Page 1

PowerStation

PA Series User Guide

May 2008

Parker Electromechanical

50 W. TechneCenter Drive, Milford, Ohio 45150

Part #: A3-06692-101

Page 2

Copyright and Trademark Notice

Copyright © 2008 by Parker Electromechanical. All rights reserved. No part

of this publication may be reproduced, transmitted, transcribed, stored in a

retrieval system, in any form or by any means, mechanical, photocopying,

recording or otherwise, without the prior written consent of Parker

Electromechanical.

While every precaution has been taken in the preparation of this manual,

Parker Electromechanical Automation and the author assume no

responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. All

product and company names are trademarks of their respective companies

and licenses.

The following products are copyright their respective owners: Microsoft,

Datalight, Intel, SanDisk, SanDisk ImageMate, Phoenix/Award, and IBM.

Product Warranty Information

Parker Electromechanical provides top quality products through rigid

testing and the highest quality control standards. However, should a

problem occur with your hardware, Parker’s standard product warranty

covers these items for 24 months from the date of shipment from Parker.

Exceptions appear below:

Supported Models

• PowerStation backlight bulbs have a 90-day warranty.

• Third-party products, such as bus cards, carry the manufacturer’s

specified warranty.

• For all displays, image retention (burn-in) is not covered by warranty.

• Software revisions that occur within 60 days after purchase are

available under warranty upon request. Please review the Interact

License Agreement for additional software warranty information.

Should you have any questions about your application or need technical

assistance, please call Parker Electromechanical Produc t Technical Support

department at 513-248-1714, 8:00 a.m. to 5:00 p.m., Eastern Time. You

may call this same number after hours for emergency assistance. See

Product Technical Support on page 1-5 for more information about s upport

products and services.

This manual is for use with the following PowerStations:

• Model PA 05/06/08” STN and TFT PowerStations

• Model PA 10/15” PowerStations

Page 3

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Downloading Applications and Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Documentation Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Documentation Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Text Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ISO Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Customer Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Product Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Technical Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 Installing the PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Selecting a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Underwriters Laboratories Approval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Environmental Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Touchscreen Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electrical Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Field Terminal Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Temperature and Humidity Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Enclosure Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Radiated Emissions Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Class I, Division 2 Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Creating the Cutout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Installing the PA PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Mounting the PA PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Installing an Optional AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Preparing a Location for the AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Prepare the Power Supply Mounting Surface . . . . . . . . . . . . . . . . . . . . . . 2-9

Mounting the AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Connecting the Power Supply to the Workstation . . . . . . . . . . . . . . . . . . . . . . 2-10

3 Starting Your PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

PowerStation Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Serial Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Settings and Pinouts for COM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Settings and Pinouts for COM2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

RS-485 Directional Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Transferring Files from a PC to the P13 PowerStation . . . . . . . . . . . . . . . . 3-7

Keyboard and Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

PA PowerStation User Guide 1

Page 4

Connecting a PS/2 Mouse on 5”, 6”, 8” and 10” Units . . . . . . . . . . . . . . . . . .3-9

Connecting a USB Mouse on 15” Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Connecting to a Serial Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

To Adjust the Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

To Print to a Port Configured for Downloading . . . . . . . . . . . . . . . . . . . . . .3-11

Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Configuring the Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

CompactFlash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Starting the PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Using the CompactFlash Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Reinstalling the PowerStation Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Restoring a CompactFlash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Writing to the CompactFlash Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Reformatting the CompactFlash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Using the BIOS Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Using the BIOS Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Entering Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4 Maintaining the PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintaining the Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cleaning the Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibrating the Touchscreen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using the MachineShop Shell Calibration Utility. . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjusting the Contrast (only available on 5”, 6”, and 8” STN Units) . . . . . . . . . . . . . . . .4-2

Contrast Adjustment Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Replacing the CompactFlash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Performing Internal Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Removing the PowerStation from an Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Opening the PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Closing the PowerStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Resolving Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Resolving Problems when Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Resolving Problems with the Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Resolving Problems after Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Accessing the PowerStation Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Ordering Replacement Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

A PowerStation Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Testing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Faceplate Chemical Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

PA PowerStation User Guide 2

Page 5

B System Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

System Configuration Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Config.sys File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Autoexec.bat File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

PA PowerStation User Guide 3

Page 6

INTRODUCTION 1

Thank you for purchasing a PA PowerStation. The PA PowerStation is a

rugged, compact PC that is designed to be used as an industrial operator

interface.

The PA PowerStation is available in five display configurations: 5”, 6”, 8”,

10”, and 15”. It has an all-in-one PC board with a Serial and Ethernet port.

The PA PowerStation’s PC architecture allows you to run Parker’s Interact

HMI software product.

Important:You must upgrade to Interact version 6.13 or later before

downloading applications to the PA PowerStation.

Please take time to review this manual and the other documentation

included with the PA PowerStation before operating the unit.

Using this Manual

This manual is designed to help you set up and use your PA PowerStation.

The manual lists the PowerStation’s specifications and describes its

replacement and optional components. It also explains how to install the

unit, how to maintain the unit in good condition, and how to solve common

problems that may occur in operation.

This manual is divided into the following chapters:

Chapter 1 — Introduction: Presents an overview of this manual, the

other documentation and software provided with the PA PowerStation, and

the steps necessary to get your PowerStation up and running. This chapter

also describes Parker’s customer support services.

Chapter 2 — Installing the PowerStation: Explains how to select an

installation location, prepare for installation, and finally install the PA

PowerStation.

Chapter 3 — Starting Your PowerStation: Describes the ports available

to connect the PowerStation to other devices and to a power source. This

chapter also describes the PowerStation’s drive definitions and the unit’s

replacement and optional components.

Chapter 4 — Maintaining the PowerStation: Explains how to maintain

the PA PowerStation, including the touchscreen, replacing the

CompactFlash, perform internal maintenance, and to solve problems that

may occur during operation.

Appendix A — PowerStation Specifications: Describes the PA

PowerStation’s specificat i o ns .

PA PowerStation User Guide 1-1

Page 7

Chapter 1: Introduction Hardware Versions

Appendix B - System Configuration Files: This section includes a

complete listing of the Config.sys and Autoexec.bat files.

Hardware Versions

There are three display resolutions offered with the PA PowerStation:

• PA05S-1XX, STN, 320x240 (QVGA)

• PA06S-1XX, STN, 320x240 (QVGA)

• PA08S-1XX, STN, 640x480 (VGA)

• PA08T-1XX, TFT, 640x480 (VGA)

• PA10T-1XX, TFT, 640x480 (VGA)

• PA15T-1XX, TFT, 1024x768 (XGA)

All versions are shipped with both Datalights ROM-DOS operating system

and Interact HMI runtime software on a removeable compact flash card.

Each PowerStation is also shipped with a utilities CD containing drivers and

backup copies of available software.

Downloading Applications and Projects

The PA PowerStation is a runtime-only system, which means that you must

develop your applications and projects on a development PC and download

the application to the PowerStation.

Note Throughout this manual, all references to “development PC” or

“development system” refer to the computer you use to develop

applications.

See the documentation that came with your development software, such

as Interact, for information about how to develop your applications or

projects and download them to the PowerStation.

PA PowerStation User Guide 1-2

Page 8

Chapter 1: Introduction Documentation Library

Documentation Library

The documentation set for this product contains:

Release Notes - Release notes are provided whenever there is important

information about the PowerStation that does not appear in this manual.

Be sure to read any available release notes before installing or operating

the unit.

PA PowerStation User Guide - This document contains all the

information you need to configure, install and use the PowerStation. Please

read this manual in its entirety before operating the unit.

You can download Parker Electromechanical product documentation from

our web site at www.ctcusa.com. Click on the Support link then select

Product Manuals to find the appropriate manual.

Documentation Standards

Text Conventions

As you read this manual, notice that it uses the following documentation

standards:

Style Type of Text

Bold Names of buttons, tabs, menus, menu items, commands, files,

keyboard keys, dialog boxes and other important terms.

Italic Titles of User Guides, chapters, or sections and cross-references.

Courier

font

+ Indicates two or more keyboard keys that must be pressed

Note Alternative approaches or issues you should be aware of while

Important Information that will save time and minimize problems.

Warning Information that will prevent equipment damage or personal

Text to be entered from a keyboard.

simultaneously. For example, Ctrl+Alt+Delete.

using a particular function.

injury.

