Page 1

Page 2

User Information

Warning!

ACR Series products are used to control electrical and mechanical

components of motion control systems. You should test your motion system

for safety under all potential conditions. Failure to do so can result in damage

to equipment and/or serious injury to personnel.

ACR Series products and the information in this user guide are the proprietary property of Parker

Hannifin Corporation or its licensers, and may not be copied, disclosed, or used for any purpose

not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to

change this user guide and software and hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or

special damages of any kind or nature whatsoever, including but not limited to lost profits arising

from or in any way connected with the use of the equipment or this user guide.

© 2004 Parker Hannifin Corporation

All Rights Reserved

Technical Assistance:

North America and Asia

Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

E-mail: cmr_help@parker.com

Internet: www.parkermotion.com

Contact your local automation technology center (ATC) or distributor, or ...

Germany, Austria, Switzerland

Parker Hannifin

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0) 781 509-0

Fax: +49 (0) 781 509-176

Europe (non-German speaking)

Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

E-mail: emn_support@parker.com

Internet: www.parkermotion.com

– ii –

Italy

Parker Hannifin

20092 Cinisello Balsamo

Milan, Italy via Gounod, 1

Telephone: +49 (0) 781 509-0

Fax: +49 (0) 781 509-176

Technical Support E-mail

emn_support@parker.com

Page 3

Table of Contents

Important Information for Users .................................................................................................iv

Chapter 1 – ACRCOMM................................................................................................................. 2

ACRCOMM Overview ................................................................................................................3

Serial Communications............................................................................................................ 3

ACRCOMM Hardware Setup................................................................................................... 5

Jumpers ................................................................................................................................... 5

Communications—P5 Connector ............................................................................................ 8

Chapter 2 – EXPAXIS .................................................................................................................... 9

EXPAXIS Overview .................................................................................................................. 10

Cables.................................................................................................................................... 10

Encoder Inputs—XP1A, XP1B, and XP1C ............................................................................ 12

Hardware Wiring .................................................................................................................... 16

Module Encoder Pull-ups (Optional)...................................................................................... 18

Module Software.................................................................................................................... 18

Chapter 3 – Additional Specifications....................................................................................... 19

Suggested Stacking of Modules............................................................................................... 20

Environment and Cooling .........................................................................................................21

Table of Tables

Figure 1 ACRCOMM RS-422 Interface Schematic .................................................................... 4

Figure 2 ACRCOMM Module—PCI version ............................................................................... 5

Figure 3 EXPAXIS (9-16) Axis Expansion Board for the ACR1505......................................... 11

Figure 4 XP1A and XP1B ENCODER connector diagram .............................................................. 13

Figure 5 XP1C ENCODER connector diagram ............................................................................. 14

Figure 6 XP2 ANALOG I/O connector diagram............................................................................ 17

Figure 7 Recommended Stacking for ACR1505 Add-on Modules........................................... 20

Table of Figures

Table 1 COM1: MUX Flags and COM Functions ....................................................................... 3

Table 2 Receive/Transmit Flags and COM Functions ............................................................... 4

Table 3 ACRCOMM Jumper Functions...................................................................................... 6

Table 4 ACRCOMM RS-422 Termination Jumpers ................................................................... 6

Table 5 ACRCOMM Autobaud Detect Jumper .......................................................................... 7

Table 6 ACRCOMM P5 Communications Connector ................................................................ 8

Table 7 EPXAXIS Feedback devices....................................................................................... 12

Table 8 EXPAXIS Encoder Input Connectors XP1A and XP1B .............................................. 13

Table 9 EXPAXIS Encoder Input Connector XP1C ................................................................. 14

Table 10 EXPAXIS XP1C to two 9 Pin D-Sub Connector Pinout ............................................ 15

Table 11 EXPAXIS XP9 Connector Pinout .............................................................................. 15

Table 12 EXPAXIS XP10 Connector Pinout ............................................................................ 16

Table 13 EXPAXIS Analog I/O Cable Connector DXP2 .......................................................... 17

Table 14 EXPAXIS Module Encoder Pull-Up Jumpers............................................................ 18

-- iii –

Page 4

Important Information for Users

Important Information for Users

It is important that motion control equipment is installed and operated in such a way

that all applicable safety requirements are met. It is your responsibility as an installer

to ensure that you identify the relevant safety standards and comply with them; failure

to do so may result in damage to equipment and personal injury. In particular, you

should study the contents of this user guide carefully before installing or operating the

equipment.

