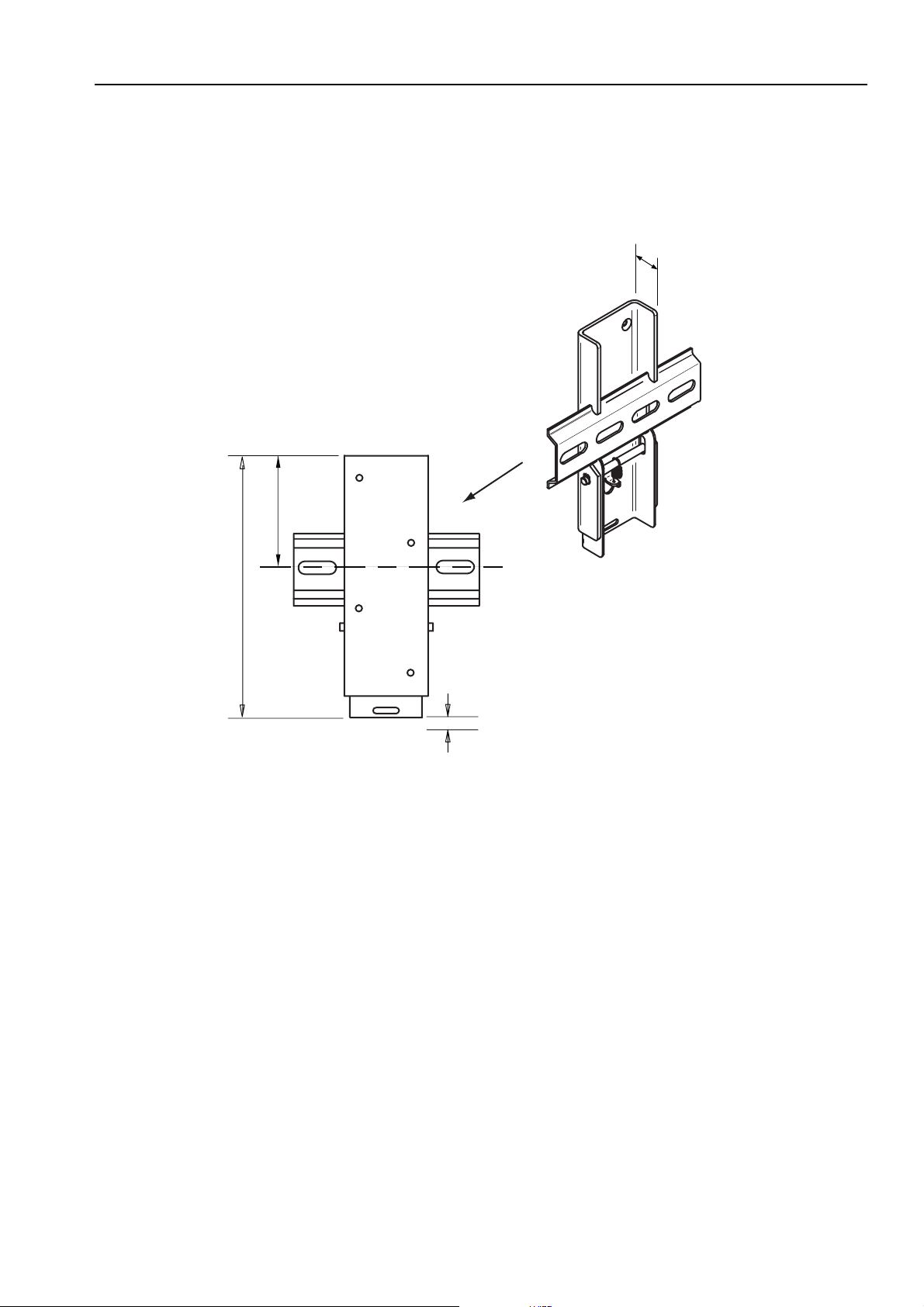

If you require a DIN-Rail mounting ViX drive use the optional DIN-Rail clip adapter bracket

shown in Figure 2-2.

16mm

57.2mm

Viewed from the back

131.2mm

of the DIN rail

Allow 10mm

for release

Figure 2-2. DIN-Rail Adapter Bracket

Remove the panel mounting plate from the back of the drive and attach the bracket to the

back of the drive using the screws provided. The drive and bracket can now be fixed to a

DIN rail by hooking the top of the bracket over the top of the DIN rail and gently pushing the

drive forward to engage the lower section of the bracket. Remove the bracket by inserting a

flat bladed screwdriver into the release slot to pull down the bottom of the bracket, releasing

it from the DIN rail.

8 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Motor Mounting Mechanical Considerations

Keep motors securely fixed in position at all times. Do not test a motor/drive combination

without first securing the motor – see the Safety Warning at the front of this user guide.

CAUTION – risk of equipment damage

Do not back drive the motor, that is use the motor in an application that causes

mechanical rotation of the motor shaft in a manner uncontrolled by the drive.

Back driving the motor at high speed may damage the drive.

3. ELECTRICAL INSTALLATION 9

3. Electrical Installation

Installation Safety Requirements

ViX stepper drives meet the requirements of both the European LVD & EMC directives when

installed according to the instructions given within this section. It is recommended the drive

be installed in an enclosure to protect it from atmospheric contaminants and to prevent

operator access while it has power applied. Metal equipment cabinets are ideally suited for

housing the equipment since they can provide operator protection, EMC screening, and can

be fitted with interlocks arranged to remove all hazardous motor and drive power when the

cabinet door is opened. Do not arrange interlocks to open circuit the motor phase

connections while the system is still powered, as this could cause damage to the drive.

Precautions

During installation, take the normal precautions against damage caused by electrostatic

discharges. Wear earth wrist straps. A switch or circuit breaker must be included in the

installation, which must be clearly marked as the disconnecting device and should be within

easy reach of the machine operator.

Cabinet Installation

To produce an EMC and LVD compliant installation we recommend that drives are mounted

within a steel equipment cabinet. This form of enclosure is not essential to achieving EMC

compliance, but does offer the benefits of operator protection and reduces the contamination

of the equipment from industrial processes.

A steel equipment cabinet will screen radiated emissions provided all panels are bonded to a

central earth point. Separate earth circuits are commonly used within equipment cabinets to

minimise the interaction between independent circuits. A circuit switching large currents and

sharing a common earth return with another low level signal circuit could conduct electrical

noise into the low level circuit, thereby possibly interfering with its operation. For this reason

so called ‘dirty earth’ and ‘clean earth’ circuits may be formed within the same cabinet, but all

such circuits will eventually need to be returned to the cabinet’s main star earth point.

Mount the individual drives and EMC filter on a metal earth plane. The earth plane will have

its own individual star point earth which should be hard wired (using an insulated copper

conductor) back to the cabinet’s ‘clean earth’ connection point.

