Page 1

Daedal

Manual No. 100-5326-01

Rev. 4

MX80L Precision Grade

MX80L Standard Grade

Product Manual

Effective: May 21, 2007

Supersedes: July 1, 2006

Electromechanical

Positioning Systems

Automation

Page 2

MX80L Series Product Manual

,

Important User Information

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries, and authorized distributors provide

product and/or systems options for further investigation by users having technical expertise. It is important that you

analyze all aspects of your application and review the information concerning the product or system in the current product

catalog. Due to the variety of operating conditions and applications for these product systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of the products and systems and assuming that all

performance, safety, and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and

pricing, are subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice.

The information in the product manual, including any apparatus, methods, techniques, and concepts

described herein, are the proprietary property of Parker Hannifin Corporation, Daedal Division or its

licensors, and may not be copied, disclosed, or used for any purpose not expressly authorized by the

owner thereof.

Since Parker Hannifin Corporation, Daedal Division constantly strives to improve all of its products, we

reserve the right to change this product manual and equipment mentioned therein at any time without

notice.

WARNING

For assistance contact:

Parker Hannifin Corporation

Daedal Division

1140 Sandy Hill Road

Irwin, PA 15642

Phone: 724/861-8200

800/245-6903

Fax: 724/861-3330

E-mail: ddlcat@parker.com

Web site: www.daedalpositioning.com

2

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 3

MX80L Series Product Manual

,

MX80L Series Product Manual

Table of Contents

IMPORTANT USER INFORMATION............................................................................................................................................ 2

REVISION NOTES........................................................................................................................................................................ 4

CHAPTER 1 - INTRODUCTION ...................................................................................................................................................5

PRODUCT DESCRIPTION ............................................................................................................................................................... 5

UNPACKING ................................................................................................................................................................................. 5

RETURN INFORMATION.................................................................................................................................................................. 6

REPAIR INFORMATION................................................................................................................................................................... 6

WARNINGS AND PRECAUTIONS ...................................................................................................................................................... 6

SPECIFICATION CONDITIONS ......................................................................................................................................................... 7

ASSEMBLY DIAGRAM .................................................................................................................................................................... 8

CHAPTER 2 – MX80L SERIES TABLE SPECIFICATIONS ........................................................................................................ 9

ORDER NUMBER NOMENCLATURE ................................................................................................................................................. 9

DIMENSIONAL DRAWINGS............................................................................................................................................................ 10

GENERAL TABLE SPECIFICATIONS................................................................................................................................................ 13

MX80L SERIES TECHNICAL DATA................................................................................................................................................ 15

LINEAR MOTION GUIDE BEARING LIFE/LOAD COMPUTATION ........................................................................................................... 20

MX80L SERIES TECHNICAL DATA................................................................................................................................................ 21

ELECTRICAL SPECIFICATIONS ...................................................................................................................................................... 23

CLEAN ROOM PREPARATION ....................................................................................................................................................... 24

ENCODER SPECIFICATIONS ......................................................................................................................................................... 25

HALL EFFECT SPECIFICATION ...................................................................................................................................................... 25

LIMIT AND HOME SENSOR SPECIFICATIONS................................................................................................................................... 25

LOW ESD SPECIFICATIONS......................................................................................................................................................... 25

VIX DRIVE SPECIFICATIONS ........................................................................................................................................................ 25

CABLING AND WIRING DIAGRAMS................................................................................................................................................. 26

CHAPTER 3 - HOW TO USE THE MX80L................................................................................................................................. 27

MOUNTING ORIENTATIONS .......................................................................................................................................................... 27

MOUNTING SURFACE REQUIREMENTS .......................................................................................................................................... 27

LOAD MOUNTING REQUIREMENTS................................................................................................................................................ 28

LIMIT AND HOME SENSOR OPERATION........................................................................................................................................... 29

ADJUSTING THE LIMIT FLAG PROCEDURE...................................................................................................................................... 30

SETTING HOME SENSOR............................................................................................................................................................. 31

Z CHANNEL POSITION REFERENCE .............................................................................................................................................. 31

GROUNDING / SHIELDING ............................................................................................................................................................ 32

CABLING ................................................................................................................................................................................... 32

CABLE MANAGEMENT ................................................................................................................................................................. 32

PNEUMATIC COUNTERBALANCE ................................................................................................................................................... 33

CHAPTER 4 - PERFORMANCE................................................................................................................................................. 34

ACCELERATION LIMITS................................................................................................................................................................ 34

SPEED LIMITS ............................................................................................................................................................................ 34

THERMAL EFFECTS ON ACCURACY............................................................................................................................................... 35

THERMAL EFFECTS ON REPEATABILITY......................................................................................................................................... 35

CAUSES OF TEMPERATURE INCREASES ........................................................................................................................................ 36

COMPENSATING FOR THERMAL EFFECTS ...................................................................................................................................... 36

CHAPTER 5 - CONNECTING TO THE VIX AMPLIFIER............................................................................................................ 37

CHAPTER 6 - MAINTENANCE AND LUBRICATION................................................................................................................ 38

CROSS ROLLER BEARING LUBRICATION ....................................................................................................................................... 38

APPENDIX A - INTERNAL PROTECTION.................................................................................................................................39

INDEX.........................................................................................................................................................................................40

3

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 4

MX80L Series Product Manual Revision Notes

,

Revision Notes

Revision 1

Original Document

Revision 2 – 8/25/03

General

Made numerous spelling corrections

Added precision grade tables

Page 9 – Modified configurable to include precision grade tables

Page 13 – Modified specifications to include precision grade tables

Page 25 – Modified Low ESD description to include precision grade tables

Revision 3

Changed wiring block extension dimension on page 10

Page 29, 30, & 31, Changed Limits/Home from optical sensors to magnetic sensors

Revision 4

Removed Steps 5a & 5b from page 30 (Steps 5a & 5b were for optical Limits/Home)

4

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 5

MX80L Series Product Manual Chapter 1 - Introduction

,

Chapter 1 - Introduction

Product Description

MX80L Positioner

Although the MX80L is small in size and weight, it is large on performance and reliability. All key

components are integral to the unit - residing within the body of the stage to provide a clean looking,

reliable, unobstructed package. At the heart of the MX80L is an innovative non-contact linear servo

motor (patent pending). This direct drive motor has been optimized for force, speed, and acceleration, to

deliver outstanding performance and response. A high precision non-contact linear encoder provides

sub-micron resolution and repeatability. Selectable resolutions range from 10 nanometers to 5 microns.

Precision ground “zero cage creep” crossed roller bearing sets provide extremely smooth - precise linear

translation. Travel limit and home sensors are conveniently designed into the unit for easy adjustment

over the entire travel of the stage. Although there are no moving cables, 1 or 3 meters of hi-flex cabling

depending on configuration option is included and wired directly into the units. This hi-flex cabling

addresses cable flexing concerns associated with the second or third axis in multi-axis system.

Unpacking

Unpacking

Carefully remove the positioner from the shipping container and inspect the unit for any evidence of

shipping damage. Report any damage immediately to your local authorized distributor. Please save the

shipping container for damage inspection or future transportation.

Incorrect handling of the positioner may adversely affect the performance of the unit in its application.

Please observe the following guidelines for handling and mounting of your new positioner.

• DO NOT allow the positioner to drop onto the mounting surface. Dropping the positioner can

generate impact loads that may result in flat spots on bearing surfaces or misalignment of drive

components.

• DO NOT drill holes into the positioner. Drilling holes into the positioner can generate particles and

machining forces that may effect the operation of the positioner. Daedal will drill holes if

necessary; contact your local authorized distributor.

• DO NOT subject the unit to impact loads such as hammering, riveting, etc. Impacts loads

generated by hammering or riveting may result in flat spots on bearing surfaces or misalignment of

drive components.

• DO NOT lift the positioner by cables or cable management system. Lifting positioner by cables or

cable management system may effect electrical connections and/or cable management assembly.

The unit should be lifted by the base structure only.

• DO NOT expose positioner to mist, spray or submersion in liquids.

• DO NOT disassemble positioner. Unauthorized adjustments may alter the positioner’s

specifications and void the product warranty.

5

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 6

MX80L Series Product Manual Chapter 1 - Introduction

,

Return Information

Returns

All returns must reference a “Return Material Authorization” (RMA) number. Please call your local

authorized distributor or Daedal Customer Service Department at 800-245-6903 to obtain a “RMA”

number. See Daedal Catalog #8083/USA, for additional information on returns and warranty.

Repair Information

Out-of-Warranty Repair

Our Customer Service Department repairs Out-of-Warranty products. All returns must reference a “RMA”

number. Please call your local authorized distributor or Daedal Customer Service Department at 800245-6903 to obtain a “RMA” number. You will be notified of any cost prior to making the repair.

Warnings and Precautions

Hot Surfaces

DO NOT touch linear motor coils located in the base of the MX80, (see page 7, Assembly Diagram, for

component location), after high duty operation. Motor temperature may approach 125 C. The unit itself

may become warm or hot to the touch.

Electrical Shock

DO NOT take apart or touch any internal components of the positioner while unit is plugged into an

electrical outlet. SHUT OFF power before replacing components to avoid electrical shock.

High Magnetic Field

Unit may be HAZARDOUS to people with Pace Makers or any other 'magnetically-sensitive' medical

devices. Unit may have an effect on 'magnetically-sensitive' applications.

