Parker Hannifin OEM6250 User Manual

OEM6250 Servo Controller

Installation Guide

Compumotor Division

Compumotor

Parker Hannifin Corporation

p/n 88-016524-01B March 1998

User Information

! !

WARNING

6000 Series products are used to control electrical and mechanical

components of motion control systems. You should test your motion

system for safety under all potential conditions. Failure to do so can result

in damage to equipment and/or serious injury to personnel.

6000 Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and

may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and

hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or special damages of any kind or nature

whatsoever, including but not limited to lost profits arising from or in any way connected with the use of the equipment or this user guide.

© 1991-7, Parker Hannifin Corporation

All Rights Reserved

Motion Architect is a registered trademark of Parker Hannifin Corporation.

Motion Builder, Motion OCX, Servo Tuner, CompuCAM and DDE6000 are trademarks of Parker Hannifin Corporation.

Microsoft and MS-DOS are registered trademarks, and Windows, DDE and NetDDE are trademarks of Microsoft Corporation.

Motion Toolbox is a trademark of Snider Consultants, Inc.

LabVIEW is a registered trademark of National Instruments Corporation.

Technical Assistance

North America and Asia:

Compumotor Division of Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

FaxBack: (800) 936-6939 or (707) 586-8586

BBS: (707) 584-4059

e-mail: tech_help@cmotor.com

Internet: http://www.compumotor.com

Automation

Contact your local automation technology center (ATC) or distributor, or ...

Europe

Parker Digiplan

21 Balena Close

Poole, Dorset

England BH17 7DX

Telephone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

(non-German speaking)

:

Germany, Austria, Switzerland:

HAUSER Elektronik GmbH

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0)781 509-0

Fax: +49 (0)781 509-176

Product Feedback Welcome

E-mail: 6000user@cmotor.com

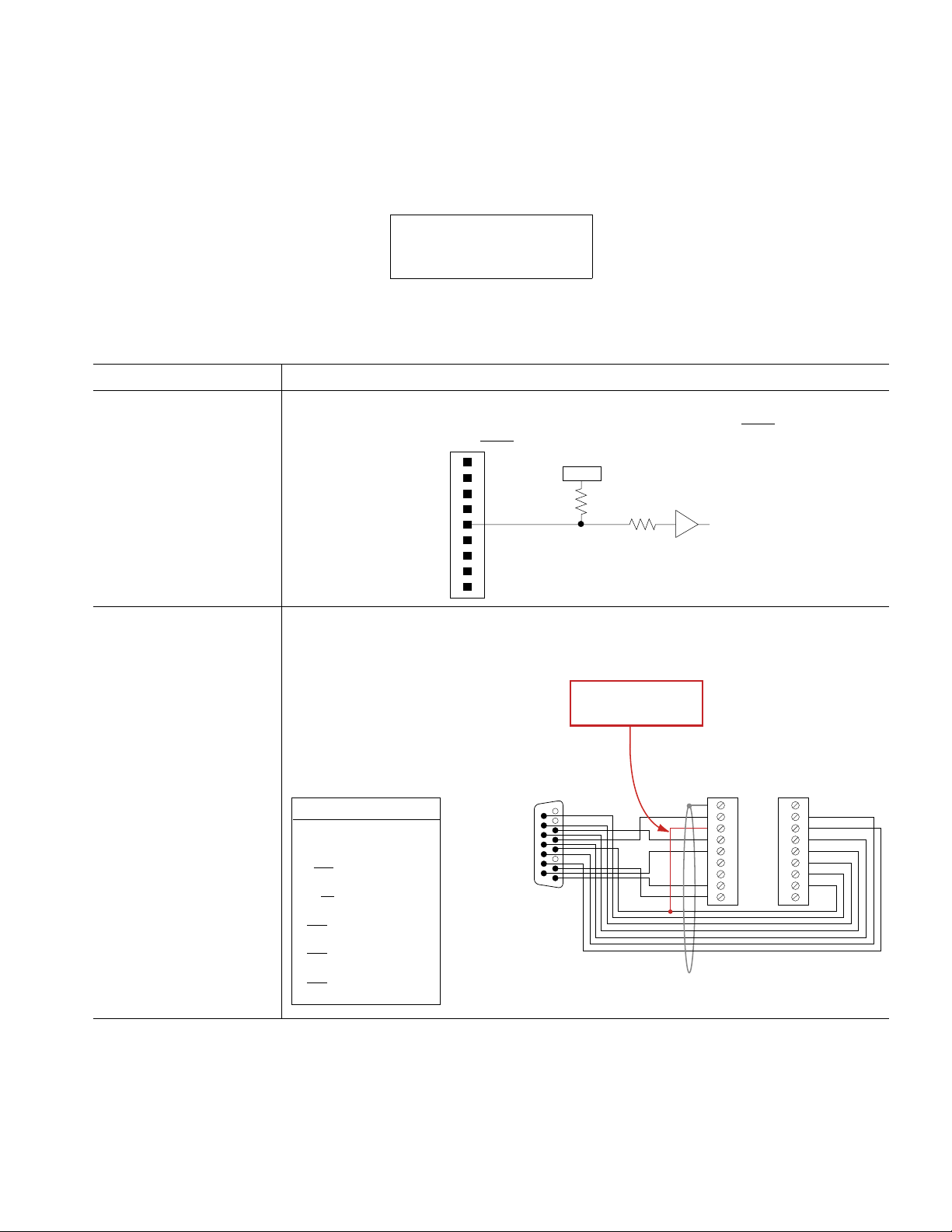

Change Summary

OEM6250 Installation Guide

The following is a summary of the primary technical changes to this document.

This book, p/n 88-016524-01B, supersedes 88-016524-01A.

Topic Description

Error Correction:

DFT Input Circuit

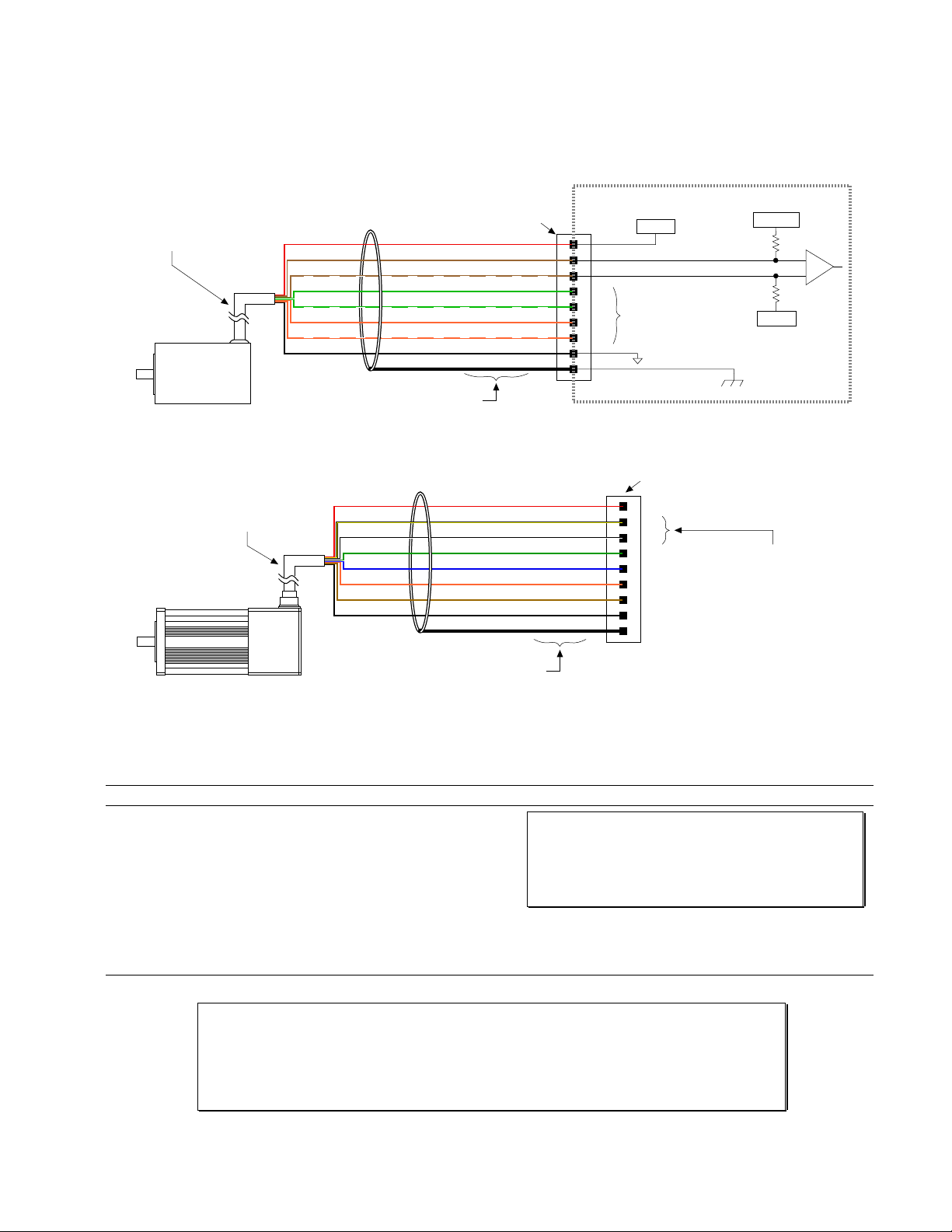

Revision A incorrectly stated that the drive fault input (DFT pin on the DRIVE connectors)

shared the same circuit design as the limit inputs and trigger inputs. DFT

the AUX-P pullup terminal and

Rev B

March 1998

is not controlled by

is not affected by the R45 resistor. The DFT input circuit is:

Clarification:

BD-E Drive Connections

SHLD

COM

SHTNC

SHTNO

DFT

AGND

+5VDC

6.8 KW

47 KW

74HCxx

RSVD

CMD–

CMD+

With a BD-E drive connected as illustrated in revision A, the motor has a tendency to lunge for

several revolutions at full torque when power is removed simultaneously from the OEM6250 and

the BD-E drive (as would be the case in a power outage). The correction is to connect the

OEM6250’s SHTNC terminal to the BD-E’s GND terminal (pin 4).