LVD - Low voltage directive

EMC – Electro Magnetic Compatibility directive

10 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Power Supply Connections

Power drives from a DC supply derived from an isolating transformer or a DC power supply

(See Power Supply Options later in this section).

Note: Pin 10 is at the top of the connector X1 and pin 1 at the bottom.

Power & motor

10-way

connector

X1

10

+HV

9

8

7

6

5

4

3

2

1

-HV

PE

+24V DC

0V (GND 24v DC)

GND

MOTOR

CONNECTIONS

Figure 3-1. X1 Power Connections

WARNING – Possible drive damage

If you use Parker XL Series stepper drives, do not attempt to use any power wiring

harness taken from an XL drive. Although the same mating connector is used for

both an XL and a ViX, the ViX wiring is the reverse of the XL and the wrong wiring

connection will damage the drive.

Mating connector type is: Wieland 8213B/10 F OB, Part number 25.323.4053.0 (Parker part

number 0405.811).

Supply Requirements

Power the ViX drives from DC supplies as specified below:

Volts

Drive Type DC Supply Voltage

between +HV and -HV

ViX500 48V to 80V (recommended)

ViX250 24V to 80V

Table 3-1. Drive Supply Voltages

3. ELECTRICAL INSTALLATION 11

WARNING

The drive HV supply input is not reverse polarity protected.

Reverse polarity connections will damage the drive.

Current and Capacitance

A supply must have a minimum amount of capacitance to support a drive at peak power

draw.

Drive Type DC Supply Current Supply Capacitance

ViX500 5.6A RMS

ViX250 2.8A RMS

Table 3-2. Drive Supply Currents

6600µF

3300µF

+24V Requirements

Both drive types require a +24V controller and logic supply. The supply may also be

required for an encoder and a Fieldbus Expansion Module (FEM).

Absolute voltage range 20 to 27V

Nominal drive current 250mA (excluding encoder, & FEM)

Encoder supply loading 150mA (if required)

FEM current 50mA

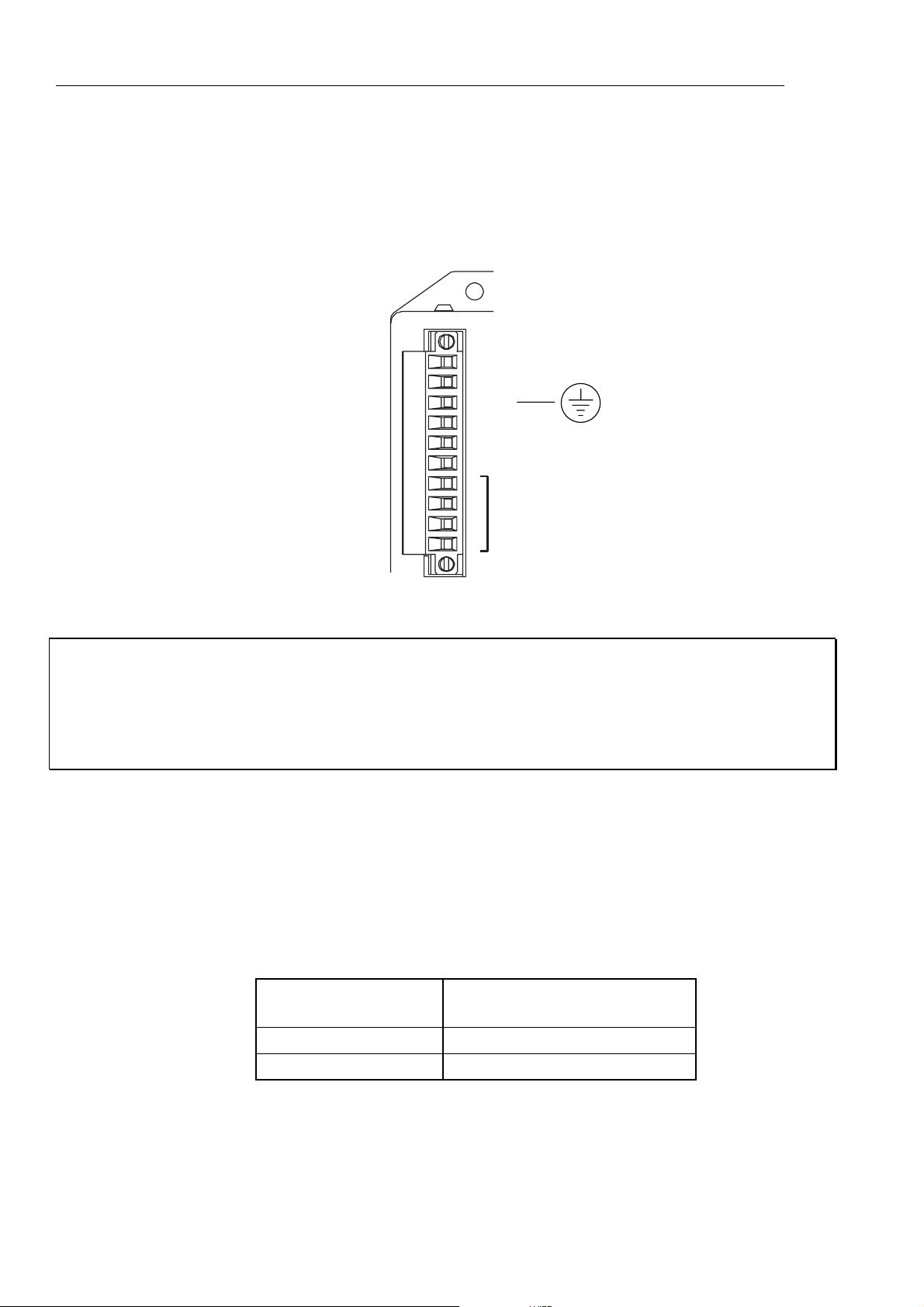

Safety Earth Requirements

Earth the drive using the earth pin on X1 (pin 8).