The installation, set up, test, and maintenance procedures given in this User Guide

should only be carried out by competent personnel trained in the installation of

electronic equipment. Such personnel should be aware of the potential electrical and

mechanical hazards associated with mains-powered motion control equipment—

please see the safety warnings below. The individual or group having overall

responsibility for this equipment must ensure that operators are adequately trained.

Under no circumstances will the suppliers of the equipment be liable for any

incidental, consequential or special damages of any kind whatsoever, including but

not limited to lost profits arising from or in any way connected with the use of the

equipment or this guide.

High-performance motion control equipment is capable of producing rapid

movement and very high forces. Unexpected motion may occur especially during

the development of controller programs. KEEP WELL CLEAR of any machinery

driven by stepper or servo motors. Never touch any part of the equipment while it is

in operation.

This product is sold as a motion control component to be installed in a complete

system using good engineering practice. Care must be taken to ensure that the

product is installed and used in a safe manner according to local safety laws and

regulations. In particular, the product must be positioned such that no part is

accessible while power may be applied.

This and other information from Parker Hannifin Corporation, its subsidiaries, and

authorized distributors provides product or system options for further investigation

by users having technical expertise. Before you select or use any product or

system, it is important that you analyze all aspects of your application and review

the information concerning the product in the current product catalog. The user,

through its own analysis and testing, is solely responsible for making the final

selection of the system and components and assuring that all performance, safety,

and warning requirements of the application are met.

If the equipment is used in any manner that does not conform to the instructions

given in this user guide, then the protection provided by the equipment may be

impaired.

The information in this user guide, including any apparatus, methods, techniques, and

concepts described herein, are the proprietary property of Parker Hannifin or its

licensors, and may not be copied disclosed, or used for any purpose not expressly

authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the

right to modify equipment and user guides without prior notice. No part of this user

guide may be reproduced in any form without the prior consent of Parker Hannifin.

Safety Warning!

– iv –

Page 5

Page 6

CHAPTER ONE

Chapter 1 – ACRCOMM

ACRCOMM

IN THIS CHAPTER

• ACRCOMM Overview ........................................................................... 3

• Serial Communications ......................................................................... 3

• ACRCOMM Hardware Setup ................................................................ 5

• Jumpers................................................................................................. 5

• Communications—P5 Connector.......................................................... 8

Page 7

ACRCOMM Overview

The ACRCOMM Plug-In Module provides serial communication ports (2

serial, 1 parallel) capability for the ACR1505 motherboard. ACRCOMM

external power input and User-SRAM battery back-up functions are not used

with the ACR1505 motherboard. These circuits are not populated on the

ACR1505 COMM Board.

This section contains diagrams of the jumpers and switches on the

ACRCOMM module.

Serial Communications

The ACR1505 serial communication interface is software configurable. At

power-up, the default COM1/COM2 communications mode is RS-232. For

ACR1505 boards with the communications option, the serial ports can be

configured by a serial port, or at power-up (or any time) via the PCI bus

communications port.

Table 1 and Table 2 show the configuration schemes for the ACR1505 board

with the serial communication ACRCOMM module option.

Factory Default........................................ RS-232

MUX Flags

You can set the communications mode for each COM port. Table 1 shows

how to set up COM1and COM2.

MUX0 MUX1 COM Function

CLR (0) CLR (0) Not Used

SET (1) CLR (0) RS-232

CLR (0) SET (1) RS-422

SET (1) SET (1) Not Used

Note: For bit and flag numbers, see “COM1 Stream Flags” and “COM2

Stream Flags” in “Appendix B” of the “ACR Motion Controller User’s Guide,

Part 2.”

Table 1 COM1: MUX Flags and COM Functions

Chapter 1 – ACRCOMM – 3 –

Page 8

Receive/Transmit Flags

You can set the flow control flags for RS-422 communications mode for each

COM port. Table 2 shows how to set up COM1and COM2.