PA PowerStation User Guide 1-3

Page 9

Chapter 1: Introduction Customer Support Services

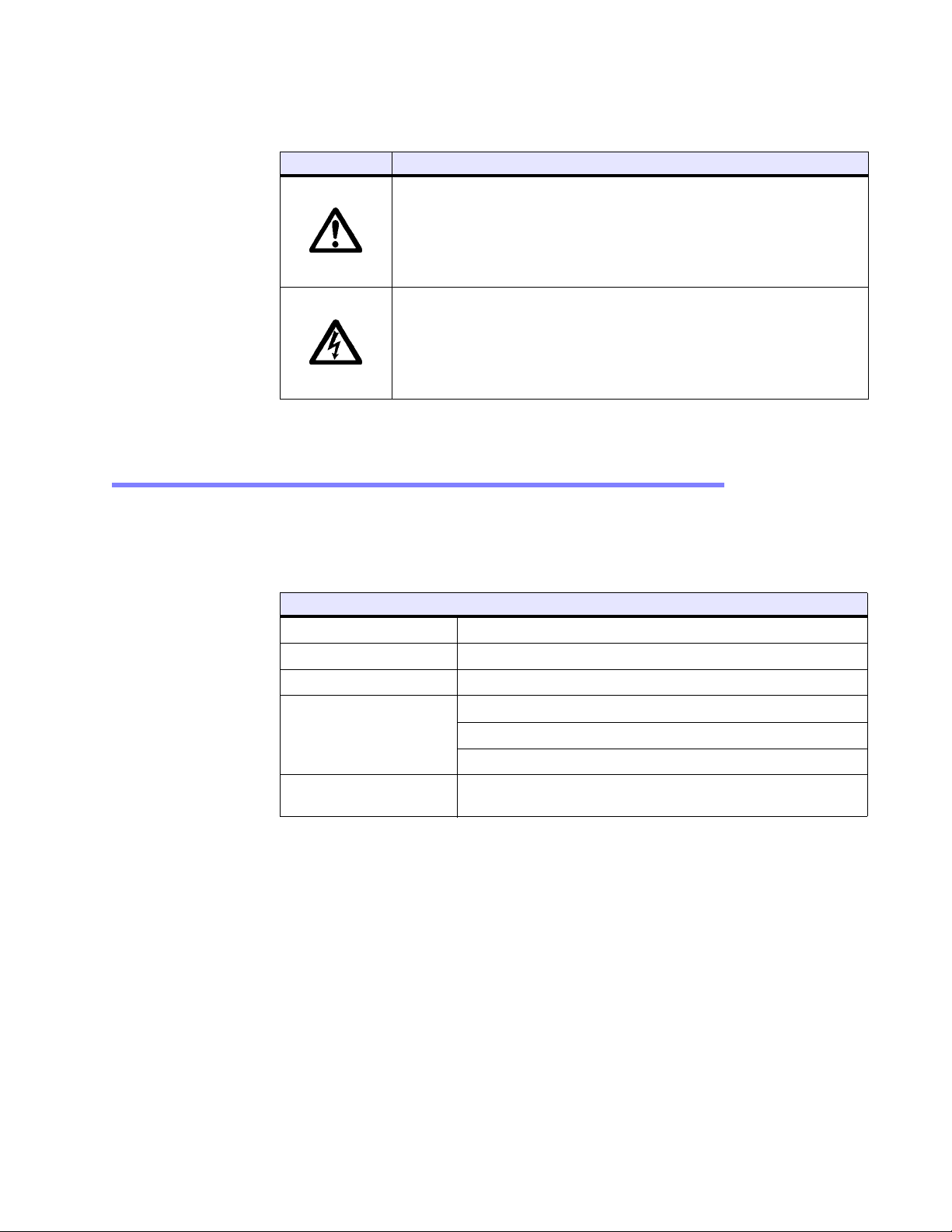

ISO Symbols

Symbol Meaning

This symbol is the International Standards Organization (ISO)

symbol for Caution (ISO 3864 No. B.3.1). This symbol denotes

information that could affect operation of the PowerStation if the

information is not properly followed.

This symbol is the ISO symbol for Caution - risk of electrical

shock (ISO 3864 No. B.3.6). This symbol denotes information

that could cause personal injury from electrical shock or damage

to equipment if the information is not properly followed.

Customer Support Services

Parker welcomes your thoughts and suggestions on our products and

services. You can contact Parker Electromechanical by telephone, email or

fax. You can also visit us on the World Wide Web to learn about the latest

hardware, software, and customer support services.

Customer Support

Main Telephone 513-831-2340

Technical Support 513-248-1714

Fax 513-831-5042

E-mail Sales: emn_sales_ctc@parker.com

Support: emn_support_ctc@parker.com

Training: emn_training_ctc@parker.com

World Wide Web http://www.parkermotion.com or

http://www.ctcusa.com

Parker recognizes that every customer and every application has different

support needs, as a result Parker offers a variety of support services

designed to meet these needs. Parker offers two types of customer support

services:

• Product Technical Support

• Technical Training

PA PowerStation User Guide 1-4

Page 10

Chapter 1: Introduction Customer Support Services

Product Technical Support

The Product Technical Support department welcomes any questions that

might arise as you develop or run your applications. We offer

complimentary support for all customers, including end users, original

equipment manufacturers (OEM), system integrators or distributors.

If you have a question about the PA PowerStation, be sure to complete the

following steps:

• Check any release notes that shipped with the unit. These notes

provide important information about the PowerStation.

• Consult the documentation and other printed materials included with

the PowerStation.

•Review Chapter 4, Maintaining the PowerStation.

• Visit the Parker Automation - CTC Web site and register for the support

forum. You can find the support forum by clicking on the Support tab

from the Web site’s home page: http://www.ctcusa.com.

Technical Training

If you cannot find a solution using one of the above sources, contact our

Product Technical Support department at 513-248-1714, 8:00am to

5:00pm Eastern Standard time.

Parker Electromechanical offers training on all of our products, either at

Parker in our state-of-the-art training facility, or at your site.

You can contact the Training Coordinator by telephone or e-mail:

• Telephone: 1-800-233-3329

• E-mail Parker Training: emn_training_ctc@parker.com

You can view a current training schedule on our web site at

www.ctcusa.com or www.parkermotion.com.

PA PowerStation User Guide 1-5

Page 11

Chapter 1: Introduction Getting Started

Getting Started

Now that you have opened the PA PowerStation, you are ready to unpack

the unit, install it in a permanent location, and develop an application for it.

Follow the steps below to get started.

1 Unpack the PowerStation and verify that you have rec eiv ed all of the

components you ordered.

2 Install the PowerStation in a permanent location. See Chapter 2,

Installing the PowerStation, for complete installation instructions.

3 Review the available connectors for the PowerStation, see

PowerStation Connectors on page 3-1, for details.

4 Start up your PowerStation. See Starting the PowerStation on page

3-13, for more information.

5 Develop your application and download it to the PowerStation.

Important:You must upgrade to Interact version 6.13 or later before

downloading applications to the PA PowerStation.

PA PowerStation User Guide 1-6

Page 12

INSTALLING THE POWERSTATION 2

Once you have unpacked the PA PowerStation and verified that you have

received all of the components you ordered, you are ready to install the

PowerStation in a permanent location.

This chapter covers the following topics:

• Selecting a Location

• Preparing for Installation

• Installing the PA PowerStation

Selecting a Location

The first step when installing the PA PowerStation is to select an

appropriate location for the unit. This is the most important aspect of the

installation process because the location you select can affect the

PowerStation’s performance, ease-of-use, and life-expectancy. This section

provides some guideline s t ha t yo u should follow when selecting a location

for the PowerStation.

Underwriters Laboratories Approval

In order to obtain Underwriters Laboratories (UL) approval for your

PowerStation installation, the installation must meet the following criteria:

1 The PowerStation must be mounted in a standard industrial enclosure

that provides fire protection.

2 The PowerStation products have been approved for NEMA Type 4/4X

(indoor) ratings when mounted in a customer provided enclosure

listed Type 4/4X.