Ferrous Materials

The positioner's open design WILL ATTRACT ferrous materials. The customer must take additional

precautions in these applications to keep positioner free of these highly magnetic particles.

Vertical Operation

The MX80L is NOT recommended for vertical operation unless it is configured with the pneumatic assist

option. If the pneumatic assist is not used, the carriage and customer's load will fall in power loss

situations potentially causing product or load damage or personal injury.

General Safety

Because linear motors can accelerate up to 5 g's, and sometimes positioners move without warning,

keep all personnel away from dynamic travel range of positioner.

6

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 7

MX80L Series Product Manual Chapter 1 - Introduction

,

Specification Conditions

Specifications Are Temperature Dependent

Catalog specifications are obtained and measured at 20 Degrees C. Specifications at any other

temperature may deviate from catalog specifications. Minimum to maximum continuous operating

temperature range (with NO guarantee of any specification except motion) of a standard unit before

failure is 5 - 40 degrees C.

Specifications Are Mounting Surface Dependent

Catalog specifications are obtained and measured when the positioner is fully supported, bolted

down, and is mounted to a work surface that has a maximum flatness error of:

• Standard Grade: 0.003mm/300mm (0.0001”/ft)

• Precision Grade: 0.001mm/300mm (0.00004”/ft)

Table will operate with work surface 0.100mm/300mm but performance specifications will be

significantly effected.

Specifications Are Point of Measurement Dependent

Catalog specifications and specifications in this manual are measured from the center of the carriage,

38 mm above the carriage surface. All measurements taken at any other location may deviate from

these values.

