Page 1

Use Parker Push-Lok hose

cutters to ensure quick and

easy cutting.They are designed

for use on all Push-Lok hose

sizes and non-wire hose up

to 1-1/8" O.D.

TH11-1

Hose Cutter

Designed to squarely cut

Push-Lok hose 1/4" I.D.

through 3/4" I.D.

881540

Hose Cutter with Toggle

This unique tool combines a hose

cutter with a toggle action that

presses the fitting into the hose,

making every job easier, whether

you are making one assembly

or a hundred. It is designed to

handle Push-Lok hose from

1/4" through 3/4".

Overall length:16"

Weight

: approximately 4 pounds

Parker Hannifin Corporation

Hose Products Division

30240 Lakeland Boulevard

Wickliffe, Ohio 44092 USA

Phone: (440) 943-5700 • Fax:(440) 943-3129

www.parkerhose .com

4281-B1-US 2/03 MK 15M

Push-Lok Hose Cutters

Parker Instrumentation worldwide locations:

Parker Push-Lok

®

Hose and Fittings

Bulletin 4281-B1-US

February 2003

The World Standard

Africa (27) 11 9610700

Argentina (54) 3327 444129

Australia (61) (2) 9634 7777

Azerbaijan (99 412) 983 966

Brazil (55) (12) 354 5304

Canada (905) 945 2274

China (86) (21) 6445 9339

Finland (358) 9 47673200

France (33) 141 115390

Germany (49) 2131 40610

Hong Kong (852) 2260 8289

India (91) 22 55907081

Italy (39) (2) 451921

Japan (81) (3) 6408 3900

Korea (82) 55 3890100

Latin/Caribbean Countries

(305) 470 8800

Mexico (52) (722) 272 22 22

Norway (47) (64) 91100

Portugal (351) 229997360

Russia (7) 095 2340054

Singapore (65) 6887 6300

Spain (34) 916757300

Sweden (46) 8 59795120

Taiwan (886) (2) 2298 8987

Thailand (662) 717 8140

United Arab Emirates

(971) (2) 67888587

United Kingdom (44) 1271 313131

Venezuela (58) 212 2385 422

Failure or improper selection or improper use of hose,tubing, fittings,assemblies or related accessories (“Products”) can

cause death, personal injury and property damage. Possible consequences of failure or improper selection or improper

use of these Products include but are not limited to:

W ARNING

Before selecting or using any of these Products, it is important that you read and follow Parker Safety Guide for Selecting and Using

Hose, Tubing, Fittings and Related Accessories (Parker Publication No.4400-B.1- Revised May, 2002). Only Hose from Parker’s Stratoflex

Products Division is approved for in flight aerospace applications, and no other Hose can be used f or such in flight applications .

• Fittings thrown off at high speed

• High velocity fluid discharge

• Explosion or burning of the conveyed fluid

• Electrocution from high voltage electric power lines

• Contact with suddenly moving or falling objects that are

controlled by the conveyed fluid

• Injections by high-pressure fluid discharge

• Dangerously whipping Hose

• Contact with conveyed fluids that may be hot, cold, toxic

or otherwise injurious

• Sparking or explosion caused by static electricity buildup

or other sources of electricity

• Sparking or explosion while spraying paint or flammable liquids

• Injuries resulting from inhalation, ingestion or exposure to fluids

!

Page 2

Easier, faster line

identification

In applications where a number

of hose lines carry different media,

Push-Lok colors reduce timely

“tracing” of lines, preventing

disconnection of the wrong line and

unnecessary, costly downtime.

More efficient,

preventive maintenance

Using color-coded Push-Lok hose

is an excellent way to keep track

of scheduled replacement of lowpressure hose in your operations.

Just assign a different color hose

to each replacement period and

eliminate the possibility of missing

lines scheduled for replacement.

Enhance your

products’ appearance

For equipment manufacturers and

their customers, using Push-Lok

color hoses can vastly improve the

visual and functional appeal of

work equipment, on-line systems

and the overall facility.

Create efficient

inventory control

Assign a Push-Lok

color to each

department for

its maintenance

requirements.

The color

system helps

assure that

hoses are

routed to their

correct areas,

resulting in better

control over hose

inventories.

Help identify

industrial drop lines

Use Push-Lok colors to identify

drop line length and diameter for

faster and easier replacement.

When replacing by color, the

right size and length are

automatically set.