Power Supply Options

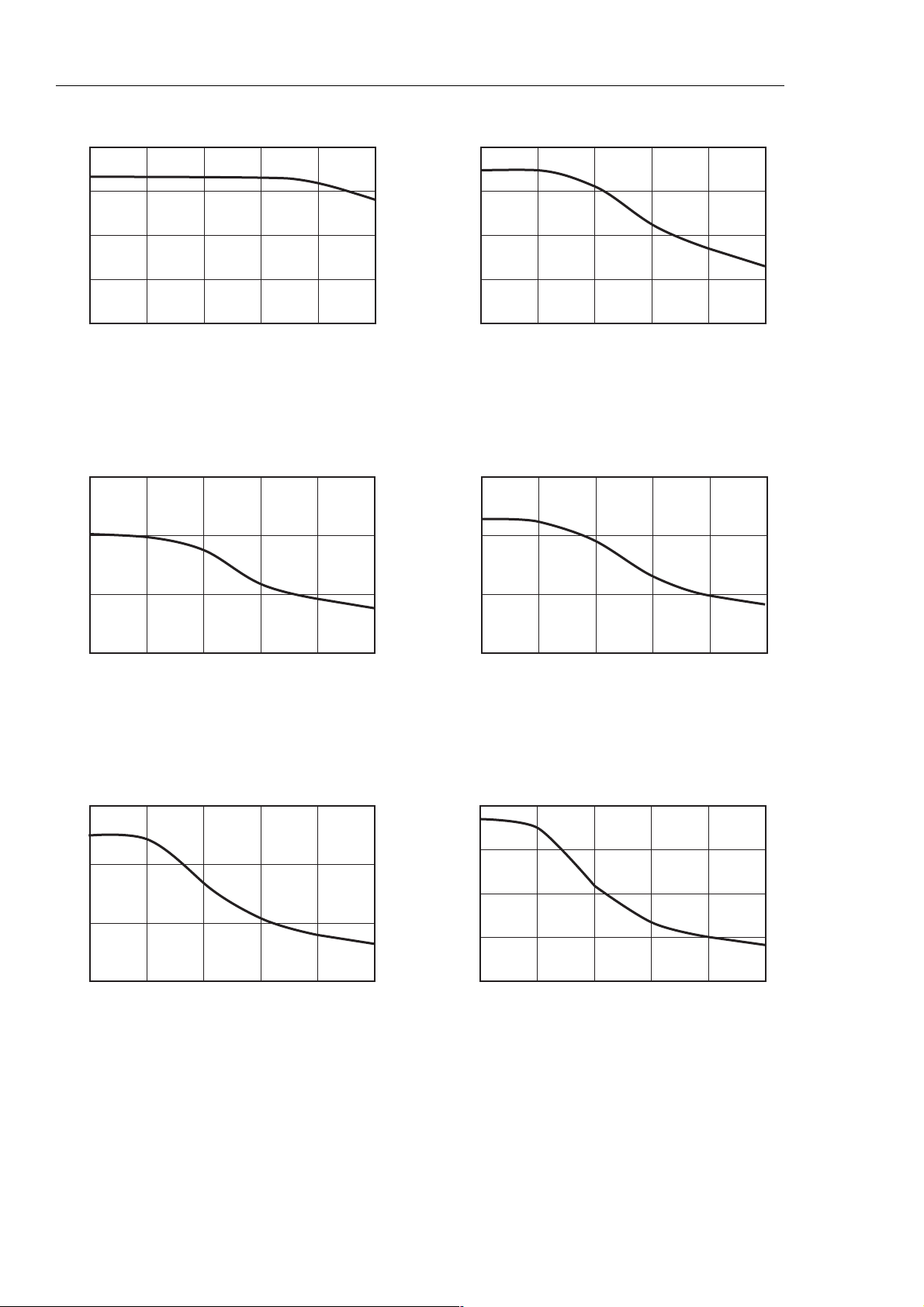

A set of torque curves (Figure 3-2) for various motor/drive combinations can be used for

calculating an applications likely power requirements.

Higher torque/current requirements will need to use the ViX500 drive and a high current

linear supply, such as the PL1100. Further power supply information is given in Appendix A.

12 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

N

N

N

mNm

0.4

0.3

0.2

0.1

0

0

ViX250 with SY561

10 20 30 40 50

0.8

0.6

0.4

0.2

0

0

ViX250 with SY562

10 20 30 40 50

Speed, revs/sec Speed, revs/sec

mNm

1.5

1.0

ViX500 with SY563

1.5

1.0

ViX250 with SY871

0.5

0

0

10 20 30 40

50

0.5

0

0

10 20 30 40 50

Speed, revs/sec Speed, revs/sec

mNm

3.0

2.0

1.0

0

0

ViX500 with SY872

10 20 30 40 50

4.0

3.0

2.0

1.0

0

0

ViX500 with SY873

10 20 30 40 50

Speed, revs/sec Speed, revs/sec

Figure 3-2. Stepper Drive Torque/Speed Data

3. ELECTRICAL INSTALLATION 13

XL-PSU Power Supply

The XL-PSU is a 250W, power factor corrected, switched mode power supply. Designed for

direct operation from world wide single phase AC input voltages, the supply is capable of

powering up to two ViX250 drives (see note 1) without the need for an EMC mains input filter

(see note 2). The use of the XL-PSU offers the following benefits:

• Auto-adapts to supplies between 95 and 264V AC

• No external EMC filter required

• Compact size

• Built-in +24V DC supply

Note 1: Check the application’s power requirements from the torque/speed curve of the

motor used.

Note 2: For drives with up to 30 metre motor leads.

For full installation instructions see the XL Power Supply leaflet 1600.300.XX.