7

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 8

MX80L Series Product Manual Chapter 1 - Introduction

,

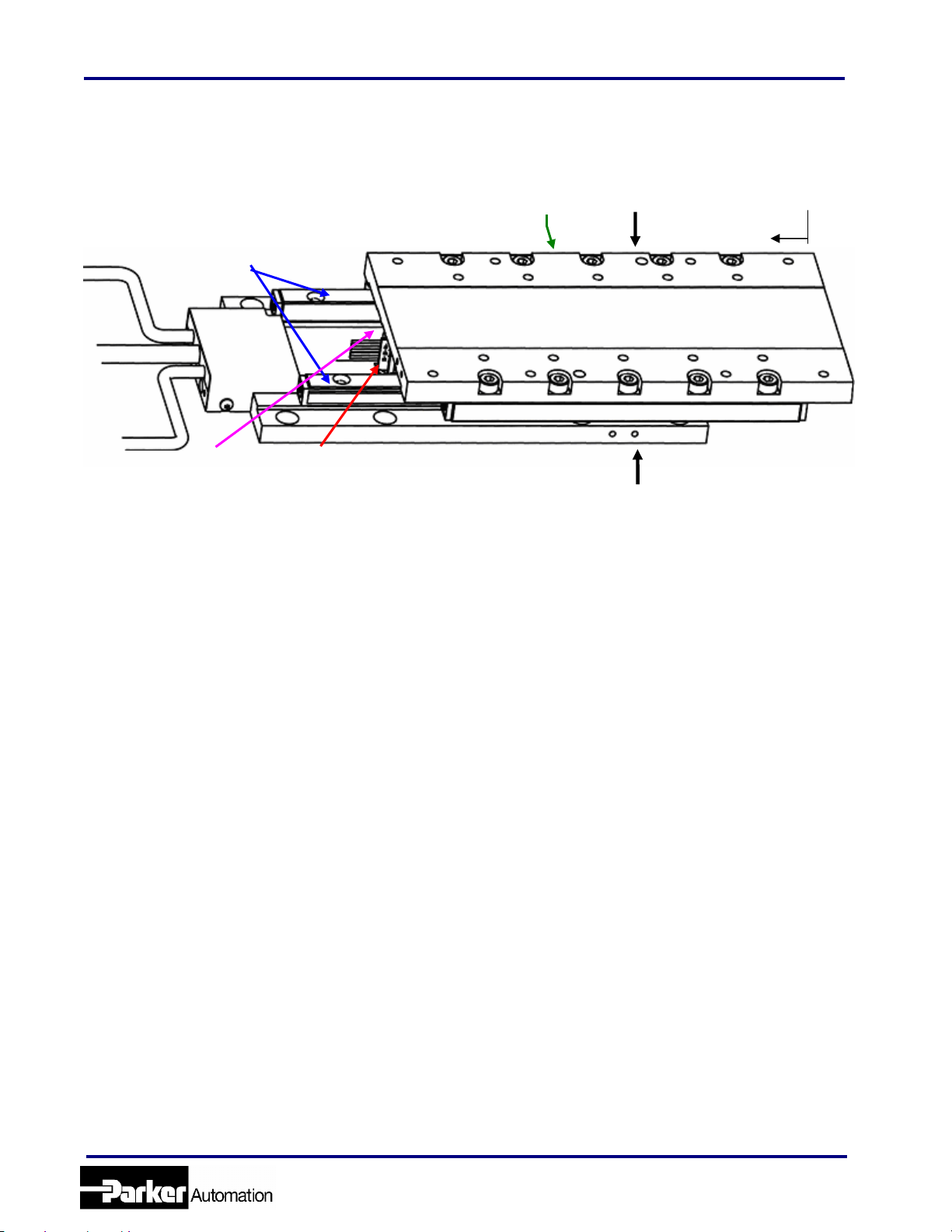

Assembly Diagram

Anti Cage Creep

Cross Roller Bearings

Limit Flag Bracket

Left side of stage w.r.t. cables

CARRIAGE

+X

Travel

Encoder

Read

Head

Linear Motor

Coils

BASE

8

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 9

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

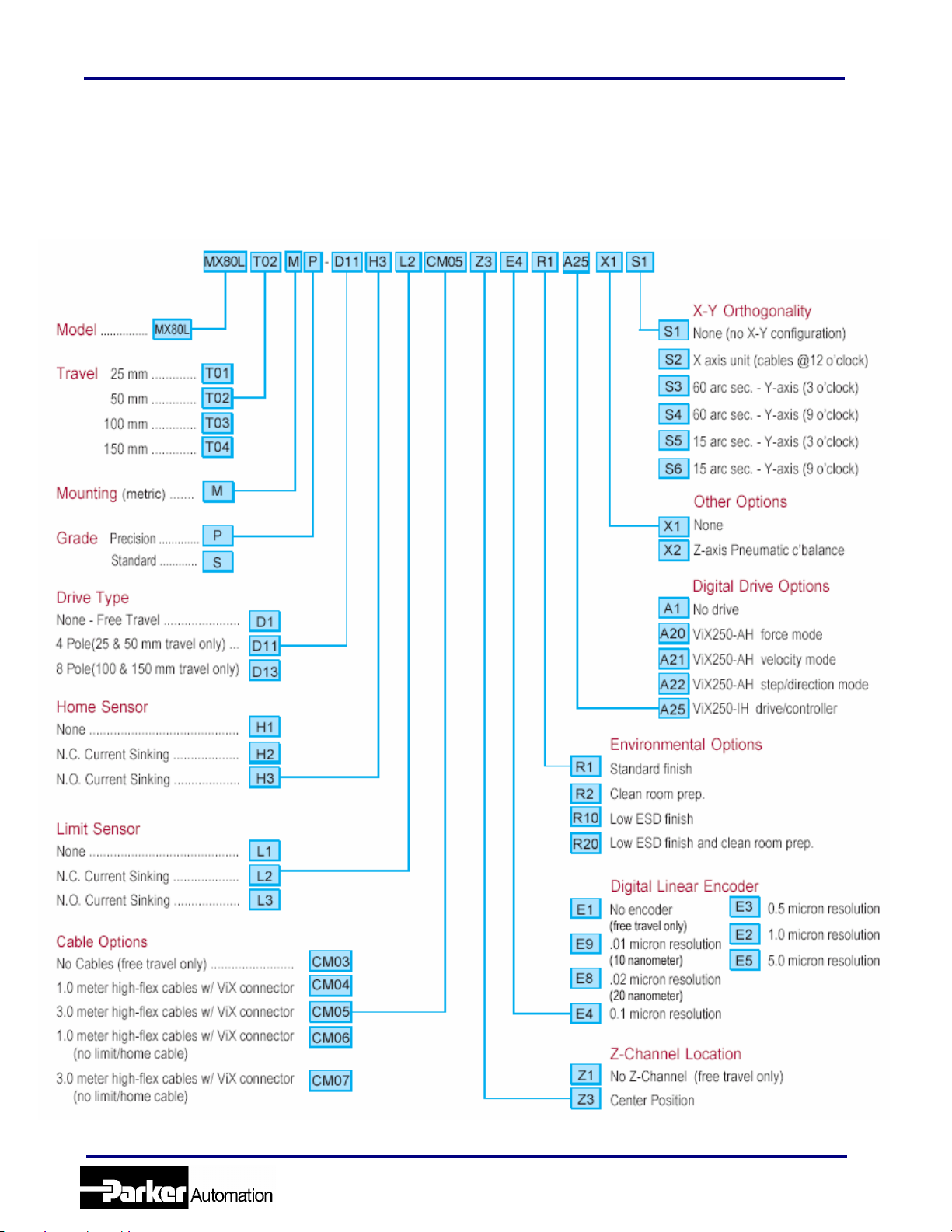

Chapter 2 – MX80L Series Table Specifications

Order Number Nomenclature

9

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 10

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

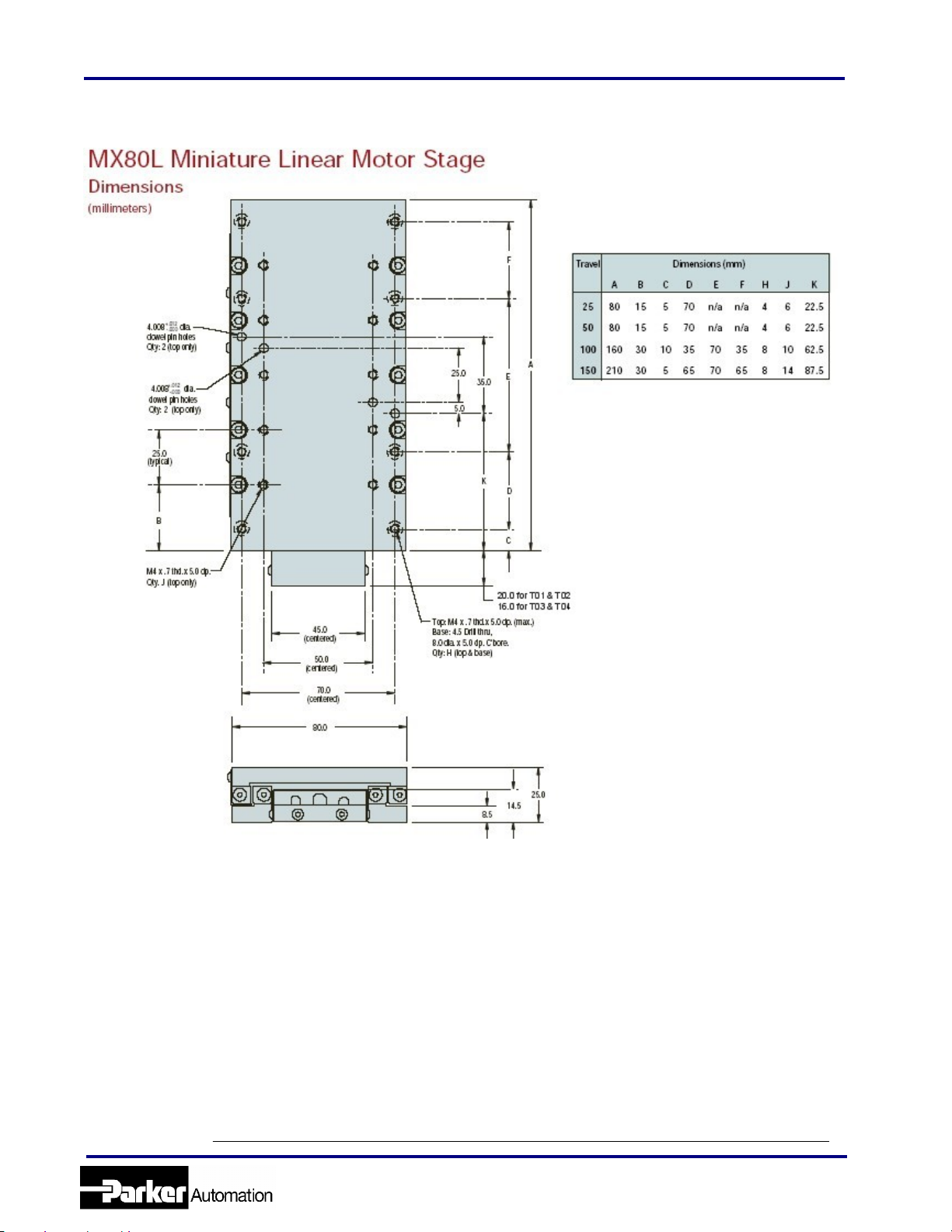

Dimensional Drawings

10

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 11

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

02

,

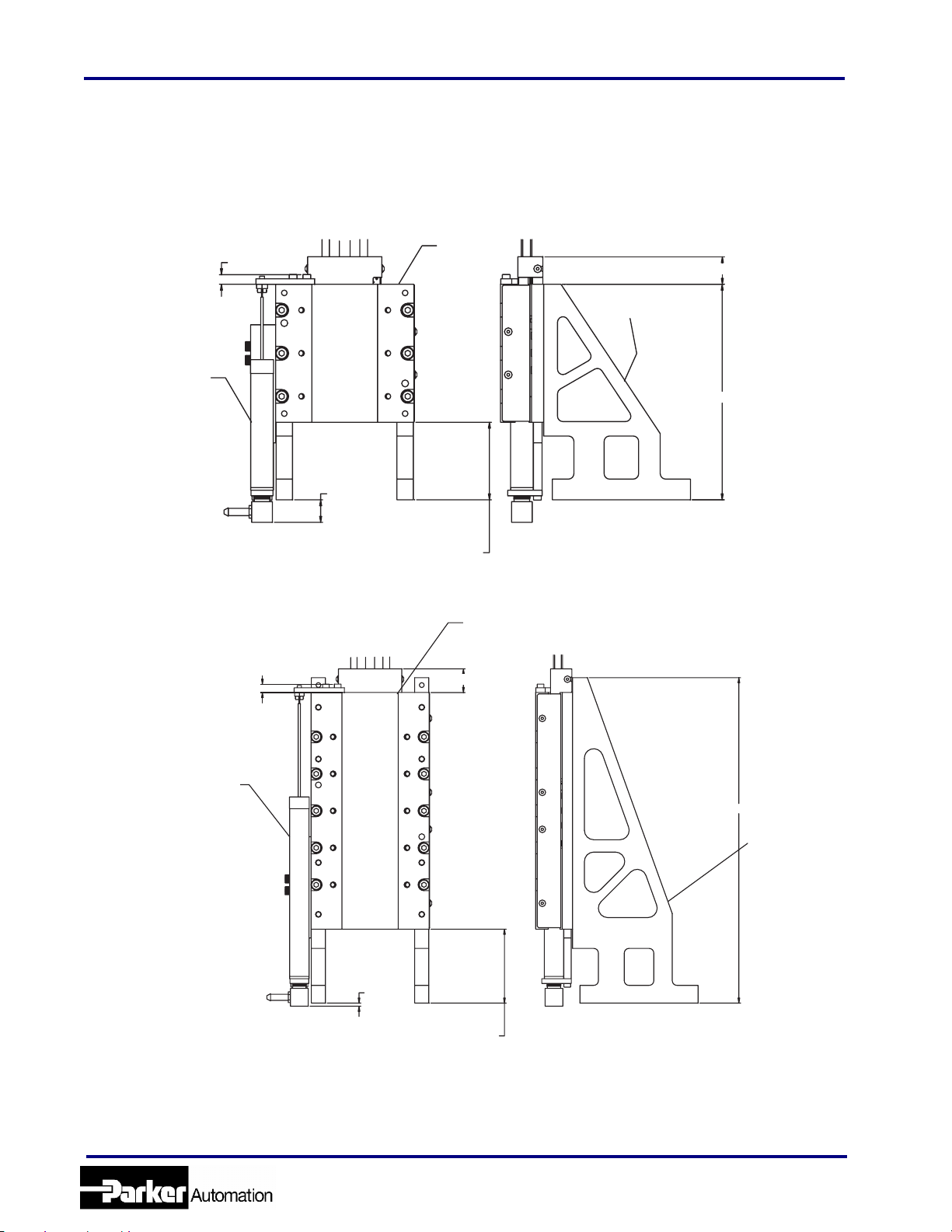

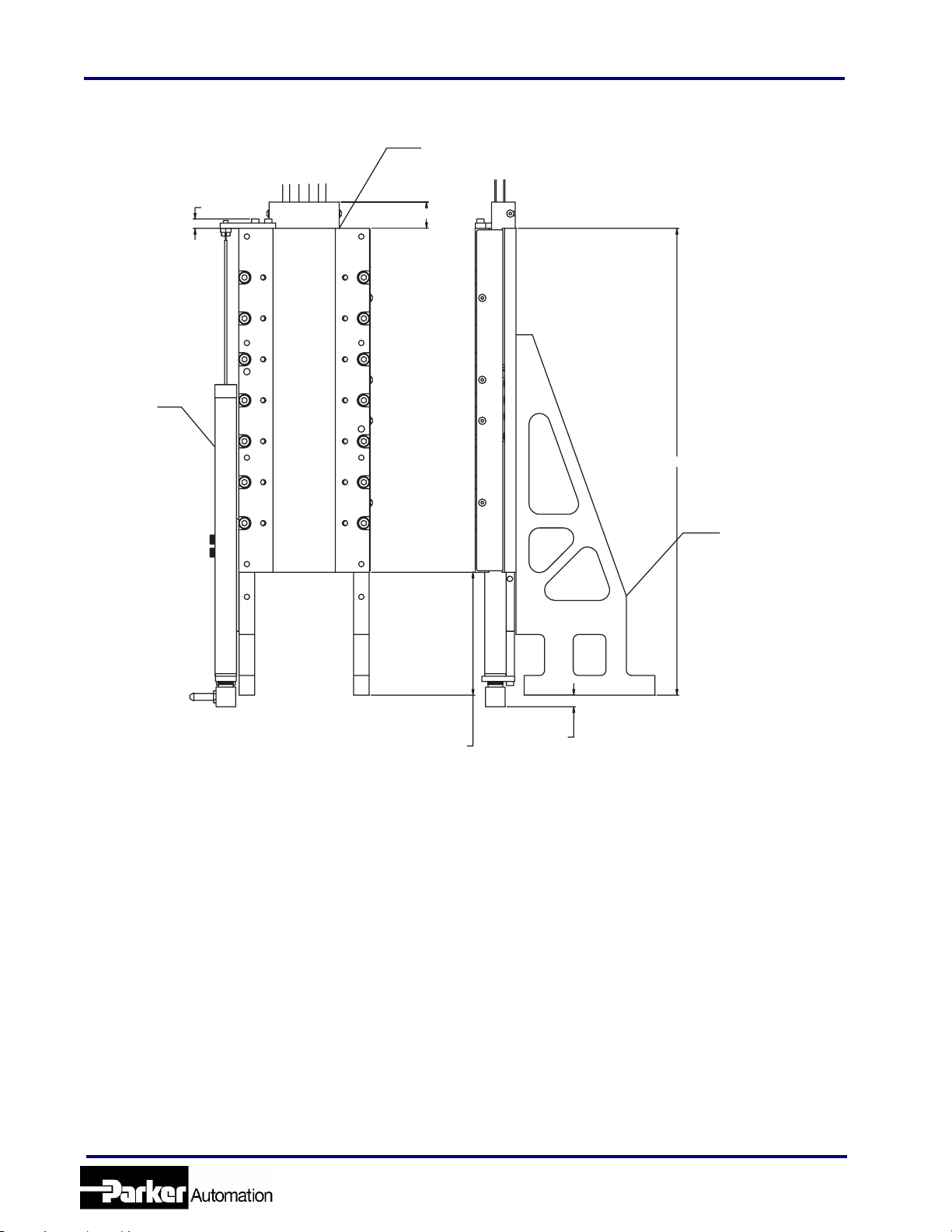

Z-axis configuration with counter balance

25 and 50mm travel

MX80L-T01 OR T02

P/N 002-2223-01

CYLINDER ASSY.

5.6 [0.22]

13.1 [0.51]

P/N 100-9822-01

QTY.(2)

16.0 [0.63]

125.0 [4.92]

100mm travel

5.6 [0.22]

5.6 [0.22]

002-2223-02

CYLINDER ASSY.

002-2223-02

Cylinder Ass'y.

45.0 [1.77]

Z-AXIS SHOWN AT MID-TRAVEL POSITION

MX80L-T03

16.0 [0.63]

16.0 [0.63]

2.1 [0.08]

2.1 [0.08]

50.0 [1.97]

Z-Axis - shown at Mid-travel

MX80L-T03

220.0 [8.66]

P/N 100-9822Qty.(2)

11

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 12

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

P

C

,

150mm travel

MX80L-T04

/N 002-2223-03

YLINDER ASSY

5.7 [0.22]

16.0 [0.63]

285.0 [11.22]

P/N 100-9822-02

QTY.(2)

75.0 [2.95]

Z-Axis at Mid-travel

7.1 [0.28]

12

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 13

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

y

y

y

,

General Table Specifications

Specifications

Normal Load Capacity

25mm 50mm 100mm 150mm

8 kg 8 kg 8 kg 8 kg

Maximum Acceleration

Precision Grade 4G 4G 4G 3G

Standard Grade 5G 5G 5G 4G

Maximum Velocit

5.0 um resolution 1100 mm/sec 1500 mm/sec 2000 mm/sec 2000 mm/sec

1.0 um resolution 1100 mm/sec 1500 mm/sec 2000 mm/sec 2000 mm/sec

0.5 um resolution 1100 mm/sec 1500 mm/sec 1500 mm/sec 1500 mm/sec

0.1 um resolution 300 mm/sec 300 mm/sec 300 mm/sec 300 mm/sec

0.02 um resolution 60 mm/sec 60 mm/sec 60 mm/sec 60 mm/sec

0.01 um resolution 30 mm/sec 30 mm/sec 30 mm/sec 30 mm/sec

Peak Force

Continuous Force

Duty Cycle

12.0N (2.7 lbs) 12.0N (2.7 lbs) 24.0N (5.4 lbs) 24.0N (5.4 lbs)

4.0N (0.9 lbs) 4.0N (0.9 lbs) 8.0N (1.8 lbs) 8.0N (1.8 lbs)

100% 100% 100% 100%

Straightness & Flatness

Precision Grade 4 microns 4 microns 5 microns 6 microns

Standard Grade 6 microns 6 microns 10 microns 12 microns

Positional Accurac

Precision Grade (1)(2)(3)

0.01 um resolution 3 microns 4 microns 5 microns 5 microns

0.02 um resolution 3 microns 4 microns 5 microns 5 microns

0.1 um resolution 3 microns 4 microns 5 microns 5 microns

0.5 um resolution 4 microns 5 microns 6 microns 6 microns

1.0 um resolution 5 microns 6 microns 7 microns 7 microns

5.0 um resolution 13 microns 14 microns 15 microns 15 microns

Standard Grade (2)

0.01 um resolution 12 microns 15 microns 20 microns 20 microns

0.02 um resolution 12 microns 15 microns 20 microns 20 microns

0.1 um resolution 12 microns 15 microns 20 microns 20 microns

0.5 um resolution 12 microns 15 microns 20 microns 20 microns

1.0 um resolution 15 microns 20 microns 25 microns 25 microns

5.0 um resolution 25 microns 30 microns 35 microns 35 microns

Bi-directional Repeatabilit

Precision Grade (1)(2)(3)

0.01 um resolution

0.02 um resolution

0.1 um resolution

0.5 um resolution

1.0 um resolution

5.0 um resolution

Standard Grade (2)

0.01 um resolution

0.02 um resolution

0.1 um resolution

0.5 um resolution

1.0 um resolution

5.0 um resolution

Unit Mass

Precision Grade 590g 590g 1027g 1345g

Standard Grade

475g 475g 875g 1125g

Carriage Mass

Precision Grade 282g 282g 509g 676g

Standard Grade

(1) Measured at the carriage center, 35mm off mounting surface @ 20C with no load. Unit bolted to granite surface, flat to within 1 micron/300mm

(2) Total accuracy and bi-directional repeatability over full travel (peak to peak)

(3) Precision grade with slope correction value provided. Consult factory if better accuracy is required.

213g 213g 405g 537g

Travel

+/- 0.4 microns

+/- 0.4 microns

+/- 0.5 microns

+/- 1.0 microns

+/- 2.0 microns

+/- 10.0 microns

+/- 0.8 microns

+/- 0.8 microns

+/- 0.8 microns

+/- 1.5 microns

+/- 2.0 microns

+/- 10.0 microns

13

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 14

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

Test Methodology