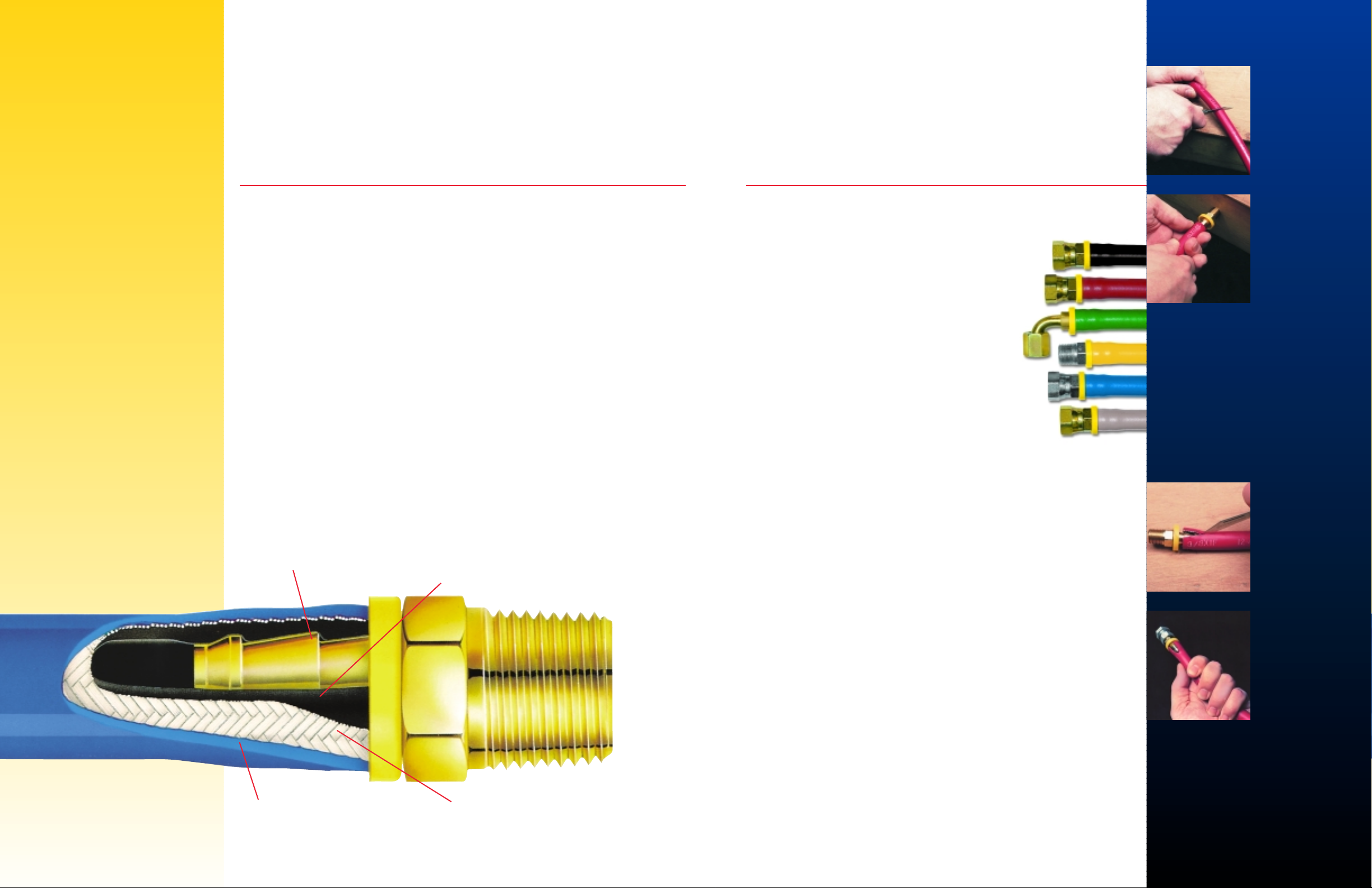

Inner liner is an extruded, synthetic

rubber, making it resistant to

petroleum-base oil, air and water.

Barbed Push-Lok fitting seals

tightly, securely.

High-quality elastomer cover –

lively feel, excellent flexibility

and resistance to abrasion.

Fiber braid reinforcement layer

is impregnated with synthetic

rubber for added durability.

Advantages of the Push-Lok

Color Coding System

1.Cut hose cleanly

and squarely with

a sharp knife or a

Parker Push-Lok

cut-off tool.

2.Lubricate the

Push-Lok fitting

and/or hose I.D.

with a light oil or

soapy water only.

Do not use heavy

oil or grease.

3.Insert fitting into

hose until the

barb is in the

hose.