Added connection

to prevent lunge.

BD-E Drive

V2 (pin 1)

V1 (pin 2)

GND (pin 4)

RST (pin 5)

+15V (pin 6)

FT (pin 9)

AOP (pin 10)

AOP (pin 11)

BOP (pin 12)

BOP (pin 13)

ZOP (pin 14)

ZOP (pin 15)

«

«

«

«

«

«

«

«

«

«

«

«

OEM6250

CMD–

CMD+

GND

COM

SHTNO

DFT

A–

A+

B+

B–

Z+

Z–

BD-E Drive

User I/O Connector

815

9

1

NOTE: These connections will work only if

BD-E jumper LK2 is set to position B

(not the factory default position).

OEM6250

DRIVE 1

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDÐ

CMD+

ENCODER 1

+5V

A+

AÐ

B+

BÐ

Z+

ZÐ

GND

SHLD

ABOUT THIS GUIDE

Chapter 1. Installation

What You Should Have (ship kit)........................................................... 2

Before You Begin..................................................................................... 2

Recommended Installation Process............................................. 2

Electrical Noise Guidelines........................................................... 2

General Specifications............................................................................ 3

Mounting the OEM6250........................................................................... 4

Electrical Connections............................................................................ 5

Grounding System.......................................................................... 5

Serial Communication................................................................... 6

Motor Drivers................................................................................. 7

ANI Analog Input........................................................................... 11

Enable (ENBL) Input — Emergency Stop Switch...................... 11

End-of-Travel and Home Limit Inputs......................................... 12

Encoder......................................................................................... 13

Joystick & Analog Inputs ............................................................. 14

Trigger Inputs................................................................................ 15

General-Purpose Programmable Inputs & Outputs................... 16

RP240 Remote Operator Panel................................................... 20

Input Power................................................................................... 20

Lengthening I/O Cables................................................................ 21

Testing the Installation........................................................................... 22

Tuning the OEM6250............................................................................. 24

What’s Next?......................................................................................... 25

Program Your Motion Control Functions.................................... 25

Chapter 2. Troubleshooting

Troubleshooting Basics......................................................................... 28

Reducing Electrical Noise........................................................... 28

Diagnostic LEDs........................................................................... 28

Test Options.................................................................................. 28

Technical Support......................................................................... 28

Common Problems & Solutions........................................................... 29

Troubleshooting Serial Communication Problems............................. 30

Product Return Procedure.................................................................... 32

Appendix A:

Appendix B:

Index.................................................................................................. 51

Tuning

EMC Installation Guidelines

................................................................... 33

Purpose of This Guide

This document is designed to help you install and troubleshoot your OEM6250 hardware

system. Programming related issues are covered in the 6000 Series Programmer’s Guide and

the 6000 Series Software Reference. (These reference documents are available by ordering the

“OEM6250 MANUALS” ship kit add-on, or they can be downloaded from Compumotor’s web

site at http://www.compumotor.com).

......................... 47

What You Should Know

To install and troubleshoot the OEM6250, you should have a fundamental understanding of:

• Electronics concepts, such as voltage, current, switches.

• Mechanical motion control concepts, such as inertia, torque, velocity, distance, force.

• Serial communication and terminal emulator experience: RS-232C

Related Publications

• 6000 Series Software Reference, Parker Hannifin Corporation, Compumotor Division;

part number 88-012966-01

• 6000 Series Programmer’s Guide, Parker Hannifin Corporation, Compumotor Division;

part number 88-014540-01

• Current Parker Compumotor Motion Control Catalog

• Schram, Peter (editor). The National Electric Code Handbook (Third Edition). Quincy,

MA: National Fire Protection Association

EMC Installation Guidelines

The OEM6250 is sold as a complex component to professional assemblers. As a component,

it is not required to be compliant with Electromagnetic Compatibility Directive 89/336/EEC.

However, Appendix B provides guidelines on how to install the OEM6250 in a manner most

likely to minimize the OEM6250’s emissions and to maximize the OEM6250’s immunity to

externally generated electromagnetic interference.

Online Manuals

This manual (in Acrobat PDF format) is available from our web site: http://www.compumotor.com

CHAPTER ONE

Installation

1

IN THIS CHAPTER

• Product ship kit list

• Things to consider before you install the OEM6250

• General specifications table

• Mounting the OEM6250

• Connecting all electrical components (includes specifications)

• Testing the installation

• Tuning the OEM6250 (refer to Servo Tuner User Guide or to Appendix A)

• Preparing for what to do next

Appendix B provides guidelines on how to install the OEM6250 in a manner most likely

to minimize the OEM6250’s emissions and to maximize the OEM6250’s immunity to

externally generated electromagnetic interference.

What You Should Have

Part Name Part Number

If an item is missing,

call the factory (see

phone numbers on

inside front cover).

One of the following line items:

OEM6250 standard product (with ship kit).............................. OEM6250

OEM6250 product with ANI input board (with ship kit)........... OEM6250-ANI

Ship kit: This manual (

Motion Architect response card ** ............................... 88-013715-01

If you order “OEM6250 MANUALS”, the ship kit would also include:

6000 Series Software Reference

6000 Series Programmer’s Guide

* These manuals are available in electronic form (Adobe Acrobat PDF files)

from our web site — http://www.compumotor.com.

** Motion Architect may be downloaded from our web site.

Before You Begin

The OEM6250 is used to control your system's electrical and mechanical components.

Therefore, you should test your system for safety under all potential conditions. Failure to do

so can result in damage to equipment and/or serious injury to personnel.

(ship kit)

OEM6250 Installation Guide

) * ............. 88-016524-01

* .............................. 88-012966-01

* ............................ 88-014540-01

WARNINGS

¬

The ANI input board

provides two ±10V,

14-bit analog inputs.

To order the ANI input

board separately,

order part number

OPT-OEM6250-A.

Always remove power to the OEM6250 before:

• Connecting any electrical device (e.g., drive, encoder, inputs, outputs, etc.)

• Adjusting the DIP switches or other internal components

Recommended Installation Process

This chapter is

organized

sequentially to best

approximate a typical

installation process.

1. Review the general specifications.

2. Mount the OEM6250.

3. Connect all electrical system components.

4. Test the installation.

5. Mount the motor and couple the load.

6. Tune the OEM6250 for optimum performance. If you are using Servo Tuner, refer to the

instructions in the Servo Tuner User Guide; otherwise, refer to Appendix A (page 33).

7. Program your motion control functions. Programming instructions are provided in the

6000 Series Programmer's Guide and the 6000 Series Software Reference. We recommend

using the programming tools provided in Motion Architect for Windows. You can also

benefit from the optional iconic programming interface called Motion Builder (sold

separately). For information on support software, refer to page 25.

Electrical Noise Guidelines

• Do not route high-voltage wires and low-level signals in the same conduit.

• Ensure that all components are properly grounded.

• Ensure that all wiring is properly shielded.

• Noise suppression guidelines for I/O cables are provided on page 21.

• Appendix B (page 47) provides guidelines on how to install the OEM6250 in a manner

most likely to minimize the OEM6250’s emissions and to maximize the OEM6250’s

immunity to externally generated electromagnetic interference.

2

OEM6250 Installation Guide

General Specifications

Parameter Specification

Power

DC input.................................................................... 5VDC ±5%, 4A minimum

Status LEDs/fault detection...................................... Refer to

Environmental

Operating Temperature .......................................... 32 to 122°F (0 to 50°C)

Storage Temperature............................................... -22 to 185°F (-30 to 85°C)

Humidity................................................................... 0 to 95% non-condensing

Performance

Position Range & Accuracy..................................... Position range: ±2,147,483,648 counts;

Velocity Range, Accuracy, & Repeatability............ Range: 1-2,000,000 counts/sec;

(commanded velocity) Accuracy: ±0.02% of maximum rate;

Acceleration Range.................................................. 1-24,999,975 counts/sec

Motion Trajectory Update Rate............................... See SSFR command description in the

Servo Sampling Update Rate.................................. See SSFR command description in the

Serial Communication

Connection Options.................................................. RS-232C, 3-wire (Rx, Tx & GND on the AUX connector).

Maximum units in daisy-chain................................ 99 (use DIP switch or ADDR command to set individual addresses for each unit)

Communication Parameters................................... 9600 baud (range is 9600-1200—see

Inputs

HOM, POS, NEG, TRG-A, TRG-B, & ENBL ............... HCMOS compatible* with internal 6.8 KW pull-up resistor to AUX-P terminal. Voltage range

DFT ........................................................................... HCMOS compatible* with internal 6.8 KW pull-up resistor to +5VDC. Voltage range for

Joystick inputs: Axes Select, Velocity Select, ...... HCMOS compatible* with internal 6.8 KW pull-ups to +5V; voltage range is 0-24V.

Trigger, Release, and Auxiliary

Encoder..................................................................... Differential comparator accepts two-phase quadrature incremental encoders with differential

16 General-Purpose Programmable Inputs .......... HCMOS compatible* with internal 6.8 KW pull-up resistor to IN-P terminal. As shipped from

(PROGRAMMABLE INPUT/OUTPUT connector)............. the factory, IN-P is internally connected to +5V via resistor R12 (inputs sinking current). To

Analog input channels (JOYSTICK connector)....... Voltage range = 0-2.5VDC; 8-bit A/D converter. Input voltage must not exceed 5V.

Analog Inputs (optional ANI input board)................ Voltage range = ± 10V, 14-bit A/D (OEM6250-ANI or OPT-OEM6250-A product only)

Outputs

8 Programmable Outputs ....................................... Open-collector output with internal 4.7 KW pull-up resistor to OUT-P terminal. Shipped from

(PROGRAMMABLE INPUT/OUTPUT connector)............. factory with these outputs internally pulled up to +5V through a zero ohm resistor – R13. If

+5V Output................................................................ Internally supplied +5VDC. +5V terminals are available on multiple connectors. The amount

Command Out (CMD).............................................. ±10V analog output. 12-bit DAC. Load should be > 2KW impedance.

Shutdown (SHTNO, SHTNC, and COM)................... Shutdown relay output. Max. rating: 175VDC, 0.25A, 3W.