Receive Flag Transmit Flag COM Function

CLR (0) CLR (0) Not Used (Default)

CLR (0) SET (1) Use for RS-422 Operation:

Full Duplex

Receiver Enabled

Transmitter Enabled

SET (1) CLR (0) Not Used

SET (1) SET (1) Not Used

Note: For bit and flag numbers, see “COM1 Stream Flags” and “COM2 Stream Flags” in

“Appendix B” of the “ACR Motion Controller User’s Guide, Part 2.”

Table 2 Receive/Transmit Flags and COM Functions

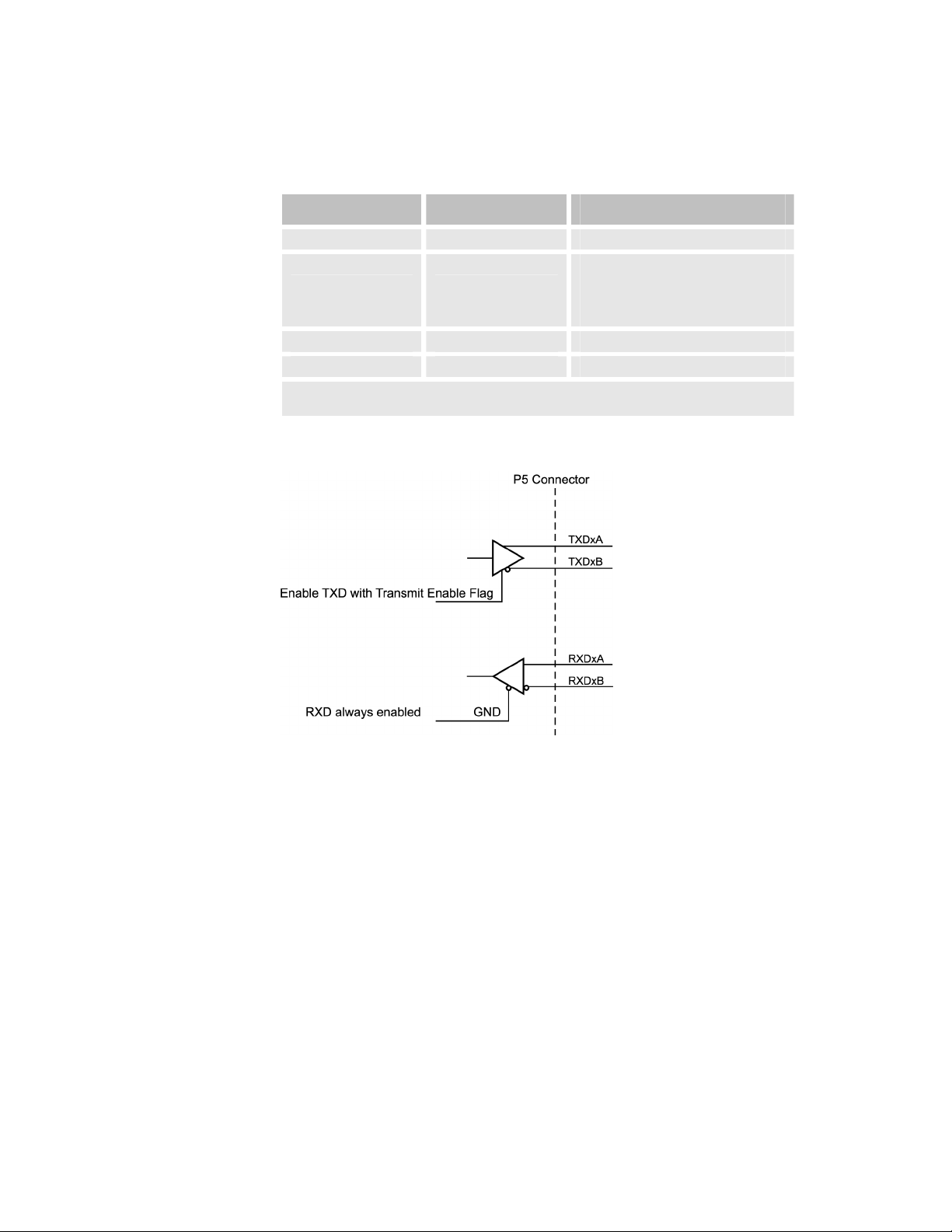

Figure 1 ACRCOMM RS-422 Interface Schematic

– 4 – ACRCOMM and ACREXPAXIS User’s Guide

Page 9

ACRCOMM Hardware Setup

The PCI version of the ACRCOMM module (part number SBD12550) does

not require an external power source.

