Page 1

aerospace

climate control

electromechanical

filtration

fluid & gas handling

hydraulics

pneumatics

process control

sealing & shielding

PSG Combination

Moisture & Liquid Indicator

Catalog B-1, October 2007

Page 2

Page 2 / Catalog B-1, PSG Moisture/Liquid Indicator

Parker PSG Moisture & Liquid Indicator

The Parker PSG Moisture and Liquid

Indicator combines the two functions

of moisture and liquid indication into

a single economical product. It takes

the guess work out of servicing refrigeration and air conditioning equipment.

The PSG assists the technician in determining the state of the circulating refrigerant at a particular location and if a safe

moisture level exists in the system. Excessive moisture in refrigerant systems

can cause unwanted chemistries such as

hydrolysis of lubricants and other materials, corrosion of metals, copper plating, ice formation at the metering device

and a chemical change in the motor insulation of a hermetic compressor.

8 Outstanding Benefits

One Indicator For All Refrigerants —

provides a true moisture indication for

Refrigerant 12, 134a, 22, 404A, 407C, 410A,

502 or 507.

Reliable And Accurately Calibrated Color

Change Points — calibration in parts per

million of moisture for each refrigerant. 3%

relative humidity indicator for CFC, HCFC,

and HFC, including R410A.

Replaceable Indicator Element — the color

indicator paper can be changed without removing the PSG from the line.

Indicator Protected From Discoloration

And Dirt — by a filter pad and screen. This

prevents washing of the indicator by the

refrigerant and protects it from system

contamination and turbulence.

Color Changes Are Easily Distinguished

And Reversible —

widely between the wet and dry condition,

there is no possibility of confusion. Colors reverse as often as moisture concentration in

the system changes.

indicator colors differ so

Plastic Cap — is supplied with PSG to keep

the glass free from dust, dirt and grease.