* HCMOS-compatible switching voltage levels: Low £ 1.00V, High ³ 3.25V.

TTL-compatible switching voltage levels: Low £ 0.4V, High ³ 2.4V.

(current requirements depend on the type and amount of I/O used – see page 20).

Diagnostic LEDs

Accuracy: ±0 counts from preset total

Repeatability: ±0.02% of set rate

on page 28

2

6000 Series Software Reference

6000 Series Software Reference

RS-232: Full duplex; XON/XOFF enabled.

AutoBaud

for these inputs is 0-24V. As shipped from the factory, AUX-P is internally connected to +5V

via resistor R45 (input is sinking current). To make the input sink current to a supply other

than +5V, first remove R45 and then connect an external 5-24V supply to the AUX-P terminal.

To source current, first remove R45 and then connect the AUX-P terminal to the GND

terminal. CAUTION: Failure to remove R45 before connecting AUX-P to an external supply,

or to the GND terminal, or to the +5V terminal will damage the OEM6250.

NOTE: As shipped from the factory, the ENBL (enable) input is connected to ground via zeroohm resistor R25, thereby allowing motion. To control the ENBL input with an external switch

(i.e., to use it as an emergency stop input), remove R25.

these inputs is 0-24V.

(recommended) or single-ended outputs.

Maximum voltage = 5VDC. Switching levels (TTL-compatible): Low £ 0.4V, High ³ 2.4V.

Maximum frequency = 1.6 MHz. Minimum time between transitions = 625 ns.

make the inputs sink current to a supply other than +5V, first remove R12 and then connect an

external 5-24V supply to the IN-P terminal. (IN-P can handle 0-24V with max. current of

100 mA.) To source current, first remove R12 and then connect the IN-P terminal to the GND

terminal. CAUTION: Failure to remove R12 before connecting IN-P to an external supply, or

to the GND terminal, or to the +5V terminal will damage the OEM6250. Voltage range = 0-24V.

you remove resistor R13 first, you can pull up these outputs by connecting OUT-P to the +5V

terminal or to an external 5-24V power source. Max. voltage in the OFF state (not sinking

current) = 24V; max. current in the ON state (sinking) = 30mA.

of current available depends on the current that you supply to the +5V terminal on the input

power connector (see page 20).

, page 6), 8 data bits, 1 stop bit, no parity;

Chapter 1. Installation

3

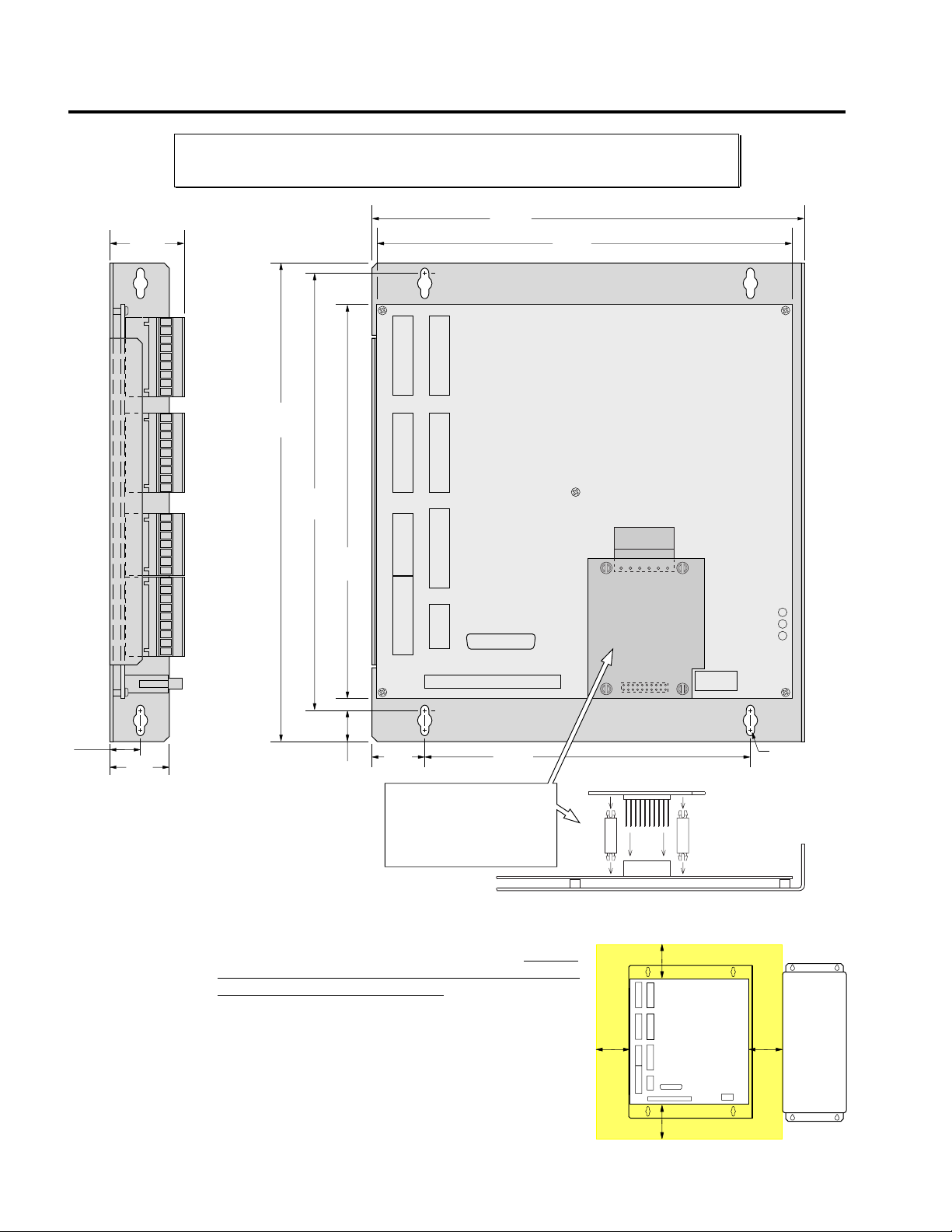

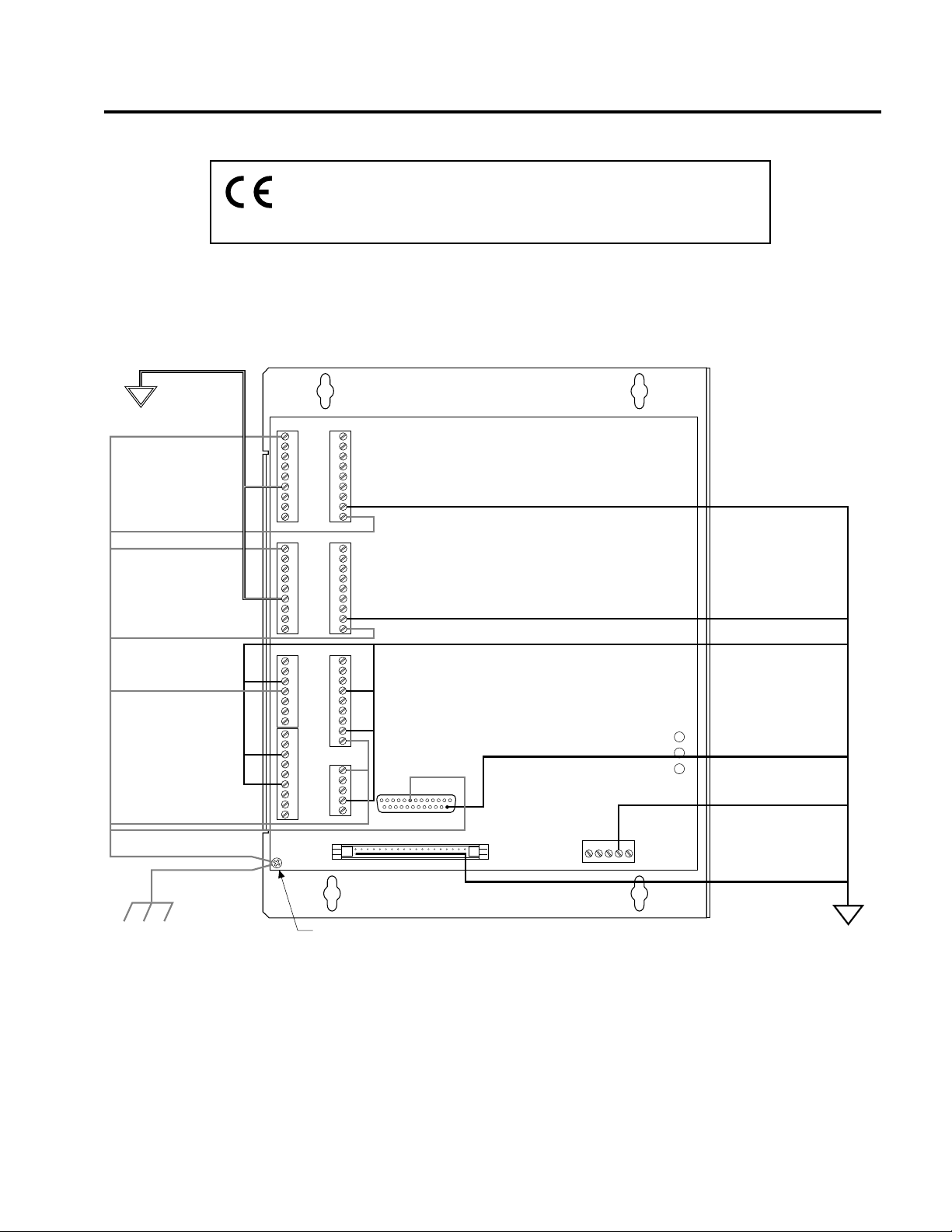

Mounting the OEM6250

Mini

NOTE: The drawing below illustrates the dimensions of the OEM6250 printed circuit board. The

board is shipped from the factory attached to sheet metal which allows either flat mounting or side

mounting of the OEM6250. This board will fit in a 6U rack (if you remove the PCB from the sheet metal).

Max.