Note: In Figure 2, the black square on the jumpers indicates pin 1.

Jumpers

Figure 2 ACRCOMM Module—PCI version

The PCI version of the ACRCOMM module is not populated with the following

components: F1 through F3, D1 through D3, and PWR2.

If your ACRCOMM module is populated with the above components, you

have an ISA version of the ACRCOMM module, which is incompatible with

the ACR1505.

Warning!

Chapter 1 – ACRCOMM – 5 –

Page 10

The following is a list of the jumper functions on the ACRCOMM module:

Jumper Description

J1 COM1 RS-422 Termination Resistor Select

J2 COM1 RS-422 Termination Resistor Select

J3 COM2 RS-422 Termination Resistor Select

J4 COM2 RS-422 Termination Resistor Select

J5 Not used with the ACR1505

J6 Not used with the ACR1505

J7 COM1 and COM2 Autobaud Detect Enable

J8 Reserved

J9 Reserved

J10 Reserved

Table 3 ACRCOMM Jumper Functions

(see Table 4, on page 6)

(see Table 4, on page 6)

(see Table 4, on page 6)

(see Table 4, on page 6)

(see Table 4, on page 6)

RS-422 Communication Ports Line Terminator Jumpers (J1

thru J4)

These jumpers provide termination resistors for the RS-422signals. For

jumper locations, see Figure 2 on page 5.

Factory Default........................................ Jumpers in

Communication Ports Termination Jumpers

Signal Jumper Termination No Termination

RXD1A/RXD1B J1 Jumper In Jumper Out

TXD1A/TXD1B J2 Jumper In Jumper Out

RXD2A/RXD2B J3 Jumper In Jumper Out

TXD2A/TXD2B J4 Jumper In Jumper Out

Table 4 ACRCOMM RS-422 Termination Jumpers

– 6 – ACRCOMM and ACREXPAXIS User’s Guide

Page 11

Battery Enable Jumpers (J5 and J6)

These jumpers are not used with the ACR1505 Controller.

Autobaud Detect Jumper (J7)

This jumper enables or disables the Autobaud detect feature of the serial

communications channels on the ACRCOMM module. This jumper works in

conjunction with the COM1 Startup Mode (P7013) and COM2 Startup Mode

(P7029) parameters. For more information, see “Miscellaneous Parameters

P6912-P7029” in the “ACR Motion Controller’s User’s Guide Part 2”.

When the COM1/2 Startup Mode parameters (bit 15) are set to zero (factory

default-0), the Autobaud detect is enabled and the Autobaud Detect Jumper

(J7) is ignored.

When the COM1/2 Startup Mode parameters (bit 15) are set to one, the

Autobaud Detect Jumper (J7) defines the autobaud detect function (see

Table 5). For jumper locations, see Figure 2 on page 5.

Factory Default........................................ Autobaud Detect Enabled

Autobaud Detect Jumper

Function J7

Autobaud Detect Enabled ON

Autobaud Detect Disabled OFF

Table 5 ACRCOMM Autobaud Detect Jumper

Chapter 1 – ACRCOMM – 7 –

Page 12

Communications—P5 Connector

There is one 34 pin header provided on the ACRCOMM module for the 2

serial and 1 parallel communications ports. The two serial ports, COM1 and

COM2, can be individually configured as RS-232 or RS-422 interfaces.

Configuration of the COM ports is software selectable by the user.

The following diagram shows the connections for the 3 communications

ports. For jumper locations, see Figure 2 on page 5.

Note: P5 is a 34-pin shrouded male header.

Signal Pin Signal Pin

RXD1 1 TXD1 2

GND 3 MUX1 4

TXD1A 5 TXD1B 6

RXD1A 7 RXD1B 8

RXD2 9 TXD2 10

GND 11 MUX2 12

TXD2A 13 TXD2B 14

RXD2A 15 RXD2B 16

STB 17 AFD 18

ERR 19 INIT 20

SLIN 21 GND 22

PD0 23 PD1 24

PD2 25 PD3 26

PD4 27 PD5 28

PD6 29 PD7 30

ACK 31 BUSY 32

PE 33 SLCT 34

Table 6 ACRCOMM P5 Communications Connector

– 8 – ACRCOMM and ACREXPAXIS User’s Guide

Page 13

CHAPTER TWO

Chapter 2 – EXPAXIS

EXPAXIS

IN THIS CHAPTER

• EXPAXIS Overview............................................................................. 10