14 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

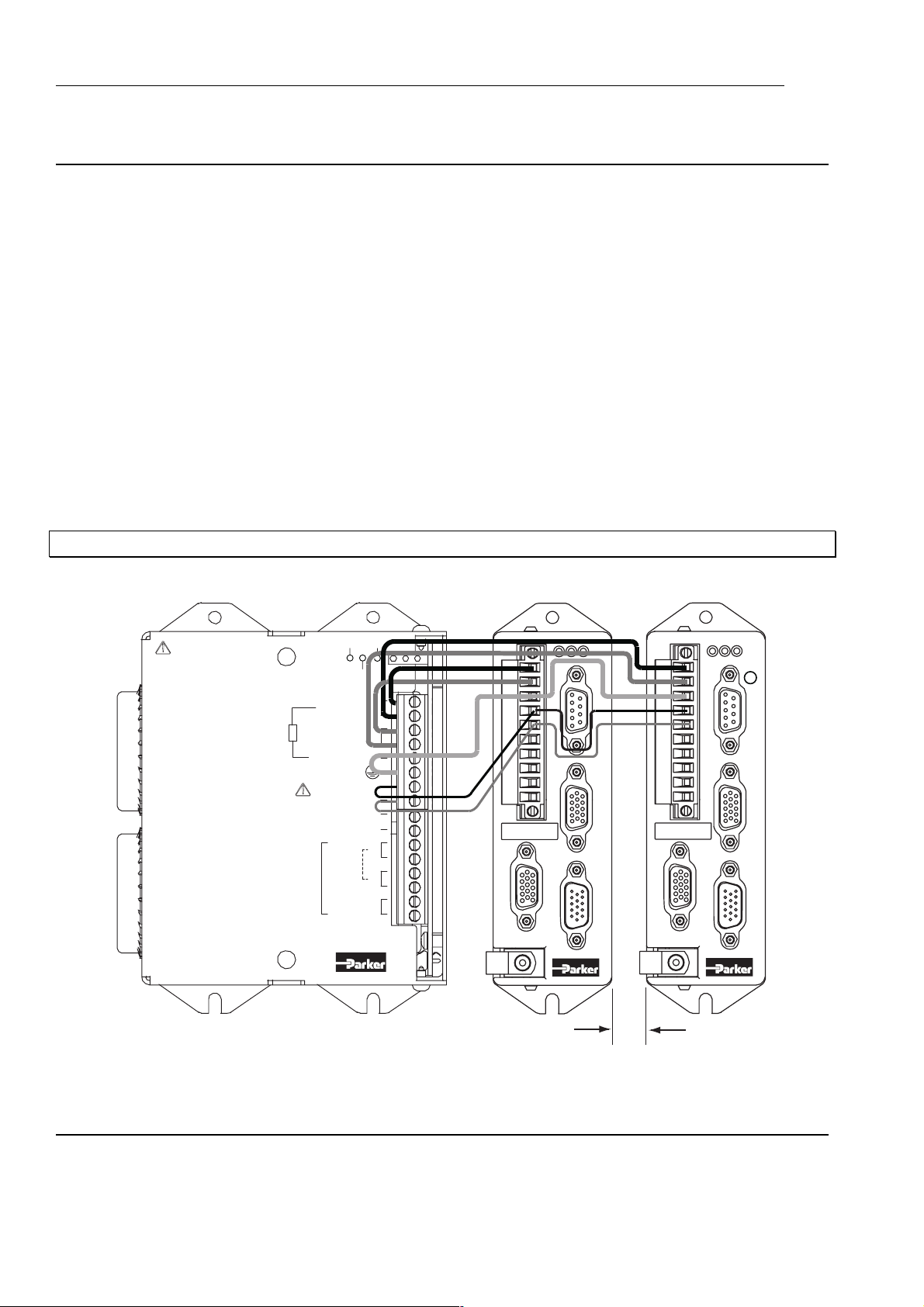

XL-PSU Supply/Drive Connections

When used to supply up to two drives the power supply can be wired as shown in Figure 3-3.

X1

10

1

ST

HV FB

X3

X4

10 mm

Mininum spacing

between drives & PSU

1

+DC (80V)

-DC

EXT. BRAKING RES.

+24V

GND

10

If the supply is positioned

this side of the drive

avoid blocking access to

D-type X3

P1

P2 mating socket

X2

MAINS

N

INPUT

X5

L

110V-230V~

50/60 Hz

250VA

P2

XL

Power

Supply

Unit

HV STATUS

BRAKING RES.

24V STATUS

Figure 3-3. XL Power Supply and Drive Connections

LN

EARTH (GND.)

The XL_PSU must

be securely earthed

Note: A kit of five connecting links is available, called ‘XL-connect’. You will need one kit for

every drive.

3. ELECTRICAL INSTALLATION 15

XL-PSU Mounting Information

Mount the supply vertically, near the drives it will supply. Both the top 4.5mm diameter fixing

hole and the bottom two 4.5mm width fixing slots should be used.

Allow a minimum free space of 50mm both below and above its case and 10mm free space

on both sides.

Do not mount the supply above or close to other products that generate a significant amount

of heat by radiation or convection.

16 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

PL1100 Power Supply

General Description

The PL1100 is a linear power supply with a rated output of 1120W (80V/14A) for use with

ViX and XL series drives. The supply requires a suitably rated transformer supplying 50V

AC RMS for the HV and 20V AC RMS for the +24V DC. The use of the PL1100 offers the

following benefits:

• Provides 80V HV and +24V DC output

• Single or three phase operation

• Built-in power dump switch

• Integral fusing

Figure 3-4 shows the PL1100 output wiring for two ViX drives. This illustrates how to route

the main HV supply separately to each drive. The lower current requirements of the +24V

logic/brake supply can allow the wiring to be linked between drives.

For full installation instructions see the PL1100 Power Supply leaflet 1600.323.XX.

ST

CAUTION

Risk of electric shock.

High voltage remains on terminals

after power is removed.

Allow 5 minutes for capacitors

to discharge.

PL1100

Power Supply

55V

AC IN

1/3 PH.

HV

REGEN

X1

MOTOR HV OUT

MOTOR 0V.

EXT. BRAKING RES.

PE

+24V DC OUT

20V AC IN

20V AC IN

LINK

FOR

SINGLE

PHASE

X2

+24V

0V

L3

L2

L1

X1

X2

ST

HV FB

10

X3

X4

1

X5

X1

10

X2

HV FB

X3

X4

1

X5

10 mm MIN

Figure 3-4. PL1100 Power Supply and Drive Connections

3. ELECTRICAL INSTALLATION 17

EMC Installation

These EMC installation recommendations are based on the expertise acquired during the

development of compliant applications, which Parker believes are typical of the way, a drive

or drives may be used. Provided you have no special installation requirements or untypical

operating environment requirements, ViX drives will conform to current EMC Directives, as

defined at the front of this user guide.

General Requirements

ViX mounted drives, unless used with an XL-PSU, will require an EMC supply filter to meet

EMC installation compliance requirements. Mount the drive on a conductive panel which is

shared with the EMC filters. If the panel has a paint finish, it will be necessary to remove the

paint in certain areas to ensure filters and drive make a good large-area metal to metal

contact between filter case and panel.

Mount filters close to the drive and keep the supply wiring as short as practical. Attempt to

layout the wiring in a way that minimises cross coupling between filtered and non-filtered

conductors. This means avoiding running wires from the output of a filter close to those

connected to its input. Where you wish to minimise the cross coupling between wires avoid

running them side-by-side one another, if they must cross, cross them at 90° to each other.

Keep wiring supported and close to cabinet metalwork.

Recommended EMC filter types are CORCOM 6FC10 for loads up to 6A and 3VK1 for the

+24V supply up to 3A. Multi-axis systems may require higher current rated filters.

+24V Supply Connections

ViX drives not using an XL-PSU will require a logic supply of +24V DC at 250mA (nominal)

per drive. The +24V powers the controller and I/O circuits. Keeping the +24V independent

of the drive’s internal high voltage bus supply allows the option of keeping the I/O and

controller active when no main supply is present.

Connect the +24V supply to X1 pin7 and the return to X1 pin6, the total wire length, from

supply to drive, must not exceed 10m.

Connect the +24V supply 0V line to system earth (0V) at some convenient point before the

EMC filter input, as shown in the recommended EMC layout diagram, Figure 3-5.

The 24V supply to each drive should be fitted with a time-delay fuse, rated at 3A. Note: The

+24V supply used must meet the voltage requirement specification of +24V DC +10% -15%,

ripple <1V p-p.