Component

Height

1.48

(37.59)

11.00

(279.40)

10.10

(256.54)

9.19

(233.43)

10.01

(254.25)

9.67

(245.62)

6 5 4 3 2 1

0.50

(12.70)

Inches (Millimeters)

Environmental

Considerations

4

1.00

(25.40)

Temperature. Operate the OEM6250 in ambient

temperatures between 32°F (0°C) and 122°F (50°C).

minimum of 2 inches (50.8 mm) of unrestricted air-flow space

around the OEM6250 (see illustration). Fan cooling may be

necessary if adequate air flow is not provided.

Humidity. Keep below 95%, non-condensing.

Airborne Contaminants, Liquids. Particulate

contaminants, especially electrically conductive material,

such as metal shavings and grinding dust, can damage the

OEM6250. Do not allow liquids or fluids to come in contact

with the OEM6250 or its cables.

OEM6250 Installation Guide

0.70

(17.78)

1.00

(25.40)

ANI Option Board

If you ordered the “OEM6250-ANI”

product, this option board is factory

installed. If you ordered the board

separately (p/n “OPT-OEM6250-A”),

install it now. Allow 0.91 (23.11)

mimimum for component height

8.00

(203.20)

Provide a

2.0

(50.8)

Provision for #10

Mounting Screws

(6 Plcs.)

mum Airfow Space = 2 inches

2.0

(50.8)

2.0

(50.8)

2.0

(50.8)

Electrical Connections

Appendix B (page 47) provides guidelines on how to install the OEM6250

in a manner most likely to minimize the OEM6250’s emissions and to

maximize the OEM6250’s immunity to externally generated

electromagnetic interference.

Grounding System

ANALOG

GROUND

SHLD Terminal

SHLD Terminal

SHLD Terminal

SHLD Terminal

SHLD Terminal

SHLD Terminals

SHLD Pin (#8)

Shield Screw

1

AGND Terminals

9

DRIVE 1

DRIVE 2

1

9

1

7

1

9

TH1

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

Rx

Tx

GND

SHLD

+5V

OUT-P

IN-P

TRG-A

TRG-B

GND

OUT-A

OUT-B

GND

ENBL

+5V

AUX-P

9

+5V

A+

AB+

BZ+

ZGND

SHLD

1

ENCODER 1

ENCODER 2

9

+5V

A+

AB+

BZ+

ZGND

SHLD

1

LIMITSAUX

9

1POS

1NEG

1HOM

GND

2POS

2NEG

2HOM

GND

SHLD

1

RP240

5

SHLD

Tx

13 1

Rx

GND

+5V

1

25 14

49

50

PROGRAMMABLE INPUT/OUTPUT

JOYSTICK

GND Terminal

GND Terminal

GND Terminals

GND Pin (#14)

DSBL2 DSBL1 STATUS

GND Terminal

1

2

POWER

15

+15V NC -15V GND +5V

GND Pins

(even numbered pins)

EARTH

This connection is critical for providing adequate shielding.

Chapter 1. Installation

DIGITAL

GROUND

5

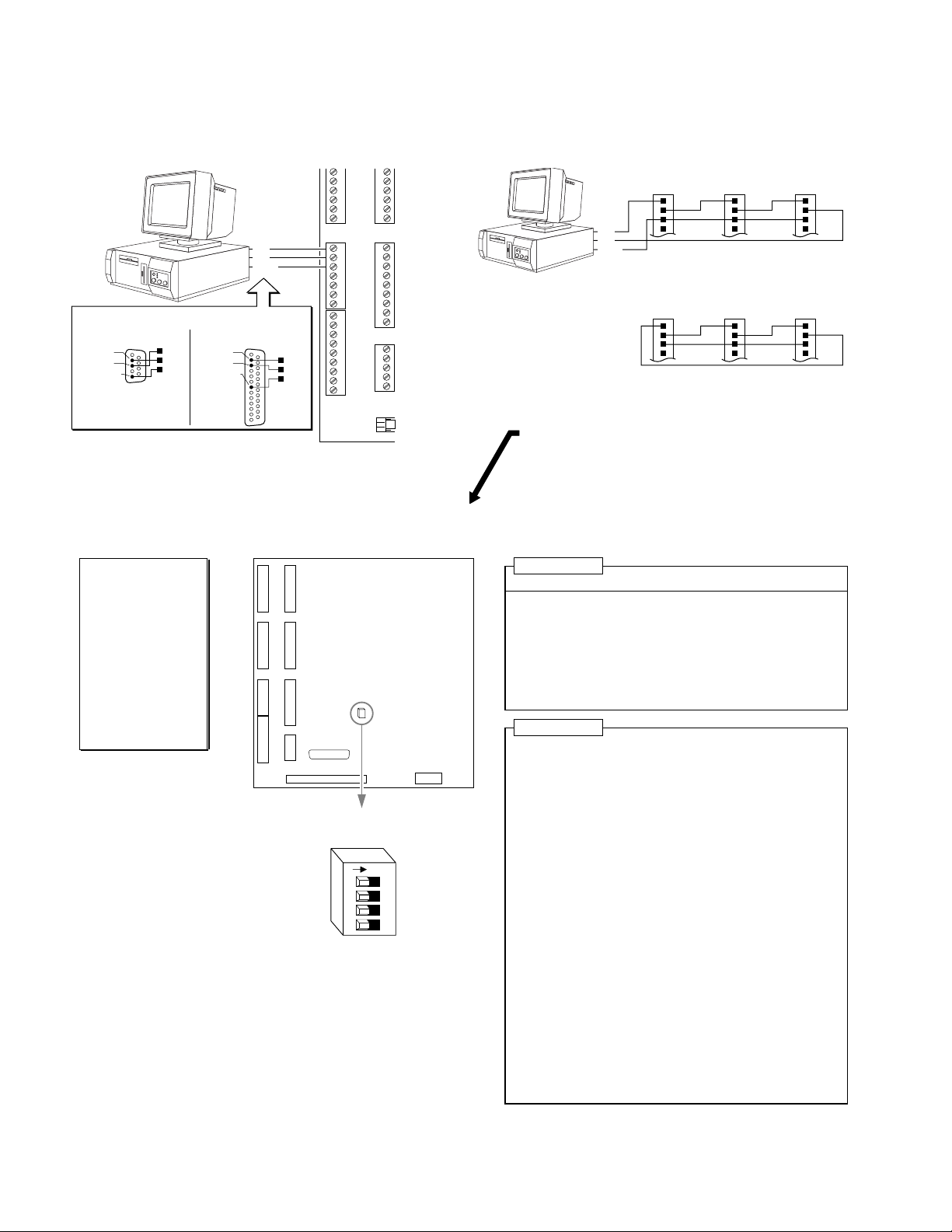

Serial Communication

RS-232C Connections

Tx

Rx

GND

Serial Port Connection

25-Pin COM Port:9-Pin COM Port:

Pin 2 (Rx)

Pin 3 (Tx)

Pin 5 (GND)

NOTE: Max. cable length is 50 ft (15.25 m)

Rx

Tx

GND

Pin 2 (Tx)

Pin 3 (Rx)

Pin 7 (GND)

Rx

Tx

GND

9

1

7

1

9

AUX

Rx

Tx

GND

SHLD

1

9

1

5

1

LIMITS

RP240

49

50

Changing the address and baud rate (OPTIONAL)

Factory Settings

May Be Sufficient

• Device address is

set to zero (if you

are connecting

multiple units in a

daisy-chain, you

can automatically

establish the device

address by using

the ADDR

command).

• Factory default

baud rate is 9600.

DIP Switch

Factory Default Setting Shown

OEM6250

N

O

1234

RS-232C Daisy-Chain Connections *

Unit 0 Unit 1 Unit 2

Rx

Tx

GND

Tx

Rx

GND

Daisy Chain to a Computer or Terminal

Stand-Alone Daisy Chain

Be sure to set unique devices addresses for each unit.

*

To set the address, use the DIP switch (see below),

or use the ADDR command (see

ADDRESS

Switch #1 Switch #2 Switch #3 Device Address

OFF OFF OFF Ø (default)

ON OFF OFF 1

OFF ON OFF 2

ON ON OFF 3

OFF OFF ON 4

ON OFF ON 5

OFF ON ON 6

ON ON ON 7

* Device address is checked upon power up or reset.

AUTO BAUD

Switch #4 ON = Auto Baud Enabled

Switch #4 OFF = Auto Baud Disabled (default)

To implement the Auto Baud feature:

The default baud rate is 9600. As an alternative, you can use

this procedure to automatically match your terminal's speed

of 1200, 2400, 4800, or 9600 baud.

1. Set switch 4 to ON.

2. Connect the OEM6250 to the terminal.

3. Power up the terminal.

4. Cycle power to the OEM6250 and immediately press the

space bar several times.

5. The OEM6250 should send a message with the baud rate

on the first line of the response. If no baud rate message

is displayed, verify steps 1-3 and repeat step 4.

6. Change switch 4 to OFF.

7. Cycle power to the OEM6250. This stores the baud rate

in non-volatile memory.

NOTE: If Auto Baud is enabled, the OEM6250 performs its

auto baud routine every time it is powered up or reset. The

OEM6250 is only capable of matching 1200, 2400, 4800, and

9600 baud. Once the baud rate has been determined, the

OEM6250 stores that baud rate in non-volatile memory;

therefore, Switch #4 should be set to the OFF position after

the baud rate has been determined.

SHLD

Unit 0 Unit 1 Unit 2

Rx

Tx

GND

SHLD

6000 Series Software Reference

Rx

Tx

GND

SHLD

Rx

Tx

GND

SHLD

Rx

Tx

GND

SHLD

Rx

Tx

GND

SHLD

).