4.Place end fitting against a flat object

(bench or wall).Grip hose approximately

one inch from end and push with steady

force until the end of the hose bottoms

on the fitting and is covered by the

yellow plastic cap.

1.Leave fitting in

place and cut

hose lengthwise

from the yellow

cap approximately

one inch.

IMPORTANT:

Be careful not to

nick barbs when

cutting hose.

2.Grip hose and

give a sharp

downward tug

to disengage

the fitting.

Caution: Push-Lok fittings will properly

grip Push-Lok hose only when pushed

all the way in with the cut end of the

hose completely concealed by the

yellow plastic cap.

Sealing integrity may be damaged

by using exterior clamps.

Premium products and

leak-free solutions are

what you’ll get with every

Parker Push-Lok hose and

fitting system. With the

most complete line of

high-quality, low-pressure

hose and fittings, Push-Lok

is the answer to all your

instrumentation needs.

The Benefits of Parker Push-Lok

®

Offering easy assembly

and organization

The Push-Lok system is easy

to use.No clamps or special tools

are required during installation.

And with Parker’s exclusive colorcode system, you can inventory,

maintain and identify your hose

needs easily and efficiently.

Providing exceptional value

Parker Push-Lok assemblies

can be made in seconds, saving

valuable time and money.What’s

more, Push-Lok fittings are

reusable.Just replace the hose

at the job site without any

special tools or clamps.

Meeting all your

special needs

Helping you maintain a clean

environment on the job is another

important reason to use Parker’s

Push-Lok system. Its unique seal

ensures reliability and durability

for clean-environment use .

Assembly is easy

Disassembles fast

Page 3

Color Codes:

Example: 801-8-RED is 1/2" 801 Red hose.

If no color is specified, 801 Gray

will be supplied.

Fittings: Push-Lok 82 Series.

Parker Push-Lok Hose

801 Color-Coded Hose

Made of the highest-quality elastomeric compounds for a lively feel, excellent flexibility

and long-lasting service on the job.

831 Heavy-Duty Hose

Produced to handle higher-pressure jobs with ease and dependability.

836 Hi-Temp, Heat-Resistant Hose

Ideal for high-temperature applications.

Construction:

Synthetic rubber tube; one textile braid

reinforcement;MSHA accepted synthetic

rubber cover. Furnished in gray, red,

yellow, blue, green or black.

Application and Temperature Range:

Widely used for shop air systems and

general industrial, maintenance and

automotive applications.

Low-pressure service hose for use with:

• Petroleum-based hydraulic fluids and

lubricating oils within a temperature range

of -40°F to +212°F (-40°C to +100°C).

• Water, water/oil emulsion, and water/

glycol hydraulic fluids up to +185°F

(+85°C).

• Air within a temperature range of -40°F

to 158°F (-40°C to +70°C).

Construction:

Synthetic rubber tube; one textile braid

reinforcement;MSHA accepted synthetic

rubber cover. Furnished in red, blue,

green, or black.

Application and Temperature Range:

Widely used for shop air systems and

general industrial, maintenance and

automotive applications.

Low-pressure service hose for use with:

• Petroleum-based hydraulic fluids and

lubricating oils within a temperature range

of -40°F to +212°F (-40°C to +100°C).

• Water, water/oil emulsion, and water/

glycol hydraulic fluids up to +185°F

(+85°C).

• Air within a temperature range of -40°F

to 158°F (-40°C to +70°C).

Construction:

PKR

®

elastomer tube; one textile braid

reinforcement;MSHA accepted blue

synthetic rubber cover with

embossed layline.

Application and Temperature Range:

High-temperature service hose for use with:

• Petroleum based hydraulic fluids and

lubricating oils within a temperature range

of -55°F to +302°F (-48°C to +150°C).

• Water, water/oil emulsion, water/glycol,

and hydraulic fluids up to +185°F

(+85°C).

• Air within a temperature range of -40°F

to +158°F (-40°C to +70°C).

GRA RED YEL BLU GRN BLK

Color Codes:

Example: 831-8-BLU is 1/2" 831 Blue hose.

If no color is specified, 831 Black

will be supplied.

Fittings: Push-Lok 82 Series.

RED BLU GRN BLK

Color Codes:

Fittings: Push-Lok 82 Series.