PA PowerStation User Guide 2-1

Page 13

Chapter 2: Installing the PowerStation Selecting a Location

Environmental Guidelines

The environment is the area where the PA PowerStation will be located. In

general, you should select a place that limits the unit’s exposure to adverse

conditions such as dust, oil, moisture, and corrosive vapors.

Touchscreen Considerations

The PA PowerStation’s touchscreen is designed to meet the NEMA 4/4X

rating. However, it is only rated NEMA 4/4X when properly mounted in a

NEMA 4/4X enclosure.

The PA PowerStation’s touchscreen is resistant to a variety of chemicals.

See Faceplate Chemical Resistance on page A-8 for a list of these

chemicals. Make sure that the touchscreen is not exposed to chemicals

other than those listed in Faceplate Chemical Resistance on page A-8.

Electrical Guidelines

To minimize unwanted electrical interference, select a location away from

machinery that produces intense electrical noise. If you cannot do this,

isolate input power to the unit and separate all data communication cables

used with the unit from all AC power lines.

All serial communication cables should be 100% shielded with the shield

tied to chassis ground at one end of the cable only.

See Electrical Specifications on page A-6 for a list of the PA PowerStation’s

electrical specifications. Make sure that your power source is compatible

with the PowerStation before starting the unit.

Field Terminal Wiring Requirements

In order to comply with UL 508 and 1604 requirements, use copper wire

with 60C or 60/75C insulation and a tightening torque of 7.0 lb/in. (0. 79 Nm) when connecting field terminal wiring to the PowerStation.

Temperature and Humidity Guidelines

You can safely operate the PA PowerStation within the temperature range

specified in Environmental Specifications on page A-5. However, if you are

using a protective enclosure, remember that the temperature within an

enclosure is generally higher than the external temperature. Read these

guidelines to fully understand temperature implications.

The PA PowerStation can dissipate no more than 10 watts maximum.

Heat builds up rapidly in enclosed environments, compromising the

performance and life span of electrical equipment. If the PowerStation is

operating inside an enclosure at temperature levels above its rated

ambient temperature, you must cool the enclosure.

PA PowerStation User Guide 2-2

Page 14

Chapter 2: Installing the PowerStation Selecting a Location

PA PowerStation’s have been tested for use in 50oC ambient, still air

locations. This means that when installed, the ambient air surrounding the

backside of the PowerStation is not expected to exceed 50

o

C. An example

of this type of installation would be a PowerStation mounted in a small,

sealed industrial enclosure.

The most commonly overlooked aspect of this type of installation is that

heat generated by the device becomes trapped inside the enclosure and

increases the ambient temperature surrounding the PowerStation. This

increase in temperature can sometimes exceed an additional 15

Although the thermal dynamics are not always linear, a temperature rise of

o

15

C would imply that the environment outside the sealed enclosure could

not exceed 35

o

C (95oF), or the PowerStation would surpass its maximum

o

C or more.

operating temperature.

Do not mount a PowerStation into a sealed enclosure and mistakenly think

that due to the 50

operate in a 50

o

C rating of the product, the sealed enclosure can

o

C ambient environment without considering the affects of

the internal heat build up.

Since elevated operating temperatures can have negative affect on the life

of electronics, it is wise to consider the internal thermal rise. Passive

venting for thermal convection, internal air circulation fans, filtered

exhaust fans with filtered inlets, air conditioners, an d ot her products are

available in the market to assist in reducing the heat build up in the

industrial enclosure.

There are many attractive NEMA Type 12, dust-tight fan/filter assemblies

available today in which the filter can be inexpensively replaced or cleaned

as part of a periodic maintenance schedule. Or in some cases, simply

increasing the size of the enclosure, and thus the outside surface area for

example, can have a significant, positive affect on the installation’s thermal

response.

Points to consider when performing a site review are:

1 What is the expected maximum outside ambient temperature that

the industrial enclosure will experience?

2 Are there additional heat-generating components inside the

enclosure?

3 What is the size of the enclosure? Larger enclosures dissipate more

thermal energy than smaller ones.

4 In what kind of environment will the enclosure be installed - clean,

water-tight, dust-tight? Can the enclosure be convection cooled or is

active cooling required?

In summary, it is a wise investm ent to thermally plan the instal l a ti on by

anticipating, and eliminating, the heat build up inside a sealed enclosure.

Not only will this extend the life of the electronics, but it will also reduce

costly equipment downtime.

PA PowerStation User Guide 2-3

Page 15

Chapter 2: Installing the PowerStation Selecting a Location

Enclosure Guidelines

Select an enclosure that is large enough to allow free airflow in and around

the unit. You should allow a minimum of 2 inches between the enclosure

and the top, bottom, and sides of the PA PowerStation to allow access to

the cabling and CompactFlash.

Also, make sure that the surface of the enclosure on which the PA

PowerStation is mounted is flat and free of raised or depressed areas.

Radiated Emissions Guidelines

This PowerStation has been tested to com p l y with international

electromagnetic and emission standards. To reduce radiated emissions,

ensure that there is a good earth connection to the PowerStation, which

can be accomplished by utilizing the grounding stud located on the rear

chassis of the product.This connection must be made with the shortest

possible, heavy gage wire or braided cable. Low-resistance (<0.5 ohms)

continuity should be verified with an ohmmeter for proper grounding. In

addition, all communication cables should be shielded and grounded on

only one end.

PA PowerStation User Guide 2-4

Page 16

Chapter 2: Installing the PowerStation Selecting a Location

Class I, Division 2 Guidelines

If you purchased a Class I, Division 2-compliant PowerStation, it is suitabl e

for use in Groups A, B, C, and D hazardous locations. You must follow

these guidelines in order to maintain a safe operating environment.

• When performing field wiring, always use copper wire with 60C or

60/75C insulation and a tightening torque of 7.0lbs/in (0.79 N-m).

• Substitution of components can impair suitability for Class I, Division 2.

• The PA PowerStation is intended to use a branch circuit protection rated

20 Amps or less.

• Make sure that the PA PowerStation’s “ON/OFF” switch is secured in the

“ON” position using the supplied bracket.

Explosion Hazard!

• Do not connect or disconnect cables unless the power has been

switched off, or the area is known to be non-hazardous. Keyboard,

WARNING!

mouse, and USB ports are for system setup and diagnostics only and

are not intended for permanent connection.

• Class I, Division 2 approval requires nonincendive field wiring for

Class I, Groups A, B, C, and D hazardous locations only. With a

temperature code of T5.

• Class I, Division 2 approval requires power switch restraints in

hazardous environments.

PA PowerStation User Guide 2-5

Page 17

Chapter 2: Installing the PowerStation Preparing for Installation

Preparing for Installation

Once you select a location for the PA PowerStation, you will need to create

a cutout for the unit.

If you plan to operate the PA PowerStation using AC power, and you

purchased Parker’s optional AC Power Supply, you will need to prepare a

location for the Power Supply also.

Procedures for creating the cutout and preparing a location for the AC

Power Supply are described below. If you already have an appropriate

cutout and are using DC power, continue with Installing the PA

PowerStation on page 2-7.

Creating the Cutout

Be sure to follow the cutout diagrams in the dimensional drawings

precisely. This ensures that the PowerStation is properly sealed in its

enclosure. You can find the dimensional drawings on the PA PowerStation

CD shipped with your unit.

1 Measure the cutout dimensions as shown in the table below.

2 Attach the template securely to the mounting surface.

3 Cut out the shaded area on the template referred to as the Panel

Cutout Area. To ensure the flatness of the mounting surface, when

punching out the mounting hole, maintain proper surface flatness

and edge quality.

The cutout dimensions for the PA PowerS t a ti on are sh own in the following

table:

PA Model Cutout Height Cutout Width

PA05S

PA06S

PA08S

PA08T

PA10T 9.86” 12.60”

PA15T 12.40” 15.90”

4 Debur the edges of the cutout area, rem oving dirt and debris that

might come in contact with the unit .

5 More information is available on the CD that comes with the PA

PowerStation. Be sure to refer to the dimensional drawings found on

the CD when creating your cutout.

4.91” 6.20”

6.08” 8.67”

PA PowerStation User Guide 2-6

Page 18

Chapter 2: Installing the PowerStation Installing the PA PowerStation

Installing the PA PowerStation

Once you have prepared the location for your PowerStation, you are ready

to install the unit. To do so, you need to mount the PowerStation to your

enclosure using screws and metal clamps in what is called a bracket

assembly. The bracket assembly contains a mounting clamp with “feet”

and a screw.