2.64

6.32

-3.68

Published accuracy and repeatability specifications are subject to the testing methodology. Daedal’s

methodology provides specifications over the entire table travel regardless of start or finish position. The

accuracy and repeatability specifications are based on the peak to peak error measured by a laser

interferometer and prism located at 38mm above the center of the table. This type of measurement sums

the X, Y, Z, roll, pitch, and yaw errors. Temperature deviations from test condition may cause deviations

in straightness, flatness, accuracy, and repeatability from catalog specifications. Tests are performed with

the table mounted to a granite table, unloaded at 20

o

C.

In this example, the accuracy of an MX80L-T02 ranges from -3.68 microns to 2.64 microns. This table

would have its accuracy specified as 6.32 micron since the worst case would be starting at one extreme

and traveling to the other.

14

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 15

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

MX80L Series Technical Data

The useful life of a linear table at full catalog specifications is dependent on the forces acting upon it.

These forces include both static components resulting from payload weight, and dynamic components due

to acceleration/deceleration of the load. In multi-axes applications, the primary positioner at the bottom of

the stack usually establishes the load limits for the combined axes. When determining load/life, it is critical

to include the weight of all positioning elements that contribute to the load supported by the primary axis.

The life/load charts are used to establish the table life relative to the applied loads.

Life-Load Curve All Travels

Life vs Normal or Side load

1000000

T01

T02

100000

T03

T04

Life (km)

10000

1000

012345678

Load (kg)

Moment Load – Life Curves

The effect of moment loading on the bearing life is dependent upon load and lever arm. The lever arm in

this case is measured from the center of the surface of the table to the point where the load is applied. For

dynamic loading, use the distance from the center of the table to the center of mass of the load. The LifeLoad charts show curves for various lever arm lengths (units in [mm]). Note Pitch moments and Yaw

moments use the same curves.

Yaw Moment Loading Roll Moment Loading Pitch Moment Loading

ForceForce

ForceForce

ForceForce

15

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 16

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

[T01] Travel Moment Life – Load Charts

Lif e - M om ent Chart 2 5m m trav el Pi t ch- Yaw Loading

100000

10000

25

Life [km]

1000

100

100000

10000

Life [km]

1000

50

75

100

250 300

012345678

200

150

Load [kg]

Lif e - M om ent Chart 2 5m m t r av el Rol l Loadi ng

25

50

75

100

300

200250

150

100

012345678

Load [kg]

16

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 17

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

[T02] Travel Moment Life – Load Charts

Lif e - M om ent Chart 5 0m m t r a vel Pi t c h- Yaw Loadi ng

100000

10000

25

Life [km]

100000

Lif e [ km ]

1000

250300

100

012345678

200

Load [kg]

Lif e - M om ent Chart 5 0m m t r a vel Roll Loadi ng

10000

300

1000

250

150

200

50

75

100

25

50

75

100

150

100

012345678

Load [kg]

17

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 18

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

[T03] Travel Moment Life – Load Charts

Lif e - M om ent Chart 1 00m m tra vel Pi t ch-Y a w Loadi ng

100000

25

10000

50

75

Life [km]

1000

250300

100

150

200

100000

10000

Life [km]

1000

100

012345678

Load [kg]

Lif e - M om ent Char t 1 00m m t r a vel Roll Loadi ng

25

100

150

200

250

300

100

012345678

Load [kg]

50

75

18

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 19

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

[T04] Travel Moment Life – Load Charts

Lif e - M om e nt Char t 15 0m m t r a vel Pi t ch-Y a w Loadi ng

100000

25

Life [km]

100000

Life [km]

10000

1000

100

012345678

Load [kg]

Lif e - M om ent Chart 15 0m m t r a vel Rol l Loading

10000

1000

250300

75

100

150

200

300

50

25

50

75

100

150

200

250

100

012345678

Load [kg]

19

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 20

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

Linear Motion Guide Bearing Life/Load Computation

To predict the travel life of the MX80L cross roller bearings under a moment load use the curve with the

corresponding lever arm and given load. Factor in dynamic as well as static loads. For compound loading

(multiple moments) use an “effective lever arm of 2x actual lever arm.