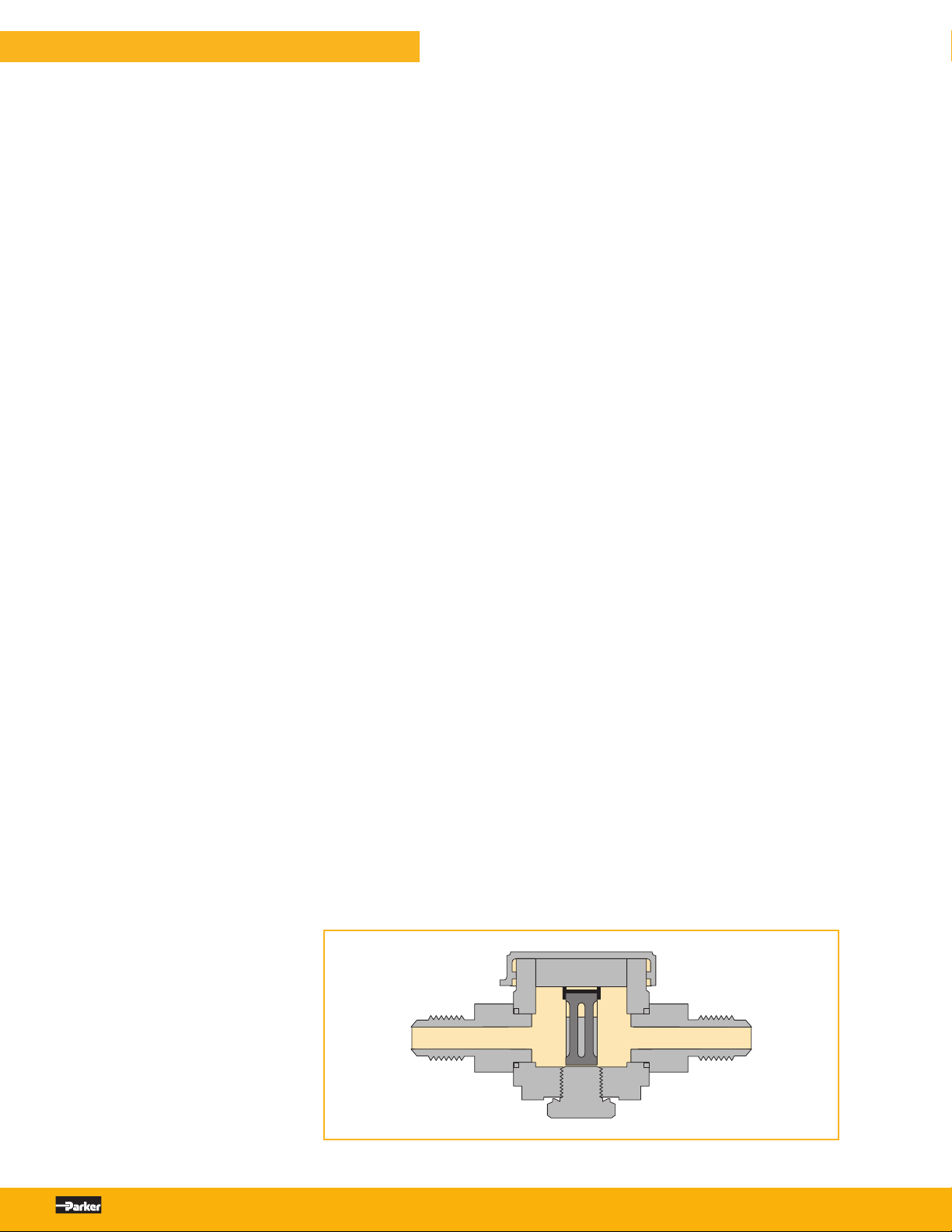

How It’s Made

The plated steel and copper ttings are

copper brazed to the heavily copper

plated steel body. A glass disc is inserted

in the body and heated, just to the melting point, under carefully controlled

conditions. This fuses the glass to the

body in a permanent leak-free joint. The

indicator paper (retained in a small brass

ferrule) is inserted from the back and

held in place with a slotted cylinder. The

slotted cylinder and indicator assembly

is mounted on a post that screws into

the bottom of the body, and seals with a

knife-edge joint. This overall construction is highly effective in preventing refrigerant leakage. The unit is painted to

protect it from corrosion.

Paper indicator elements are made in

the Parker laboratory under the strictest

quality control procedures. The indicator is tested for proper color change

ability in the laboratory and twice more

during assembly.

How It Works

The indicator is a porous lter paper

impregnated with a chemical salt that is

sensitive to moisture. The salt changes

color according to the moisture content

(relative saturation) in the refrigerant.

A dark blue color indicates the refrigerant is DRY and pink indicates a WET

condition. The indicator is formulated

so that it changes color at the moisture

levels generally accepted as the safe operating range.

Figure 1

The PSG calibration information in

Tables 1 and 2 is based on detailed

experimental data for Refrigerants 12,

22, 134a, 404A, 407C, 410A, 502 and

507. The PSG change points occur at

similar or lower moisture levels than

competing models promoted to have 3%

relative humidity indication.

For Air — Tests on air show that the PSG

changes color in the range of 0.5% to 2.0%

R.H. In ordinary air lines this means that the

PSG will change color at dew points in the

range of minus 40°F to -60°F (-40°C to -51°C).

Brazing

PSGs with 1/4” through 1-1/8” ODF

Solder connections are constructed with

long ttings made from either heavily

copper plated steel or copper. Both t-

ting types are suitable for soldering or

brazing using any of the common alloys,

such as silver solder, soft solder, StaBrite, or Sil-Fos or PhosCopper. PSGs

do not require disassembly in the eld

for brazing because the extended ttings

reduce the possibility of damaging the

moisture indicator element when the

PSG is brazed into the system. To prevent damaging the PSG, ensure ample

heat is supplied to the ttings and point

the torch tip away from the PSG body.

Proper brazing technique ensures proper

capillary action of the alloy.

The ODF Solder connections on the

PSG are clean when shipped. Polishing

the inside of the ttings before brazing is unnecessary, and could be harm-

ful on the copper plated steel ttings if

an excessive amount of copper plating

Large Full View Sight Glass — extra large

crystal clear sight glass for viewing the refrigerant. Bubbles indicate a shortage of

refrigerant or a restriction in the liquid line.