BLU

Part Working Burst Minimum

Number I.D. O.D. Pressure Pressure Bend Radius Weight inches kPa

inch mm inch mm psi MPa Bar psi MPa Bar inch mm lbs/ft kg/m of Hg (abs)

836-4 1/4 6,3 0.50 12,7 250 1,7 17 1000 6,8 68 2-1/2 65 0.09 0,13 28 6

836-6 3/8 10 0.63 15,9 250 1,7 17 1000 6,8 68 3 75 0.11 0,16 28 6

836-8 1/2 12,5 0.78 19,8 250 1,7 17 1000 6,8 68 5 125 0.18 0,27 28 6

836-10 5/8 16 0.91 23 250 1,7 17 1000 6,8 68 6 150 0.19 0,28 15 50

Part Working Burst Minimum

Number I.D. O.D. Pressure Pressure Bend Radius Weight inches kPa

inch mm inch mm psi MPa Bar psi MPa Bar inch mm lbs/ft kg/m of Hg (abs)

801-4 1/4 6,3 0.50 12,7 250 1,7 17 1000 6,8 68 2-1/2 65 0.09 0,13 28 6

801-6 3/8 10 0.63 15,9 250 1,7 17 1000 6,8 68 3 75 0.11 0,16 28 6

801-8 1/2 12,5 0.78 19,8 250 1,7 17 1000 6,8 68 5 125 0.18 0,27 28 6

801-10 5/8 16 0.91 23 250 1,7 17 1000 6,8 68 6 150 0.19 0,28 15 50

801-12 3/4 19 1.03 26,2 250 1,7 17 1000 6,8 68 7 180 0.24 0,36 15 50

801-16 1 25 1.28 32,6 175 1,2 12 700 4,8 48 10 250 0.37 0,55 15 50

Part Working Burst Minimum

Number I.D. O.D. Pressure Pressure Bend Radius Weight inches kPa

inch mm inch mm psi MPa Bar psi MPa Bar inch mm lbs/ft kg/m of Hg (abs)

831-4 1/4 6,3 0.50 12,7 350 2,4 24 1400 9,7 97 2-1/2 65 0.09 0,13 28 6

831-6 3/8 10 0.63 16 300 2,0 20 1200 8,3 83 3 75 0.11 0,16 28 6

831-8 1/2 12,5 0.78 20 300 2,0 20 1200 8,3 83 5 125 0.18 0,27 28 6

831-10 5/8 16 0.91 23 300 2,0 20 1200 8,3 83 6 150 0.19 0,28 15 50

831-12 3/4 19 1.03 26 300 2,0 20 1200 8,3 83 7 180 0.24 0,36 15 50

Note: Push-Lok hose is recommended for vacuum applications but not for cooling lines in air conditioners and heat pumps, or for hydraulic applications

where extreme pulsations are encountered.Push-Lok is not recommended for any fuel.