Example:

Given a MX80L-T02 with a 2 kg load mounted 35 mm off of the end

ForceForce

of the carriage in line with the travel path. The lever arm is 35 mm

+ 40 mm (center of table to edge) = 75 mm

This loading produces a pitch moment. Therefore, using the Pitch

curve for the 50mm travel, draw a vertical line up from the x-axis at

the 2 kg load point until it intersects the 75 curve. The point of

intersect is the predicted bearing life of the table. In this example

the life is 10,000 km of travel

Lif e - M om ent Chart 5 0m m t r av el Pit ch- Yaw Loadi ng

100000

10000

25

Life [km]

1000

250300

100

012345678

200

150

50

75

100

Load [kg]

20

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 21

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

MX80L Series Technical Data

Force/Speed Charts

The Force/Speed Charts for the MX80L are shown for each available travel. In the maximum allowable

travel range the motor force is the same for 80 and 48 VDC bus voltage. See Electrical Specifications for

motor parameters. Performance based on table mounted to 200mmx150mmx20mm Aluminum plate.

Curves shown include friction and viscous damping values of table. Peak speed is limited by travel

length for 25mm [T01] and 50mm [T02] travel lengths.

[D11] 4-pole Motor Force-Speed Curve ([T01] 25 mm travel)

Rated Force Speed Curve

14

12

Peak

10

8

6

Force N

4

Continuous

2

0

0 200 400 600 800 1000 1200

Speed mm/s

( 80 & 48 VDC)

[D11] 4-pole Motor Force-Speed Curve ([T02] 50 mm travel)

(80 & 48VDC)

14

12

10

Rated Force Speed Curve

Peak

8

6

Force N

4

Continuous

2

0

0 300 600 900 1200 1500

Speed mm/s

21

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 22

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

[D13] 4-pole Motor Force-Speed Curve ([T03] 100 mm travel)

Rated Force Speed Curve

(80 & 48VDC)

30

25

Peak

20

15

Force N

10

Continuous

5

0

0 400 800 1200 1600 2000

Speed mm/s

[D13] 4-pole Motor Force-Speed Curve ([T04] 150 mm travel)

Rated Force Speed Curve

30

(80 & 48VDC)

25

Peak

20

15

Force N

10

Continuous

5

0

0 400 800 1200 1600 2000

Speed mm/s

22

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 23

MX80L Series Product Manual Chapter 2 – MX80L Series Table Specifications

,

Electrical Specifications

Specifications for both the 4 pole and 8 pole linear servo motors

Parameter:

Stall Force Continuous [1] Fcs N 4.0 8.0 8.0

Stall Current Continuous [1, 4, 8] Ics(sine) Amps Peak 1.13 2.26 2.26

Stall Current Continuous [1, 7] Ics(trap) Amps DC 0.92 1.84 1.84

Stall Current Continuous [1] Ics(RMS) Amps RMS 0.8 1.6 1.6

Peak Force [6] Fpk N 12 24 24

Peak Current [4, 6, 8] Ipk(sine) Amps Peak 3.2 6.4 6.4

Peak Current [6, 7] Ipk(trap) Amps DC 2.8 5.5 5.5

Peak Current [6] Ipk(RMS) Amps RMS 2.4 4.8 4.8

Voltage Constant [3, 4] Ke Volts/m/s 4.5 4.5 4.5

Voltage Constant [3] Ke (RMS) Volts RMS/m/s 3.2 3.2 3.2

Force Constant [9] Kf(sine) N/Amps Peak 3.90 3.90 3.90

Force Constant [3, 4] Kf(trap) N/Amps DC 4.50 4.50 4.50

Force Constant [3] Kf(RMS) N/Amps RMS 5.51 5.51 5.51

Resistance [3] R Ohms 9.50 4.75 4.75

Inductance [5] L mH 3.60 1.80 1.80

Maximum Bus Voltage Vm Volts DC 80 80 80

Thermal Resistance Wind-Amb Rth w-a C/watt 6.8400 3.4000 3.4200

Motor Constant Km N/sqrt(watt) 1.46 2.06 2.06

Viscous Damping B N/m/s 0.500 0.5 0.800

Static Friction [13] Fs N 0.5 1.0 1.0

Motor Thermal Time Constant Tau_th minutes 0.8 0.8 0.8

Winding Thermal Time Const Tau_wnd minutes 0.5 0.5 0.5

Intermittent Force Duration [10] T_2x seconds 8.0 10.0 10.0

Peak Force Duration [11] T_3x seconds 1.2 2.3 2.3

Electrical Pitch [12] Pe mm 13 13 13

Rated Winding Temperature RT C 95 95 95

Rated Ambient Temperature AT C 20 20 20

Winding Class H H H

o

1. @ 25

C ambient, 125C Winding Temperature with the table mounted to a 200mm x

150mm x 20mm aluminum plate

2. Measured with a 0.33 mm gap

3. Measured Line to Line +/-10%

4. Value is measured peak of sine

5. +/-30% Line to Line, inductance bridge measurement @1Khz

6. Initial winding temperature must be 60 C or less before Peak Current is applied

7. DC current through a pair of motor phases of a trapezoidal (six state) commutated

8. Peak of the sinusoidal current in any phase for a sinusoidal commutated motor

9. Total motor force per peak of the sinusoidal amps measured in any phase, +/-10%

10. Maximum time duration with 2 times rated current applied with initial winding temp

at 60 C

11. Maximum time duration with 3 times rated current applied with initial winding temp at

60 C

12. The Distance from the leading edge of the north pole to the leading edge of the next

north pole

13. Average friction over total table travel

Symbol: Units: 25 & 50 mm

D11

100 mm

D13

150 mm

D13

23

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 24

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

Clean Room Preparation

There is no clean room ‘rating’ for motion control products just individual compatibility with class of clean

rooms. The compatibility is also dependant on measurement location. A point directly below a component

may have a different particle count than at a side location. In an effort to clarify the class of clean room

that our products can be used in with out affecting the overall rating of the clean room, Daedal provides a

Clean Room Class Compatibility chart for product intended for use in such environments. Due to the

moving magnet design of the MX80L, minimal particle generation occurs during operation. MX80L tables

with clean room preparation were tested in Daedal’s vertical laminar flow work station which utilizes ULPA

filters to produce an environment having a cleanliness of class 10 prior to testing. Tables were tested in a

variety of orientations with sampling both below the table and at the carriage mounting surface with a

particle counter capable of measuring 0.3 µm diameter and larger particles. Based on results from testing

following the 209E Federal Standard, the following chart shows the expected clean room compatibility of

the MX80L with Class 10 clean room prep. Consult factory for details on test methodology and results.

* Compatibility is defined as not affecting the clean room class rating with the addition of this product for classes shown.

For example a MX80L with 50mm travel with a velocity of 500mm/sec will not effect a class 10 clean room or higher.

The Class 1 rating in the table refers to class 1 levels of 0.3µ and larger particles detected in Daedal’s Class 10

chamber. For complete class 1 compatibility, the particle count for the 0.1 and 0.2µm particles would also need to be

taken into consideration.

Standard Clean Room Preparation

• Stringent cleaning and handling measures

• Clean room rated lubricant

• Reduce force specification by 25%

MX80L Clean Room Class Compatibility*

100 & 150 mm

Velocity 25 & 50 mm Travel

[mm/sec]

4.5" below At stage top 4.5" below At stage top

1 1 1 5 1

5 1 1 5 1

10 1 1 5 1

25 1 1 5 1

50 1 1 10 5

100 1 1 10 5

250 1 5 25 10

500 10 5 50 10

1000 25 10 50 25

1500 n/a 25 100 25

2000 n/a n/a 100 25

Travel

24

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 25

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

Encoder Specifications

Description Specification

Input Power 5 VDC +/-5% 150 to 220 mA depending on encoder resolution

Output

(Incremental)

E2, E3, E4, E5,

E8

Reference (Z

Channel)

Maximum Speed 5.0 micron resolution = 2.0 meters/sec (limited by table)

Square wave differential line driver (EIA RS422) 2 channels A and B in

quadrature (90

Synchronized pulse, duration equal to one resolution bit. Repeatability of

position is unidirectional moving toward positive direction and is equal to

table repeatability specifications.

1.0 micron resolution = 2.0 meters/sec (limited by table)

0.5 micron resolution = 1.5 meters/sec

0.1 micron resolution = 0.3 meters/sec

20 nanometer resolution = 0.06 meters/sec

10 nanometer resolution = 0.03 meters/sec

o

) phase shift.