• Cables .................................................................................................10

• Encoder Inputs—XP1A, XP1B, and XP1C .........................................12

• Hardware Wiring..................................................................................16

• Module Encoder Pull-ups (Optional) ...................................................18

• Module Software .................................................................................18

Page 14

EXPAXIS Overview

The EXPAXIS Plug-In Module provides additional axes support to the base

ACR1505. A maximum of 8 Axes (Stepper or Servo) and up to 10 Encoders

are available. Additionally, either of the 12 Bit or the 16 Bit ADC option can

be added to this board.

With the fully loaded EXPAXIS option, an ACR1505 can have up to 12

Servo/Stepper Outputs, 14 Incremental Encoders, and 16 Single Ended (8

Differential) ADC Channels.

Plugs on the EXPAXIS module for ENCODERS, DAC/STEPPER and ADC

are different from the base ACR1505 board and caution should be used

when wiring.

Cables

The EXPAXIS module has the following cables:

• XP1A—For ENC10,11,12, and 13

• XP1B—For ENC14,15,16, and 17

• XP1C—For ENC18 and19

• XP9—For Stepper power and ground.

• XP10—For High speed interrupt (INTCAP) inputs. EXP-IN0…EXP-IN7

are TTL logic only.

• XP2—For DAC/STEPPER/ADC I/O. (Corresponds to P2 connector on

the ACR1505 Controller board.

The P2 connector on the ACR1505 Controller board is a DSubminiature connector; whereas XP2 on the EXPAXIS module is a 0.1

inch Center Header ribbon cable. To convert the XP2 connector

(EXPAXIS module) for use with the P2 connector (ACR1505), use the

DXP2 cable assembly (part number PWH80500) supplied with the

EXPAXIS module.

Note: There is no watchdog relay on the EXPAXIS module, so the

watchdog signals are not wired on the DXP2 cable assembly. Therefore,

you must use the watchdog safety contacts from the ACR1505

Controller P2 connector for safeguarding the machine.

– 10 – ACRCOMM and ACREXPAXIS User’s Guide

Page 15

Figure 3 EXPAXIS (9-16) Axis Expansion Board for the ACR1505

Chapter 2 – EXPAXIS – 11 –

Page 16

Encoder Inputs—XP1A, XP1B, and XP1C

The EXPAXIS module accepts any feedback device that supplies either a +5

VDC or +12 VDC differential signal. The most common type of device is a

differential encoder. For common encoder setups, see Table 7. For

connector locations, see Figure 3 on page 11.

There are two 34 pin headers and one 20 pin header provided on the

EXPAXIS module for encoder feedback. The two 34 pin header provide up to

eight (8) axes of encoder feedback (Encoders 10 thru 17). The 20 pin header

provides 2 axes of encoder feedback (Encoder 18 and 19). For connector

locations, see Figure 3 on page 11.

EXPAXIS

Encoder Pull-up Jumper

Length of Cable/Type

Setting

Differential Line Driver Remove Pull-ups 100 ft.(Beldon 9330 Shielded

Open Collector Driver

(No Pull-ups on Encoder)

Open Collector Driver

(With Pull-ups to +5 VDC on

Encoder)

TTL Driver

(+5 VDC Outputs)

Table 7 EPXAXIS Feedback devices

Install Pull-ups and Jumper to

+12 VDC

Install Pull-ups and Jumper

to +5 VDC

(factory Default)

Remove Pull-ups 50 ft. (Beldon 9330 Shielded

Twisted Pair)

75 ft. (Beldon 9330 Shielded

Twisted Pair)

50 ft. (Beldon 9330 Shielded

Twisted Pair)

Twisted Pair)

Note: The EXPAXIS module default settings for the encoder input resistor

types and configuration are not the same as the base ACR1505 board. The

EXPAXIS board is set-up for open-collector drivers with pull-ups to +5V on

the encoder inputs.

When using a single-ended encoder (an encoder without the A-, B-, or Zoutputs), additional pull-ups and pull-down resistors must be added

externally to the EXPAXIS module in order for the EXPAXIS module to read

the encoder signals.