18 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

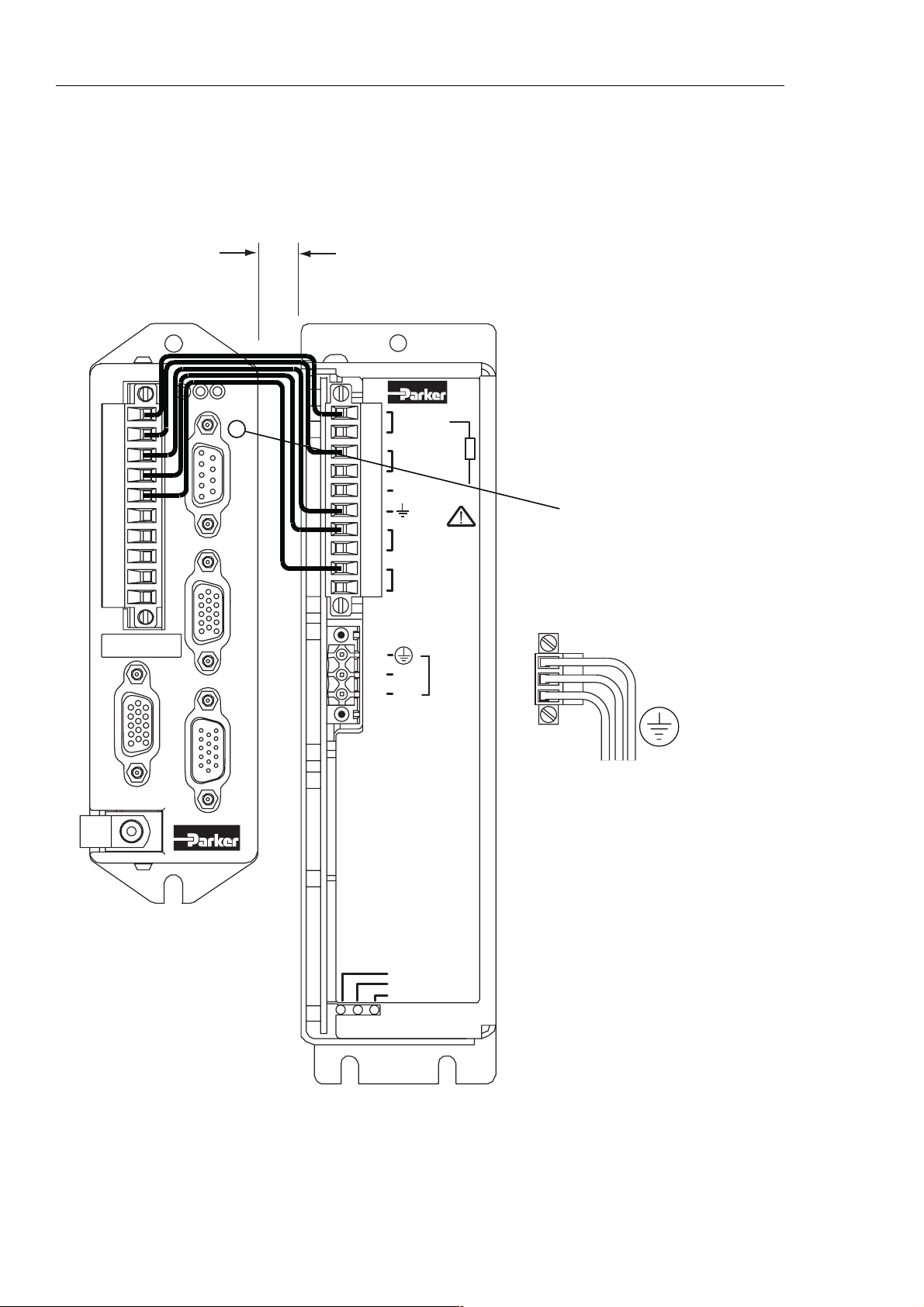

ST

HV FB

X1

10

X3

Lead length

restriction

(less than 1 metre)

DC Supply

X4

1

X2

X5

CABINET

BACK

PLANE

Star earth point

to the metal

backplane

Located in

the base of

the cabinet

Transformer

AC Supply

CORCOM

Figure 3-5. ViX EMC Installation

(load)

Output

6FC10

(line)