Hall Effect Specification

Description Specifications

Input Power +5 VDC, 30 mA

Output Open collector, Current Sinking, 20 mA Max

Limit and Home Sensor Specifications

Description Specification

Input Power +5 VDC 60 mA (power from encoder, no additional connection needed)

Output Output form is selectable with product:

- Normally Closed Current Sinking

- Normally Open Current Sinking

NPN open collector +5 to +24 VDC All types Sink maximum of 50 mA

Repeatability

Home Sensor: +/- 5 µm (unidirectional) with 1.0 micron or better encoder

NOTE: Repeatability using z-channel refers to encoder specifications

Low ESD Specifications

The low ESD (ElectroStatic Discharge) option refers to either an electroless nickel coating on standard

grade tables or an Armoloy® coating on precision grade tables that provides a very low resistance path to

ground from all surfaces of the MX80.

ViX Drive Specifications

Refer to Specifications provided in ViX Manual.

25

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 26

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

Cabling and Wiring Diagrams

Connector Pin Out and Extension Cable Wire Color Codes for the 5, 1, 0.5 and 0.1

micron resolution encoders

PIN FUNCTION WIRE COLOR

1 GND BLACK

6 + End of travel ORANGE

7 - End of travel BLUE

8 Home GREEN

X5 – LIMITS CONNECTOR

X1 – MOTOR LEADS

WIRE COLOR DRIVE

RED U

WHITE V

BLACK W

GREEN GND

The 10 and 20 nanometer resolution

encoders have an interpolator box and

bypass cable

Not included with

[H1][L1] option

X2 – FEEDBACK-HALL CONNECTOR

PIN FUNCTION WIRE COLOR

1 Encoder Z+ ORANGE

2 Encoder Z- BROWN

3 GND BLACK

5 +5V RED

6 Temperature- YELLOW/BLACK

7 Encoder A+ WHITE

8 Encoder A- YELLOW

9 Hall#1 WHITE/BROWN

10 Temperature+ YELLOW/RED

11 Encoder B- BLUE

12 Encoder B+ GREEN

13 Hall#2 WHITE/ORANGE

14 Hall#3 WHITE/VIOLET

26

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 27

MX80L Series Product Manual Chapter 3 - How to Use the MX80

P

,

Chapter 3 - How to Use the MX80L

Mounting Orientations

The MX80L can be mounted normal, inverted, side or vertically. For vertical (z-axis) mounting the

pneumatic counter balance is recommended to compensate for the effect of gravity on the carriage and

the load. For all mounting orientations, the cables should be secured as to not interfere with the movement

of the carriage and bearings.

.

HORIZONTAL

INVERTED

SIDE MOUNTED

/N 100-9822-02 QTY.(2)

VERTICAL

With c’balance and z-bracket

Mounting Surface Requirements

Proper mounting of the MX80L is essential to optimize product performance. All specifications are based

on the following conditions:

• The positioner must be bolted down using all counter bored mounting holes provided (4 on T01 &

T02, 8 on T03 and T04) using M4 socket head cap screws.

"E

70.0 [2.76]

CENTERED

T01 T02 T03 T04

‘E’ n/a n/a 35.0 65.0

50.0 [1.97]

CENTERED

• The positioner must be mounted to a flat, stable surface, with a flatness error less than or equal to

0.025mm/300mm for operation (specifications will be greatly varied from published specification).

To meet catalog specifications the surface must have a flatness error less than or equal to

0.003mm/300mm for Standard grade and 0.001mm/300mm for Precision grade.

70.0 [2.76]

CENTERED

25.0 [0.98]

CENTERED

BASE

27

"E"

C-BORED HOLES ON BASE

FOR M4 X 0.7 X 8.0 LENGTH SOCKET CAP HEAD SCREW

+0.012-0.000

[

Ø4.008

Ø0.1578

]

DOWEL PIN HOLES QTY.(2)

0000

+0.0005-0.

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 28

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

• Catalog specifications may deviate for positioners mounted to surfaces that do not meet the above

conditions.

• If the intended mounting surface cannot meet these specifications a separate rigid mounting plate

meeting these specifications should be used to mount to the main structure.

• If mounting conditions require that the table base is overhung, table specifications will not be met

over that portion of the table. Additionally, in X-Y Systems the overhung portion of the Y-axis may

not met specifications due to the additional error caused by deflection and non-support of the

base. Contact Daedal for guidelines on specifications of overhang applications

Load Mounting Requirements

Dowel holes are included in the carriage of the MX80L for repeatable mounting of loads/fixturing. When

bolting payload to carriage take precaution in using bolts M4 with 7mm of engagement as to not damage

the table.

Use appropriate length bolt.

The MX80L compact design requires proper sized bolts to be used when mounting payloads to the

carriage. Excessive length bolts can damage bearings or pin the table in position.

28

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 29

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

Limit and Home sensor operation

The MX80L utilizes an innovative method for setting limit and home positions. The magnetic sensors

embedded in the base of the MX80L change state based on the limit “flag”. This space saving, compact design

consists of three (3) parts; magnetic sensors, limit flag and limit flag bracket. The limit and home magnetic

sensors are mounted to a PCB in a fixed position to the base of the unit. The flag bracket is mounted to the left

side of the carriage with respect to the cables. The Limit Flag is a pattern of thin magnets which triggers the

sensors. This pattern defines whether the switch functions as normally open or normally closed. A limit is

normally closed when the switch operates from non-magnet to magnet surfaces. The home switch is normally

open when the switch operates from non-magnet to magnet surfaces. To change from normally open to

normally closed operation of the sensor the patterns are reversed.

Example of Limit and Home Flag magnets corresponding to possible MX80L Limit Home configurations:

Config Home End of Travel Limit Flag Magnets

Normally

Closed

Normally

Closed

Normally

Open

Normally

Open

Normally

Closed

Normally

Open

Normally

Closed

Normally

Open

H1L1 Option Upgrades

• Limits and Homes can not be added to the MX80S table in the field due to the integrated design

which encloses the sensor on a printed circuit board in the base. If the magnetic sensor limit

and home are desired the unit must be returned to the factory on an RMA.

• To change Limit/Home operation from Normally Open to Normally Closed or from Normally

Closed to Normally Open a new limit flag bracket must be purchased, contact factory for proper

configuration and part number.

• To adjust the operating position of the limits, limit/home adjustment magnets can be adhered on

top of the existing limit flag. These adjustment magnets are included with the unit.

To change the activation position of the sensors:

Determine desired position

Cut magnet to proper length

Follow Adjusting Limit Flag Procedure to add to the adjustment

Determining Desired Position

The limit sensors are set at the factory for maximum travel. These factory settings only allow for 3mm

(0.12”) before the carriage contacts the end stop. In slow speed applications this may be adequate,

however as the top speed of the application increases the required deceleration distance increases. To

determine the safe Deceleration Distance the Maximum Speed and the Maximum Obtainable

Deceleration Rate must be known or calculated. The maximum speed should be known from your

application requirements. Velocity limits should be set in your program or in your amplifier to cause a

fault if the speed exceeds this value. The maximum deceleration is a factor of load and available peak

force of the table. Using F = ma, calculate maximum acceleration and then required deceleration

distance. See the following example for calculating maximum deceleration for an application with a

payload = 0.25 kg on an MX80-T01 with a maximum speed of 500 mm/s.

29

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 30

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

Total mass = 0.46 kg (Payload mass = 250 grams + Carriage mass = 213 grams)

Application Speed = 500mm/sec

Available peak force at .25 m/sec = 11.8 N (See Chapter 2, Force / Speed Curve)

Maximum Obtainable Deceleration Rate

Thus: F = ma Æ a = F/m Æ a = 11.8N / 0.46kg Æ 25.6 m/sec

2

Now, calculate the Deceleration Distance for linear deceleration:

First… find the Deceleration time:

Ta = Max Velocity / Deceleration Rate

Ta = .50 m/sec / 25.6 m/sec

2

Æ 0.020 seconds

Second… find the Deceleration Distance:

Distance = ((Max Velocity) * (Ta)) / 2

Distance = ((500 mm/sec) * (0.020)) / 2 Æ 5.0 mm

This means that both the positive and negative limit switch targets must be moved inward by 5.0 mm.

The limit deceleration rate should be set to 25.6 meters/sec

2

. Using the supplied limit flag sheet cut two

5.0mm long strips from the appropriate white or black (depending on configuration) marked Limit/Home

Adjustment overlay decal and follow the procedure for changing the limits.

Adjusting the Limit Flag Procedure

The following procedure is to be used for changing the limit flag (switching activation from N.O. to N.C. or

vice versa) and adjusting the activation position of the end of travel limits on the MX80: (Images shown

are for changing H3L2 to H2L3

Step 1: Remove power from the unit and allow time for stage

base and carriage to reach room temperature

Step 2: Remove the limit flag bracket from the MX80L by

removing the button head cap screws (BHCS) that secure the

bracket to the side of the carriage.

Step 3: Gently slide the bracket from out from under the carriage.

Step 4a: To adjust limits to increase travel: With a razor, cut and remove

the desired amount of protective sticker and magnet which equals the

amount of desired travel increase.

30

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 31

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

Step 4b: To adjust limits to reduce travel: With a razor, cut the clear

protective sticker at the end of the magnet that is to be adjusted.