6

OEM6250 Installation Guide

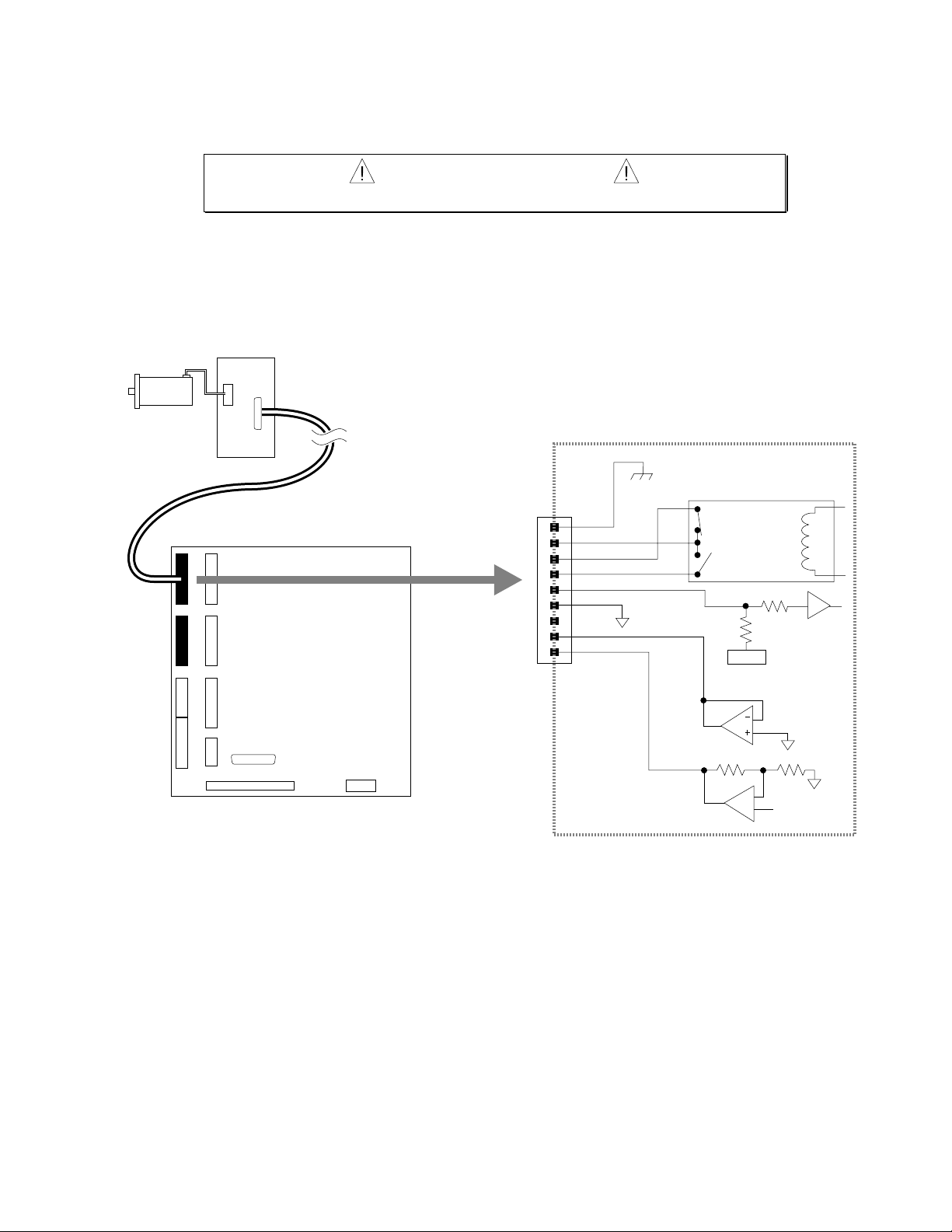

Motor Drivers

WARNING

REMOVE DC POWER FIRST before connecting or disconnecting the drive.

CONNECTIONS & INTERNAL SCHEMATICS

Drive

Motor

Maximum recommended cable

length is 15 feet (4.56 m).

Use 22 AWG wire.

DRIVE Connector

OEM6250

DRIVE 1

DRIVE 2

AUX

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMD–

CMD+

Chassis Ground

Analog Ground

(AGND)

Internal Schematics

Solid State Relay

Closed if DRIVE¯

Open if DRIVE1

Open if DRIVE¯

Closed if DRIVE1

47 KW

6.8 KW

+5VDC

74HCxx

AGND

-

+

DFT (Drive Fault) input:

HCMOS compatible switching: low £ 1.00V, high ³ 3.25V.

Voltage range = 0-24V.

AGND

Command +

Chapter 1. Installation

7

PIN OUTS & SPECIFICATIONS

(9-pin DRIVE Connector)

Name In/Out Description and Specifications

SHLD — Shield—Internally connected to chassis (earth) ground.

COM — Signal common for shutdown. Not connected to any ground or other COM.

SHTNC OUT Shutdown relay output to drives that require a closed contact to disable the drive. The shutdown relay is active (disabling the

drive) when no power is applied to the OEM6250. When the OEM6250 is powered up, the shutdown relay remains active until

you issue the DRIVE11 command. Max. rating: 175VDC, 0.25A, 3W.

Shutdown active (DRIVE¯¯): this output is internally connected to COM (see schematic above).

Shutdown inactive (DRIVE11): this output is disconnected from COM (see schematic above).

SHTNO OUT Shutdown relay output to drives that require an open contact to disable the drive. The shutdown relay is active (disabling the

drive) when no power is applied to the OEM6250. When the OEM6250 is powered up, the shutdown relay remains active until

you issue the DRIVE11 command. Max. rating: 175VDC, 0.25A, 3W.

Shutdown active (DRIVE¯¯): this output is disconnected from COM (see schematic above).

Shutdown inactive (DRIVE11): this output is internally connected to COM (see schematic above).

DFT IN Drive fault input. Set active level with the DRFLVL command. The drive fault input will not be recognized until you enable the

input functions with the INFEN1 command. HCMOS compatible (Low £ 1.00V, High ³ 3.25V) with internal 6.8 KW pull-up

resistor to internal +5VDC supply.

AGND — Analog ground.

RSVD —

reserved

CMD– IN Command signal return.

CMD+ OUT Command output signal. ±10V analog output. 12-bit DAC. Load should be > 2KW impedance.

CONNECTIONS TO SPECIFIC DRIVES

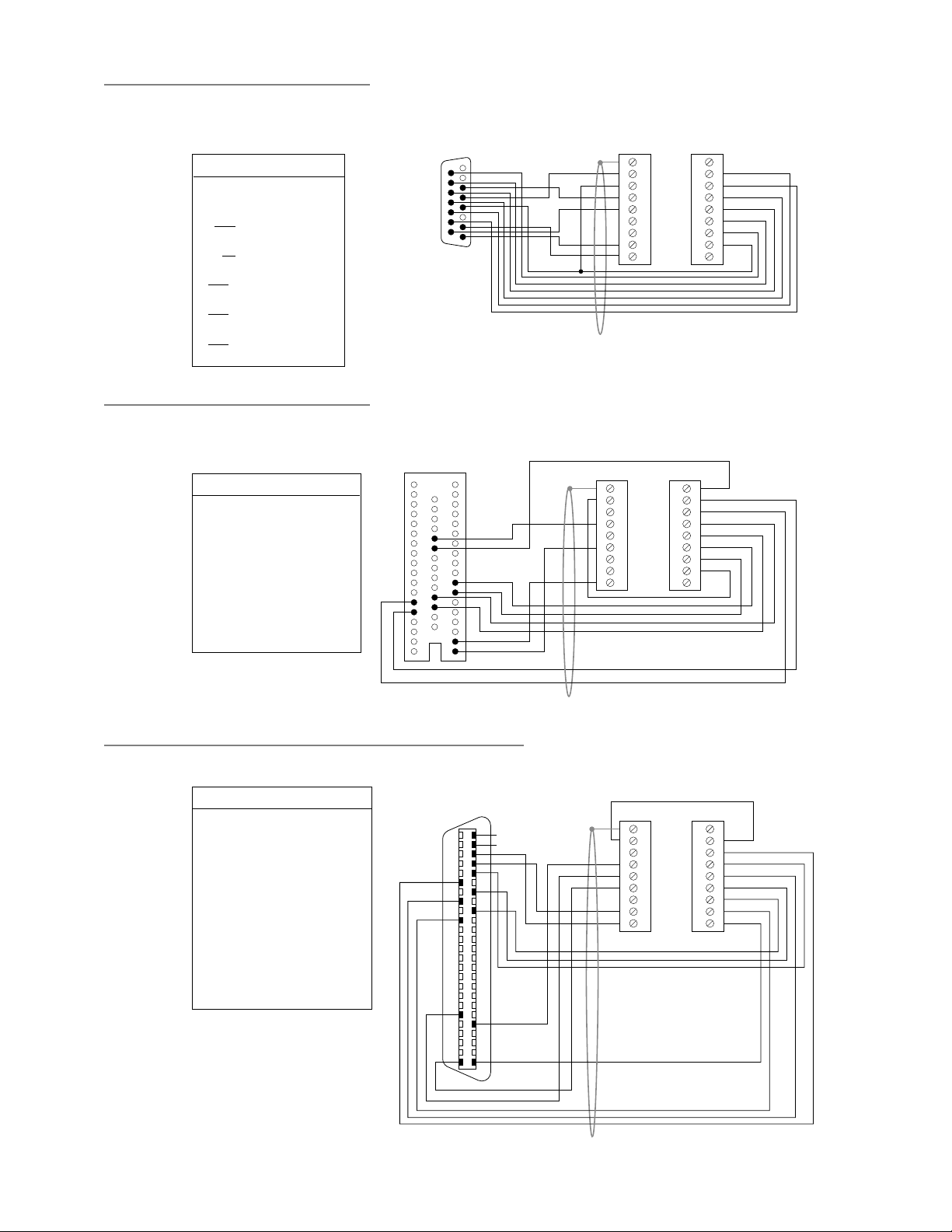

APEX Series Drives

APEX Series Drive

Enable In

Fault Out

Gnd

Command+

Command–

CHA+

CHA–

CHB+

CHB–

CHZ+

CHZ–

Gnd

Apex Series CHA+ connected to OEM6250’s A–

Apex Series CHA– connected to OEM6250’s A+

«

«

«

«

«

«

«

«

«

«

«

«

NOTE:

OEM6250

SHTNO

DFT

AGND

CMD+

CMD–

A–

A+

B+

B–

Z+

Z–

GND

Vel Int Enable

Enable In

Command+

CommandÐ

Tach Output

APEX Series

Drive

Reset

Gnd

Fault Out

Gnd

Gnd

+15V

Gnd

-15V

CHA+

CHAÐ

CHB+

CHBÐ

CHZ+

CHZÐ

Gnd

OEM6250

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

ENCODER 1

DRIVE 1

+5V

A+

AÐ

B+

BÐ

Z+

ZÐ

GND

SHLD

8

OEM6250 Installation Guide

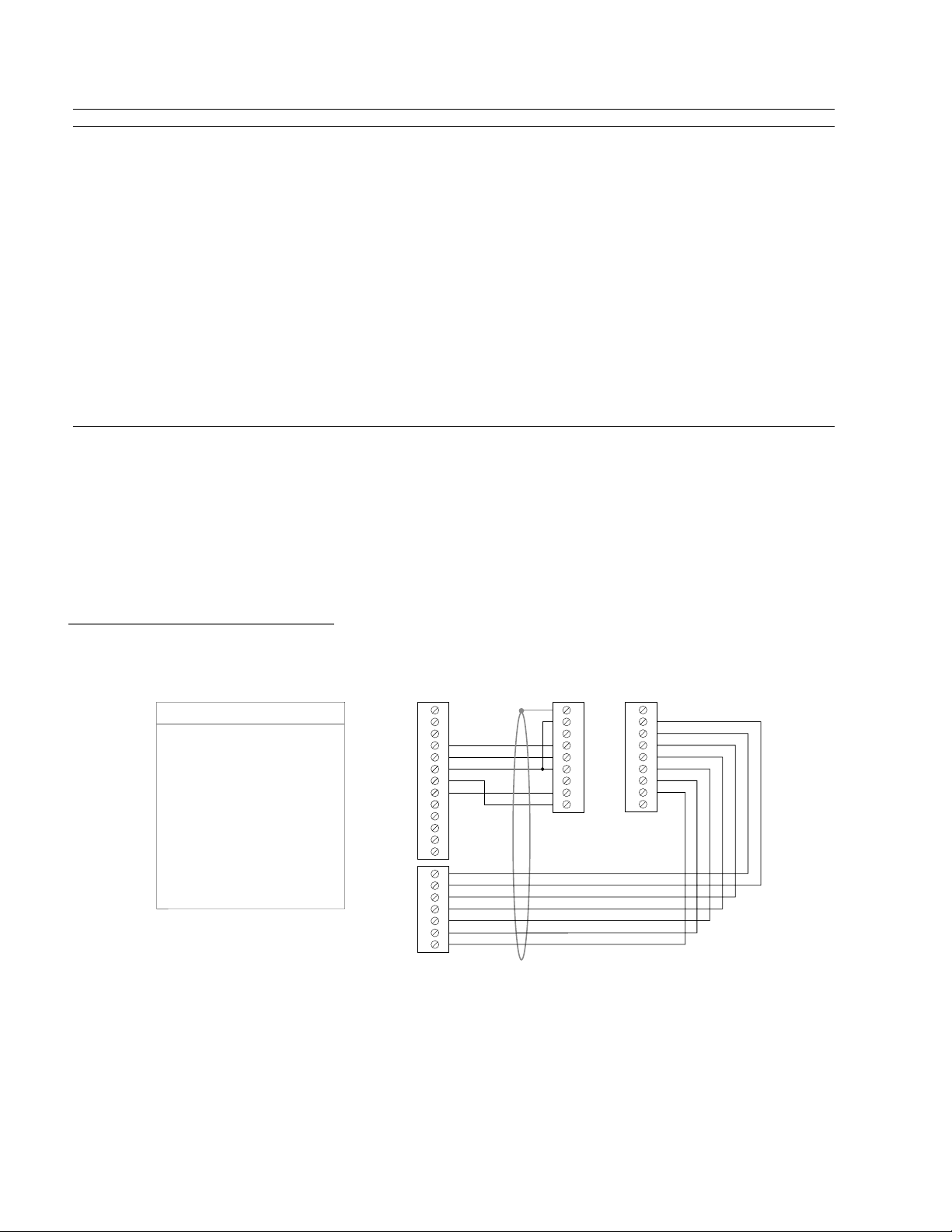

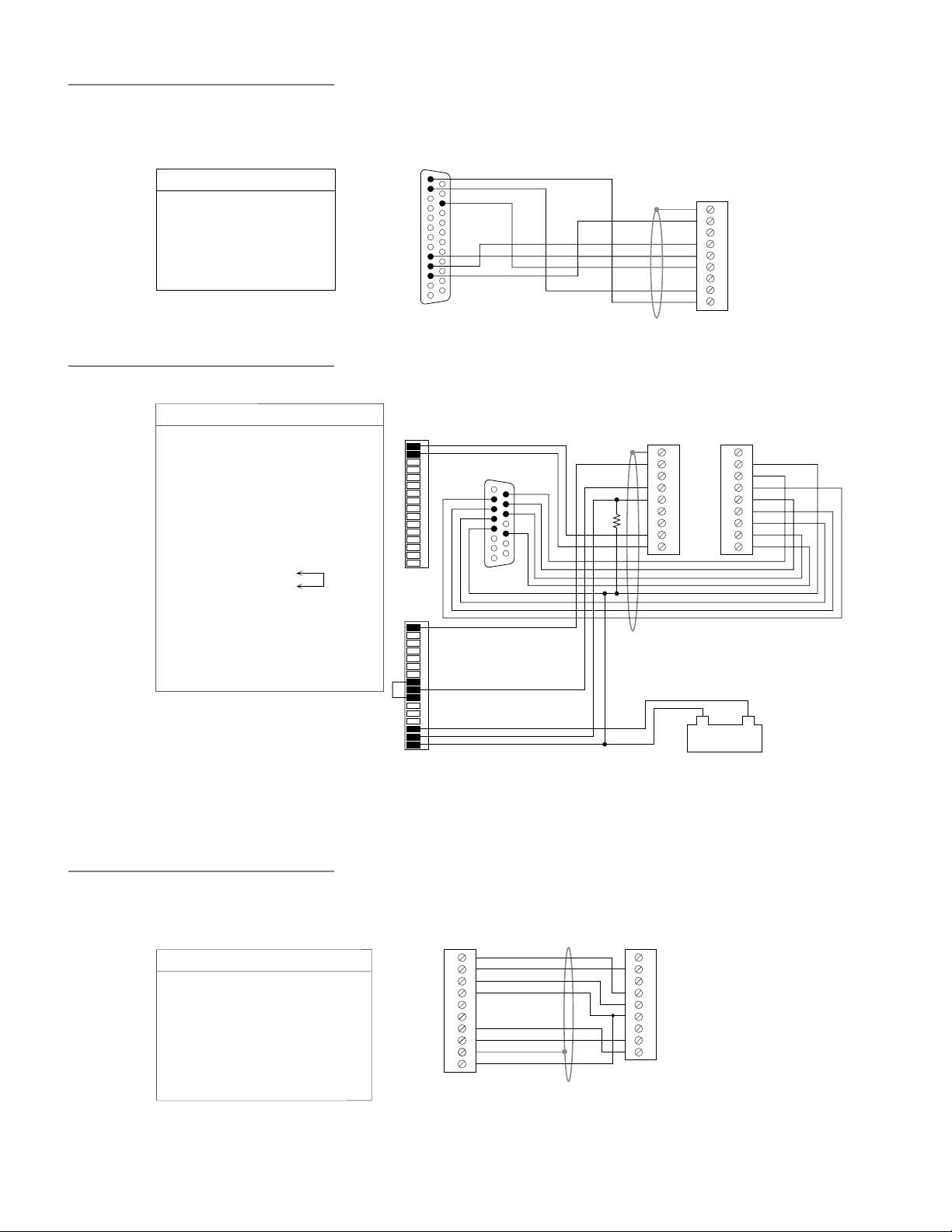

BD-E Drive

BD-E Drive

V2 (pin 1)

V1 (pin 2)

GND (pin 4)

RST (pin 5)

+15V (pin 6)

FT (pin 9)

AOP (pin 10)

AOP (pin 11)

BOP (pin 12)

BOP (pin 13)

ZOP (pin 14)

ZOP (pin 15)

«

«

«

«

«

«

«

«

«

«

«

«

Dynaserv Drives (most)

Dynaserv Drive

A+ (pin 13)

A– (pin 14)

SRVON (pin 23)

Vcc (pin 24)

B+ (pin 29)

B– (pin 30)

Z+ (pin 43)

Z– (pin 44)

VIN (pin 49)

AGND (pin 50)

Dynaserv A+ connected to OEM6250’s A–

Dynaserv A– connected to OEM6250’s A+

OEM6250 GND connected to OEM6250 COM

«

«

«

«

«

«

«

«

«

«

NOTE:

OEM6250

CMD–

CMD+

GND

COM

SHTNO

DFT

A–

A+

B+

B–

Z+

Z–

OEM6250

A–

A+

SHTNO

+5V

B+

B–

Z+

Z–

CMD+

AGND

BD-E Drive

User I/O Connector

815

9

1

NOTE: These connections will work only if

BD-E jumper LK2 is set to position B

(not the factory default position).