801 Color-

Coded Hose

831 Heavy-

Duty Hose

836

Hi-Temp,

Heat-

Resistant

Hose

Page 4

Cut-Off

Allowance

Part Number Thread I.D. A H B

inch inch inch mm inch inch mm

30682-4-4 7/16x20 1/4 1.52 39 9/16 0.77 20

30682-6-6 9/16x18 3/8 1.75 44 11/16 0.85 22

30682-8-8 3/4x16 1/2 2.02 51 7/8 0.97 25

30682-10-10 7/8x14 5/8 2.54 65 1 1.09 28

30682-12-12 1-1/16x12 3/4 2.65 67 1-1/14 1.20 30

30682-16-16B 1-5/16x12 1 2.77 70 1-3/8 1.32 34

INCHES

ICD HPD Tube Hose W

Part Number Part Number Size R Size A K Hex

4-4 P2TU 3TU82-4-4 1/4 -4 1.77 .72 7/16

6-6 P2TU 3TU82-6-6 3/8 -6 1.98 .78 9/16

8-8 P2TU 3TU82-8-8 1/2 -8 2.42 1.03 11/16

INCHES

ICD HPD Tube Hose W

Part Number Part Number Size R Size A K Hex

4-4 P2T2 3T282-4-4 1/4 -4 1.77 .72 7/16

6-6 P2T2 3T282-6-6 3/8 -6 1.98 .78 9/16

8-8 P2T2 3T282-8-8 1/2 -8 2.42 1.03 11/16

Part Number I.D. A

inch inch mm

38282-4-4B 1/4 1.80 46

38282-6-6B 3/8 2.15 55

38282-8-8B 1/2 2.51 64

38282-10-10B 5/8 3.31 84

38282-12-12B 3/4 3.31 84

38282-16-16 1 3.31 84

Cut-Off

Allowance

Part Number Thread I.D. A H B

inch inch inch mm inch inch mm

39182-4-4B 1/4x19 1/4 1.65 42 14 0.83 21

39182-4-6B 1/4x19 3/8 1.83 46 19 0.94 24

39182-6-6B 3/8x19 3/8 1.89 48 19 0.98 25

39182-6-8B 3/8x19 1/2 1.93 49 19 0.98 25

39182-8-8B 1/2x14 12 2.20 56 22 1.10 28

39182-12-10B 3/4x14 5/8 2.64 67 27 1.14 29

39182-12-12B 3/4x14 3/4 2.72 69 27 1.22 31

Cut-Off

Allowance

Part Number Thread I.D. A H B

inch inch inch mm inch inch mm

30182-2-4 1/8x27 1/4 1.39 35 7/16 0.64 16

30182-4-4 1/4x18 1/4 1.57 40 9/16 0.82 21

30182-4-6 1/4x18 3/8 1.78 45 9/16 0.88 22

30182-6-6 3/8x18 3/8 1.78 45 11/16 0.88 22

30182-6-8 3/8x18 1/2 1.93 49 11/16 0.88 22

30182-8-8 1/2x14 1/2 2.18 55 7/8 1.13 29

30182-8-10 1/2x14 5/8 2.58 66 7/8 1.13 29

30182-12-12 3/4x14 3/4 2.61 66 1-1/16 1.16 29

30182-16-16B 1x11-1/2 1 3.06 78 1-3/8 1.61 41

Tube Cut-Off

ICD HPD Size Allowance

Part Number Part Number R I.D. A K B

inch inch inch mm inch mm inch mm

33482-3-4B 3/16 1/4 1.63 41 0.75 19 0.88 22

4-4 P2TA 33482-4-4B 1/4 1/4 1.89 48 1.02 26 1.14 29

33482-4-4C 1/4 1/4 1.89 48 1.02 26 1.14 29

33482-5-4B 5/16 1/4 1.93 49 1.08 27 1.18 30

33482-6-6B 3/8 3/8 2.23 57 1.22 31 1.33 34

6-6 P2TA 33482-6-6C 3/8 3/8 2.23 57 1.22 31 1.33 34

33482-8-8B 1/2 1/2 2.16 55 0.97 25 1.11 28

8-8 P2TA 33482-8-8C 1/2 1/2 2.16 55 0.97 25 1.11 28

33482-10-10B 5/8 5/8 2.62 67 1.00 25 1.17 30

33482-12-12B* 3/4 3/4 2.62 67 1.00 25 1.17 30

Push-Lok Fittings

39182 Male

BSP Tapered

30182 Male NPTF

33482 Parker

Tube Adapter

38282 Union

Push-Lok to

CPI

™

P2T2

Push-Lok to

A-LOK

®

P2TU

30682 Female

JIC 37° Swivel

A

B

K

R

A

B

H

A

B

H

A

B

W

A

A

R

W

K

A

R

W

K

3JC82 Female Seal-Lok

®

Swivel-Straight-Short

A

B

C

W

H

Cut-Off

Allowance

Part Number Thread I.D. A H W B

inch inch inch mm inch inch inch mm

3JC82-4-4 9/16x18 1/4 1.4 36 9/16 11/16 0.65 17

3JC82-6-6 11/16x16 3/8 1.59 40 11/16 13/16 0.69 18

3JC82-8-8 13/16x16 1/2 1.8 46 13/16 15/16 0.75 19

3JC82-12-12 1-3/16x12 3/4 2.63 67 1-1/8 1-3/8 1.18 30

3JC82-16-16B 1-7/16x12 1 2.61 66 1-3/8 1-5/8 1.16 29

*Non

standard

Standard available in Brass.

Stainless Steel available

upon request.

Available in 316

Stainless Steel.

Use a “C”suffix for

316 Stainless Steel

after part number.

Example:

3JC82-8-8C.

Available in Brass and

316 Stainless Steel.

Use “B” suffix for Brass

and “C” suffix for 316

Stainless Steel after

part number.

Examples: 30182-8-8B

and 30182-8-8C.

Available in Brass and

316 Stainless Steel.

Use “B” suffix for Brass

and “C” suffix for 316

Stainless Steel after

part number.

Examples: 30682-8-8B

and 30682-8-8C.

Consult factory for

non-standard

material orders.

To order assembled with

nut and ferrule, add Z6

to part number.

Example: 4-4 P2T2Z6

To order assembled with

nut and ferrule, add Z6

to part number.

Example: 4-4 P2TUZ6

Loading...

Loading...