– 12 – ACRCOMM and ACREXPAXIS User’s Guide

Page 17

XP1A and XP1B Connector

The XP1A connector provides access to encoders ENC10, ENC11, ENC12,

and ENC13, which use jumpers J1, J2, J3, and J4 respectively.

The XP1B connector provides access to encoders ENC14, ENC15, ENC16,

and ENC17, which use jumpers J6, J7, J8, and J9 respectively.

XP1A and XP1B are 34-pin shrouded male headers.

Figure 4 XP1A and XP1B ENCODER connector diagram

XP1A Pinout XP1B Pinout

Signal Pin Pin Signal Signal Pin Pin Signal

CHA10 1 2 CHA10' CHA14 1 2 CHA14'

CHB10 3 4 CHB10' CHB14 3 4 CHB14'

MRK10 5 6 MRK10' MRK14 5 6 MRK14'

+5 VDC (100

mA, max)

CHA11 9 10 CHA11' CHA15 9 10 CHA15'

CHB11 11 12 CHB11' CHB15 11 12 CHB15'

MRK11 13 14 MRK11' MRK15 13 14 MRK15'

+5 VDC (100

mA, max)

CHA12 17 18 CHA12' CHA16 17 18 CHA16'

CHB12 19 20 CHB12' CHB16 19 20 CHB16'

MRK12 21 22 MRK12' MRK16 21 22 MRK16'

+5 VDC (100

mA, max)

CHA13 25 26 CHA13' CHA17 25 26 CHA17'

CHB13 27 28 CHB13' CHB17 27 28 CHB17'

MRK13 29 30 MRK13' MRK17 29 30 MRK17'

+5 VDC (100

mA, max)

n/c 33 34 n/c n/c 33 34 n/c

Note: 100 mA maximum, per encoder. Note: 100 mA maximum, per encoder.

7 8 GND +5 VDC (100

mA, max)

15 16 GND +5 VDC (100

mA, max)

23 24 GND +5 VDC (100

mA, max)

31 32 GND +5 VDC (100

mA, max)

7 8 GND

15 16 GND

23 24 GND

31 32 GND

Table 8 EXPAXIS Encoder Input Connectors XP1A and XP1B

Chapter 2 – EXPAXIS – 13 –

Page 18

XP1C Connector

The XP1C connector provides access to encoders ENC18, and ENC19,

which use jumpers J5 and J10 respectively.

XP1C is a 20-pin shrouded male header.

Figure 5 XP1C ENCODER connector diagram

XP1C Pinout

Signal Pin Signal Pin

CHA18 1 MRK18’ 2

CHA18’ 3 +5 VDC

(100 mA, max)

CHB18 5 GND 6

CHB18’ 7 n/c 8

MRK18 9 KEY* 10

CHA19 11 MRK19’ 12

CHA19’ 13 +5 VDC

(100 mA, max)

CHB19 15 GND 16

CHB19’ 17 n/c 18

MRK19 19 n/c 20

* P1C pin 10 is used as a key pin.

4

14

Table 9 EXPAXIS Encoder Input Connector XP1C

XP1C is designed to work in conjunction with a 20 pin ribbon cable

terminated to two (2) standard 9-pin female D-sub type connectors. This 12

inch cable, AMCS part number PWH015, is supplied with the Encoder 18/19

Option.

Ribbon cable conductors 1 thru 9 connect to D-Subminiature Number 1

(conductor 10 is a No Connect). Ribbon cable conductors 11 thru 19 connect

to D- Subminiature Number 2 (conductor 20 is a No Connect). When used in

this manner, the D-sub pinouts are as follows:

– 14 – ACRCOMM and ACREXPAXIS User’s Guide

Page 19

XP1C Y-Cable Pinout

Signal D-Sub No. 1 Signal D-Sub No. 2

CHA18 1 CHA19 1

CHA18’ 2 CHA19’ 2

CHB18 3 CHB19 3

CHB18’ 4 CHB19’ 4

MRK18 5 MRK19 5

MRK18’ 6 MRK19’ 6

+5 VDC 7 +5 VDC 7

GND 8 GND 8

n/c 9 n/c 9

Table 10 EXPAXIS XP1C to two 9 Pin D-Sub Connector Pinout

XP9 Connector

The XP9 connector provides fused, +5 VDC power for open collector stepper

outputs. or connector locations, see Figure 3 on page 11.