Input

Power wiring conduit

LOAD

3VK1

LINE

+-

DC 24V Supply

3. ELECTRICAL INSTALLATION 19

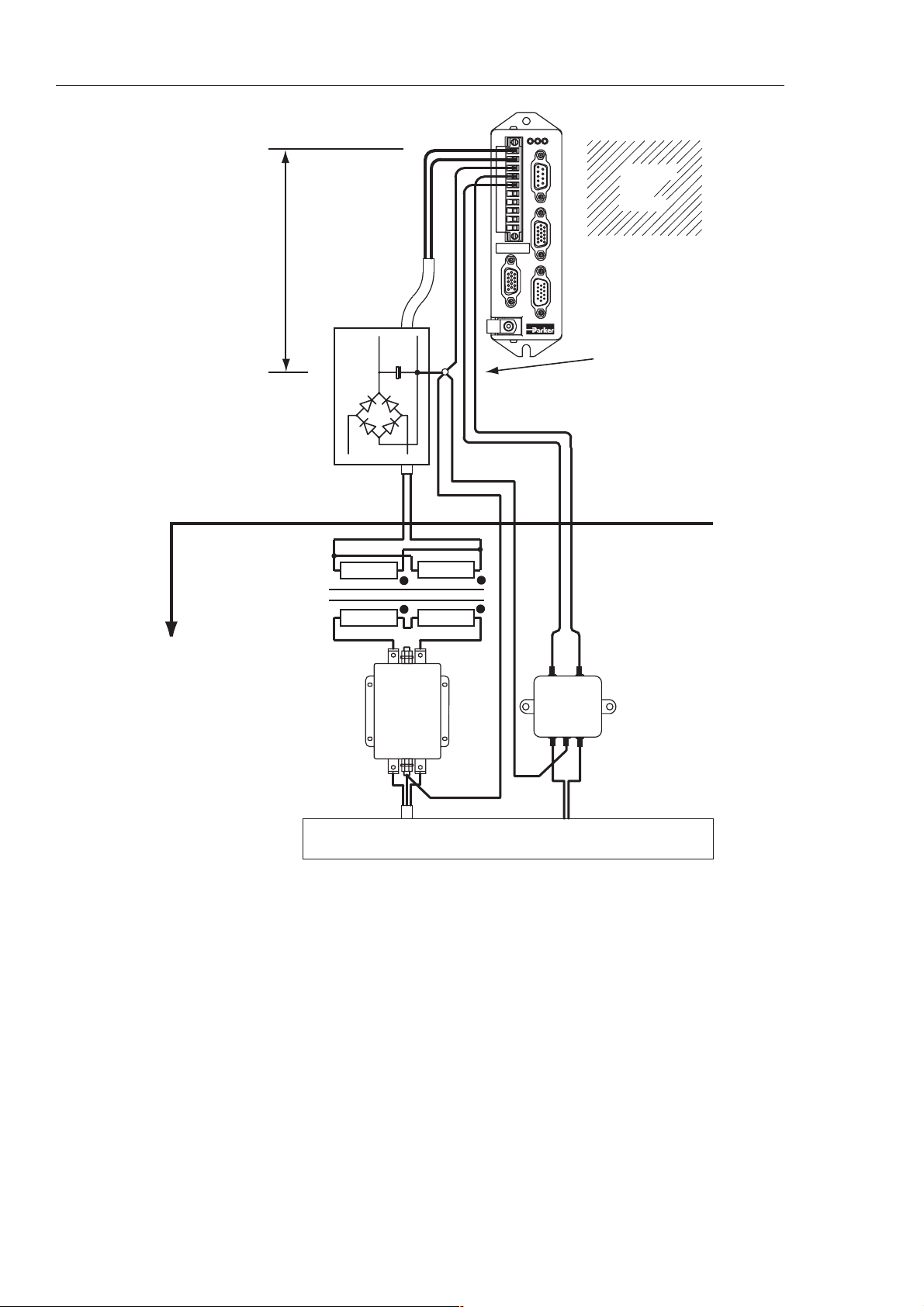

Motor Connections to the Drive

The recommended wire size for ViX250IM/500IM motor cables, of length less than 20m, is

1mm2. For motor cable lengths greater than 20m (up to a maximum of 50m) use a wire size

of 2.5mm

34805), the green wire being used to provide an earth return to the drive. Termination at the

motor must be made using a 360° bond to the motor body, and this may be achieved by

using a suitable clamp. Many stepper motors are designed to accommodate an appropriate

terminal gland which can be used for this purpose.

At the drive end of the cable, a 360° connection to the screen should be made using the

P-clip provided beneath the motor connector. The P-clip needs to be firmly clamped to the

copper braid. If the connection appears loose, fold the braid back on itself to increase the

amount of braid under the clip and re-tighten.

Custom cables will require the cable insulation to be removed to expose the braided screen.

If you are using a motor cable with 2.5mm

9mm to accommodate the increased cable diameter. A ferrite absorber, with a specification

matching that of the Chomerics H8FE-1115-NC, is also required to be positioned on the

motor cable using heat shrink sleeving or cable ties. The position of the absorber should be

within 150mm of the drive. Always secure the cable using the P-clip, as shown. Do not rely

upon the connector alone holding the motor cable in place. Avoid stress on the X1

connector by hanging cables, as this may lead to connector over-heating.

2

. Use a cable containing five conductors plus the braided screen (such as Lapp

2

conductors the size of the P-clip will need to be

Make a 360° connection to the screen using one of the stainless steel or brass P-clips

supplied within the fit kit.

Size Parker part number

9mm ID 4216.101

10.7mm ID 4216.102

12.3mm ID 4216.103

Table 3-3. P Clip sizes

Three different size ‘P’ clips allow the use of a variety of motor power cables from different

manufactures.

There must be no break in the 360° coverage that the screen provides around the cable

conductors. If a connector must be used it should retain the 360° coverage, possibly by the

use of an additional metallic casing where it passes through the bulkhead of the enclosure.

The cable screen must not be bonded to the cabinet at the point of entry. Its function is to

return high-frequency chopping current back to the drive. This may require mounting the

connector on a sub-panel insulated from the main cabinet, or using a connector having an

internal screen which is insulated from the connector housing. Within the cabinet itself, all

the motor cables should lie in the same trunking as far as possible. They must be kept

separate from any low-level control signal cables. This applies particularly where the control

cables are unscreened and run close to the drive.

20 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Note that the motor cable routing within the equipment cabinet should be kept at least

300mm away from I/O cables carrying control signals.

All motor connections must be made using a high quality braided-screen cable. Cables

using a metallised plastic bandage for an earth screen are unsuitable and in fact provide

very little screening. Care must be taken when terminating the cable screen, the screen

itself is comparatively fragile; bending it round a tight radius can seriously affect the

screening performance. The selected cable must have a temperature rating which is

adequate for the expected operating temperature of the motor case.

Motor Cables

Motor cables may be ordered using the part numbers listed in Table 3-4.

Product code/Part

number

STC20-0300 3

STC20-0500 5

STC20-1500 15

Table 3-4. Motor Cables

Length (metres)

Motor Phase Contactors

We recommend that motor phase contactors are not used within the motor power cables. As

an alternative, make use of the drive’s power stage ‘enable’ control signal.

Ferrite absorber specifications

The absorbers described in these installation instructions use a low-grade ferrite material

that has high losses at radio frequencies. They therefore act like a high impedance in this

waveband. Produced by Parker Chomerics, the recommended component is suitable for use

with cable having an outside diameter up to 10mm. The specification is as follows:

Chomerics part number H8FE-1115-NC (Parker part number 0313.020)

Outside diameter 17.5mm

Inside diameter 10.7mm

Length 28.5mm

Impedance at 25MHz 80 ohm

Impedance at 100MHz 120ohm

Curie temperature 130°C (the device should not be operated near this temperature)

3. ELECTRICAL INSTALLATION 21

Motor Selection

Usually optimum performance will be obtained when the current rating of the motor is

between 1 and 1.5 times the drive rating. Drives can be de-rated to accommodate motors

with lower current ratings (using variable MC within the MOTOR command), however the

high speed torque will be reduced.

Do not use a drive setting which gives an output current greater than the motor rating.

With 4 lead motors the bipolar rating is quoted and this should match the criteria stated

above.

With 8 lead motors the bipolar rating of the motor, which is normally quoted, refers to a

parallel winding connection. With the windings connected in series the current rating of the

motor connection will be 50% that of the bipolar rating, and the motor will give improved lowspeed torque, but reduced high-speed torque.

The ViX250IM/ViX500IM will drive motors having an inductance as low as 0.5mH and as

high as 20mH, but the recommended motor inductance range is between 0.8mH and 10mH.