Flatten out protective sticker at the cut, this allows a flat surface to

adhere additional magnet. Place additional self adhesive magnet

(supplied with positioner) at the end of the existing magnet which

equals the amount of desired travel reduction. Confirm that there is

no gap between the original magnet and the additional magnet just

applied. If there is a gap, remove the additional magnet, discard it,

and apply a new magnet.

Step 5: Gently slide bracket under carriage. Push up on bracket, insert 0.5mm to 1.0mm shims

between bracket and base, insert and tighten BHCS.

Setting Home Sensor

The MX80L is equipped with a “home” position reference sensor when purchased with Home

configuration option [H2] or [H3]. The home sensor is located on the same PCB as the limit sensors and

the target is located between the limit targets. The sensor is typically used in conjunction with the

encoder ‘Z’ marker. If another home location is desired, the home target can be adjusted by removing

the limit flag decal and applying adjustment overlay decals in the desired location.

Z Channel Position Reference

The Z channel is an output on the encoder. Many servo controllers support this input. The Z channel on

the MX80L is at mid travel. The Z channel is a unidirectional device. This means that the final homing

direction must occur in one direction. The MX80L is set that the final home direction is to be toward the

positive end of the table (See Chapter 2, Dimensional Drawing, for positive direction definition). The

repeatability of the Z channel is equal to the repeatability of the table. Thus the repeatability of the “Z”

channel equals:

Encoder Resolution Z Channel Repeatability

5 micron +/- 10 micron

1 micron +/- 2 micron

0.5 micron +/- 1 micron

0.1 micron +/- 0.4 micron

0.02 micron +/- 0.4 micron

0.01 micron +/- 0.4 micron

NOTE

: Home repeatability is also very dependent on controller input speed and homing algorithms. The

above repeatability does not include possible controller tolerance. Additionally, to achieve the highest

31

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 32

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

repeatability the final homing speed must be slow. Slower final speed usually results in higher

repeatability.

: The “Z” channel output is only one resolution count wide. Thus the on-time may be very brief.

NOTE

Due to this some controllers may have difficulty reading the signal. If you are experiencing the positioner

not finding the “Z” channel during homing, try reducing final homing speed; also refer to your controller

manual for frequency rates of the “Z” channel input.

Grounding / Shielding

All cables are shielded. These shields are to be grounded to a good earth ground. Failure to ground

shields properly may cause electrical noise problems. These noise problems may result in positioning

errors and possible run away conditions.

The motor cable has an area of the shield exposed to allow a grounding path from shield to drive ground.

The Hall/Encoder and Limit/Home cables have the shield carried through the connector hood that is in

turn grounded through the drive. MX80L purchased with ViX drives as part of the configurable part

number come equipped with p-clips designed for the small OD of the motor cable to allow the cable

shield to be grounded to the ViX ground.

Cabling

The MX80L is provided with high flex cabling which is strain relieved at the connection point on the

positioner. The Hall/Encoder cable is terminated with a high density 15 pin D-sub connector which is

compatible with the ViX drive from Parker. The motor cable is terminated with flying leads which are

stripped and tinned and ready for installation into the screw terminals on the ViX drive. For wire color

codes and pin outs see tables in electrical section of manual.

The limit/home cable is optional and therefore if not ordered a space will be open in the clamp at the

connection point. The limit/home cable is provided with a 15 pin D-sub connector which is compatible

with the ViX drive. For wire color codes and pin outs see tables in electrical section of manual.

Recommended bend radius for these cables is 50mm. This radius will provide a minimum of 10 million

cycles of the cable. Smaller bend radius will reduce cable life while larger bend radius will increase life.

If the positioner is mounted in a multi-axis configuration special care should be taken in routing and strain

relieving the cables so as to prevent flexing of the cable at the connection to the table and where

mounted stationary to the structure. Provide sufficient service loop that the cable bends a minimum of

25mm from these end points. It is also recommended to avoid twisting the cable. The cable should be

secured in a position which will orient it in a direction that creates a single plane of operation for the

cable.

To replace extension cables 1.) Disconnect power to positioner. 2.) Remove two button head screws

from side of shield and remove the shield. 3.) Remove the two cap head screws from the strain relief

and remove the strain relief. 4.) unplug extension cables. 5.) Reverse steps to reassemble.

: When reassembling the strain relief, take care not to pinch any wires and be certain that the

Note

exposed braided shield on the cables lies under the strain relief.

Cable Management

32

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 33

MX80L Series Product Manual Chapter 3 - How to Use the MX80

,

For multi-axis configurations special attention needs to be taken into account for the moving cables on

the non-base axis.

TIP: For Multi-axis Configurations.

Consider using the top axis for the highest frequency move in the application. The top axis will have

the least amount of weight to move and will reduce the cycles on the cables.

Pneumatic Counterbalance

Cylinder Specification

Description Specifications

Cylinder Piston Area 0.105 in

Cylinder Mounting Torque Head nut 0.45 – 0.90 Nm (4 – 8 in-lbs)

Maximum Compressive Rod Force 10 lbs

Allowable Input Pressure 0 – 100 psi

Coefficient of Friction 0.015 (assuming no side load)

Operating Temperature -20 – 175o F

Counter Balance Force

For ‘Z’-axis (vertical) applications, the use of the pneumatic counter balance and accessory kit is

strongly recommended. The pneumatic accessory kit includes a filter-regulator-precision regulator,

fittings and 1/8” ID tubing. The pressure in the pneumatic cylinder can be set to provide a balancing

force to counter act the effect of gravity. The counter balance force (F

pressure (P) and the cylinder piston area (A

balance force.

The yaw force generated by the counter balance will add 0.2 arc-sec of yaw per psi of pressure.

The Pressure regulation during motion is dependent on the speed and acceleration of the motion

profile. The following table shows the expected pressure fluctuation based on the move dynamics.

Acceleration Velocity Fluctuation*

Clean Room Compatibility

The vertical counter balance is compatible with clean rooms of class 250-500 for speeds below 500

mm/sec or class 1000 for higher speeds due to the particle generation on the plunger.

Rod End. 0.23 – 0.56 Nm (2 – 5 in-lbs)

F

C

0.25 kg 5.2 psi

0.5 kg 10.5 psi

1 kg 21 psi

2 kg 42 psi

4 kg 84 psi

1 g ≤ 500 mm/sec < 1 psi

3 g ≤ 500 mm/sec < 2 psi

3 g ≤ 2000 mm/sec < 3 psi

* 1 psi = 1.68oz (0.47 N) of force

2

) is a linear function of the

); FC = PxAC. See the following table to set the counter

C

P

C

33

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 34

MX80L Series Product Manual Chapter 4 - Performance

,

Chapter 4 - Performance

Acceleration Limits

Acceleration of linear servo driven tables is typically limited by three (3) factors; linear bearings,

available motor force and settling time. Due to the high load bearings used in the MX80, the

acceleration is only limited by the available motor force and the settling time.

• Available Motor Force

This is the primary factor that reduces acceleration. This is simply the amount of motor force

available to produce acceleration. The larger the inertial and or frictional load the lower the

accelerations limit.

• Settling Time

In many applications reducing cycle time is a primary concern. To this end, the “settling” time (the

amount of time needed after a move is completed for table and load oscillating to come within

acceptable limits) become very important. In many cases where very small incrementing moves are

executed, the settling time is greater than the actual move time. In these cases accelerations may

need to be reduced thus reducing the settling time.

Speed Limits

The Maximum Speed of the MX80L is limited by three (3) factors:

• Travel Length

The short travel length of the MX80L is the main limiting factor for maximum speed. The T01 and

T02 options (25mm and 50mm) a triangular motion profile with 5g accel/decel will only yield peak

speeds of 1.1m/sec and 1.5 m/s respectively.

• Linear Encoder Limit

The linear encoder has speed limits relative to encoder resolution; these limits are listed below:

Encoder

Resolution

5 micron 5 meters/second (¹) 2 MHz

1 micron 3 meters/second(1) 6.7 MHz

0.5 micron 1.5 meters/second 6.7 MHz

0.1 micron 0.3 meters/second 10 MHz

0.02 micron 0.06 meters/second 10 MHz

(¹) When using an encoder with 5 micron resolution, velocity limited by speed dependant force.

(²) This is the bandwidth frequency that the amplifier or servo control input should have to operate properly with the encoder output at

maximum speeds. This frequency is post-quadrature, to determine pre-quadrature divide above values by 4. Above frequencies include a

safety factor for encoder tolerances and line loses.

• Force / Speed Limit

The available force of the MX80L reduces as speed increases.

0.01 micron 0.03 meters/second 10 MHz

Maximum Velocity Required Post

Quadrature Input

Bandwidth (²)

(Chapter 2, MX80L Series Technical Data)

34

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 35

MX80L Series Product Manual Chapter 4 - Performance

,

Thermal Effects on Accuracy

The MX80L uses a moving magnet linear servo motor. The magnet rails and the encoder tape are

mounted to the carriage. The motor coils are mounted in the base and unless the table is mounted

to an insulated surface, the heat generated in the coils should radiate out the base maintaining a

low thermal delta between base and carriage. All specifications for the MX80L are taken at 20 C.

Variation from this temperature will cause additional positional errors. If the carriage of the MX80L

varies from this temperature the encoder scale will expand or contract, thus changing its measuring

length and thus encoder resolution.