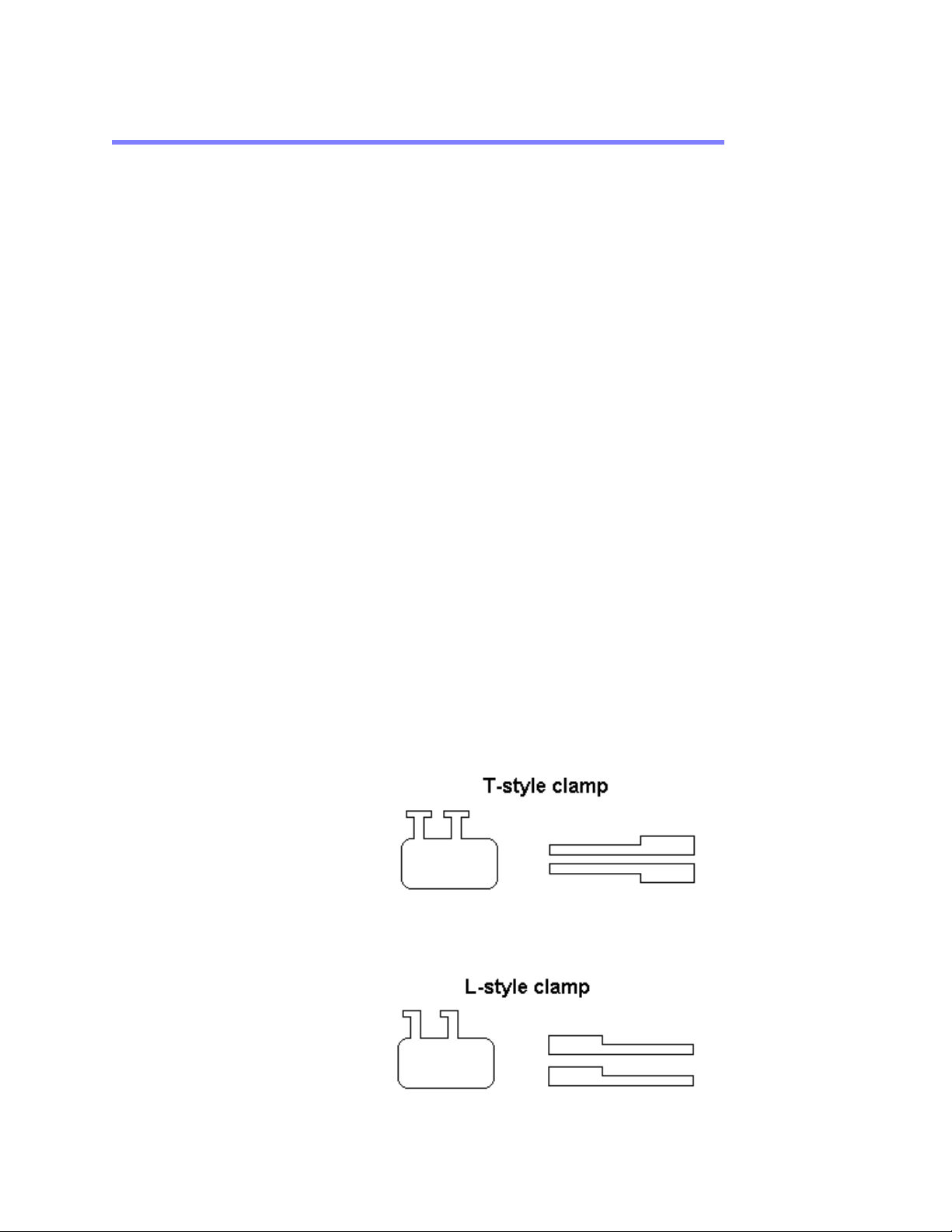

The number of clamps depends on the PA PowerStation model. The shape

of the prongs at the bottom of each clamp also depends on t he model. The

5”, 6”, and 8” models use a T-shape clamp, and the 10” and 15” models

use an L-shape clamp.

The mounting clamps secure to the PowerStation using a sliding

mechanism. You must slide the feet of the mounting clamp into the

appropriate slot on the PowerStation.

For your convenience, all necessary mounting hardware is included with

the unit.

Mounting the PA PowerStation

Complete the instructions b elow:

1 Slide the PowerStation into the cutout from the front.

2 Attach the 4-8 mounting clamps, with their screws to the back of the

unit in the spaces provided.

The clamps secure to the unit using the sliding mechanism shown in

Figure 2-1 for 5”, 6” and 8” units or Figure 2-2 for 10” and 15” units.

Figure 2-1: Sliding Mechanism for the 5”, 6”, and 8” PA PowerStations

Figure 2-2: Sliding Mechanism for the 10” and 15” PA PowerStations

PA PowerStation User Guide 2-7

Page 19

Chapter 2: Installing the PowerStation Installing the PA PowerStation

3 Slide the feet of the mounting clip into the larger portion of the slot,

then slide the clip over to properly mount the unit.

4 Tighten each of the mounting screws against the front of the

enclosure.

5 For 5” and 6” units: Torque them down to 6 in/lbs.

For 8” and 15” units: Torque them down to 7in/lbs.

For 10” units: Tighten so that the gasket seal maintains a 50%

compression of the gasket. You may see a small gap between the

bezel and the enclosure.

6 Tighten the screws in a crosswise sequence to ensure a good seal

and prevent damage. Tightening the bracket assembly may not

ensure that the gasket seal is totally depressed by the bezel. You

may see a small gap between the bezel and the enclosure.

PA PowerStation User Guide 2-8

Page 20

Chapter 2: Installing the PowerStation Installing an Optional AC Power Supply

Installing an Optional AC Power Supply

The PA PowerStation uses only 12 or 24 volt DC power. However, you can

operate the PowerStation with AC power by using an optional AC Power

Supply available from Parker. Use this section only if you intend to operate

the PA PowerStation using AC power. If you plan to use DC power, refer to

Installing the PA PowerStation on page 2-7.

Caution: Do not apply AC power directly to the unit or damage may

occur.

Preparing a Location for the AC Power Supply

Be sure to select a location that provides protection from dust, oil,

moisture, and corrosive vapors. If your enclosure is large enough, you can

mount the Power Supply in the enclosure with the unit.

If you purchased Parker’s optional AC Power Supply and mounting kit use

the template that came with the mounting kit to prepare your location for

the power supply. This can be inside or outside the enclosure where the

PowerStation is installed.

Note: If you decide to mount the Power Supply in an enclosure, mount it

on the bottom or on the side of the enclosure to provide the best

convection cooling.

Prepare the Power Supply Mounting Surface

The P1X-PWRAC AC power supply is designed to be mounted using two

metal brackets provided in the optional BKT-1000 mounting kit. These

brackets are secured to the mounting surface using four screws. To

prepare the mounting surface, complete the following steps:

1 Measure the cutout dimensions.

2 Securely attach the power supply template to the mounting surface.

3 Cutout the four 0.17” (4.3mm) holes as shown on the template.

4 Debur the edges of the cutout area, rem oving dirt and debris.

Mounting the AC Power Supply

After drilling the holes for the four screws, you can follow the steps below

to mount the power supply:

1 Attach the power supply to the mounting surface using the supplied

metal brackets.

2 Connect the power cord from the power supply to an AC power

source.

3 Attach the ferrite to the section of the cord closest to the loose wires.

The ferrite is located in the PA mounting kit.

PA PowerStation User Guide 2-9

Page 21

Chapter 2: Installing the PowerStation Installing an Optional AC Power Supply

Connecting the Power Supply to the Workstation

Once you have mounted the power supply, you are ready to connect it to

the workstation.

1 Slide the positive and negative wires into the appropriate slots on the

power connector that was shipped with the workstation. See Figure

2-3.

Figure 2-3: Power Connector and Positive/Negative Wires

Power Connector

Power Supply +/- Wires

2 Connect the ground cable from the power connector to an earth

ground.

3 Connect the power cord from the power supply to an AC power

source.

4 Attach the power connector that you prepared in Step 1, to the

workstation.

You have successfully connected the power supply to your workstation.