Disassembly For Installation Is Unnecessary

— with extended fittings on small size solder

models. PSGs are easy to braze.

Parker Hannifin Corporation, Climate and Industrial Controls Group, Cleveland, OH

Page 3

Table 1

Screen

Slotted Cylinder

Indicator

Paper

Filter

Pad

Brass

Ferrule

Moisture Content - PPM/°F

Catalog B-1, PSG Moisture/Liquid Indicator / Page 3

PSG

SHOWS

Blue - DRY

Intermediate Color - CAUTION

Pink - WET

Table 2

REFRIGERANT12REFRIGERANT22REFRIGERANT

75°F 100°F 75°F 100°F 75°F 100°F 75°F 100°F 75°F 100°F 75°F 75°F

Below5Below10Below30Below45Below50Below80Below10Below20Below15Below

5-15 10-30 30-90 45-130 50-200 80-225 10-45 20-65 15-90 30-140 120-280 75-150

Above15Above30Above90Above

130

Above

200

134a

Moisture Content - PPM/°C

REFRIGERANT12REFRIGERANT22REFRIGERANT

PSG

SHOWS

24°C 38°C 24°C 38°C 24°C 38°C 24°C 38°C 24°C 38°C 24°C 24°C

Blue - DRY

Intermediate Color - CAUTION

Pink - WET

NOTE: Change or add Parker Filter-Drier when paper turns from blue to intermediate color.

is removed. PSGs with 1/4” through

1-1/8” ODF Solder ttings stated in

this publication are with copper plated

steel ttings.

Below5Below10Below30Below45Below50Below80Below10Below20Below15Below

5-15 10-30 30-90 45-130 50-200 80-225 10-45 20-65 15-90 30-140 120-280 75-150

Above15Above30Above90Above

130

replacement of a drier on existing installations. In some cases the PSG will

change in as short a time as 15 minutes.

However, it is recommended that the

equipment operate for about 12 hours

The larger PSGs with 1-3/8”, 1-5/8”, and

2-1/8” ODF Solder connections utilize

copper connections and require removal

of the cartridge from the brass saddle

adaptor before brazing. The cartridge is

shipped hand tight for easy removal.

The PSG may be installed anywhere in

the the liquid line, but preferably after

the Parker Filter-Drier and ahead of the

metering device.

to allow the moisture in the system and

the PSG color to come to complete equi-

librium. The action of the indicator ele-

ment is completely reversible and will

change color as often as the moisture

content of the system varies.

The drying of the system should be

continued until the indicating element

changes from the intermediate color to

blue. The actual moisture content of the

refrigerant will be in accordance with

the above table.

Above

200

134a

Application

The indicator element of the PSG prior

to installation will be pink, indicating

a wet condition. This is a normal situation since the air in contact with the

element is above 0.5% Relative Humidity. This does not affect the operation or

calibration of the PSG. As soon as it is

installed in a system, the indicator element will begin to change according to

the moisture content of the refrigerant.

Some change may take place rapidly

at the start-up of a new system or after

For best results with the nickel plated

SAE are ttings that are used on PSGs,

lubricate the are surface and the back

Figure 2

REFRIGERANT

502

LIQUID LINE TEMPERATURE

Above

Above45Above65Above90Above

225

REFRIGERANT

502

LIQUID LINE TEMPERATURE

Above

Above45Above65Above90Above

225

REFRIGERANT

404A & 507

REFRIGERANT

404A & 507

30

140

30

140

REFRIGERANT

407C

Below

120

Above

280

REFRIGERANT

407C

Below

120

Above

280

REFRIGERANT

410A

Below

75

Above

150

REFRIGERANT

410A

Below

75

Above

150

of the are nut with refrigerant grade

oil during assembly. This is particularly necessary to avoid leaks if the PSG

is being assembled to another plated

steel are tting, such as the Parker

Filter-Drier.

Service Pointers

Replacement Indicator Paper — Parker

kit K-PSG-1 consisting of a slotted cylinder

and indicator paper assembly is available

for replacing the indicator in the fused glass

style Parker PSGs (1/4” thru 1-1/8” sizes). Replacement is through the bottom (see Figure

1). If the indicator becomes damaged, it is

generally recommended that the entire PSG

be replaced. However, the parts kit can be

used in situations where it is difficult to remove the PSG.