Dynaserv Drive

DN1

(50-pin Connector)

1

18

33

19

50

OEM6250

DRIVE 1

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDÐ

CMD+

ENCODER 1

OEM6250

DRIVE 1 ENCODER 1

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

+5V

A+

AB+

BZ+

ZGND

SHLD

+5V

A+

AÐ

B+

BÐ

Z+

ZÐ

GND

SHLD

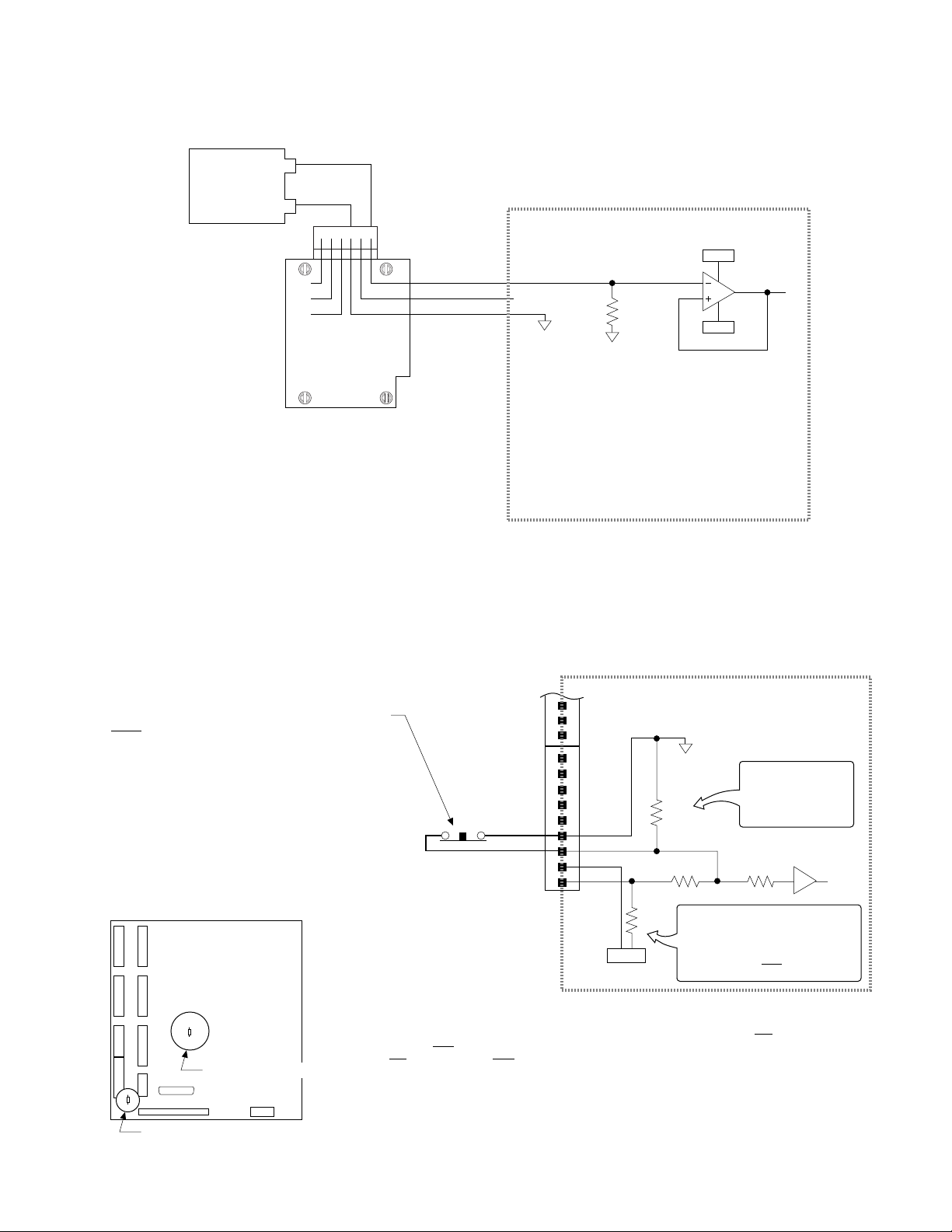

Linearserv Drive and Dynaserv DM1004 Drive

Linearserv, DM1004

Com+ (pin 01)

Servo On– (pin 05)

A+ (pin 17)

B+ (pin 19)

Z+ (pin 21)

Agnd-TQ (pin 22)

Vin-TQ (pin 23)

Agnd-VEL (pin 24)

Vin-VEL (pin 25)

Com– (pin 26)

Ready+ (pin 31)

A– (pin 41)

B– (pin 43)

Z– (pin 45)

*

When the Linearserv is in Torque Mode,

connect Linearserv pins 23 & 22 to CMD+

& CMD-. When in the Velocity Mode,

connect pins 25 & 24 are CMD+ & CMD-.

**

Connect Linearserv A+ to OEM6250 A–.

**

Connect Linearserv A– to OEM6250 A+.

Connect OEM6250 GND to OEM6250 COM.

NOTE:

«

«

«

«

«

«

«

«

«

«

«

«

«

«

OEM6250

+5V

SHTNO

A–

**

B+

Z+

CMD-

*

CMD+

*

CMD-

*

CMD+

*

AGND

DFT

A+

**

B–

Z–

Linearserv or DM1004 Drive

CN1

(50-pin Connector)

50 25

26 1

OEM6250

DRIVE 1 ENCODER 1

*

*

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

SHLD

GND

ZÐ

Z+

BÐ

B+

AÐ

A+

+5V

Chapter 1. Installation

9

OEM670 Drive

0

0

ENABLE (pin 10)

SV Drive

ENABLE GND (X10 pin 08)

+24V OUT GND (X10 pin 10)

+24V OUT (X10 pin 09)

Fault Output (X10 pin 15)

GND for +24V (X10 pin 16)

*

**

***

OEM670 Drive

CMD+ (pin 1)

CMD– (pin 2)

FAULT (pin 9)

GND (pin 11)

GND (pin 16)

SOLL1+ (X8 pin 01)

SOLL1– (X8 pin 02)

N (X13 pin 02)

B (X13 pin 03)

A (X13 pin 04)

GND (X13 pin 05)

N/ (X13 pin 09)

B/ (X13 pin 10)

A/ (X13 pin 11)

+5V (X13 pin 13)

ENABLE (X10 pin 01)

+24V IN (X10 pin 14)

Connect SV A+ (called “A”) to OEM6250 A–.

Connect SV A– (called “A/”) to OEM6250 A+.

Connect SV’s X10 pins 14 & 16 to an

external 24V power supply. Also connect

SV X10 pin 16 to OEM6250 GND.

Connect a 500½ resistor between the

OEM6250’s GND and DFT terminals.

«

«

«

«

«

«

SV Drive

NOTE:

OEM6250

CMD+

CMD–

DFT

SHTNO

COM

AGND

«

«

«

«

«

«

«

«

«

«

«

«

«

«

«

OEM6250

CMD+

CMD–

Z+

B+

A– *

GND

Z–

B–

A+ *

+5V

Short these

two terminals

COM

SHTNO

+24V **

(Ext. Supply)

DFT ***

GND **

(& Ext. Supply)

OEM670

Drive

1

13

X8

1

16

X10

1

16

14

25

SV Drive

1

8

X13

OEM625

DRIVE 1

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDÐ

CMD+

OEM6250

DRIVE 1 ENCODER 1

SHLD

COM

9

500

½

15

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

Power Supply

External 24V

SHLD

GND

ZÐ

Z+

BÐ

B+

AÐ

A+

+5V

+–

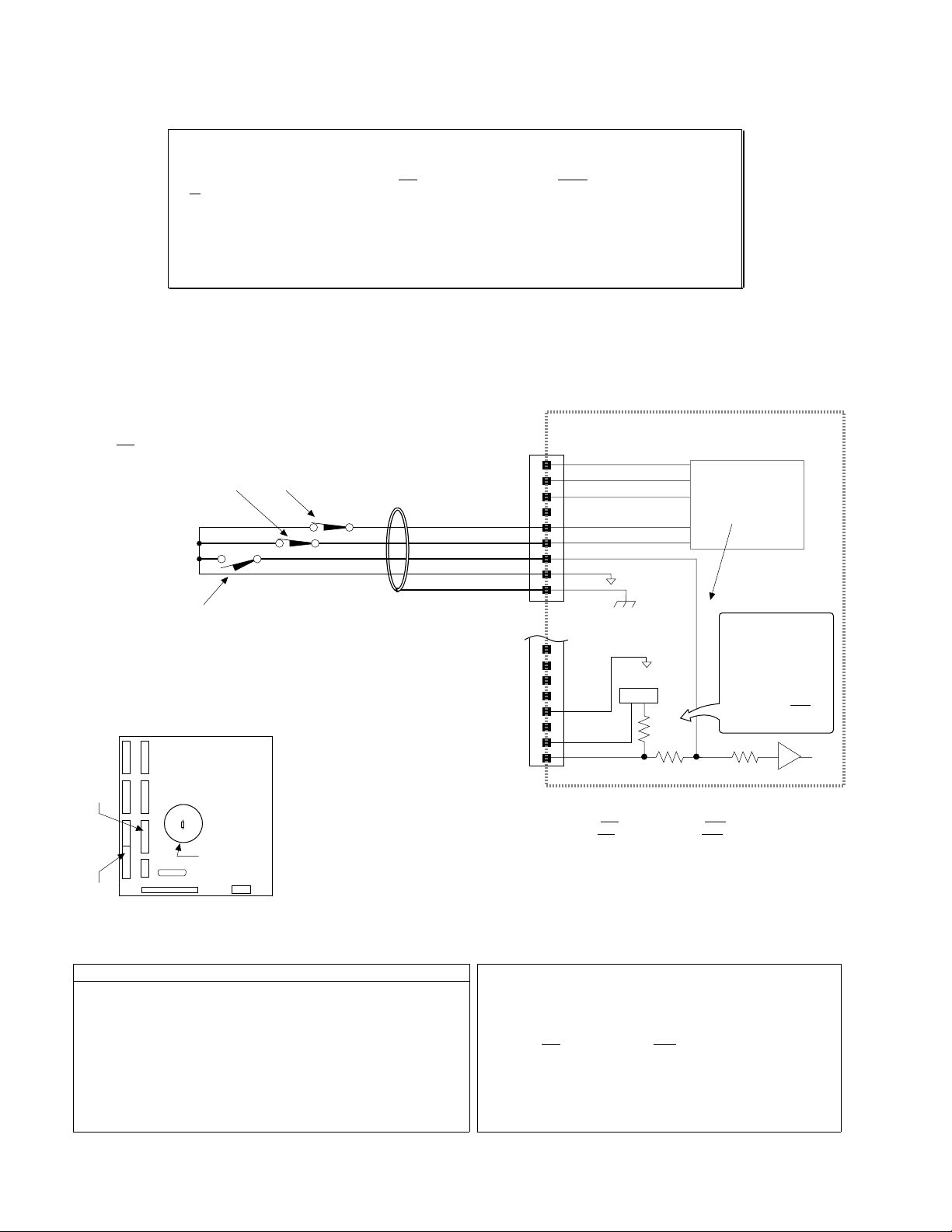

TQ Series Drive

ENABLE IN (pin 1)

ENABLE GND (pin 2)

FAULT OUT+ (pin 3)

FAULT OUT– (pin 4)

COMMAND+ (pin 7)

COMMAND– (pin 8)

COMMAND SHLD (pin 9)

10

OEM6250 Installation Guide

TQ Series Drive

GND (pin 10)

OEM6250

«

SHTNO

«

COM

«

DFT

«

AGND

«

CMD+

«

CMD–

«

(cable shield)

«

AGND

TQ Series

Drive

ENABLE IN

ENABLE GND

FAULT OUT+

FAULT OUTÐ

RESET IN

RESET GND

COMMAND+

COMMANDÐ

COMMAND SHLD

GND

OEM625

DRIVE 1

SHLD

COM

SHTNC

SHTNO

DFT

AGND

RSVD

CMDCMD+

ANI Analog Input (OEM6250-ANI or OPT-OEM6250-A product only)

10V A

±

na og

Input Source

Signal Source +

Ground –

6 5 4 3 2 1

N.C.