You can now operate the workstation using AC power.

Caution: All PA PowerStations are powered from a 12VDC or 24VDC

power source. DO NOT connect AC power to the unit.

PA PowerStation User Guide 2-10

Page 22

STARTING YOUR POWERSTATION 3

This chapter discusses the following topics:

• PowerStation Connectors

• Starting the PA PowerStation

• Using the CompactFlash Card

• Using the BIOS Utility

The PA PowerStation is shipped with the Documentation and Utilities CD.

This CD contains all of the dimensional drawings, software, and drivers

needed. If any of the software on your system becomes lost or corrupted,

you can reinstall it from this distribution disk.

PowerStation Connectors

All PA PowerStations have the following connectors:

Serial Ports

• 2 serial ports

• 2 PS/2 ports for the keyboard and mouse (PA05 - PA10 only)

• 2 USB ports (PA15 only)

• 1 Ethernet port

• 1 Compact Flash connector

• Power switch

•1 ground stud

See the PA PowerStation CD for dimensional drawings and a diagram to

locate the components.

The PA PowerStation has two serial ports that you can use to communicate

with external devices at baud rates of up to 115 Kbaud.

The COM1 port supports RS-232, while COM2 supports configurable RS232, RS-422, and RS-485 communication standards.

The communication standard you select for COM2 depends upon the

distance between the PA PowerStation and the controller, as well as the

PA PowerStation User Guide 3-1

Page 23

Chapter 3: Starting Your PowerStation PowerStation Connectors

communication standards that the controller supports. Use a standard DB9

connector for communicating with this port.

Note: If you are using RS-232 communications, the length of the serial

cable should not exceed 50 feet (15 meters).

RS-422 and RS-485 communications offer greater noise immunity than

RS-232. These standards increase the maximum cable length to 4,000 feet

(1,200 meters).

RS-422 communications are full-duplex (send and receive simultaneously),

while RS-485 communications are half-duplex (send or receive).

For either configuration, be careful not to connect any wires to unused

connector pins. If you are using Parker’s MachineShop software,

information on the specific connection required for the Interact drivers you

will use is located in the Help file associated with the driver.

PA PowerStation User Guide 3-2

Page 24

Chapter 3: Starting Your PowerStation PowerStation Connectors

Settings and Pinouts for COM1

If you need to make a cable for communicating with COM1, Table 3-1

shows the pinouts and signal information for this port.

Table 3-1: COM1 Pinouts

Pin# Signal

1 DCD, data carrier detect

2RXD, received data

3 TXD, transmitted data

4 DTR, data terminal ready

5 Signal ground

6DSR

7 RTS, request to send

8 CTS, clear to send

9RI

Dip Switch Settings and Pinouts for COM2 on the 5”, 6”, 8”, and 10” Units

If you need to make a cable for communicating with COM2 on a 5”, 6”, 8”

and 10” unit, Table 3-2, shows the pinouts and signal information for this

port.

Table 3-2: COM2 Pinouts on 5”, 6”, 8”, and 10” Units

RS-232

Pin#

1 DCD, data carrier

2 RXD, received data TXD+, transmitted

3 TXD, transmitted

4 DTR, data terminal

5 Signal ground Signal ground Signal ground

6 DSR, data set ready DSR, data set ready DSR, data set ready

Communication

detect

data

ready

RS-422

Communication

TXD-, transmitted

data -

data +

RXD+, received data +RXD+, received data

RXD-, received data

-

RS-485

Communication

TXD-, transmitted

data -

TXD+, transmitted

data +

+

RXD-, received data

-

7 RTS, request to send RTS, request to send RTS, request to send

8 CTS, clear to send CTS, clear to send CTS, clear to send

9RIRIRI

Caution: Note that RTS and CTS signals are not active in RS-422 and RS-

485 configurations.

PA PowerStation User Guide 3-3

Page 25

Chapter 3: Starting Your PowerStation PowerStation Connectors

Once you make a cable for communicating with COM2, you will need to set

the COM2 DIP switch settings.

COM2 is set to the RS-485 protocol by default. To change COM2 to the RS232 or RS-422 protocol, you must change the COM2 DIP switch settings.

The DIP switch for COM2 is located on the side of the PA PowerStation, as

shown in Figure 3-1 for the 5”, 6”, 8”, and 10” units.

Figure 3-1:

• The white boxes represent the tip of the switch.

• The upper half of the switch is the ON position, and the lower half of the

switch is the OFF position.

To change the DIP switch settings, complete the following steps:

1 Choose the appropriate DIP switch settings from the diagram

Figure 3-2: DIP Switch on 5”, 6”, 8” and 10” Units

COM2 Dip Switch Settings for 5”, 6”, 8”, and 10” Units

displayed on the side of the PA PowerStation and the chart below.

2 Using a pointed instrument such as a pen or pencil, flip the switches

to the appropriate settings through the viewing window.

Figure 3-3, displays the connector pinouts and cable wiring required for

communicating with COM1 or COM2 using the RS-232, RS-422 or the RS485 protocol. This figure is for the 5”, 6”, 8”, and 10” units only.

PA PowerStation User Guide 3-4

Page 26

Chapter 3: Starting Your PowerStation PowerStation Connectors

Figure 3-3: Connector Pinouts and Cable W iring on 5”, 6”, 8” and 10” Units

RS-232 RS-422 RS-485

Note: Be careful not to connect any wires to unused connector pins.

Dip Switch Settings and Pinouts for COM2 on 15” Units

If you need to make a cable for communicating with COM2 on a 15” unit,

Table 3-3, shows the pinouts and signal information for this port.

Table 3-3: COM2 Pinouts on 15” Units

RS-232

Pin#

1 N/C TXD-, transmitted

2 RXD, received data TXD+, transmitted

3 TXD, transmitted

4N/C RXD-, received data

5 Signal ground Signal ground Signal ground

6 N/C N/C N/C

7 RTS, request to send RTS, request to send RTS, request to send

Communication

data

RS-422

Communication

data -

data +

RXD+, received data +RXD+, received data

-

RS-485

Communication

TXD-, transmitted

data -

TXD+, transmitted

data +

+

RXD-, received data

-

8 CTS, clear to send CTS, clear to send CTS, clear to send

9 N/C N/C N/C

PA PowerStation User Guide 3-5

Page 27

Chapter 3: Starting Your PowerStation PowerStation Connectors

Caution: Note that RTS and CTS signals are not active in RS-422 and RS-

485 configurations.

Once you make a cable for communicating with COM2, you will need to set

the COM2 DIP switch settings.

COM2 is set to the RS-485 protocol by default. To change COM2 to the RS232 or RS-422 protocol, you must change the COM2 DIP switch settings.

The DIP switch for COM2 is located on the side of the PA PowerStation, as

shown in Figure 3-4 for the 15” unit.

Figure 3-4:

• The white boxes represent the tip of the switch.

• The upper half of the switch is the ON position, and the lower half of the

switch is the OFF position.

To change the DIP switch settings, complete the following steps:

1 Choose the appropriate DIP switch settings from the diagram

Figure 3-5: DIP Switch on 15” Units

COM2 Dip Switch Settings for 15” Units

displayed on the side of the PA PowerStation and the chart below.

2 Using a pointed instrument such as a pen or pencil, flip the switches

to the appropriate settings through the viewing window.

PA PowerStation User Guide 3-6

Page 28

Chapter 3: Starting Your PowerStation PowerStation Connectors

Figure 3-6, displays the connector pinouts and cable wiring required for

communicating with COM1 or COM2 using the RS-232, RS-422 or the RS485 protocol. This figure is for the 15” unit only.

Figure 3-6: Connector Pinouts and Cable Wiring on 15” Units

RS-232 RS-422 RS-485

Note: Be careful not to connect any wires to unused connector pins.

RS-485 Directional Control

Many device drivers use the RTS signal to switch between receive and

transmit mode. Some third party communication drivers expect the

directional control to be automatic. The PA PowerStation does not

automatically switch between modes and depends on the driver to use the

RTS signal to perform this operation.

Transferring Files from a PC to the PA PowerStation

You can transfer files from a PC to the PA PowerStation in one of three

ways—through the Ethernet, the CompactFlash, or a Serial Transfer. If you

plan to use a Serial Transfer, you will need a null modem cable. To

construct your own cables, refer to Figure 3-7, for the appropriate settings,

then continue with step 1 below.