Performance of the ViX250/ViX500IM is optimised for the following motor types, listed in

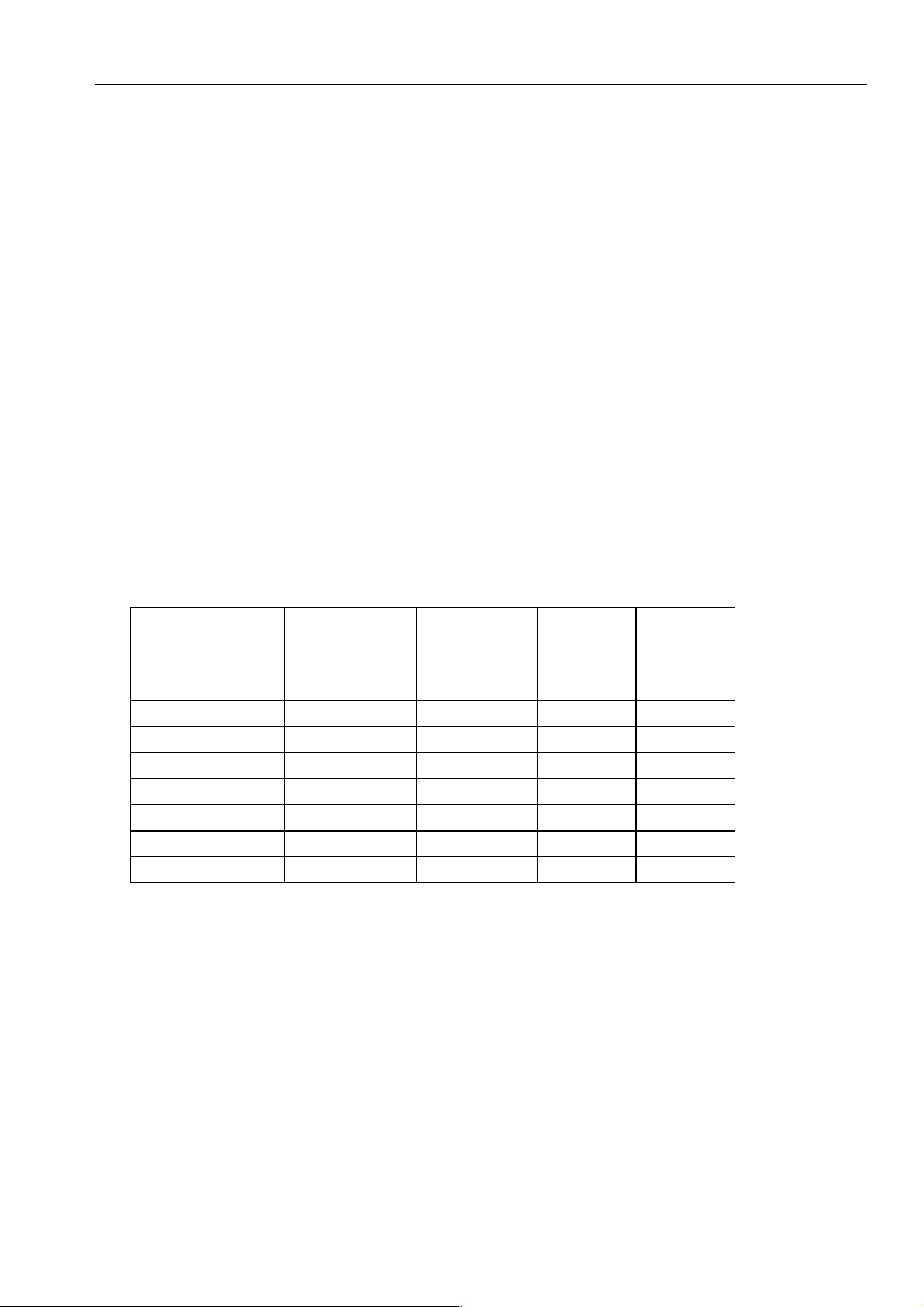

Table 3-5.

Motor Type Motor Rated

Current in

Amps*

SY561 4.2 1.0

SY562 4.2 2.6

SY563 6.5 1.2

SY871 4.2 1.6

SY872 6.5 1.5

SY873 8.4 1.7

SY1072 8.0 2.4

*(parallel connection)

Table 3-5. SY Optimum Motor Types

Motor Voltage Ratings

Motors with a withstand voltage rating from phase to earth of 1000V AC should be used. An

insulation withstand rating of 500V AC is acceptable if an isolating transformer with earthed

screen is used to power the system, and 0V input is earthed, as specified.

Motor

Inductance

in mH per

phase*

ViX500IM ViX250IM

✔

✔✔

✔

✔✔

✔

✔

✔

22 VIX IM MICROSTEPPER INDEXER DRIVE USER GUIDE

Large Motors

The largest recommended motor size is a 34-frame 3-stack. Please contact Parker if

you wish to use a larger frame motor.

Motor Connections at the Motor

Motor connections should be made directly between the drive and motor, the use of any

switching devices, such as contactors is not recommended.