XP9 Pinout

Definition Pin Definition Pin

+5 VDC (250 mA, max) 1 +5 VDC (250 mA, max) 2

+5 VDC (250 mA, max) 3 +5 VDC (250 mA, max) 4

GND 5 GND 6

RESERVED 7 RESERVED 8

RESERVED 9 RESERVED 10

GND 11 GND 12

RESERVED 13 RESERVED 14

RESERVED 15 RESERVED 16

Table 11 EXPAXIS XP9 Connector Pinout

Chapter 2 – EXPAXIS – 15 –

Page 20

XP10 Connector

The XP10 connector provides +5 VDC TTL I/O for INTCAP and other special

functions. For connector locations, see Figure 3 on page 11.

Voltage .................................................... +5 VDC

Current Rating......................................... 0.100A maximum

XP10 Pinout

Definition Pin Definition Pin

EXP_IN0 1 EXP_IN1 2

EXP_IN2 3 EXP_IN3 4

EXP_IN4 5 EXP_IN5 6

EXP_IN6 7 EXP_IN7 8

EXP_OUT0 9 EXP_OUT1 10

RESERVED 11 RESERVED 12

RESERVED 13 RESERVED 14

Table 12 EXPAXIS XP10 Connector Pinout

F1 Fuse

When replacing fuses for the EXPAXIS module, use the following tables to

determine the correct part numbers for different vendors.

For fuse location, see Figure 3 on page 11.

Voltage .................................................... +5 VDC

Current Rating.........................................0.250A

Type ........................................................ Littelfuse 454.500

Hardware Wiring

Analog I/O—XP2

The Analog I/O connections on the EXPAXIS module is a 40 Pin Header. To

convert the XP2 connector (EXPAXIS module) for use with the P2 connector

(ACR1505), use the DXP2 cable assembly (part number PWH80500)

supplied with the EXPAXIS module.

Time Delay Fuse

– 16 – ACRCOMM and ACREXPAXIS User’s Guide

Page 21

The XP2 connector is not pin compatible with the P2 connector on the

ACR1505. This is because the ACR1505 has differential stepper outputs and

the watchdog relay.

Important!: Single-ended encoders are not recommended mode of

operation. Noise immunity is significantly reduced.

Note: DXP2 is a standard 40-pin female D-plug.

XP2 is a 40-pin shrouded male header.

Figure 6 XP2 ANALOG I/O connector diagram

DXP2 Pinout

Definition Pin Pin Definition Module

ASIG-8 ( STEP-8 ) 1 20 AGND-8 ( DIR-8 )

ASIG-9 ( STEP-9 ) 2 21 AGND-9 ( DIR-9 ) Module 0

ASIG-10 ( STEP-10 ) 3 22 AGND-10 ( DIR-10 )

ASIG-11 ( STEP-11 ) 4 23 AGND-11 ( DIR-11 )

ASIG-12 ( STEP-12 ) 5 24 AGND-12 ( DIR-12 )

ASIG-13 ( STEP-13 ) 6 25 AGND-13 ( DIR-13 ) Module 1

ASIG-14 ( STEP-14 ) 7 26 AGND-14 ( DIR-14 )

ASIG-15 ( STEP-15 ) 8 27 AGND-15 ( DIR-15 )

AIN-8 9 28 AIN-9

AIN-10 10 29 AIN-11 Module 2

AIN-12 11 30 AIN-13

AIN-14 12 31 AIN-15

( LCUR-8 ) 13 32 ( LCUR-9 ) Module 0

( LCUR-10 ) 14 33 ( LCUR-11 )

( LCUR-12 ) 15 34 ( LCUR-13 ) Module 1

( LCUR-14 ) 16 35 ( LCUR-15 )

RESERVED 17 36 RESERVED None

RESERVED 18 37 RESERVED None

AGND 19 RESERVED Module 2

Note: Pin definitions in parentheses are for stepper modules.

Table 13 EXPAXIS Analog I/O Cable Connector DXP2

Chapter 2 – EXPAXIS – 17 –

Page 22

Module Encoder Pull-ups (Optional)

The ACR1505 can supply +5 VDC or +12 VDC pull-up resistors to each

encoder. Use Table 14 to determine the correct jumper configurations. For

jumper locations, see Figure 3 on page 11.