PA PowerStation User Guide 3-7

Page 29

Chapter 3: Starting Your PowerStation PowerStation Connectors

Figure 3-7: Serial Transfer Cable Diagram

1 Connect a null modem serial cable to an available serial port on your

development PC.

2 Connect the other end of the cable to the serial port on the PA

PowerStation.

3 Launch the MachineShop Toolbar on your development PC.

4 Select File - Open Project then select the project you wish to transfer.

5 Select Transfer from the menu bar and follow the transfer wizard

steps.

PA PowerStation User Guide 3-8

Page 30

Chapter 3: Starting Your PowerStation PowerStation Connectors

Keyboard and Mouse

The PA PowerStation’s CPU board includes a keyboard port that accepts

any IBM AT-compatible keyboard, including 84-key standard keyboards

and 101-key enhanced keyboards.

Connecting a PS/2 Mouse on 5”, 6”, 8”, and 10” Units

If you prefer to use a mouse instead of the touchscreen, Parker

recommends that you only use a Microsoft PS/2-style mouse, specifically

an 802.3 Microsoft-compatible mouse.

Parker has found that some Microsoft-compatible PS/2 mice do not work

correctly with the PA PowerStation. In addition, connecting any mouse

directly to the keyboard port will cause the mouse to malfunction.

Connecting a USB Mouse on 15” Units

If you prefer to use a mouse instead of the touchscreen, the 15” unit

supports any USB style mouse.

Serial and PS/2 mice are not supported on 15” units.

Connecting to a Serial Printer

When connecting a serial printer to the PA PowerStation, you will need to

prepare the serial port for the printer. First you will need to adjust the

mode settings to the settin g s o n the printer. See To Adjust the Mode

Settings below.

If you plan to print to a serial port that was configured for downloading,

you will need to reconfigure the serial port. See To Print to a Port

Configured for Downloading on page 3-11.

To Adjust the Mode Settings

To connect a serial printer to the PA PowerStation, you must change the

mode settings for one of the serial ports to match those of your printer.

The easiest way to change these settings is to use MODE.COM. MODE.COM

can modify the following options:

• baud: 110, 150, 300, 600, 1200, 2400, 4800, 9600

• parity: N - none, O - odd, E - even

• databits: either 7 or 8

• stopbits: either 1 or 2

Parker includes MODE.COM on the PA PowerStation’s Compact Flash card

and the ROM-DOS installation CD shipped with your PowerStation.

Figure 3-8 illustrates the appropriate settings for the PA PowerStation COM

Port and the Serial Printer Connector with hardware handshaking and

without hardware handshaking.

PA PowerStation User Guide 3-9

Page 31

Chapter 3: Starting Your PowerStation PowerStation Connectors

Figure 3-8: Serial Printer Cable Diagram

Use Figure 3-8 as a reference when connecting a serial printer to the PA

PowerStation. Then complete the following steps:

1 From the Windows desktop, open the Startup directory within

Interact project:

C:\Machshop\Projects\Interact\*Project Name*\Startup\

Important Be sure to replace the pound sign with the appropriate

port number when completing the next step.

2 Within the Startup folder, create a new AUTOEXEC.BAT file with the

following line.

MODE COM#:baud,parity,databits,stopbits

For example, if you are communicating at 9600, NONE, 8, and 1, use

MODE COM1: 9600,N,8,1

3 Launch the MachineShop Toolbar.

Note When you download the project

containing AUTOEXEC.BAT

and MODE.COM from your development system to the

PowerStation

created in step 2 and MODE.COM into the \STARTUP directory

specified by the INTERACT_STARTUP environment variable. This

environment variable resides in the PowerStation’s AUTOEXEC.BAT

file.

4 Download the project.

Note When MachineShop finishes the download, a prompt will

display asking whether you want to restart the computer.

, MachineShop transfers the AUTOEXEC.BAT file you

When you restart, MODE.COM will configure the COM port to the

required baud rate.

5 Restart the PowerStation.

PA PowerStation User Guide 3-10

Page 32

Chapter 3: Starting Your PowerStation PowerStation Connectors

To Print to a Port Configured for Downloading

If you plan to print to a port that is configured for downloading, you will

need to reconfigure the port before you can print to it. To reconfigure the

port, complete the following steps:

1 Disable downloading for that port.

2 Restart the PA PowerStation.

Note Restarting the PowerS t a ti on all ows MO DE.COM to reset the

communication settings for that port.

3 Select Settings from the Main Menu.

4 Choose TCP/IP from the selections displayed.

5 Select Net Setup from the menu.

Important The configuration may already be set to Download Only.

If not, continue with step 6. Otherwise, skip to step 8.

6 Depending on how your PA PowerStation is configured, select the

appropriate Net (Net 1, Net 2, or Net 3).

7 Choose Download Only from the options displayed.

8 Continue to Back out until you reach a prompt that indicates the

TCP/IP configuration has changed and asks whether you want to

Reboot.

Ethernet Port

9 Choose Yes to reboot the PA PowerStation. This will save your

changes.

The PA PowerStation has an Ethernet RJ45 port with an Intel 82551ER

10/100 Mbps base-T controller that allows you to connect the PowerStation

to a Local Area Network.

Table 3-4: Ethernet Pinouts

Pin# Signal

1TX+

2TX3RX+

4N/C

5N/C

6RX7N/C

8N/C

PA PowerStation User Guide 3-11

Page 33

Chapter 3: Starting Your PowerStation PowerStation Connectors

Configuring the Ethernet Interface

The \NET directory of the PA PowerStation’s CompactFlash contains a

configuration utility and all drivers necessary to configure the Ethernet

interface on the PowerStation. These files are restored when performing a

reflash of the compact flash card using the Flashback Utility. A link to the

Flashback Utility is listed in the PA Drivers, Documentation, and Utilities CD

included with the PA PowerStation.

Table 3-5: NET Directory Files

File Name Description

NET.BAT A sample batch file you can use to run NetBIOS.

NET.CFG Stores the interrupts and memory for the network

drivers. The default PowerStation configuration

reserves the following interrupts and I/O addresses.

You cannot use these for the Ethernet interface.

• COM1: Int 4, I/O 3F8

• COM2: Int 3, I/O 2F8

• Touchscreen: Int 11, I/O 3E8

NETX.EXE The Novell Netware shell program that makes the

final connection with the server.

*LSL.COM A Novell driver that enables the workstation to

communicate with different protocols.

*IPXODI.COM A Novell driver that supports IPX protocol and other

protocols over the same network.

Plug and Play Pro 100 The Plug and Play interface: 82557

E100BODI This driver allows the PowerStation to communicate

over a local area network.

*NETBIOS.EXE Used by Interact to communicate over a network.

RSET8019.EXE Configures interrupts and I/O addresses for the

network.

TCPIP.EXE Used by the P owerStation for T CP/IP communications.

TCPIP.INI Stores settings for TCP/IP communications.

* Denotes files that can be downloaded from Novell’s FTP site.

Interact will also communicate over any network or operating system that

supports NetBIOS protocols. Examples include Lantastic, T CP/IP, Microsoft,

and IBM.

CompactFlash

If you need assistance with NetBIOS and networking, consult your network

administrator or a certified network technician.

The PA PowerStation comes with a CompactFlash (CF) card. The CF is used

as a removable hard drive that is recognized as drive C and provides non-

PA PowerStation User Guide 3-12

Page 34

Chapter 3: Starting Your PowerStation Starting the PowerStation

volatile memory storage. The CF is well-suited for rugged environments

where the PowerStation may vibrate or shake. Although the CF is

removable, it is used as an IDE drive, which means you cannot remove it

while the PowerStation is switched on.

The PA PowerStation supports Type 1 or Type 2 CF cards.

You should purchase at least one additional CF card to serve as a backup

for your primary CF card. It is also useful to own several cards to store

different projects. You can purchase additional CF cards through Parker.

Note: Do not remove or insert the CF card when the unit is powered on or

data on the card could be corrupted.

Starting the PowerStation

Once the PA PowerStation has been mounted, you are ready to start up the

unit. This procedure is describ ed below.