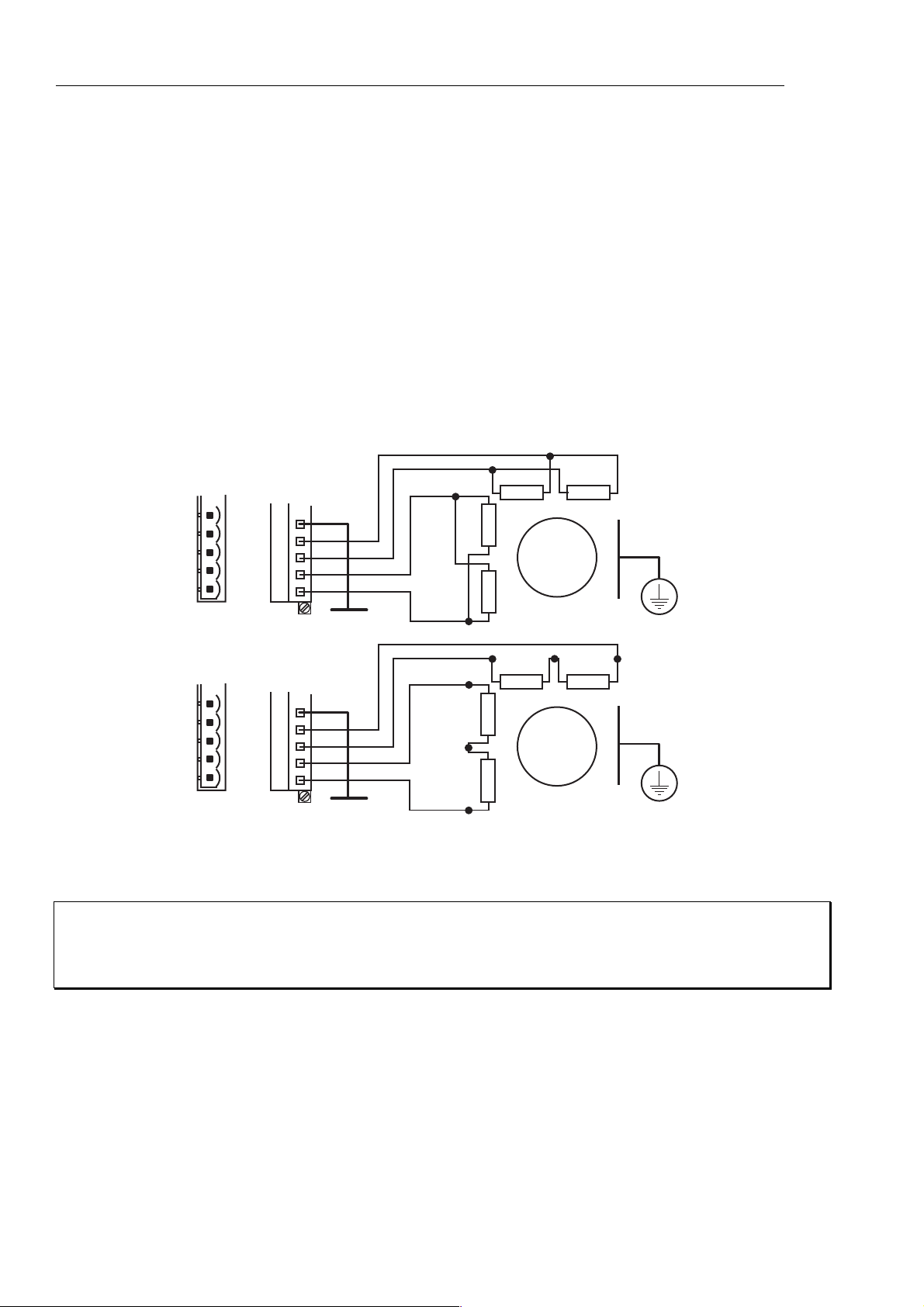

In the majority of applications the drive will be used with an eight lead motor with the

windings connected in parallel or series, as shown in Figure 3-6. Motor connections will

need to be determined from the motors data sheet or Appendix B. These are normally

identified by wire colour or terminal markings, depending upon the make of the motor.

+

-

+

MOTOR CONNECTOR

X1

5

4

3

2

1

Gnd

A+

AB+

B-

Motor case

-

+

-

+

-

MOTOR

PARALLEL

CONNECTIONS

SAFETY

EARTH

MOTOR CONNECTOR

X1

5

4

3

2

1

Gnd

A+

AB+

B-

Motor case

-

+

-

+

-

SERIES

CONNECTIONS

MOTOR

SAFETY

EARTH

+

-

+

Figure 3-6. 8 Lead Motor Connection Options

WARNING - High Temperature

The motor case temperature may exceed 70°C and should be guarded from operator

contact.

Motor Safety Earth/Ground Connection

It is recommended that the motor is independently bonded to a local safety earth point. The

safety earth lead should be at least 2.5mm

2

in area.

3. ELECTRICAL INSTALLATION 23

Custom Motor Set Up

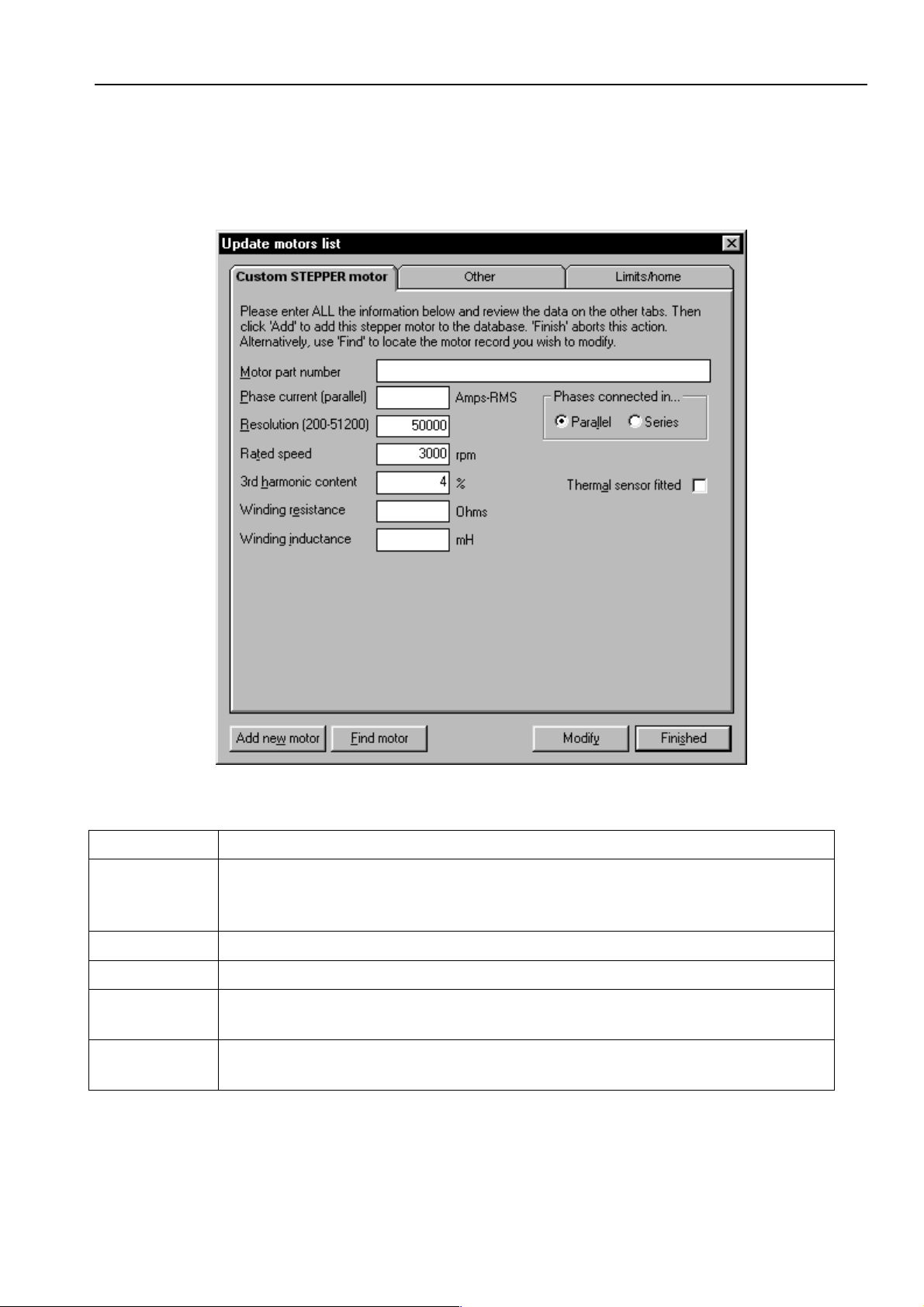

Within screen 2 of Guided stepper initialisation, clicking upon the Setup custom button will

open the window shown in Figure 3-7.

Figure 3-7. EASI-V Custom Motor Configuration Window

Motor the general name/number for the motor.

Phase

current

(parallel)

Resolution number of steps per revolution

Rated speed shaft speed in rpm for a rotary stepper.

Winding

resistance

Winding

inductance

continuous current rating of the motor in Amps RMS.

resistance of a single phase winding measured line-to-line in Ohms.

inductance of a single phase winding measured line-to-line in mH.

Loading...

Loading...