The factor by which this thermal effect occurs is 0.000022mm/mm/° C. Although this sounds like a

very small number it can make significant accuracy and repeatability effects on your applications,

especially on longer travel applications. To understand this better let’s look at an example:

Example

travel is 25 microns @ 20° C. If the carriage temperature increases by 5 C an additional error of 17

microns will be added over the total travel (0.000022mm/mm/° C)*150mm*5 C. However, this

additional error can be compensated for since the error is linear.

The accuracy of the MX80L is plotted with respect to carriage temperature in the graph below for

the 25 mm, 50 mm, 100 mm and 150 mm travel lengths.

: A standard grade MX80L with 150mm travel is being used. The accuracy over the entire

Temperature Effect on Accuracy

0.07

0.06

0.05

0.04

0.03

Error (mm)

0.02

0.01

0

0 25 50 75 100 125 150

Travel (mm)

5 degrees C 10 degrees C 15 degrees C 20 degrees C

Thermal Effects on Repeatability

Repeatability will not be affected as long as the temperature remains constant. However the

repeatability will be affected as the temperature changes from one level to another. This is most

commonly experienced when starting an application cold. Then as the application runs the MX80L

comes to its operational temperature. The positions defined when the unit was “cold” will now be

offset by the thermal expansion of the unit. To compensate for this offset, all positions should be

defined after the system has been exercised and brought to operational temperature.

35

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 36

MX80L Series Product Manual Chapter 4 - Performance

,

Causes of Temperature Increases

One or more of the following conditions may affect the temperature of the MX80L

carriage:

• Ambient Temperature

This is the air temperature that surrounds the MX80L

• Application or Environment Sources

These are mounting surfaces or other items which produce a thermal change that affect the

temperature of the MX80L carriage (i.e. X/Y configurations with motors or other heat generating

devices that heat the mounting surface and thus thermally affect the MX80L carriage).

• Motor heating from MX80L

Since the MX80L uses a servo motor as its drive, it produces no heat unless there is motion, or a

force being generated. In low duty cycle applications heat generation is low, however as duty

cycles increase, temperature of the MX80L will increase, causing thermal expansion of the base.

With very high duty cycles these temperatures can reach temperatures as high as 30° C above

ambient.

Compensating for Thermal Effects

If the application requires high accuracy, the thermal effects must either be removed by regulating

carriage temperature or compensated for with a correction factor added to the commanded

position. Controlling the carriage temperature is the best method. However, this means controlling

the ambient temperature by removing all heat/cold generators from the area and operating at very

low duty cycles. Compensation is the other way of achieving accuracy without sacrificing

performance. In this case the system must be exercised through its normal operating cycle. The

temperature of the carriage should be measured and recorded from the beginning (cold) until the

carriage becomes thermally stable. This carriage temperature should be used in a compensation

equation. Below is the fundamental thermal compensation equation:

Cd = (Id - ((Id) * (Te) * ∆T))

Cd = Corrected displacement (mm)

= Incremental displacement (mm)

I

d

= Thermal Expansion (0.000022 mm/mm/° C)

T

e

∆T = Temperature Differential from 20° C

Example:

• Carriage Temperature of 32° C required move of 100mm

Cd = 100mm - (100mm * Te * 12° C) = 99.9736mm

In this example the commanded move should be 26.4 microns less (100mm – 99.9736mm) than

the desired move. This will compensate for the thermal expansion of the scale. This is a simple

linear correction factor and can be programmed in to most servo controllers using variables for the

position commands.

36

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 37

MX80L Series Product Manual Chapter 5 - Connecting the ViX Amplifier

,

Chapter 5 - Connecting to the ViX Amplifier

The MX80L is designed to be plug and run compatible with the Parker ViX drive. The cables on

the MX80L are labeled to match the labels on the ViX for ease of use and quick installation. When

purchased as part of the part number, the ViX will have the motor parameters already downloaded.

X1 – MOTOR LEADS

WIRE COLOR DRIVE

RED U

WHITE V

BLACK W

GREEN GND

X2 – FEEDBACK-HALL CONNECTOR

PIN FUNCTION WIRE COLOR

1 Encoder Z+ ORANGE

2 Encoder Z- BROWN

3 GND BLACK

5 +5V RED

6 Temperature- YELLOW/BLACK

7 Encoder A+ WHITE

8 Encoder A- YELLOW

9 Hall#1 WHITE/BROWN

10 Temperature+ YELLOW/RED

11 Encoder B- BLUE

12 Encoder B+ GREEN

13 Hall#2 WHITE/ORANGE

14 Hall#3 WHITE/VIOLET

Limits use Inputs

The ViX drive has 5 digital inputs. When using with MX 80L, the EOT Limits and Home use 3 of the 5 inputs.

A VM15-PF screw terminal breakout board may be purchased to allow access to the remaining 2 inputs and all

of the outputs.

X5 – LIMITS CONNECTOR*

PIN FUNCTION WIRE COLOR

1 GND BLACK

6 + End of travel ORANGE

7 - End of travel BLUE

8 Home GREEN

* For Drive Only versions of the ViX, the limits need to

be connected to the motion controller NOT the drive.

37

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 38

MX80L Series Product Manual Appendix

,

Chapter 6 - Maintenance and Lubrication

Cross Roller Bearing Lubrication

Standard Prep:

• Recommended Lubricant: Mobil Vactra No. 2, oil

• Lubrication Interval: 1000 hours*

• Method:

Lightly coat the bearing surfaces with oil. Bearings surfaces can be exposed by moving the table

to the end of travel lubricating the now exposed surfaces, then moving the table to the other end

of travel and lubricating the other set of surfaces.

Warning

Excessive oiling of the bearings--particularly the limit side bearing--can cause unit to

malfunction. Excess oil can damage limit sensor and target.

Clean Room Prep:

• Recommended Lubricant: Castrol Braycote 803, grease

• Lubrication Interval: 2000 hours*

• Method:

Lightly coat the bearing surfaces with grease. Bearings surfaces can be exposed by moving the

table to the end of travel lubricating the now exposed surfaces, then moving the table to the

other end of travel and lubricating the other set of surfaces.

Warning

Excessive greasing of the bearings--particularly the limit side bearing--can cause unit to

malfunction. Excess grease can damage limit sensor and target.

* General notes: Shorter lubrication interval may be required in environments with high amounts of dust and other contamination.

38

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Page 39

MX80L Series Product Manual Appendix

,

Appendix A - Internal Protection

Daedal has conducted testing to determine the degree to which the positioner is protected by

using a British standard called an Ingress Protection Rating (IP Rating). The MX80L has an

IP 10 protection rating.

Definition

Reference

This standard describes a system of classifying degrees of protection provided by enclosures of

electrical equipment. Standardized test methods and the establishment of a two digit numeric

rating verify the extent of protection provided against access to hazardous parts, against ingress

of solid foreign objects, and against the ingress of water.

First Number

Second Number

0 - No special protection provided.

Note

: British standard EN 60529 : 1992

– The first number indicates protection of persons against access to dangerous

parts and protection of internal equipment against the ingress of solid foreign objects.

1 - Protection against access to hazardous parts with the back of a hand, and protected

against solid foreign objects of 50 mm diameter and larger.

– The second number indicates protection of internal equipment against harmful

ingress of water.

: Number Indicators above represent only a partial list of IP Rating specifications.

Warning

Particles as small as 0.005” diameter could lodge between the table and internal components

causing the motor to stall.

39

Parker Hannifin Corporation

Daedal Division

Irwin

Pennsylvania

Page 40

MX80L Series Product Manual Index

,

Index

Acceleration

Limits, 39

Specifications, 13

Accuracy

Specifications, 13

Thermal Effects, 40, 41

Assembly Diagram, 8, 44

Bearing

Life, 16

Load, 21

Lubrication, 45

Bend Radius, 36

Cabling, 9, 36, 37

Cleanroom, 25, 38, 45

Counter Balance, 37

Deceleration Distance, 33

Dimensional Drawings, 11

Drive Ampilifier, 9

Electrostatic Discharge (ESD),

27

Encoder, 35, 39, 40

Options, 9

Resolution, 39

Specifications, 27

Velocity Limit, 39

Z Channel, 9

Force/Speed Charts, 23, 26

General Specifications, 14

Grounding, 36

Hall Effect

Specifications, 27

Home Sensor, 9

Adjusting, 35

Specifications, 27

ViX, 43

Horizontal Translation, 21

Ingress Protection Rating, 46

Internal Protection, 46

Limit Sensor, 9

Adjusting, 34

Specifications, 27

ViX, 43

Lubrication, 45

Maintenance, 45

Mass, 13

Motor Force, 39

Motor Heating, 41

Mounting, 9, 31

Surface Requirements, 31, 32

Order Number Nomenclature, 9

Overhang, 32

Pinning, 9

Repair Information, 6

Repeatability, 35

Specifications, 13

Thermal Effects, 41

Return Information, 6

Settling Time, 39

Shielding, 36

Specifications

Bearing, 16

Electrical, 24

Encoder, 27

Force, 22

General, 13

Hall Effect Sensors, 27

Speed

Limits, 39

Maximum, 33

Table Load, 16

Thermal Effects

Accuracy, 40

Causes, 41

Compensation, 41

Repeatability, 41

Thrust

Specifications, 13

Travel, 9

Setting Limit Sensors, 33

Unpacking, 5

Velocity

Maximum, 39

Specifications, 13

ViX

Amplifier, 43

Drive Specifications, 28

Warnings, 6

Wiring Diagrams, 29

Z Channel, 35

40

Parker Hannifin Corporation

Daedal Division

Pennsylvania

Irwin

Loading...

Loading...