Liquid Water — On occasion it is possible for large quantities of water to enter a

Parker Hannifin Corporation, Climate and Industrial Controls Group, Cleveland, OH

Page 4

Page 4 / Catalog B-1, PSG Moisture/Liquid Indicator

refrigeration system. An example would be a

broken tube in a water cooled condenser. If

this happens and free water comes in contact with the indicator element, the element

will be damaged.

All moisture indicating elements use a chemical salt (see “How It Works”). These salts

must be soluble in water in order to change

color. If excessive water is present, then

the salts will dissolve, causing permanent

damage to the indicator. The indicator paper

may remain pink or turn white.

Hermetic Motor Burnouts — After a hermet-

ic motor burnout, install a Parker Filter-Drier

to remove the acid and sludge contamination. When the system has operated for 48

hours, replace the Parker Filter-Drier and

install a PSG.

Since the acid formed by the burnout may

damage the indicator element of the PSG,

it is preferable to install it after most of the

contaminants have been removed.

Excess Oil — When a system is circulating

an excessive amount of oil, the PSG indicator

paper may become saturated. This causes

the indicator to appear brown or translucent and lose its ability to change color, but

does not permanently damage the PSG. Let

the PSG remain in the system. The circulating refrigerant will remove the excess oil,

and the indicator element will return to its

proper color.

Leak Detectors — Certain dye type liquid

leak detectors may interfere with the color

change of the indicator paper. If desired,

many of these leak detectors can be removed

by installing a Parker SLD Series Filter-Drier

in the system. The PSG can then be installed

on the system without risk of damaging the

indicator paper.

Alcohol — Do NOT install a PSG in a system

that contains methyl alcohol or similar liquid

dehydrating agents. Remove the alcohol by

using a Parker Filter-Drier, and then install

the PSG. Otherwise the alcohol will damage

the PSG color indicator.