Before connecting a power cord to your unit, make sure that you have read

and understood Environmental Specifications on page A-5, and the Testing

Specifications on page A-7, of this manual. Also, be sure to follow the

guidelines listed below:

For permanently connected equipment, incorporate a readily accessible

disconnect device in the fixed wiring.

Important:Proper installation of this PowerStation model for use in

European Union countries requires the use of a harmonized power

cord (the power cord must be identified with the <HAR> symbol).

Make sure that the PowerStation is connected to the main supply

only with a harmonized power cord.

1 Ensure the power on/off switch is in the off position.

2 Connect the power cord to a DC voltage source. Voltage input to the

unit should be within the range specified in the Environmental

Specifications.

3 Turn the PA Power Station on.

The PowerStation will automatically load the MachineShop Shell or an

Interact application, if the Shell is configured to start Interact

automatically.

You are now ready to download a project to the PA PowerStation. If

you’re using MachineShop software, refer to the MachineShop

Getting Started Guide or the MachineShop Toolbar help system for

information about downloading projects.

Important:You must upgrade to Interact version 6.13 or later before

downloading applications to the PA PowerStation.

PA PowerStation User Guide 3-13

Page 35

Chapter 3: Starting Your PowerStation Using the CompactFlash Card

Using the CompactFlash Card

You can remove the CF card, update the application files on the CF card

from a PC, and then reinstall the CF card in the PowerStation.

Reinstalling the PowerStation Utilities

The PA PowerStation is shipped with the operating system and software,

which is installed on the CF card that comes with your system.

Backup copies of your software are provided on the PA PowerStation CD

that ships with your system. If any of the software on your system

becomes lost or corrupted, you can reinstall it from this distribution disk.

Restoring a CompactFlash Card

Because you use a CF card as the startup drive in a PA PowerStation, you

should create a bootable CF card for the system from a blank or used card.

This procedure will fix a ROM-DOS Shell CompactFlash card and let you do

the following:

• Reinstall the PowerStation Utilities onto a CF card

• Prepare a new CF card for use

You can easily reformat a CF card by using Parker’s Flashback Utility, which

restores the ROM-DOS operating system and PA PowerStation operating

files to a CF card in one operation.

When you use Flashback, the following software will be replaced on your

CompactFlash card:

• Operating system

• System drivers

• MachineShop Shell

Writing to the CompactFlash Card

To write to the CompactFlash card, you will need one of the following:

• A personal computer running Windows with a CD-ROM drive and a

SanDisk ImageMate or any CompactFlash card PC reader/writer. A

SanDisk Imagemate is a CompactFlash reader/writer that connects to

the personal computer through a USB port.

• A laptop computer running Windows with a CD-ROM drive and a

PCMCIA-to-CompactFlash adapter. The PCMCIA-to-CompactFlash

adapter lets you read from or write to a CompactFlash card through

your laptop’s PCMCIA slot.

PA PowerStation User Guide 3-14

Page 36

Chapter 3: Starting Your PowerStation Using the BIOS Utility

Reformating the CompactFlash Card

Warning:Manually formatting a CompactFlash card in Windows NT, 2000,

XP, or Vista before using Flashback could possibly make the CF

card unusable.

Warning:Removing the CompactFlash card: During a disk transfer

procedure, do not remove the CF card before issuing a Stop or

shutting down the USB port service. Otherwise the last part of

the data will not transfer to the CF card.

To reformat a CF card for a PA PowerStation, complete the following steps

on a personal computer or laptop:

1 Insert the CompactFlash card into the CompactFlash card PC

reader/writer or the PCMCIA slot.

2 Insert the PA PowerStation CD into the CD-ROM drive.

3 Select the Drivers/Utilities selection from the CD menu. On the

Utilities page you will find a link to the web site that contains the

Flashback utility image.

4 Select the Flashback utility web link to open your browser to the

location of the utility.

5 Download the utility from the web site and ins t all it on your

6 Double-click the executable file.

Note: Reformatting a CompactFlash card using Flashback will erase your

7 Click the down arrow for the destination drive and choose the correct

8 Press the Restore Image button.

Note The Flashback Utility, will first format the compact flash, and then

Using the BIOS Utility

This section discusses how to use the BIOS utility on the PowerStation.

There are three instances in which you will need to use the BIOS utility

program:

development laptop.

The Flashback Utility dialog box appears.

projects from the CF card. You will need to download your projects

to the CF card again. After using Flashback, you may also need to

recalibrate your PA PowerStation display. For instructions, see

Calibrating the Touchscreen on page 4-2.

drive letter that was assigned to the CF.

copy ROM-DOS, the Shell, and the utilities to the compact flash.

1 You are starting your system for the first time.

2 You have changed the hardware attached to your system.

PA PowerStation User Guide 3-15

Page 37

Chapter 3: Starting Your PowerStation Using the BIOS Utility

3 The CMOS memory has lost power and the configuration information

has been erased.

Every computer with a motherboard includes a special chip referred to as

the BIOS or ROM BIOS (Read Only Memory Basic Input/Output System).

The BIOS includes instructions to interact with the computer hardware. It

also includes a test which ensures that the computer meets requirements

to boot up properly. If the computer encounters an error during the test,

you either hear a combination of beeps or see an error message on the

screen.

Error messages can be fatal or non-fatal. Generally, the system can

continue the boot up sequence with a non-fatal error. These are usually

displayed on the screen along with the following instructions:

Press <F1> to RESUME

Write down the error message and press the F1 key to continue booting the

system. If you want to change BIOS settings, refer to the following

sections.

Using the BIOS Utility

Entering Setup

Before changing any of the BIOS settings, shut down the system and

connect a keyboard to the PowerStation.

1 Turn on the PowerStation.

2 Press the F1 key while the system sp lash screen displays to enter the

When the BIOS utility is displayed, press a letter key or use the arrow keys

to navigate through the menu.

BIOS setup utility.

PA PowerStation User Guide 3-16

Page 38

MAINTAINING THE POWERSTATION 4

The PowerStation has been designed to provide years of trouble-free

operation even in the harshest environments. However, occasionally you

need to perform routine maintenance on some of the PowerStation’s

components.

This chapter provides instructions on maintaining your PowerStation:

• Maintaining the Touchscreen

• Replacing the CompactFlash

• Performing Internal Maintenance

•Optional Components

• Resolving Problems

Maintaining the Touchscreen

This section discusses the basic maintenance of your PowerStation’s

touchscreen, including:

• Cleaning the Touchscreen

• Calibrating the Touchscreen

• Adjusting the Contrast(only available on 5”, 6”, and 8” STN units)

Cleaning the Touchscreen

Occasionally, you may need to clean the monitor’s screen. Clean the

screen using warm, soapy water and a cloth. You can also use any nonabrasive cleaner. See Faceplate Chemical Resistance on page A-8, for a list

of substances the screen can resist with no visible effect.

Do not use any harsh material or powder, such as steel wool or abrasive

cleansers, to clean the screen surface. The surface is sensitive to scraping,

sharp blows, or punctures. Therefore, keep screwdrivers or other sharp

objects away from the screen surface.

Warning Do not clean the unit while it is running. Turn off the monitor

before cleaning it in order to avoid inadvertently activating

the touchscreen.

PA PowerStation User Guide 4-1

Page 39

Chapter 4: Maintaining the PowerStation Maintaining the Touchscreen

Calibrating the Touchscreen

The monitor’s touchscreen is calibrated before leaving Parker. However,

you may need to recalibrate the touchscreen in certain circumstances, such

as:

• Moving a CompactFlash card between PA PowerStations

• After re-imaging the CompactFlash card

• When you use the PA PowerStation for the first time

• When you replace the touchscreen

• Whenever the cursor does not follow the location where you touch the

screen

Using the MachineShop Shell Calibration Utility

The MachineShop Shell comes with a calibration utility that allows you to

calibrate the touchscreen. To calibrate the touchscreen, complete the

following steps:

1 From the MachineShop Shell Main Menu, select the Settings option,

then select the PowerStation option.

2 The PowerStation Settings page will appear.

3 Select the Calibrate Touchscreen option. The calibration routine will

run automatically.

4 Follow the instructions on the screen.

5 Use your finger to touch the + on the screen.

6 Repeat the previous step two more times. Each time you touch the +

you will hear a faint beep to indicate that the touch has been

accepted.