N.C.

N.C.

ANI Option

Board

Analog Input #1

Analog Input #2

Analog Ground

(same as #1)

Analog

Ground

Analog

Ground

150 KW

¥ Each input is a ±10V analog input with a 14-bit

analog-to-digital converter.

¥ The ANI input is sampled at the servo sampling

rate (see table for SSFR command).

¥ Voltage value reported with the TANI and

ANI commands; Position value (819 counts/volt)

reported with the TPANI and PANI commands.

Internal Schematics

+15V

LF412

-15V

Enable (ENBL) Input — Emergency Stop Switch

AUX Connector

ENBL connected to GND (normally-closed switch).

—You must first remove resistor R25 before you can

(NOTE

use a switch on this input.) If this connection is opened,

motion is killed and the program in progress is terminated.

If the ENBL input is not grounded when motion is

commanded, motion will not occur and the error message

“WARNING: ENABLE INPUT ACTIVE” will be displayed in

the terminal emulator.

OEM6250

AUX

Location of resistor R25.

R45

AUX-P

Location of resistor R45.

As shipped from the factory, AUX-P is internally connected to +5V via resistor R45 (input

is sinking current). To make the ENBL input sink current to a supply other than +5V, first

remove R45 and then connect an external 5-24V supply to the AUX-P terminal. To source

current, first

CAUTION: Failure to remove R45 before connecting AUX-P to an external supply or

to the GND terminal or to the +5V terminal will damage the OEM6250.

NOTE: AUX-P (and R45) are also used by the HOM, NEG, POS, & TRG inputs.

HCMOS compatible (switching levels: low £ 1.00V, high ³ 3.25V).

Voltage range = 0-24V.

remove R45 and then connect the AUX-P terminal to the GND terminal.

+5V

OUT-P

IN-P

TRG-A

TRG-B

GND

OUT-A

OUT-B

GND

ENBL

+5V

AUX-P

+5VDC

Digital

Ground

(GND)

R25

(0 KW)

6.8 KW

R45

Remove R45 before connecting

(0 KW)

AUX-P to an external 5-24VDC

supply (sink current) or to the GND

terminal (source current). Failure

to remove R45 first will damage

the OEM6250.

To control the ENBL

input with a switch,

first remove R25 and

then wire the switch

as shown.

47 KW

Internal Schematic

74HCxx

Chapter 1. Installation

11

End-of-Travel and Home Limit Inputs

• CAUTION: As shipped from the factory, the limit inputs are pulled up to +5V through the R45 resistor. To

use a voltage reference other than +5V, first remove R45 and then use either the on-board +5V terminal

or an external power supply to power the AUX-P pull-up resistor (using both will damage the OEM6250).

• Motion will not occur on an axis until you do one of the following:

- Install end-of-travel (POS & NEG) limit switches.

- Disable the limits with the LH¯ command (recommended only if load is not coupled).

- Change the active level of the limits with the LHLVL command.

• Refer to the

discussions about using end-of-travel limits and homing.

CONNECTIONS & INTERNAL SCHEMATICS

POS & NEG connected to GND (normally-closed switches).

Mount each switch such that the load forces it to open before it

reaches the physical travel limit (leave enough room for the load to

stop). When the load opens the switch, the axis stops at the decel

value set with the LHAD command. The motor will not be able to

move in that same direction until you execute a move in the opposite

direction and

the limits with the LH¯ command, but this is recommended only if the

motor is not coupled to the load). The active level (default is active

low) can be changed with the LHLVL command.

HOM connected to GND (normally-open switch).

The home limit input is used during a homing move, which is initiated

with the HOM command. After initiating the homing move, the controller

waits for the home switch to close, indicating that the load has reached

the “home” reference position. The active level (default is active low) can

be changed with the HOMLVL command. You can also use an encoder’s

Z channel pulse, in conjunction with the home switch, to determine the

home position (this feature is enabled with the HOMZ1 command).

clear the limit by closing the switch (or you can disable

OEM6250

LIMITS

Connector

R45

AUX-P

Location of

resistor R45.

AUX

Connector

Basic Operation Setup

As shipped from the factory, AUX-P is internally connected to +5V via resistor R45 (input is sinking current).

To make the Limit inputs sink current to a supply other than +5V, first remove R45 and then connect an

external 5-24V supply to the AUX-P terminal. To source current, first

terminal to the GND terminal. CAUTION: Failure to remove R45 before connecting AUX-P to an external

supply or to the GND terminal or to the +5V terminal will damage the OEM6250.

NOTE: AUX-P (and R45) are also used by the ENBL & TRG inputs.

HCMOS compatible (switching levels: low £ 1.00V, high ³ 3.25V). Voltage range = 0-24V.

chapter in the

NOTES

6000 Series Programmer’s Guide

LIMITS Connector

AUX Connector

1POS

1NEG

1HOM

GND

2POS

2NEG

2HOM

GND

SHLD

TRG-B

GND

OUT-A

OUT-B

GND

ENBL

+5V

AUX-P

for in-depth

Internal Schematic

All limit inputs share the

same circuit design.

Digital

GND

Chassis

Ground

Remove R45 before

connecting AUX-P to

an external 5-24VDC

Digital

GND

+5VDC

R45

(0 KW)

6.8 KW

remove R45 and then connect the AUX-P

supply (sink current)

or to the GND

terminal (source

current). Failure to

remove R45 first

will damage the

OEM6250.

47 KW

74HCxx

PIN OUTS & SPECIFICATIONS

(LIMITS Connector)

Pin Name In/Out Description Specification for all limit inputs

9

8

7

6

5

4

3

2

1

12

1POS

1NEG

1HOM

GND

2POS

2NEG

2HOM

GND

SHLD

IN

IN

IN

—

IN

IN

IN

—

—

Positive-direction end-of-travel limit input, axis 1.

Negative-direction end-of-travel limit input, axis 1.

Home limit input, axis 1.

Digital ground.

Positive-direction end-of-travel limit input, axis 2.

Negative-direction end-of-travel limit input, axis 2.

Home limit input, axis 2.

Digital ground.

Chassis ground (earth).

OEM6250 Installation Guide

• HCMOS compatible (Low £ 1.00V, High ³ 3.25V) with internal

6.8 KW pull-up resistor to AUX-P terminal. As shipped from the

factory, AUX-P is internally connected to +5V via resistor R45.

To connect AUX-P to a supply other than +5V or to connect to

ground, first remove R45 and then connect AUX-P to an external

5-24V supply or to the GND terminal. Voltage range for these

inputs is 0-24V.

• Active level for HOM is set with HOMLVL (default is active low,

requires n.o. switch).

• Active level for POS & NEG is set with LHLVL (default is active

low, requires n.c. switch).

Encoder

CONNECTIONS & INTERNAL SCHEMATICS

Max. Cable Length is 100 feet.

Use 22 AWG wire.

Incremental

Encoder

Wire colors for Compumotor E Series encoders

ENCODER Connector

+5VDC

A Channel +

A Channel –

B Channel +

B Channel –

Z Channel +

Z Channel –

Ground

Shield

Red

Brown

Brown/White

Green

Green/White

Orange

Orange/White

Black

Shield

+5VDC

+5V

A+

A–

B+

B–

Same Circuit

as A Channel

Z+

ZGND

SHLD

Digital Ground

ENCODER Connector

Internal Schematic

+1.8VDC

22 KW

22 KW

+5VDC

Chassis Ground

Encoder Cable

SM Motor

PIN OUTS & SPECIFICATIONS

Pin Name In/Out Description

9

+5V

8

A+

7

A–

6

B+

5

B–

4

Z+

3

Z–

2

GND

1

SHLD

OUT

IN

IN

IN

IN

IN

IN

-----

-----

+5VDC output to power the encoder.

A+ Channel quadrature signal input.

A– Channel quadrature signal input.

B+ Channel quadrature signal input.

B– Channel quadrature signal input.

Z+ Channel signal input.

Z– Channel signal input.

Digital ground.

Shield

—Internally connected to chassis ground (earth).

+5VDC

A Channel –

A Channel +

B Channel +

B Channel –

Z Channel +

Z Channel –

Ground

Shield

Wire colors

(ENCODER Connector)

Red

Yellow

White

Green

Blue

Orange

Brown

Black

Shield

+5V

A+

A–

B+

B–

Z+

ZGND

SHLD

NOTE: Be sure to connect

the A– encoder lead (yellow)

to the A+ terminal, and

connect the A+ encoder lead

(white) to the A– terminal.

Specification for all encoder inputs

Differential comparator accepts two-phase quadrature

incremental encoders with differential (recommended) or

single-ended outputs. Max. frequency is 1.6 MHz. Minimum

time between transitions is 625 ns. TTL-compatible voltage

levels: Low £ 0.4V, High ³ 2.4V. Maximum input voltage is

5VDC.

Requirements for Non-Compumotor Encoders

• Use incremental encoders with two-phase quadrature output. An index or

Differential outputs are recommended.

• It must be a 5V (< 200mA) encoder to use the OEM6250’s +5V output. Otherwise, it must be separately

powered with TTL-compatible (low £ 0.4V, high ³ 2.4V) or open-collector outputs.

• If you are using a single-ended encoder, leave the A–, B– and Z– terminals on the OEM6250 unconnected.

Z channel

output is optional.

Chapter 1. Installation

13

Loading...

Loading...