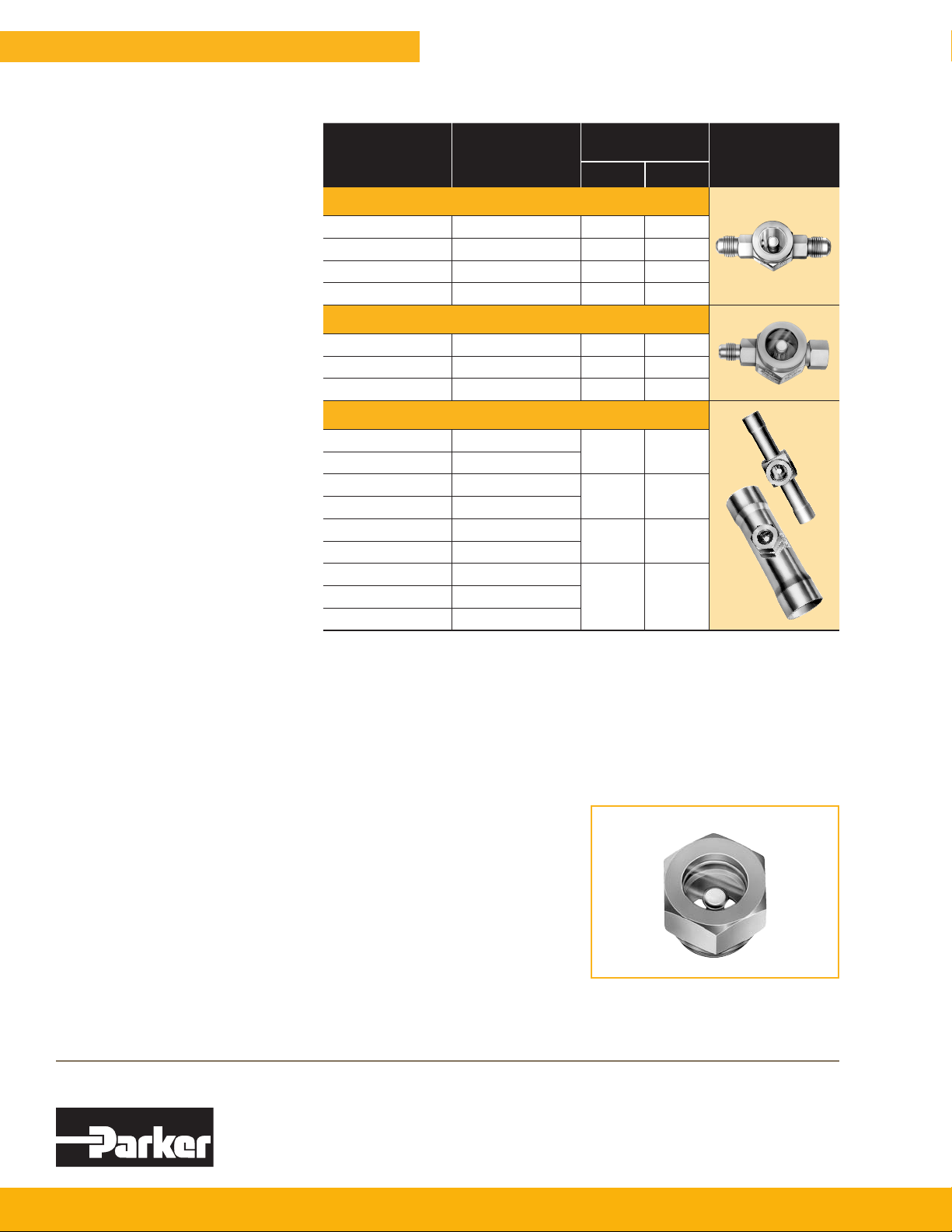

Table 3

Specifications

Connection

Sizes

(Inches)

1/4 PSG-2 2.87 72.9

3/8 PSG-3 3.37 85.6

1/2 PSG-4 3.82 97.0

5/8 PSG-5 4.12 105.0

1/4 PSG-2MF 2.56 65.0

3/8 PSG-3MF 2.97 75.4

1/2 PSG-4MF 3.44 87.4

1/4 PSG-2S

3/8 PSG-3S

1/2 PSG-4S

5/8 PSG-5S

7/8 PSG-7S

1-1/8 PSG-9S

1-3/8 PSG-11S

2-1/8 PSG-17S

Most solder connections can be used as male fittings as well as female fittings. The 1/4” ODF is 3/8” ODM, the 3/8” ODF

is 1/2” ODM, the 1/2” ODF is 5/8” ODM and the 5/8” ODF is 3/4” ODM. Models with female flare connections are supplied

with a copper gasket in the fitting.

Overall width is: 1.31” (33.3 mm) for 1/4” and 3/8” sizes, 1.58” (40.1 mm) for 1/2” and 5/8” sizes, and 1.38” (35.1 mm) for

7/8” and 1-1/8” sizes. Shipping weight is: 7 oz. (.20 kg) for 1/4” and 3/8” sizes, 10 oz. (.28 kg) for 1/2” and 5/8” sizes, 15 oz.

(.43 kg) for 7/8” and 1-1/8” sizes and 1.5 Ibs. (.68 kg) for the PSG-11S, 13S, and 17S series.

UL and ULc Listed - Guide - SEYW - File No. SA-3182. Maximum Rated Pressure is 650 psig (44.8 bar).

Type

No.

Male Flare

Female X Male Flare

ODF Solder

Removable Cartridge

Types PSG-11S, 13S and 17S have copper connections and feature a removable cartridge containing the moisture

indicating element. The cartridge has a

knife edge joint and is available as a

separate unit for eld replacement purposes if necessary. It is designated as

PSG-10TS and ts all three sizes.

Overall

Length

Inches mm

4.63 118.0

4.88 124.0

6.32 161.0

8.00 203.01-5/8 PSG-13S

PSG-10TS

PSG

Parker Hannifin Corporation

Climate and Industrial Controls Group

2445 South 25th Avenue • Broadview, IL 60155-3891 USA

phone 800 742 2681 • fax 800 241 2872

www.parker.com/coolparts

102007 / Catalog B-1

Loading...

Loading...