Factory Default........................................ Configured for +5 VDC for standard

Encoder Pull-Up Jumpers

Encoder Resistor Jumper +5 VDC +12 VDC

10 RP1 JP1 Pins 1 & 2 Pins 2 & 3

11 RP2 JP2 Pins 1 & 2 Pins 2 & 3

12 RP3 JP3 Pins 1 & 2 Pins 2 & 3

13 RP4 JP4 Pins 1 & 2 Pins 2 & 3

14 RP6 JP6 Pins 1 & 2 Pins 2 & 3

15 RP7 JP7 Pins 1 & 2 Pins 2 & 3

16 RP8 JP8 Pins 1 & 2 Pins 2 & 3

17 RP9 JP9 Pins 1 & 2 Pins 2 & 3

18 RP5 JP5 Pins 1 & 2 Pins 2 & 3

19 RP10 JP10 Pins 1 & 2 Pins 2 & 3

Parker encoders

Table 14 EXPAXIS Module Encoder Pull-Up Jumpers

Module Software

To access axes 9 through 16, refer to the software manual for the

commands. In addition, AcroView Version 3.11 and higher can display the

extra parameters, and show and program axes 9 through 16.

– 18 – ACRCOMM and ACREXPAXIS User’s Guide

Page 23

CHAPTER THREE

Additional

Specifications

Chapter 3 – Additional Specifications

IN THIS CHAPTER

• Suggested Stacking of Modules .......................................................20

• Environment and Cooling..................................................................21

Page 24

Suggested Stacking of Modules

Figure 7 Recommended Stacking for ACR1505 Add-on Modules.

– 20 – ACRCOMM and ACREXPAXIS User’s Guide

Page 25

Environment and Cooling

The Add-on modules operates in an ambient temperature range of 0°C

(32°F) to 45°C (113°F). The modules can tolerate atmospheric pollution

degree 2—only

recommended that the cards be mounted in a suitable enclosure.

As you add modules, you must ensure that there are no hot spots created in

the board stack due to airflow impairment.

Airflow impairment might result from cables coming in the way or lack of fan

direction towards the stack. Record the temperature in several places

(especially around I/O and DSP locations) to ensure even heat flow. Impaired

heat flow might cause malfunctions and eventually lead to permanent loss of

function.

Ambient Operating Temperature ............0°C (32°F) to 45°C (113°F)

Storage Temperature.............................. –40°C to 85°C (–40°F to 185°F)

Humidity ..................................................0–95%, non-condensing

Pollution Degree...................................... 2 (per IEC 61010)

Installation Category ............................... 2 (per IEC 61010)

dry, non-conductive pollution is acceptable. Therefore, it is

Chapter 3 – Additional Specifications – 21 –

Page 26

Index

ACRCOMM module.................................................... 3

autobaud detect ................................................... 7

connector, P5....................................................... 8

hardware setup .................................................... 5

jumpers ............................................................... 6

autobaud ......................................................... 7

battery enable ................................................. 7

termination ...................................................... 6

serial communications

MUX flags ........................................................ 3

receive/transmit flags ....................................... 4

add-on modules

cooling ...............................................................21

environment .......................................................21

stacking..............................................................20

autobaud detect ....................................................... 7

environment............................................................21

EXPAXIS module

axes 9-16 ...........................................................18

cables.................................................................10

connector

XP10 ..............................................................16

XP1A ..............................................................13

XP1B ..............................................................13

XP1C ..............................................................14

XP2 ................................................................16

XP9................................................................ 15

fuse ................................................................... 16

jumper

resistor packs ........................................... 12, 18

voltage configuration ................................ 12, 18

watchdog ........................................................... 10

feedback

encoder input ..................................................... 12

fuses

EXPAXIS module................................................. 16

locations ............................................................ 11

inputs

encoder.............................................................. 12

installation category ................................................ 21

jumpers

ACRCOMM module ................................................ 6

pollution degree...................................................... 21

RS-232..................................................................... 3

RS-422 ......................................................... 3, 4, 6, 8

specifications

cooling ............................................................... 21

environmental .................................................... 21

technical support ...................................................... ii

temperature, environment ....................................... 21

watchdog signal...................................................... 10

Loading...

Loading...