After the third time, your touchscreen will be calibrated.

Adjusting the Contrast (only available on 5”, 6”, and 8” STN units)

You may adjust the contrast on the PA PowerStation. The contrast is a

property of the LCD.

Note The Brightness property is fixed and cannot be adjusted.

This property can be adjusted on the STN display only. So before you

begin, you will need to determine whether you own an STN or a TFT

display. To distinguish between the two types of displays and their

resolution, locate the model number on the back of the PA PowerStation

unit and compare the third digit in the model number with the third digit in

Table 4-1: Display Type to determine the ty p e of d i sp l a y you own.

Table 4-1: Display Type

Model No. View S ize

PA-05S/06S-1XX STN Display - Quarter VGA

PA PowerStation User Guide 4-2

Page 40

Chapter 4: Maintaining the PowerStation Maintaining the Touchscreen

Model No. View S ize

PA-08S-1XX STN Display - Full VGA

PA-08T/10T/15T-1XX TFT Display - Full VGA

• If your PA Series has an STN display, continue with Contrast

Adjustment Steps.

• If you have a TFT display, you cannot adjust the contrast.

Contrast Adjustment Steps

1 Find the contrast adjustment on the back of the PowerStation. See

Figure 4-1.

Figure 4-1:Contrast Adjustment

Contrast

Adjustment

2 Using a Phillips screwdriver, turn the screw to adjust the contrast to

the desired level. This is a very small adjustment.

PA PowerStation User Guide 4-3

Page 41

Chapter 4: Maintaining the PowerStation Replacing the CompactFlash

Replacing the CompactFlash

At some point, you will probably need to remove the CompactFlash (CF)

card from the PA PowerStation flash socket for one reason or another. To

do so, complete the following steps:

1 Turn off the PA PowerStation.

Caution: The PowerStation must be turned off when inserting or

removing the CF card to avoid corrupting data.

2 Locate the ejector next to the CF socket similiar to that shown in

Figure 4-2.

Figure 4-2: CompactFlash Ejector.

Ejector Button

3 Push the ejector button two times, once to extend the button, then

again to pop out the CF card.

4 Remove the CF card.

5 Carefully insert the new card with the connector on the card aligning

with the pins inside the socket.

6 Push the CF card into the slot until the card is securely seated in the

socket. Do not force!

Note: The CompactFlash has an arrow near one edge that always lines up

with a matching arrow on the label of the PA PowerStation. Insert the

CompactFlash so the arrows line up and the card seats properly. Do

not force the CompactFlash in the wrong way.

If you need additional storage capacity for the PA PowerStation, you can

purchase additional CompactFlash cards from Parker. Be sure to purchase

at least one additional flash card to serve as a backup for your primary

card.

PA PowerStation User Guide 4-4

Page 42

Chapter 4: Maintaining the PowerSt ation Performing Internal Maintenance

Performing Internal Maintenance

Before doing any internal maintenance, be sure to read and understand the

following procedures to prevent injury to yourself and/or damage to the

PowerStation.

• Electrostatic Discharge (ESD) Precautions

• Removing the PowerStation from an Enclosure

• Opening the PowerStation

• Replacing the Fuse

Important: For safety reasons, the PowerStation should be opened only

by qualified service personnel.

Electrostatic Discharge (ESD) Precautions

Modern integrated electronic devices, including the PowerStation, are

extremely sensitive to electrostatic discharges (ESD) and fields. Before you

open the system, be sure to follow these simple precautions to protect you

and the PowerStation from harm resulting from ESD.

Once you have read and understood the ESD safety precautions, you are

ready to continue with the appropriate instructions.

• Always disconnect power from the PowerStation before opening. Do

not touch any internal components of the PowerStation while the

system is on.

• Disconnect power before performing any internal maintenance or

troubleshooting. A sudden static discharge as you connect a jumper or

touch any internal parts may damage sensitive electronic components.

• Only handle internal components of the PowerStation in an ESD-safe

location, using appropriate grounding methods.

• Wear a grounding wrist strap for continuous protection.

• Always ground yourself to rem ove any static charge before you touch

the CPU card.

• Be particularly careful not to touch the components on the printed

circuit boards.

• Keep any PowerStation part in its anti-static packaging when it is not

installed in the unit and place it on a static dissipative mat when you

are working on it.

PA PowerStation User Guide 4-5

Page 43

Chapter 4: Maintaining the PowerSt ation Performing Internal Maintenance

Removing the PowerStation from an Enclosure

To remove the PowerStation from it’s enclosure, follow the steps below.

Explosion Hazard!

• Do not connect or disconnect cables unless the power has been

switched off, or the area is known to be safe.

WARNING!

1 Turn off the power to the unit.

2 Disconnect the following cables:

• Power Input cable

• Ground cable

• any communication cables

• any keyboard and mouse cables

3 Take off the clamps.

4 Place the PowerStation face down on a static dissipative mat, in a

location free from dirt and moisture and protected against static

discharge.

Opening the PowerStation

Once you have removed the PowerStation from it’s enclosure, you can

open it up. Follow the steps below.

1 Remove the CompactFlash card from it’s slot by pressing the eject

button on the side of the PowerStation, similiar to that shown below.

Figure 4-3: Eject Button

CompactFlash

Card

CompactFlash

Eject Button

2 Press in the eject button to return it to it’s retracted position.

3 Remove the backshell screws on the PA PowerStation.

PA PowerStation User Guide 4-6

Page 44

Chapter 4: Maintaining the PowerSt ation Performing Internal Maintenance

4 Lift the backshell off of the PowerStation to expose the board.

You are now ready to perform any internal maintenance necessary.

Closing the PowerStation

1 Replace the backshell on the PowerStati on.

2 Remount the PowerStation in the enclosure, refer to Installing the PA

PowerStation on page 2-7.

3 Reconnect the following cables:

• Power Input cable

• Ground cable

• any communication cables

• any keyboard and mouse cables

4 Turn on the PowerStation.

PA PowerStation User Guide 4-7

Page 45

Chapter 4: Maintaining the PowerSt ation Performing Internal Maintenance

Replacing the Fuse

The PA PowerStation has a protective fuse that you can replace by opening

up the back cover. An ohm meter is required to see whether the fuse is

open or closed. The required fuse is listed below.

• Use a Littlefuse Nano SMF Slow Blow Type fuse. The part number is

R452 002.

Caution: Using a fuse that is rated differently than indicated, can cause

damage or fire to occur.

To replace the fuse, complete the following steps:

1 Remove the PowerStation from its enclosure then open the

PowerStation as discussed on page 4-6.

2 Locate the fuse on the board according to the picture below.

Figure 4-4: Fuse Location (PA5 - PA10 on left, PA15 on right)

Fuse Location

3 Use an ohm meter to see if the fuse is open or closed.

• If open, use a pair of needle nose pliers to lift the fuse from the

fuse holder.

• If closed, the fuse is okay and the r e is no need to replace it.

4 Insert the new fuse into the fuse holder and reassemble the unit.

PA PowerStation User Guide 4-8

Page 46

Chapter 4: Maintaining the PowerStation Optional Components

Optional Components

Parker has an optional component that you may want to purchase for the

PA PowerStation —an AC Power Supply.

AC Power Supply

The PA PowerStation uses DC power to save space and limit the amount of

heat generated by the unit. However, if you require the PowerStation to

use AC power, you can purchase an AC Power Supply, P1X-PWRAC, that

includes an AC Power Supply and a power cord.

You can also purchase a mounting bracket kit, BKT-1000, for the Power

Supply. See Preparing a Location for the AC Power Supply on page 2-9 for

instructions on how to mount the AC Power Supply.

Do not apply AC power directly to the unit or damage could occur.

PA PowerStation User Guide 4-9

Page 47

Chapter 4: Maintaining the PowerStation Resolving Problems

Resolving Problems

This section provides some basic troubleshooting steps to help you

indentify and correct problems you may have with the PA PowerStation.

Each problem is described and followed with one or more possible

solutions. Begin with the first solu t ion and continue until you have solved

the problem or tried all of the solutions.

If the problem persists, look through the other problems listed in this

section to determine if addit ion al sy m p tom s exist that might require

action. If you cannot solve the problem, or if you encounter a problem that